Seamless steel tube for X80 delivery line and its manufacturing method

A technology of a seamless steel pipe and a manufacturing method, which is applied in the field of low-alloy steel manufacturing, can solve the problems of increased environmental pollution, long manufacturing cycle, and reduced yield, and achieves the effects of low alloy component cost, short manufacturing cycle, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

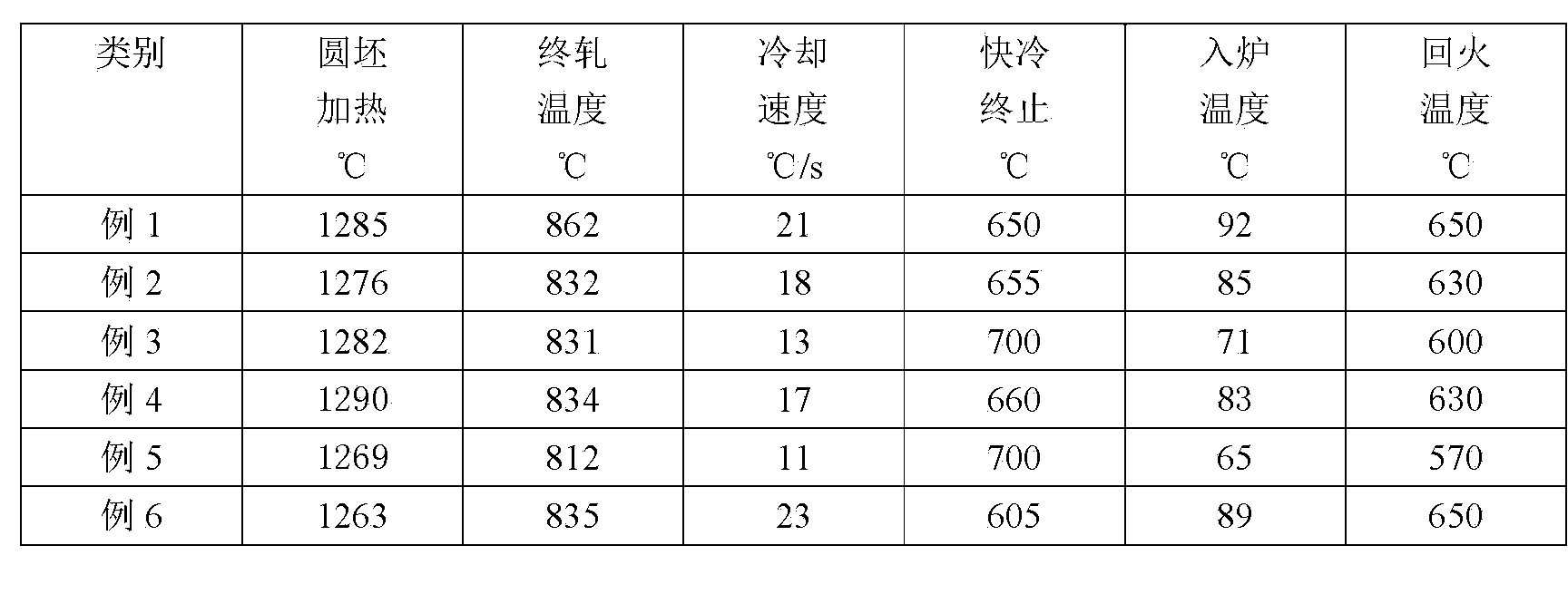

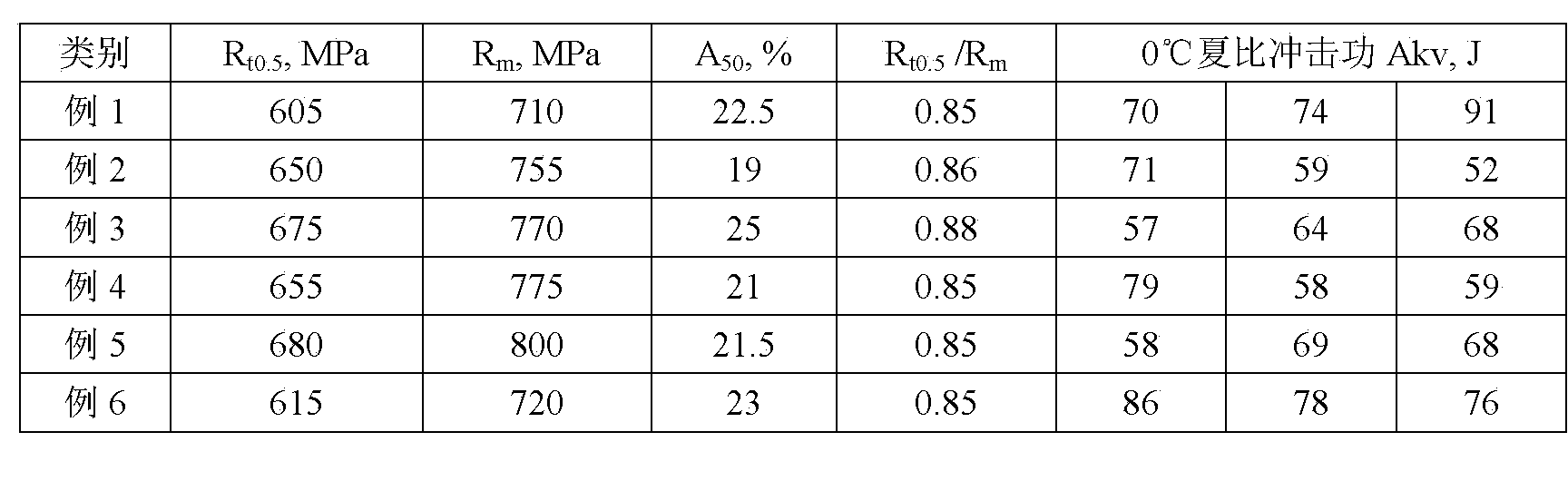

[0030] The following examples illustrate the implementation of the present invention, and these examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way. Table 1 shows the chemical composition of the steel in the example, and its technological process is converter smelting—external refining—square billet continuous casting—round billet rolling—ring furnace heating—bacterial piercing machine pipe piercing—continuous pipe rolling mill pipe rolling—fixed Diameter forming - controlled cooling - tempering heat treatment. The specific process system of the embodiment is shown in Table 2, and Table 3 shows the mechanical properties of the steel of the embodiment.

[0031] The chemical composition (wt %) of the embodiment of table 1

[0032] category

C

Si

mn

P

S

Nb

Ti

Cr

Fe

CE IIW

example 1

0.14

0.31

1.33

0.010

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com