Patents

Literature

113results about How to "Low cost of ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

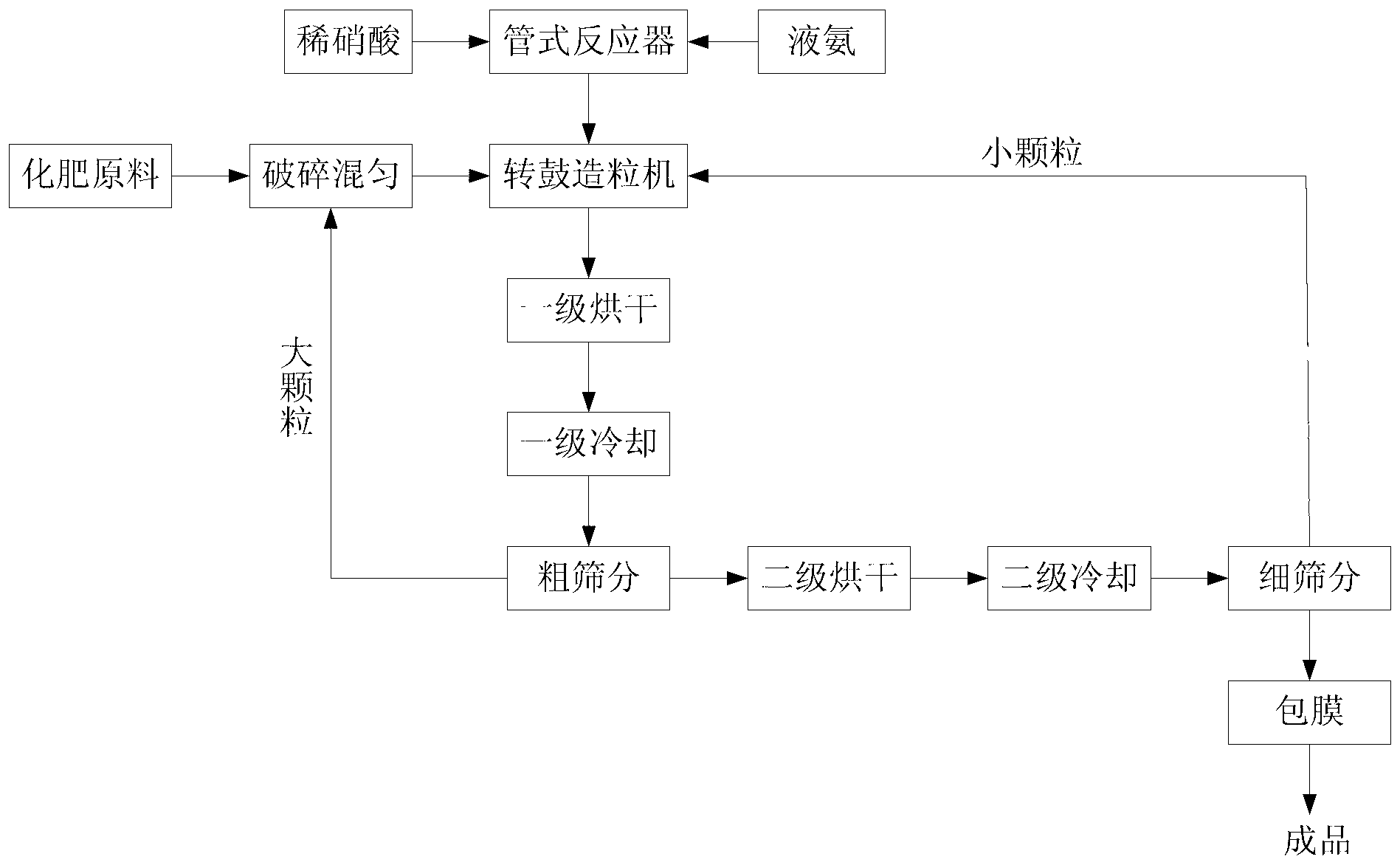

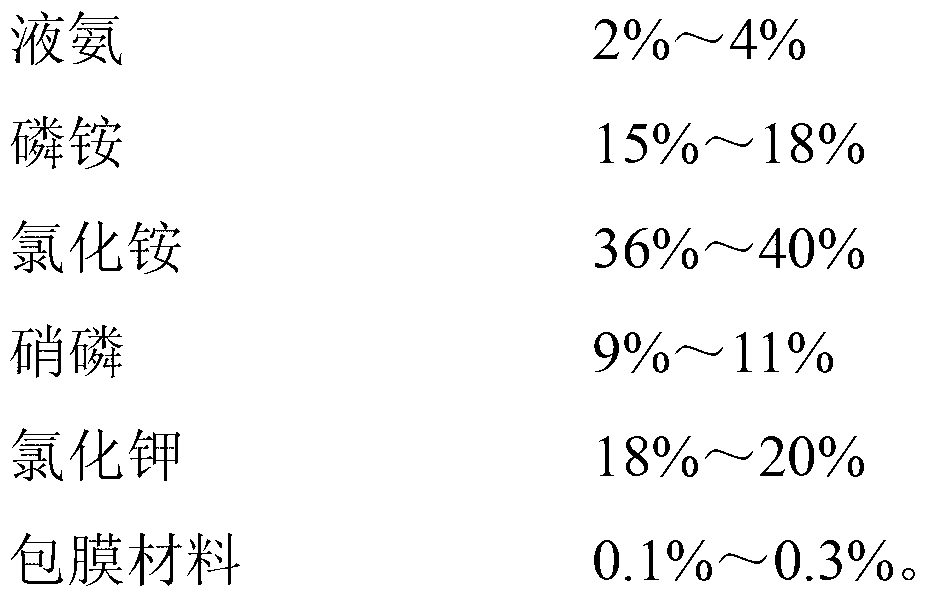

High-concentration compound fertilizer and production method thereof

ActiveCN103232293AHigh strengthImprove solubilityFertilizer mixturesHigh concentrationChemical reaction

The invention provides a high-concentration compound fertilizer and a production method thereof. The production method comprises the following steps of: smashing materials, and uniformly mixing; weighting ammonium dihydrogenphosphate, ammonium chloride, nitrophosphate, potassium chloride in a formula proportion, smashing, uniformly mixing, feeding the mixture into a rotor drum granulator; feeding liquid ammonia and dilute nitric acid into a tubular reactor for carrying out amino acid reaction; pelleting in a rotary drum, namely, after the liquid ammonia and the dilute nitric acid react in the tubular reactor, spraying into the rotor drum granulator, and pelleting by the chemical reaction of the liquid ammonia and the dilute nitric acid; drying, cooling and screening pelleted particles, wherein the particles with qualified particle size enter a coating machine, the large particles return to be smashed, and the small particles return to the granulator; coating by an anti-blocking agent; and spraying the anti-blocking agent into the coating machine for coating, thus obtaining the high-concentration compound fertilizer. According to the production method, the pelleting temperature is increased by using the chemical reaction heat between the nitric acid and ammonia, the characteristic of the material is improved, the production capacity of devices is improved, and the production cost is reduced.

Owner:嘉施利(应城)化肥有限公司

Preparation method of composite preservative film

The invention provides a preparation method of a composite nylon material. The preparation method comprises the following steps: I. adding natural polysaccharide into an acetic acid water solution, heating to be completely gelatinized, to obtain a mixture I; II, adding an emulsifier and a plasticizer into the mixture I, heating and stirring, to obtain a mixture II; III, then adding natural functional materials into water, stirring to be completely dissolved, to prepare a natural functional material water solution; IV. cooling the mixture II to 50DEG C, adding protein, performing water bath heating and stirring, to obtain a mixture III; V, mixing the mixture III with the natural functional material water solution, to obtain a mixture IV; VI, pouring the mixture IV into a mould, drying and forming a film; and VII, cooling the film obtained in the step VI to be at normal temperature. The preparation method is simple, the production cost is low, the formed preservative film has the characteristics of being non-toxic and harmless, and good in moisture barrier property, so that the preservation effect of food can be effectively enhanced.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

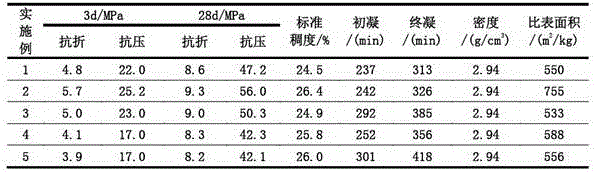

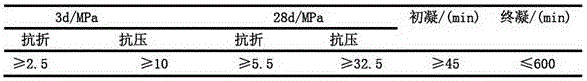

Retarded portland cement and preparation method thereof

InactiveCN105948544AProlong clotting timeIncrease late strengthCement productionSlagMaterials science

The invention relates to a retarded Portland cement and a preparation method thereof. The retarded Portland cement is prepared from the following components in percentage by weight: 52 to 58 percent of Portland cement clinkers, 22.2 to 25.5 percent of mixed slags, 14.8 to 17.5 percent of silica fume, and 5 percent of gypsum. The preparation method comprises the following steps of premixing a phosphorus slag, a vanadium-titanium bearing slag and a zinc slag according to the proportion to obtain a mixed slag a; mixing and grinding the mixed slag a, the Portland cement clinkers, the silica fume and the gypsum to prepare the retarded Portland cement. According to the retarded Portland cement provided by the invention, the usage amount of the Portland cement clinkers is reduced, so that the ingredient cost of producing the cement is effectively reduced, and the discharge of carbon dioxide is reduced; meanwhile, with the adding of the phosphorus slag and the silica fume, the problem that the long-term strength is reduced since the Portland cement clinkers are reduced is solved. The defects that the setting time is prolonged and the strength is reduced, or the strength is increased and the setting time is shorter due to the utilization of other materials in the prior art are overcome, and the obtained retarded Portland cement is remarkably prolonged in initial setting time and remarkably improved in long-term strength.

Owner:四川省宁南县白鹤滩水泥有限责任公司

Technique for smelting mother liquor of stainless steel from electric furnace

InactiveCN1796586ALow cost of ingredientsAlleviate the tension of insufficient resourcesElectric arc furnaceFerrosilicon

This invention relates to an electric furnace smelting technique for crude stainless steel liquid with its process including: a) materials proportioning. Waste stainless steel shares 15~25% in total added metal. Chromium-iron alloy shares 15~25% in total added metal. Lime is added to an amount of 30~45 kg per ton of added metal. And dephosphorized molten iron shares 35~60% with its element content of 2.50~3.80% of C, less than 0.020% of phosphorus, less than 0.040% of sulfur. b) Smelting. Oxygen blowing amount is controlled at 5~10 cu m / t and blowing flux is controlled at 1500~2500N cu m / h. c) reduction. Ferrosilicon powders are spitted at 2.5~3.5kg / t and carbon powders at 1.5~2.5kg / t. Or ferrosilicon is added at 2.5~3.5kg / t and aluminium at 1.5~2.5kg / t. d) tapping, with ultimate temperature controlled at 1640~1660 deg.C. This invention employs dephosphorized molten iron, which reduces the raw materials proportioning cost and smelting time as well as the consumption of electricity power, electrodes and patching materials in electric furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

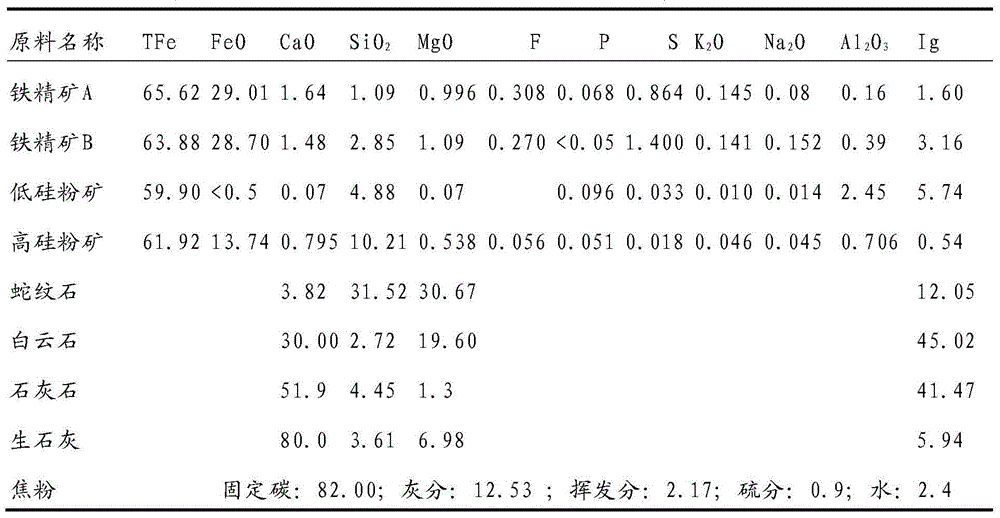

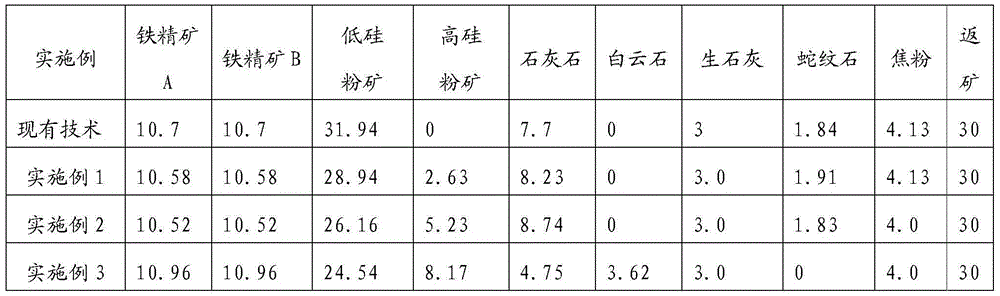

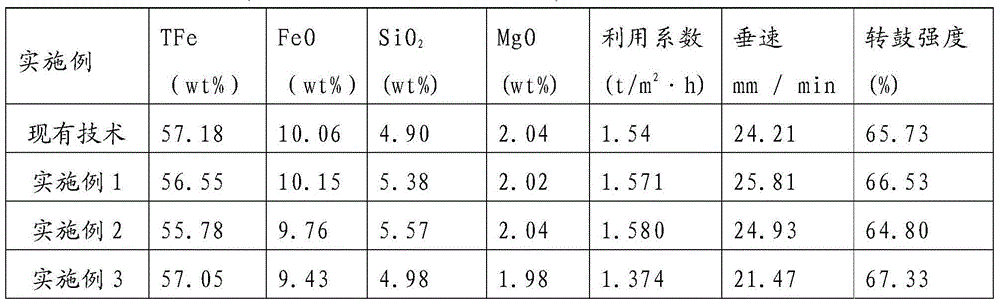

Method for preparing sinter ore by using high-silicon fine ore

The invention discloses a method for preparing sinter ore by using high-silicon fine ore. The method comprises the following steps: preparing raw materials in percentage by mass: 9-12% of iron ore concentrate A, 9-12% of iron ore concentrate B, 23-30% of low-silicon fine ore, 2-9% of high-silicon fine ore, 4.5-9.0% of limestone, 0-2.0% of serpentine, 0-4% of dolomite, 2.5-3.5% of quick lime, 4.0-4.5% of coke powder and 28-35% of return mine; adding water to the raw materials, mixing and granulating to obtain a mixed material, wherein the water accounts for 7-8% of the mixed material; sintering the mixed material for 25-40 minutes at 1000-1500 DEG C to prepare the sinter ore, wherein the sintering ignition time is 1-3 minutes, the ignition negative pressure is 3000-6000Pa; an air extracting operation is carried out in the sintering process, the air extracting negative pressure is 9000-12000Pa. According to the method for preparing sinter ore, low-price high-silicon fine ore is matched with other iron materials, so that the use of the high-price silicon-containing solvent serpentine can be reduced or even not needed; the enough strength of the sinter ore can be ensured; meanwhile, the raw material cost can be reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

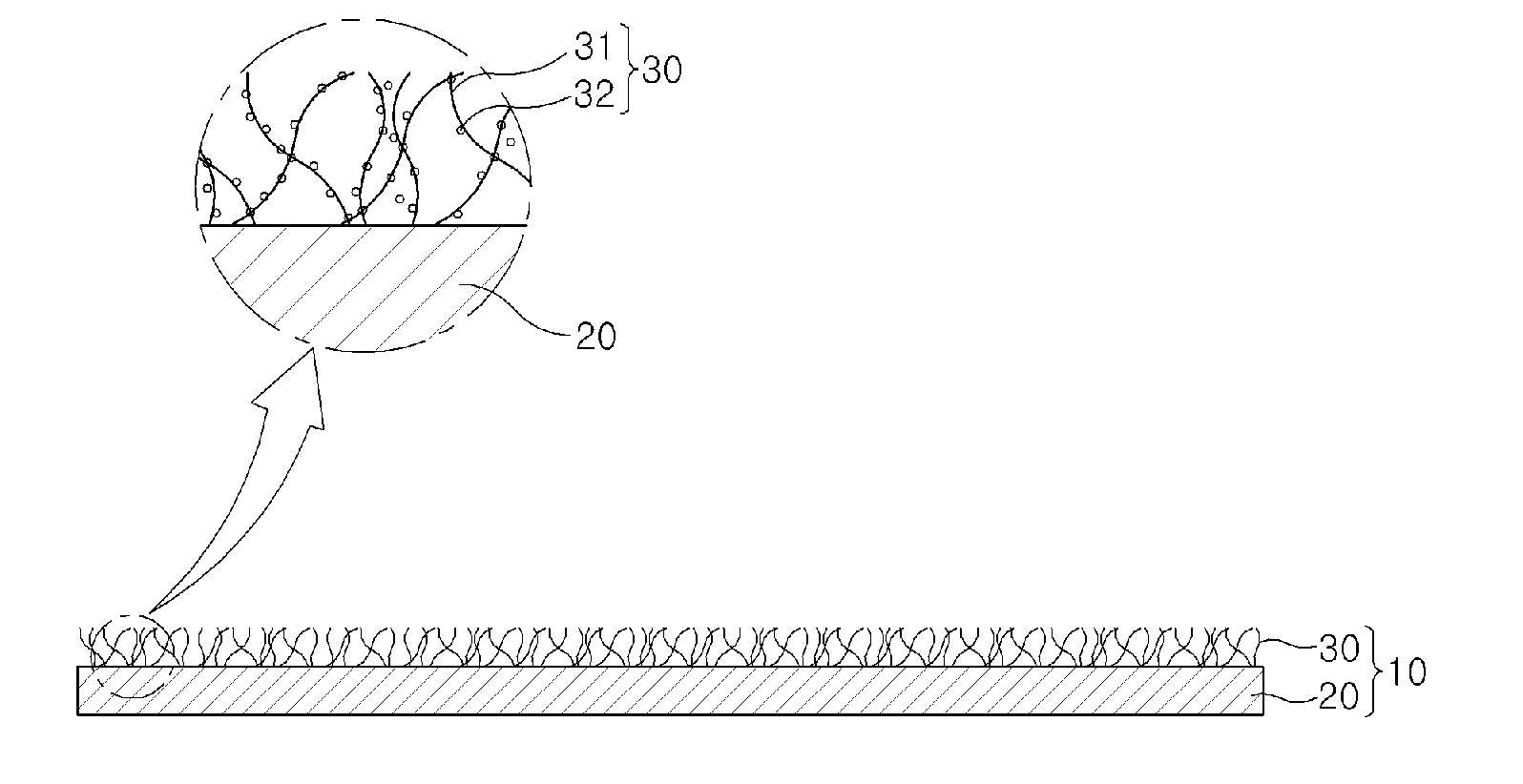

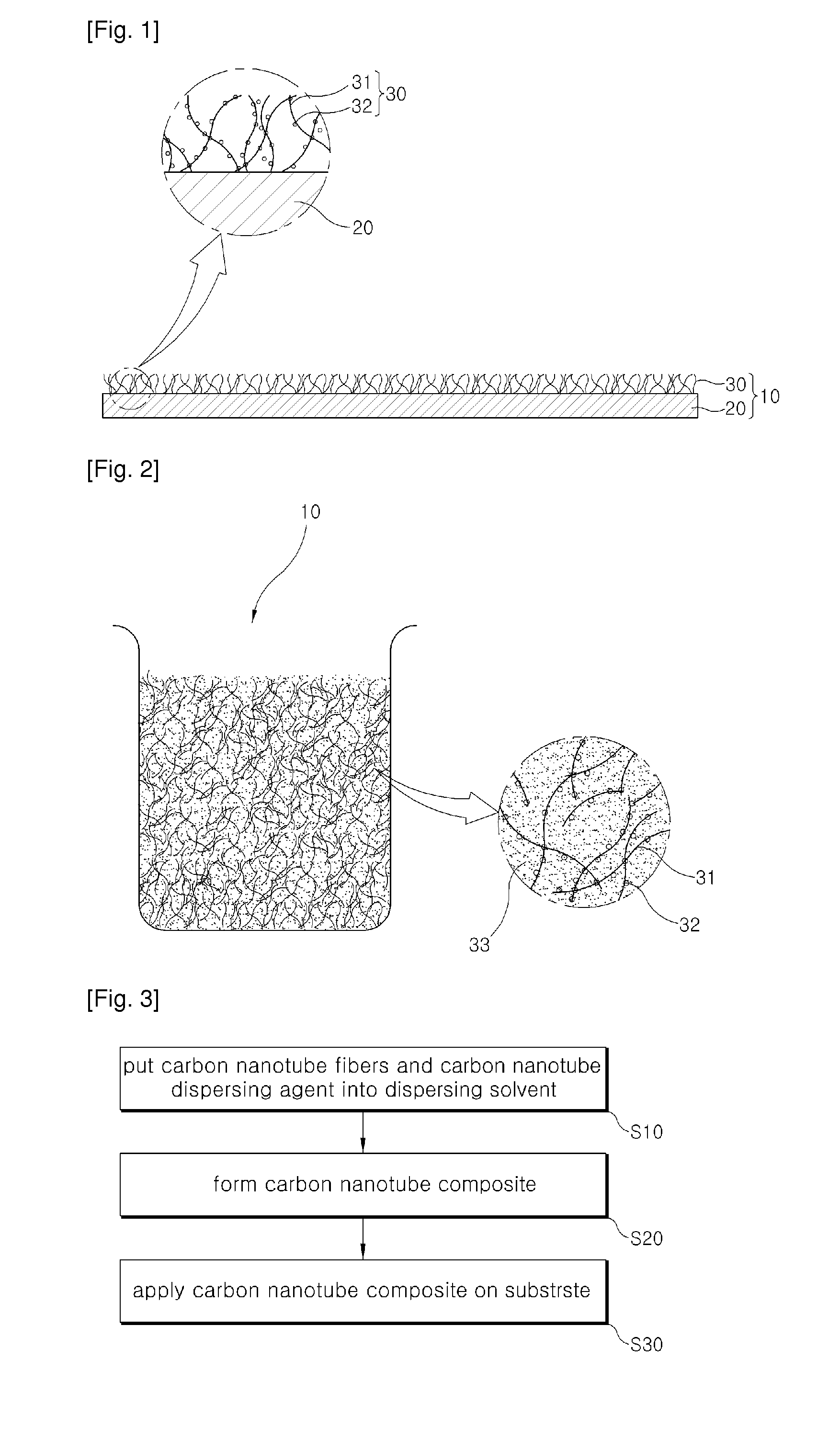

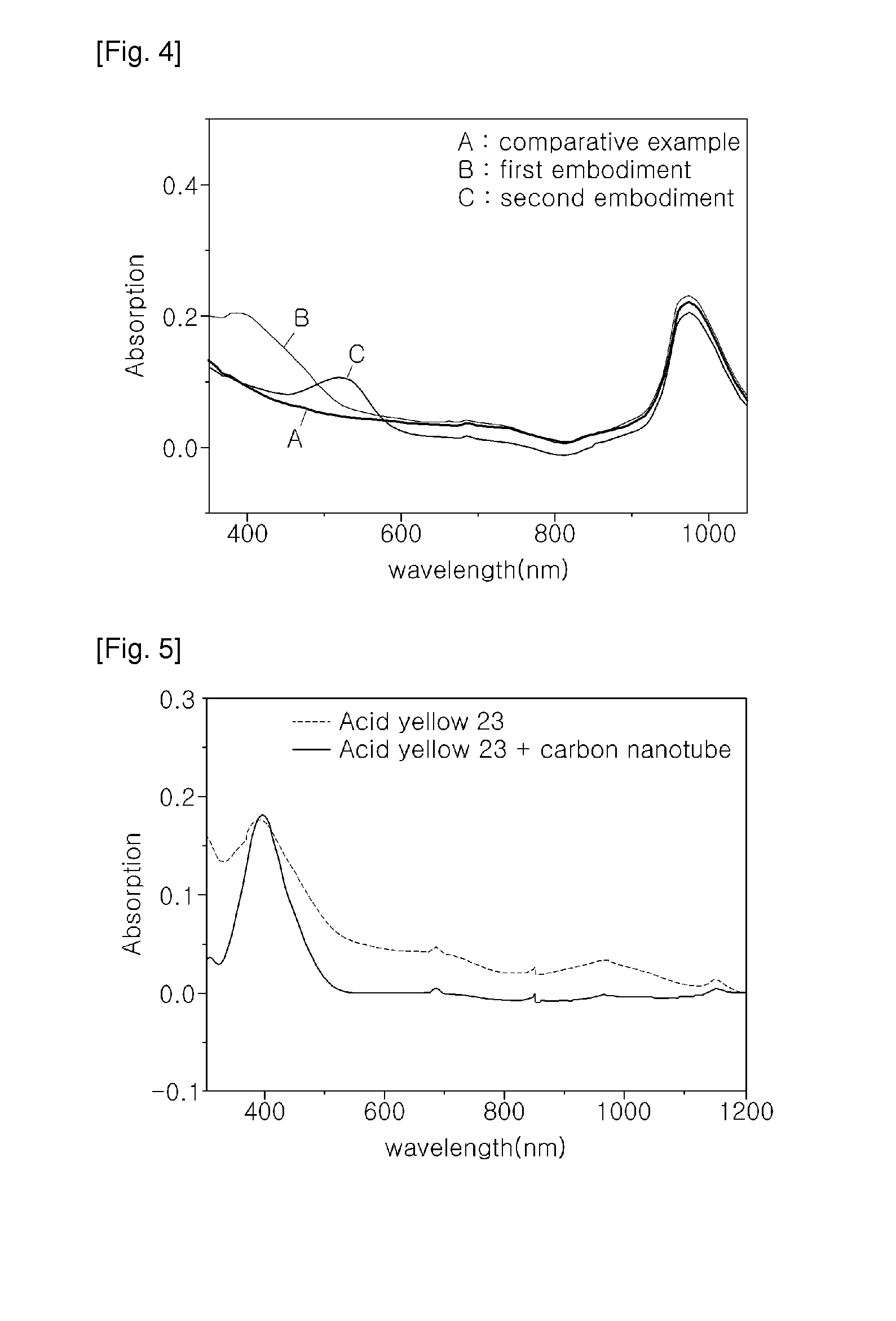

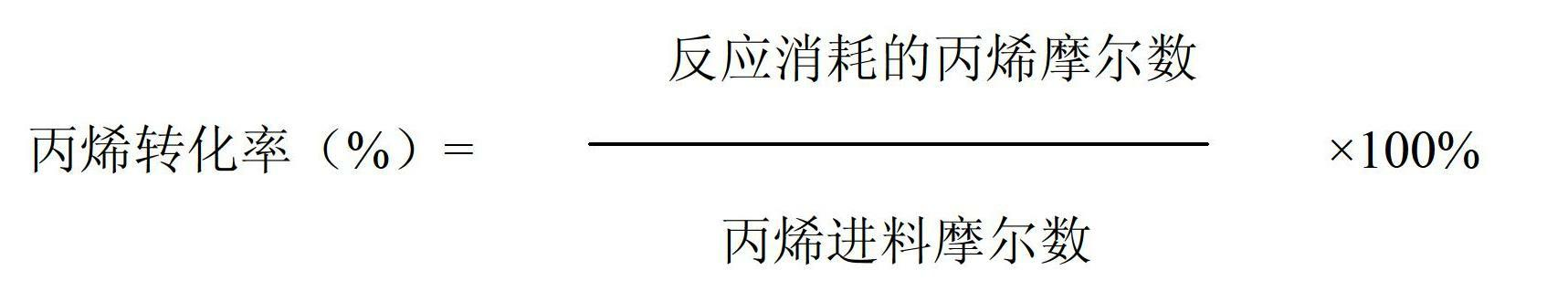

Carbon nanotube dispersing agent, carbon nanotube composite, carbon nanotube film, and method for manufacturing the carbon nanotube film

InactiveUS20090311554A1Improve conductivityLow cost of ingredientsElectrolysis componentsCarbon compoundsCarbon nanotubeNanometre

Provided are a carbon nanotube dispersing agent, a carbon nanotube composite, a carbon nanotube film, and a method for manufacturing the carbon nanotube film. The carbon nanotube dispersing agent has at least one chromophore including at least one aromatic carbon ring, and has a plane structure.

Owner:TOP NANOSYS

Cement-containing compositions and method of use

InactiveUS20090229492A1Improve contactImproved support characteristicSolid waste managementCeramicwareWater solublePortland cement

The invention provides a system comprising two components to be mixed together to form a settable cementitious composition wherein a first component comprises: (a) Portland cement; (b) calcium sulphate; and (c) water in a weight ratio of water to Portland cement and calcium sulphate solids of from 0.5:1 to 5:1; and a second component comprises: (d) a water soluble silicate; and (e) water, in a weight ratio of water to silicate solids of from 1.5:1 to 25:1; which cementitious composition has a higher early strength than known compositions.

Owner:MINOVA INT

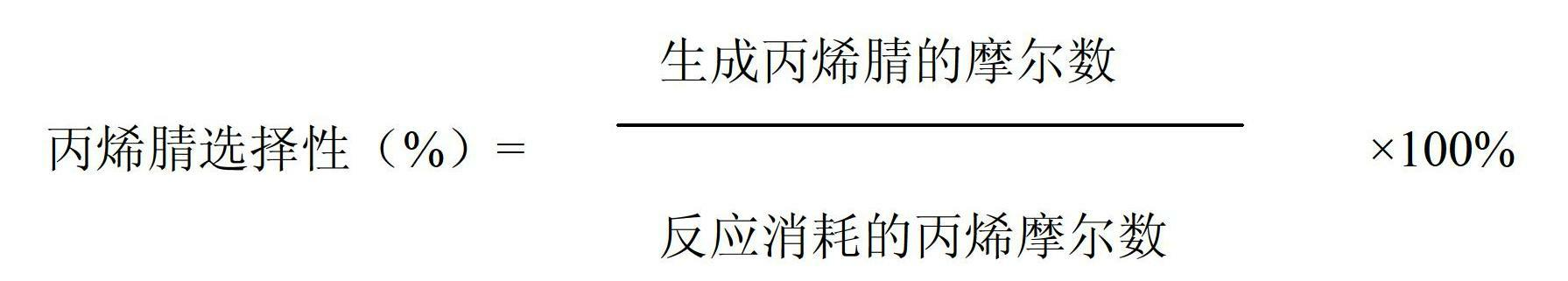

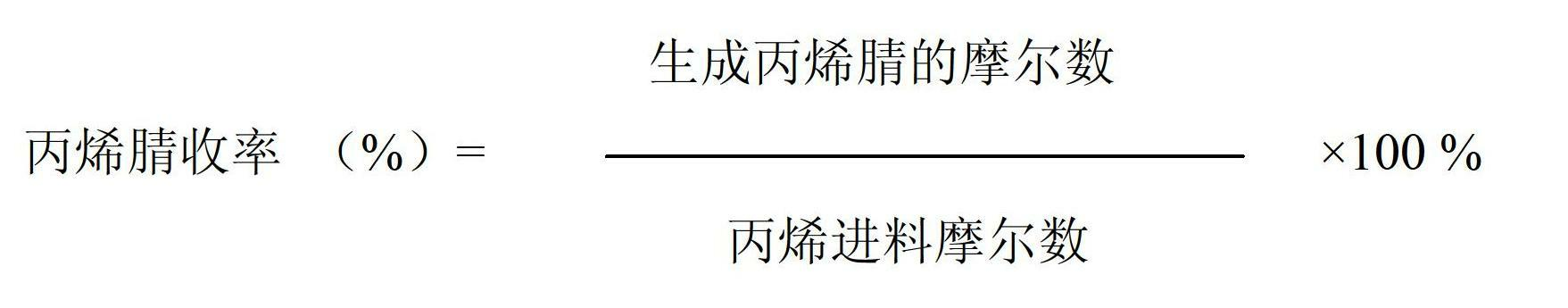

Catalyst for use in preparation of acrylonitrile by performing ammonia oxidation on propylene

ActiveCN102658167AOptimizing ElectronegativityExtend the life cyclePreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsRubidiumPotassium

The invention relates to a catalyst for use in preparation of acrylonitrile by performing ammonia oxidation on propylene. An active ingredient of the catalyst contains a compound of which the general formula is shown as BiaFebNicMgdCeeLafCsgAghCliAljAkBlCmMo12Ox, wherein A is one or two of lithium, sodium, potassium and rubidium; B is one or more of samarium, neodymium and gadolinium; C is one or more of cobalt, calcium, tungsten and phosphorus; a-m are atomic numbers of corresponding elements; and x is an oxygen atom number which is required by the valence of other elements. In the catalyst, a plurality of element compositions are adopted, so that the surface electronegativity of the catalyst is optimized, the catalyst can generate a small amount of static electricity in a reactor under the action of high-speed air flow impact, a fine particle catalyst which flows onto a quenching tower is not adsorbed by the tube wall of the quenching tower, the service life of the device is prolonged, and production efficiency is increased.

Owner:YINGKOU XIANGYANG CATALYST

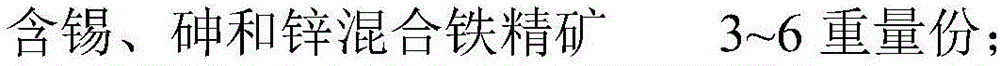

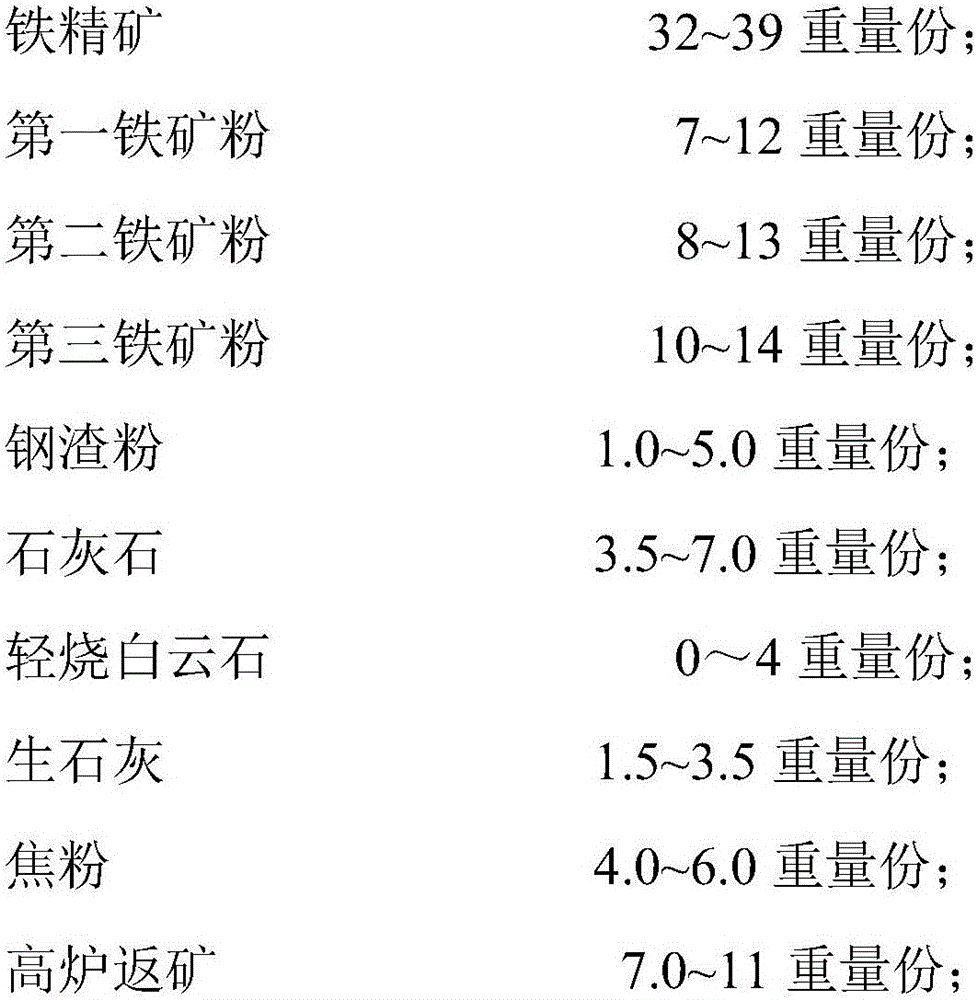

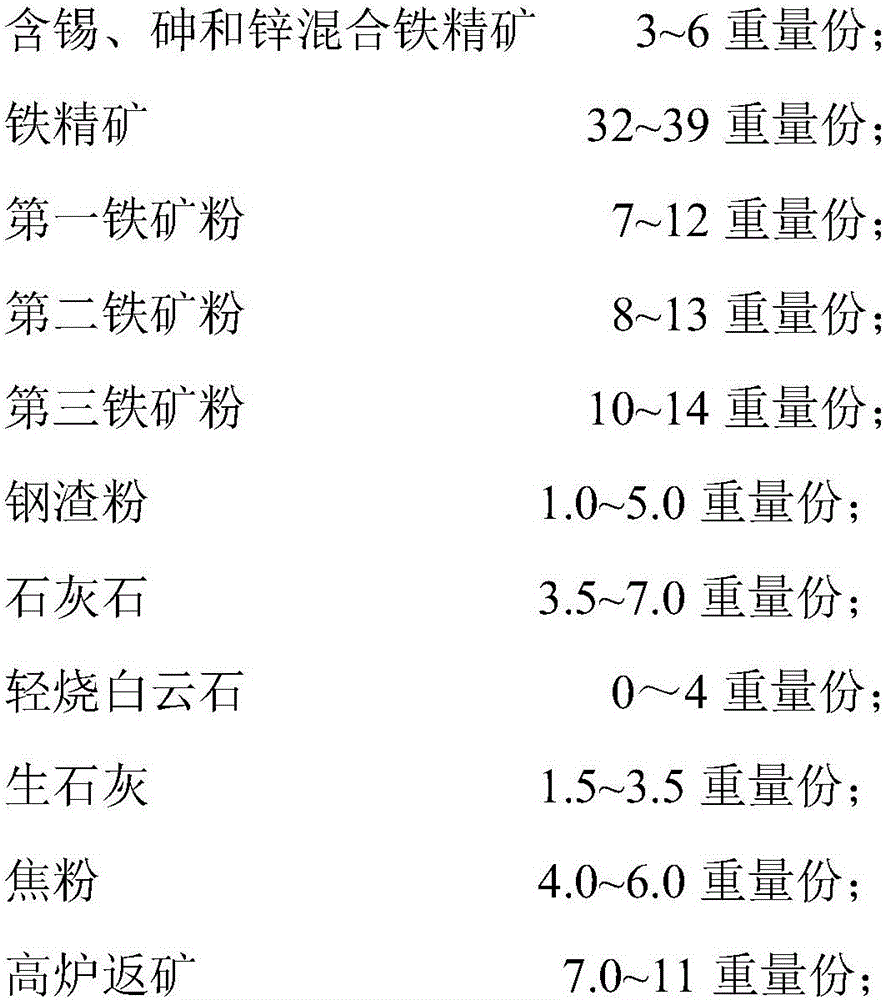

Preparing method of sintered ore

The invention relates to the technical field of sintered ore, in particular to a preparing method of the sintered ore. The method comprises the steps of S1, preparing raw materials, wherein the raw materials comprise a mixed iron concentrate containing tin, arsenic and zinc, an iron concentrate, first iron mineral powder, second iron mineral powder, third iron mineral powder, steel slag powder, limestone, light burned dolomite, quick lime, coke powder and blast furnace return fines; S2, carrying out pelleting after water is added into the raw materials for mixing, and obtaining a mixture; S3, sintering the mixture, and obtaining the sintered ore. According to the method, the mixed iron concentrate containing tin, arsenic and zinc is matched with other iron materials, under the condition that it is ensured that the content of tin, arsenic and zinc of the sintered ore meets blast furnace smelting and steel product requirements, the part of iron concentrate can be effectively used for producing the sintered ore, enough strength of the sintered ore is ensured, and meanwhile the burdening cost can be reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

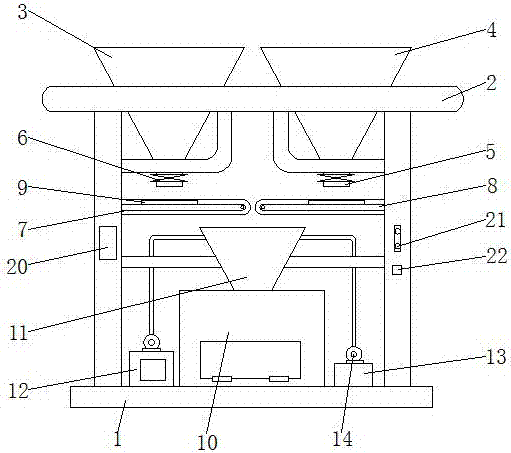

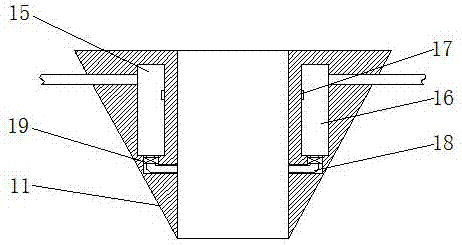

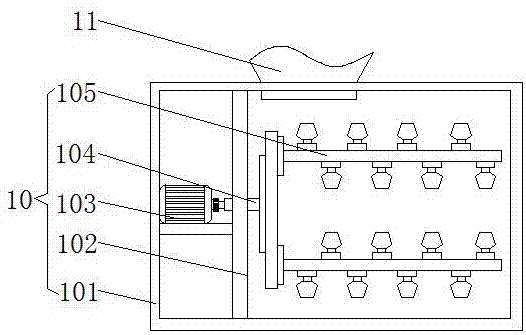

Precise preparing device for food processing and production

ActiveCN107136548AImprove batching accuracyConvenient and accurate ingredientsMachines/enginesFood shapingEngineeringFood processing

The invention discloses a precise preparing device for food processing and production. The precise preparing device comprises a base, wherein a support frame is fixedly connected to the top of the base, a first feed hopper and a second feed hopper are sequentially arranged at the top of the support frame from left to right, material leakage pipes separately communicate with the bottom of the first feed hopper and the bottom of the second feed hopper, and an electromagnetic material leakage unit is arranged in the corresponding material leakage pipe; and a first electric conveyor belt is arranged on one side of the inner wall of the support frame and is located at the bottom of the first feed hopper. The invention relates to the technical field of food preparing facility. The precise preparing device for food processing and production can realize precise measurement on the food raw materials, so that the preparing precision of the food preparing device is greatly improved; a plurality of measurement funnels do not need to be mounted on the preparing equipment to measure and compound different food raw materials, so that personnel can precisely prepare the foods conveniently, and the preparing cost of the foods is saved.

Owner:HUNAN UNIV OF ARTS & SCI

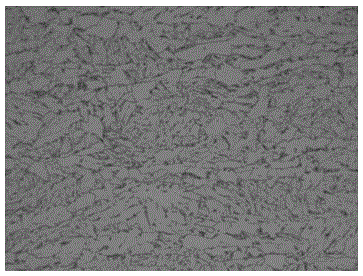

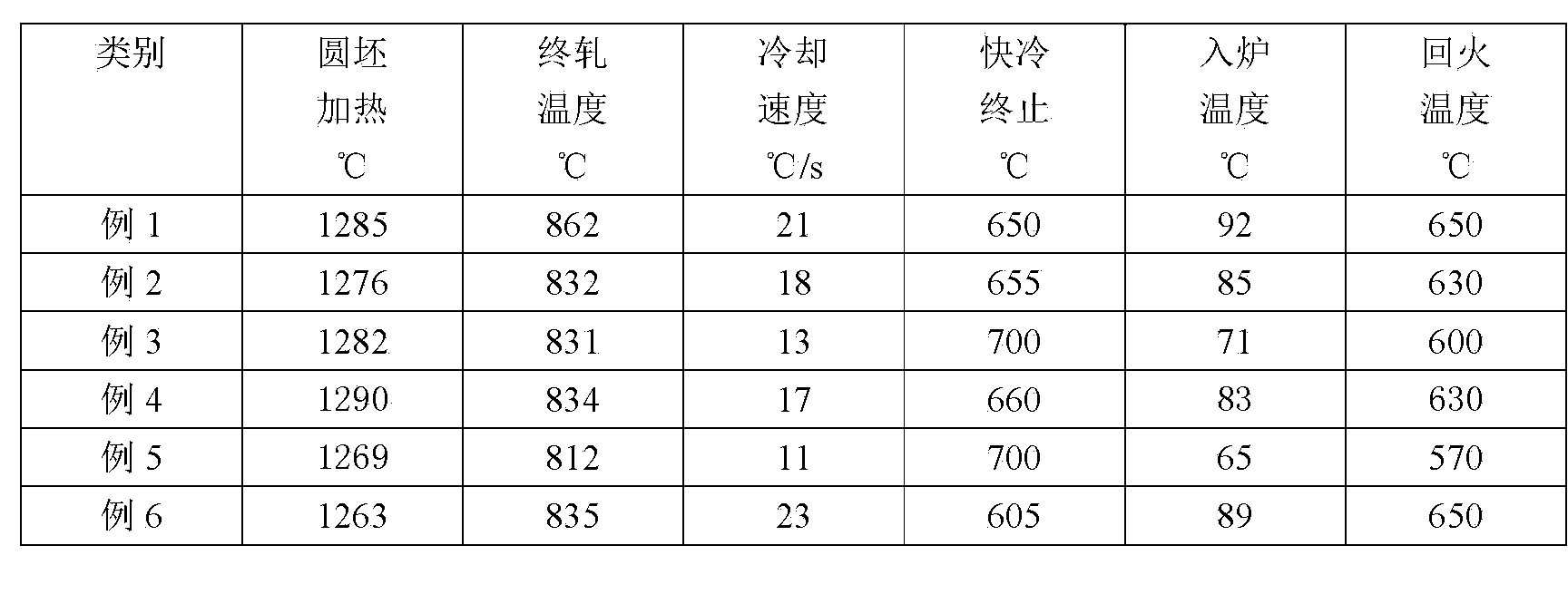

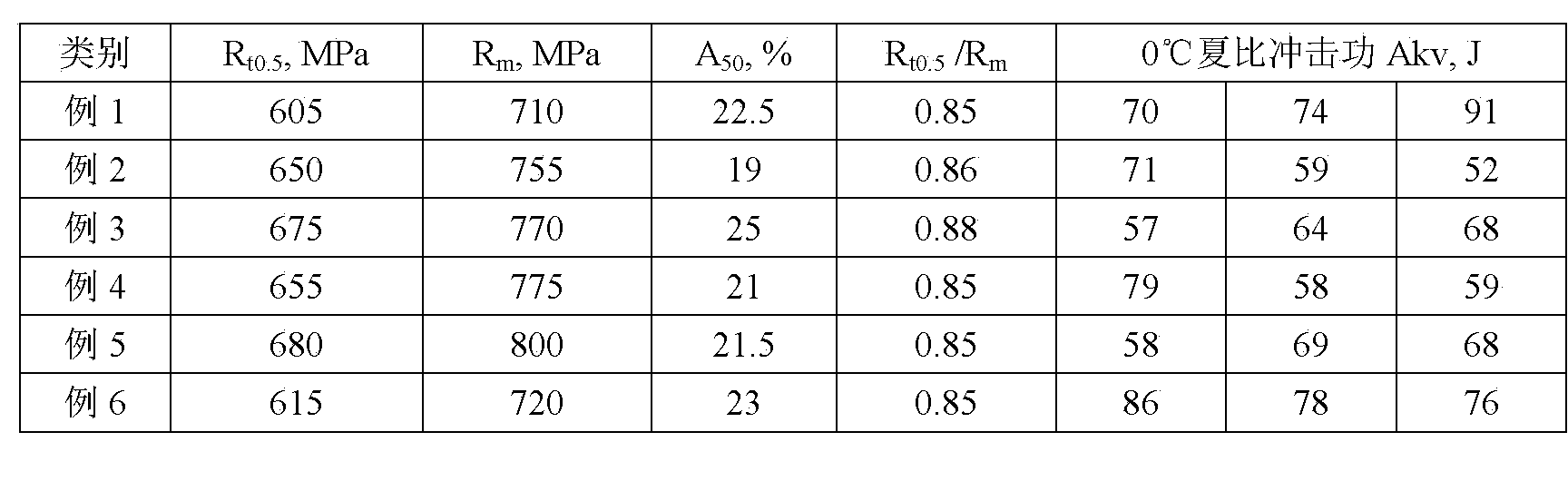

Large, thick, high-strength and high-toughness TMCP type steel plate and production method thereof

The invention discloses a large, thick, high-strength and high-toughness TMCP type steel plate and a production method thereof. The large, thick, high-strength and high-toughness TMCP type steel plate is composed of, by weight, 0.06%-0.08% of C, 0.20%-0.40% of Si, 1.40%-1.50% of Mn, 0.015% or less of P, 0.005% or less of S, 0.020-0.030% of Nb, 0.030%-0.050% of Alt, the balance Fe and inevitable impurities and 0.20% or less of Pcm. According to the steel plate, the components are simple, only a proper amount of microalloy Nb is added, and the precious elements such as V, Ti and Ni are not added; production cost is low, and the probability of large-scale production is increased. The steel plate is of a mixed structure mainly containing bainite, ferrite, pearlite and martensite and has a good comprehensive mechanical property; the steel plate is better in matching of the components and the strength and toughness, and it is guaranteed that the steel plate has the excellent comprehensive mechanical property; particularly, the impact performance of half of the plate in the thickness direction is good at the low temperature of minus 40 DEG C, and the method can be widely used for producing low-temperature-resistant building steel and engineering steel used in extremely cold climate. The method has the advantages that the production cost is low, and the technique is simple; the performance of products is excellent, and the comprehensive mechanical property of the products is stable.

Owner:WUYANG IRON & STEEL

Low-melting-point mixed molten salt heat transfer and thermal storage working medium and application thereof

InactiveCN105199677ALow cost of ingredientsSimple preparation processHeat-exchange elementsLiquid temperatureIndustrial waste

The invention belongs to the field of mixed molten salt as an energy storage material and particularly relates to a low-melting-point mixed molten salt heat transfer and thermal storage working medium and an application thereof. The working medium is characterized by comprising components in percentage by weight as follows: 16wt%-27wt% of Ca(NO3)2*4H2O, 49wt%-57wt% of KNO3, 5wt%-13wt% of NaNO3, 6wt%-12wt% of LiNO3 and 4wt%-11wt% of Na2CO3. The application of the low-melting-point mixed molten salt heat transfer and thermal storage working medium is characterized in that the working medium is widely applied to the medium-and-high-temperature heat transfer and thermal storage fields of solar thermal power generation energy storage, wind curtailment and photoelectricity curtailment as well as coal-to-electricity thermal storage heating or industrial waste heat recovery storage. The preparation components of the mixed molten salt are low in cost, and the preparation technology is quite simple. The thermophysical property of the mixed molten salt is quite stable, the phenomenon of separation of a single component in a use process is avoided, the mixed molten salt has the good heat transfer property in a liquid temperature zone, and the saturated steam pressure is lower than 2 atmospheres. The working medium has little metal corrosion and has a wide application range.

Owner:百吉瑞(天津)新能源有限公司

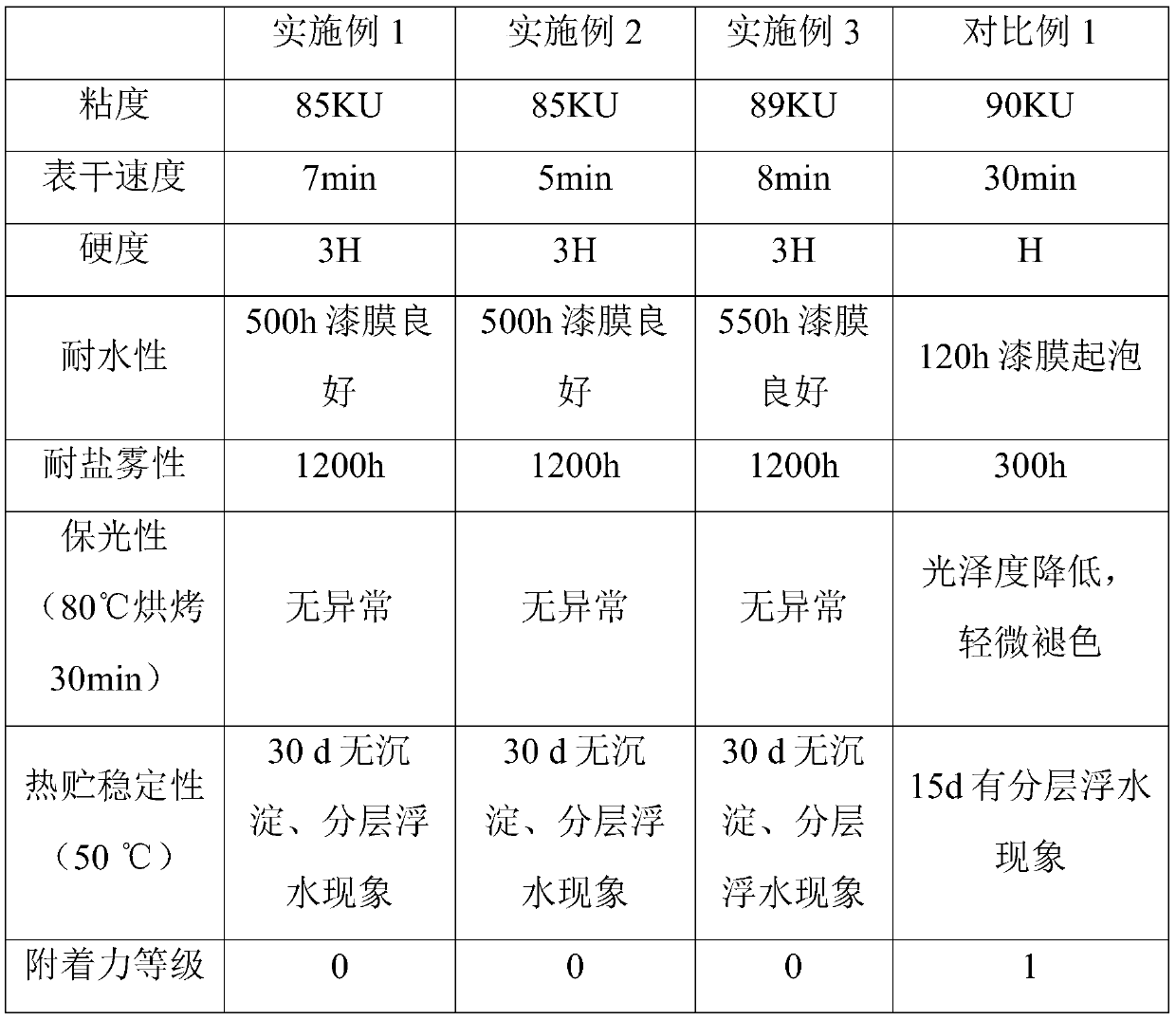

Waterborne epoxy primer and preparation method thereof

InactiveCN110041795AGood gloss retentionImprove salt spray resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention relates to the technical field of coatings, and particularly discloses waterborne epoxy primer and a preparation method thereof. The waterborne epoxy primer comprises a component A and acomponent B, wherein the component A comprises ingredients in percentage by mass as follows: a waterborne epoxy emulsion, a waterborne epoxy acrylic emulsion, a defoaming agent, a dispersing agent, pigment and filler, a base material wetting agent, anti-rust pigment, a thickening agent, an anti-rust auxiliary, an anti-settling agent and the balance deionized water; the component B comprises an amine curing agent and deionized water; a mass ratio of the component A to the component B in the waterborne epoxy primer is (4-6):1. The waterborne epoxy primer is good in gloss retention, good in saltfog resistance, good in stability and low in ingredient cost, has low construction difficulty and is excellent waterborne epoxy primer with good performance and low cost.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

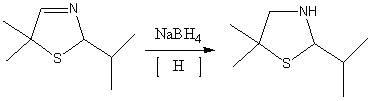

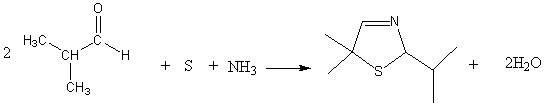

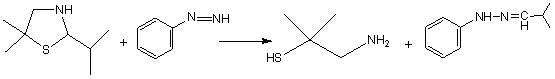

Synthetic method of dimethyl cysteamine hydrochloride

ActiveCN102432510AHigh purityReaction raw materials are readily availableThiol preparationThiazolineCYSTEAMINE HYDROCHLORIDE

The invention discloses a synthetic method of dimethyl cysteamine hydrochloride. The method comprises the following steps of: synthesizing 5,5-dimethyl-2-isopropyl thiazoline by taking isobutylaldehyde, element sulfur, ammonia gas and triethylamine as raw materials; reducing the 5,5-dimethyl-2-isopropyl thiazoline into 5,5-dimethyl-2-isopropyl thiazolidine under the actions of sodium borohydride and acid; and reacting the 5,5-dimethyl-2-isopropyl thiazolidine and phenyl hydrazine under the air insulating situation to obtain dimethyl cysteamine hydrochloride. The method has the advantages of readily-available reaction raw materials, easiness for operating the reaction process, low requirement on the reaction equipment, relatively mild reaction conditions, feeding of the product of every step of reaction into a next step reaction after refining and purifying, high yield and high purity, and the purity of the finally-obtained dimethyl cysteamine hydrochloride is close to 100 percent.

Owner:山东胜利生物工程有限公司

Seamless steel tube for X80 delivery line and its manufacturing method

The invention discloses a seamless steel tube for an X80 delivery line and its manufacturing method; the seamless steel tube comprises 0.12%-0.16% of C, 0.30%-0.45% of Si, 1.24%-1.44% of Mn, 0.30%-0.50% of Cr, 0.02%-0.05% of Nb, 0.01%-0.03% of Ti, less than or equal to 0.020% of P, less than or equal to 0.012% of S and the balance of Fe and unavoidable impurities, and the carbon equivalent CEIIW is 0.39-0.50. After sizing finish rolling, the steel tube temperature is controlled to be more than 800 DEG C, and accelerated cooling of 10 DEG C / s-25 DEG C / s is performed, so that the steel tube temperature is rapidly cooled to 600-700 DEG C, the rapidly-cooled steel tube can be transferred to air cooling for cooling to less than 100 DEG C, and tempering treatment is performed on the steel tube at 550-650 DEG C.

Owner:ANGANG STEEL CO LTD

Preparation method and application of pleurotus ostreatus culture medium by using bagasse

InactiveCN104341236AMeet the nutritional elementsShorten the cultivation cycleBioloigcal waste fertilisersFertilizer mixturesDry weightCorn flour

The invention discloses a medium for cultivating pleurotus ostreatus by using bagasse. The medium comprises the following components by dry weight percent: 75%-80% of bagasse, 10%-20% of beer gains, 5%-10% of bran, 2%-5% of corn flour, 0.5%-1% of sugar, 1%-2% of lime and 0-1% of gypsum. Furthermore, a preparation method of the medium for cultivating pleurotus ostreatus by using bagasse comprises the following steps: (1) fully soaking the bagasse by virtue of water; (2) evenly mixing with the beer gains, the brain, the corn flour, the sugar, the lime and the gypsum form a medium; (3) enclosing the medium into a culture bag; and (4) sterilizing and cooling the culture bag with the medium for later use. According to the preparation and application methods of the medium for cultivating pleurotus ostreatus by using bagasse disclosed by the invention, the bagasse is utilized in a high-valued manner; the production cost of the pleurotus ostreatus is reduced; and meanwhile, the quality of the pleurotus ostreatus is improved.

Owner:GUANGZHOU SUGARCANE IND RES INST

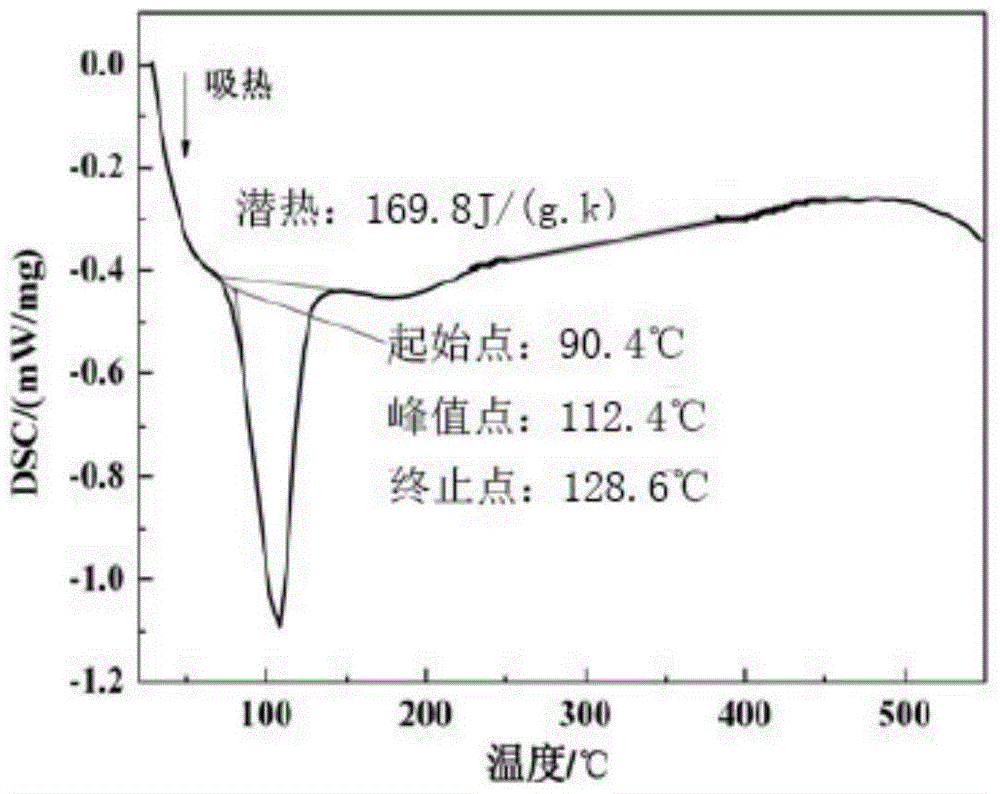

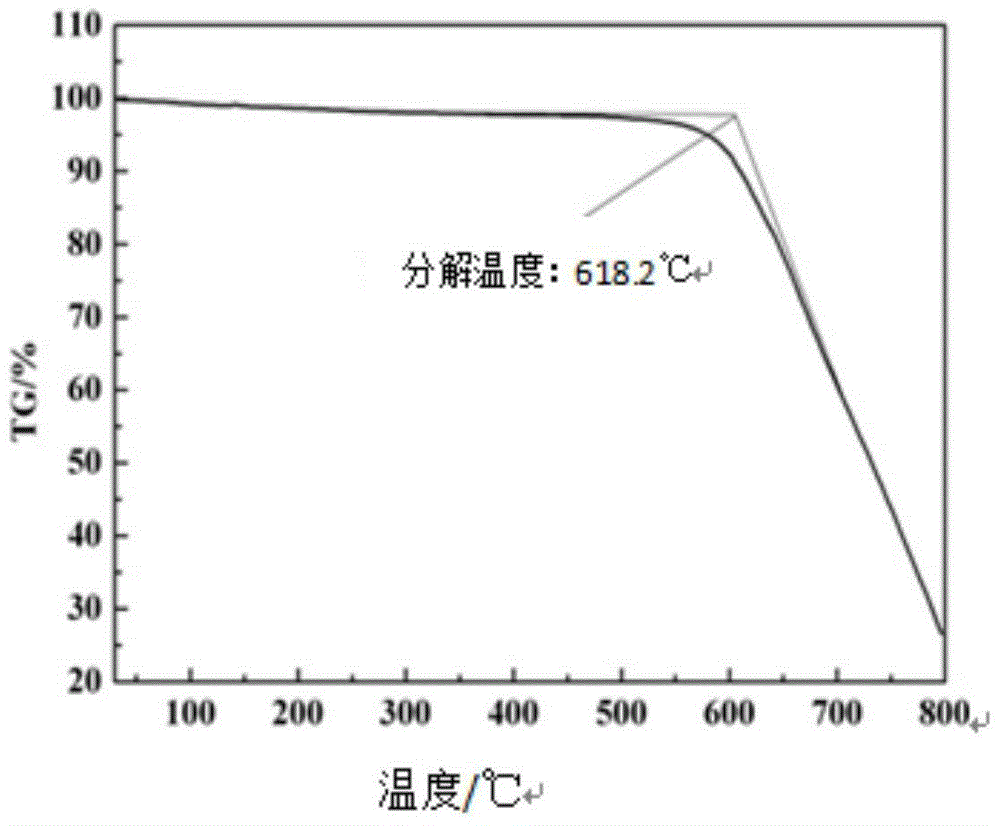

Mixed molten salt heat transfer and storage working medium and preparing method and application thereof

InactiveCN105542726ALow cost of ingredientsSimple preparation processSolar heating energySolar heat devicesCoalToxic industrial waste

The invention belongs to the field of the energy storage material mixed molten salt, and particularly relates to a mixed molten salt heat transfer and storage working medium. The mixed molten salt heat transfer and storage working medium is characterized by being prepared from 13.4 wt% of Ca(NO3)2, 56-60 wt% of KNO3, 6-15 wt% of NaNO3, 9-14 wt% of LiNO3 and 8-13 wt% of K2CO3, the melting point of the mixed molten salt heat transfer and storage working medium is 102 DEG C, and the boiling point of the mixed molten salt heat transfer and storage working medium is 623 DEG C. The application of the mixed molten salt heat transfer and storage working medium is characterized in that the mixed molten salt heat transfer and storage working medium is applied to medium-high-temperature heat transfer and storage fields including solar heat power generation energy storage, wind and photoelectricity curtailment and 'coal to electricity' thermal storage heating and industrial waste heat recovery and storage. The constituents for preparing mixed molten salt are low in cost, and the preparing process is extremely simple. The thermophysical property of the mixed molten salt is quite stable, separation of any constituent does not occur in use, heat transfer property is high in the liquid state temperature zone, and saturated vapor pressure is lower than two atmospheres. The corrosion capacity to metal of the working medium is low.

Owner:百吉瑞(天津)新能源有限公司

Airtight sizing material for repairing tyres and preparation method thereof

InactiveCN104673132AImprove applicabilityGood tire repair effectNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesEconomic benefitsEngineering

The invention provides an airtight sizing material for repairing tyres and a preparation method thereof. The an airtight sizing material is used for repairing the tyres, the performance of the tyres are good after being repaired with the airtight sizing material, experiments prove that the material can be used for repairing 7mm holes; inflating and air leakage tests of the repaired tyres show that the performance of the sealant prepared by the method disclosed by the invention can fully meet the repairing and sealing requirement of the tyres of large automobiles or trucks. The sealant prepared with the method disclosed by the invention is simple in component, the preparation process is easy to operate, besides, the preparation cost is low, and certain economic benefit can be achieved.

Owner:大连轮胎有限公司

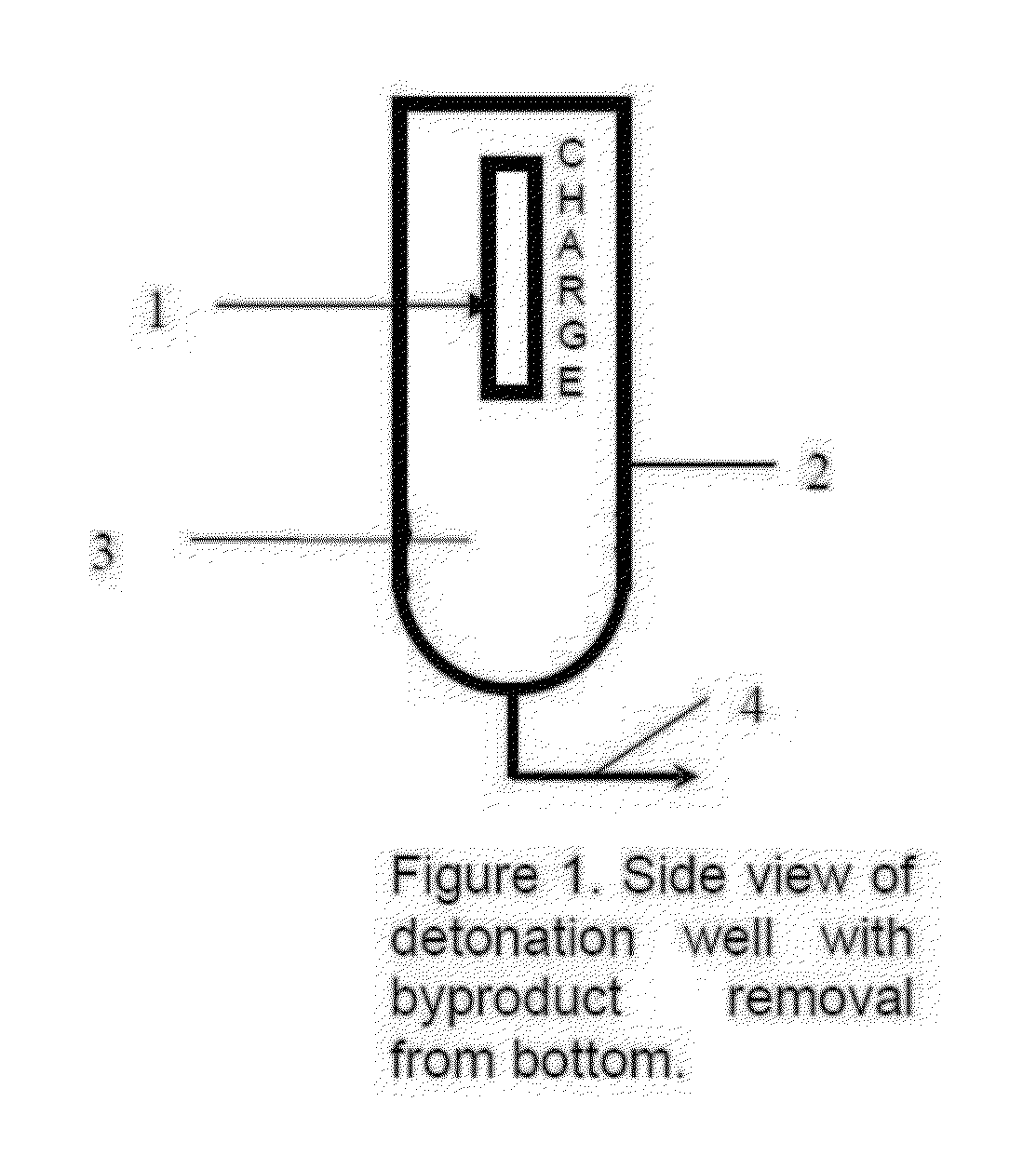

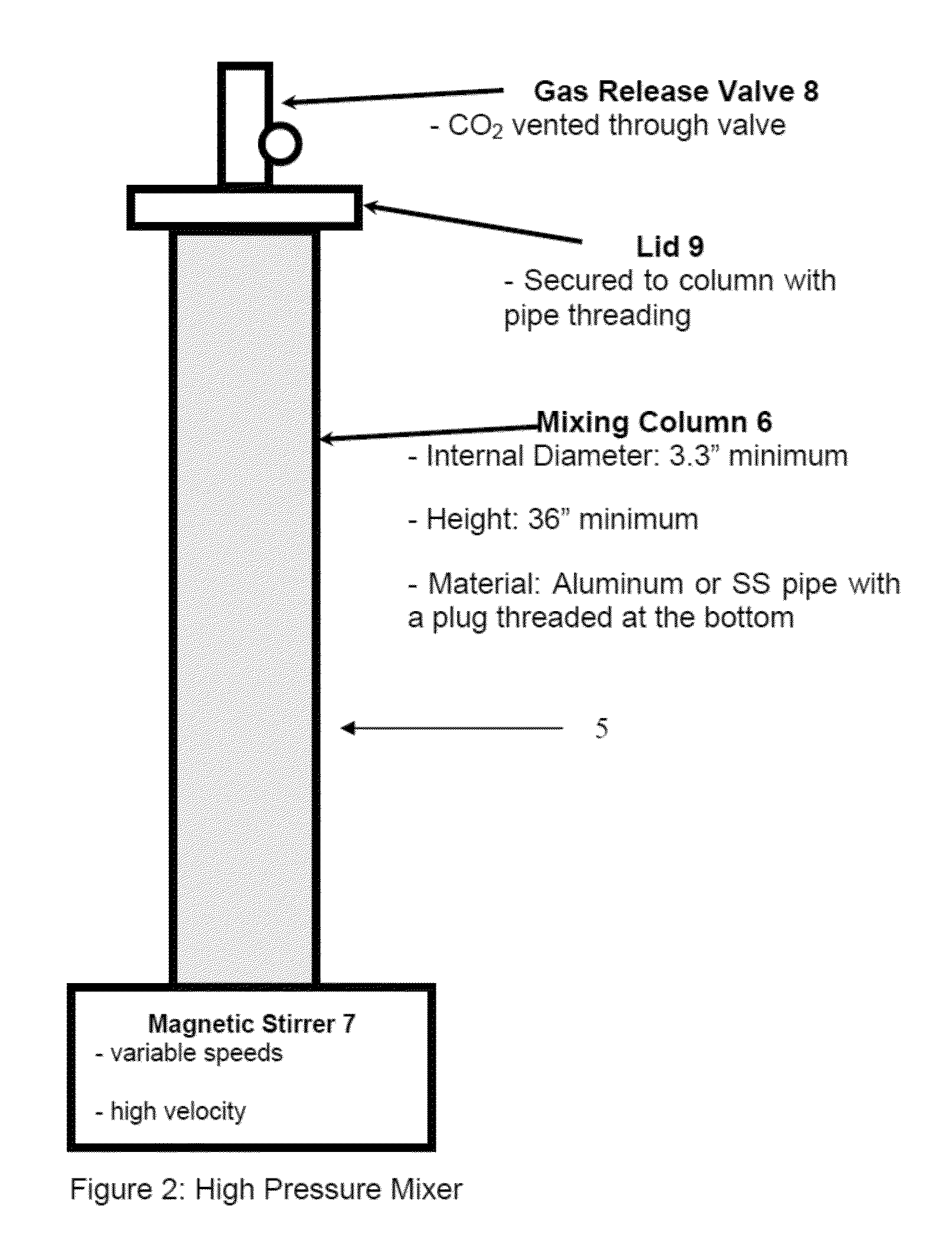

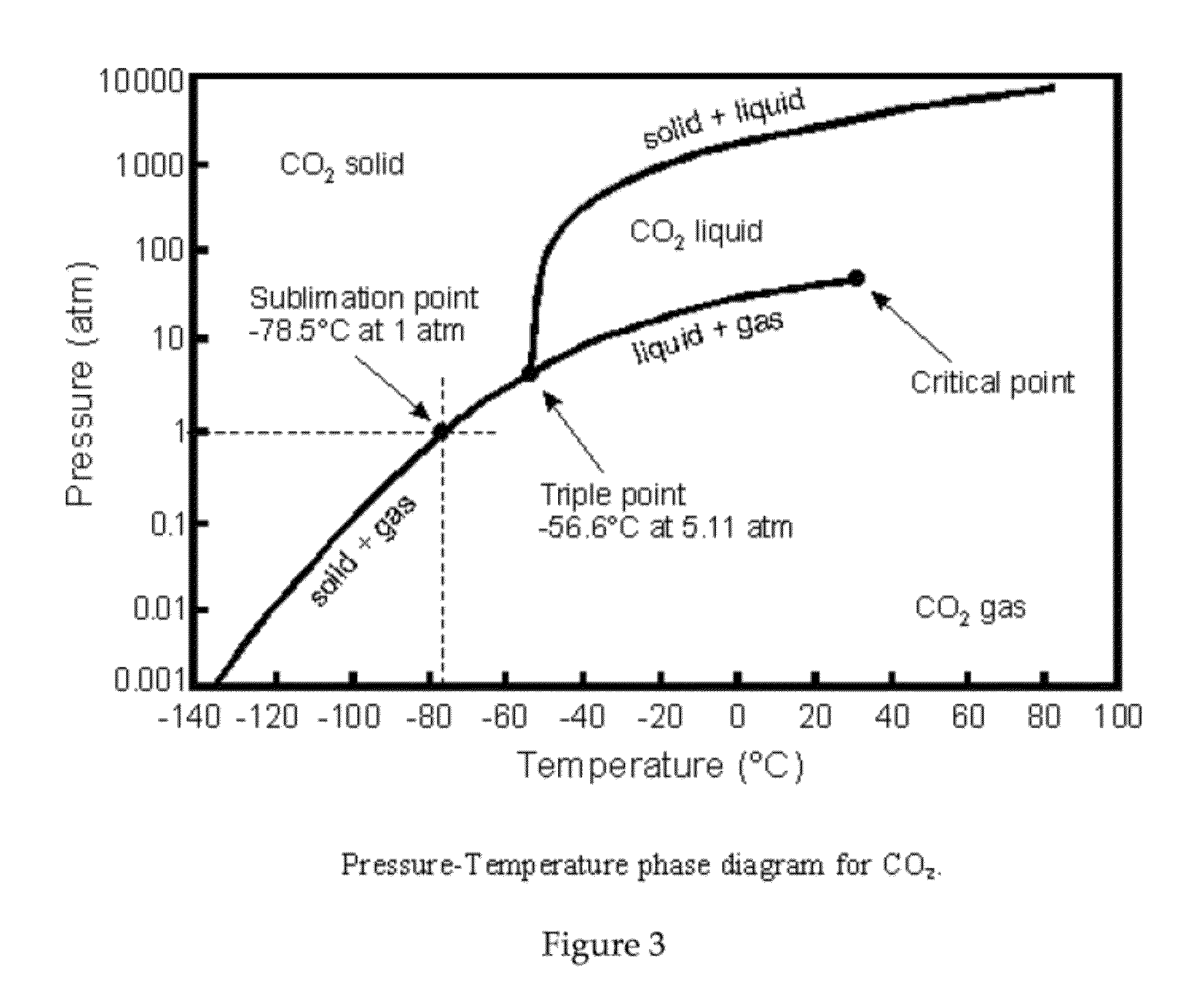

Explosive Formulations of Mixture of Carbon Dioxide and a Reducing Agent and Methods of Using Same

ActiveUS20160046538A1Low cost of ingredientsIncrease variabilityUltra-high pressure processesAluminium oxide/hydroxide preparationEmulsion explosiveANFO

The disclosure relates to embodiments of an explosive formulation comprising a detonable mixture of an oxidizing agent such as carbon dioxide, and a material that decomposes the oxidizing agent exothermically (a reducing agent), and additives that increase the mixture's shock sensitivity. The formulations may be used in a method to produce diamonds or nano oxides or in other applications that use traditional explosives such as, but not limited to: ammonium nitrate and fuel oil combinations (ANFO), watergel explosives, emulsion explosives and RDX.

Owner:SWANSON DAREN NORMAND

Lubricating oil additive for electromechanical devices, and preparation method thereof

The invention provides a lubricating oil additive for electromechanical devices, and a preparation method thereof. The lubricating oil comprises, by weight, 20-30 parts of an antioxidant, 20-33 parts of an anti-wear agent, 12-25 parts of an extreme pressure agent and 8-18 parts of organic molybdenum. The preparation method comprises the following steps: mixing the antioxidant, the anti-wear agent, the extreme pressure agent and the organic molybdenum, heating and stirring the obtained mixture at 80-100 DEG C for 30-50 min to obtain the lubricating oil additive. The content of the antioxidant is increased, and then is used as a carrier, so anti-oxidation requirements under a high speed at a high temperature under a high pressure are met, oil product failure caused by oxidation is prevented, and the life time of lubricating oil is prolonged; high efficiency synergism of the antioxidant and other components can be used to improve the extreme pressure anti-wear property of the oil product; and the lubricating oil additive also has a good self-repairing effect.

Owner:合肥市闵葵电力工程有限公司

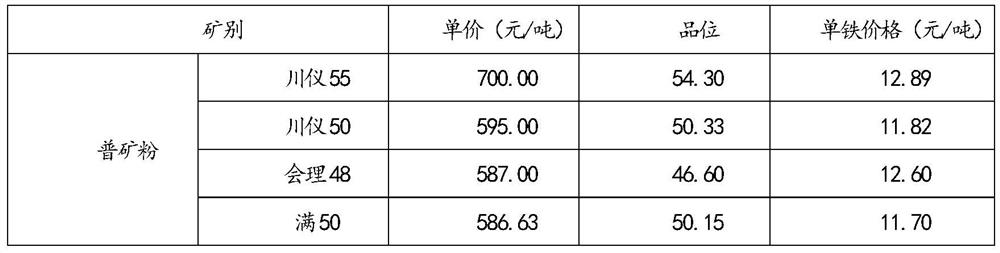

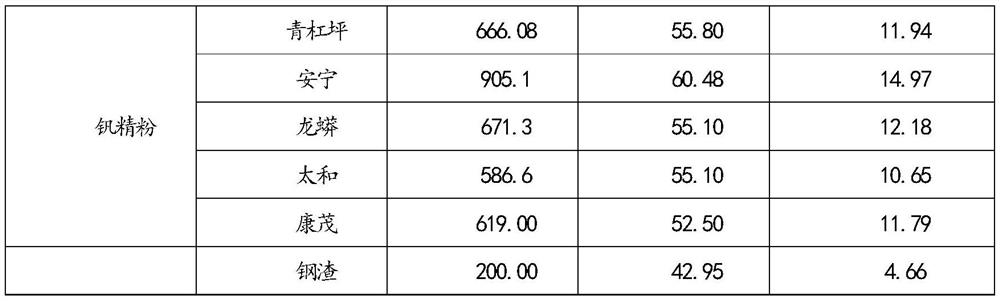

Method for improving proportion of steel slag in blended ore

PendingCN113930613AImprove the degree of mixingReduce ingredient costsMagnetic separationProcess efficiency improvementIron contentMagnetic separation

The invention discloses a method for improving the proportion of steel slag in blended ore. The method comprises the following four steps: (1), crushing the steel slag until the granularity of the crushed steel slag is less than or equal to 10 mm; (2), carrying out magnetic separation treatment on the steel slag, wherein the total iron content TFe of the steel slag after magnetic separation is greater than or equal to 18% and less than or equal to 23%; (3), and adjusting a batching structure participating in uniform ore blending according to the requirements of different types of steel for steelmaking smelting on the P content of molten iron; and (4), making a thick material layer and forming a low machine speed in the sintering mode of the uniformly mixed ore. The method solves the problems of resource occupation caused by steel slag accumulation and loss and waste of an iron element in steel slag takeout due to a low steel slag utilization rate.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Mixed molten salt heat transfer and storage working medium and preparation method and application thereof

InactiveCN107057656ALow cost of ingredientsSimple preparation processHeat-exchange elementsLiquid temperatureSteam pressure

The invention belongs to the field of energy storage material mixed molten salt and particularly relates to a mixed molten salt heat transfer and storage working medium. The mixed molten salt heat transfer and storage working medium is characterized by consisting of the following components by mass: 17.3 wt% of Ca(NO3)2, 40-45 wt% of KNO3, 4-10 wt% of NaNO3 and 30-38 wt% of NaNO2, and has the melting point of 85 DEG C and the boiling point of 590 DEG C. Application of the mixed molten salt heat transfer and storage working medium is characterized in that the mixed molten salt heat transfer and storage working medium is applied to the medium-high-temperature heat transfer and storage field of solar thermal power generation energy storage, wind and photoelectricity curtailment and 'coal to electricity' heat storage and supply or industrial waste heat recovery and storage. Mixed molten salt is low in component cost and extremely simple in preparation process, has very stable thermophysical property, is free from separation of a certain component in the use process, has favorable heat transfer performance in a liquid temperature zone, and has the saturated steam pressure of lower than two atmospheres. The mixed molten salt heat transfer and storage working medium is low in metal corrosivity and wide in application.

Owner:百吉瑞(天津)新能源有限公司

Novel light-colored casting material

InactiveCN106694795AImprove working environmentLow cost of ingredientsFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention relates to the technical field of casting materials, in particular to a novel light-colored casting material. The novel light-colored casting material is prepared from, by mass part, 15-19 parts of crystalline flake graphite powder, 20-30 parts of iron sesquioxide, 5-12 parts of divinyl polyamine, 10-20 parts of zircon powder, 21-32 parts of brown aluminium oxide powder, 25-35 parts of bauxite powder, 15-20 parts of bentonite, 4-9 parts of talcum powder, 1.8-3.2 parts of calcium stearate and 4.8-6.5 parts of polyvinyl butyral. After the formula is adopted, the surface quality of an iron casting cast through the light-colored casting material is obviously superior to that of traditional black graphite paint, and the work environment is powerfully improved. In addition, the novel light-colored casting material is low in ingredient cost and convenient to apply and popularize.

Owner:潘文进

Soil modifier, and preparation and application method thereof

The invention provides a soil modifier and an application method thereof. The soil modifier is an aqueous solution consisting of acrylamide, polyvinyl alcohol, sodium dodecyl benzene sulfonate and calcium chloride with certain mass fractions. In actual usage process, the soil modifier is uniformly mixed with an initiator and soil according to a certain mass ratio, and the soil is compacted for forming and is irradiated by microwaves for a certain time, so that a soil modifying building material is obtained. The soil modifier and the application method are simple, and additionally the soil modifier takes mine tailings, waste soil and other solid wastes as application targets and is beneficial for environment protection.

Owner:安徽红太阳新材料有限公司

Technique for smelting mother liquor of stainless steel from electric furnace

InactiveCN100348765CLow cost of ingredientsAlleviate the tension of insufficient resourcesElectric arc furnaceFerrosilicon

This invention relates to an electric furnace smelting technique for crude stainless steel liquid with its process including: a) materials proportioning. Waste stainless steel shares 15~25% in total added metal. Chromium-iron alloy shares 15~25% in total added metal. Lime is added to an amount of 30~45 kg per ton of added metal. And dephosphorized molten iron shares 35~60% with its element content of 2.50~3.80% of C, less than 0.020% of phosphorus, less than 0.040% of sulfur. b) Smelting. Oxygen blowing amount is controlled at 5~10 cu m / t and blowing flux is controlled at 1500~2500N cu m / h. c) reduction. Ferrosilicon powders are spitted at 2.5~3.5kg / t and carbon powders at 1.5~2.5kg / t. Or ferrosilicon is added at 2.5~3.5kg / t and aluminium at 1.5~2.5kg / t. d) tapping, with ultimate temperature controlled at 1640~1660 deg.C. This invention employs dephosphorized molten iron, which reduces the raw materials proportioning cost and smelting time as well as the consumption of electricity power, electrodes and patching materials in electric furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

Composite acidic blocking remover for oil well

InactiveCN106467729AImprove corrosion resistanceNo pollution in the processDrilling compositionBorehole/well accessoriesSodium BentoniteSilicon dioxide

The invention especially relates to a composite acidic blocking remover for an oil well, belonging to the technical field of blocking removers. The composite acidic blocking remover comprises, by mass, 10 to 15 parts of hydrochloric acid, 2.5 to 4.2 parts of diatomite, 3 to 9 parts of bentonite, 4 to 13 parts of a clay stabilizing agent, 12 to 18 parts of nanometer silica, 20 to 35 parts of acetic acid, 2.1 to 3.6 parts of nitric acid, 25 to 40 parts of glass fiber, 8 to 15 parts of methyl methacrylate and 5 to 10 parts of polyoxyethylene alkyl alcohol ether. With such a formula, the composite acidic blocking remover for the oil well has good anticorrosion effect and can both remove blocking and cleaning the oil well; moreover, the components of the composite acidic blocking remover are low in cost and friendly to environment, so the composite acidic blocking remover is easy to promote and apply.

Owner:王娟

Dyeing process of textile fabric

The invention provides a dyeing process of a textile fabric. The dyeing process comprises the following steps: 1, putting the textile fabric into a high-pressure dye vat; after injecting water into the high-pressure dye vat, injecting steam; 2, when the temprature of the water in the high-pressure dye vat is raised to 80 DEG C to 100 DEG C, adding a scouring agent into the high-pressure dye vat and stirring a solution; meanwhile, adding an alkaline solution and regulating the pH (Potential of Hydrogen) value; carrying out sealing treatment; 3, raising the pressure and temperature in the high-pressure dye vat; 4, keeping the pressure and temperature in the high-pressure dye vat and continually scouring; 5, after finishing scouring, reducing the pressure and temperature in the high-pressure dye vat to normal temperature and normal pressure; then draining the solution in the high-pressure dye vat; 6, carrying out water washing treatment on the textile fabric obtained by step 5 under normal temperature and normal pressure conditions; 7, putting the textile fabric washed with the water in step 6 into the dye vat and carrying out dyeing treatment. According to the dyeing process of the textile fabric, the dyeing effect of the textile fabric is excellent; the method is simple and convenient to operate, the dyeing is rapid and the coloring time is short, so that the dyeing process of the textile fabric is suitable for industrial and large-batch production.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Mixed nitrate heat-transfer and heat-storage working medium and application thereof

InactiveCN105385420ALow cost of ingredientsThe preparation process is simpleHeat-exchange elementsIndustrial wasteLiquid temperature

The invention belongs to the field of mixed molten salts of energy storage materials, and specifically relates to a mixed nitrate heat-transfer and heat-storage working medium. The working medium is characterized by being composed of, by mass, 15 to 22 wt% of Ca(NO3)2.4H2O, 50 to 56 wt% of KNO3, 10 to 18 wt% of NaNO3 and 9 to 20 wt% of LiNO3. The application of the mixed nitrate heat-transfer and heat-storage working medium is characterized in that the working medium is applied in the fields of medium-high temperature heat transfer and heat storage of solar-thermal power-generation energy storage, heat storage and heat supply of waste wind and photoelectricity and coal-converted electricity, or recovery and storage of industrial waste heat. According to the invention, the mixed molten salt has the advantages of low cost of preparation components, simple preparation process, stable thermophysical property, no occurrence of a separation phenomenon of a single component in the application process, and good heat-transfer performance in a liquid temperature range; meanwhile, saturated vapor pressure is lower than 2 atm. The working medium provided by the invention has low corrosivity to metals.

Owner:百吉瑞(天津)新能源有限公司

Health food for preventing prostatitis

InactiveCN1935032AGood treatment effectImprove stabilityFood preparationHot peppersTraditional medicine

The present invention relates to a health-care food for preventing and curing prostatitis. Its composition includes (by wt%) 25-35% of garlic, 12-17% of sauce, 2-5% of sesame oil, 8-11% of edible salt, 8-11% of hot pepper and 25-35% of water. Said health-care food can be made into tinned product form, bottled product form or vauum bagged product form.

Owner:上海旭东海普南通药业有限公司

High-temperature-resisting soft PVC (Polyvinyl Chloride) pipe fitting

InactiveCN103739992AImprove antioxidant capacitySmooth appearanceFlexible pipesHazardous substancePolyvinyl chloride

The invention discloses a high-temperature-resisting soft PVC (Polyvinyl Chloride) pipe fitting. The high-temperature-resisting soft PVC pipe fitting is composed of following components in parts by weight: 40-50 parts of polyvinyl chloride resin, 15-20 parts of crossed starch, 2-6 parts of magnesium stearate, 3-8 parts of hexamethylphosphoric triamide, 3-5 parts of PE (Polyethylene) wax with a high molecular weight, 2-8 parts of a wear-resisting modifying agent and 3-5 parts of powdered paraffin. According to the high-temperature-resisting soft PVC pipe fitting, hxamethylphosphoric triamide and the crossed starch are added so that the oxidization resistance of the PVC pipe fitting is greatly improved; the cost of the components is low and the high-temperature-resisting soft PVC pipe fitting is suitable for popularization and application; a high-temperature-resisting inflaming retarding and environment-friendly PVC modified material prepared from a plurality of environment-friendly materials has a smooth appearance and does not contain phthalate, polycyclic aromatic hydrocarbons, free phenols, free phenol flame retardants or boron compounds; the environment-friendly performance is better than national standards including European Union ROHS (Restriction of the use of certain Hazardous Substances), DEHP (Di-(2-ethylhexyl)phthalate), ATBC (Acetyl Tributyl Citrate) and the like; the high-temperature-resisting soft PVC pipe fitting can be widely applied to industrial fields of automobiles, electronic devices, instruments and meters, textiles, buildings and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com