Molding die and molding process of thick-wall spherical seal head for hydrogenation reactor

A technology of hydrogenation reactor and spherical head, which is applied in the direction of forming tools, applications, household appliances, etc., can solve the problems of large machining allowance, poor product quality, and heavy billet weight, etc., and achieve short processing cycle, external dimensions and Excellent roundness and good shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

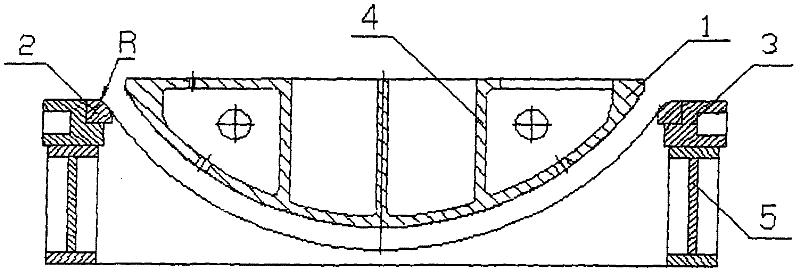

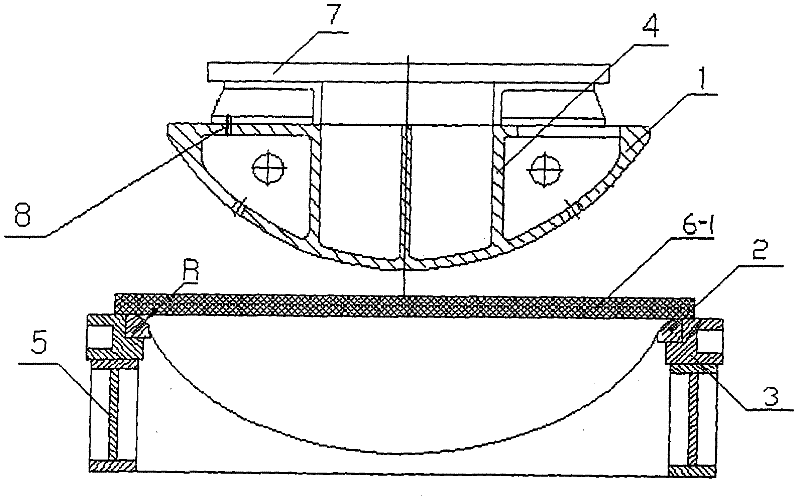

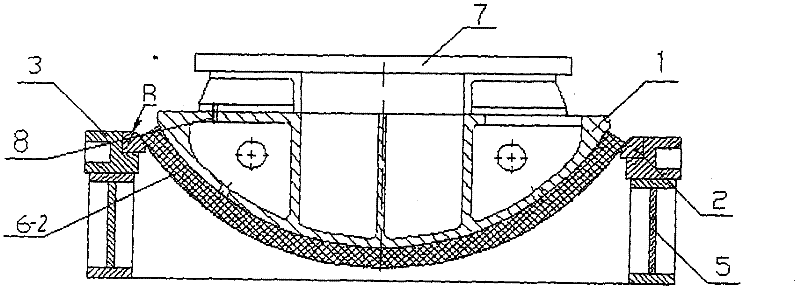

[0021] see figure 1 , the present invention provides a molding die for making a thick-walled spherical head for a hydrogenation reactor, which includes an upper die 1 and a lower die 2, the upper die 1 is a stamping die, and is in the shape of a downwardly convex spherical arc surface. In order to reduce the weight of the upper die 1 under the requirement of ensuring the necessary rigidity and strength, the inner part of the upper die 1 is hollowed out, and is connected and supported by reinforcement ribs 4 according to the regular hollowing out design. The lower mold 2 is a pressure-bearing mold, which is in the shape of a concave spherical arc surface. The outside of the lower mold 2 is covered by the lower mold jacket 3, which is combined into a whole lower mold assembly, connected to the lower mold supporting leg 5, and supported by the lower mold supporting leg 5. Lower mold supporting leg 5 adopts 8-12 supporting legs. In order to reduce the impact on the stamping and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com