Patents

Literature

251results about How to "Increase the drying area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

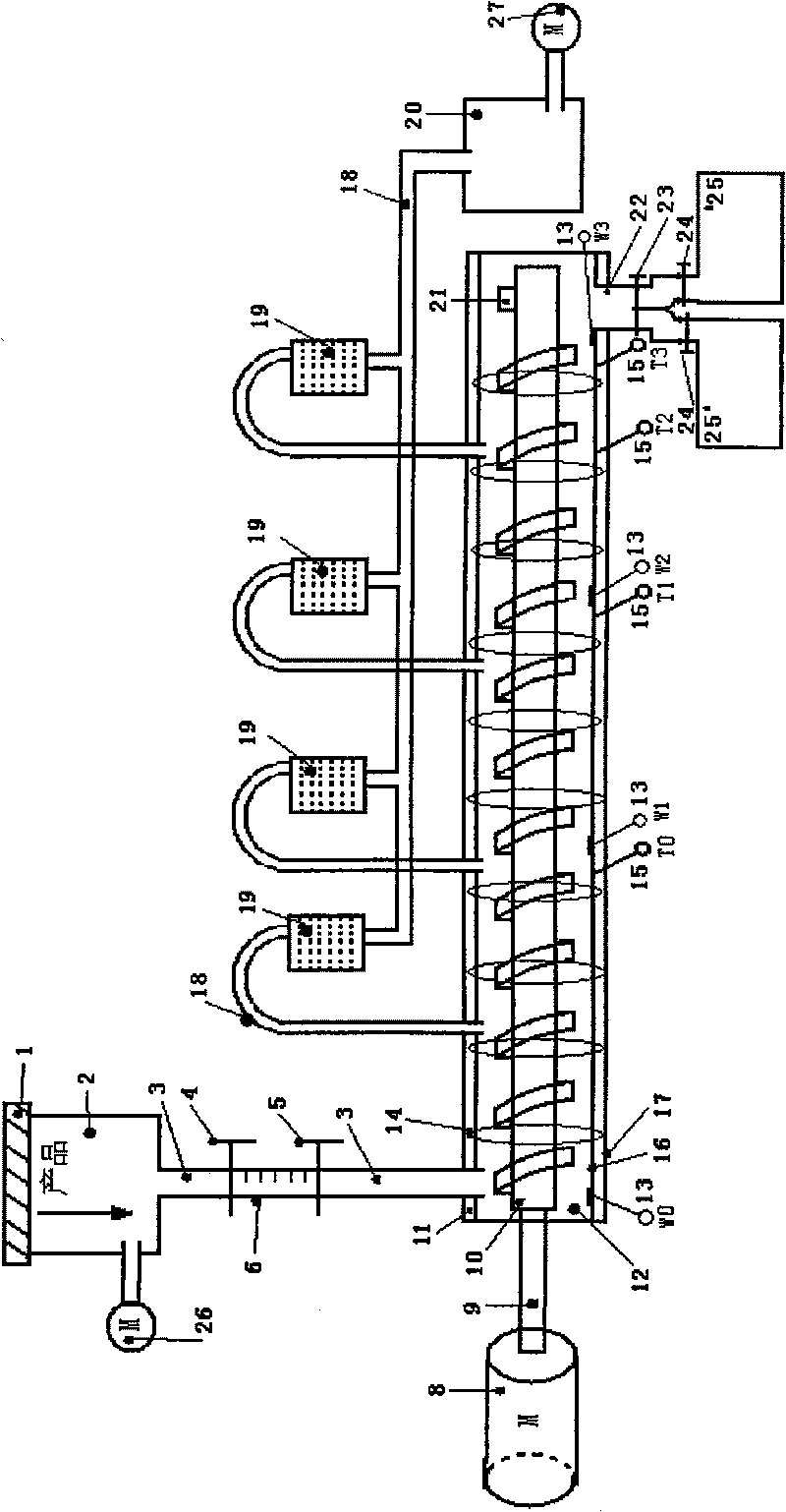

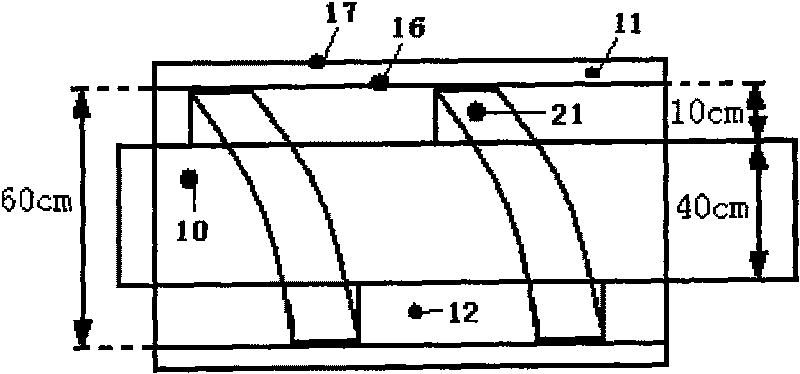

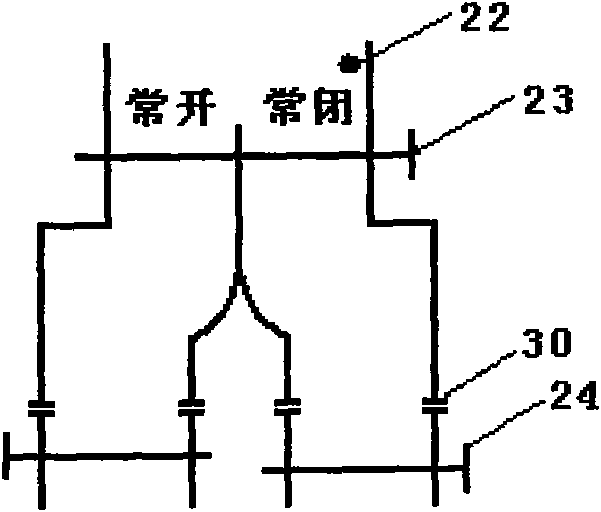

Vacuum dryer for screw to convey materials and method thereof

InactiveCN101762146AIncrease temperature differenceImprove qualityDrying using combination processesHeating arrangementElectrical resistance and conductanceSteam pressure

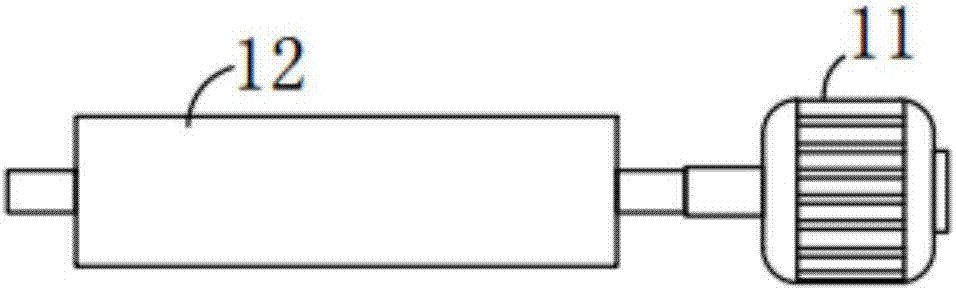

The invention discloses a vacuum dryer for a screw to convey materials and a method thereof. The dryer comprises a vacuum drying device and a controller; the controller mainly comprising PLC and an upper computer, timely controls the rotate speed of a screw and the heating power of a ten-section resistance according to the detection data of the temperature and the humidity of the materials. The invention adopts a subsectional heating and drying control strategy giving consideration to both the drying quality and the production efficiency, comprises PID and predictive control, and a drying control strategy of the heating control and the linkage of the screw rotating speed; and the drying precision can be 98.8%. The invention is characterized by drying the inflammable and explosive materials and materials easy to be decomposed at a high temperature and no-air contacted materials. Furthermore, the vacuum operation reduces the steam pressure and the temperature, improves the temperature range between heating elements and the dried materials; the screw conveying increases the drying area, is benefit to evenly heating; a mechanism of screw rotating speed linkage based on the subsectional drying control strategy can not only ensure the high quality of the dried materials but also has high production efficiency.

Owner:ZHEJIANG UNIV

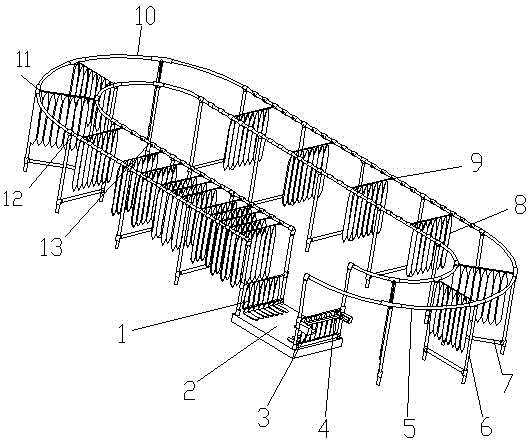

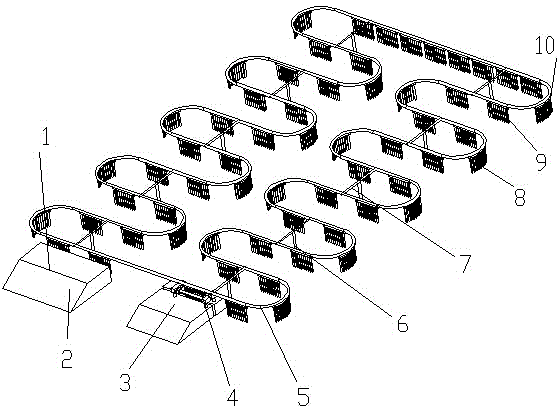

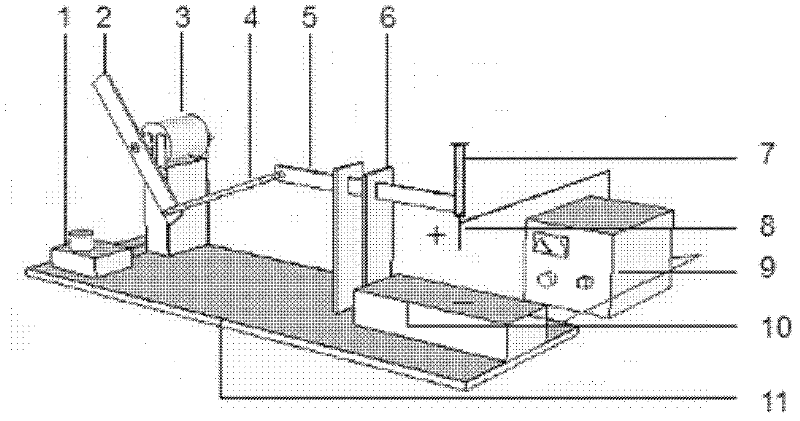

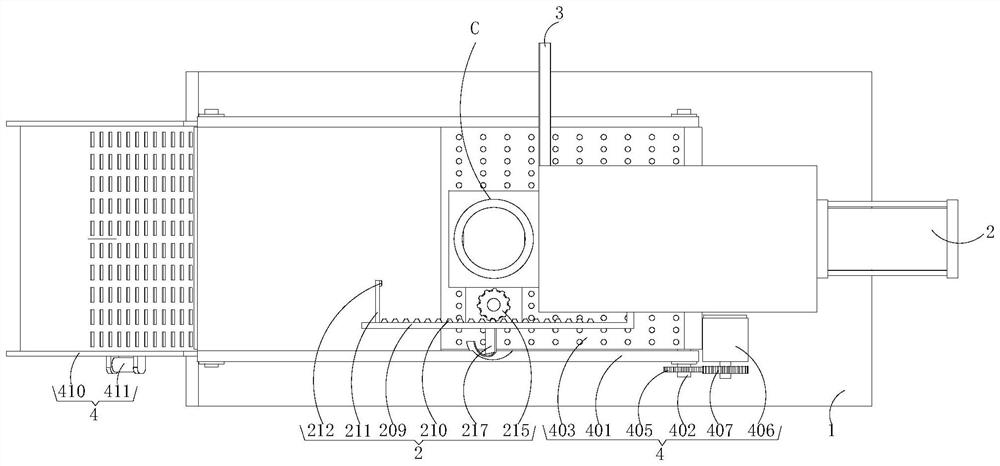

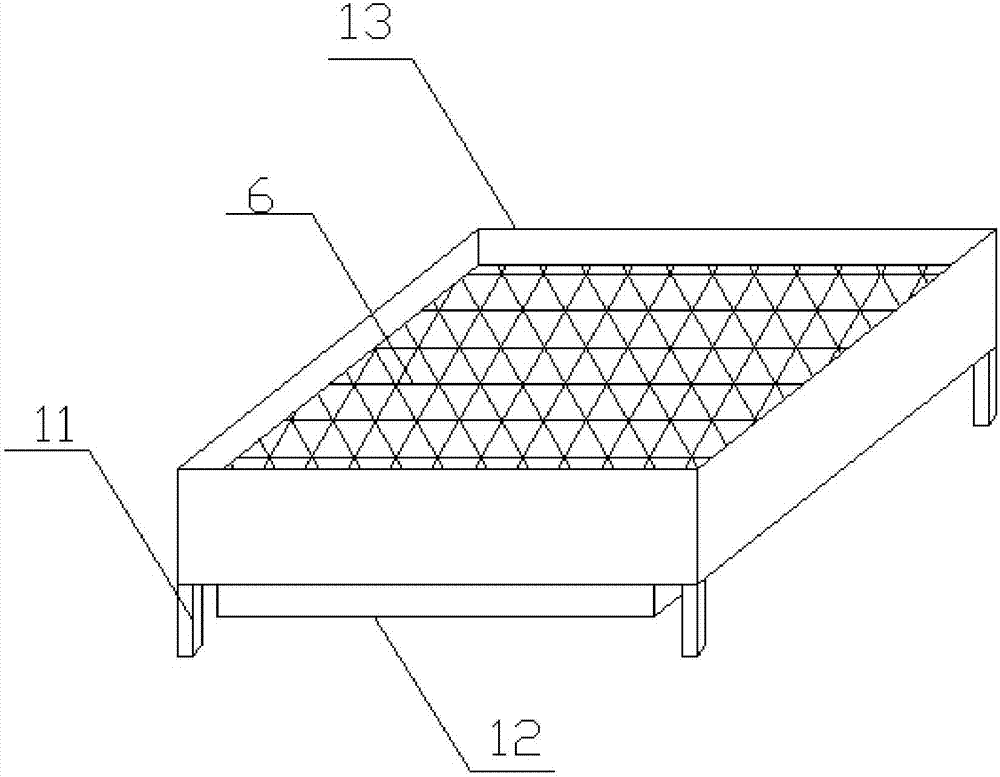

Automation equipment for naturally airing kelp

InactiveCN104055199AImprove drying efficiencyGuaranteed qualityFood treatmentChain conveyorAutomation

The invention discloses automation equipment for naturally airing kelp. The automation equipment comprises an airing system and a cutting system, wherein the airing system comprises a chain conveyor belt used for hanging kelp bunches; a plurality of seeding rope clamping heads used for clamping the kelp bunches are arranged on the chain conveyor belt; the beginning end of the chain conveyor belt is a feeding end, and the terminal of the chain conveyor belt is a cutting end; the cutting end is connected with the cutting system; the kelp bunches are moved from the feeding end to the cutting end of the chain conveyor belt. The automation equipment can improve the kelp airing efficiency and ensure the product quality, is relatively low in cost, saves labor greatly, and is very suitable for popularization and utilization.

Owner:SHANDONG UNIV

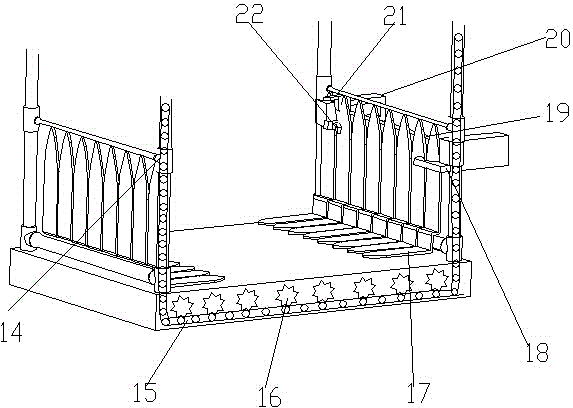

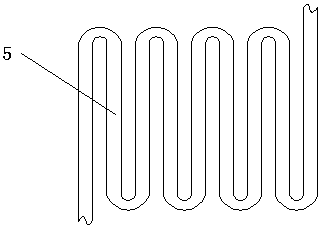

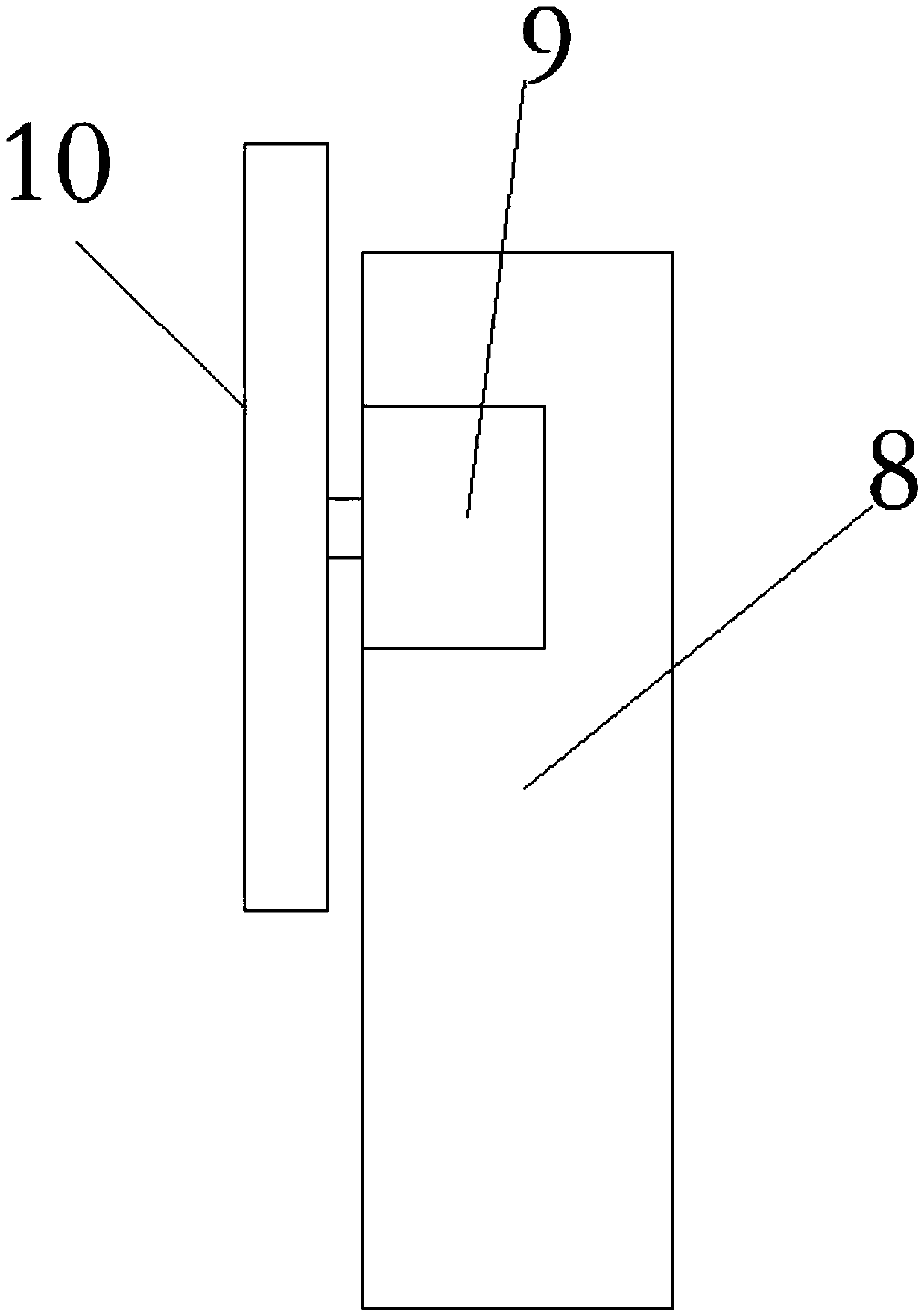

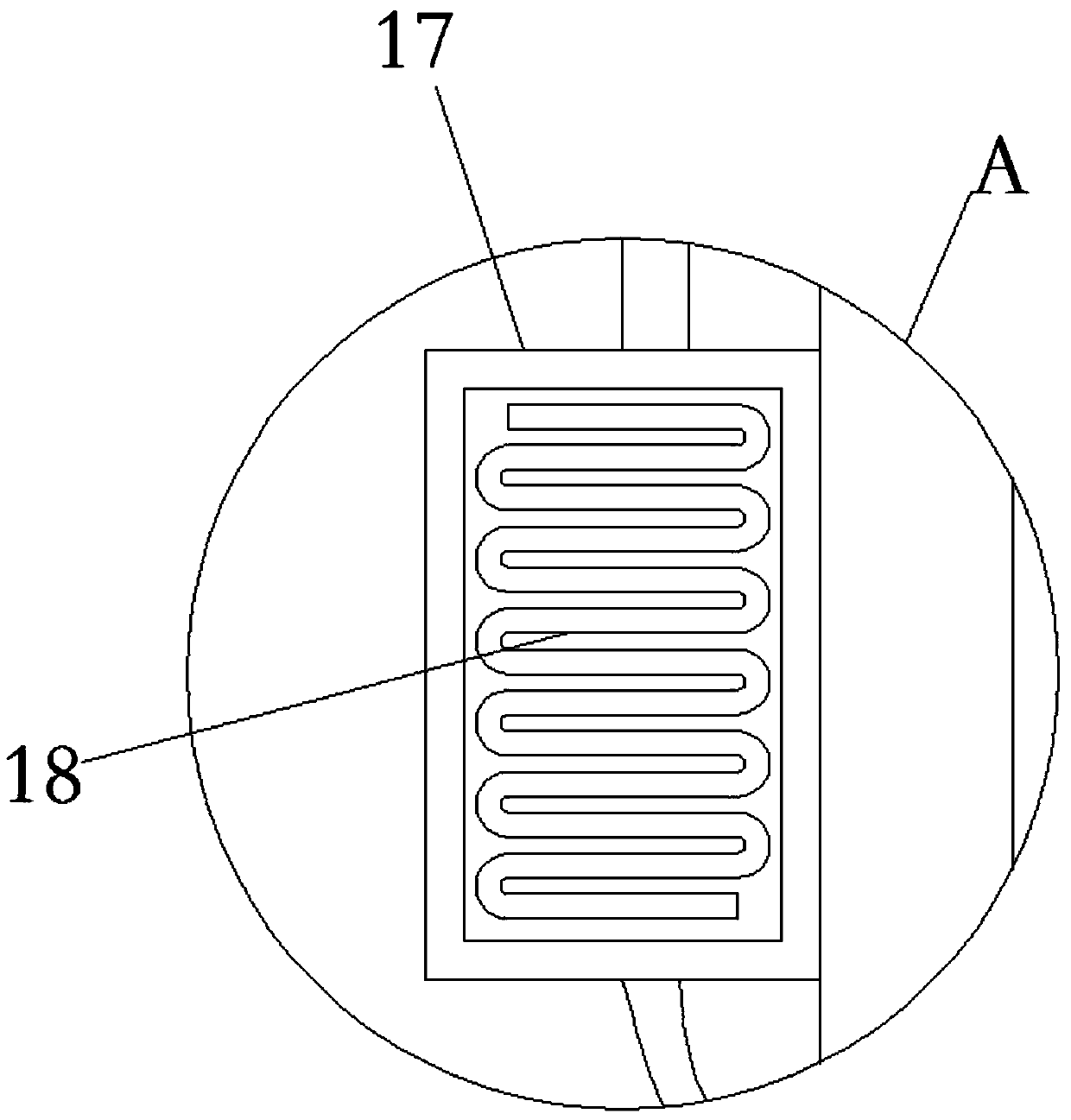

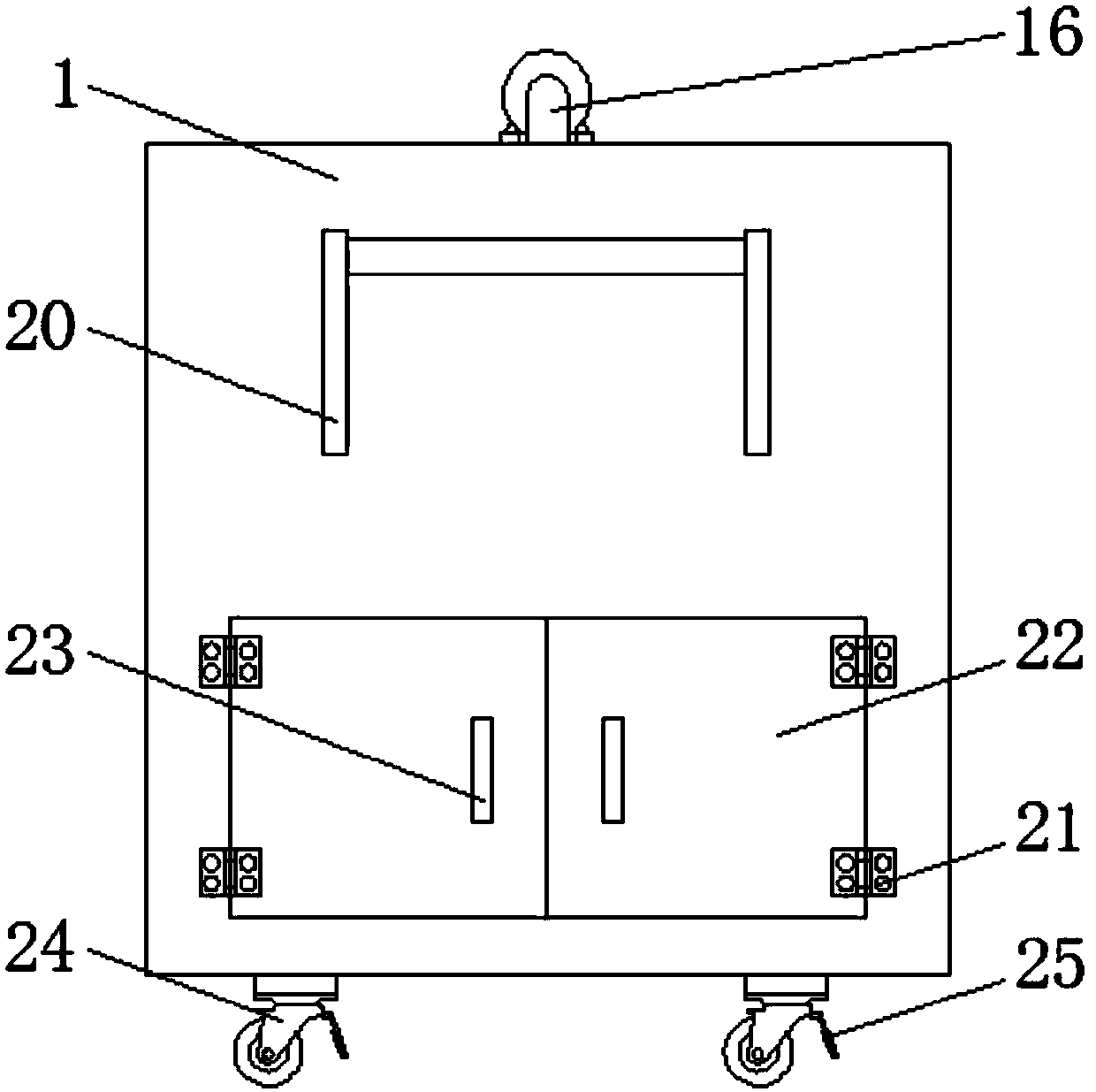

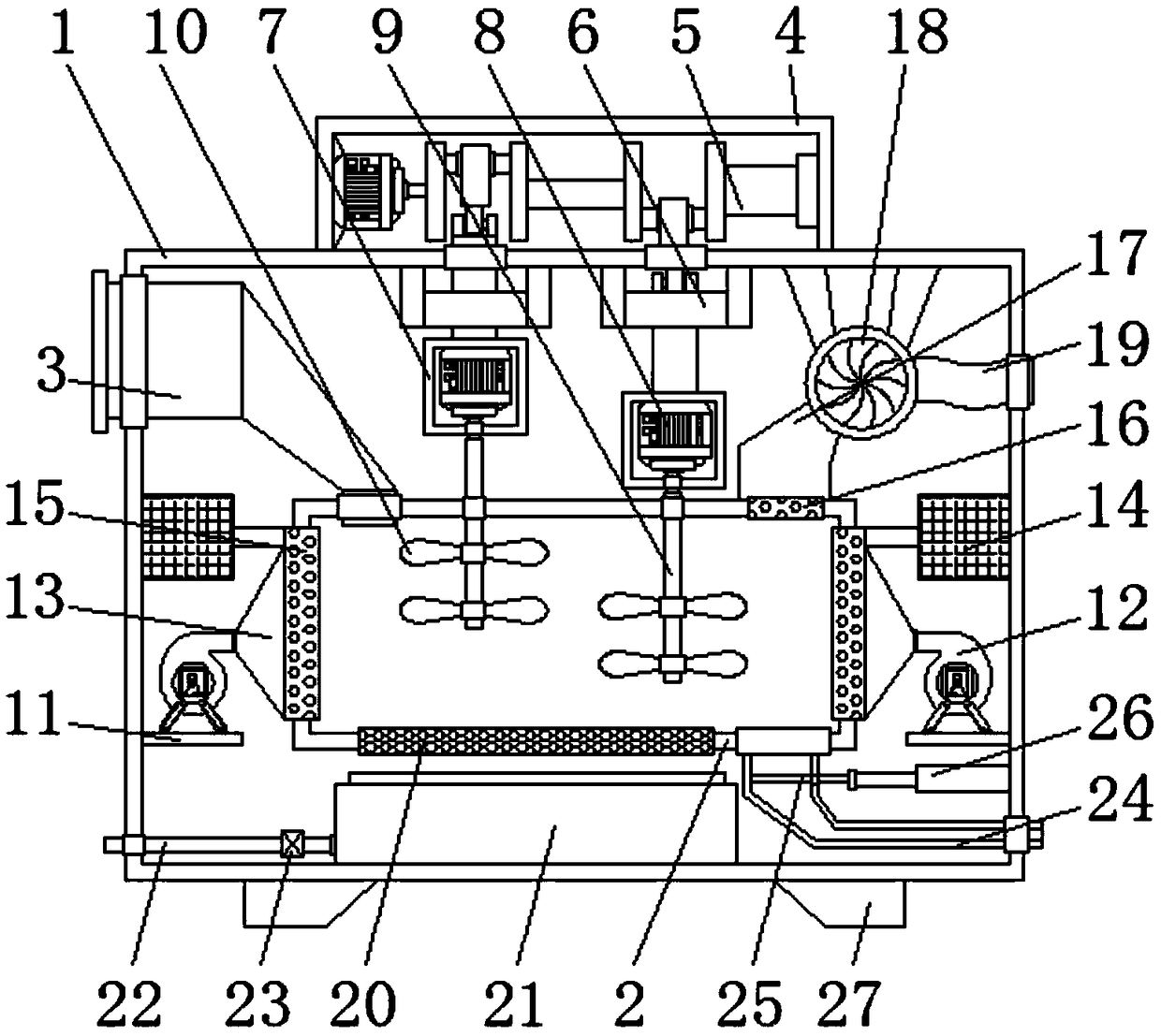

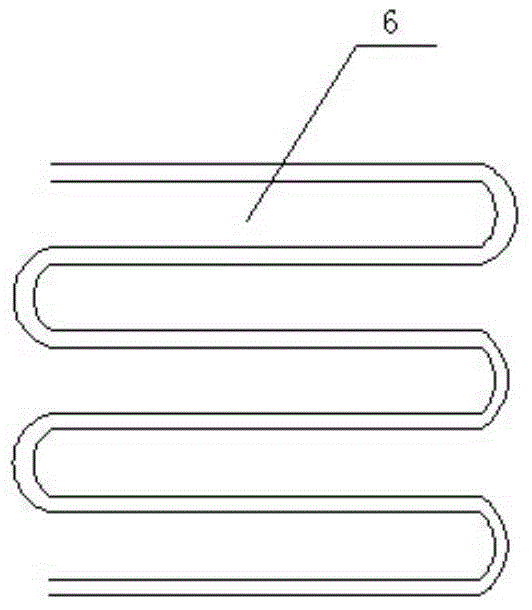

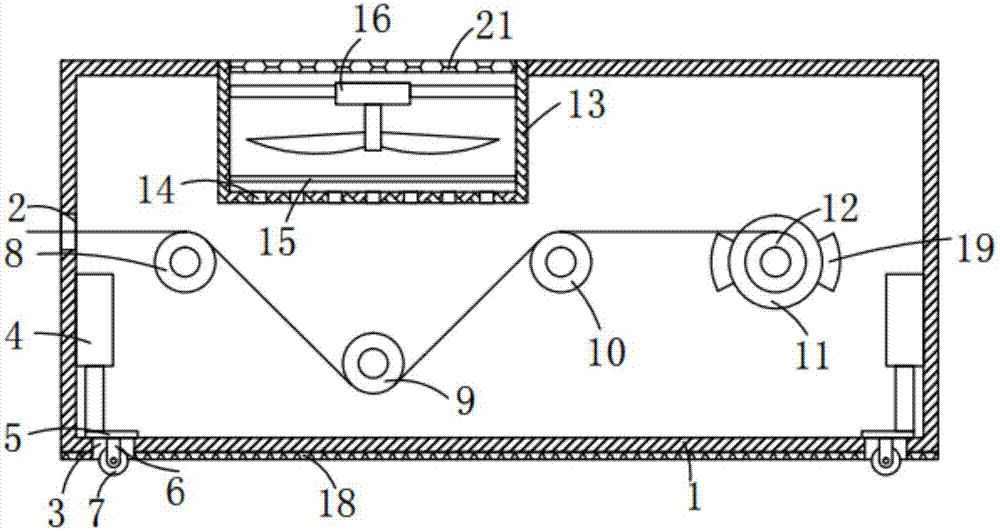

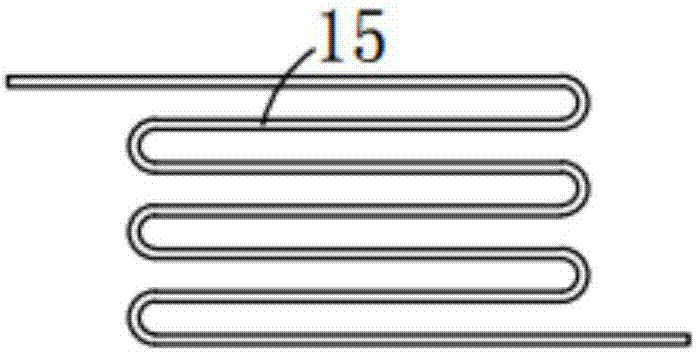

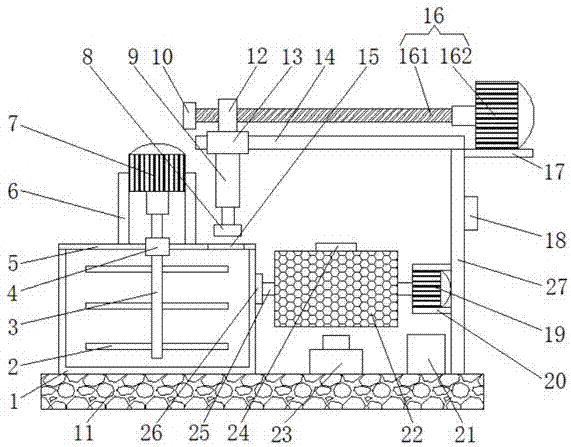

Efficient drying device for textile processing

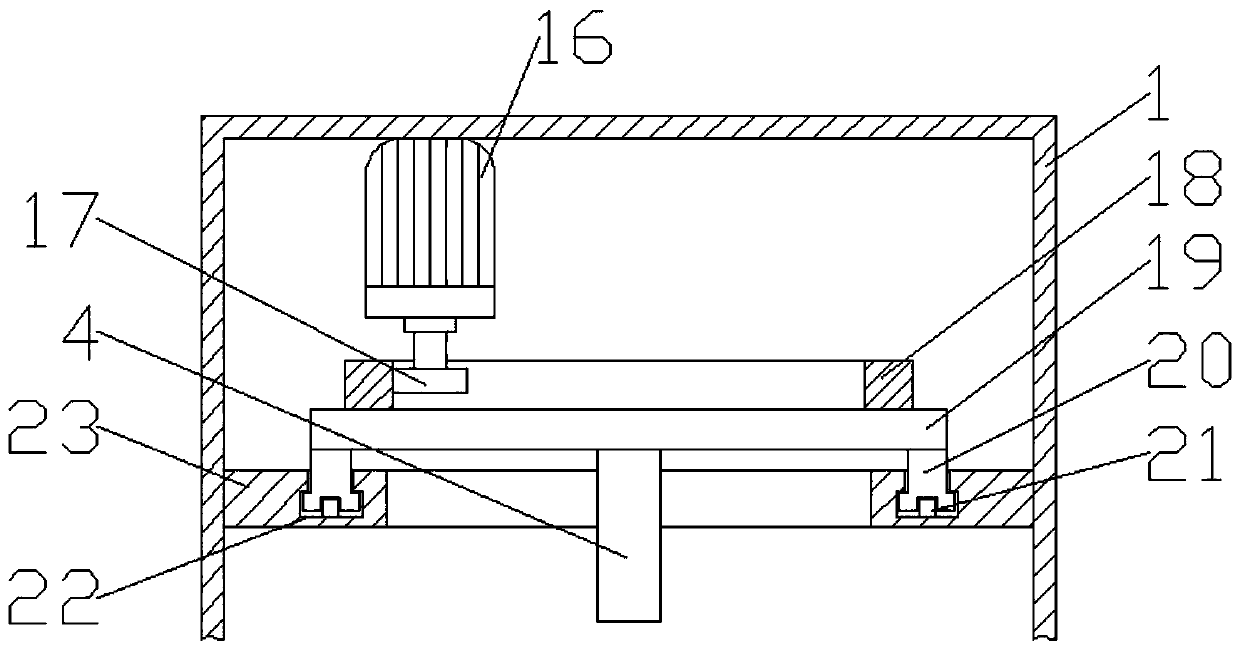

InactiveCN107655294AIncrease the drying areaAvoid damageDrying gas arrangementsDrying machines with progressive movementsLeather beltTextile processing

The invention discloses a high-efficiency drying device for textile processing, which comprises a base, a first belt and a second belt, the top of the base is fixedly connected with a connecting block, the top of the connecting block is fixedly connected with an organic case, and the Fans are fixedly connected to both sides of the top of the inner chamber of the case, and the fan runs through the case and extends to the outside of the case. An S-shaped heating pipe is installed on the top of the inner chamber of the case and directly below the fan. The front surface of the case Combination rollers are arranged, and the surface of the combination rollers is driven and connected with textiles. This high-efficiency drying device for textile processing, through the arrangement of S-shaped heating tubes, textiles, reciprocating screw rods, and heating sheets, jointly constructs a high-efficiency drying device for textile processing that can dry both sides at the same time. The device expands the drying area of the textiles, and the combination of the above structures solves the problem that the two sides of the high-efficiency textile processing drying device cannot be dried at the same time.

Owner:薛帅龙

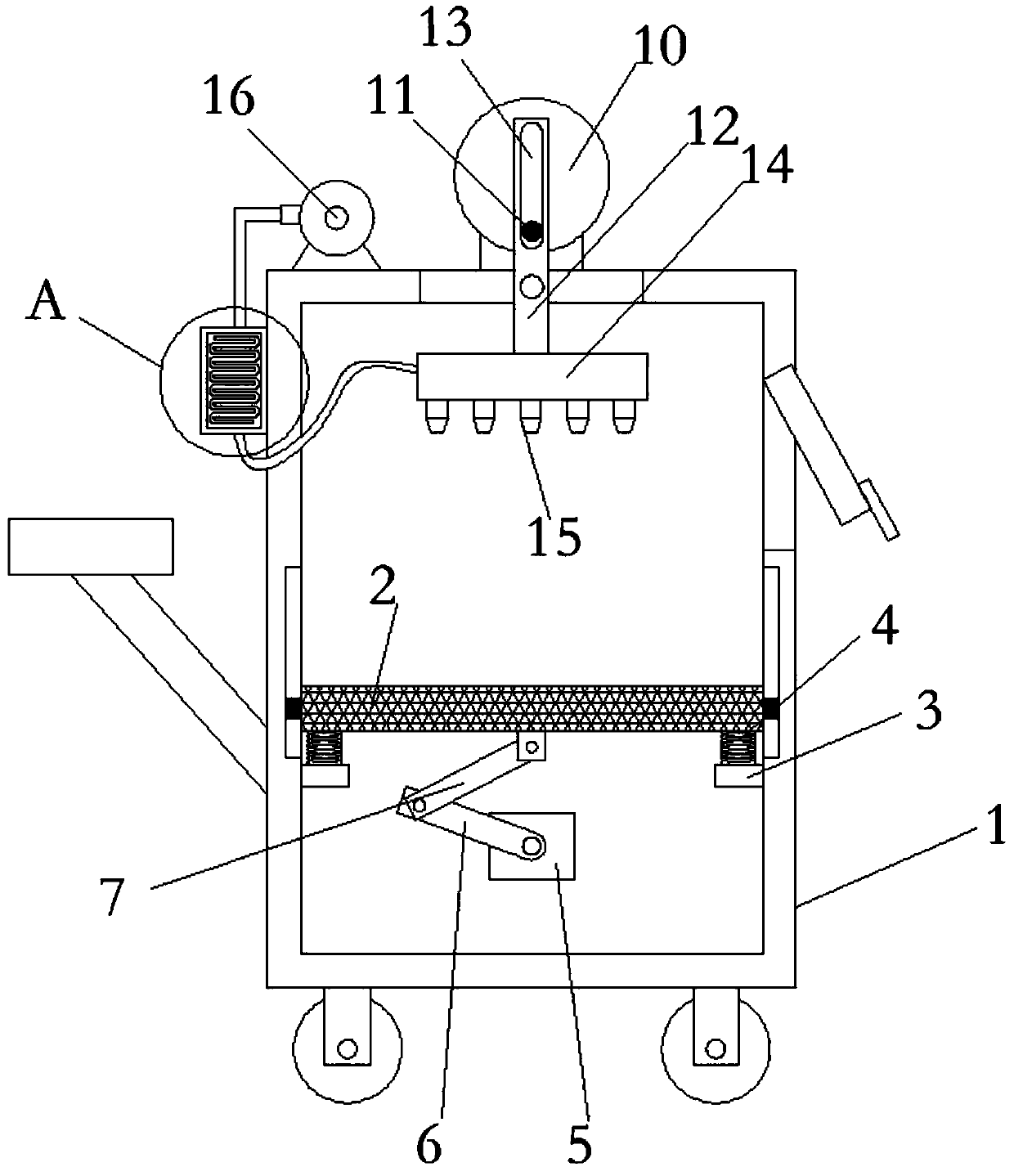

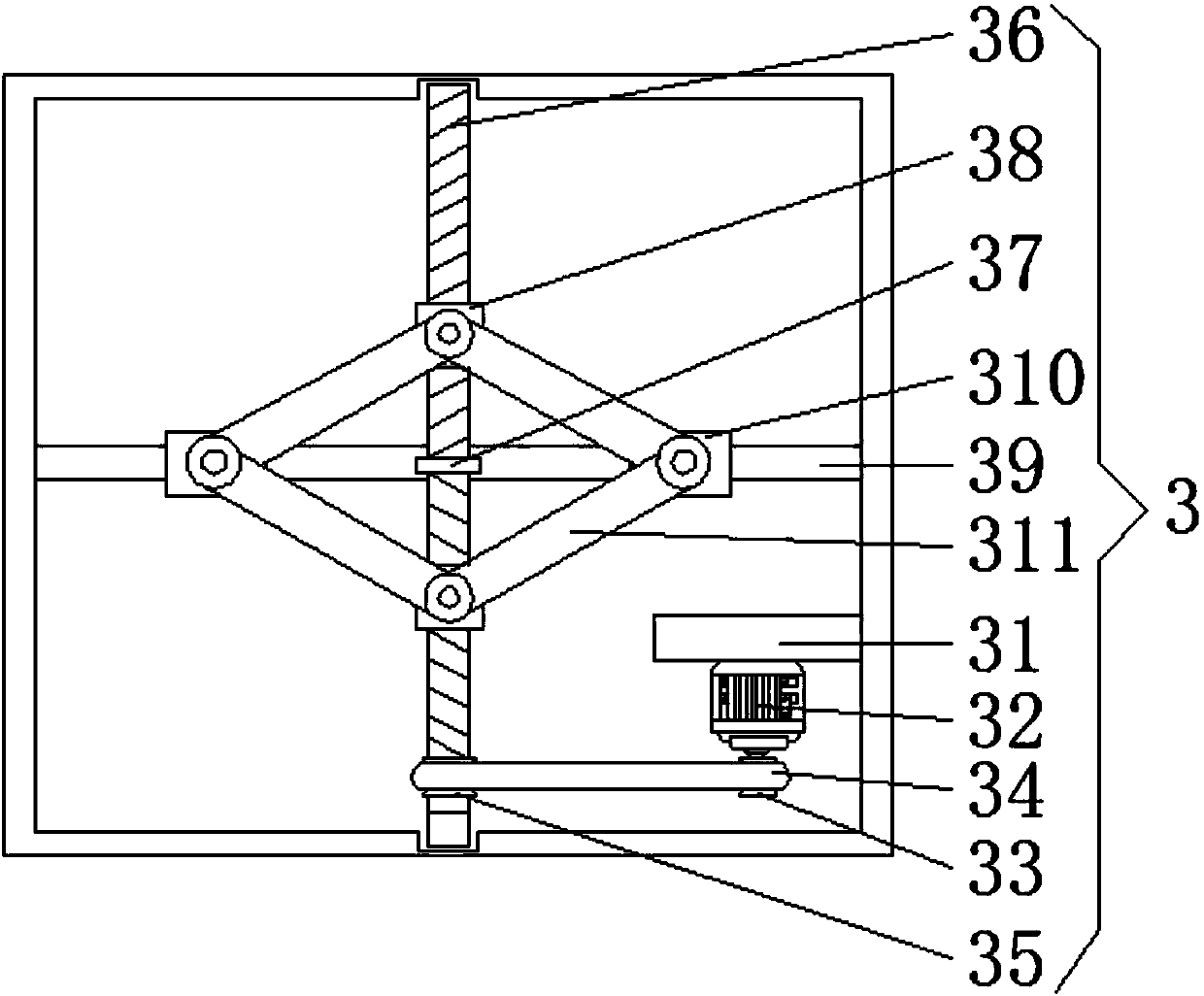

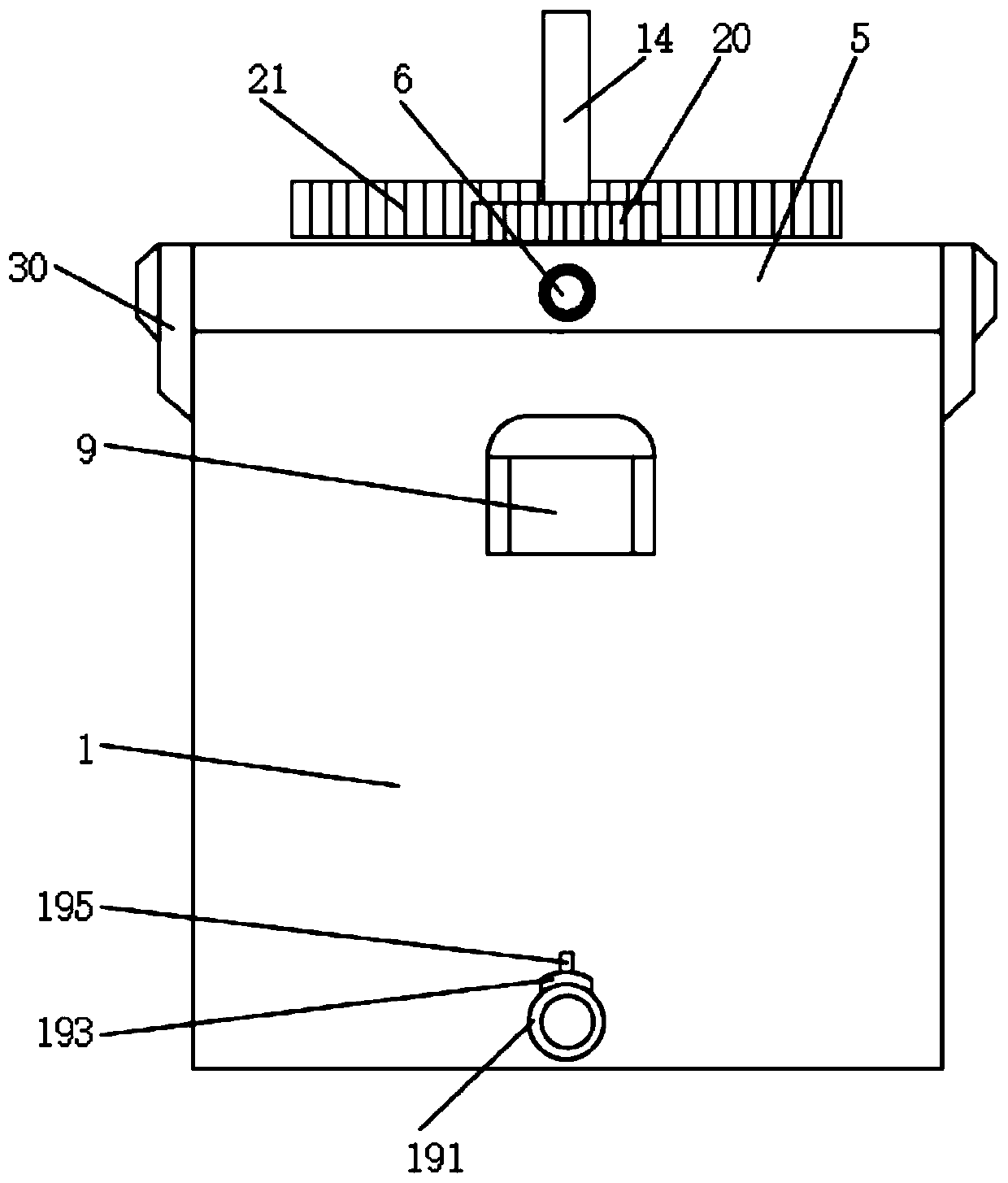

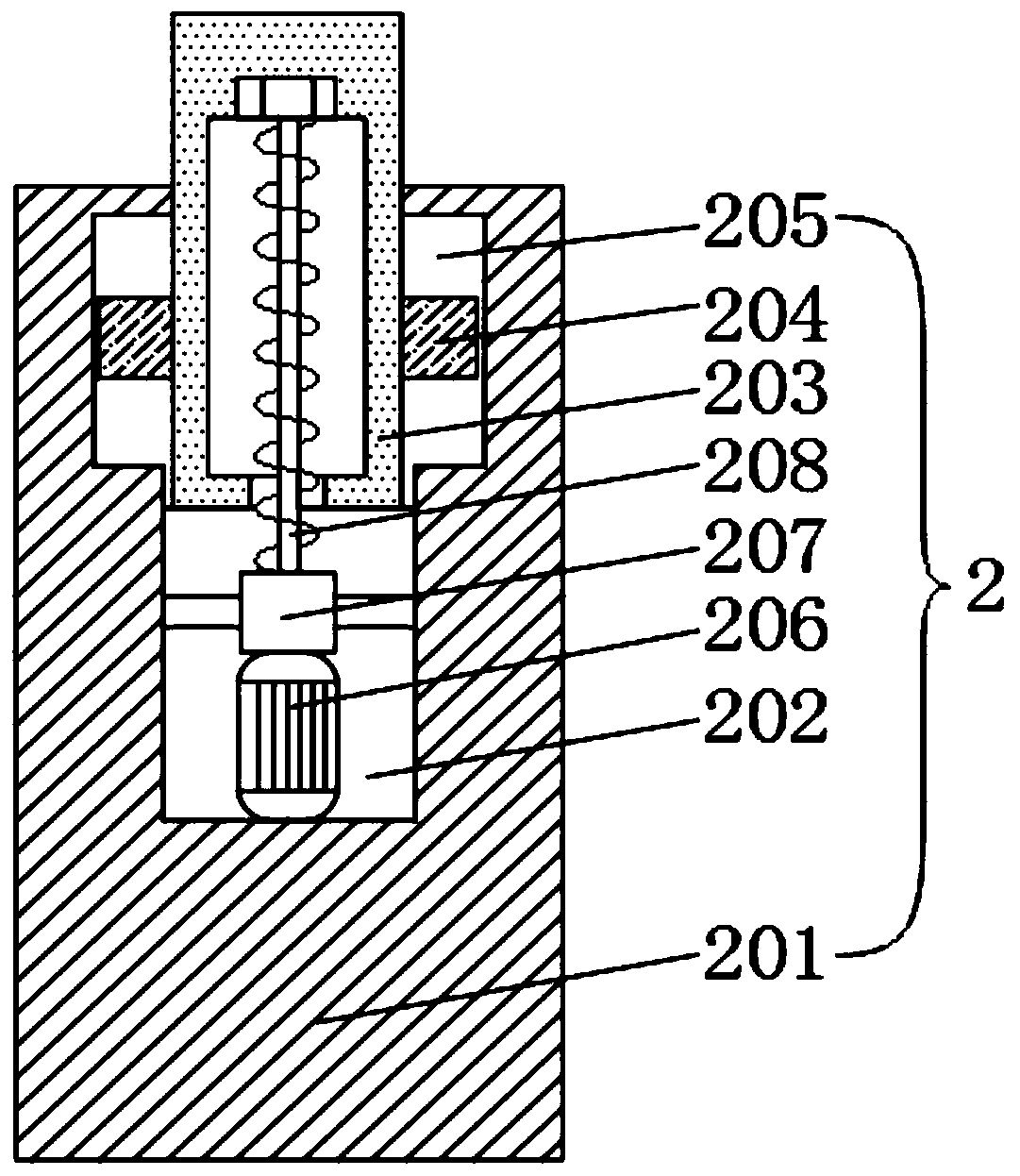

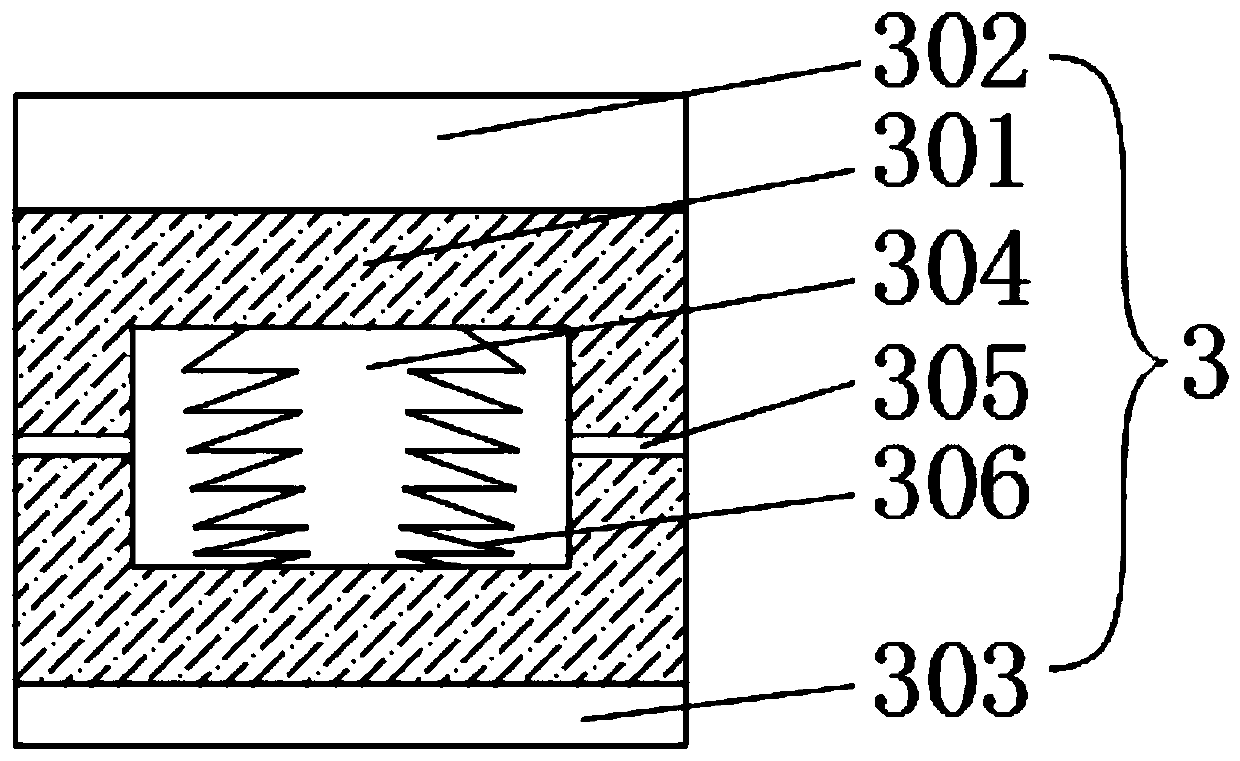

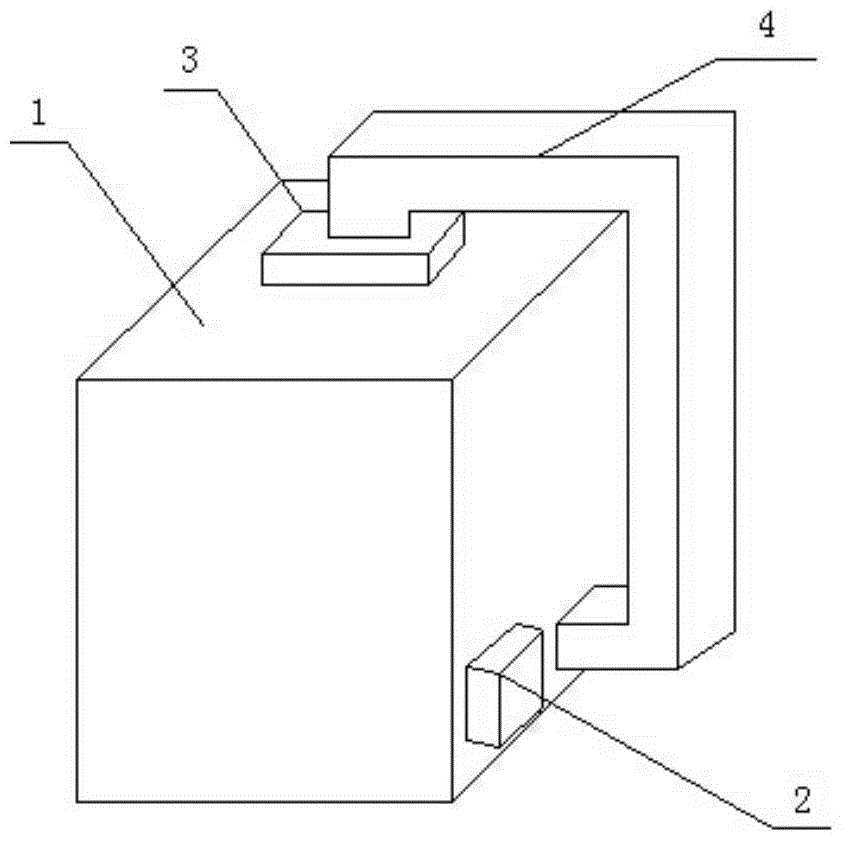

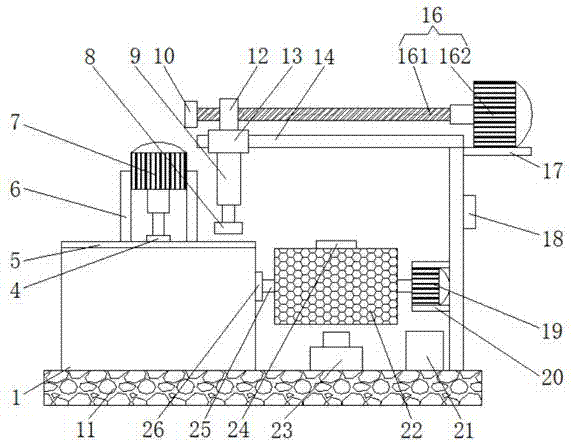

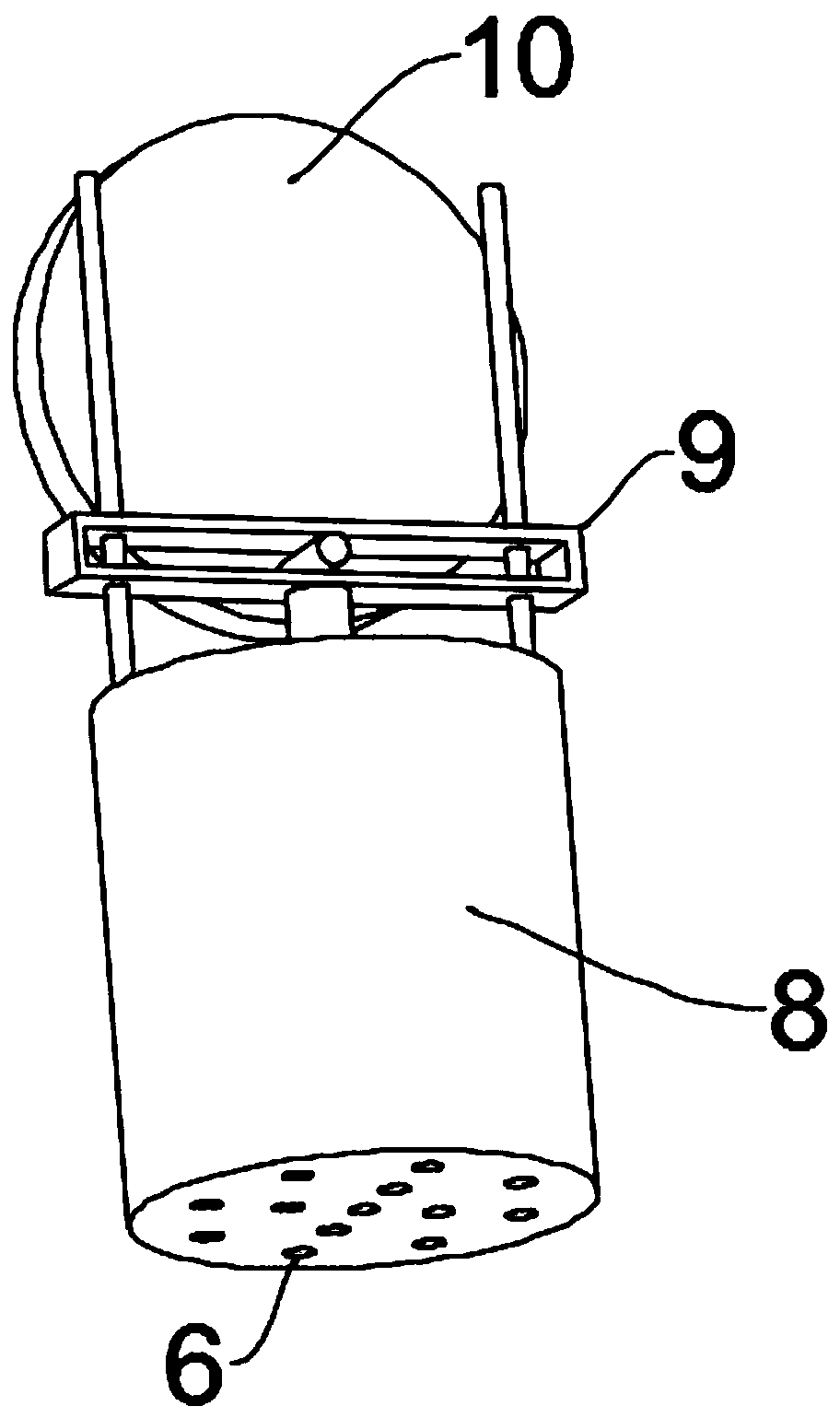

Drying device for traditional Chinese medicinal materials

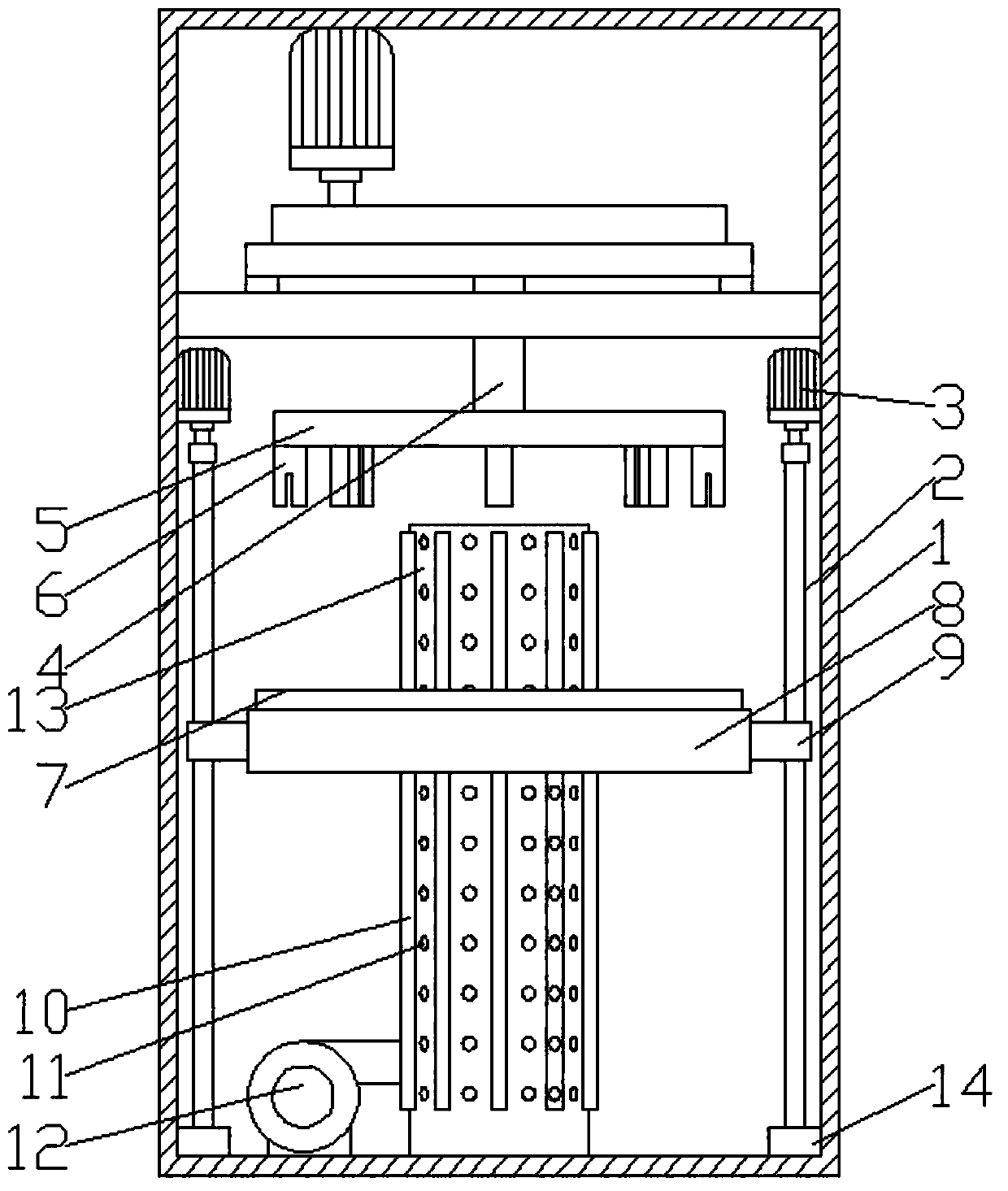

InactiveCN108679976AIncrease the drying areaEasy to useDrying gas arrangementsDrying solid materialsMedicinal herbsOperations management

The invention discloses a drying device for traditional Chinese medicinal materials. The drying device for the traditional Chinese medicinal materials comprises a drying box. The inner wall of the drying box is in sliding connection with a placement net plate. The positions, corresponding to the lower portion of the placement net plate, of the inner wall of the drying box are fixedly connected with supporting annular plates. The upper ends of the supporting annular plates are fixedly connected with the lower end of the placement net plate through a plurality of buffering springs. The inner wall of the lower end of the drying box is fixedly connected with a first motor. An output shaft of the first motor is fixedly connected with a rotating rod. The end, far away from the first motor, of the rotating rod is rotationally connected with a push-pull rod. The end, far away from the rotating rod, of the push-pull rod is rotationally connected with the lower end of the placement net plate. The upper end of the drying box is fixedly connected with a stand column. The side wall of the stand column is fixedly provided with a second motor in an embedded manner. An output shaft of the second motor is fixedly connected with a rotary table. The surface of the rotary table is fixedly connected with an eccentric rod. According to the drying device for the traditional Chinese medicinal materials, the drying area can be greatly increased, and the drying efficiency of the medicinal materials is higher.

Owner:广西奕琦科技有限公司

Textile cotton yarn drying machine

InactiveCN108036620AIncrease the drying areaImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsYarnAir blower

The invention discloses a textile cotton yarn drying machine, and relates to the technical field of textile machinery. The textile cotton yarn drying machine comprises a tank body, and a drying tank is fixedly connected to the bottom of the inner wall of the tank body; an adjusting device is fixedly connected to the inner wall of the drying tank; an air blower is fixedly connected to the top of the adjusting device; an air outlet is formed in the top of the drying tank; heating tanks are fixedly connected to the two sides of the top of the inner wall of the drying tank; a heating resistance wire is fixedly connected in the position, between the two heating tanks, on the surface of the air outlet; a cloth guide roller mechanism is fixedly connected in the tank body; and a fixed rack is fixedly connected to one side of the inner wall of the tank body. According to the textile cotton yarn drying machine, the drying area of cotton yarns is increased, conversion of heat is maximumly utilized, a quite good drying effect is achieved, a dehumidification function is achieved, a dry air circulation environment can be created, drying efficiency of cotton yarns is improved, collection and arrangement functions are achieved, and utilization is convenient.

Owner:彭素珍

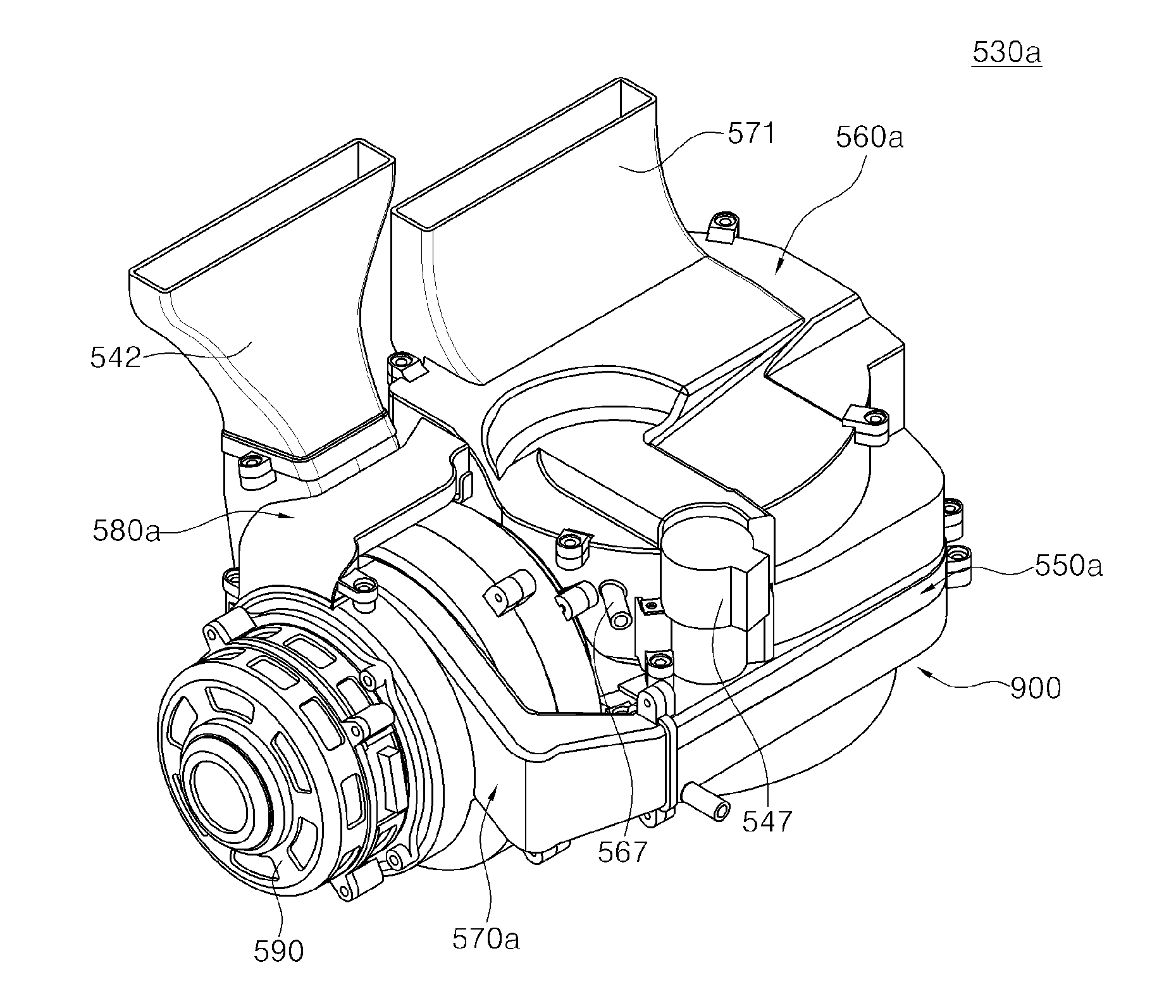

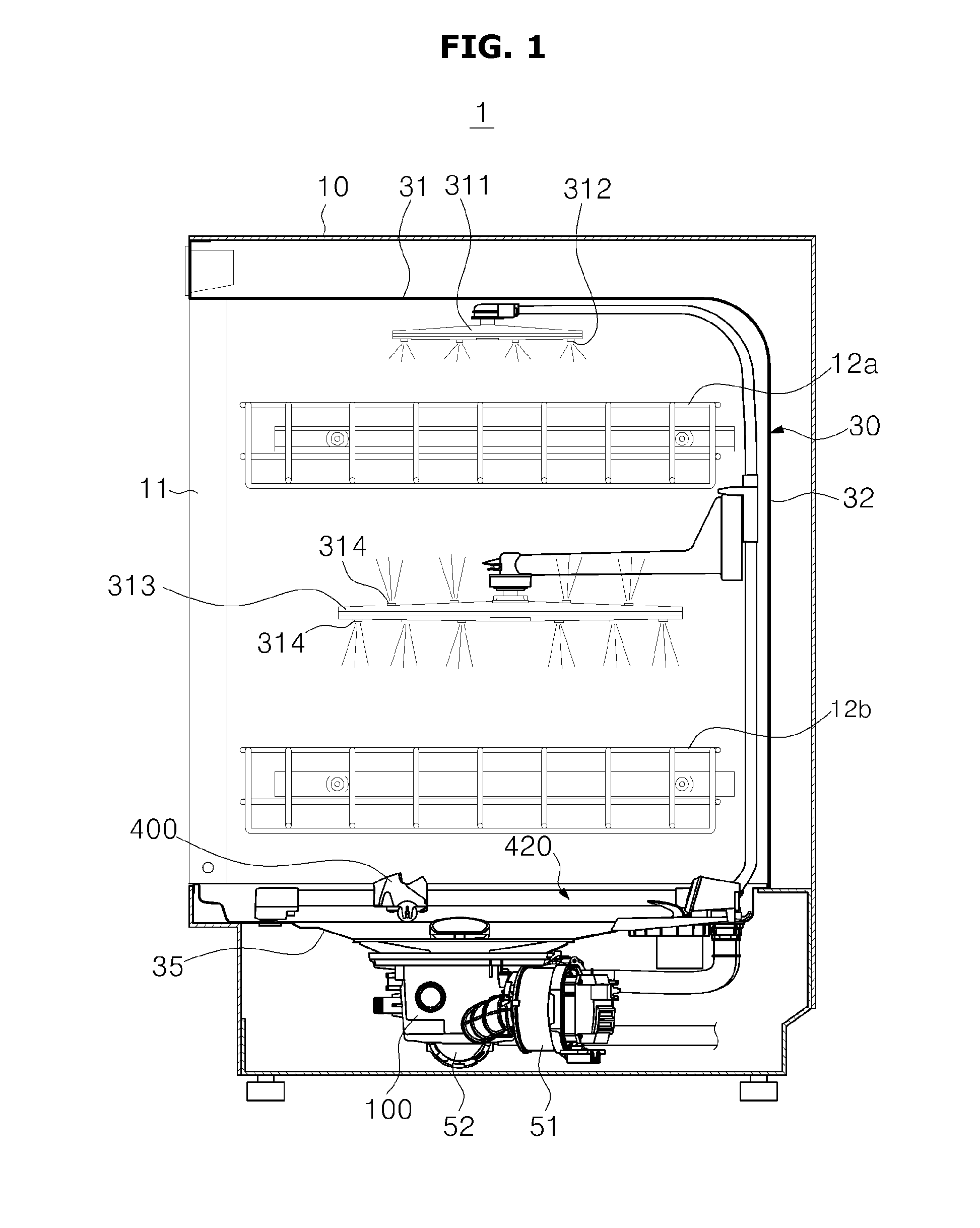

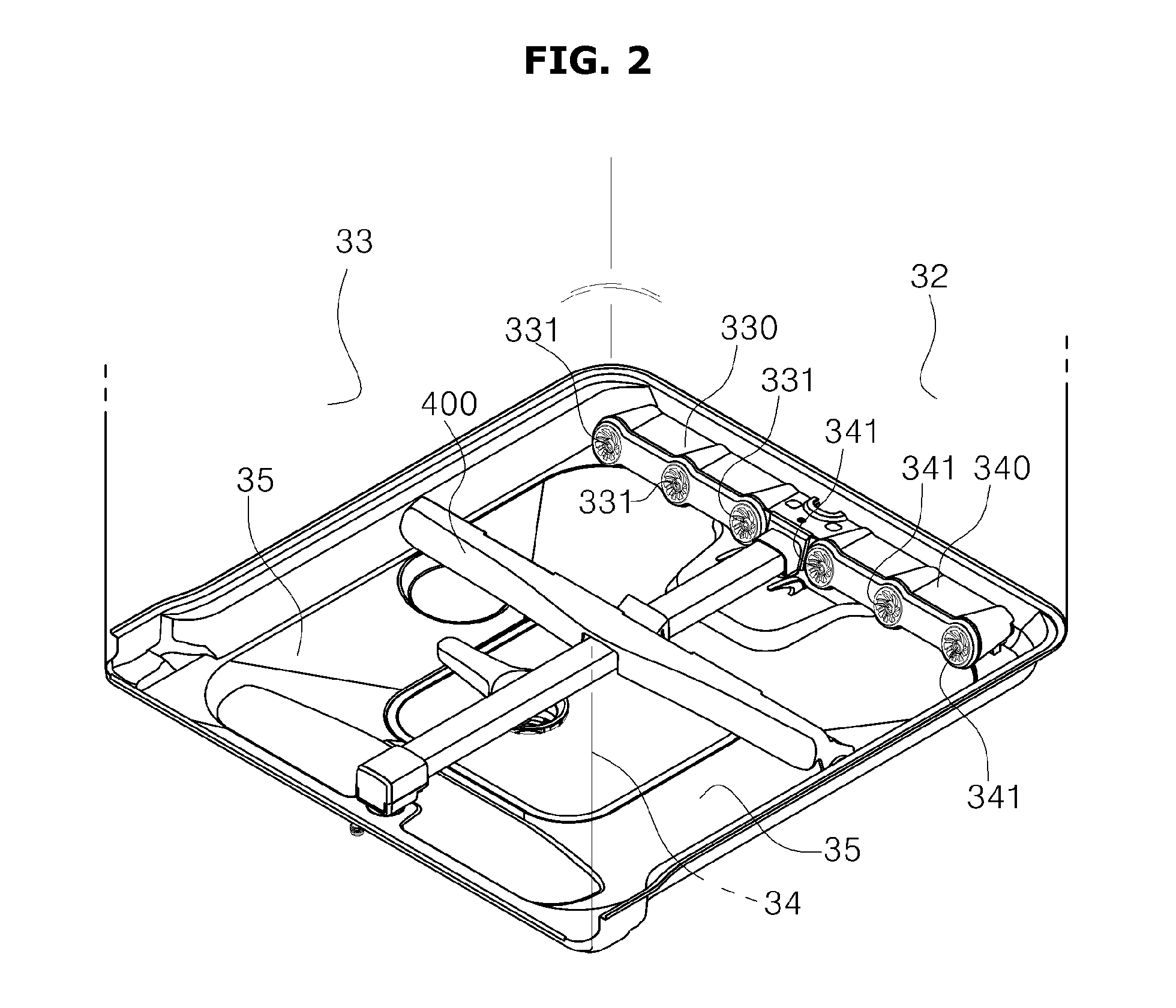

Dishwasher

ActiveUS20150342441A1Increase the drying areaReduce energy consumptionTableware washing/rinsing machine detailsDrying gas arrangementsEngineeringEnergy consumption

Disclosed herein is a dishwasher having a structure capable of reducing energy consumption, and improving drying performance. The dishwasher includes a body, a washing tub provided inside the body and a drying unit in which a dehumidifying member is rotatably accommodated, wherein the dehumidifying member may include a dehumidifying area and a regenerating area separated from the dehumidifying area to perform dehumidifying and regenerating concurrently.

Owner:SAMSUNG ELECTRONICS CO LTD

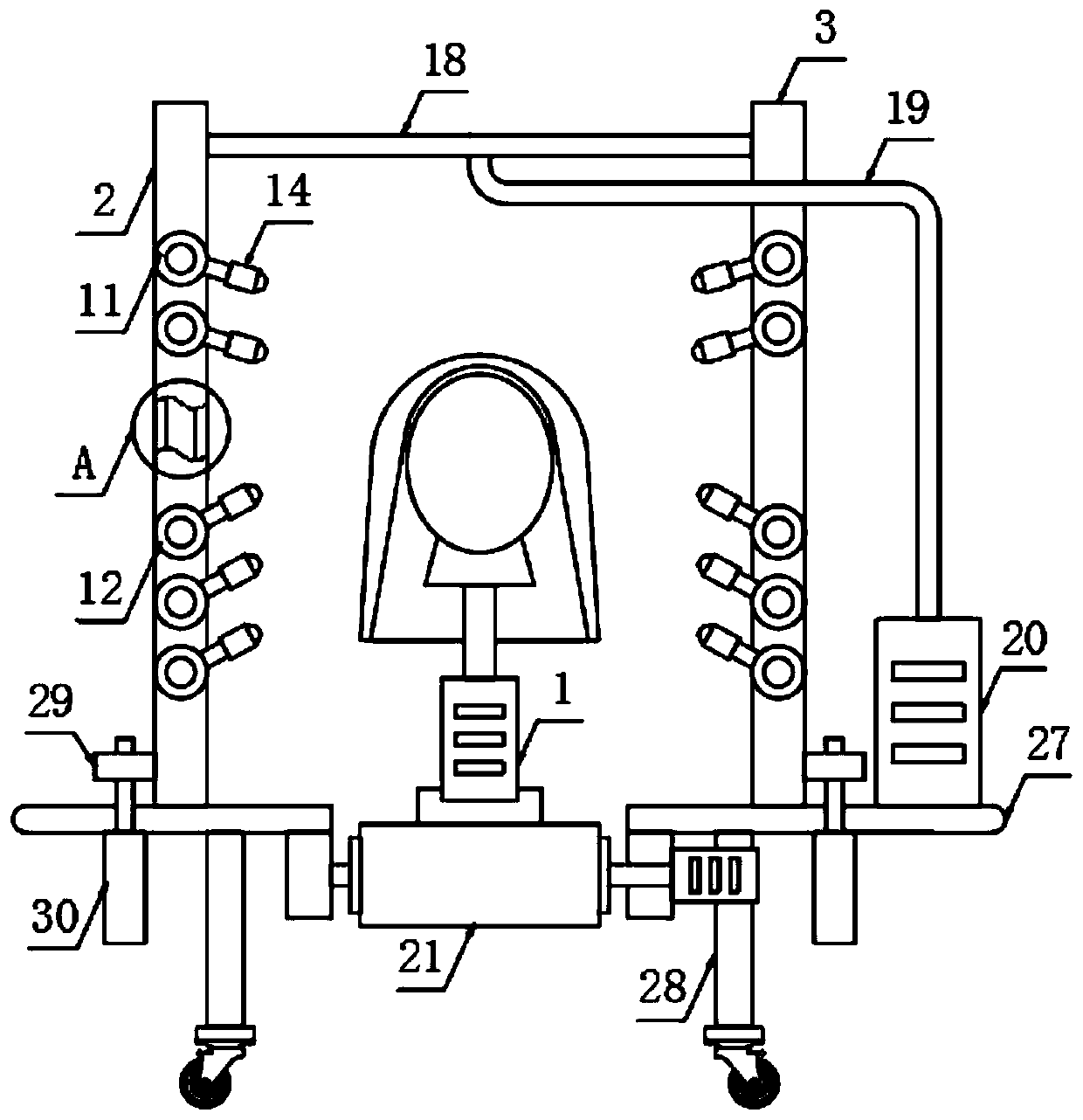

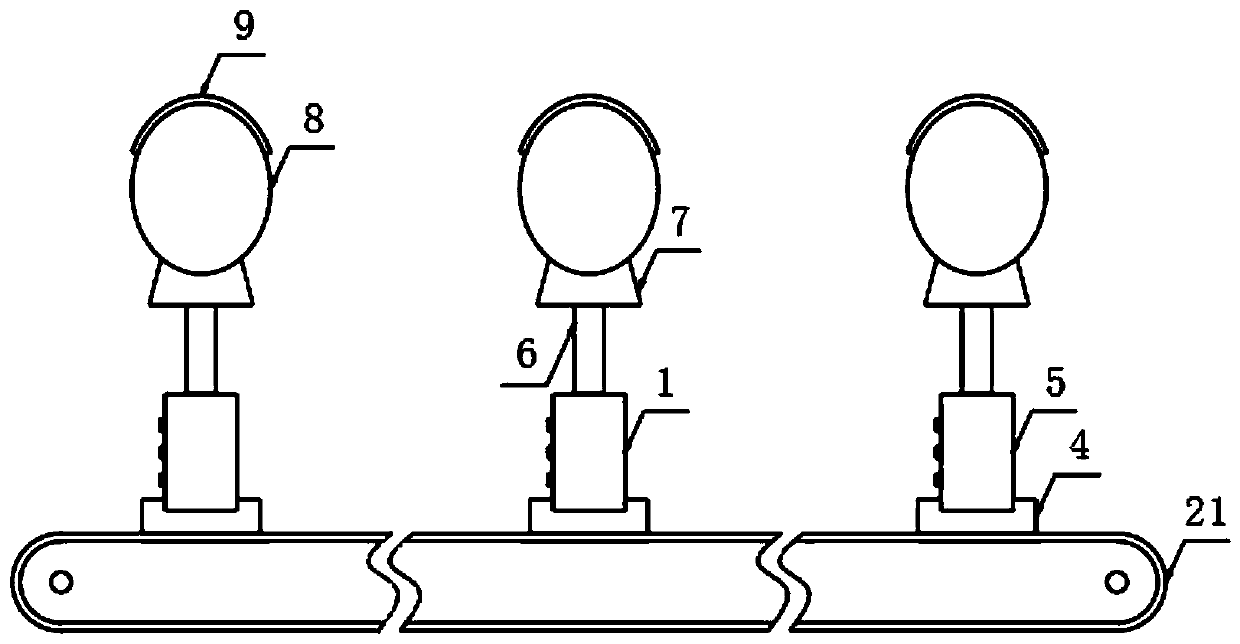

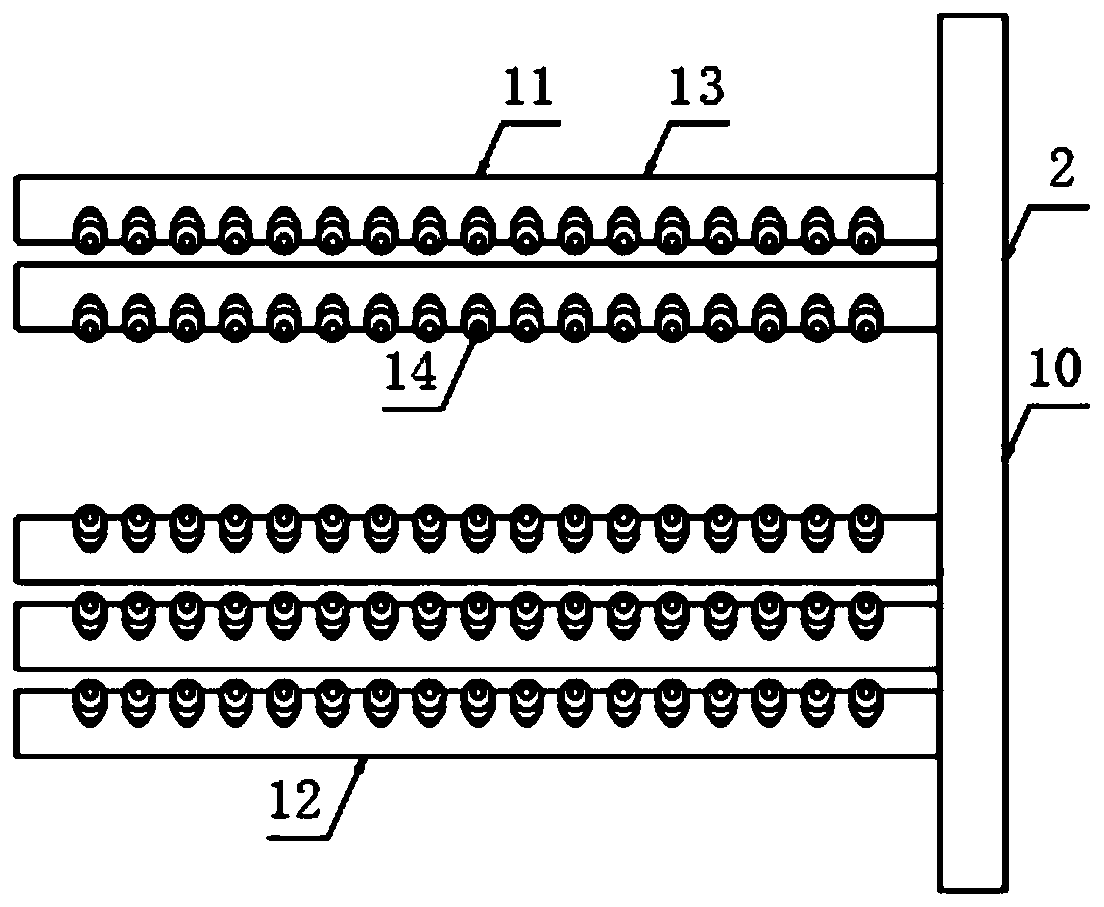

Automatic paint spraying device for electric vehicle accessories

InactiveCN113369066AImprove spraying effectEvenly paintedPretreated surfacesCoatingsElectric carsElectric vehicle

The invention belongs to the technical field of paint spraying equipment, and particularly relates to an automatic paint spraying device for electric vehicle accessories. The device comprises a base, a paint spraying box and a paint spraying mechanism. The paint spraying box is fixedly connected to the top of the base, and one side of the paint spraying box is open; the paint spraying mechanism is arranged in the paint spraying box; the paint spraying mechanism comprises a first servo motor, a first shell, a threaded rod and a paint spraying gun; the first servo motor is fixedly connected to the top of the paint spraying box; the threaded rod is fixedly connected to an output shaft of the first servo motor; the first shell is fixedly connected to the inner wall of the paint spraying box; the paint spraying gun sequentially penetrates through the paint spraying box and the first shell and is slidably connected into the first shell; the outer side wall of the paint spraying gun is fixedly connected with a connecting plate; and the threaded rod penetrates through the connecting plate, and the threaded rod is connected with the connecting plate through a lead screw nut pair. Paint can be evenly sprayed to the surfaces of the electric vehicle accessories, and the problem of uneven paint spraying caused by manual paint brushing is avoided.

Owner:徐州台邦机车有限公司

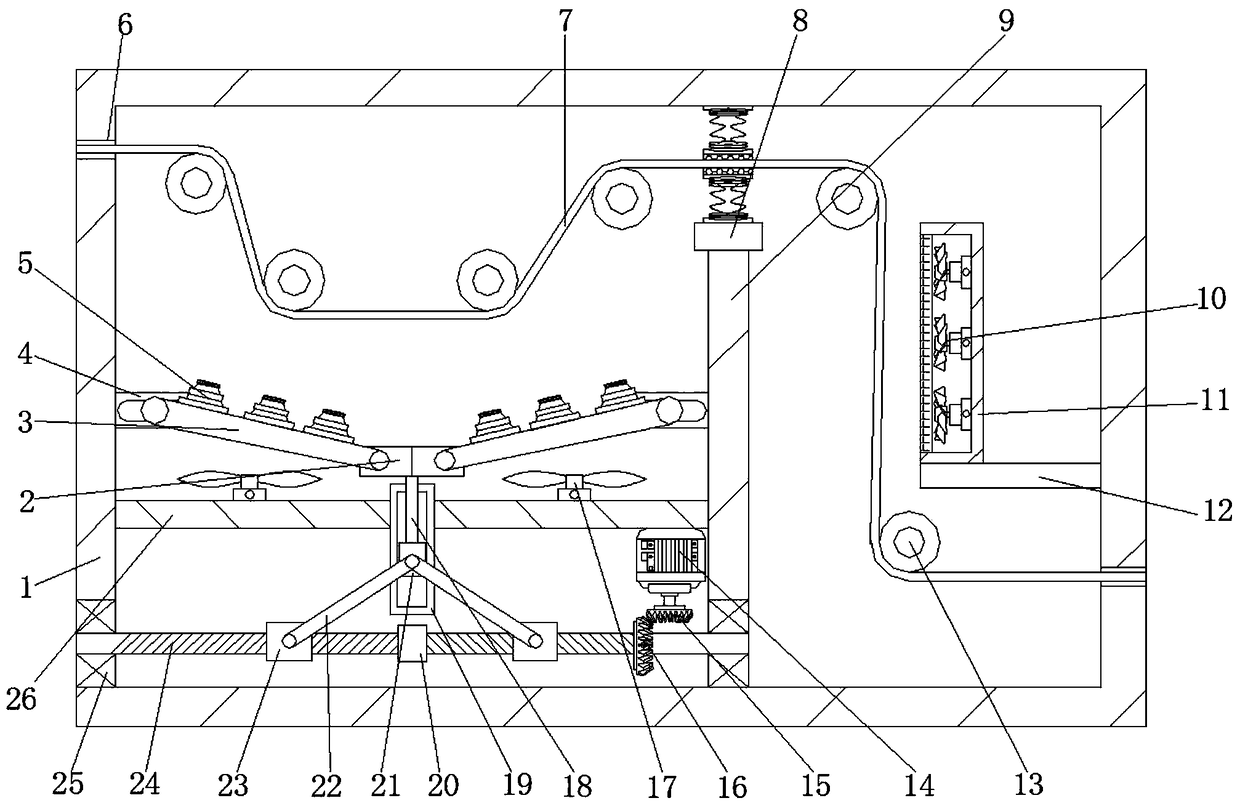

Cleaning device for metal surface treatment

InactiveCN110252705AClean and dry thoroughlyImprove cleaning effectDrying gas arrangementsCleaning using toolsPistonEngineering

The invention discloses a cleaning device for metal surface treatment. The cleaning device comprises a cleaning box, the bottom of the inner wall of the cleaning box is fixedly connected with an air cylinder, and the piston end of the air cylinder is fixedly connected with a supporting plate. According to the cleaning device for the metal surface treatment, cleaning discs are driven to rotate through a transmission mechanism, the cleaning discs rotate to drive second hairbrushes to rotate to perform cleaning on the surfaces of metal parts, meanwhile, cleaning liquid enters a cleaning cover through a three-way connection head to perform the cleaning, after the cleaning is finished, drying wind is conveyed into the cleaning cover to dry the cleaned metal parts after a user starts an air fan, and finally, the cleaning liquid is discharged through a sewage discharge mouth. By means of the cleaning device for the metal surface treatment, the problems that an existing cleaning device cannot perform effective cleaning on metal workpieces of relatively complex structures when treating the metal workpieces of the relatively complex structures and the cleaning liquid cannot be dried rapidly after the cleaning are solved, the cleaning device for the metal surface treatment has the advantages of being thorough in cleaning and convenient and fast in drying, and the cleaning effect and the drying effect are improved.

Owner:ANHUI QIMING SURFACE TECH

Cloth drying device for textile processing

ActiveCN109282614AIncrease the drying areaSuitable for dryingMechanical cleaningPressure cleaningFixed frameEngineering

The invention provides a cloth drying device for textile processing. The cloth drying device comprises a drying box. A bearing plate is welded and fixed to an inner wall of the lower portion of the drying box. The left end of a threaded rod is rotatably installed in an inner wall of the left side of the drying box, the right end of the threaded rod is rotatably installed in an inner wall of a partition plate, and connecting bearings are arranged at the connecting positions correspondingly. A limiting block is fixedly connected to the middle portion of the threaded rod in a sleeving mode, and threads at the left end and the right end of the limiting block have opposite screwing directions. A lifting rod penetrates upwards through a fixed frame in a connecting mode, and the upper end of thelifting rod is welded and fixed to a moving block. Cloth is placed in the upper portion of the interior of the drying box through a fixed guide roller in a bending mode, and brushes are arranged in the middle of the cloth. The upper end of a connecting plate is welded and fixed to an inner wall of the upper end of the drying box, and the lower end of the connecting plate is welded and fixed to a fixed plate. The left side of an air drying box is provided with an air dispersing hole, and a blow drying fan is arranged inside the air drying box. The cloth drying device has the advantages of beingsimple in structure, convenient to operate and high in efficiency, can complete cloth drying quickly, and is worthy of popularization and use.

Owner:安徽豹子头服饰股份有限公司

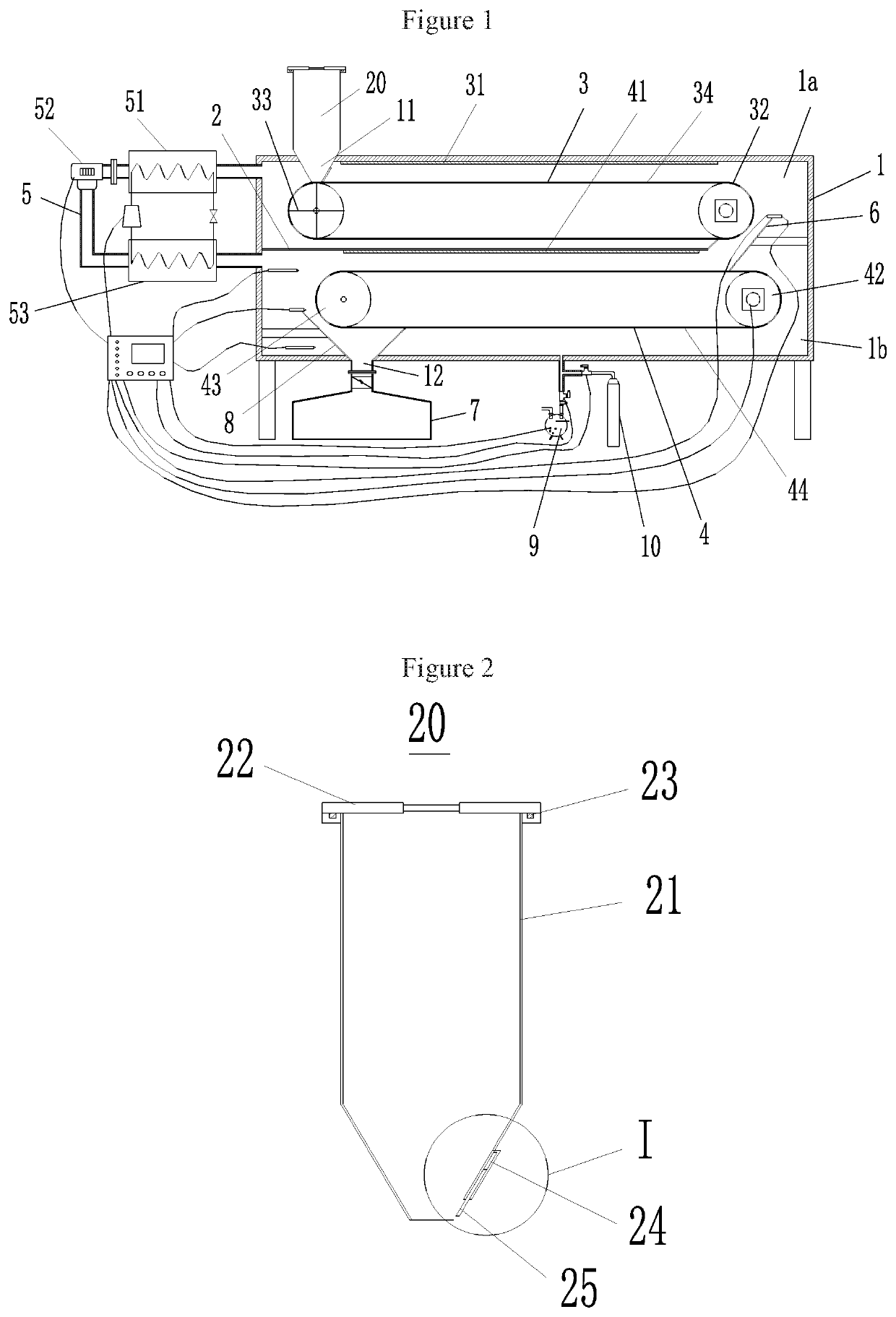

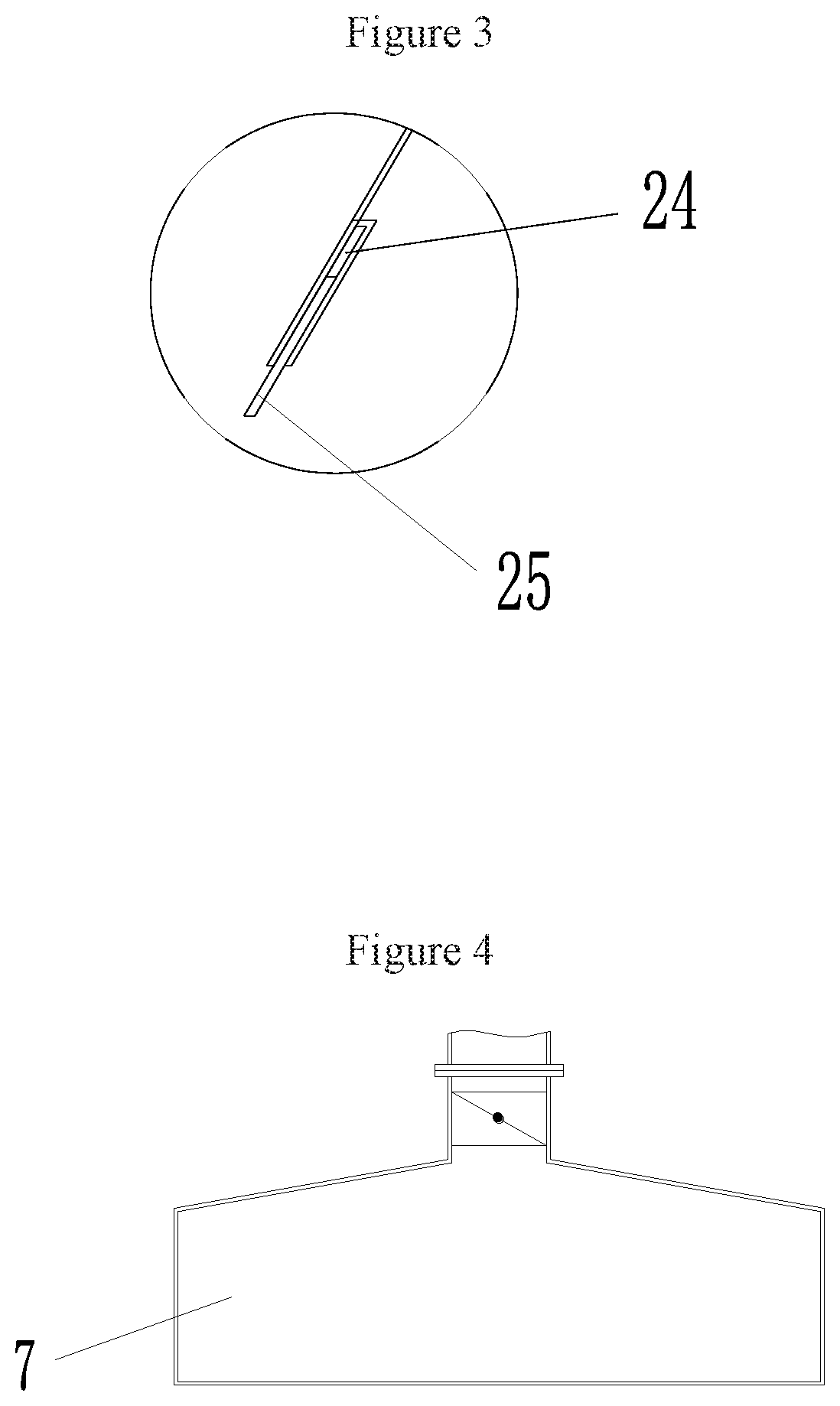

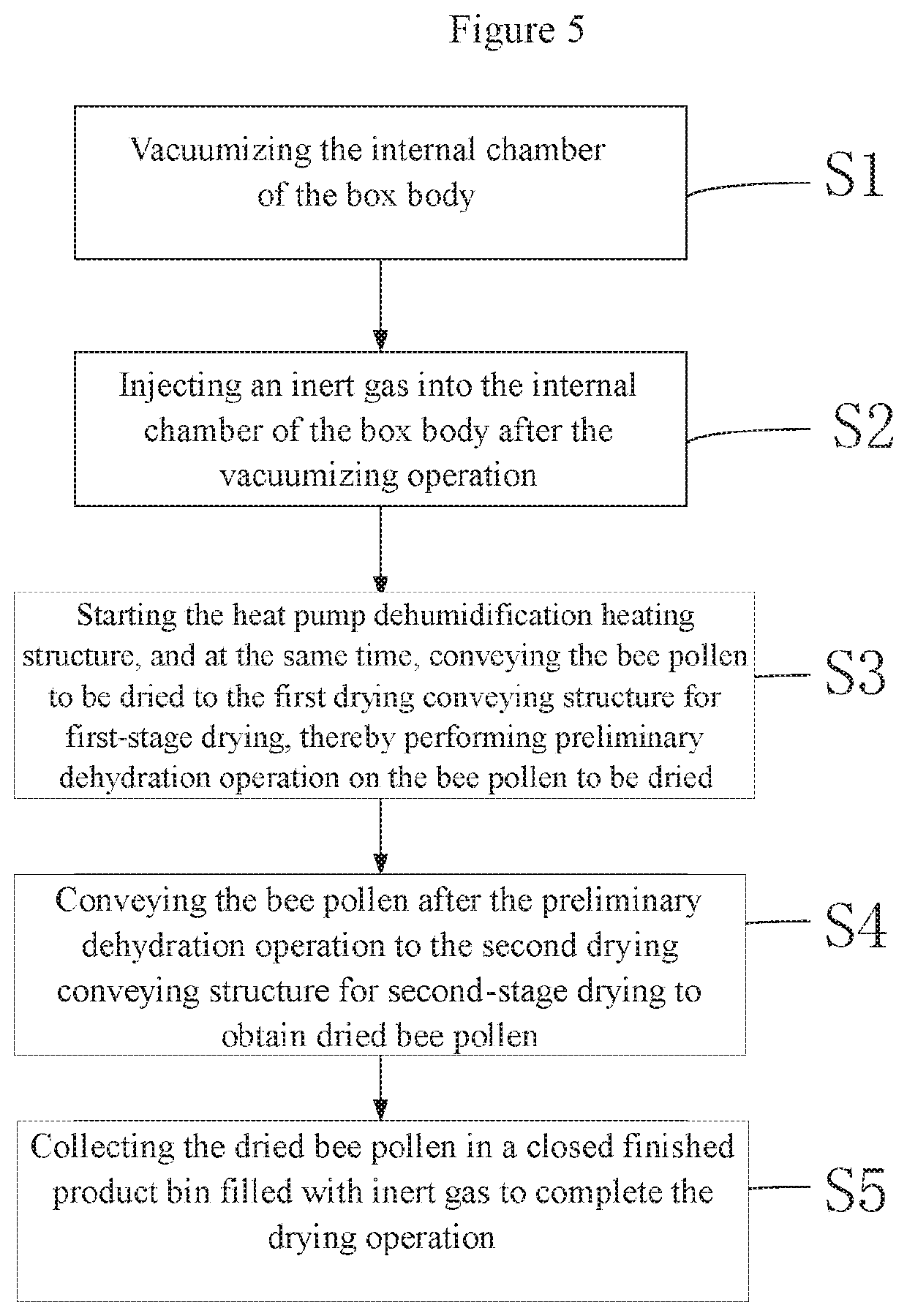

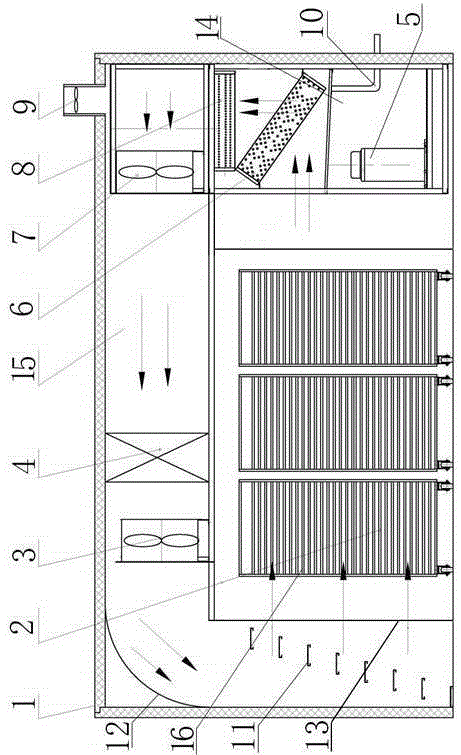

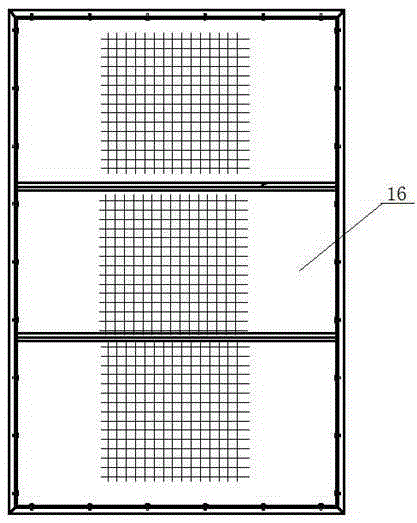

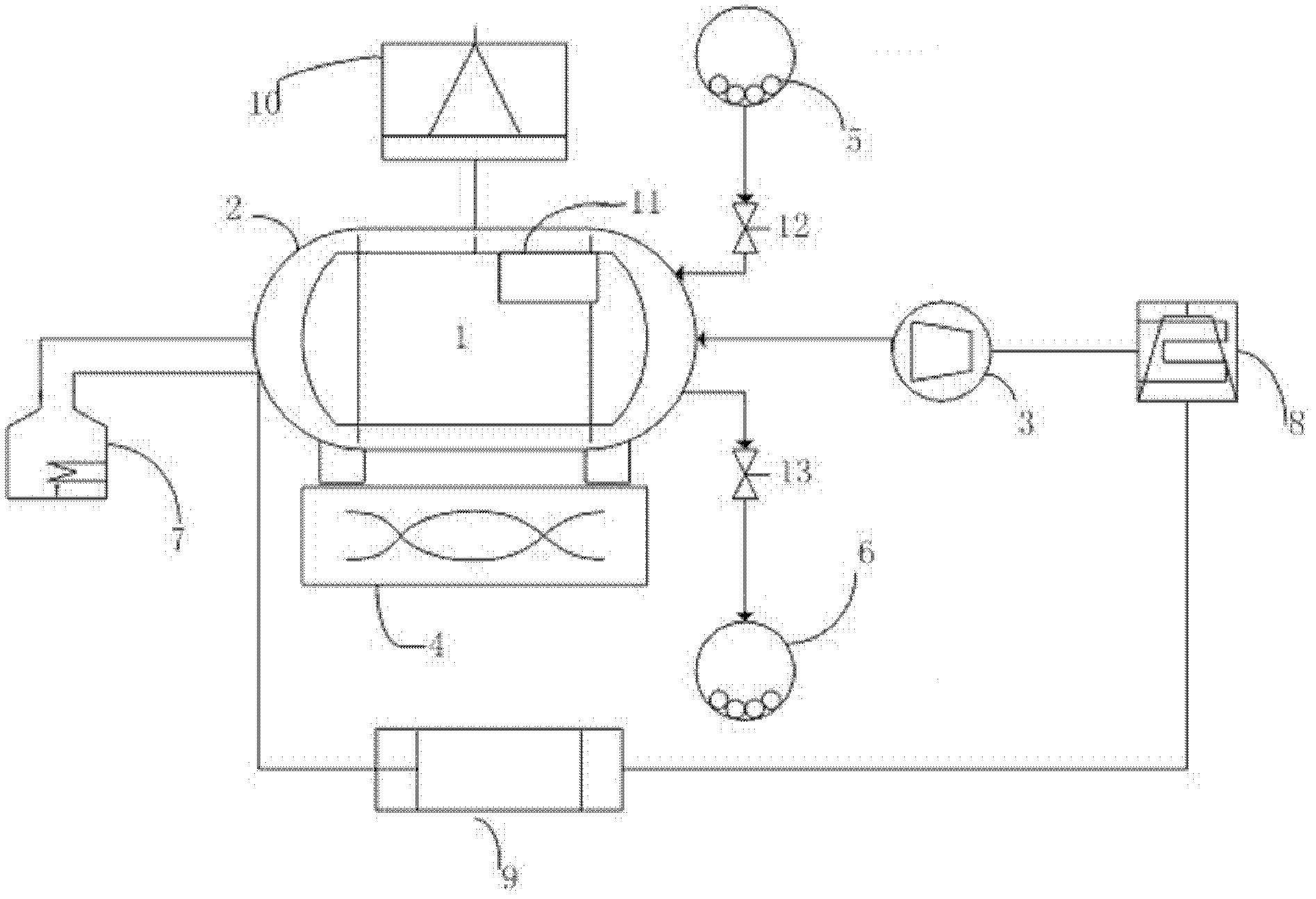

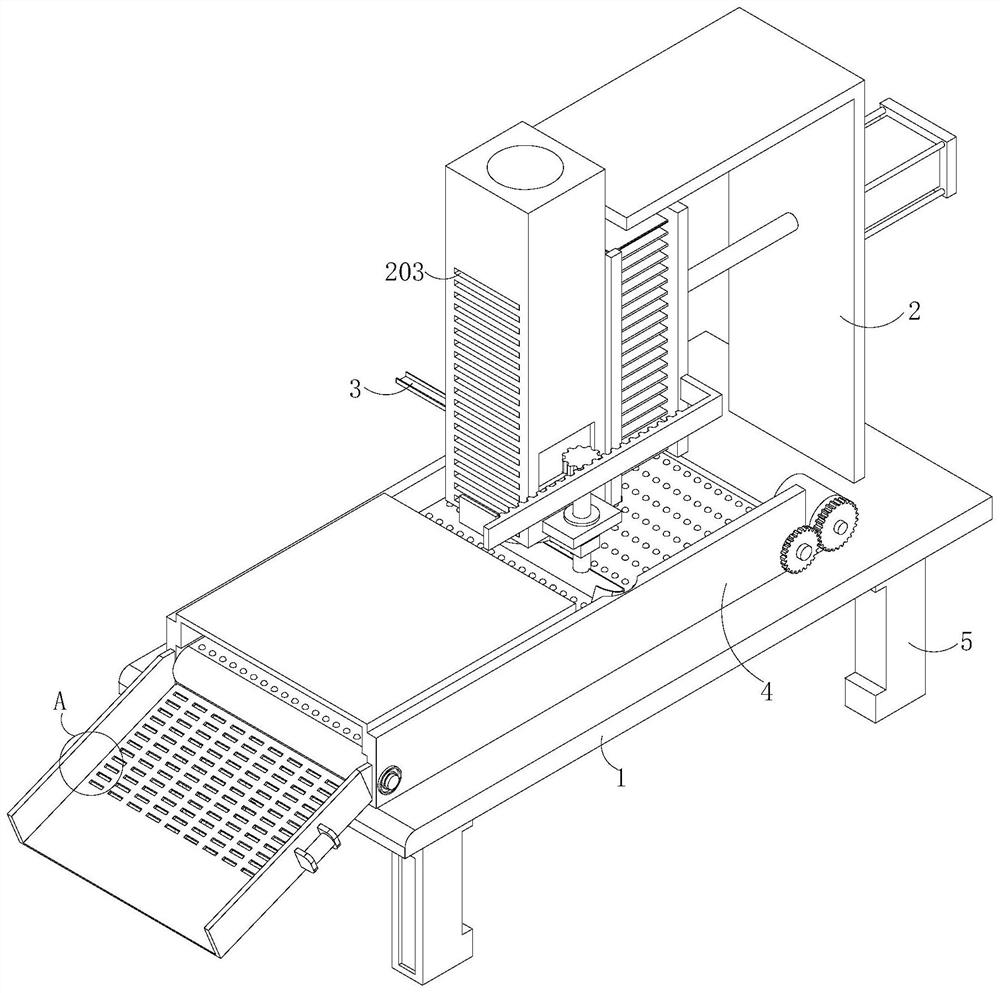

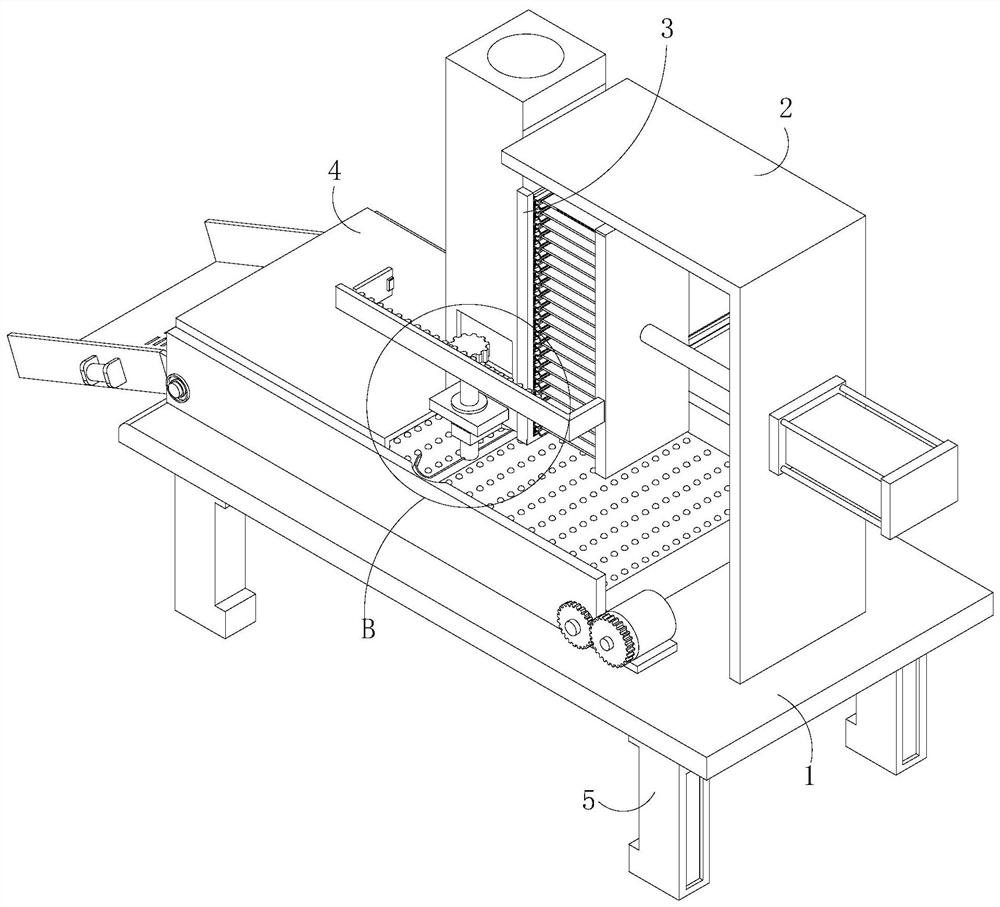

Continuous drying apparatus for bee pollen and related drying method

ActiveUS20210293479A1Increase drying speedImprove product qualityHeat pumpsDrying solid materials with heatBiotechnologyBee products

The present invention relates to the technical field of bee product processing, and discloses a continuous drying apparatus for bee pollen and related drying method. The continuous drying apparatus for bee pollen comprises: a box body; a first drying conveying structure; a second drying conveying structure; and a heat pump dehumidification heating structure. The continuous drying apparatus for bee pollen has the advantage of high drying efficiency.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

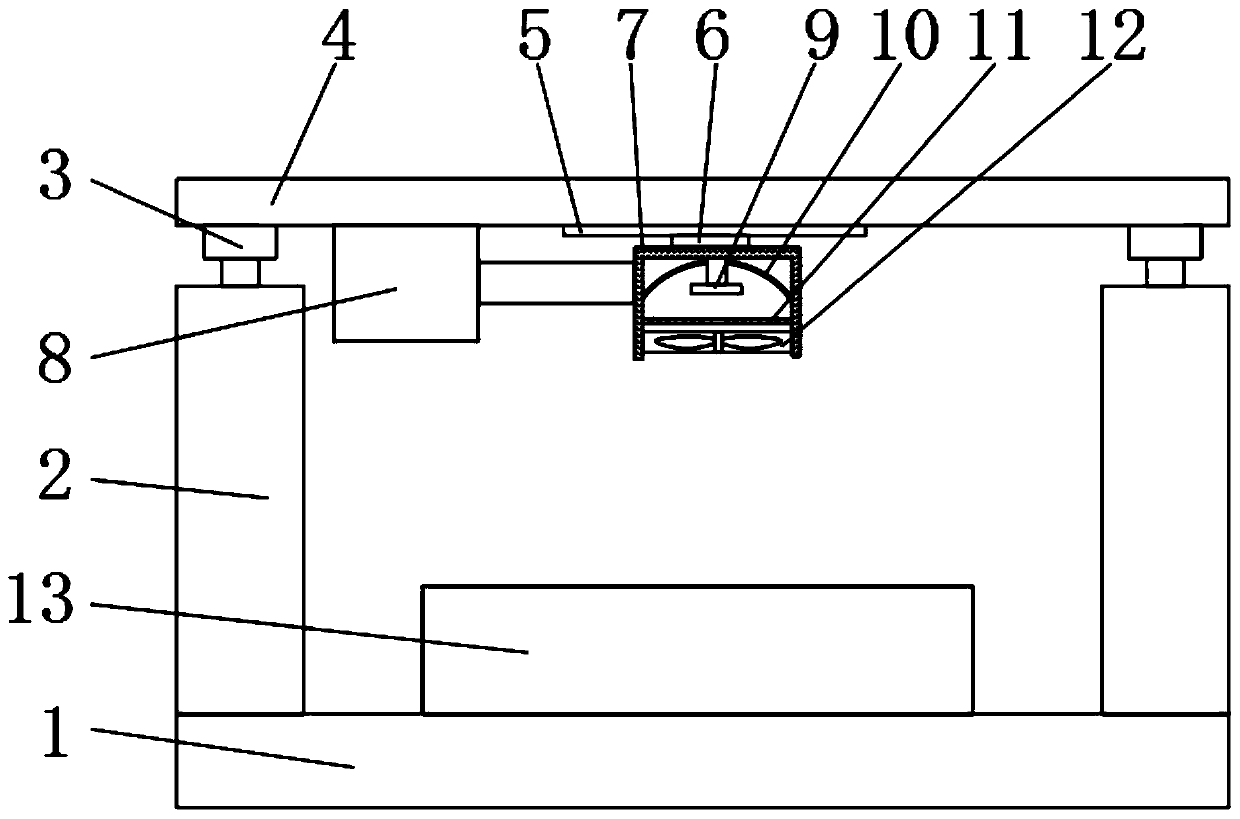

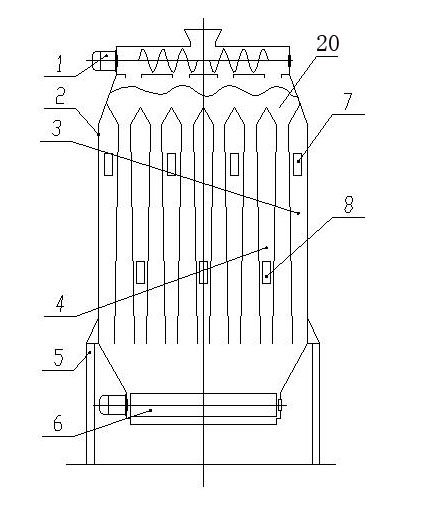

Three-dimensional box-type hot air circulation device

InactiveCN105300053AReduce lossesAchieve energy saving and emission reductionDrying gas arrangementsDrying chambers/containersControl flowHeat losses

The invention relates to the technical field of agricultural product processing equipment and discloses a three-dimensional box-type hot air circulation device. The three-dimensional box-type hot air circulation device comprises a box body composed of a main machine room, an air flue and a drying chamber, wherein the main machine room is located on one side of the drying chamber and the air flue is located above the drying chamber. A compressor and an evaporator are arranged in the main machine room, the evaporator is installed above the compressor in an inclined mode, a condenser is arranged above the evaporator, and the air outlet of the condenser is connected to one end of the air flue. A moisture removal fan is arranged at the top end of the air flue, a main fan is arranged at the part, close to the condenser, in the air flue, a circulating fan is arranged at the other end of the air flue, and an auxiliary heater is arranged between the circulating fan and the main fan. According to the invention, an arc-shaped air guide plate is adopted for guiding hot air, the hot air is prevented from suddenly turning and generating vortexes, and therefore loss of wind energy is prevented; air dividing plates are arranged to control flow of the hot air; the hot air mingled with moisture is recycled, so that heat loss is reduced. The three-dimensional box-type hot air circulation device effectively achieves energy conservation and emission reduction and is an environment-friendly and energy-saving device.

Owner:甘肃奥凯农产品干燥装备工程研究院有限公司

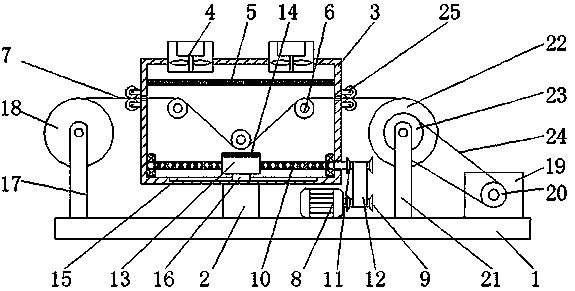

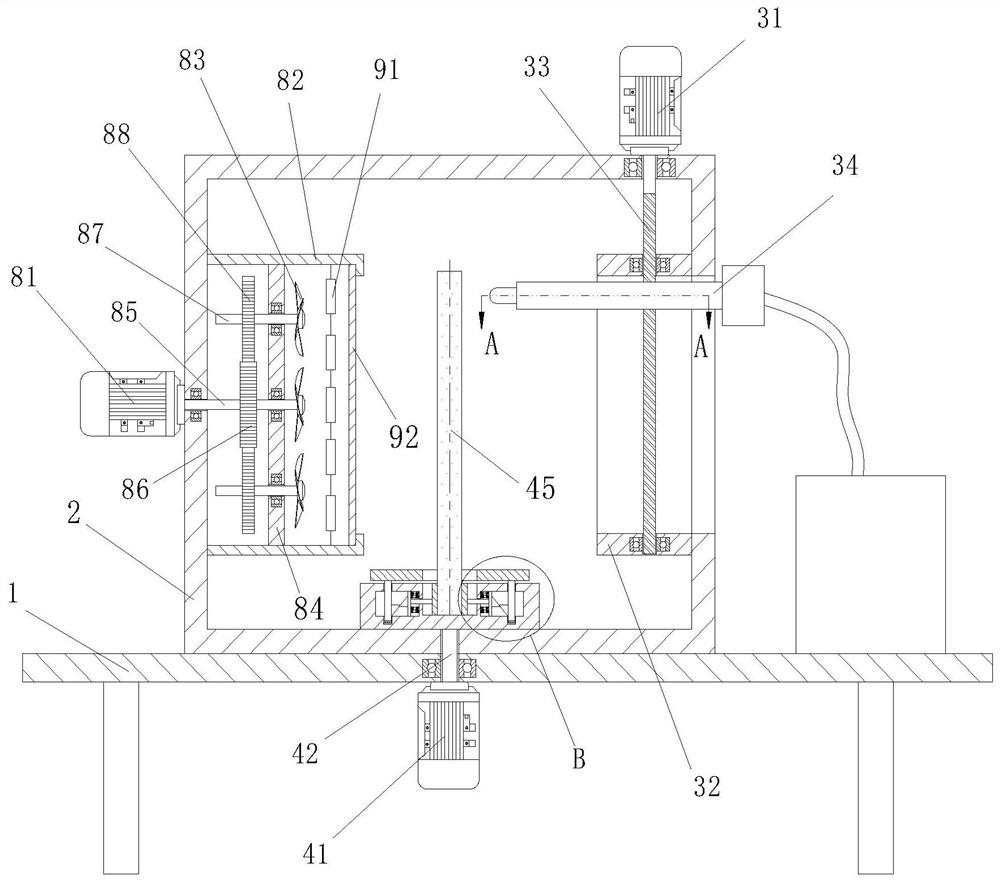

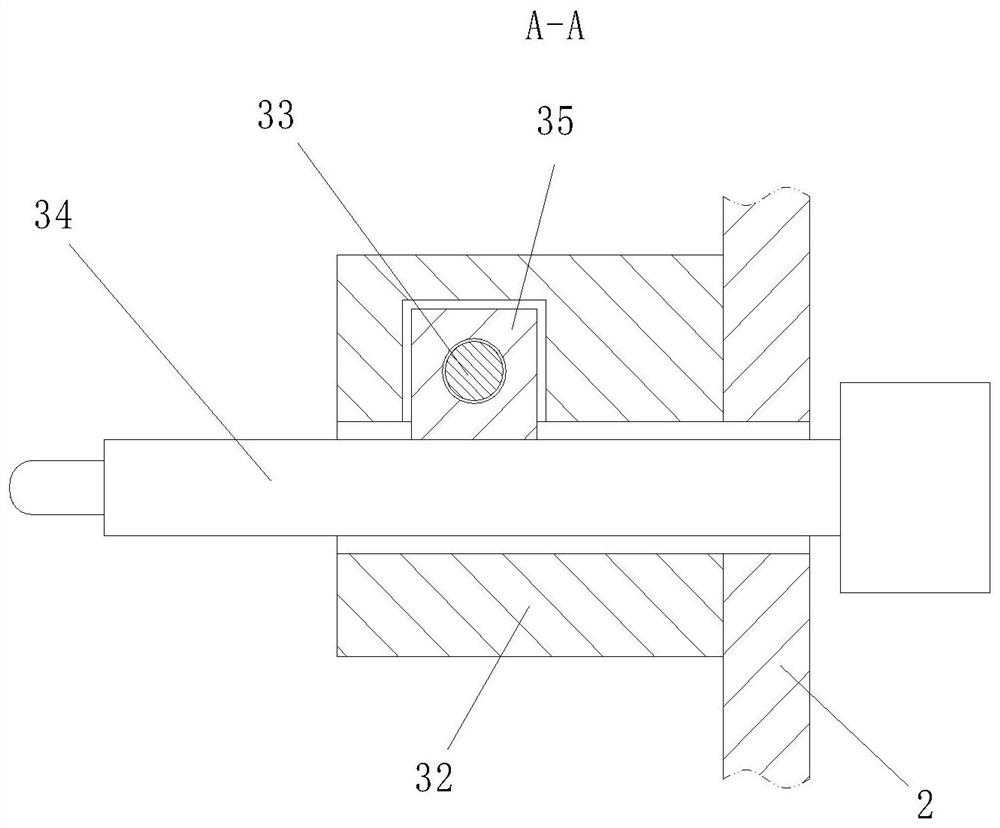

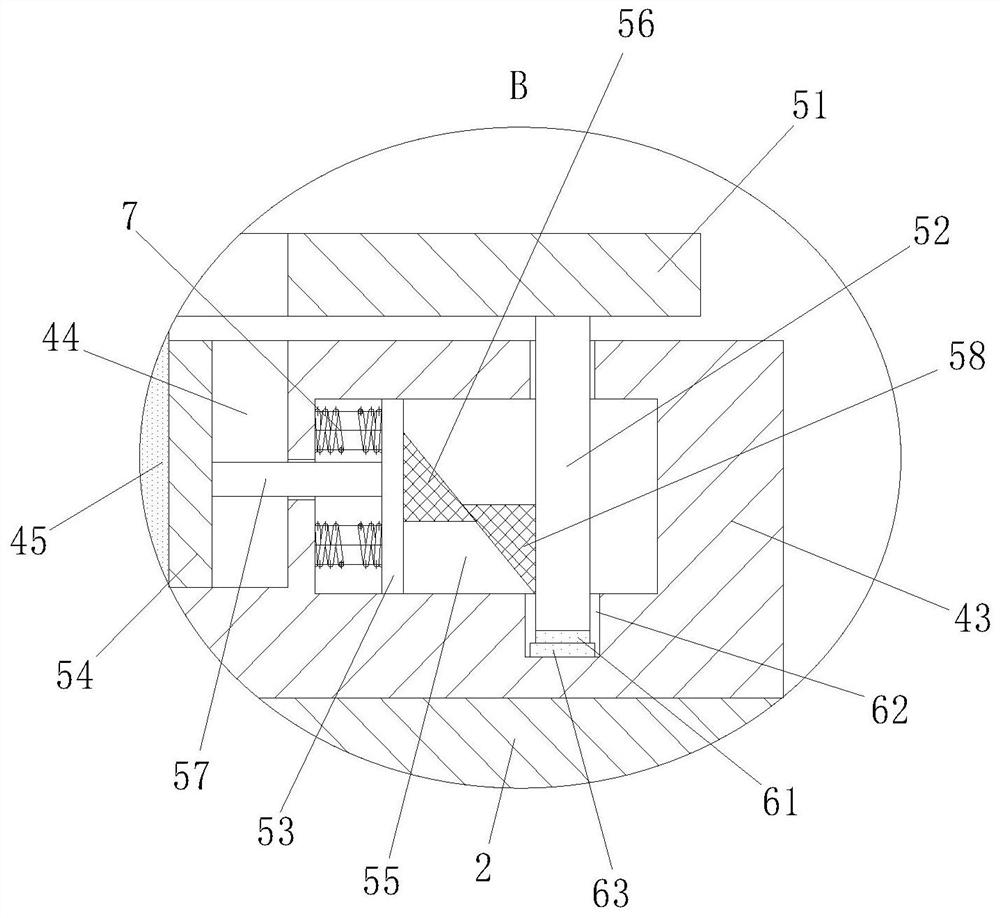

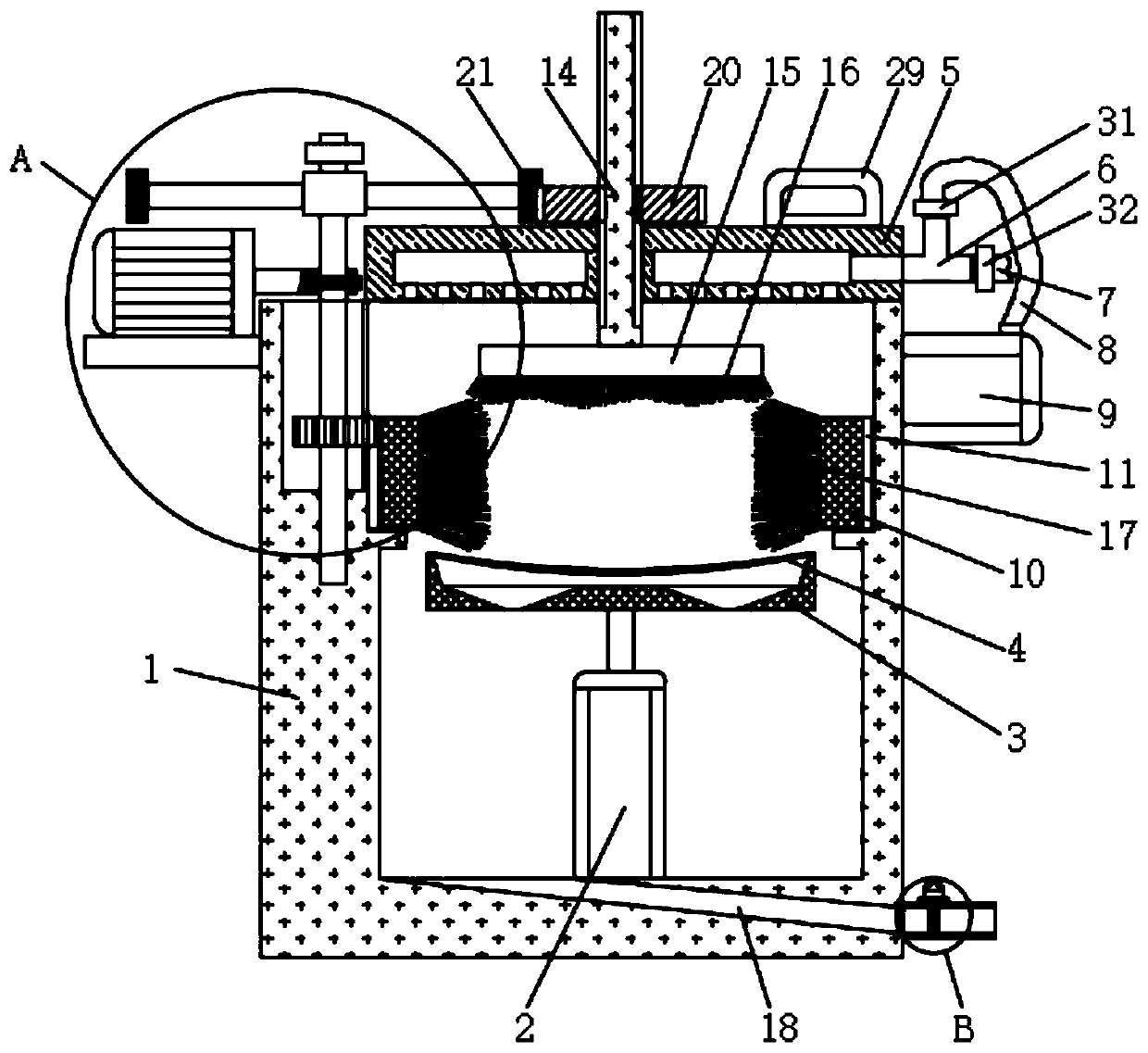

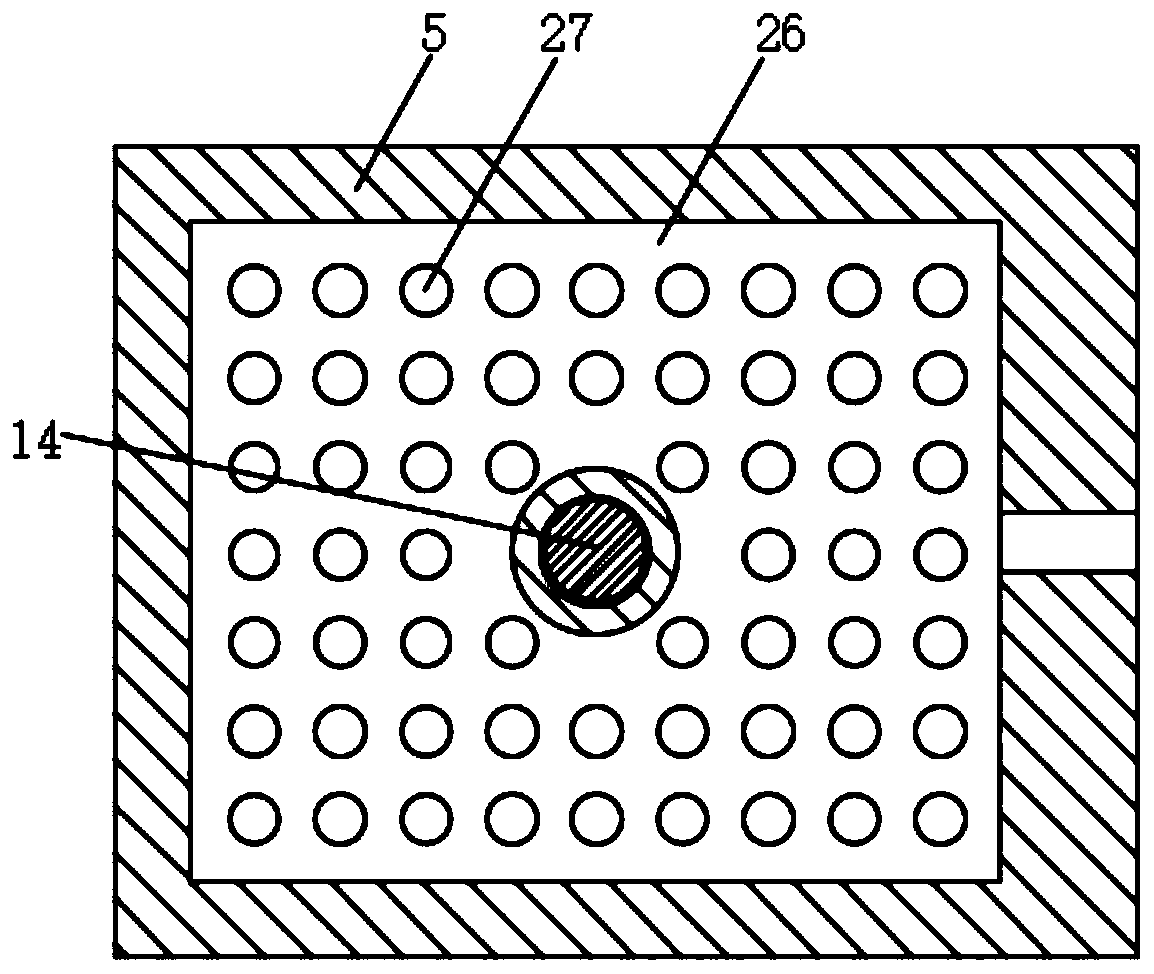

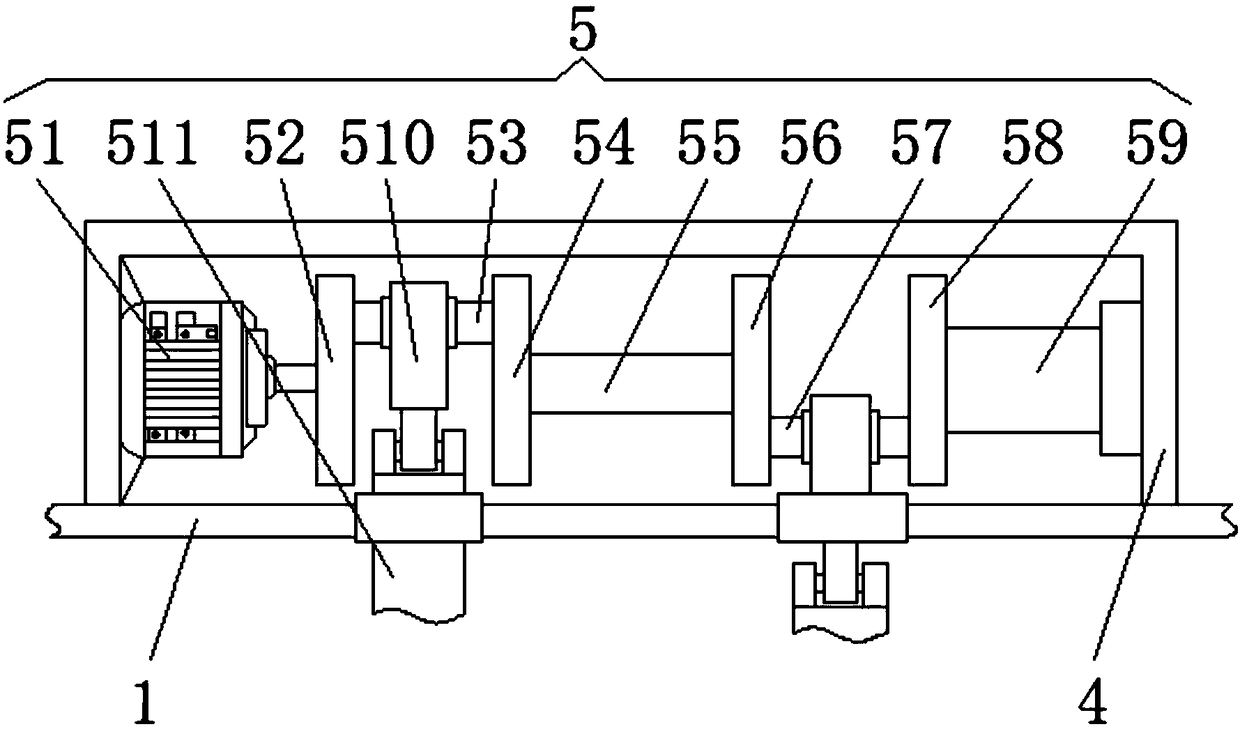

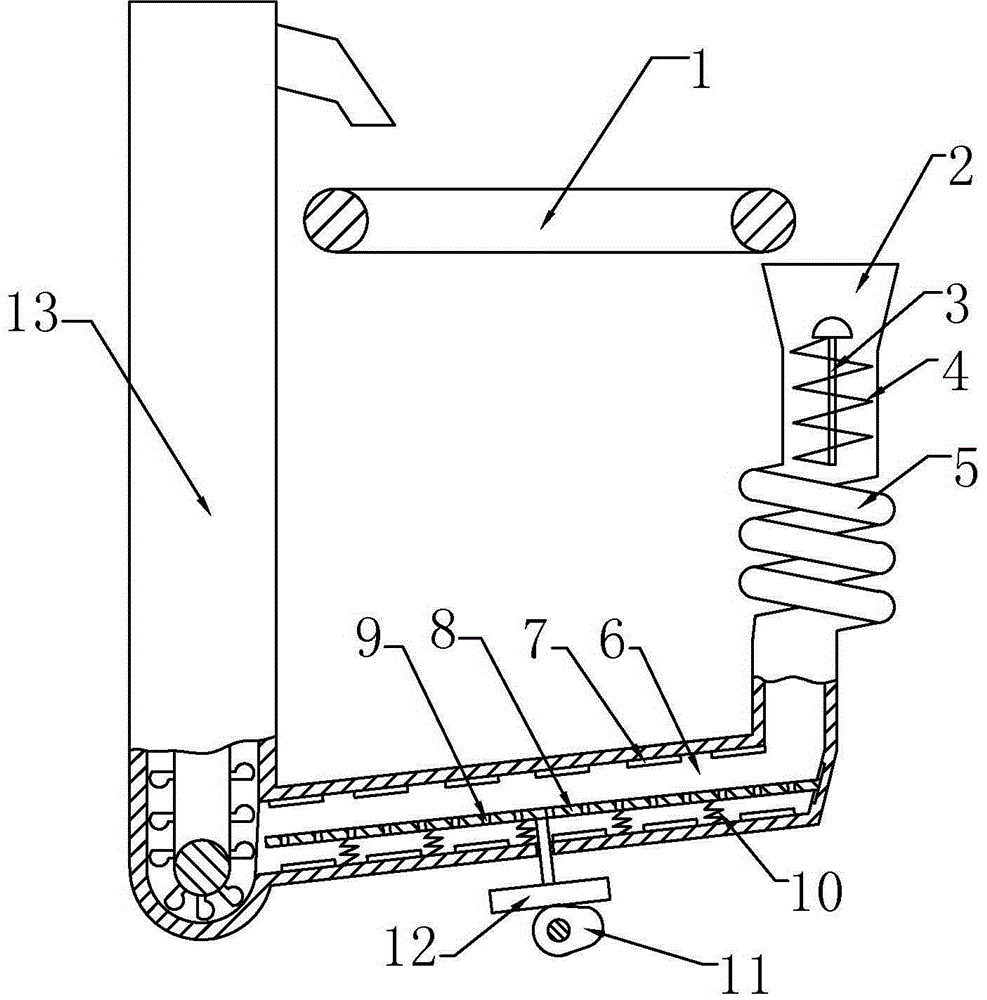

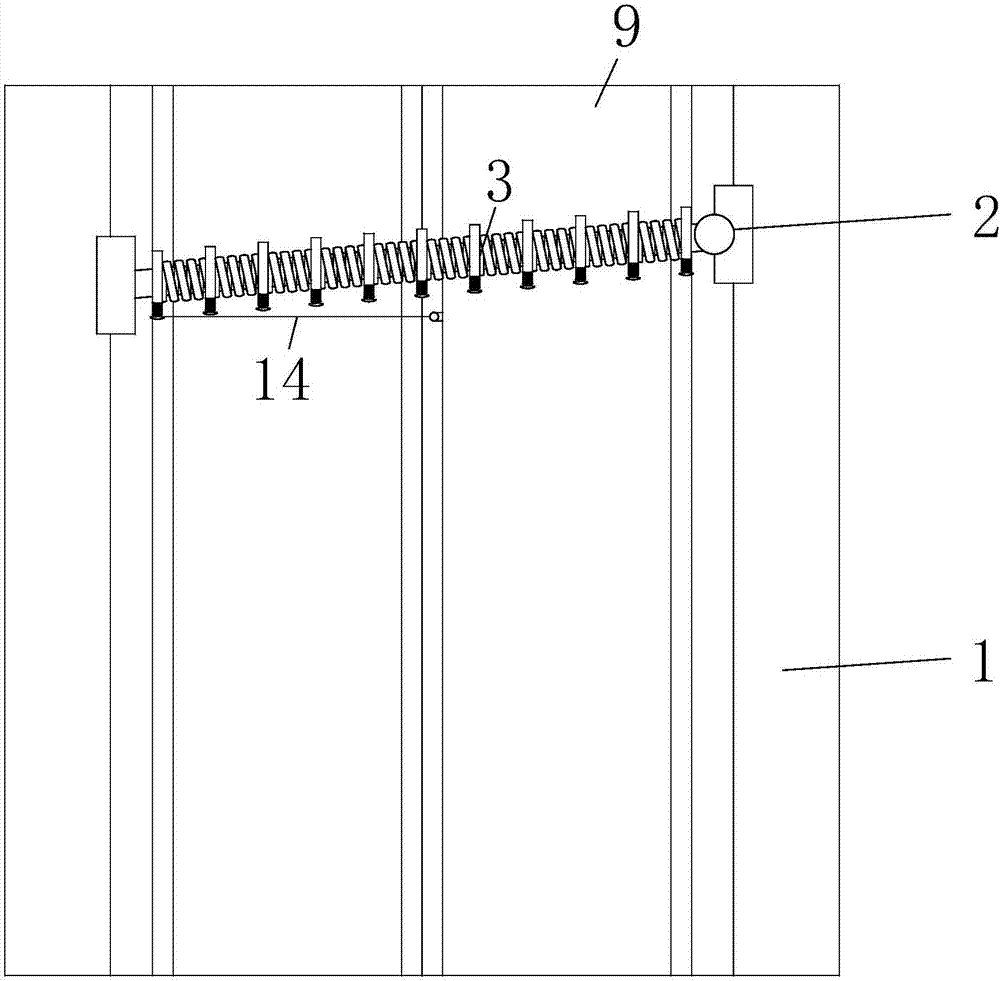

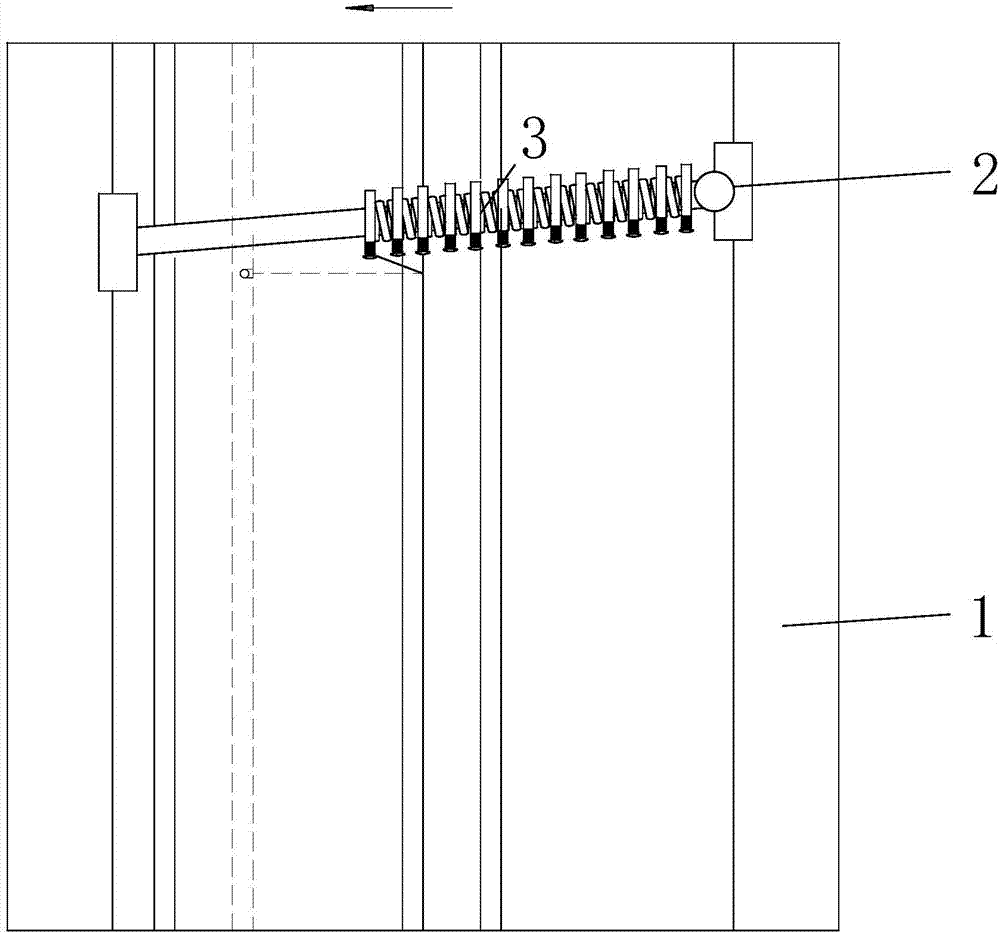

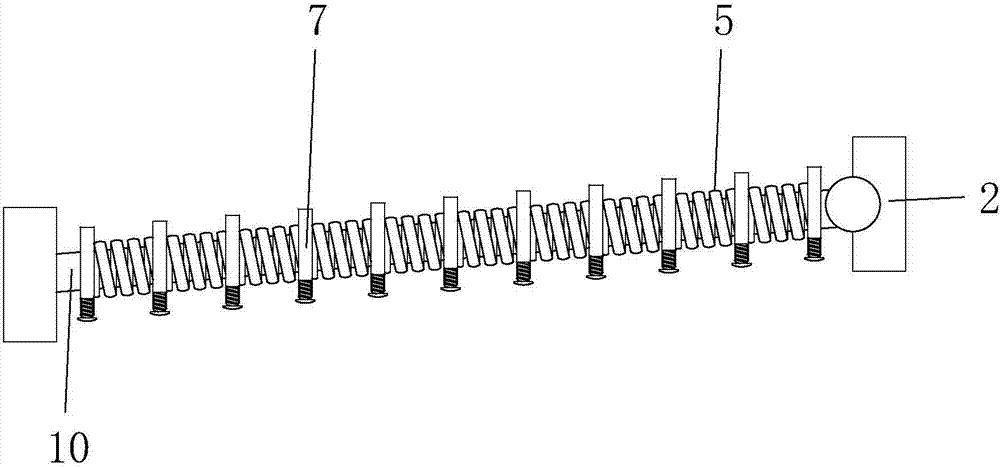

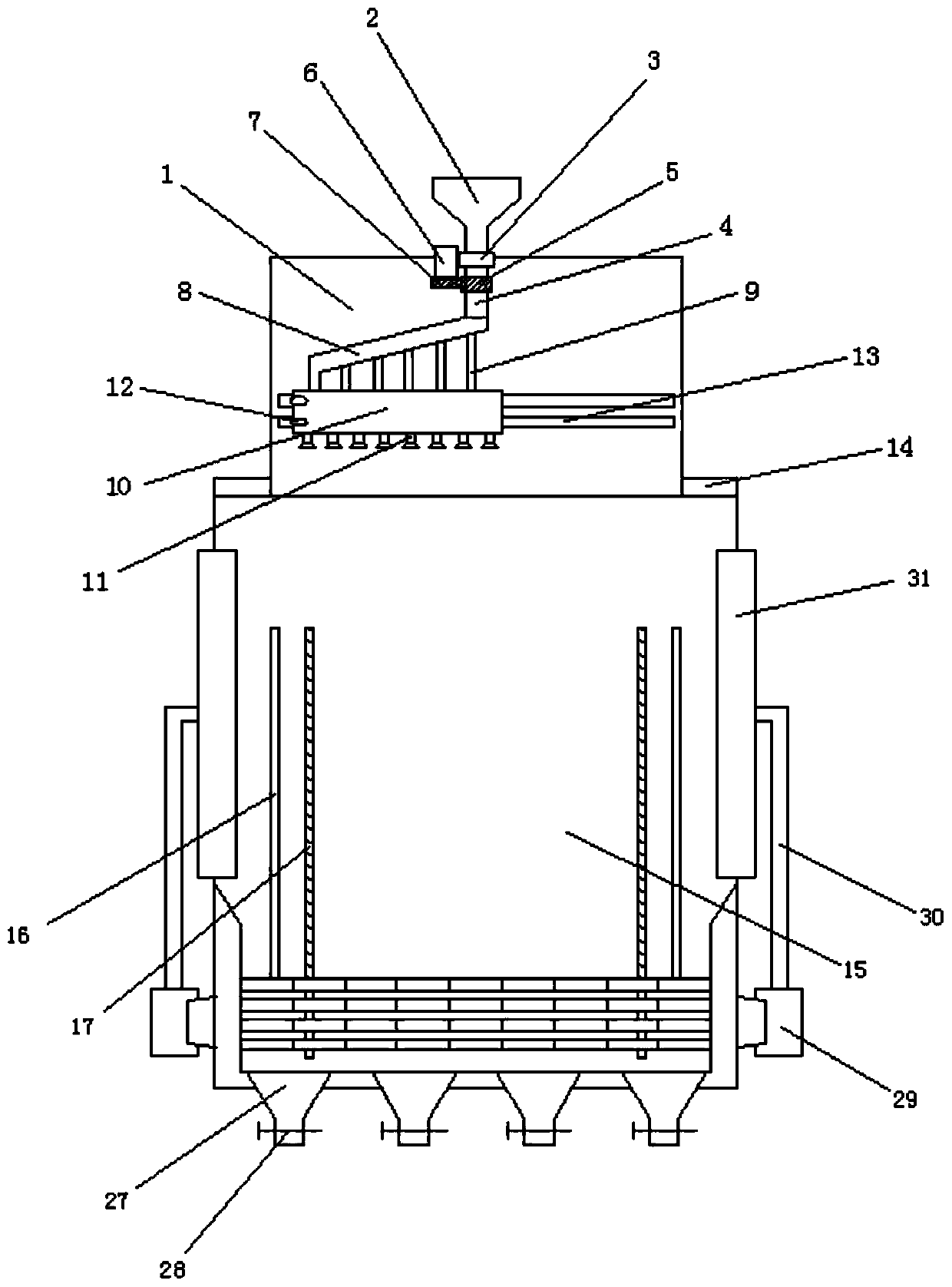

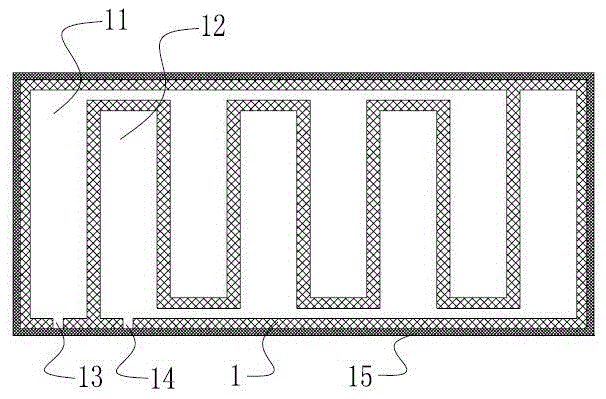

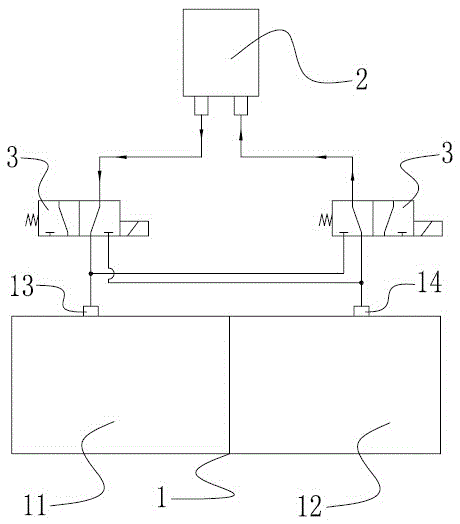

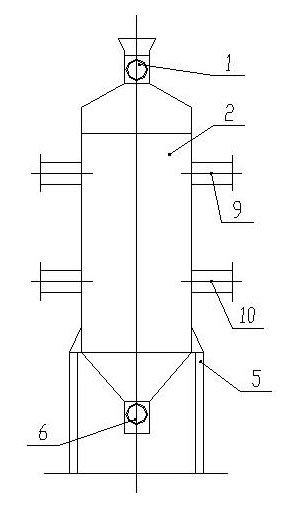

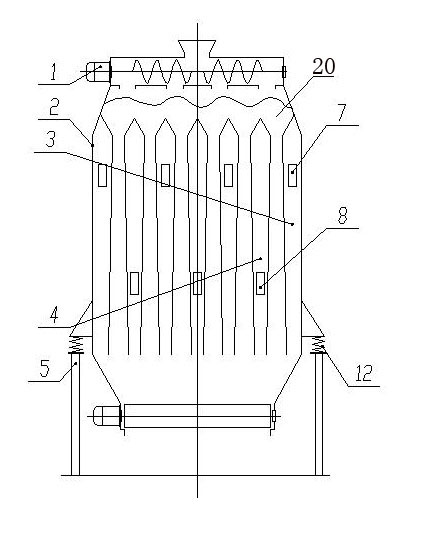

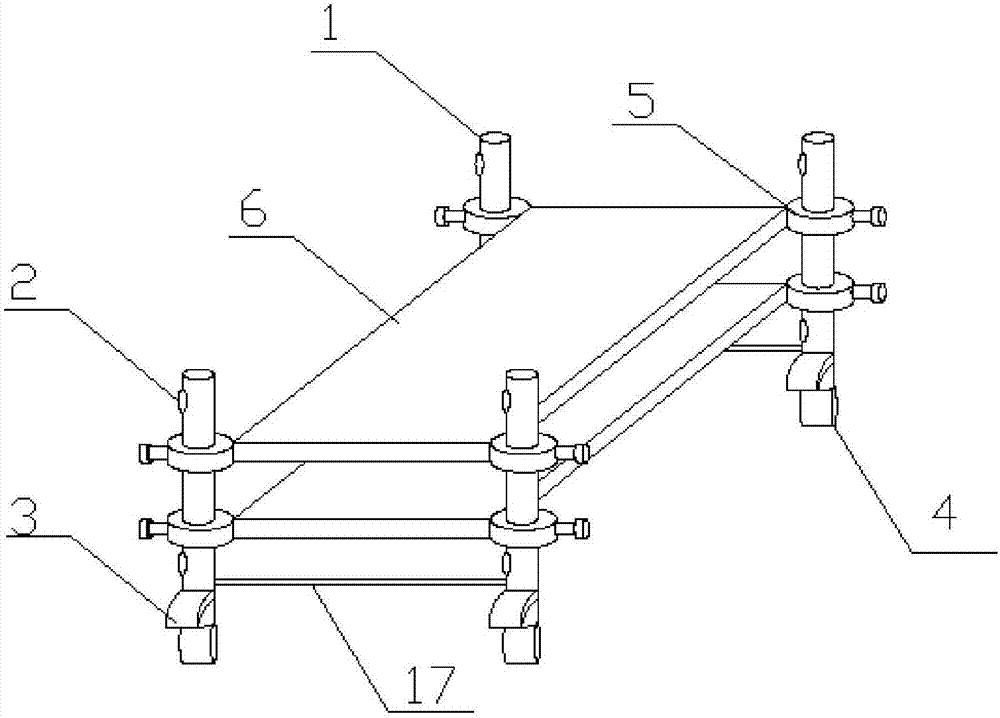

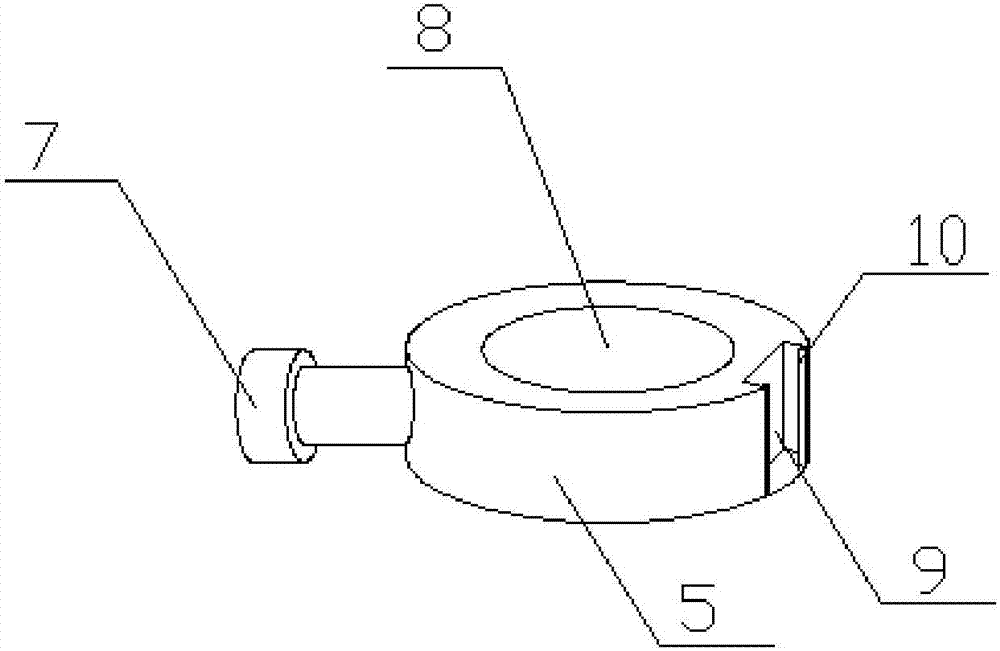

Vacuum drying device and drying method

ActiveCN102865723AIncrease the drying areaFast dryingDrying using combination processesDrying machines with local agitationIsolation valveProcess engineering

The invention discloses a vacuum drying device and a method for drying materials by the aid of the vacuum drying device. The technical scheme mainly includes that the vacuum drying device comprises a horizontal tank, a feed port, a discharge port, a feed port isolation valve, a discharge port isolation valve, a vacuum pump and a heating device, the horizontal tank is respectively connected with the feed port, the discharge port and the vacuum pump, the horizontal tank is respectively isolated from the feed port and the discharge port by the feed port isolation valve and the discharge port isolation valve, the horizontal tank is provided with a heating jacket, and the heating jacket is connected with the heating device. The vacuum drying device is characterized by further comprising a vibrating device connected with the horizontal tank. The vacuum drying device is mainly used for drying the materials at a low temperature in a vacuum environment and liquefying the materials by means of mechanical vibration, material drying efficiency and drying degree are improved by heating and evacuating, and the vacuum drying device is particularly applicable to heat sensitive materials, anaerobic materials or materials with special drying requirements.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

Efficiently drying cement drier

InactiveCN108106369AEfficient dryingDry fastDrying gas arrangementsDrying machines with non-progressive movementsGas phaseEngineering

The invention discloses an efficiently drying cement drier. The efficiently drying cement drier comprises a box body, wherein the inner wall of the box body is fixedly connected to a drying box and afeeding hopper penetrates through the top of one side of the box body, the bottom of the feeding hopper communicates to the drying box, the top of the box body is fixedly connected to a fixed rack andthe inner wall of the fixed rack is fixedly connected to a transmission device, the top of the inner wall of the box body is fixedly connected to a carriage adaptive to the transmission device, and the bottom of the transmission device is fixedly connected to a motor box. The invention relates to the cement drying technical field. The efficiently drying cement drier is high in drying intensity, high in efficiency and high in circulating hot air flow rate, and materials are dispersed well in a gas phase. As a result of dispersing and stirring actions during drying, gasified surfaces are updated continuously, so that the heat transfer process of drying is great in intensity and high in efficiency. All the surfaces of the materials can be taken as effective drying areas, so that the drying area is increased greatly and the efficiently drying cement drier is quite environment-friendly and energy-saving.

Owner:杨涛

Drying device for building board with adjusting function

PendingCN109737706AGuaranteed linearityReasonable structural designDrying gas arrangementsDrying chambers/containersEngineeringLateral position

The invention discloses a drying device for building boards with an adjusting function, and belongs to the technical field of drying of building boards. Adjusting devices are arranged on the left sideand the right side of the top of a base respectively, and damping devices are arranged at the top of the adjusting devices, a cross beam is arranged at the top of the damping devices, a sliding railis arranged at the center of the bottom of the cross beam, a guide block is embedded in the slide rail, a drying box is fixedly connected to the bottom of the guide block, a heater is arranged on theside, far away from a opening, of an inner cavity of the drying box, reflecting plates are arranged on the left side and the right side of the heater respectively, a filtering plate is fixedly arranged below the heater, and a fan is arranged below the filter plate. According to the device, the height and the transverse position of the drying box can be adjusted, the drying area of the building boards can be improved, the drying effect can be improved, the drying efficiency is improved, and the drying uniformity is good.

Owner:王程

Method for continuously drying polycarbonate

InactiveCN102645085ADry evenlyShort stayDrying solid materials with heatHearth type furnacesSolventPolycarbonate

The invention belongs to the technical field of drying, and relates to a method for continuously drying polycarbonate, polycarbonate powdery materials are firstly fed into a pneumatic drying accelerator, superheat steam is simultaneously fed, in a pneumatic drying bushing, the polycarbonate powdery materials and the superheat steam concurrently flow forwards, are subjected to heat and mass transfer, and most solvent and water removal to complete the flow drying; then, the materials are mixed up with the steam flow to enter a cyclone drier, the materials and the steam do rotational motion along the inner wall to be subjected to fierce mass and heat transfer, then enter a cyclone separator to realize gas-solid separation for completing the cyclone drying; and the gas which is separated by the cyclone separator enters a solvent recovery system after being filtered by a bag-type dust collector, and the materials enter a primary fluidized bed to be mixed with high-temperature dry air, are subjected to full fluidization and heat transfer to remove the water content, enter a secondary fluidized bed to be cooled to normal temperature, and then enter the next process. The method has a simple technology, is easy to control in operation, has high thermal efficiency, saves energy sources, is environment-friendly, and has a good drying effect, large solvent recovery amount and obvious benefits.

Owner:QINGDAO UNIV OF SCI & TECH +2

Slicing device for angelica sinensis processing

ActiveCN113370278AImprove product qualityEasy for slicing workSievingScreeningAngelica Sinensis RootKnife blades

The invention provides a slicing device for angelica sinensis processing, and relates to the field of traditional Chinese medicinal material processing. The slicing device for angelica sinensis processing comprises a carrying table, a slicing mechanism, a cleaning mechanism, a material guiding mechanism and supporting legs; the bottom of the right end of the slicing mechanism is fixedly connected with the top face of the right end of the carrying table; the left end of the cleaning mechanism is fixedly connected with the right side face of the left end of the slicing mechanism; the bottom of the material guiding mechanism is fixedly connected with the top face of the left end of the carrying table; and the top ends of the supporting legs are connected with the four corners of the bottom face of the carrying table respectively. According to the slicing device for angelica sinensis processing, through an arranged cleaning piece, firstly, the shape of the cleaning piece can prevent a blade from damaging the cleaning piece; then, cutter teeth on the cleaning piece can prevent sliced angelica sinensis pieces from adhering to the surface of the cleaning piece; impurities on the blade can be effectively scraped, and juice in angelica sinensis is prevented from adhering to the surface of the blade; and therefore, the service life of the blade is prolonged to a great extent.

Owner:JILIN AODONG SHIHANG PHARMA

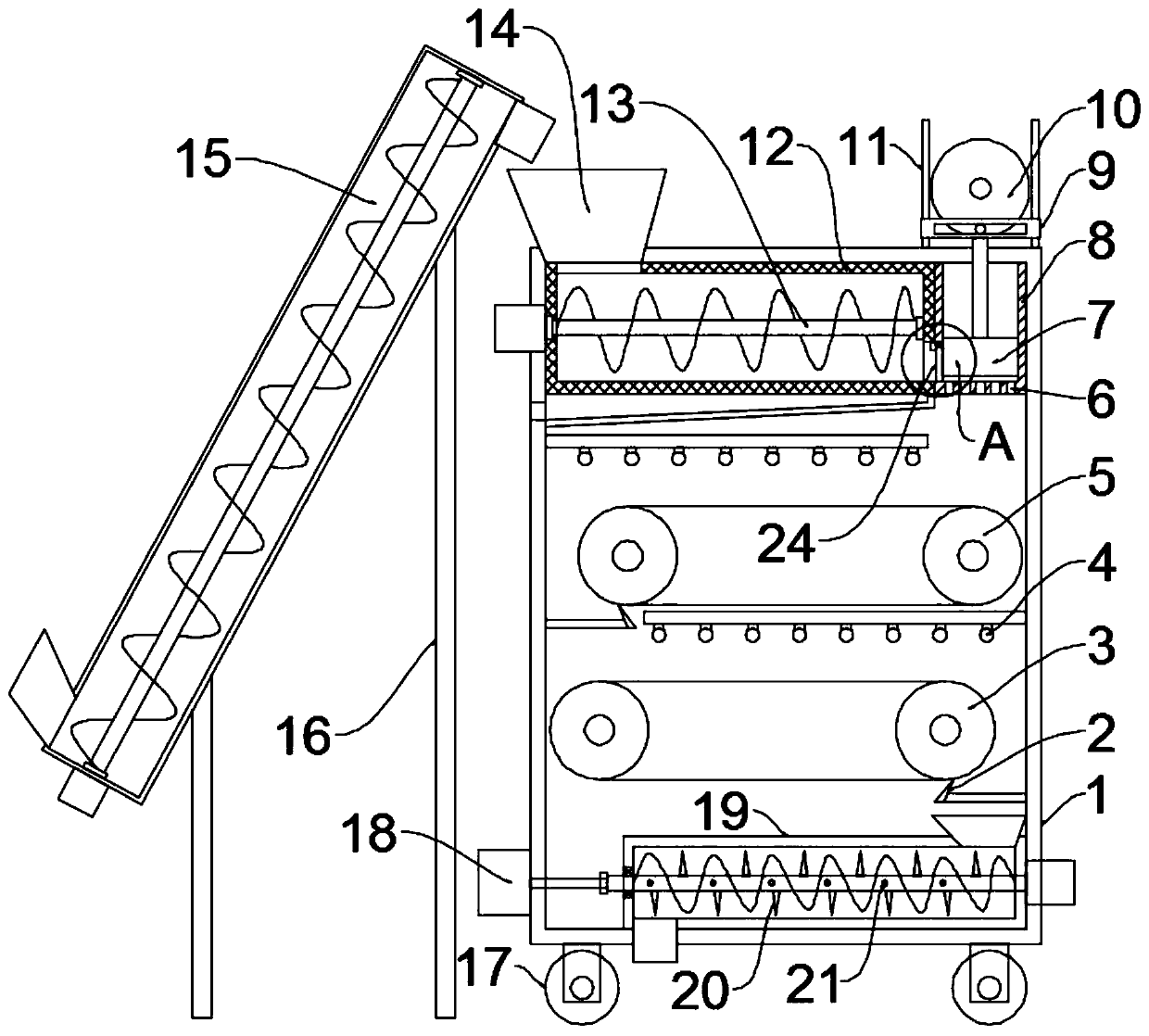

Wheat drying device

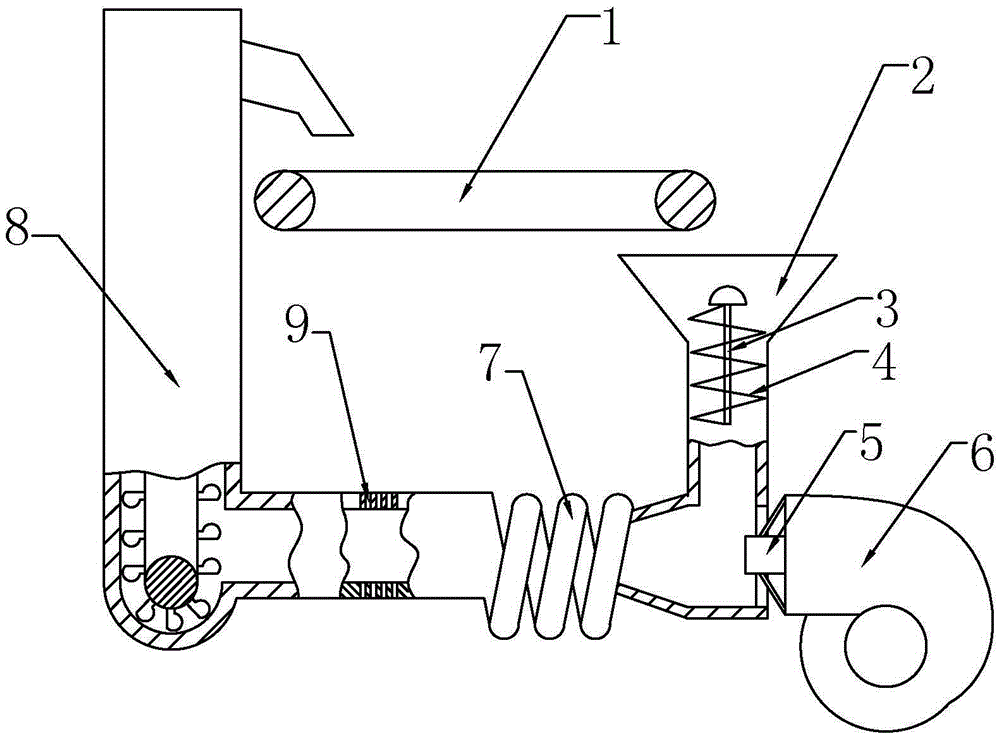

InactiveCN105248629AIncrease the drying areaSpeed up dryingSeed preservation by dryingSpiral bladeThree stage

The application relates to a drying device and discloses a wheat drying device. The wheat drying device comprises a conveying device, wherein the conveying device is provided with a drying belt; a feeding hopper is arranged under the conveying device and is internally provided with a main shaft; a spiral blade is connected on the main shaft; an outlet of the feeding hopper is communicated with a vertical spiral pipeline; a first electric-heating wire is arranged in the pipe wall of the spiral pipeline which is communicated with an inclined pipeline; a plurality of heaters are arranged in the inclined pipeline which is internally provided with an inclined plate; a spring is arranged between the inclined plate and the inclined pipeline; a connecting rod is connected to the inclined plate; a cam is arranged at one side of the inclined pipeline; one end, which penetrates through the inclined pipe, of the connecting rod abuts against the cam; one end, which is away from the feeding hopper, of the inclined pipeline is connected with a lifting device; a discharging port of the lifting device is arranged above one side close to the conveying device. Compared with the prior art, the wheat drying device has the advantages that wheat is subjected to three-stage drying, airing is not needed, and wheat does not need to be spread, so that the drying time and the labor intensity are reduced and the drying efficiency is improved.

Owner:CHONGQING YUXI FLOUR PROD

Drying oven control system

InactiveCN104534830AKeep drySimple structureDrying gas arrangementsDrying chambers/containersTemperature controlHeat conducting

The invention provides a drying oven control system and belongs to the field of heating mechanical equipment. The drying oven control system comprises a box body. An exhaust fan is arranged at the top of the box body. An air blower is arranged on one side of the box body. An outlet of the air blower is connected with one end of a ventilation pipeline. The other end of the ventilation pipeline is arranged on the box body on the same side of the air blower and is communicated with the inner portion of the box body, and a heat circulating system is formed. A temperature control box is arranged on the other side of the box body. A U-shaped coil pipe is laid on the inner wall of the box body. Heat conducting oil is arranged in the U-shaped coil pipe. An inlet and an outlet of the U-shaped coil pipe are connected with the temperature control box which can adjust the heating temperature of heat conducting oil. A plurality of shelf layers are arranged in the box body. Trays are arranged on the shelf layers respectively. The drying oven control system is simple in structure, low in cost and high in efficient drying area, object drying effect is improved, meanwhile, great temperature control and heat preservation effects are achieved, the heat using rate is improved, accordingly, product quality is improved, and following production is guaranteed reliably.

Owner:TIANJIN YIKUO METAL PROD

Aluminum alloy door window with clothes air-drying function

InactiveCN107246217ARealize limitAchieve fasteningOther drying apparatusWing arrangementsEngineeringFastener

The invention discloses a clothes-drying aluminum alloy door and window. Clothes buttons, two ends of each first spring are elastically fixed with two clothes-hanging buttons, and a limiting cavity is set on the said hanging buttons, and a second spring is fixed inside the limiting cavity, and the second spring is A coat hanger is installed. The invention can realize the position limitation of the clothes hanging buckle, reserve enough space for drying clothes; enable operators to quickly dry and collect clothes quickly; the inclined design of the rod body also enables each clothes to accept a larger drying area.

Owner:宿州云宏建设安装有限公司

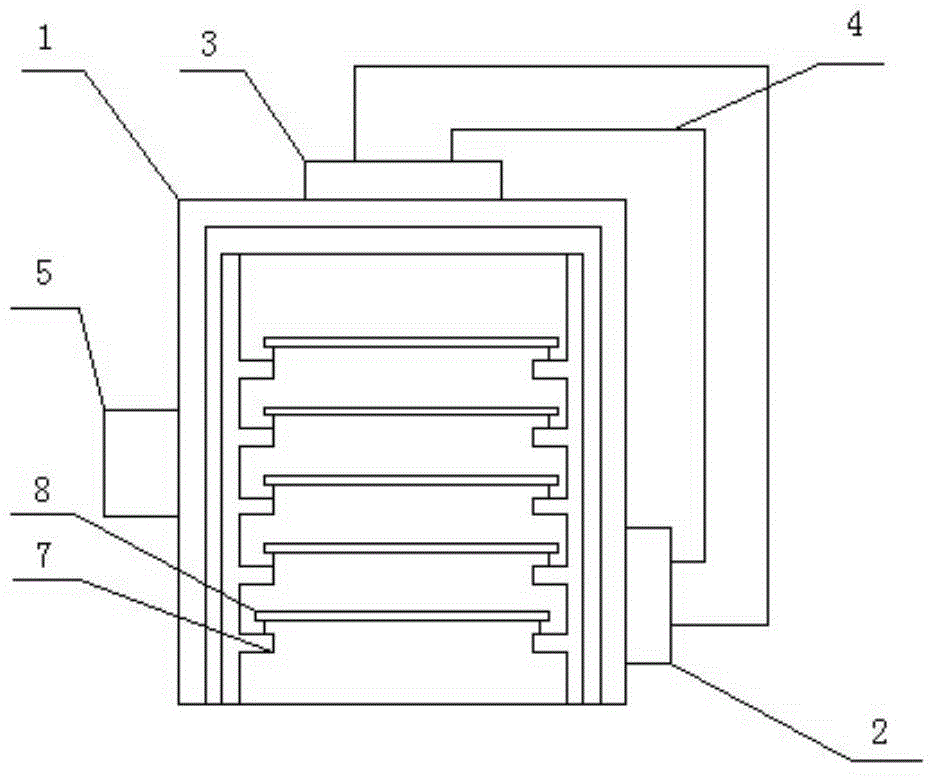

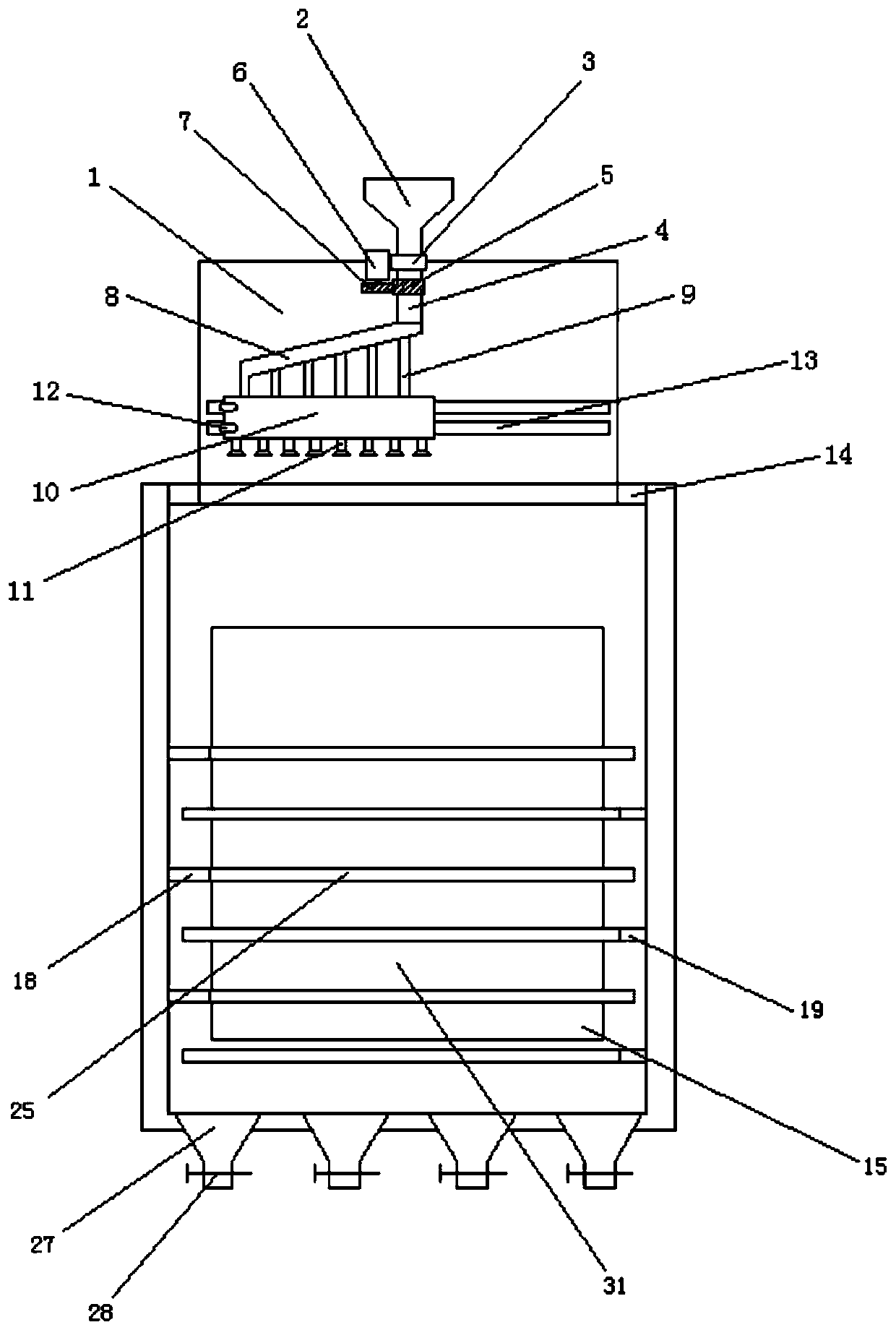

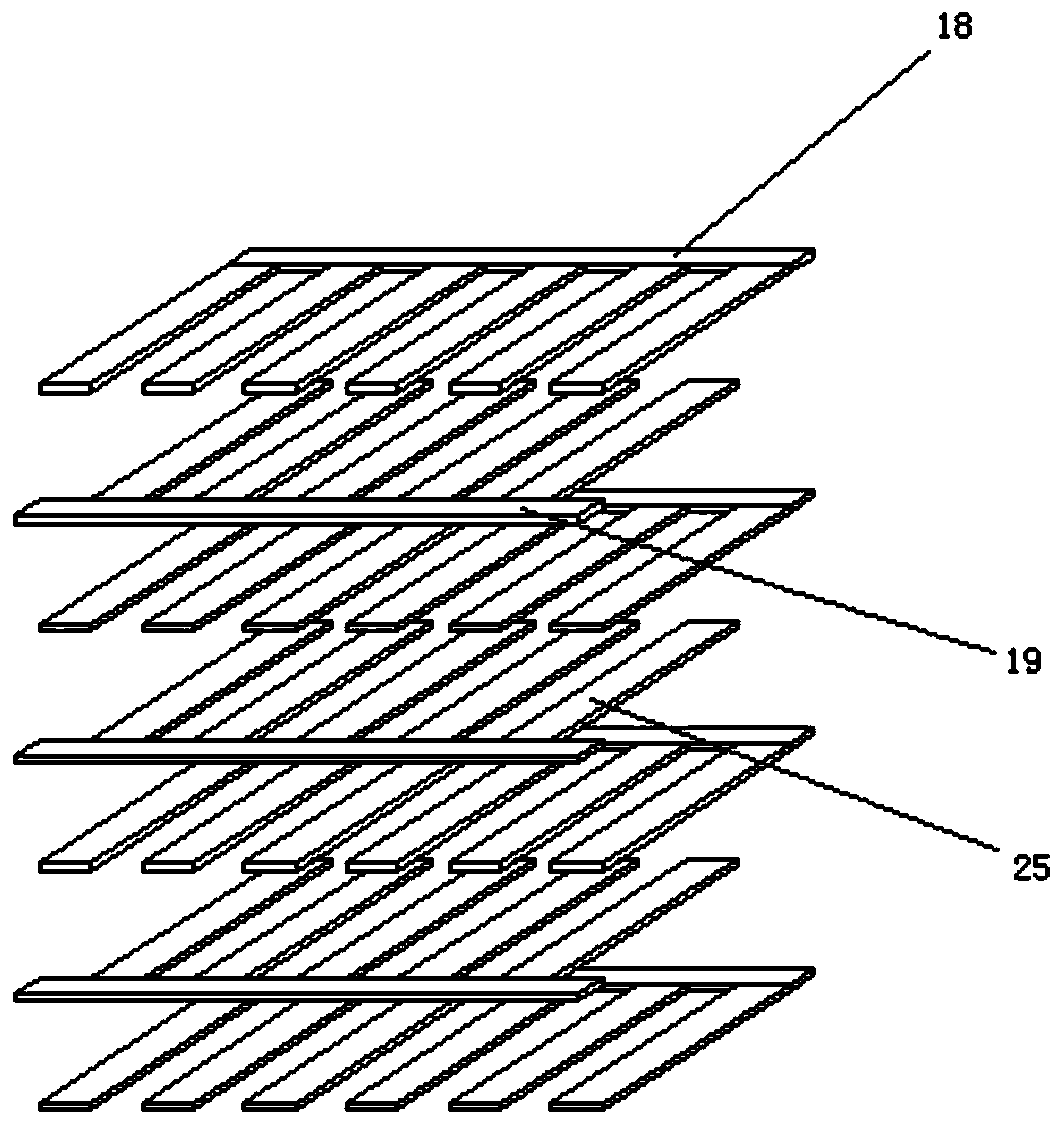

Grain drying device

InactiveCN111156795AUniform feedingAvoid insufficient dryingDrying gas arrangementsSeed preservation by dryingGear wheelAgricultural engineering

The invention discloses a grain drying device. The grain drying device comprises a feeding bin and a drying bin, and the feeding bin is located at the top of the drying bin; a feed hopper is fixedly mounted in the top center of the feeding bin; a first motor is fixedly mounted on the side wall of the feed hopper; two sets of rails and two sets of toothed rails are mounted on the side walls of thetwo sides of an inner cavity of the drying bin correspondingly, the rails on the side walls of the two sides of the inner cavity of the drying bin are movably connected with three sets of first lifting frames and second lifting frames correspondingly, two sets of second motors are fixedly mounted on the rear sides of the first lifting frame and the second lifting frame of each set, one sides of the second motors are fixedly connected with second gears, the second gears are mutually engaged with the corresponding toothed rails, and the inner side walls of the first lifting frames and the secondlifting frames are horizontally provided and connected with a plurality of sets of bearing plates; and a plurality of discharge hoppers are fixedly mounted at the bottom of the drying bin. The graindrying device is simple in structure, convenient and practical, grain can be distributed on all the bearing plates layer by layer, the drying area is increased, and the drying efficiency is improved.

Owner:杨文耀

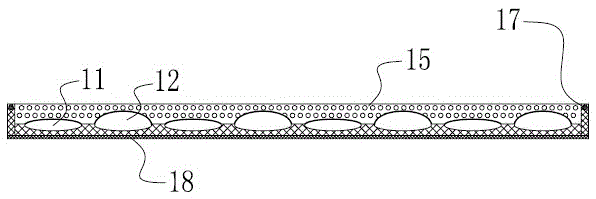

Air bag, automatic airing device and airing method

InactiveCN105651020AGood drying effectSave human resourcesClimate change adaptationSeed preservation by dryingAirflowEngineering

The invention relates to the technical field of drying devices and discloses an air bag, an automatic airing device and an airing method. A plurality of air cavities are arranged in the air bag and are sequentially adjacent, every two adjacent air cavities do not communicate with each other, spaced air cavities communicate with each other through an air channel, and therefore a first air cavity set and a second air cavity set disconnected to the first air cavity set are formed and are respectively provided with an airflow connection port. According to the air bag, the automatic airing device and the airing method, objects to be aired are aired through the combined effect of heating by the warm air bag at the lower part and heating by sun irradiation at the upper part, the evaporation speed of water is high, the airing effect is good, and subsequent processing or storing of the objects to be aired is convenient.

Owner:周湘博

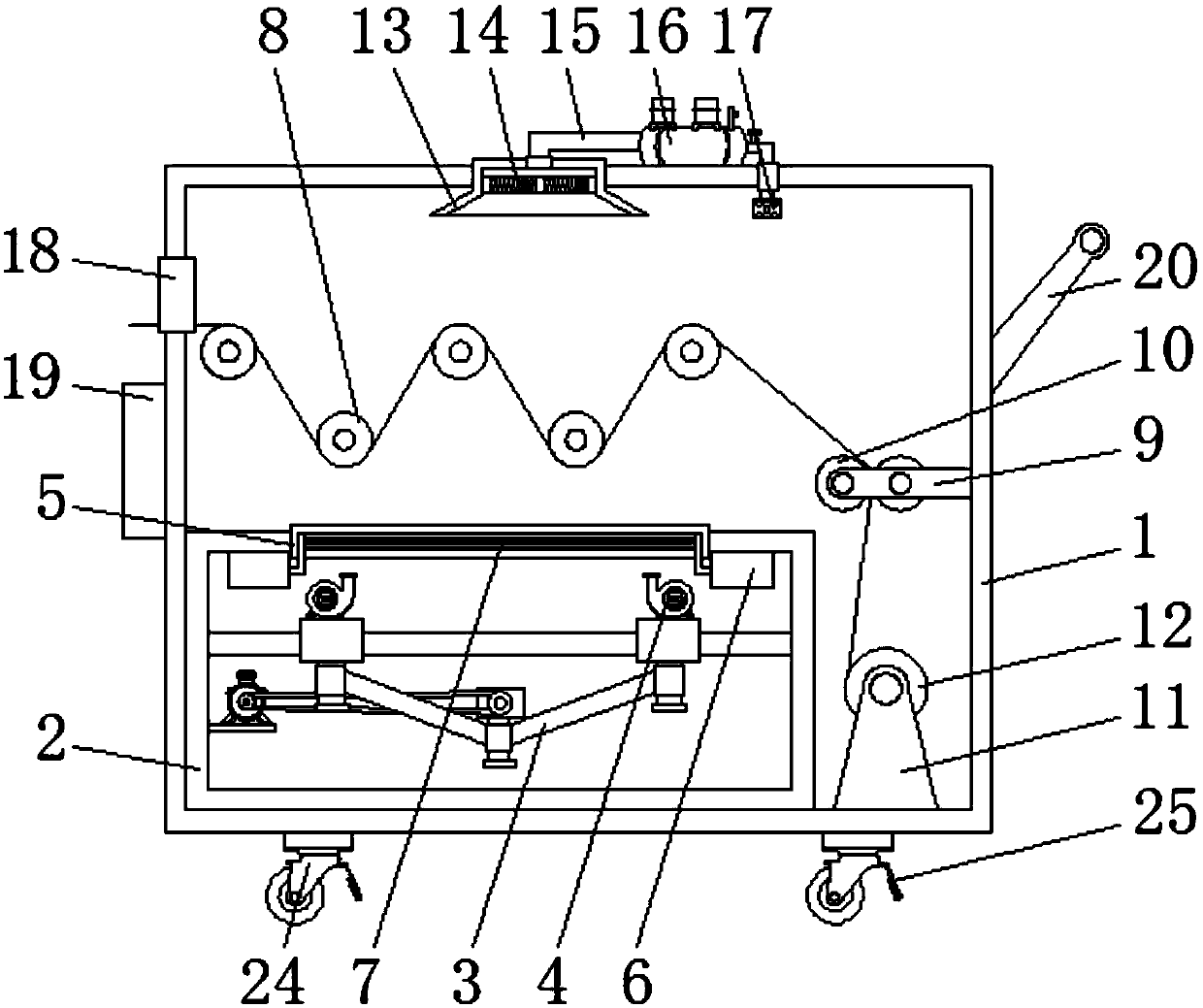

Military multifunctional textile fabric high-efficient drying and sizing equipment

InactiveCN107119414AEasy to moveReduce laborLiquid/gas/vapor removalHeating/cooling textile fabricsElectric machineryEngineering

The invention discloses an efficient drying and setting equipment for multifunctional textile fabrics for military use. Both sides of the inner cavity of the box are fixedly connected with electric extension rods, the bottom of the electric extension rod is fixedly connected with a flat plate, the bottom of the flat plate and the inner cavity of the through hole is fixedly connected with a bracket, and the bottom of the bracket is fixedly connected with a bracket. The bottom runs through the through hole and extends to the outside of the through hole. The bottom of the bracket is articulated with rollers through the rotating shaft. roller. The present invention can dry the fabric, increase the drying area of the fabric, improve the drying efficiency of the fabric, cooperate with the motor and the reel, can store the dried fabric, and integrate the drying and storage , Improve the production efficiency of the fabric.

Owner:浙江盛伦科技有限公司

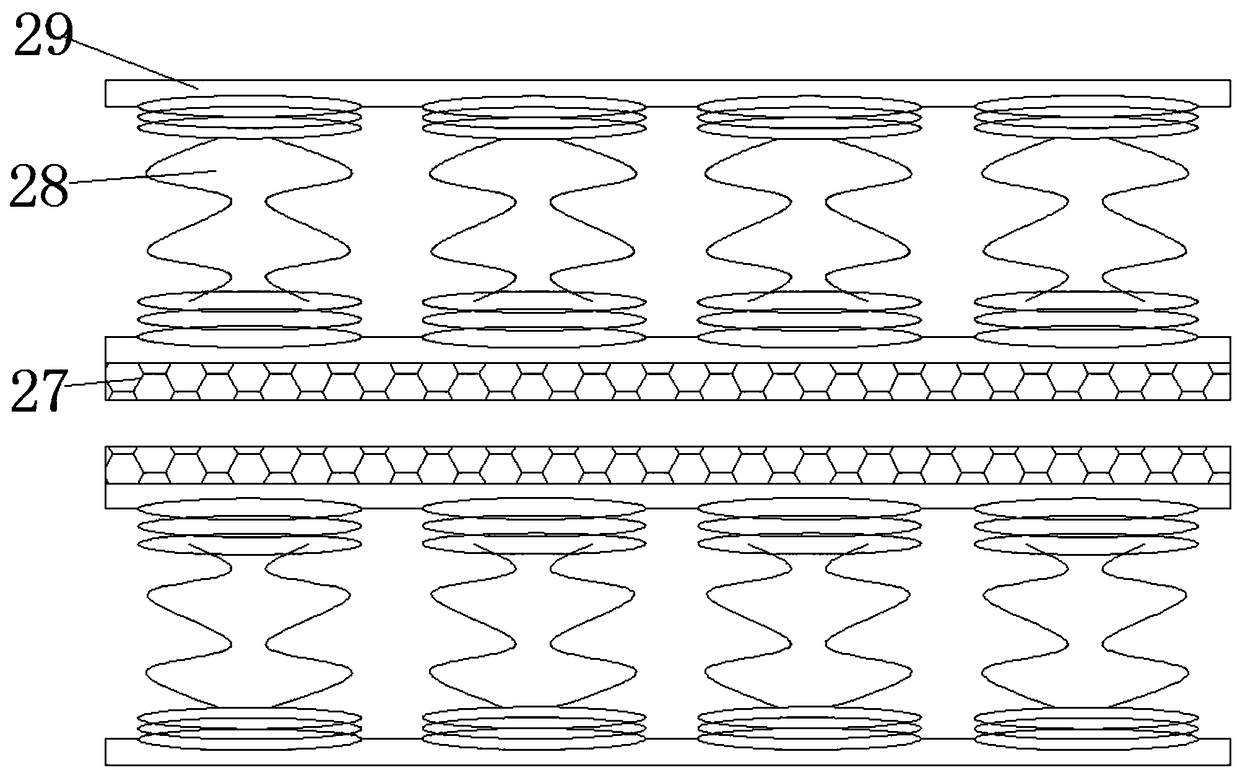

Quilt dryer

ActiveCN110592909AEvenly heatedImprove drying effectTextiles and paperLaundry driersEngineeringAir blower

The invention discloses a quilt dryer. The quilt dryer comprises a tank body, wherein a tank door is hinged to the front face of the tank body, the top end of the inner portion of the tank body is provided with a rotating assembly, an output end of the rotating assembly is horizontally provided with a circular fixed plate, the rotating assembly is used for driving the fixed plate to rotate, the lower surface of the fixed plate is uniformly provided with a plurality of quilt clips in the circumferential direction, the center of the bottom of the tank body is provided with a vertical cylinder, the bottom of the tank body is further provided with a hot-air blower, the outer circumferential surface of the cylinder is provided with a plurality of air outlet holes, air outlet ports of the hot-air blower are communicated with the inner portion of the cylinder, the inner portion of the tank body is further horizontally provided with an annular lifting ring, the inner wall, close to the inner ring, of the lifting ring is provided with a heating wire, the inner all of the tank body is provided with a reciprocating drive assembly, and the reciprocating drive assembly is used for driving the lifting ring to perform linear reciprocating movement in the vertical direction. The quilt dryer coils a quilt into a cylindrical shape, and dries the inner surface and outer surface of the quilt, so that the drying area is increased, the drying efficiency is accelerated; the rotation of the quilt in the drying process is kept, so that heating of the quilt is uniform, and the drying effect is good.

Owner:WUHU INST OF TECH

Recombined bamboo timber processing technology

InactiveCN107498666AReduce transshipment costsSimple processWood treatment detailsCane mechanical workingCarbonizationEngineering

The invention discloses a recombined bamboo timber processing technology. The recombined bamboo timber processing technology comprises the following steps that a bamboo is sawed off, specifically, the bamboo is sawed off by utilizing a cut-off machine, and the number of the bamboo sections obtained by once sawing through the cut-off machine is greater than two; bamboo ties are prepared, specifically, the multiple bamboo sections are conveyed to different bamboo tying machines correspondingly, and the bamboo sections are defibered by utilizing the bamboo tying machines to obtain the bamboo ties; sterilization and carbonization are conducted, specifically, the bamboo ties are conveyed to a drying and sterilizing carbon drying machine, carbonized, and then taken out; primary drying is conducted, specifically, the bamboo ties are conveyed to a reciprocating type drying line to be subjected to drying for the first time; gumming is conducted, specifically, the dried bamboo ties are conveyed to a gumming line to be subjected to gumming, and after gumming is completed, the bamboo ties are subjected to drying for the second time; quantitative mat formation is conducted, specifically, after the secondary drying is completed, the bamboo ties are conveyed to a forming machine to be subjected to quantitative mat formation; and compression moulding is conducted, specifically, the bamboo ties which are subjected to mat formation are conveyed to a loader through a base plate, and the bamboo ties on the loader are conveyed to a pressing machine through the base plate to be subjected to compression moulding.

Owner:蒋红卫

Drying device for manufacturing flour

InactiveCN105248628AIncrease the drying areaSpeed up the drying processSeed preservation by dryingGrain millingEngineeringSpiral blade

The application of the invention relates to a drying device, and discloses a drying device for manufacturing flour. The drying device comprises a conveyer, wherein a drying belt is arranged on the conveyer, a feeding hopper is arranged below the conveyer, a main shaft is arranged in the feeding hopper, a spiral blade is fixedly connected on the main shaft, a spiral pipe is communicated with an exit of the feeding hopper, a first electrical heating wire is arranged on the pipe wall of the spiral pipe, an opening is formed in a feeding hopper wall on a relative side of the spiral pipe, a fan is arranged in the opening, a ventilating hole is formed in the spiral pipe, a lifter is connected with one end, far away the feeding hopper, of the spiral pipe, and a discharge hole of the lifter is arranged on one side close to the conveyer. Compared with the prior art, the drying device provided by the application of the invention dries wheat without airing depending on weather and spreading, so that the wheat drying time is largely shortened, the labor intensity of farmers is reduced, and the drying efficiency is improved.

Owner:CHONGQING YUXI FLOUR PROD

Efficient lathe scrap recycling device

InactiveCN107971286AImprove worker productivityImprove work efficiencySolid waste disposalDrying gas arrangementsScrapLap joint

The invention discloses an efficient lathe scrap recycling device which comprises a bottom plate. The upper surface of the bottom plate is fixedly connected with a shell. The upper surface of the shell is in lap joint with a first cover plate. The upper surface of the first cover plate is connected with a first bearing in a clamping mode. A first rotary shaft is sleeved with the first bearing. Thetop end of the first rotary shaft is fixedly connected with an output shaft of a first motor. According to the efficient lathe scrap recycling device, a control panel, the first motor, a second motor, a third motor, a net barrel, the first bearing, the first rotary shaft, an air blower and an electric push rod are arranged, the first rotary shaft rotates and drives stirring rods to rotate by controlling the first motor to work, the stirring rods drive scrap and water in the shell to rotate, meanwhile, the air blower is controlled to work and blow air towards the net barrel so that water spotson iron scrap can be blown away, thus, the workload is reduced, operation steps are reduced, the recycling speed is increased, therefore, the working efficiency of workers is improved, and meanwhile,machining of factories to parts is not delayed.

Owner:佘峰

Vertical gravity conveying enforced cross-flow drying method and device

InactiveCN101793457AEnhanced flow capacityReduce disturbanceDrying solid materials with heatDrying solid materials without heatFlaky pastryPositive pressure

The invention relates to a vertical gravity conveying enforced cross-flow drying method and a device. The invention is suitable for removing surface moisture from particle materials by utilizing hot air in the industries of mine, building materials, metallurgy, ceramics, chemical engineering and the like, and is also suitable for removing moisture from particle materials by utilizing hot air in the industries of foodstuff and feedstuff. The invention has the following technical scheme: hot airflow suitable for the dried material temperature is enforced into a storehouse; under the positive action of the external pressure, the hot airflow penetrates through the voids among the granules and is discharged out of the storehouse; the hot airflow and the material contact each other and exchange heat when the hot airflow penetrates through the voids among the granules; thus, the material temperature is increased, the moisture is evaporated, and the generated water vapor is discharged out of the storehouse along with the airflow; and under the action of gravity, the material on the same cross section in the drying storehouse continuously descends, and is continuously penetrated through and dried by the hot air in the descending process. Due to the adoption of the vertical gravity descending conveying, the invention is simple and reliable in structure; due to the adoption of the drum suction mode with multiple sets of positive pressure chambers and negative pressure chambers which are vertically arranged, the invention strengthens the airflow penetration capability, so that the airflow completely penetrates through the material, thereby enhancing the thermal efficiency; the flaky pastry mode increases the flow penetration drying area and enhances the yield; and since the material is dried in the descending process, the invention has the advantages of small disturbance, little exhaust dust and low pollution.

Owner:王文民

Mushroom-airing device

The invention discloses a mushroom-airing device. The device includes supporting legs, position-limiting holes, fasteners, rollers, connecting joints, airing boards, fixation columns, through holes, grooves, vertical plates, mounting plates, heating plates, baffle plates, a power line, slide-proof pads, inserting rods and stabilizing rods. The beneficial effects of the device provided by the invention are as follows: a plurality of the position-limiting holes are arranged on the supporting legs which are connected with the connecting joints through the position-limiting holes so that the plurality of the connecting joints can be arranged on the supporting legs. The connecting joints and the supporting legs are stably connected by the fixation columns. The distance between the connecting joints can be adjusted through the different position-limiting holes. One end of each of the connecting joints is connected with an airing board through a groove so that the plurality of the airing boards can be arranged on the supporting legs so as to increase the airing area. The heating plates under the airing boards can heat and bake mushrooms on the airing boards to speed up water evaporation of the mushrooms. The device is simple in structure and is convenient to use and each part of the device can be dismantled freely for convenient storage.

Owner:柳州市北部科技服务有限公司

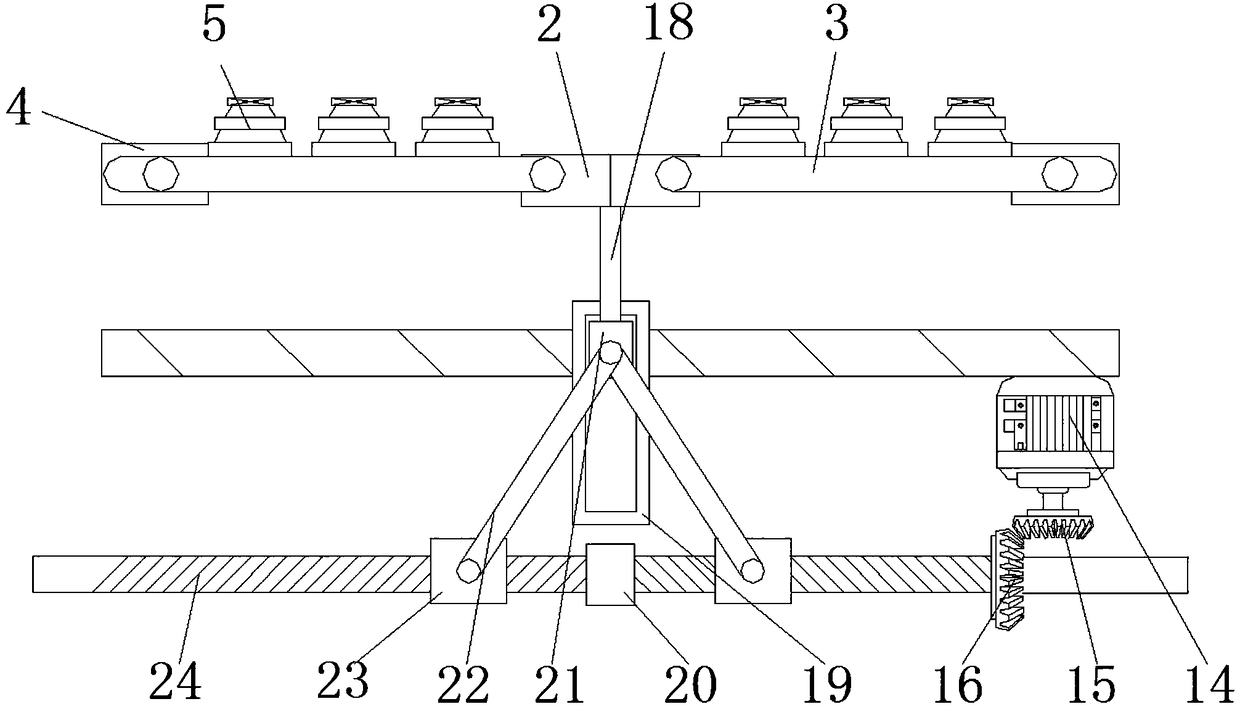

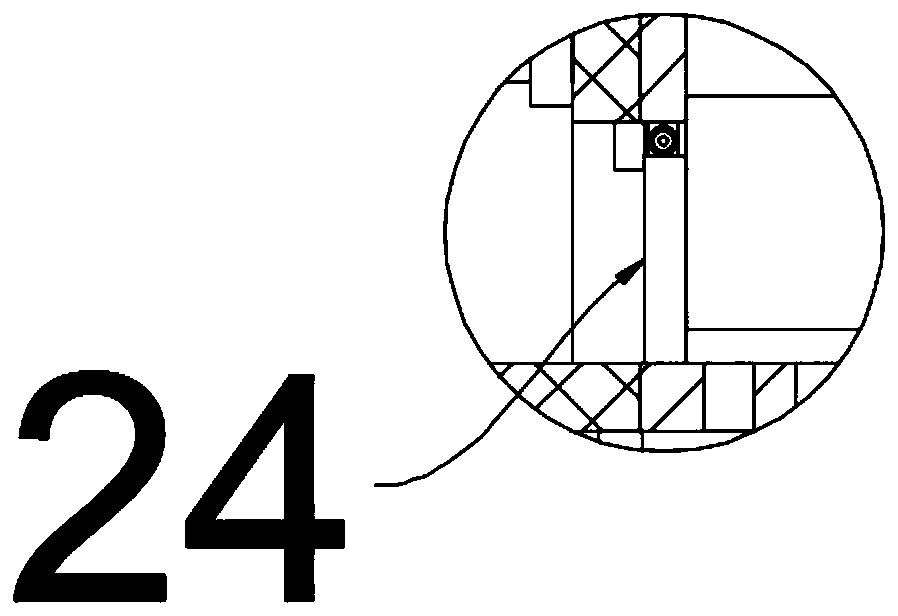

Automatic feeding type sludge treatment equipment

ActiveCN110342771AIncrease the drying areaImprove drying efficiencySludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeReciprocating motion

The invention discloses automatic feeding type sludge treatment equipment. The equipment comprises a box body, a feeding unit, a drying unit and a discharging unit; the feeding unit, the drying unit and the discharging unit are all installed in the box body; the drying unit communicates with the discharging unit; the equipment further comprises an extrusion unit; the extrusion unit is arranged between the feeding unit and the drying unit and communicates with the feeding unit and the drying unit; the extrusion unit comprises an extrusion bin, extrusion holes and a driving assembly for drivingthe extrusion block to reciprocate; the driving assembly comprises a driving motor, a disc, a movable rod and a connecting rod; the drying unit comprises a drying lamp, an upper conveying belt and a lower conveying belt; and the discharging unit comprises a discharging auger and crushing blades. The equipment is provided with the extrusion unit, and the driving unit drives the extrusion block to move up and down, then moisture in sludge can be extruded out, and meanwhile, sludge is continuously extruded out of the extrusion holes to be in a long strip shape, so that the sludge drying area is increased, and drying efficiency is improved.

Owner:梁秀宜

Fluffy device for wig processing

The invention discloses a fluffy device for wig processing, and particularly relates to the field of wig processing. The fluffy device comprises a wig carrying mechanism, wherein a first side surfaceair supply mechanism is arranged at one side of the wig carrying mechanism; a second side air supply mechanism is arranged at the other side of the wig carrying mechanism; the wig carrying mechanism comprises a carrying seat; the top of the carrying seat is fixedly provided with a servo motor; a transmission shaft is arranged on the top of the servo motor; a connecting block is sleeved and connected onto the outer side of the top end of the transmission shaft; a spherical block is fixedly arranged on the top of the connecting block; the top of the spherical block is bonded and provided with asilica gel layer; each of the first side surface air supply mechanism and the second side surface air supply mechanism comprises a longitudinal hollow pipe; an upper air supply mechanism and a lower air supply mechanism are fixedly arranged at the front side of the longitudinal hollow pipe. During the blowing drying, the blowing drying can be performed in a mode of simulating the human hand to take an air blower for blowing drying; after the blowing drying, the fluffy effect is good; meanwhile, the blowing drying area is larger; the fluffy operation is more uniform, so that the fluffy effect is more ideal; the fluffy quality is higher.

Owner:ANHUI FORTUNE FASHION CULTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com