A method for installing the cylinder liner of a tube mill

An installation method and tube mill technology, applied in the fields of cement, mining, and metallurgy, can solve problems such as low mold usage, occupation of production and operation funds, and increased burden on small and medium-sized foundry enterprises, so as to improve efficiency, reduce reserves, and increase versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

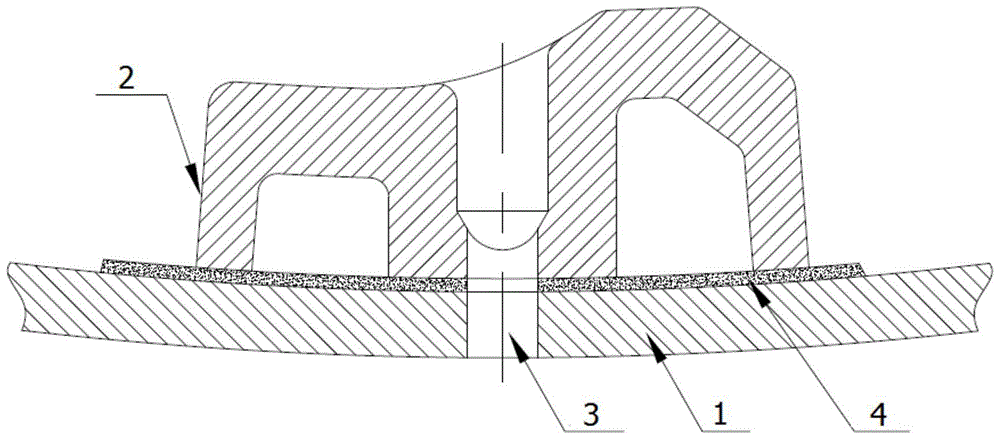

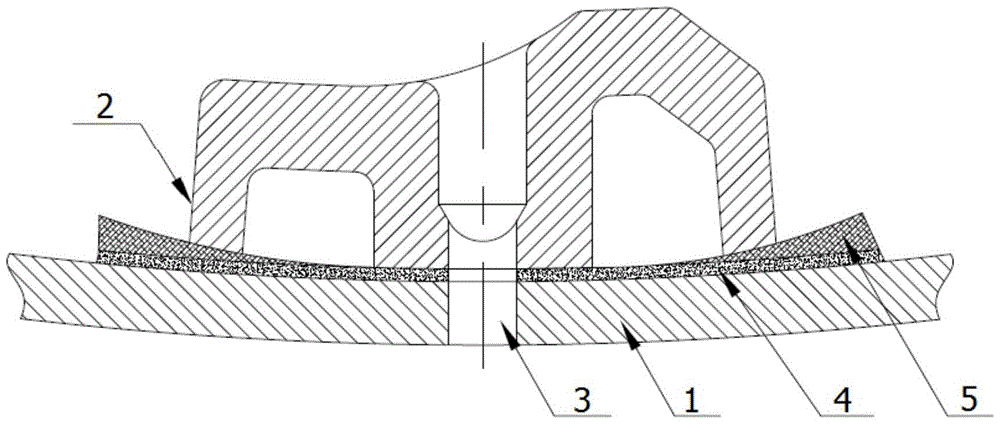

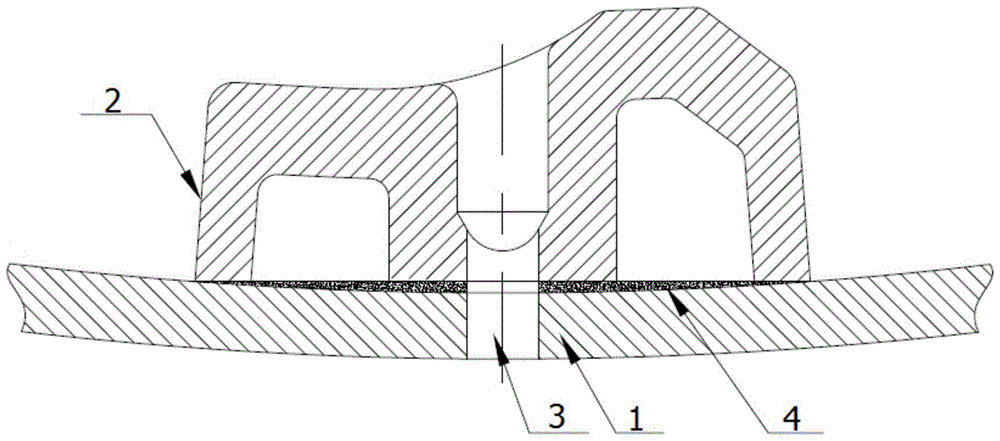

[0017] The present invention improves the utilization rate of the mill cylinder 1 liner 2 mould, commonizes the mill cylinder 1 liner 2 with different diameters on the premise of meeting the original design requirements of the mill, and reduces the reserve types of the liner 2 molds. Reduce the production cost and capital occupation of the foundry, increase the versatility of the cylinder 1 liner 2 spare parts and facilitate the production organization and improve efficiency.

[0018] In order to ensure the installation quality, the installation method needs to meet the following conditions: the arc length of the liner 2 is within 400mm, the diameter difference (wall thickness) of the cylinder 1 is within 600mm, and when the liner 2 is placed on the cylinder 1 without filler 4, the gap between the center of the liner 2 and the inside of the cylinder 1 is less than 4mm, or the gap between the two sides of the liner 2 and the inside of the cylinder 1 is less than 2mm. If the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com