Solar heat collection type drying device and control method thereof

A technology of solar heat collection and solar heat collector, which is applied in the direction of dry gas arrangement, pump device, biomass drying, etc., can solve the problems of reducing the calorific value of biomass, difficult operation of enterprises, and increasing cash flow, so as to increase the speed and Efficiency, reduction of material reserves, and improvement of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

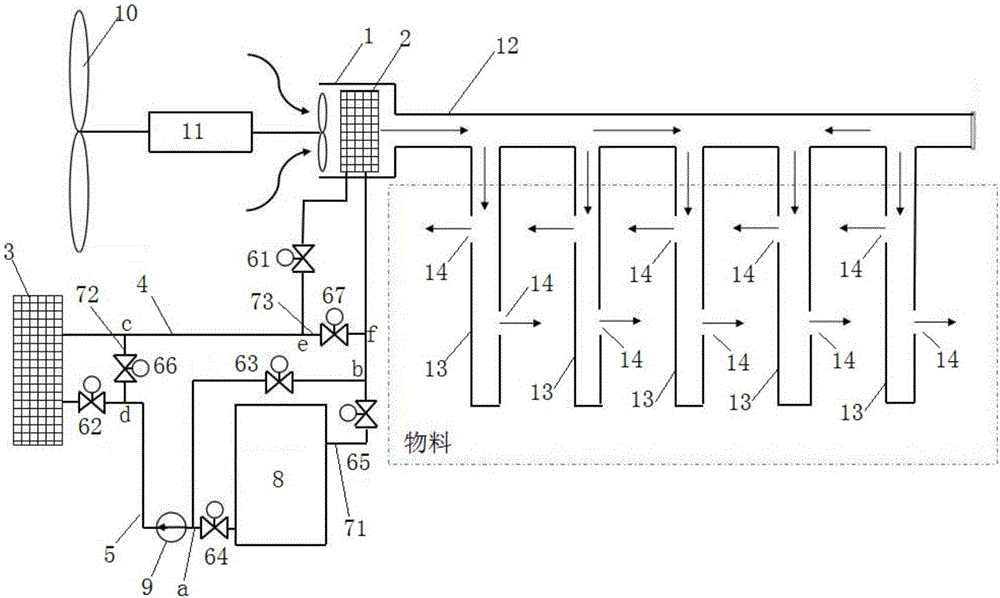

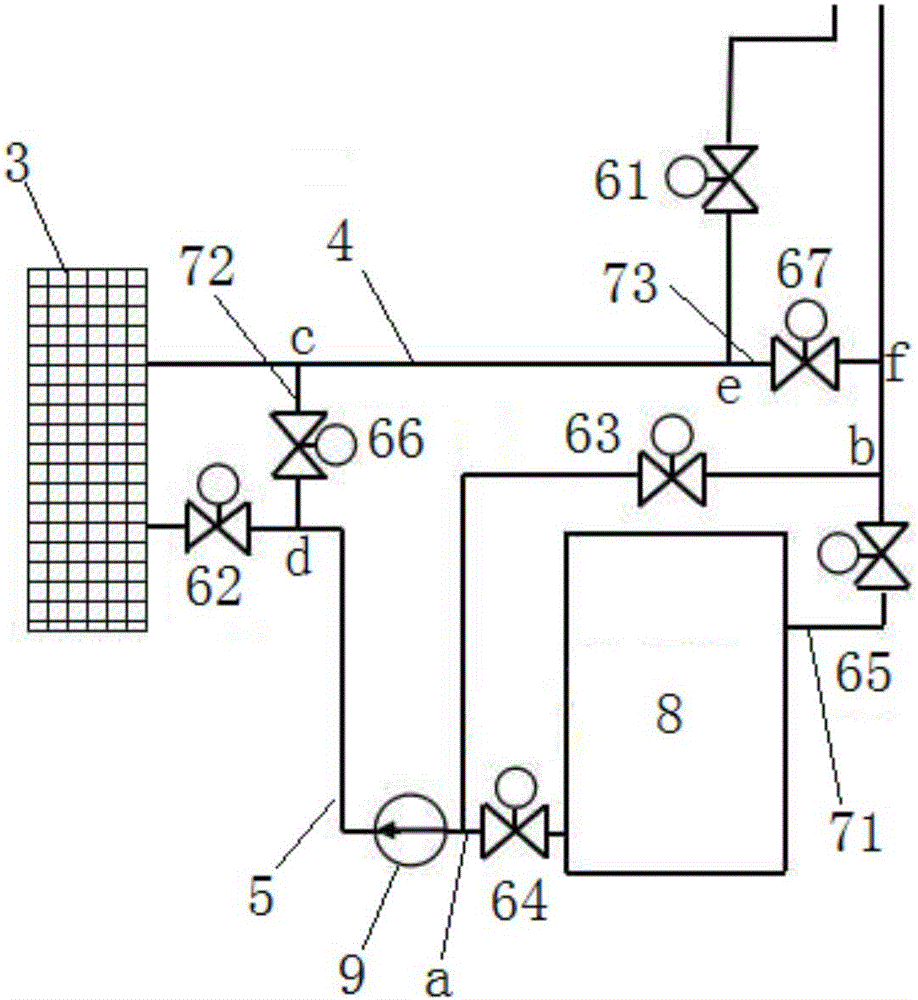

[0053] see in conjunction Figure 1 to Figure 2 As shown, the present invention provides a kind of solar heat collecting type drying device, it comprises:

[0054] The air supply device includes a fan 1 capable of rotating and absorbing external airflow and accelerating and pressurizing it, so as to dry the material through the accelerated and pressurized airflow;

[0055] The heat exchange device 2 is arranged inside the fan to exchange heat for the airflow entering the fan;

[0056] The solar heat collecting device is used to obtain solar energy and transfer the obtained energy to the airflow in the fan through the heat exchange device, so as to heat the airflow.

[0057] By adding a solar heat collection device to the original drying device, it is possible to effectively obtain solar energy through the solar heat collection device, and transfer the acquired energy to the airflow in the fan through the heat exchange device to play the role of heating the airflow. Therefore...

Embodiment 2

[0069] This embodiment is a further improvement made on the basis of Embodiment 1. Preferably, it also includes a wind energy harvesting device, including a wind blade device 10 that can rotate under the action of natural wind, and the wind blade device 10 includes a rotating shaft and Two or more blades are arranged on the rotating shaft, and the rotating shaft can rotate with the rotation of the blades; the fan 1 can be driven by the wind blade device 10 to rotate.

[0070] By also including a wind energy acquisition device, including a wind blade device that can rotate under the action of natural wind, the fan can be driven to rotate by the wind blade device, and the wind energy can be effectively utilized to drive the wind blade device to rotate, thereby Further driving the fan to rotate can reduce energy input and realize material drying with no or less power consumption, so that the energy efficiency of the material drying system and even the biomass power generation syst...

Embodiment 3

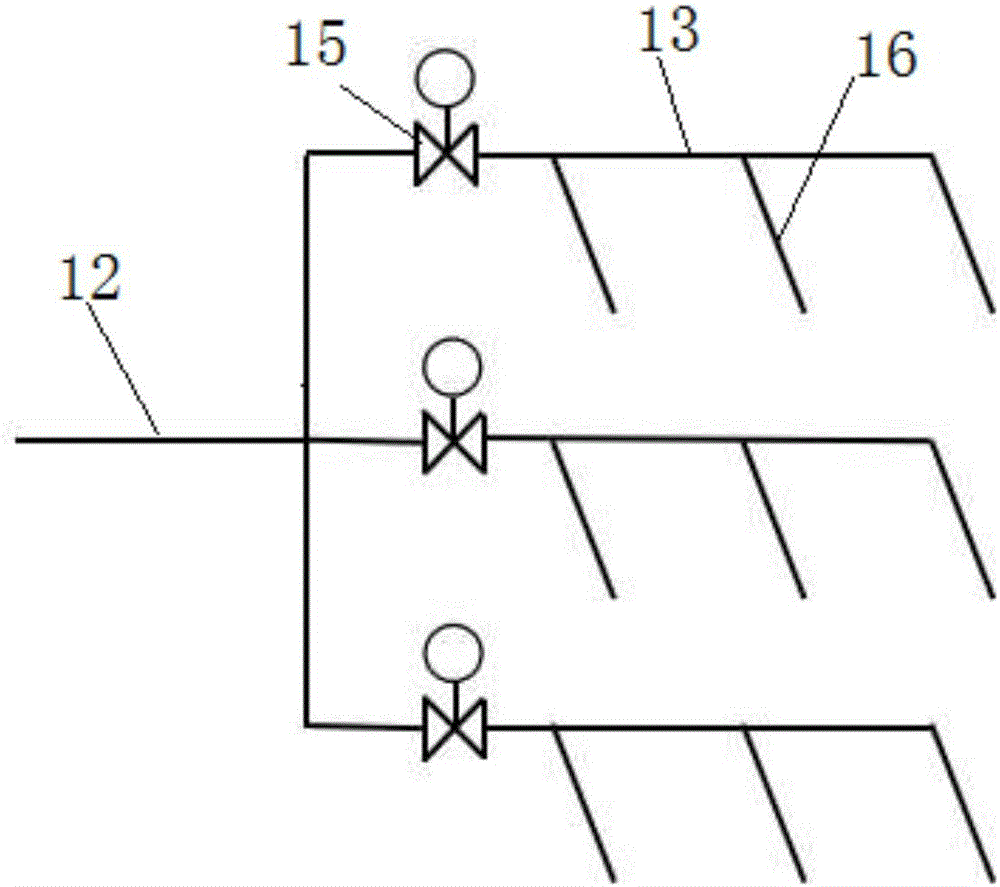

[0073] This embodiment is a further improvement made on the basis of Embodiment 1 and / or 2. Preferably, it also includes an air distribution pipe air distribution device, which is connected to the air supply end of the air supply device for distributing the air. The wind sent by the air distribution device is used to dry the material. By setting up the air distribution device of the air distribution pipe, the wind delivered by the air supply device can be distributed, so that the air flow can be distributed into multiple air paths of different sizes, and the air flow can be effectively increased when the material is dried. The contact area between materials increases the heat exchange area and effectively improves the drying efficiency of materials.

[0074] Such as image 3 As shown, preferably, the air distribution pipe air distribution device includes an air inlet main pipe 12 and a plurality of first air distribution branch pipes 13 connected to the air inlet main pipe 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com