Imitating handmade full-automatic raw twisted cruller production line

A fully automatic, manual imitation technology, which is applied in the direction of dough sheeting machine/rolling machine/rolling pin, baking, dough forming and cutting combination, which can solve the problem of not being able to realize fully automatic production and imitation Manual processing effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

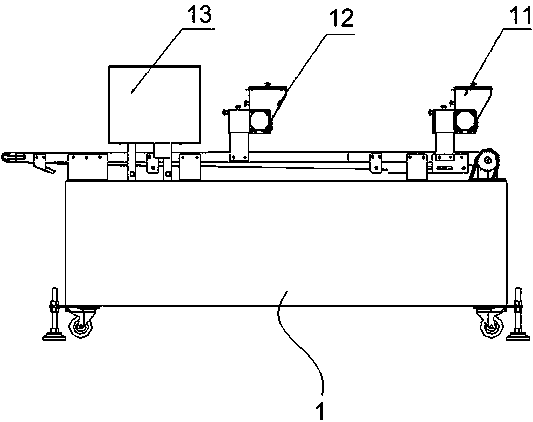

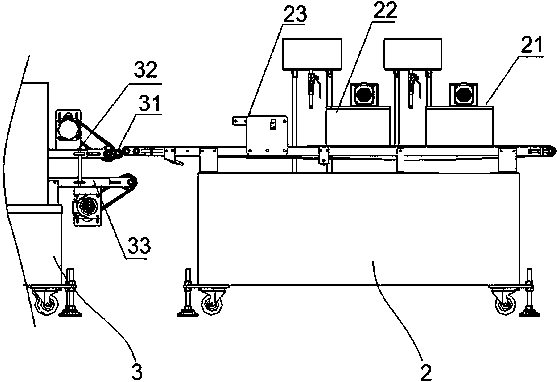

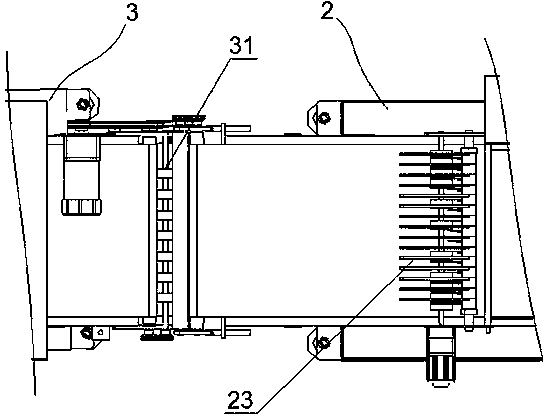

[0024] A manual imitation full-automatic deep-fried dough stick embryo production line at least includes a horizontal reciprocating noodle rolling device 1, an interval brush oil-water cutting device 2, a stacking creasing device 3, a stretching device 4, and a cutting device 5.

[0025] Such as figure 1 Shown, horizontally reciprocating noodle rolling device 1 comprises conveyer belt mechanism, is installed on the belt dusting mechanism or refueling device 11 on the conveyer belt mechanism, flour spreading mechanism or refueling device 12 and reciprocating noodle rolling mechanism 13 on the belt, spreads on the belt The powder mechanism or oiling device 11 sprinkles flour or oil on the conveying surface of the conveyor belt, and the flour spreading mechanism or oiling device 13 sprinkles flour or oil on the conveyed noodle raw materials, and the reciprocating noodle rolling mechanism 13 applies to the noodle raw materials. Reciprocating rolling that is not parallel to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com