Multi-stage push cylinder

A technology of pushing cylinders and cylinder barrels, which is applied in the direction of fluid pressure actuating devices, etc., can solve the problems of complex structure, large volume, and unadjustable pressure, and achieve the effects of optimized external dimensions, reliable operation, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

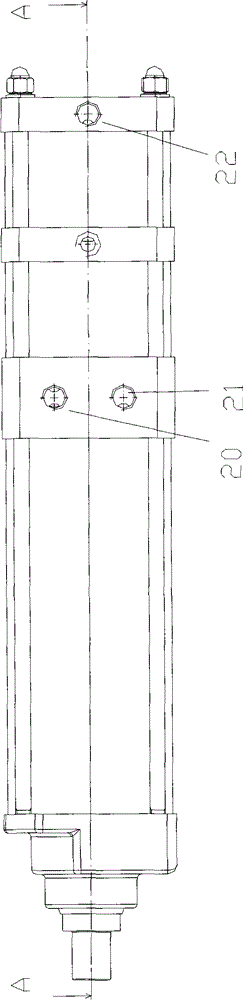

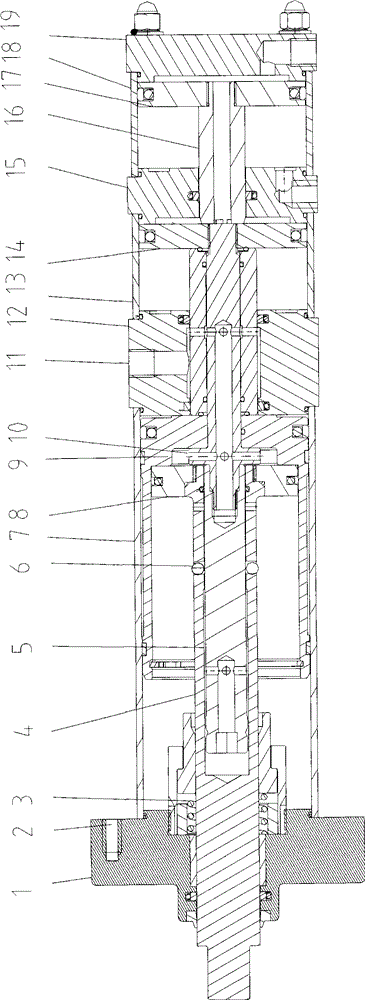

[0010] Such as figure 1 and figure 2 As shown, a kind of multi-stage push cylinder of this embodiment has two stages of pistons and two partitions, including: cylinder shaft 4, mandrel 5, connecting shaft 9, short shaft 16, first piston 10, second Piston 8, third piston 14, fourth piston 17, first cylinder 7, second cylinder 13, third cylinder 18, steel ball 6, first partition 12, second partition 15, first air hole 11 , the second air hole 21, the third air hole 20, the fourth air hole 22, the fifth air hole 2, two partitions 12, 15 divide the cylinder into three chambers, and the three chambers are independent of each other; wherein the first piston 10 is a sleeve Piston, simultaneously serves as the second piston 8 cylinders; Connection, the cylinder shaft 9 and the second piston 8 are threaded, the mandrel 5, the connecting shaft 9, and the third piston 14 are threaded, the short shaft 16 and the fourth piston 17 are threaded, and the second piston 8 is mounted on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com