Patents

Literature

689results about "Biomass drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

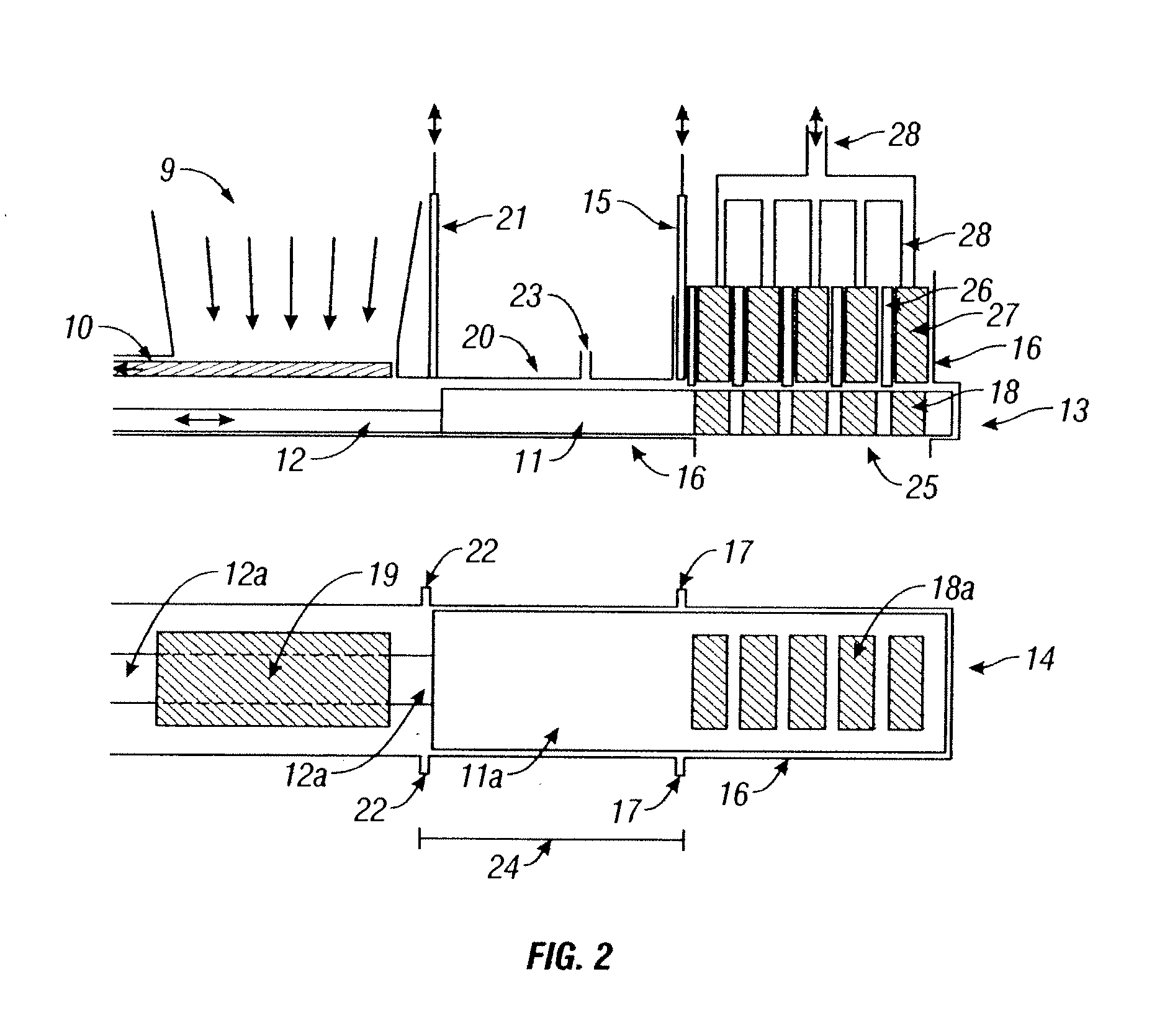

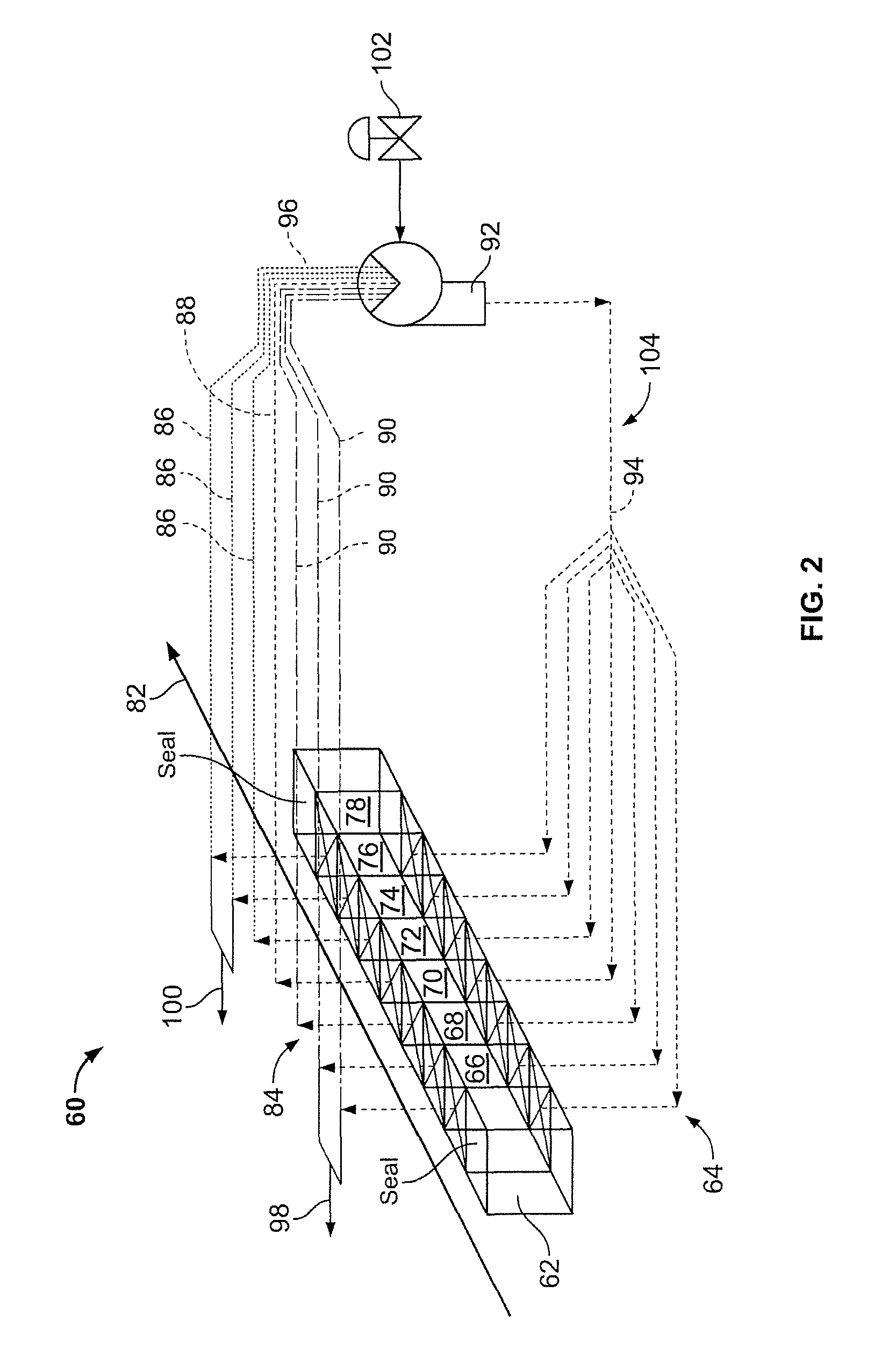

System and method for biomass fractioning

ActiveUS20100180805A1Easy inputIncrease productionDrying solid materials with heatBiofuelsSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

System and method for biomass fractioning

ActiveUS20110177466A1Easy inputIncrease productionDrying solid materials with heatOther heat production devicesSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

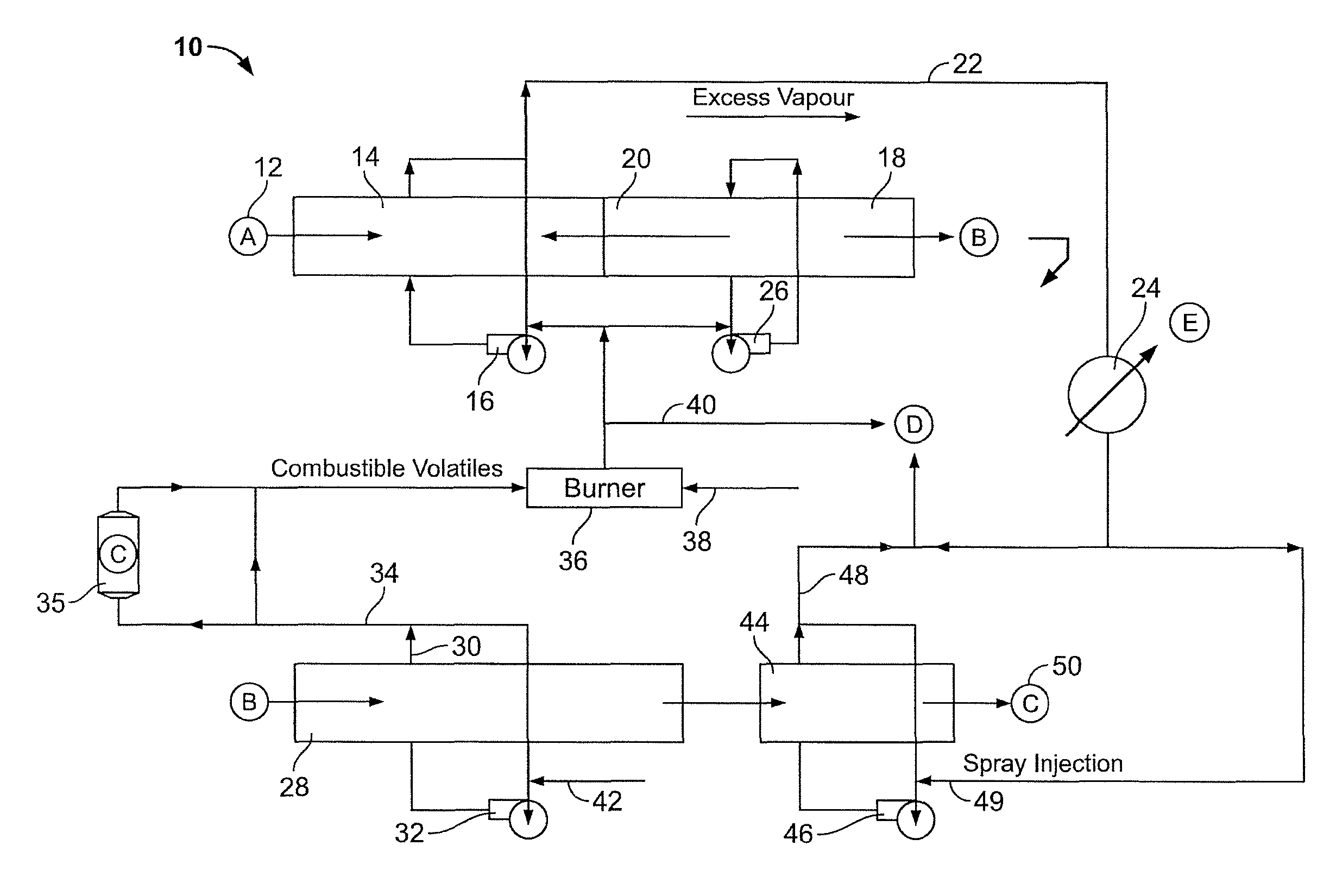

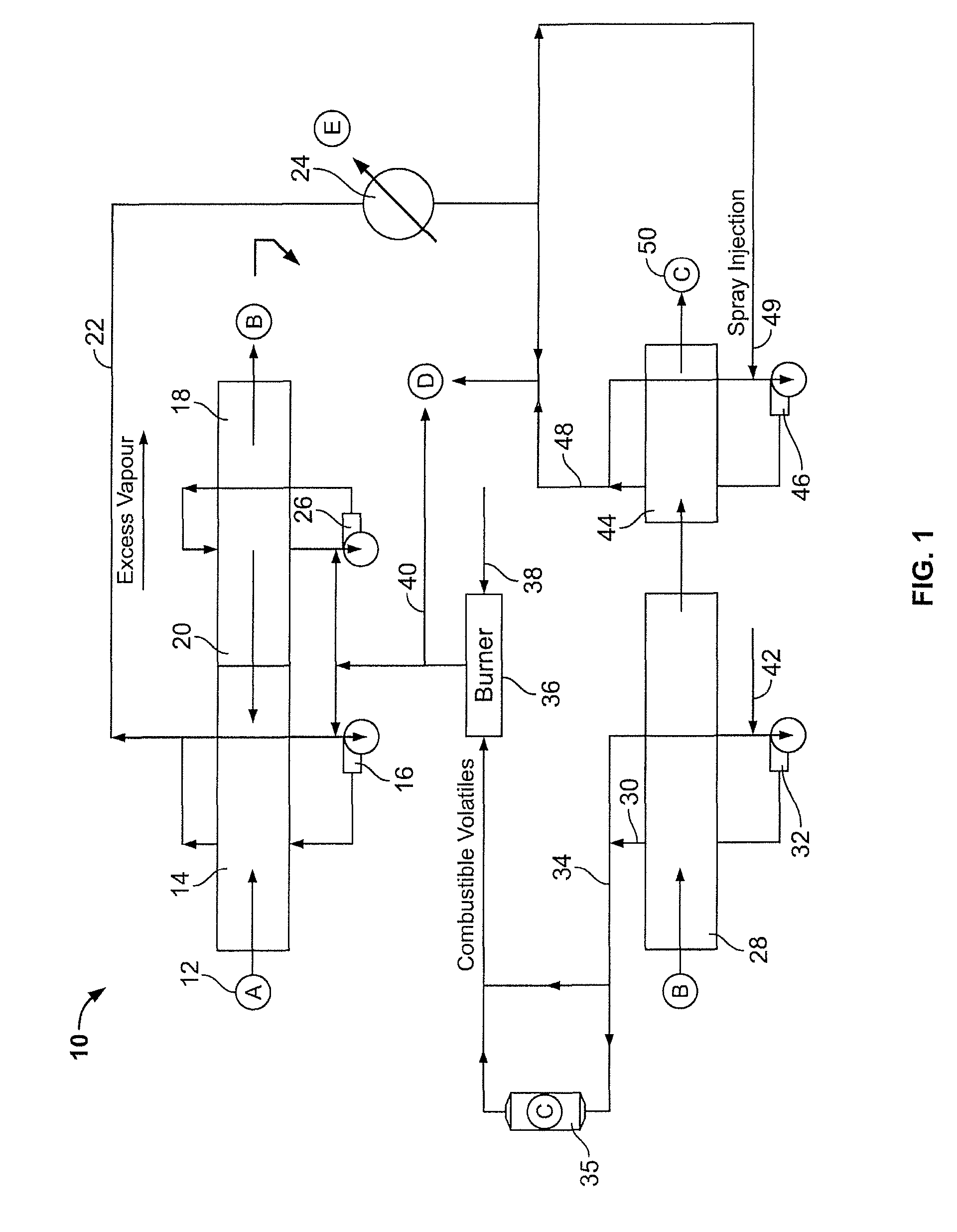

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

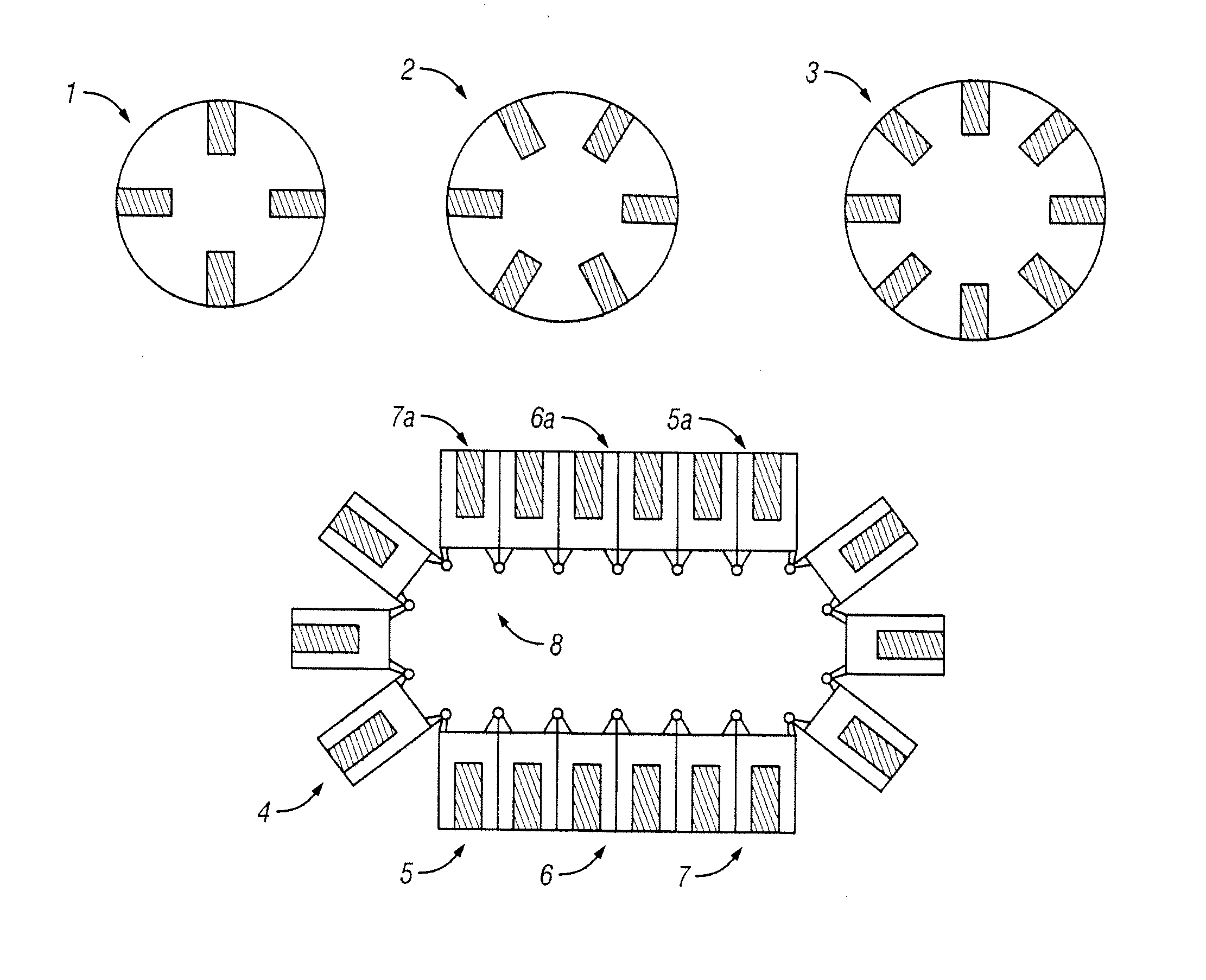

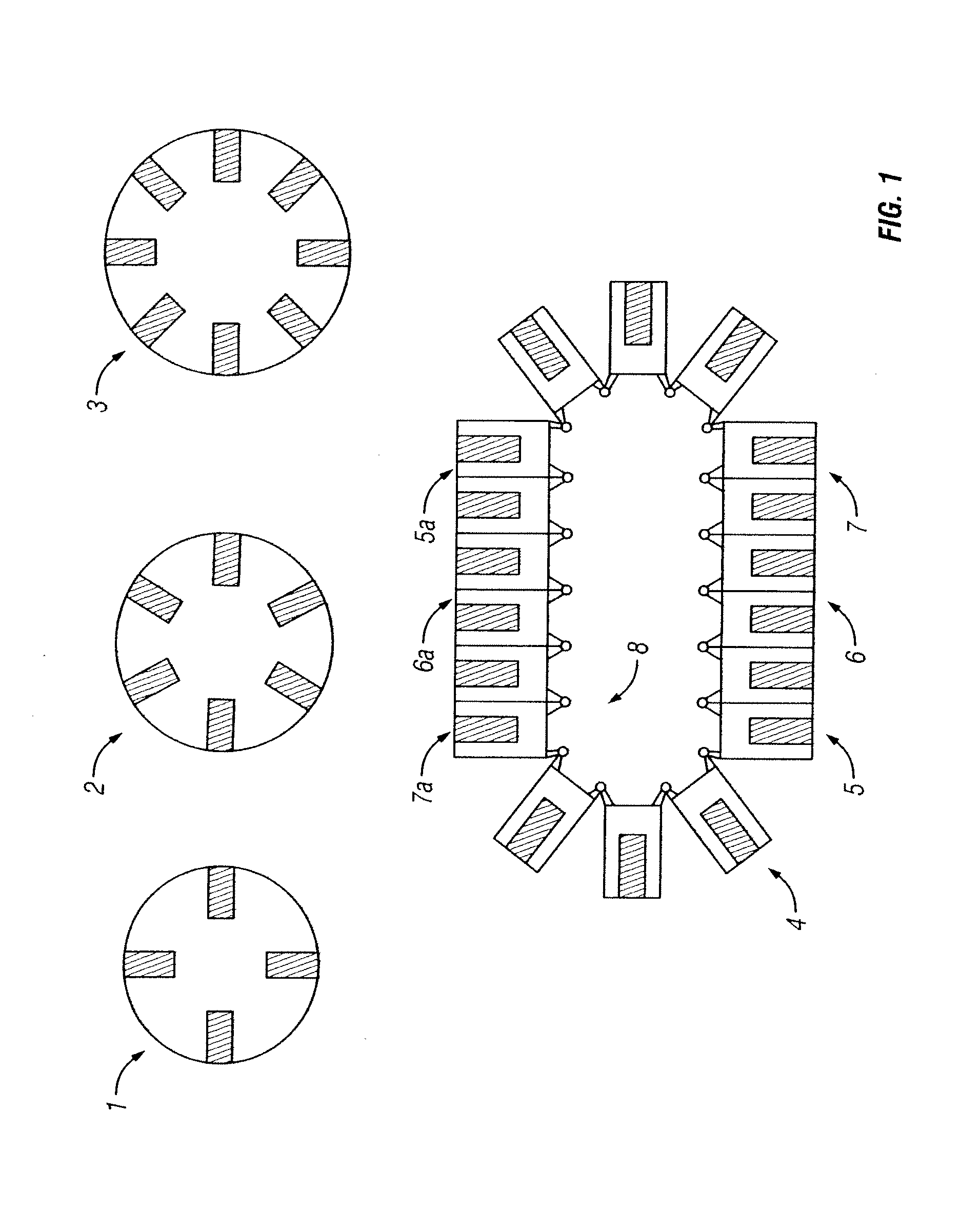

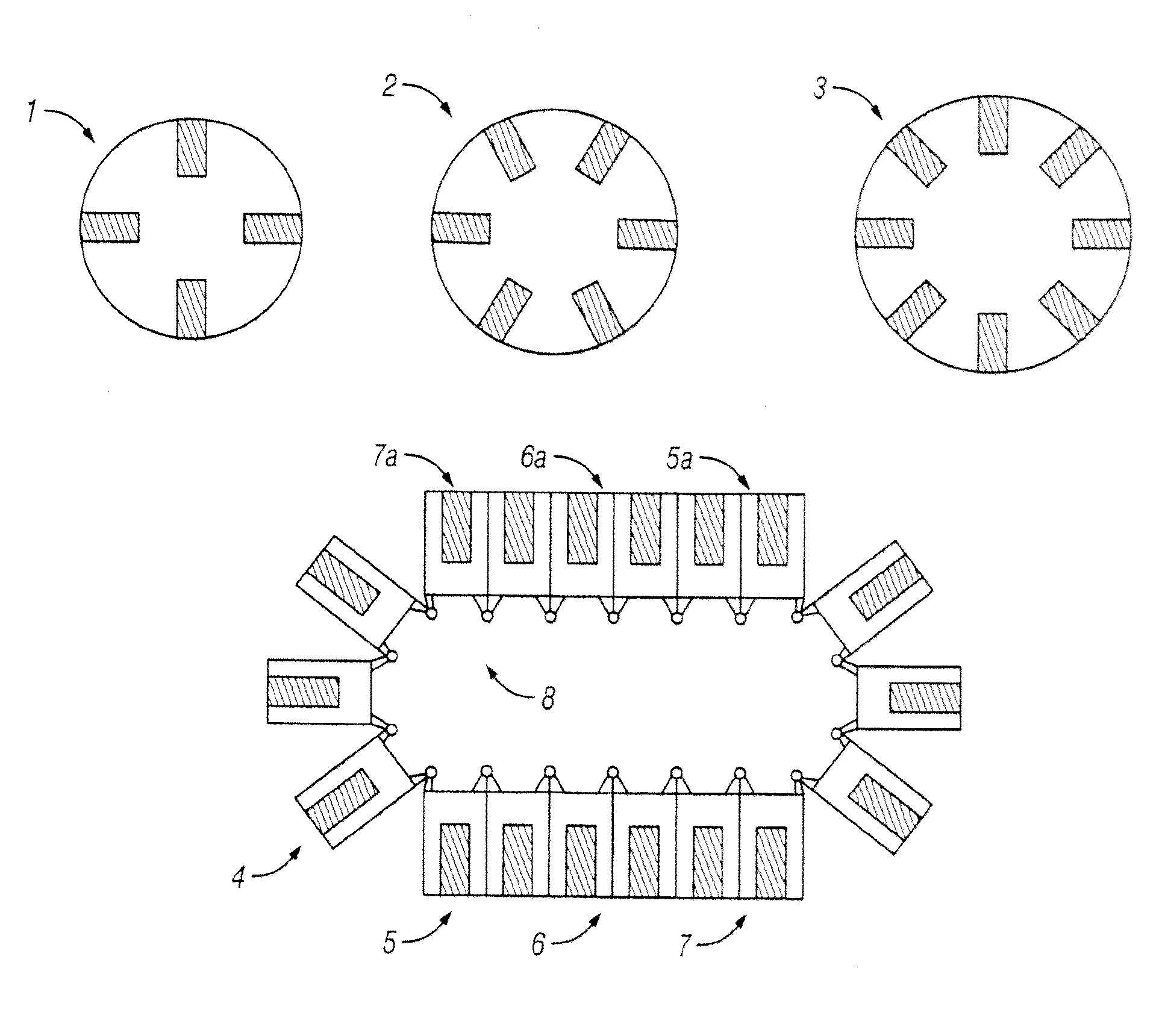

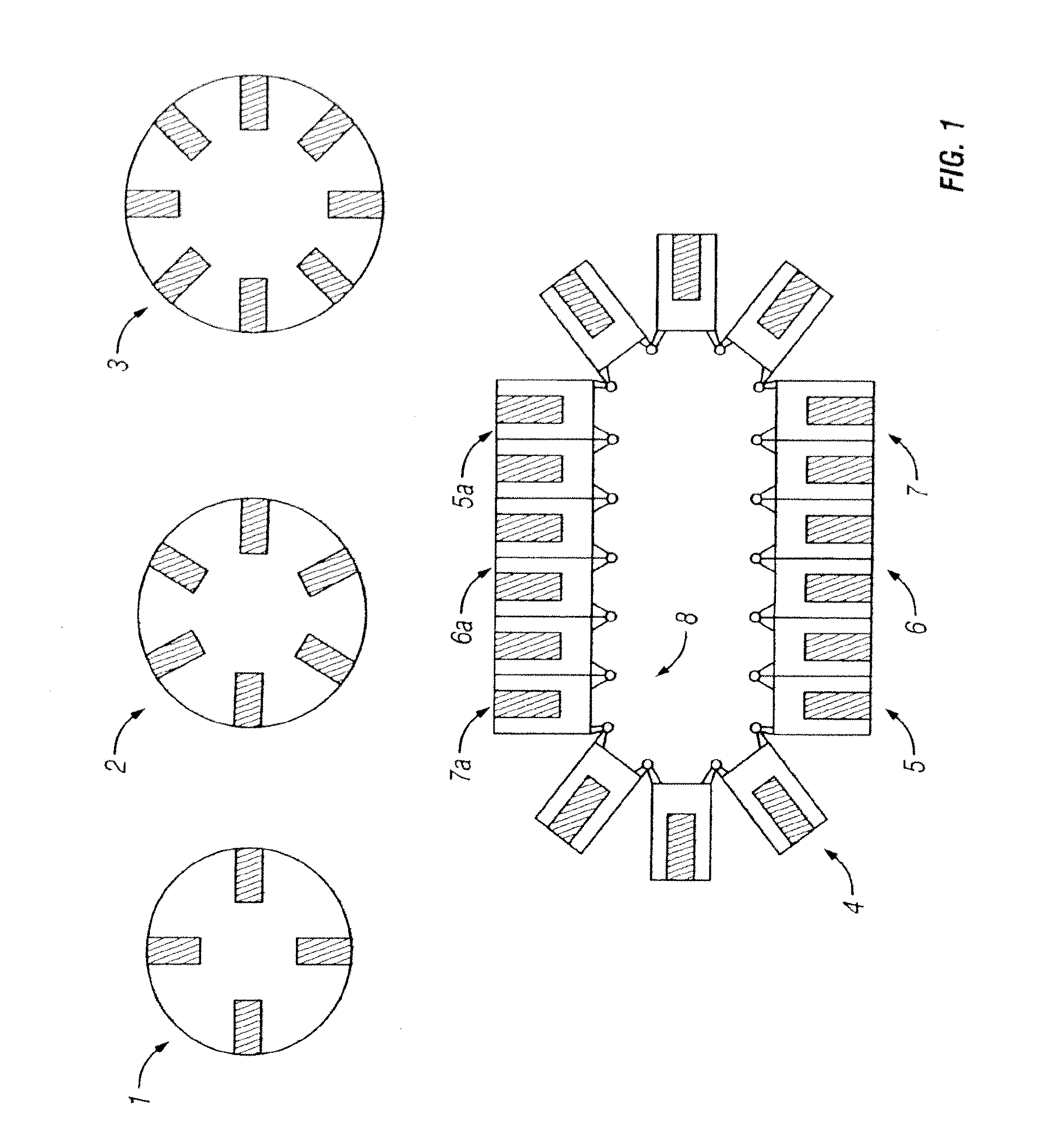

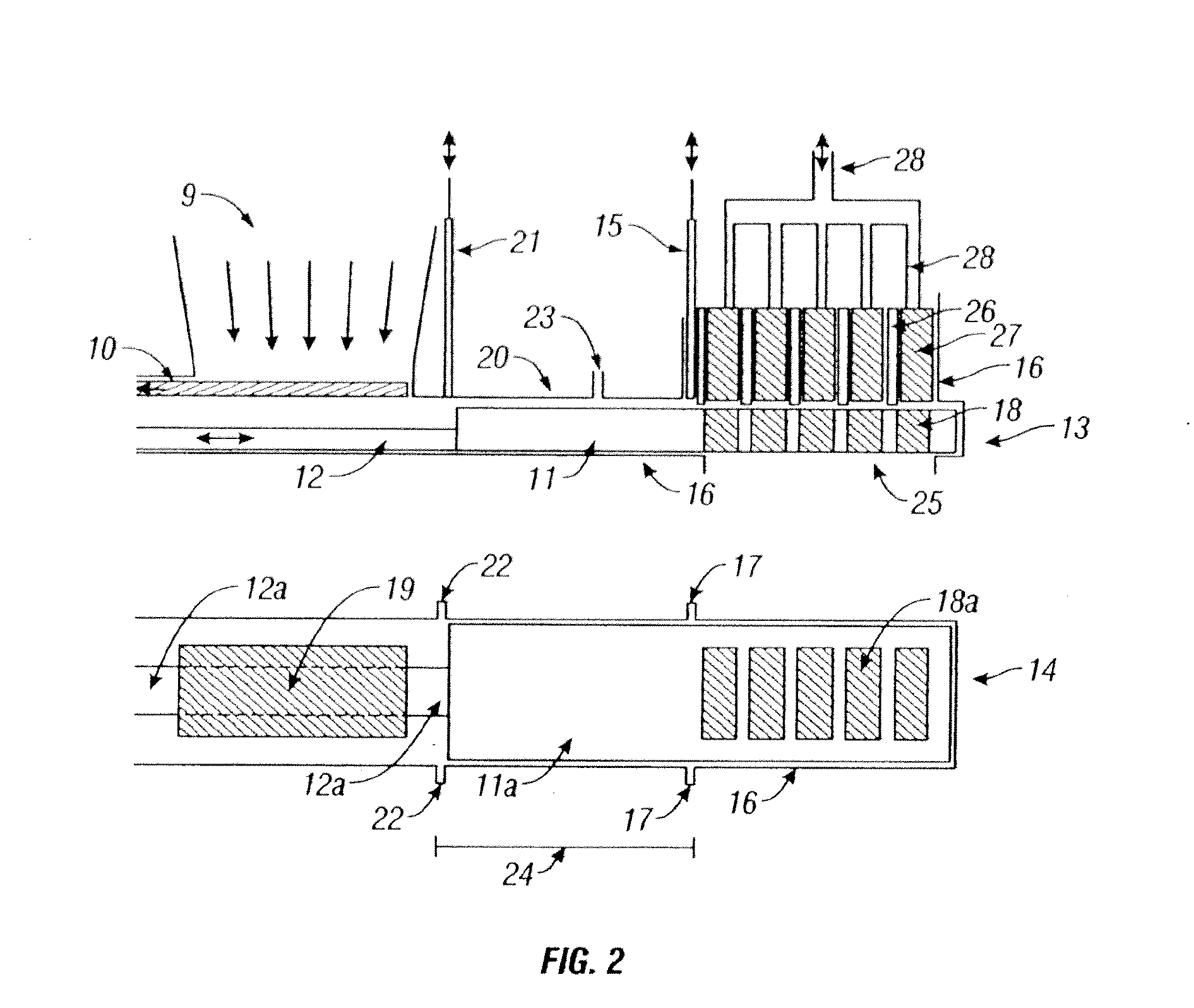

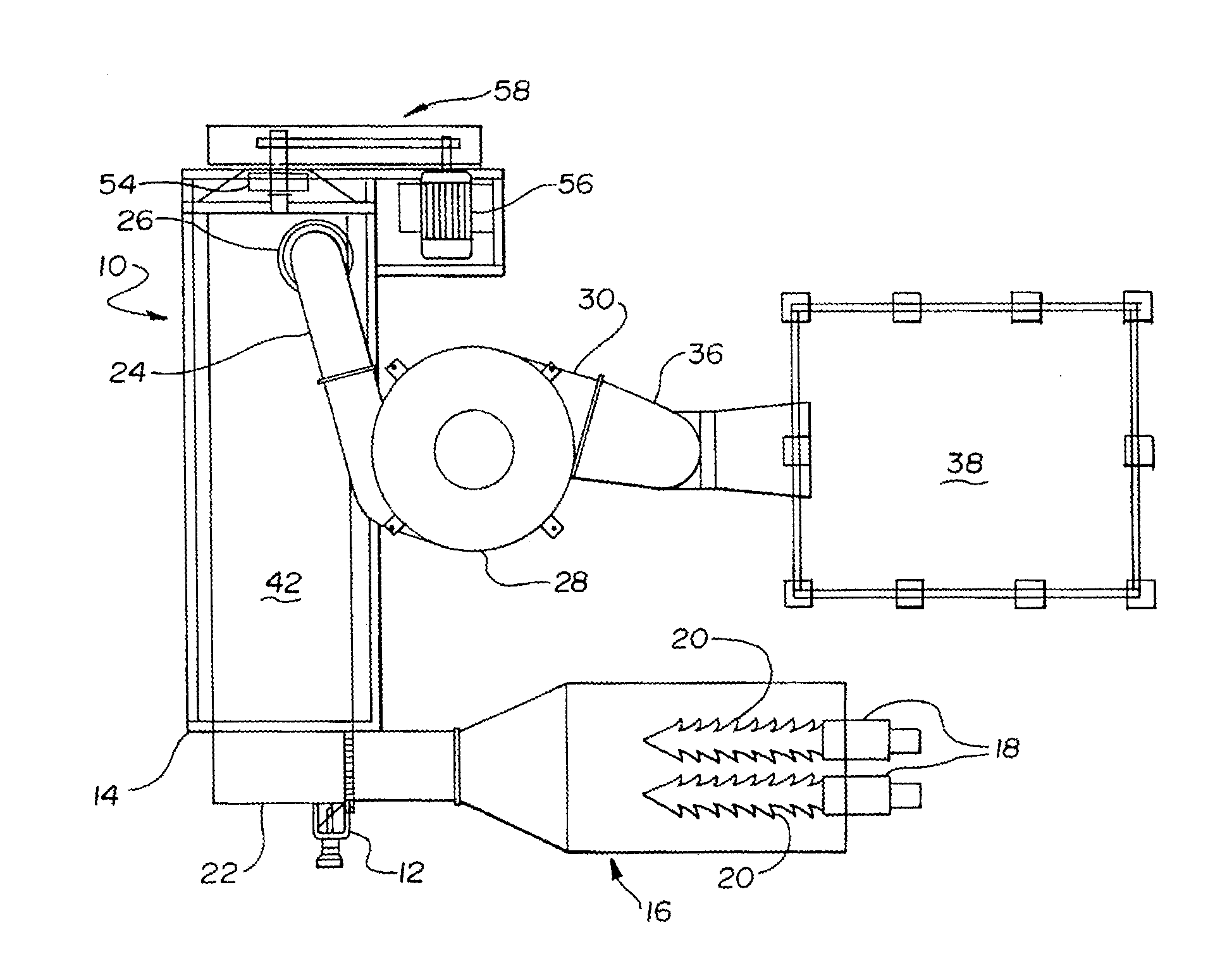

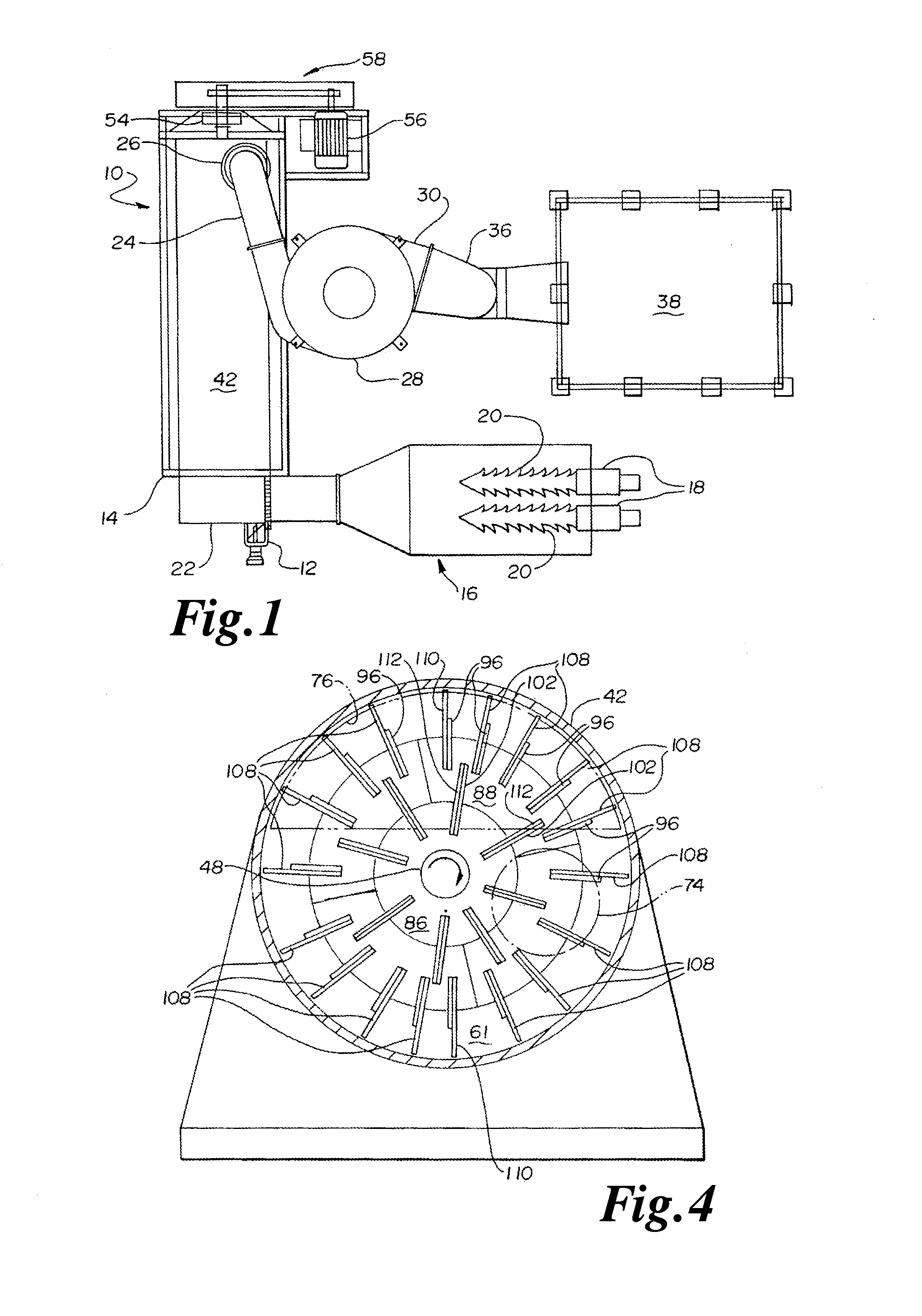

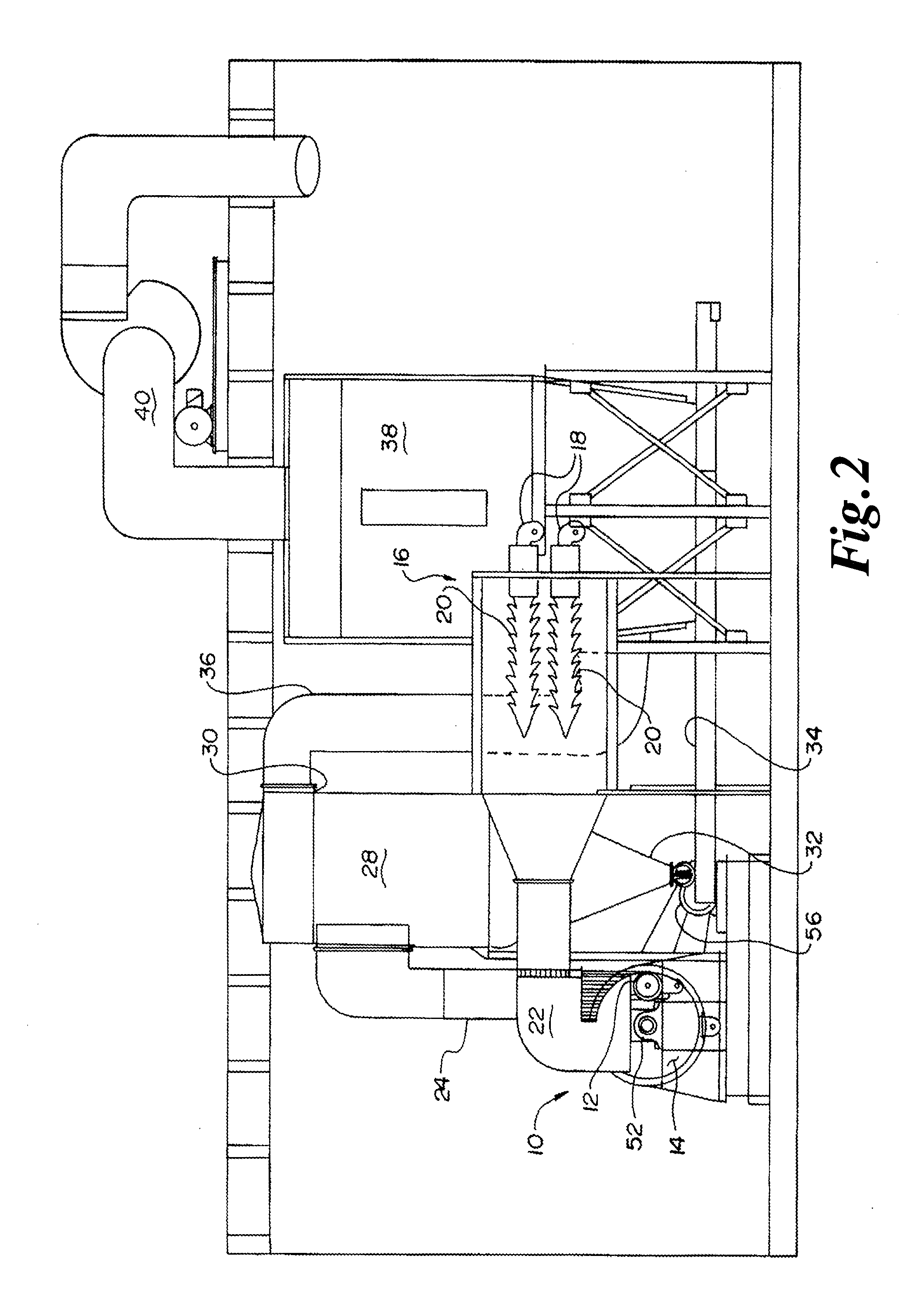

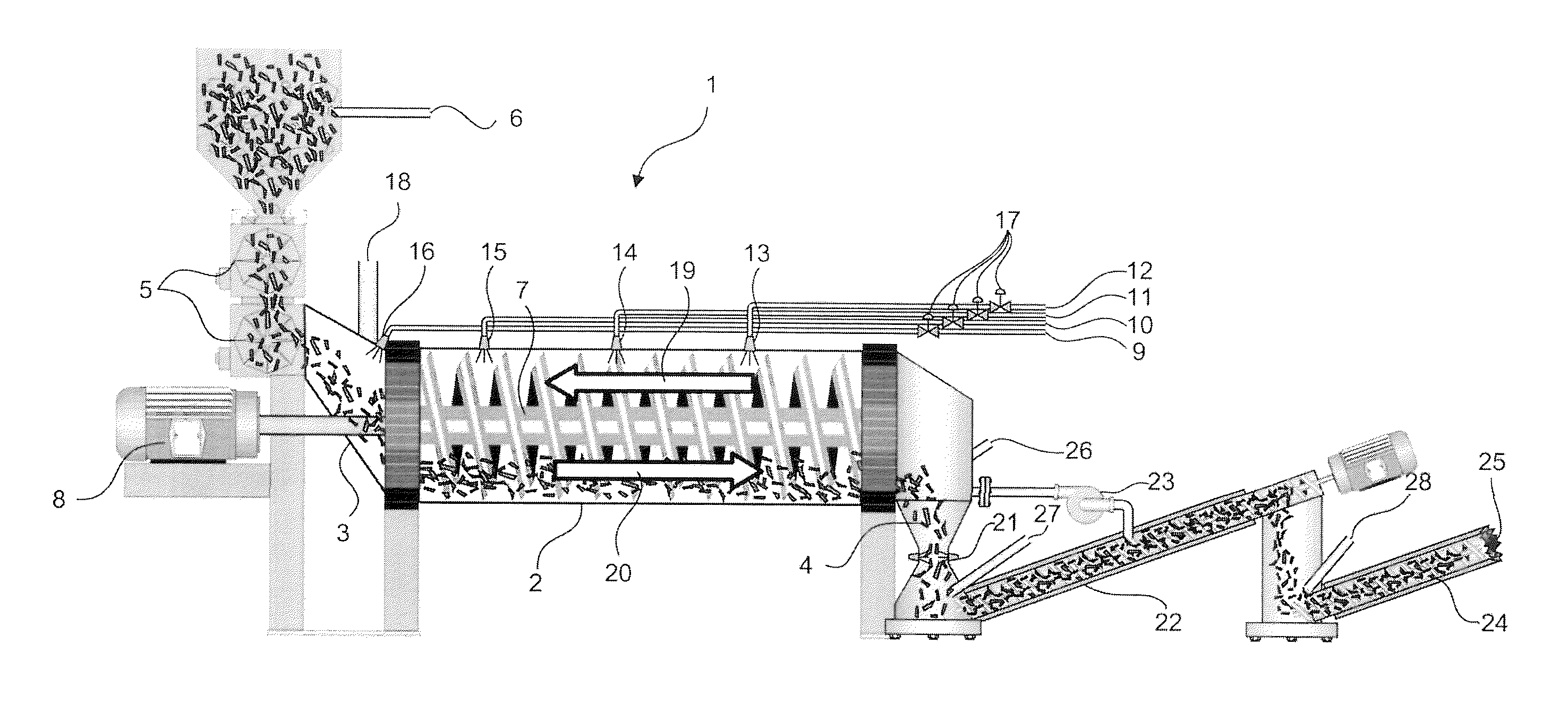

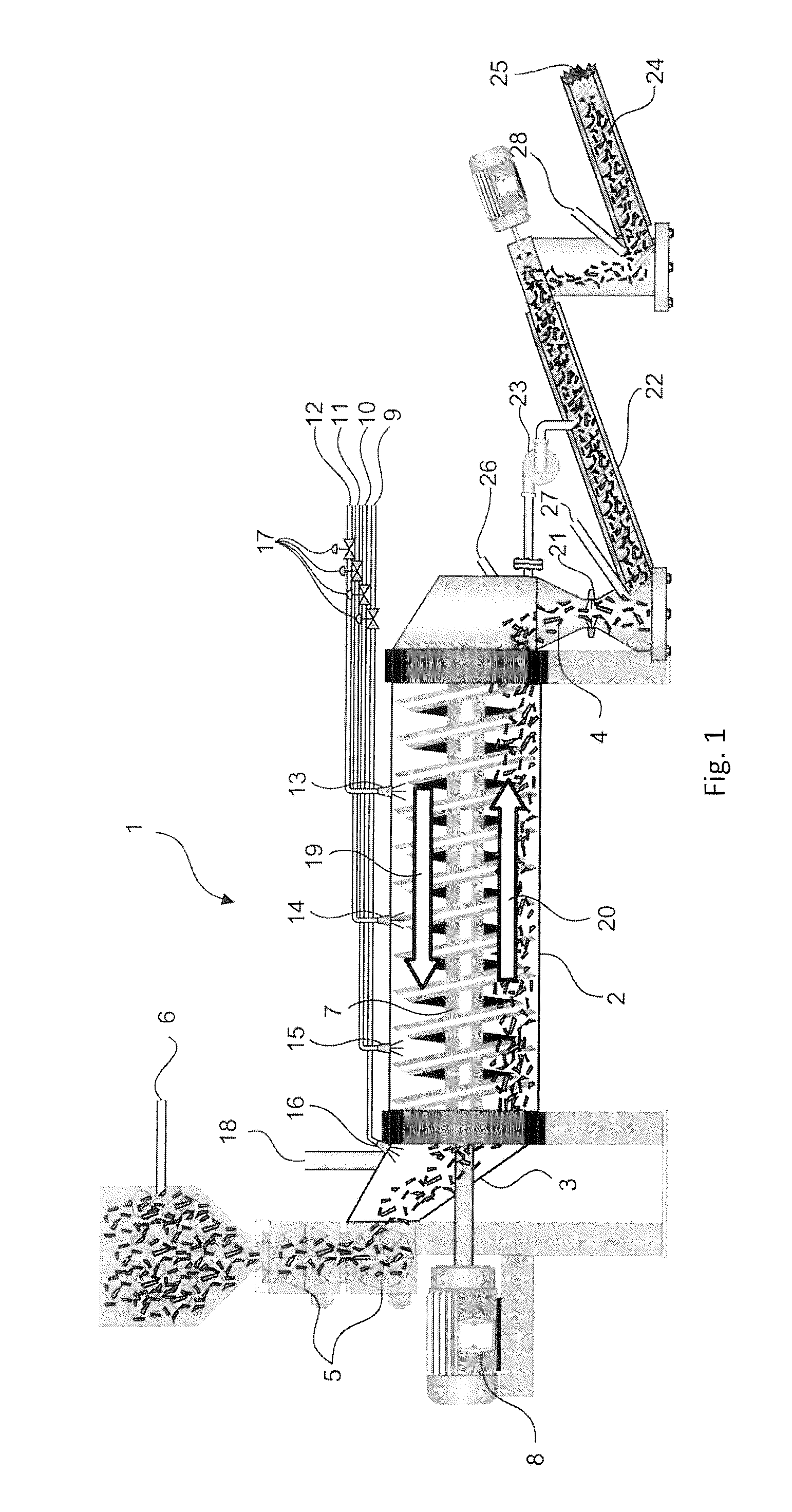

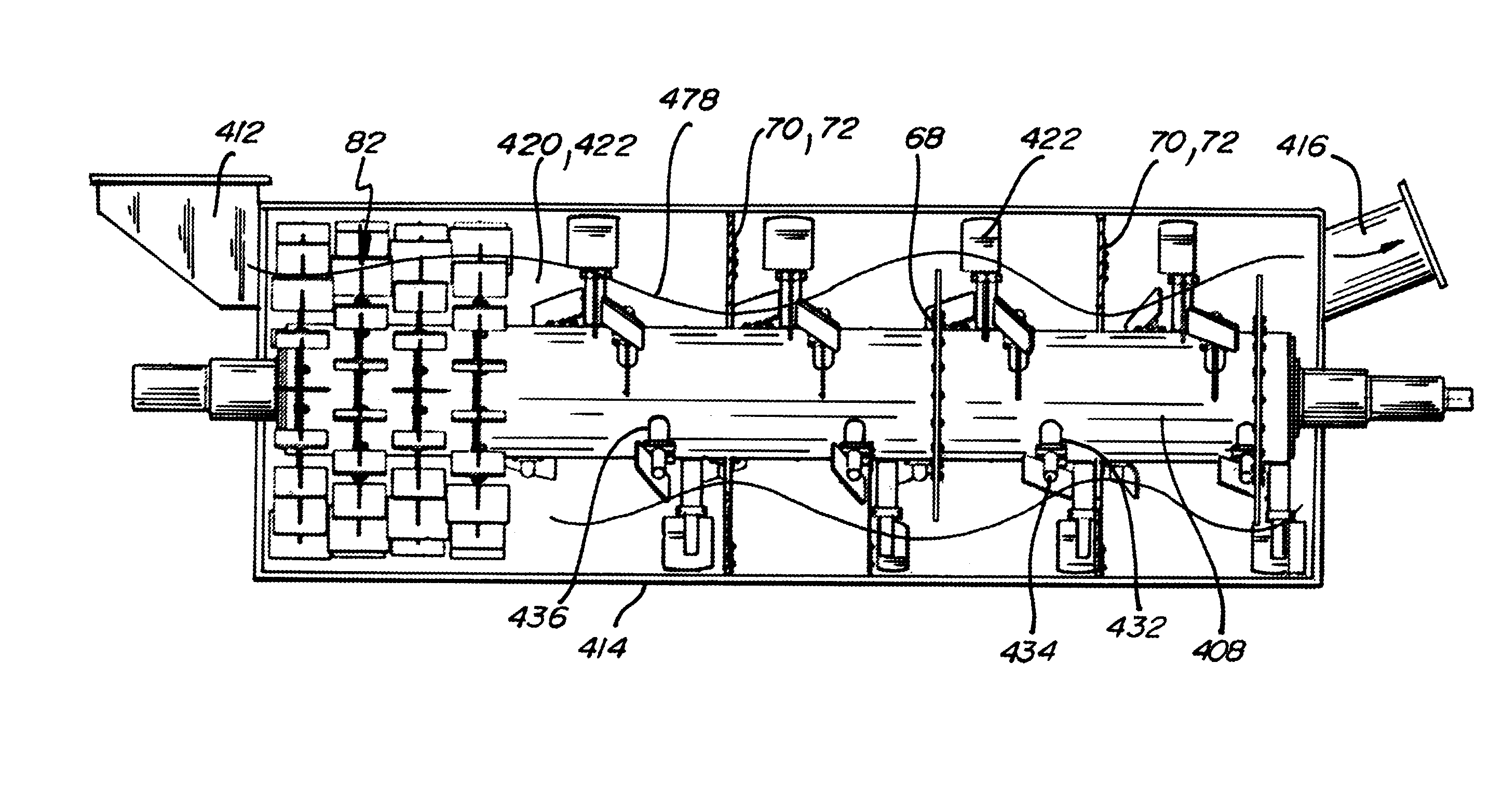

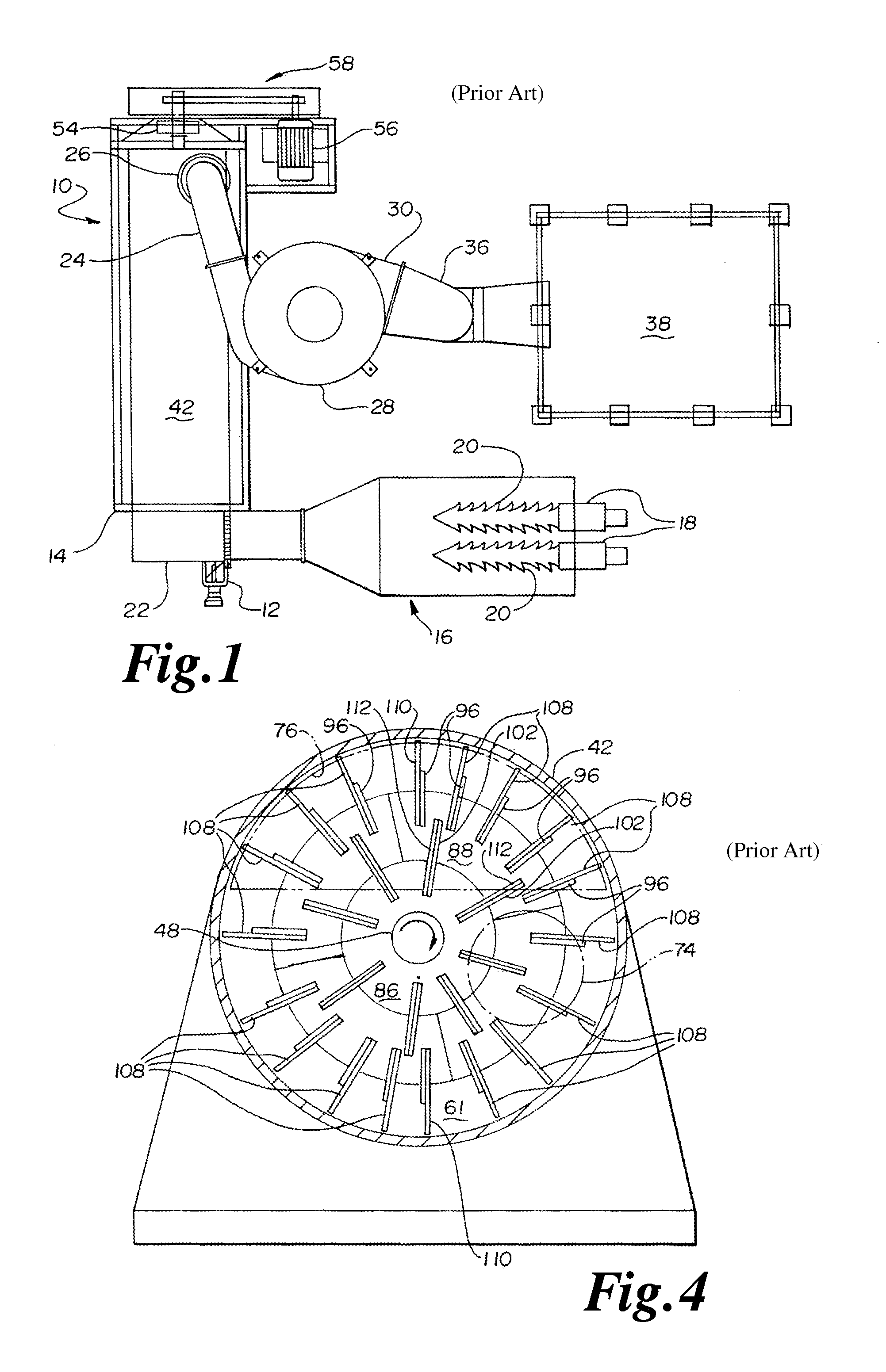

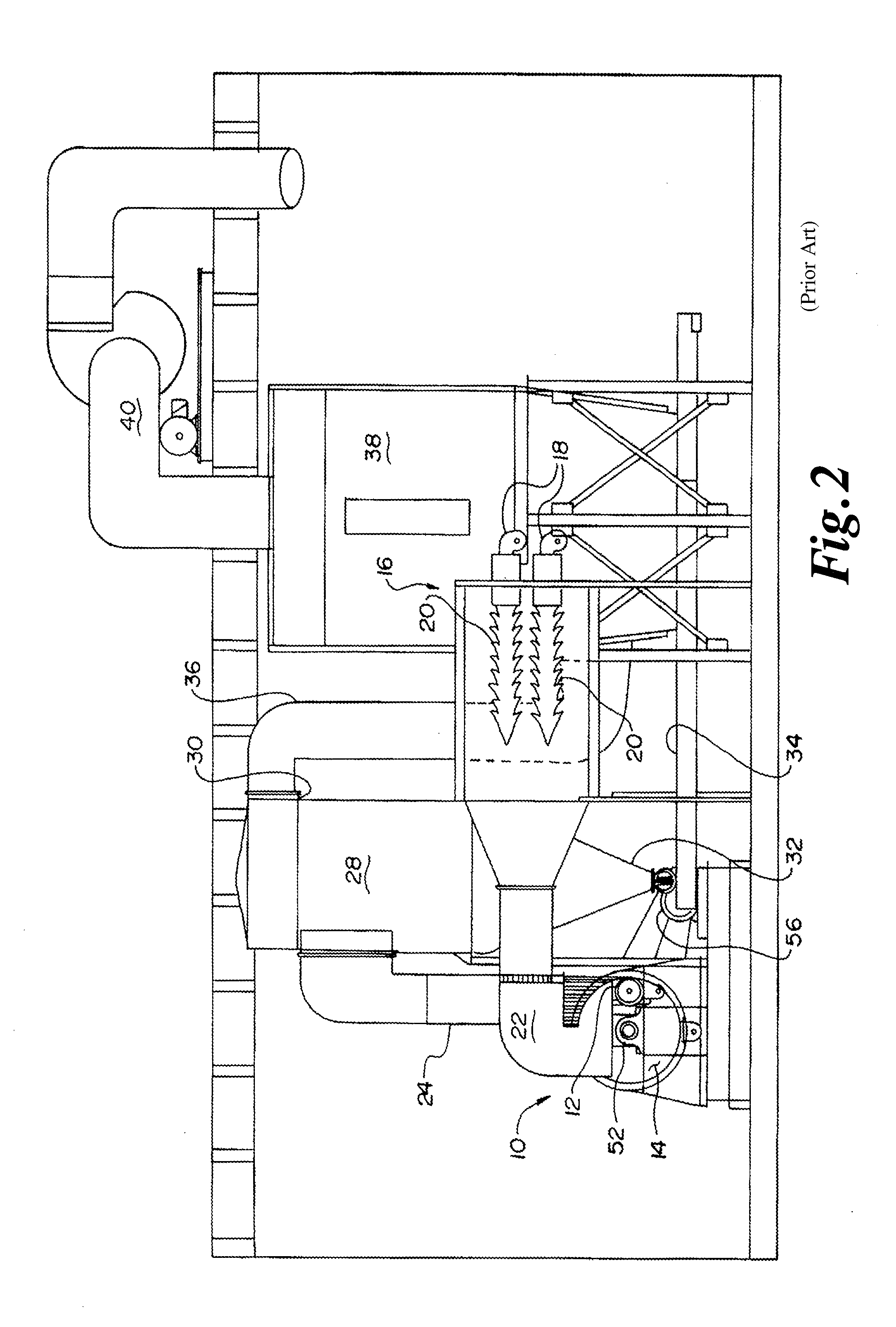

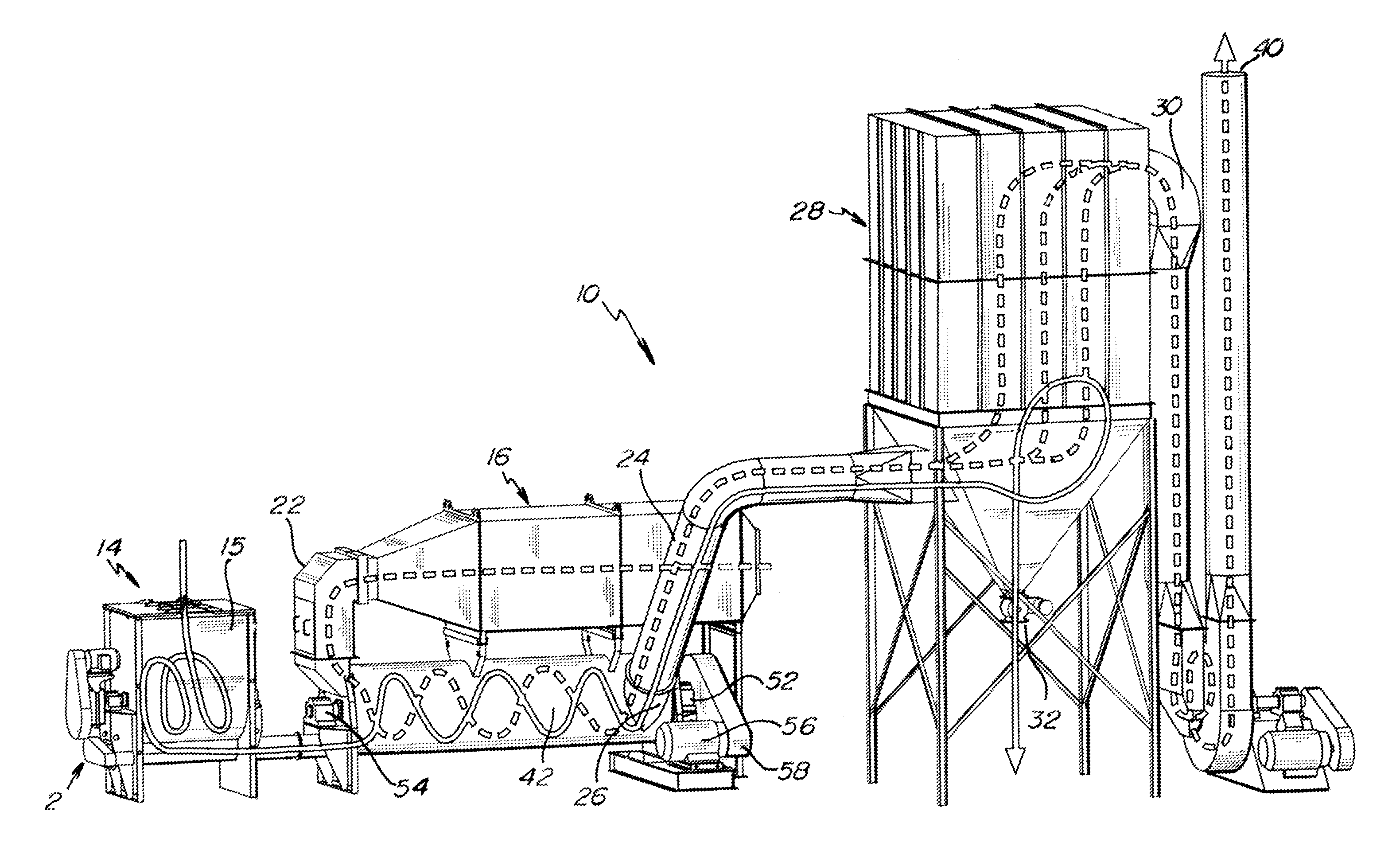

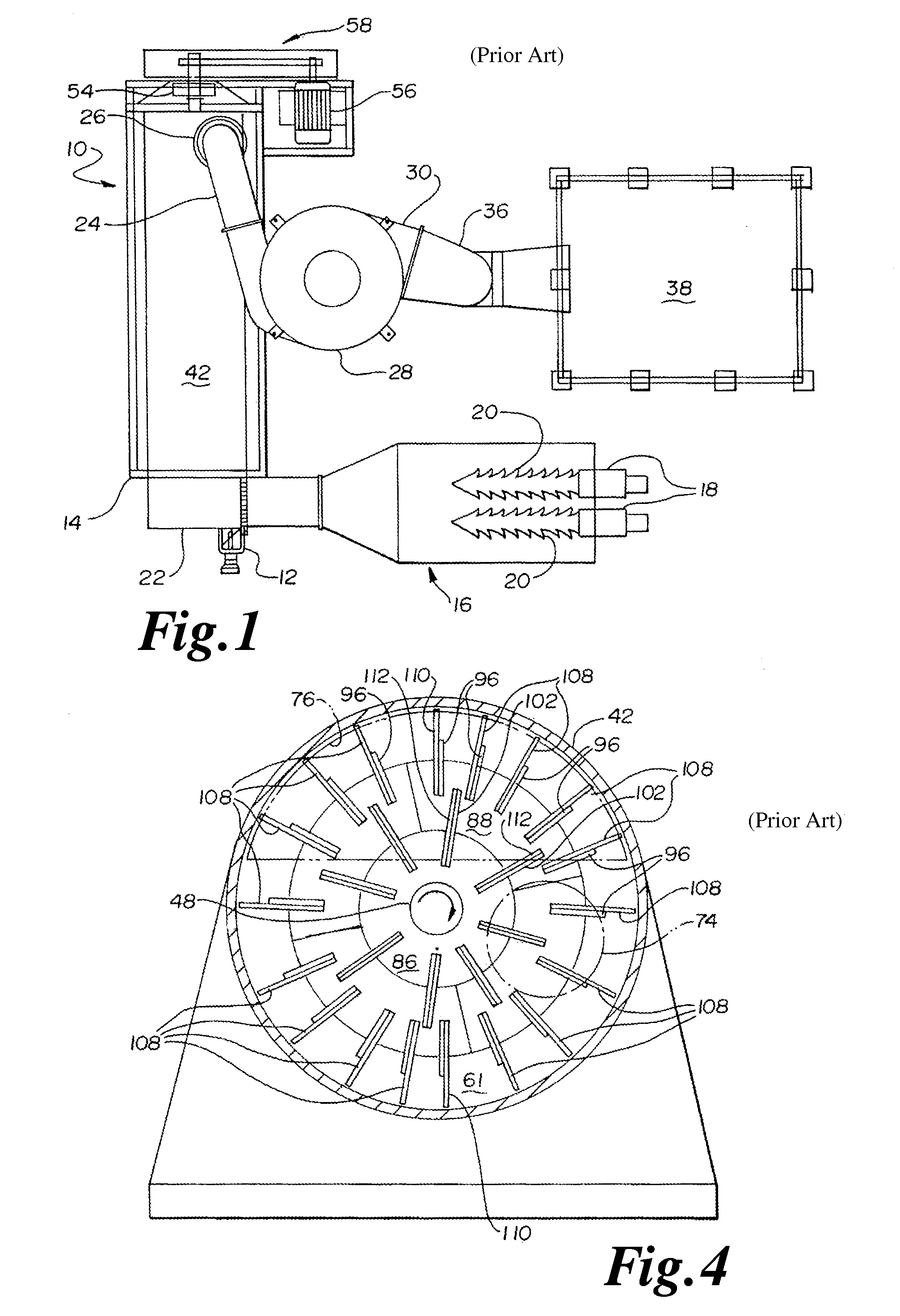

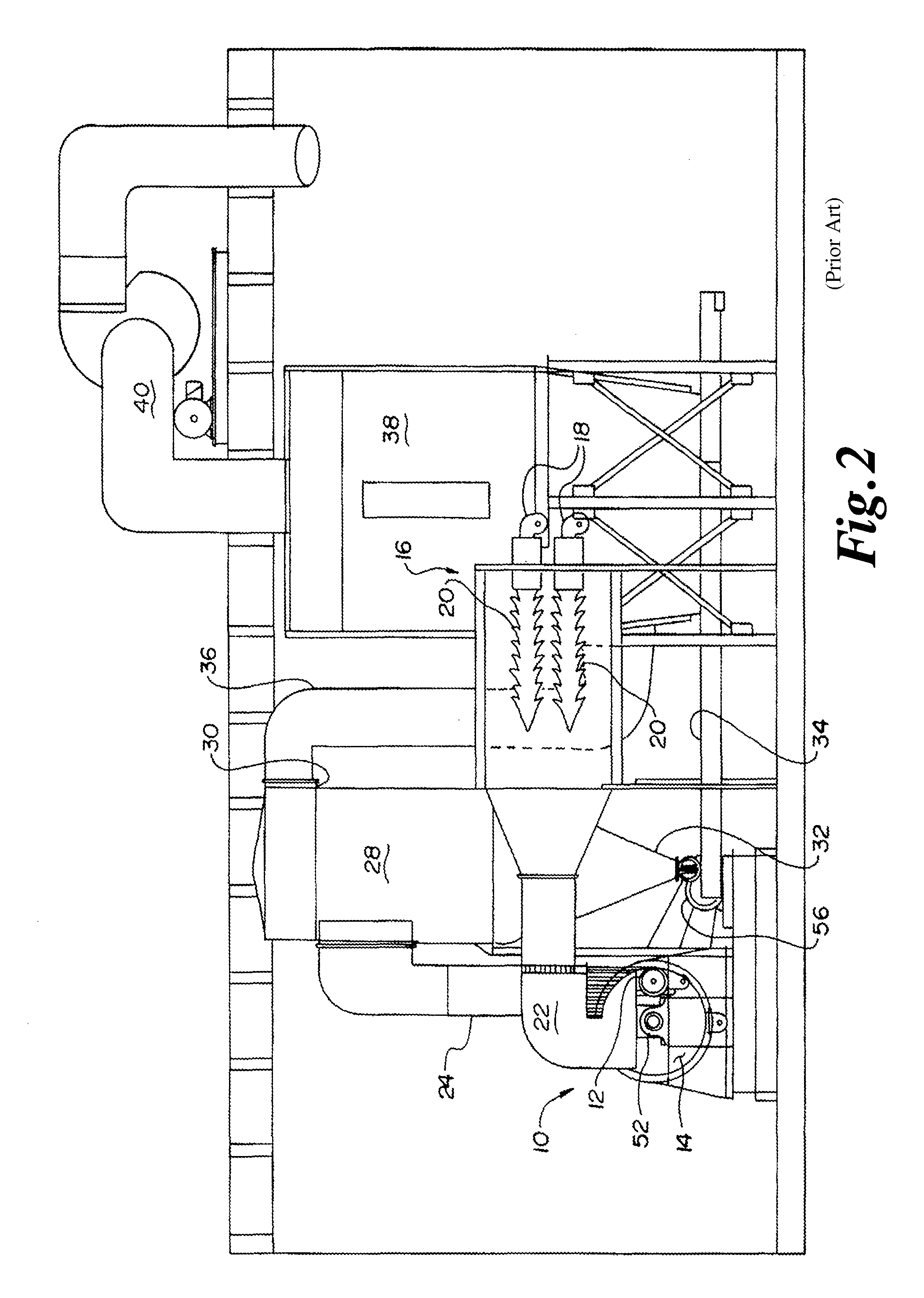

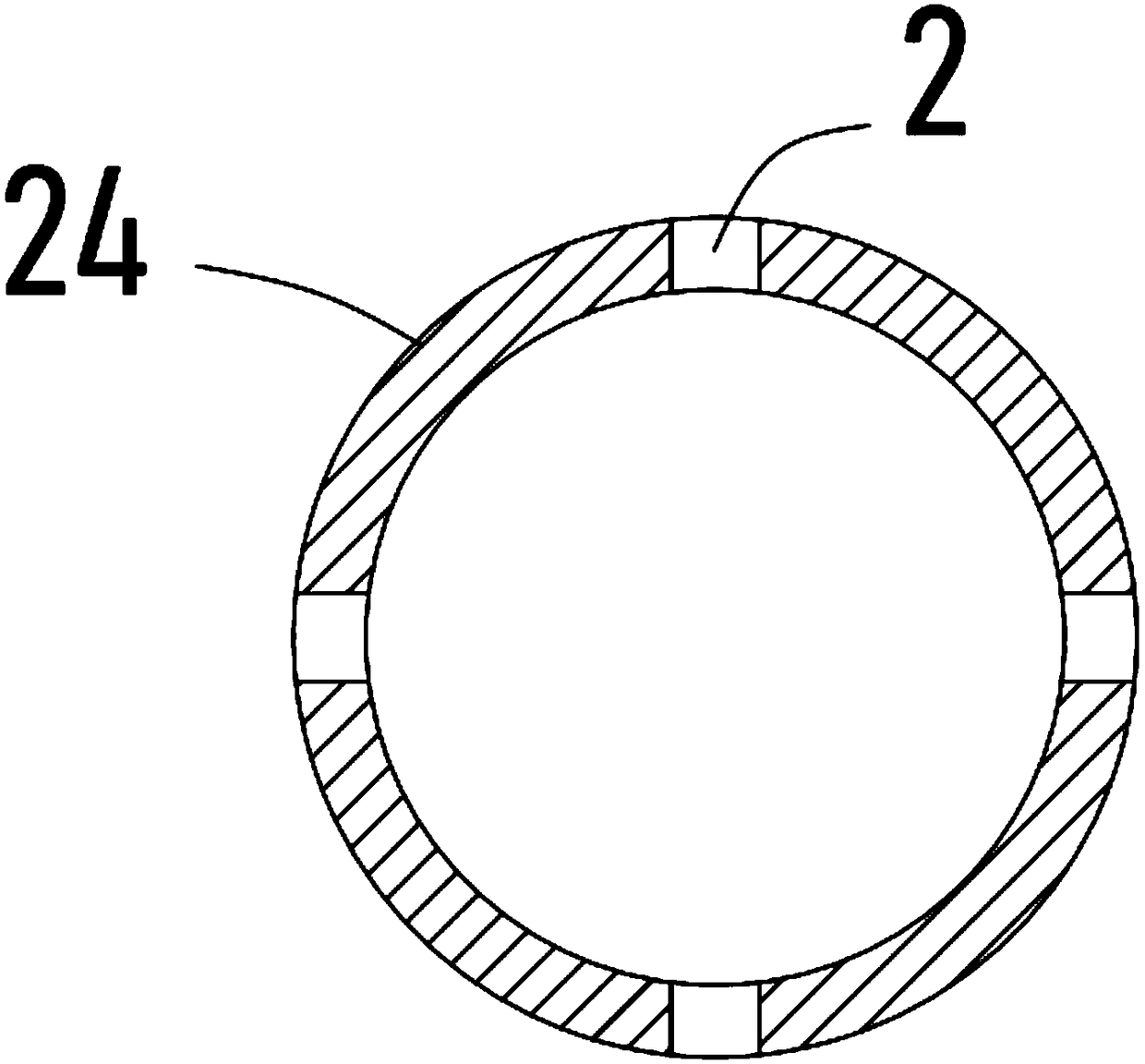

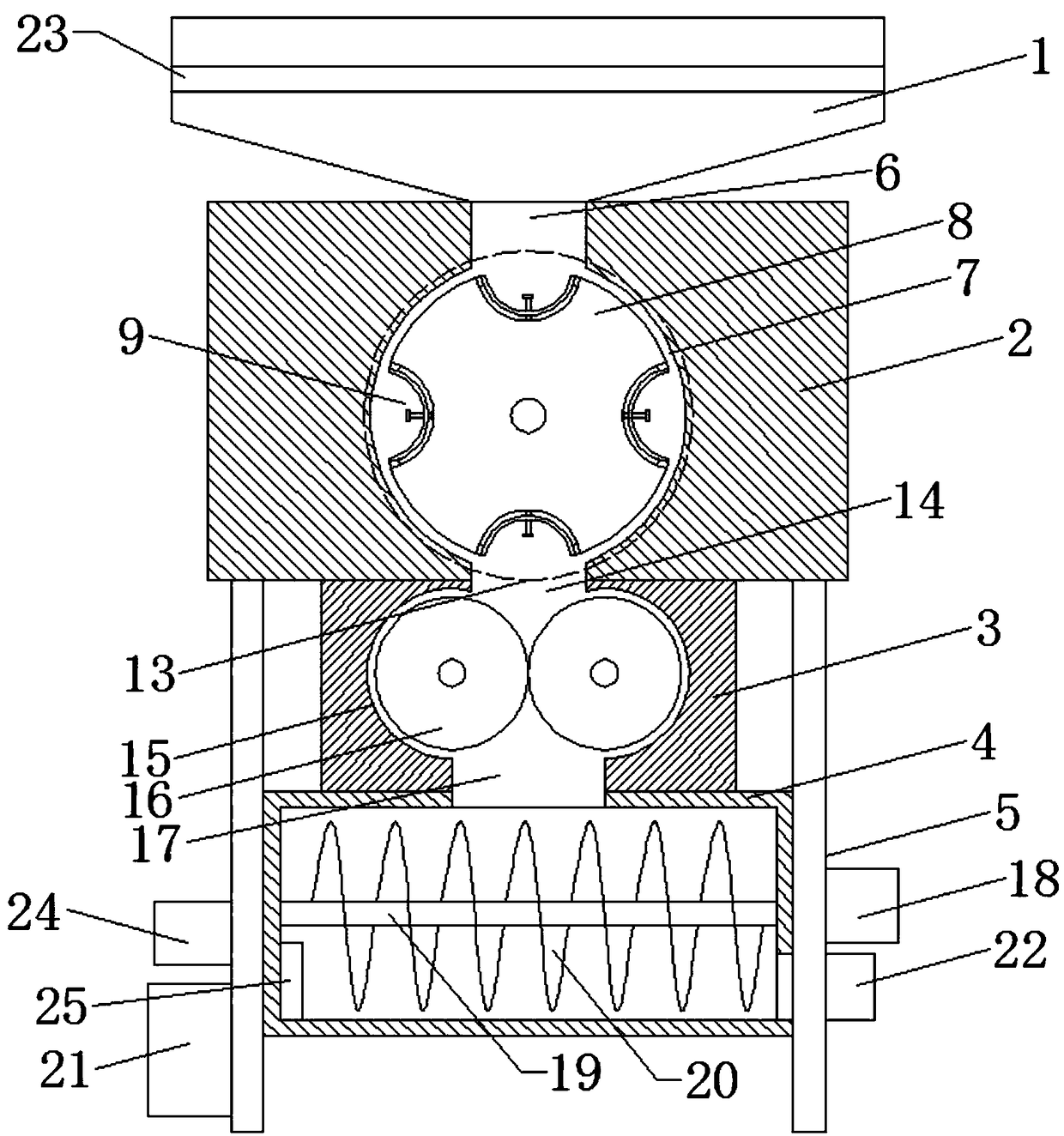

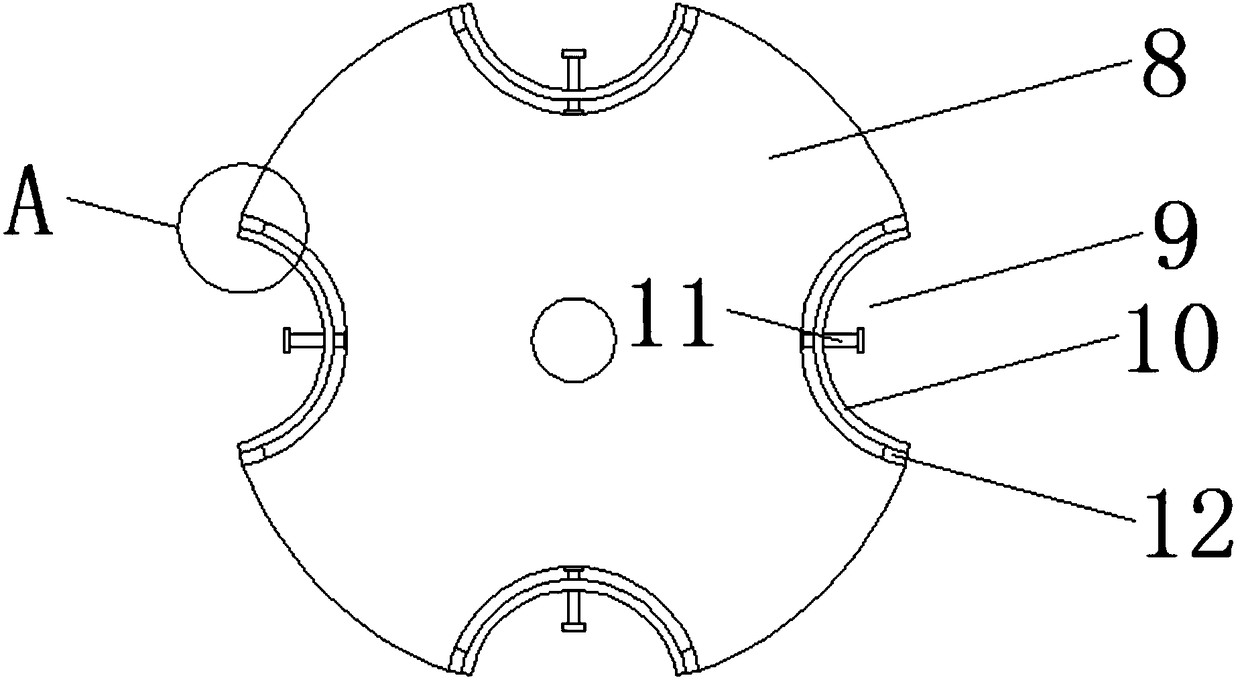

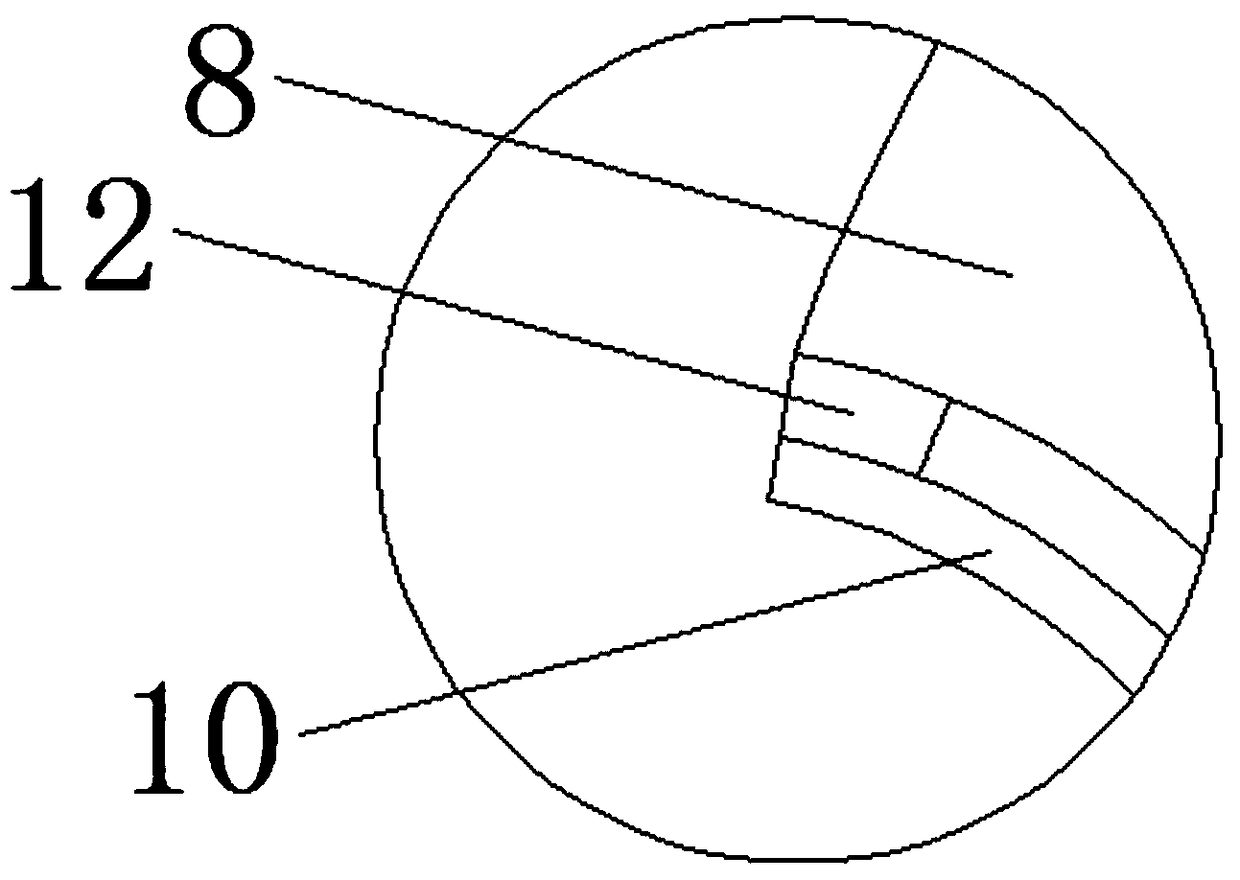

Dryer/Grinder

A grinder / dryer having a plurality of beater blades carried on a rotating shaft in a cylindrical housing, including one or a plurality of grinding members on the cylindrical side wall. The grinding members are adjustably positioned at different locations within the cylinder. The grinding members may be provided in a variety of different combination of elevated ridges and / or valleys used to dry and classify materials.

Owner:SCOTT EQUIP

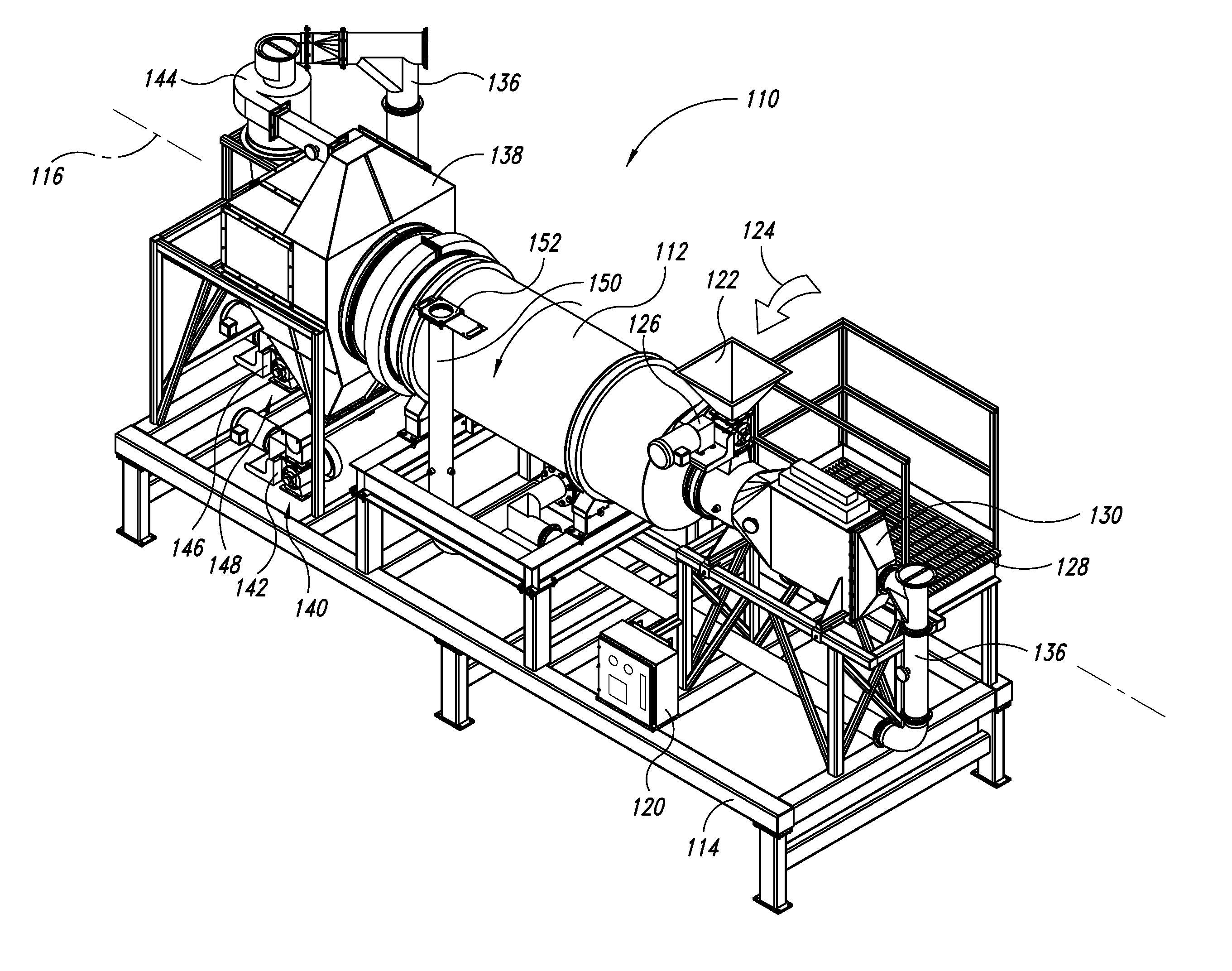

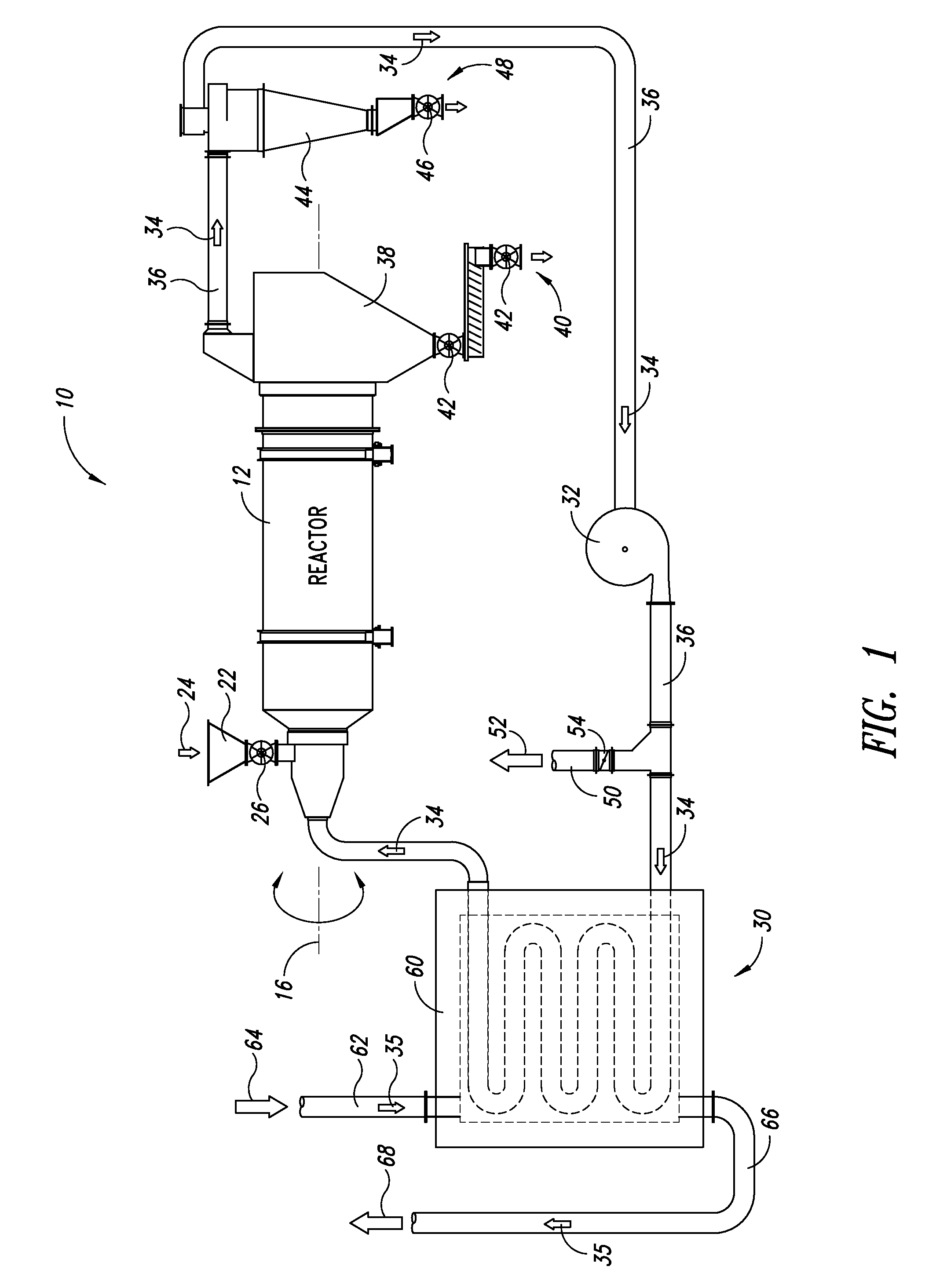

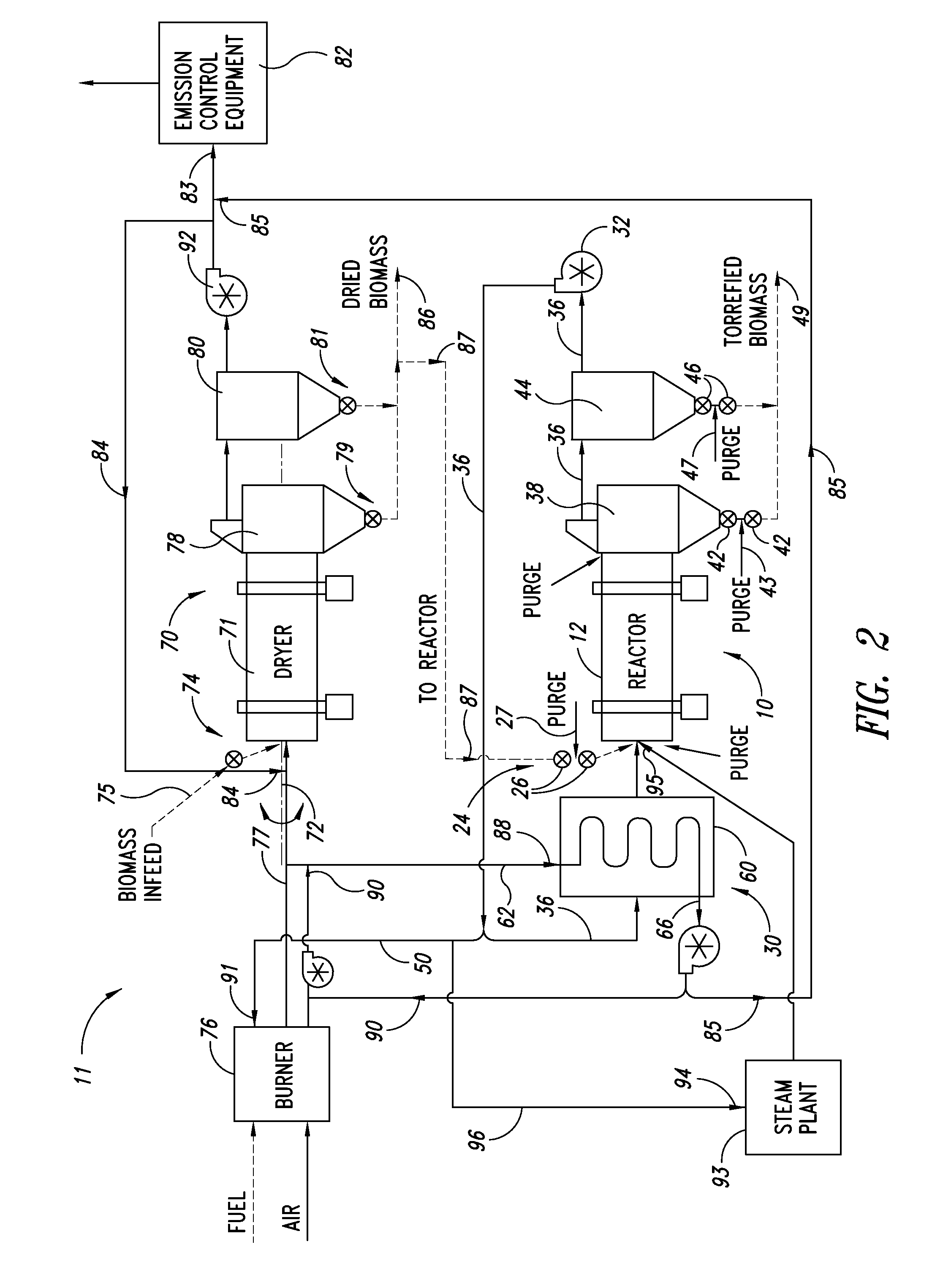

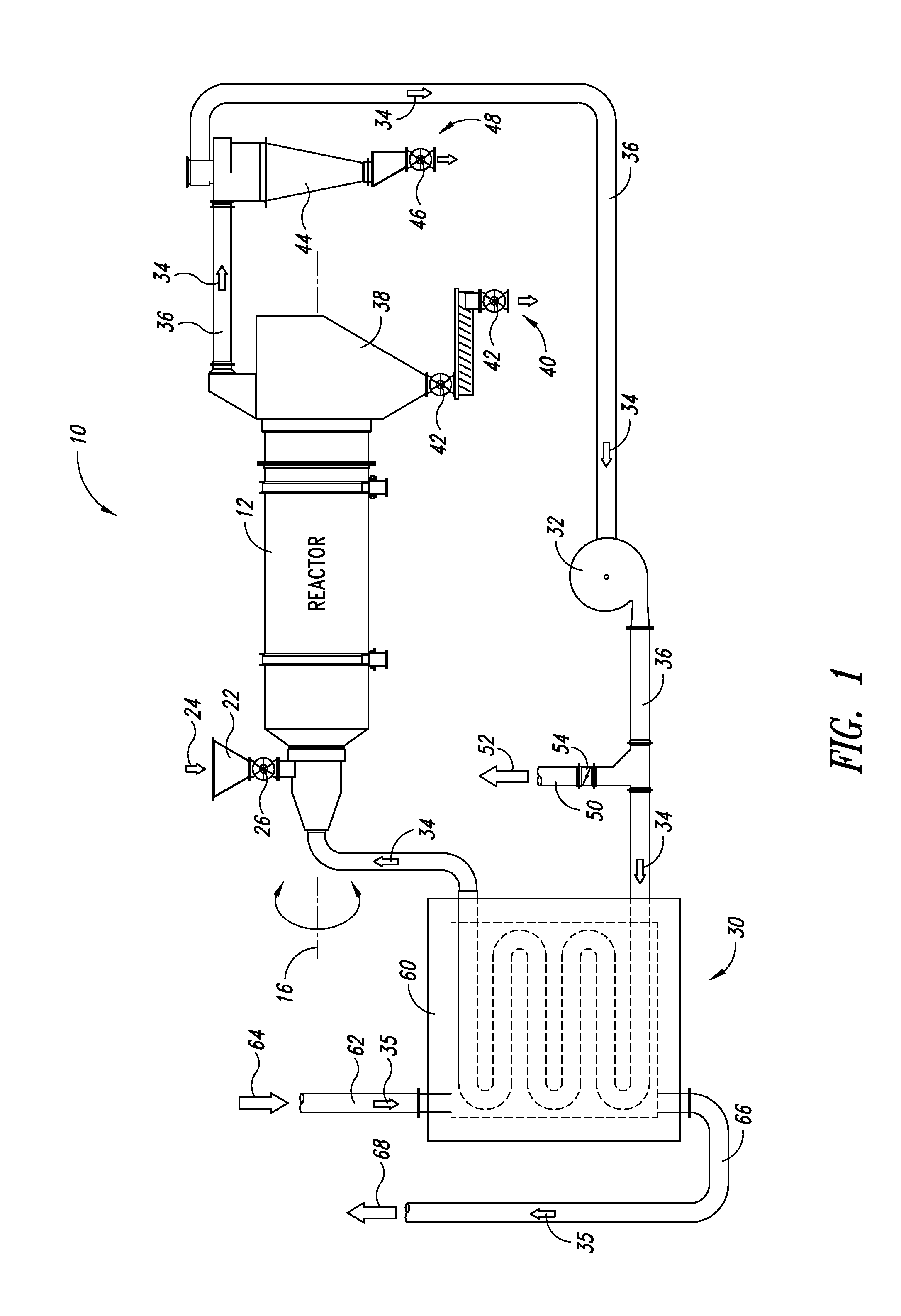

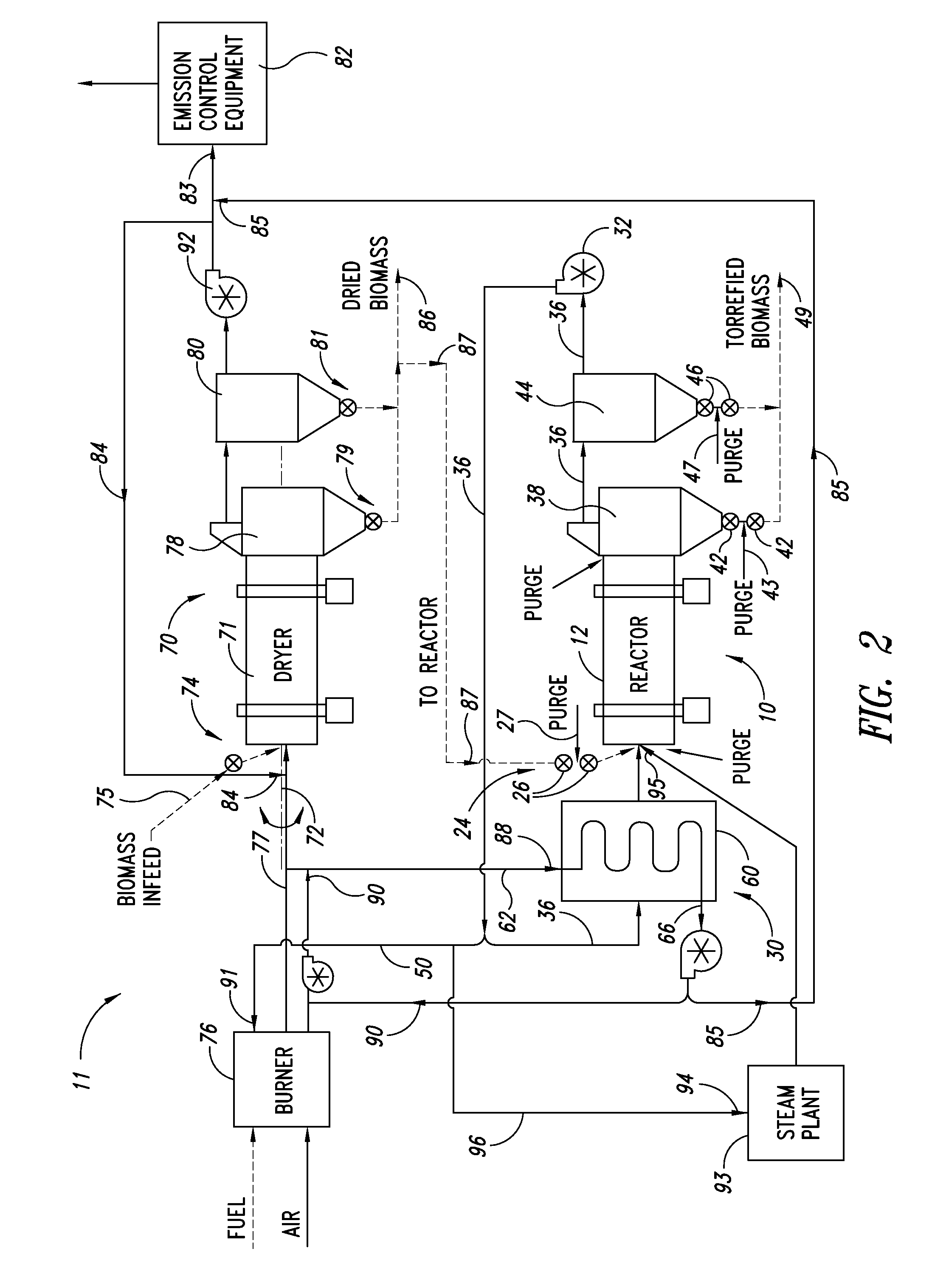

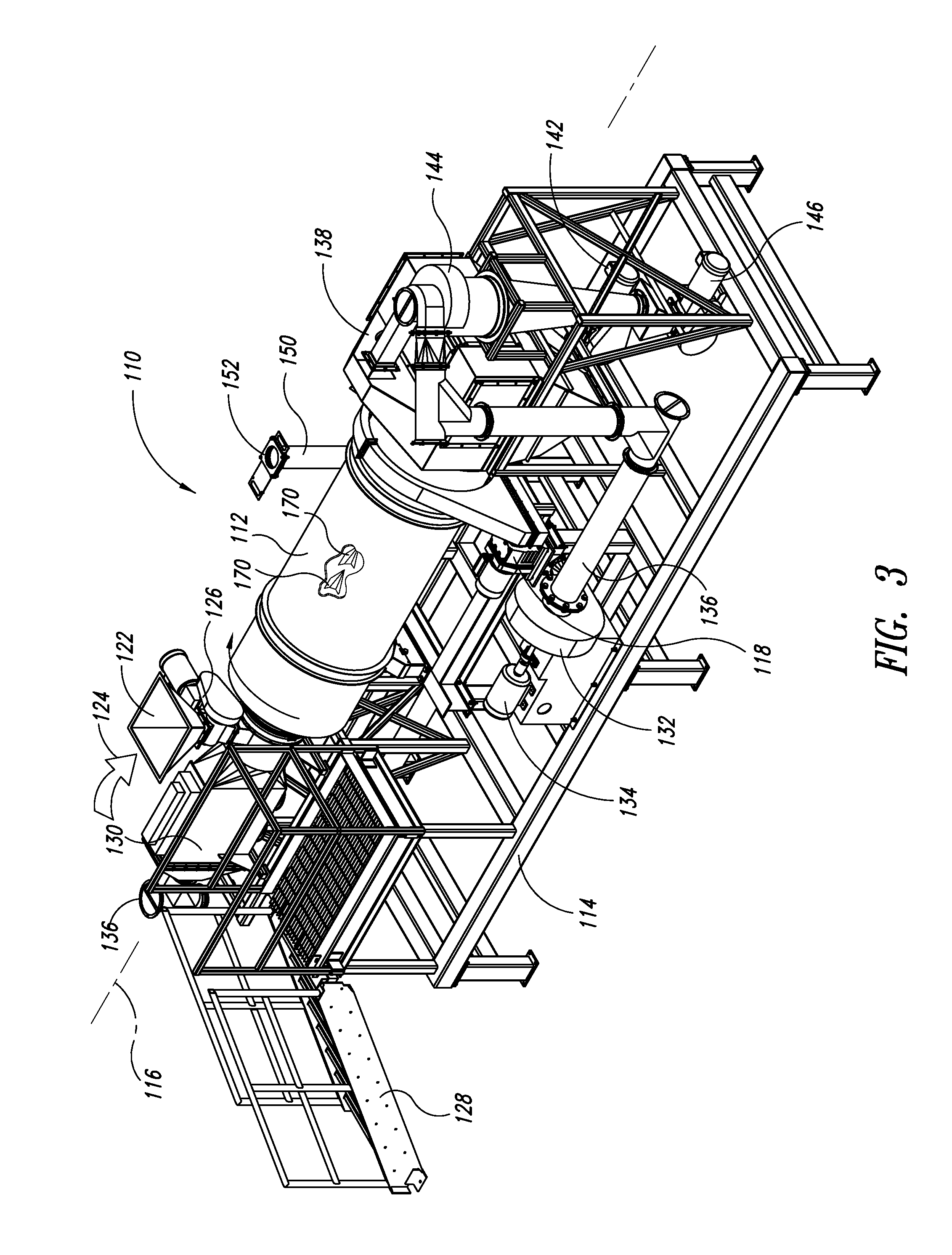

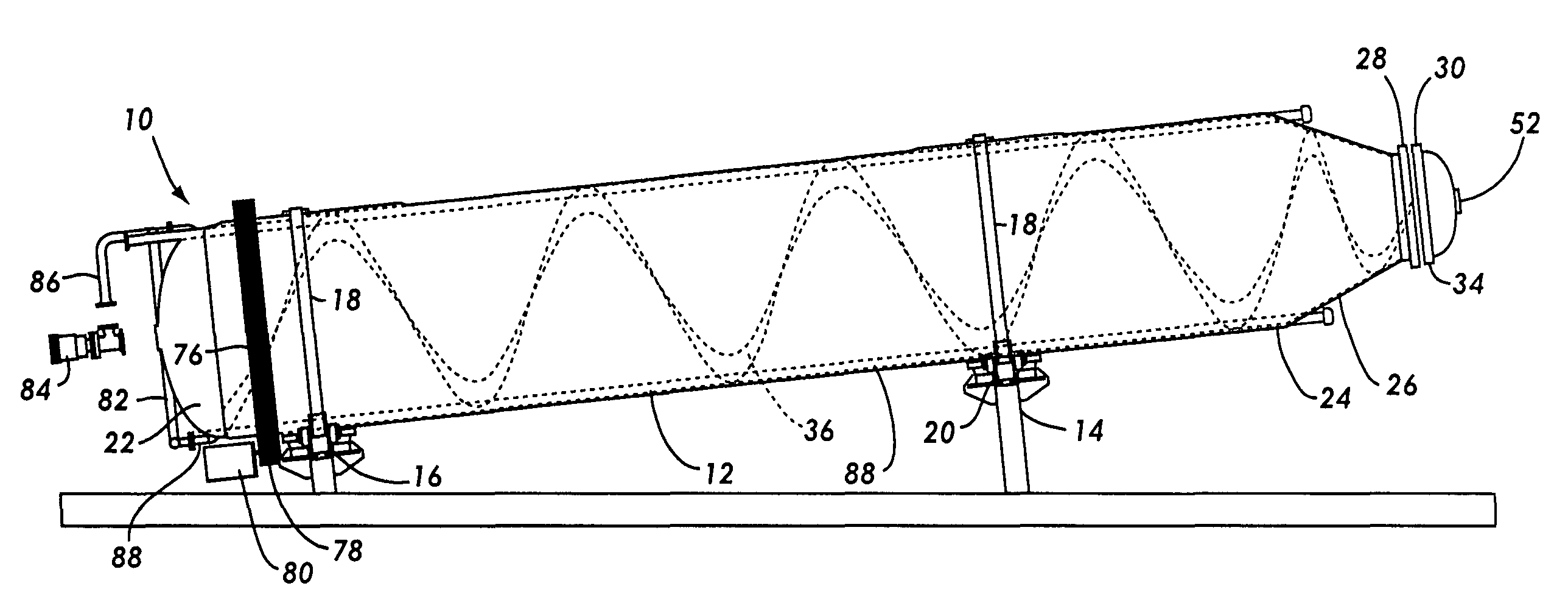

Biomass torrefaction system and method

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

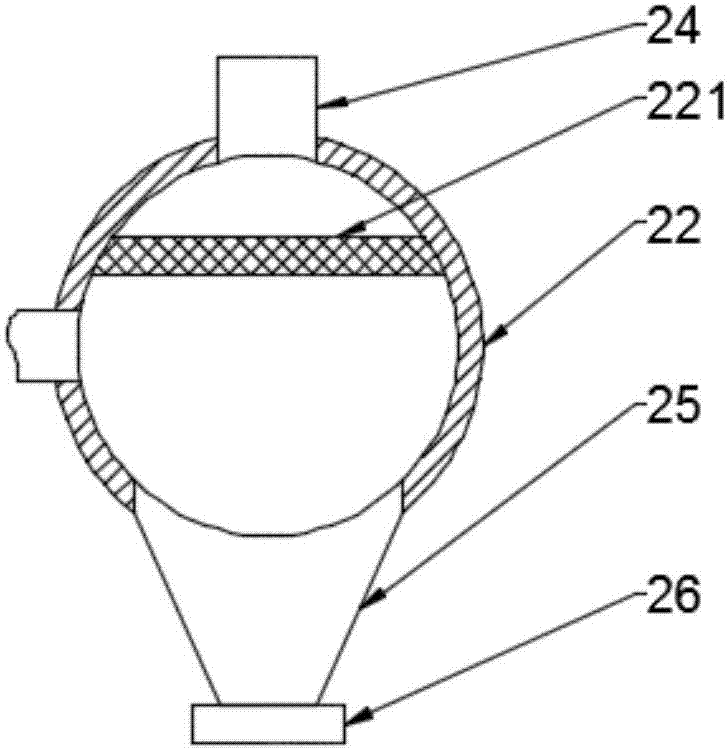

Mixing type fructus lycii drying device

InactiveCN106959002AAvoid passingReduce pollutionDrying gas arrangementsDrying solid materialsHelical bladeEngineering

The invention discloses a mixing-type wolfberry drying device, which comprises a drying box. Outriggers are arranged symmetrically on both sides of the lower end of the drying box. The position is vertically provided with a lifting tube, and a rotating shaft is arranged inside the lifting tube, and a spiral blade is arranged on the outside of the rotating shaft in the lifting tube. Suspenders are provided between the two sides and the inner wall of the top of the drying box, and a leveling grid is provided on the outside of the lifting tube near the suspenders. Environmental pollution, this drying method not only avoids the problem of insufficient drying of the existing device, but also removes the dust in the material. It has the disadvantage of being inconvenient for the device to discharge the material, and has strong practicability.

Owner:合肥图腾龙企业管理事务所(有限合伙)

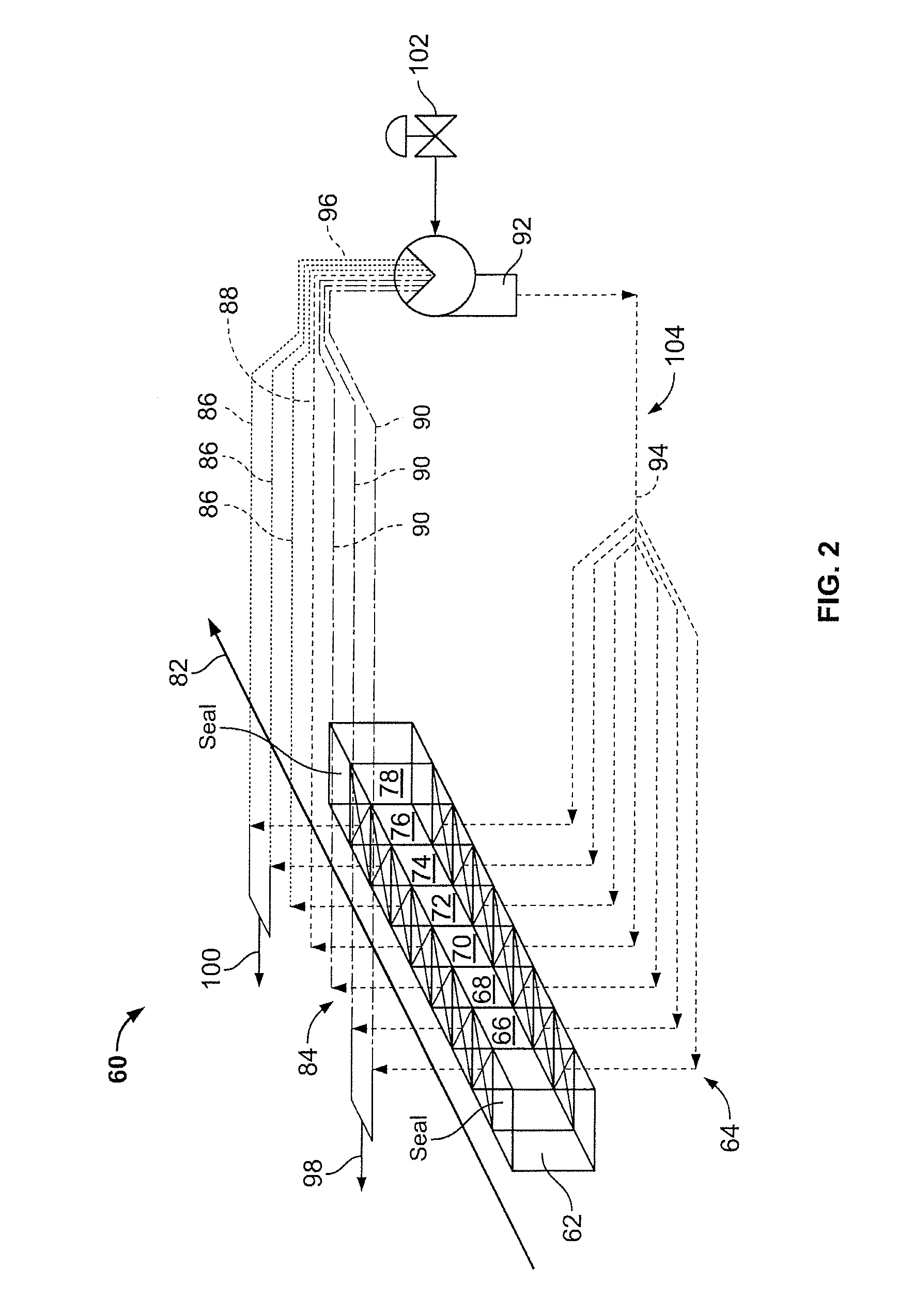

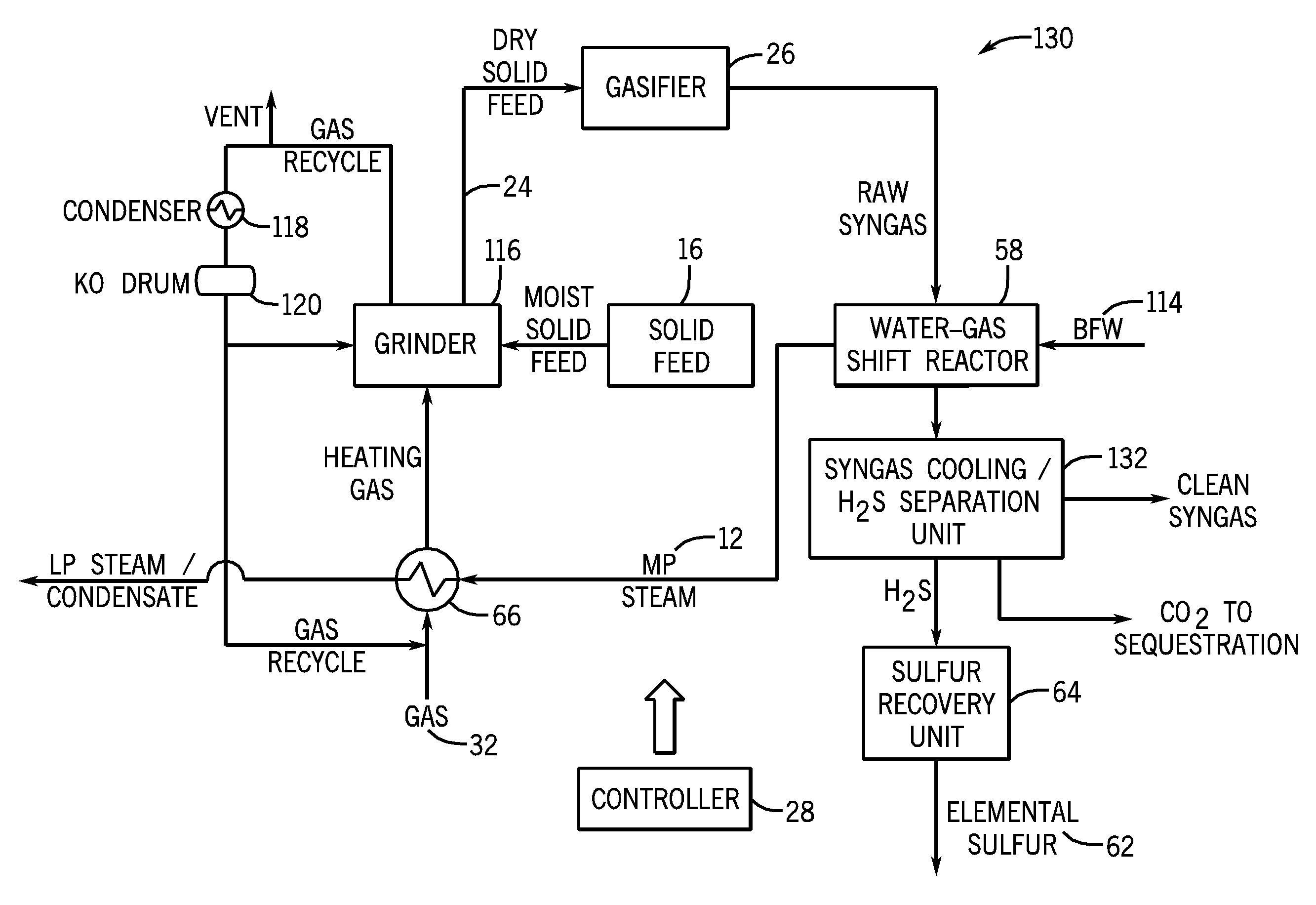

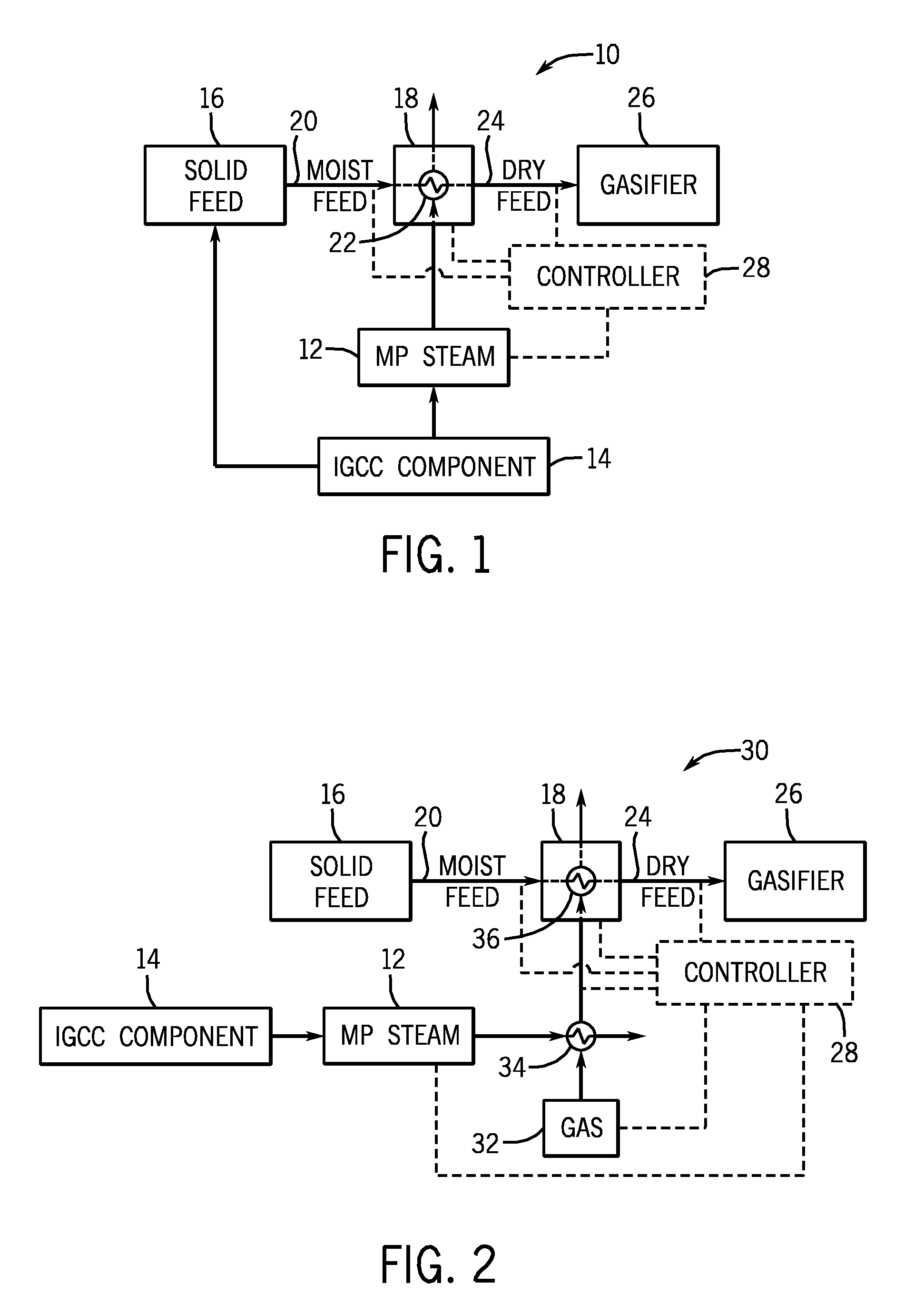

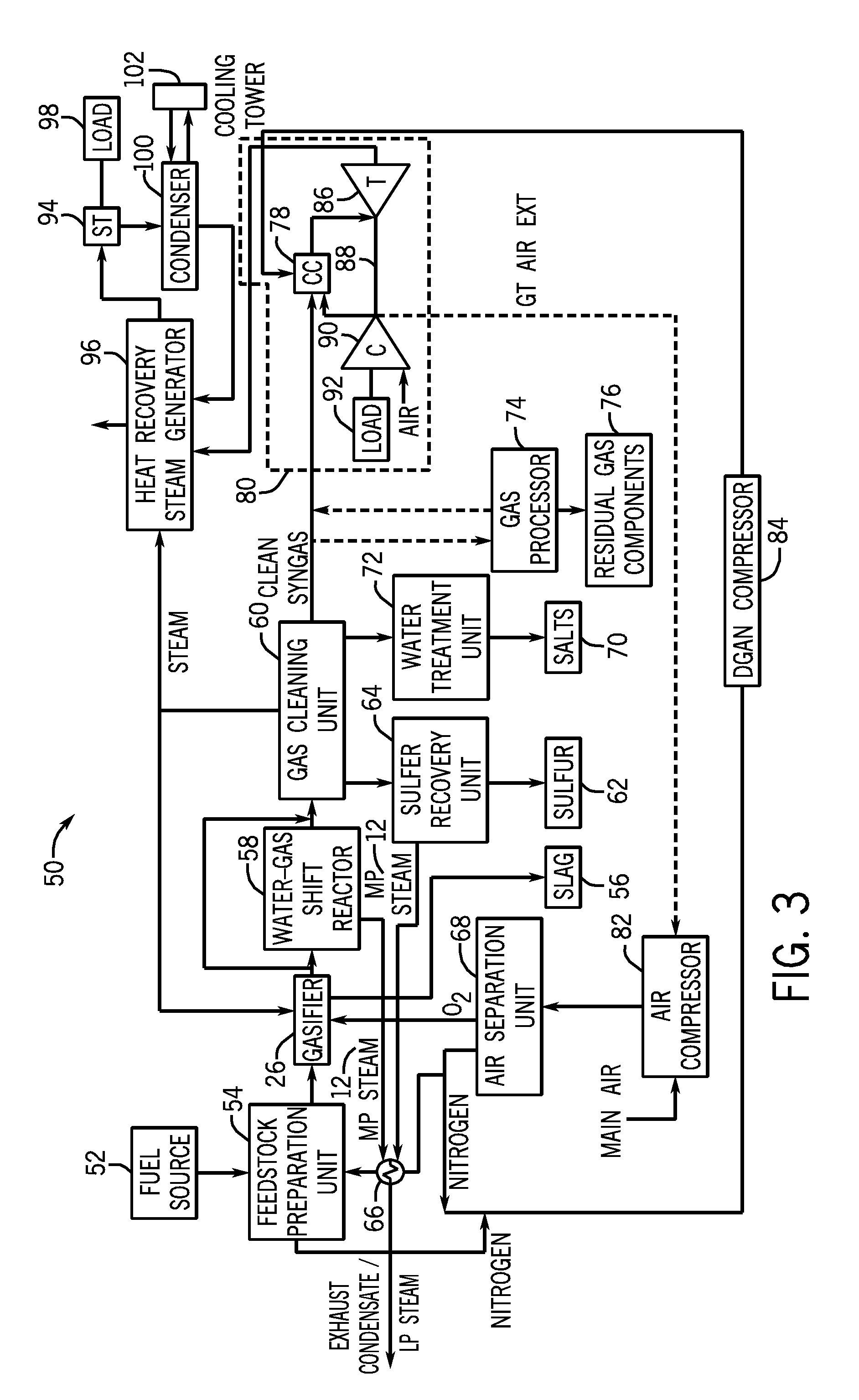

Method and apparatus for drying solid feedstock using steam

ActiveUS20110061298A1Solid fuel pretreatmentDrying gas arrangementsSteam pressureProcess engineering

Steam may be used to dry feedstock prior to delivery to a gasifier. A steam supply may be delivered to embodiments such as a feedstock dryer. Heat from the steam may then be transferred into the feedstock and used in drying the feedstock. Steam pressures may include pressures from 75 pounds per square inch up to and including 900 pounds per square inch.

Owner:AIR PROD & CHEM INC

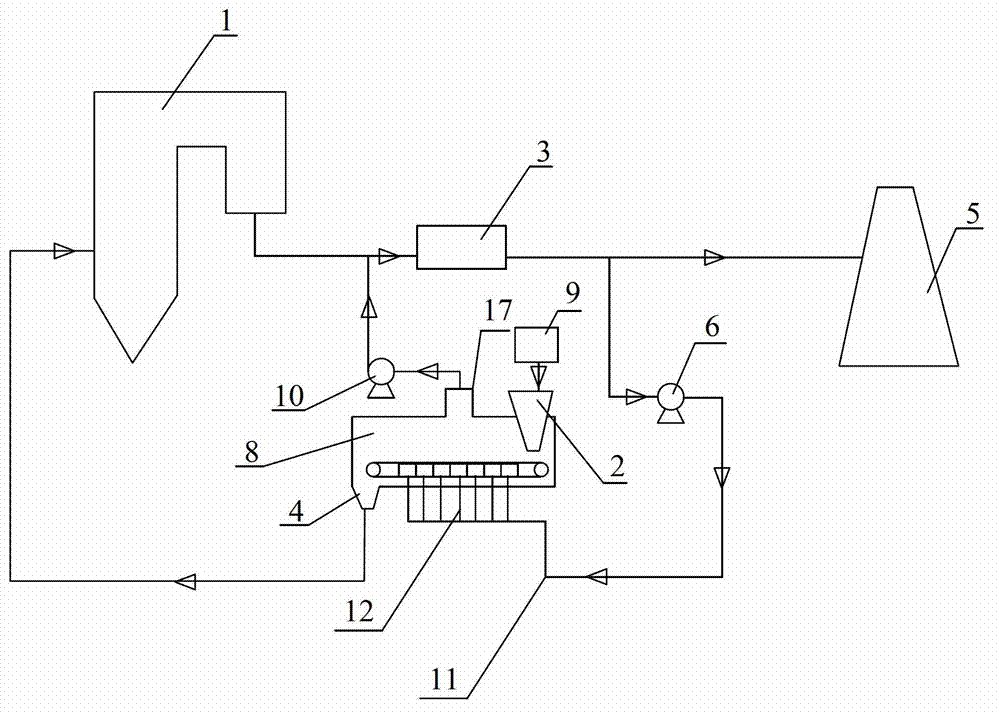

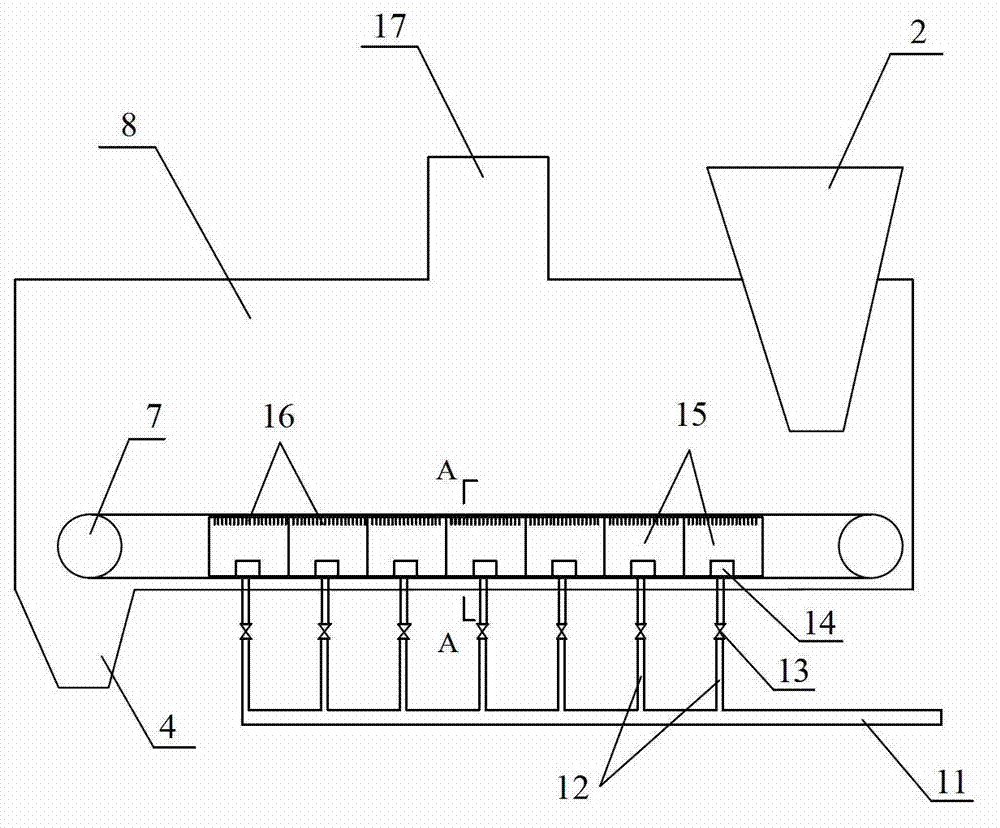

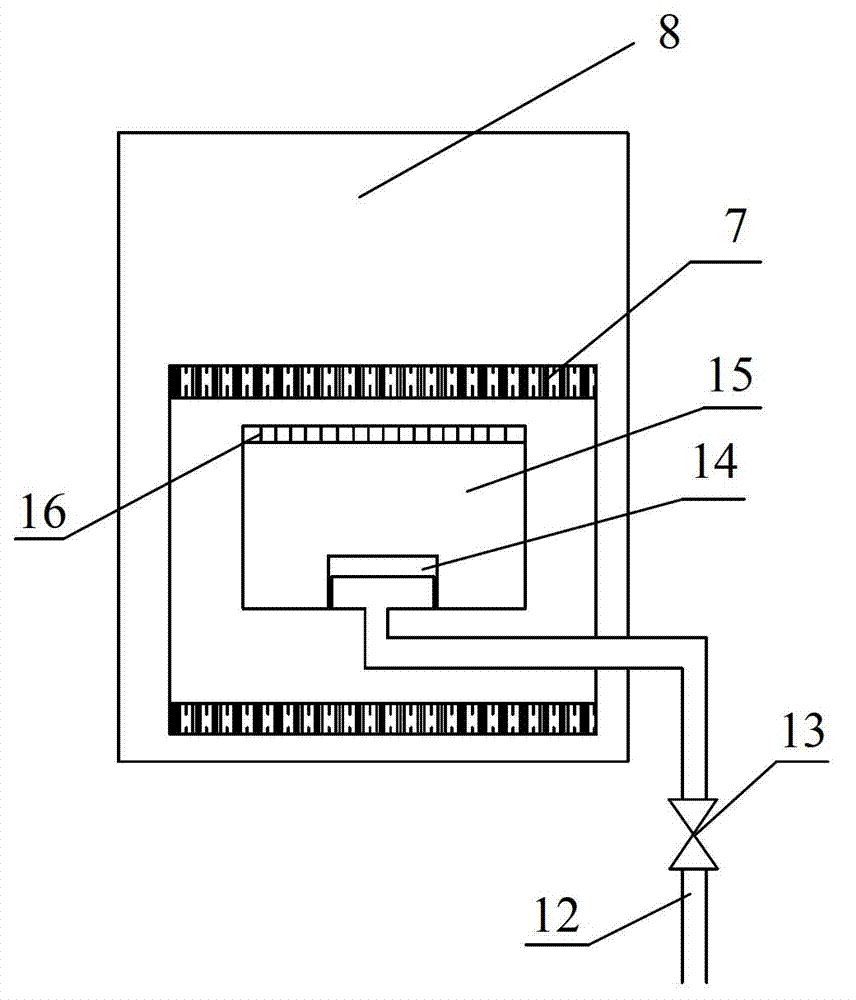

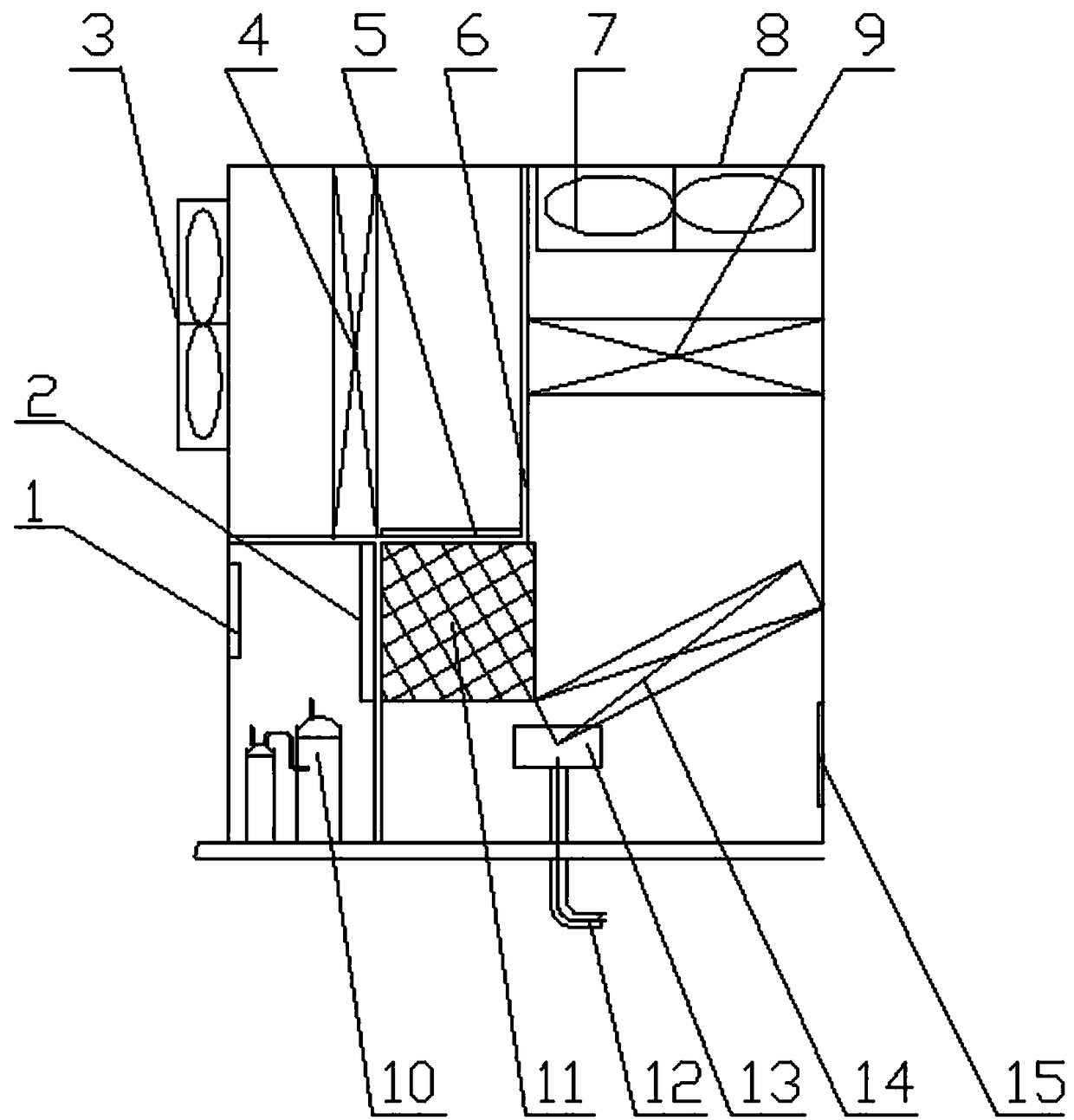

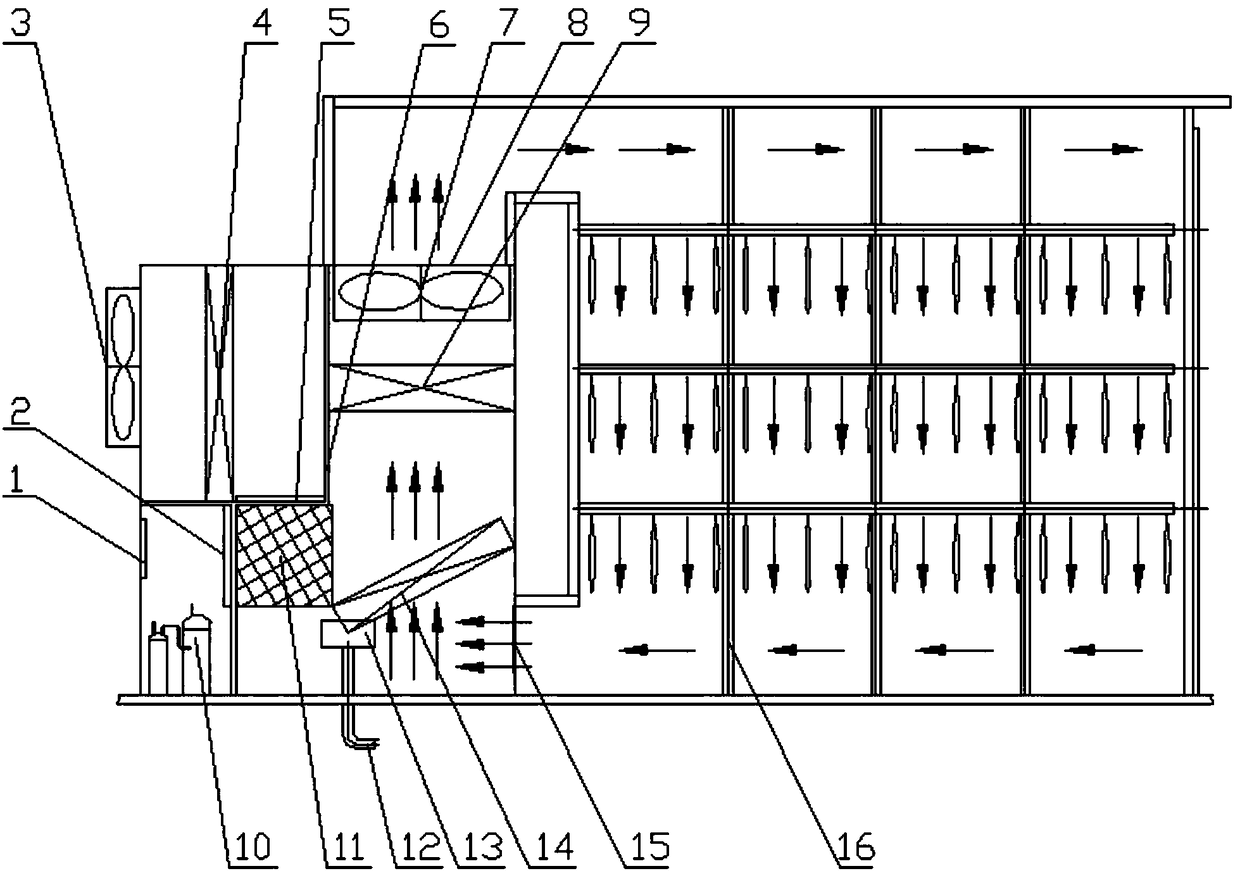

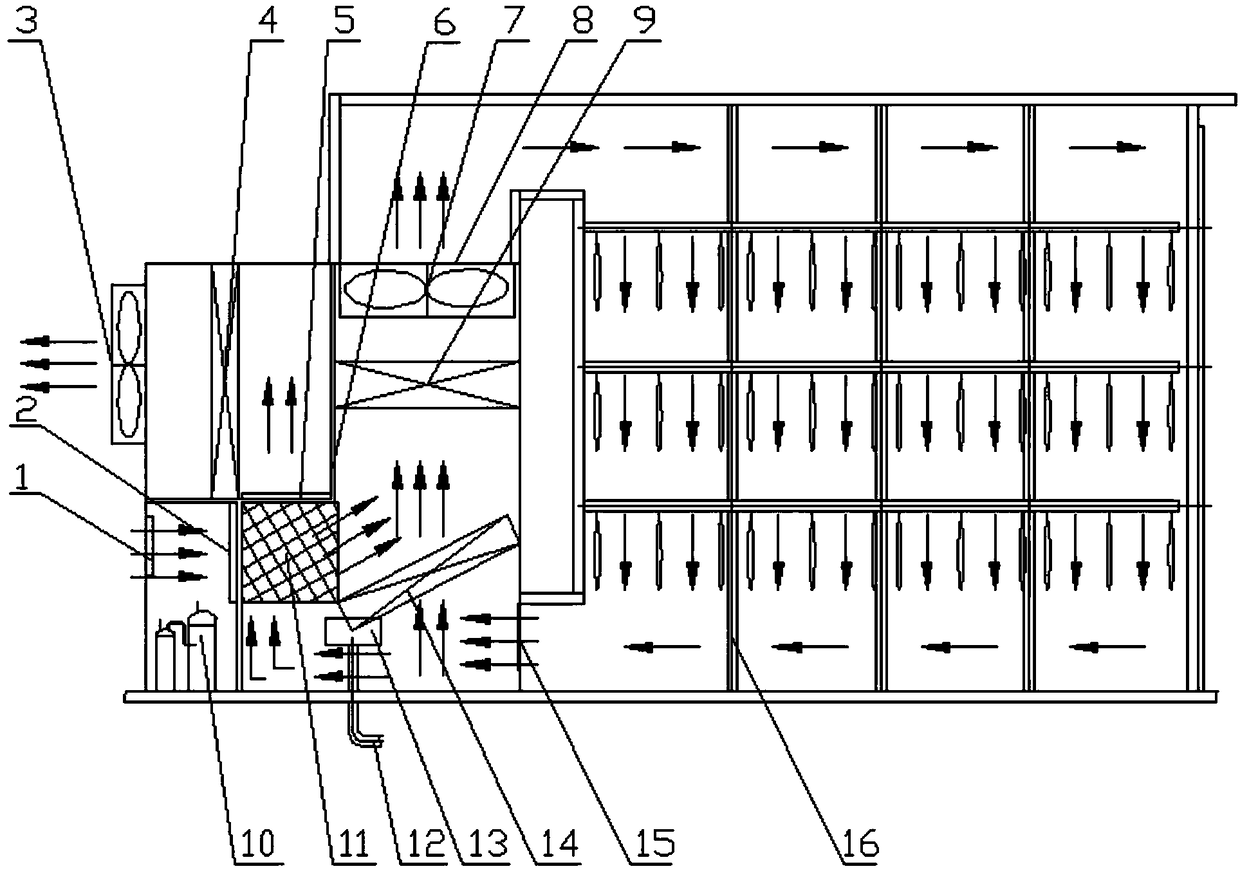

Method and device using biomass boiler smoke to dry biomass raw material

ActiveCN102954678AReduce trafficLow costDrying gas arrangementsHeating arrangementProcess engineeringBiomass boiler

The invention discloses a method and device using biomass boiler smoke to dry biomass raw material. The method comprises the following steps of guiding the biomass raw material to a belt conveyor in a drying chamber, carrying out dynamic conveying, guiding the biomass boiler smoke after being subjected to the dust removal treatment into the biomass raw material to carry out contact heat exchanging, and then removing part of moisture from the biomass raw material; carrying out dust removal treatment on the smoke after being subjected to the heat exchange, directly using the dried biomass raw material as the fuel of a biomass boiler, or storing the dried biomass material for standby. The device mainly consists of a smoke circulation system and the belt conveyor, wherein the smoke circulation system consists of a dust remover, the drying chamber, a booster fan, a draught fan and the like, and the belt conveyor is arranged in the drying chamber and is used for conveying the biomass raw material. The method and the device have the advantages that the structure is simple, the technology is economic, the drying effect is good, the size of the biomass boiler system can be effectively reduced, and the heat efficiency of the biomass boiler system is greatly improved.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

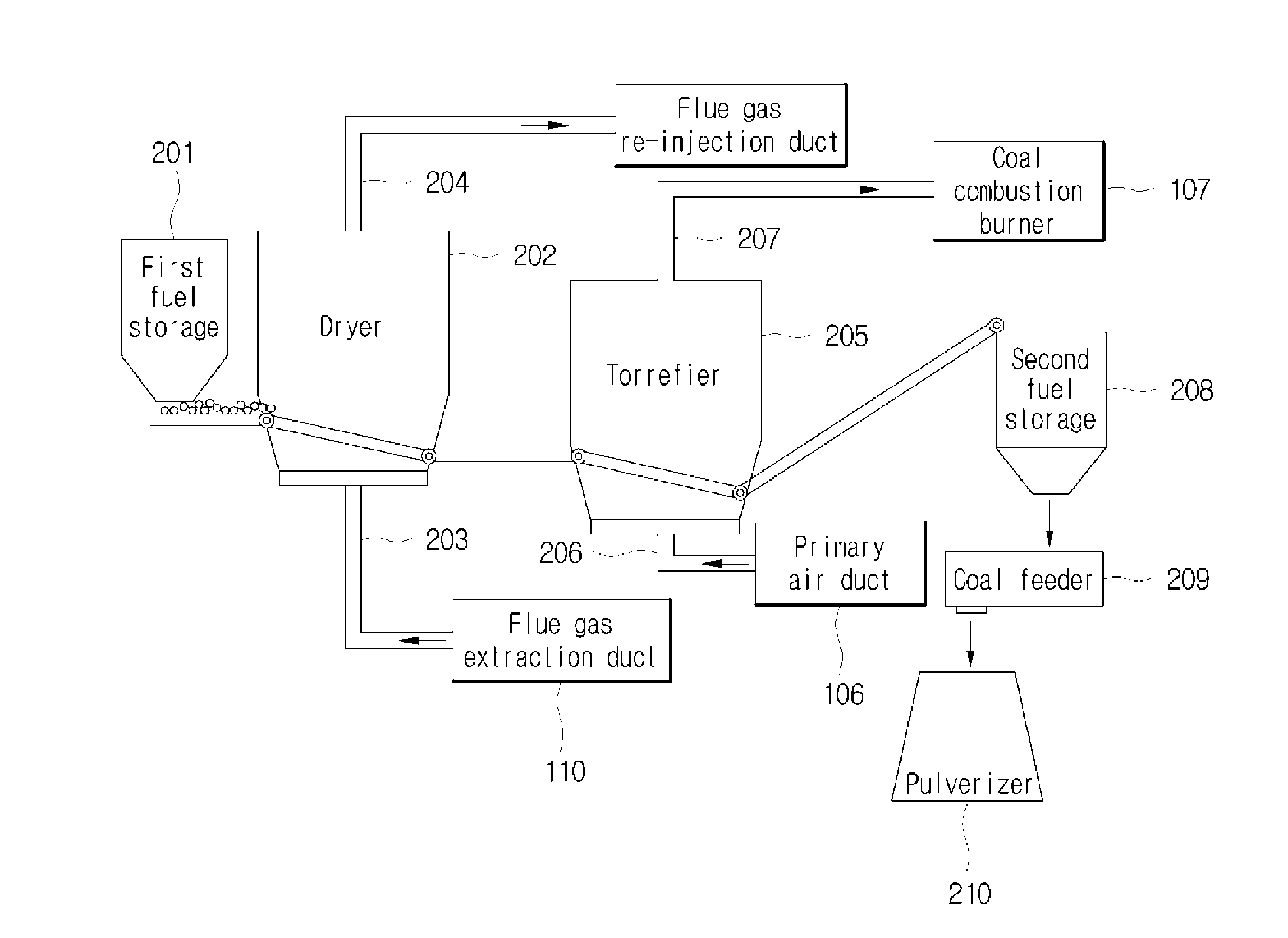

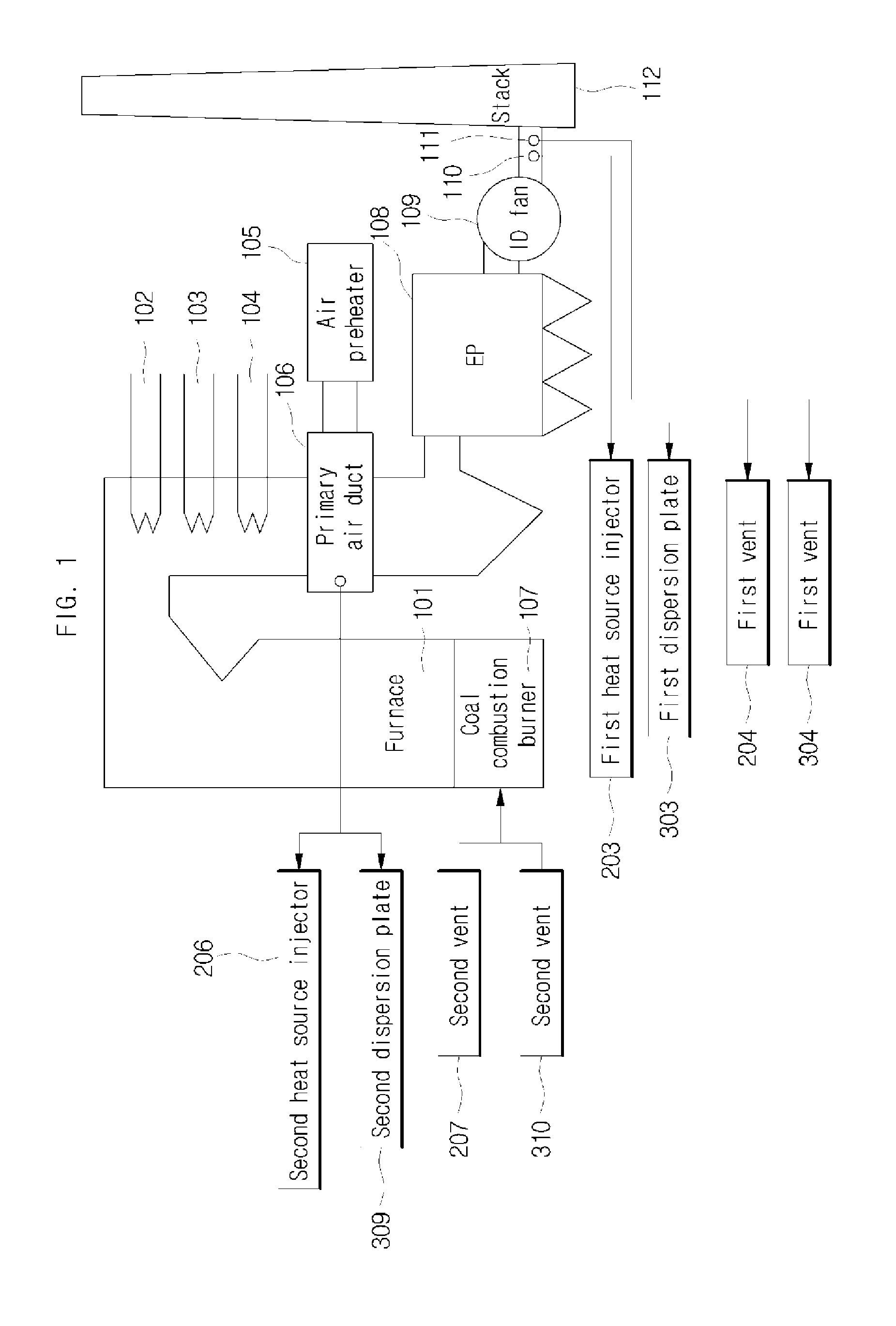

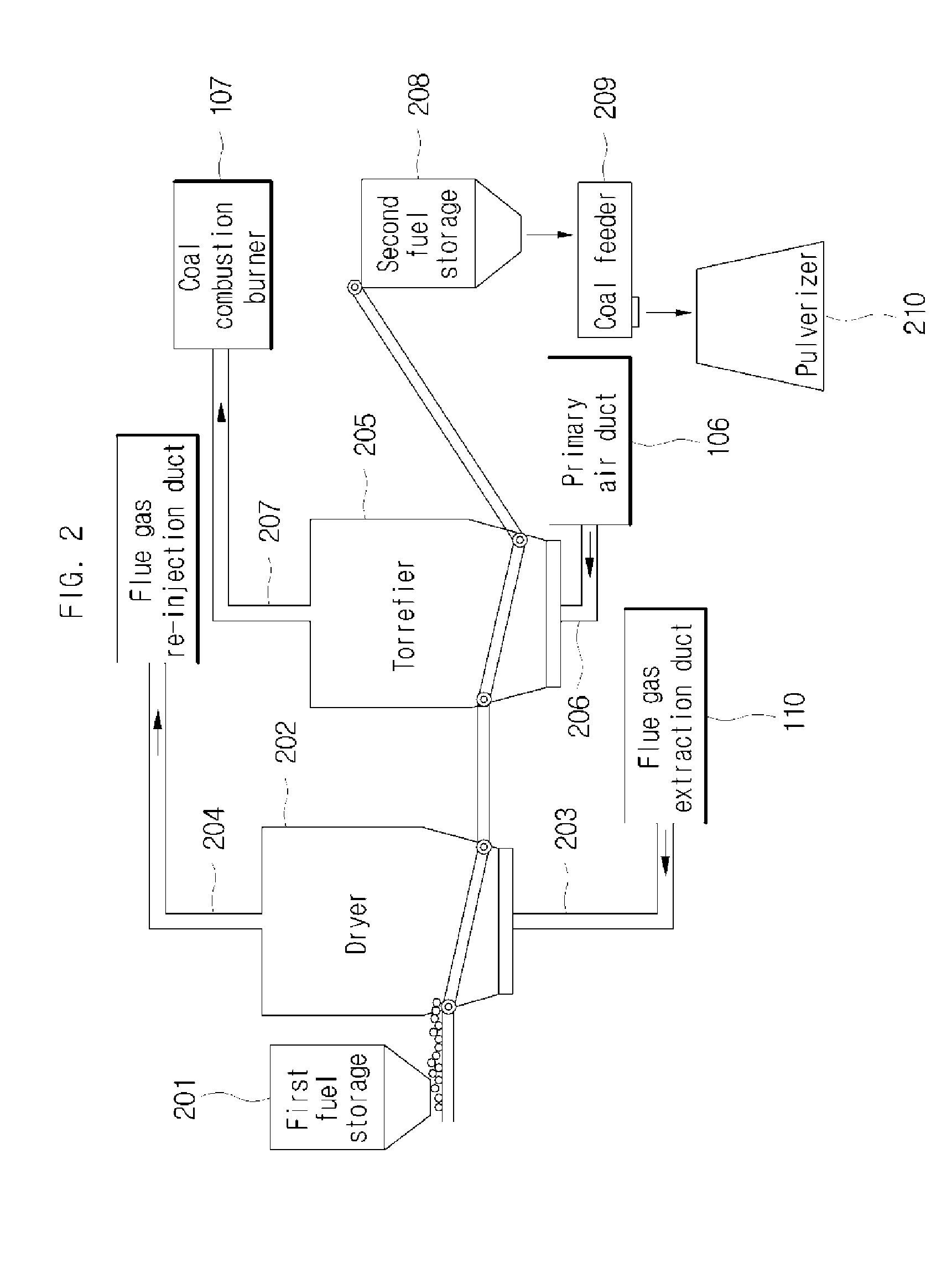

Fuel preprocess system for coal combustion boiler

A fuel preprocess system for a coal combustion boiler is disclosed. The fuel preprocess system for a coal combustion boiler that dries biomass or refuse-derived fuel in accordance with the present invention can include: a dryer configured to dry the biomass or refuse-derived fuel by use of flue gas generated after combustion in the boiler; and a torrefier configured to devolatilize a fibrous component contained in the dried fuel from the fuel dried in the dryer by use of primary air that is heat-exchanged after the combustion in the boiler.

Owner:KOREA ELECTRIC POWER CORP

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS8226798B2Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

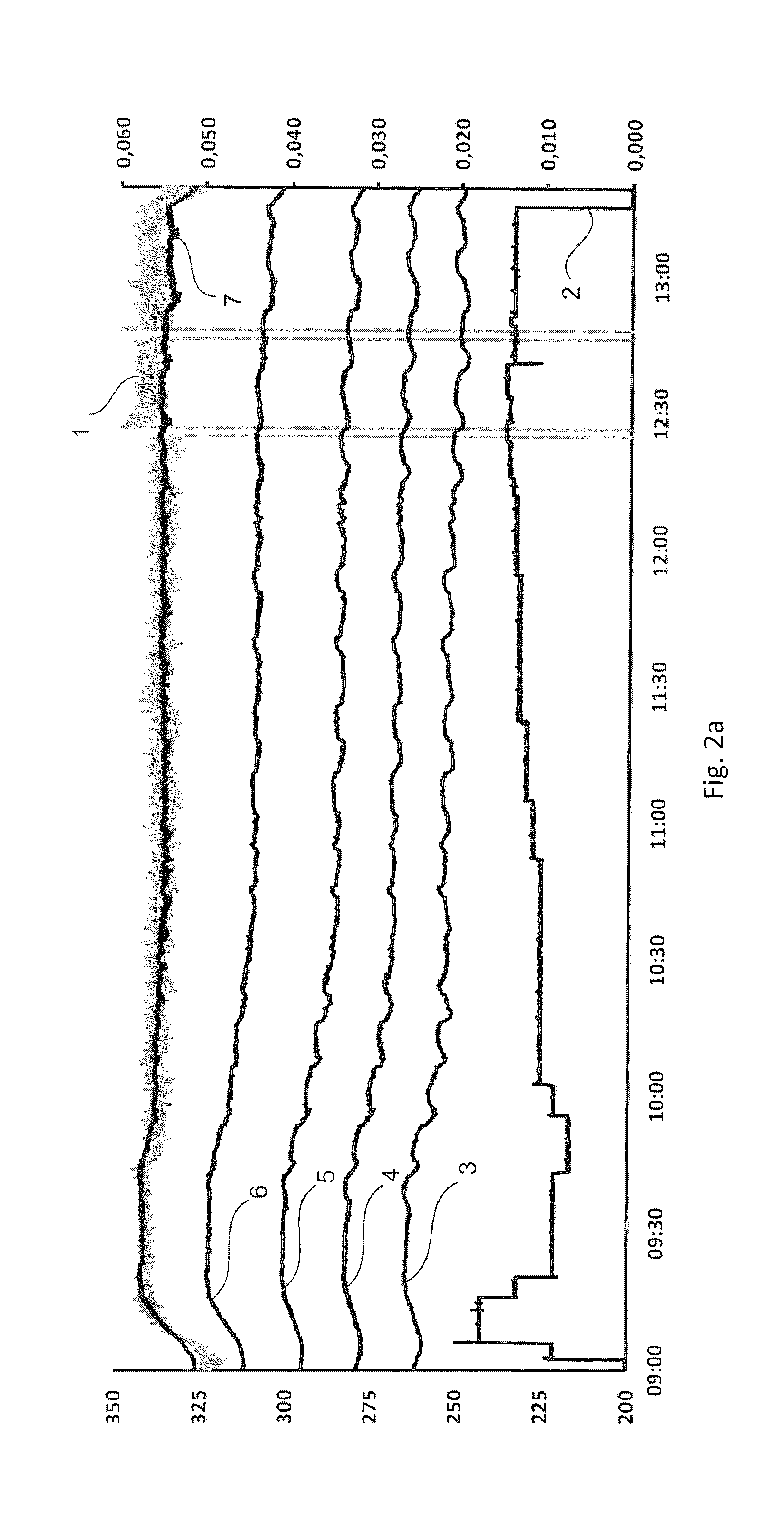

Countercurrent oxygen enhanced torrefaction

ActiveUS20140208995A1Reduce shipping costsLow calorific valueHydrogenHydrocarbon from carbon oxidesOxygen enhancedTorrefaction

The invention relates to a method of torrefaction of an optionally predried biomass in a torrefaction reactor such that torrefied biomass and torrefaction gases are obtained, and wherein an oxygen-containing gas is supplied to the torrefaction reactor at a first position in the reactor such that oxygen reacts with components of the torrefaction gases under the formation of heat and wherein torrefaction gases are withdrawn from the torrefaction reactor at a second position of the torrefaction reactor and wherein the first position is located downstream of the second position in relation to a biomass transport direction in the torrefaction reactor such that the torrefaction gases moves through the torrefaction reactor countercurrent with the biomass transport and wherein the optionally predried biomass has a temperature of between 30° C. and 230° C., preferably between 50° C. and 200° C., most preferably between 60° C. and 180° C. when entering the torrefaction rector.

Owner:BIOENDEV

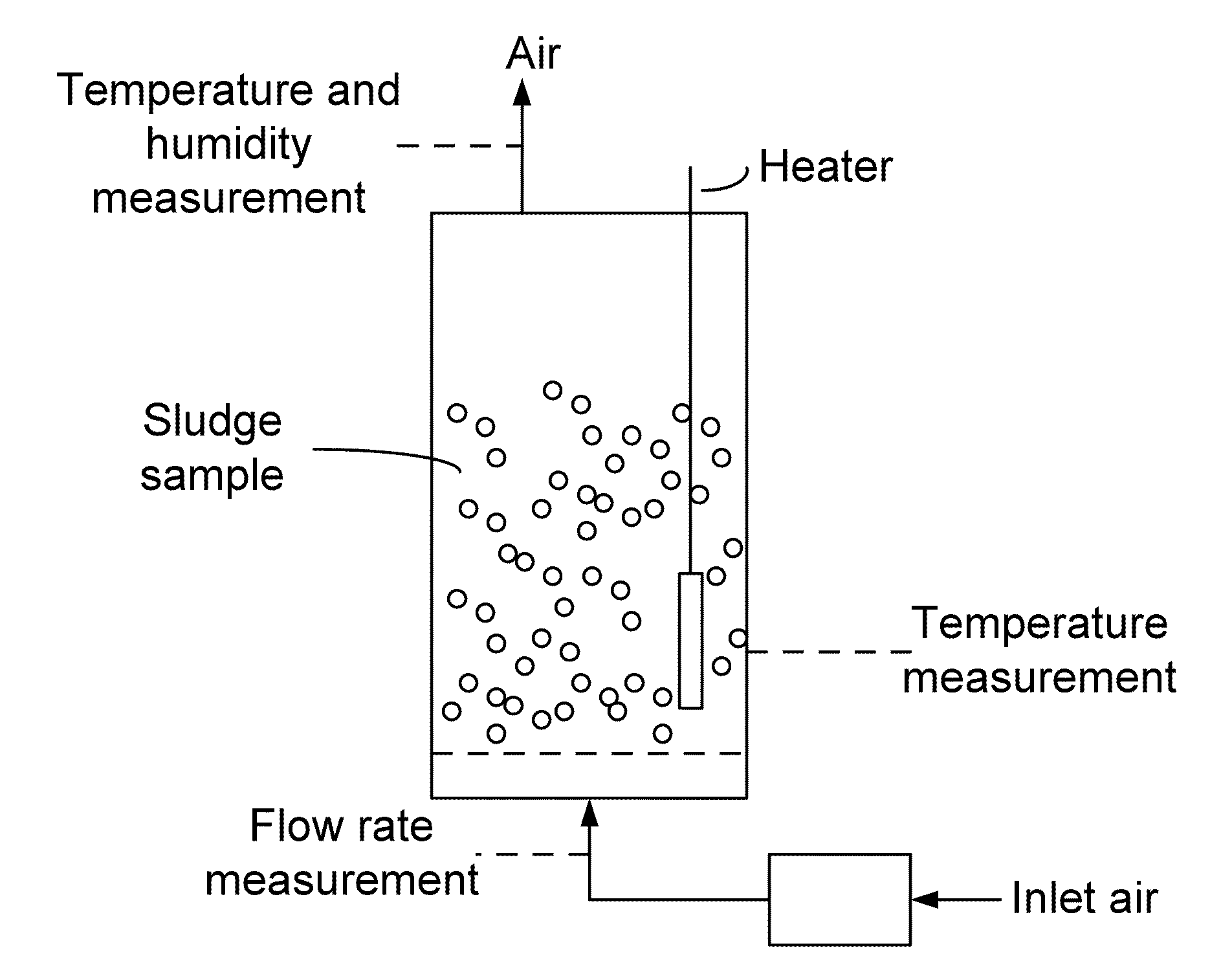

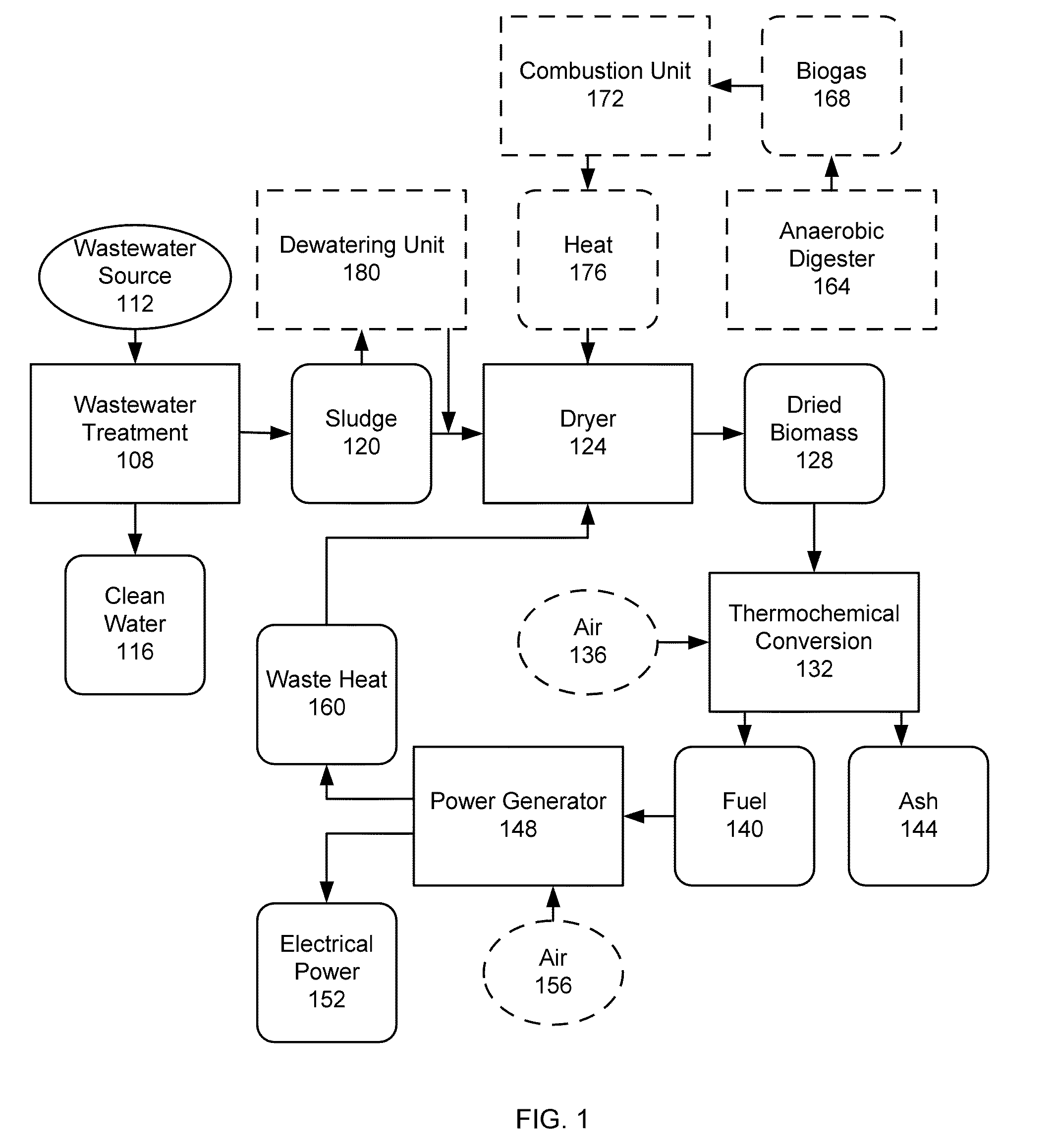

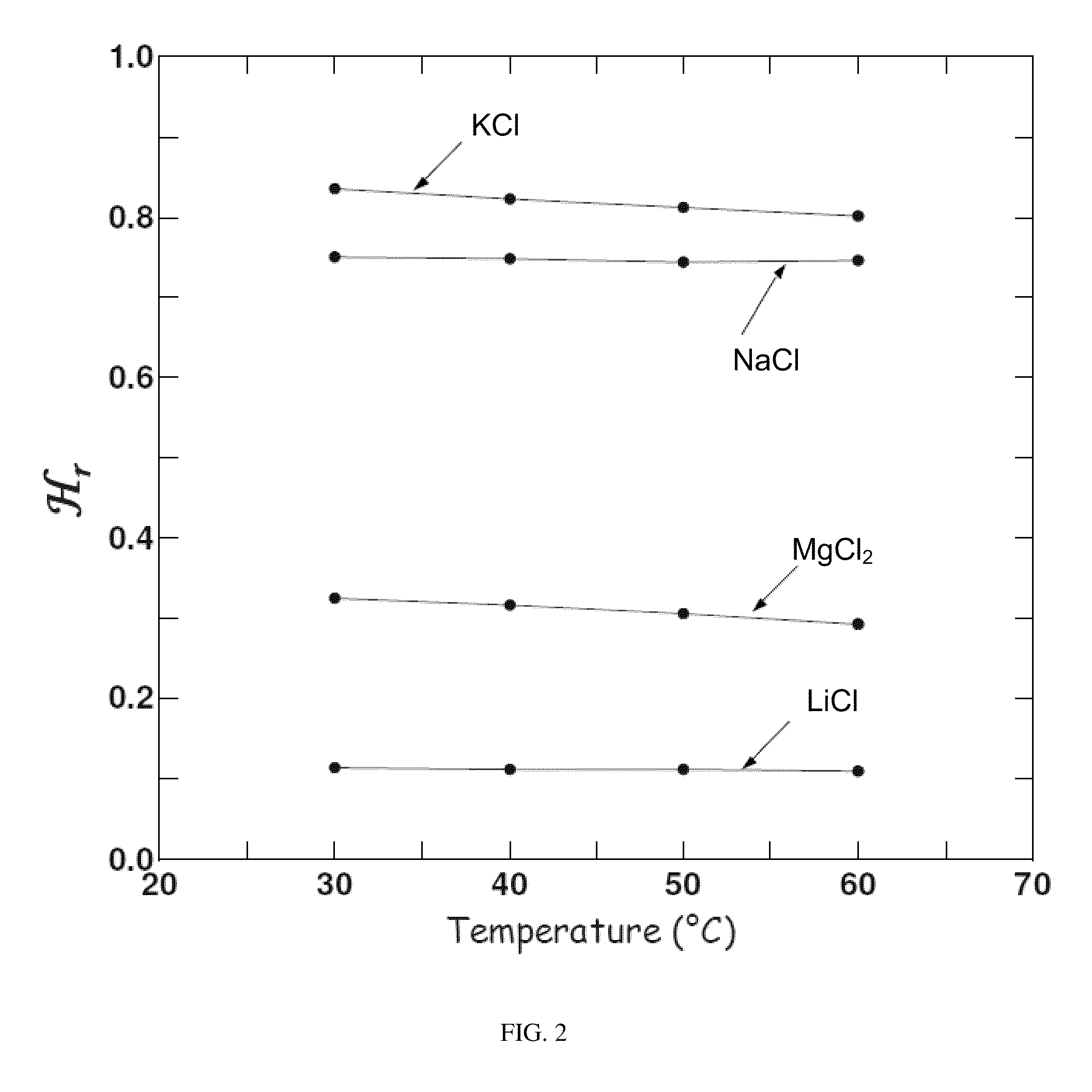

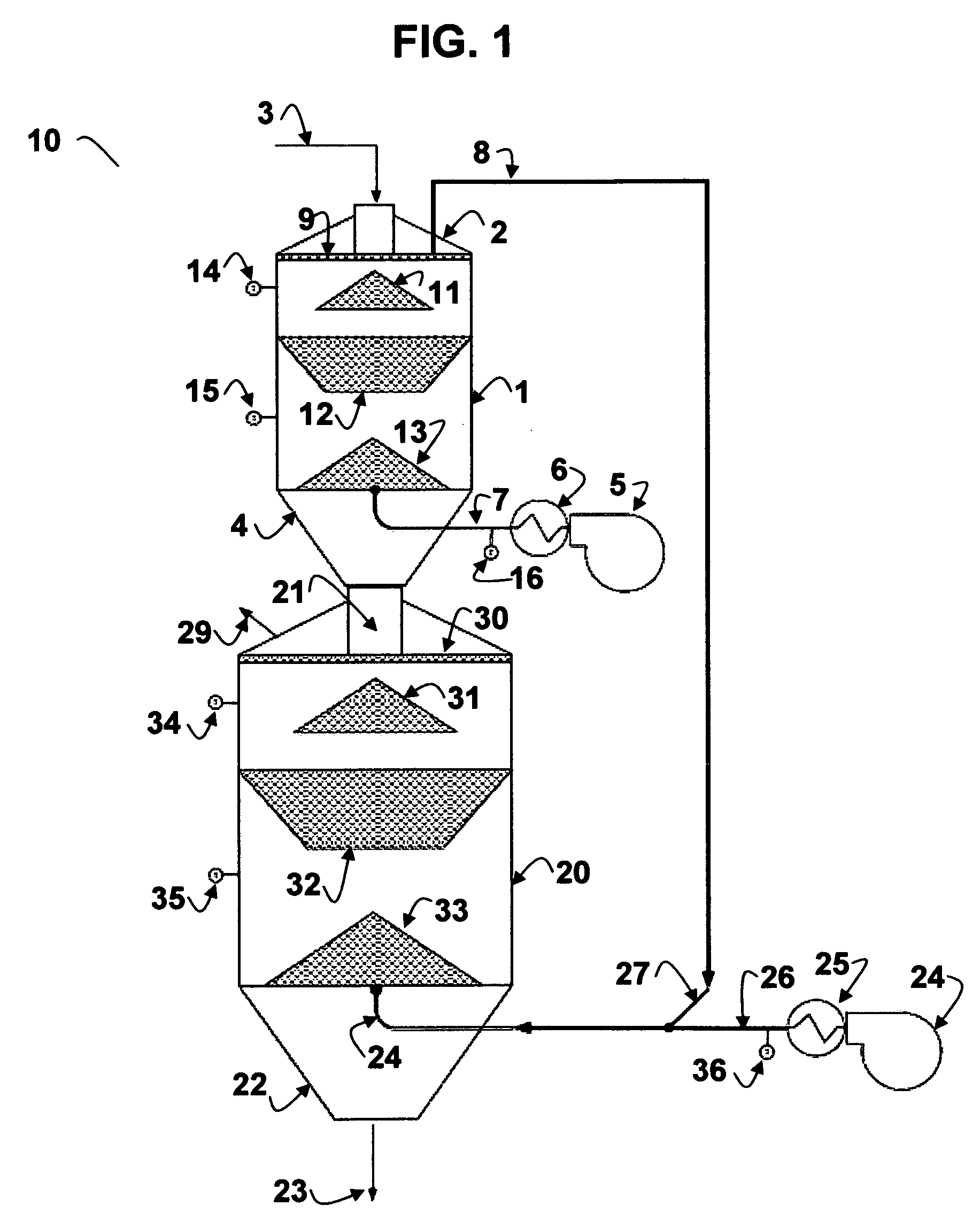

System and method for energy production from sludge

InactiveUS20100043445A1Keep dryDrying using combination processesDrilling rodsFluidized bed dryingCombustion

The present disclosure provides, among other things, a system and process for drying a biosolid or sludge, such as wastewater sludge. The system and method include a fluidized bed dryer in which the sludge is dried. The fluidized bed includes bed media. In particular examples, the bed media is different than the sludge. The system and method can include additional features, such treating the sludge using a thermochemical process in a thermochemical reactor, such as a gasifier, to produce a fuel. The fuel is then combusted to produce energy and heat. The heat is recycled to the drier to help dry sludge. In particular examples, sludge input to the dryer is not first treated using a high-pressure dewatering technique. In some embodiments, the system and method include an anaerobic digester coupled to a combustion unit coupled to the dryer.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Dryer/Grinder

A grinder / dryer having a plurality of beater blades carried on a rotating shaft in a cylindrical housing, including one or a plurality of grinding members on the cylindrical side wall. The grinding members are adjustably positioned at different locations within the cylinder. The grinding members may be provided in a variety of different combination of elevated ridges and / or valleys used to dry and classify materials.

Owner:SCOTT EQUIP

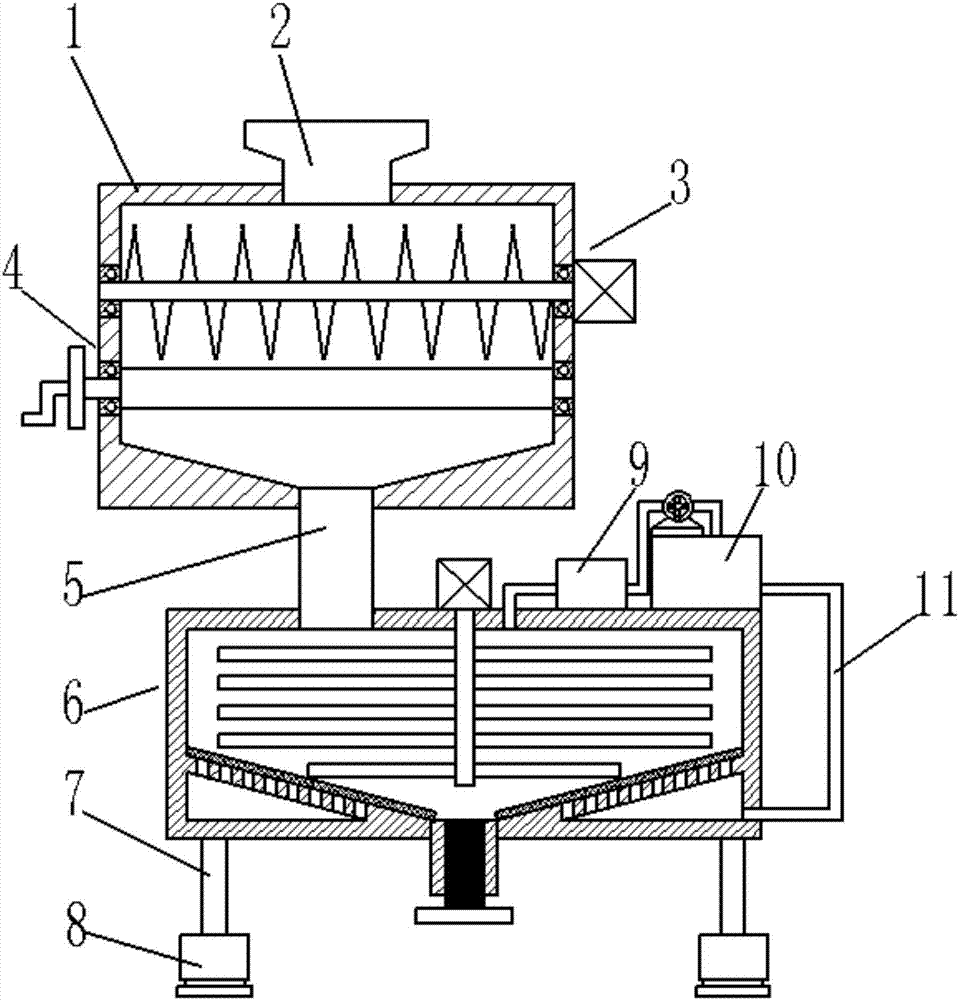

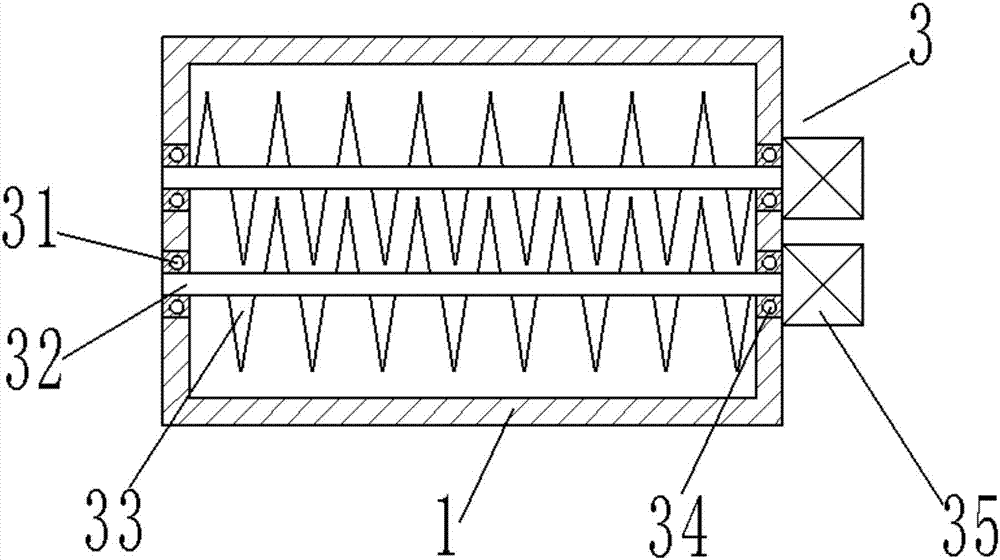

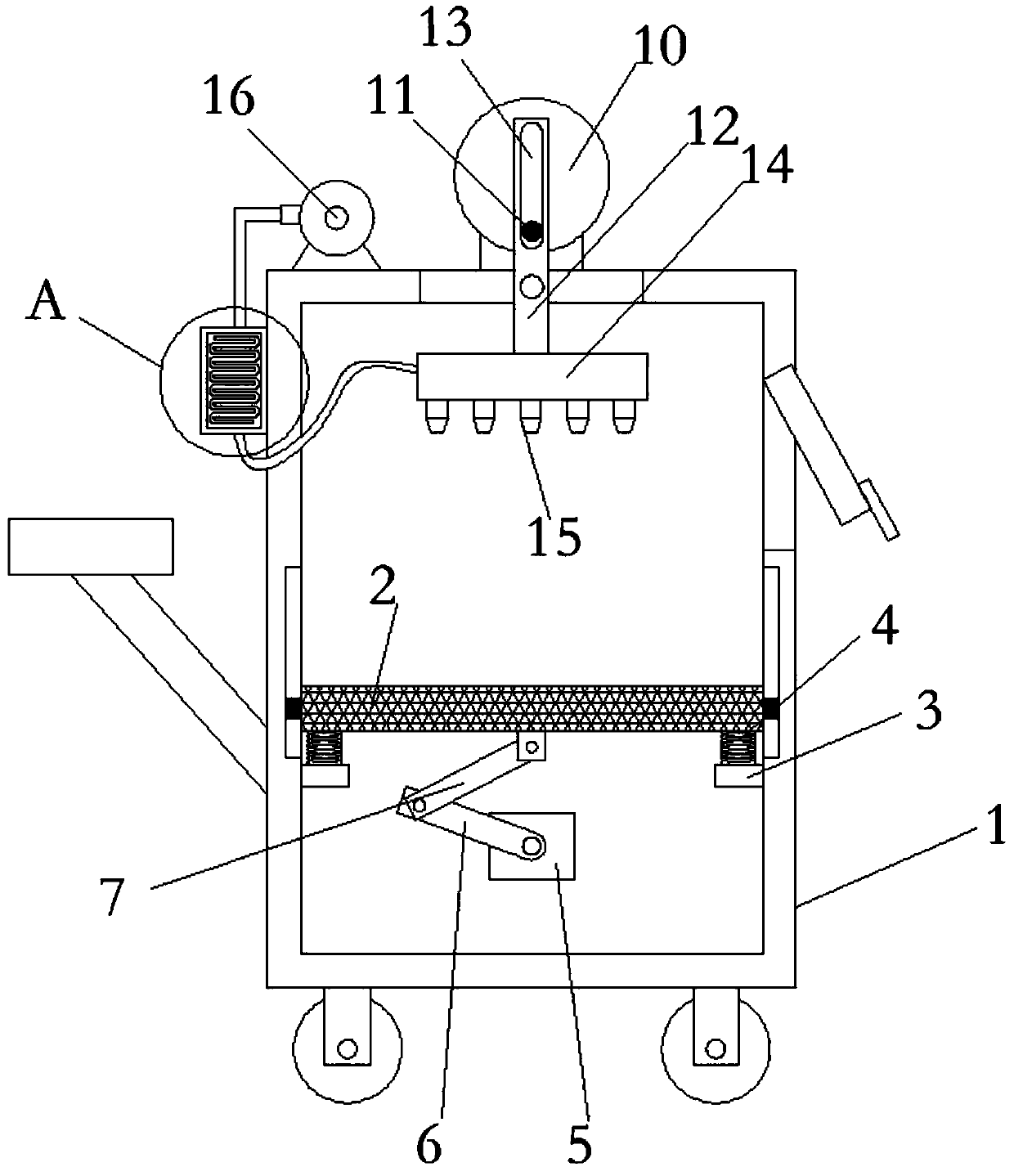

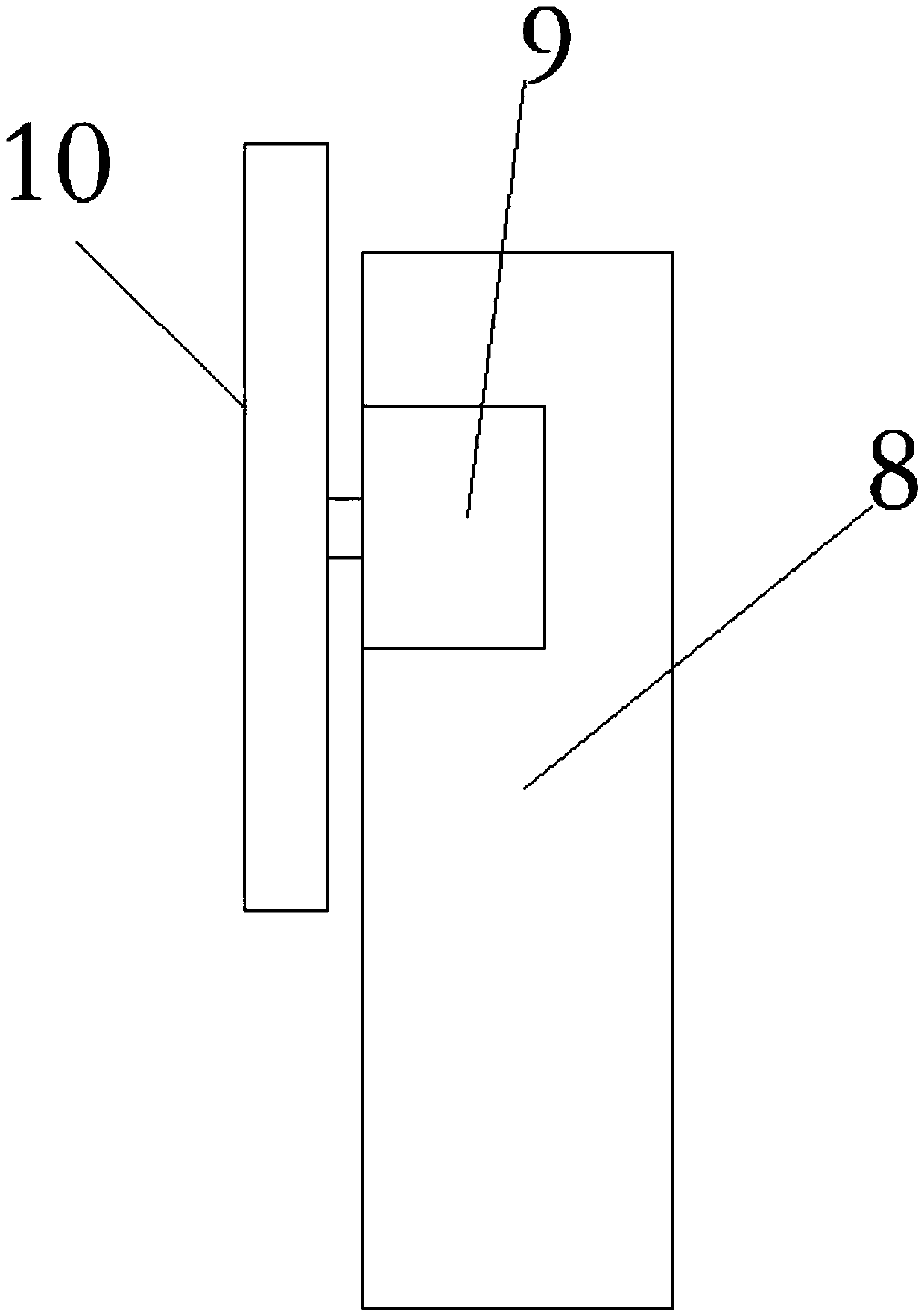

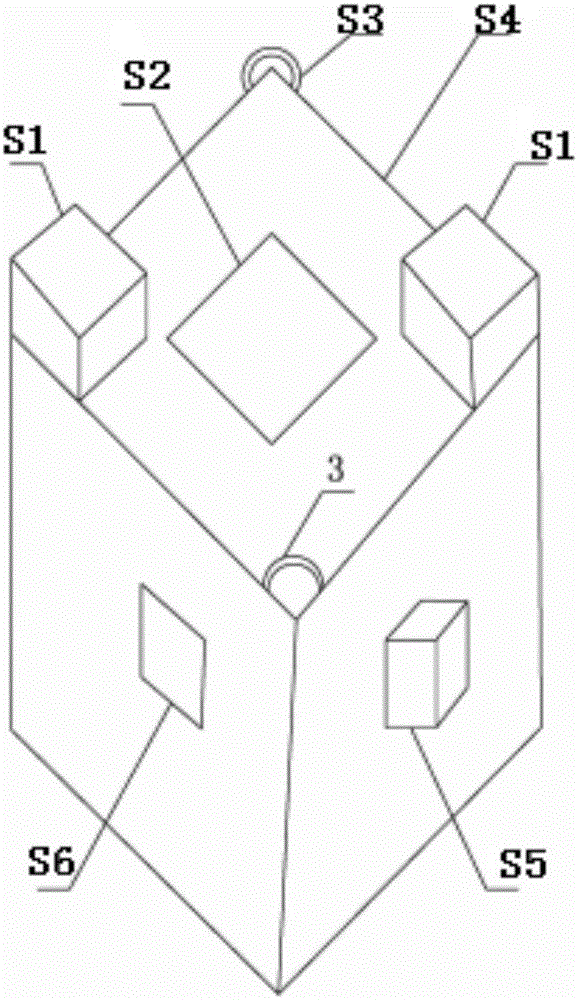

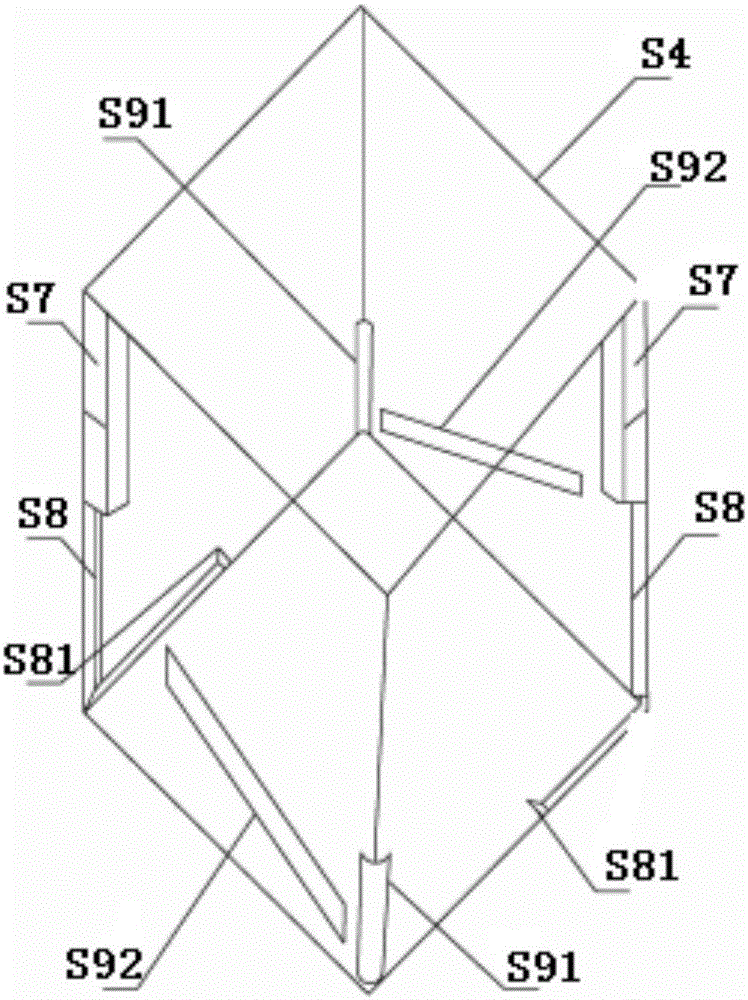

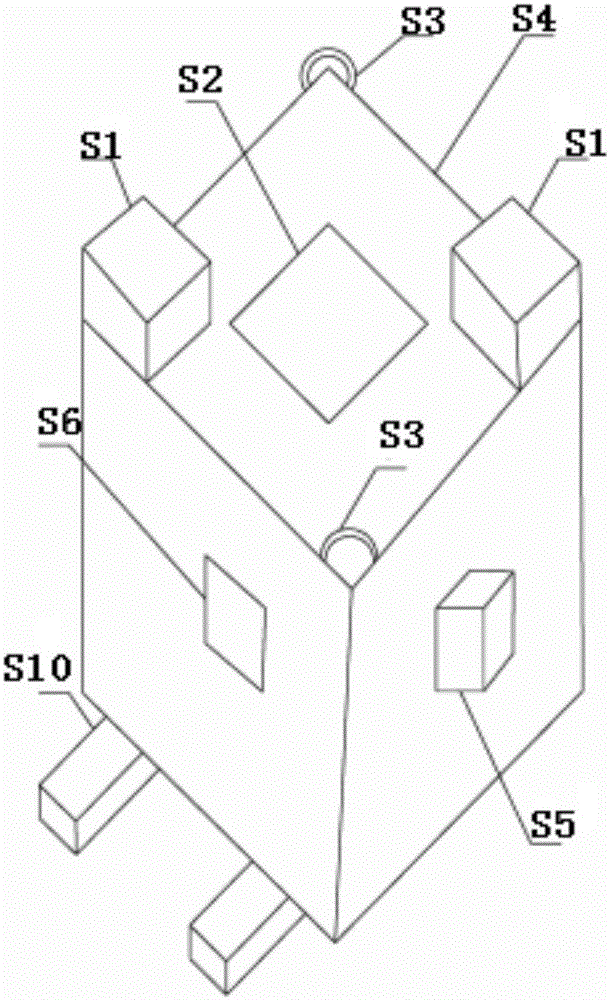

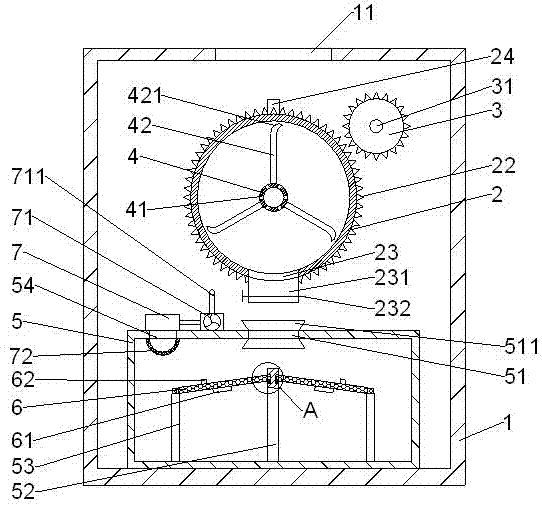

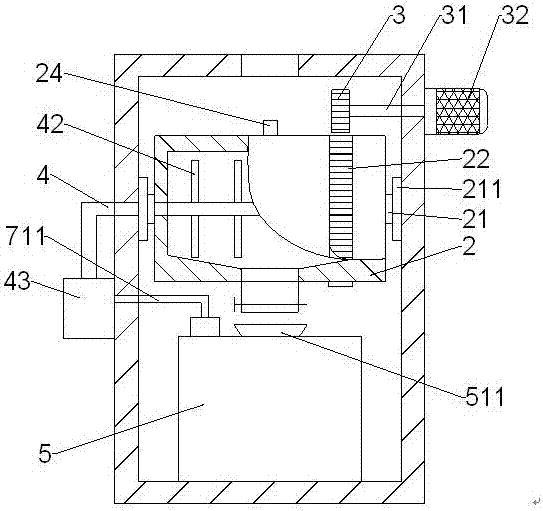

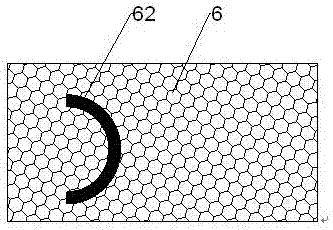

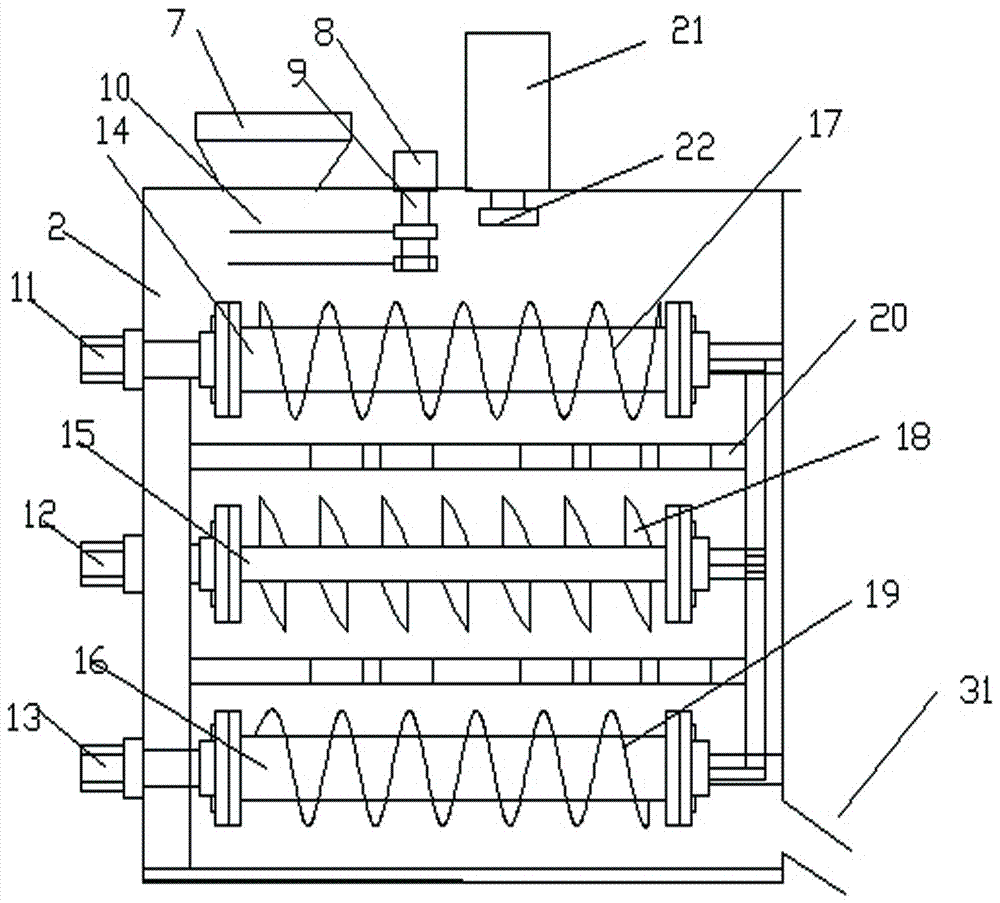

Straw grinding stirring drying device

InactiveCN107211666ACrushed fullyImprove crushing qualityDrying gas arrangementsCuttersPulp and paper industryComminution

The invention provides a novel straw crushing, stirring and drying device, which belongs to the technical field of mechanical equipment. It includes a crushing device (3), a stirring and drying device (6), a dehumidification device (9) and an air heating device (10); the crushing device (3) is fixed above the inside of the crushing box (1); the stirring and drying device (6) Welded on the four supporting columns (7); the dehumidification device (9) is fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6); the air heating device ( 10) Fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6), on the right side of the dehumidification device (9). The novel device of the invention has high crushing quality of straw, and after crushing, the straw is stirred and dried, and the air in the stirring drying box is extracted to carry out circulating hot air drying, thereby ensuring the drying efficiency of the straw, and the dried straw is convenient for storage.

Owner:合肥多智科技开发有限公司

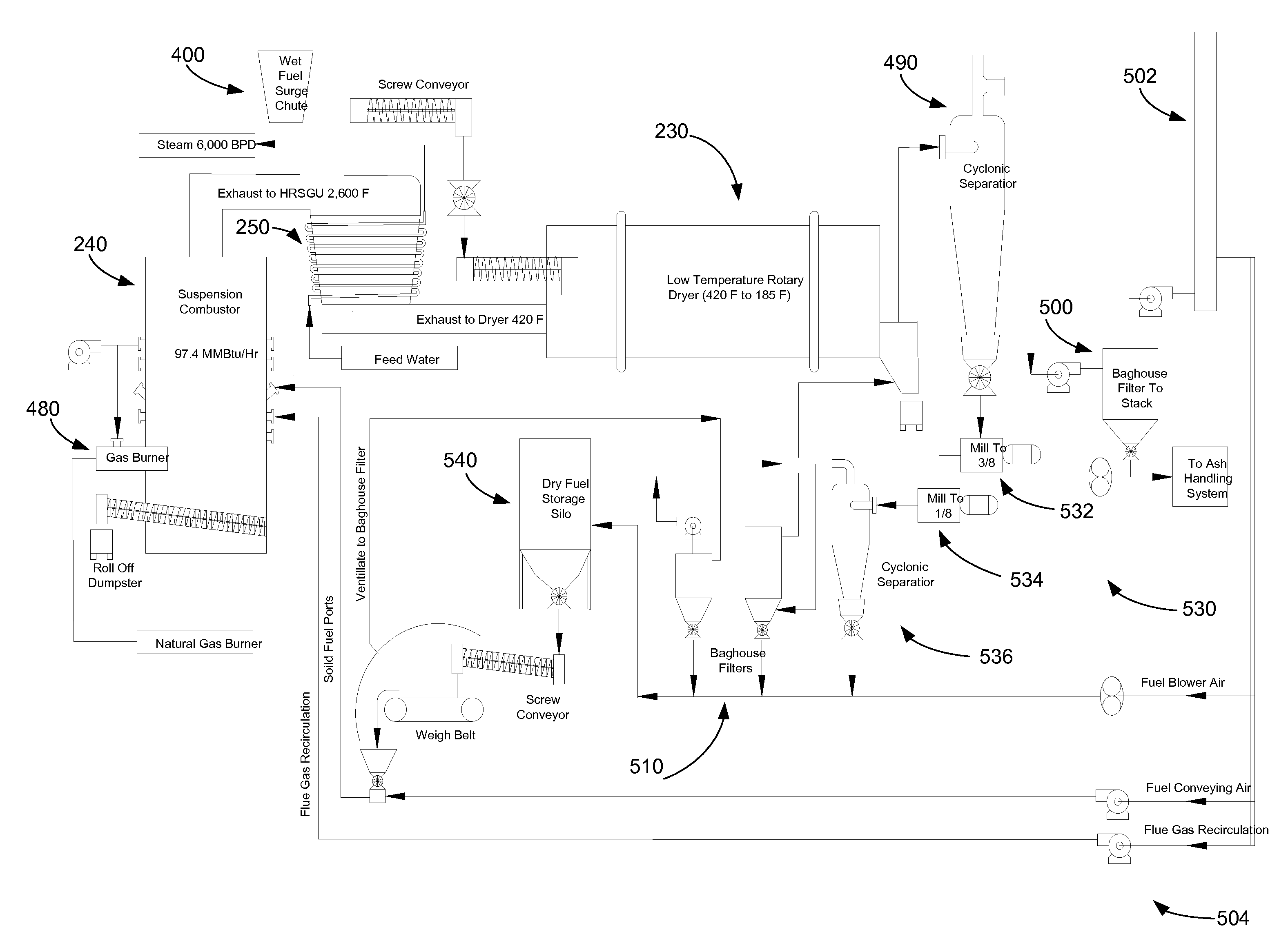

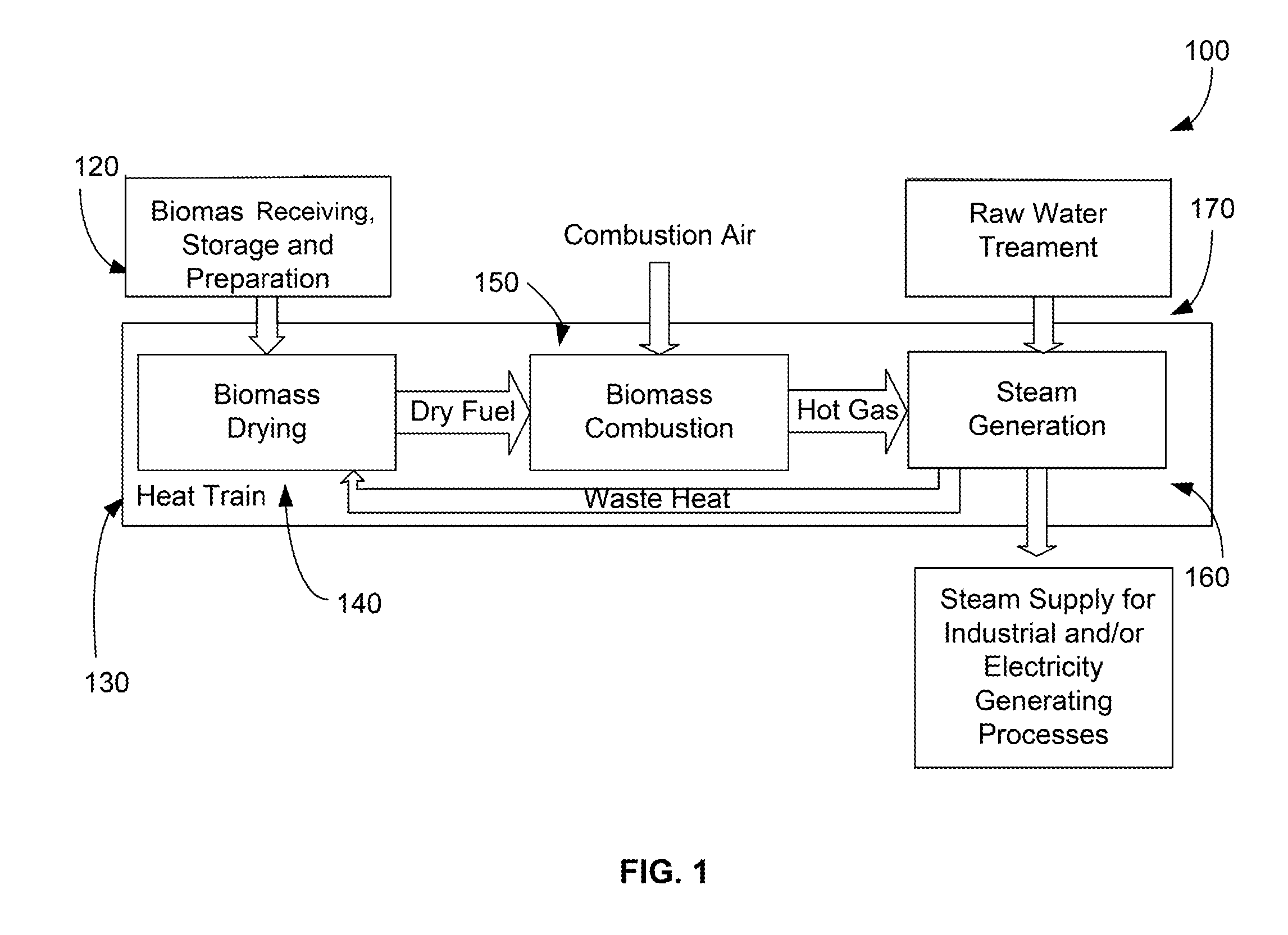

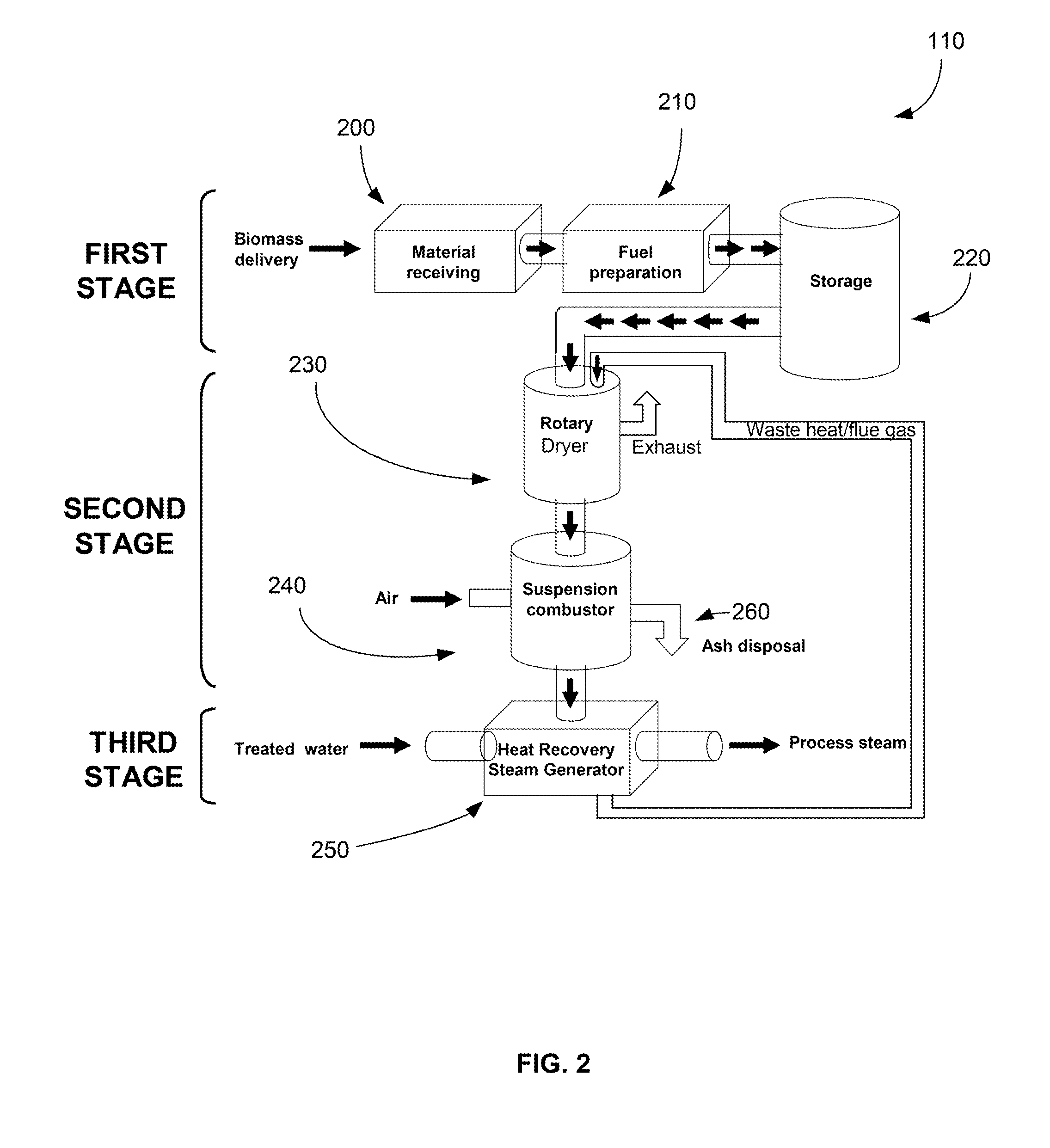

Biomass-to-energy combustion method

InactiveUS20110209647A1Improve efficiencyAvoid spendingSolid fuel pretreatmentPulverulent fuel combustion burnersParticulatesCombustion chamber

A solid biomass-to-energy combustion method includes introducing an oxygen containing gas into a combustion chamber of a suspension furnace to form a flow of gas through the combustion chamber; injecting a particulate solid biomass fuel into the combustion chamber through a port in the furnace wall and into the gas flow, and combusting the particulate solid biomass fuel in the gas flow to form a flame in the gas flow.

Owner:GLOBAL GREENSTEAM

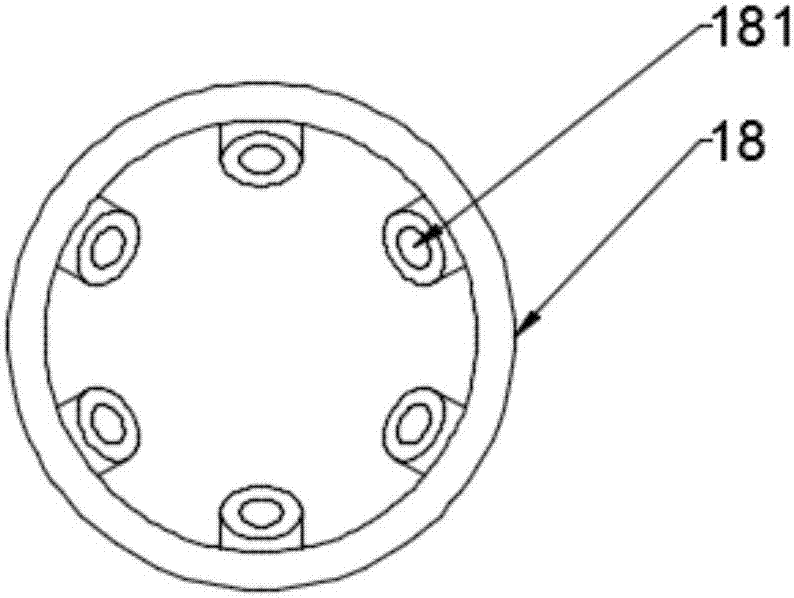

Dryer/grinder

ActiveUS8714467B2Drying chambers/containersDrying machines with non-progressive movementsEngineering

A grinder / dryer having a plurality of beater blades carried on a rotating shaft in a cylindrical housing, including one or a plurality of grinding members on the cylindrical side wall. The grinding members are adjustably positioned at different locations within the cylinder. The grinding members may be provided in a variety of different combination of elevated ridges and / or valleys used to dry and classify materials.

Owner:SCOTT EQUIP

Drying and dedusting integrated machine for traditional Chinese medicine

The invention discloses an integrated machine for drying and dust removal of traditional Chinese medicine, which comprises a drying box, a winnowing box and a screening box. A drying net is arranged in the drying box, and a first air injection device is embedded in the bottom wall of the inner cavity of the drying box. The inner cavity of the winnowing box is provided with a partition, which divides the inner cavity of the winnowing box into an ascending chamber and a winnowing chamber. A stirring shaft is arranged in the ascending chamber, and an auger is set on the stirring shaft. The bottom of the winnowing chamber There is a second air injection device, the upper part of the inner wall of one side of the winnowing chamber is connected to the dust filter through the dust discharge pipe, and the winnowing chamber is connected to the screening box through the third communication hole; the inner cavity of the screening box is provided with a screening net, and the screening box The bottom wall of the screen is connected to the slag discharge pipe, and the bottom of the screening box is evenly equipped with several legs; the invention provides a space spiral drying net, so that the medicinal materials and hot air have sufficient contact time to ensure that the medicinal materials are dried; The air separation chamber and the screening box are set so that light impurities such as residual leaves and granular impurities in the medicinal materials are filtered cleanly and thoroughly.

Owner:安庆海维环保设备有限公司

Drying device for traditional Chinese medicinal materials

InactiveCN108679976AIncrease the drying areaEasy to useDrying gas arrangementsDrying solid materialsMedicinal herbsOperations management

The invention discloses a drying device for traditional Chinese medicinal materials. The drying device for the traditional Chinese medicinal materials comprises a drying box. The inner wall of the drying box is in sliding connection with a placement net plate. The positions, corresponding to the lower portion of the placement net plate, of the inner wall of the drying box are fixedly connected with supporting annular plates. The upper ends of the supporting annular plates are fixedly connected with the lower end of the placement net plate through a plurality of buffering springs. The inner wall of the lower end of the drying box is fixedly connected with a first motor. An output shaft of the first motor is fixedly connected with a rotating rod. The end, far away from the first motor, of the rotating rod is rotationally connected with a push-pull rod. The end, far away from the rotating rod, of the push-pull rod is rotationally connected with the lower end of the placement net plate. The upper end of the drying box is fixedly connected with a stand column. The side wall of the stand column is fixedly provided with a second motor in an embedded manner. An output shaft of the second motor is fixedly connected with a rotary table. The surface of the rotary table is fixedly connected with an eccentric rod. According to the drying device for the traditional Chinese medicinal materials, the drying area can be greatly increased, and the drying efficiency of the medicinal materials is higher.

Owner:广西奕琦科技有限公司

Automatic processing device for Chinese herbology

InactiveCN108020051AImprove the mixing effectImprove drying efficiencyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringExhaust pipe

The invention discloses an automatic processing device for Chinese herbology. The automatic processing device comprises a box body; a material carrying screen plate is arranged on the inner side of the box body; a feeding pipe is arranged in the middle of the top of the box body; a storage box is arranged at the upper end of the feeding pipe; an air heater is further arranged at the top of the boxbody; an exhaust pipe connected to an air inlet of the air heater extends into the feeding pipe from the top of the storage box; an air conveying pipe connected to an air outlet of the air heater isconnected to a ring pipe; a plurality of air inlet branch pipes communicating with an inner cavity of the box body are arranged on the inner side of the ring pipe; a plurality of supporting rods are arranged on the side surface of the lower end of the feeding pipe; supporting sleeves are arranged at the outer ends of the supporting rods; vertical rods are arranged in the supporting sleeves; stirring blades matched with the material carrying screen plate are arranged at the lower ends of the vertical rods; outer gear rings are connected and fixed to the upper ends of the vertical rods through aplurality of connecting rods; and inner gear rings meshed with the outer gear rings are further arranged on the inner wall of the box body. The automatic processing device has the advantages of beingnovel in structure, high in processing efficiency, high in heat utilization rate, energy-saving, environment-friendly, capable of discharging materials conveniently and capable of improving the processing efficiency.

Owner:合肥红蔻健康管理有限公司

Biomass torrefaction system and method

ActiveUS20120159842A1Improve scalabilityEasy to controlDrying solid materials with heatDirect heating destructive distillationProcess engineeringTorrefaction

Owner:TEAL SALES

Selenium-rich culture medium for hericium erinaceus and method for producing hericium erinaceus

InactiveCN106242763AHigh nutritional valueIncrease selenium contentCalcareous fertilisersFungiNutritive valuesEnrichment methods

The invention provides a selenium-rich culture medium for hericium erinaceus. The selenium-rich culture medium for hericium erinaceus is mainly prepared from wood flour, bran, selenium-rich fungus grass and gypsum. The invention further provides a method for producing hericium erinaceus with the selenium-rich culture medium for hericium erinaceus. A traditional production method of a hericium erinaceus strain is changed, a liquid strain technology is utilized in hericium erinaceus strain production, and a selenium-rich liquid strain is prepared; meanwhile, the solid selenium-rich culture medium and a secondary selenium enrichment method are adopted, and produced hericium erinaceus is high in selenium content and high in nutritive value. Production efficiency is improved, and production cost is greatly reduced; besides, the production method is simple in process, and the produced strain is high in utilization rate and low in contamination rate.

Owner:井冈山井祥菌草生态科技股份有限公司

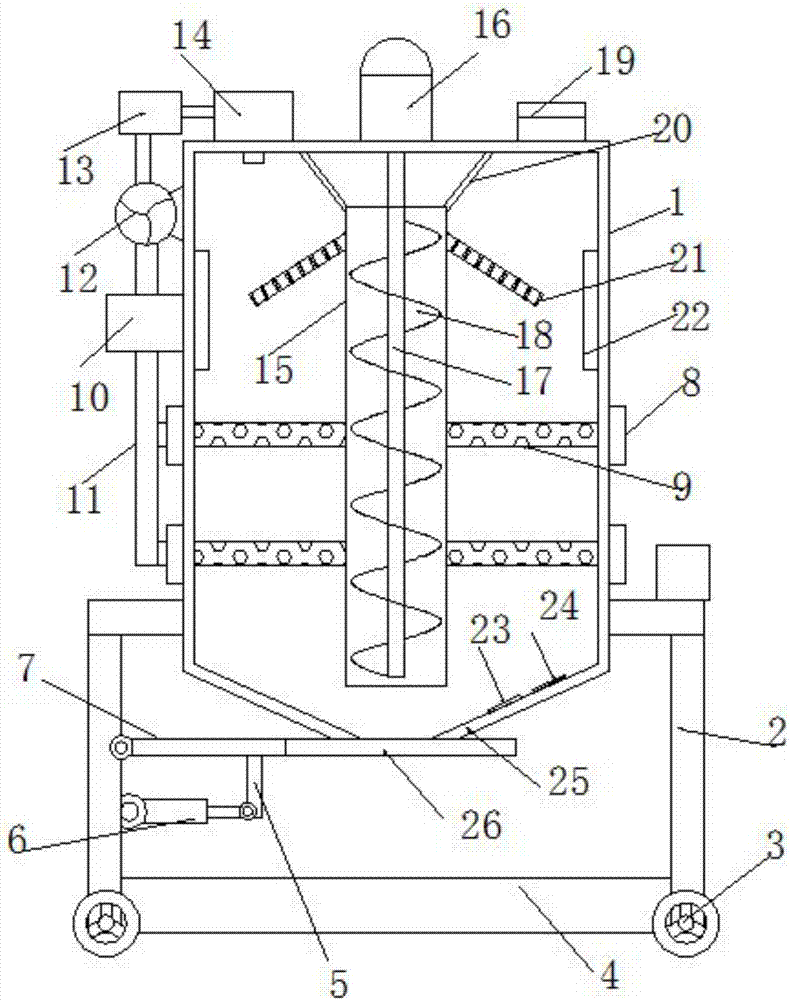

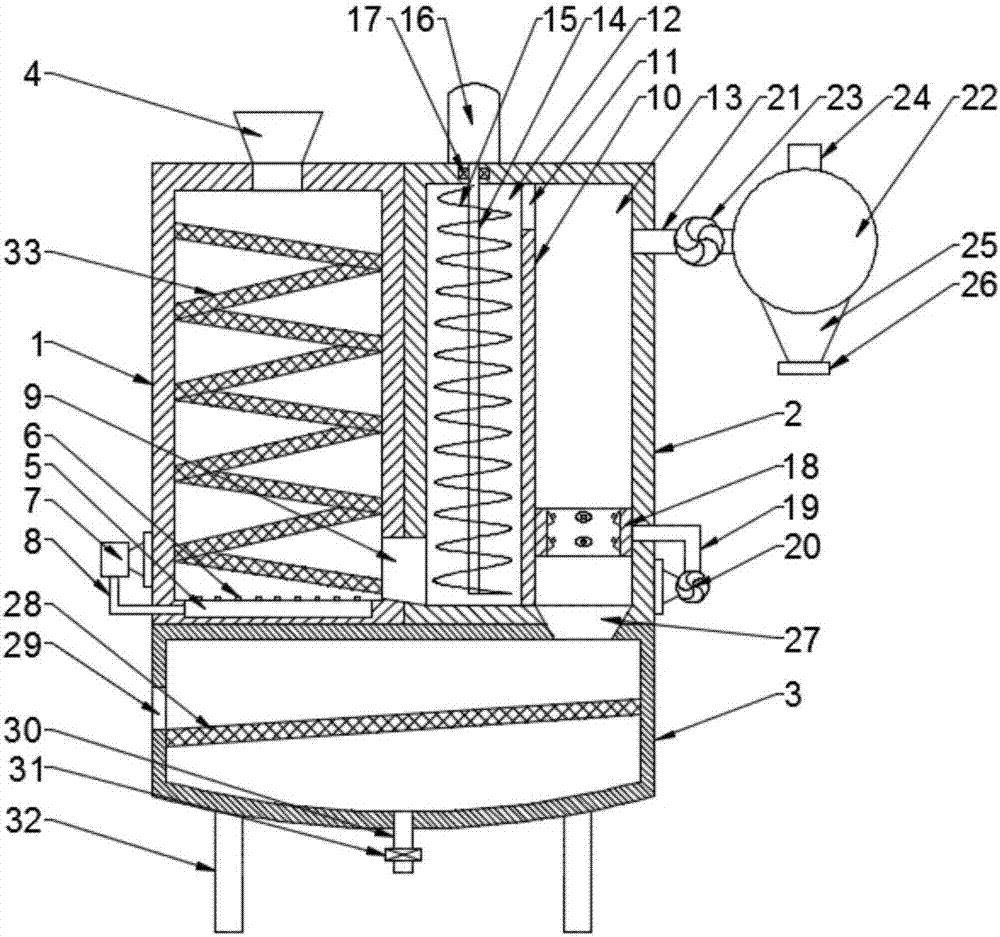

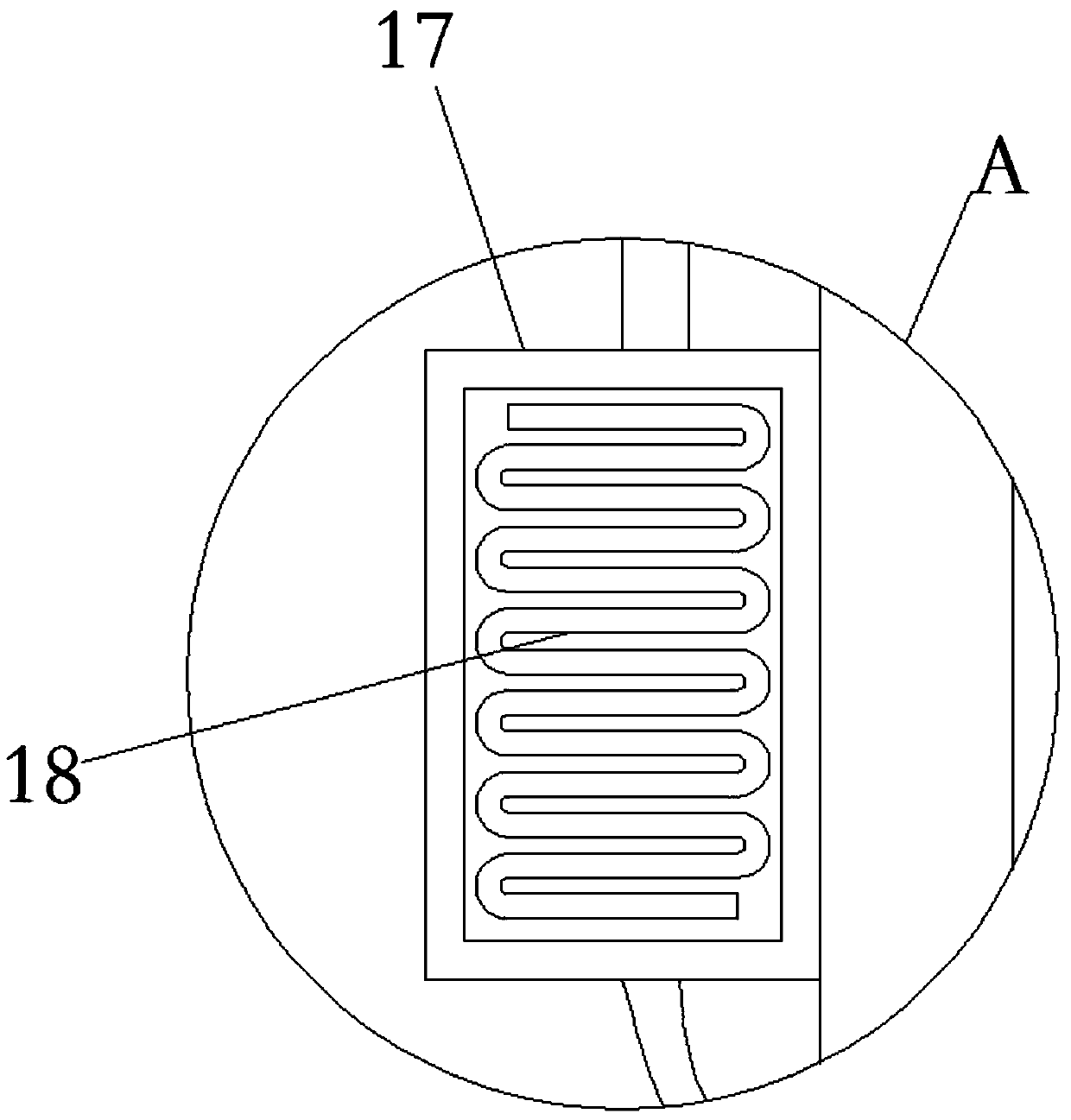

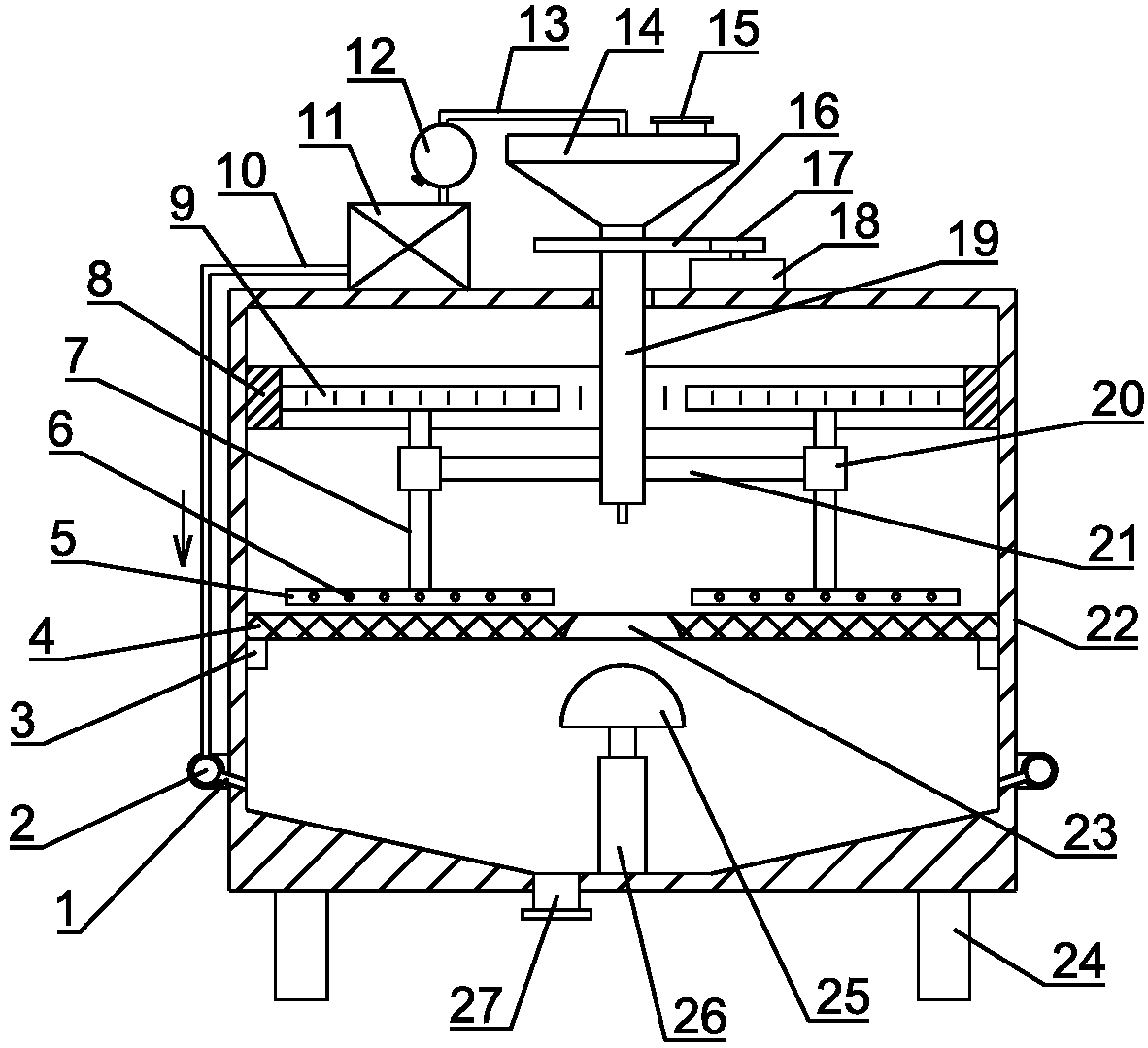

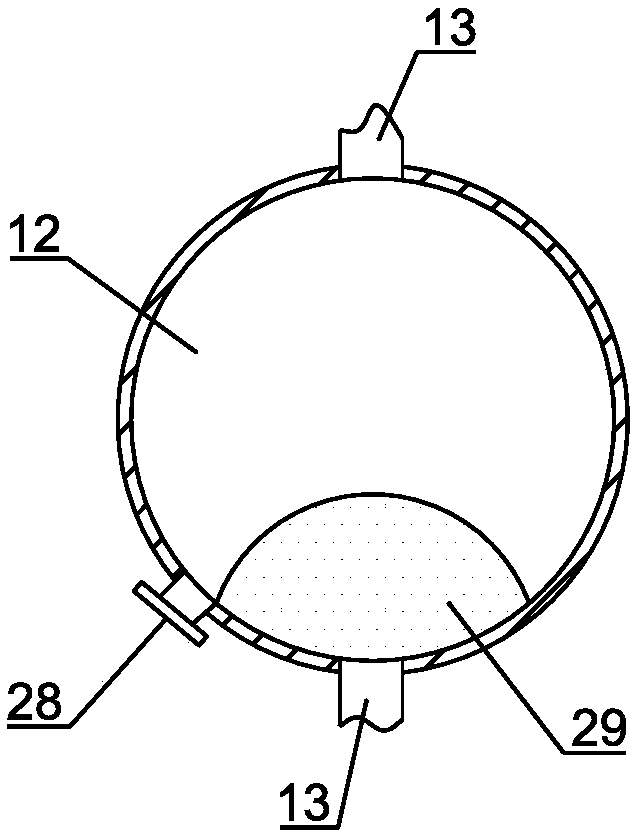

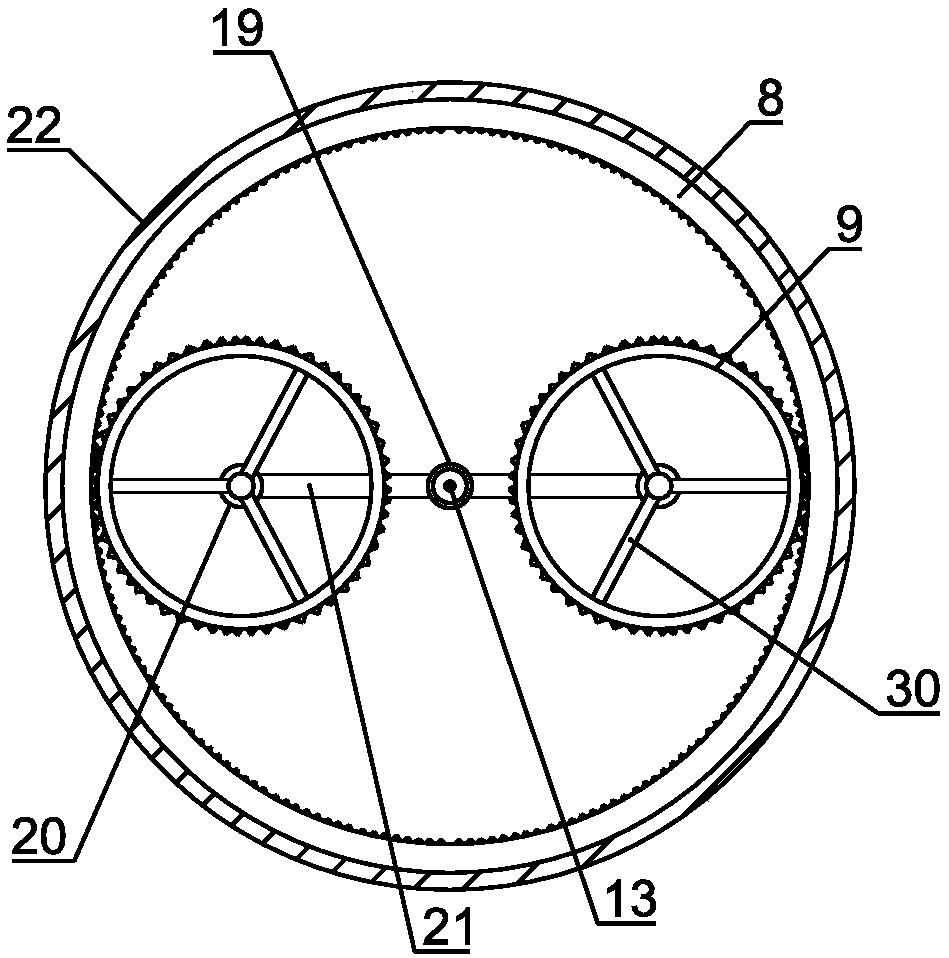

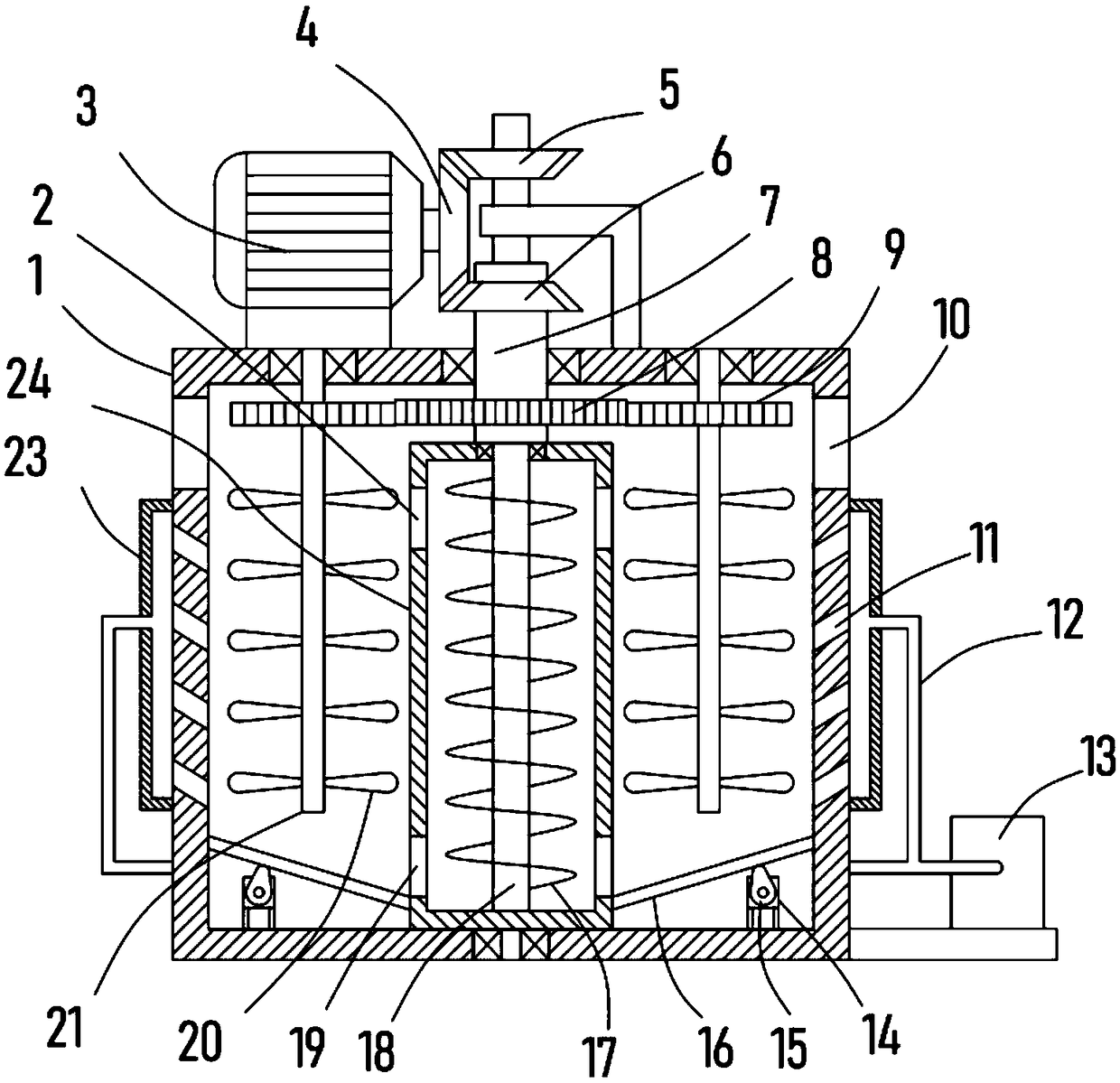

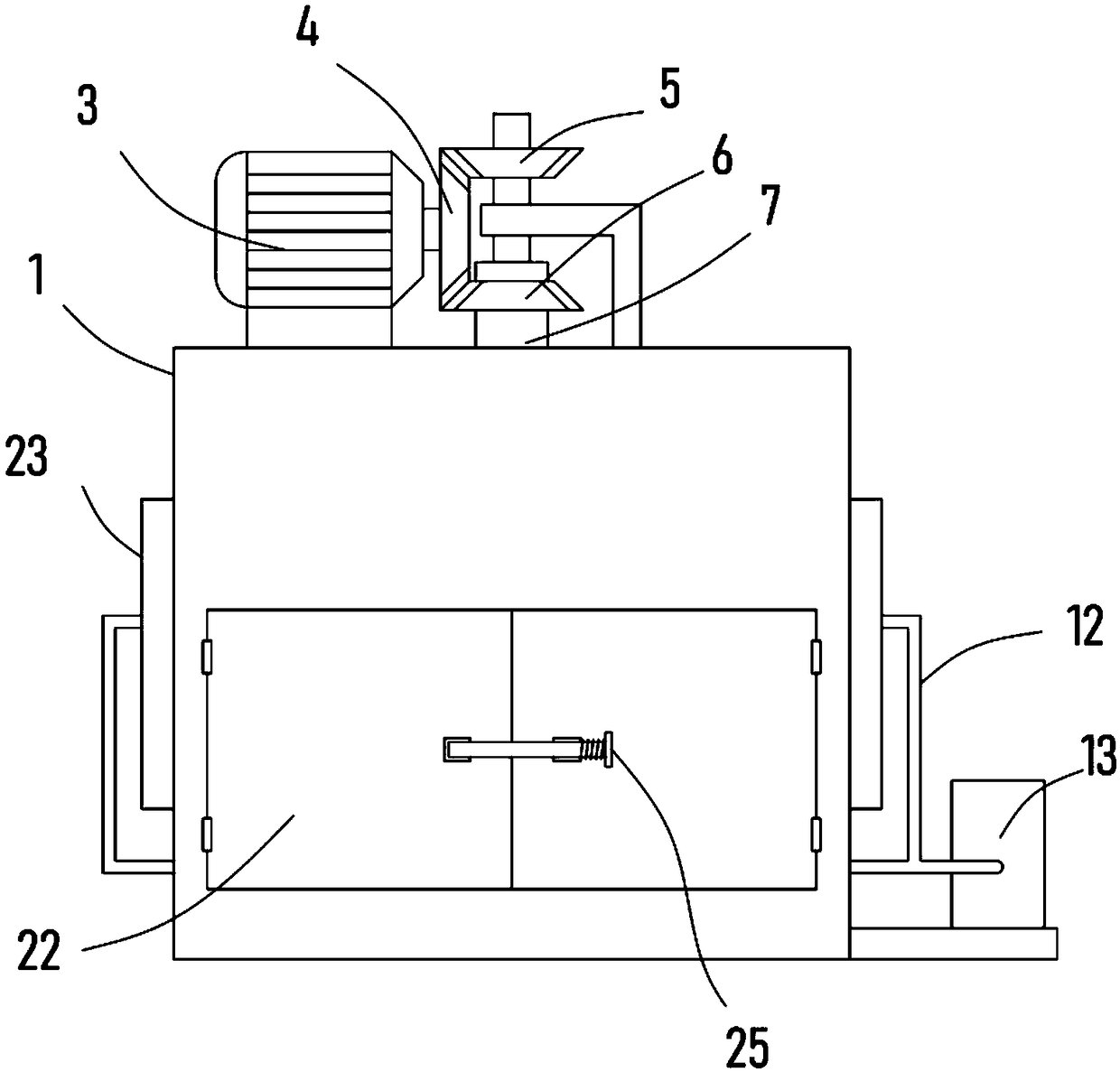

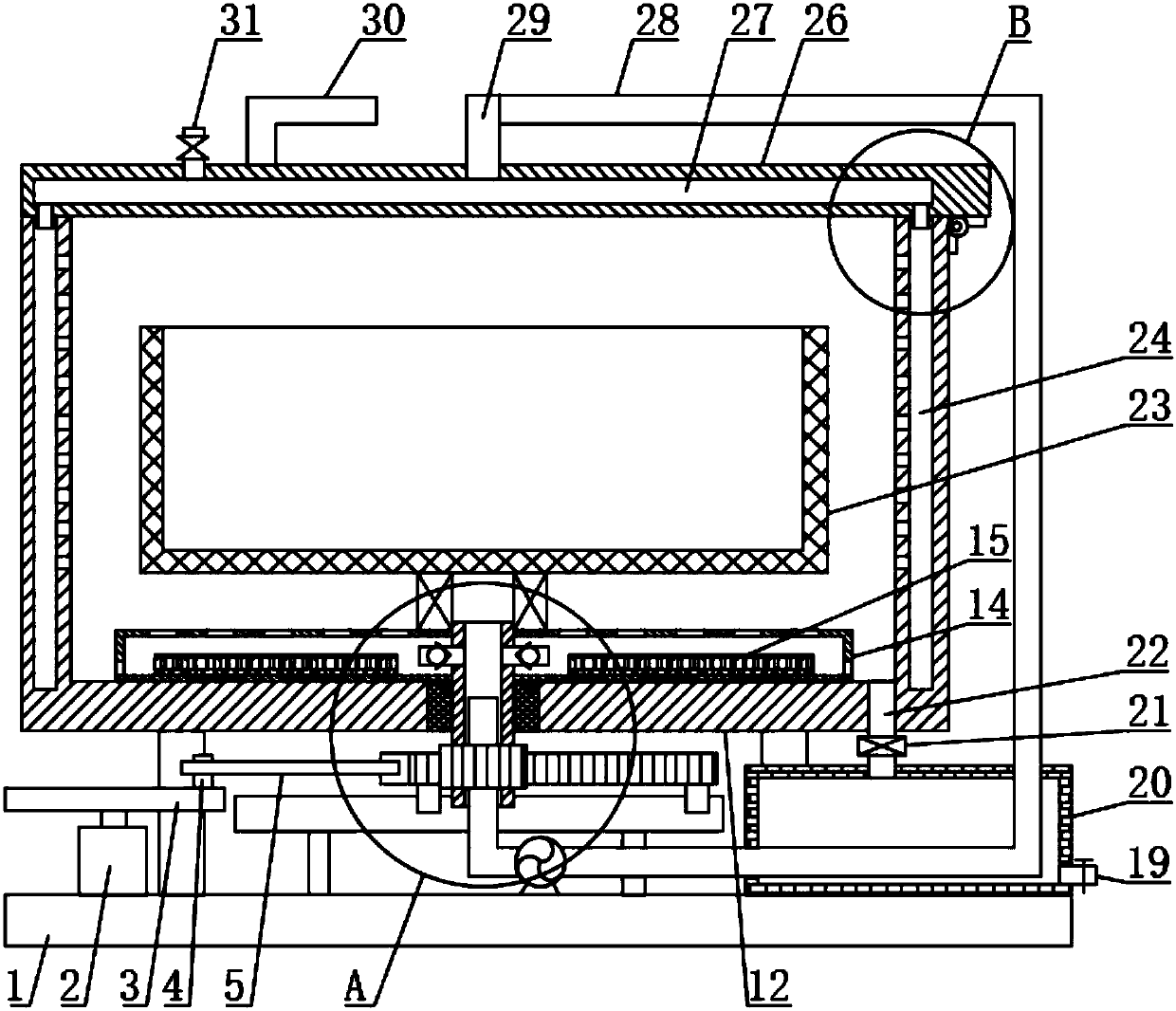

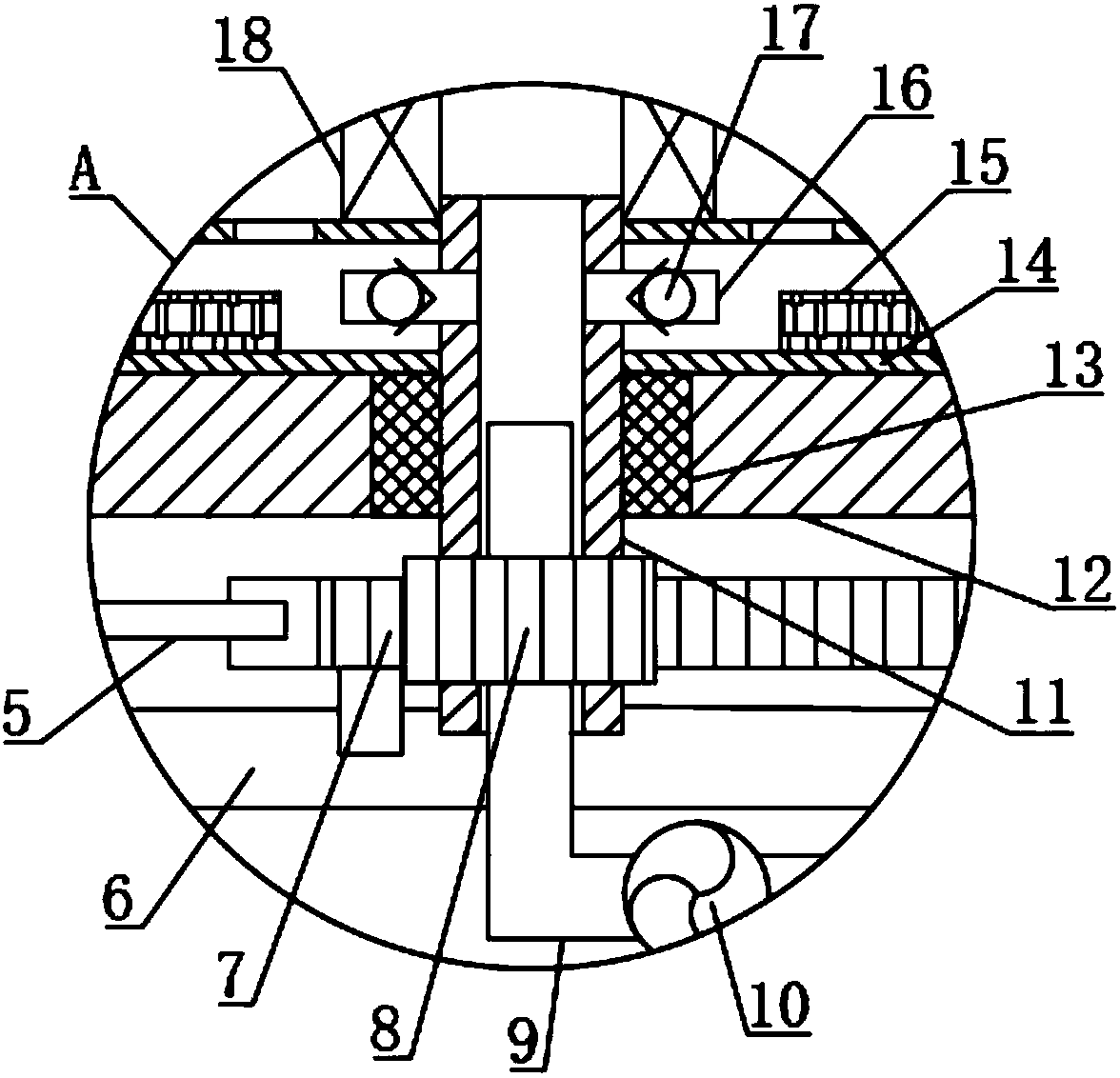

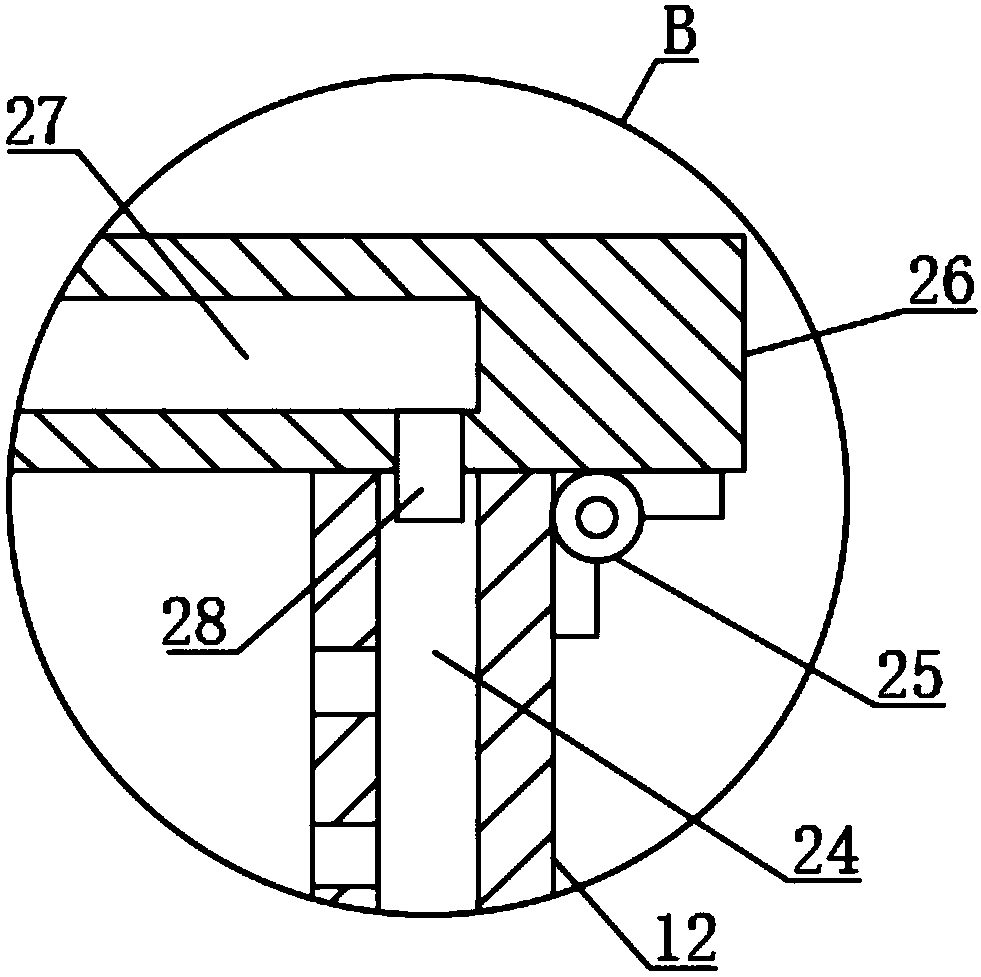

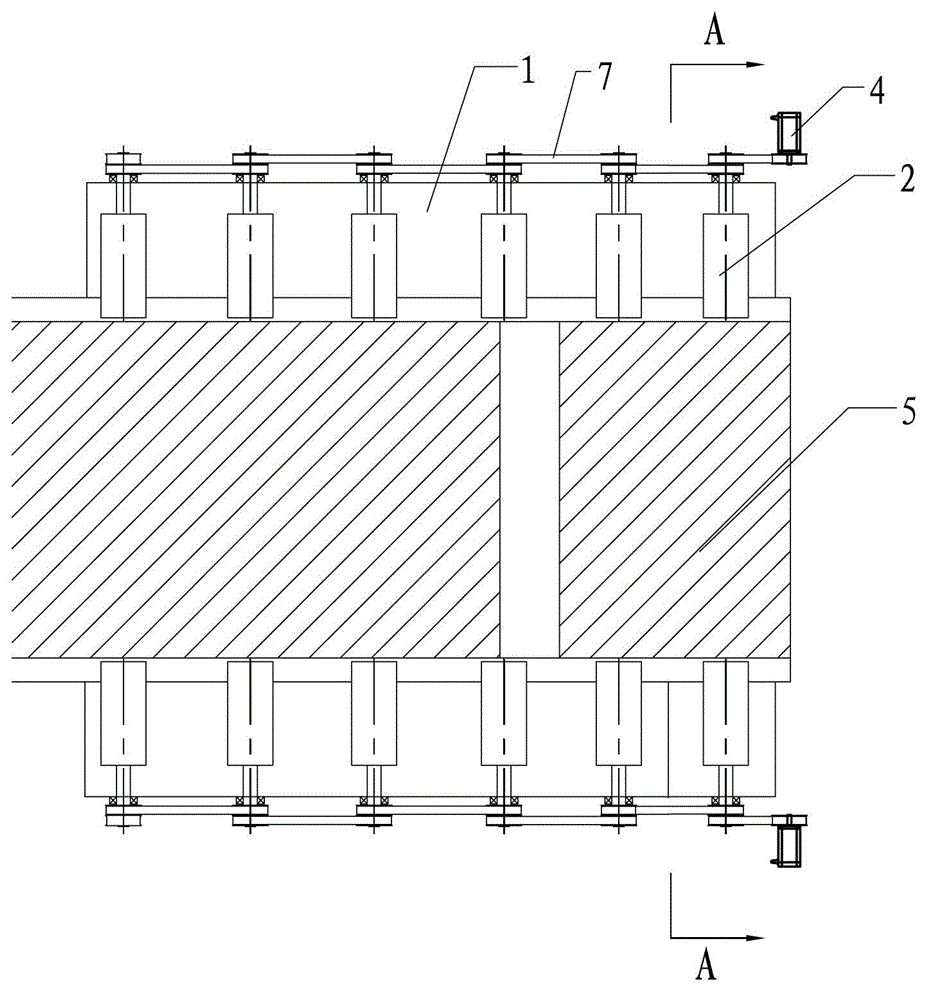

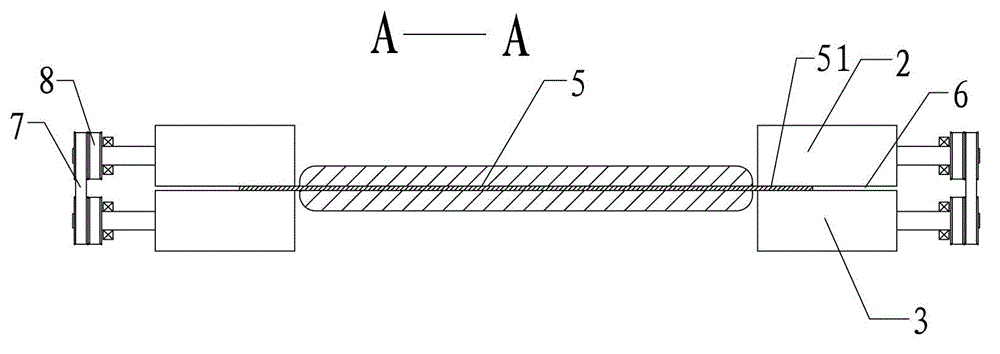

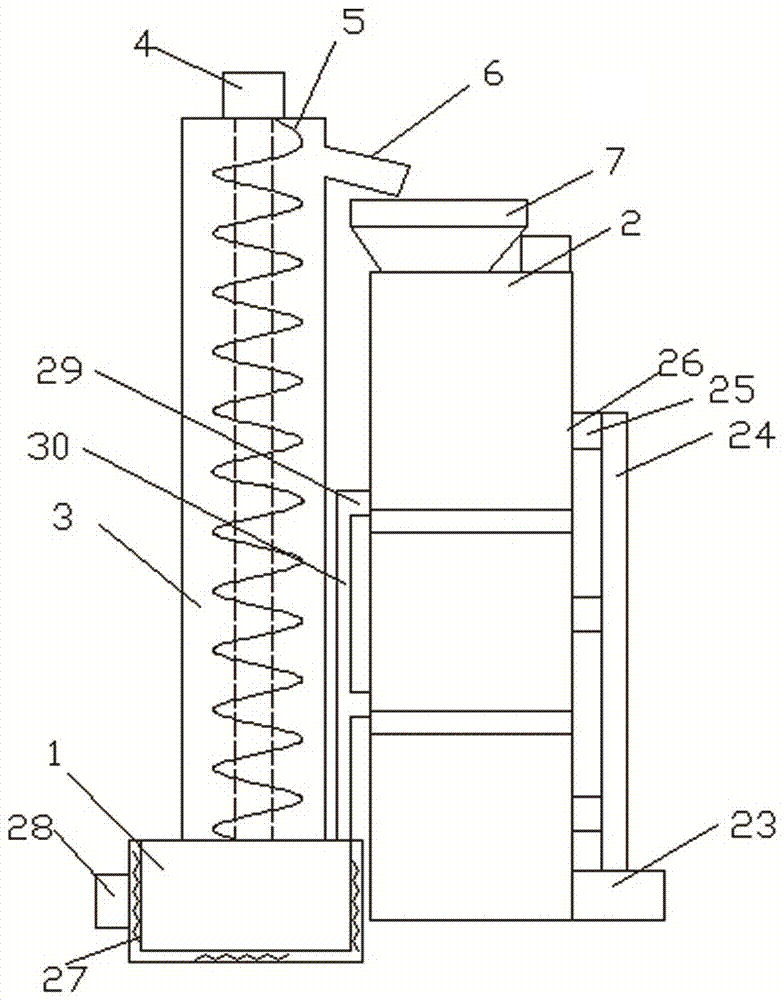

Biomass fuel drying device

InactiveCN109458827AFull dispersionFully contactedDrying gas arrangementsDrying solid materialsSpiral bladeFuel treatment

The invention discloses a biomass fuel drying device, and relates to the technical field of biological fuel treatment. The biomass fuel drying device comprises a drying box and a hot fan communicatedwith the interior of the drying box, the top of the drying box is fixedly provided with a driving motor, an output shaft of the driving motor is coaxially and fixedly provided with a driving bevel gear, a driven bevel gear I meshed with the driving bevel gear is fixed on the surface of a lifting rotating shaft, spiral blades positioned in a lifting sleeve are fixed on the surface of the lifting rotating shaft, a plurality of discharge ports are formed in the upper side wall of the lifting sleeve, and a plurality of feeding ports are formed in the lower side wall of the lifting sleeve. According to the biomass fuel drying device, the rotating shaft drives the spiral blades to rotate, the rotating spiral direction of the biomass fuel is improved upwards, the biomass fuel is discharged from the discharging port to be scattered by the dispersing blades in a rotating mode, the full-dispersion effect of the fuel is realized, the full contact of the hot air is realized, the fuel can be circularly lifted, fell and scattered, and the drying process is more efficient and thorough.

Owner:郑州韦尔特生物科技有限公司

Leaf crushing and drying equipment for garden maintenance

ActiveCN108273592AReduce weightShatter safe and stableDrying gas arrangementsDrying machines with non-progressive movementsSpiral bladeHardness

The invention discloses leaf crushing and drying equipment for garden maintenance. The leaf crushing and drying equipment comprises a material inlet hopper, a fixed seat, a crushing box, a drying boxand supports, an inner cavity is internally and coaxially provided with a horizontal rotating roller, the rotating roller is provided with storage grooves which are concaved towards the center of therotating roller, the inner wall of each storage groove is provided with a layer of adjusting plate, a crushing cavity is internally provided with two crushing rollers which perform squeezing horizontally side by side in a matching manner, an output shaft of a stirring motor is fixedly provided with a horizontal stirring shaft, a spiral blade is fixedly installed on the stirring shaft, an air fan communicates with a heating box through a pipeline, and the heating box communicates with an air blowing mouth located inside the drying box through the pipeline. According to the leaf crushing and drying equipment for the garden maintenance, by means of the rotation of the arranged rotating roller, the different storage grooves on the rotating roller are made to be upward for leaves entering, crushing of the crushing rollers is made to be safe and stable, the volume of the leaves capable of entering the storage grooves can be adjusted manually according to the hardness of the leaves, the leafcrushing and drying equipment for the garden maintenance is more flexible to use, by means of stirring and hot air blowing on the crushed leaves, drying of leaf broken materials is realized, and the drying efficiency is high.

Owner:盐城恒茂园林绿化有限公司

Drying device for traditional Chinese medicine preparation

InactiveCN107401903AEvenly heatedImprove functionalityDrying gas arrangementsDrying machines with non-progressive movementsMedicinal herbsAgricultural engineering

The invention discloses a drying device for traditional Chinese medicine preparation. The drying device comprises a frame, a drying drum and a screening box, wherein the drying drum and the screening box are arranged in an inner cavity of the frame; a feeding inlet is formed in the center of a top plate of the frame; the drying drum is rotatably arranged on the upper portion of the inner cavity of the frame; the drying drum is provided with a feeding and discharging port; a hot air box is installed on the exterior of the frame and connected with a hot air pipe, a rotation shaft arranged on the end face of the front side of the drying drum is designed to be hollow, and the hot air pipe penetrates through the rotation shaft from the axis of the rotation shaft to stretch into the drying drum and then extend; the screening box is located under the drying drum, and an air suction inlet is formed in the left side of a top plate of the screening box; a dehumidifying box is installed on the portion, corresponding to the air suction inlet, of the top of the screening box and connected with an exhaust fan through a pipeline, the exhaust fan is connected with an air pipe, and the air pipe is connected with the hot air box. According to the drying device, medical materials are heated uniformly, and then the drying effect is guaranteed; meanwhile, reutilization on heat can be completed, and therefore energy conservation and environment protection are achieved.

Owner:华润三九(郴州)制药有限公司

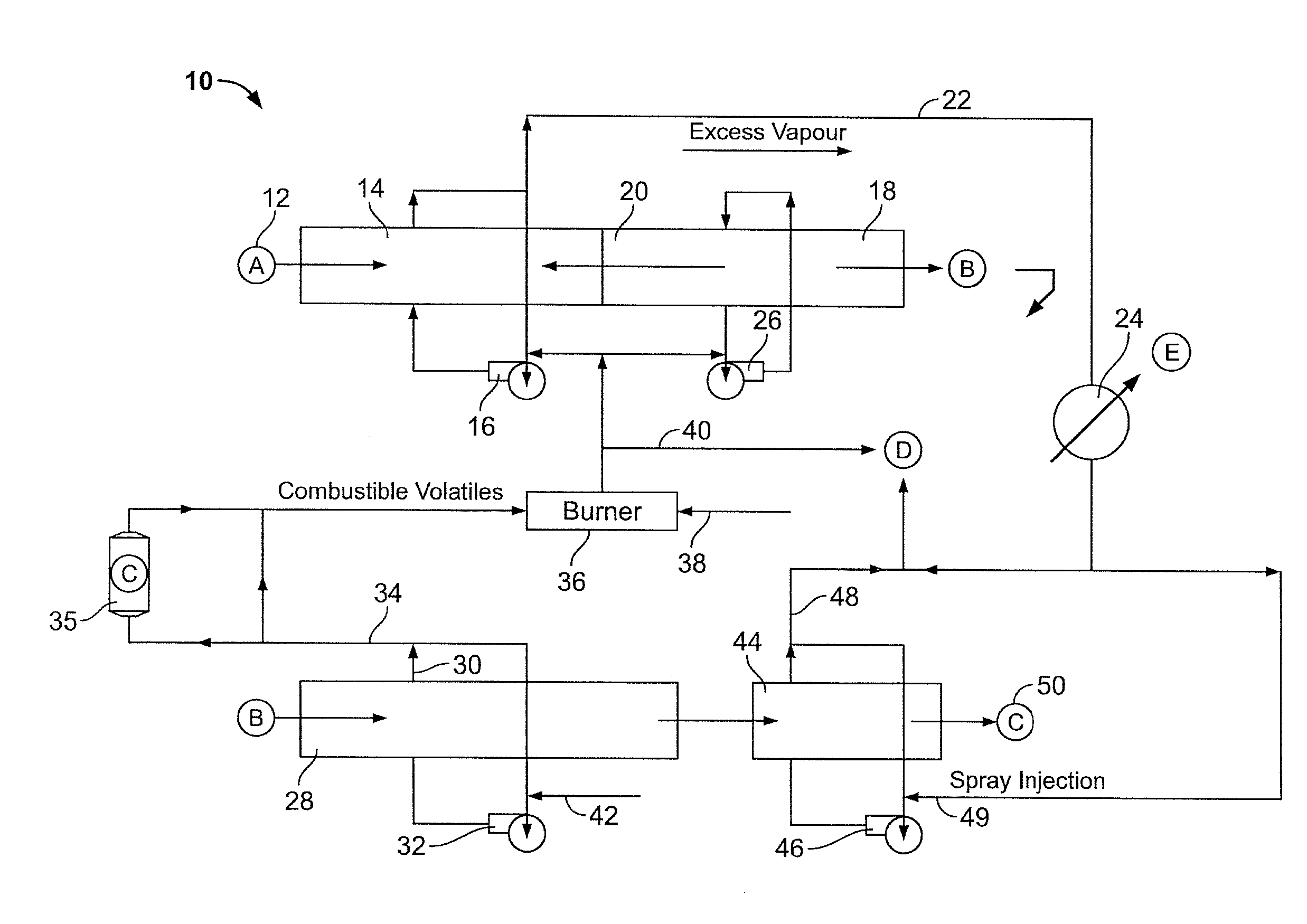

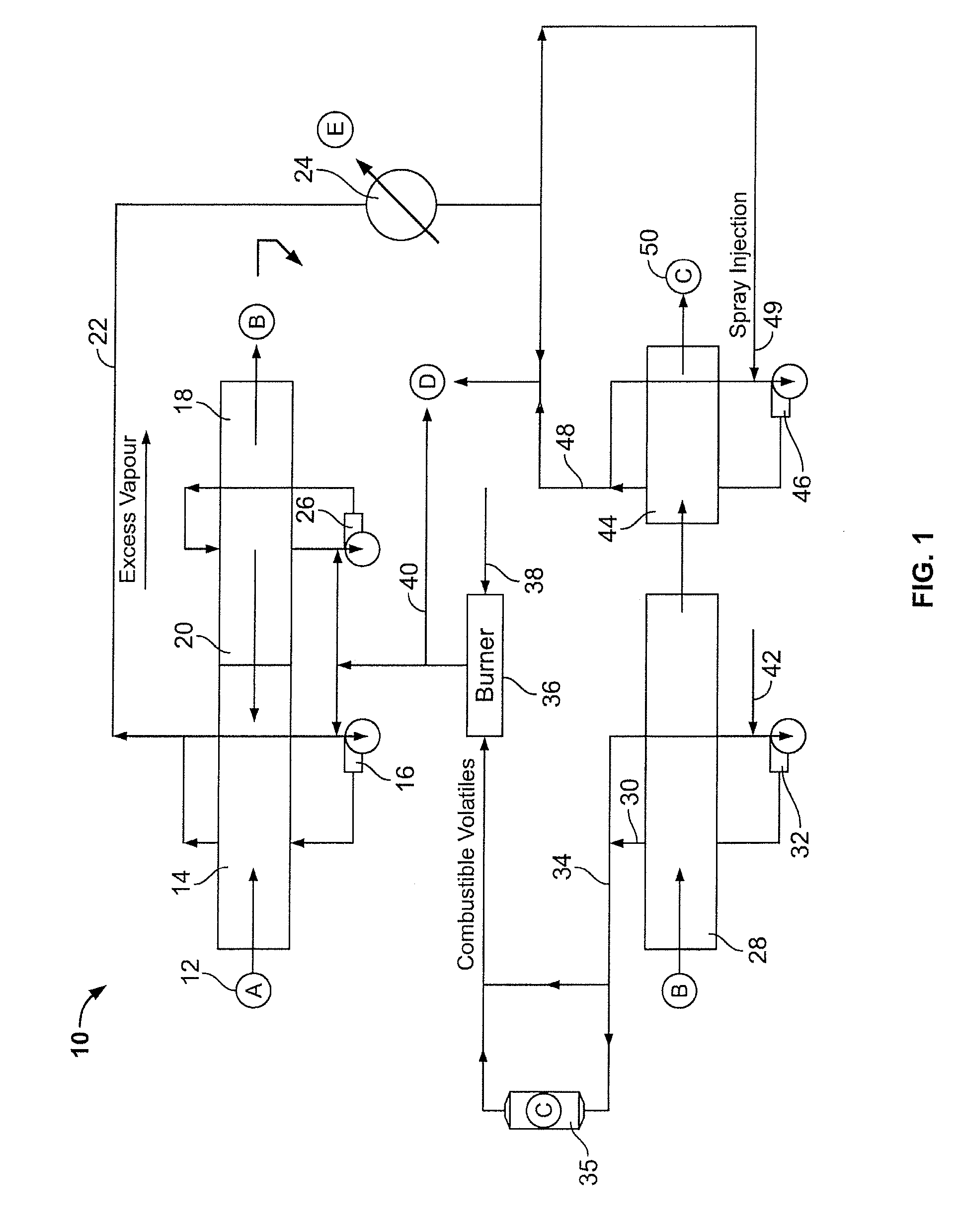

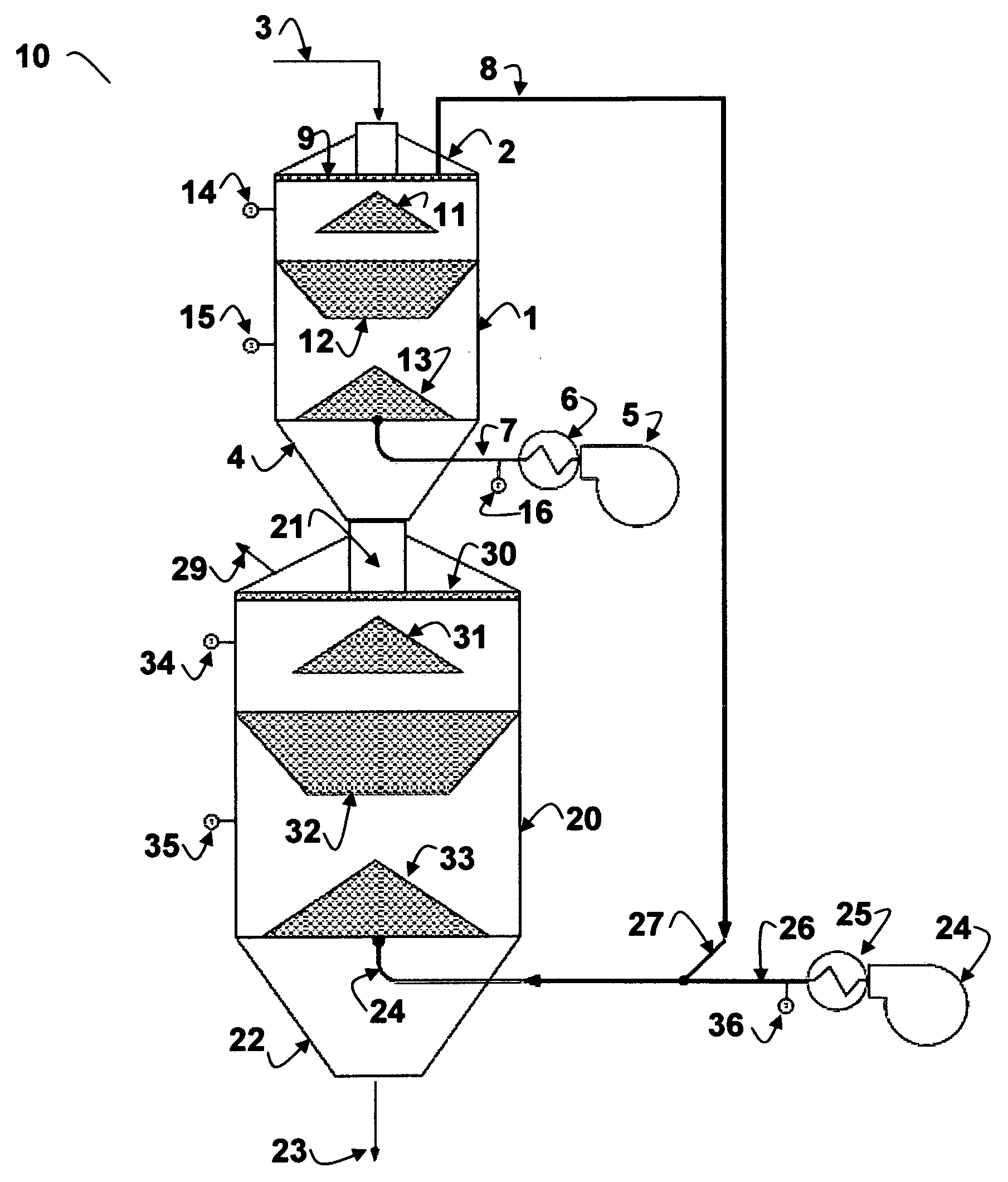

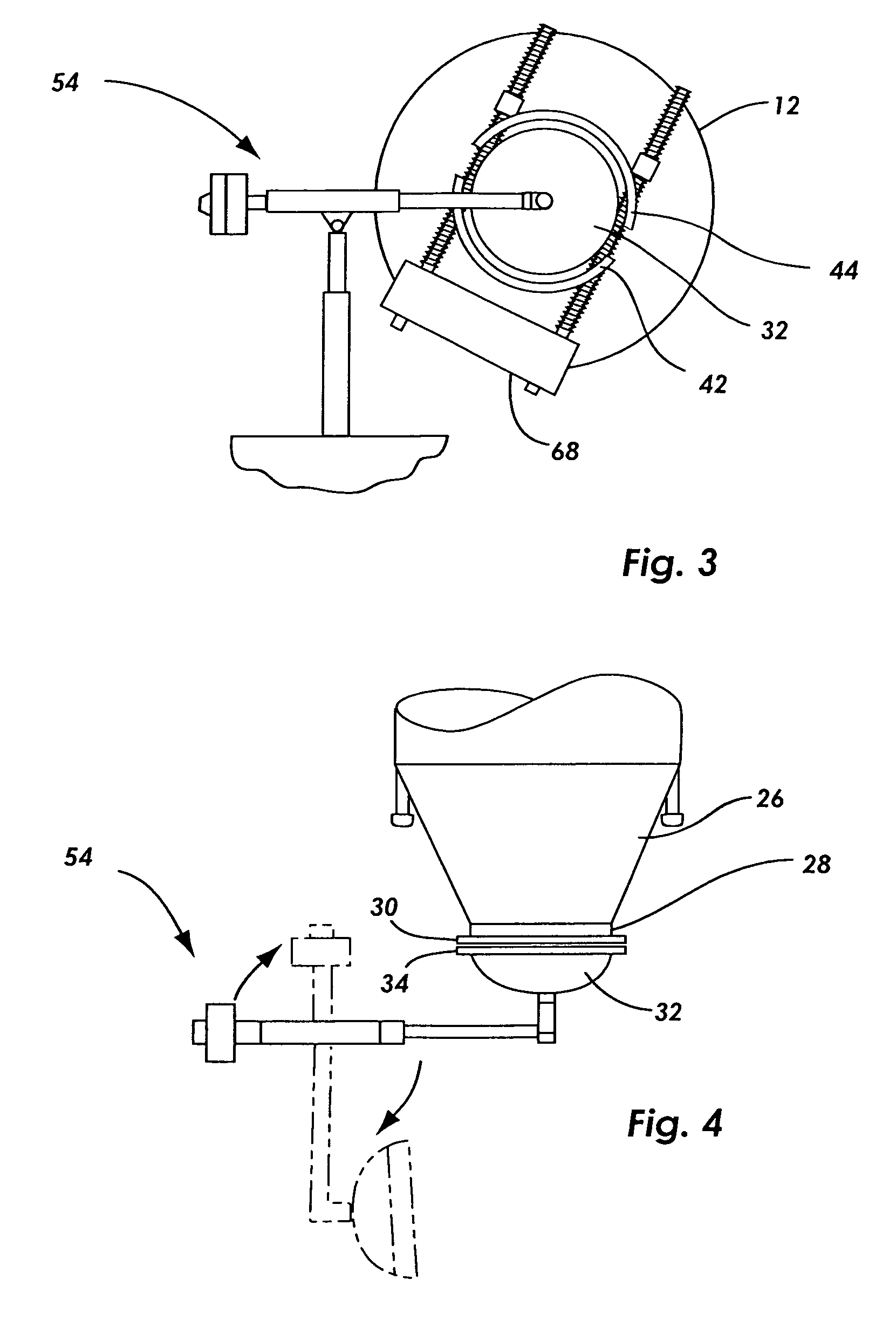

Two-stage static dryer for converting organic waste to solid fuel

InactiveUS20100126037A1Maintaining energy efficiencyAvoid ignitionDrying using combination processesDrying solid materials with heatThermal energySludge

An energy-efficient method and apparatus for drying pelletized, moist organic material is described. The method consists of a rapid, high temperature static drying process in a shallow bed, followed by traditional vertical static drying in a deep bed. Hot exhaust gas from the shallow-bed, hot-temperature static dryer is then recirculated to provide thermal energy to the deep-bed, warn-temperature static dryer. This invention can be used to convert wet, organic waste materials such as animal and poultry waste, municipal wastewater sludge, urban post-consumer food waste, or manufactured food byproducts and residuals into solid fuel.

Owner:MOSS WILLIAM H +1

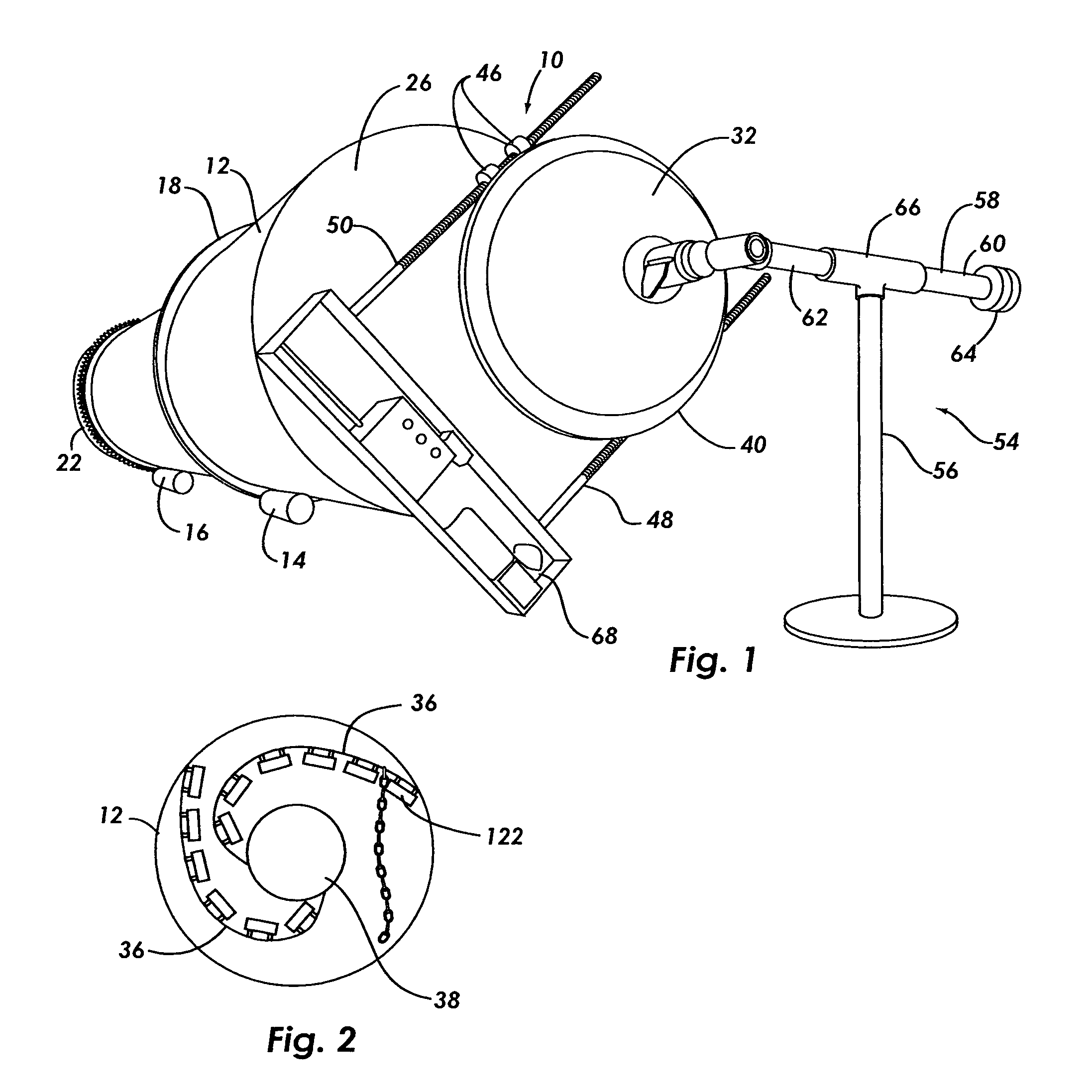

Angled reaction vessel

InactiveUS7745208B2Improve automationBioreactor/fermenter combinationsRotating receptacle mixersEnvironmental engineeringUrban solid waste

The invention is an apparatus and a process for treating biomass bearing material including municipal solid waste (MSW). The apparatus includes a reaction vessel held at an angle and configured for rotation and steam injection, with helically arranged internal flights, a self-aligning door closure, and a swing-away door assembly. It also includes a novel structure for shredding biomass bearing material attached to the edges of the flights. This structure is a number of projecting tooth like points and paddles.

Owner:BIOMASS WORLDWIDE GROUP

Heat circulation type drying-after-steaming device for gastrodia elata

InactiveCN107726734AImprove processing efficiencyGuaranteed to steam throughDrying gas arrangementsDrying chambers/containersSolenoid valveEngineering

The invention discloses a heat circulation type drying-after-steaming device for gastrodia elata. The heat circulation type drying-after-steaming device includes a base. The top of the base is fixedlyprovided with a working box through a bracket. An annular groove is formed in the side wall of the working box. A plurality of through holes are further evenly formed in the inner wall of the workingbox. A water outlet pipe is connected with the right side of the bottom of the working box. A solenoid valve is arranged on the water outlet pipe. A water tank is arranged on the right side of the top of the base. A draining pipe is connected with the lower right corner of the water tank. A valve is arranged on the draining pipe. The bottom end of the draining pipe is connected into the water tank. A heating box is arranged at the inner bottom of the working box. A plurality of through holes are evenly formed in the top and the side walls of the heating box. The heating box is further internally provided with a waterproof electric hot tray. A steamer is further arranged above the heating box. According to the heat circulation type drying-after-steaming device for gastrodia elata, two processes of steaming and drying gastrodia elata can be implemented, using is more convenient, and the processing efficiency of gastrodia elata is improved; and by forming the annular groove in the side wall of the working box, heat emitted to the periphery in the processing process of gastrodia elata is recycled and used, so that the steaming efficiency and drying efficiency are improved, and meanwhile energy is saved.

Owner:李欢欢

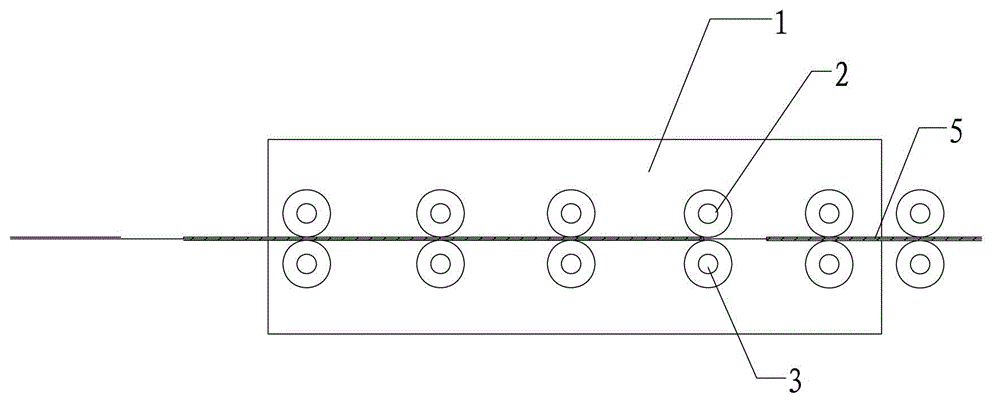

Drying device specially for coating

InactiveCN102744189AFully dryReduce replacement timeDrying solid materials without heatPretreated surfacesMechanical engineeringEnergy consumption

The invention relates to a drying device specially for coating and specifically for transmitting and drying a coated base material. The drying device comprises a box body and press roller assemblies, wherein the press roller assemblies are arranged in the box body and correspondingly arranged at both sides inside the box body; each press roller assembly comprises an upper press roller and a lower press roller which are correspondingly arranged top and bottom, the upper press roller and the lower press roller are driven by a power device to rotate, and a gap used for clamping the blank part of the side edge of the base material is arranged between the upper press roller and the lower press roller. In the invention, the blank with certain width of the edge of the base material is clamped through roller clamping type transmission, and therefore, liquid size is prevented from being influenced in thickness uniformity by flowing because a foil is bent and shifted; a single-layer drying box can not only realize that double surfaces of the base material are both dried and save the energy consumption more than 50 percent, but also save the replacement time of materials; and in addition, the drying device is compact in structure and is increased the operation efficiency.

Owner:SHENZHEN HAONENG TECH

Multifunctional humidity control drying plant and humidity control manner

PendingCN108072246AImprove applicabilityReduce lossesDrying gas arrangementsDrying solid materialsElectricityControl manner

The invention relates to the field of drying, in particular to a multifunctional humidity control drying plant and a humidity control manner. The multifunctional humidity control drying plant comprises a curing barn, and further comprises an air inlet door, a humidity discharging opening, a compressor, an evaporator, a condenser, an auxiliary condenser, a crossed flow heat exchanger, an air returning opening, an air outlet and a control module, and the auxiliary condenser is connected with the air returning opening; the condenser is connected with the auxiliary condenser so as to be connectedwith an internal circulation draught fan, the air outlet is connected with the curing barn, the crossed flow heat exchanger is connected with the air returning opening so as to be connected with the air inlet door and the humidity discharging opening, and the evaporator is connected with the humidity discharging opening so as to be connected with an external circulation draught fan; and the compressor is connected with the evaporator, the condenser and the auxiliary condenser, and the control module is electrically connected with the compressor, the internal circulation draught fan, the external circulation draught fan, the air inlet door, the humidity discharging opening and the auxiliary condenser. By means of the multifunctional humidity control drying plant, multiple humidity control manners can be achieved in the drying process, free switching can be achieved, and the aims of improving the drying efficiency and enlarging the applicability are achieved.

Owner:云南中海路德清洁技术有限公司

Straw pulverizer

InactiveCN107318399ASmash thoroughlyEasy to cleanHollow article cleaningCuttersHelical bladeMotor shaft

The invention discloses a straw pulverizer, which comprises a feeding box and a crushing box, a lifting cylinder and a driving auger are connected above the feeding box, a cutting motor is installed on the upper surface of the pulverizing box, and the cutting motor is connected with a cutting shaft, and the left side of the pulverizing box is The side outer wall is equidistantly equipped with rotating shaft motor 1, rotating shaft motor 2 and rotating shaft motor 3, the right end of rotating shaft motor 1 is connected with rotating shaft 1, the right end of rotating shaft motor 2 is connected with rotating shaft 2, the right end of rotating shaft motor 3 is connected with rotating shaft 3, rotating shaft The first outer surface is equipped with a spiral blade, the second outer surface of the rotating shaft is equipped with a bidirectional cutting knife, the third outer surface of the rotating shaft is equipped with a discharge spiral blade, the left end of the feeding box is equipped with a heating power supply; the lower right corner of the crushing box is equipped with a discharge port. The invention can crush the stalks more thoroughly; and dry the stalks with moisture; the top of the crushing box is equipped with a spray head, which is convenient for cleaning.

Owner:何天行

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com