Saving type handwork-imitated steamed stuffed bun wrapper rolling machine

A kind of artificial and economical technology, which is applied in the direction of dough forming machinery or equipment, dough extruder, dough forming and cutting combination, etc. Efficiency, the effect of liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

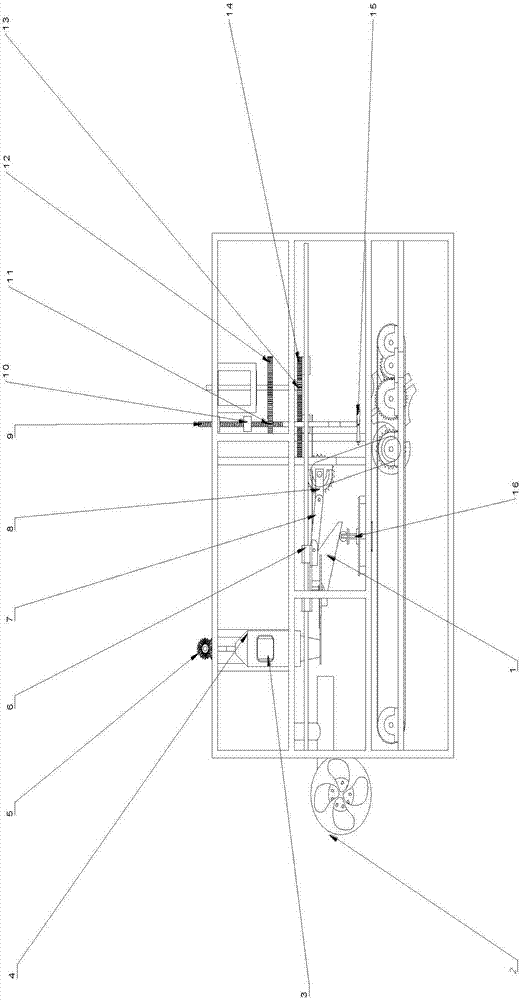

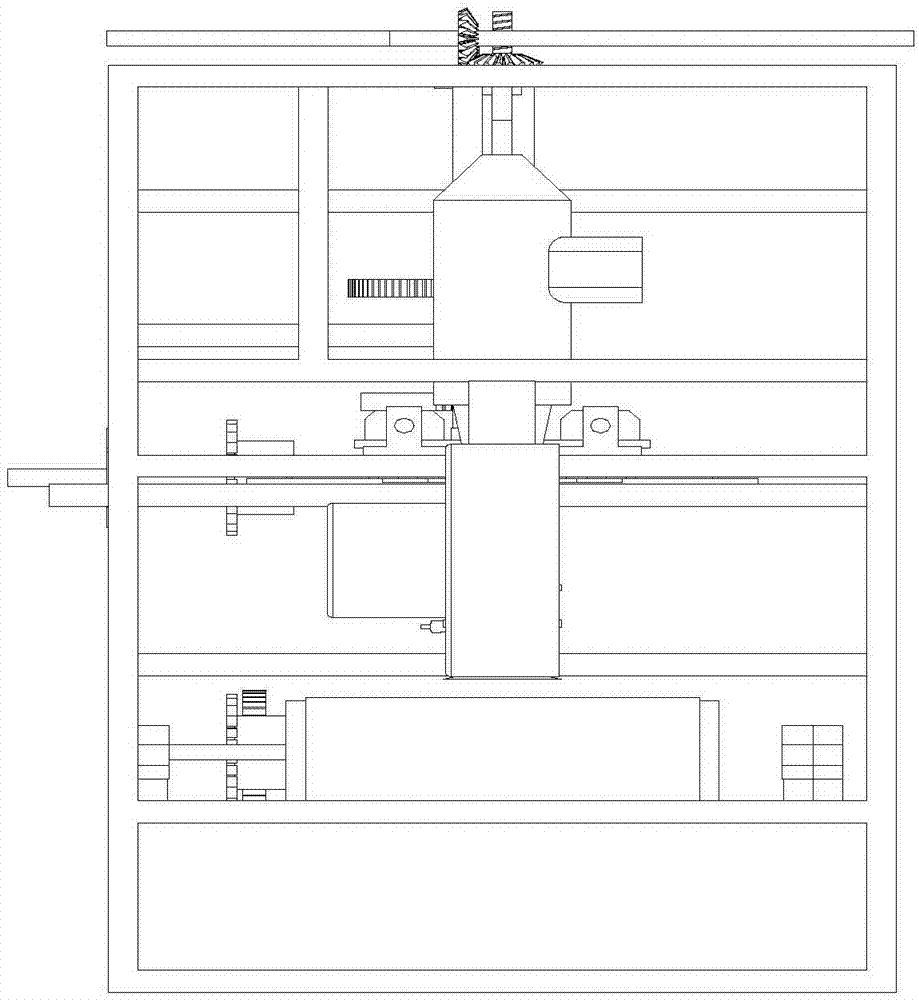

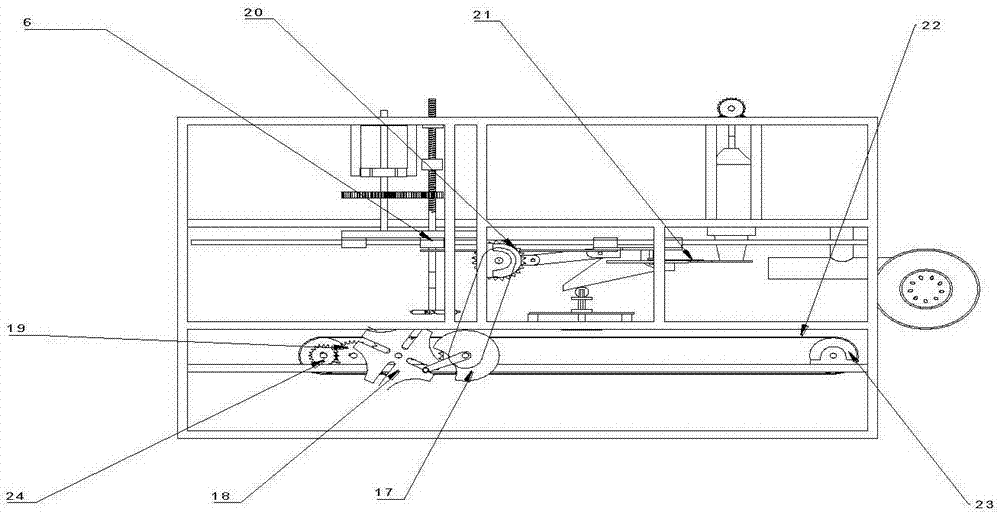

[0028] The present invention mainly realizes that the dough kneaded in advance is rolled into ready-made steamed stuffed bun skins: the dough is extruded into noodle cylinders by using the principle of extrusion, and cut into sections of "noodle embryos", and the process of rolling skins is imitated by human beings. , Sprinkle noodles on the "noodle embryo", press it and roll it into a skin.

[0029] Performance index of the present invention is as follows:

[0030] (1) The motor used in the auger for extruding noodles is 220V / 25w, and the working speed is 135r / min;

[0031] (2) The crank speed of the rolling part is 20r / min, and 20 skins are rolled per minute.

[0032] (3) The thickness of the cut surface is 25mm and the diameter is 30mm; the thickness of the pressed surface is 12mm, the thickness of the rolling surface is 5mm, and the diameter is 100mm; the thickness difference between the middle and edge of the dough is 6mm.

[0033] (4) Sending the dough into the extrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com