Method for preparing curdlan gel granules and product thereof

A gel granule and gel-gel technology, which is applied to the preparation method of gel granules and the product field thereof, can solve the problems of poor taste, cannot be made, weak market acceptance, etc., and achieves crisp taste, smooth taste, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

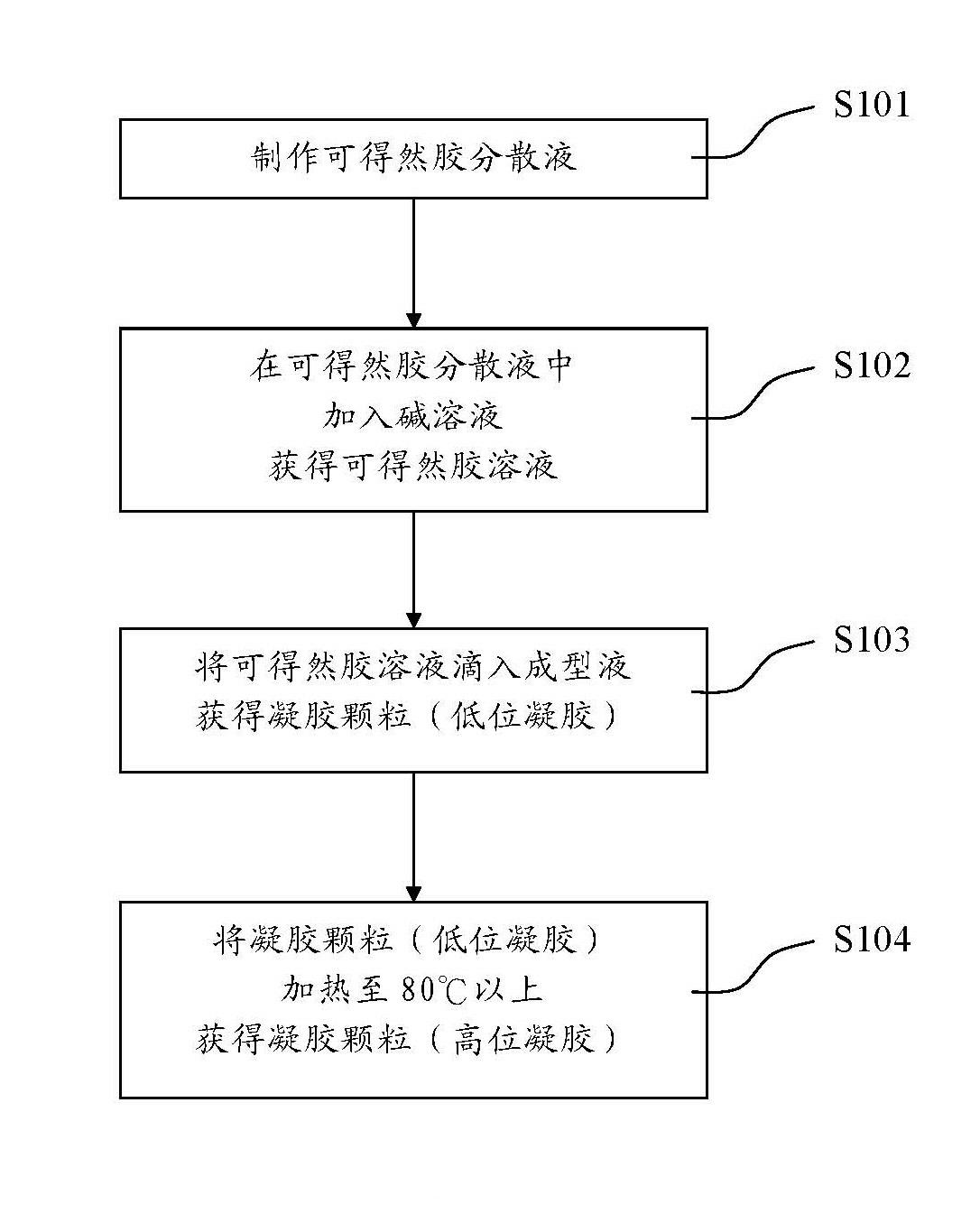

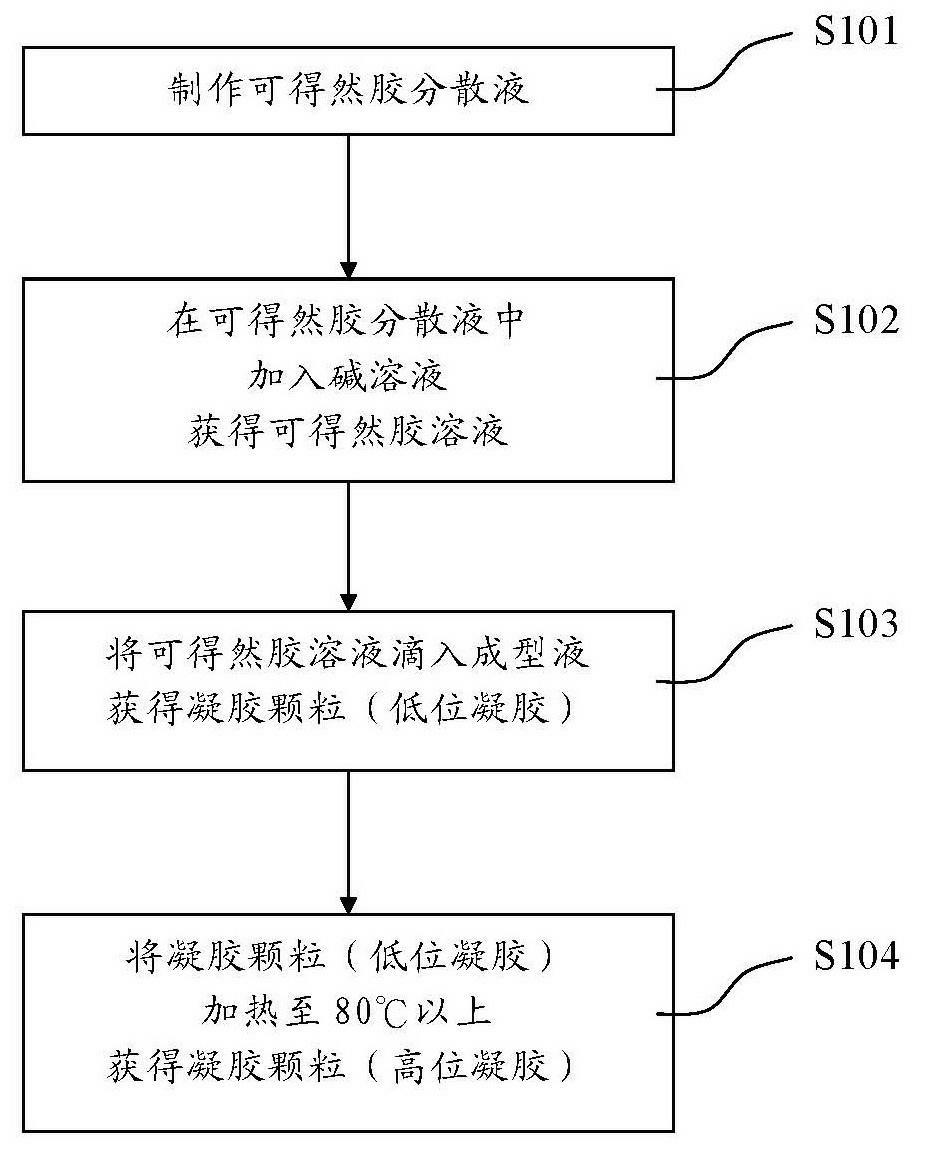

Method used

Image

Examples

Embodiment 1

[0030] 1. Glue solution components

[0031] curdlan gum

2.5%

Water1

96.4%

0.1%

water 2

1%

[0032] Curdlan gum is dispersed in water 1 to obtain curdlan gum dispersion liquid,

[0033] Sodium hydroxide is dissolved in water 2 to form an alkaline solution,

[0034] Slowly add the alkali solution into the curdlan dispersion and stir until the curdan is completely dissolved into a gel solution.

[0035] 2. Acidic molding fluid components

[0036] citric acid

1%

water

99%

[0037] Dissolve citric acid in water to become an acidic forming liquid.

[0038] 3. Drop the gel solution into the acidic forming liquid to form low-level gel particles.

[0039] 4. Heat the low-level gel particles to 90-95°C to form Curdlan high-level gel particles.

Embodiment 2

[0041] 1. Glue solution components

[0042] curdlan gum

1%

Water1

97.9%

0.1%

water 2

1%

[0043] Curdlan gum is dispersed in water 1 to obtain curdlan gum dispersion liquid,

[0044] Sodium hydroxide is dissolved in water 2 to form an alkaline solution,

[0045] Slowly add the alkali solution into the curdlan dispersion and stir until the curdan is completely dissolved into a gel solution.

[0046] 2. Acidic molding fluid components

[0047] citric acid

1%

water

99%

[0048] Dissolve citric acid in water to become an acidic forming liquid.

[0049] 3. Drop the gel solution into the acidic forming liquid to form low-level gel particles.

[0050] 4. Heat the low-level gel particles to 80-90°C to form Curdlan high-level gel particles.

Embodiment 3

[0052] 1. Glue solution components

[0053] curdlan gum

3.5%

Water1

95.4%

0.1%

water 2

1%

[0054] Curdlan gum is dispersed in water 1 to obtain curdlan gum dispersion liquid,

[0055] Sodium hydroxide is dissolved in water 2 to form an alkaline solution,

[0056] Slowly add the alkali solution into the curdlan dispersion and stir until the curdan is completely dissolved into a gel solution.

[0057] 2. Acidic molding fluid components

[0058] citric acid

1%

water

99%

[0059] Dissolve citric acid in water to become an acidic forming liquid.

[0060] 3. Drop the gel solution into the acidic forming liquid to form low-level gel particles.

[0061] 4. Heat the low-level gel particles to 95-130°C to form the available high-level gel particles.

[0062] The water described in the aforementioned preferred embodiment is drinking water; the alkaline solution can also be trisodium phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com