Patents

Literature

35results about How to "Optimize form factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

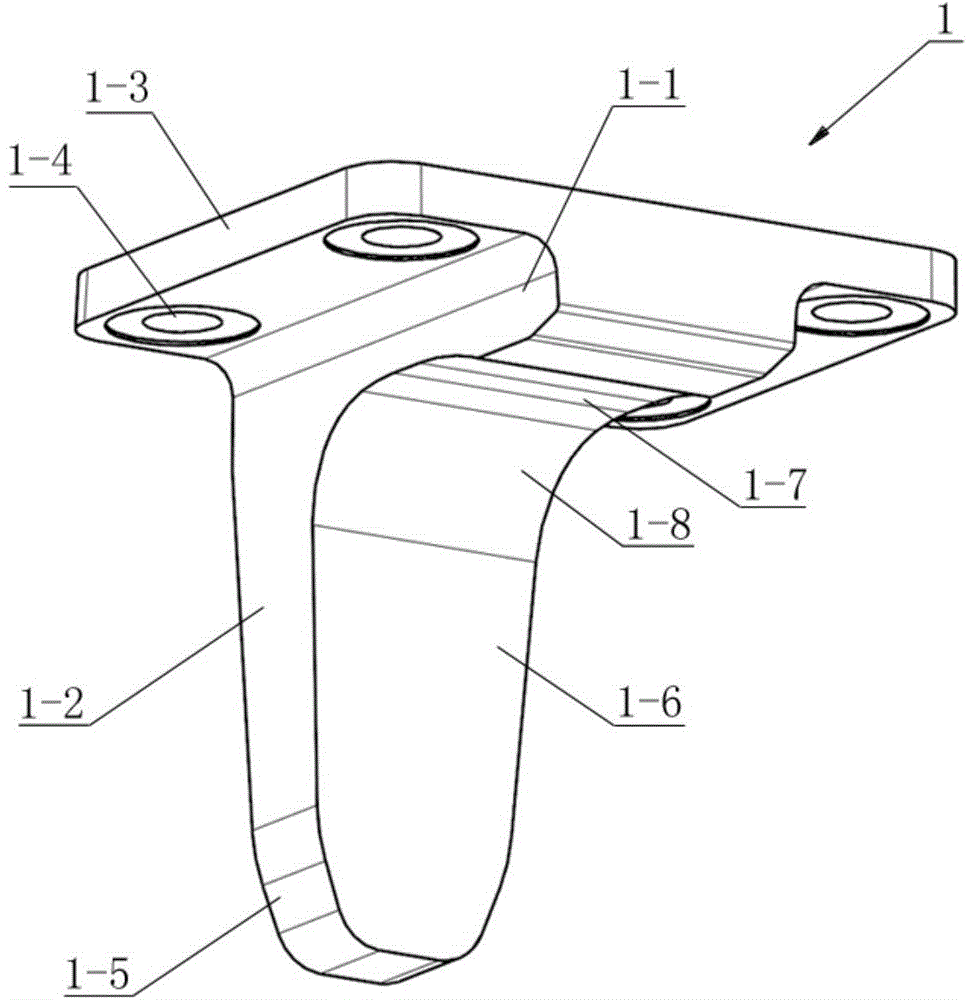

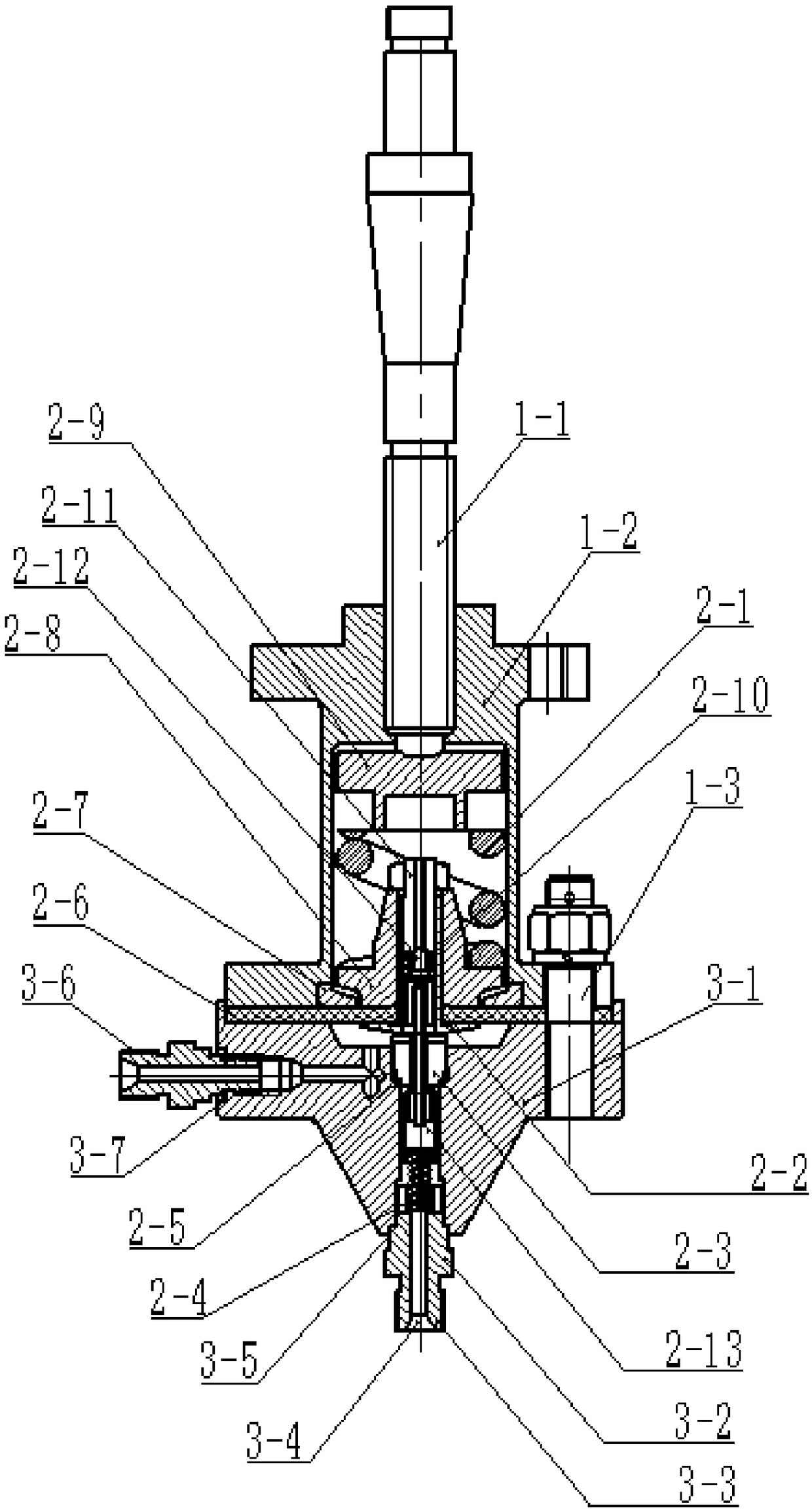

Railway vehicle and derailment safety protective device thereof

ActiveCN104627195AStrength requirements to prevent off-lineDoes not affect normal drivingRail derailment preventionDerailmentContact mode

The invention discloses a derailment safety protective device which is shaped like an inverted L. The derailment safety protective device comprises a transverse part (1-1) and a longitudinal part (1-2) which is located below one side of the transverse part (1-1) and perpendicular to the transverse part (1-1). An installation seat formed by an outwards extending wing plate (1-3) is arranged at the two sides of the transverse part (1-1) in the width direction, and bolt holes (1-4) are formed in the installation seat; the inner side face of the longitudinal part (1-2) is a stopping face (1-6). The derailment safety protective device is simple in structure, small in size, light in weight, easy to install, maintain and replace, reasonable in structural design, stable and reliable in contact mode with a rail, stable and reliable in mechanical property during contact, and capable of remarkably improving the safety protective level of a vehicle.

Owner:CRRC QINGDAO SIFANG CO LTD +1

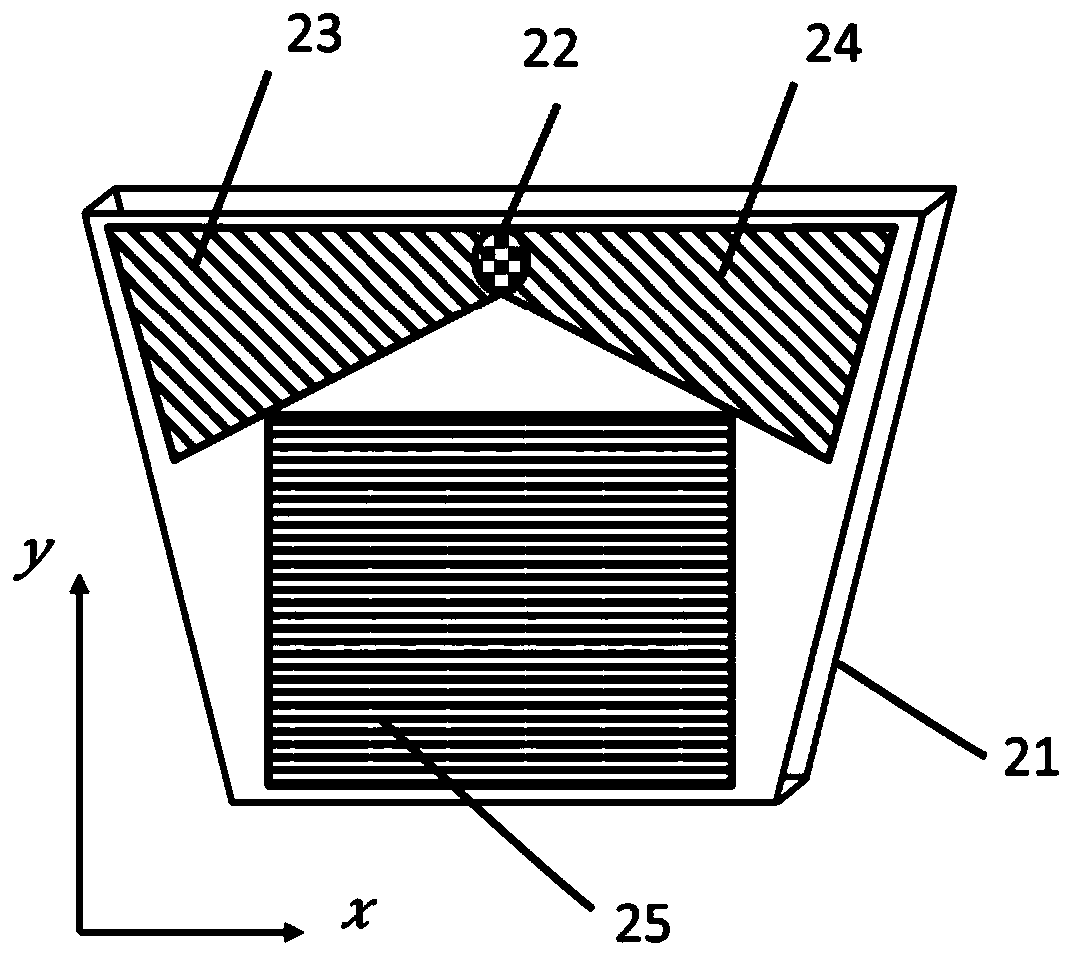

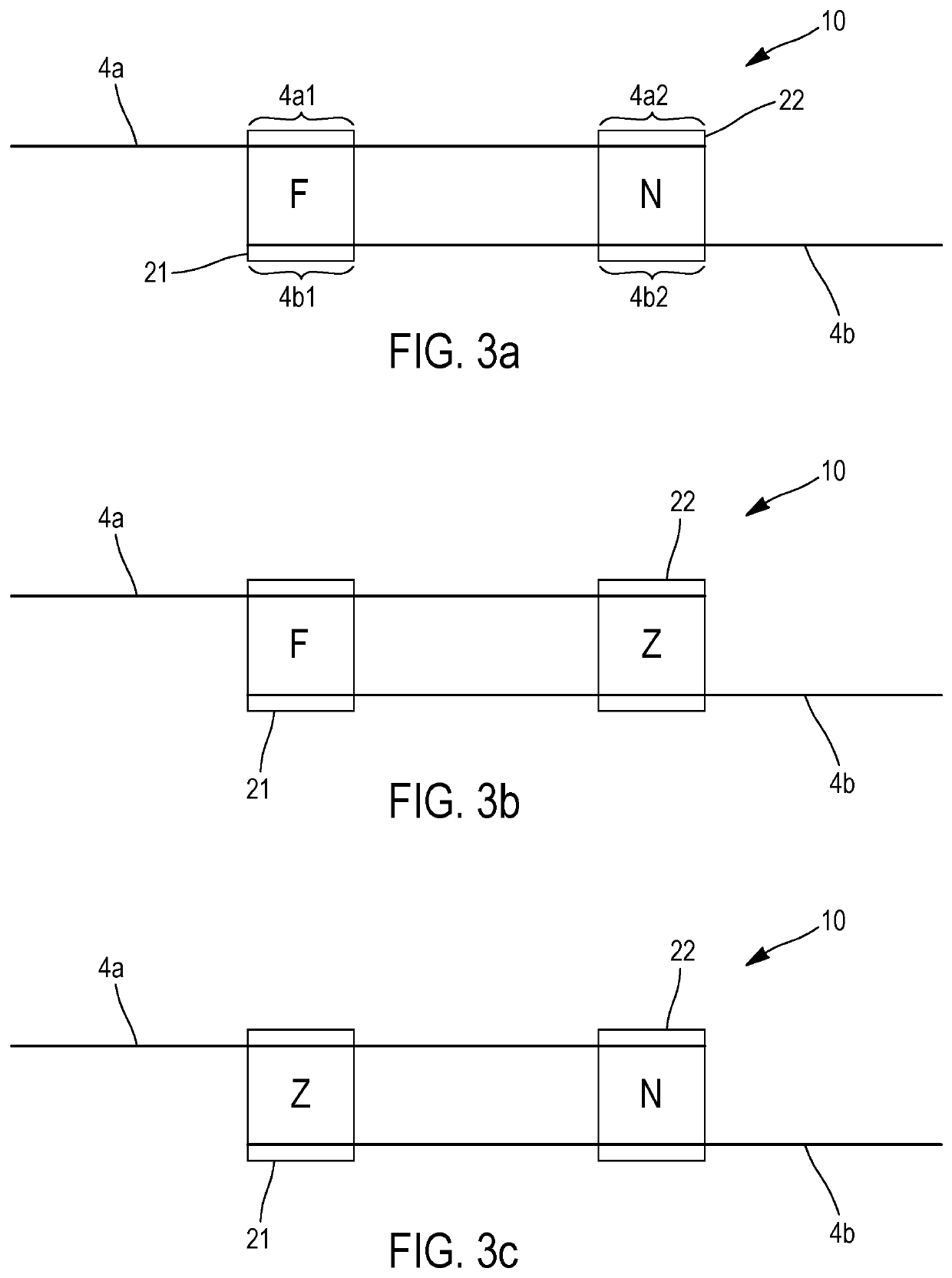

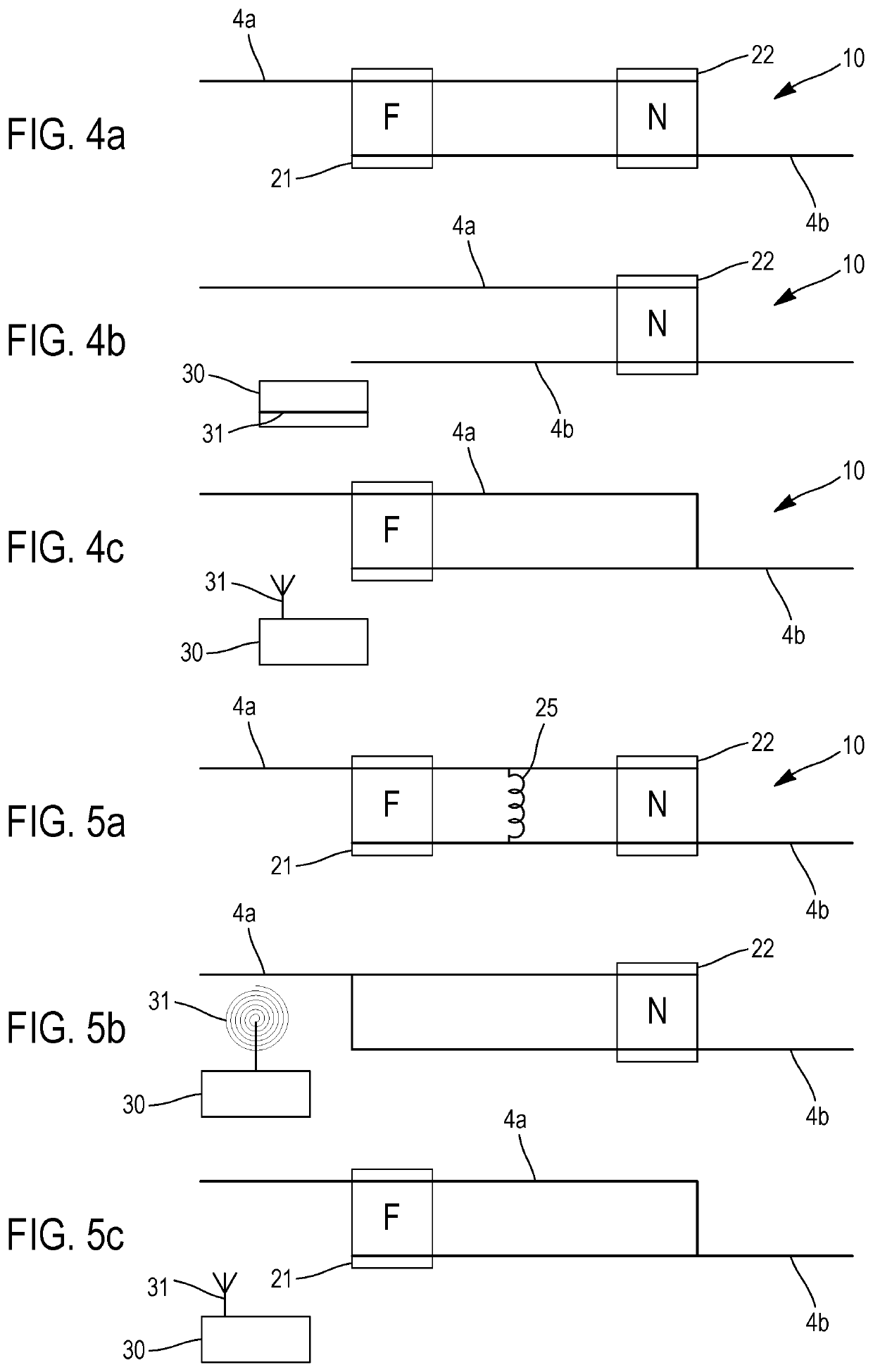

Display element, personal display device, method and use for displaying images on a personal display

ActiveCN110582716AReduce horizontal sizeEfficient arrangementDiffraction gratingsPlanar/plate-like light guidesWavefrontTotal internal reflection

The present invention relates to a display element for a personal display system, a personal display, and methods and uses. The display element comprises a light guide (21) capable of guiding light by total internal reflection, a diffractive in-coupling grating (22) and a diffractive out-coupling grating (25). The in-coupling grating is adapted to couple light directed thereto to the light guide to allow the light to propagate to the out-coupling grating. According to the invention, the incoupling grating is adapted to couple light into at least the light guide as at least two diffracted wavefronts, and the display element further comprises at least two different exit pupil expansion gratings (23, 24) adapted along the Different paths direct the wavefronts to the outcoupling gratings respectively. The invention allows reducing the size of diffractive display elements.

Owner:DISPELIX OY

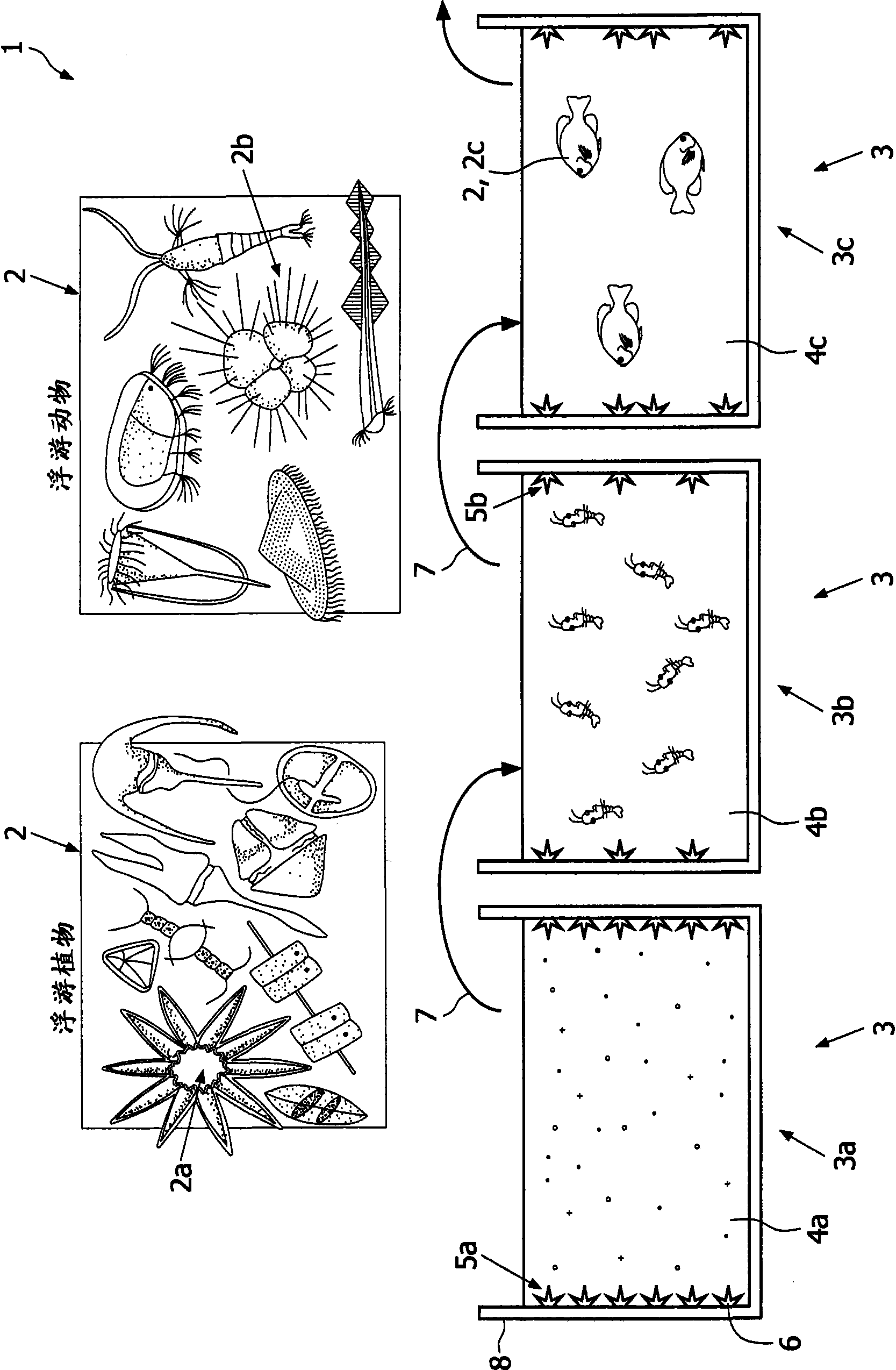

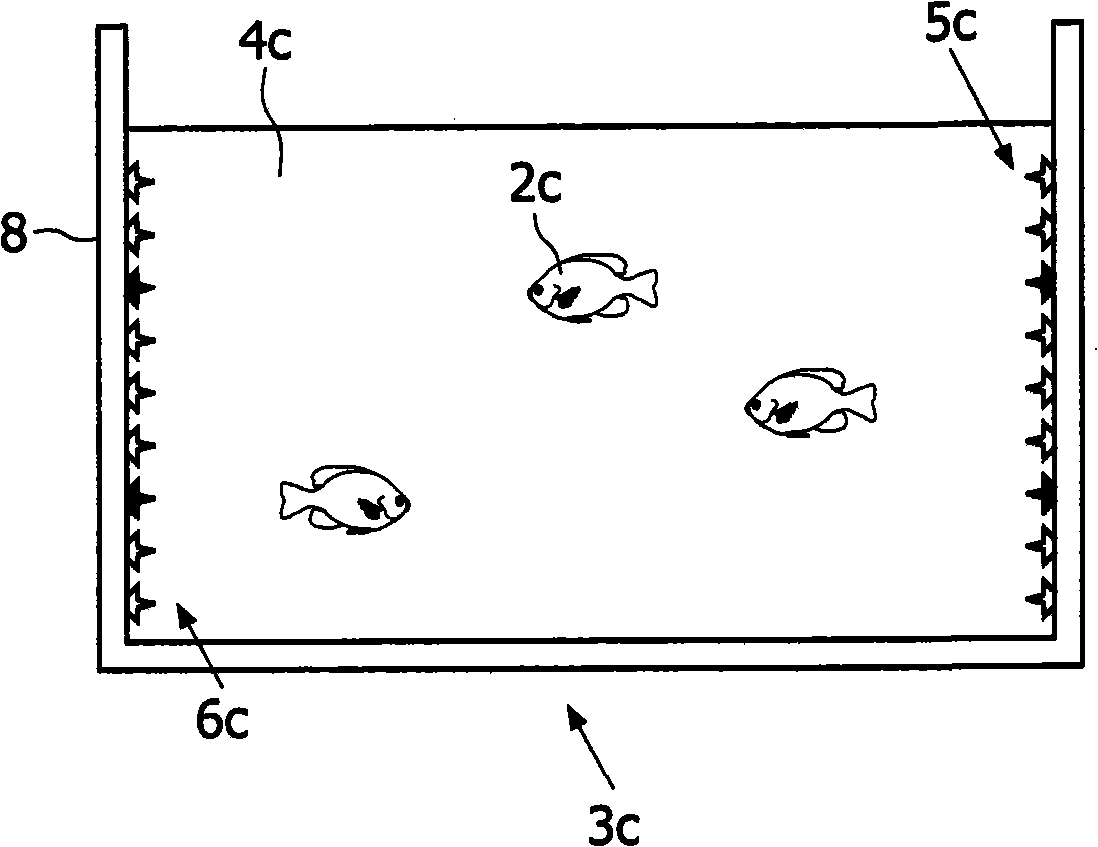

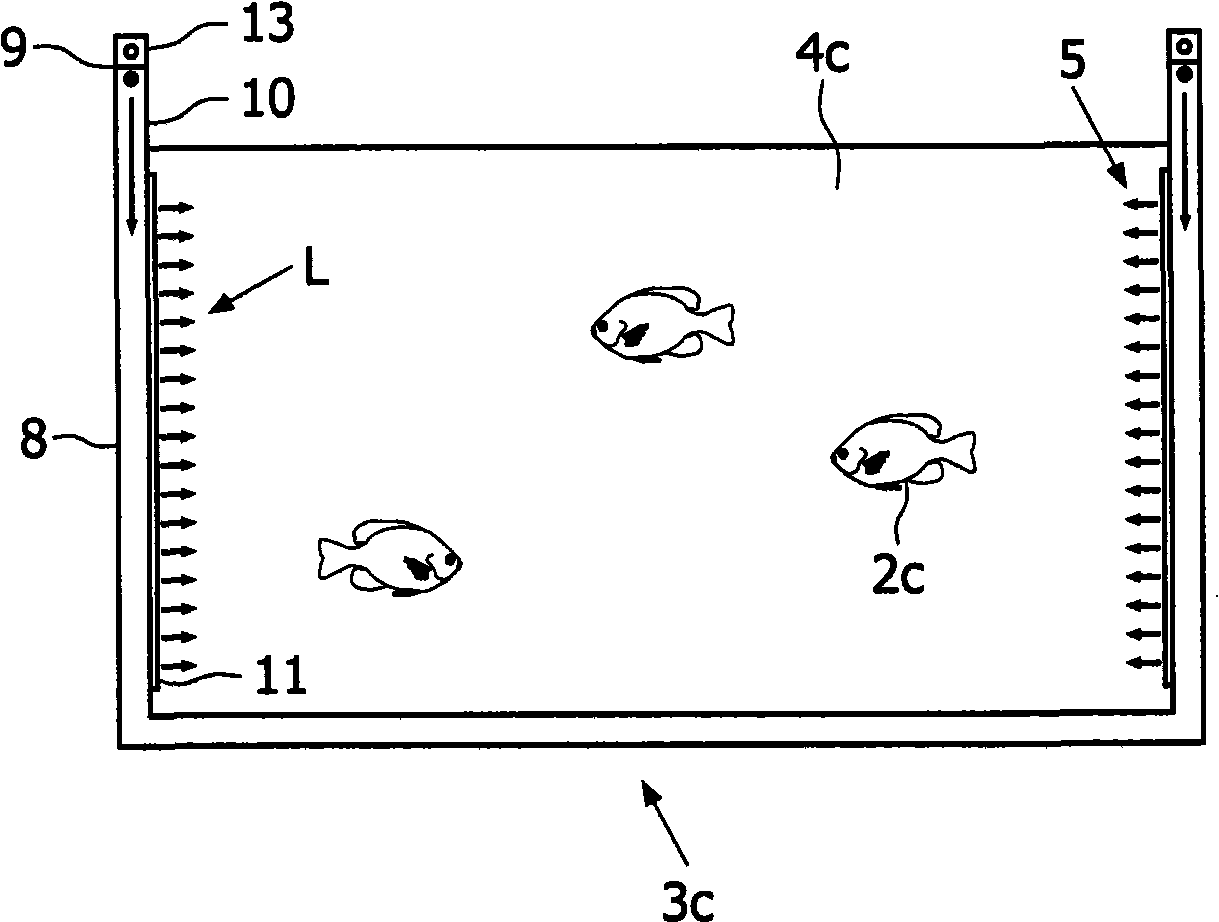

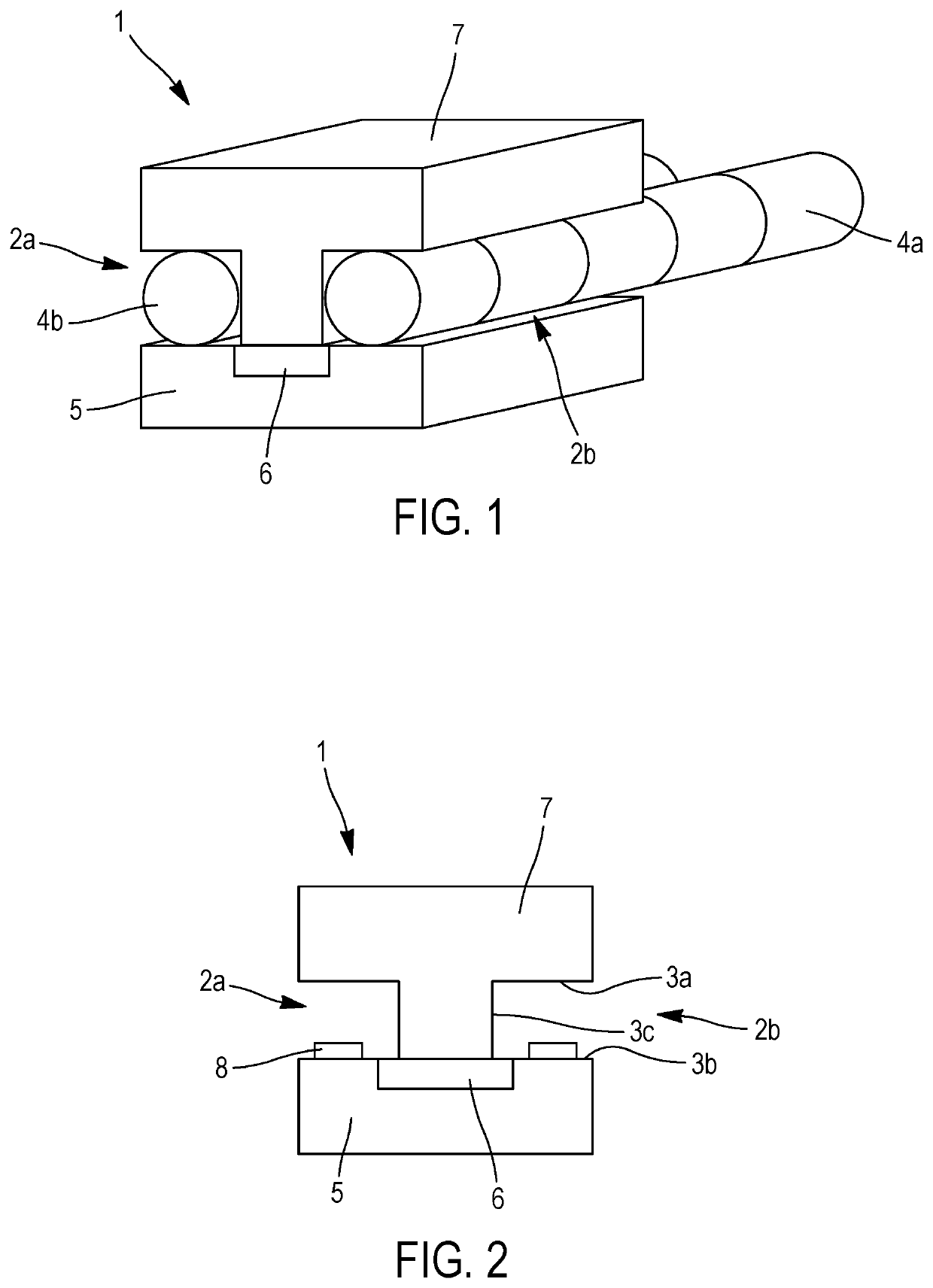

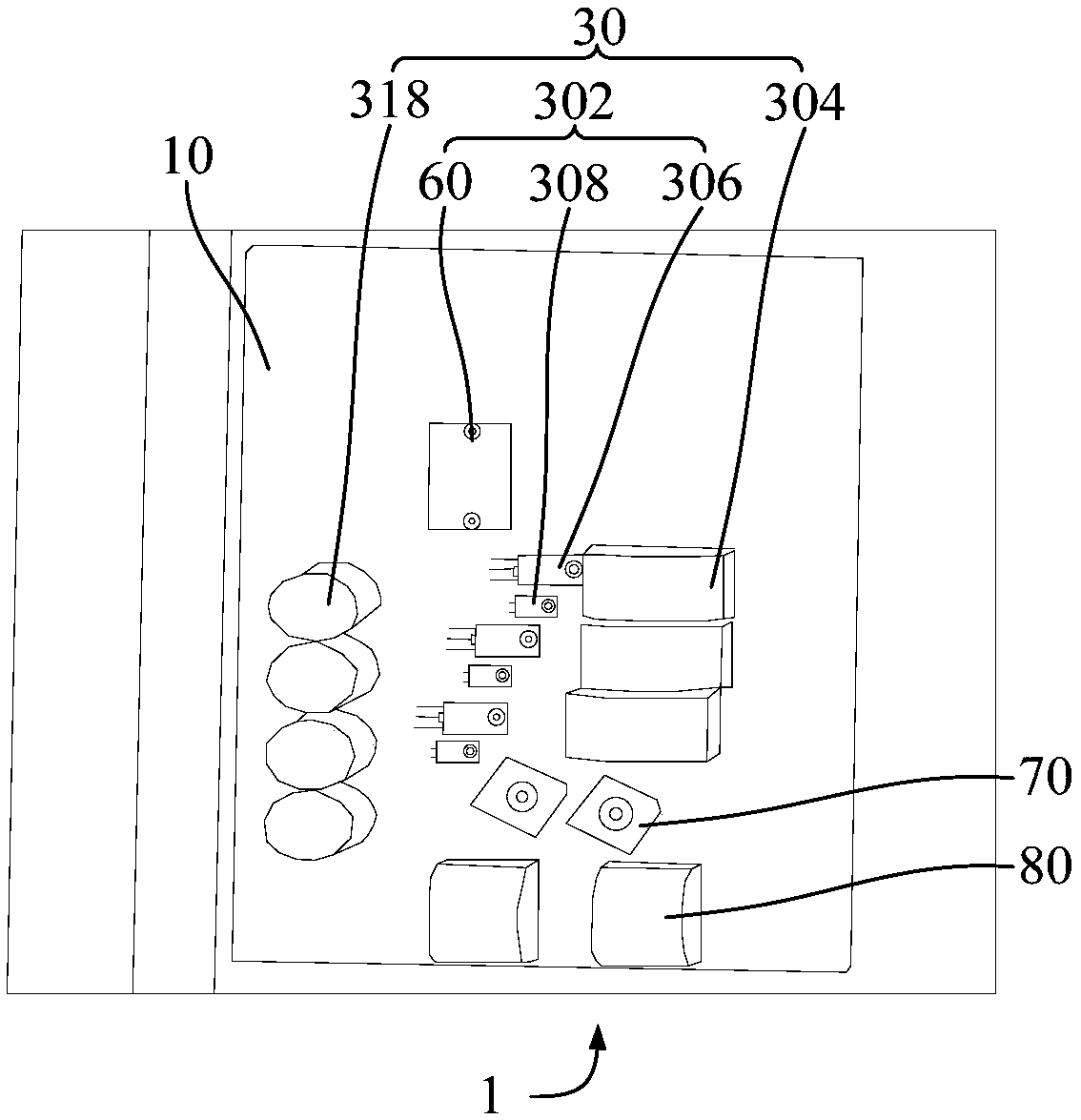

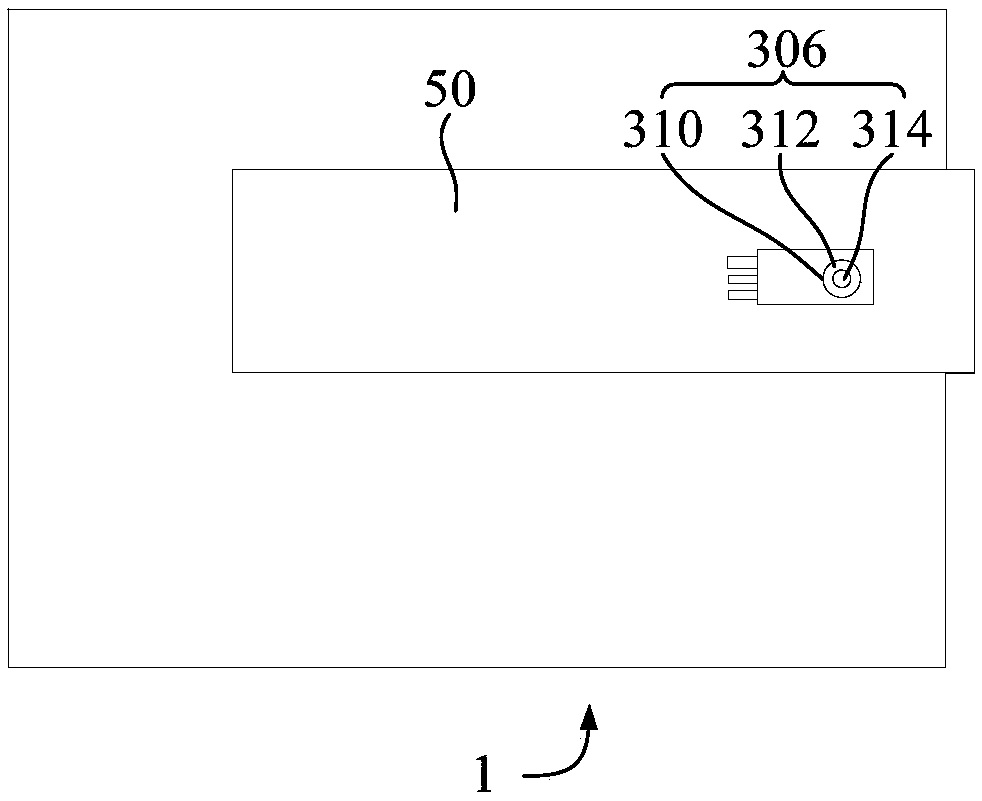

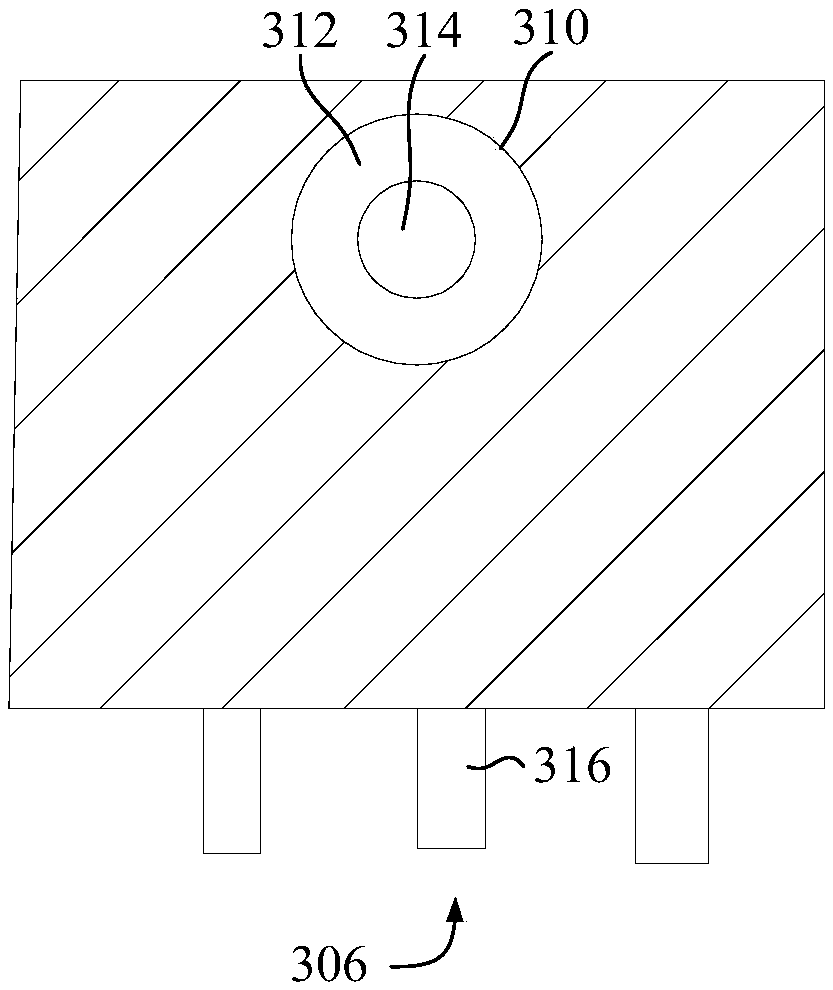

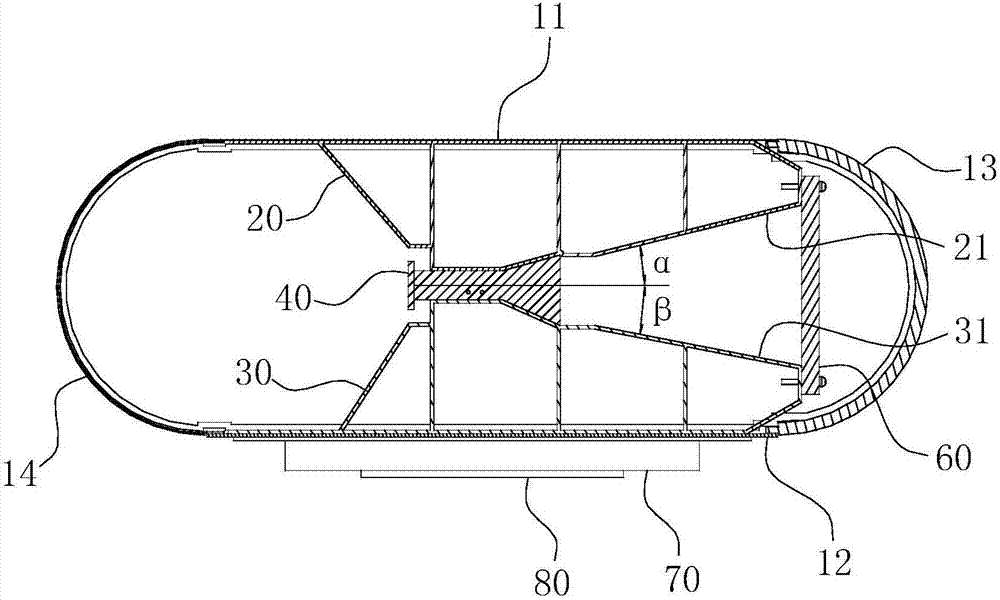

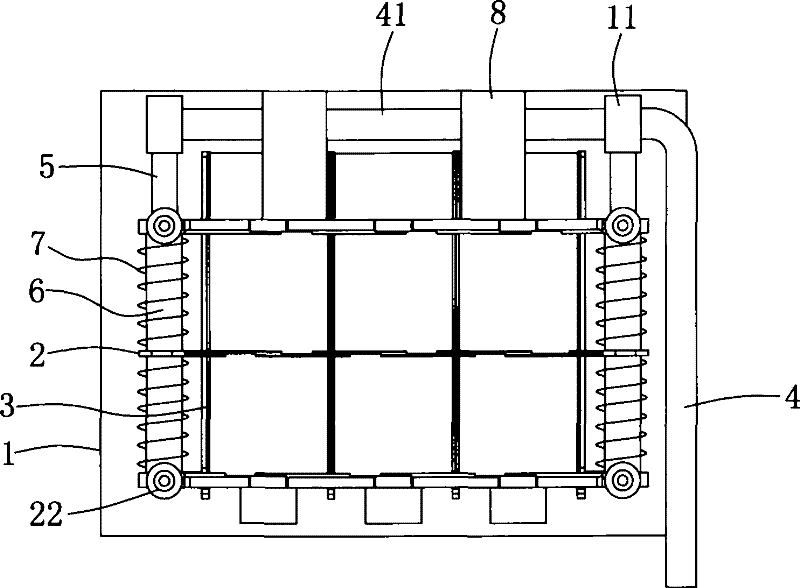

Bioreactor apparatus, bioreactor system, and method for growing light energy dependant biological species

InactiveCN101868529AImprove performanceImprove cooling effectBioreactor/fermenter combinationsBiological substance pretreatmentsEcoregionLight energy

The invention relates to a bioreactor apparatus(1) for growing of biological species(2), comprising at least one basin device(3) defining a first habitat(4a) for a first species(2a), and a first lighting device(5a) having one light emitting solid- state lighting source(6), adapted for the first species(2a) by emitting light(L), wherein the solid-state lighting source(6) illuminates said habitat(4) using light energy emitted from the solid-state lighting source(6), wherein the bioreactor apparatus(1) comprises a second habitat(4b), adapted for a second species(2b). The invention further relates to a bioreactor system(20) comprising two bioreactor apparatus(1a,1b), one adopted as an aquatic ecoregion, one adopted as a terrestrial ecoregion, both combined to form a complex artificial ecoregion and a method for growing light energy dependant biological species(2) in one bioreactor apparatus(1), comprising: illuminating a first species(1) in a first habitat(4a) by a first lighting device(5a), transferring the grown first species(2a) to a successive habitat(4b, 4c, 4d,... ), separated from the previous habitat(4), via a connection system(7), illuminating a successive species(2b,2c,... ) in said successive habitat(4b,4c,4d,... ) by a successive lighting device(5b,5c,... ), and repeating the steps transferring and illuminating until the desired species(2) has grown to an optimum.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

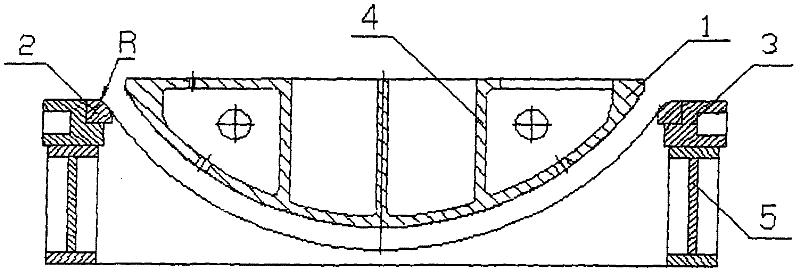

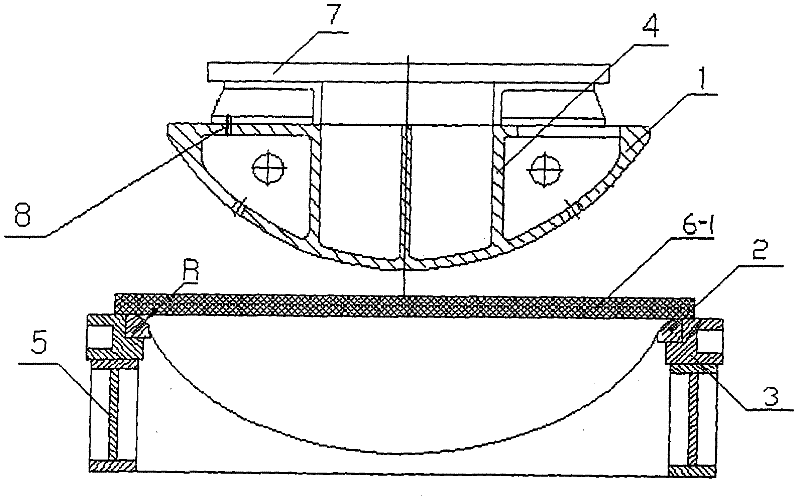

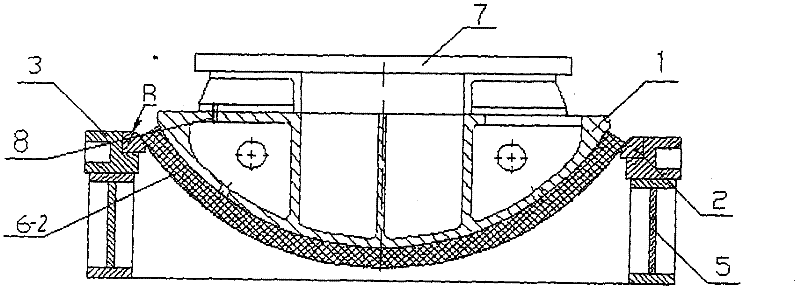

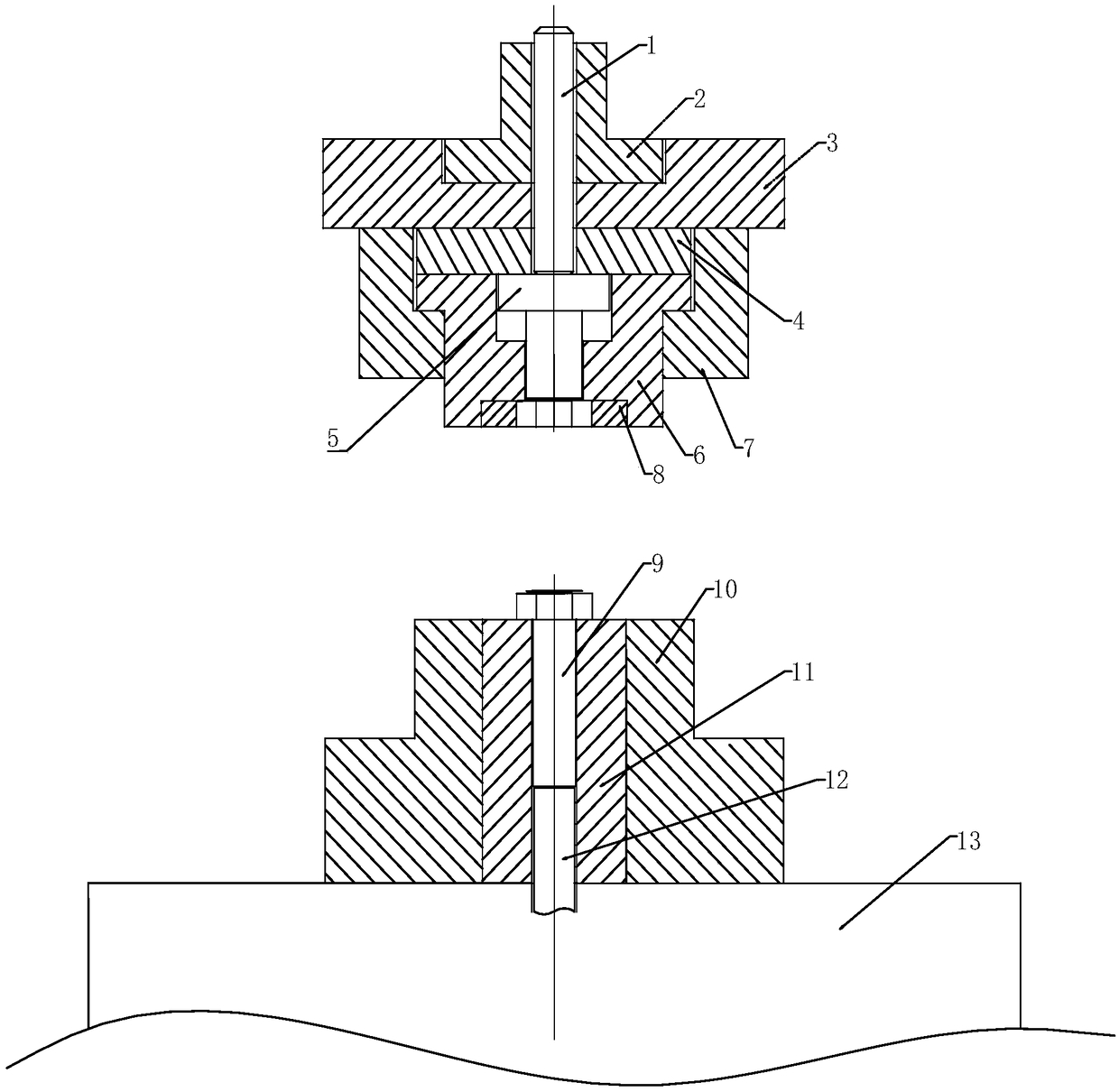

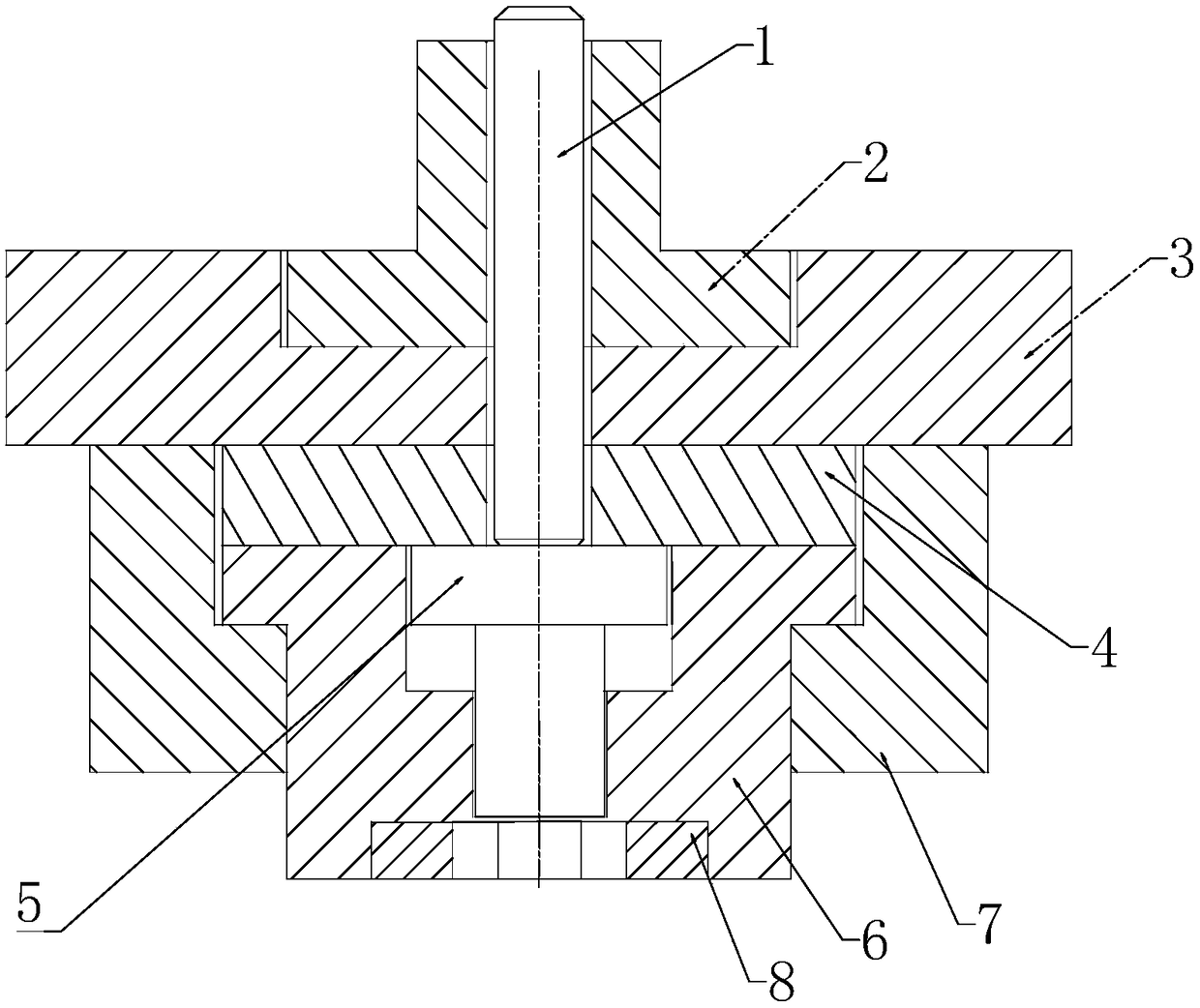

Molding die and molding process of thick-wall spherical seal head for hydrogenation reactor

InactiveCN102161064AImprove surface qualityDoes not cause surface microcracksShaping toolsHollow articlesPunchingThick wall

The invention relates to a molding die and an advanced molding and punching process method of a thick-wall spherical seal head product for a big hydrogenation reactor. The molding die comprises an upper die and a lower die, wherein the upper die is in a shape of a downwards convex spherical circular arc face; the lower die is in a shape of a downwards concave spherical circular arc face; and the upper die and the lower die have the same axle center and are placed in the same direction. The molding process method comprises the following steps that: the upper die is fixedly connected to a press machine; a supporting leg of the lower die is placed on a lower worktable of the press machine; the upper die and the lower die are aligned to have the same center when arranged; and a heated workpiece is punched into the thick-wall spherical seal head. By the molding process method, the surface quality of the spherical seal head is highly improved; a surface microcrack caused by uneven molding cannot be generated; the thickness of punched wall is uniform; and the outline dimension and the circular degree are better. By the process method, additionally feeding and discharging allowance is not required for the thick-wall spherical seal head product for the big hydrogenation reactor. The process method is simple in operation, high in molding reliability, good in outline dimension and short in process period.

Owner:XINXIANG ZHONGLIAN PETROCHEM CONTAINER HEAD FORMING

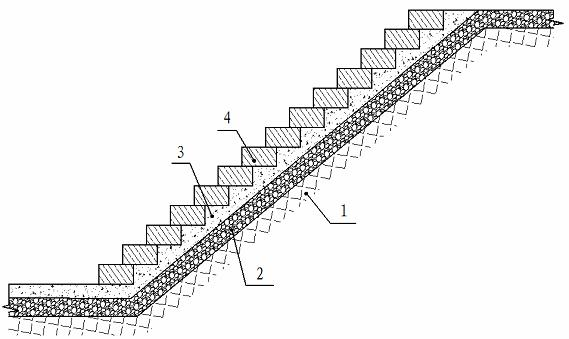

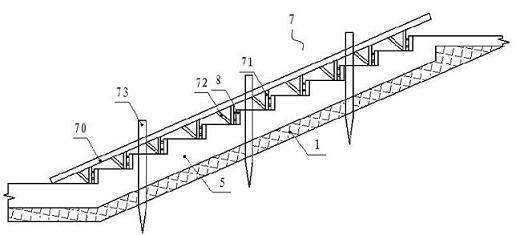

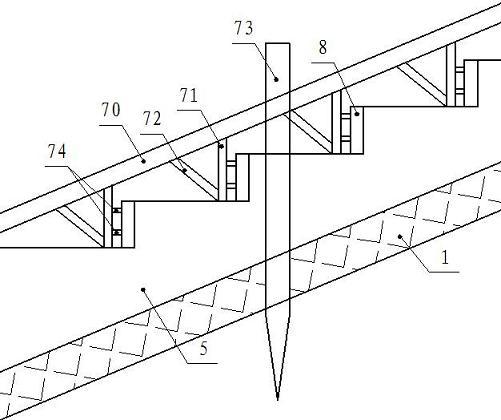

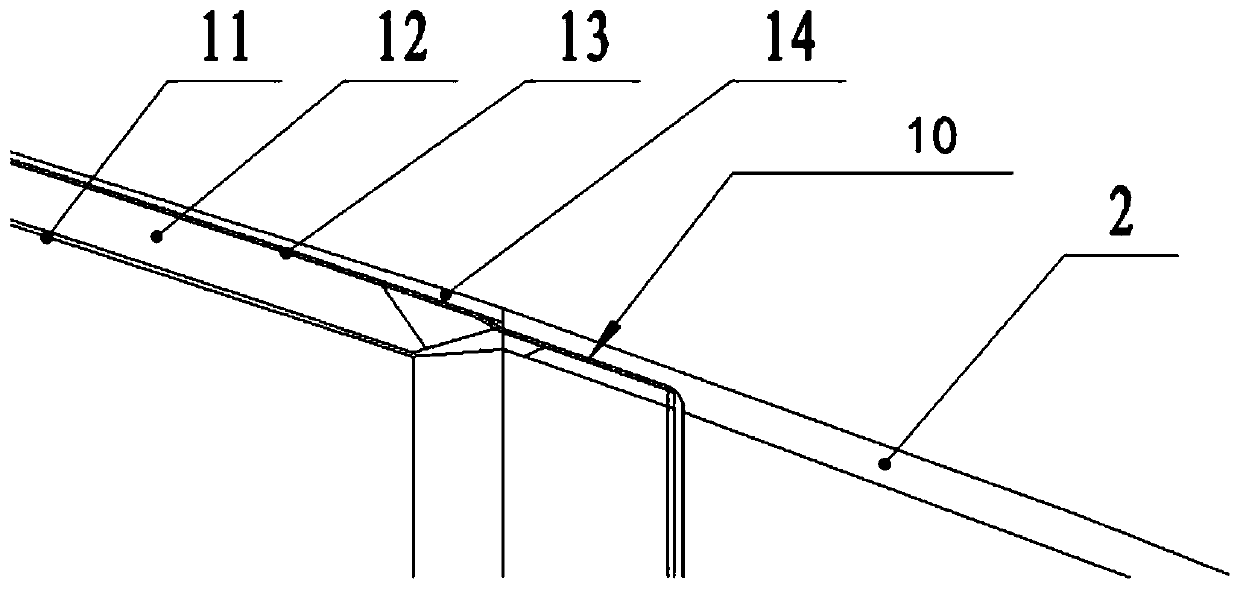

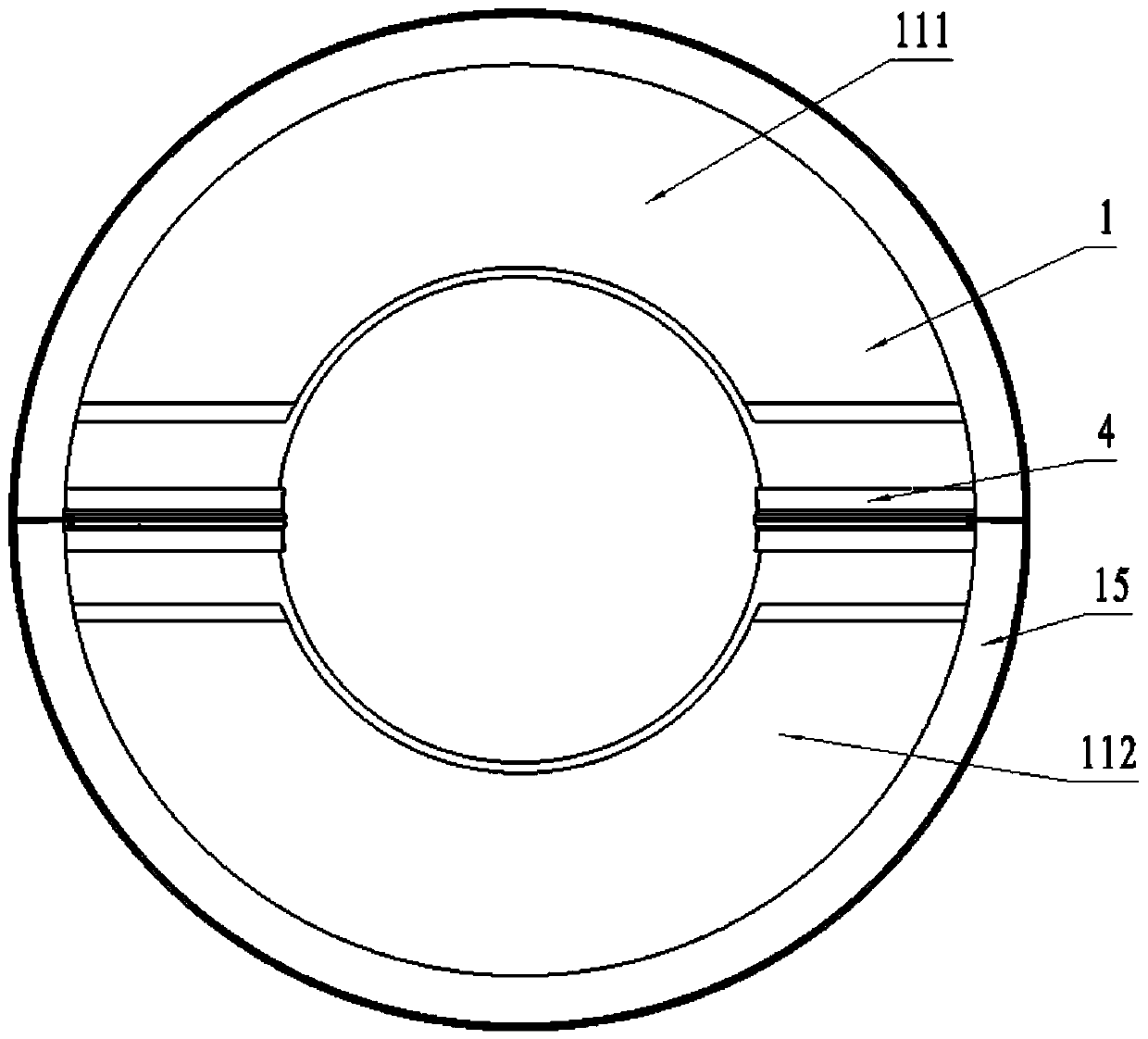

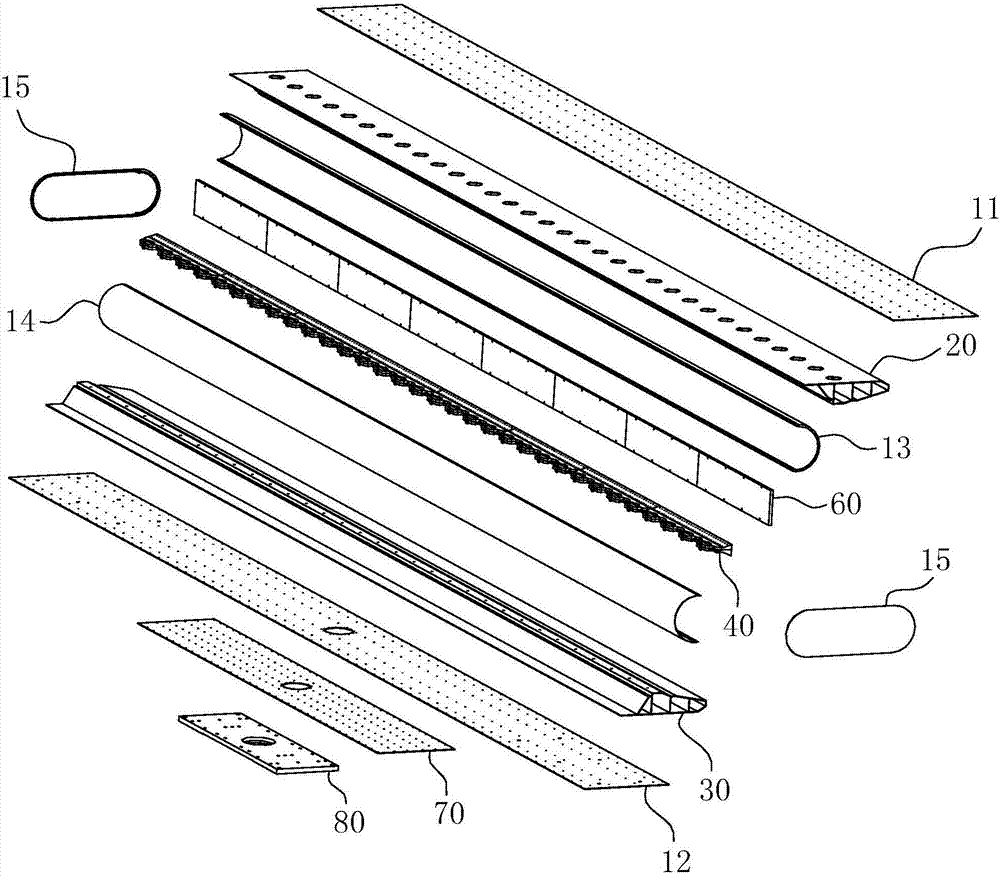

Suspended formwork pouring method for concrete foundation steps

ActiveCN102677895AEasy to assemblePrecise positioningForms/shuttering/falseworksBuilding material handlingStructural engineeringUltimate tensile strength

The invention relates to a suspended formwork for concrete foundation steps and a suspended formwork pouring method for pouring concrete foundation steps by using the suspended formwork. The suspended formwork comprises one or a plurality of formwork racks, each formwork rack comprises at least one longitudinal beam and a plurality of structural units distributed along the longitudinal beams in turn, each structural unit comprises a vertical formwork rack for mounting a vertical formwork and an inclined strengthening rib for fixing the vertical formwork rack, one end of the vertical formwork rack is fixedly connected with the longitudinal beam, and the two ends of the inclined strengthening rib are fixedly connected with the longitudinal beam and the vertical formwork rack respectively to form a steady triangular structure. The method comprises the following steps: (1) leveling up and tamping a foundation; (2) mounting a suspended formwork; and (3) pouring concrete foundation steps by use of the suspended formwork fabricated in step (2). The suspended formwork provided by the invention has the advantages of simple structure, accurate positioning and easiness in operation, and can be repeatedly used. The steps constructed using the method provided by the invention have the advantages of regular structure, esthetic appearance, high strength, and greatly improved quality.

Owner:北京正和恒基滨水生态环境治理股份有限公司

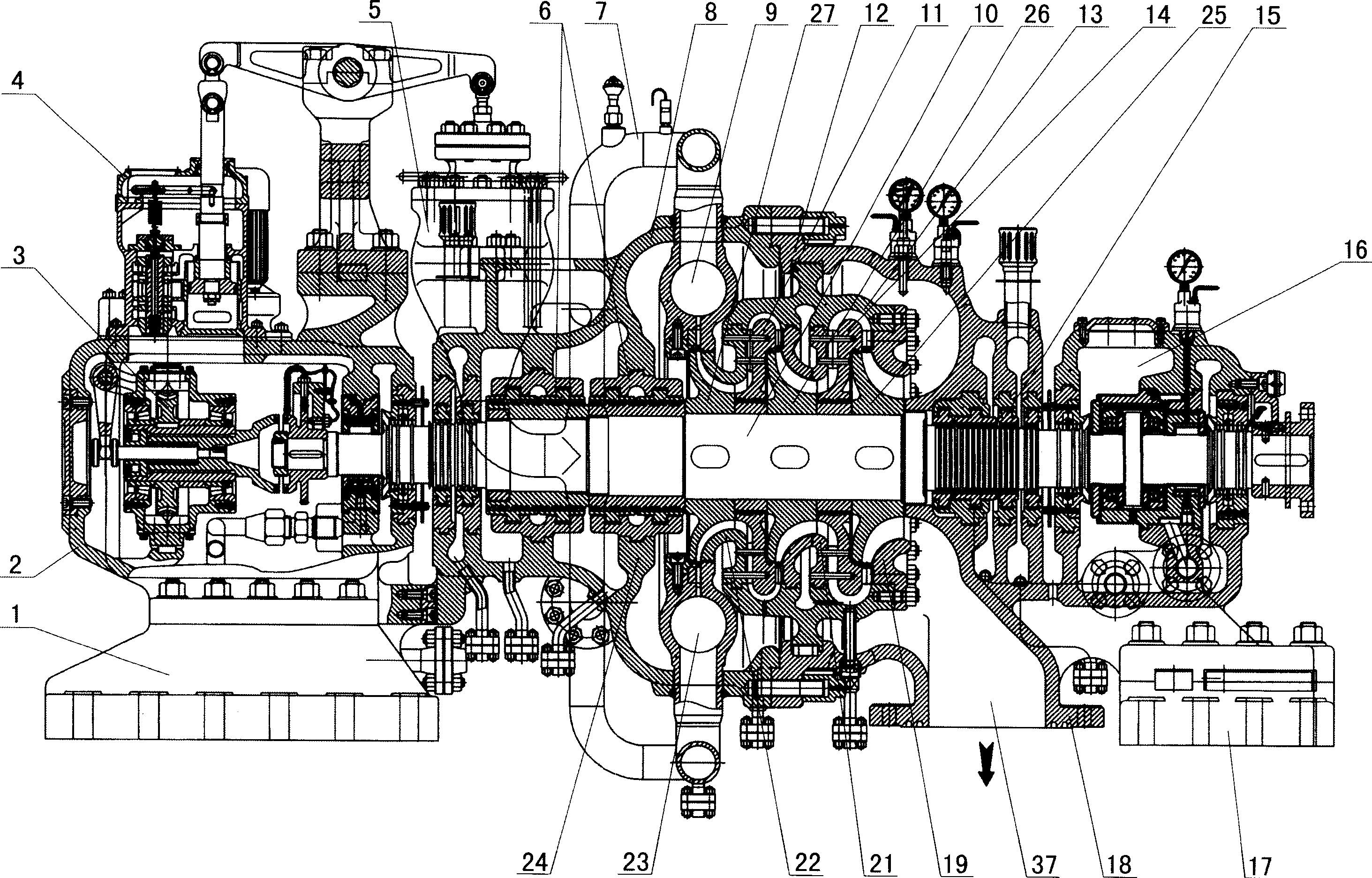

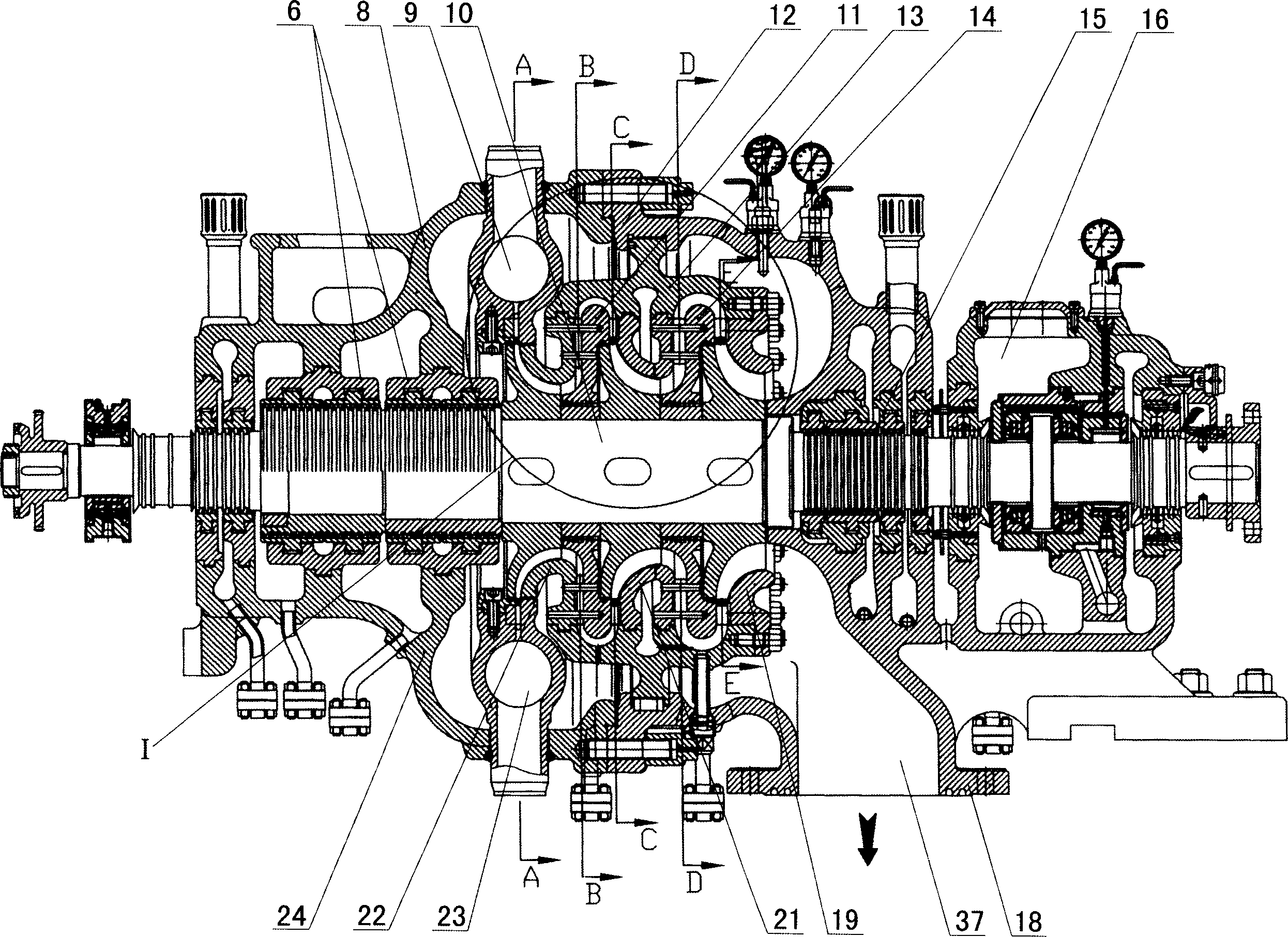

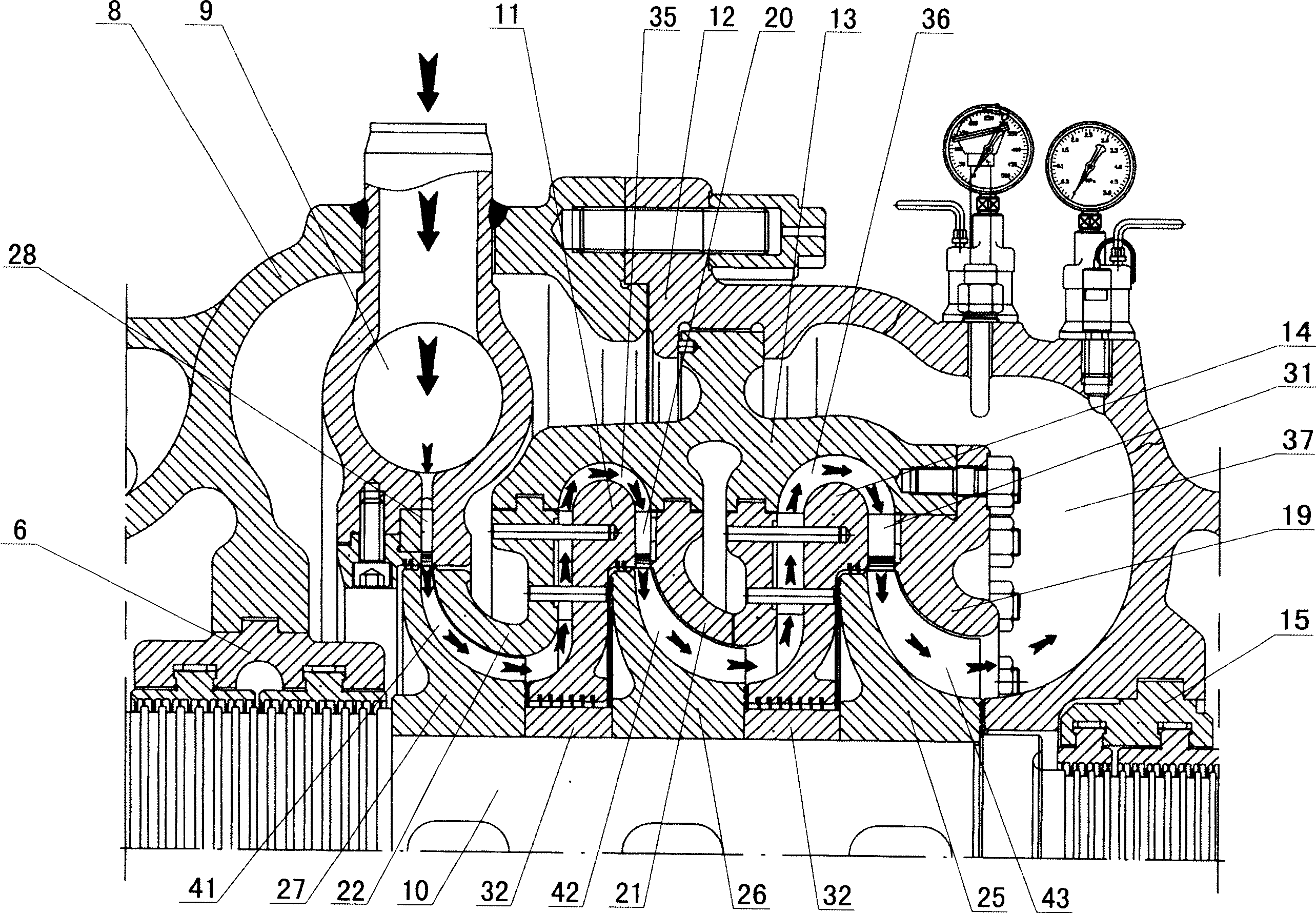

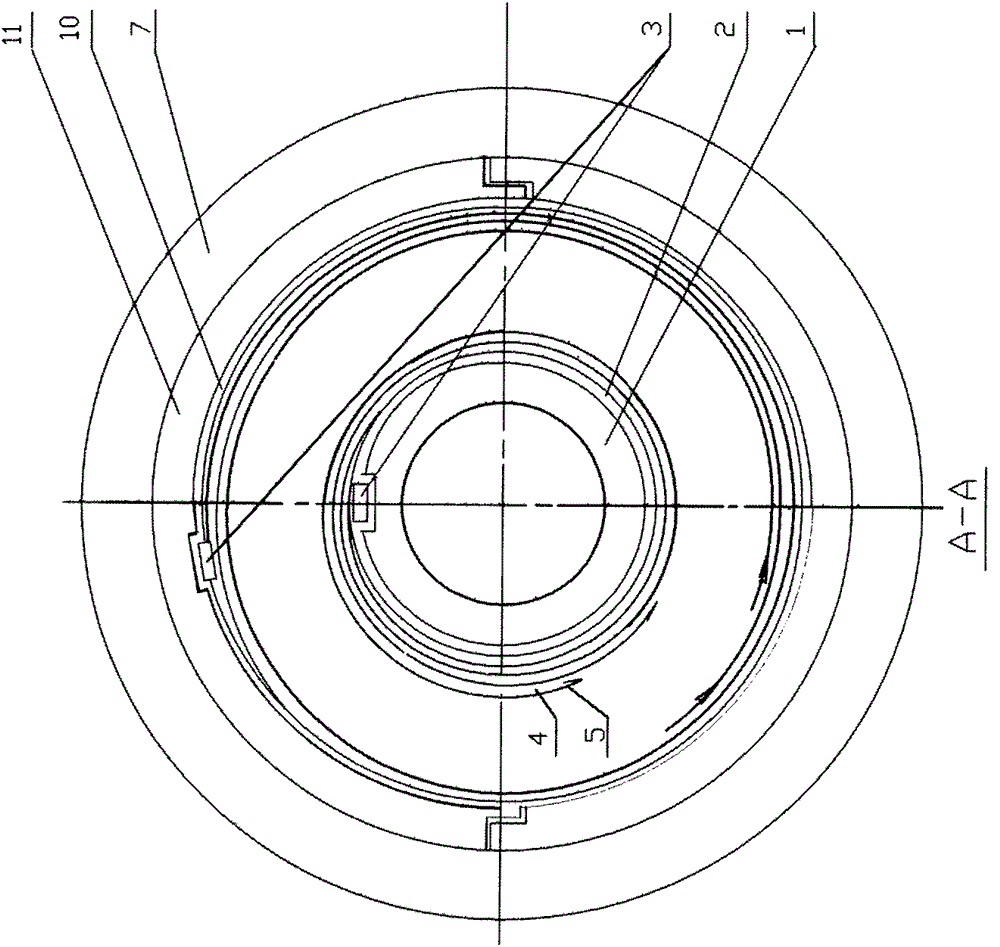

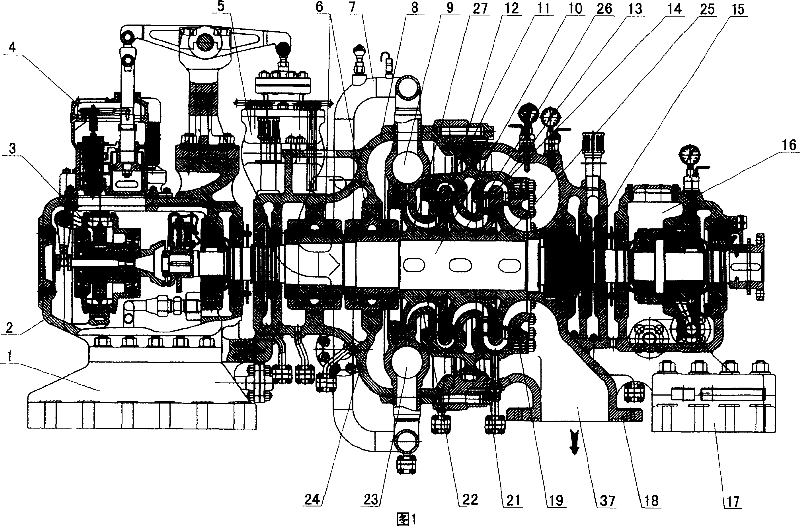

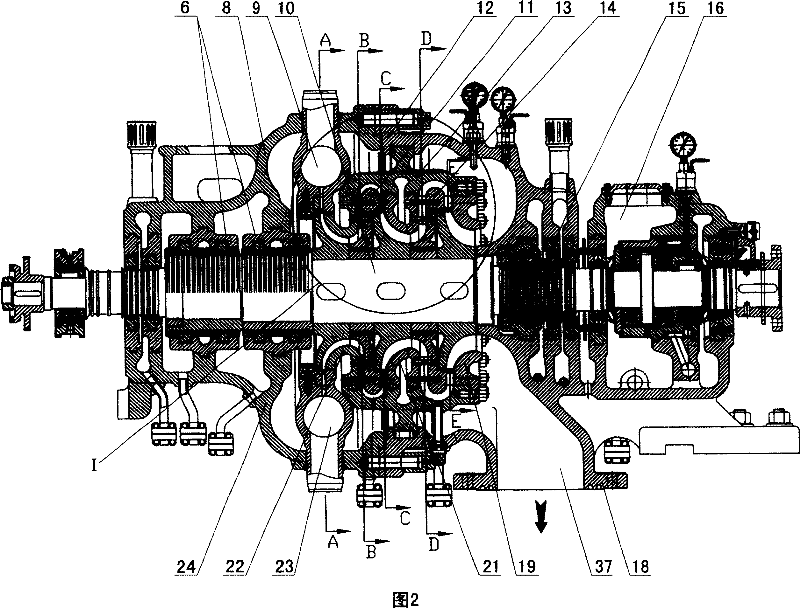

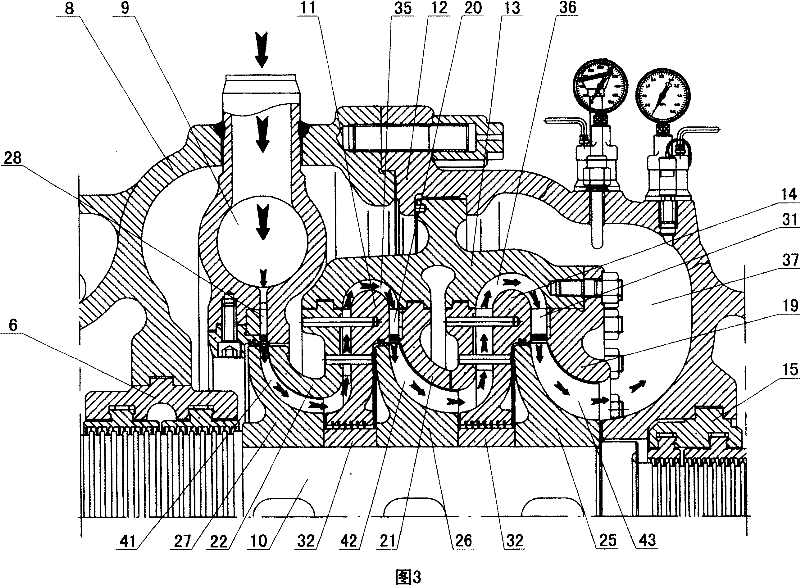

Radial-flow steam turbine

ActiveCN1743645AReasonable internal structureImprove heat conversion efficiencyNon-positive displacement enginesHigh energyStator

A radial-flow turbine containing cylinder, stator and rotor installed in cylinder, featuring a complete steam flow path, steam admission pipe, steam admission chamber, at least two or plurality of endiocentric energy converting flow path groups, at least one steam flow reversible flow path group and exhausting chamber, wherein the number of steam flow reversible flow path group is one less then that of endiocentric energy converting flow path groups, all endiocentric energy converting flow path groups and steam flow reversible flow path group are alternately arranged along axial direction of rotor, plurality of convergent nozzles are set at the outlet of steam admission chamber and end of flow reversible flow path groups, comparing with current technology. Said invention has advantages of high energy conversion efficiency and fine anti overspeed, anti vibration and shock resistance performance.

Owner:黄少斌 +2

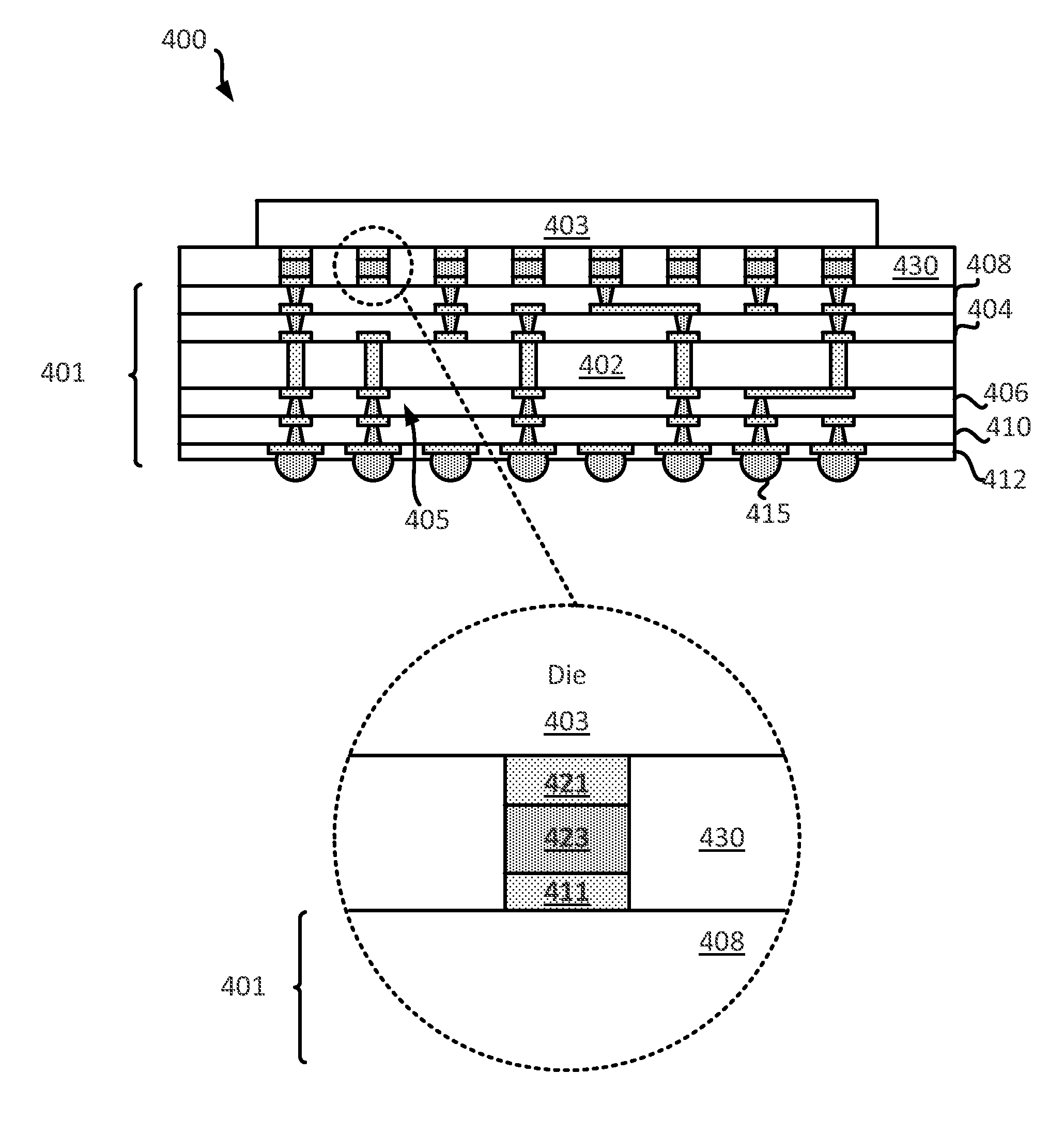

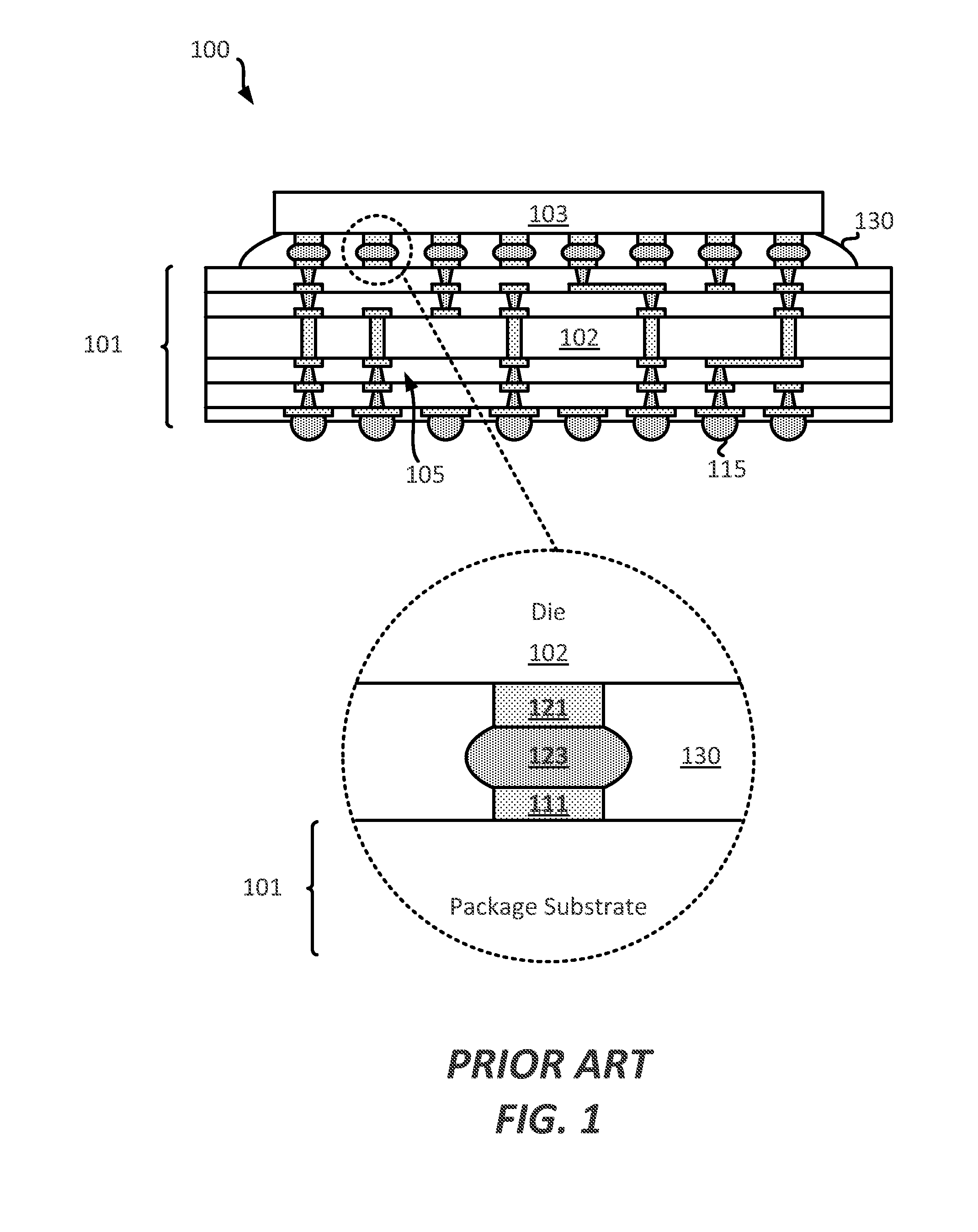

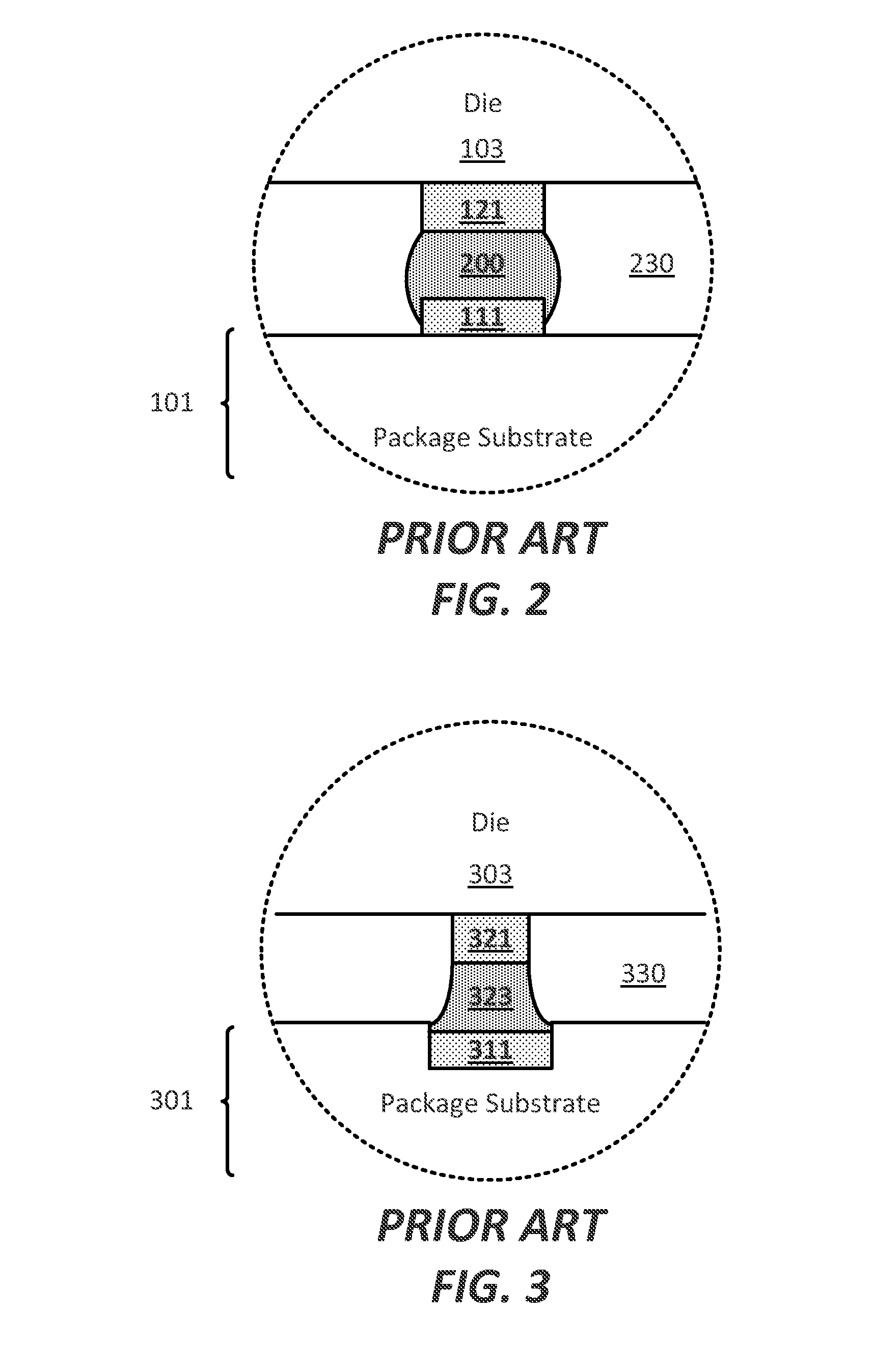

Integrated device package comprising photo sensitive fill between a substrate and a die

InactiveUS20160172299A1Simple designOptimize form factorSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated devices

An integrated device package that includes a die, a substrate, a fill and a conductive interconnect. The die includes a pillar, where the pillar has a first pillar width. The substrate (e.g., package substrate, interposer) includes a dielectric layer and a substrate interconnect (e.g., surface interconnect, embedded interconnect). The fill is located between the die and the substrate. The conductive interconnect is located within the fill. The conductive interconnect includes a first interconnect width that is about the same or less than the first pillar width. The conductive interconnect is coupled to the pillar and the substrate interconnect. The fill is a non-conductive photosensitive material. The fill is a photosensitive film. The substrate interconnect includes a second interconnect width that is equal or greater than the first pillar width. The conductive interconnect includes one of at least a paste, a solder and / or an enhanced solder comprising a polymeric material.

Owner:QUALCOMM INC

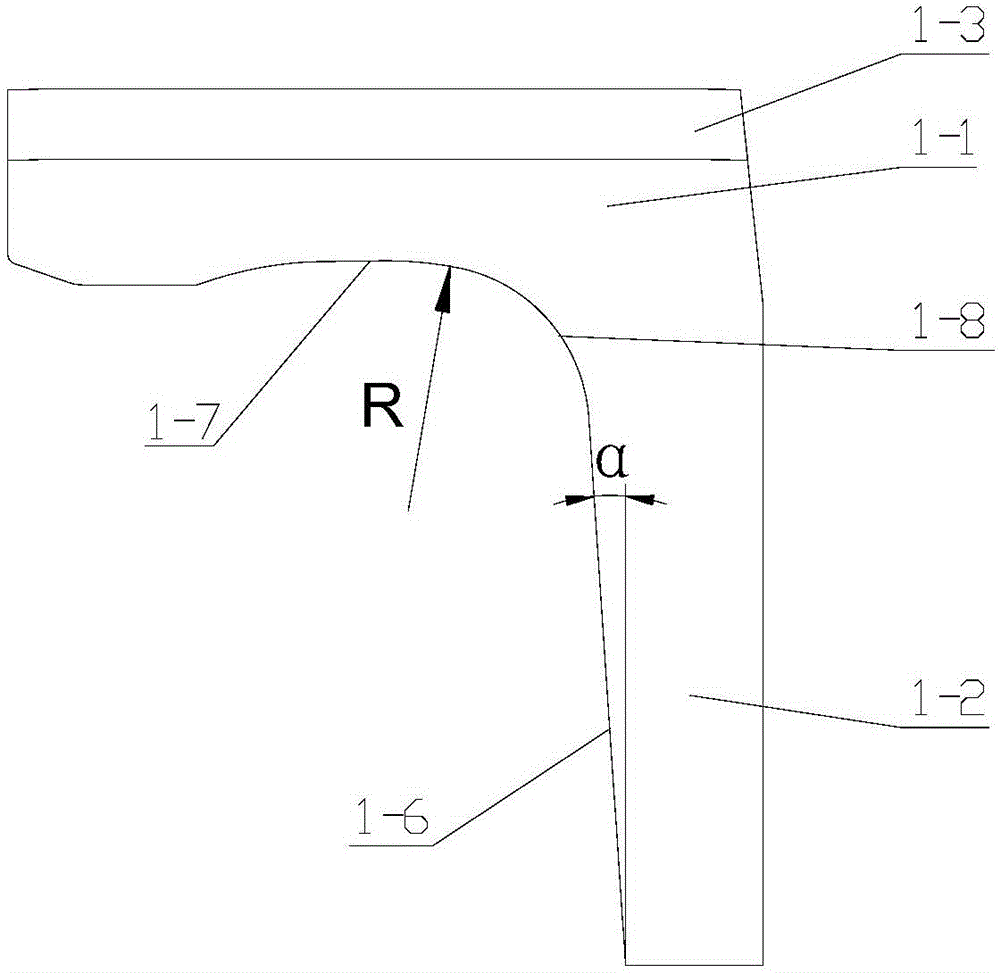

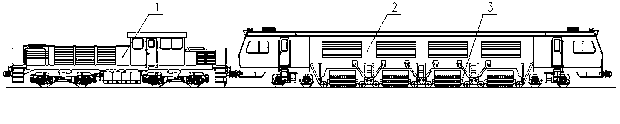

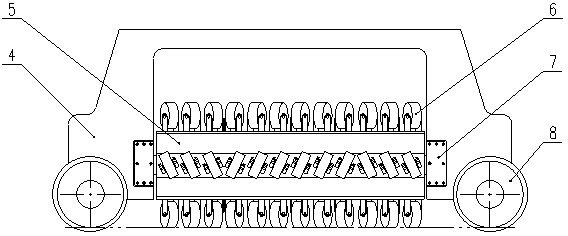

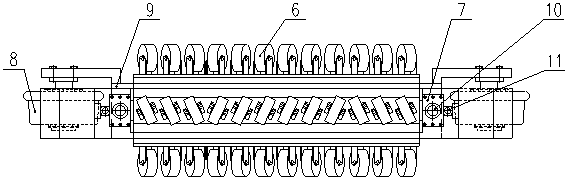

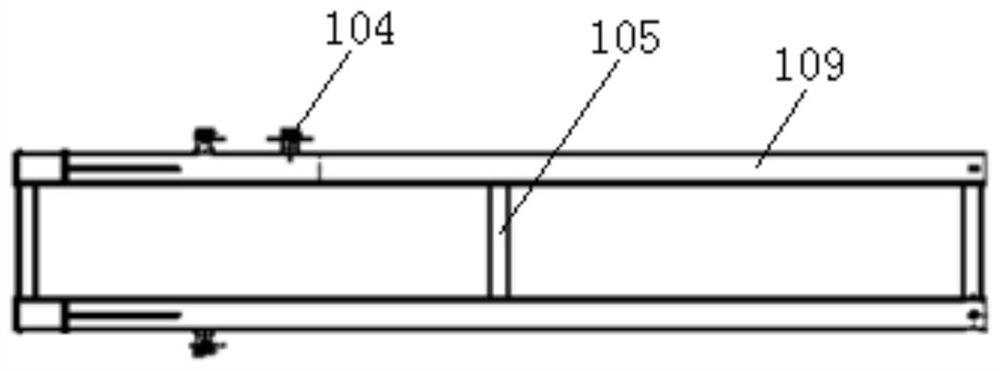

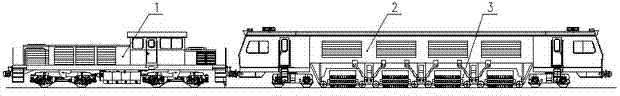

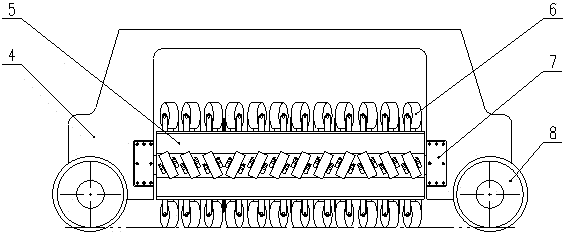

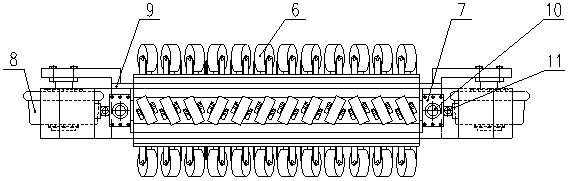

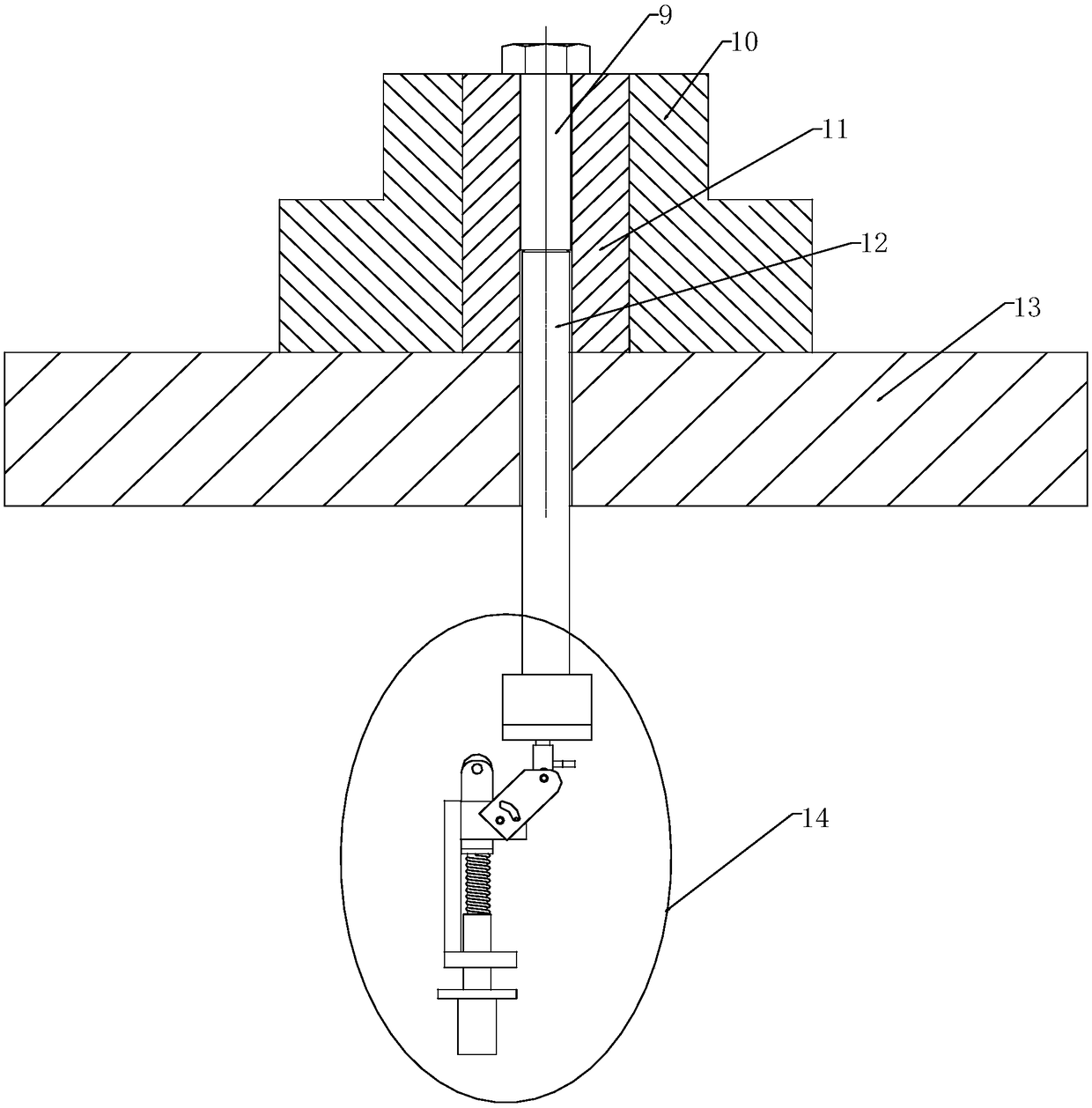

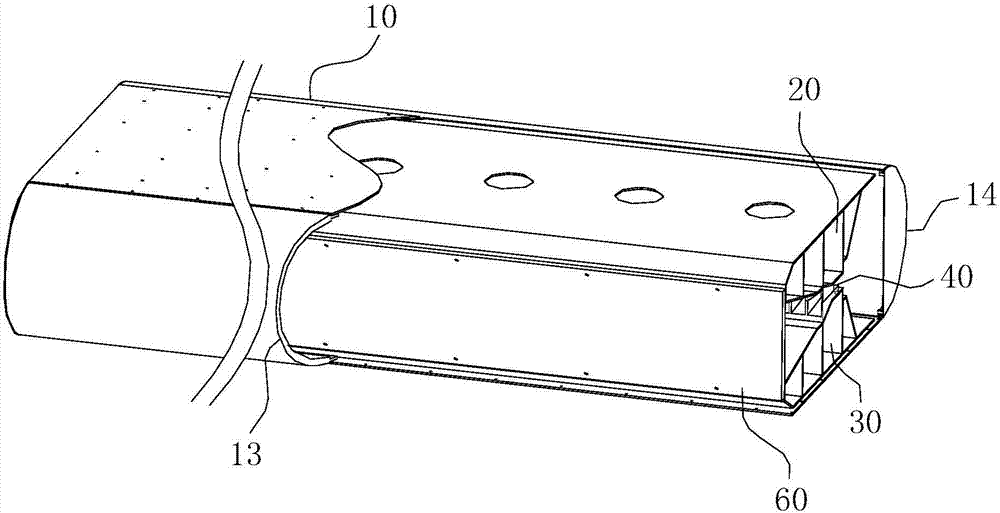

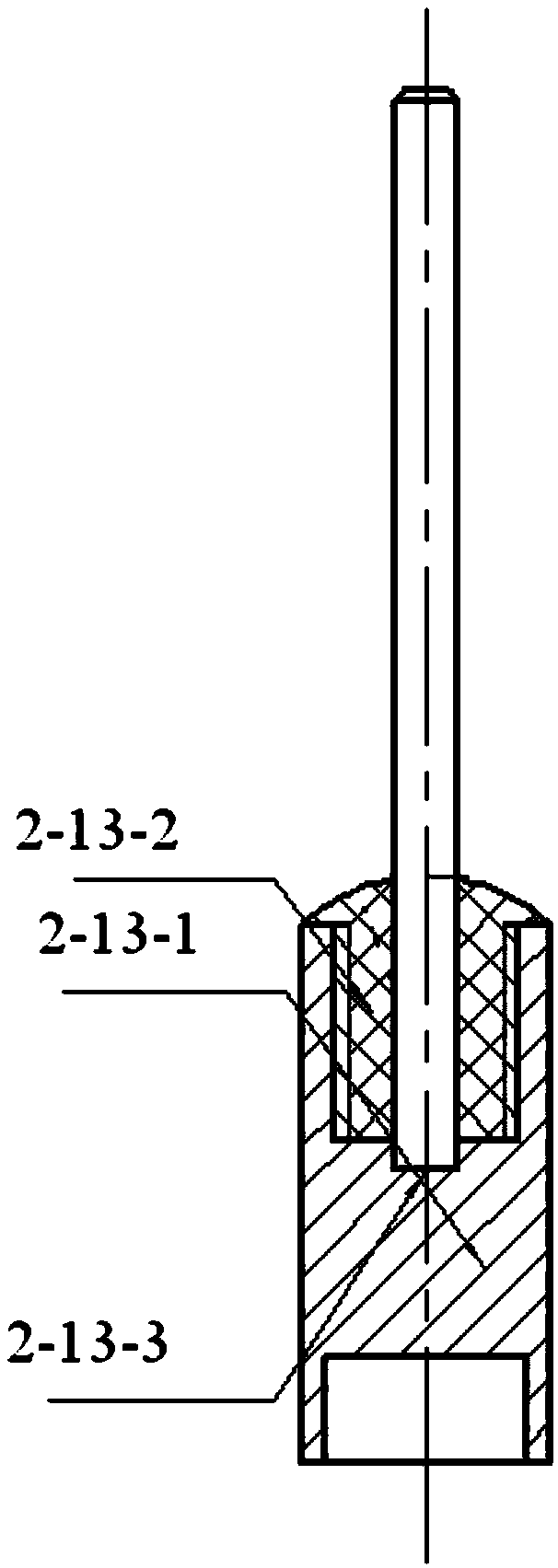

Grinding device for steel rail high-speed grinding train

ActiveCN103132410AImprove transportation economicsEfficient grinding work efficiencyRailway track constructionHigh-speed grindingEconomic benefits

The invention provides a grinding device for a steel rail high-speed grinding train. The grinding device includes a grinding trolley, a rotary bracket arranged on the grinding trolley and a grinding wheel group. Guiding wheels are arranged on the lower portion of the grinding trolley. Automatic rotary devices are arranged at two ends of the rotary bracket. Automatic rotary devices are connected with a grinding trolley frame through a vertical cylinder. One end of a guiding column which is used for guiding up and down of the rotary bracket is arranged on an upper crossbeam of the grinding trolley frame, and the other end is arranged on a lower crossbeam of the grinding trolley frame. The grinding device for the steel rail high-speed grinding train has the advantages of being high in grinding efficiency and enabling the steel rail high-speed grinding train to be utilized in a railway operation system; opening skylight points which are additionally opened is unnecessary and economic benefits of railway transportation are effectively improved.

Owner:CHINA RAILWAYS CORPORATION +1

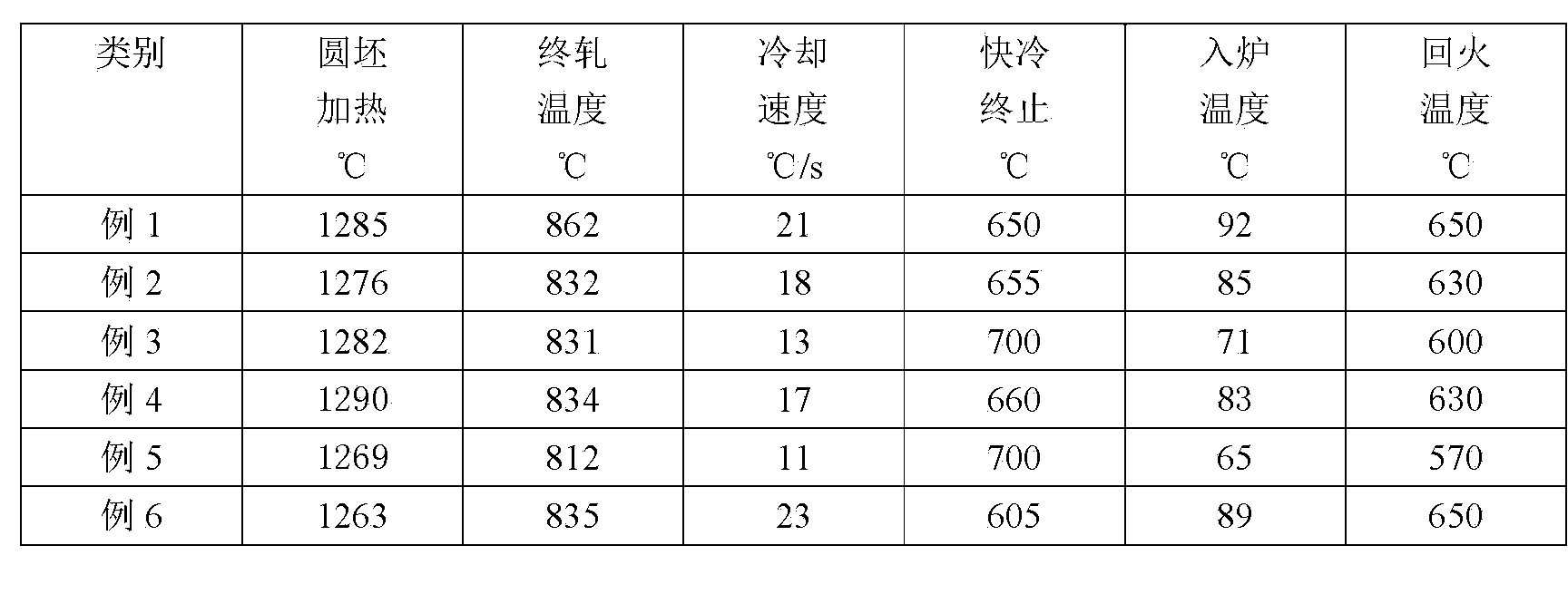

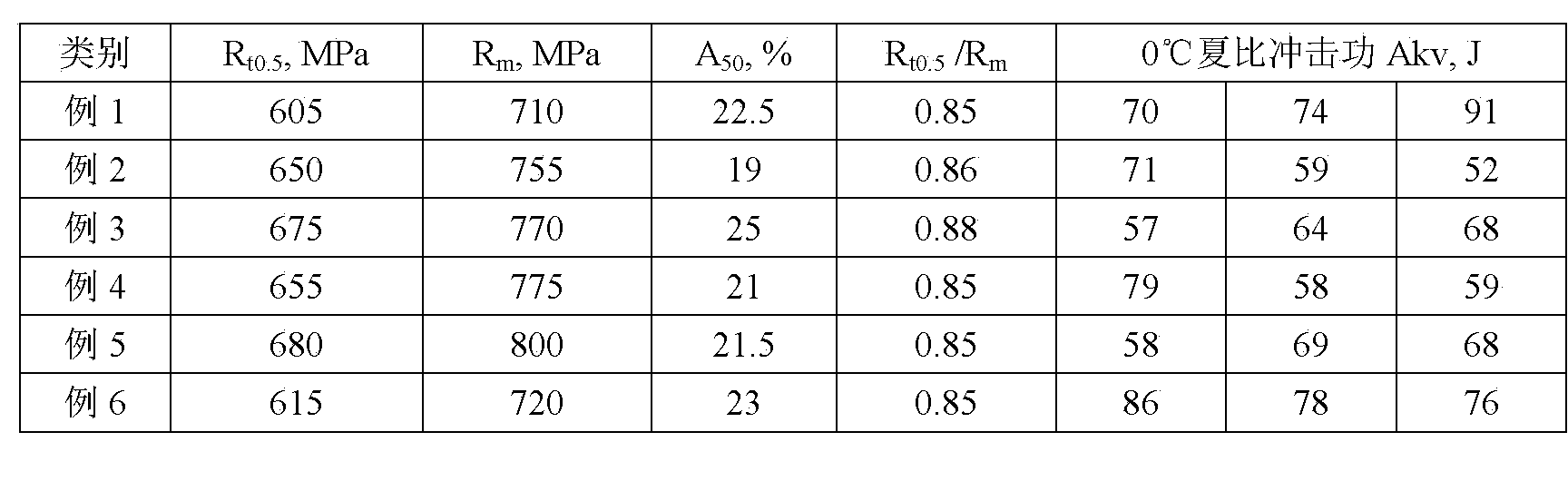

Seamless steel tube for X80 delivery line and its manufacturing method

The invention discloses a seamless steel tube for an X80 delivery line and its manufacturing method; the seamless steel tube comprises 0.12%-0.16% of C, 0.30%-0.45% of Si, 1.24%-1.44% of Mn, 0.30%-0.50% of Cr, 0.02%-0.05% of Nb, 0.01%-0.03% of Ti, less than or equal to 0.020% of P, less than or equal to 0.012% of S and the balance of Fe and unavoidable impurities, and the carbon equivalent CEIIW is 0.39-0.50. After sizing finish rolling, the steel tube temperature is controlled to be more than 800 DEG C, and accelerated cooling of 10 DEG C / s-25 DEG C / s is performed, so that the steel tube temperature is rapidly cooled to 600-700 DEG C, the rapidly-cooled steel tube can be transferred to air cooling for cooling to less than 100 DEG C, and tempering treatment is performed on the steel tube at 550-650 DEG C.

Owner:ANGANG STEEL CO LTD

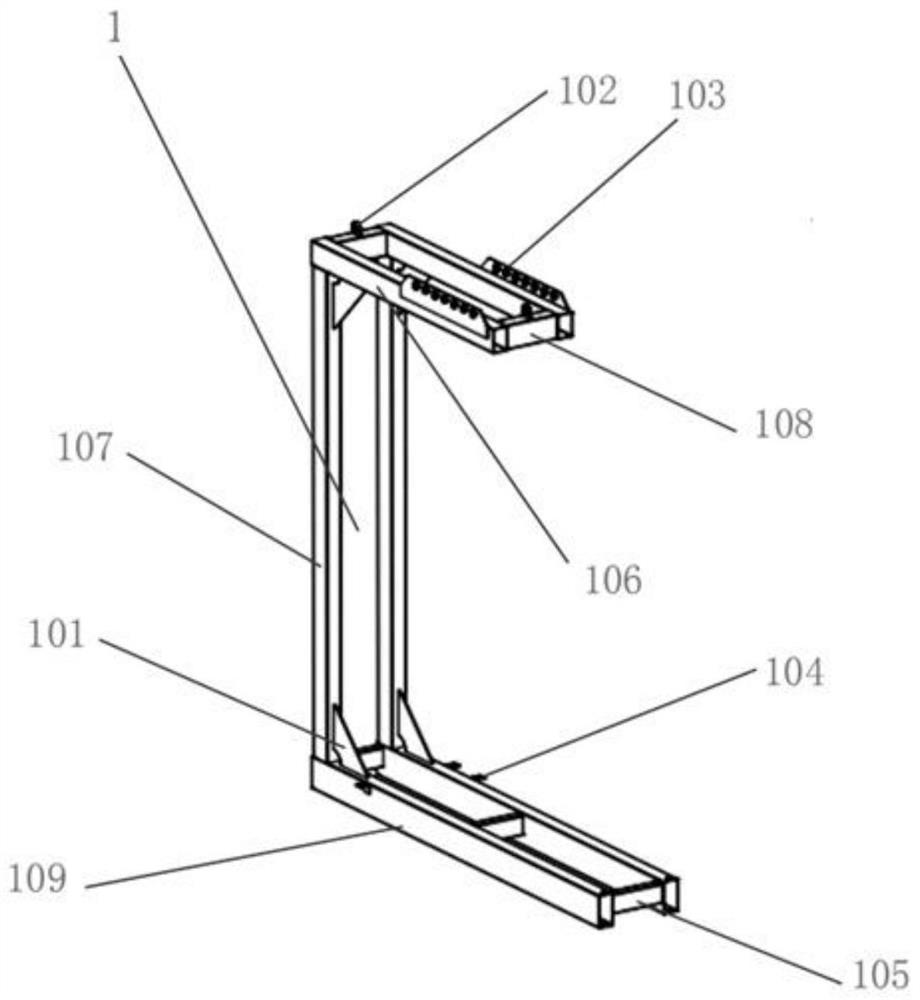

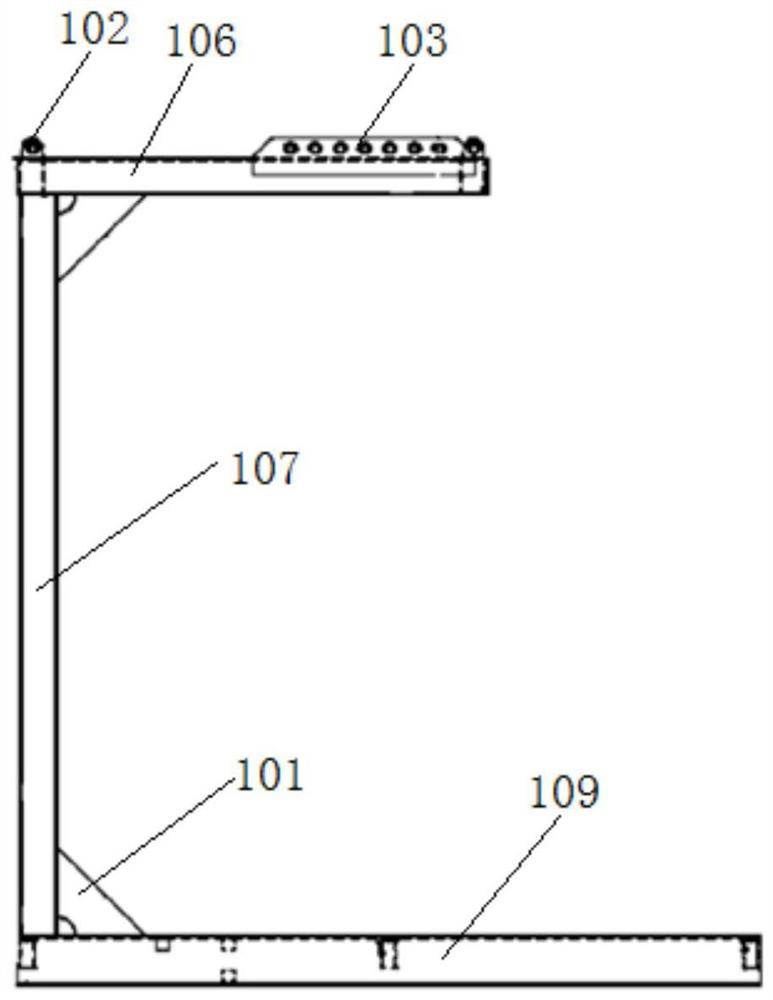

Auxiliary support for electric control cabinet installation

PendingCN112224343AReduce random shakingReduce occupancyCargo handling apparatusPassenger handling apparatusEngineeringElectric control

The invention relates to an auxiliary support for electric control cabinet installation. The auxiliary support is mainly composed of a hoisting movable support and an electric control cabinet fixing support matched with the hoisting movable support; the hoisting movable support is of a first frame structure defined by a plurality of rod pieces, a plurality of hoisting holes are formed in the top of the first frame structure, and a plurality of connecting pieces are arranged at the bottom of the first frame structure. The electric control cabinet fixing support is of a second frame structure defined by a plurality of rod pieces, a fixing piece and a connecting piece are arranged on the second frame structure, the fixing piece is used for installing an electric control cabinet, and the connecting piece is used for connecting the first frame structure and the second frame structure. By means of the auxiliary support, the electric control cabinet can be conveniently and rapidly installed in place in a limited space, various electric control cabinets can be installed, the tower body space occupied by the electric control cabinets is reduced, the boundary dimension of the tower body is optimized, the weight of the tower body is reduced, and then the core competitiveness of ship and ocean engineering equipment in China is improved.

Owner:CSSC NANJING LUZHOU MACHINE

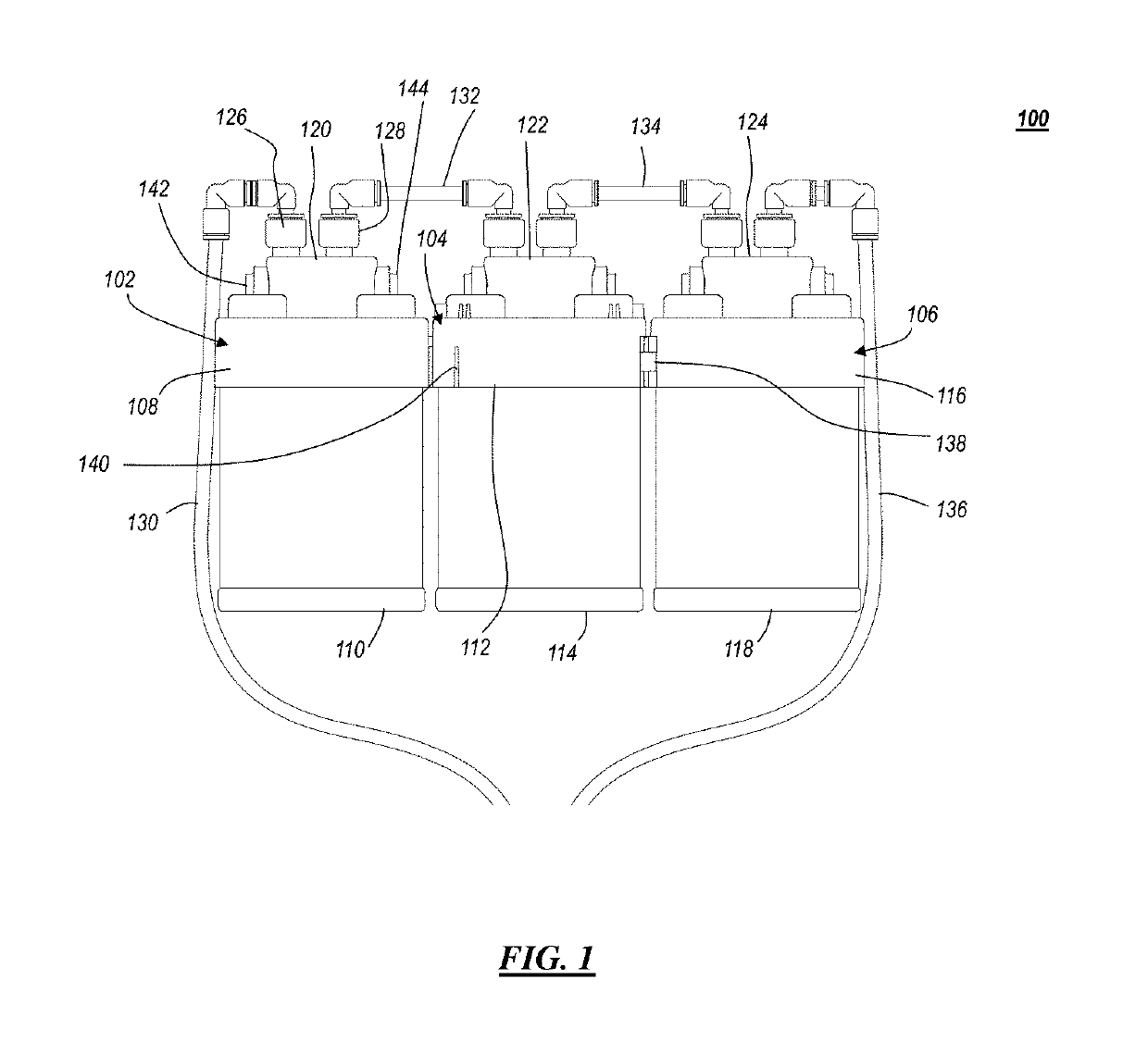

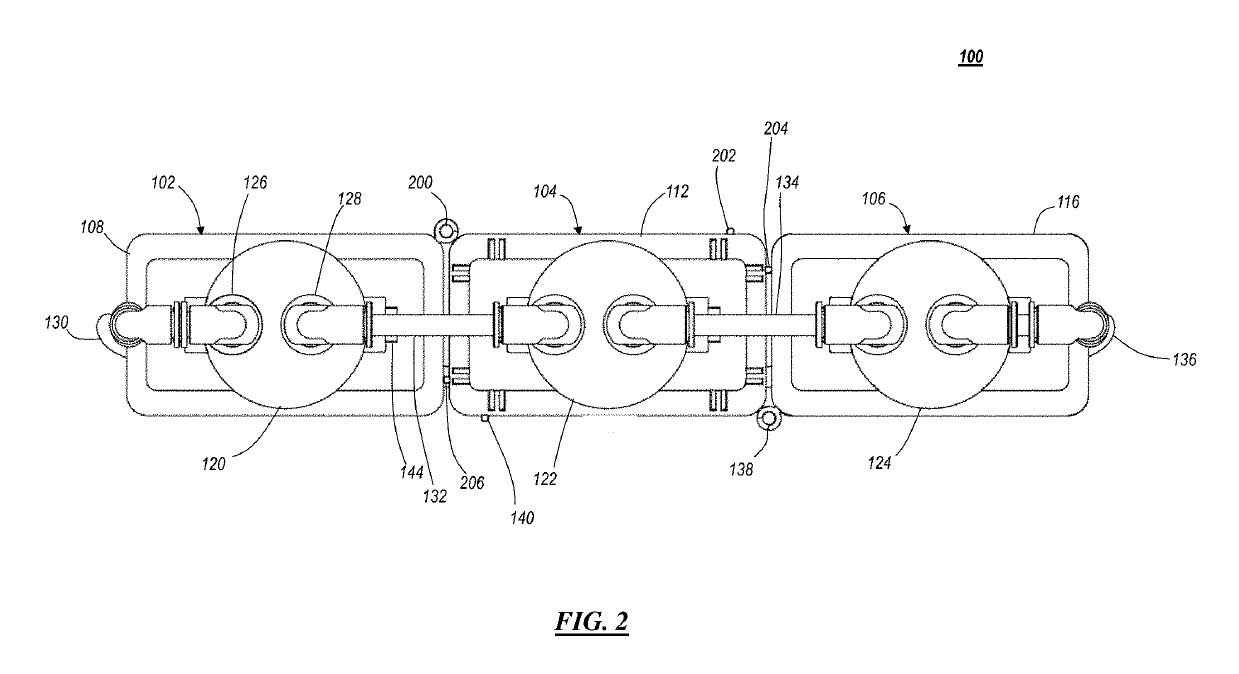

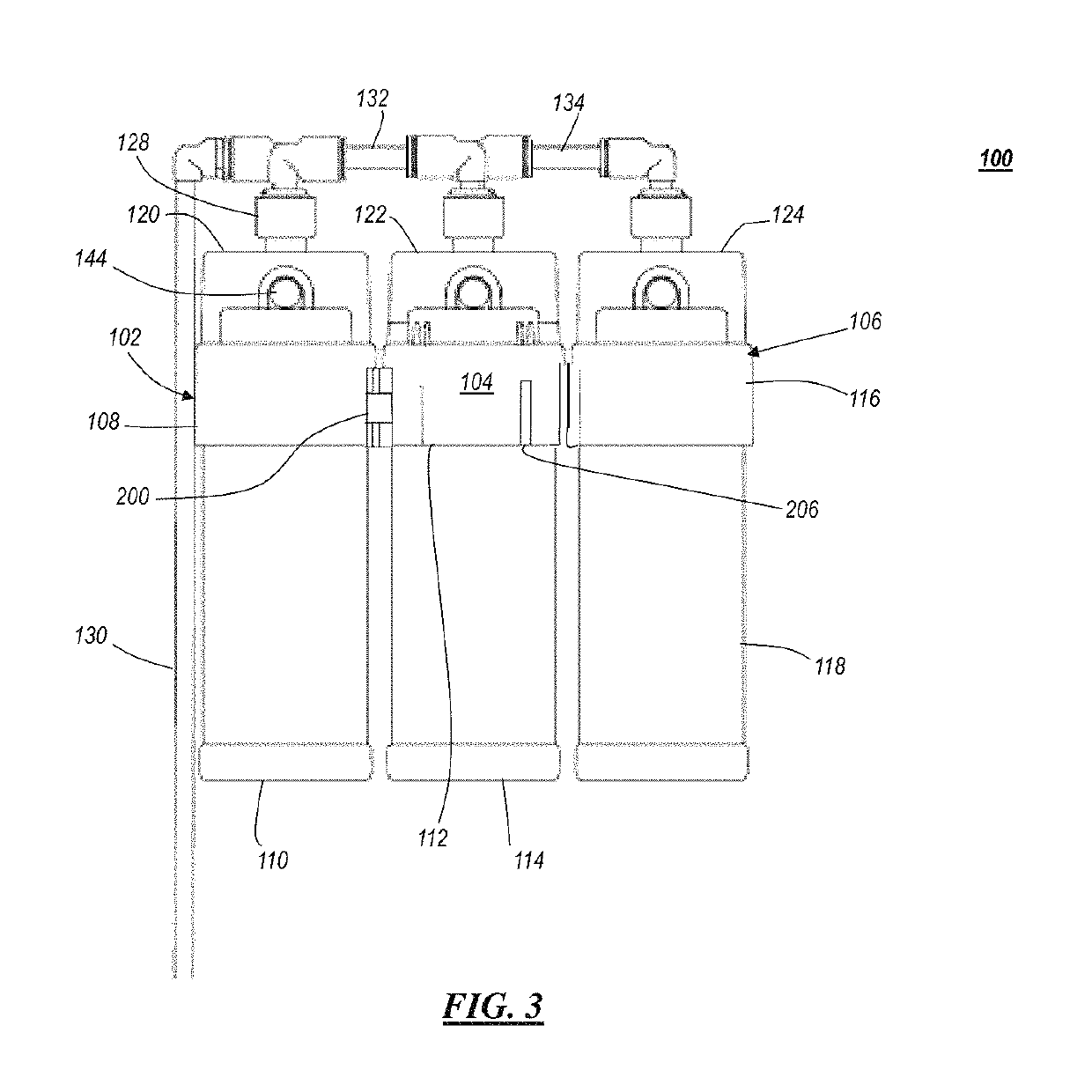

Foldable multi-stage water filter system

ActiveUS10363503B1Optimize form factorWell formedTreatment involving filtrationMultistage water/sewage treatmentWaste managementWater filter

A reconfigurable foldable water filter system includes a plurality of filter units. Each filter unit includes a filter cartridge receiver that can accept and retain a water filter cartridge which includes a water filter. Both the well of each filter cartridge receiver and each filter cartridge are have a rectangular horizontal cross section. The filter cartridge receivers are joined together at corresponding corners, consecutively, in a series in a way that allows the filter cartridge receivers to pivot with respect to each other about the corresponding corners where they are joined. This allows the series of filter units to be arranged in a flat configuration or a folded configuration.

Owner:SALGANOV MARVIN

Grinding device for steel rail high-speed grinding train

ActiveCN103132410BOptimize form factorReduce manufacturing costRailway track constructionHigh-speed grindingEconomic benefits

The invention provides a grinding device for a steel rail high-speed grinding train. The grinding device includes a grinding trolley, a rotary bracket arranged on the grinding trolley and a grinding wheel group. Guiding wheels are arranged on the lower portion of the grinding trolley. Automatic rotary devices are arranged at two ends of the rotary bracket. Automatic rotary devices are connected with a grinding trolley frame through a vertical cylinder. One end of a guiding column which is used for guiding up and down of the rotary bracket is arranged on an upper crossbeam of the grinding trolley frame, and the other end is arranged on a lower crossbeam of the grinding trolley frame. The grinding device for the steel rail high-speed grinding train has the advantages of being high in grinding efficiency and enabling the steel rail high-speed grinding train to be utilized in a railway operation system; opening skylight points which are additionally opened is unnecessary and economic benefits of railway transportation are effectively improved.

Owner:CHINA RAILWAYS CORPORATION +1

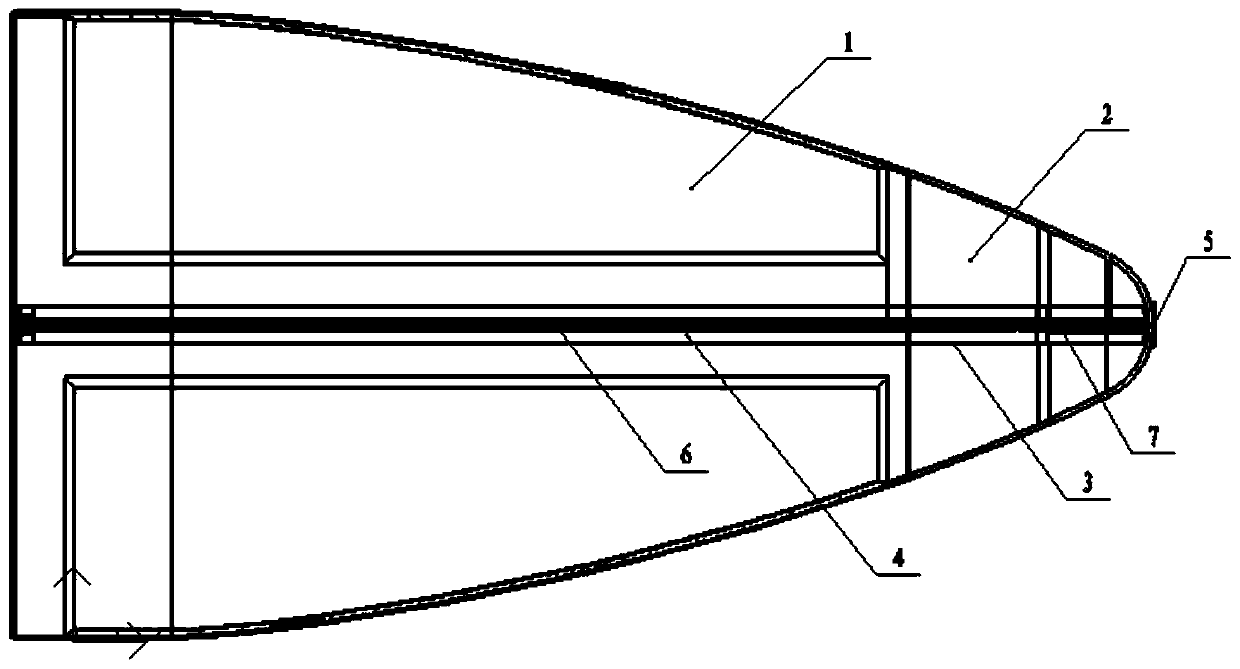

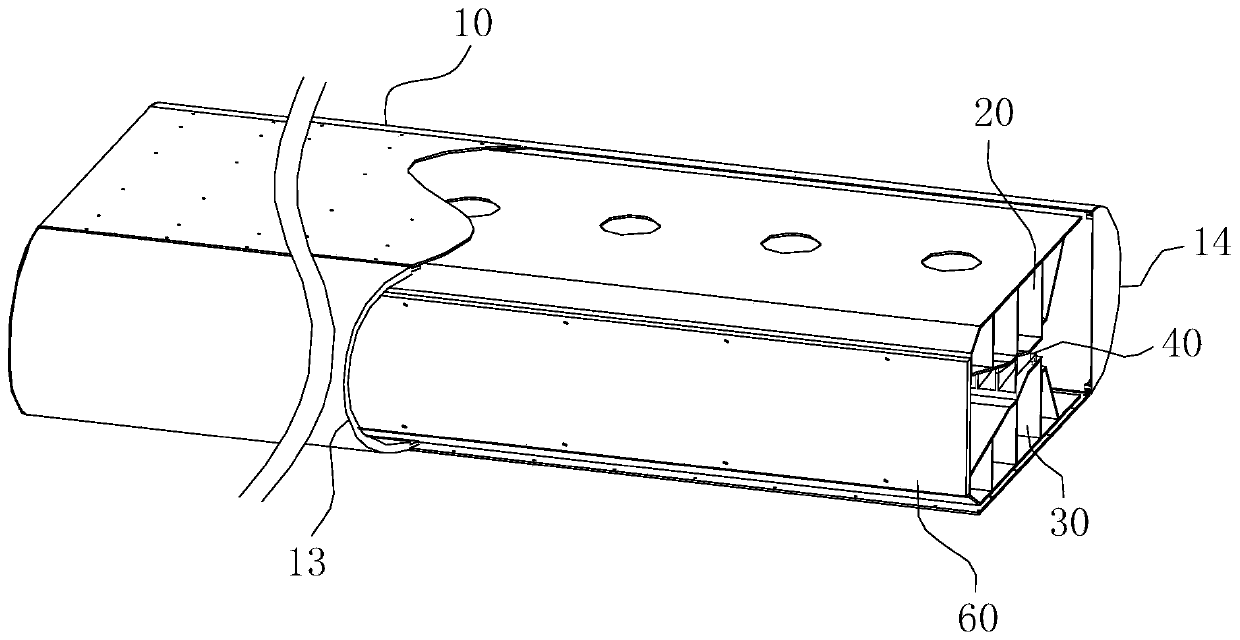

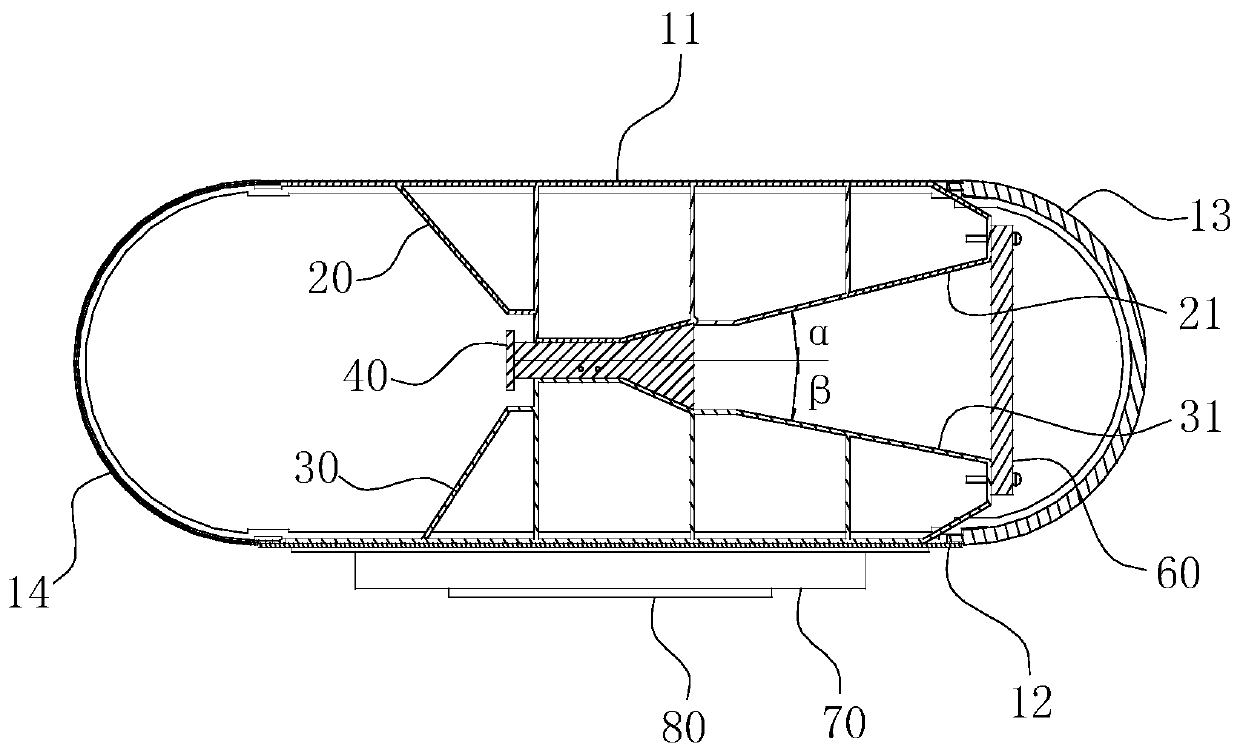

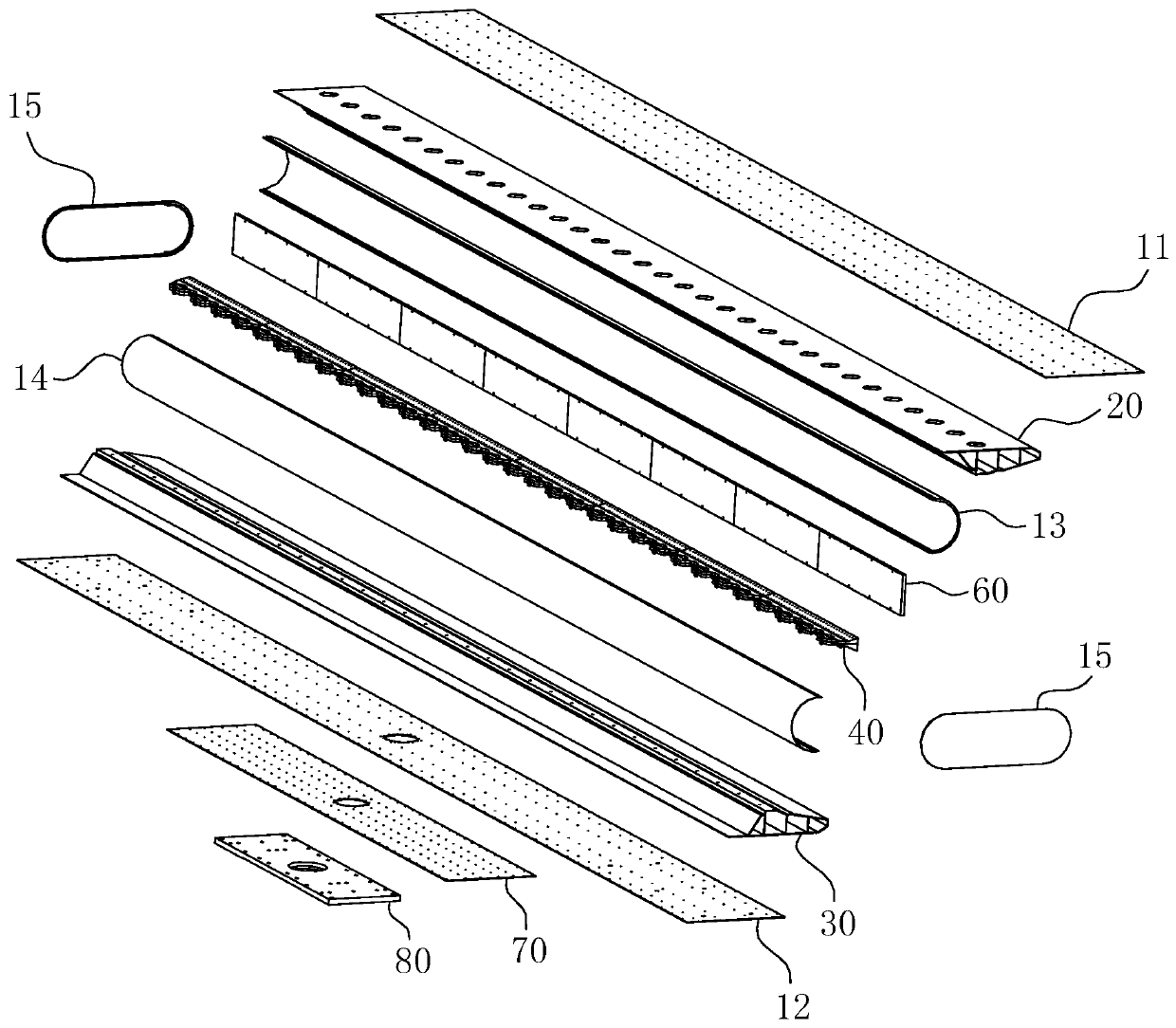

Fairing and spacecraft

PendingCN110341988AOptimize form factorImprove overall assembly accuracyCosmonautic vehiclesCosmonautic safety/emergency devicesSpacecraftInternal stress

The embodiment of the present invention provides a fairing and a spacecraft, wherein the fairing includes a fairing body and a head cover connected to the fairing body; the fairing body and the head cover are separately formed; and the fairing body and the head cover are made of different materials. In the scheme of the invention, the fairing is formed by separately forming the fairing body and the head cover; the internal stress of the forming is effectively released on the basis of ensuring the overall rigidity, strength, heat resistance and overall light weight of the fairing; and the outerdimensions of the fairing are optimized to improve the overall assembly accuracy.

Owner:天津爱思达航天科技有限公司

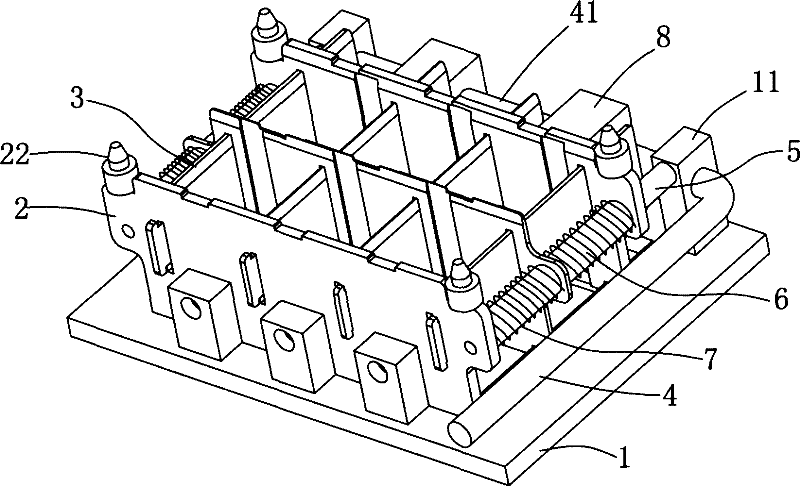

Hexagon head bolt hot heading forming die and machining technology thereof

PendingCN108787978AOptimize form factorIncrease productivityForging/hammering/pressing machinesEngineeringBlind hole

The invention discloses a hexagon head bolt hot heading forming die. A step hole with the wide upper portion and the narrow lower portion is formed in a forming die fixing base from top to bottom in apenetration manner. The step hole is internally provided with a T-shaped combined forming die. A horizontal arm of the T-shaped combined forming die sleeves the step position of the step hole. A vertical arm of the T-shaped combined forming die extends out of the lower surface of the forming die fixing base. The T-shaped combined forming die is provided with a T-shaped blind hole from top to bottom. A piece pushing device is arranged in the T-shaped blind hole. The upper surface of the T-shaped combined forming die is provided with a cushion plate, and the cushion plate is arranged at the upper portion of the step hole. The lower end of the T-shaped blind hole in the T-shaped combined forming die is provided with a hexagon head forming die. A lower die comprises a lower die base and a lower die fixing base fixed to the lower die base, a lower die core is sleeved with the lower die fixing base, and a second straight hole is coaxially formed in the lower die core and the step hole and internally provided with a lower ejection rod. The lower ejection rod is driven by a drive mechanism to move up and down.

Owner:CHONGQING STANDARD FASTNERS IND CO LTD

Instantly soluble hard alloy block and preparation method and application thereof

The invention discloses an instantly soluble hard alloy block and a preparation method and application thereof. The instantly soluble hard alloy block is made from materials in following percent by weight by binding with an adhesive: 25-35% of high carbon ferro-chrome, 0.5-1%. of rare earth, 15-40% of ferro-boron, 25-55% of ferro-vanadium, 2-6% of ferrosilicon, and 2-3% of ferronickel, wherein the adhesive is a resin adhesive. The instantly soluble hard alloy block has high hardness (Rockwell hardness HRC > / =73), good wear resistance, manufacture process simplicity, low cost, low surfacing current, convenience of selecting dimensions and shape, low time and labor consumption for a welder, etc., the problem that a quick-wear apparatus is short in life is solved, and the life of an original member is prolonged by 3-10 times.

Owner:苑俊奎

Radiofrequency transmission/reception device

ActiveUS11502411B2Optimize form factorDisadvantage is compensatedLoop antennas with ferromagnetic coreSimultaneous aerial operationsEngineeringCharacteristic impedance

A radiofrequency transmission / reception device includes a first and a second conductive wire element, a first far-field transmission / reception chip and a second near-field transmission / reception chip. The first and the second wire element combine with the characteristic impedance of the second transmission / reception chip in order to form a coupling device associated with the first transmission / reception chip at the operating frequency of the first chip. The first and the second wire element combine with the characteristic impedance of the first transmission / reception chip in order to form a coupling device associated with the second transmission / reception chip at the operating frequency of the second chip.

Owner:PRIMO1D

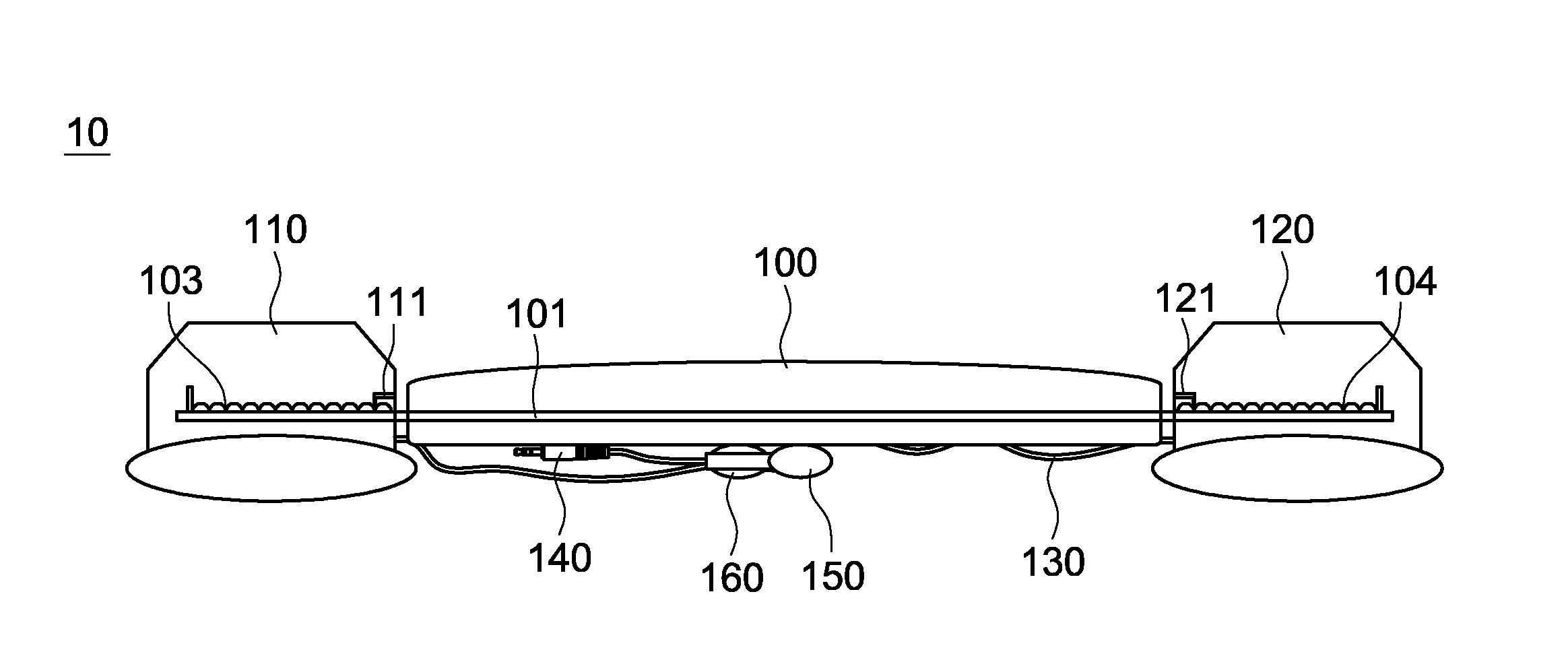

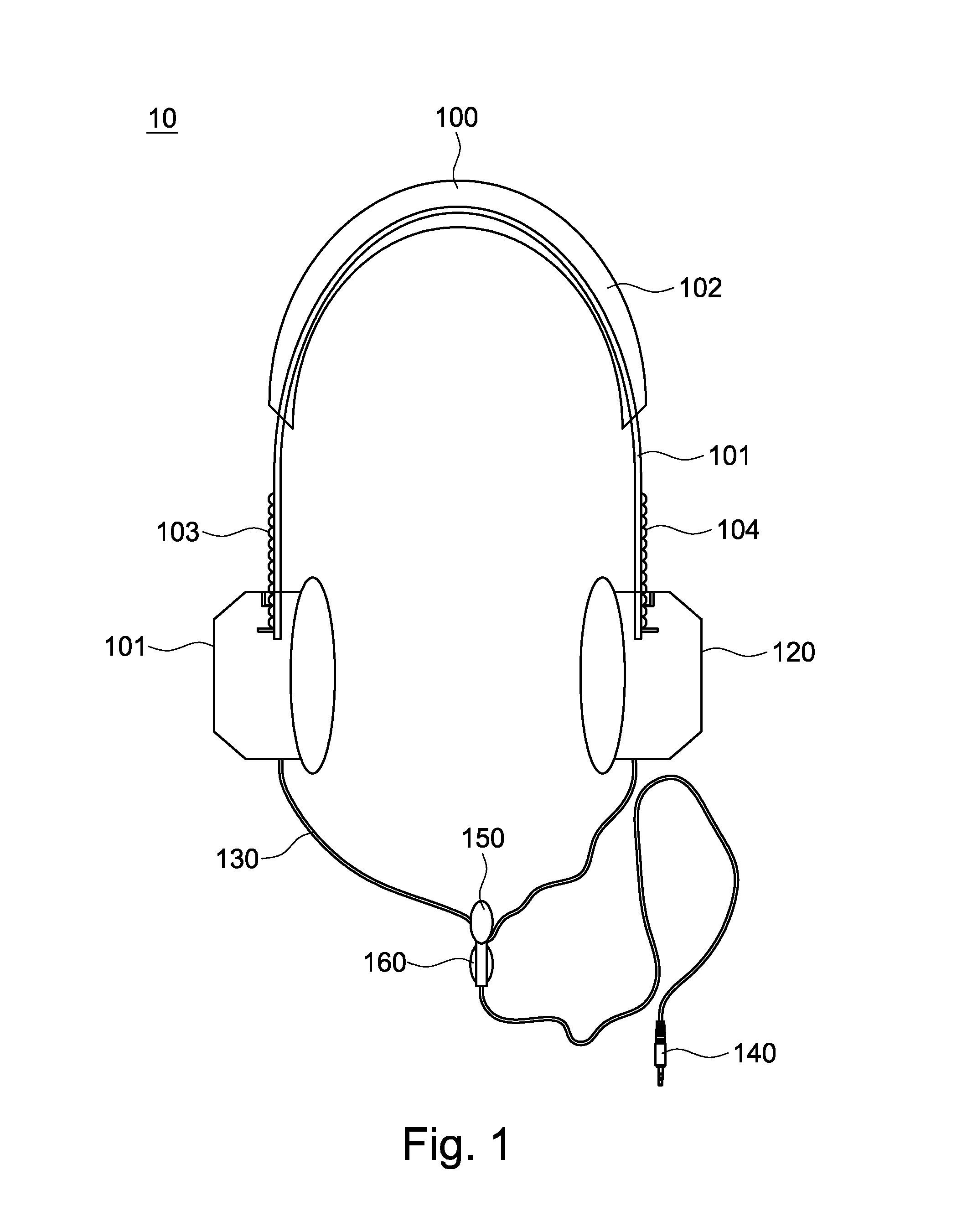

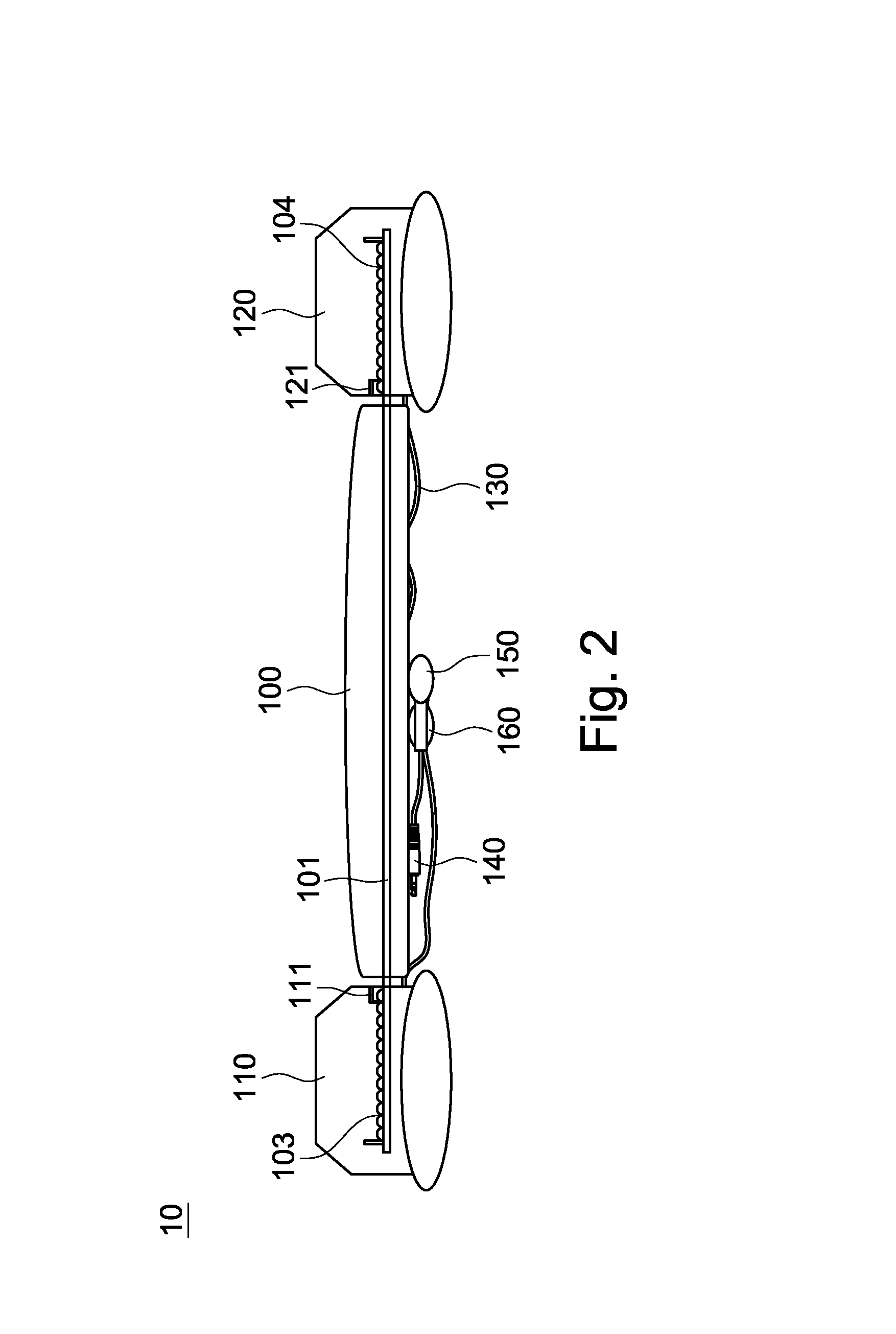

Headphone device

InactiveUS20140185855A1Optimize form factorImprove portabilityMicrophonesLoudspeakersEngineeringHeadphones

Owner:GIGA BYTE TECH CO LTD

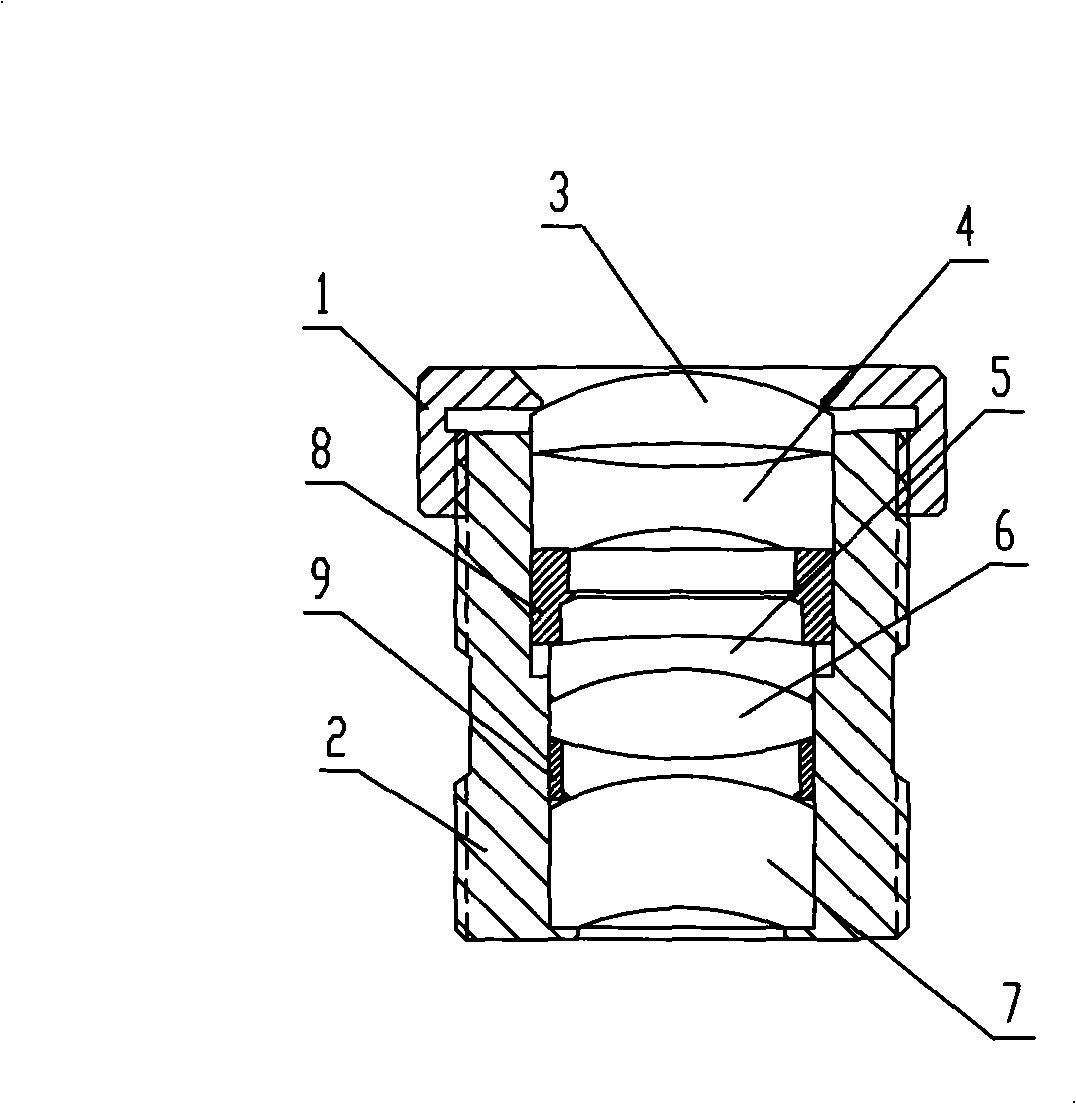

Long-focus lens

Owner:河南同城光电有限公司

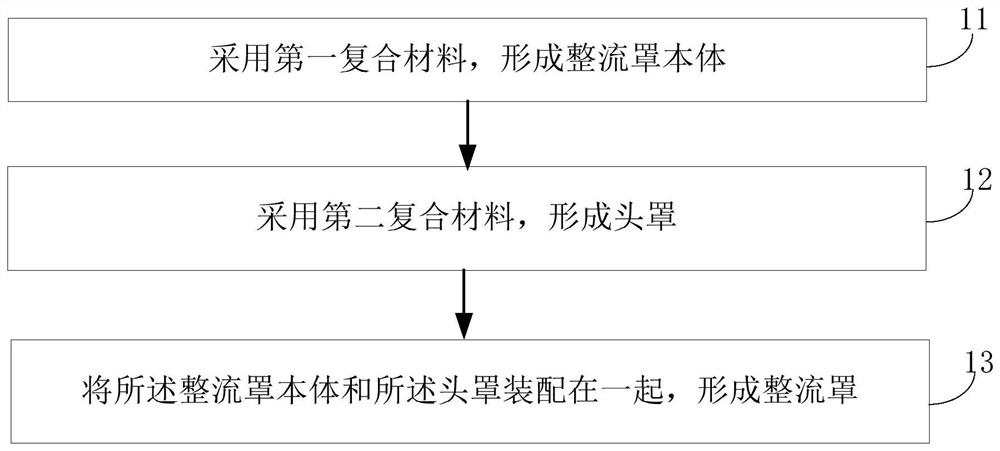

A method of manufacturing a fairing

ActiveCN110370677BEffectively release internal stressOptimize form factorCosmonautic safety/emergency devicesInternal stressCowling

An embodiment of the present invention provides a method for manufacturing a fairing. The method includes: using a first composite material to form a fairing body; using a second composite material to form a cowl; combining the second composite material with the first The materials are different; the fairing body and the cowl are assembled together to form a fairing. In the solution of the present invention, the fairing adopts the separate molding of the fairing body and the hood, which effectively releases the internal stress of the molding, optimizes the outer dimensions of the fairing, and improves its overall assembly accuracy.

Owner:TIANJIN ISTAR-SPACE TECH CO LTD

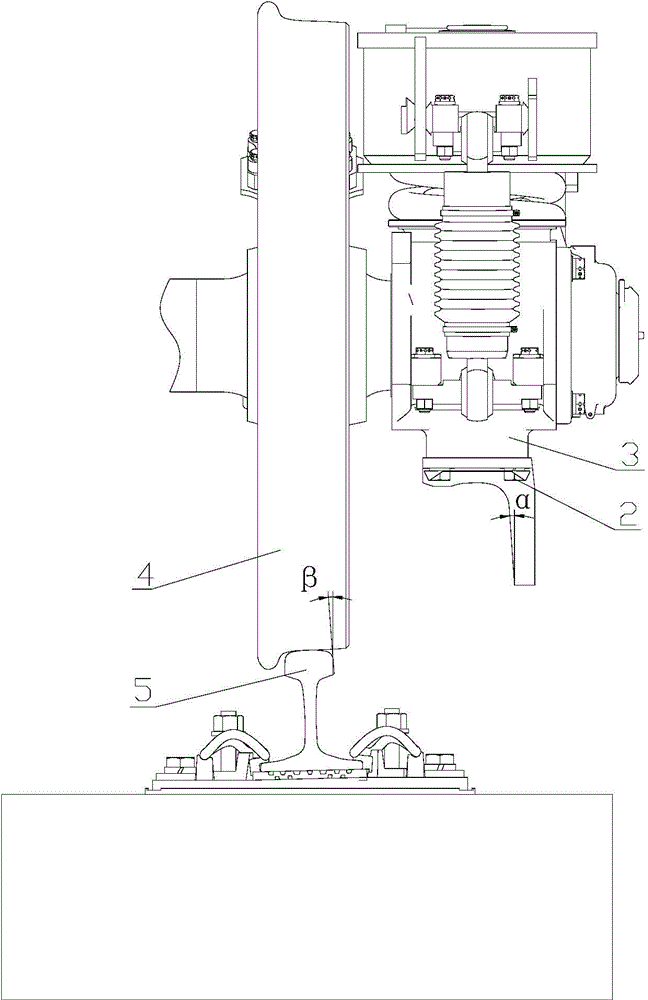

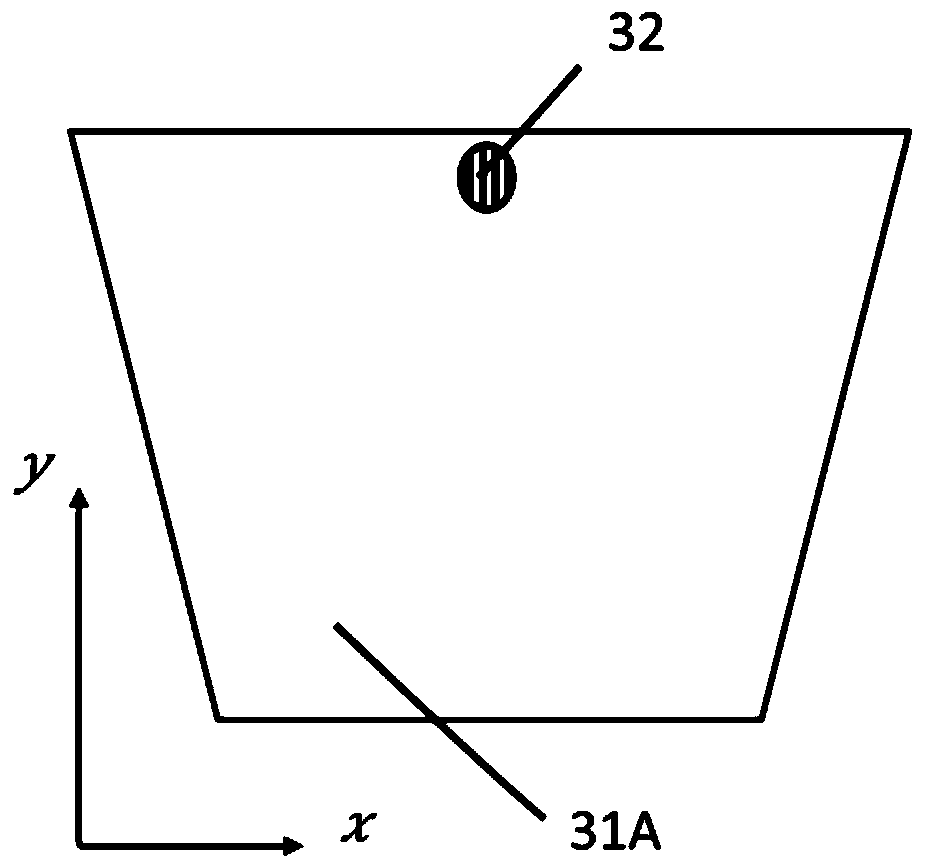

Carbon fiber composite material, preparation method thereof, and radar antenna using the same

ActiveCN106976281BHigh working reliabilityHigh strengthRadiating elements structural formsLaminationEpoxyRadar antennas

The invention belongs to the technical field of radar communication, and more specifically relates to a carbon-fibre composite as well as a preparation method thereof and a radar antenna using the carbon-fibre composite. The carbon-fibre composite comprises epoxy resin and high strength carbon fiber; the total weight of all components is 100%, the weight percentage of the high strength carbon fiber is 60-70%, and the weight percentage of epoxy resin is 30-40%; the high strength carbon fiber is continuous filament type carbon fiber treated by polyacrylonitrile; the fiber has low density, high tensile strength and yield strength. The preparation method comprises the following steps: obtaining of prepreg, layered paving as well as insulation and pressure maintaining. The radar antenna comprises a casing, a feed network, an upper frame and a lower frame, the cross sections of the upper frame and the lower frame are trapezoids with narrow top and wide bottom, and a gap between the upper frame and the top of the lower frame forms an arrangement area for clamping and fixing the feed network. The radar antenna has the advantages of light quality, maintenance convenience, short manufacture period, and low manufacture cost.

Owner:ANHUI SUN CREATE ELECTRONICS

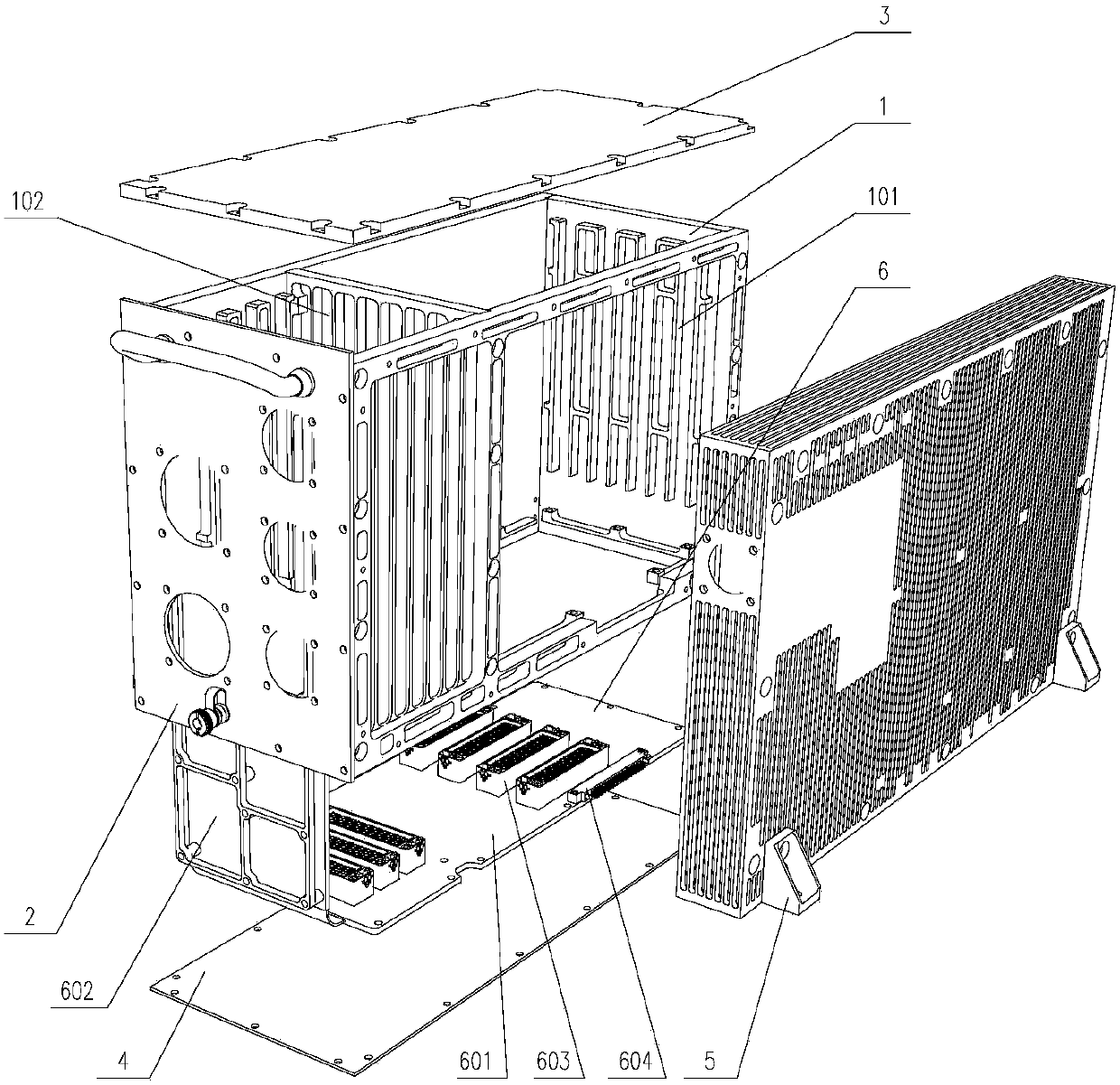

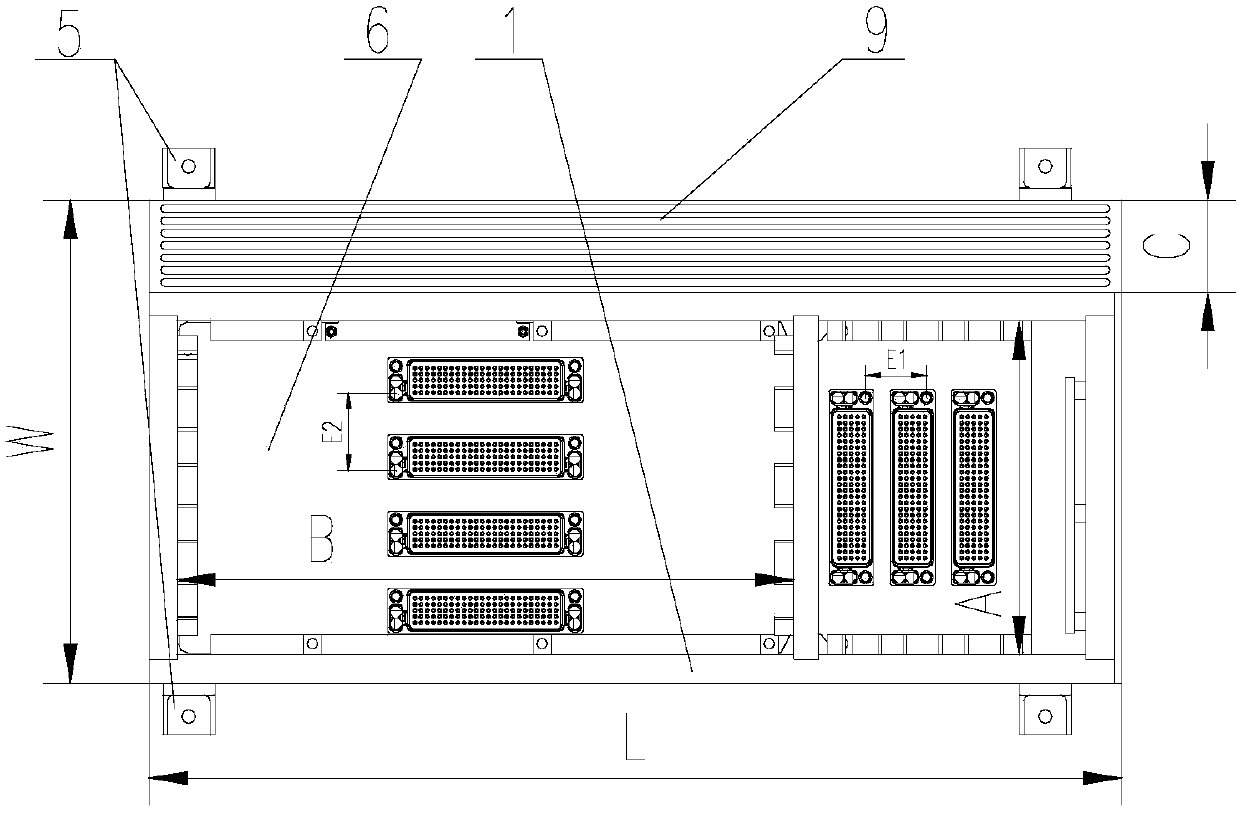

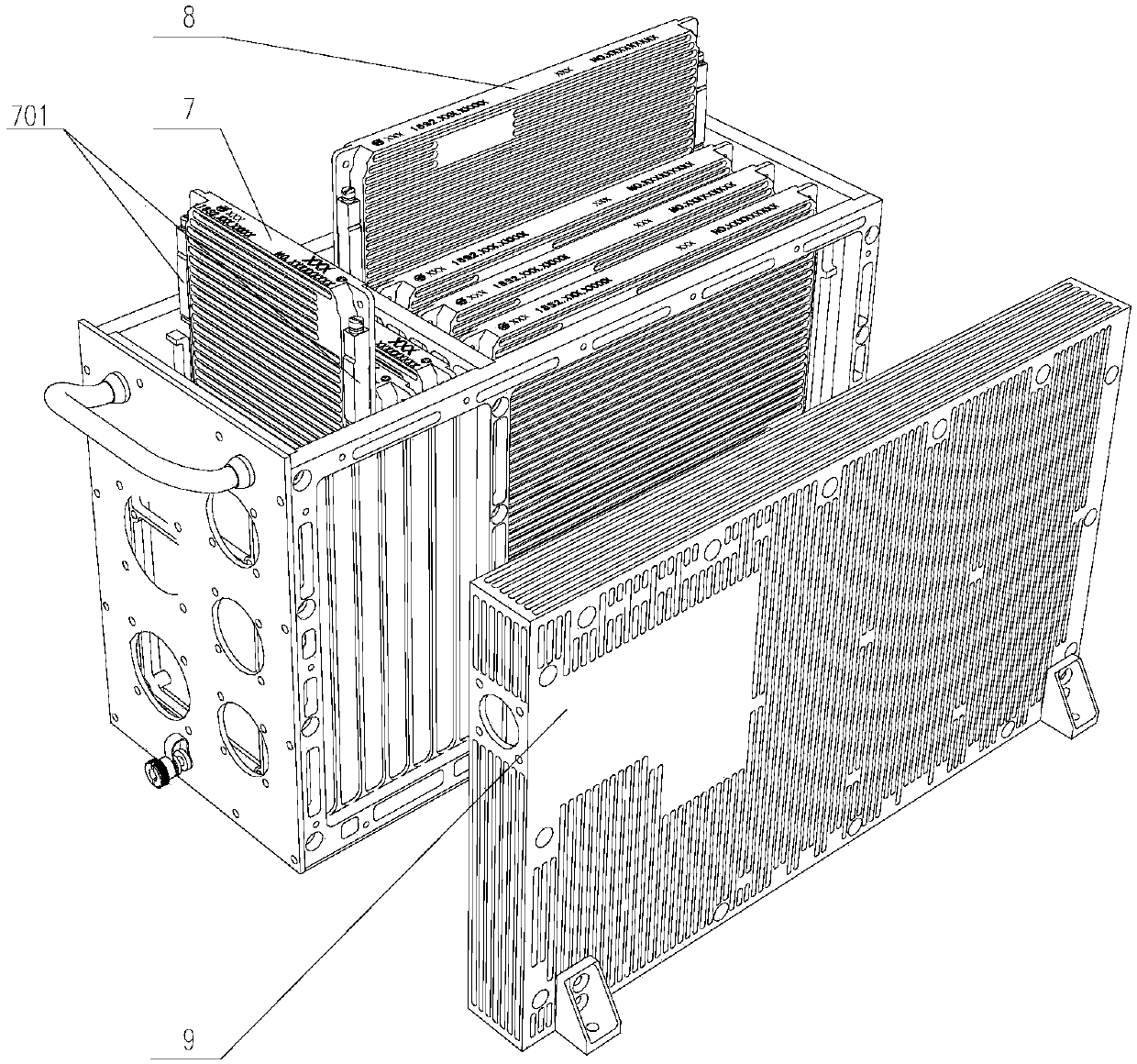

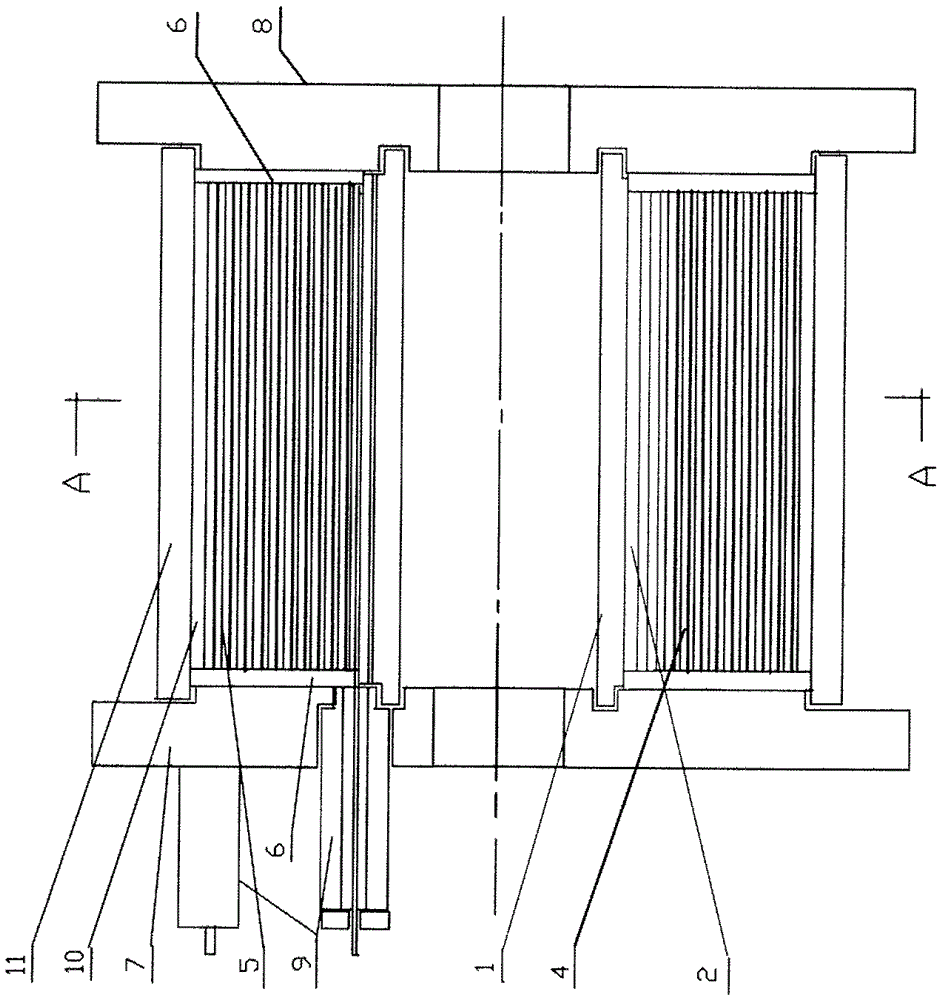

Ruggedized computer suitable for multiple sizes and specifications of modules

InactiveCN107741769ASimple structureSquare shapeDigital processing power distributionElectrical connectionElectrical bonding

The invention belongs to the technical field of airborne electronic device structure processes and relates to a ruggedized computer suitable for multiple sizes and specifications of modules. Multiplesizes and specifications of modules exist in the same device, more optimized computer appearance and weight are given, meanwhile the standard size and interface and environment conditions of an airborne electronic device can be met, and a good solution is provided for the airborne electronic device to adapt to multiple sizes and specifications of modules. In the structural form, the more optimizedcomputer structure size or a similar standard-sized computer is combined according to the area and number of printing boards needed by the functional modules while structural supporting, electrical connection, heat-dissipating protection and other functions can be provided for the modules of the airborne electronic device, and accordingly the space of the modules and the whole computer are more reasonably utilized.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

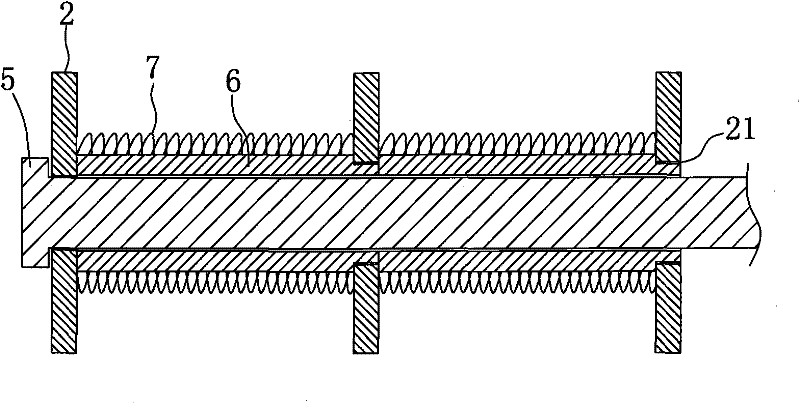

Sintering molding process of electromagnetic coil of electrical equipment

ActiveCN102890998BReduce cooling conditionsImprove cooling conditionsTransformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorVacuum pressure

The invention discloses an insulated winding or electromagnetic coil for electrical equipment and a sintering and forming process of the insulated winding or electromagnetic coil. The insulated winding or electromagnetic coil for the electrical equipment is a metal conductor for winding and welding a lead outside an inner main insulating layer; an interlayer insulating film is wound among various layers of the metal conductor; end-sealed insulating layers are wound at two ends of each layer of coil while the winding of the metal conductor and the interlayer insulation are realized simultaneously and sequentially realized; and an outer main insulating layer is wound outside the metal conductor of the winding or coil wound according to the specified turn numbers and layer numbers. The sintering and forming process of the insulated winding or electromagnetic coil is mainly characterized in that the winding or coil is wound by an inner main insulating layer, an external winding welding lead metal conductor, an interlayer insulating film, the end-sealed insulating layers and the outer main insulating layer on a die core of a metal die; a reinforced insulating layer is packed at the welded part of a lead or joint and a tap; the metal die in which the winding or coil is arranged is filled into a vacuum pressure sintering furnace, so that the insulating material and the metal conductor are bonded and integrally formed; and the electrical strength and the heat radiating effect of the insulating material are improved, so that the size is reduced, the process flow is simplified and the cost is reduced.

Owner:尤大千

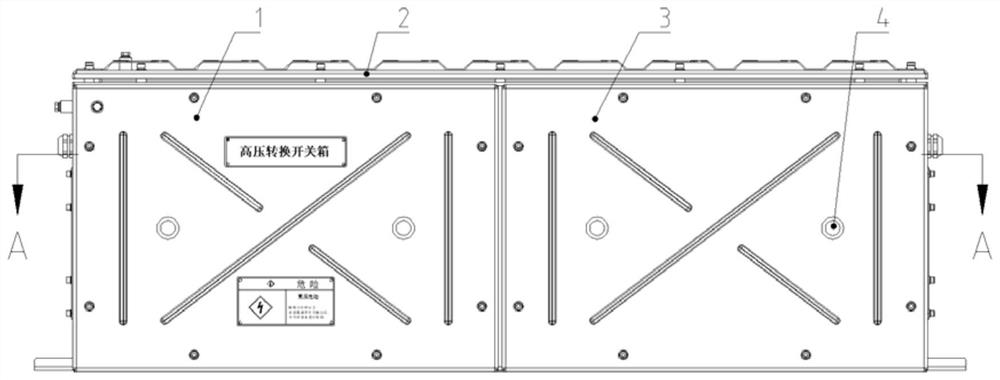

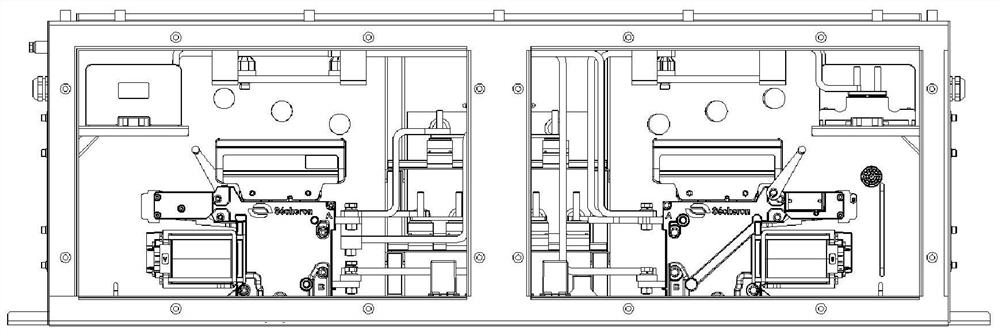

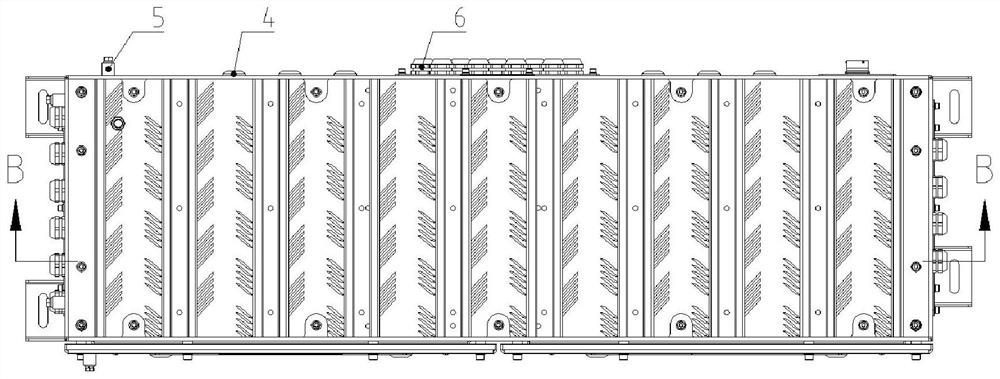

High-voltage change-over switch box

ActiveCN112531470AMinimize wiring designConducive to wiring designBus-bar/wiring layoutsBoards/switchyards circuit arrangementsSwitch boxControl system

The invention provides a high-voltage change-over switch box, which comprises a frame, a front cabinet door I, a front cabinet door II, an upper cabinet door with an anti-treading plate, a left side cover plate, a right side cover plate, a rear side cover plate, a left side wiring terminal strip, a right side wiring terminal strip, a rear side upper layer wiring terminal strip and a rear side lower layer wiring terminal strip, a plurality of contactors respectively arranged on the left and right sides, an insulating arc extinguishing cover plate arranged above an arc extinguishing cover of thecontactor, and relays, connecting copper bars and supporting insulators arranged at the bottom of the switch box body. According to the invention, the whole vehicle power supply control and protection contactor is integrated into one cabinet body, the design difficulty of other equipment of the vehicle is reduced, and the improvement of the whole vehicle counterweight design is facilitated. If avehicle breaks down, a faulty line can be checked more conveniently through the high-voltage change-over switch box. Meanwhile, state signals of the eight contactors are integrally fed back to a wholevehicle network control system through a single cabinet body, and whole vehicle wiring design and whole vehicle electromagnetic compatibility are facilitated.

Owner:CRRC DALIAN R & D CO LTD

Controller and air conditioner

PendingCN109579242AReduce flow inflectionReduce flow lossMechanical apparatusSpace heating and ventilation safety systemsCapacitanceCopper foil

The invention provides a controller and an air conditioner, wherein the controller comprises a circuit board, a power factor corrector which is connected with the circuit board; the power factor corrector is provided with a capacitor, a power part and an inductance part; the connection position of the power part and the circuit board is positioned between the connection position of the inductancepart and the circuit board and the connection position of the capacitor and the circuit board; wherein the capacitor and the inductor are positioned at one side of the circuit board; and the power part is positioned at the other side of the circuit board. According to the invention, the power factor corrector is connected with the circuit board in a copper foil welding mode by reasonably setting the positions of the circuit board and the power factor corrector and reasonably arranging various devices, so wire harnesses are eliminated, the interference and radiation conducted by the wire harness connection are reduced, the copper foil routing distance is shortened and the wiring of products is simplified; meanwhile the assembly structure is more favorable for optimizing the structure of theproduct so as to reduce the overall external dimension of the product.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

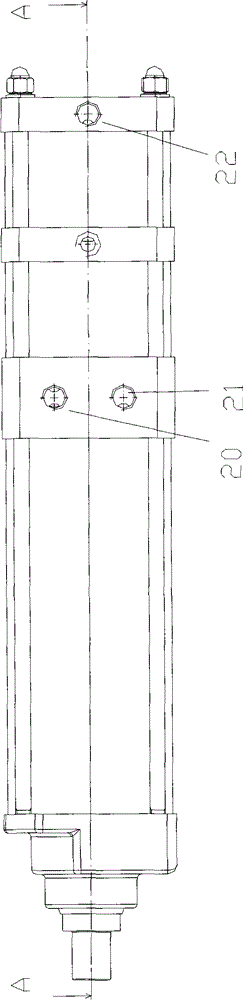

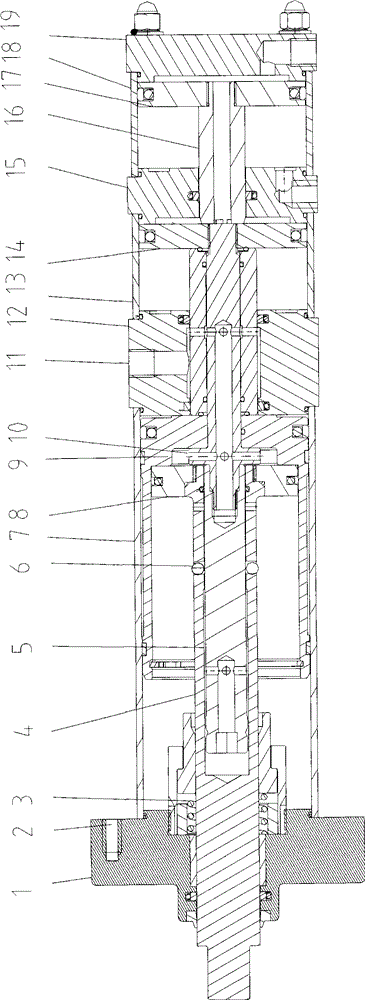

Multi-stage push cylinder

ActiveCN102720725BReduce the types of reservesPlay a multi-purpose effectFluid-pressure actuatorsEngineeringPiston

The invention relates to a multi-stage push cylinder and aims to provide a bush piston type double-stroke push cylinder with output pressure increasing with increase of the number of cylinder sections. The multi-stage push cylinder comprises a plurality of cylinder shafts, a plurality of cylinder barrels, a plurality of pistons, a plurality of partitions, a plurality of air holes, a front cover, a rear cover and the like. The multi-stage push cylinder is divided into a plurality of mutually independent chambers by the partitions. The cylinder shafts and pistons are connected in cascade. A bush piston is disposed inside at least one cylinder barrel and can serve as a pressure piston and also a cylinder barrel for another piston. The cylinder shafts of the multi-stage push cylinder are shortened, so that materials are economized, and types of stored parts are reduced. Pressure of the multi-stage push cylinder can be selected according to actual uses, and the multi-stage push cylinder is reliable to operate, convenient to use and easy to produce.

Owner:尼玛克公司

Radial-flow steam turbine

ActiveCN100337013CImprove conversion efficiencyReduce weightNon-positive displacement enginesHigh energyShock resistance

A radial-flow turbine containing cylinder, stator and rotor installed in cylinder, featuring a complete steam flow path, steam admission pipe, steam admission chamber, at least two or plurality of endiocentric energy converting flow path groups, at least one steam flow reversible flow path group and exhausting chamber, wherein the number of steam flow reversible flow path group is one less then that of endiocentric energy converting flow path groups, all endiocentric energy converting flow path groups and steam flow reversible flow path group are alternately arranged along axial direction of rotor, plurality of convergent nozzles are set at the outlet of steam admission chamber and end of flow reversible flow path groups, comparing with current technology. Said invention has advantages of high energy conversion efficiency and fine anti overspeed, anti vibration and shock resistance performance.

Owner:黄少斌 +2

Carbon-fibre composite as well as preparation method thereof and radar antenna using carbon-fibre composite

ActiveCN106976281AHigh working reliabilityHigh strengthRadiating elements structural formsLaminationEpoxyElectricity

The invention belongs to the technical field of radar communication, and more specifically relates to a carbon-fibre composite as well as a preparation method thereof and a radar antenna using the carbon-fibre composite. The carbon-fibre composite comprises epoxy resin and high strength carbon fiber; the total weight of all components is 100%, the weight percentage of the high strength carbon fiber is 60-70%, and the weight percentage of epoxy resin is 30-40%; the high strength carbon fiber is continuous filament type carbon fiber treated by polyacrylonitrile; the fiber has low density, high tensile strength and yield strength. The preparation method comprises the following steps: obtaining of prepreg, layered paving as well as insulation and pressure maintaining. The radar antenna comprises a casing, a feed network, an upper frame and a lower frame, the cross sections of the upper frame and the lower frame are trapezoids with narrow top and wide bottom, and a gap between the upper frame and the top of the lower frame forms an arrangement area for clamping and fixing the feed network. The radar antenna has the advantages of light quality, maintenance convenience, short manufacture period, and low manufacture cost.

Owner:ANHUI SUN CREATE ELECTRONICS

Instant dissolving cemented carbide block and its preparation method and use

The invention discloses an instantly soluble hard alloy block and a preparation method and application thereof. The instantly soluble hard alloy block is made from materials in following percent by weight by binding with an adhesive: 25-35% of high carbon ferro-chrome, 0.5-1%. of rare earth, 15-40% of ferro-boron, 25-55% of ferro-vanadium, 2-6% of ferrosilicon, and 2-3% of ferronickel, wherein the adhesive is a resin adhesive. The instantly soluble hard alloy block has high hardness (Rockwell hardness HRC > / =73), good wear resistance, manufacture process simplicity, low cost, low surfacing current, convenience of selecting dimensions and shape, low time and labor consumption for a welder, etc., the problem that a quick-wear apparatus is short in life is solved, and the life of an original member is prolonged by 3-10 times.

Owner:苑俊奎

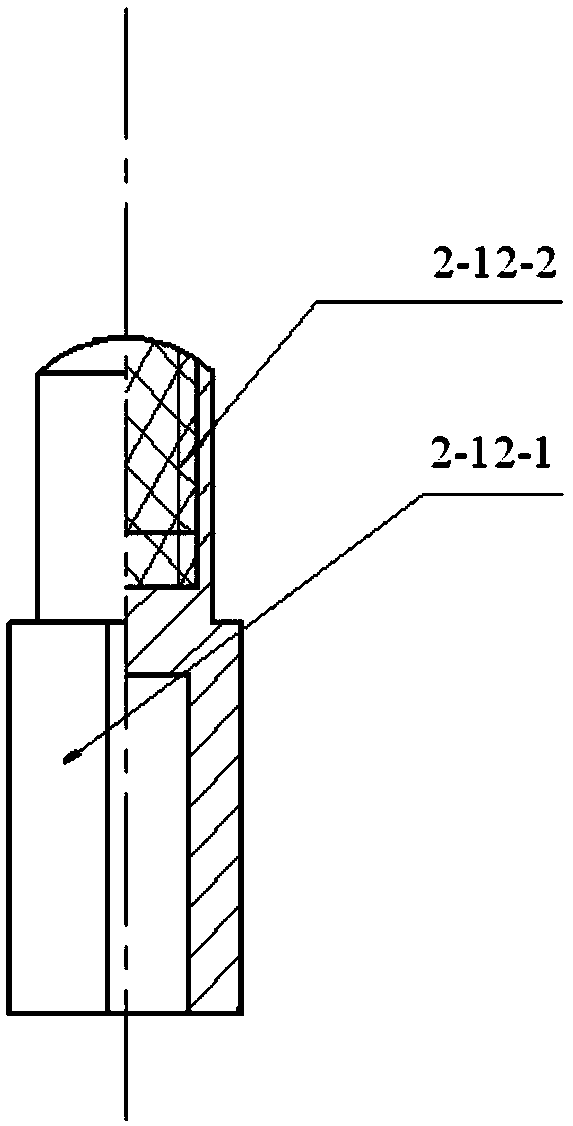

Battery integral installation jig

ActiveCN101791751BEasy to holdReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryNatural state

The invention discloses a battery integral installation jig. The jig comprises a base plate, wherein the base plate is provided with a movable frame composed of a plurality of splints and a clamping mechanism used to generate sideslip force on the splints and tighten up the movable frame, the inside of the movable frame is provided with automatic reset mechanism which acts on the splints to generate a repelling force opposite to the sideslip force generated by the clamping mechanism and ensures that the movable frame can return to a natural state. The jig can automatically return to the normal position without manual operation after clamped, thus saving the production time and reducing the labor intensity of workers.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Portable small-flow precise pressure regulating device

PendingCN109506023AAccurate pressure regulationStable pressure regulationEqualizing valvesSafety valvesEngineeringStreamflow

The invention provides a portable small-flow precise pressure regulating device. The portable small-flow precise pressure regulating device comprises an upper shell assembly, a precise pressure regulating assembly and a lower shell assembly. The upper shell assembly comprises a screw, an upper shell and a screw connecting part. The precise pressure regulating assembly comprises a first spring, aninner liner, a positioning base, a lower spring, a third gasket, a diaphragm, a limiting ring, an outer liner, a check block, an upper spring, an upper valve and a lower valve. The lower shell assembly comprises a lower shell, a first filler neck, a nut, a nozzle, a first gasket, a second filler neck and a second gasket. Precise pressure regulating of multiple media under different working conditions is achieved, and the portable small-flow precise pressure regulating device has the beneficial effects that the structure is relatively simple, output pressure is stable, and regulating is precise.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com