Patents

Literature

304results about "Dough shaping and dividing combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

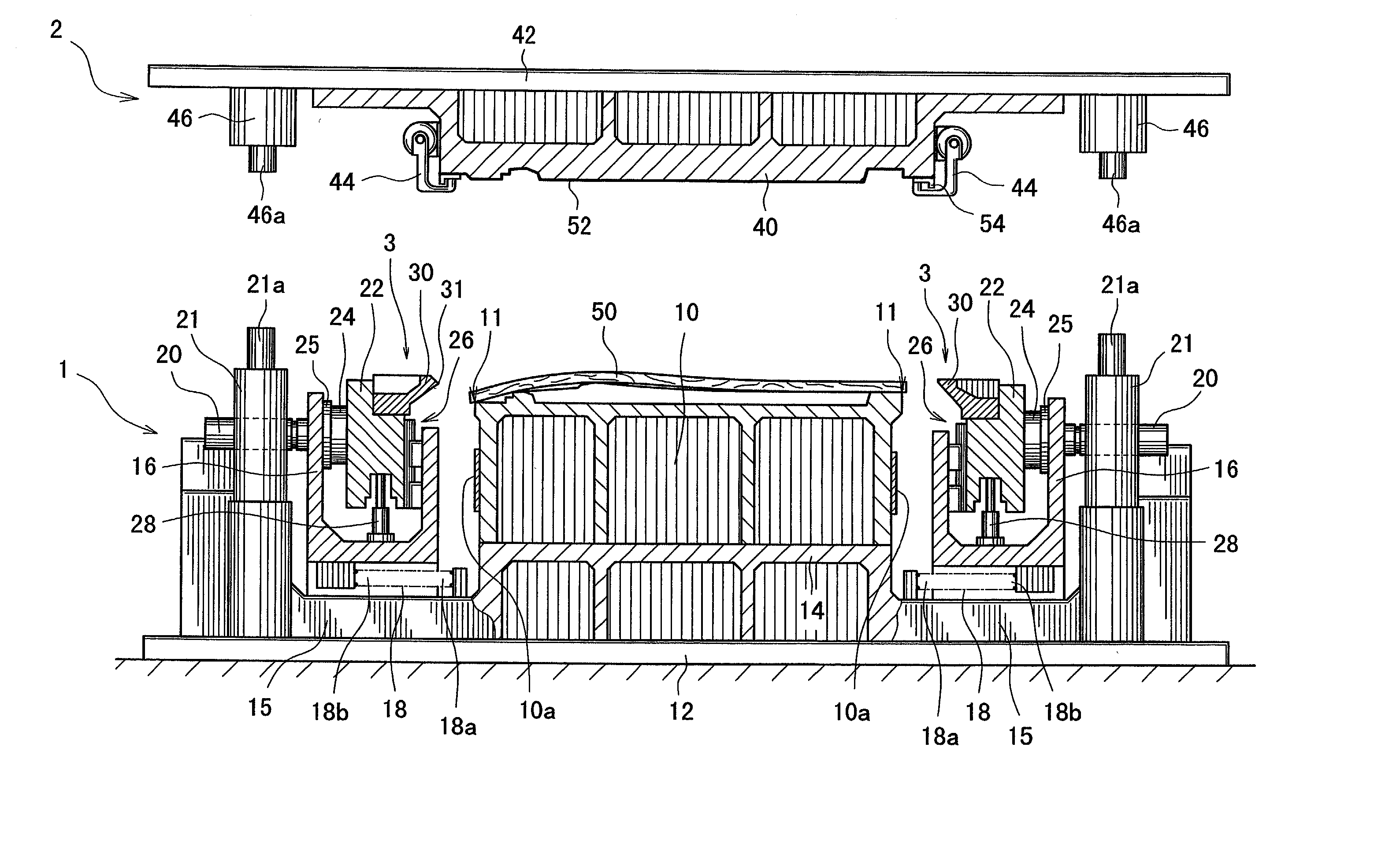

Apparatus for supplying food dough

InactiveUS6524090B1No pressureMouldsDough-sheeters/rolling-machines/rolling-pinsEngineeringFood products

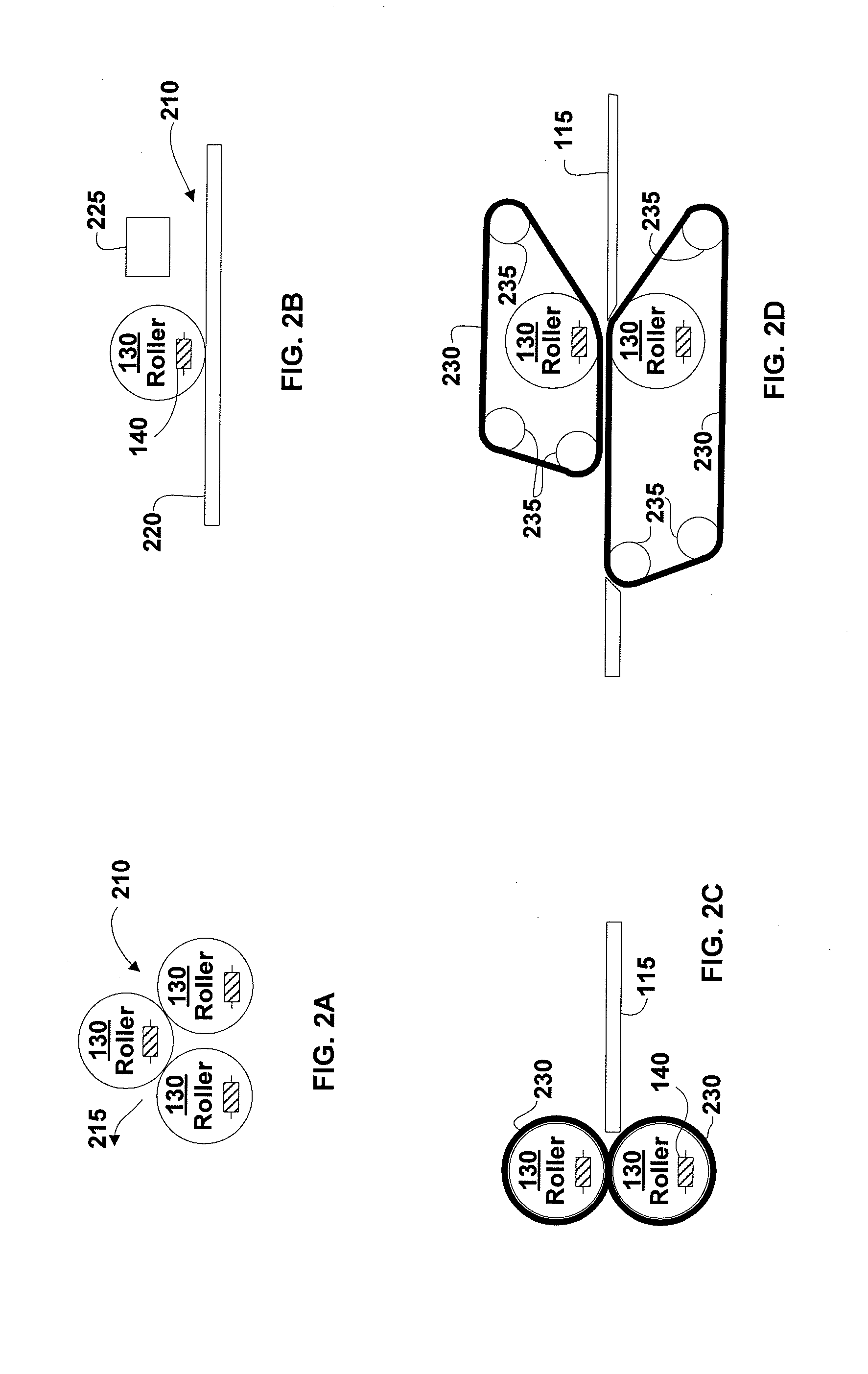

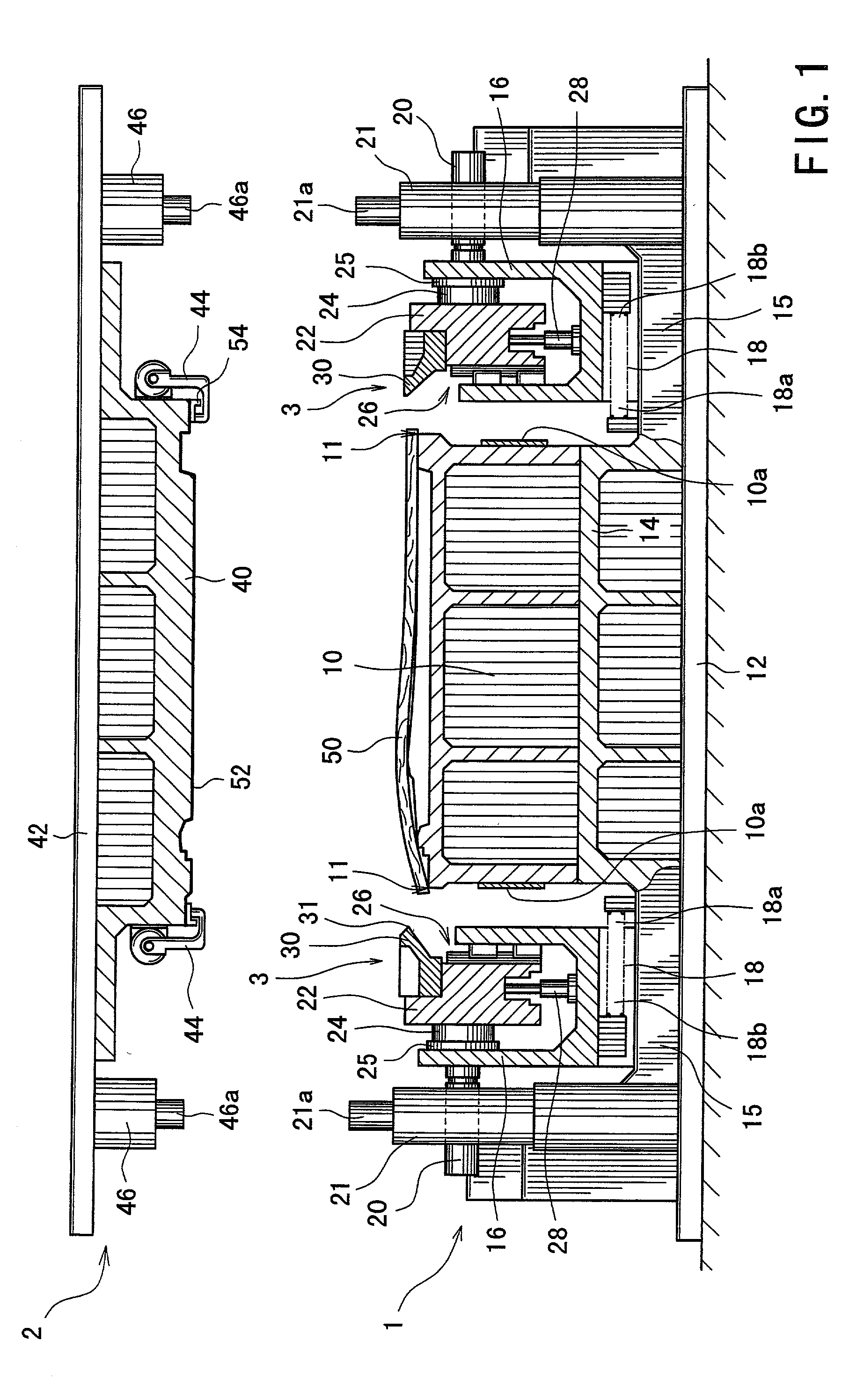

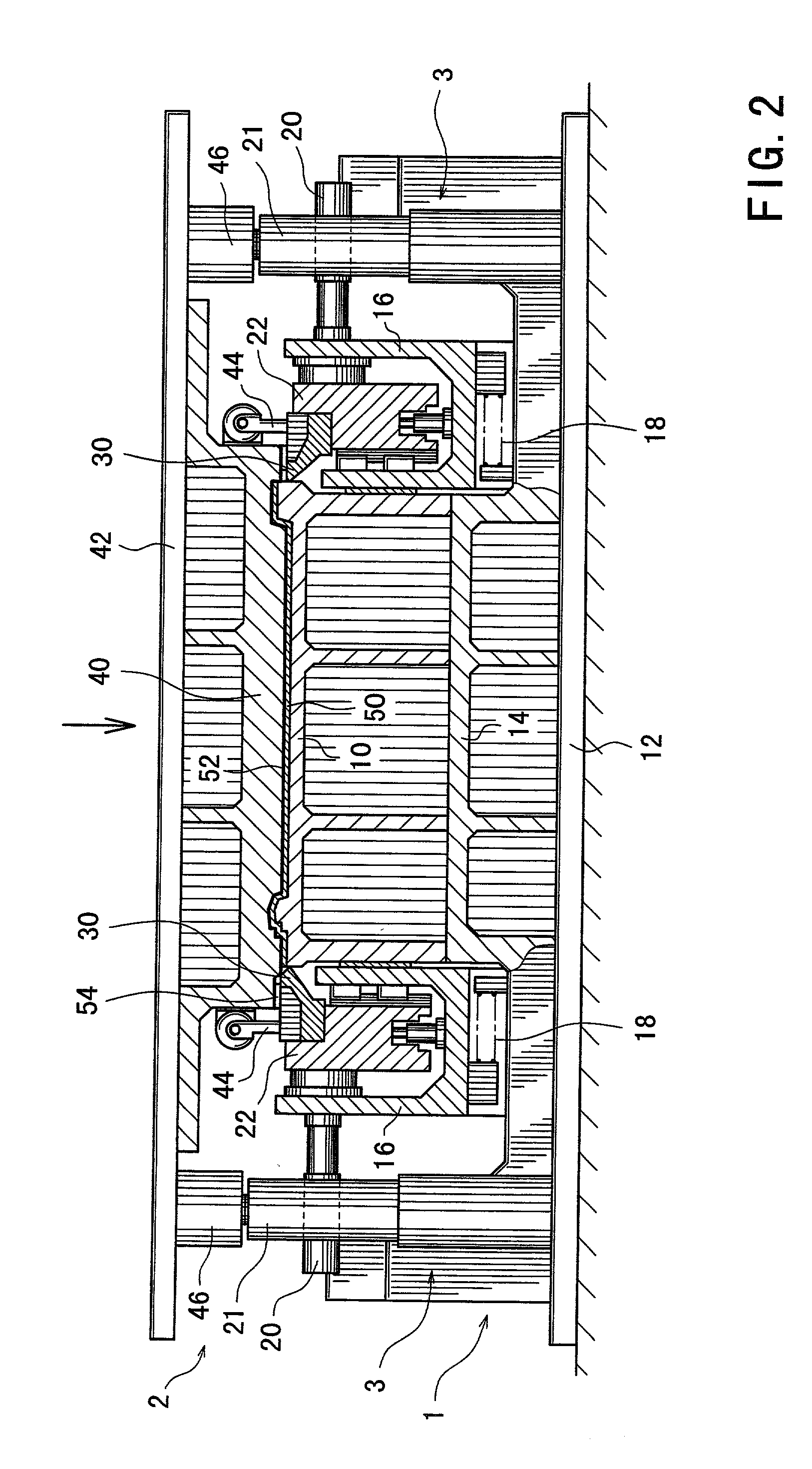

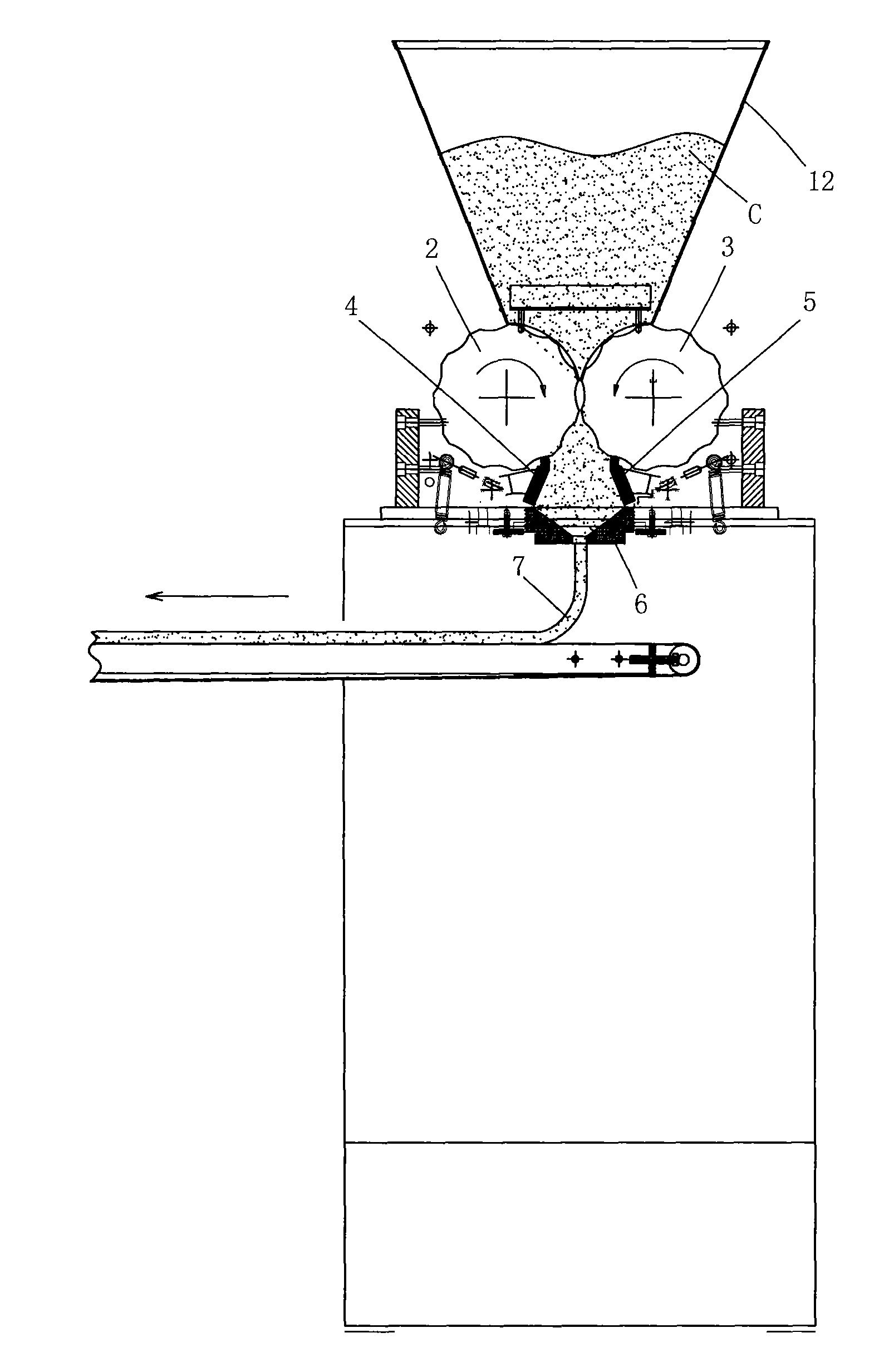

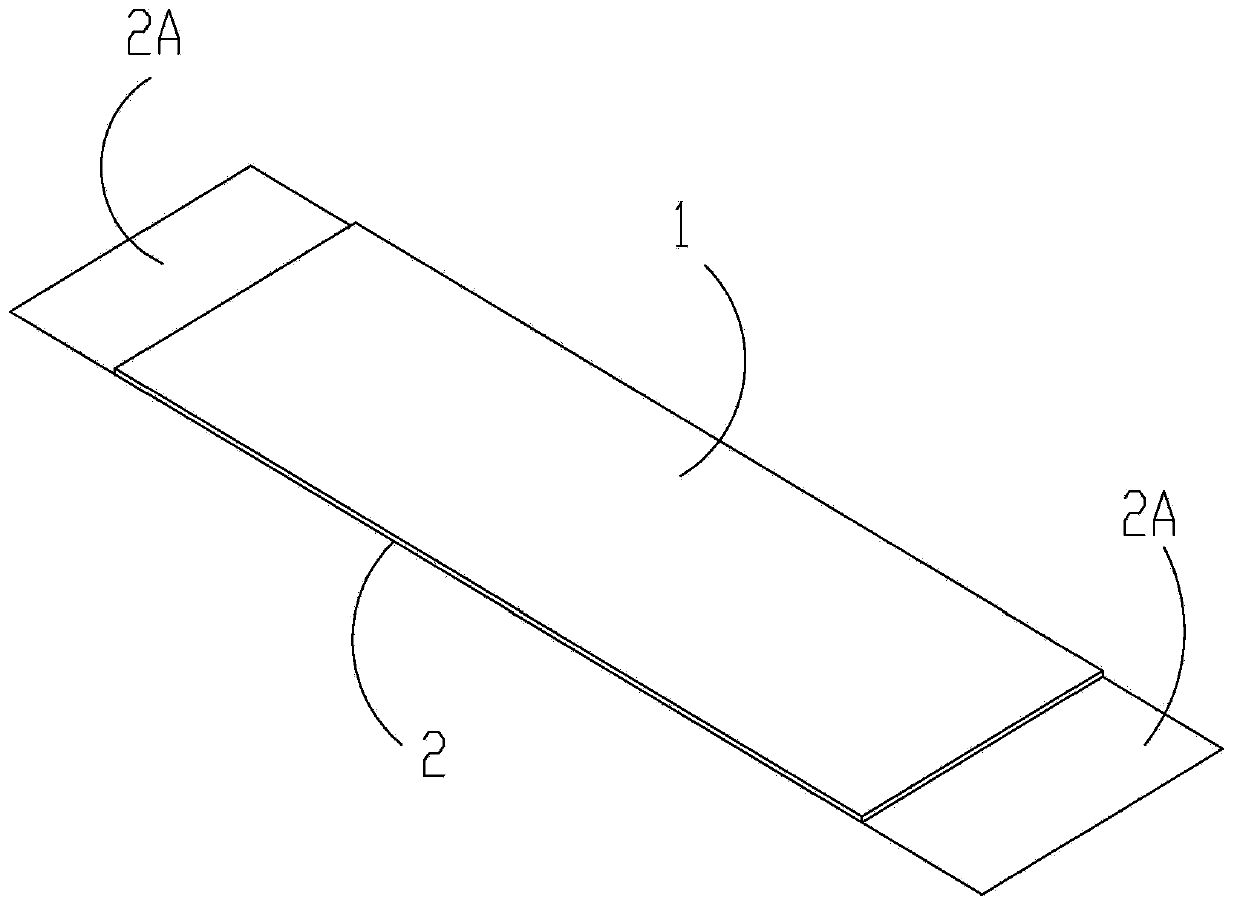

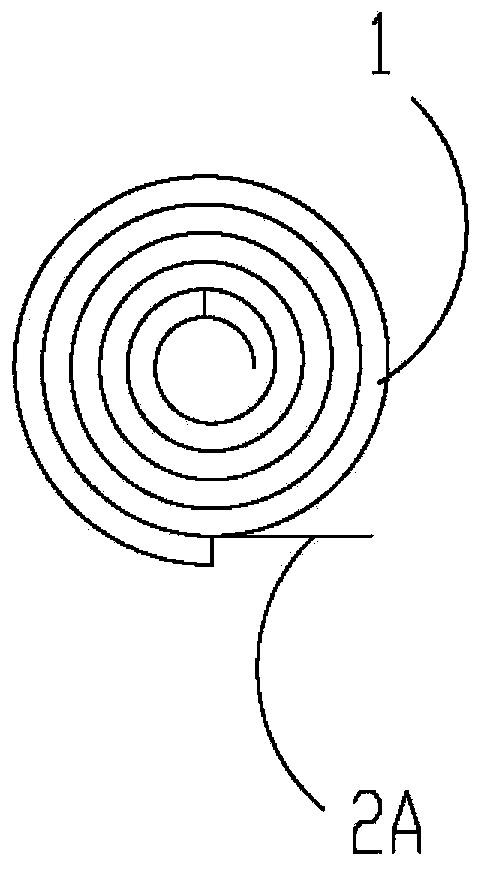

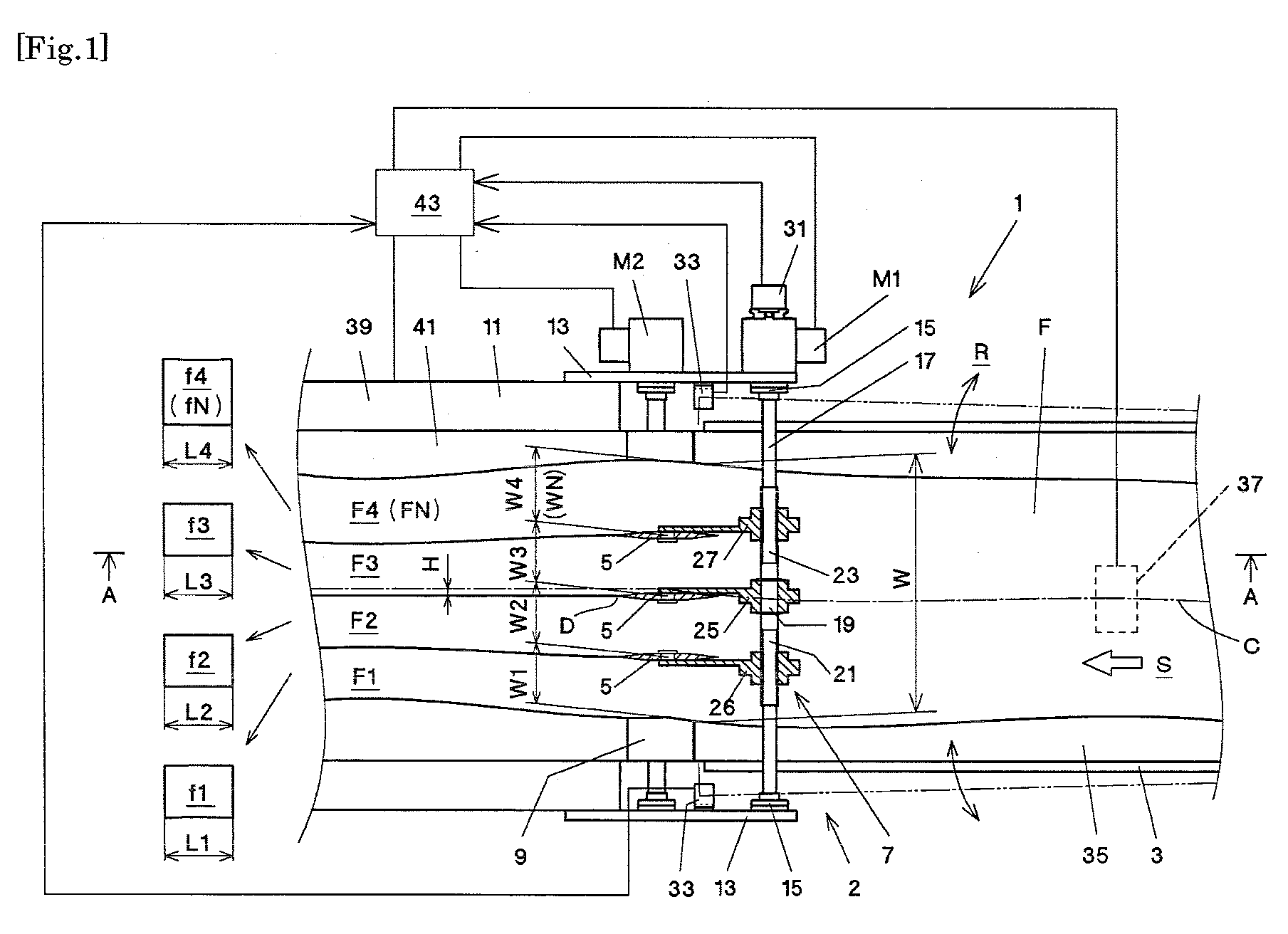

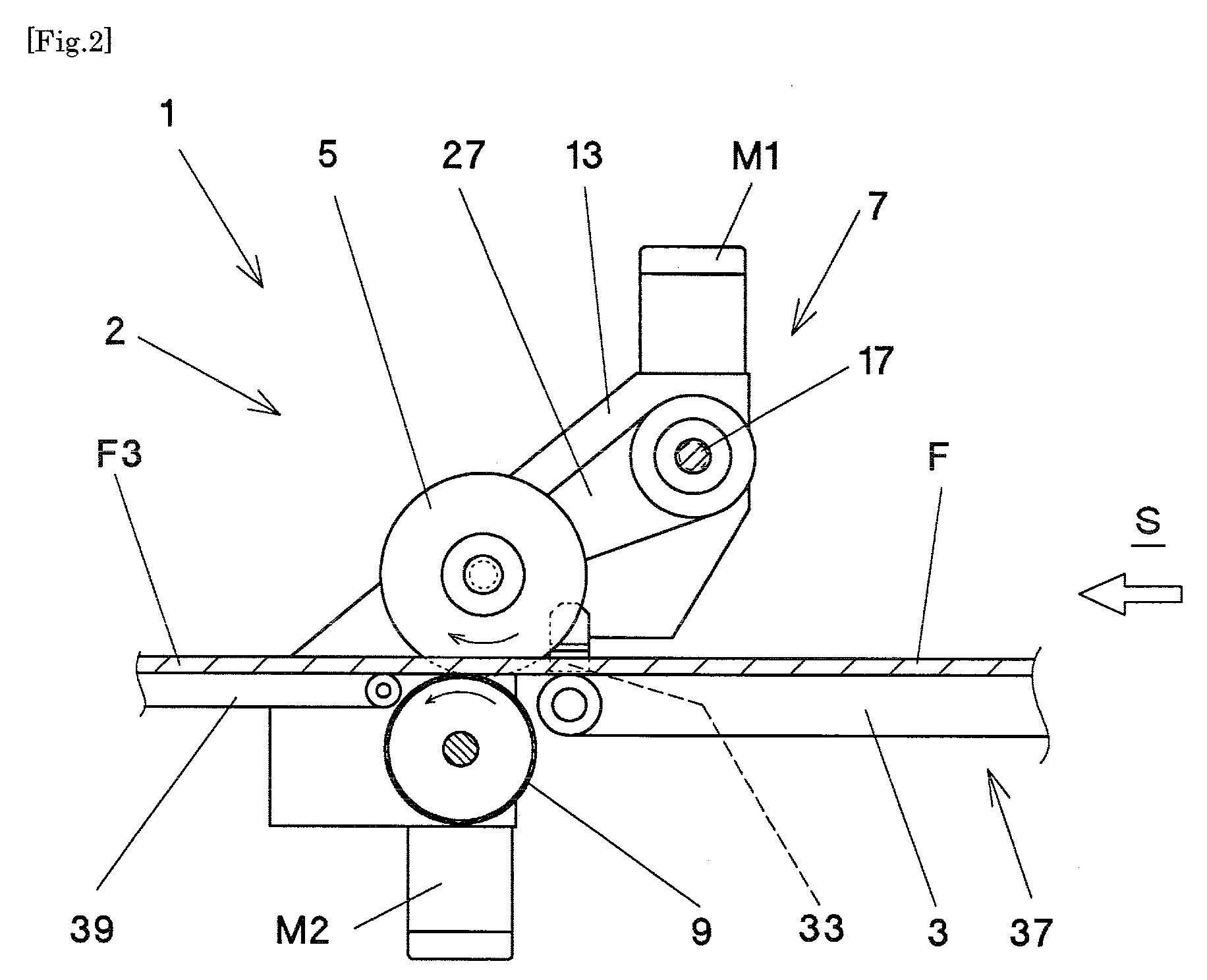

An apparatus for supplying food dough forms blocks of food dough that are continuously supplied into a sheet or belt of food dough and then divides it into chunks of food dough that have preset weights. The apparatus for supplying food dough comprises a hopper to which a large block of food dough is supplied, a cutting apparatus located at a lower opening port of the hopper to cut the block into small blocks that have substantially the same volume,a dough feeder having a plurality of rollers that are arranged as a V to form the small blocks into a sheet of the food dough, a transferring conveyor to transfer the small blocks to the dough feeder, a feeding conveyor to convey the sheet of the food dough that is formed by the dough feeder to have a constant thickness, a weighing conveyor measuring the weight of a part of the sheet that is supplied by the feeding conveyor as the sheet is being conveyed, and a cutting apparatus for cutting the sheet of the food dough when the measurement of the weighing conveyor corresponds to a preset value.

Owner:RHEON AUTOMATIC MASCH CO LTD

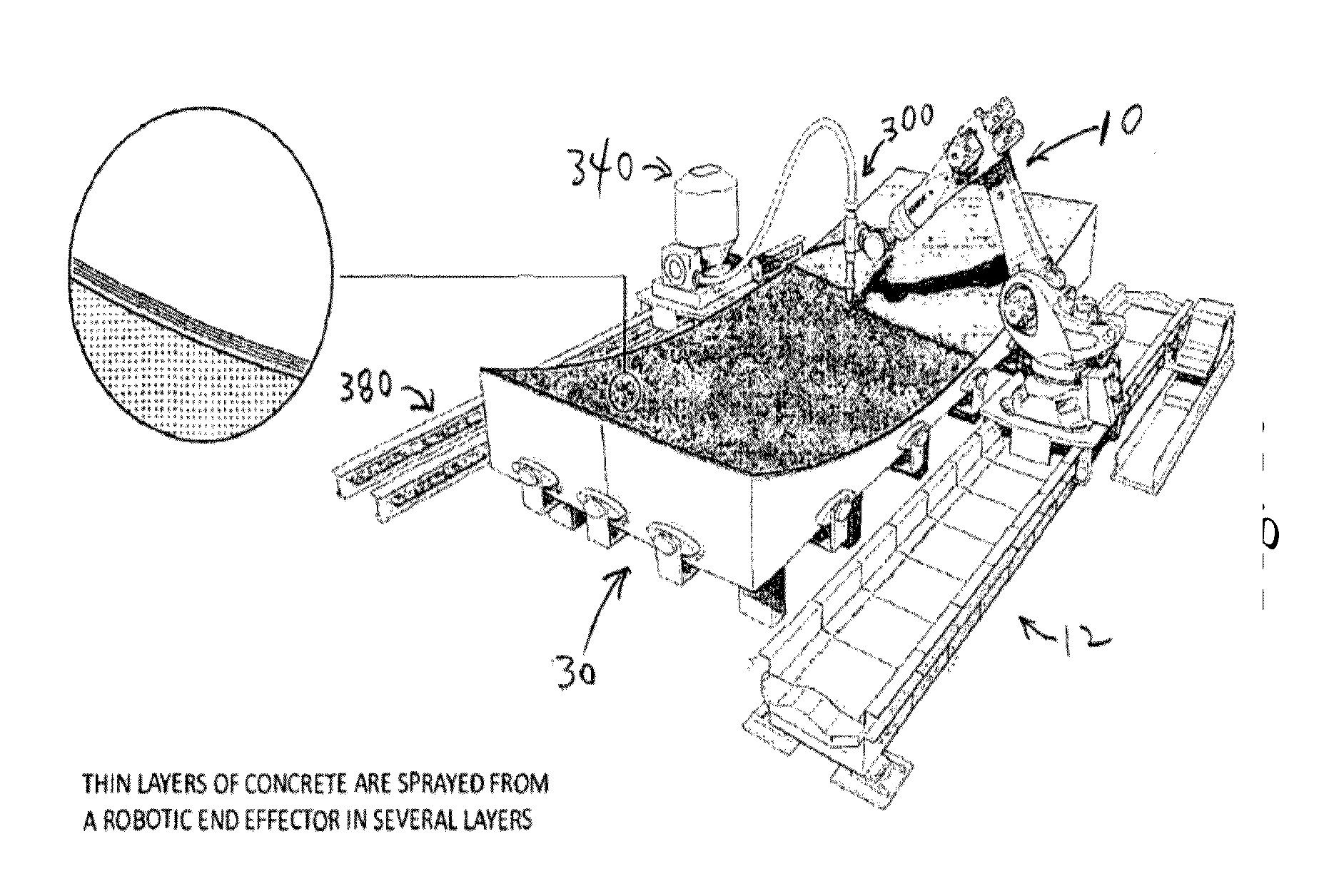

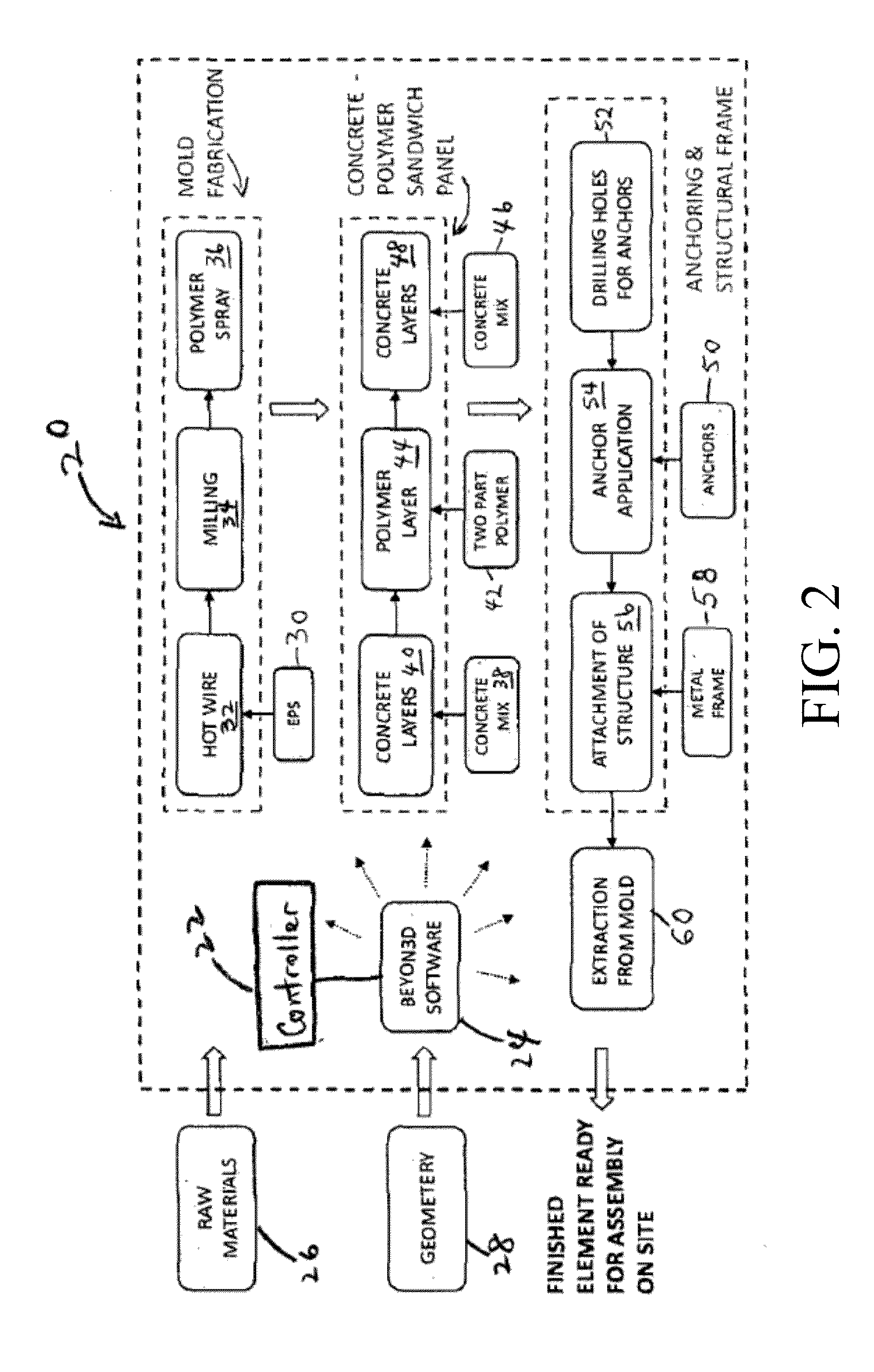

Method and system for fabrication of custom made molds and concrete architectural components

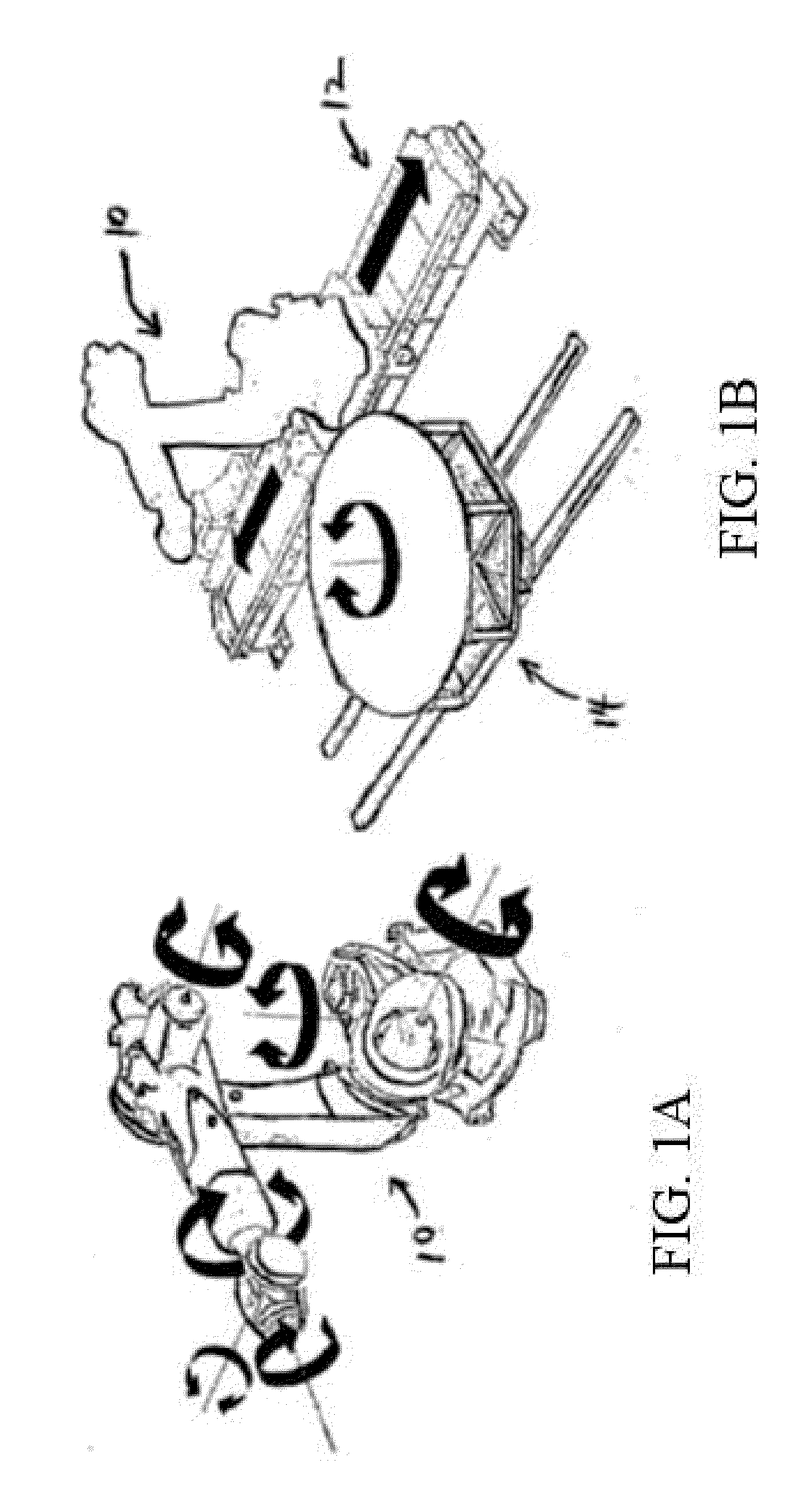

A method and system for constructing an architectural component from a three-dimensional form are disclosed. In a preferred embodiment, the system comprises a movable support table for supporting and moving a three-dimensional form; a multi-task robotic arm having a base end configured for controlled movement along a path proximate the support table and a distal end configured to extend, translate, and / or rotate relative to the base and to include an end effector for applying successive layers of material onto and / or removing material from a form on the support table; optionally, a linear rail to which said base is attached; and a computer processor for controlling a sequence of movements of the support table, the base, and the distal end of said multi-task robotic arm, and for controlling application or removal of material to or from the three-dimensional form to form an architectural component of a predetermined shape and dimension.

Owner:BEYON 3D

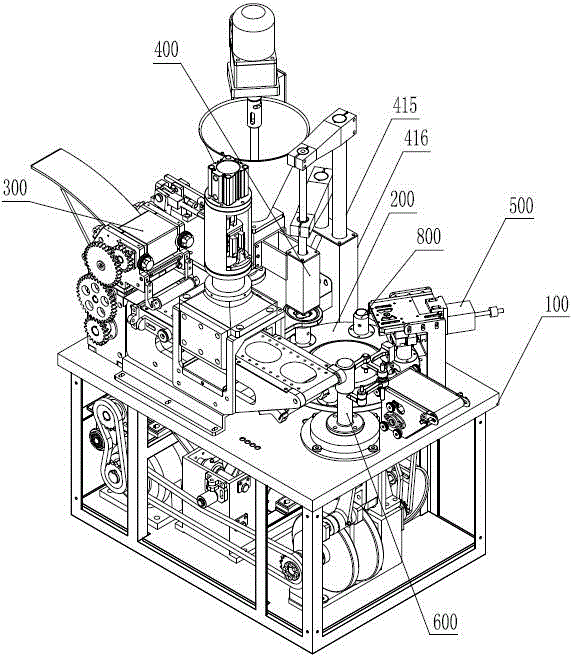

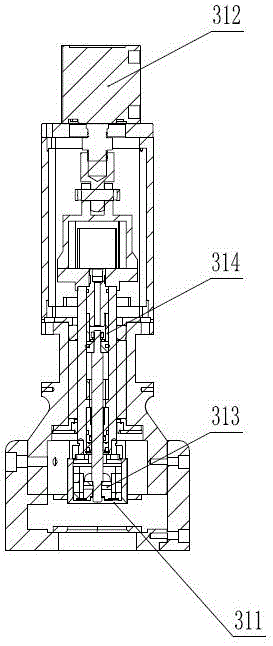

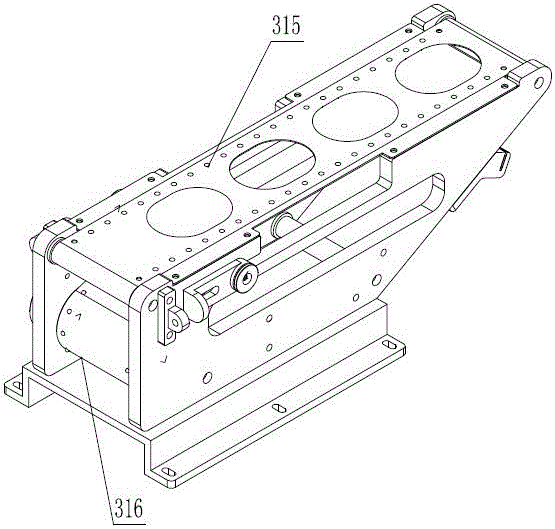

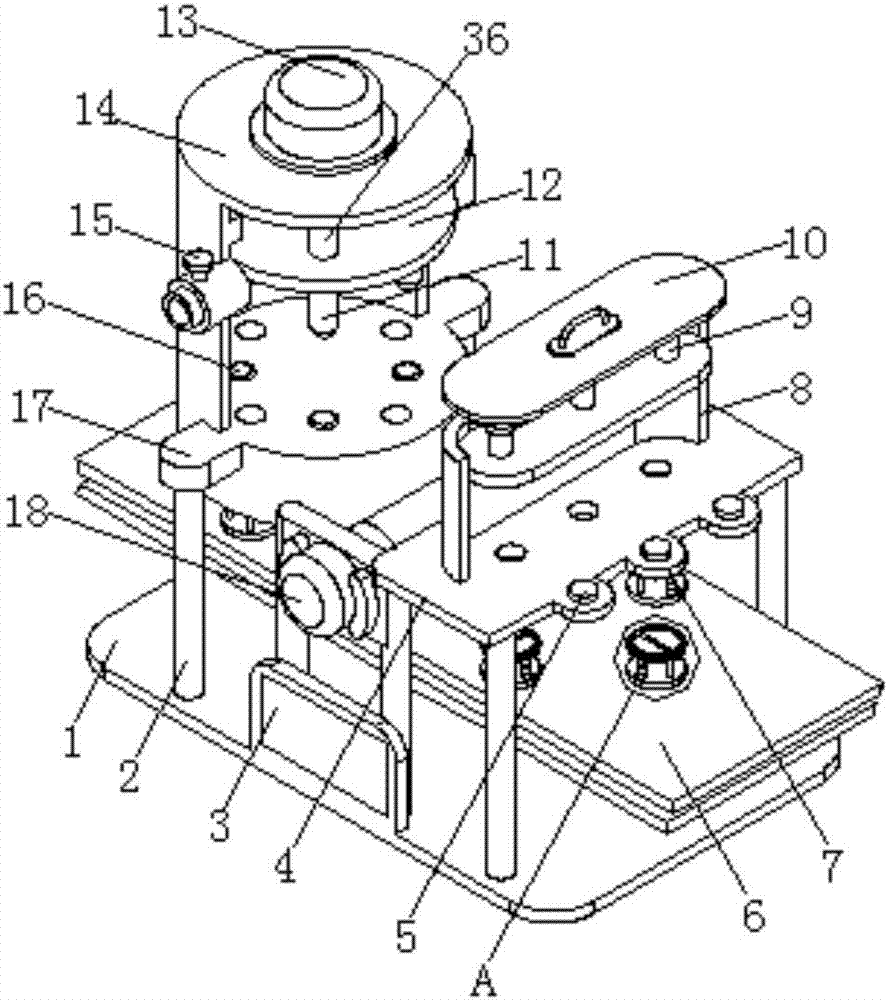

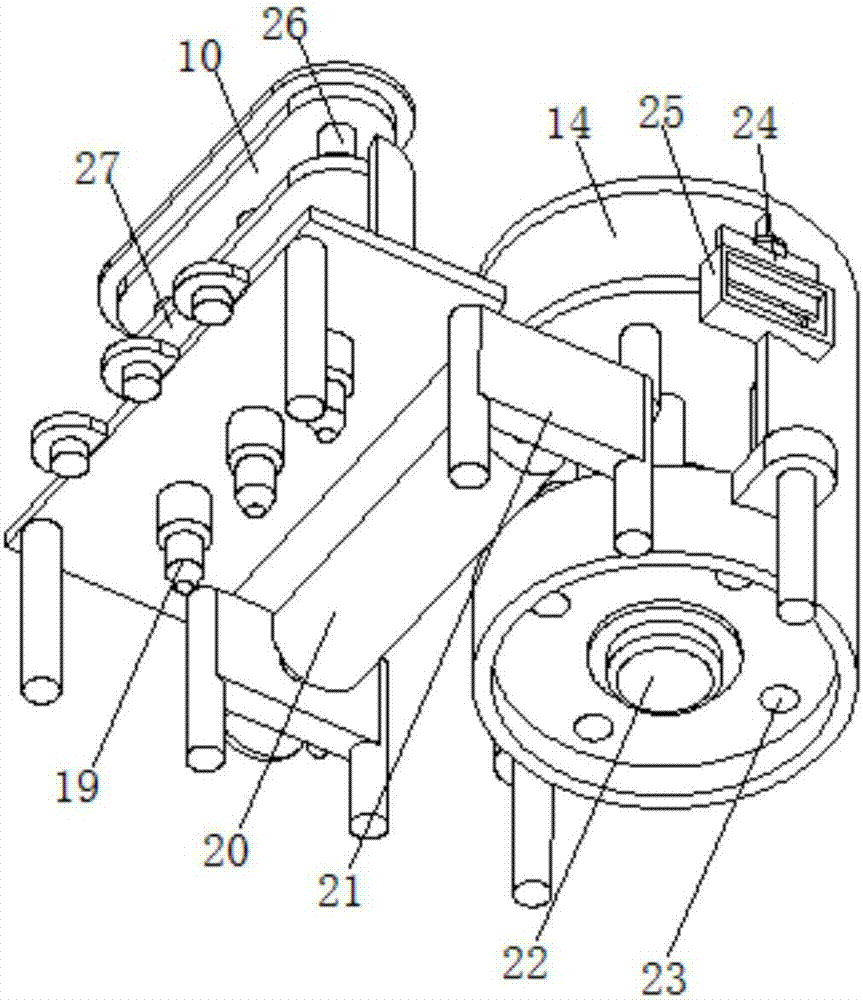

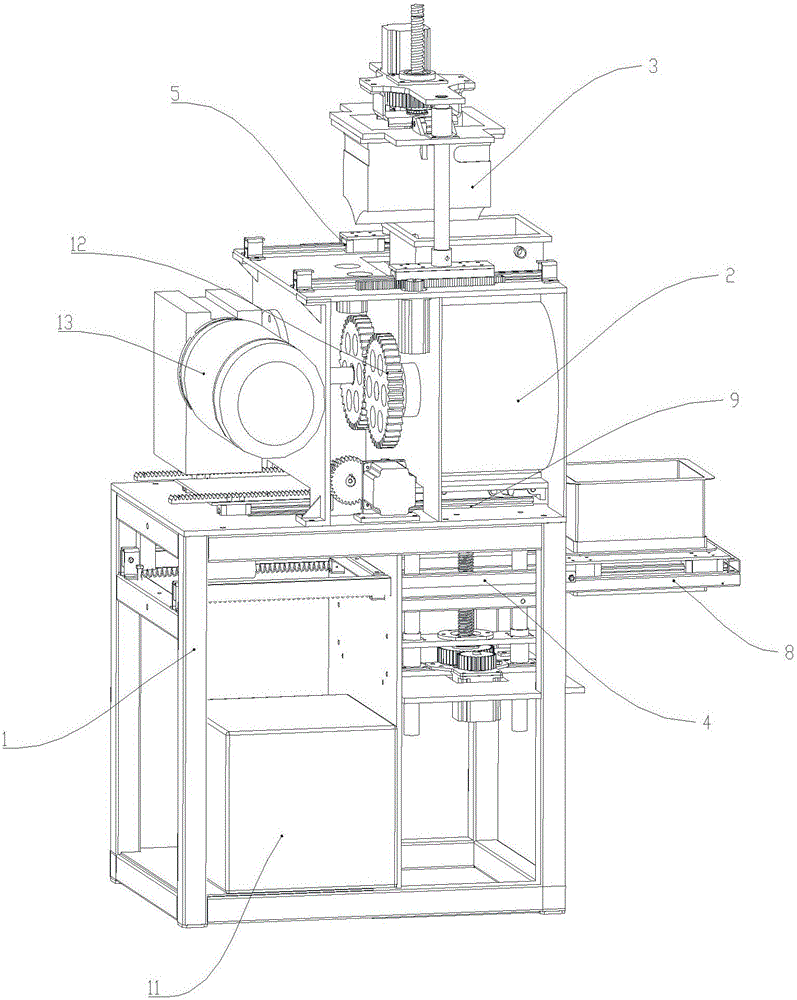

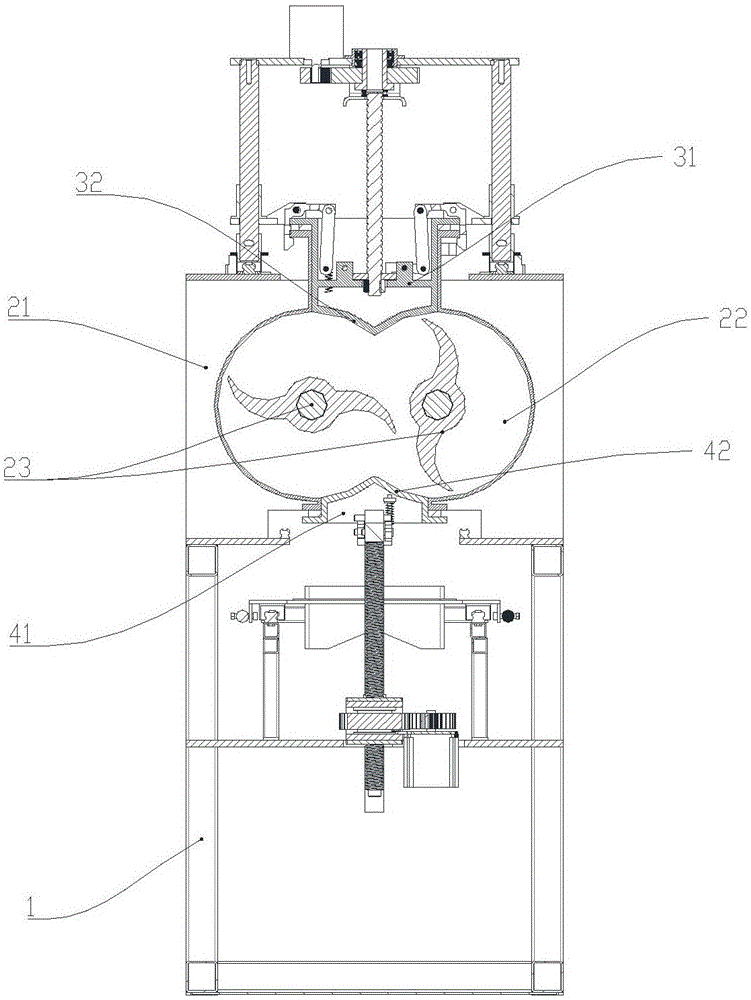

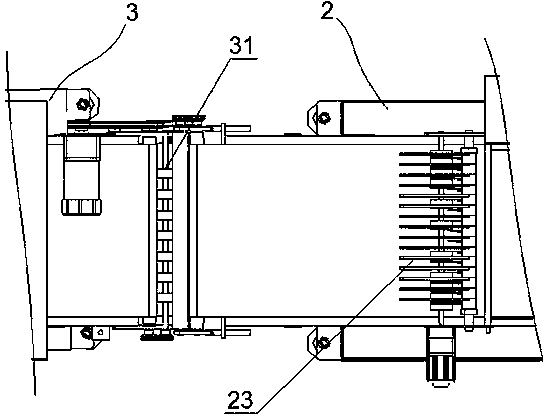

Compact stuffed food shaping machine

ActiveCN105724507AAchieve instant cookingReduce transportation and circulation linksDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationMolding machineProcess engineering

The invention belongs to the technical field of food processing and in particular relates to a compact stuffed food shaping machine. The shaping machine comprises a rack and a station turntable arranged on the rack, wherein a wrapper making device, a stuffing device, a laminating device and a discharge device are respectively arranged around the station turntable; a wrapper making station is arranged on the wrapper making device; a stuffing station is arranged on the stuffing device; a laminating station is arranged on the laminating device; a discharge station is arranged on the discharge device; a split shaping mold is also arranged on the rack and comprises a rotary wrapper receiving plate and mold cups, which are independent of each other. The compact stuffed food shaping machine can achieve immediate cooking of stuffed food and reduction of transport and circulation links, can avoid freezing, enables the taste of the stuffed food to be closer to the tastes of traditional hand-made dumplings and are applicable to the food and beverage industry, farmers' markets, dining halls of enterprises, organs and organizations, and the like.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

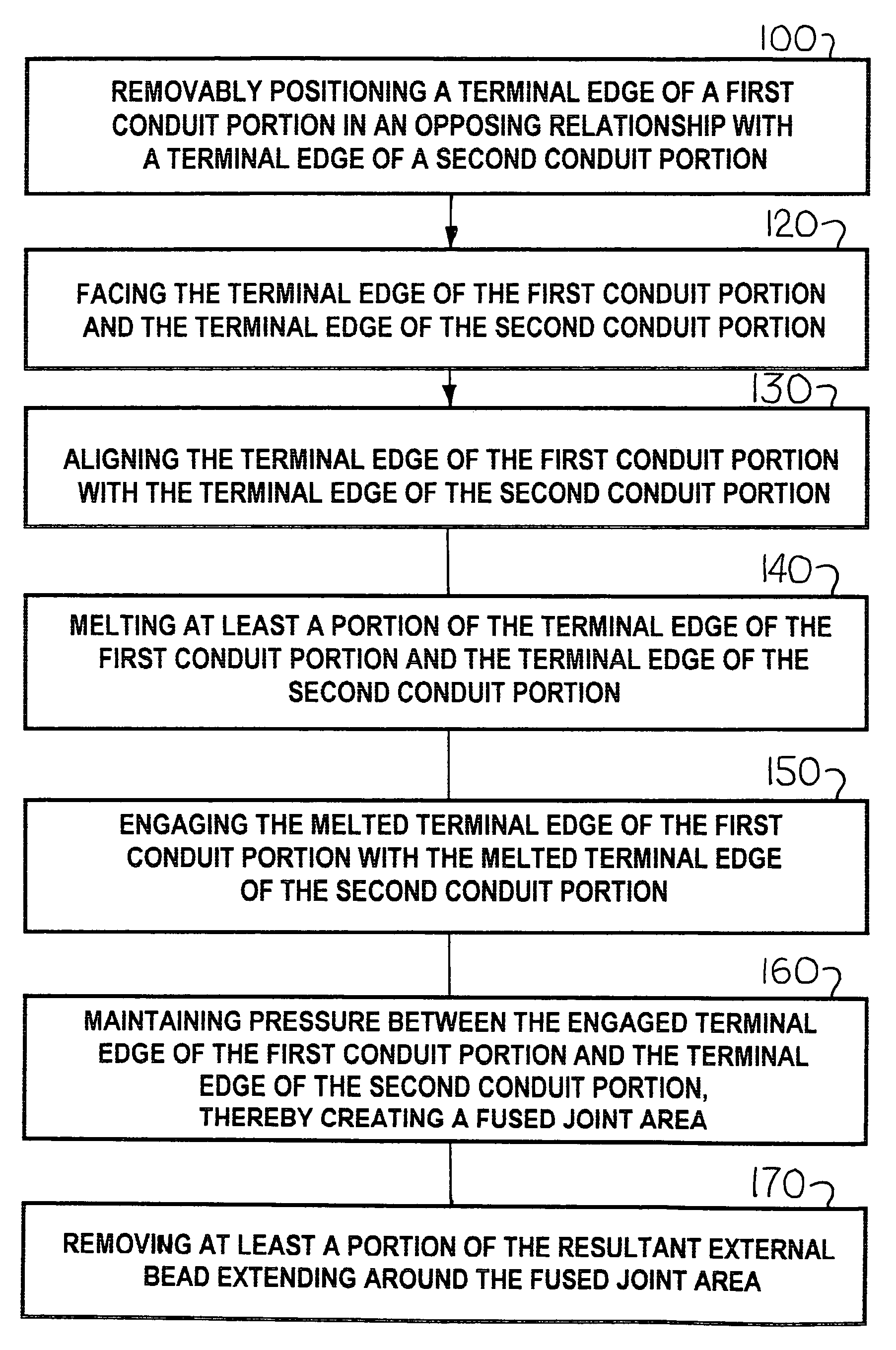

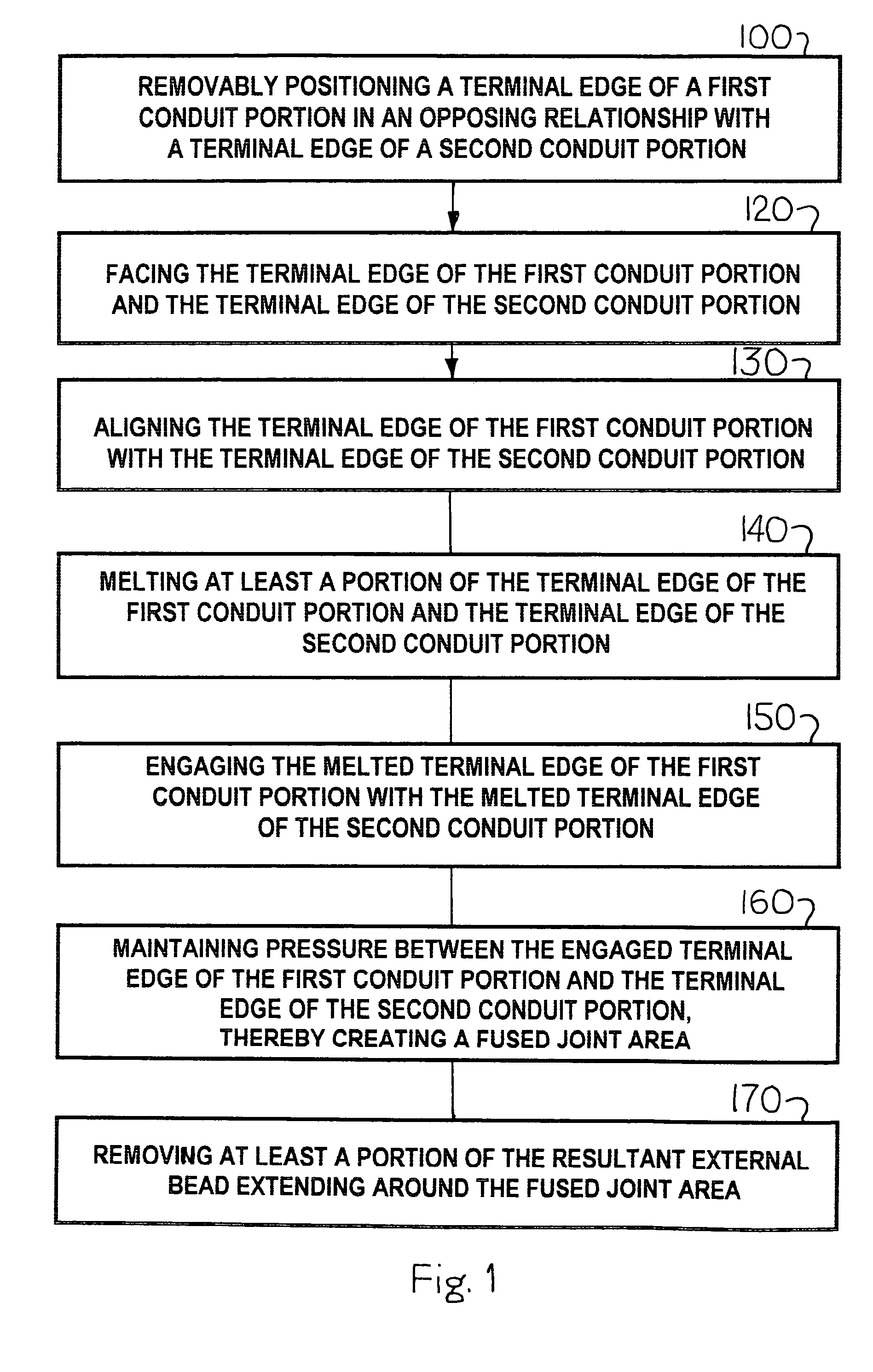

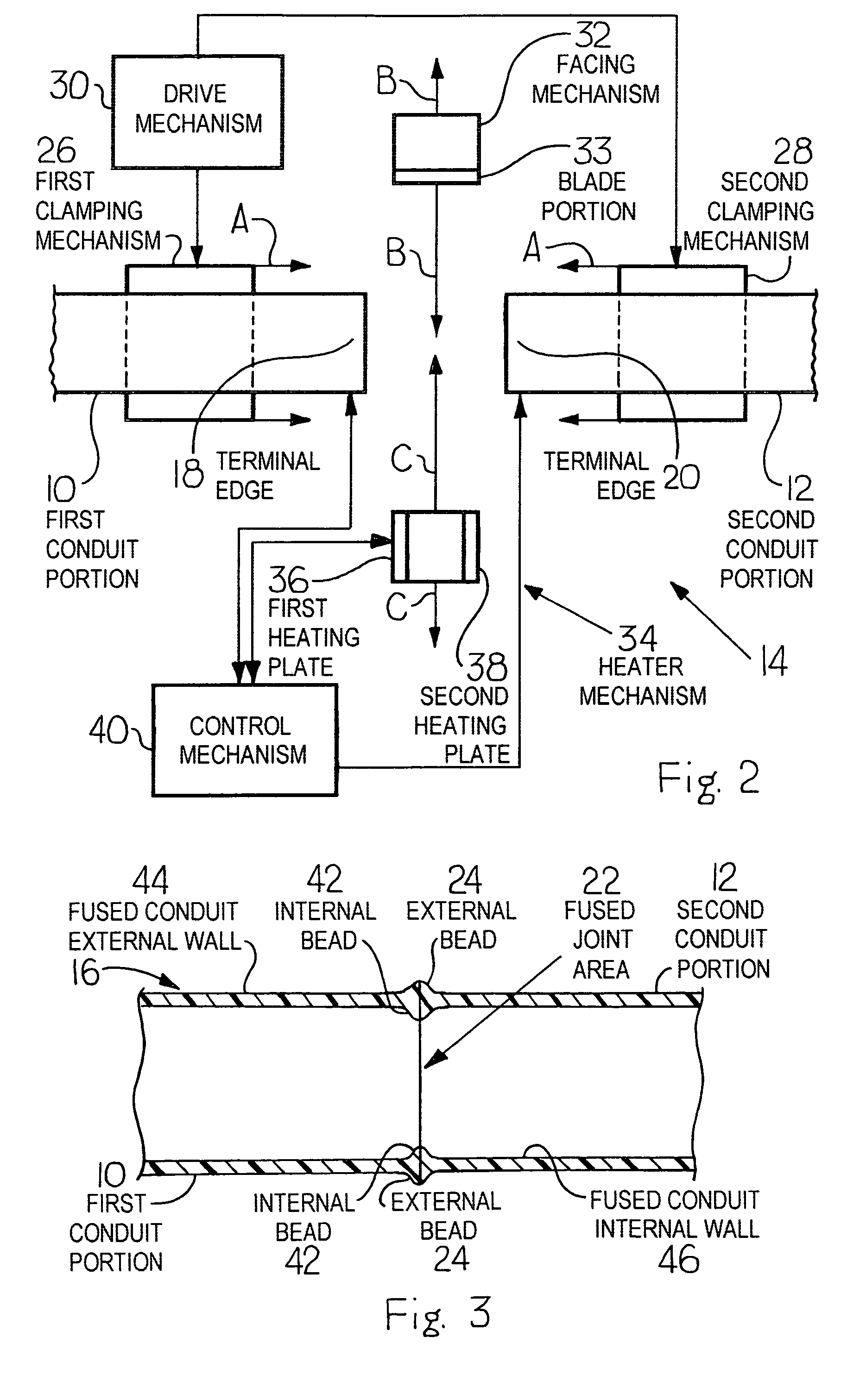

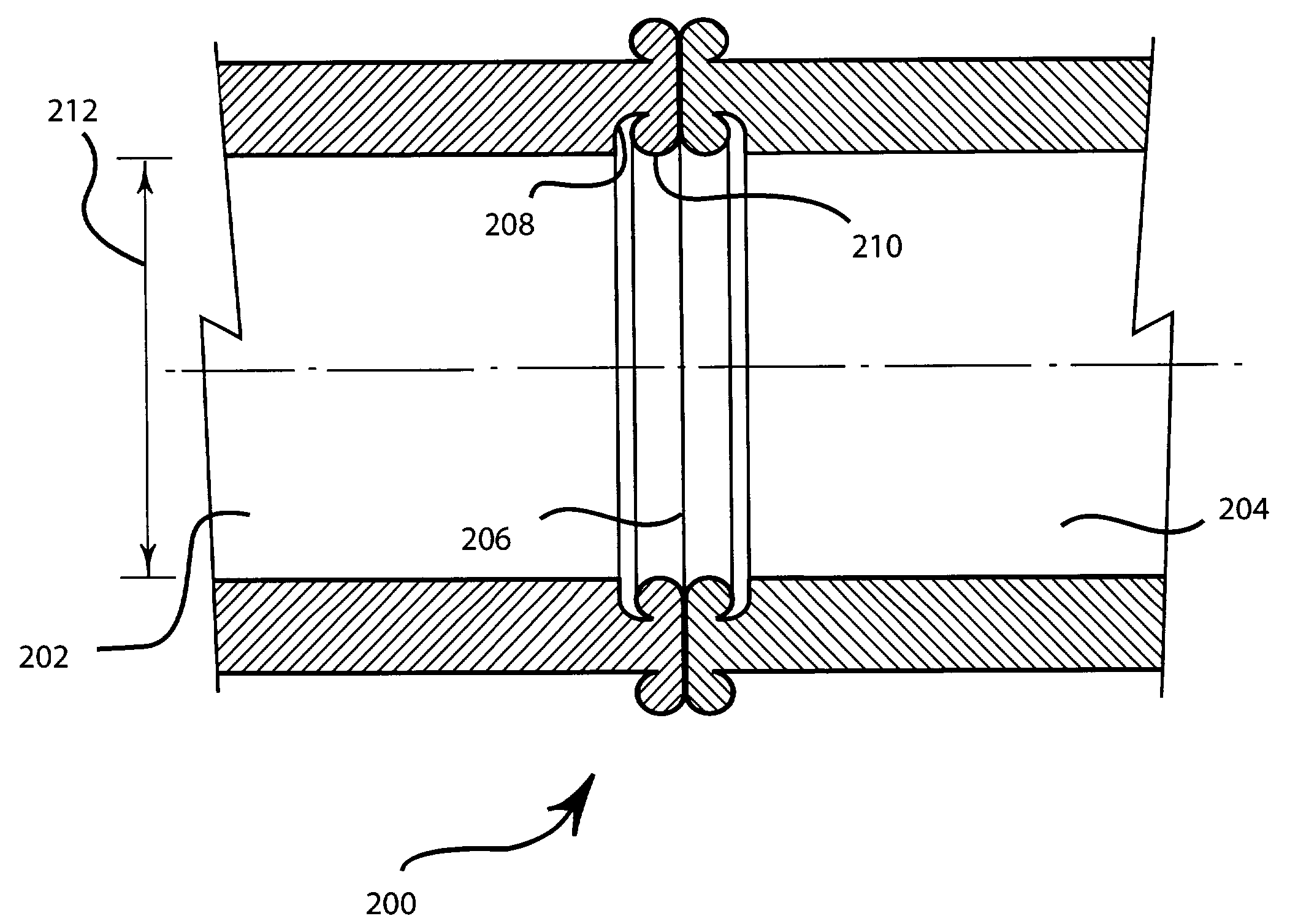

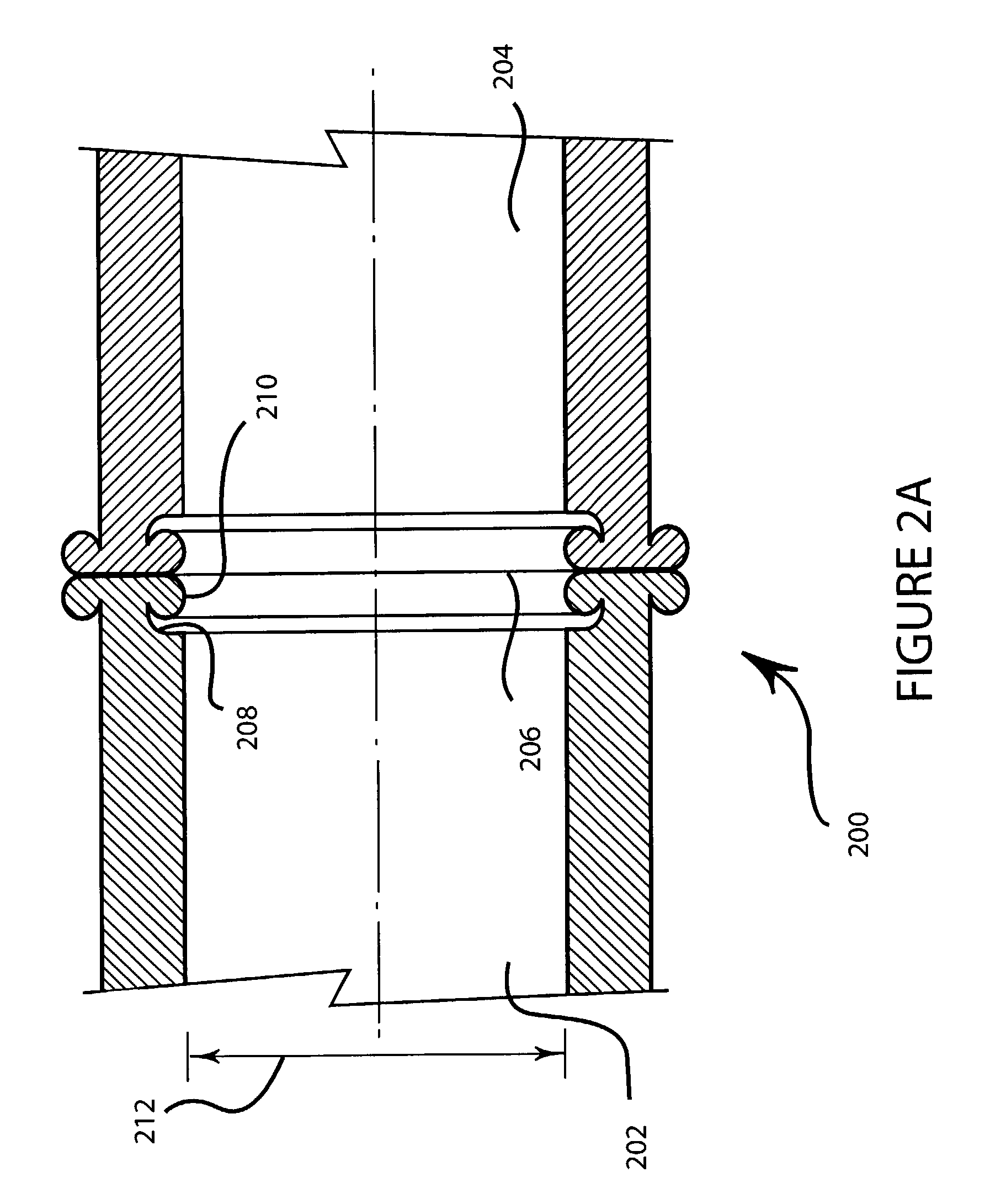

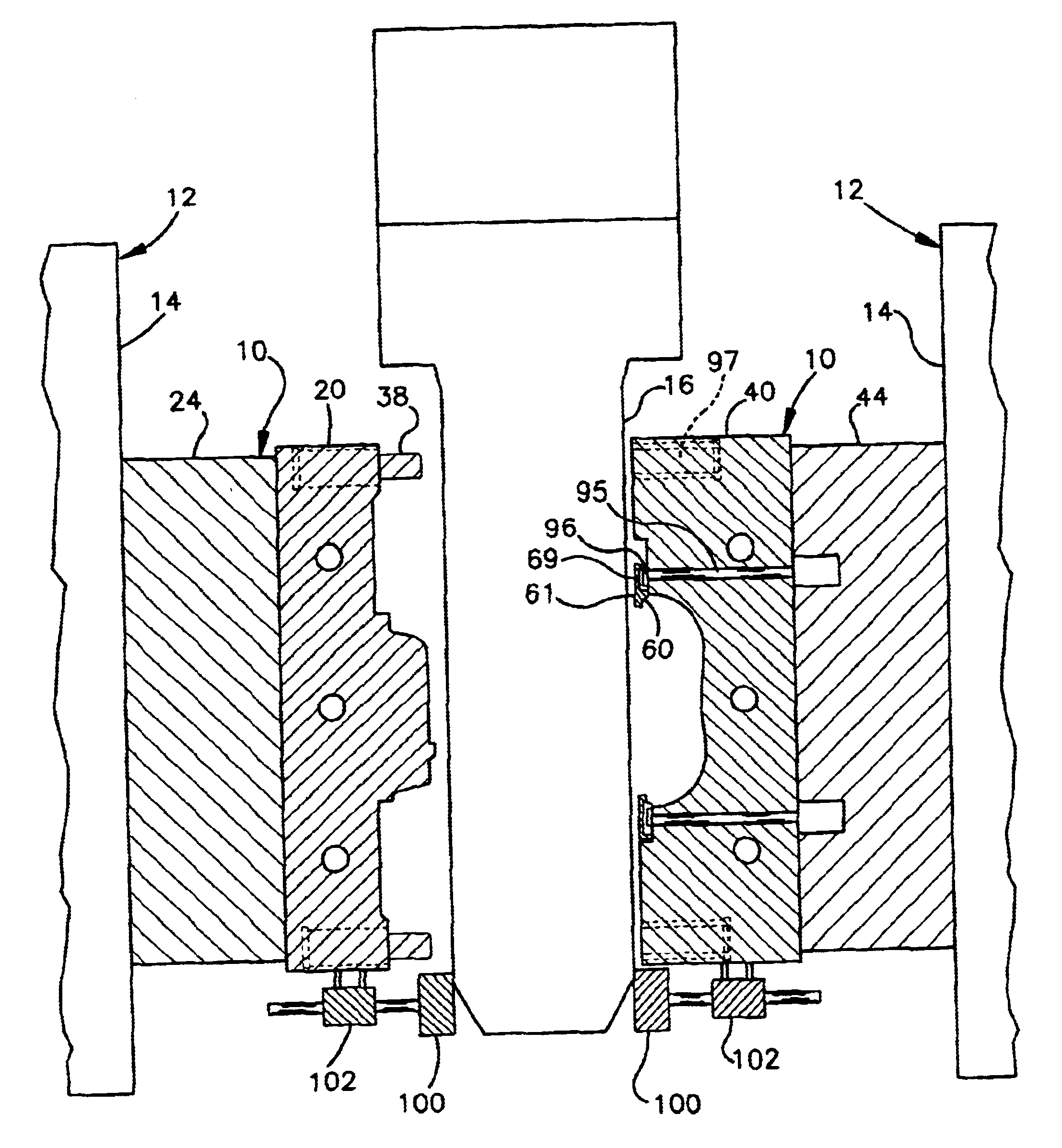

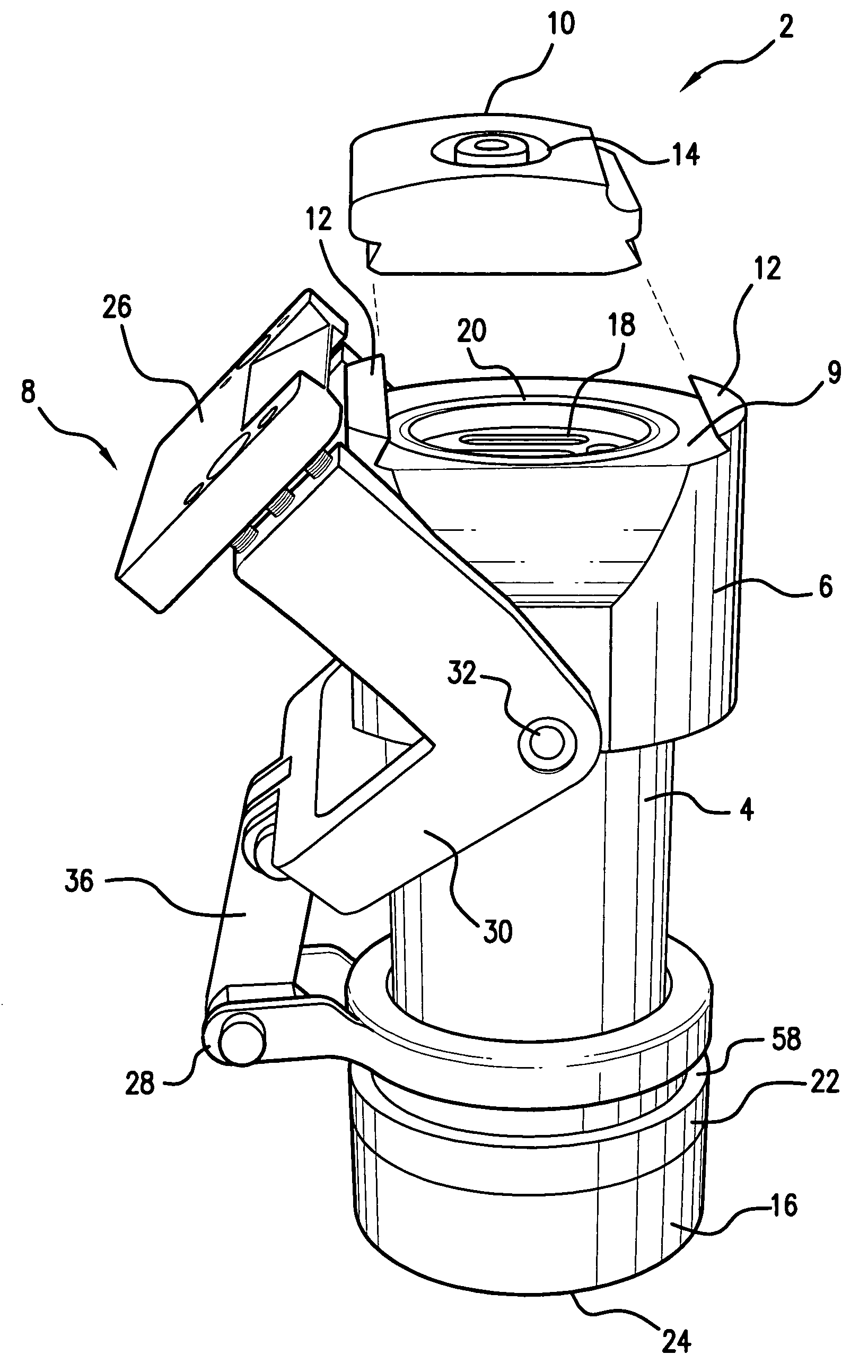

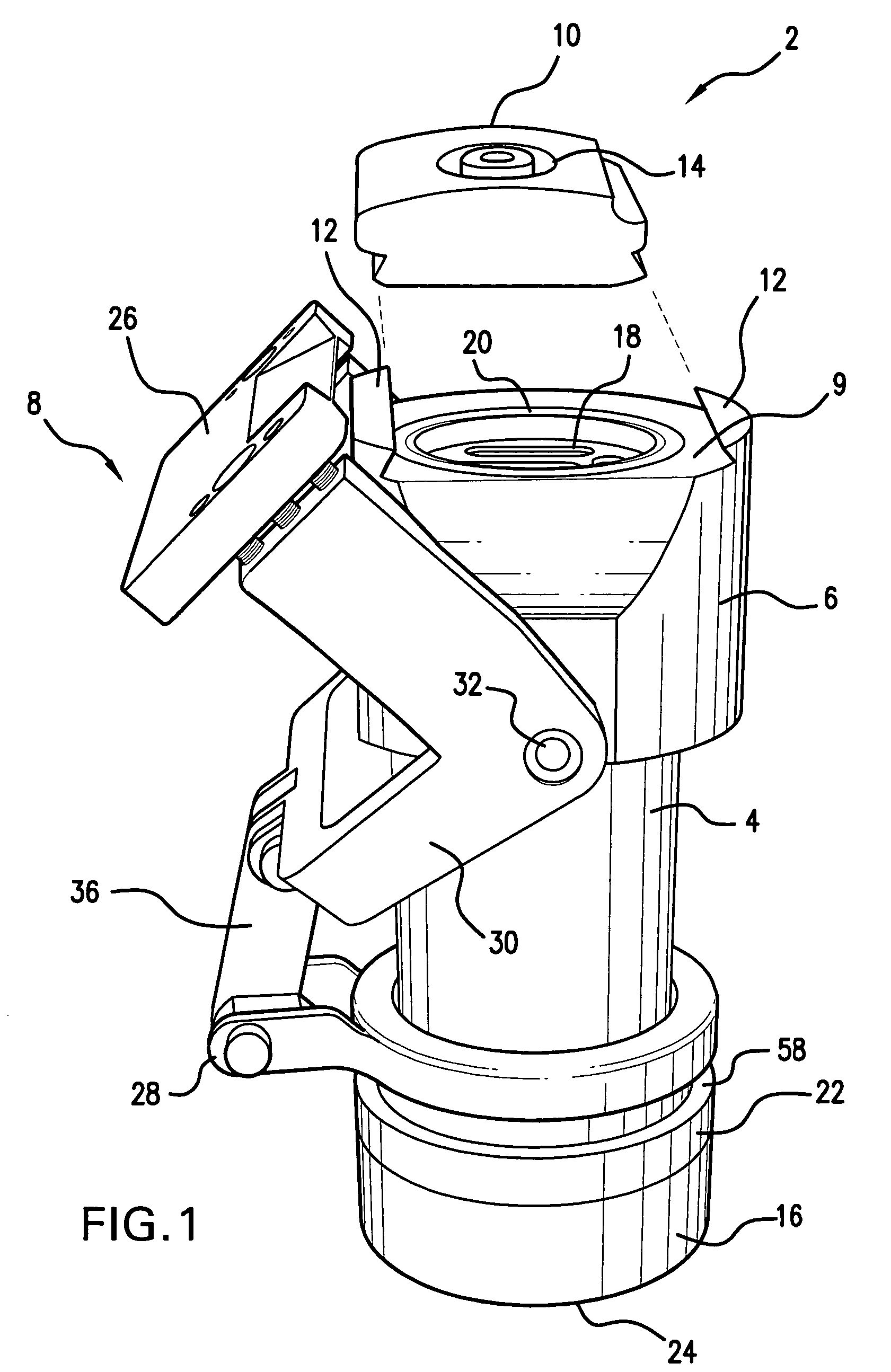

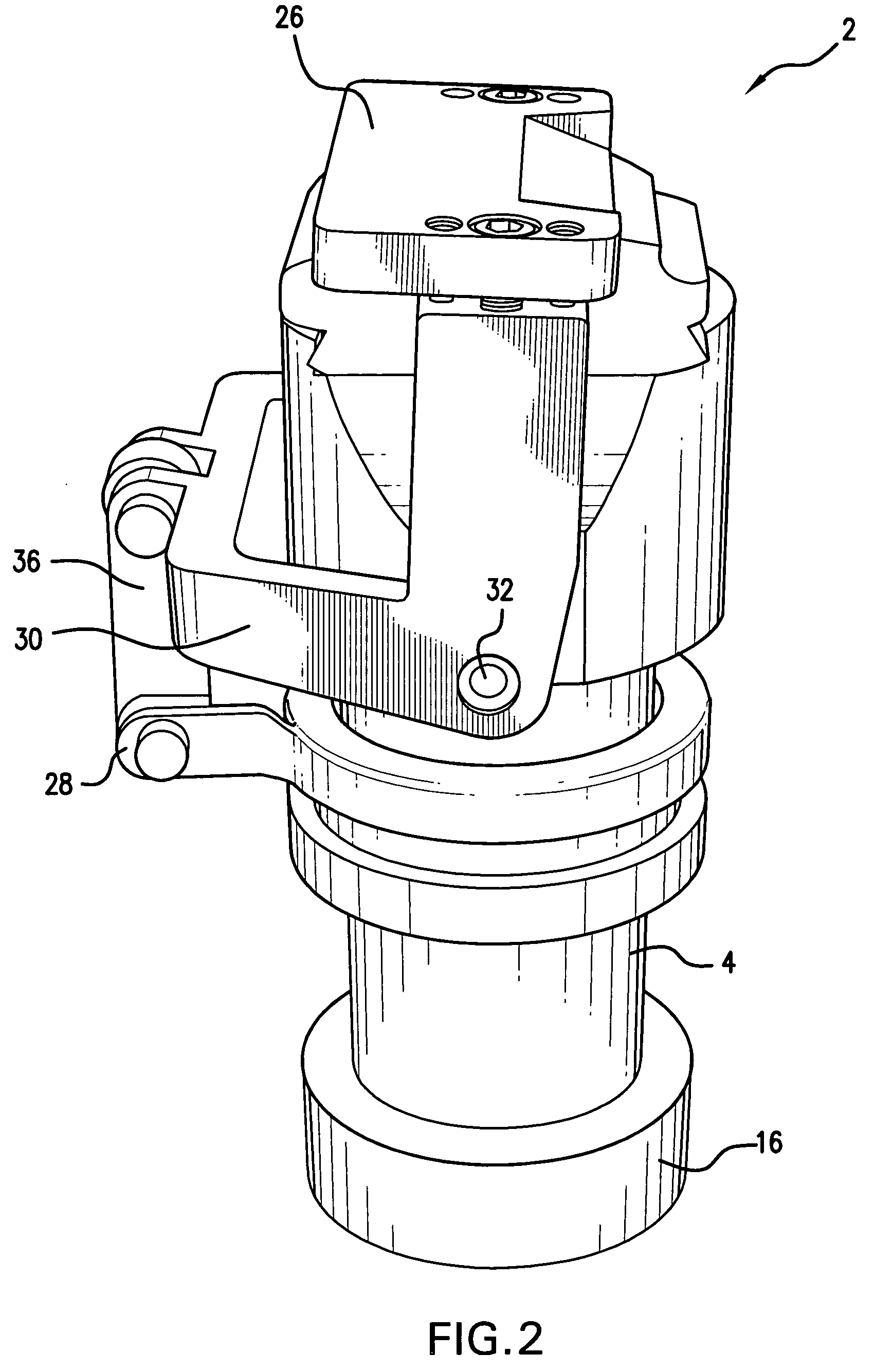

Fusion process for conduit

ActiveUS6982051B2High strength propertiesEasy to useButtonsRecord carriersEngineeringComputer terminal

Disclosed is a method and apparatus for use in a fusion process for conduit. The method includes the steps of: removably positioning a first terminal edge of a first conduit portion with a first terminal edge of a second conduit portion; facing the terminal edges of the first conduit portion and the second conduit portion; aligning the terminal edges of the first conduit portion and the second conduit portion; melting at least a portion of the terminal edges of the first conduit portion and the second conduit portion; engaging the melted terminal edge of the first conduit portion with the melted terminal edge of the second conduit portion; maintaining pressure between the engaged terminal edges, thereby creating a fused joint area; and removing at least a portion of the resultant external bead extending around the fused joint area. A fusion apparatus for employing this method is also disclosed.

Owner:UNDERGROUND SOLUTIONS INC

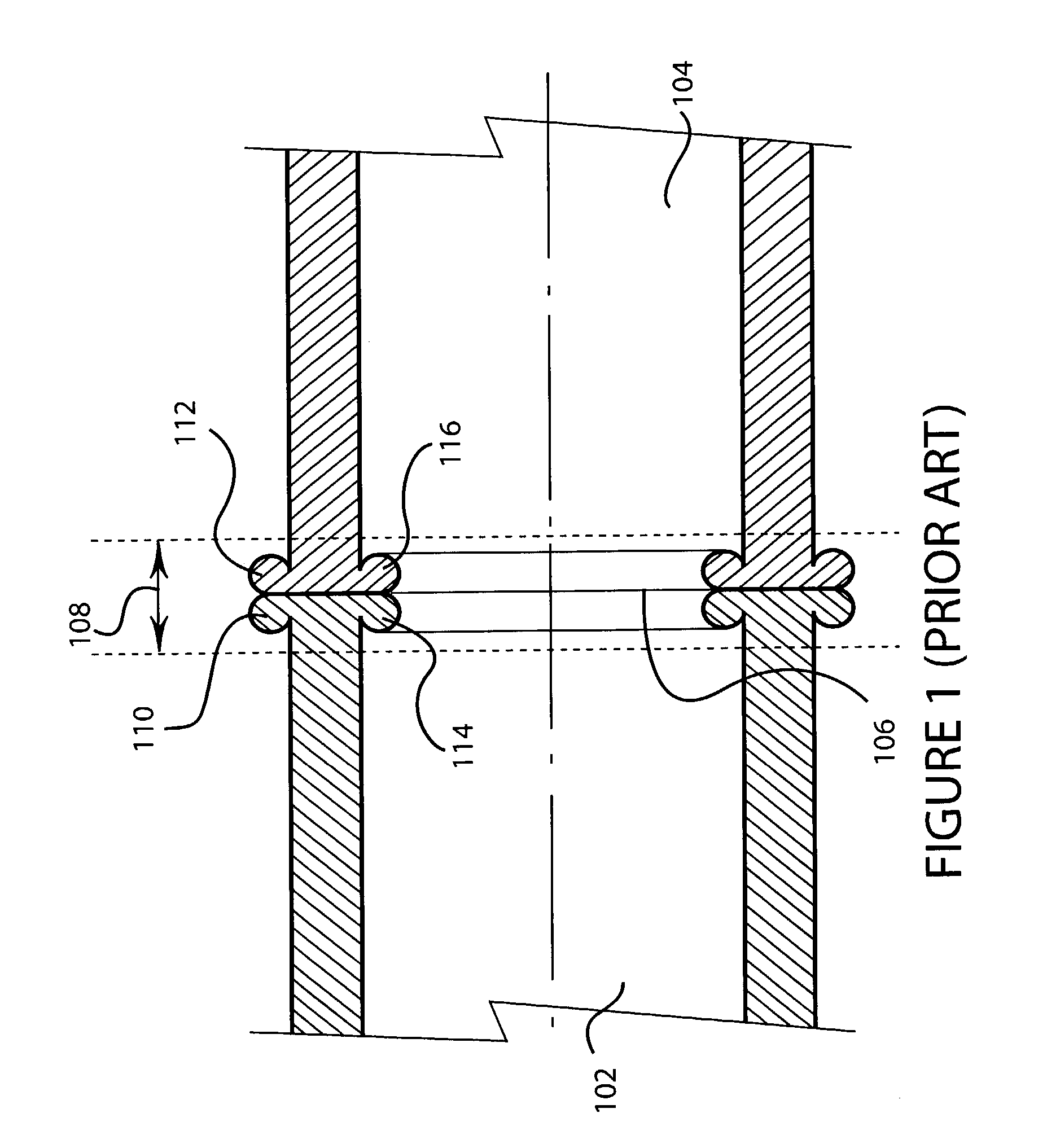

Beveled cutter

InactiveUS6994766B2Minimize external protrusionEliminate the effects ofButtonsMechanical working/deformationEngineeringFusion welding

Disclosed is a method, apparatus, and design of a fusion welded pipe wherein the effects of an inner bead of the fusion weld are minimized. The internal shape of the pipe prior to welding may be configured in several different shapes so that the beads or lips produced by the fusion welding process are unobtrusive and do not interfere with the function of the pipe. In a likewise manner, the outer shape of the pipe prior to welding may be configured so that the lips are unobtrusive on the external surface of the pipe.

Owner:FAST FUSION

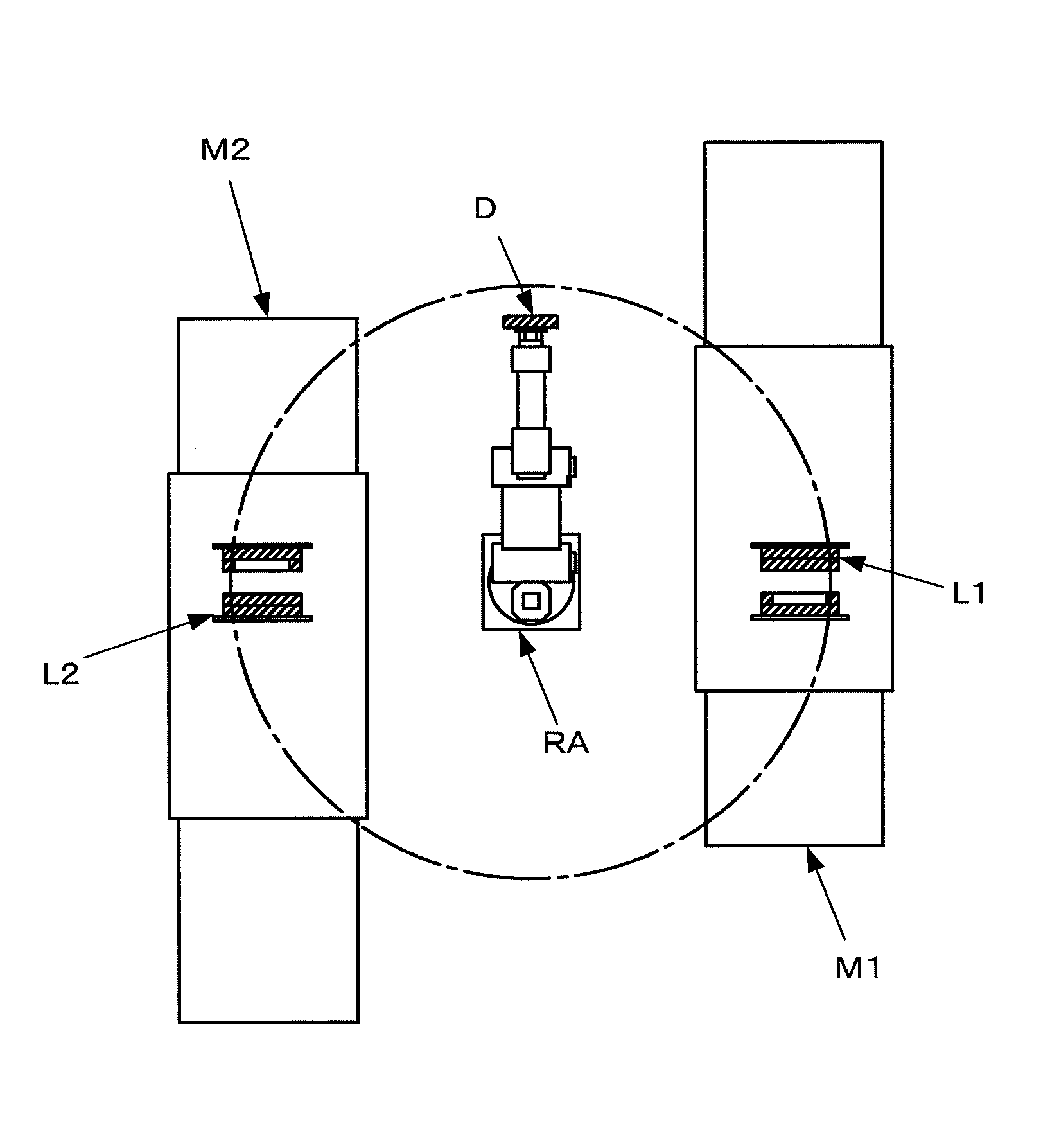

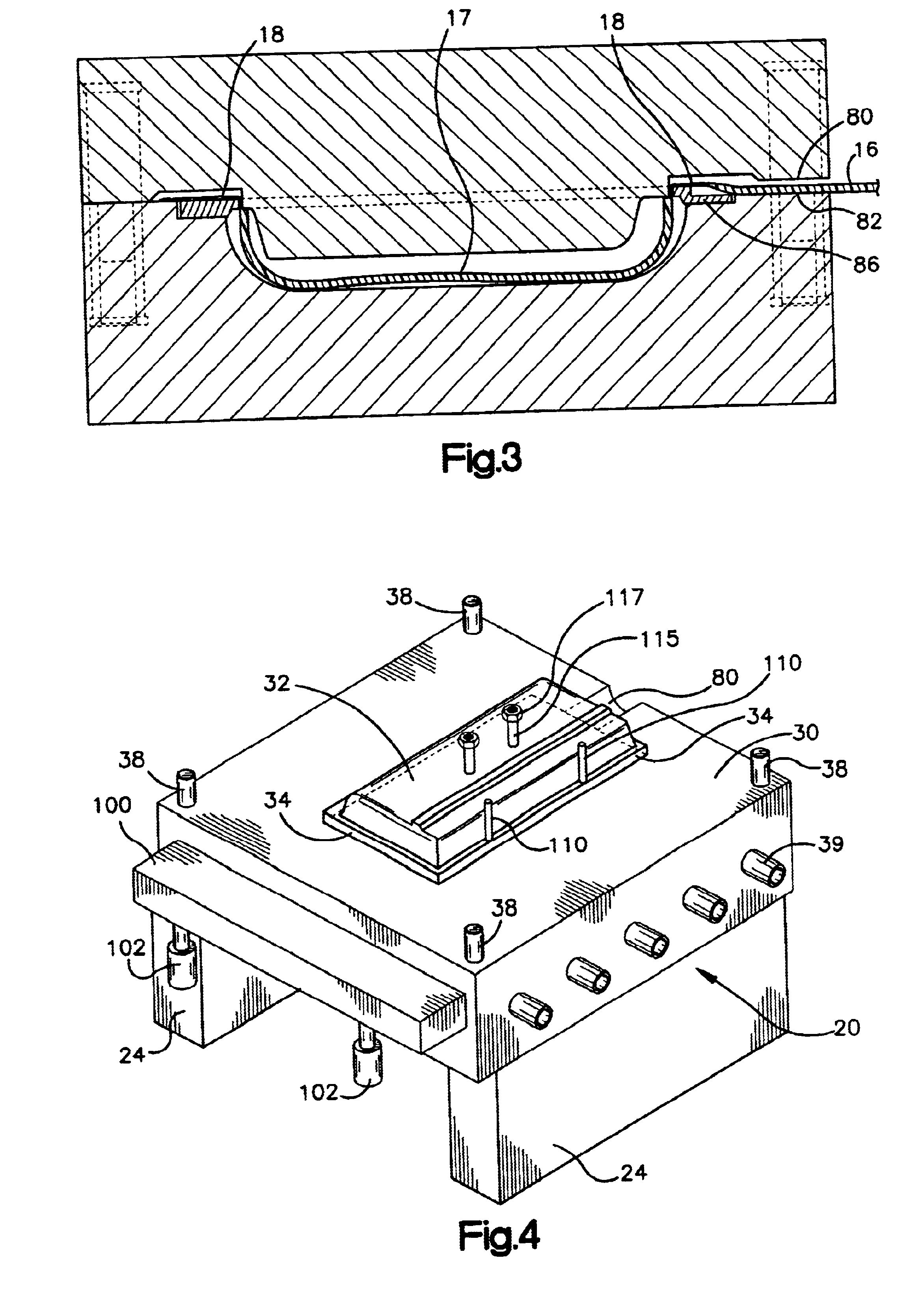

Manufacturing method and injection molding system for multi-color molded article

ActiveUS20140077410A1Preventing production of undesiredLack of versatilityButtonsRecord carriersInjection mouldingInjection molding machine

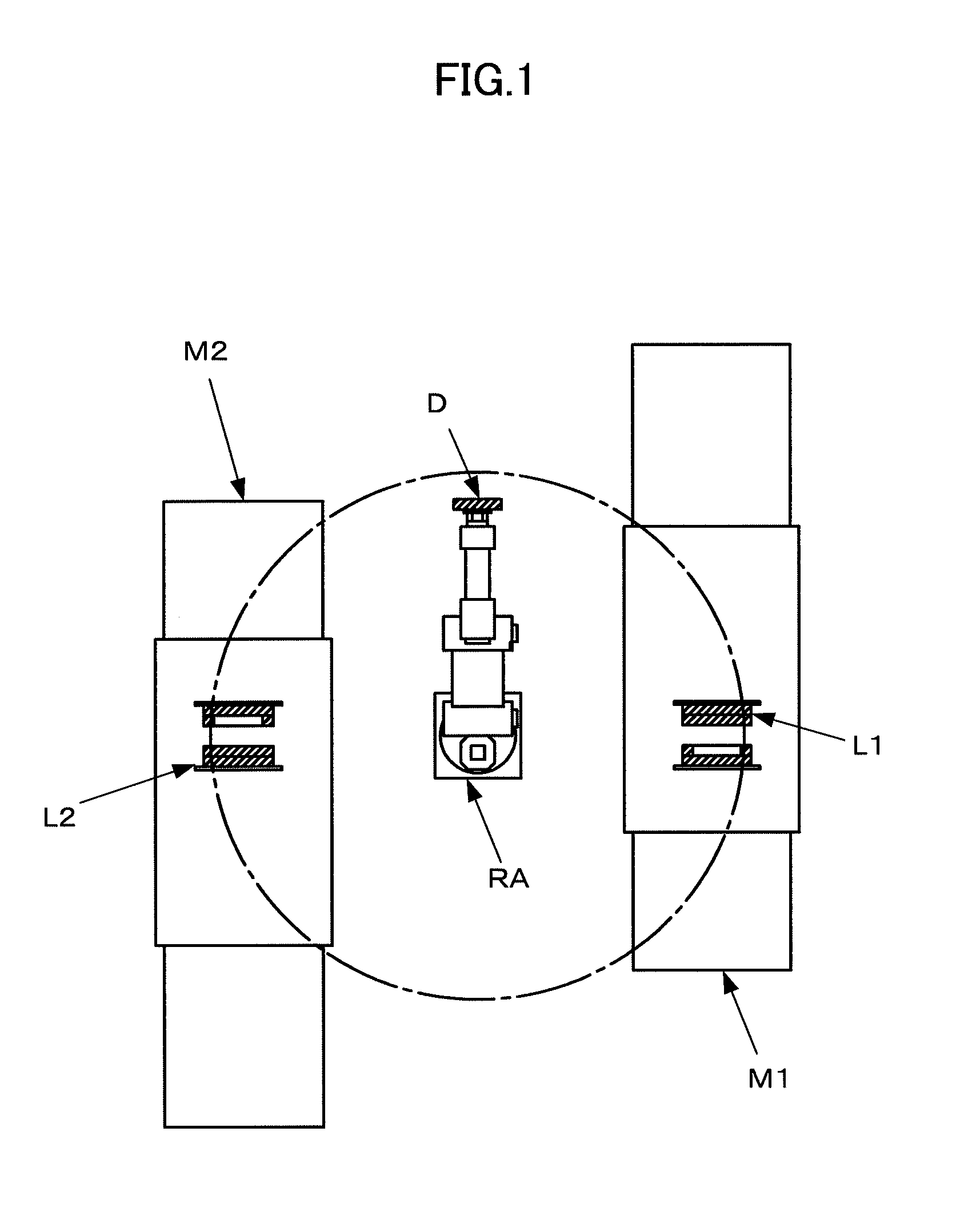

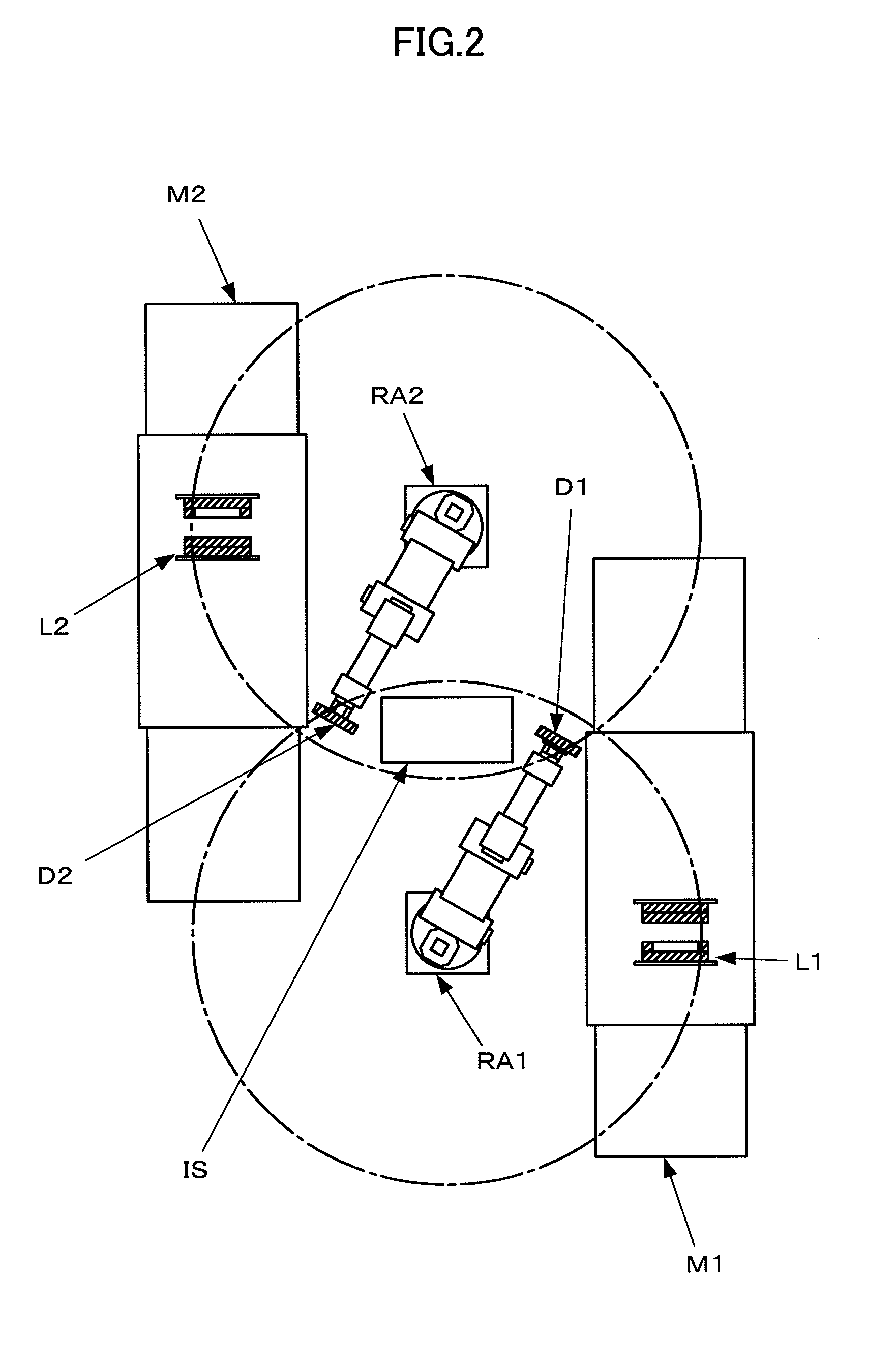

An injection molding system is configured to produce a multi-color molded article by simultaneously or sequentially injection-molding resins of a plurality of types by means of a plurality of injection molding machines. An insert mold is mounted in a mold of a first injection molding machine and a primary molded article is molded by this injection molding machine. Thereafter, a robot arm takes out the insert mold, along with the primary molded article, from the mold of the injection molding machine and attaches it to a mold of a second injection molding machine. A two-color molded article is injection-molded by the second injection molding machine and removed as a product.

Owner:FANUC CORP

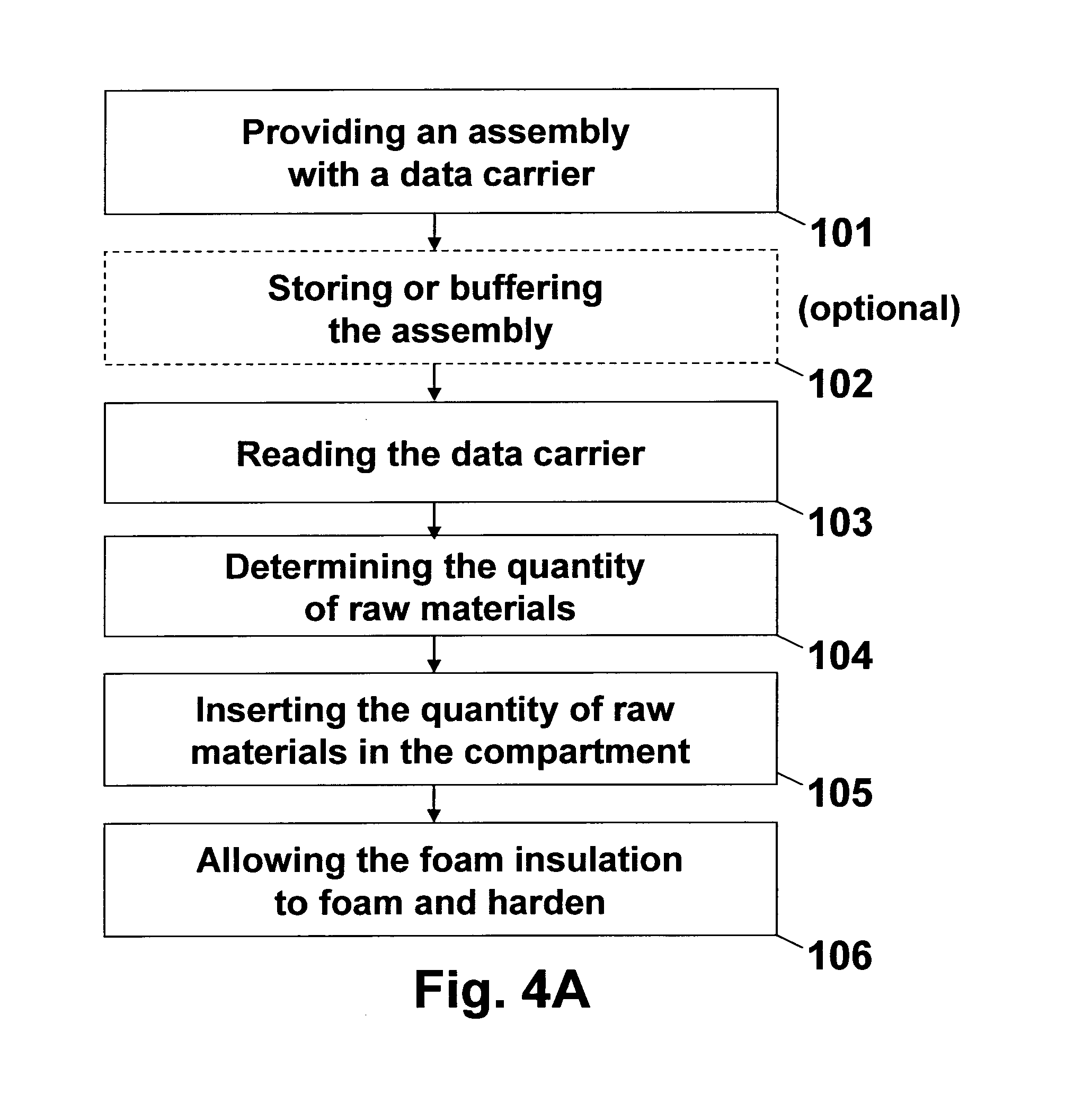

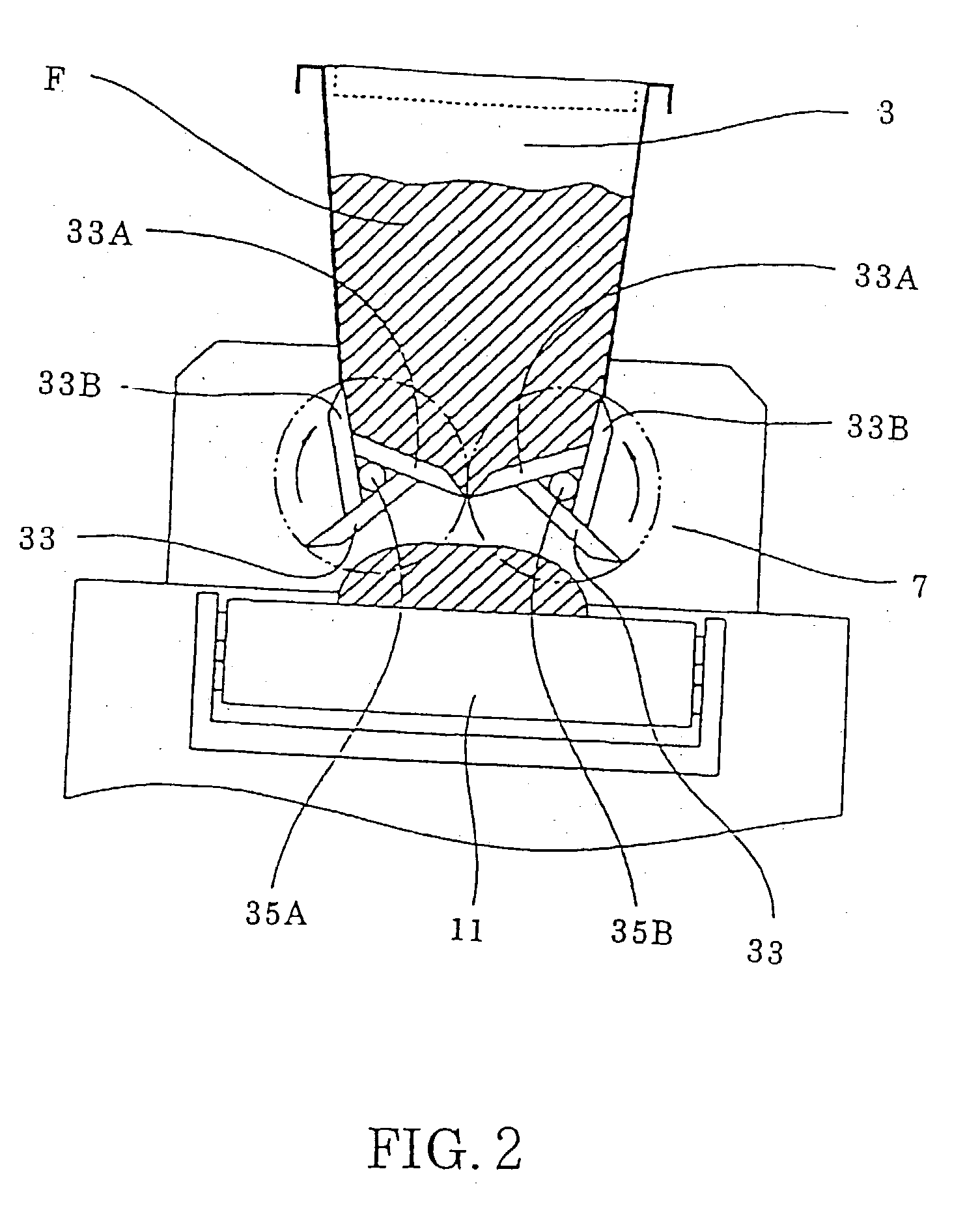

Method, device and a computer program for manufacturing a pre-insulated skeleton framing segment

ActiveUS20130037984A1Not easy to make mistakesLess laborButtonsRecord carriersInsulation layerMechanical engineering

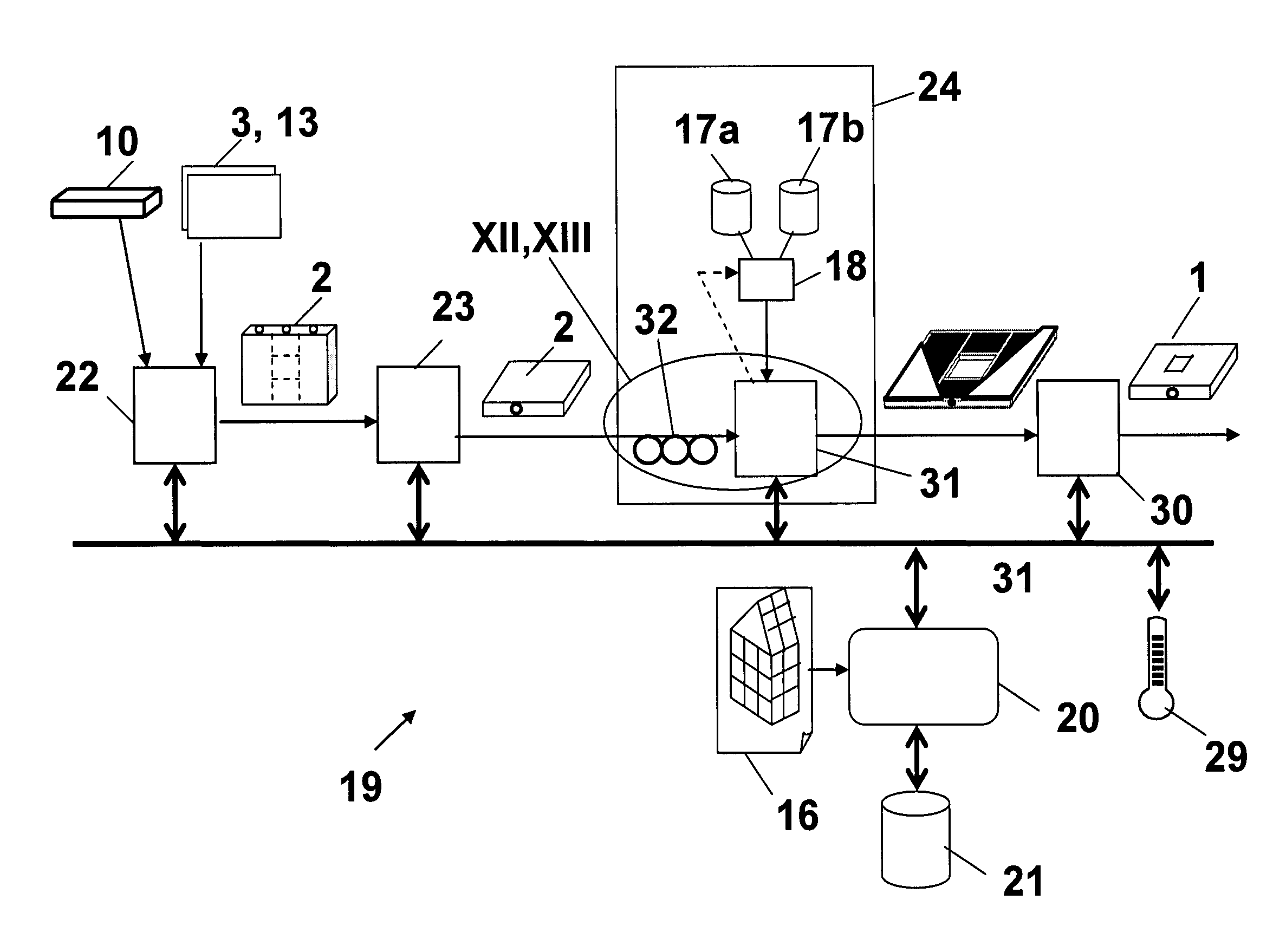

A method, a device and a computer program for manufacturing a pre-insulated skeleton framing segment (1) for a building to be constructed, wherein an assembly (2) with a hollow space (14) is provided, to which a data carrier (40) is fitted including data from which a quantity of raw materials required for forming a foam insulation layer of a thickness (15) in the hollow space (14) can be determined, which quantity is calculated, and which raw materials are inserted in the hollow space (14), and foam and harden there during a period (T).

Owner:MAC INVESTMENTS BV

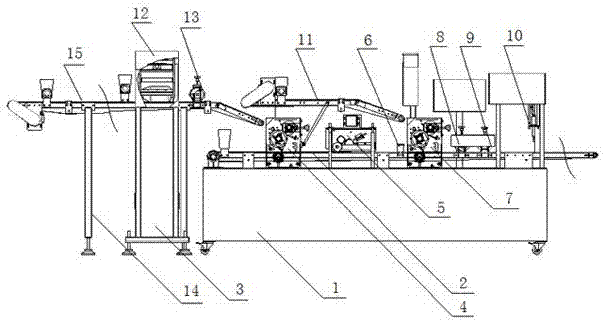

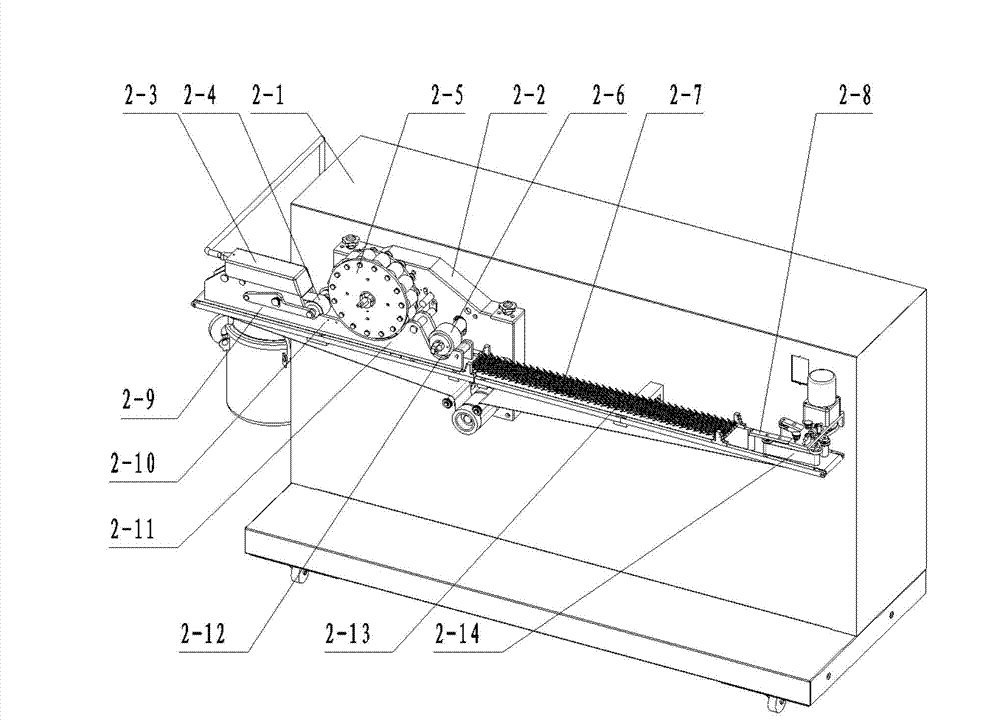

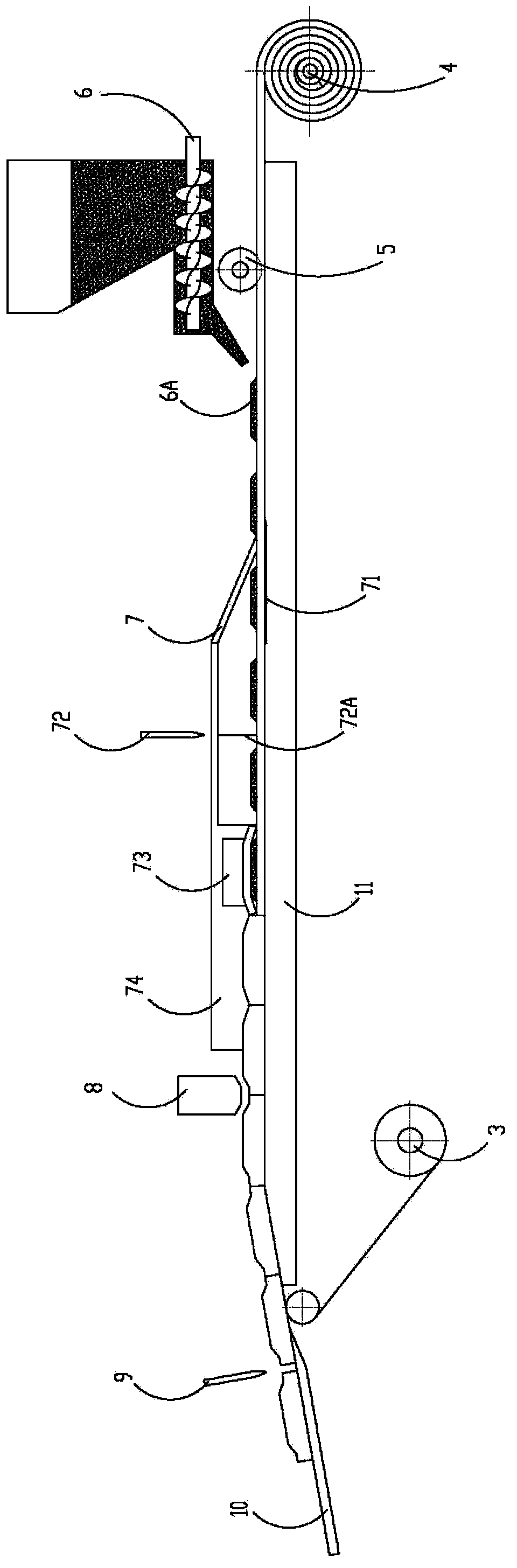

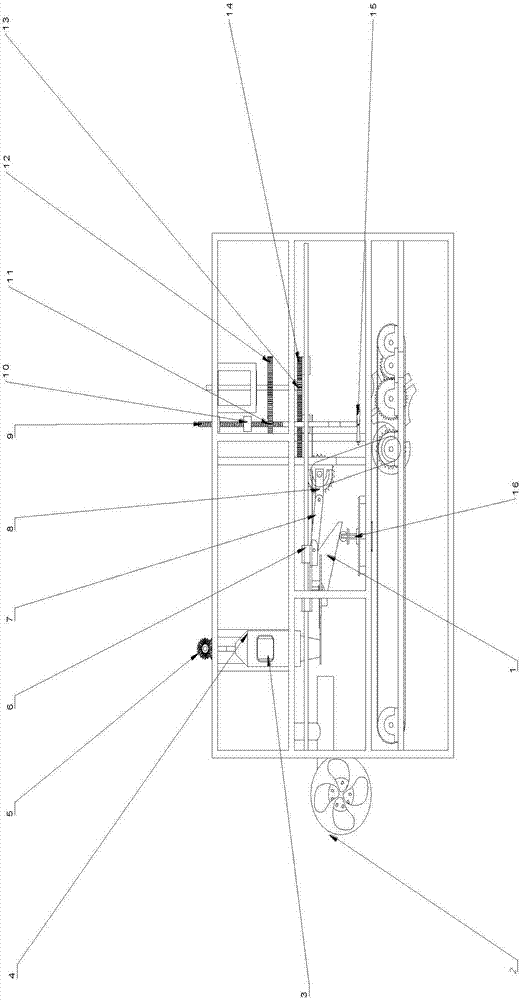

Double-layer fried bread stick machine and method of making fried bread sticks

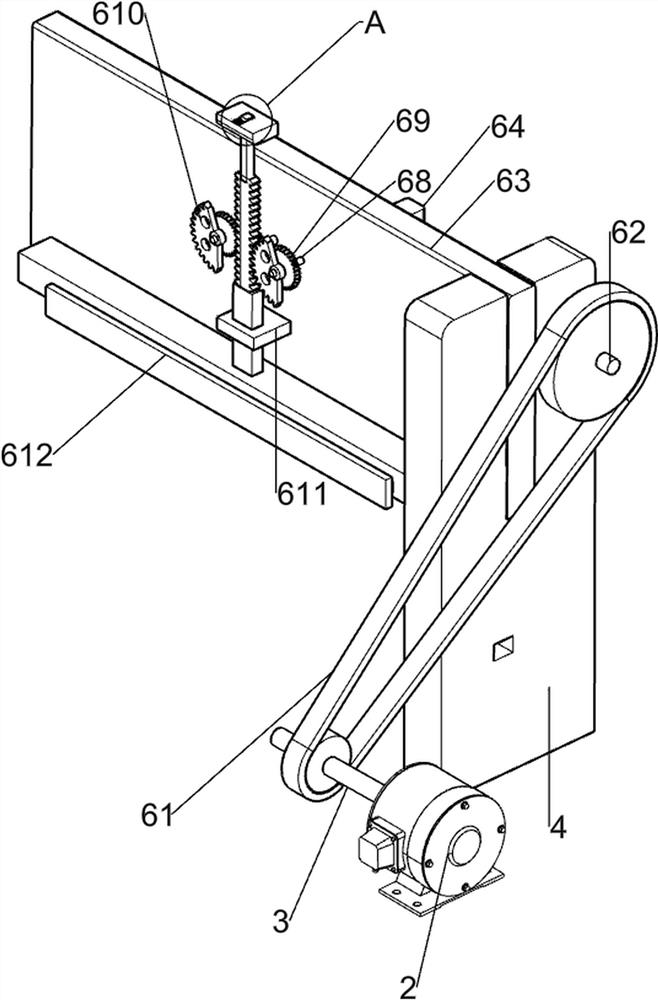

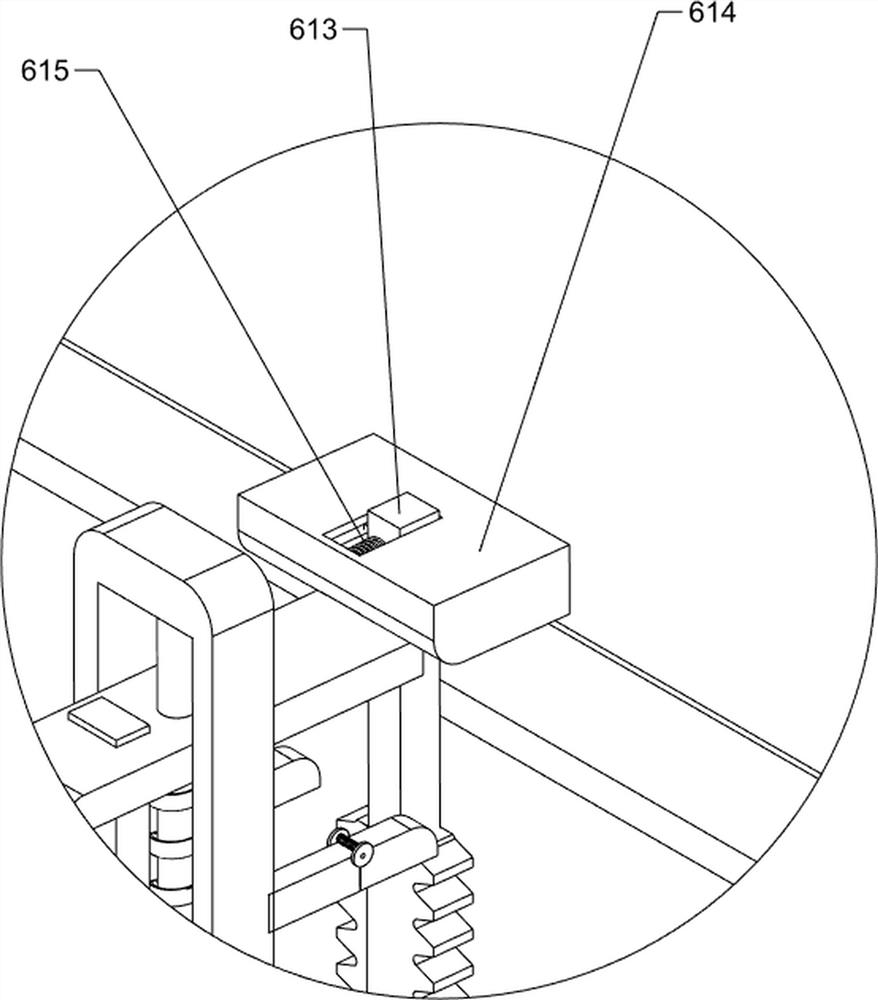

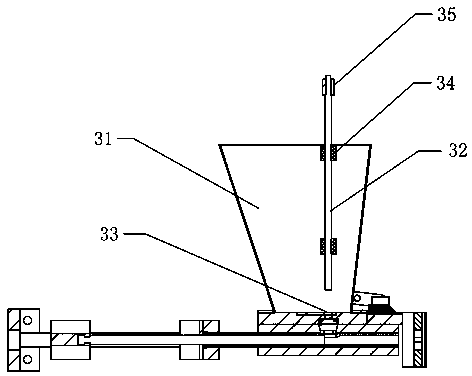

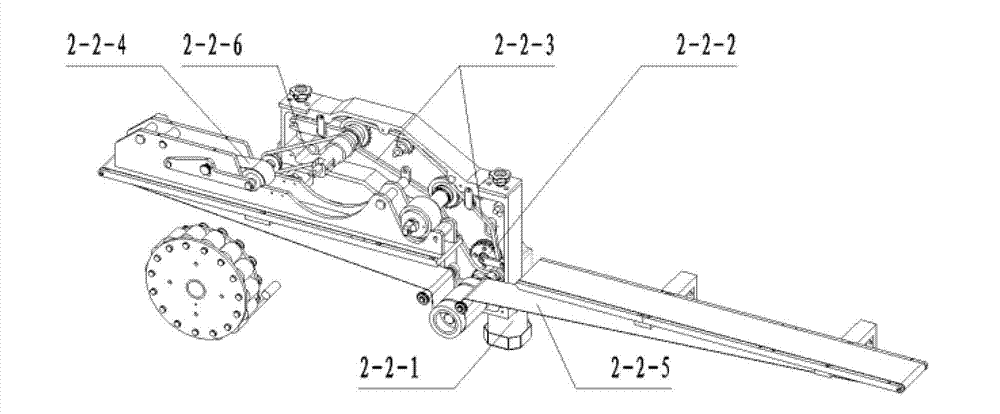

ActiveCN107439626AEasy to startMeet size requirementsOil/fat bakingDough shaping and dividing combinationEngineeringConveyor belt

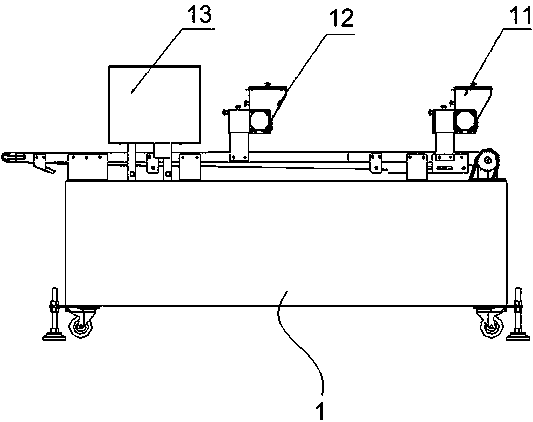

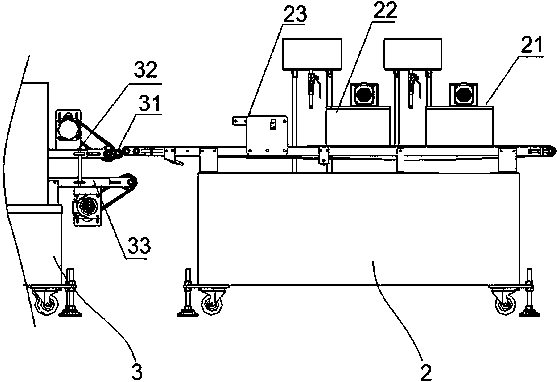

The invention discloses a double-layer fried bread stick machine. The method comprises a rack and a conveyor belt mounted on the rack, a front dough feeding mechanism located in a material feeding end of the conveyor belt, and a first dough pressing mechanism, an oil brushing mechanism, a water brushing mechanism, a second dough pressing mechanism, a round cutter mechanism, a medium press roller mechanism, a cutting table mechanism which are arranged from the material feeding end to a material discharging end; a rear dough feeding mechanism is located on the conveyor belt, and the output end of the rear dough feeding mechanism is located at an input end of the second dough pressing mechanism; a dough rolling mechanism and a three circular cutter mechanism are at least arranged on the front dough feeding mechanism. According to the double-layer fried bread stick machine, imitating manual rolling of the fried bread stick dough can be achieved; through brushing oil and water alternately, the edges of the fried bread sticks can rise easily when fried, the middle connections are good and do not explode, so that two layers of fried bread sticks stick well together, and it is not possible to cause dough stickiness for the fried bread sticks; the rising effect is good, it is ensured that the yield of finished products is 100%, the appearance is beautiful, the prepared double layer fried bread sticks are fed into a frying pan mechanism automatically, and the degree of automation is higher.

Owner:SUZHOU GUOEN FOOD MACHINERY

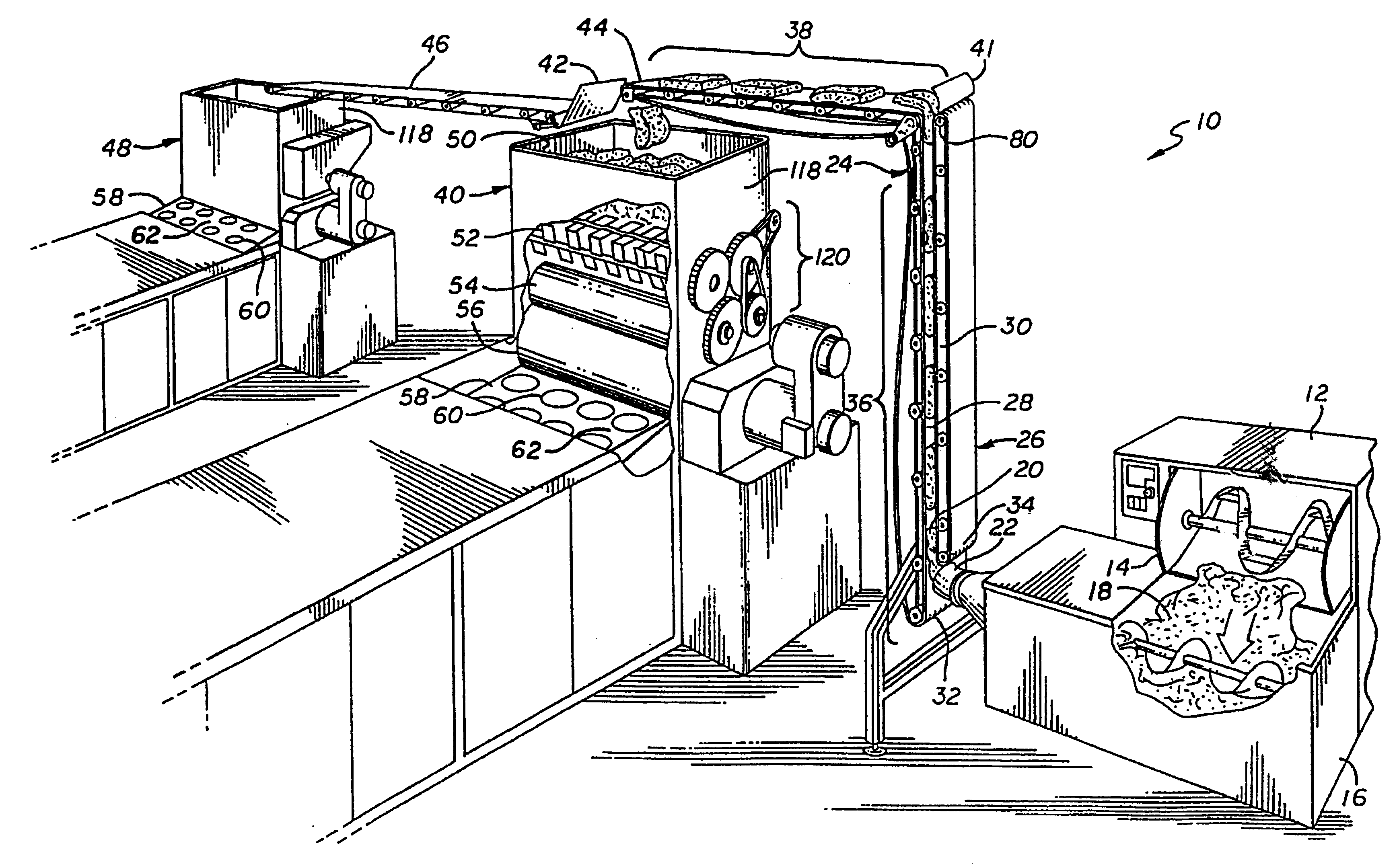

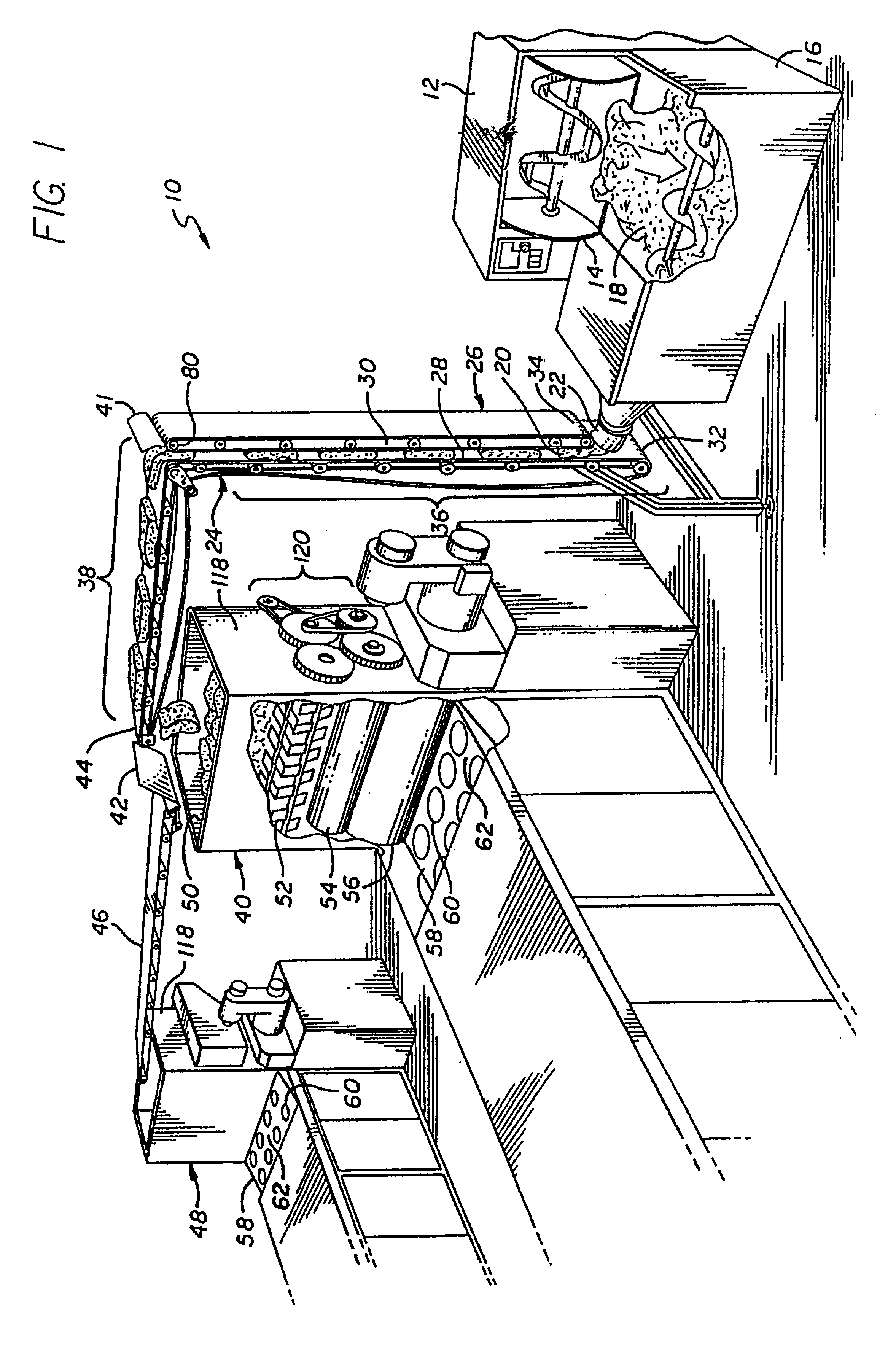

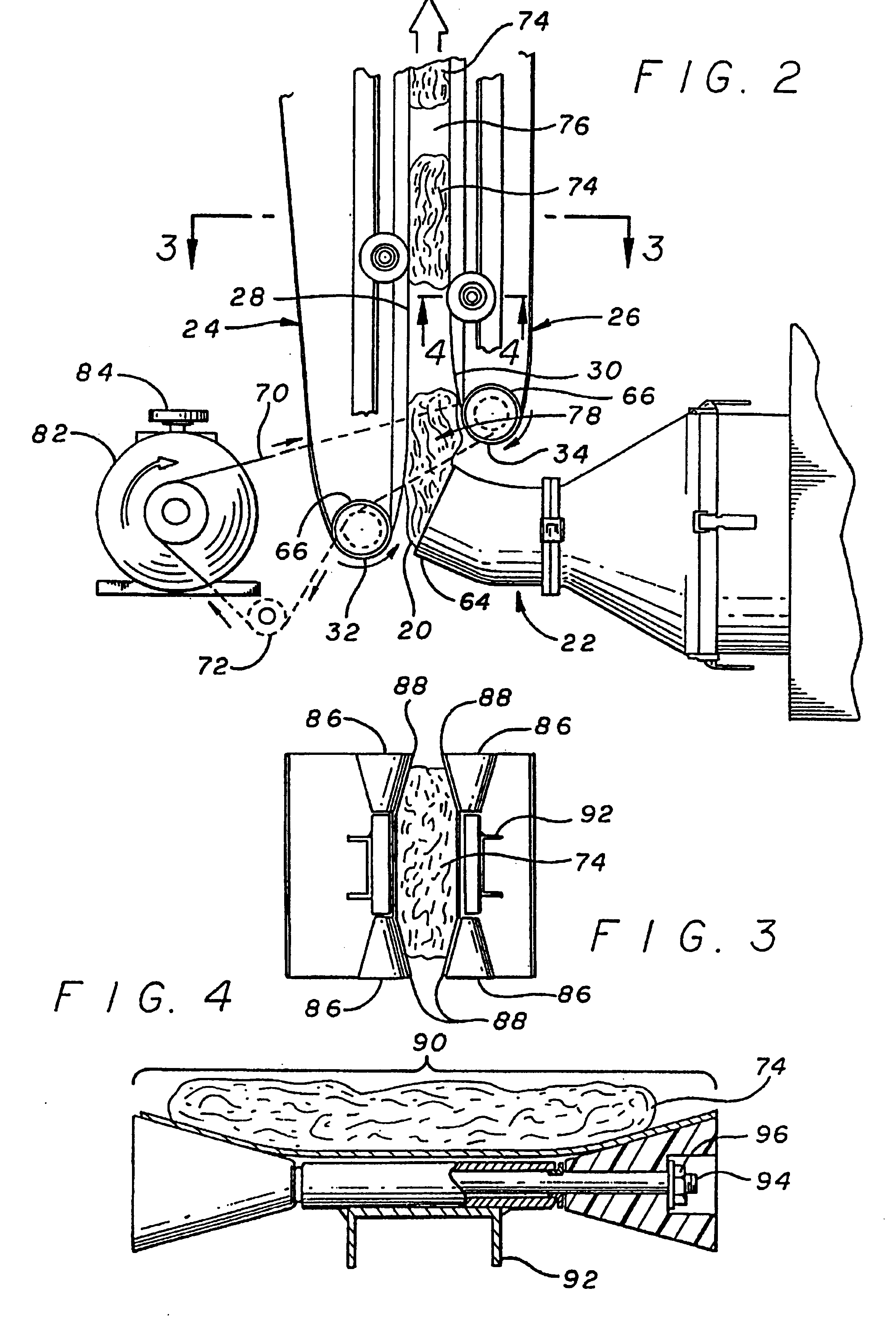

Methods for handling masa

Masa handling methods for the continuous processing of masa type dough in conjunction with commonly available feed processing equipment, such as a masa extruder, an oven, or cooling apparatus. One masa handling method includes a masa separator having a pair of opposed, endless belt conveyors having facing surfaces spaced apart to receive a generally continuous masa stream output from a nozzle on the masa extruder. When the masa stream moves between the conveyors, it is gripped by their facing surfaces and moved away from the nozzle, causing the masa to be separated into individual pieces, or logs. The masa handling method can also include feeding the masa to masa hoppers fed by at least two endless belt conveyors arranged in upstream and downstream positions relative to each other. The masa is transported along the conveyors and is automatically diverted into one masa hopper by a diverter gate operated by a controller that receives a signal from a sensor sensing a masa level within an associated one of the hoppers. The hopper has one or more rotating shafts having projections to remove gas bubbles from the masa and force it toward the sheeter rollers. A pair of primary rollers with scrapers can be provided within the hopper to roll the masa to an intermediate thickness before it passes between the sheeter rollers.

Owner:CASA HERRARA

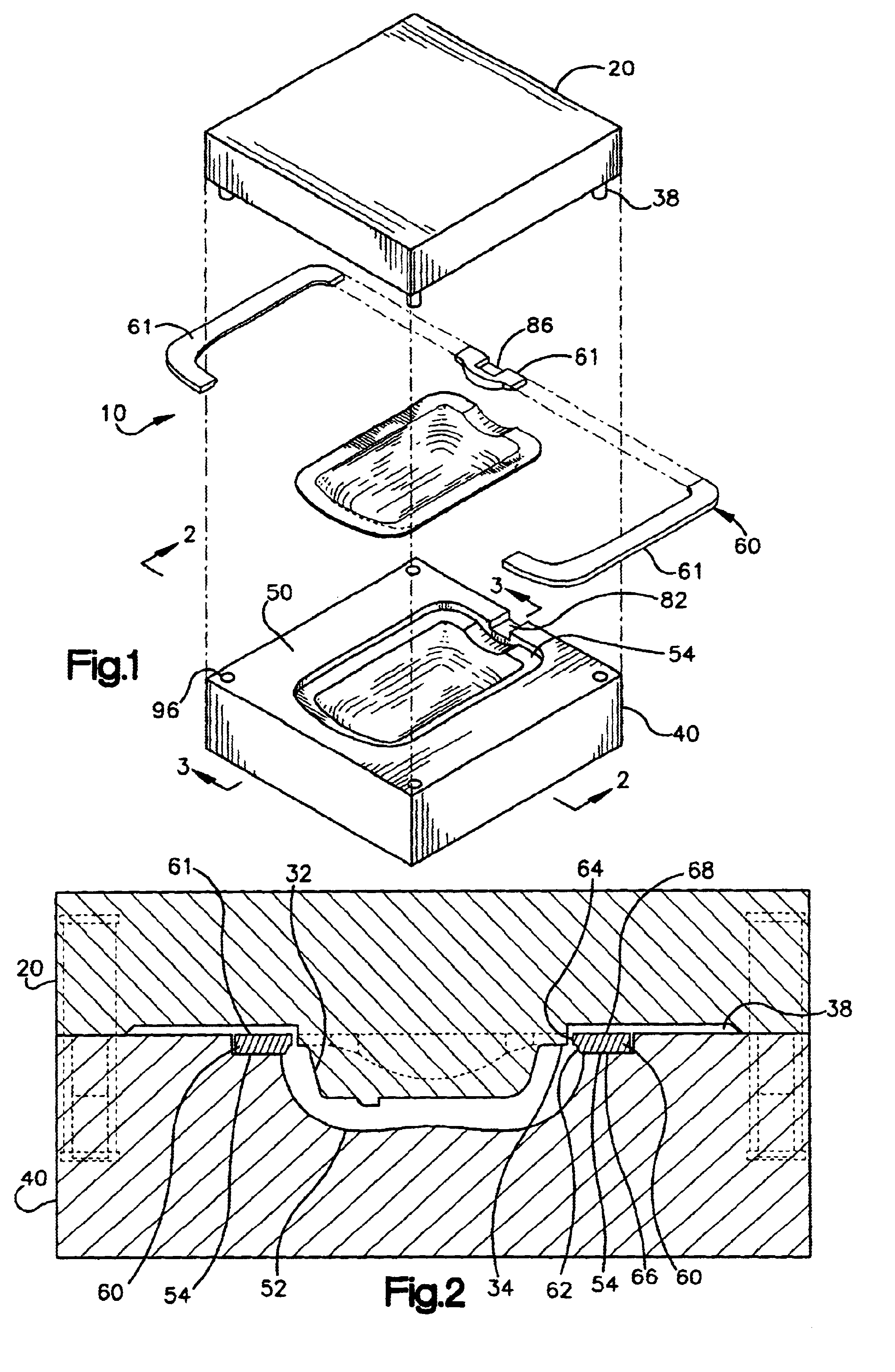

Blow mold with removable inserts

InactiveUS6659750B1Overcome disadvantagesRemove limitButtonsRecord carriersEngineeringMechanical engineering

A mold is provided for forming molded parts having flash seams which are moved to inconspicuous locations. The mold, which is typically used to make blow molded parts, includes two or more mold blocks and removable inserts which allow relocation of flash seams and at the same time allow removal of the finished part from the mold.

Owner:TOOLING TECH TOOLING & AUTOMATION

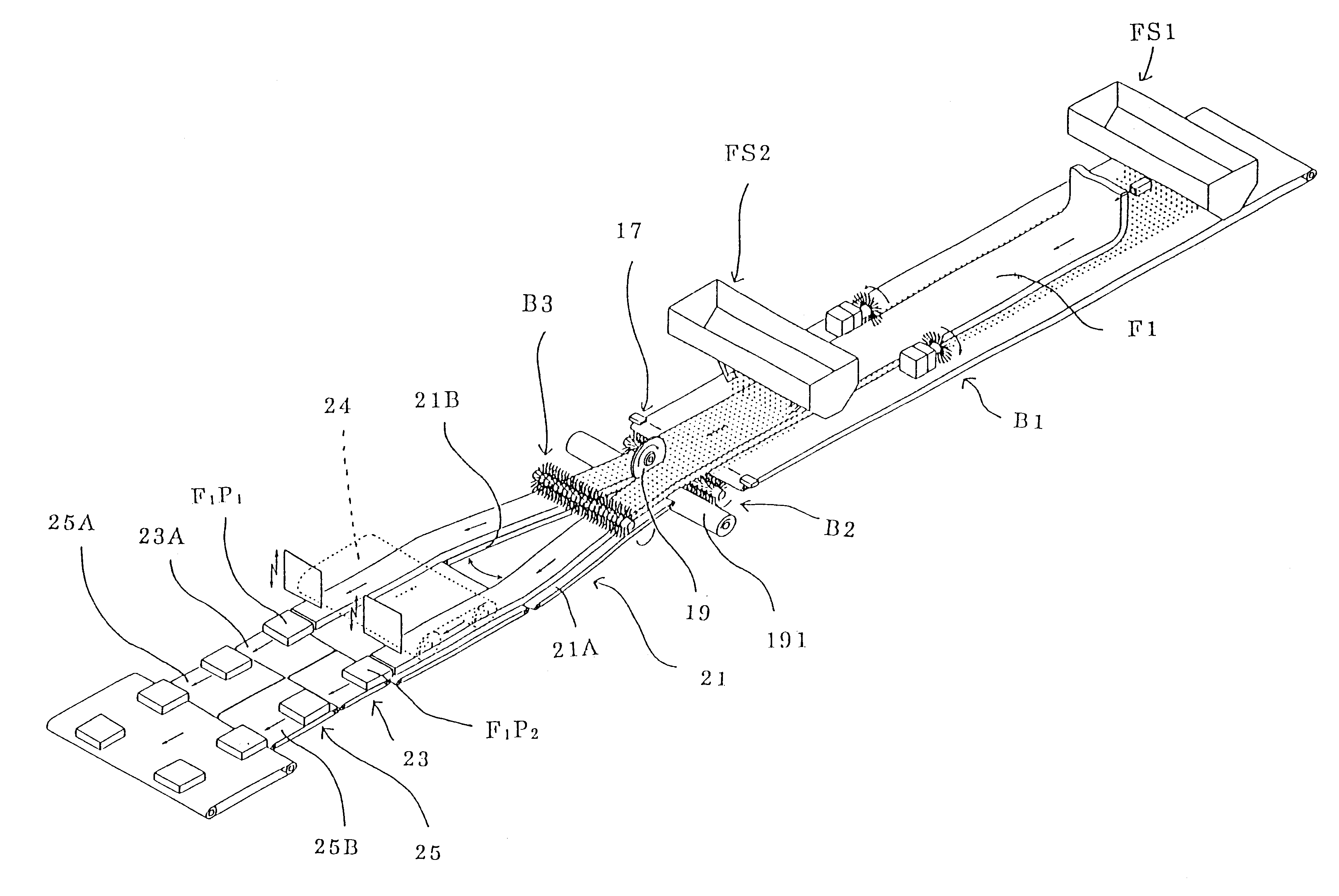

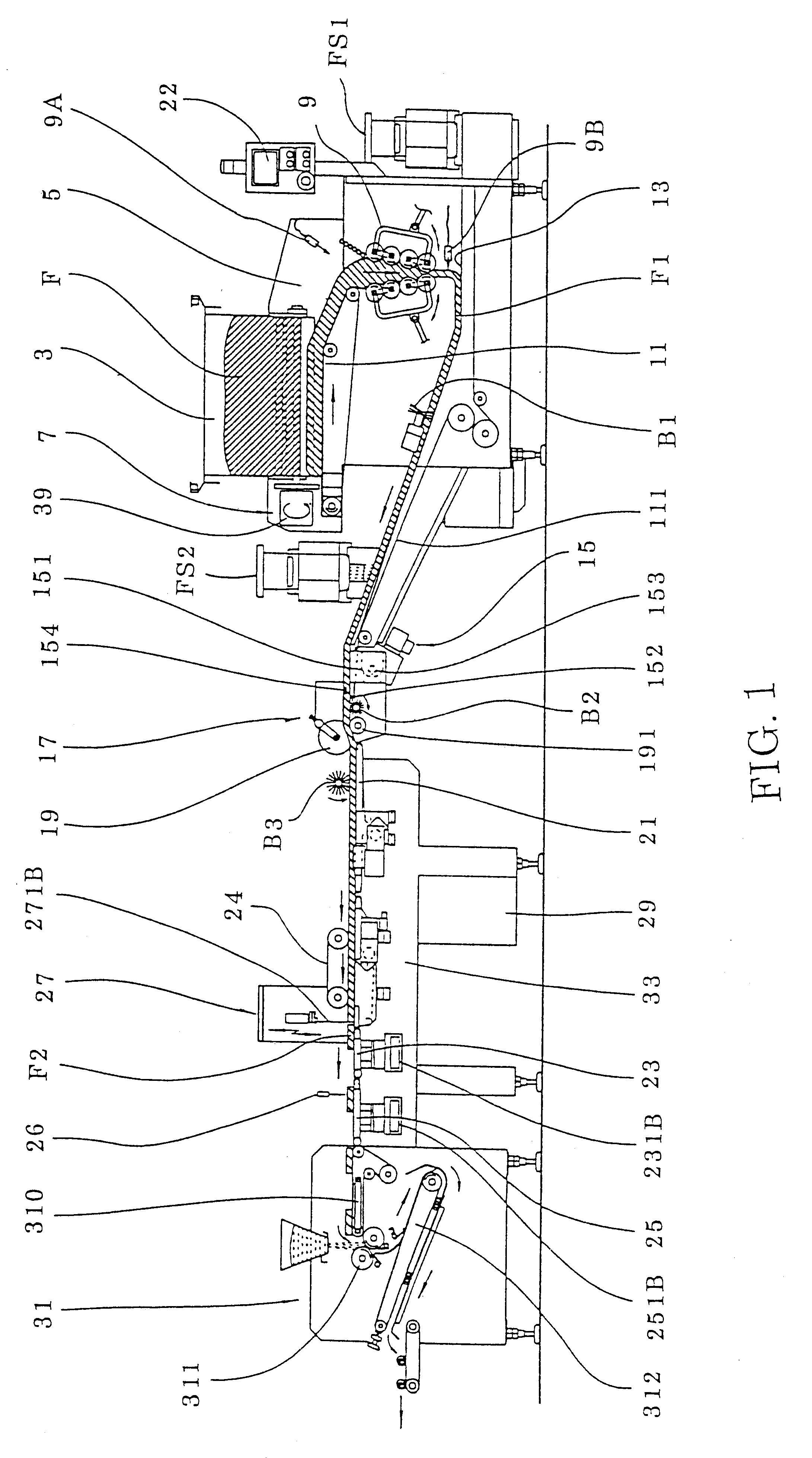

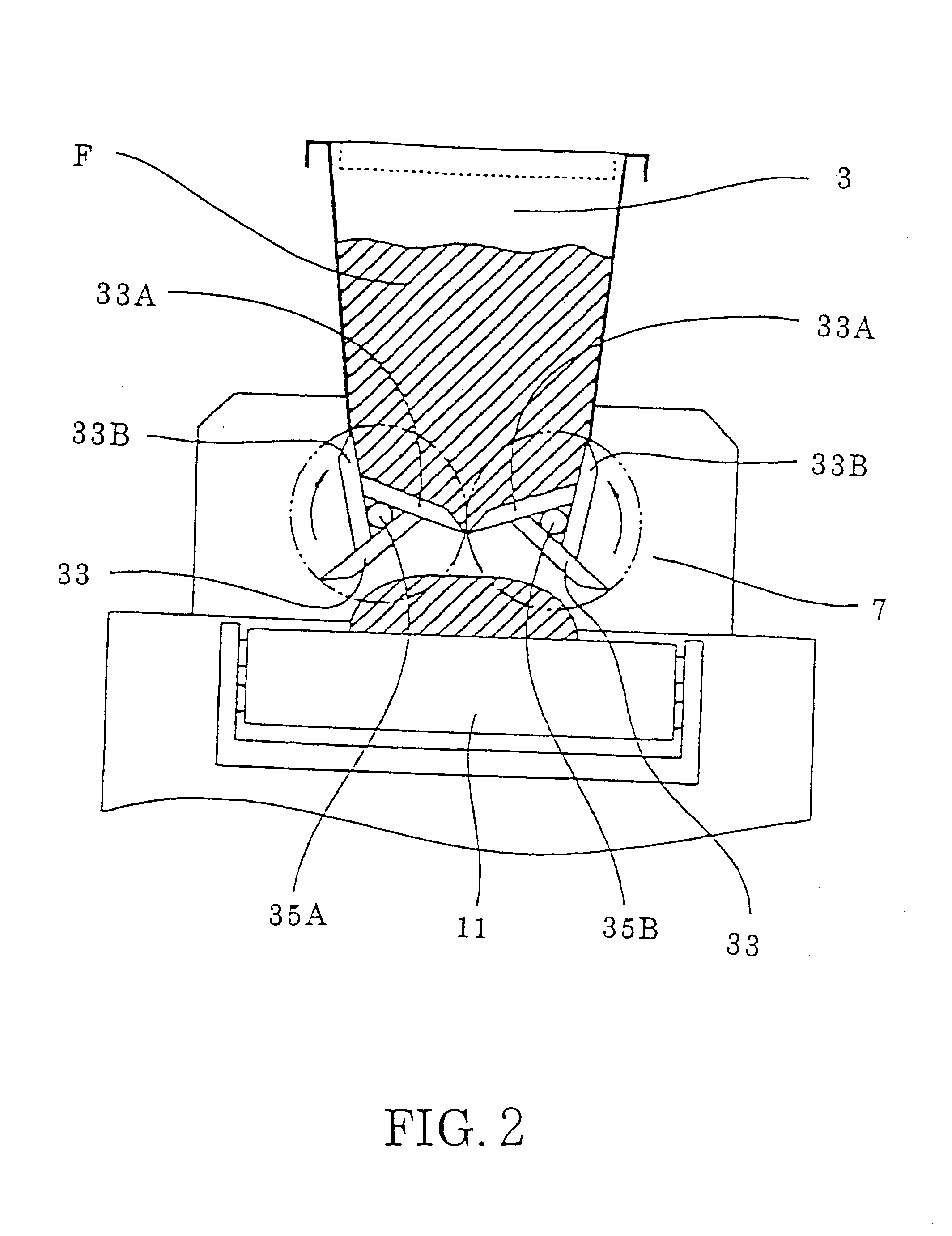

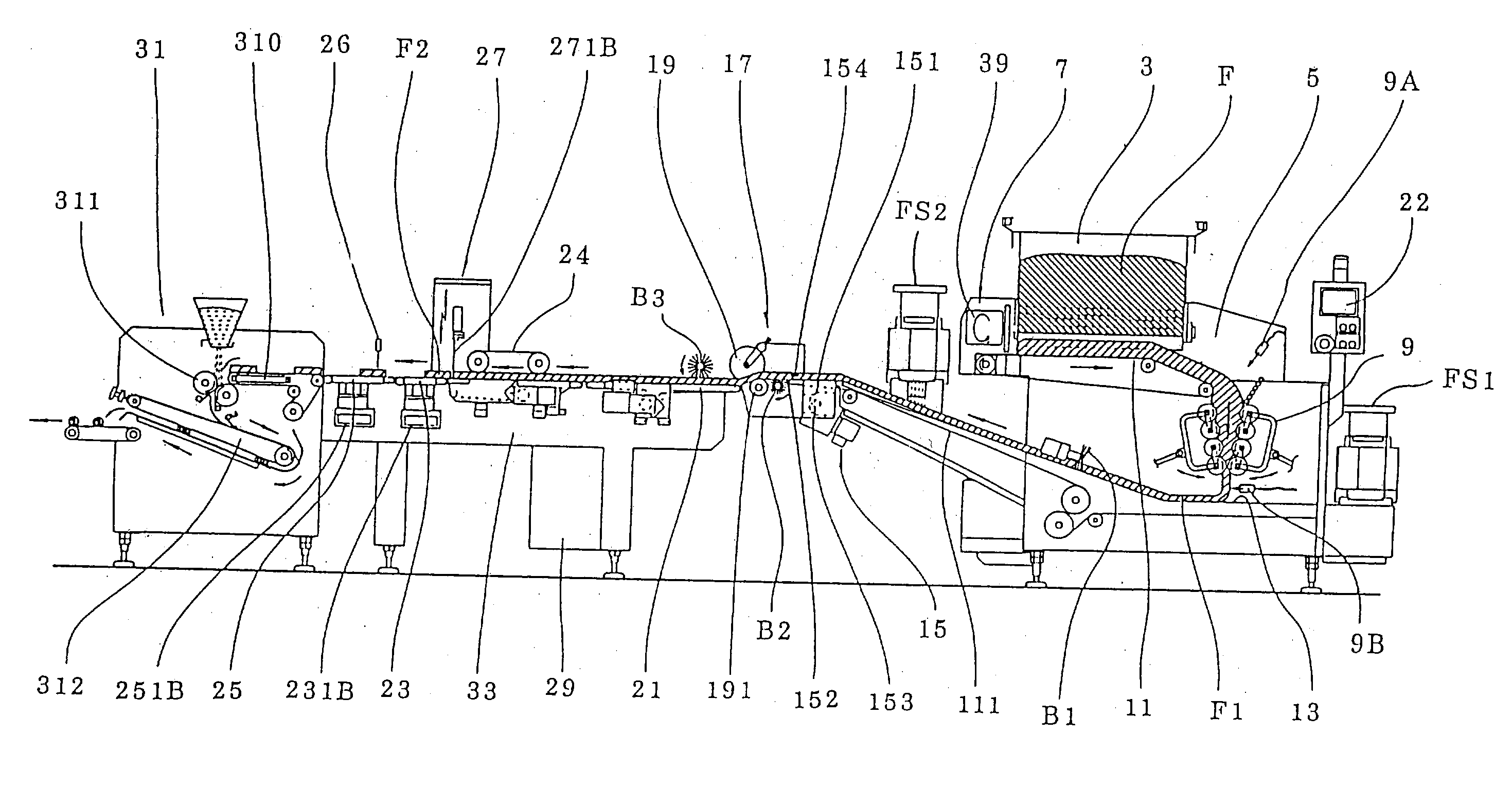

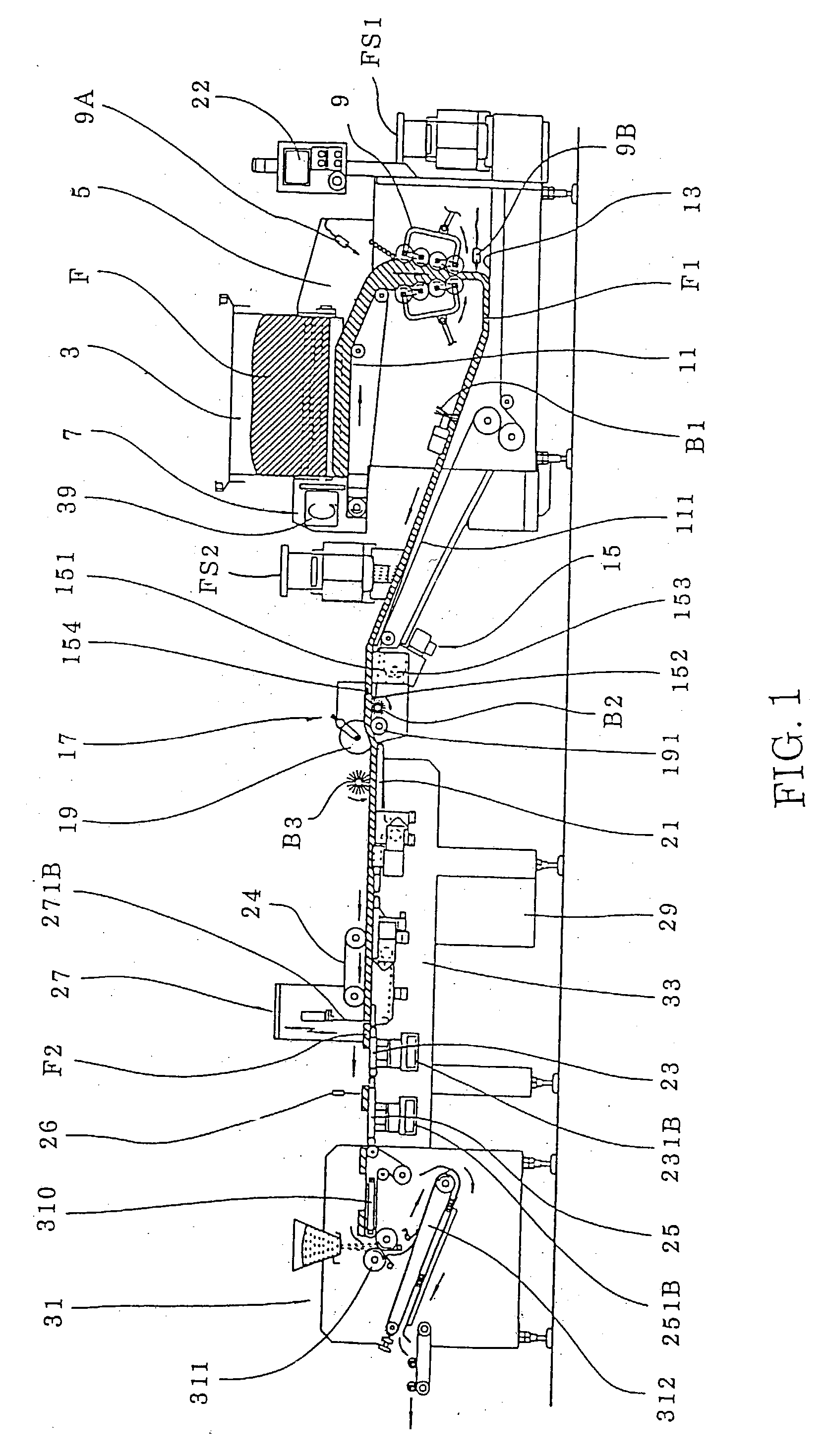

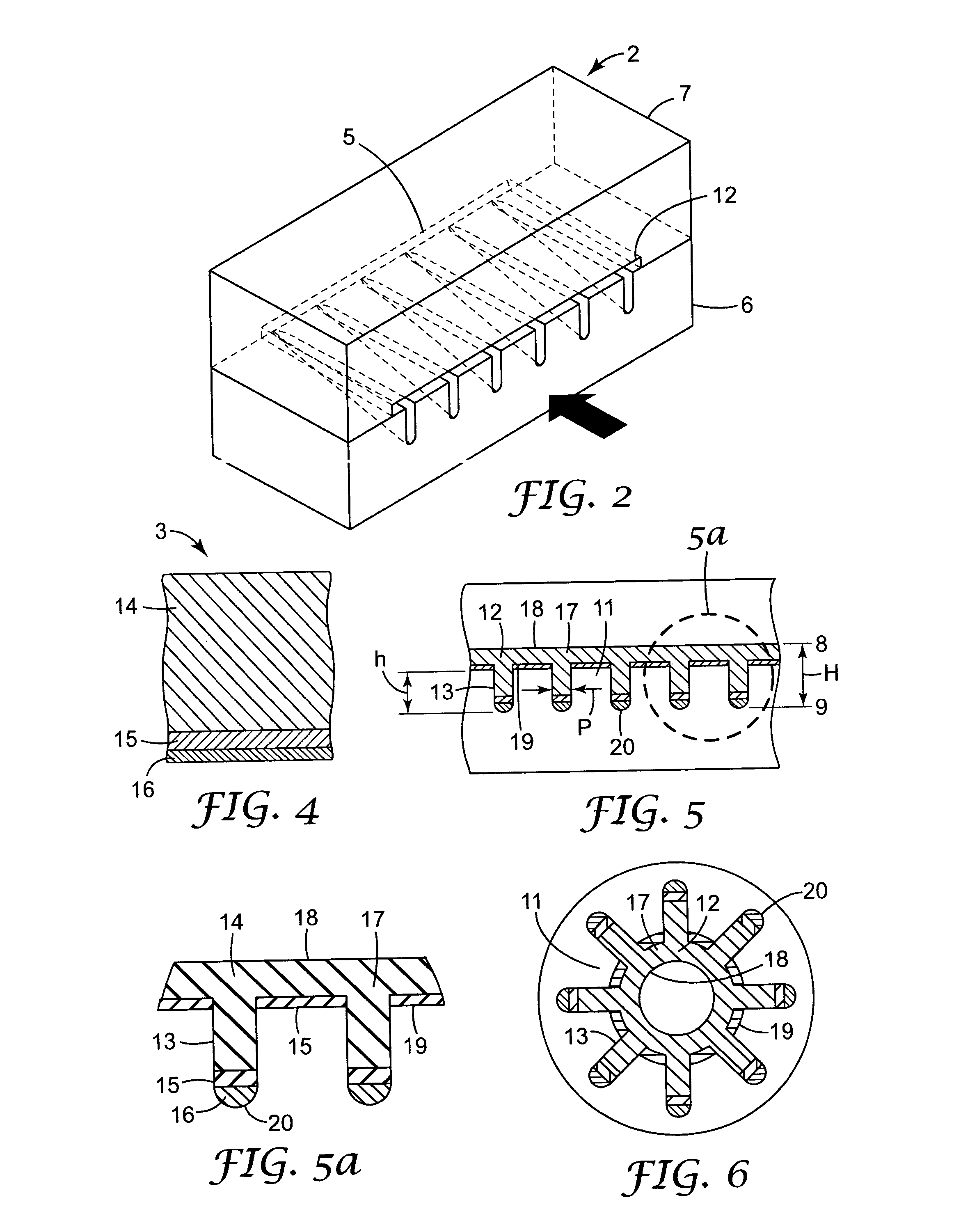

Apparatus and method for supplying food dough

InactiveUS20030124234A1No pressureDough treatmentDough-sheeters/rolling-machines/rolling-pinsMechanical engineeringFood products

An apparatus for supplying food dough forms blocks of food dough that are continuously supplied into a sheet or belt of food dough and then divides it into chunks of food dough that have preset weights. The apparatus for supplying food dough comprises a hopper to which a large block of food dough is supplied, a cutting apparatus located at a lower opening port of the hopper to cut the block into small blocks that have substantially the same volume, a dough feeder having a plurality of rollers that are arranged as a V to form the small blocks into a sheet of the food dough, a transferring conveyor to transfer the small blocks to the dough feeder, a feeding conveyor to convey the sheet of the food dough that is formed by the dough feeder to have a constant thickness, a weighing conveyor measuring the weight of a part of the sheet that is supplied by the feeding conveyor as the sheet is being conveyed, and a cutting apparatus for cutting the sheet of the food dough when the measurement of the weighing conveyor corresponds to a preset value.

Owner:RHEON AUTOMATIC MASCH CO LTD

Method of extruding articles

Owner:3M INNOVATIVE PROPERTIES CO

Methods and apparatuses for cutting dough utilizing a shaped opening

ActiveUS20060165860A1Maintain positionPrevent slippingDough homogenization and dividing combinationMouldsEngineeringRing doughnut

Methods and apparatuses for cutting dough are described. One described dough cutting apparatus comprises a barrel having two ends, a removable die comprising a shaped opening, the removable die adapted to be coupled to a first end of the barrel, and a knife adapted to cut dough extruded from the shaped opening. In one illustrative method for making doughnuts, dough is extruded and cut using such a dough cutting apparatus and the dough is then cooked.

Owner:LOWRY STANLEY N +2

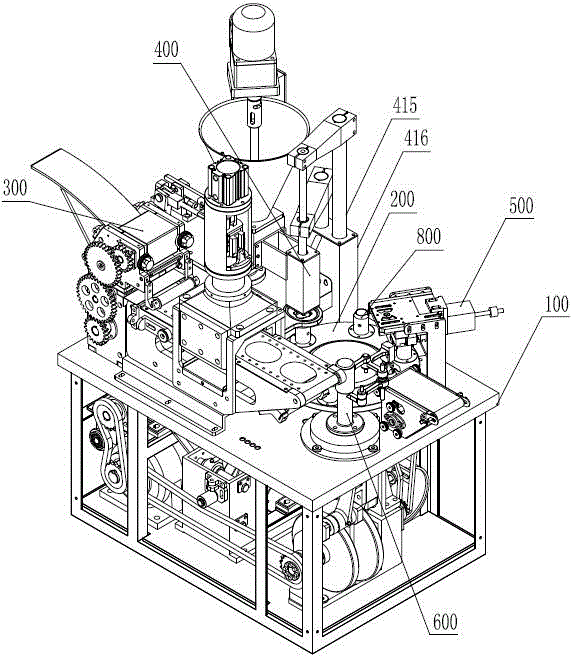

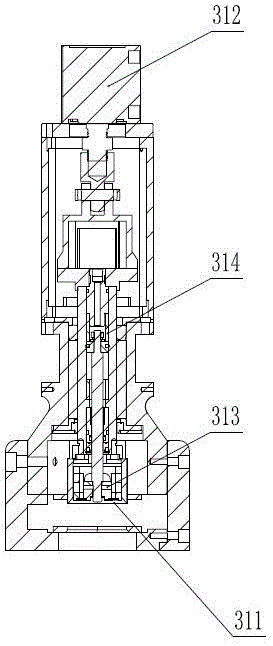

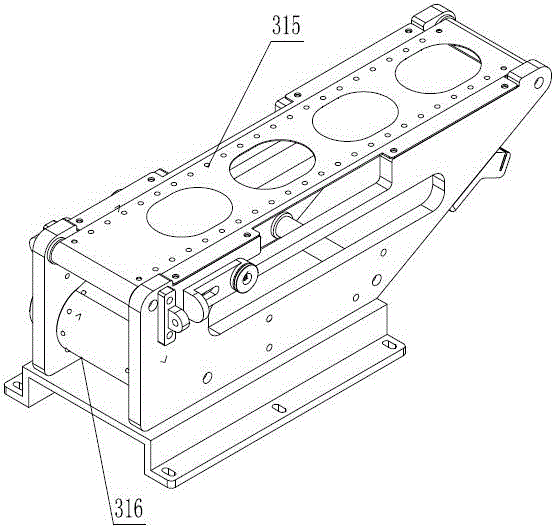

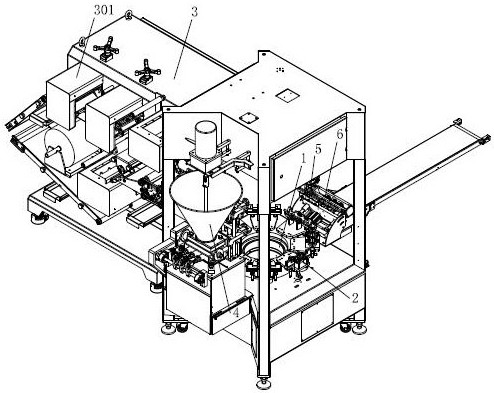

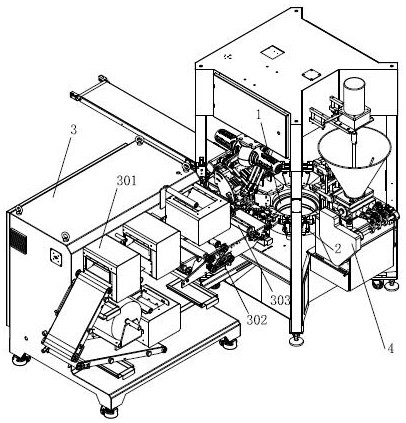

Compact stuffed food shaping machine

ActiveCN105724508AAchieve instant cookingReduce transportation and circulation linksDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationMolding machineProcess engineering

The invention belongs to the technical field of food processing and in particular relates to a compact stuffed food shaping machine. The shaping machine comprises a rack and a station turntable arranged on the rack, wherein a wrapper making device, a stuffing device, a laminating device and a discharge device are respectively arranged around the station turntable; a wrapper making station is arranged on the wrapper making device; a stuffing station is arranged on the stuffing device; a laminating station is arranged on the laminating device; a discharge station is arranged on the discharge device; a split shaping mold is also arranged on the rack and comprises a rotary wrapper receiving plate and mold cups, which are independent of each other. The compact stuffed food shaping machine can achieve immediate cooking of stuffed food and reduction of transport and circulation links, can avoid freezing, enables the taste of the stuffed food to be closer to the tastes of traditional hand-made dumplings and are applicable to the food and beverage industry, farmers' markets, dining halls of enterprises, organs and organizations, and the like.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

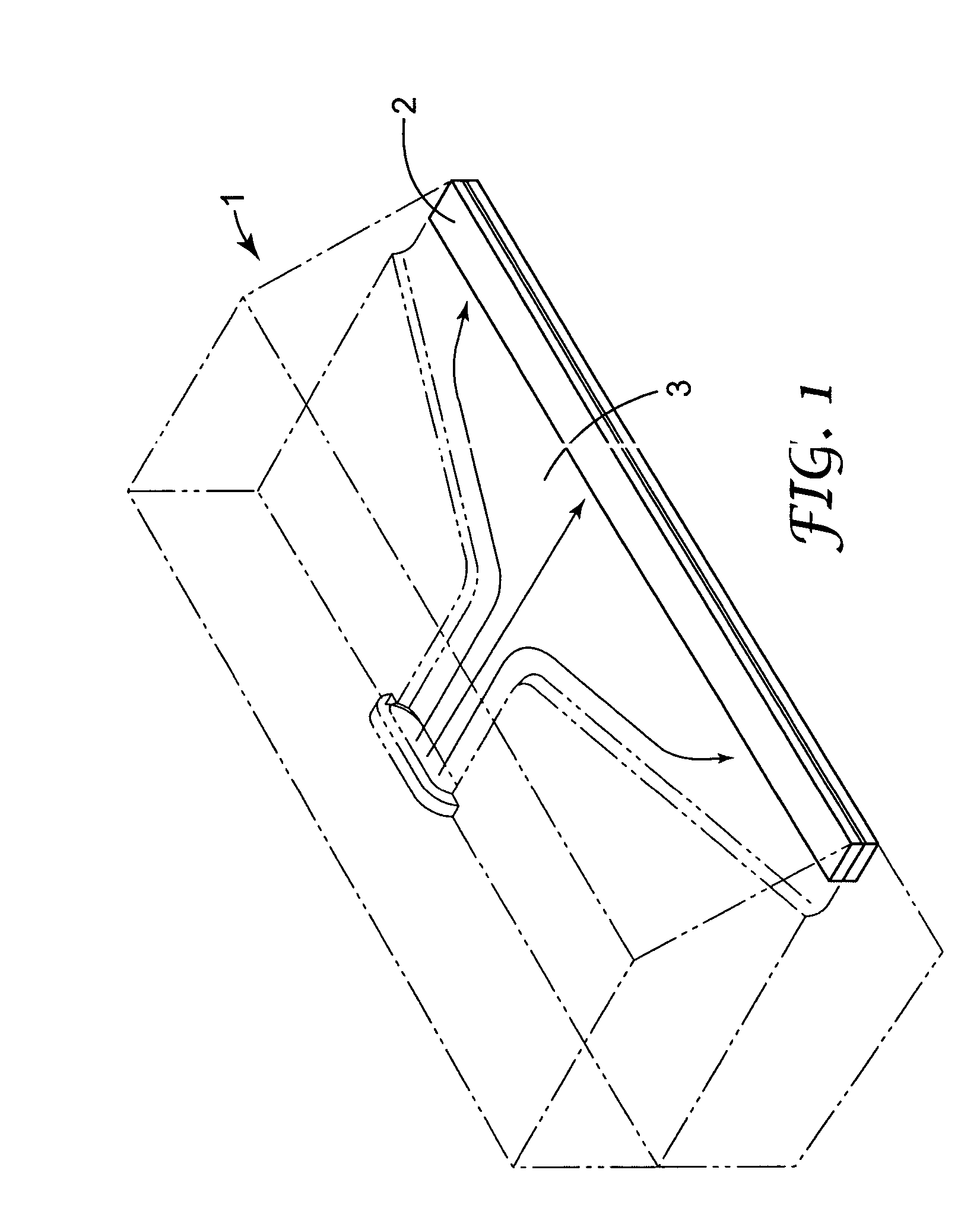

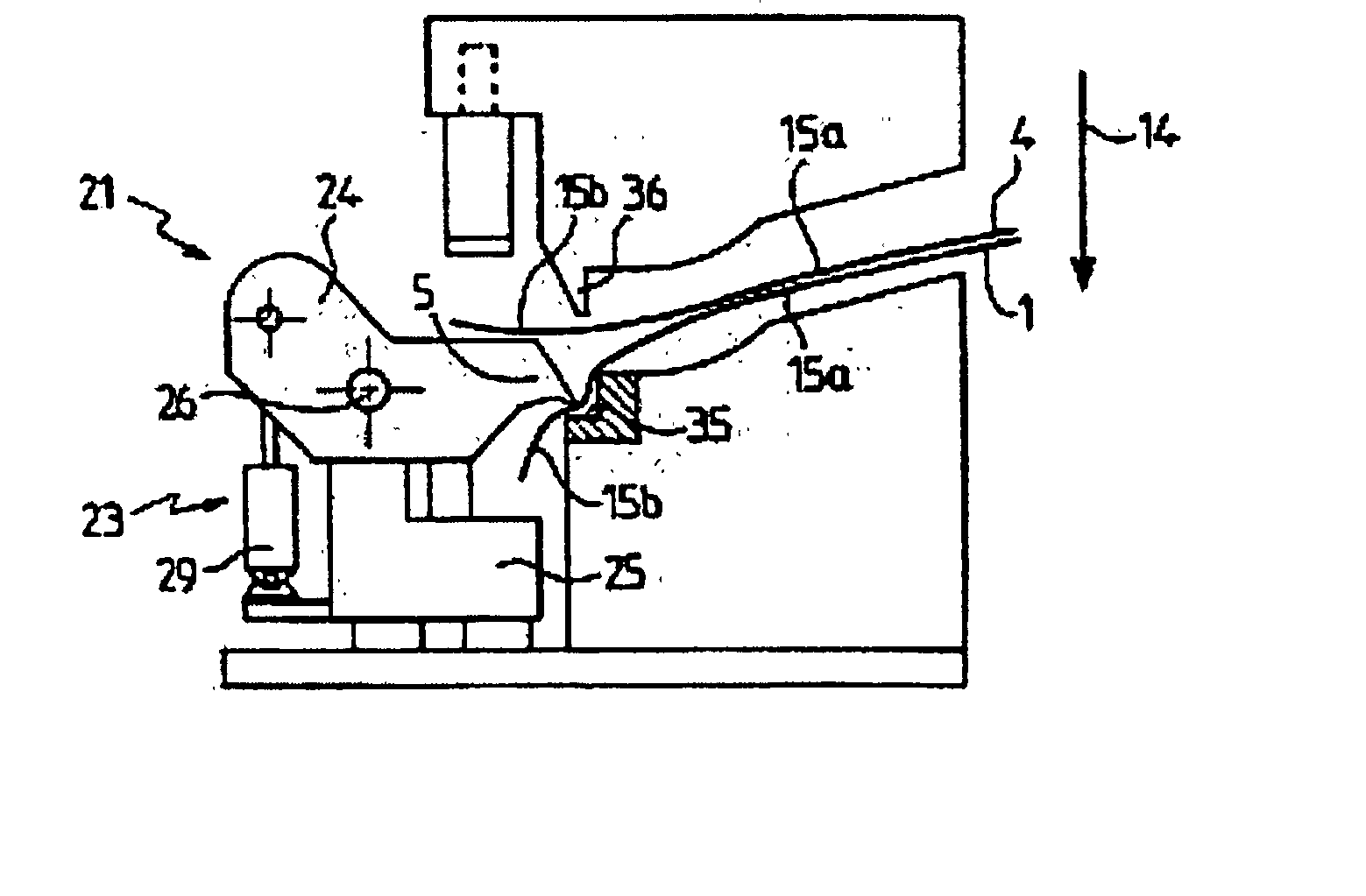

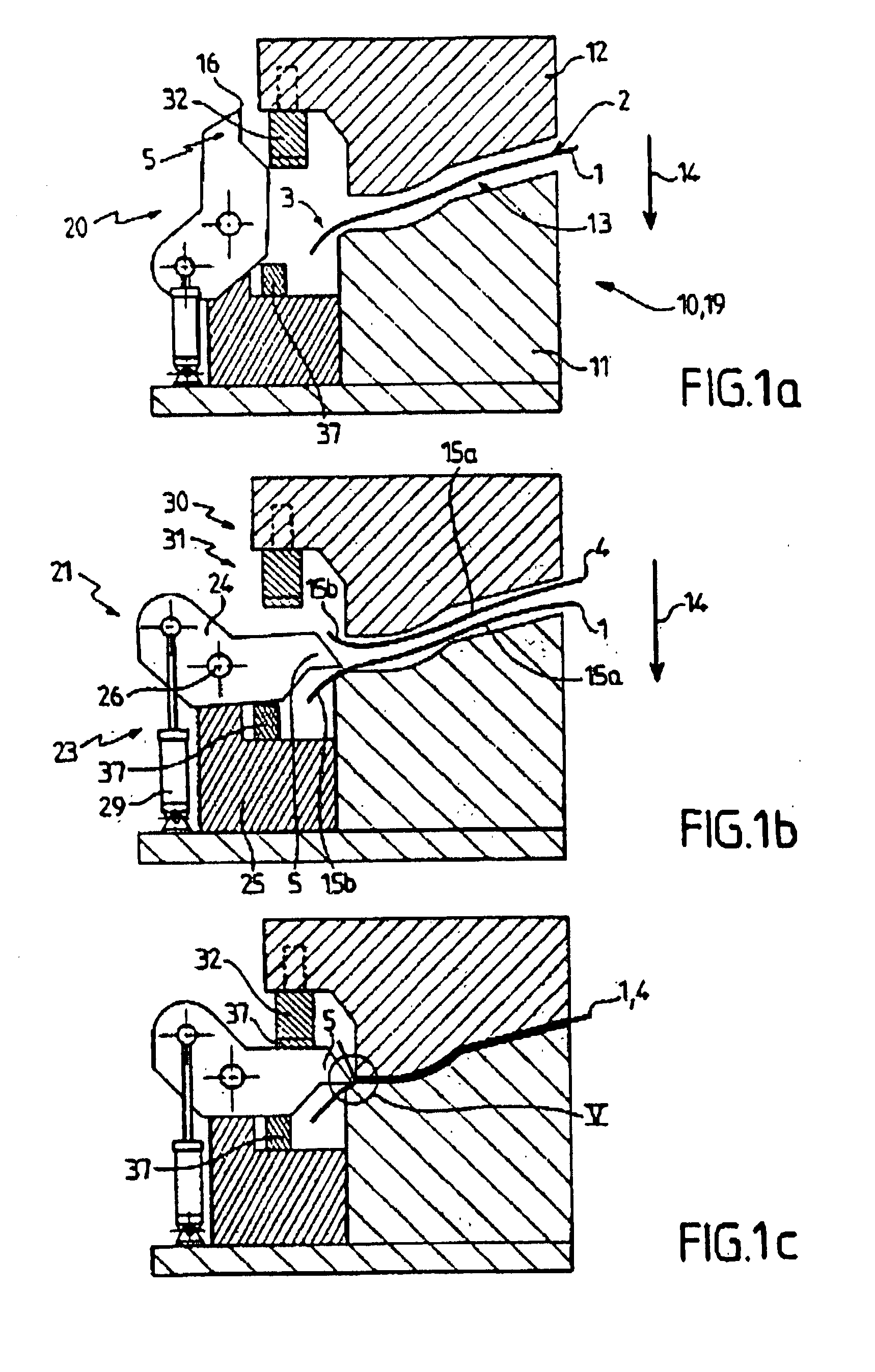

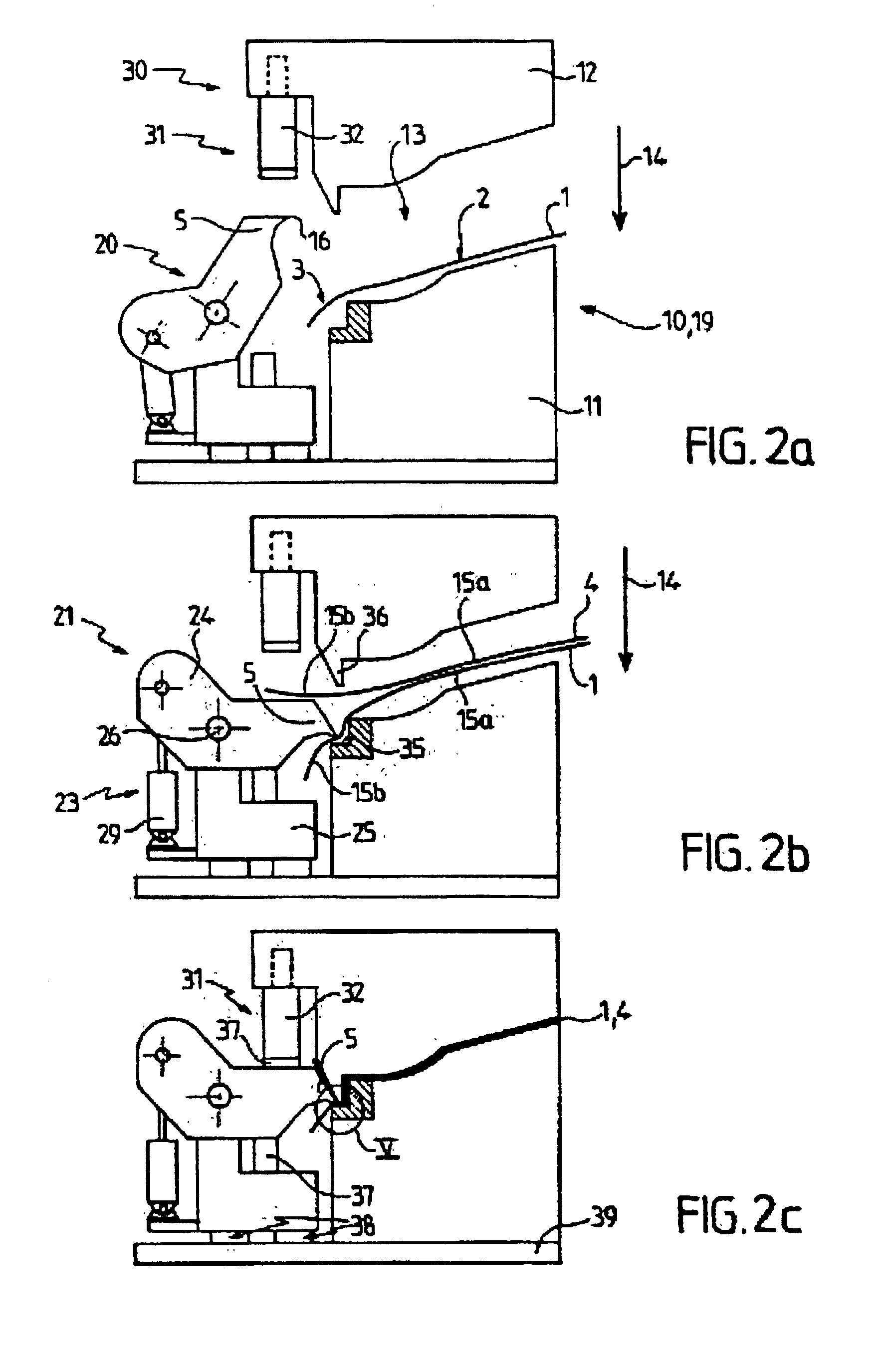

Selective cutting one shot

The invention relates to a process and a device for forming a planiform piece intended, in particular, for the interior fittings of motor vehicles, in which a layer of support material (1) is covered, at least on one of its faces (2) and in the area of a portion (3), at least, of its contour, or so-called portion to be bordered, with a cladding sheet (4) and said support (1) is cut along said portion to be bordered (3) in such a way that said cladding (4) projects from said support (1) in the area of said portion. According to the invention, a cutting tool (5) is pre-positioned between said cladding (4) and said support (1) along said portion to bordered (3) said cutting is effected with said cutting tool (5), when the support (1) is covered by the cladding (4).

Owner:VISTEON GLOBAL TECH INC

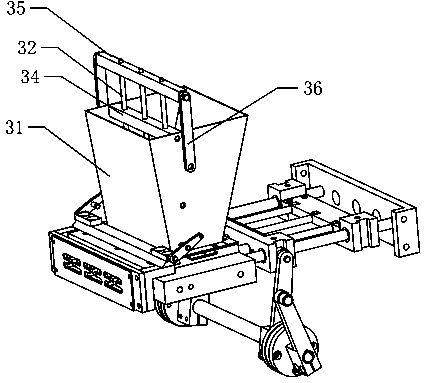

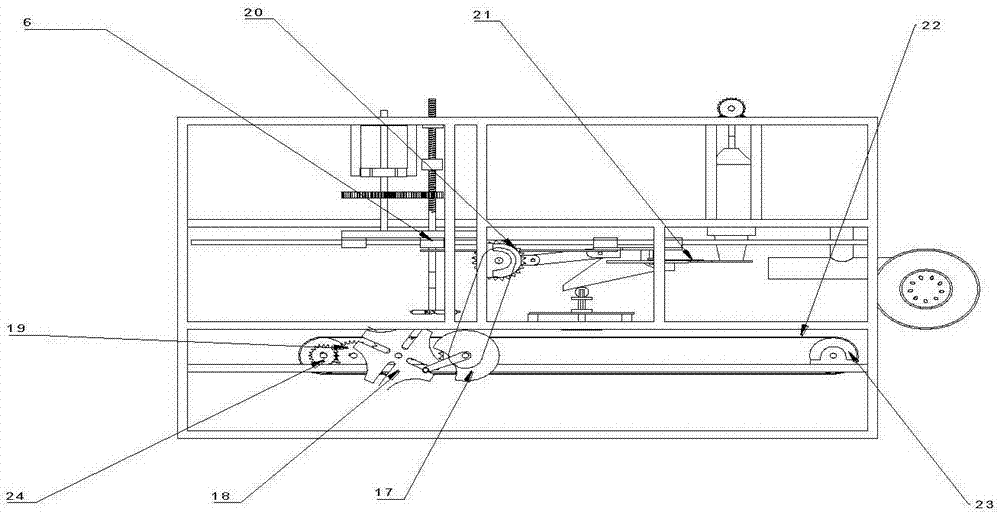

Machine for making double-stranded farci fried dough twists

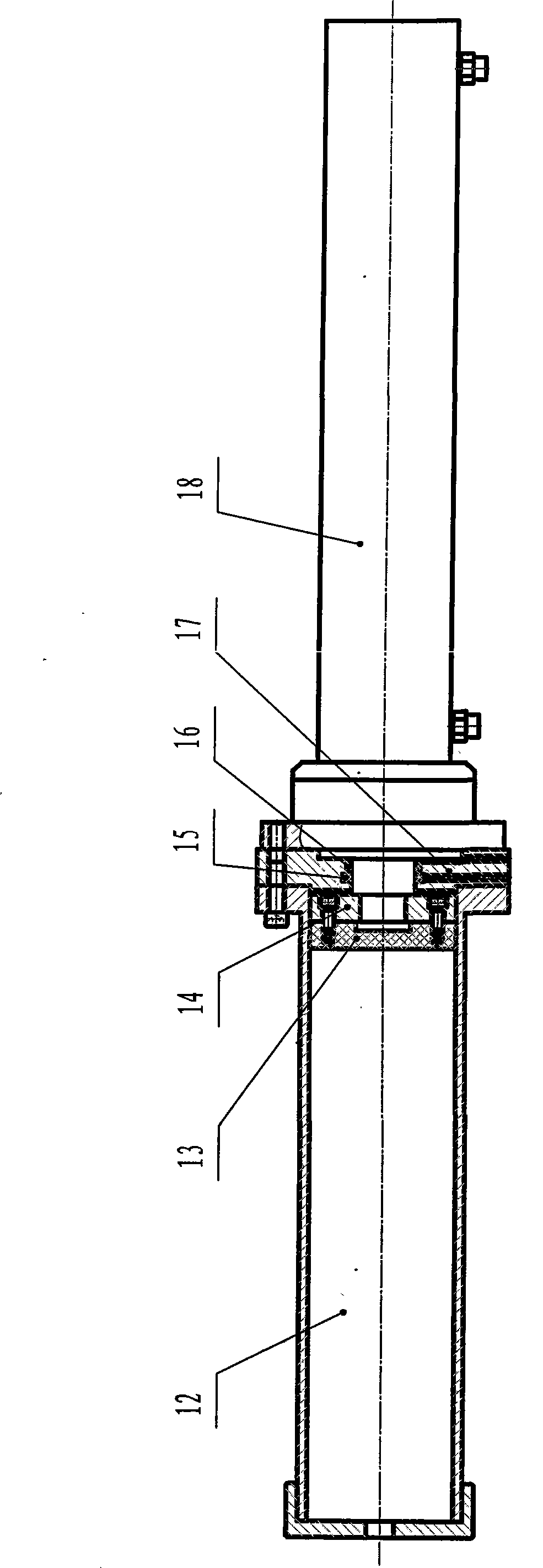

InactiveCN101461412AIngenious ideaReasonable designBakery productsDough shaping and dividing combinationHydraulic cylinderMotor drive

The invention relates to a double strand stuffing wrapped fried dough twist machine, which comprises a hydraulic four-cylinder full automatic feeding and shaping mechanism, adopts PLC program-controller to realize full-automatic circular continuous production. In the mechanism, the motor drives the oil pump which promote the hydraulic cylinder piston to drive the two dough cylinders and the two stuffing cylinders of the hydraulic four-cylinder feeding mechanism to operate alternatively. The two single strand screw shaping heads in the shaping mechanism rotates under the effect of the revolving chain wheel driving and the ring gear, to make the extruded a plurality of flour strips and a stuffing strip into two single strand screws with the flour strips round the stuffing strip; the revolving of the shaping mechanism drive the two single screws to enwind with each other into a complex screw; when the complex screw is conveyed to the cutting tool position by a conveyor belt, the rotating cutting tool cuts it into dough twists blank, and moves it forward; then the conveyor belt conveys the cut dough twist blanks into a fryer for frying to obtain the product which is same as the fried dough twist made by Tianjin traditional handwork method. The invention achieves the advantages of reasonable structure, energy saving, high efficiency and sanitary, and can make the fried dough twists with standard good appearance.

Owner:徐志兴

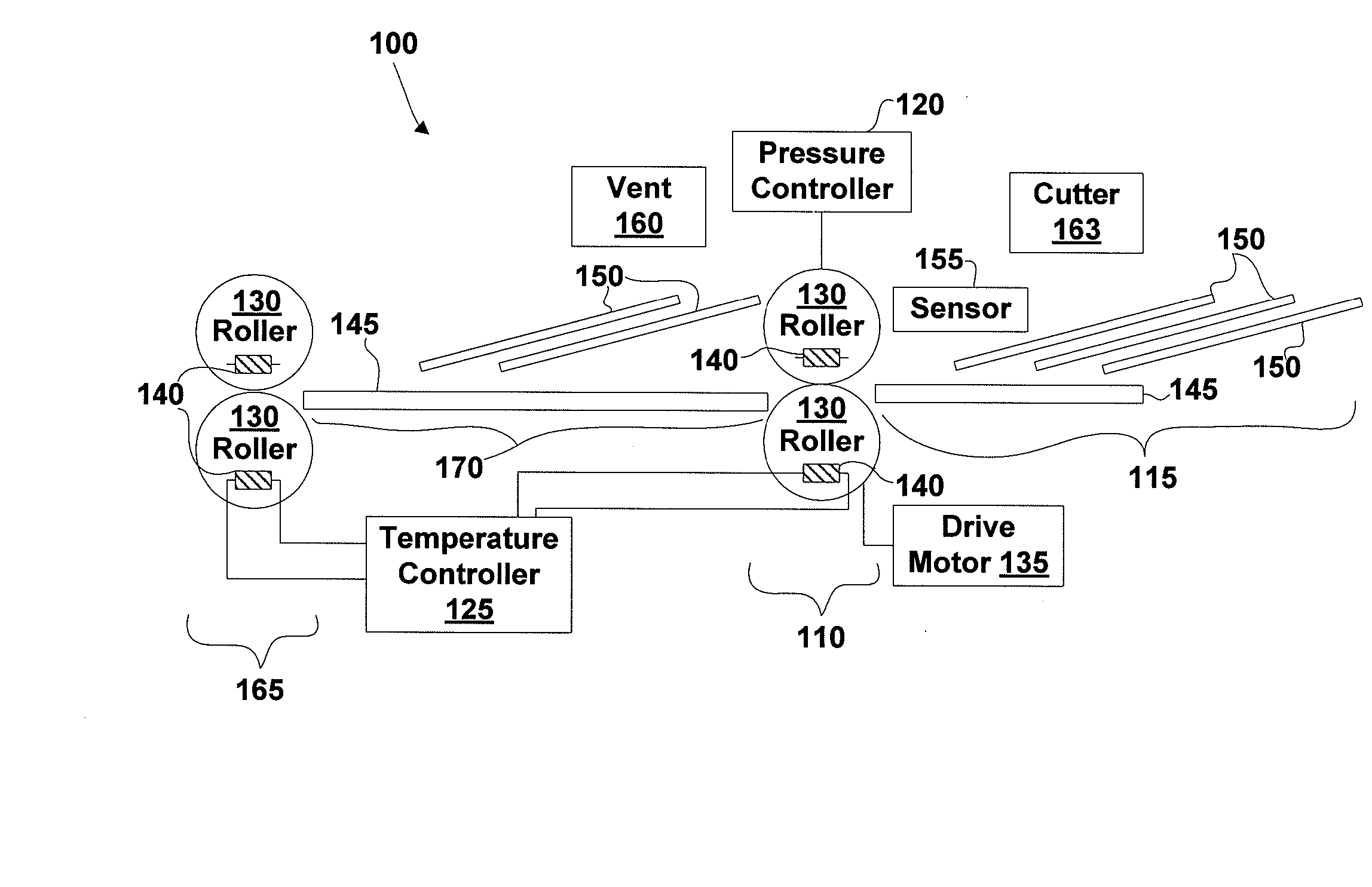

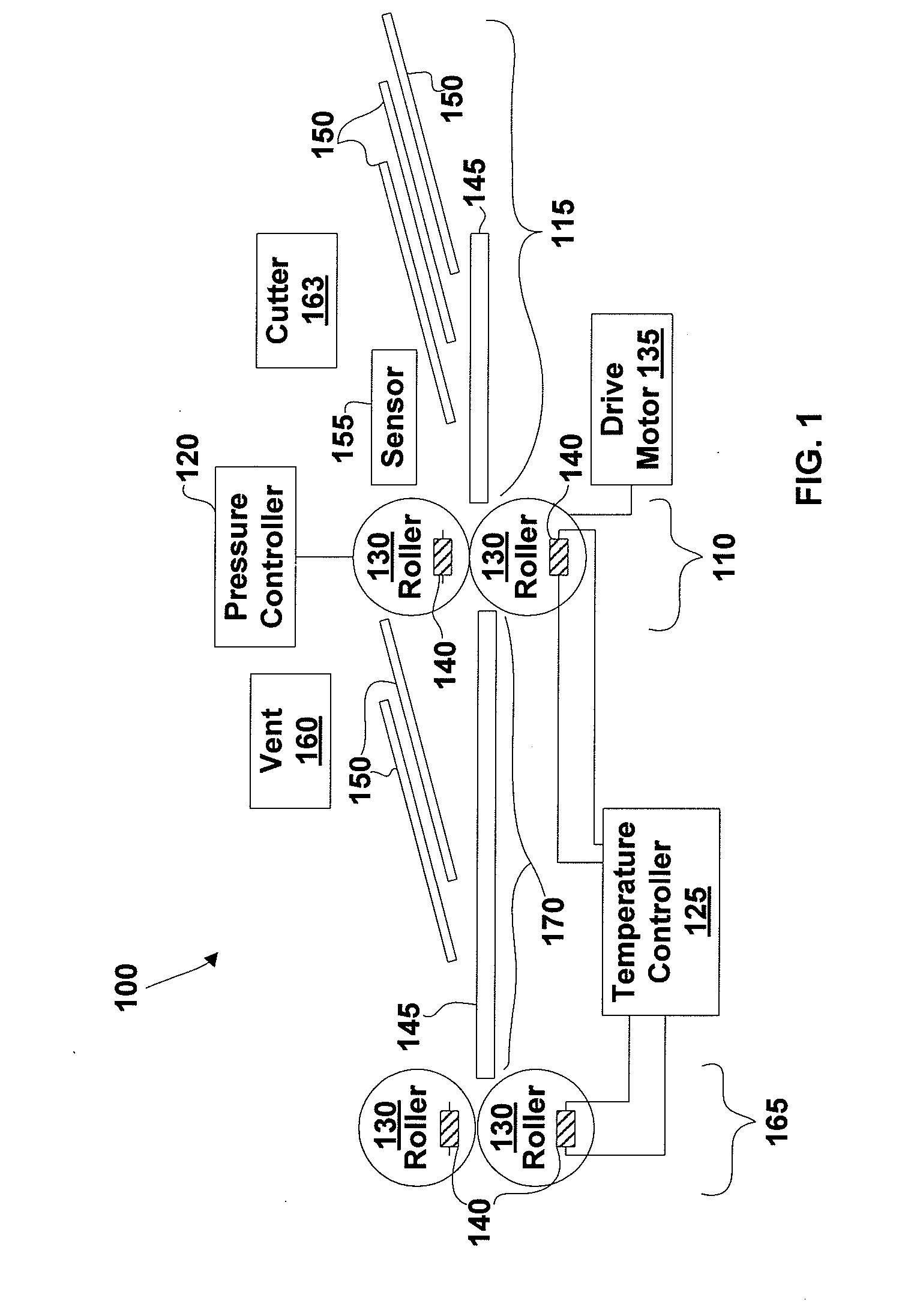

Material manufactured from recycled plastics

Systems and methods of generating a recycled output are disclosed. This recycled output may include a fabric produced by fusing reclaimed plastic bags. The reclaimed plastic bags are fused together using a material manufacturing system. This system is typically configured to heat the plastic bags to a temperature wherein the plastic bags fuse together but do completely melt. Some embodiments include the addition of different types of plastic or non-plastic materials to the recycled output. Also disclosed are systems and methods of controlling textures and patterns within the recycled output.

Owner:RECLAIM

Dumpling machine

InactiveCN107318912AHigh degree of automationDough-sheeters/rolling-machines/rolling-pinsMixing/kneading with vertically-mounted toolsIntermediate stageEngineering

The invention discloses a dumpling machine, which comprises a base, and the upper side of the base is provided with more than eight sets of support rods equidistant and symmetrically distributed, wherein the ends of the two sets of support rods away from the base are connected with connecting bosses, and the connecting bosses are The middle position of the platform is provided with a kneading box, the lower side of the kneading box is provided with a conveyor belt, the upper side of the conveyor belt is provided with equidistant and symmetrically distributed fixed bosses, and symmetrically distributed Two sets of connecting plates, one side of the connecting plate is provided with a second servo motor, the other end of the rotating shaft is connected to the connecting plate through a bearing, the middle position of the rotating shaft is provided with a pressing roller, and the kneading box passes through The flour and water can be fully stirred automatically to obtain better dough. The cutter and pressing roller can automatically cut and press the dough. The arc-shaped pressing plate can realize automatic pressing and filling. The infrared counter can count the dumplings. high degree of automation.

Owner:谢安鹏

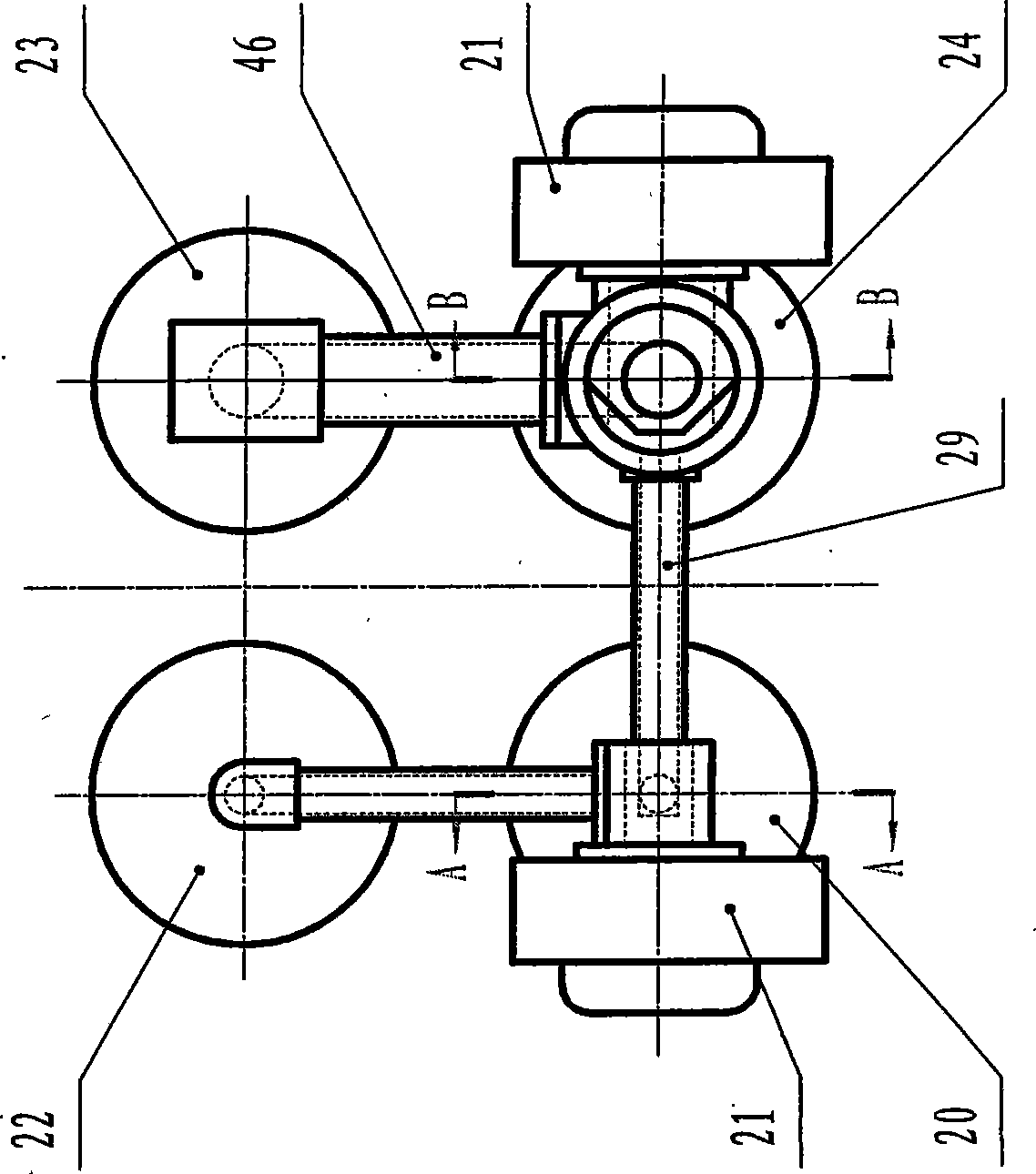

Intelligent dumpling wrapper moulding robot

ActiveCN106818968ATake advantage ofIncrease productivityDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringProduction quality

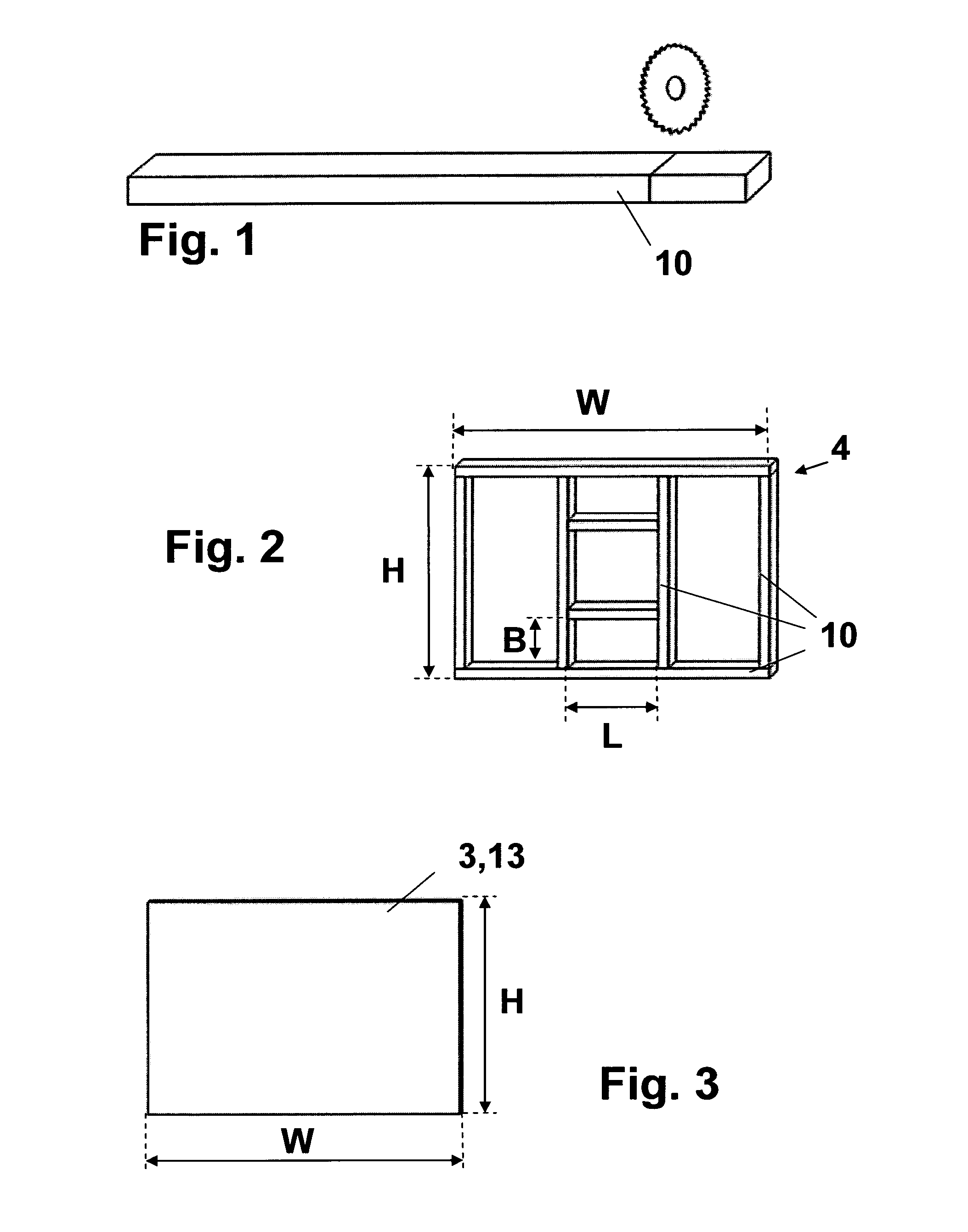

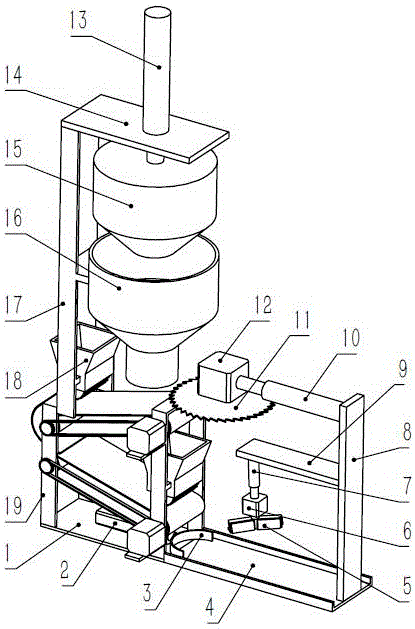

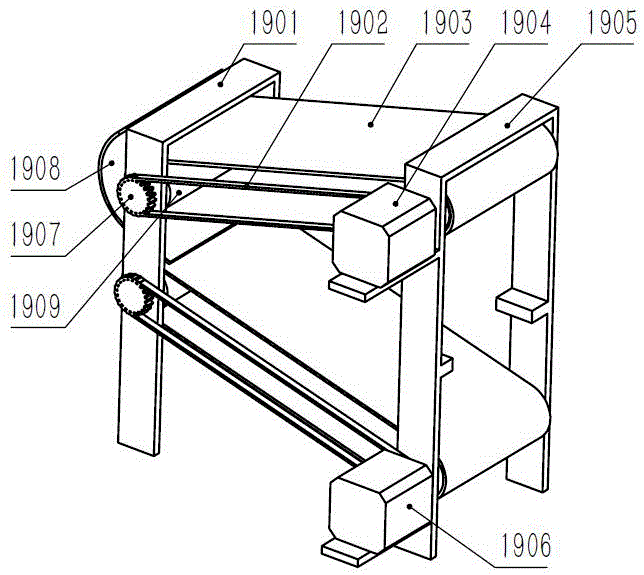

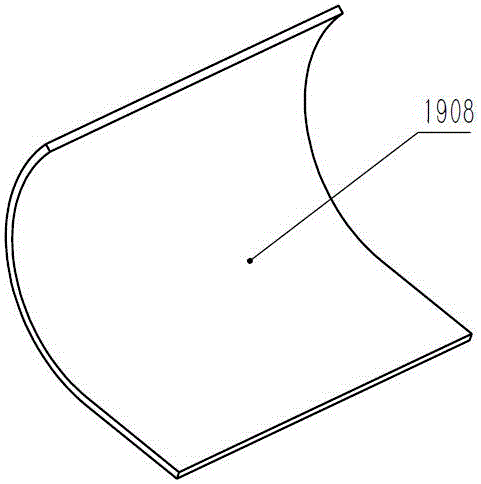

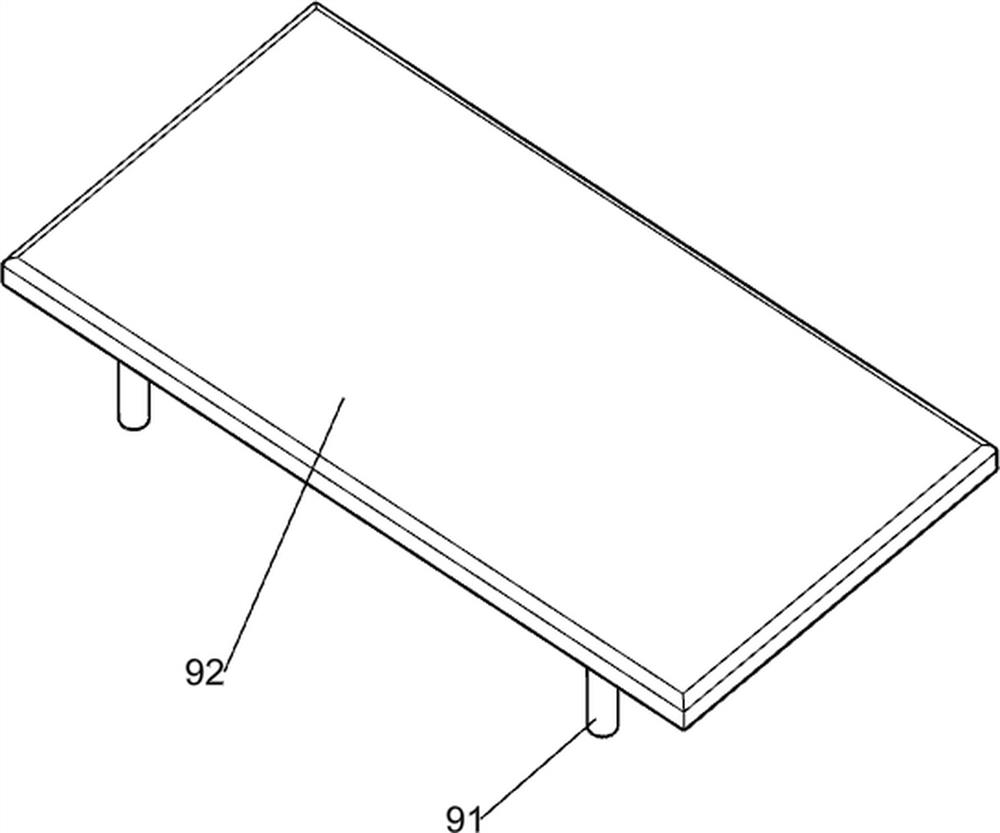

The invention discloses an intelligent dumpling wrapper moulding robot, which comprises a first electric cylinder, a semicircular push plate, a delivery sheet, a rolling subassembly, a first stepping motor, a second electric cylinder, a first support, a second support, a third electric cylinder, a saw disc, a second stepping motor, a fourth electric cylinder, a third support, a pressure plate, a flour barrel, a fourth support, two flour spray subassemblies and a conveying subassembly. The invention has the following advantages: the pressure plate is used for pressing dough into noodle with a certain size, the noodle is cut into a dough cake through the saw disc, and the well-cut dough cake is refined into a shape with the middle part being thick and the edge being thin by the use of the unique rolling subassembly; production efficiency is greatly enhanced; production quality is enhanced; dough can be fully utilized; and resources are saved.

Owner:上海熙香艺享电子商务有限公司

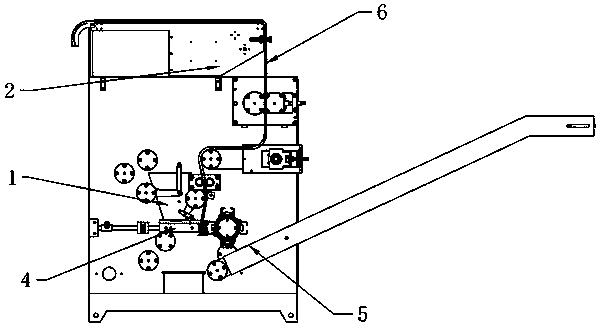

Automatic dough filling machine

ActiveCN112244049ARealize automatic unloadingRealize functionDough dividingDough extruding machinesElectric machineryEngineering

The invention relates to a filling machine, in particular to an automatic dough filling machine. The technical problem to be solved is to provide the automatic dough filling machine that dough can beautomatically discharged and cut and cut dough is identical in weight. Such automatic dough filling machine is provided, and comprises a bottom plate, a motor, a first drive rod, supports, a deliverymechanism and a cutting mechanism, wherein the motor is arranged at one side of the top part of the bottom plate; the first drive rod is arranged on an output shaft of the motor, and the other end ofthe first drove rod is rotatably connected with one side of the bottom plate; the supports are symmetrically arranged at one side of the top part of the bottom plate; the delivery mechanism is arranged at the top part of the bottom plate; and the cutting mechanism is arranged between the upper parts of the opposite sides of the supports. With the cooperation of the delivery mechanism, the cuttingmechanism, a material blocking mechanism and a material extruding mechanism, the functions of automatic discharging and automatic cutting of the dough can be achieved, the dough can be divided into multiple pieces of small dough identical in weight at a time, so that the working efficiency of people is improved.

Owner:广东嘉友食品有限公司

Instant two-layer food forming method

ActiveCN104886198AInto a stableStable forceDough-sheeters/rolling-machines/rolling-pinsDough embossing machinesBiotechnologyEngineering

The invention relates to the field of instant food, in particular to an instant two-layer food forming method. The instant two-layer food forming method comprises the following steps: 1) pressing a wrapper and cutting the wrapper into a plurality of slender flour tapes; 2) conveying uncooked or cooked stuffing to the position of the flour tapes; 3) feeding the stuffing to one side of the flour tapes, wherein an angle formed between the stuffing conveying path and the plane of the flour tapes is 45-135 degrees when the stuffing is fed to the flour tapes; 4) firstly pushing the other side of the flour tapes into forming holes of an outer forming template and an inner forming template, wherein the middle portions of the flour tapes wrap the stuffing at the moment to realize preliminary forming; 5) sealing the portions, which wrap the stuffing, of the flour tapes and simultaneously performing pattern printing forming to the flour tapes with sealed portions; 6) placing the formed instant two-layer food on a conveying belt for conveying. By improving the included angle between the stuffing and the flour tapes when the stuffing is filled into the flour tapes, the situation that the stuffing cannot be put in the flour tapes is avoided, the contact surface between the stuffing and the flour tapes is larger, the integrity of the stuffing is better, the stress surface of the flour tapes is larger and the flour tapes are prevented from being damaged.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

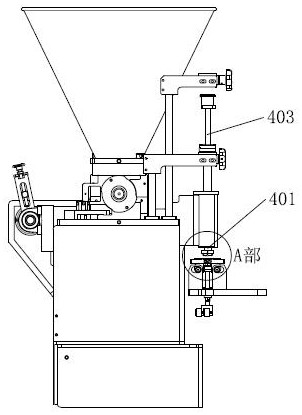

Stuffed food forming equipment and method suitable for yuanbao wontons and method thereof

InactiveCN113229302ARealize fully automatic processingAchieve a residue-free finishDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringAutomatic processing

The invention belongs to the field of food processing equipment, and particularly relates to stuffing food forming equipment and method suitable for yuanbao wontons (looks like shoe-shaped gold ingots) . The equipment can automatically process stuffed foods such as wontons, and comprises a turntable, and a wrapper making station, a stuffing injection station, a folding station and a clamping station which are sequentially distributed around the turntable, a forming station is arranged beside the clamping station, the turntable is provided with a plurality of pre-forming molds, and the pre-forming molds are driven by the turntable to rotate; and the forming station is provided with a forming device, the forming device rotates the two ends of the folded wrappers towards the middle at the same time, and the two ends of the rotated wrappers are attached together to complete final forming of the stuffed food. According to the stuffed food forming equipment suitable for the yuanbao gold ingot wontons, full-automatic processing of wonton type stuffed foods can be achieved, the overall turntable type layout is adopted, the occupied area is small, and the effect of no residual wrappers in the forming process of the stuffed food can be achieved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

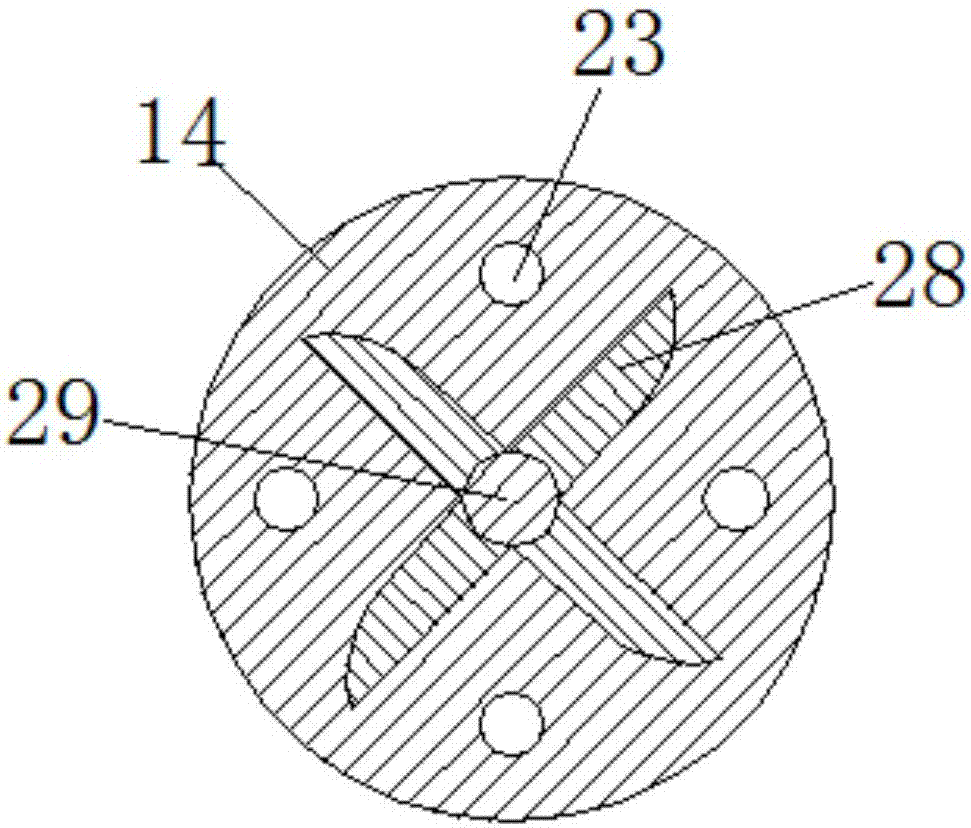

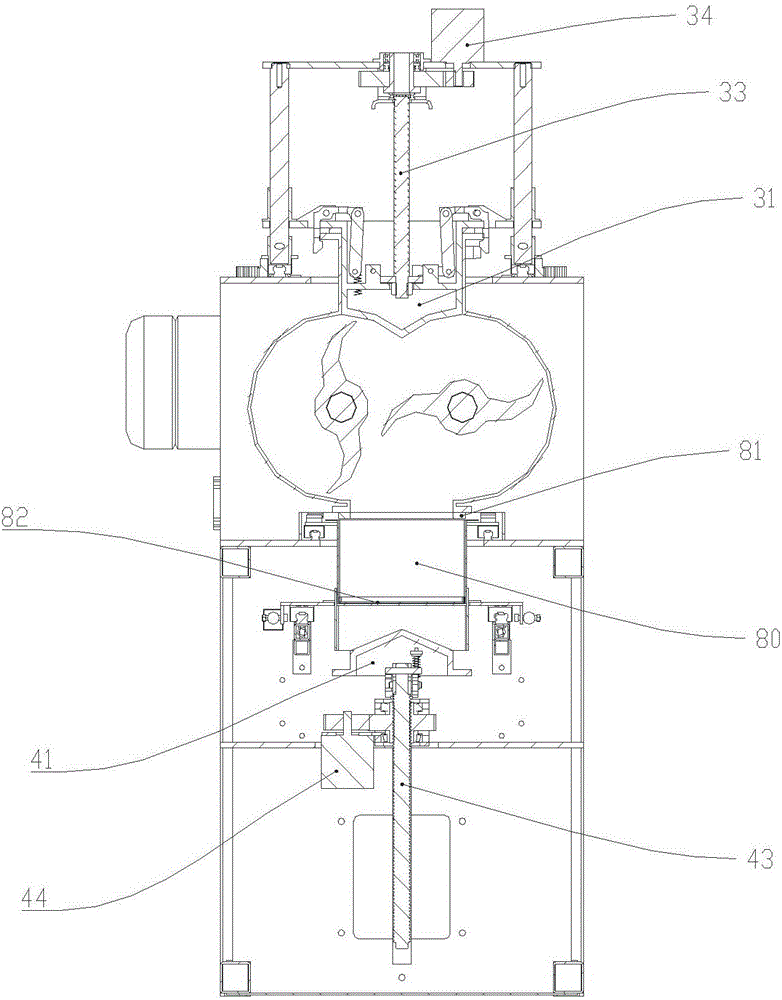

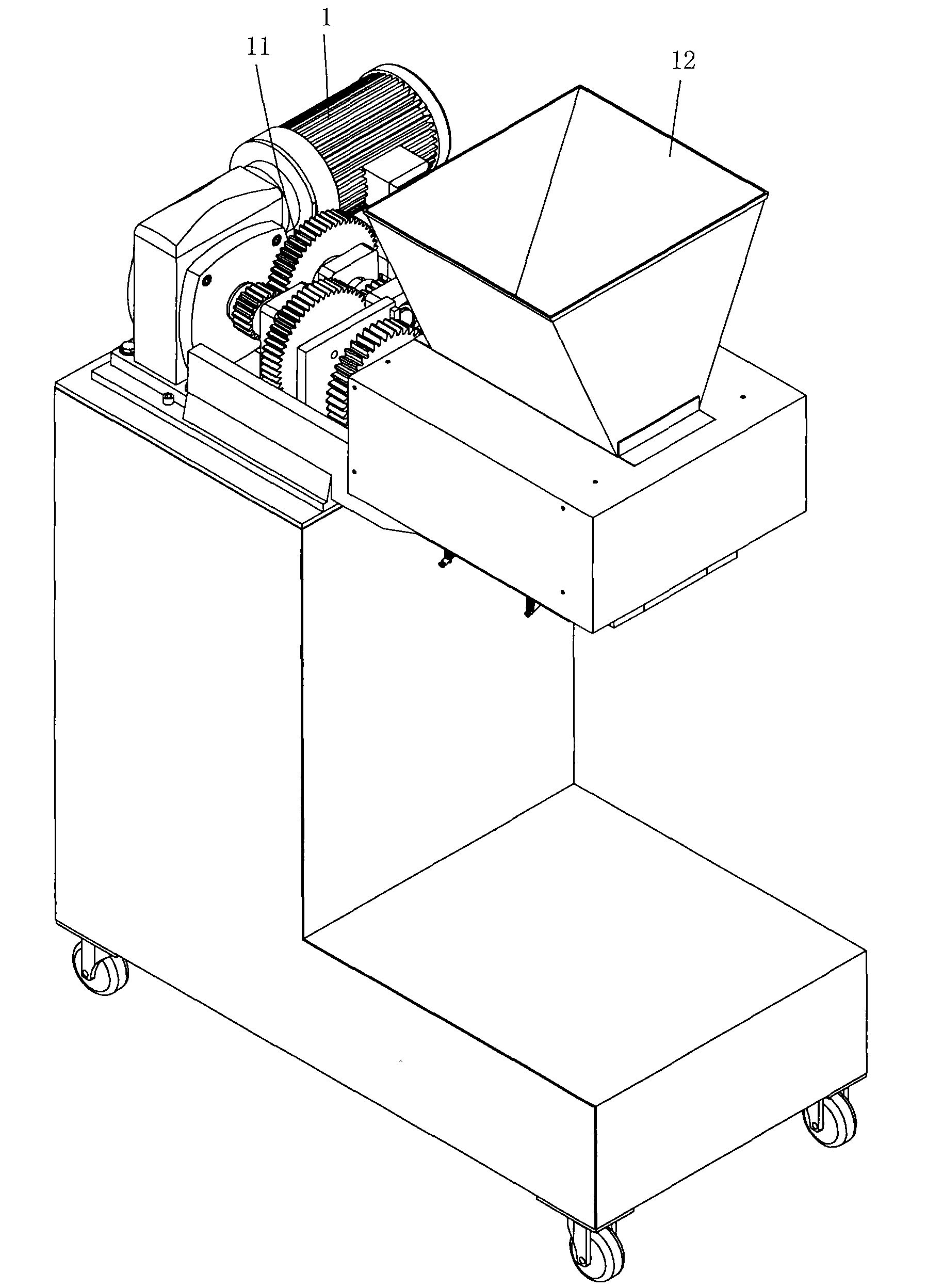

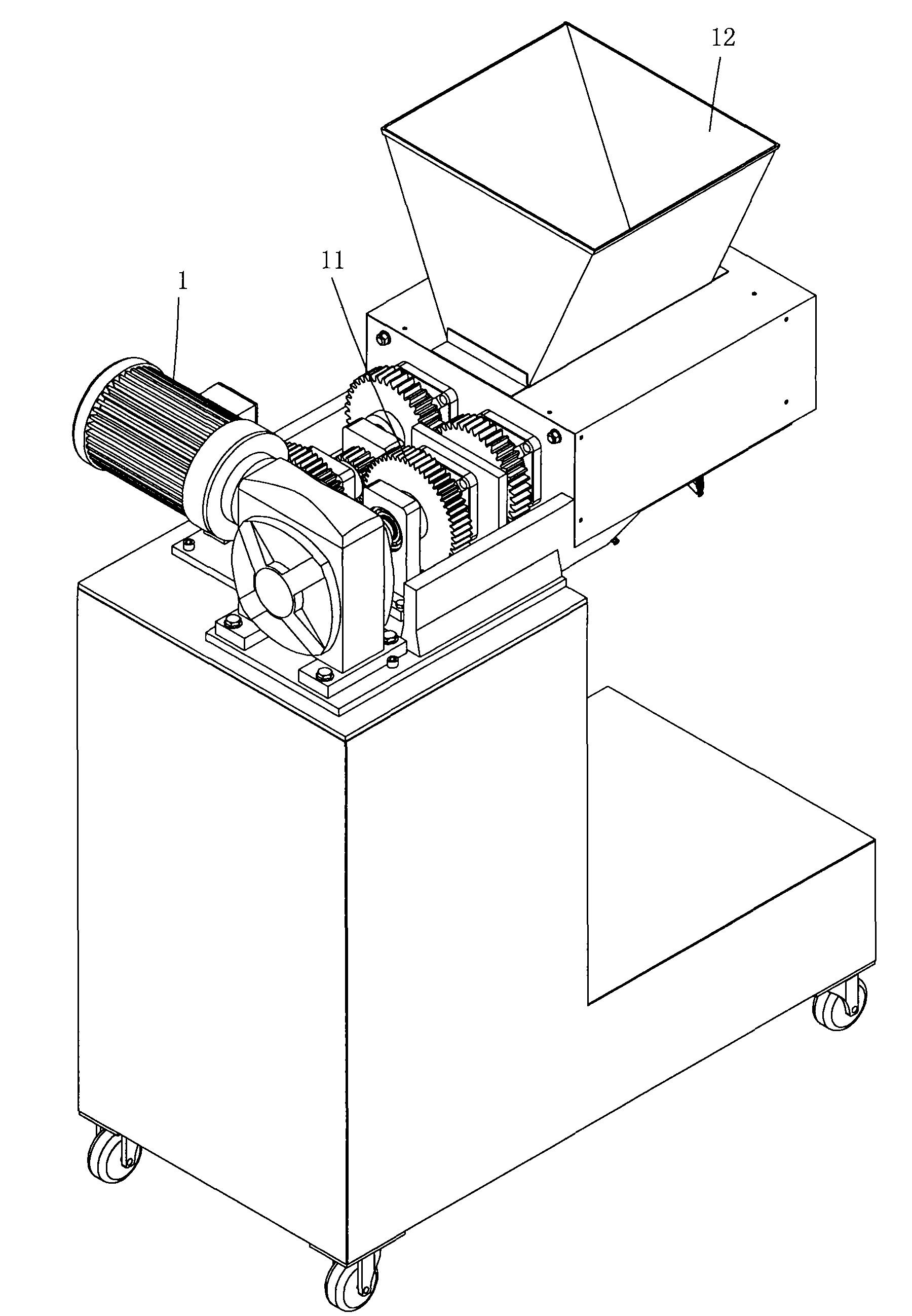

Simulated manual dough kneading robot

ActiveCN106577903AQuality assuranceGuaranteed tasteMixing/kneading structural elementsDough dividingVacuum pumpingMotor drive

The invention discloses a simulated manual dough kneading robot. The robot comprises a frame, and a motor and a dough kneading box assembly which are fixed on the frame, and the dough kneading box assembly comprises a dough kneading bin and two blades arranged in the dough kneading bin, wherein the motor drives the blades to synchronously reversely rotate in order to mix flour and knead dough, the cross section of the dough kneading bin has a two intersected circular shape, and the planes of the blades are mutually perpendicular. The simulated manual dough kneading robot simultaneously completing the flour mixing and dough kneading process has the advantages of short dough making time and high efficiency, guaranteeing of the quality and the mouthfeel of dough through controlling the rotating speed of the blades by a frequency converter and keeping the whole-process vacuum pumping state of the dough kneading bin, great reduction of the occupied area through abandoning original flour mixing, dough kneading and setting devices, simplification of the dough making process flow, and reduction of the manpower intensity and the dough making cost.

Owner:深圳厨奇自胜智能装备技术有限公司

Methods and apparatus for manufacturing molded articles

Apparatus for manufacturing a molded article having a substrate material and skin material may include a first die that receives and supports the substrate material and a second die that receives and supports the skin material. The first die is arranged and constructed to engage the first die. A cutter may be provided on the first molding die. The cutter can be actuated when the second die moves toward the first die in order to partially cut away the substrate material.

Owner:ARACO CORP

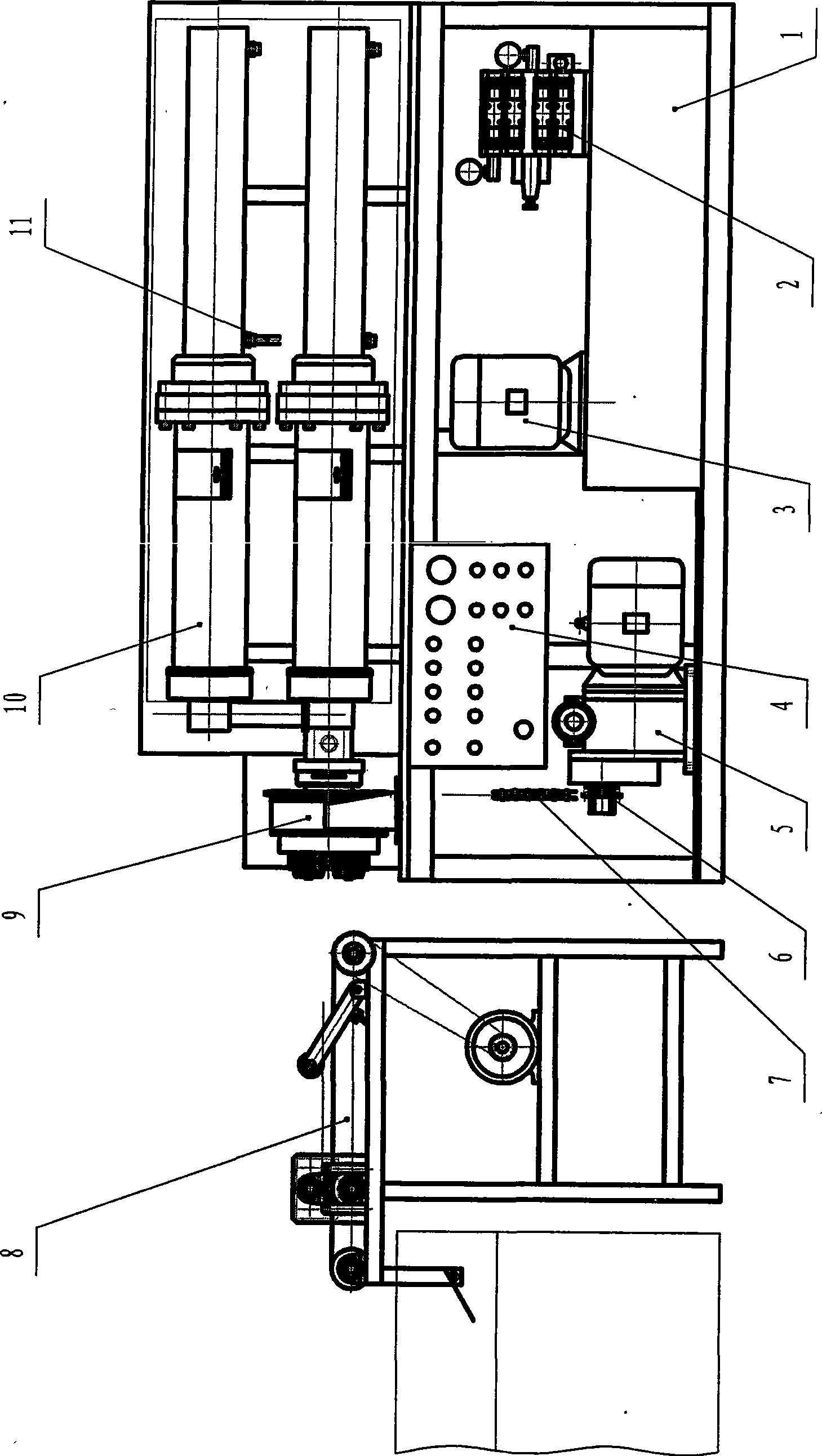

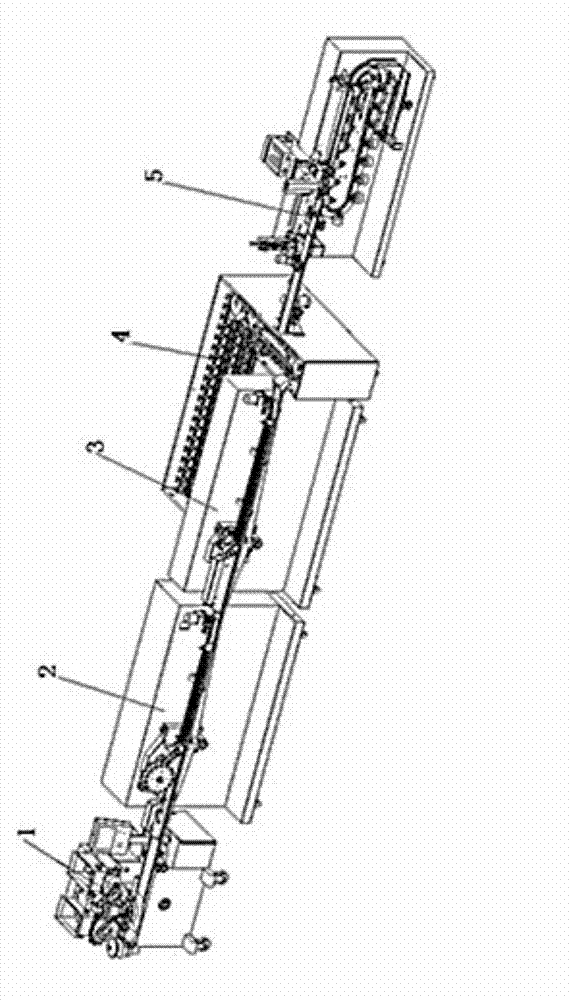

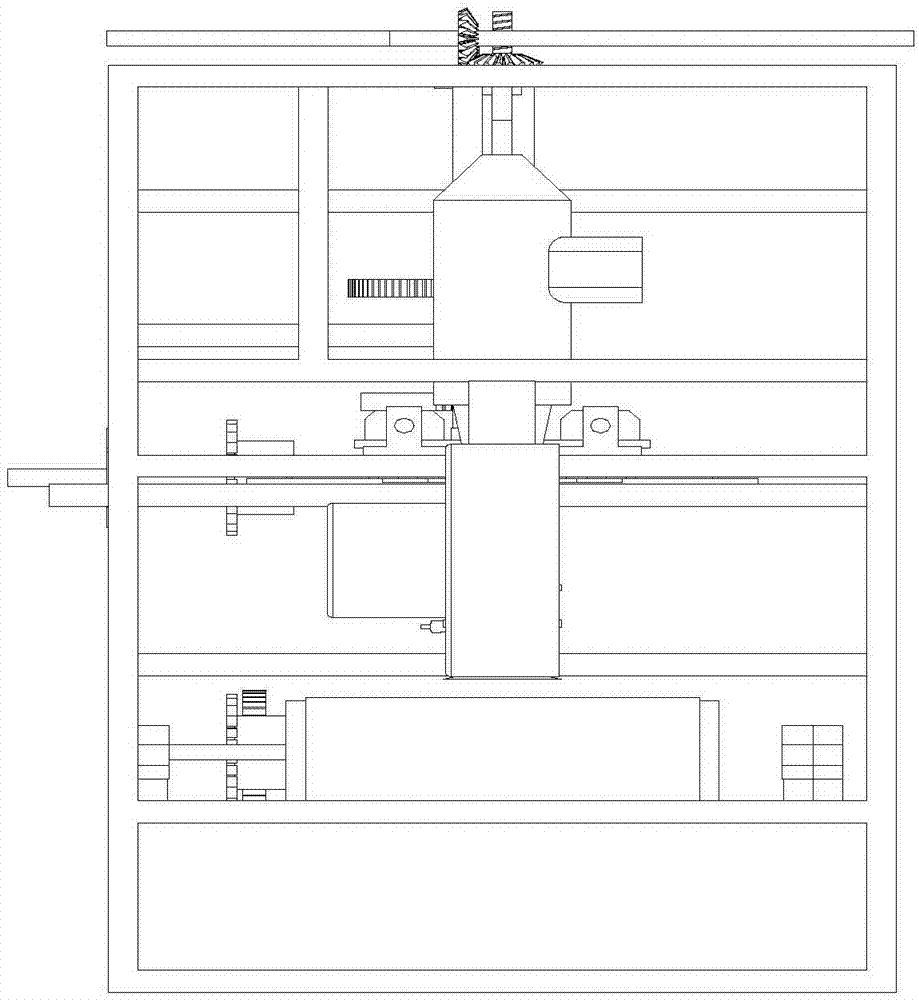

Multi-station automatic forming system device for multilayer crisp stuffed moon cakes

InactiveCN102885100AIncrease productivityAvoid congestionDough sheet coiling machinesDough-sheeters/rolling-machines/rolling-pinsFood flavorMultiple layer

The invention relates to a multi-station automatic forming system device for multilayer crisp stuffed moon cakes. The multi-station automatic forming system device comprises a dough and crisp packing and discharging machine, a first-time flattening and coiling forming machine, a second-time flattening and coiling forming machine, a crisp layer leavening machine and a follow-up stuffing supplying and sealing machine, wherein a programming controller is connected with the dough and crisp packing and discharging machine, the first-time flattening and coiling forming machine, the second-time flattening and coiling forming machine, the crisp layer leavening machine and the follow-up stuffing supplying and sealing machine respectively to control the five machines. The programming controller is connected with the five machines respectively, and sends out commands to control the five machines to execute processes on line. The five machines are connected by transmission devices on the five machines, and blank or multiple layers of cake blanks are transmitted from an inlet of the multiple players of cake blank to an outlet by the transmission devices after the mechanical action is accomplished. The multi-station automatic forming system device can ensure traditional flavor and taste of the crisp dessert, and realizes the output at the speed of 40-60 desserts per minute. The multi-station automatic forming system device opens up a new technical field of producing the multilayer crisp stuffed moon cakes through mechanical automation.

Owner:上海伟隆机械设备股份有限公司

Forming device automatically guiding flour dough into flour tapes

InactiveCN102090426ADough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringMechanical engineering

Owner:黄连福

Processing method and device for pies

InactiveCN103385271AGreat tasteHigh strengthKitchen equipmentDough shaping and dividing combinationUltimate tensile strengthComputer science

The invention relates to a processing method and device for pies, and in particular relates to a processing method and device for pies using stripy wrappers to wrap stuffing. The stripy wrapper covered with a plastic thin film related by the invention is high in strength, and can realize standardized and mechanical production; to ensure that the pie has good taste, the wrapper can be made into a multilayer mode, or wrappers prepared by kneading different types of dough. In the processing method disclosed by the invention, the stuffing both in a meat paste mode and in a particle mode can be wrapped by a paving manner; different stuffings can be added as needed to enhance the taste selection function and meet requirements on different tastes of people when the stuffing adopts an open package mode; the processing method is combined with a subsequent pie automatic heating machine, and automated vending is easily realized.

Owner:杨斌

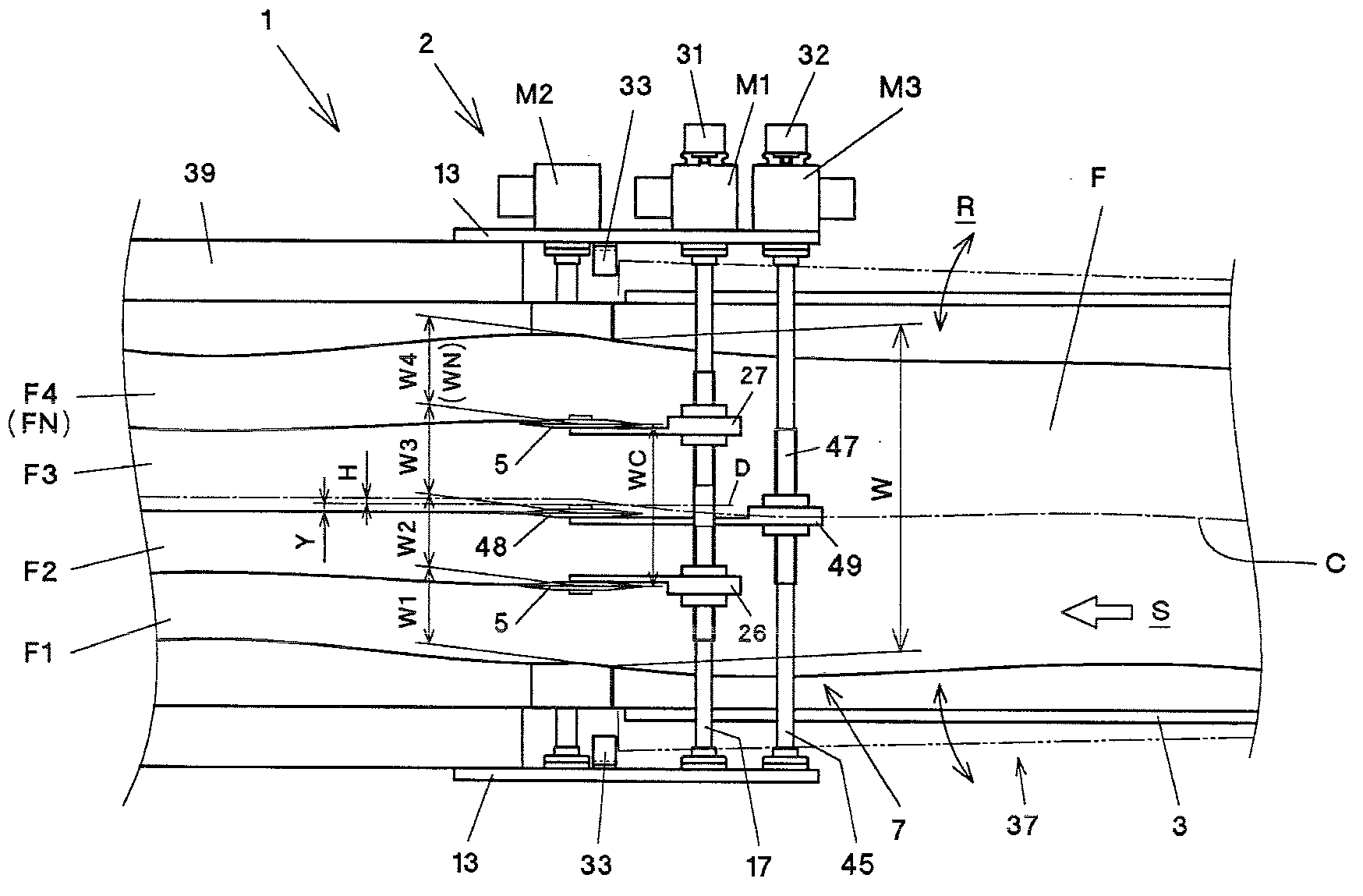

Food dough cutting method and cutting apparatus

InactiveUS20080289466A1Prevent buildupBuildDough dividingDough shaping and cutting apparatusBand shapeEngineering

The object of the present invention is to provide a food dough cutting method and cutting device thereof capable of forming conveyed food dough strips that have nearly identical weight per unit time when dividing band shaped food dough into multiple food dough strips in the conveyance direction, and is further capable of performing the same number of cuts for each food dough strip when cutting each food dough strip along the width direction into food dough pieces having a specified weight.The conveyed food dough is aligned to a position that is displaced by just an alignment displacement amount with respect to a reference position that is based on the installation position of cutting members. The alignment displacement amount is calculated based on the ratio of the width dimension of the food dough and the lengths of food dough pieces that are cut from food dough strips on both sides.

Owner:RHEON AUTOMATIC MASCH CO LTD

Imitating handmade full-automatic raw twisted cruller production line

ActiveCN111374155AReduce stressOvercome partial shrinkageDough-sheeters/rolling-machines/rolling-pinsDough dividingMechanical engineeringFully automated

The invention discloses an imitating handmade full-automatic raw twisted cruller production line which at least includes a horizontal reciprocating dough rolling device, an interval oil-water brushingcutting device, a stacking creasing device, a stretching device and a cutting device. A reciprocating dough rolling mechanism applies reciprocating rolling non-parallel to the conveying direction ona dough material to form a dough strip; the interval oil-water brushing cutting device brushes water and oil at intervals along the dough strip conveying direction and divides the dough strip into a plurality of dough strips; stacked two-layer dough strips are pressed for creasing through the stacking creasing device; the stretching device elongates the dough strips; and the cutting device cuts the elongated dough strips to form raw twisted cruller. According to the structural design of the imitating handmade full-automatic raw twisted cruller production line, full-automatic production is realized, the quality that the produced raw twisted cruller imitates hand-made raw twisted cruller is achieved, the produced raw twisted cruller are better than hand-made, the taste of the fried raw twisted cruller is the same as that of the hand-made, even better, and efficiency and high-quality production are achieved.

Owner:SUZHOU GUOEN FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com