Patents

Literature

168 results about "Flaky pastry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flaky pastry, also known as blitz pastry or rough puff, is a light and flaky unleavened pastry that is similar to, but distinct from, puff pastry. Flaky pastry relies on large lumps of butter (approximately 1 in or 2.5 cm across) mixed into the dough, as opposed to the large rectangle of butter in puff pastry. Flaky pastry dough is then rolled and folded in a manner similar to puff pastry.

Preserved vegetable flaky pastry and production method thereof

The invention relates to food and a production method thereof and particularly relates to preserved vegetable flaky pastry and a production method thereof. The production method of the preserved vegetable flaky pastry comprises the following steps of: washing preserved vegetables, cutting into shreds and drying at a low temperature; adding vanilla powder and spicy vanilla powder to season for later use; sequentially adding custard powder and white granulated sugar into low-gluten flour, adding butter and lard oil, and uniformly agitating; and adding the uniformly-mixed preserved vegetable shreds into the powder, uniformly agitating, and molding and baking. The preserved vegetable flaky pastry initiates to take the preserved vegetables as the raw materials of the flaky pastry, the vanilla powder and the spicy vanilla powder are added to season and the flaky pastry is mixed and baked by using the soft flour, so that the flaky pastry is sweet and tasty and is full of nutrition; and the special taste of the preserved vegetables is kept to the greatest extent and the product is ensured to have the previous characteristic of the preserved vegetables after being baked during the producing process, so that the characteristics of local foods is reflected and the local characteristics are rich.

Owner:邓华彪

Sweet flaky pastry making method

The invention relates to a sweet flaky pastry making method. The method is characterized by comprising the following steps of: leavening dough according to a proportion; adding dry flour, ingredients, linseed oil, white granulated sugar and water into a flour mixing machine to knead the dough; keeping the dough standing for one hour for later use; blending crisps according to a proportion; kneading the dough together with the crisps; dividing the mixture into a plurality of sections of dough of which each piece of dough is about 200 grams; kneading again; rolling; putting into a baking dish; placing for 5 to 10 minutes; putting into an oven; and baking in the oven for 30 minutes, taking the baked pastries out and cooling for eating.

Owner:席慧芳

Macadamia nut flaky pastry and processing method thereof

InactiveCN102388938ATake advantage ofReduce intakeDough treatmentBakery productsFlaky pastryMacadamia integrifolia

The invention discloses a macadamia nut flaky pastry and a processing method thereof. The flaky pastry comprises flour, macadamia nut powder, a sweetener, macadamia nut oil and water in the ratio of weight parts of (75-85):(15-25):(25-40):(5-15):(15-25), and the flaky pastry is obtained after baking the raw materials; the macadamia nut powder is obtained by drying the macadamia nut kernel, bakingand crushing the kernel slag after the oil squeezing. The processing method comprises the preparation of the macadamia nut powder and the macadamia nut oil: preparing the flour, the macadamia nut powder, the sweetener, the macadamia nut oil and water according to above parts by weight; blending the raw materials of the flaky pastry, shaping, and baking to obtain the macadamia nut flaky pastry. Compared with the directly edible macadamia nut, the macadamia nut flaky pastry can intake the nutrient component of the macadamia nut, but the intake amount of the macadamia nut oil is greatly reduced so as to avoid the over-nutrition caused by eating more nuts. Although the macadamia nut is not directly eaten, the macadamia nut is sufficiently used, and the variety of the macadamia nut processed food is enriched.

Owner:云南迪思企业集团坚果有限公司

Purple sweet potato flaky pastry and making method thereof

InactiveCN104757085ATake advantage of the benefitsImprove developmentBakery productsCarrot juiceFlaky pastry

The invention relates to purple sweet potato flaky pastry and a making method thereof, and belongs to the technical field of food. The purple sweet potato flaky pastry comprises, by weight, 100-150 parts of high-gluten flour, 50-60 parts of low-gluten flour, 100-120 parts of lotus seeds, 10-25 parts of white granulated sugar, 20-40 parts of sweet osmanthus honey, 30-50 parts of peanut oil, 50-60 parts of carrot juice, 50-80 parts of purple sweet potatoes, 20-28 parts of pumpkins, 10-15 parts of bacon, 5-8 parts of dried blueberries, 6-9 parts of dried mango and 5-9 parts of walnut kernels. The purple sweet potato flaky pastry is nutrient, healthy, reasonable in match and easy and convenient to make, has a little of fat mass, can be eaten by people at ease, can be eaten as dessert and staple food and can resist cancer if being eaten by people for a long time, so that the effect of purple sweet potatoes is sufficiently utilized, and purple sweet potatoes can be better developed and utilized.

Owner:崔子扬

Fermented bean curd flaky pastry and manufacturing method thereof

The invention discloses a fermented bean curd flaky pastry and a manufacturing method thereof. The fermented bean curd flaky pastry is composed of oil dough, pastries and fillings, wherein the oil dough is composed of weak strength flour, high gluten flour, lard oil, granulated sugar and water; the pastries are composed of weak strength flour and lard oil; and the fillings are composed of candiedmelon, ice meat, granulated sugar, fermented bean curds, cooked sesame seeds, shallots, lard oil, malt sugar, weak strength flour, starch, salt and water. According to the fermented bean curd flaky pastry and the manufacturing method thereof, the fermented bean curd flaky pastry is tasty, delicate, fragrant, sweet and palatable; the fermented bean curds serve as the flavor source, and fillings are mixed by adding special food materials, so that the flavor is authentic, characteristics are provided, and the flavor is memorable. The manufacturing method is simple, and the operation is convenient.

Owner:开平市三埠小麦田西饼店

Walnut flaky pastries and making method thereof

InactiveCN105660785ASolve the shortcomings of narrow edible rangePromote absorptionDough treatmentBakery productsYolkYeast

The invention relates to walnut flaky pastries and a making method thereof, and belongs to the technical field of food processing. The walnut flaky pastries are prepared from the following raw materials of wheat flour, walnuts, soybean flour, sesame seeds, peanuts, yeast powder, edible salt, edible oil, sesame oil, white granulated sugar, eggs, melon seeds and dried meat floss. According to the walnut flaky pastries, the raw materials for making the walnut flaky pastries are scientific in collocation and rich in nutrition, and the defect that the eating range of the walnuts is narrow is overcome. According to the walnut flaky pastries disclosed by the invention, the soybean flour is added, so that the absorption of the walnuts in the human bodies is promoted; the sesame seeds, the peanuts, the melon seeds and the like are mixed with the walnuts, so that the nutrition is richer. Under the action of yolk, the roasted walnut flaky pastries are golden in color and richer in nutrients, and after the walnut flaky pastries are eaten for a long term in an appropriate quantity, the effects of strengthening bodies, maintaining beauty and keeping young can be achieved; besides, the main raw materials of the walnut flaky pastries are from general good materials in diet of people, the making technology is simple, and the walnut flaky pastries are easy to popularize.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Citrus residue flaky pastries and making method thereof

InactiveCN105211168ATake advantage ofRealize comprehensive utilizationBakery productsFood preparationCooking & bakingFlaky pastry

The invention discloses citrus residue flaky pastries and a making method thereof. The citrus residue flaky pastries are mainly made of oil crisps, water oil wrappers and citrus fruit residue stuffing, wherein the oil crisps comprise wheat flour and oil, the water oil wrappers comprise the wheat flour, water, the oil and baking soda, and the citrus fruit residue stuffing comprises citrus fruit residues, glutinous rice flour and edible sugar. The making method comprises the steps that an appropriate amount of the wheat flour is weighed to be evenly mixed with the oil, the water, the baking soda and salt, the mixture is kneaded into dough, the water oil wrappers are obtained, the water oil wrappers wrap the oil crisps to obtain wrappers, then the stuffing is placed on the wrappers to be wrapped and formed, and lastly baking is performed to obtain the citrus residue flaky pastries. According to the citrus residue flaky pastries and the making method thereof, not only are the peel residues in residues generated in squeezing of citrus fruits utilized, but also the pulp residues in the citrus fruit residues are utilized, and therefore the citrus fruit residues are fully utilized; the essence of waste utilization of the citrus fruit processing residues is achieved and has the most essential difference with utilization of the citrus fruits.

Owner:XIANGTAN UNIV

Manufacturing method of lentinus edodes stem sweet potato residue oat flaky pastries

ActiveCN103329972AIncrease total dietary fiberIncrease soluble dietary fiberDough treatmentBakery productsSerum cholesterolFlaky pastry

The invention relates to a manufacturing method of lentinus edodes stem sweet potato residue oat flaky pastries. According to the manufacturing method, sweet potato residues are rinsed by water, a filter screen is used for filtering and draining, lentinus edodes stems are cleaned, dried and pulverized, oatmeal, berry sugar, brown sugar and shredded coconut stuffing are taken, low-gluten flour, the sweet potato residues, the lentinus edodes stems and baking soda are added, the full mixing is carried out, then, the mixed materials are added into corn syrup and butter for uniform stirring to become drier paste, a small block of paste is pinched into a ball shape, flattening, baking and cooling are carried out, and the lentinus edodes stem sweet potato residue oat flaky pastries are obtained. The manufacturing method has the advantages that the lentinus edodes stems and the sweet potato residues with high dietary fiber content are used as raw materials, the sweet potato residues and the lentinus edodes stems are reused, the environment pollution is reduced, and economy is realized; total dietary fibers and soluble dietary fibers of products are high; on the basis of maintaining the color, the fragrance and the taste of the original oat flaky pastries, vitamins, nicotinic acid, folic acid, protein, mineral elements and the like are added, and the oat flaky pastries can be used as food for loosing the weight and regulating the blood sugar, the blood pressure and the serum cholesterol; and the forming effect is good, the eating is safe, the process is simple, the continuity is good, the operation cost is low, the generated waste materials are few, and the environment cannot be polluted.

Owner:湖北金悦农产品开发有限公司

Health care sticky rice flaky pastry and production method of health care sticky rice flaky pastry

The invention discloses health care sticky rice flaky pastry, which comprises 10 to 20 percent of oligosaccharide. The health care sticky rice flaky pastry is processed according to the following steps that: sticky rice is cleanly washed; the rice is steamed; the oligosaccharide is added; the sticky rice is cooled after being steamed, then, the oligosaccharide is added, the stirring is carried out so that the sticky rice and the oligosaccharide are uniformly mixed; the trimming and the forming are carried out; the drying is carried out until the moisture of the sticky rice flaky pastry is 6 to 8 percent; and then, twice vacuum oil frying is carried out, and the fragrant, sweet and crispy functional sticky rice flaky pastry can be obtained. Through low-temperature vacuum oil frying, the functionality and the puffing effect of the products are ensured, in addition, the grease rancidity can be effectively prevented, the food safety is enhanced, meanwhile, the moisture activity of the products is reduced, and the shelf life is prolonged. In addition, the functionality is high, and the natural flavor of the sticky rice is effectively maintained. The health care sticky rice flaky pastry belong to green food with the advantages that the flavor is unique, the long-time storage can be realized, the mouth feeling is fragrant, sweet and crispy, the nutrition is rich, and the special health care function and the natural sticky rice flavor are realized.

Owner:宁夏天瑞产业集团现代农业有限公司

Tremella and peanut flaky pastries and making method thereof

ActiveCN102578187ACrispy tasteCrispy and deliciousDough treatmentBakery productsFlaky pastryTremella

The invention relates to the technical field of foods, in particular to tremella and peanut flaky pastries and a making method thereof. According to a raw material formula, the tremella and peanut flaky pastries comprise the following components in part by weight: 240 to 260 parts of self-raising flour, 170 to 190 parts of water, 140 to 160 parts of white sugar, 90 to 110 parts of peanuts, 90 to 110 parts of liquid shortening, 90 to 110 parts of eggs, 8 to 10 parts of tremella, 1 to 2 parts of cake oil and 1 to 2 parts of salt. The making method comprises the following steps of: (1) preparingmaterials; (2) crushing the tremella; (3) stirring the white sugar, the eggs, the salt and the water; (4) adding the cake oil and stirring; (5) adding flour and the crushed tremella, and stirring until the mixture is in a leavening state; (6) adding the liquid shortening and stirring; (7) molding and adding the crushed peanuts; and (8) baking. The flaky pastries have crispy mouthfeel; because thepeanuts are added, the flaky pastries have more fragrant, crispy and delicious mouthfeel; and the tremella is also added, so that the flaky pastries have nutrient components such as edible fungus protein and high dietary fiber which are not possessed by various ordinary flaky pastries, and are delicious, nutritional and healthy.

Owner:GUANGDONG YUEWEI EDIBLE FUNGI TECH

Morinda citrifolia flaky pastry and preparation method thereof

InactiveCN104206490AHigh nutritional valueNutritiousDough treatmentBakery productsFlavoring essencesFlaky pastry

The invention discloses morinda citrifolia flaky pastry and a preparation method thereof. The morinda citrifolia flaky pastry is prepared from the following raw materials: 80-120 parts of flour, 30-40 parts of maltitol, 15-25 parts of anhydrous butter, 35-45 parts of morinda citrifolia extract, 10-20 parts of morinda citrifolia powder, 1.0-1.5 parts of baking soda, 0.1-3 parts of ammonium bicarbonate, 0.1-1.5 parts of flavoring essence and an appropriate amount of water. The preparation method comprises the following steps: (1) cleaning and smashing morinda citrifolia, filtering to obtain filter residue and the morinda citrifolia extract, drying the filter residue at 80-100 DEG C, then grinding and sieving the ground filter residue with a 200-mesh sieve to obtain the morinda citrifolia powder for later use; (2) briquetting for forming; (3) baking; and (4) cooling and packaging. The morinda citrifolia flaky pastry disclosed by the invention is rich in nutrition and crisp in mouthfeel, has the effects of reducing the blood pressure and improving the gastrointestinal function and can enhance the absorption capability of the human body to various nutrients, increase the physical ability, improve the immunity and promote the human health after being used for a long time.

Owner:ANHUI MEIDAI FOOD LIMITED

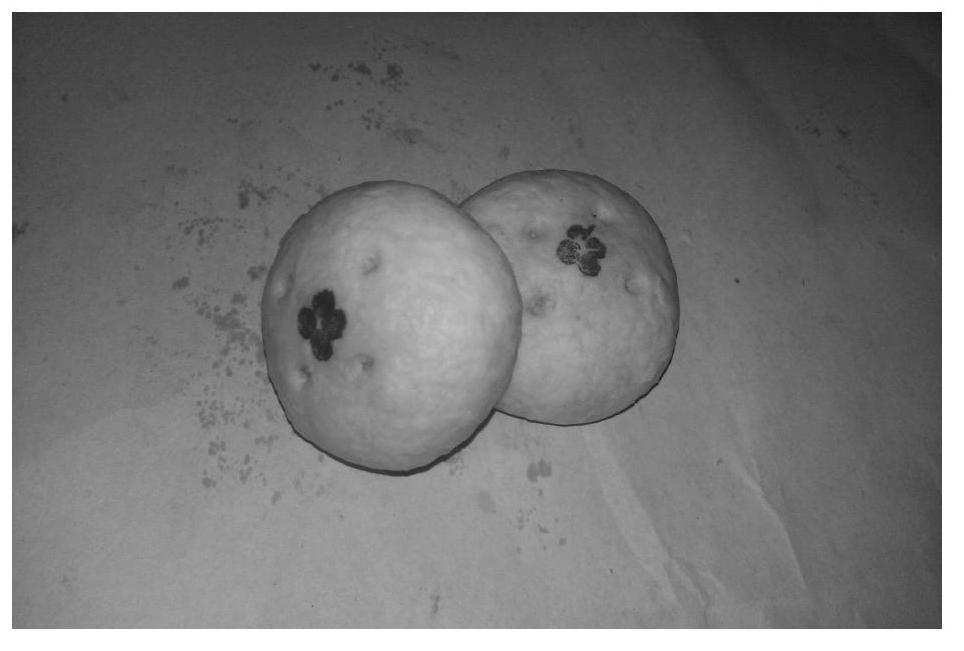

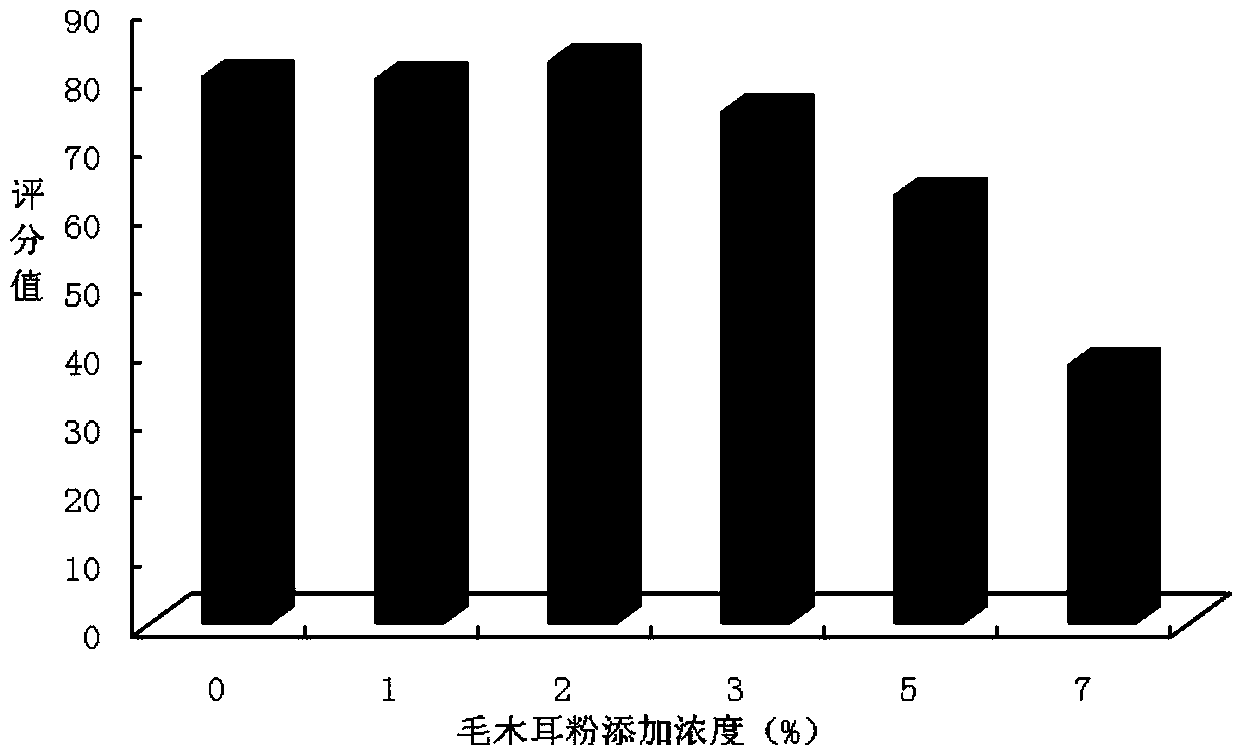

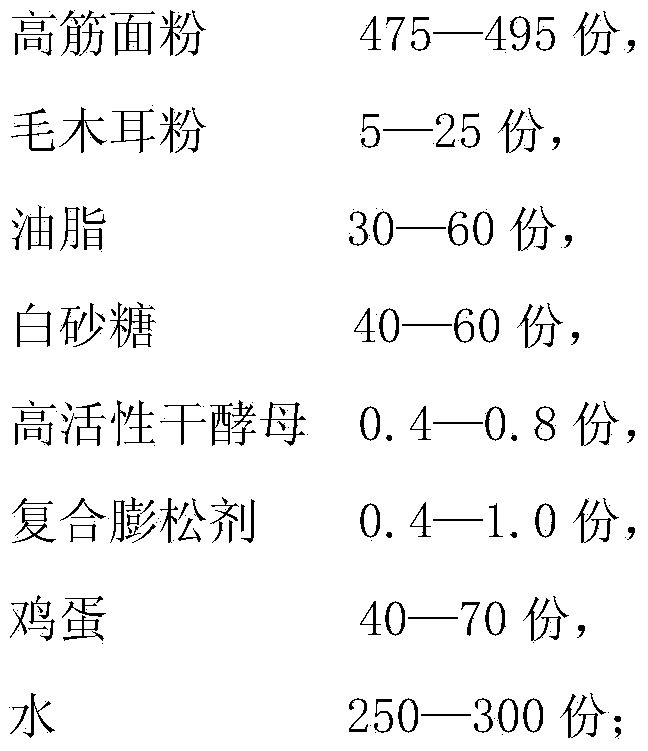

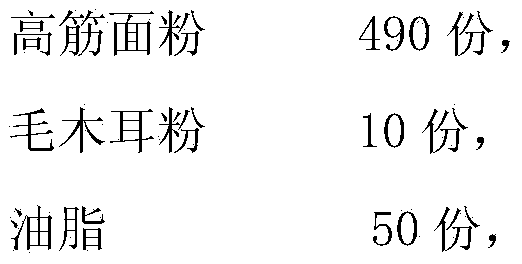

Auricularia polytricha nutritional flaky pastries and preparation method thereof

The invention relates to auricularia polytricha nutritional flaky pastries. The auricularia polytricha nutritional flaky pastries comprise crusts and fillings, wherein the crusts comprise water-oiled crusts and crisps, the water-oiled crusts contain high-gluten flour, auricularia polytricha powder, oil, white granulated sugar, high-activity dried yeast, composite swelling agents, eggs and water; and the crisps contain high-gluten flour and oil. The invention also discloses the preparation method of the nutritional flaky pastries. The preparation method comprises the steps of preparation of the auricularia polytricha powder, the preparation of the flaky pastry crusts, weighting of the flaky pastry filling, forming of the flaky pastries and baking of the flaky pastries. According to the preparation method, the auricularia polytricha powder is doped into the water-oiled crusts of the flaky pastry crusts, so that the prepared flaky pastries have the delicate fragrance of the auricularia polytricha, good color, luster and mouth feel and a good heath care function. Experiments prove that the auricularia polytricha nutritional flaky pastries prepared from the components by adopting the method have crisp, loose, fragrant, sweet, fine and smooth mouth feel. The variety of the flaky pastries is enriched, and a new approach is opened up for the deep processing of the auricularia polytricha.

Owner:SHANDONG AGRI & ENG UNIV

Snowflake flaky pastries mild in mouth feel and processing technology of snowflake flaky pastries mild in mouth feel

The invention provides snowflake flaky pastries mild in mouth feel and a processing technology of the snowflake flaky pastries mild in mouth feel, and relates to the technical field of foods. The snowflake flaky pastries mild in mouth feel comprise the following raw materials in percentage by weight of 7-10 parts of malt syrup of which the concentration is 75%, 1-4 parts of maltitol of which the concentration is 75%, 1-2 parts of trehalose, 0.8-1.2 parts of whole milk powder, 1-2 parts of butter, 0.01-0.04 part of maltol, 0.7-1.3 parts of anhydrous butter, 10-14 parts of biscuits, 0.1-0.4 partof egg white, 0.6-1 part of humid gelatin, 0.01-0.04 part of salt, 1-3 parts of white sugar and 0.4-0.6 part of water. The snowflake flaky pastries are crisp rather than hard, mild in mouth feel, sweet rather than greasy and free from peculiar smell, and do not stick to teeth; the malt syrup of which the concentration is 75% and the maltitol of which the concentration is 75% are used, so that thesnowflake flaky pastries are low in sugariness, mild, high in palatability and good in mouth feel; the processing technology is simple; and the made snowflake flaky pastries are better in mouth feel,and are easy in mass production and worth of promotion.

Owner:JIANGSU AISHINONG BIOLOGICAL TECH CO LTD

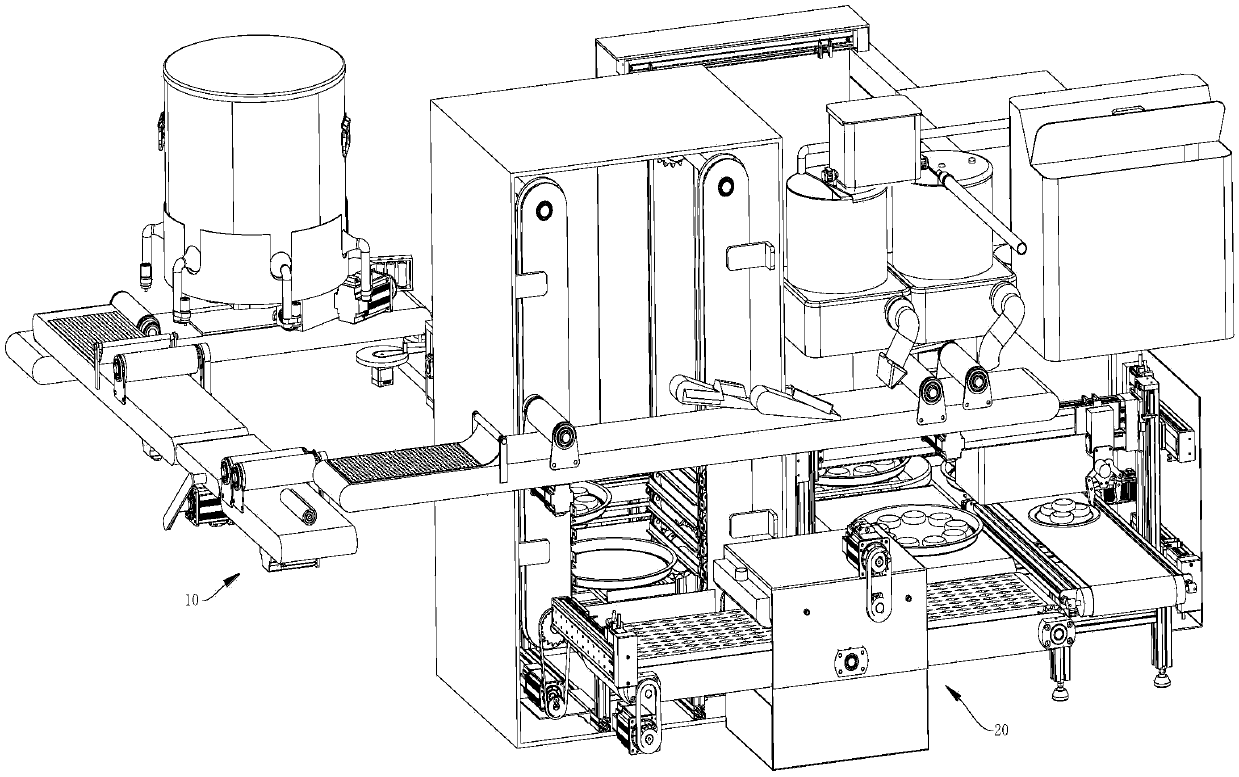

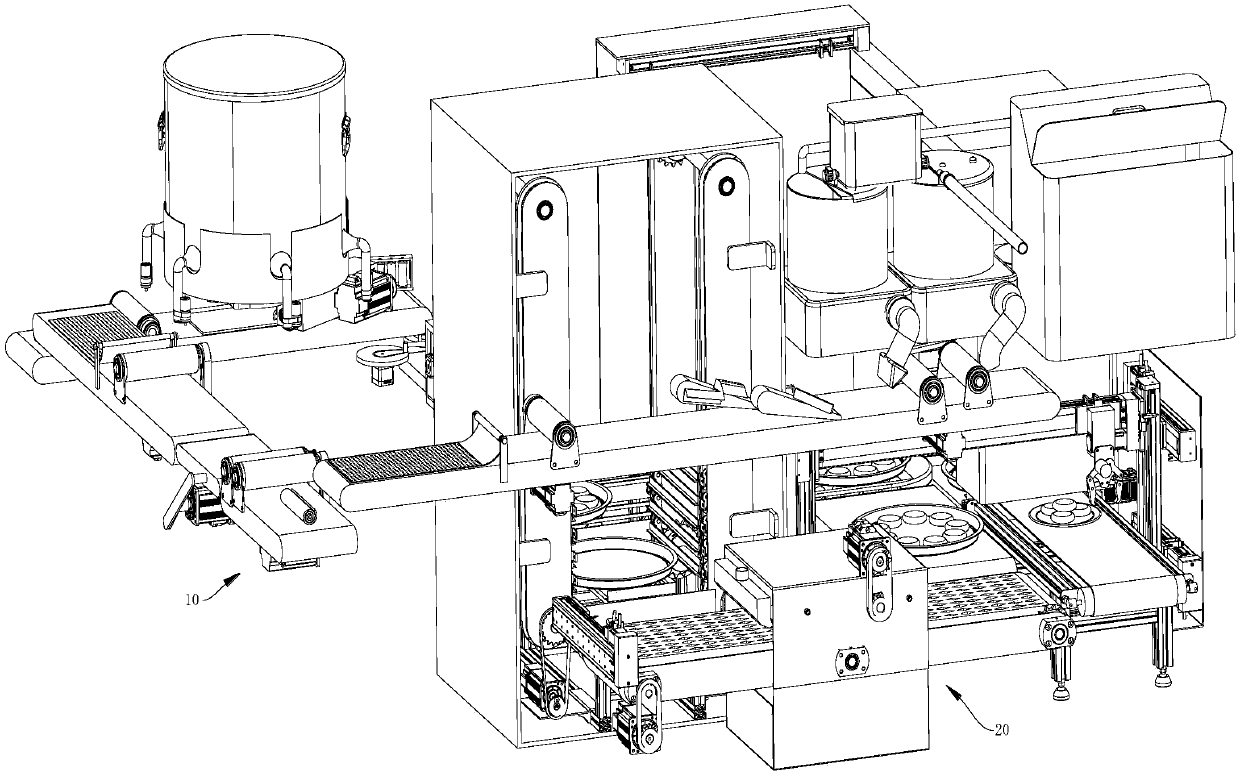

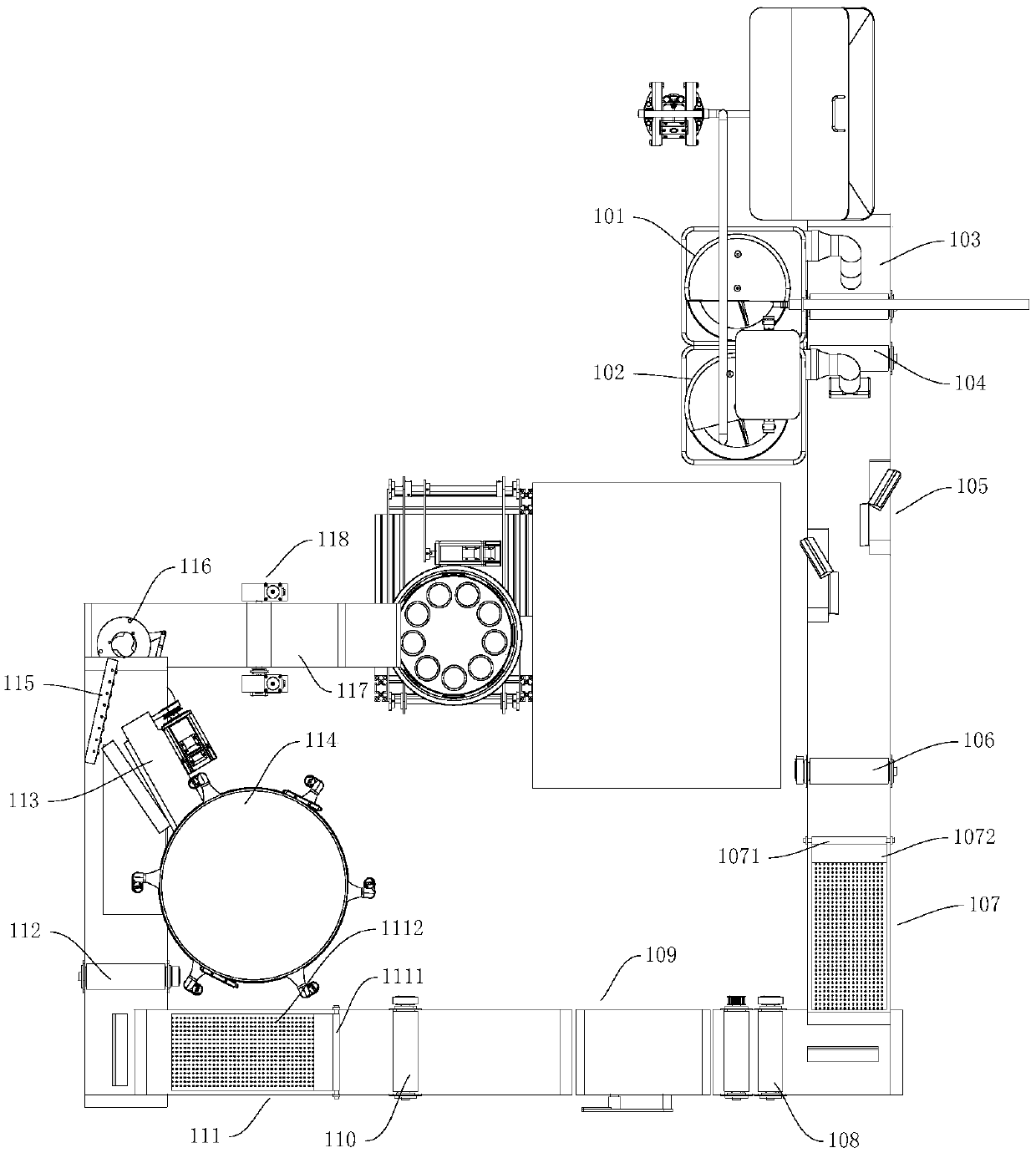

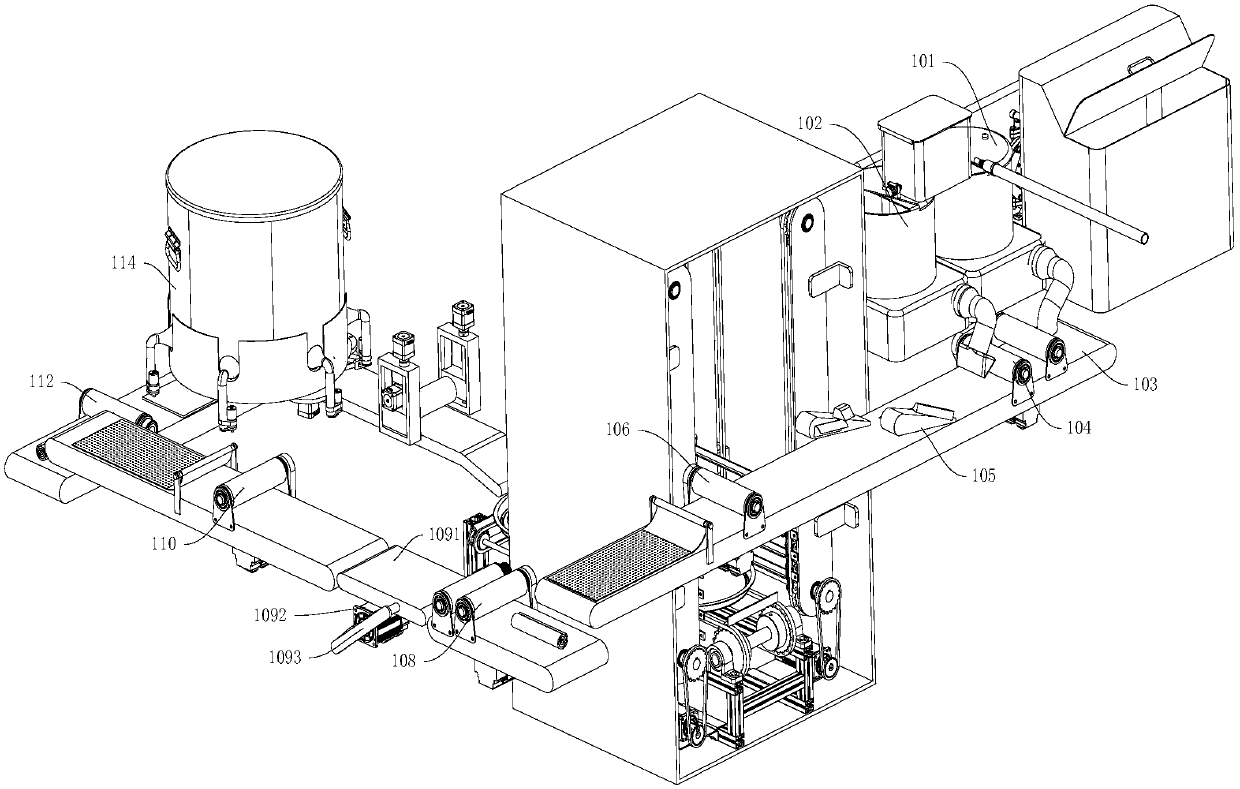

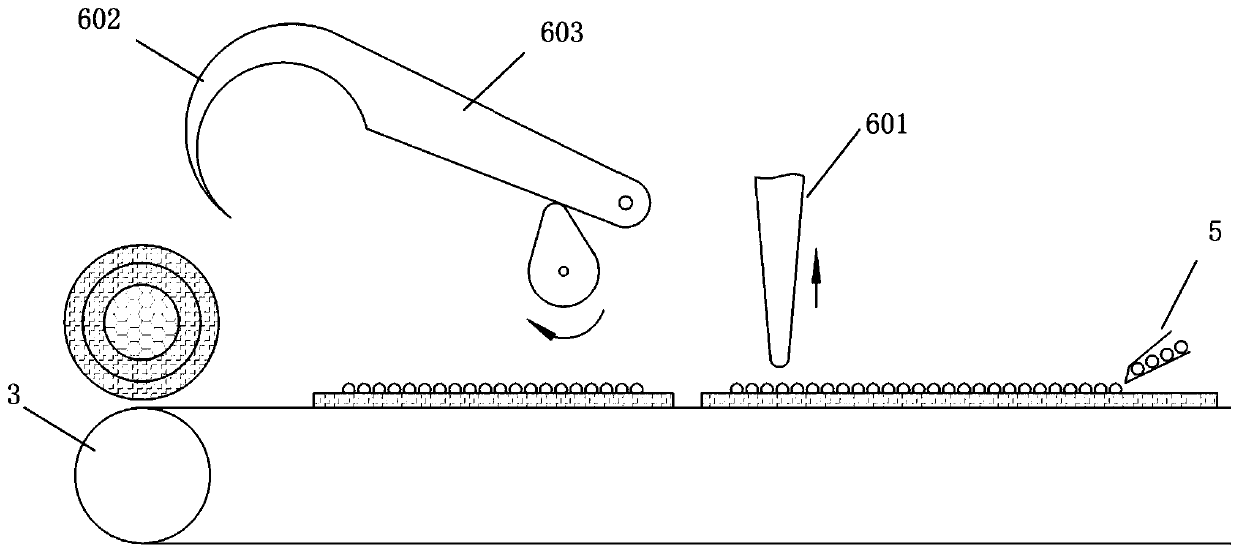

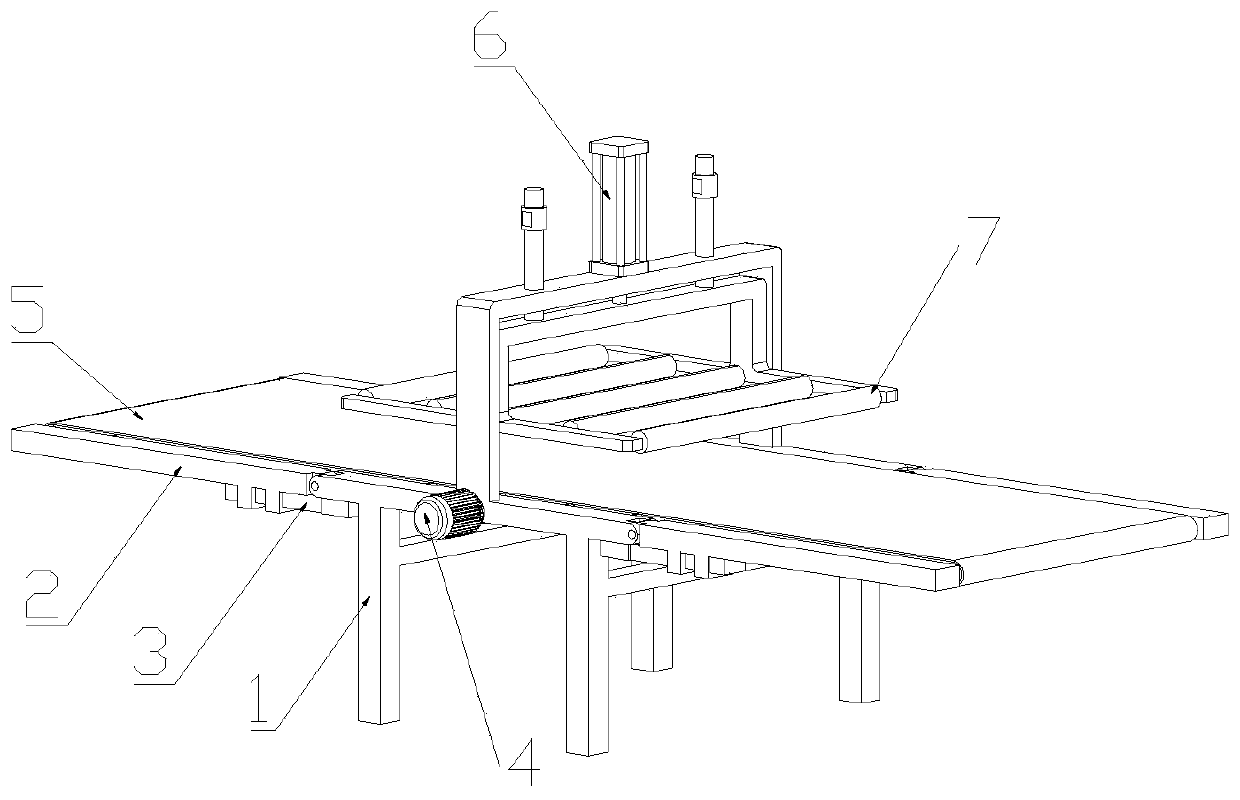

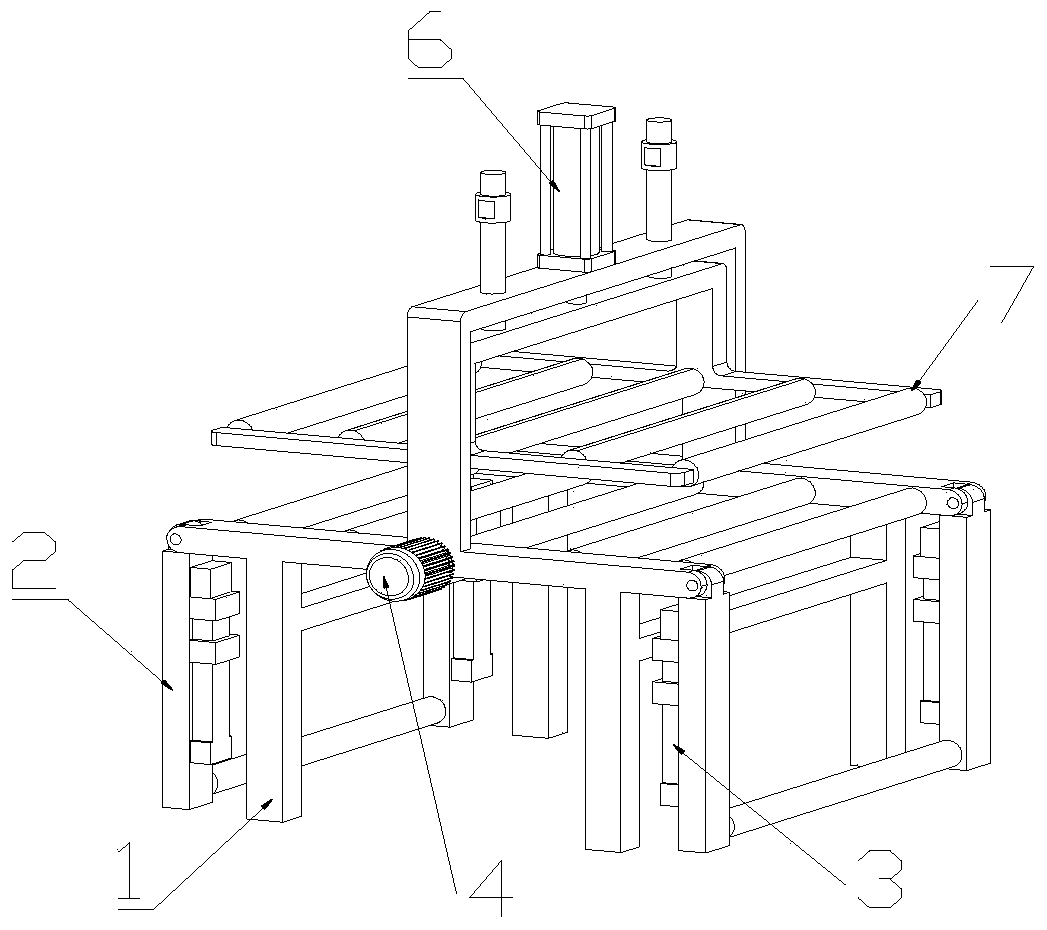

Fully automatic flaky pastry machine

The invention discloses a fully automatic flaky pastry machine. The fully automatic flaky pastry machine comprises a flaky pastry shaping device and a baking device, wherein the flaky pastry shaping device comprises a pastry shaping assembly, a pastry folding assembly and a folded pastry rolling and pressing assembly; when the pastry folding assembly is in a first state, the pastry shaped by the pastry shaping assembly is carried; when the pastry folding assembly is in a second state, the pastry folding assembly folds the pastry; the folded pastry rolling and pressing assembly rolls and presses the folded pastry formed by being folded by the pastry folding assembly; the baking device comprises a baking tray delivery mechanism, a pushing mechanism and a baking oven; the baking device has atray loading station; the baking tray delivery mechanism is used for supplying baking trays to the tray loading station one by one; the pushing mechanism moves between the tray loading station and aninlet and outlet opening of the baking oven or moves between the inlet and outlet opening of the baking oven and an outlet opening of the baking device. The fully automatic flaky pastry machine can achieve the goal of folding the pastry, automatically delivering baking trays, automatically pushing the baking trays into the baking oven or automatically pulling out the baking trays in the baking oven.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

Ham flaky pastry and preparation method thereof

InactiveCN106172626AGreat tasteHigh nutritional valueDough treatmentBakery productsIcing sugarFlavor

The invention discloses a ham flaky pastry and a preparation method thereof. A pastry wrapper of the ham flaky pastry is prepared from raw materials in parts by weight as follows: 80-100 parts of plain flour, 14-17 parts of lard oil, 4-5 parts of powdered sugar, 2.4-3 parts of honey, 0.8-1 part of ammonia bicarbonate, 1.2-1.5 parts of baking soda and 16-20 parts of water; stuffing of the ham flaky pastry is prepared from raw materials in parts by weight as follows: 80-100 parts of diced ham and 16-20 parts of honey, and the pastry wrapper wraps the stuffing and then is put in a baking oven to be baked. The honey and the ham are taken as the stuffing of the ham flaky pastry, the taste and the flavor of the ham flaky pastry can be greatly improved, the stuffing prepared from the ham and the honey can well increase the nutritional value of the ham flaky pastry, absorption and digestion by a human body are facilitated, and the preparation method is simple.

Owner:LIUPANSHUI MAIQI FOOD CO LTD

Egg-yolk flaky pastry and preparation method therefor

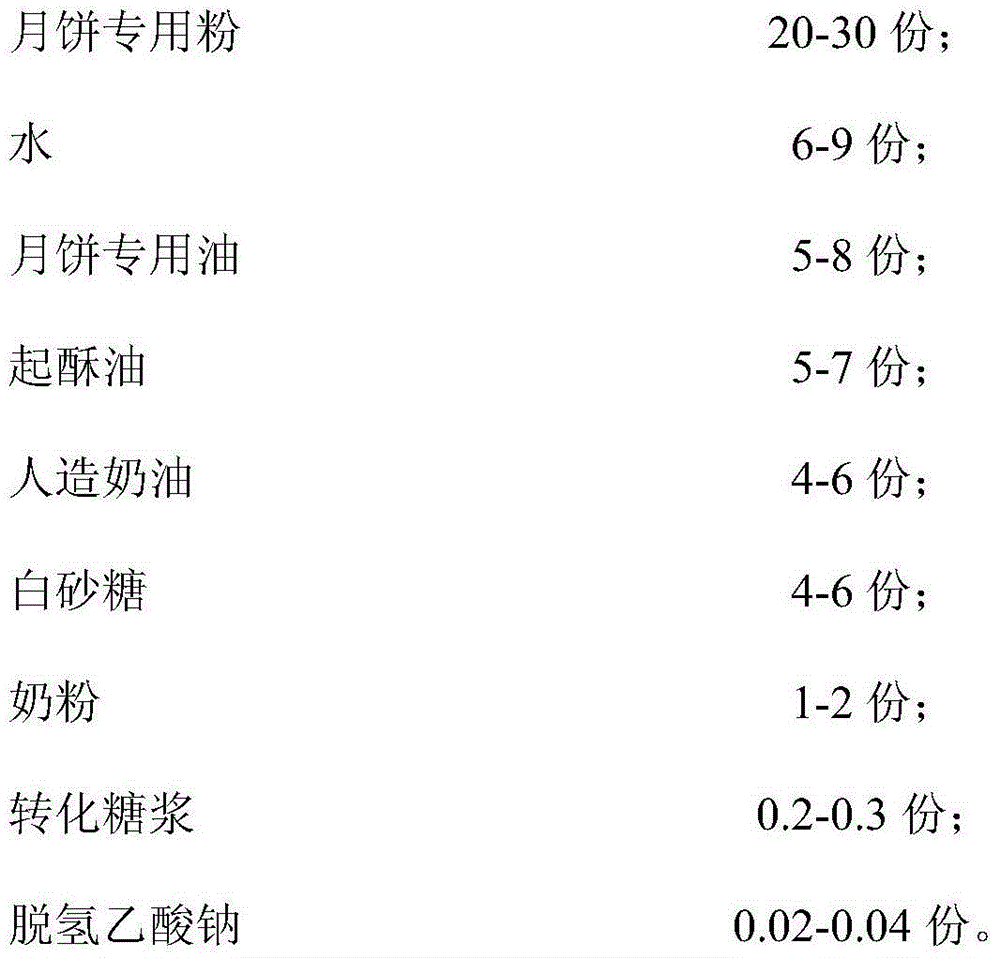

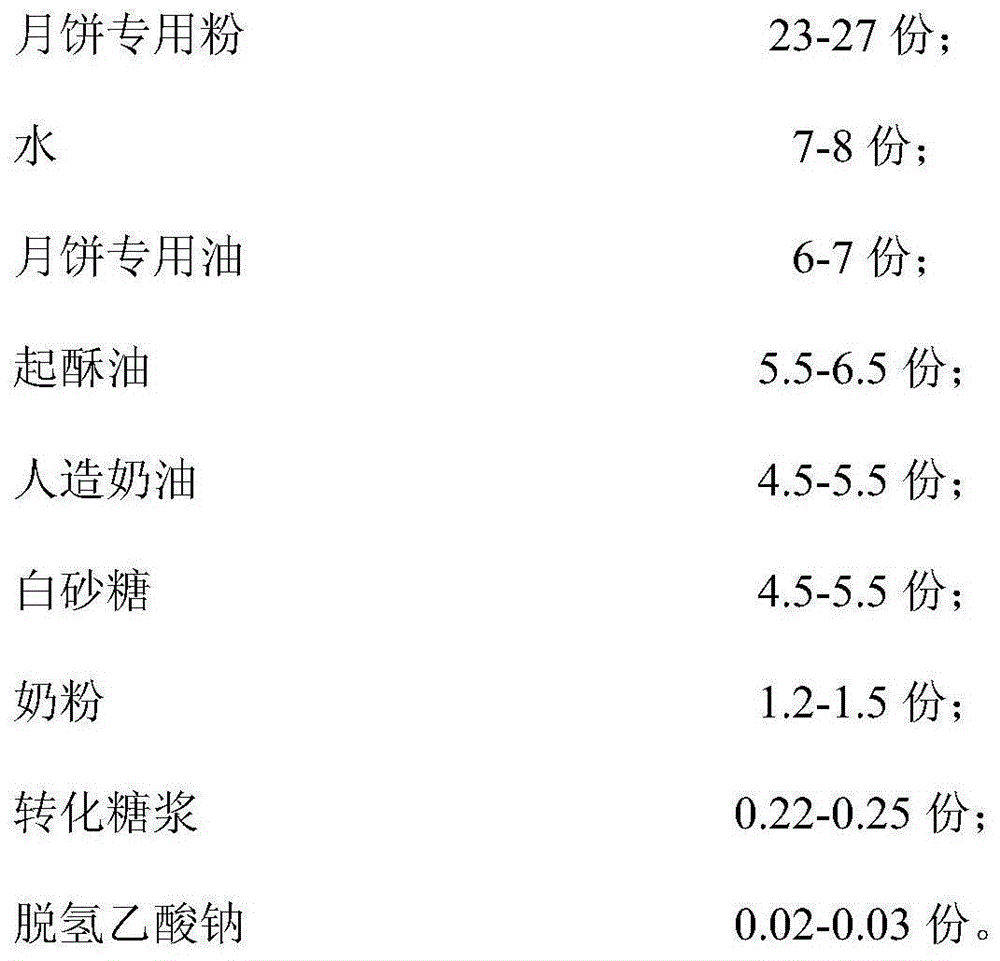

The invention discloses an egg-yolk flaky pastry and a preparation method therefor. The egg-yolk flaky pastry is prepared from the following raw materials in parts by weight: special mooncake powder, stuffing, water, special mooncake oil, pastry margarine, margarine, white granulated sugar, eggs, milk powder, invert sugar syrup and dehydrogenation sodium acetate. The preparation method for the egg-yolk flaky pastry comprises the following specific steps: weighing raw materials, preparing oil-mixed dough, preparing wrappers, covering the oil-mixed dough with the wrappers, dividing the wrappers and stuffing, covering the stuffing and forming egg-yolk flaky pastrys, pre-processing eggs, brushing the formed egg-yolk flaky pastry with the pre-treated eggs for a first time, brushing the formed egg-yolk flaky pastry with the pre-treated eggs for a second time, roasting and cooling the treated egg-yolk flaky pastry. According to the egg-yolk flaky pastry and the preparation method therefor, semi-mechanized and small-scale production is performed, the working strength is relieved, the efficiency is improved and the cost is reduced; the prepared egg-yolk flaky pastry is consistent in quality, low in sugar content, crispy in mouthfeel, fragment, but not greasy.

Owner:SHENZHEN MAI XUAN FOOD CO LTD

Sugar-controlled sweetheart cake

InactiveCN106212611ALow absorption rateAvoid absorptionDough treatmentBakery productsTagatoseSaccharum

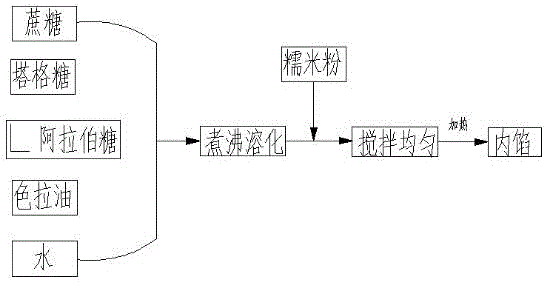

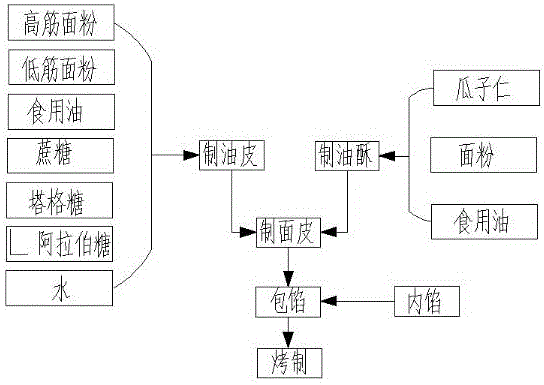

The invention discloses a sugar-controlled sweetheart cake, in particular to a sweetheart cake for stopping saccharose and glucose from being absorbed. The sugar-controlled sweetheart cake is prepared from the following components in percentage by mass: oil skin: 10 to 90 percent of high-gluten flour, 1 to 60 percent of low-gluten flour, 5 to 30 percent of edible oil, 10 to 50 percent of water or maltitol (liquid), 10 to 50 percent of saccharose, 1 to 30 percent of tagatose and 1 to 30 percent of L-arabinose; flaky pastry: 1 to 100 percent of low-gluten flour, 20 to 30 percent of edible oil and 1 to 10 percent of shelled melon-seed; filling: 1 to 100 percent of glutinous rice flour, 10 to 50 percent of saccharose, 1 to 20 percent of salad oil, 1 to 30 percent of tagatose, 1 to 30 percent of L-arabinose and a proper amount of water or maltitol (liquid). A production method comprises the following steps: firstly, preparing the filling; secondly, preparing the oil skin; thirdly, preparing the flaky pastry; fourthly, preparing a wrapper; fifthly, wrapping the filling; sixthly, baking. According to the sugar-controlled sweetheart cake disclosed by the invention, the L-arabinose and the tagatose are added in raw materials, thus stopping the absorption of a human body to the saccharose and the glucose, inhibiting the increasing of postprandial blood sugar and reducing the intake of fat.

Owner:HEFEI KANGQIAO IND & TRADE CO LTD

Processing method of functional glutinous rice flaky pastries

The invention discloses a processing method of functional glutinous rice flaky pastries. The processing method comprises the following steps: cleaning glutinous rice, steaming the rice, adding oligosaccharides, and arranging, molding and drying the mixture until moisture in glutinous rice cakes accounts for 6 percents to 8 percents. The processing method is characterized in that two times of vacuum frying are performed after drying under the pressure of 0.075 MPa to 0,085 MPa and at a temperature of 70 DEG C for 5 minutes; and the glutinous rice cakes are taken out and subjected to a second-time of vacuum frying after the temperature drops to 40 DEG C to 48 DEG C under the pressure of 0.085 MPa to 0.098 MPa and at a temperature of 105 DEG C to 110 DEG C for 15 minutes to 20 minutes, and functional glutinous rice flaky pastries can be obtained. The processing method has the advantages that functional glutinous rice flaky pastries manufactured through the method have a unique flavor, can be stored for a long time, and are tasty, fragrant, sweet and crisp, the nutrition is abundant, and the functional glutinous rice flaky pastry is a 'green food' with special health care functions and glutinous rice natural flavor.

Owner:宁夏天瑞产业集团现代农业有限公司

Baking device and food making equipment

PendingCN109588919ARealize automatic partitioningHigh degree of automationService system furnitureRoasters/grillsFlaky pastryProcess engineering

The invention discloses a baking device which comprises a baking plate delivery mechanism, a pushing mechanism, an oven, a grabbing mechanism, a tray delivery mechanism, a tray conveying mechanism, agrabbing mechanism and a flaky pastry baking plate conveying mechanism, wherein the baking device is provided with a plate loading station; the baking plate delivery mechanism is used for delivering baking plates to the plate loading station one by one; the pushing mechanism moves between the plate loading station and an entrance / exit of the oven, or moves between the entrance / exit of the oven andthe baking device; the tray delivery mechanism is used for delivering trays to the tray conveying mechanism one by one; an inlet of the flaky pastry baking plate conveying mechanism is connected withan outlet of the baking device; the grabbing mechanism moves between the flaky pastry baking plate conveying mechanism and the tray conveying mechanism. The baking device can realize all-in-one operation of delivering the baking plates, pushing the baking plates into the oven or pulling out the baking plates located in the oven and separating the plates. The invention also discloses food making equipment.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

Blended polygonatum sibiricum flaky pastry and preparation method thereof

InactiveCN105994545AUnobstructed blood vesselsImprove brain functionDough treatmentBakery productsFlavorVitamin C

The invention provides blended polygonatum sibiricum flaky pastry and a preparation method thereof. On the basis that polygonatum sibiricum powder is added to endow the flaky pastry with healthcare functions including dredging blood vessels and improving brain functions, the blended polygonatum sibiricum flaky pastry is made through blending preparation, and vitamin C, dicalcium phosphate, ferrous gluconate and the like are added to balance nutrition of the flaky pastry; soy isolate protein is used and blended, so that the nutrient components of the product are balanced; the Chinese resident reference dietary nutrition acceptable daily intake standard (adults) recommended by the Chinese Nutrition Society can be met. Meanwhile, on premise of nutrition balance, the flavor and the taste of the product are ensured, and the blended polygonatum sibiricum flaky pastry is good in crispiness, fragrant and sweet in taste, not viscous to teeth, easily acceptable by customers, and good in market prospect.

Owner:WUHAN INST OF BIOENG

Rose-containing flaky pastry and production process thereof

InactiveCN106135367AGood flexibilityFluffy goodDough treatmentBakery productsFlaky pastryBaking powder

The invention discloses rose-containing flaky pastry and a production process thereof. The rose-containing flaky pastry is prepared from raw materials in parts by mass as follows: water-processed wrappers prepared from 5-6 parts of flour, 2-4 parts of water, 0.2-0.4 parts of butter and 0.2-0.4 parts of baking powder, oil-processed wrappers prepared from 2-4 parts of flour, 0.2-0.3 parts of water and 1-3 parts of butter as well as stuffing prepared from 3-5 parts of flour, 2-3 parts of water, 1-3 parts of butter, 1-3 parts of white sugar and 1-2 parts of rose powder. Roses are directly ground into powder, the color of the roses is kept, and fragrance of the roses is also kept. The production process of the rose-containing flaky pastry is simple and is suitable for batch production in a factory; the flavonoid content of the prepared rose-containing flaky pastry is about 0.0025%, the color of the roses is kept to a greater extent, the practical mass of the rose-containing flaky pastry is improved, and the prepared rose-containing flaky pastry tastes crisp and is full of rose fragrance.

Owner:XUZHOU UNIV OF TECH

Flaky pastry biscuit manufacturing process

The invention discloses a flaky pastry biscuit manufacturing process, which comprises the following steps including (1) flour processing: the flour is averagely divided into two parts, cold water is added into one part of flour according to a flour-to-cold-water weight ratio being 3:1, stirring is carried out, hot water is added to the other part of four according to a flour-to-hot-water weight ratio being 2:1, stirring is carried out, the two parts of flour are mixed, and auxiliary ingredients are added and are stirred for 12 to 25 minutes; (2) flake making: the mixture is uniformly filled into a laminating machine through high pressure, the materials are folded into eight layers of biscuit flakes, crisp materials are spread on each layer of the biscuit flake, and the five-time flake pressing is carried out through a flake pressing machine; (3) forming; (4) baking: the materials enter a segmented baking oven to be firstly subjected to 300 to 320 DEG C high-temperature baking and then enters a natural cooling step to be cooled to normal temperature, and then, the materials are baked at 200 to 220 DEG C for 10 to 30 minutes; (5) oil spraying; and (6) cooling and packaging. The flaky pastry biscuit manufactured by the flaky pastry biscuit manufacturing process provided by the invention has the advantages that the flaky effects are good, each flake is very thin, the flakes are many, the sheds are fine, the outer side is crispy, the inner side is soft, the texture is loose and soft, the flavor is not greasy, the flaky pastry biscuit is suitable for people in all age stages to eat, the flavor is unique, and the fragrance is rich.

Owner:ANHUI MEIDAI FOOD LIMITED

Flaky pastry and producing method thereof

The invention relates to a flaky pastry and a producing method thereof. The flaky pastry is prepared from, by weight, 50-60 parts of self- raising flour, 5-10 parts of custard powder, 1-5 parts of palm oil, 10-15 parts of peanut oil, 20-30 parts of one or a plurality of red bean-filling, spicy pork floss, white sesame seed and chopped peanut, 5-10 parts of syrup and 1-5 parts of white sugar. The producing method of the flaky pastry includes separately producing semi-finished products of flaky pastry crusts and fillings and then using a filling machine to fill, mold and bake the flaky pastry. The flaky pastry using the above composition proportion is sweet, tasty and nutritious. Local food feature is remarkably reflected by matching pork floss with red bean-filling. During the producing process, the flaky pastry crusts and fillings are separately produced into semi-finished products and the flaky pastry is filled and molded by using the filling machine so that the flaky pastry is easy to mold and can be produced into various shapes..

Owner:郭亚莲

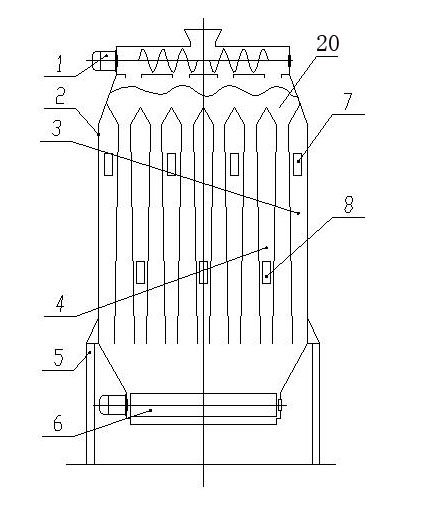

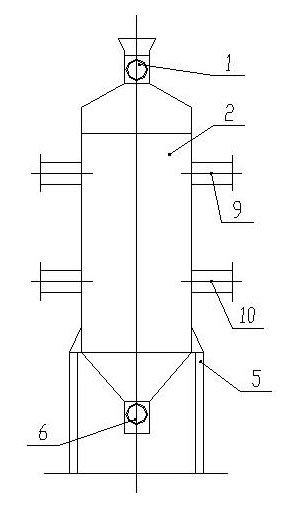

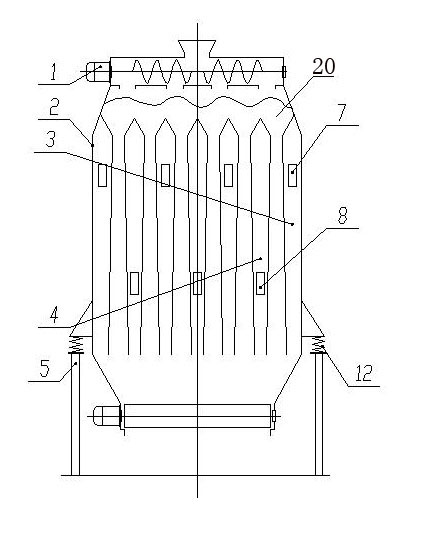

Vertical gravity conveying enforced cross-flow drying method and device

InactiveCN101793457AEnhanced flow capacityReduce disturbanceDrying solid materials with heatDrying solid materials without heatFlaky pastryPositive pressure

The invention relates to a vertical gravity conveying enforced cross-flow drying method and a device. The invention is suitable for removing surface moisture from particle materials by utilizing hot air in the industries of mine, building materials, metallurgy, ceramics, chemical engineering and the like, and is also suitable for removing moisture from particle materials by utilizing hot air in the industries of foodstuff and feedstuff. The invention has the following technical scheme: hot airflow suitable for the dried material temperature is enforced into a storehouse; under the positive action of the external pressure, the hot airflow penetrates through the voids among the granules and is discharged out of the storehouse; the hot airflow and the material contact each other and exchange heat when the hot airflow penetrates through the voids among the granules; thus, the material temperature is increased, the moisture is evaporated, and the generated water vapor is discharged out of the storehouse along with the airflow; and under the action of gravity, the material on the same cross section in the drying storehouse continuously descends, and is continuously penetrated through and dried by the hot air in the descending process. Due to the adoption of the vertical gravity descending conveying, the invention is simple and reliable in structure; due to the adoption of the drum suction mode with multiple sets of positive pressure chambers and negative pressure chambers which are vertically arranged, the invention strengthens the airflow penetration capability, so that the airflow completely penetrates through the material, thereby enhancing the thermal efficiency; the flaky pastry mode increases the flow penetration drying area and enhances the yield; and since the material is dried in the descending process, the invention has the advantages of small disturbance, little exhaust dust and low pollution.

Owner:王文民

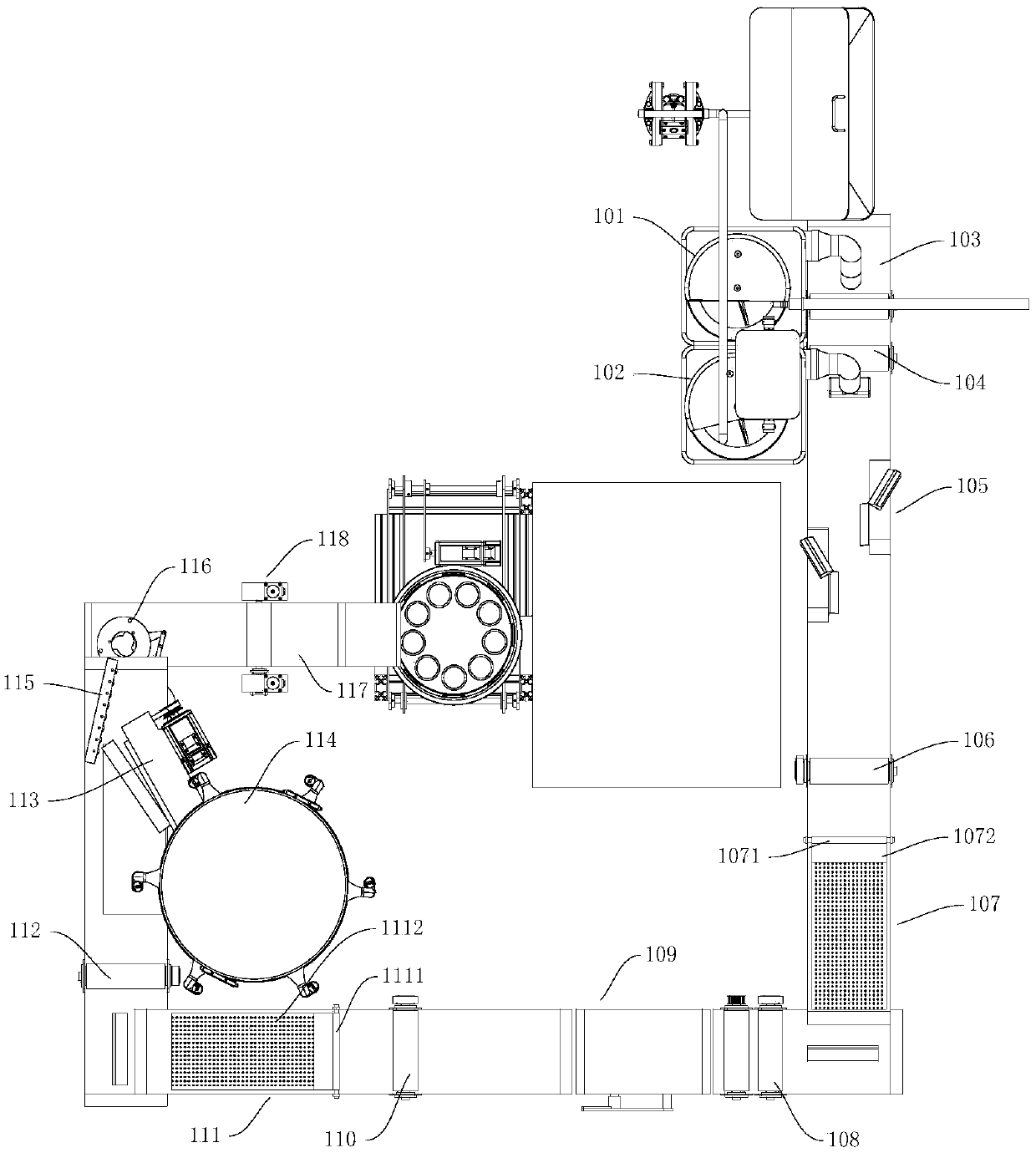

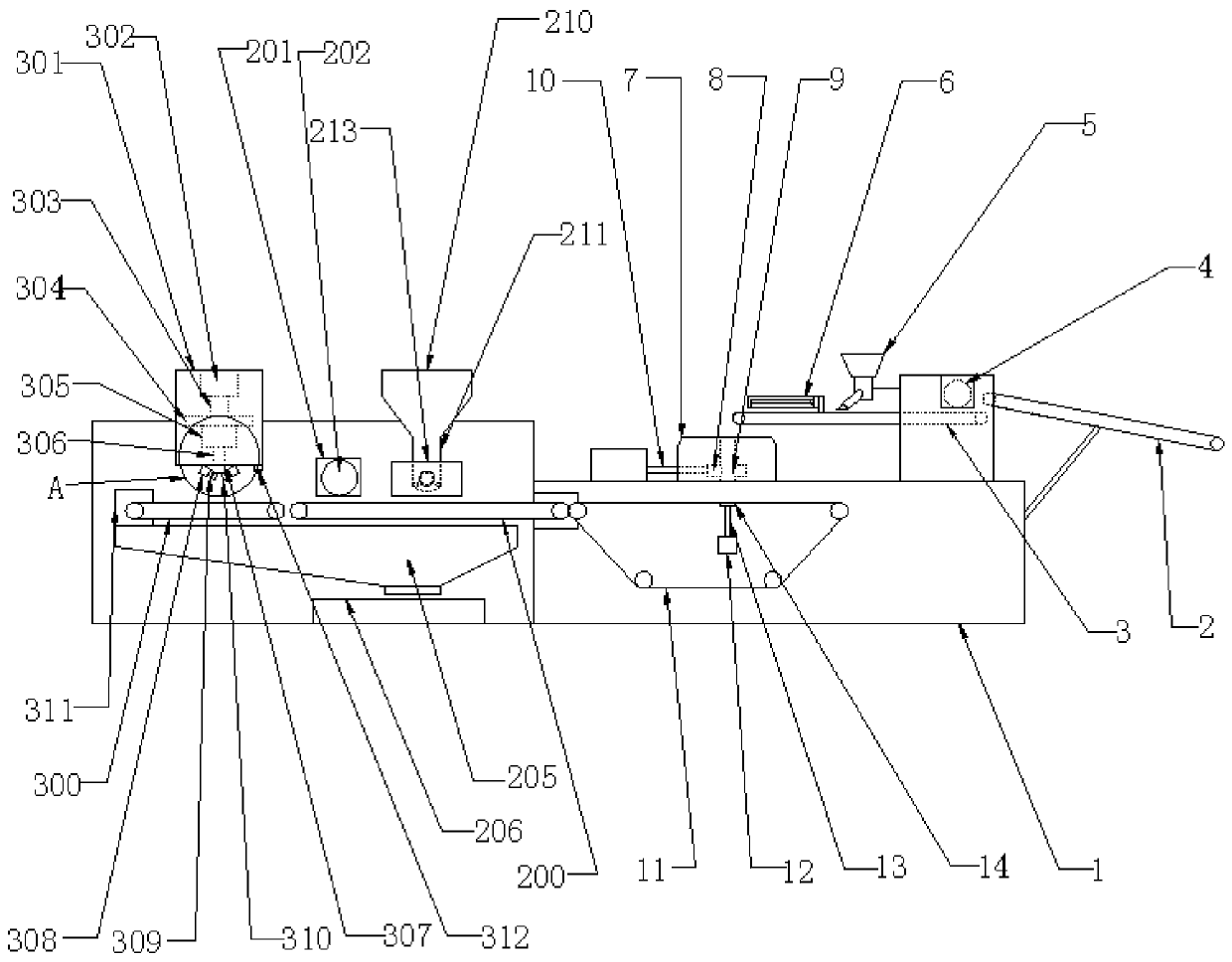

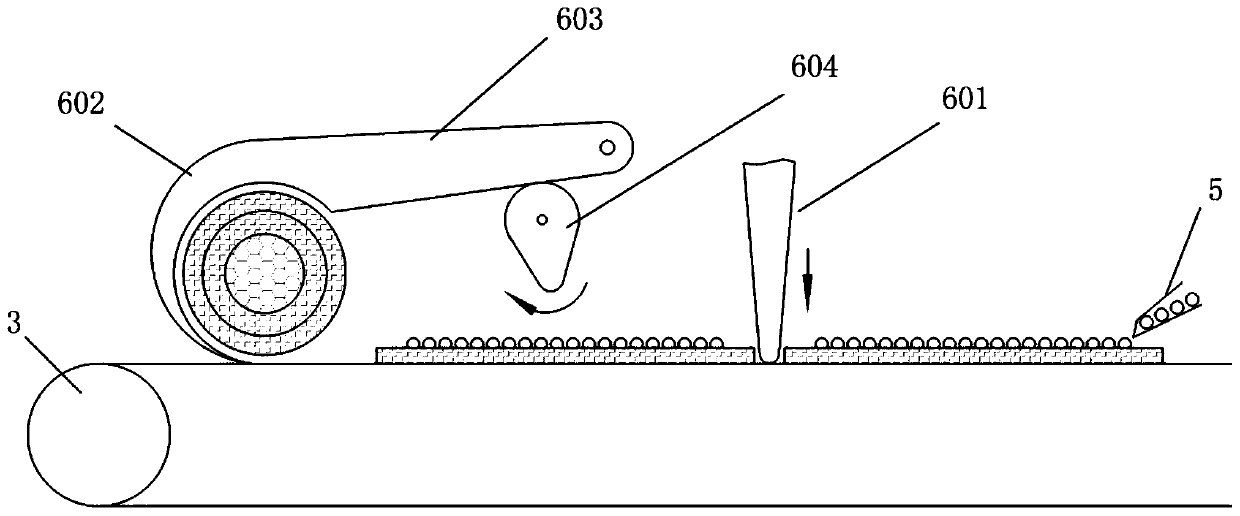

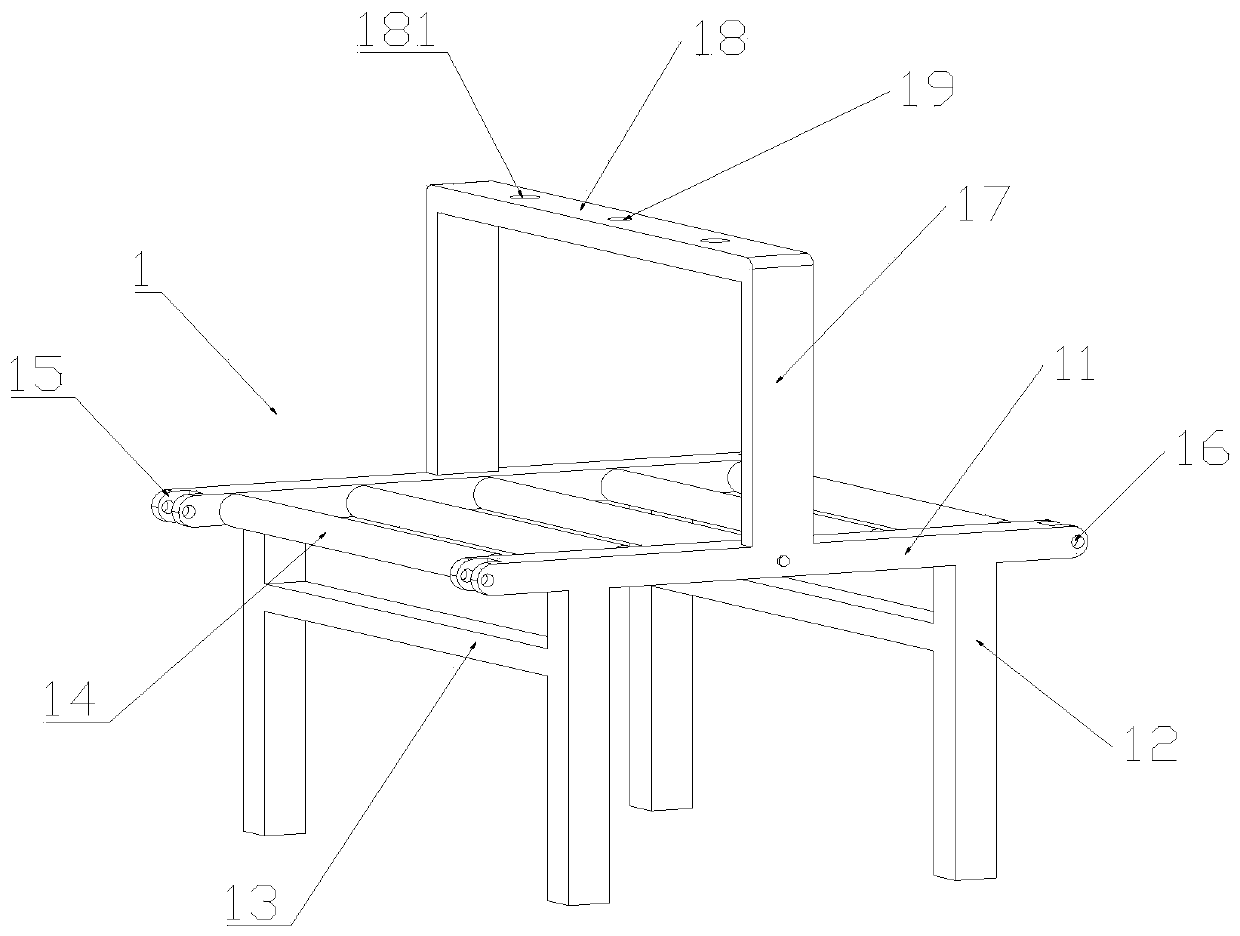

Flaky pastry automatic molding device and molding method thereof

ActiveCN109924231AImprove cutting effectImprove pass rateDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationFlaky pastryEngineering

The invention relates to a flaky pastry automatic molding device comprising a frame. A raw material conveyor belt is arranged on the frame, the discharging end of the raw material conveyor belt is provided with a pressing device, the discharging end of a filling adding machine extends to a feeding conveyor belt, and the discharging end of the feeding conveyor belt is provided with a winding mechanism. An extrusion shaping mechanism is arranged below the discharging end of the winding mechanism. The extrusion shaping mechanism comprises a shaping cylinder body, and an annular elastic ring is arranged on the inner tube wall of the shaping cylinder body in the circumferential direction. An annular inner cavity is arranged between the elastic ring and the inner tube wall of the shaping cylinder body, and an air pump is arranged on one side of the shaping cylinder body. The output end of the air pump is communicated with the annular inner cavity through a vent pipe, and a receiving conveyorbelt is arranged under the shaping cylinder body, and the frame is provided with a receiving device for jacking up the receiving conveyor belt to the lower end of the shaping cylinder body and matched with the elastic ring to squeeze a flaky pastry preliminary product. The device is high in molding quality, high in degree of automation, good in cutting effect and capable of making flaky pastry good in taste.

Owner:浙江德辉食品有限公司

Skin nourishing and beautifying bamboo-flavored dried bean curd and preparation method thereof

InactiveCN104137900ARelieve fatigueRegulate metabolismCheese manufactureFood scienceFlaky pastryPetal

The invention discloses a skin nourishing and beautifying bamboo-flavored dried bean curd which is prepared from the following raw materials in parts by weight: 90-110 parts of black soy bean, 10-20 parts of mung bean, 20-30 parts of green soya bean, 7-8 parts of nutrition additive, 4-5 parts of flaky pastry, 7-8 parts of fresh snake flesh, 4-5 parts of celery, 4-5 parts of watermelon juice, 3-4 parts of carrot, 4-5 parts of canna starch, 2-3 parts of stachyose, 6-8 parts of passion fruit, 5-6 parts of lotus seedpod, 6-7 parts of frozen bean curd, 3-4 parts of daisy petals, 2-3 parts of lophatherum gracile, 0.5-1 part of oldenlandia diffusa, 2-2.4 parts of feather cockscomb seed, 0.7-1.5 parts of exocarpium and 0.7-2 parts of lycopodium clavatum. The invention discloses a skin nourishing and beautifying bamboo-flavored dried bean curd and a preparation process thereof. The added oldenlandia diffusa has functions of relieving lung heat dyspnea with cough, swollen sore throat and the like; the snake flesh is capable of relieving the fatigue of a human body, has functions of nourishing and beautifying skin and regulating metabolism of the human body, and is capable of enhancing the immunity after being taken for a long time.

Owner:ANHUI RENRENFU BEAN IND

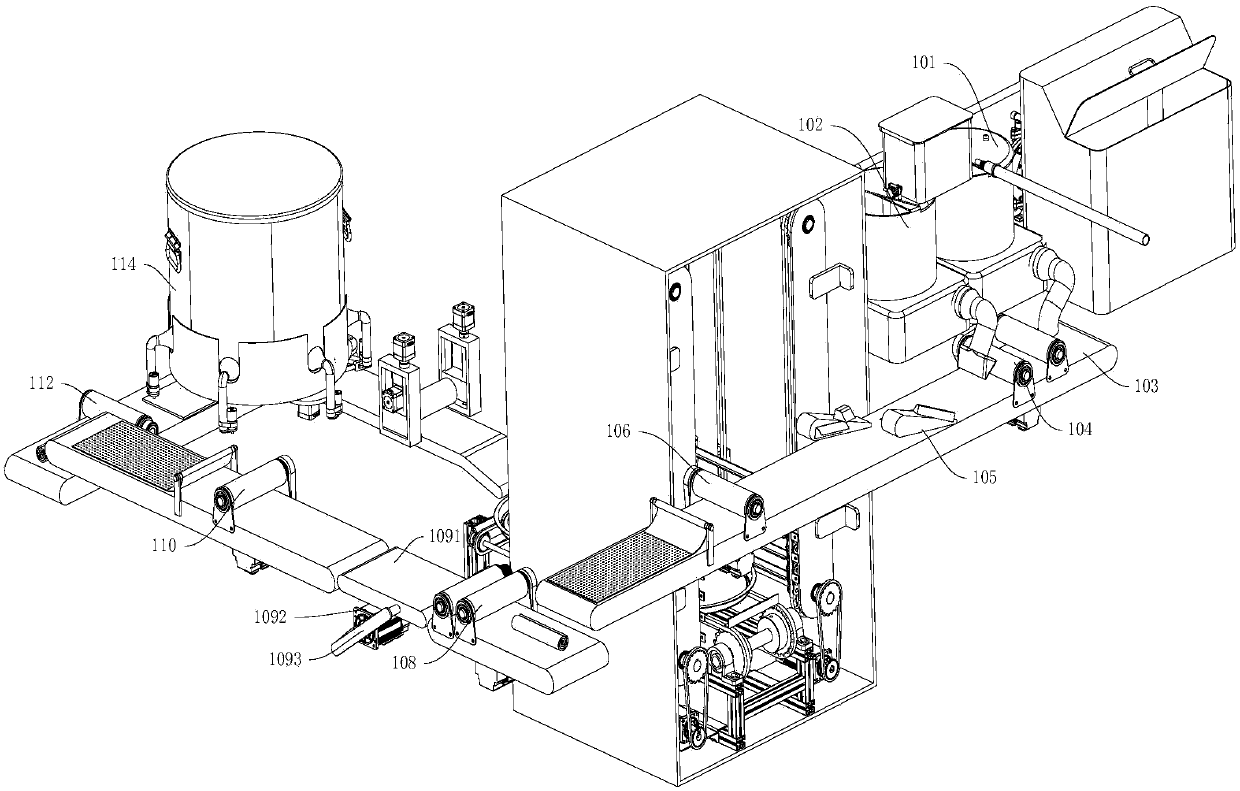

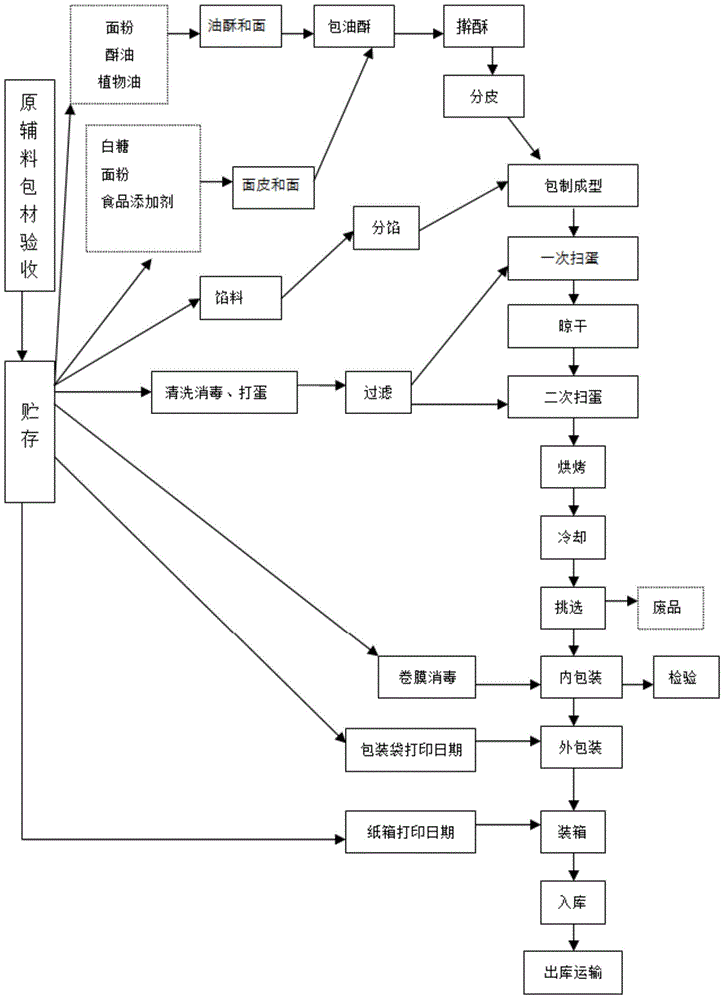

Production device and production process of Badam flaky pastry

InactiveCN110477079ASatisfy the pursuit of tasteSatisfy the pursuitDough treatmentBakery productsFlaky pastryProcess engineering

The invention discloses a production device and production process of a Badam flaky pastry. The production device includes a device bracket; the device bracket includes first supporting rods symmetrically distributed. The production process of the Badam flaky pastry is characterized in that the Badam flaky pastry comprises, in parts by weight, 12-16 parts of butter, 6-8 parts of eggs, 38-42 partsof wheat flour, 15-20 parts of white granulated sugar, and 18-22 parts of Badam slices. The production process of the Badam flaky pastry includes the following steps: raw material acceptance checking,burdening, stirring, molding, baking, cooling, inner packaging material acceptance checking, inner packaging material disinfection, packaging, cartonning and storage. The production process of the Badam flaky pastry processes Badam into flaky pastry, satisfies the pursuit of consumers on food taste, realizes the diversification of the product, and is conducive to promotion of the product by the enterprises; through the extrusion of dough with a plurality of extrusion rollers, the improvement of the efficiency of the dough extrusion molding is facilitated, so the needs of the large-scale production of the product are met, the extrusion times of the dough are also increased, and increase of the taste of the product is facilitated.

Owner:ANHUI NONG ANKANG FOODS LTD CO

Nutrition snakegourd fruit seed flaky pastry and preparing method thereof

InactiveCN104106612AImprove palatabilityGood for healthDough treatmentBakery productsLavandulaFlaky pastry

The invention discloses a nutrition snakegourd fruit seed flaky pastry which comprises, by weight, the raw materials of 100-120 parts of flour, 1-3 parts of angelica sinensis, 1-2 parts of pomegranate leaves, 2-3 parts of lavender, 0.1-1 part of caragana microphylla flowers, 5-6 parts of pumpkins, 6-7 parts of freeze-dried duck blood, 5-6 parts of celery, 1-2 parts of cortex albiziae, 1-2 parts of rice-grain sprouts, 3-4 parts of stevia rebaudian leaves, 5-6 parts of horned melons, 3-4 parts of winter bamboo shoots, 10-15 parts of Chinese date honey, 2-3 parts of olivary nucleuses, 10-20 parts of nutrition snakegourd fruit seed powder, edible oil, white granulated sugar and a proper amount of salt. The prepared nutrition snakegourd fruit seed flaky pastry is crisp and tasty, the processed snakegourd fruit seed powder is evenly distributed on the surface of the flaky pastry, the palatability of the flaky pastry is improved, snakegourd fruit seed fragrance is emitted, meanwhile, health-care function components are added, wherein the pumpkins have the effect of heat clearing and detoxifying, the olivary nucleuses can carry out detoxifying, sore healing is achieved, and body health can be well achieved if the flaky pastry is eaten for a long time.

Owner:ANHUI LUSHI ECOLOGICAL AGRI TECH

Pastry and preparation method thereof

InactiveCN106386986AOvercome the defect of softeningExtended hold timeDough treatmentBakery productsCooking & bakingFlaky pastry

The invention relates to the field of food processing technology, and particularly discloses a pastry and a preparation method thereof. The preparation method comprises the following steps: after proofing prepared dough, extending and pressing repeatedly; coating pig oil and other seasonings; re-proofing; preparing a cake base of 0.4-0.6cm; setting the upper portion temperature of an oven to 265-275 DEG C, and the lower portion temperature of the oven to 285-295 DEG C, and baking for 3-5min. Through proofing, extending and pressing, and selecting baking temperature and time, the prepared flaky pastry is crisp and chewy, not hard and not greasy, and can maintain a crisp taste for a long time. At the same time, by adjusting the raw material formula for the preparation of the flaky pastry, the holding time of the crisp taste of the product can be further prolonged.

Owner:河南创悦实业有限公司

Fermented hard-crust flaky sesame seed cakes

The invention discloses fermented hard-crust flaky sesame seed cakes prepared by the following steps of making dough by utilizing boiling water so that the prepared dough has enhanced plasticity and crispiness; performing yeast fermentation so as to increase micropores in the dough for preparing the crust, and thus, the same crisping effect can be achieved by using fewer oil, and the products haveunique aroma and nutrients of fermented products; and then, adding edible salt so as to increase tenacity and elasticity of the dough for preparing the crust, as well as enriching taste of the products. The existing flaky pastries all have the disadvantages of easy breaking and scraping. As for the fermented hard-crust flaky sesame seed cakes, a process of sticking sesame seed kernels after wateris sprinkled onto shaped cake bases is adopted so that hard crust is formed outside the cake bases; and thus, wholeness of the products can be better preserved while taste of the products is enriched. The fermented hard-crust flaky sesame seed cakes have the characteristics that the whole outside of the crust is covered with a layer of sesame kernels so that the cakes have crispy crust, as well as soft and glutinous stuffing; and thus, the fermented hard-crust flaky sesame seed cakes have gradient taste, and rich taste. Delicious, crispy, flaky and soft tastes are integrated in the fermentedhard-crust flaky sesame seed cakes. And thus, the fermented hard-crust flaky sesame seed cakes are very distinctive.

Owner:HUBEI HONGYA FOOD CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com