Production device and production process of Badam flaky pastry

A technology for producing equipment and equipment supports, applied in the food field, can solve the problems of reduced fat absorption rate, low efficiency, lack of diversified foods, etc., and achieve the effects of improving taste, improving efficiency, and increasing the number of extrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

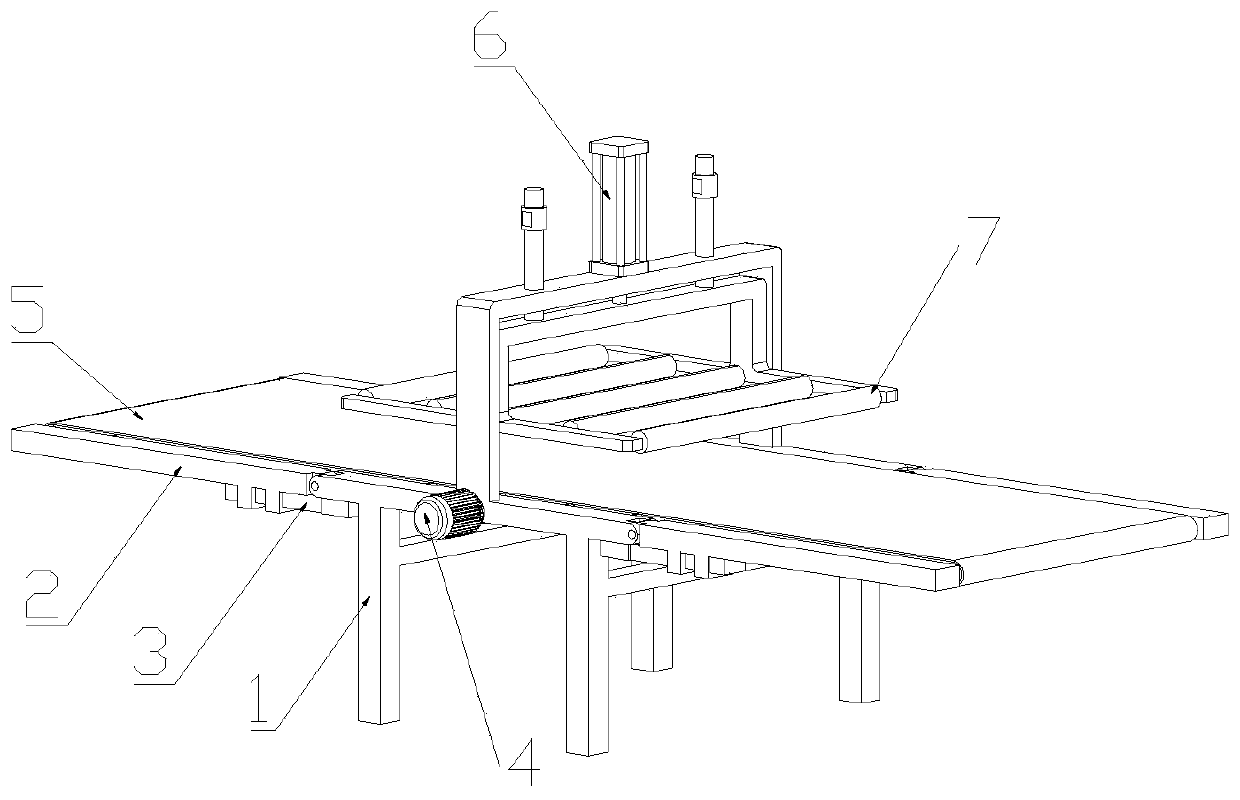

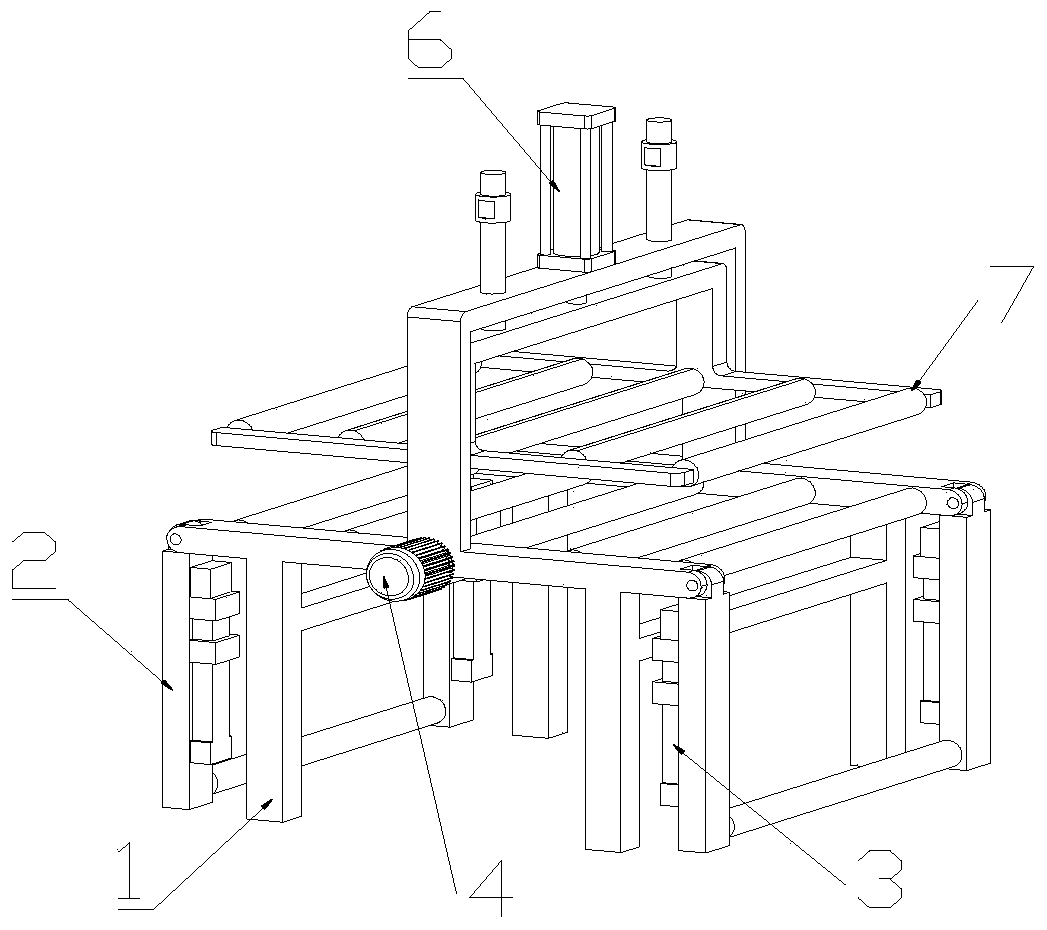

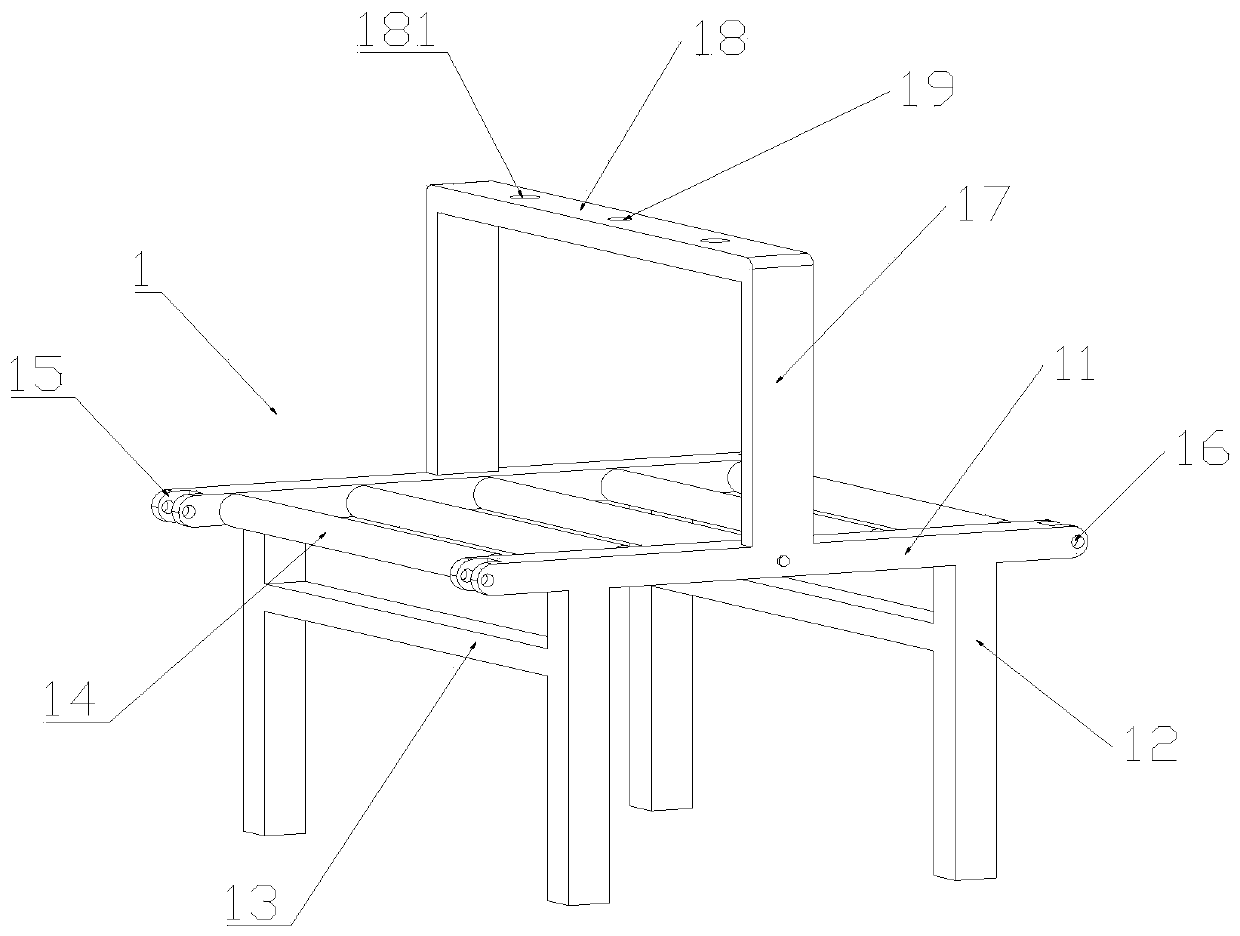

Image

Examples

Embodiment 1

[0095] A kind of production technology of almond wood shortbread, almond wood shortbread comprises by weight: 12 parts of yellow cream, 6 parts of eggs, 38 parts of wheat flour, 15 parts of white sugar, 18 parts of almond wood chips, almond wood crisp The cake production process includes the following steps:

[0096] S1: raw material acceptance

[0097] The almond wood chips are flat and oval, among which, the acid value ≤ 3mg / g, the peroxide value ≤ 0.15g / 100g, the wheat flour is fine, uniform in thickness, not damp, loose and no agglomeration, moisture ≤ 14%, the egg shell is clean, If there is no crack, the egg yolk is raised and intact after opening, the egg white is clear and transparent, and the breakage rate is ≤1%, check and accept them one by one according to the product list, and register them in the ledger after acceptance.

[0098] Store yellow butter and eggs in a fresh-keeping cabinet, the temperature of the fresh-keeping cabinet is 4°C-10°C, and the humidity is...

Embodiment 2

[0123] A kind of production technology of almond wood shortbread, almond wood shortbread comprises by weight: 14 parts of yellow cream, 7 parts of eggs, 40 parts of wheat flour, 18 parts of white granulated sugar, 20 parts of almond wood chips, almond wood shortbread The cake production process includes the following steps:

[0124] S1: raw material acceptance

[0125] The almond wood chips are flat and oval, among which, the acid value ≤ 3mg / g, the peroxide value ≤ 0.15g / 100g, the wheat flour is fine, uniform in thickness, not damp, loose and no agglomeration, moisture ≤ 14%, the egg shell is clean, If there is no crack, the egg yolk is raised and intact after opening, the egg white is clear and transparent, and the breakage rate is ≤1%, check and accept them one by one according to the product list, and register them in the ledger after acceptance.

[0126] Store yellow butter and eggs in a fresh-keeping cabinet, the temperature of the fresh-keeping cabinet is 4°C-10°C, and...

Embodiment 3

[0151] A production process of almond wood shortbread, the almond wood shortbread comprises: 16 parts of yellow cream, 8 parts of eggs, 42 parts of wheat flour, 20 parts of white granulated sugar, 22 parts of almond wood chips, and the almond wood shortbread The cake production process includes the following steps:

[0152] S1: raw material acceptance

[0153] The almond wood chips are flat and oval, among which, the acid value ≤ 3mg / g, the peroxide value ≤ 0.15g / 100g, the wheat flour is fine, uniform in thickness, not damp, loose and no agglomeration, moisture ≤ 14%, the egg shell is clean, If there is no crack, the egg yolk is raised and intact after opening, the egg white is clear and transparent, and the breakage rate is ≤1%, check and accept them one by one according to the product list, and register them in the ledger after acceptance.

[0154] Store yellow butter and eggs in a fresh-keeping cabinet, the temperature of the fresh-keeping cabinet is 4°C-10°C, and the humi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com