High-strength clinker calcined from limestone mine interlayer ingredients

A limestone, high-strength technology, applied in the field of cement clinker, can solve the problems of complex and changeable ingredients, difficult batching, etc., and achieve the effect of simple process, lower batching cost, and good social promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

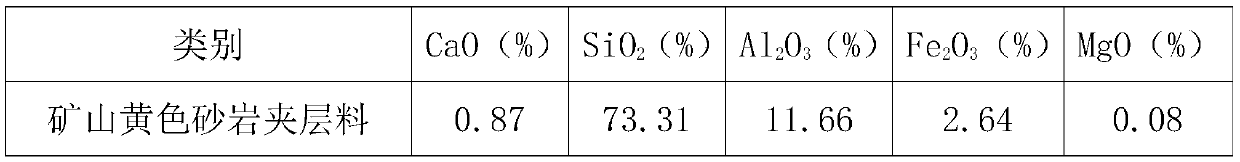

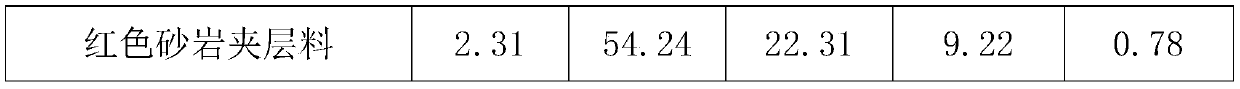

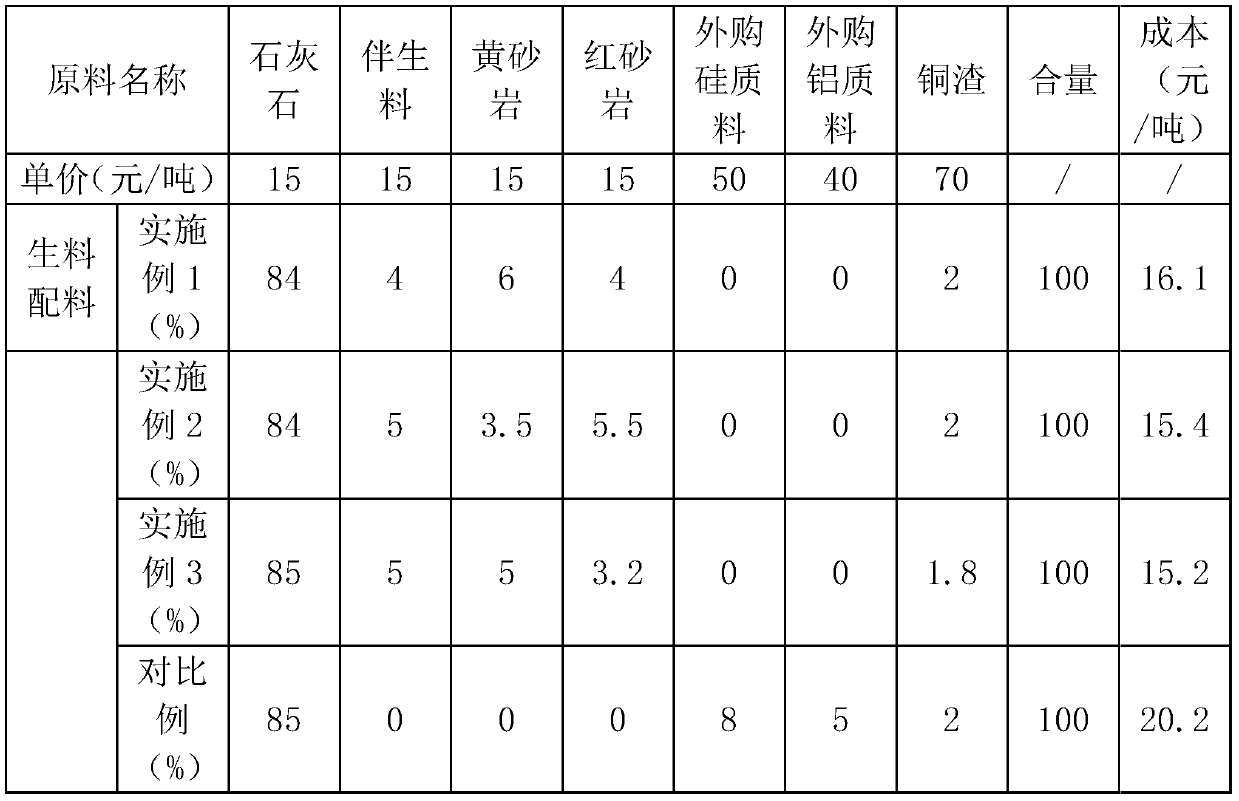

[0022] A high-strength clinker calcined using limestone mine interlayer ingredients, comprising the following components and their parts by weight: 88 parts of limestone (including about 4 parts of associated materials), 6 parts of mine yellow sandstone interlayer material, and 4 parts of mine red sandstone interlayer material , 2 parts of copper slag.

[0023] Wherein, the mine yellow sandstone interlayer material is specifically silicon material, and the SiO2 of the mine yellow sandstone interlayer material is 2 The content is 70%; the mine red sandstone interlayer material is specifically aluminum material, and the SiO2 of the mine red sandstone interlayer material is 2 The content is 45%, Al 2 o 3 The content is 25%. The associated interlayer material is specifically a material that is associated with mine yellow sandstone interlayer material and mine red sandstone interlayer material. The lime saturation coefficient KH of the high-strength clinker is 0.95, the silicon r...

Embodiment 2

[0030] A high-strength clinker calcined by using limestone mine interlayer ingredients, comprising the following components and their parts by weight: 89 parts of limestone (including about 5 parts of associated materials), 3.5 parts of mine yellow sandstone interlayer material, and 5.5 parts of mine red sandstone interlayer material , 2 parts of copper slag.

[0031] Wherein, the mine yellow sandstone interlayer material is specifically silicon material, and the SiO2 of the mine yellow sandstone interlayer material is 2 The content is 80%, the mine red sandstone interlayer material is specifically aluminum material, and the SiO2 of the mine red sandstone interlayer material is 2 The content is 60%, Al 2 o 3 The content of the associated interlayer material is 15%. The associated interlayer material is specifically a material in which the mine yellow sandstone interlayer material and the mine red sandstone interlayer material are associated together. The high-strength clinke...

Embodiment 3

[0038] A high-strength clinker calcined using limestone mine interlayer ingredients, comprising the following components and parts by weight: 90 parts of limestone (including about 5 parts of associated materials), 5 parts of mine yellow sandstone interlayer material, and 3.2 parts of mine red sandstone interlayer material , 1.8 parts of copper slag.

[0039] Wherein, the mine yellow sandstone interlayer material is specifically silicon material, and the SiO2 of the mine yellow sandstone interlayer material is 2 The content is 75%. The mine red sandstone interlayer material is specifically aluminum material, and the SiO2 of the mine red sandstone interlayer material is 2 The content is 52%, Al 2 o 3 The content is 20%. The associated interlayer material is specifically the material associated with the mine yellow sandstone interlayer material and the mine red sandstone interlayer material. The high-strength clinker has a lime saturation coefficient KH of 0.94 and a silicon r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com