Vacuum drying device and drying method

A vacuum drying device and vacuum pump technology, applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problem that the degree of drying of materials cannot meet the process standards, the degree of drying cannot meet the standards, and the exchange of internal and external materials is slow, etc. problems, to achieve the effect of increasing the drying area, preventing material agglomeration, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

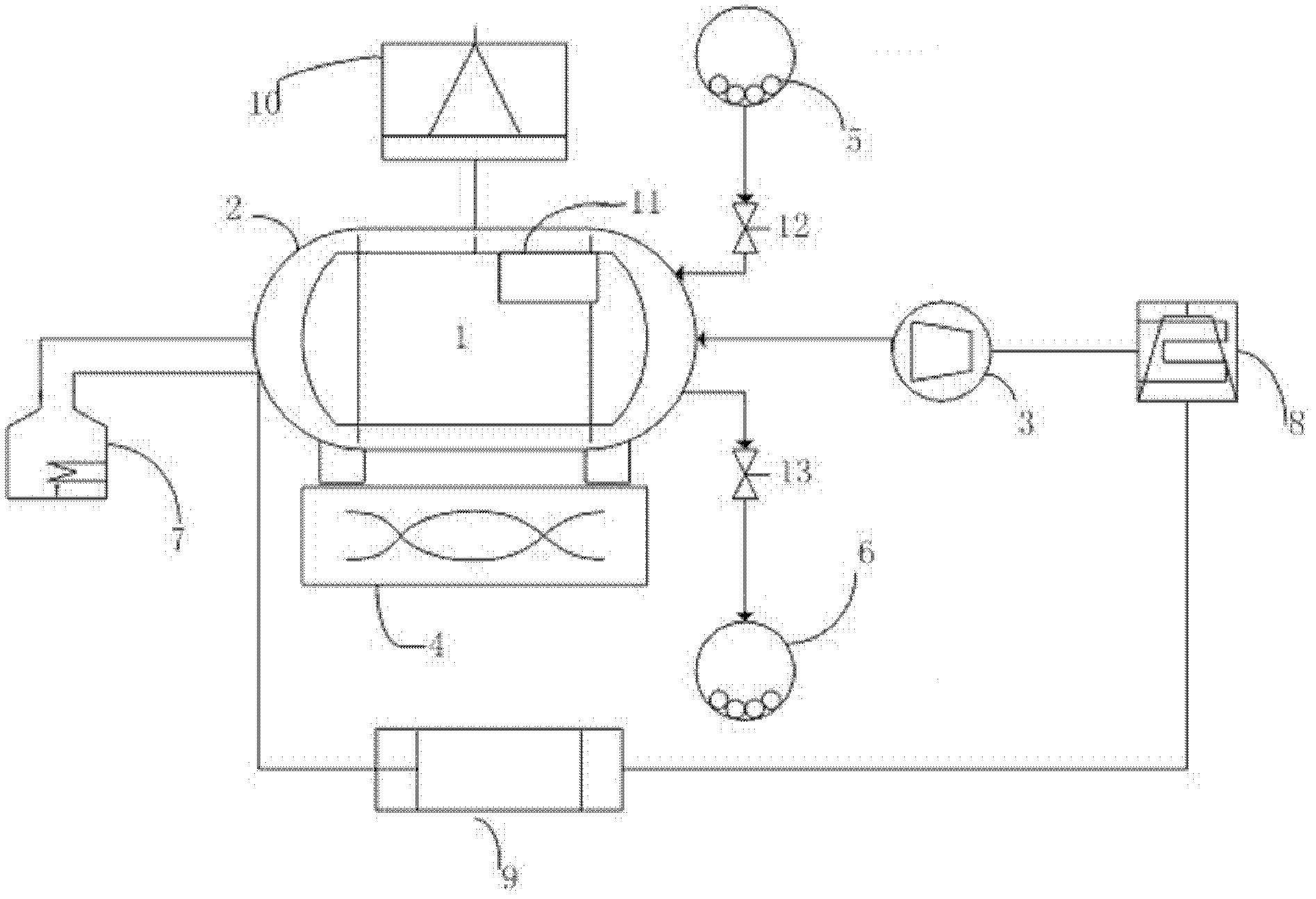

[0021] The following is a preferred embodiment of a vacuum drying device proposed by the present invention, such as figure 1 as shown,

[0022] figure 1 Among them, the horizontal tank body 1 is equipped with a heating jacket 2, and the horizontal tank body 1 is connected with the vacuum pump 3, the vibrating device 4, the feed port 5, and the discharge port 6 respectively, and the feed port isolation valve 12 connects the horizontal tank body 1 is isolated from the material inlet 5, and the material outlet isolation valve 13 isolates the horizontal tank body 1 from the material outlet 6, and these two isolation valves are in a closed state before working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com