Patents

Literature

101results about How to "Uniform elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

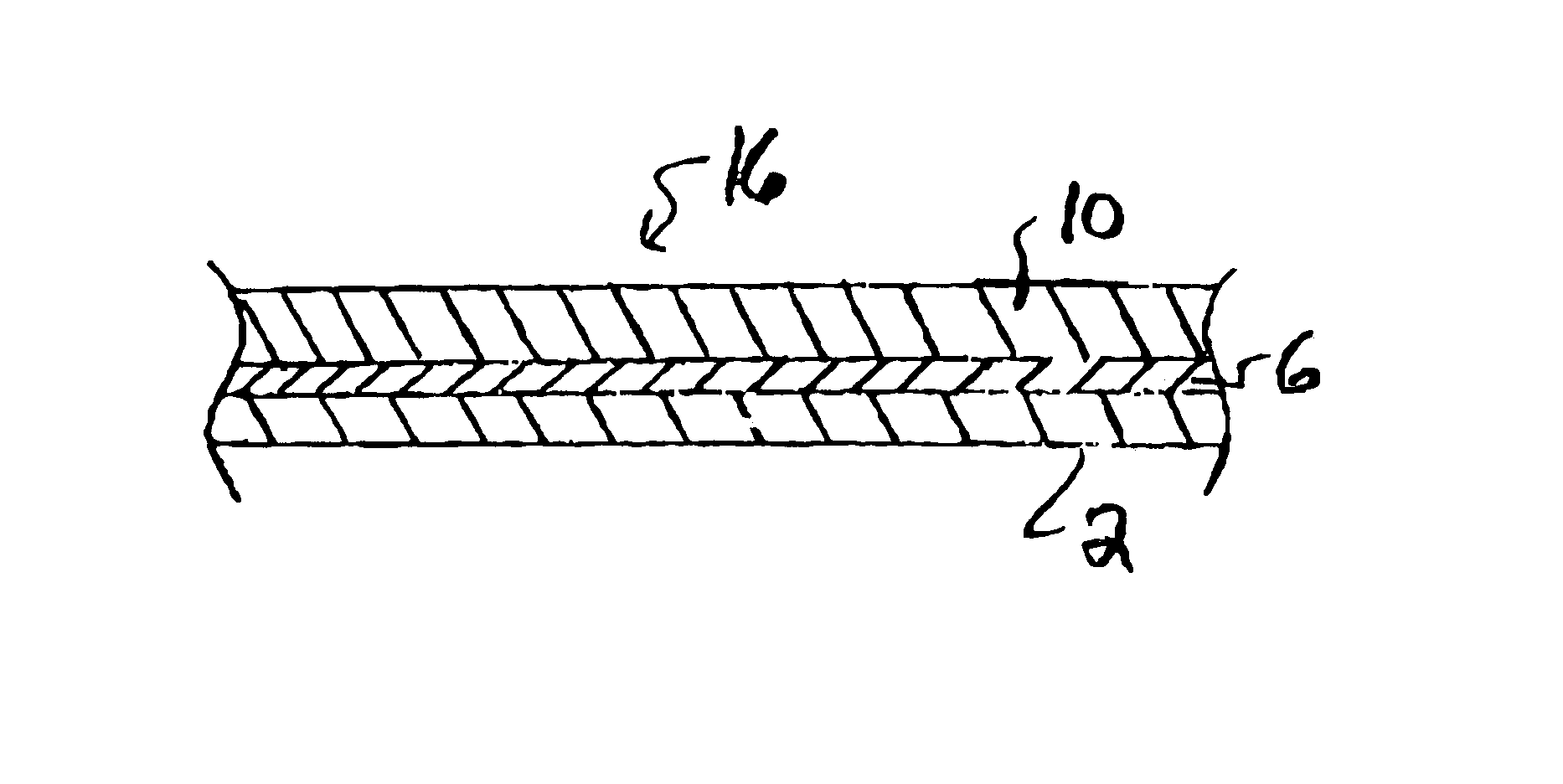

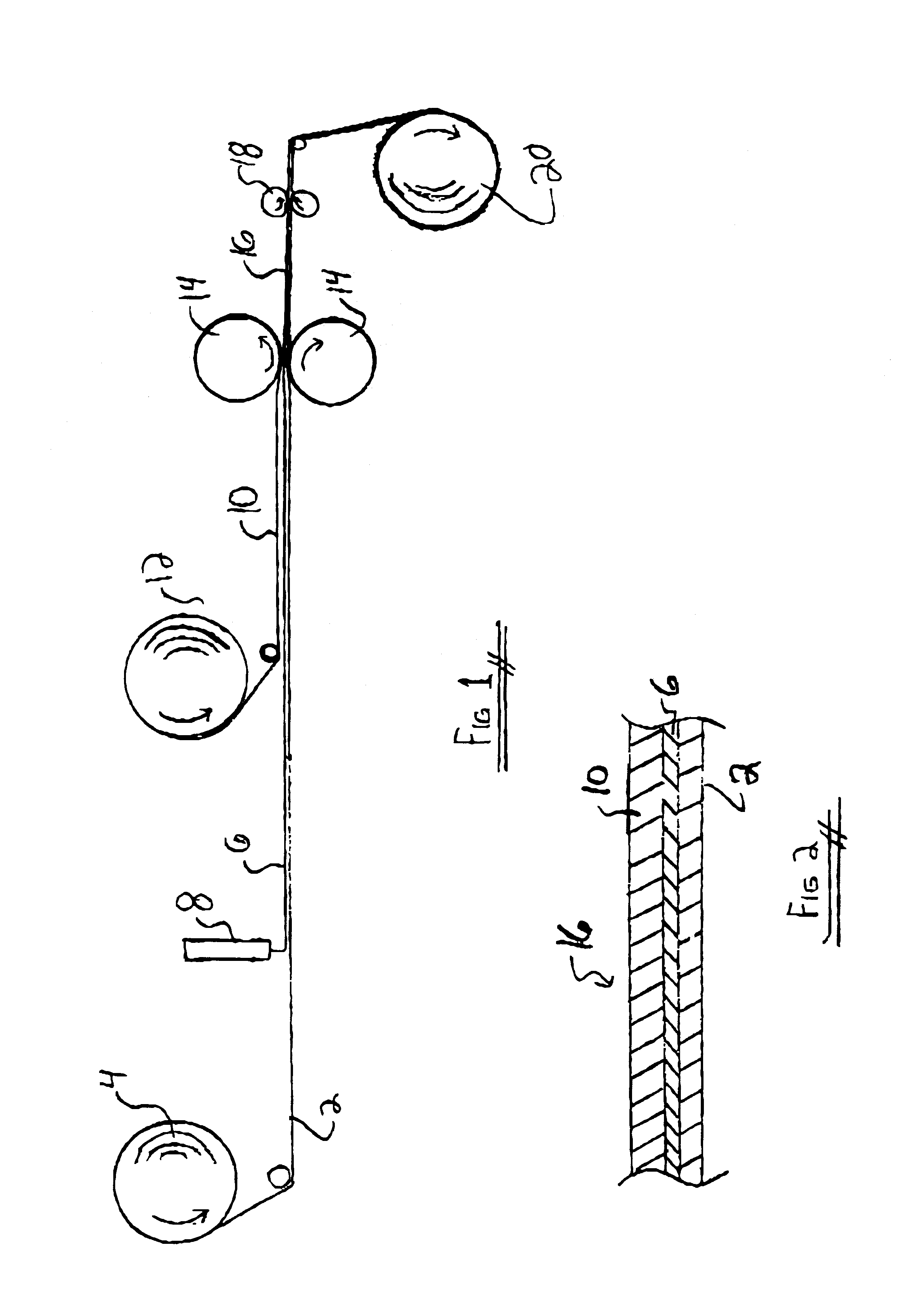

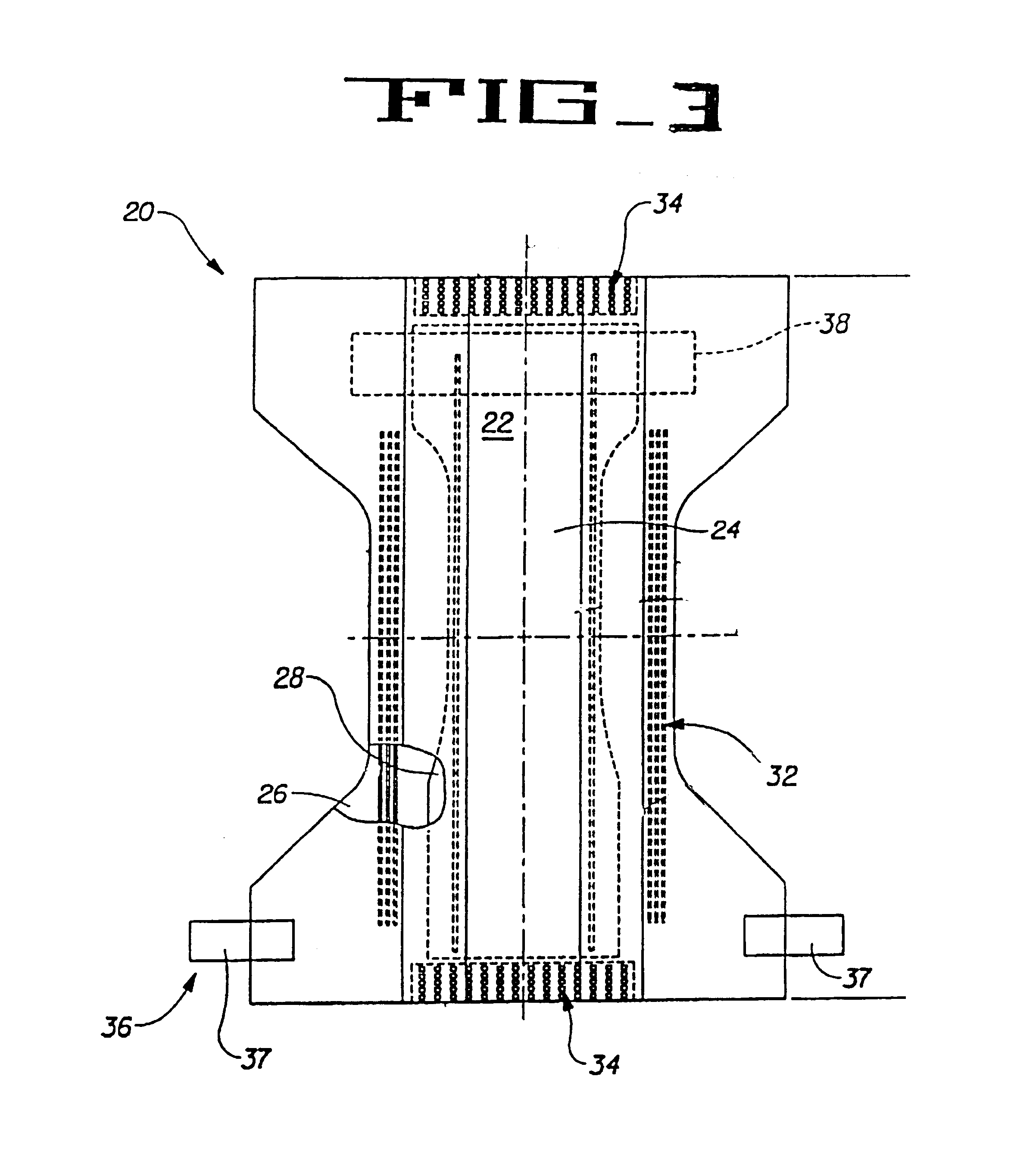

Thermocalendered non-woven elastic laminate

InactiveUS6726983B2High degreeUniform elongationDecorative surface effectsBaby linensPolymer scienceThin membrane

Owner:AVINTIV SPECIALTY MATERIALS INC

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

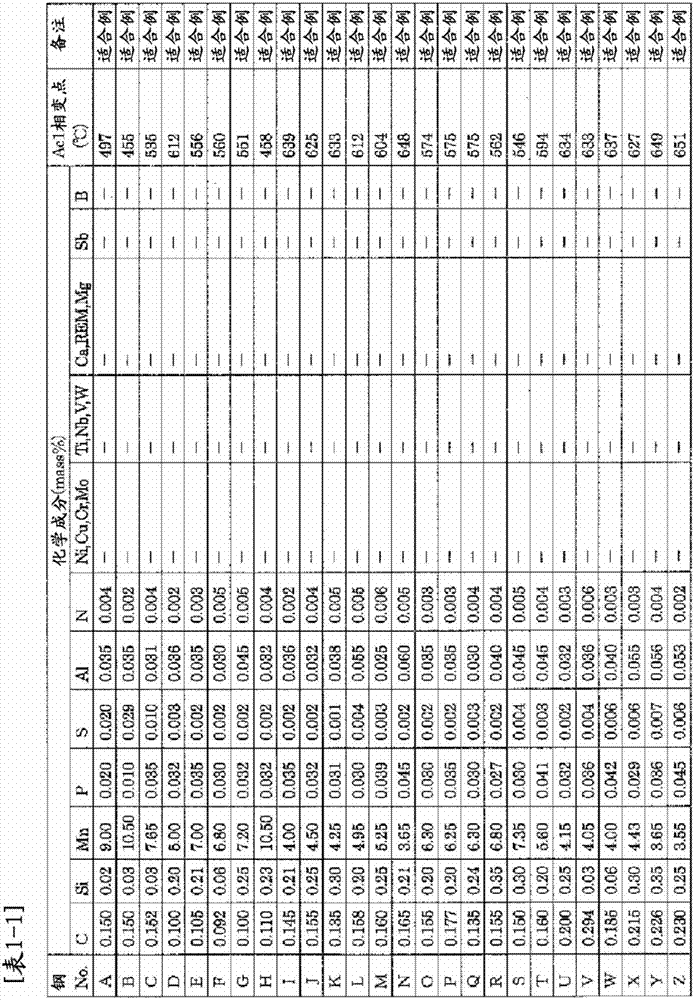

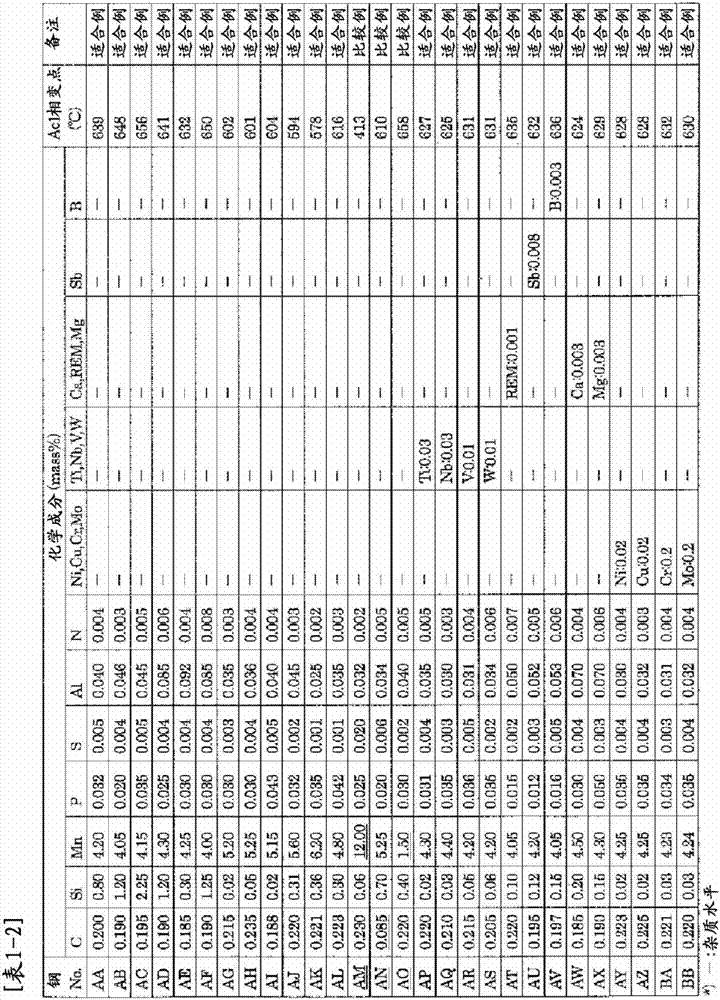

High-strength cold-rolled steel sheet excellent in uniform elongation and method for manufacturing same

A high-strength cold-rolled steel sheet excellent in uniform elongation, including in percent by mass:0.10-0.28% of C;1.0-2.0% of Si; and1.0-3.0% of Mn,and the structures of the same having the space factors below to the entire structure:30-65% of bainitic ferrite;30-50% of polygonal ferrite; and5-20% of residual austenite.

Owner:KOBE STEEL LTD

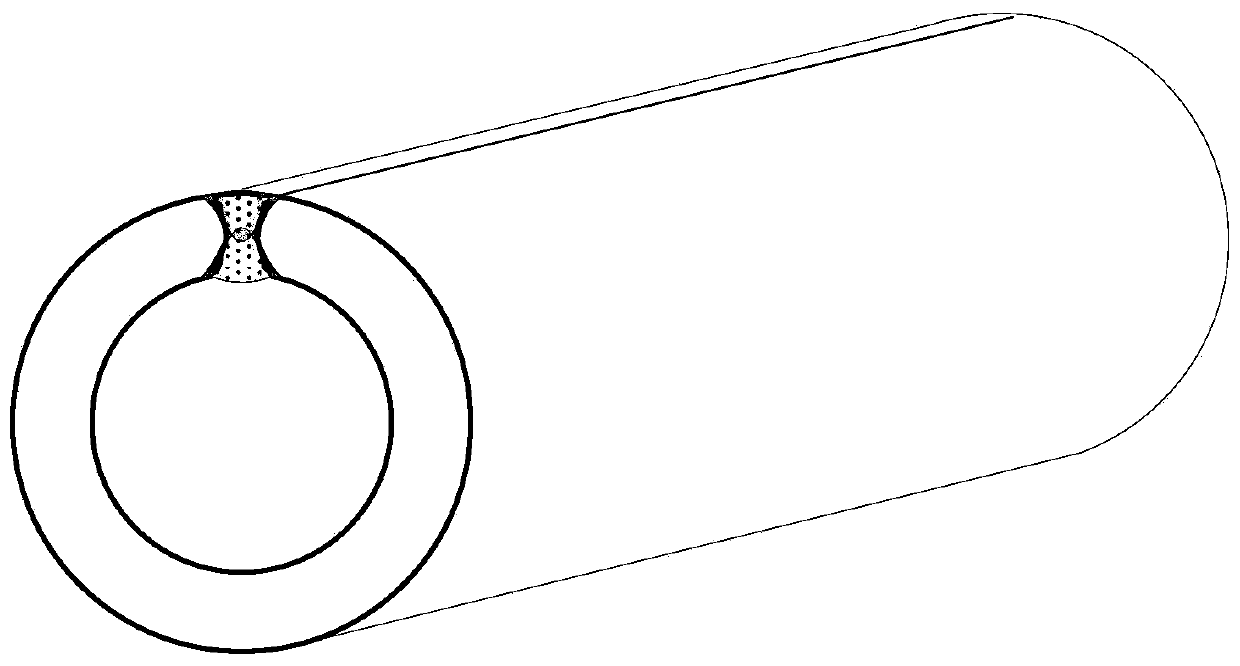

Steel used for solid expandable casing of oil and gas well and manufacturing method of expandable casing

ActiveCN101805871APerformanceHigh elongationTemperature control deviceMetal rolling arrangementsAlloyUltimate tensile strength

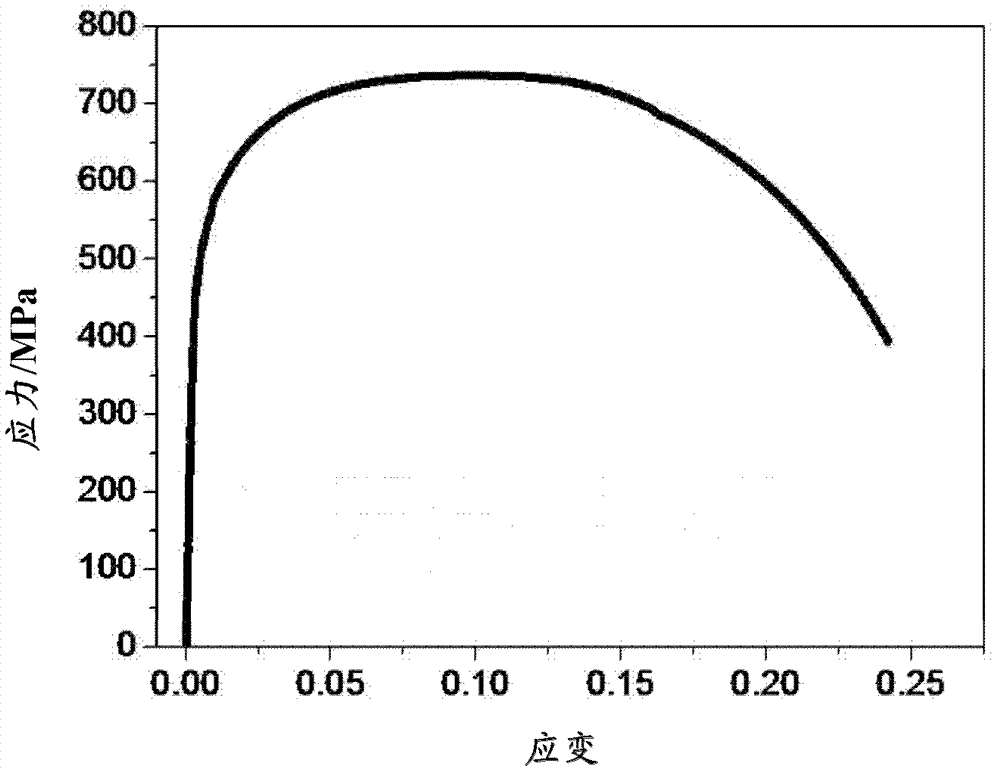

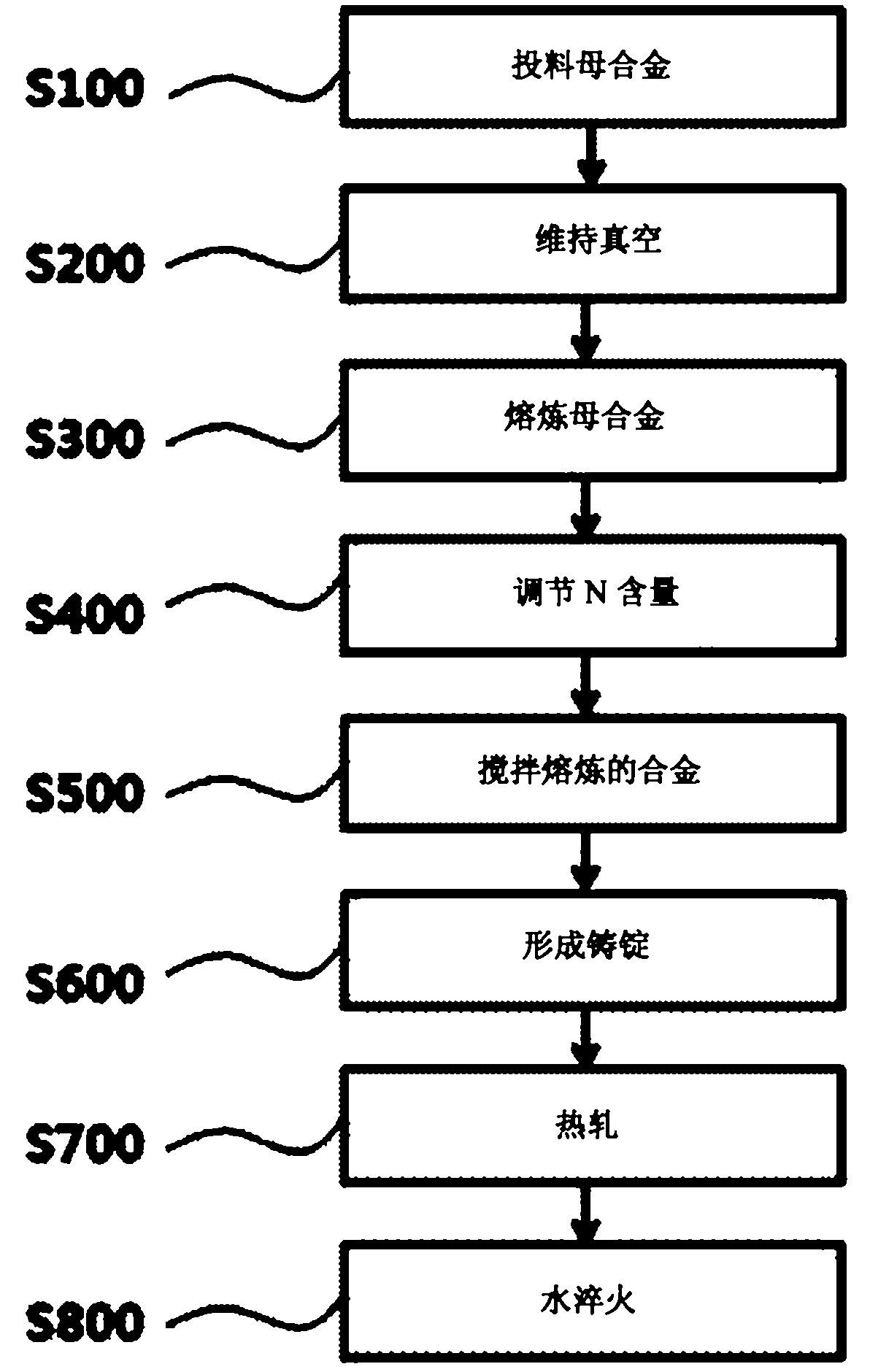

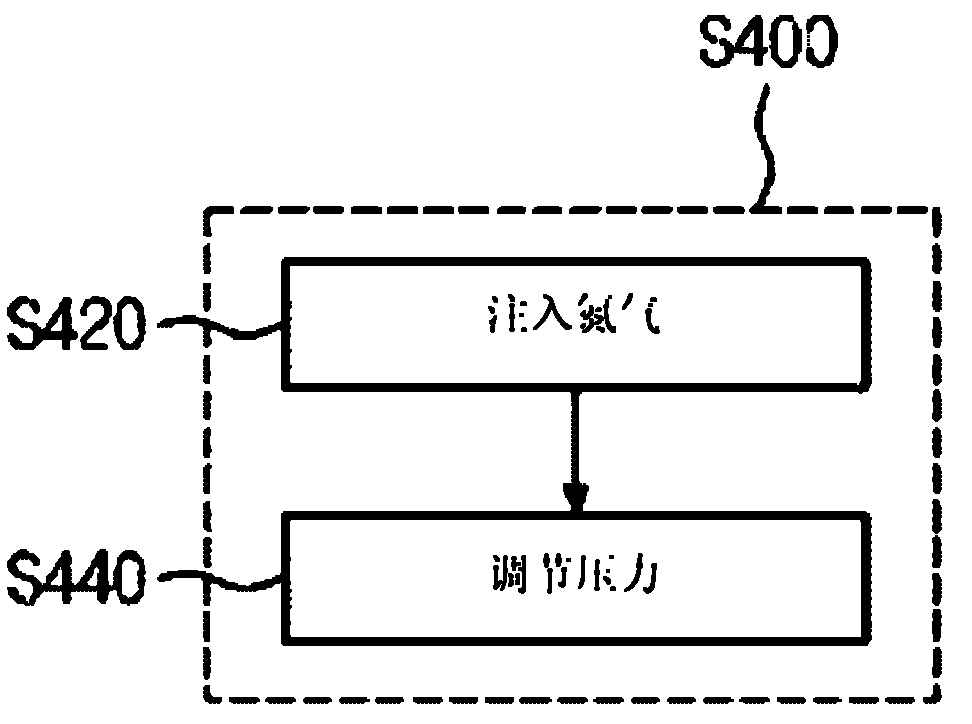

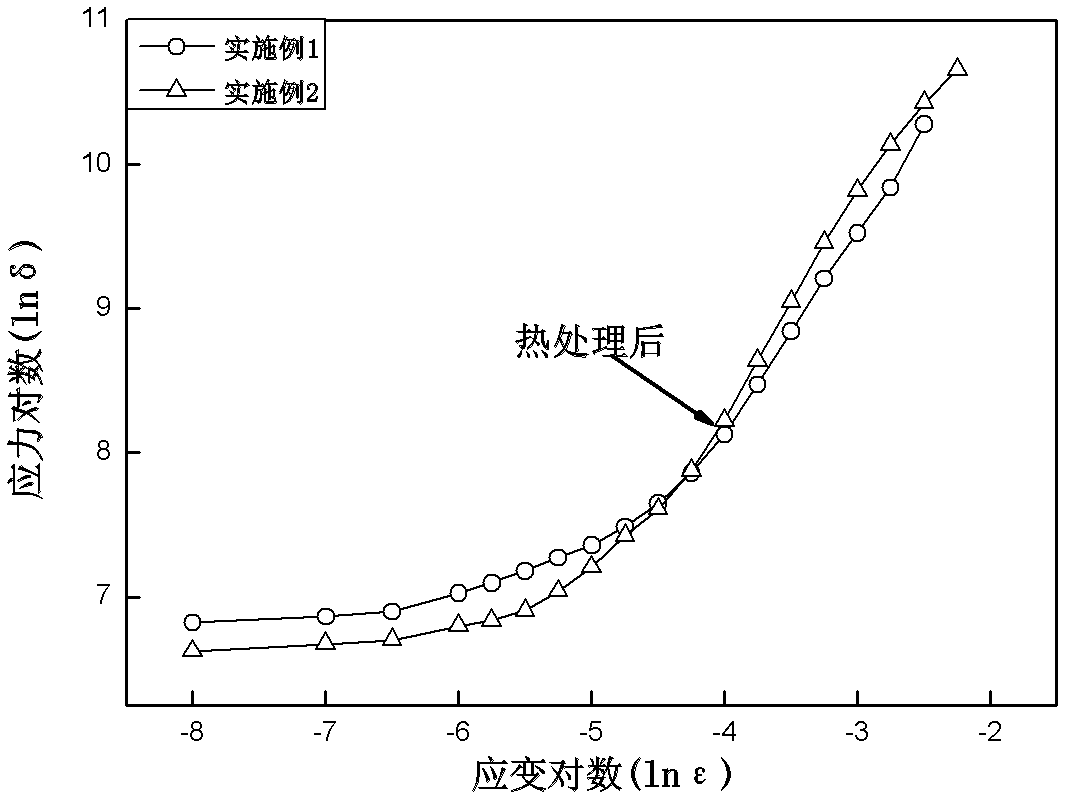

The invention relates to a steel used for a solid expandable casing of an oil and gas well and a manufacturing method of the expandable casing, which are applied to prepare the expandable casing of the oil and gas well in oil and gas industry. The steel alloy material used for the solid expandable casing of the oil and gas well comprises the following components in percentage by mass: 0.1-0.3% of C, 1.5-3.5% of Mn, 1-2.5% of Si, 0.1-3% of Al, less than or equal to 0.010% of P, less than or equal to 0.005 % of S, 0.003-0.010% of Ca, less than or equal to 0.0007% of N and the balance of Fe. The preparation method comprises the steps of vacuum melting, continuous casting and homogenizing annealing; hot rolled plate coils are prepared via controlling rolling and cooling, and the hot rolled plate coils are used for producing straight seam resistance welded steel pipes; and expandable pipe materials can be obtained via two stages of isothermal heat treatment. Threads are processed at both ends of each steel pipe. The invention has the effects that the expandable casing has the characteristics of high uniform elongation, high plasticity, low yield strength, low yield ratio and the like before expansion, and has high strength, enough plasticity, good welding seam quality and performance after expansive deformation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

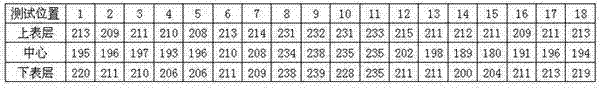

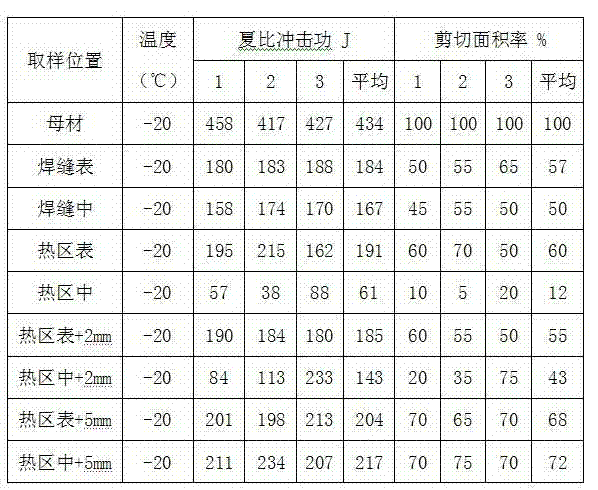

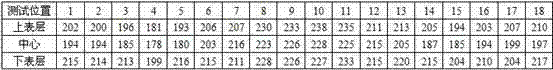

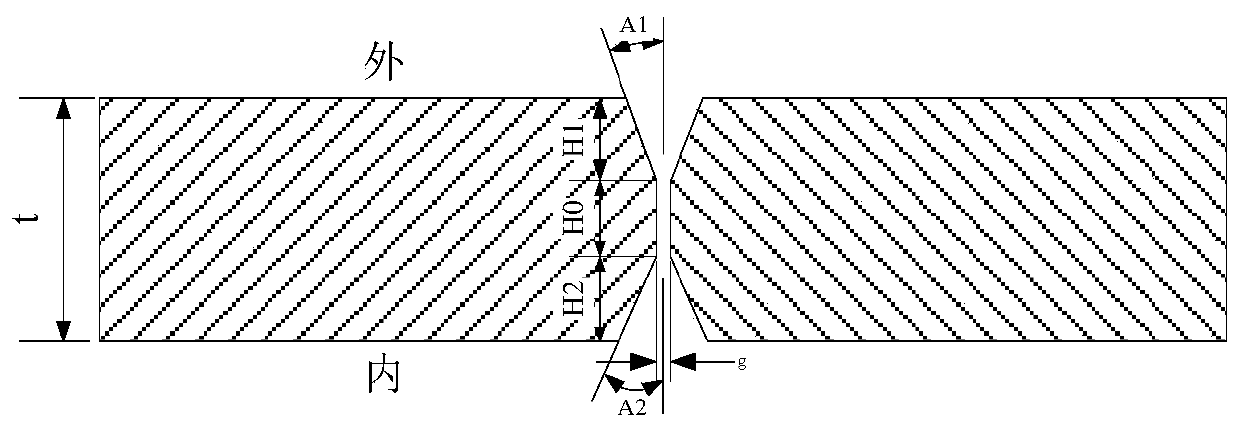

Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

ActiveCN102310119AUniform deformationUniform performanceArc welding apparatusUltrasound testMagnetic particle inspection

The invention discloses a manufacturing method of an X65 pipeline steel longitudinal submerged arc welded pipe for undersea use. The manufacturing process of the steel pipe comprises: edge milling, edge prebending, JCO moulding, prewelding, inside welding, outside welding, first ultrasonic inspection, first x-ray inspection, mechanical expanding, hydrostatic test, chamfering, groove machining, second ultrasonic inspection, second x-ray inspection, pipe end magnetic particle inspection and appearance quality inspection. The method of the invention makes each part of the X65 steel grade ongitudinal submerged arc welded pipe with a diameter of phi 762mm and wall thickness of 28.6-30.2mm has uniform deformation and performances in the process of JCO moulding; the method in the invention solves the problem that local heating of the steel pipe during welding results in severely reduced strength and toughness as well as elongation; the method provided in the invention also provides a solution to the problems of increased strength and reduced toughness and uniform elongation caused by work hardening during steel pipe mechanical expanding.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

High-Strength Cold-Rolled Steel Sheet Excellent in Uniform Elongation and Method for Manufacturing Same

A high-strength cold-rolled steel sheet excellent in uniform elongation, including in percent by mass:0.10-0.28% of C;1.0-2.0% of Si; and1.0-3.0% of Mn,and the structures of the same having the space factors below to the entire structure:30-65% of bainitic ferrite;30-50% of polygonal ferrite; and5-20% of residual austenite.

Owner:KOBE STEEL LTD

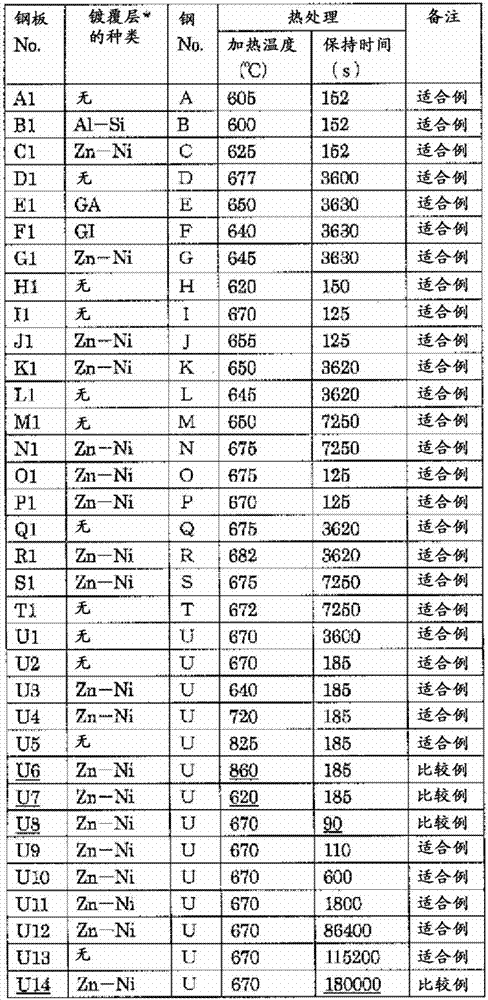

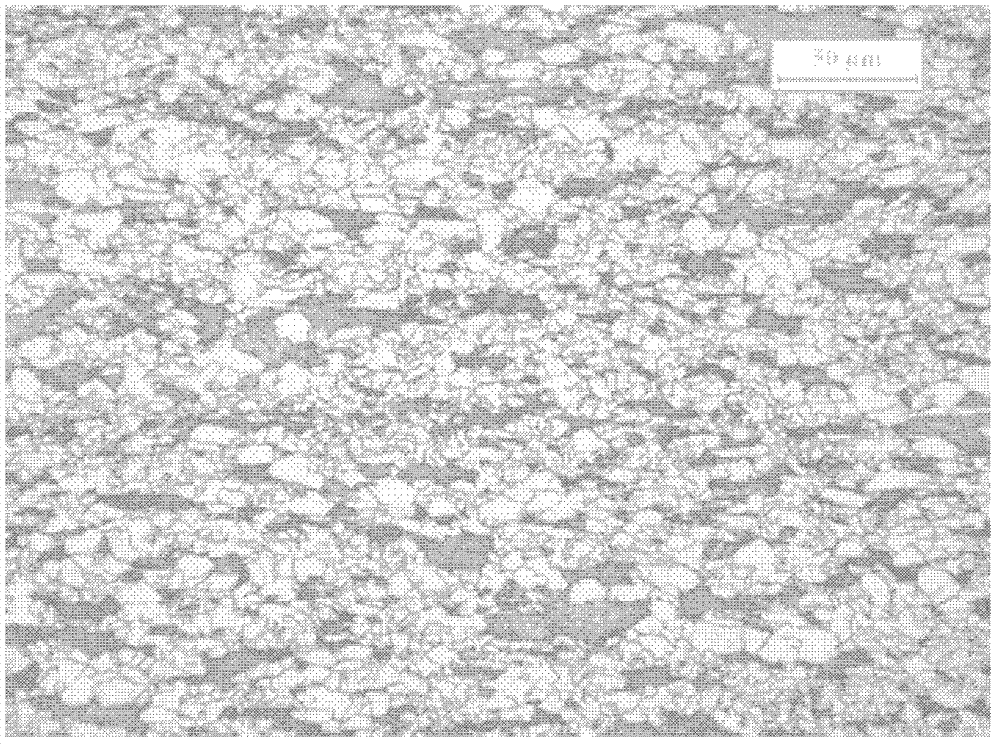

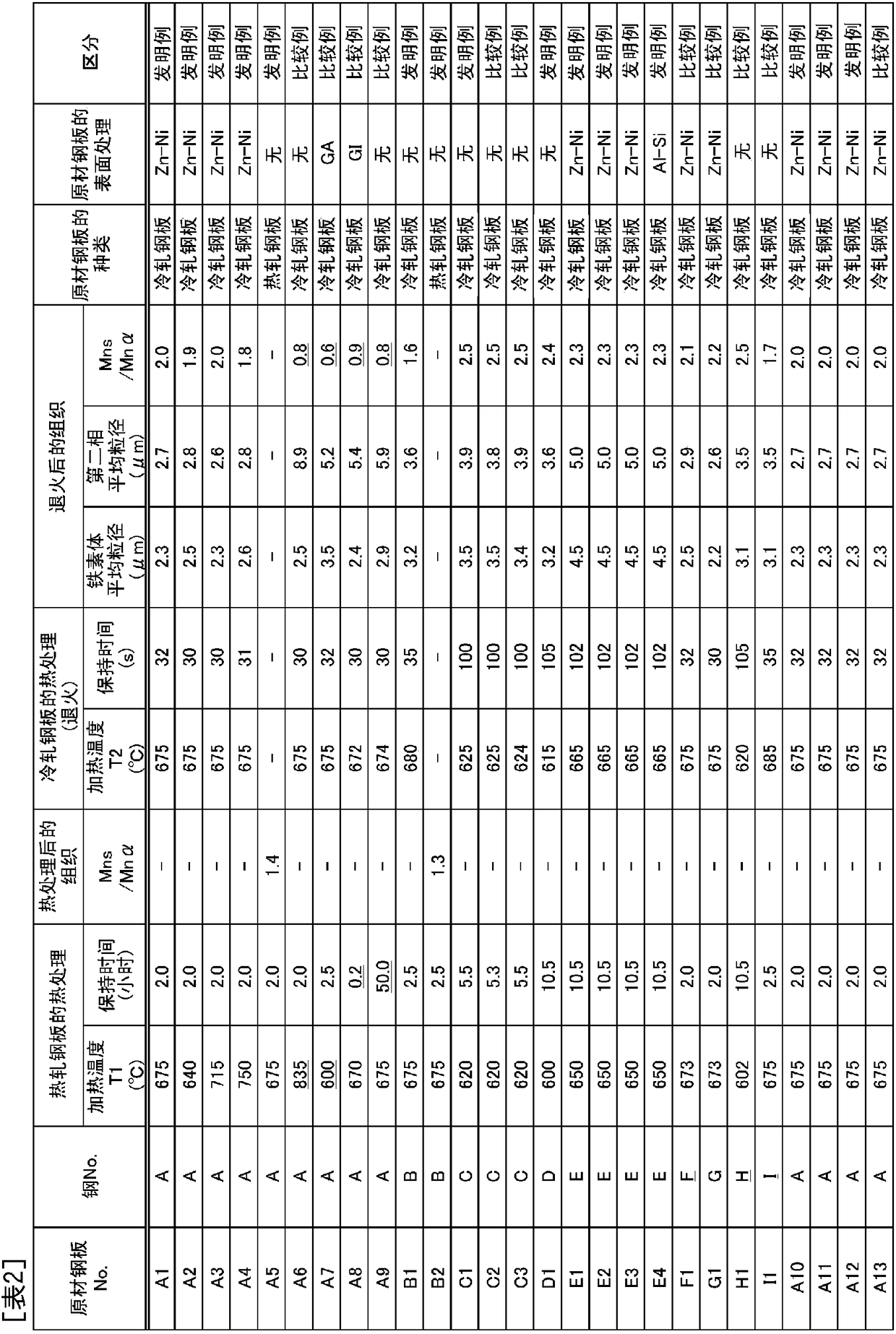

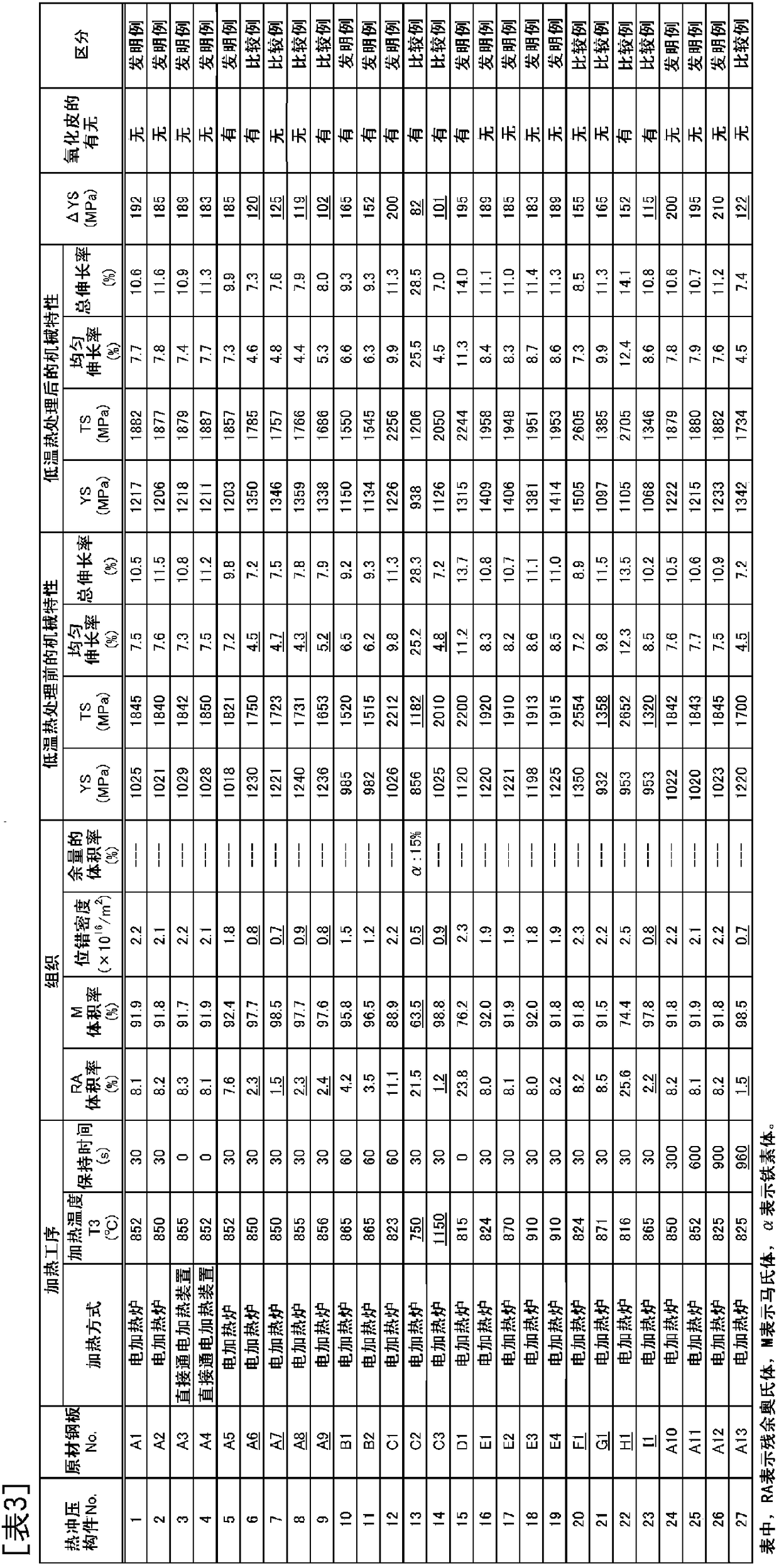

High-strength hot-pressing member and method for producing same

ActiveCN107109553ASimple and cheap to manufactureRealize thin wallHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

Owner:JFE STEEL CORP

High-strength pipeline steel, steel pipe and manufacture method thereof

ActiveCN102953018ALow yield ratioHigh strain hardening indexTemperature control deviceCooling temperatureSteel tube

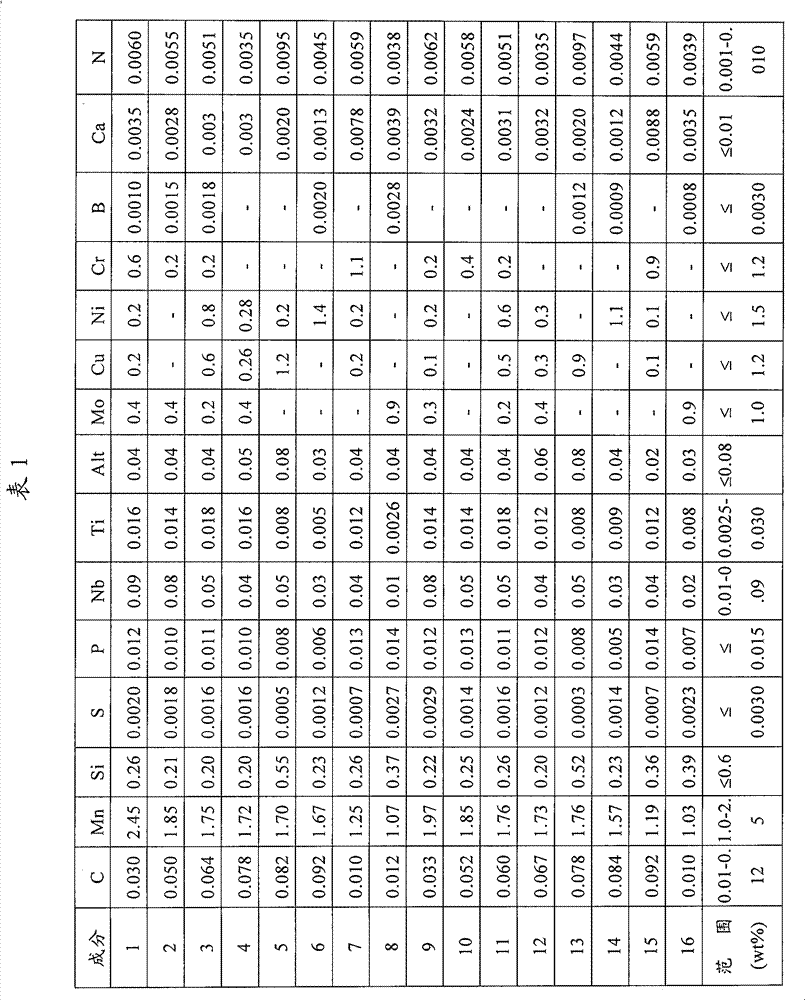

The invention relates to a high-strength pipeline steel which comprises the following chemical components by weight percent: 0.01-0.12 % of C, 1.0-2.5 % of Mn, less than or equal to 0.6 % of Si, less than or equal to 0.0030 % of S, less than or equal to 0.015 % of P, 0.01-0.09 % of Nb, 0.0025-0.030 % of Ti, less than or equal to 0.08 % of Alt, less than or equal to 1.0 % of Mo, less than or equal to 1.2 % of Cu, less than or equal to 1.5 % of Ni, less than or equal to 1.2 % of Cr, less than or equal to 0.0030 % of B, less than or equal to 0.01 % of Ca, 0.001-0.010 % of N, and the balance being iron and unavoidable impurities. The steel is polygonal ferrite and bainite duplex structure. A manufacture method of the high-strength steel pipe comprises heating slab with a temperature of 1100 to 1250 DEG C, rolling a non-recrystallization region with a starting temperature of 750 to 920 DEG C and a terminating temperature of 720 to 840 DEG C, two-stage cooling under control with an ACC terminating cooling temperature of 200 to 580 DEG C and a cooling rate of 5 to 30 DEG C per second, and manufacturing the pipe by using a UOE technology with a compression rate of 0.1 to 0.5 % and a diameter-expanding rate of 0.5 to 1.5 %. The obtained steel pipe can meet demands of low yield ratio and high uniform elongation.

Owner:BAOSHAN IRON & STEEL CO LTD

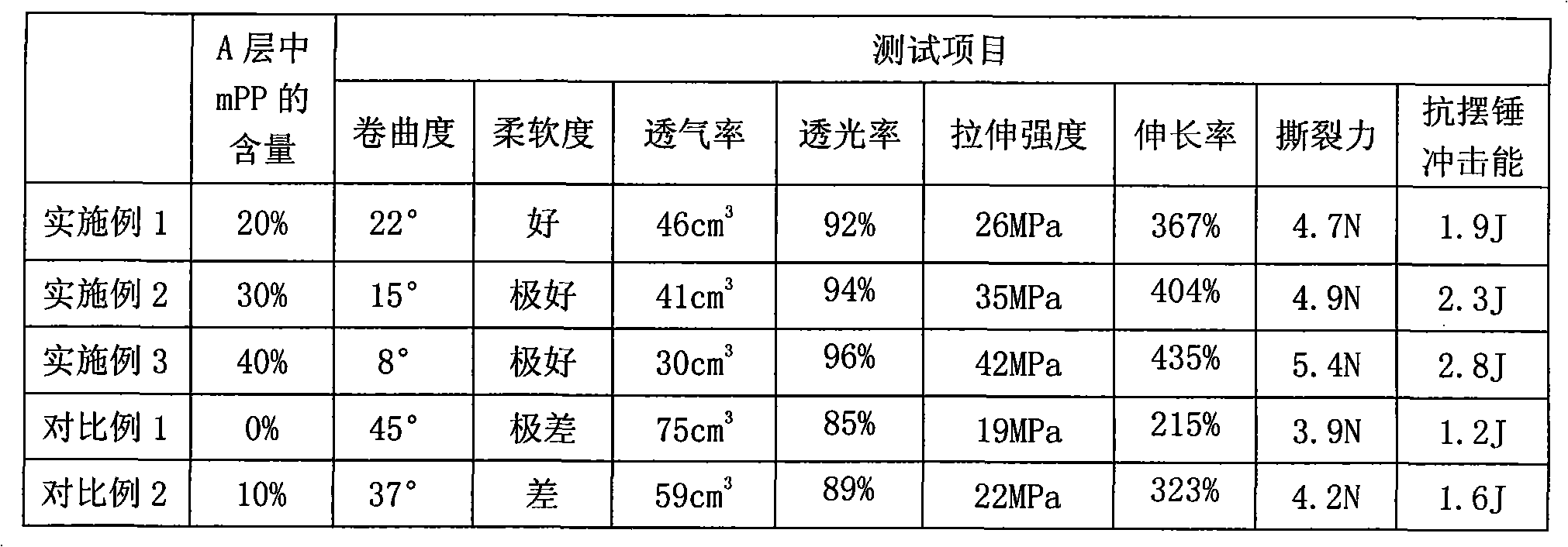

High temperature resistance film for blister package of medical equipment and preparation method thereof

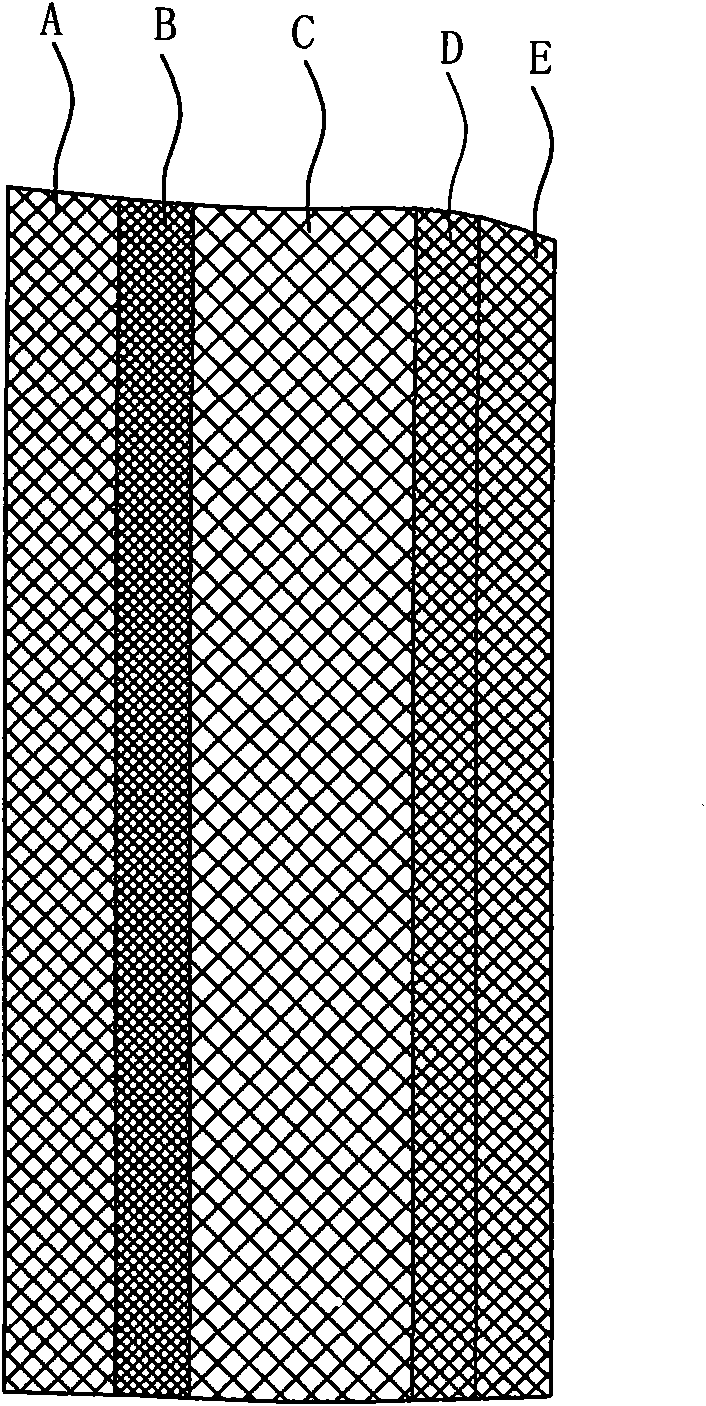

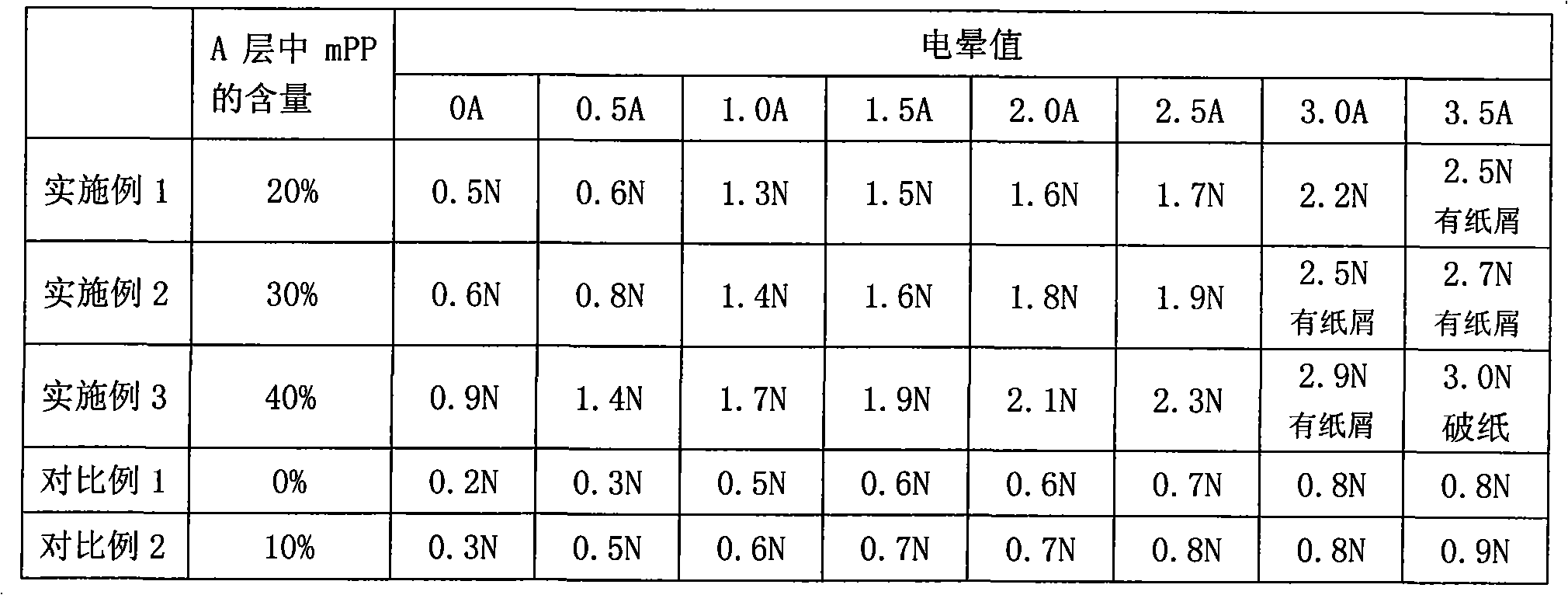

InactiveCN101607616AChange the phenomenon of weak heat sealIncrease the effect of sterilization penetrationFlexible coversWrappersMedical equipmentEngineering

The invention relates to a high temperature resistance film for blister package of medical sterilization equipment and a preparation method thereof. The first layer of the film is a heat-sealing layer A, and comprises blending resin of block copolymerized polypropylene and metallocene catalyzed polypropylene (mPP), wherein, the melting point of the block copolymerized polypropylene is more than 131 DEG C; the dosage of the mPP accounts for 20 to 50 percent of the blending rein by weight; the second layer of the film is a secondary inner layer B, and comprises homopolymerized polypropylene; the third layer of the film is an intermediate layer C, and comprises homopolymerized polypropylene; the fourth layer of the film is a binding layer D, and comprises polypropylene grafted by maleic anhydride; and the fifth layer is a weather resistance layer E, and comprises nylon 6 or 66. The film is prepared by adopting a bottom blowing water cooling type co-extrusion process or a casting method, wherein, after plastic is sufficiently melted, is inflated or cast by a die, the plastic is cooled at water temperature of between 15 and 18 DEG C. The preparation method is simple, and the product can endure high temperature steam sterilization for long time, and has good heat-sealing performance of dialyzing paper.

Owner:NINGBO HUAFENG PACKAGE

Manufacturing method of X70 large-deformation steel fire-bent pipe

InactiveCN103088270AUniform tissueOrganizational stabilityFurnace typesHeat treatment furnacesTemperingHeat conservation

The invention discloses a manufacturing method of an X70 large-deformation steel fire-bent pipe. The manufacturing method comprises the following steps of 1, utilizing a straight seam submerged-arc welding steel pipe made by steel plate controlled-rolling and controlled-cooling as a base pipe, 2, carrying out medium-frequency induction heating bending of the main pipe by an integral heating quenching bending technology under the conditions of an induction heating temperature of 950 to 1050 DEG C and a feeding rate of 40 to 80mm / min, and cooling at a cooling rate greater than or equal to20DEG C / s by an external spray cooling method, and 3, putting the fire-bent pipe obtained by the step 2 into a heating furnace, carrying out integral heating at a temperature of 700 to 850 DEG C, carrying out heat preservation for 1.0 to 2.0 hours, carrying out quenching, and carrying out integral tempering under the conditions of a tempering temperature of 350 to 550 DEG C and tempering heat preservation time of 1.5 to 2.5 hours. The X70 large-deformation steel fire-bent pipe obtained by the manufacturing method has bent pipe strength and toughness satisfying X70 standard requirements, a high longitudinal tensile stress ratio, a high uniform elongation percentage, and a good longitudinal deformation capability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

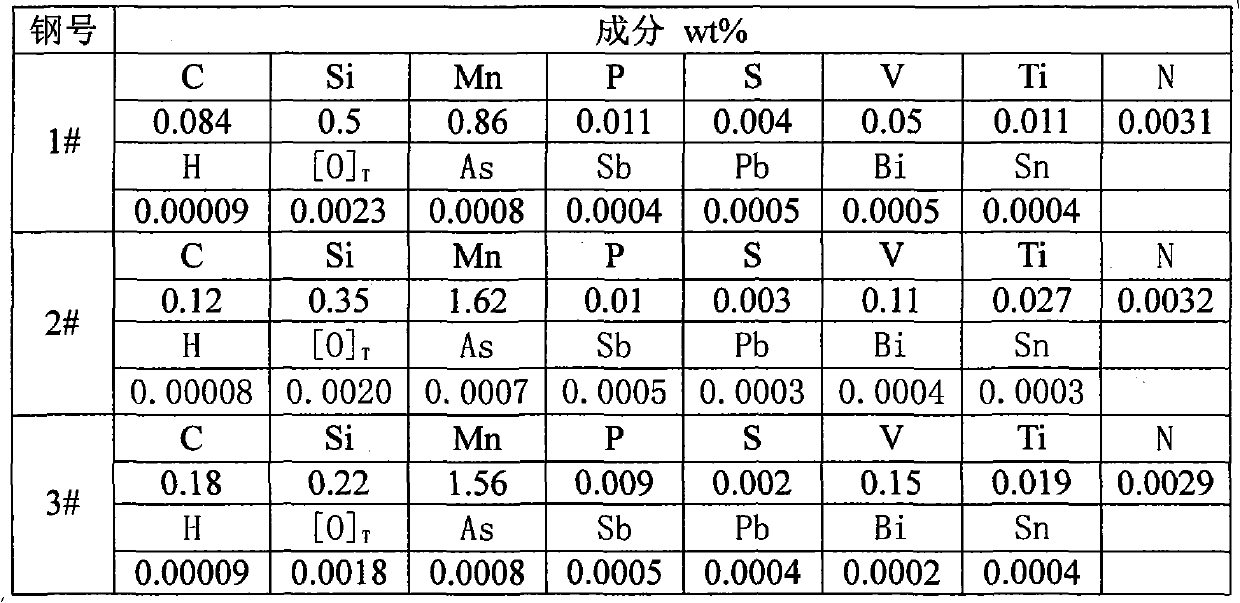

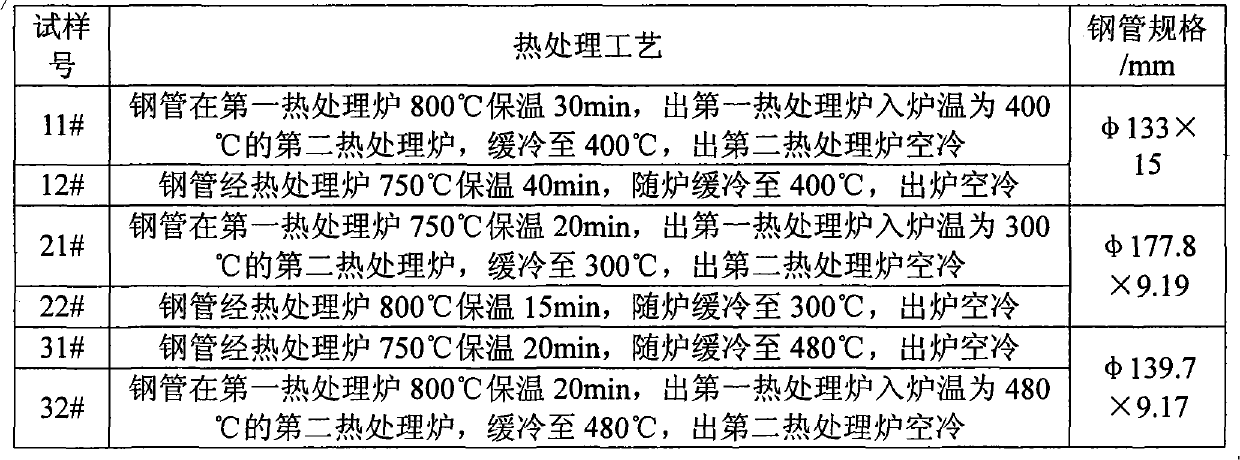

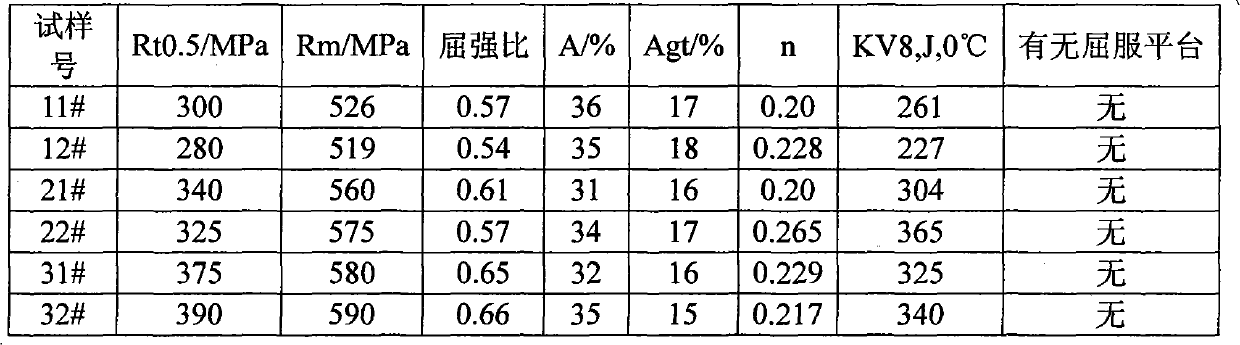

Economical seamless oil well pipe for expansion pipe and manufacturing method thereof

ActiveCN102022086AHigh elongationUniform elongationDrilling rodsManufacturing convertersChemical compositionHeat penetration

The invention provides an economical seamless oil well pipe for an expansion pipe and a manufacturing method thereof. The oil well pipe comprises the following chemical components in percentage by weight: 0.08 to 0.18 percent of C, 0.2 to 0.5 percent of Si, 0.6 to 1.7 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.005 percent of S, 0.04 to 0.15 percent of V, 0.01to 0.03 percent of Ti and the balance of Fe and inevitable impurities. A heat treatment process in the manufacturing method comprises the following steps of: incompletely quenching a hot-rolled seamless pipe, controlling the temperature of a heating furnace at 750 to 800 DEG C, keeping the temperature of the steel pipe in the range of 30 to 40 DEG C higher than Ac1 and 30 to 40 DEG C lower than Ac3 between the two phase regions of ferrite and austenite, performing calculation at the heat penetration speed of 1mm / min, preserving the heat of the oil well pipes for 10 to 60 min after the hot-rolled oil well pipes with different wall thicknesses reach the temperature of the furnace, and then cooling the oil well pipes at the speed of not higher than 0.2 DEG C per second. In the economical seamless oil well pipe and the manufacturing method thereof, the manufacturability and expandability performance of the steel pipe, the mechanical properties of the expanded steel pipe and the manufacturing cost are taken into account.

Owner:ANGANG STEEL CO LTD

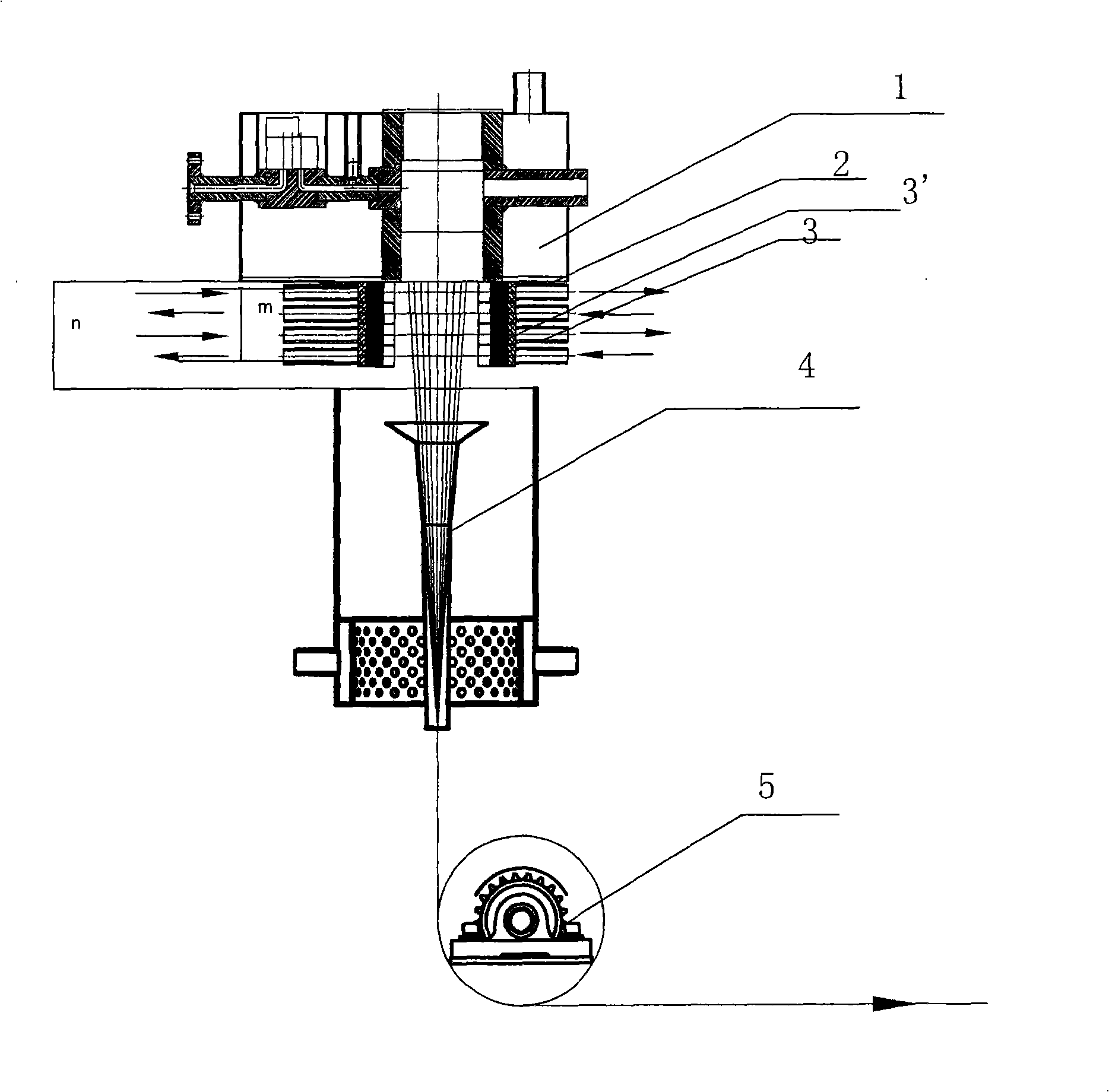

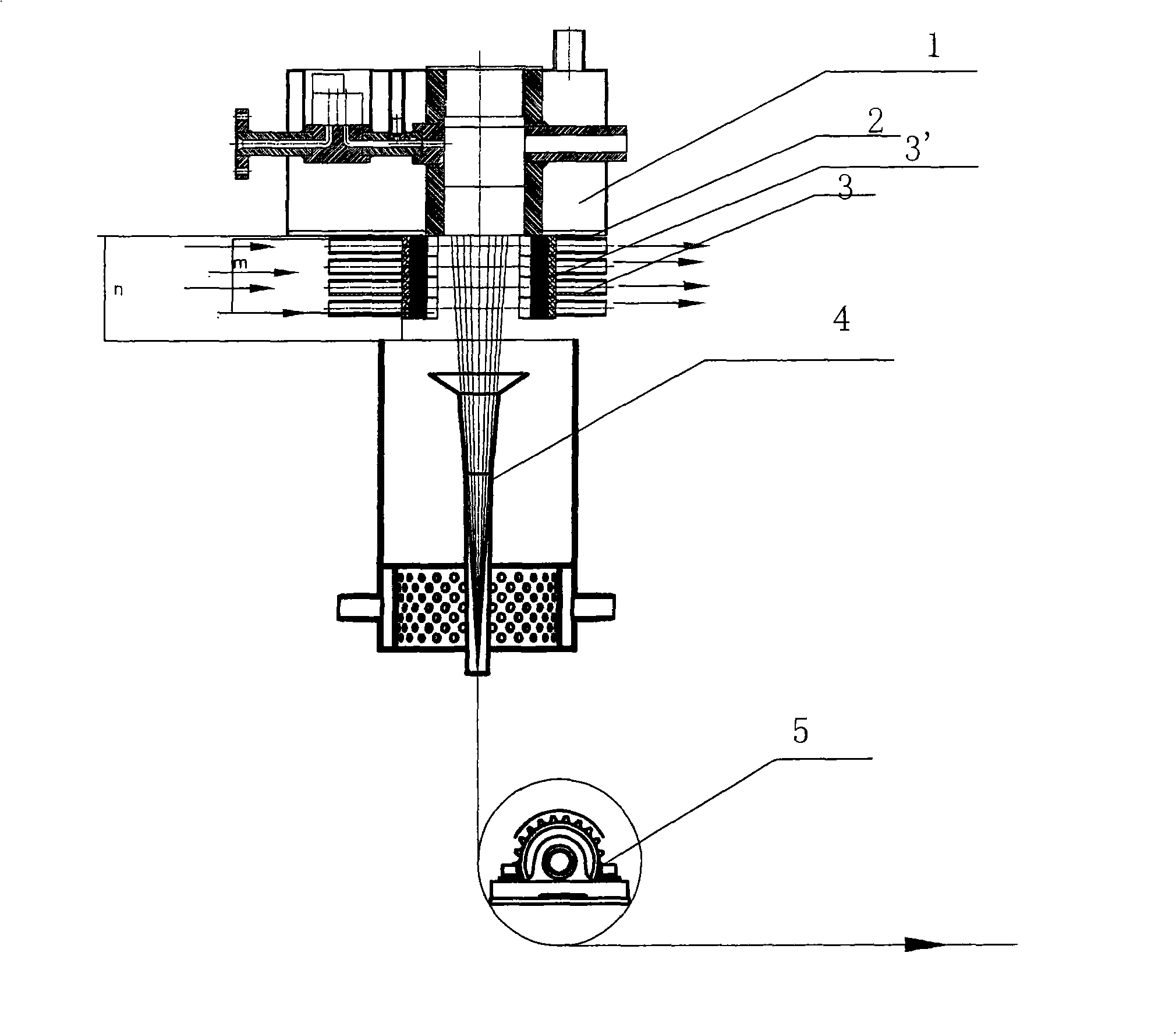

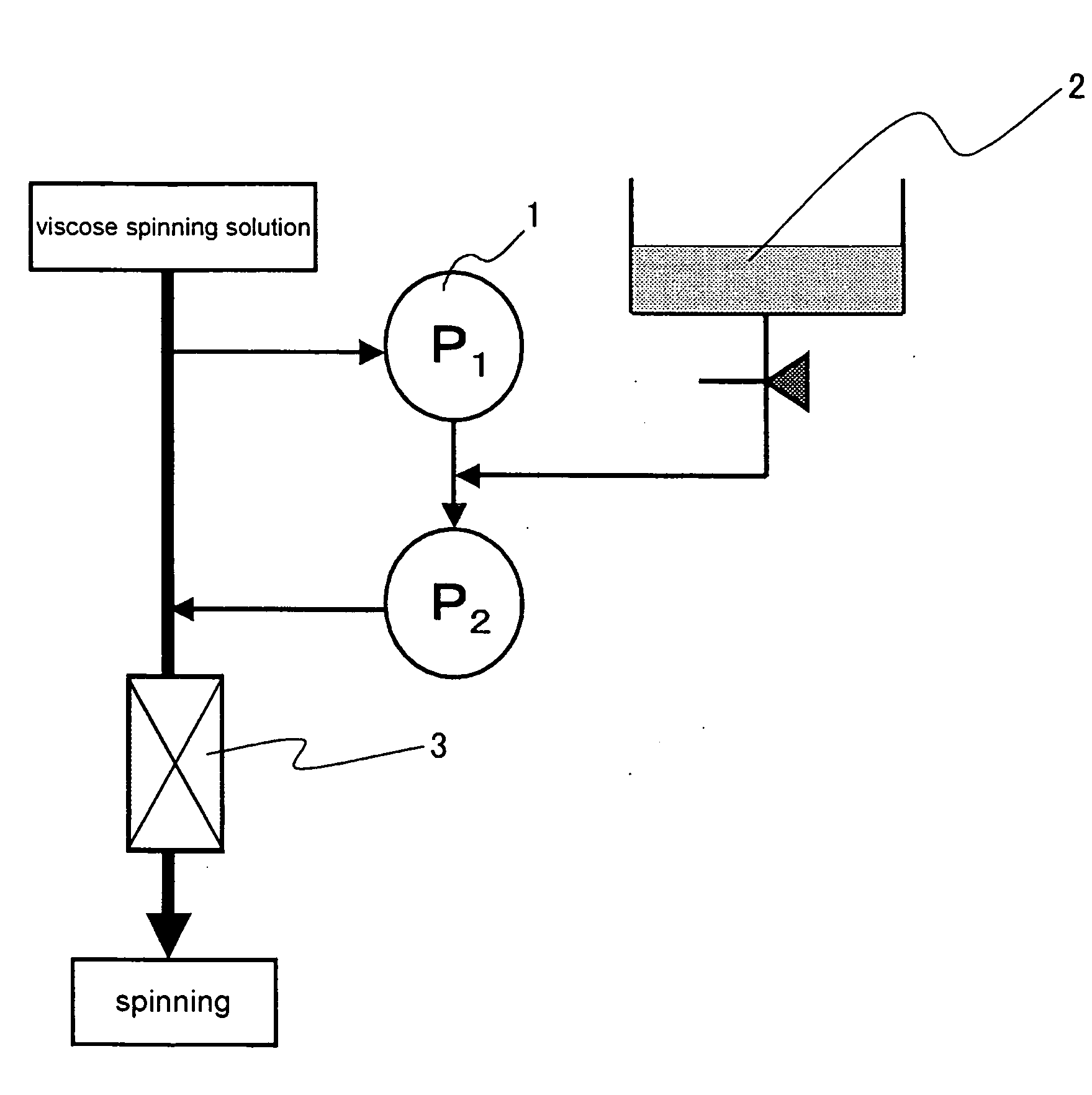

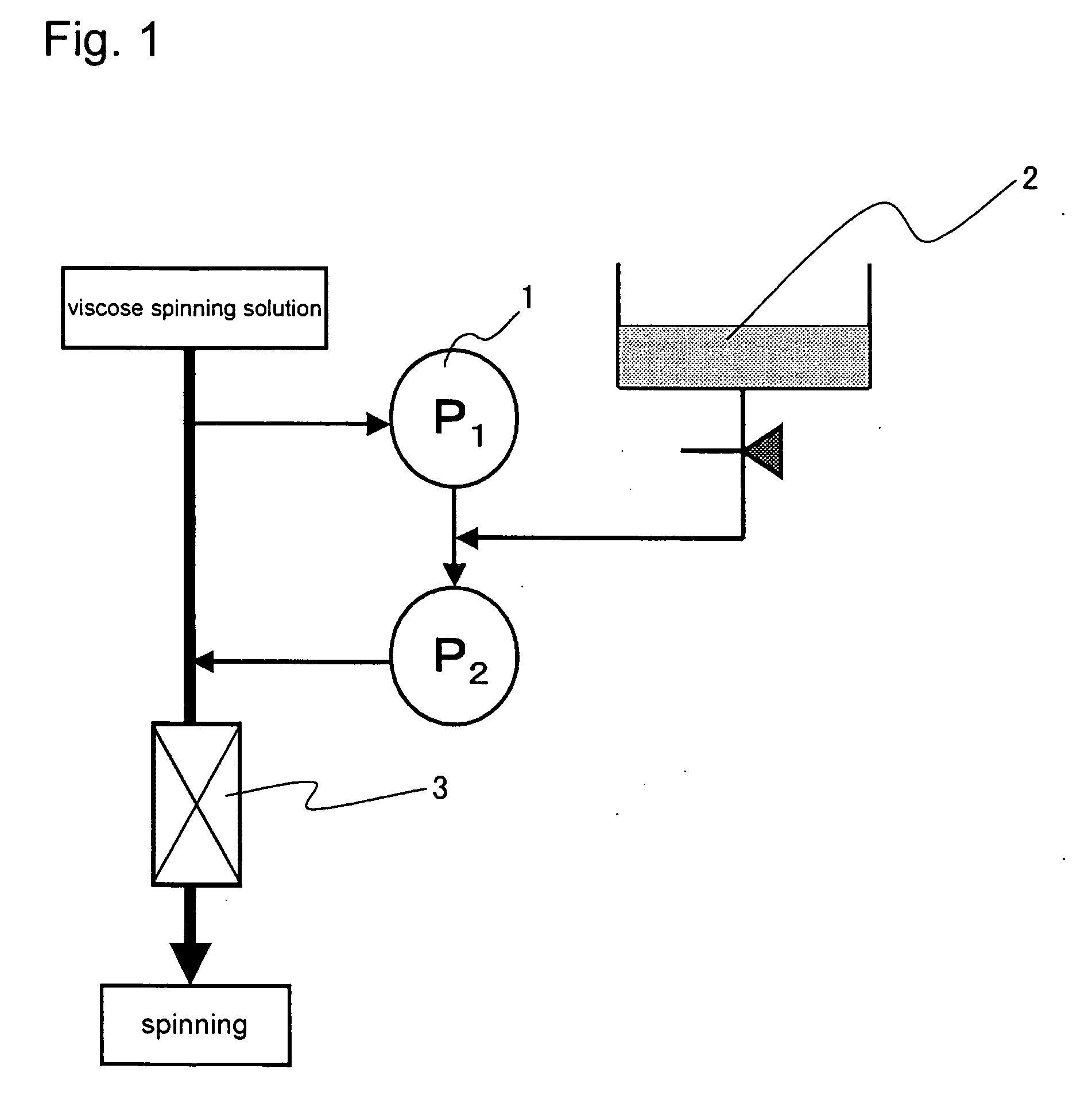

Spinning process of cellulose fibre and integration apparatus

ActiveCN101289762ACool evenlyChange flow rateSpinnerette packsArtificial filament physical treatmentOrganic solventCellulose fiber

The invention relates to a method for spinning cellulose fibers, comprising the following steps that: cellulose and organic solvent are mixed and dissolved, and mixture is obtained; the mixture enters into a section of air gap layer via a spinneret and ejected tows are blown and sucked by cooling air; the tows is brought into a precipitating bath via precipitating solution and led out by a spinning reel under the guidance of hauling equipment, wherein, the tows are blown and sucked by the cooling air by means of multi-layered laminar flow wind and the outlet velocity of the precipitating bath is between 20 and 150 meters per minute. The invention also relates to a device for completing the spinning method. By adoption of the spinning method and the spinning device, cellulose filaments or staple fibers obtained finally have uniform strength and elongation amount and the effect is also suitable for fibers with high or low size as well.

Owner:CHINESE TEXTILE ACAD

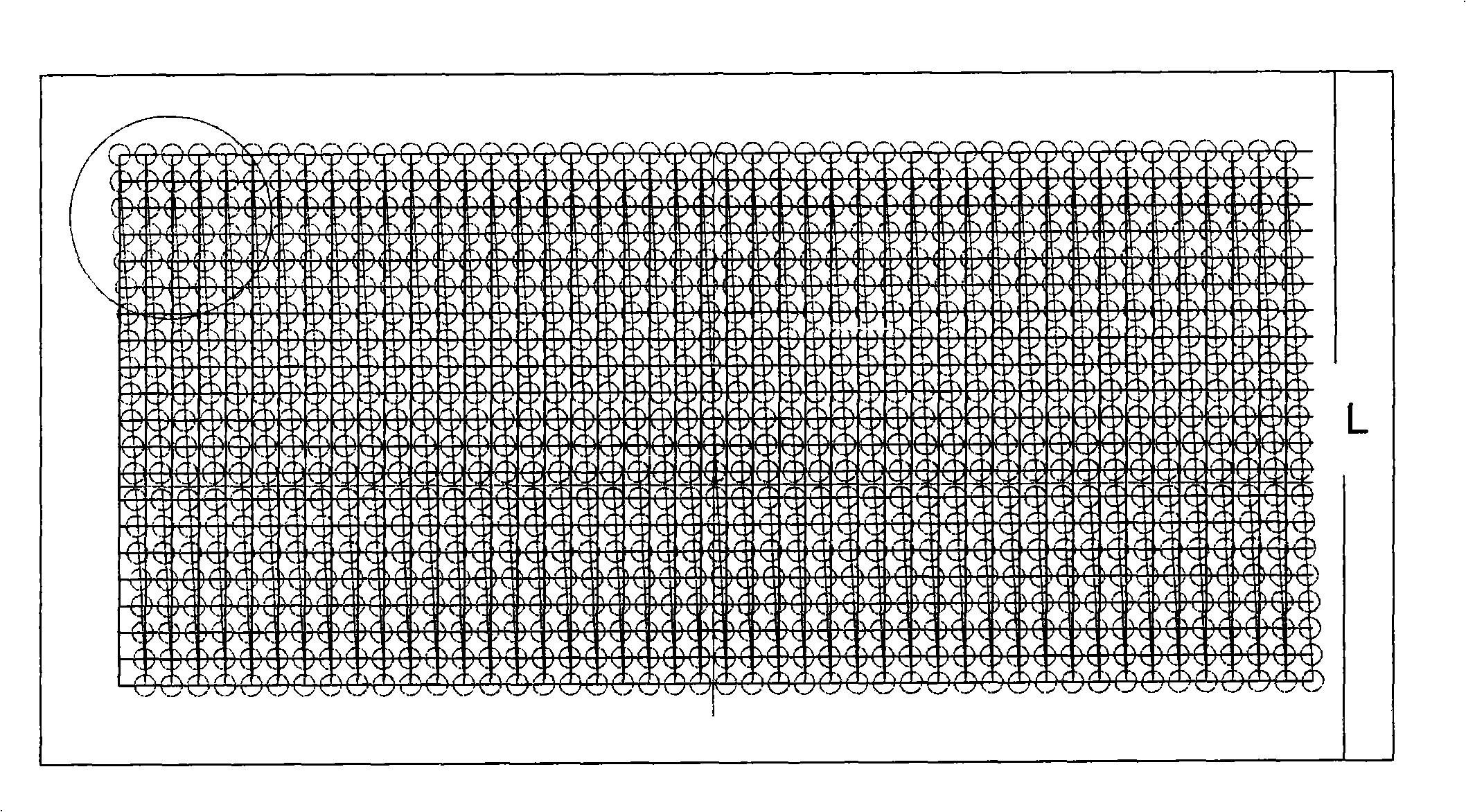

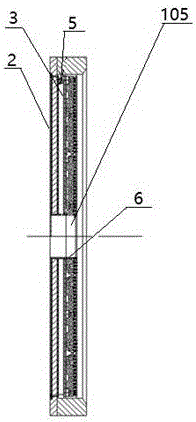

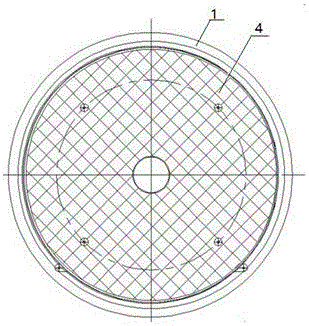

Filter plate and pressing filter assembly for electroosmotic sludge high-dryness dewatering equipment

ActiveCN105967489AHigh pressing pressureReduce moisture contentSludge treatment by de-watering/drying/thickeningWaste based fuelSludgeEngineering

The invention provides a pressing filter plate for electroosmotic sludge high-dryness dewatering equipment. The pressing filter plate comprises a filter plate frame, filter cloth, a filter disc and sludge conveying concentric holes, wherein the front surface of the filter plate frame unidirectionally sinks to form a pressing filter chamber; the filter disc is arranged at the bottom of the pressing filter chamber; the filter cloth is arranged on the filter disc; a cathode conductive filter screen connected with a cathode copper row is arranged between the filter disc and the filter cloth; an anode plate is arranged at the back of the plate frame; a cavity into which liquid or gas can be charged is formed between the filter disc and the plate frame; a push plate device is further arranged between the cavity and the filter disc; the cavity consists of a drum membrane, an inner steel base plate and an outer steel base plate; and the drum membrane is arranged on the inner peripheries of the steel base plates. By charging water to pressurize the cavity, a sludge pressing pressure is increased; meanwhile, through the push plate device, the uniformity of a pressing force is ensured and whole-process pressing is achieved; therefore, the moisture content of the sludge is further reduced.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD +1

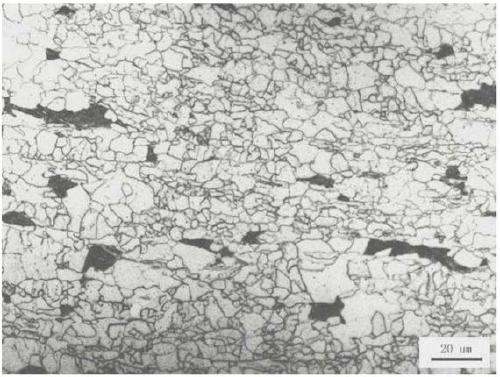

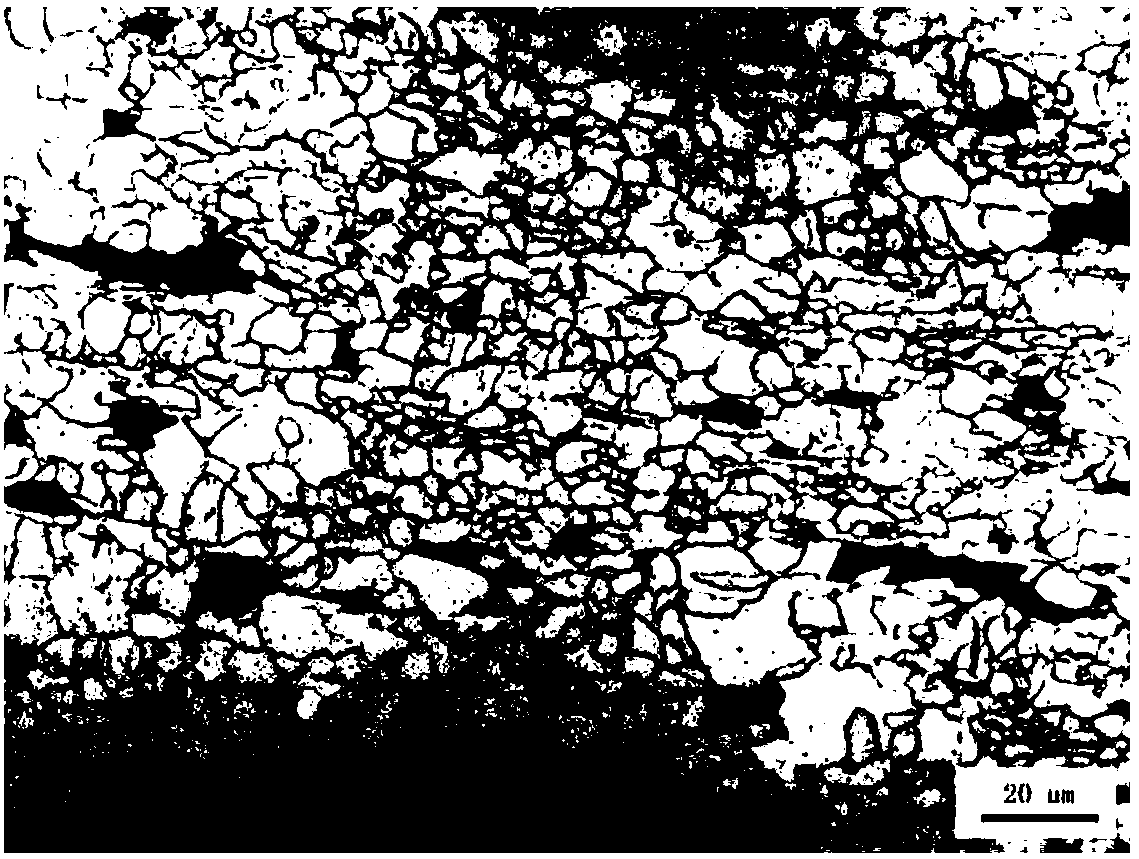

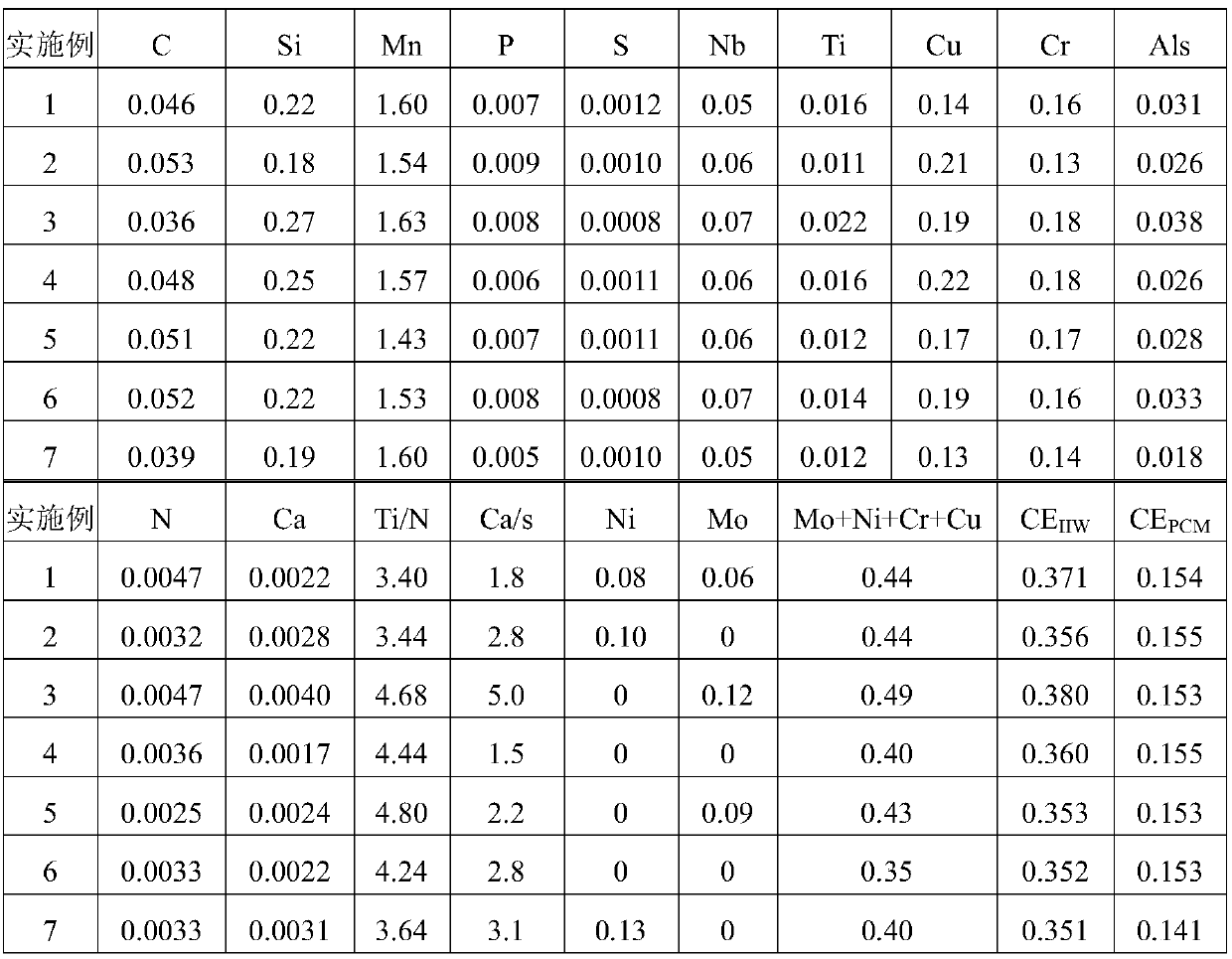

Flat plate for high-plasticity thick-wall deep sea pipeline and production method thereof

The invention discloses a flat plate for a high-plasticity thick-wall deep sea pipeline and a production method of the flat plate. The steel contains 0.030%-0.055% of C, 0.16%-0.30% of Si, 1.36%-1.65%of Mn, 0.04%-0.07% of Nb, 0.008%-0.025% of Ti, 0.11%-0.24% of Cu, 0.10%-0.20% of Cr, 0.015%-0.040% of Als, 0.0021%-0.0049% of N, smaller than or equal to 0.010% of P, smaller than or equal to 0.0015%of S, 0.0015%-0.0045% of Ca, smaller than or equal to 0.00015% of H, smaller than or equal to 0.0020% of O, smaller than or equal to 0.14% of Ni, smaller than or equal to 0.15% of Mo, 0.31%-0.50% ofMo+Ni+Cr+Cu, and the balance of Fe and inevitable impurities. The casting blank heating process is divided into four stages, and the rough rolling temperature is 1050-1150 DEG C. The total deformationrate is larger than or equal to 51%, and the finish rolling temperature is 800-890 DEG C. The final cooling temperature is 350-430 DEG C. A produced steel plate has good plasticity, low-temperature toughness and low yield ratio.

Owner:ANGANG STEEL CO LTD

Method of Manufacturing Cellulose/Gelatin Composite Viscose Rayon Filament

InactiveUS20090166919A1Uniform elongationUniform strengthMonocomponent protein artificial filamentArtificial filaments from viscoseCelluloseYarn

A method of manufacturing a cellulose / gelatin composite viscose rayon filament that is characterized by including a process in which a spinning process is carried out while a viscose spinning solution is mixed with a gelatin crosslinking solution, which makes it possible to produce a cellulose / gelatin composite viscose rayon having uniform strength and elongation without yarn disconnection.

Owner:KURASHIKI BOSEKI KK

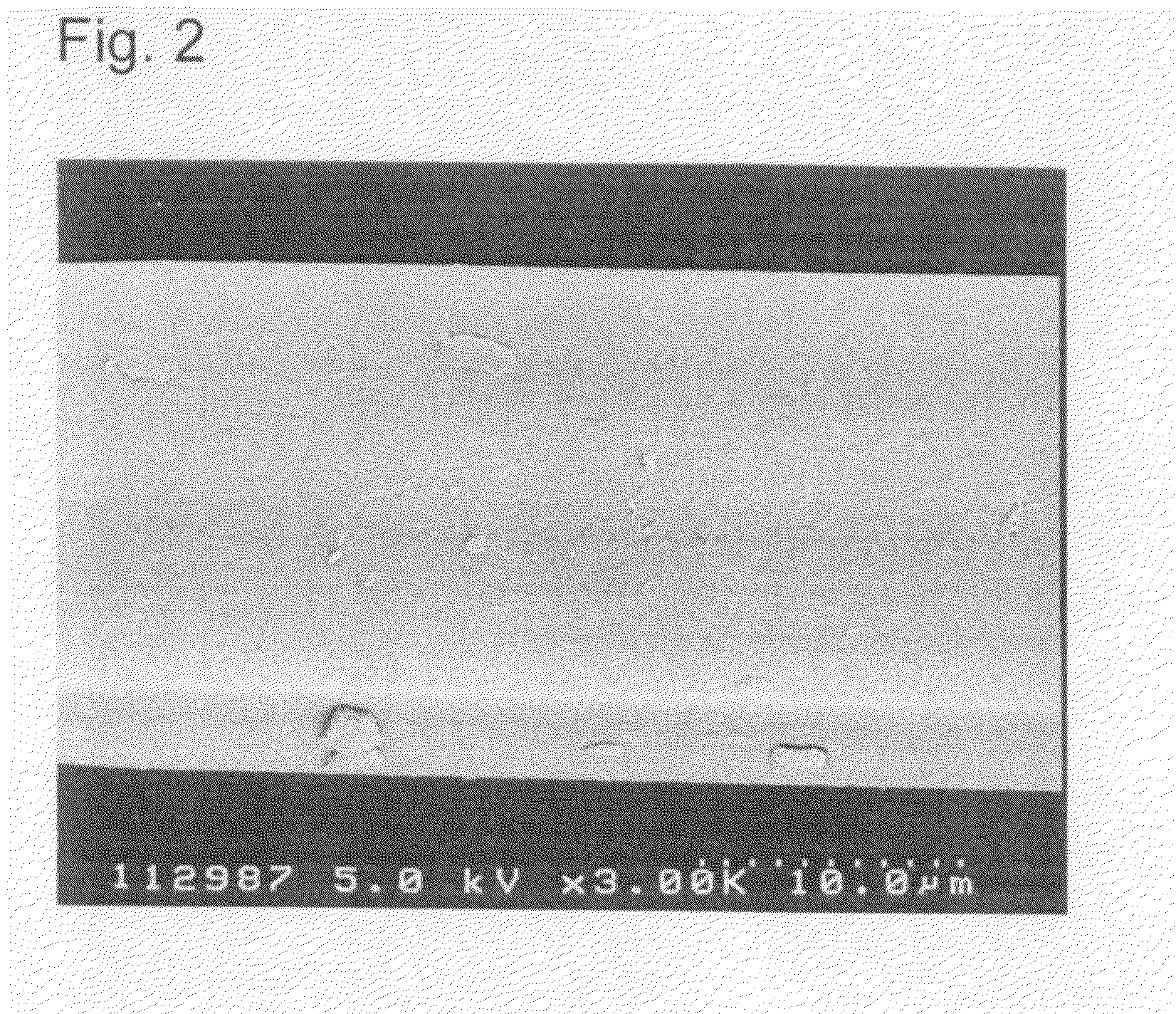

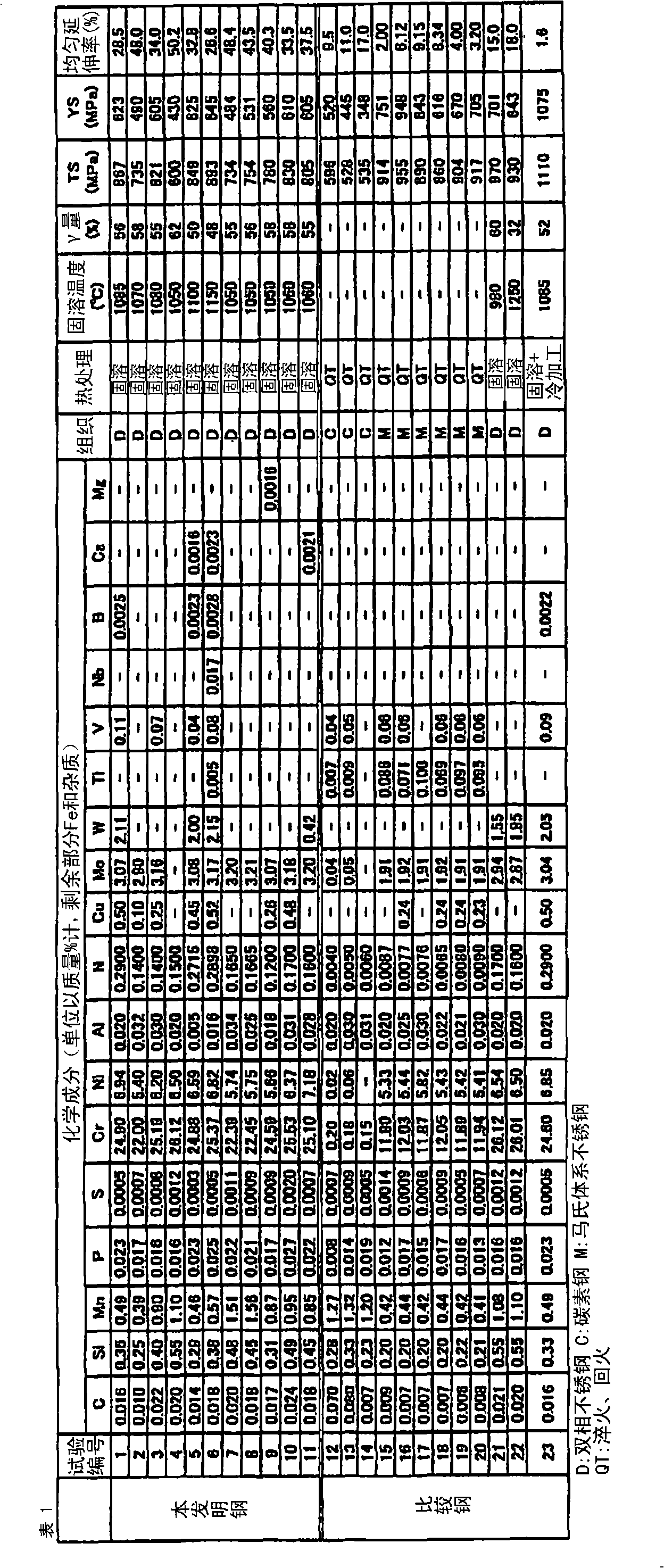

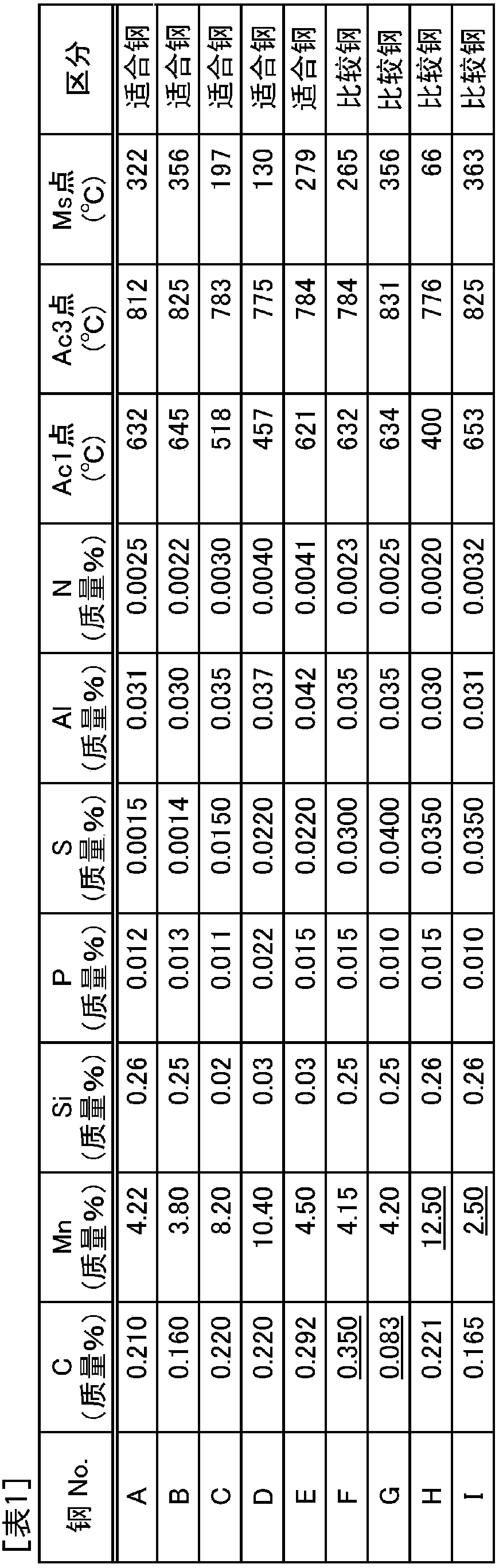

High strength/corrosion-resistant austenitic stainless steel with carbon - nitrogen complex additive, and method for manufacturing same

ActiveCN102428200AHigh tensile strengthImprove mechanical propertiesManganeseBiocompatibility Testing

The present invention relates to high strength / corrosion-resistant austenitic stainless steel with a carbon-nitrogen complex additive, and particularly, to an austenitic stainless steel with a carbon (C) and nitrogen (N) complex additive containing: 8-12 wt % of manganese (Mn); 15-20 wt % of chromium (Cr); less than 2 wt % of nickel (Ni); less than 4 wt % of tungsten (W); less than 2 wt % of molybdenum (Mo); 0.6-1.0 wt % of the total content (C+N) of carbon (C) and nitrogen (N); with the remainder being iron (Fe) and other unavoidable impurities, and to a method for manufacturing same. By controlling the content of the interstitial elements (C+N, C / N) and the substitution elements (Mn+Cr, Mn / Cr, or 0.5W+Mo), the austenitic stainless steel manufactured according to the present invention has a tensile strength of more than 850 MPa and uniform elongation of more than around 45%, thereby exhibiting excellent corrosion resistance as well as improving processability, and the content of Ni, a toxic alloy element, is minimized to improve biocompatibility, making the austenite stainless steel applicable to conventional and offshore structures, desalination facilities, and materials for oil and gas facilities / drilling, transportation and the like, which require high strength and high corrosion resistance, and may also be used to manufacture various functional parts for medical prosthetic materials, and accessories such as jewelry, watches, and the like.

Owner:KOREA INST OF MATERIAL SCI

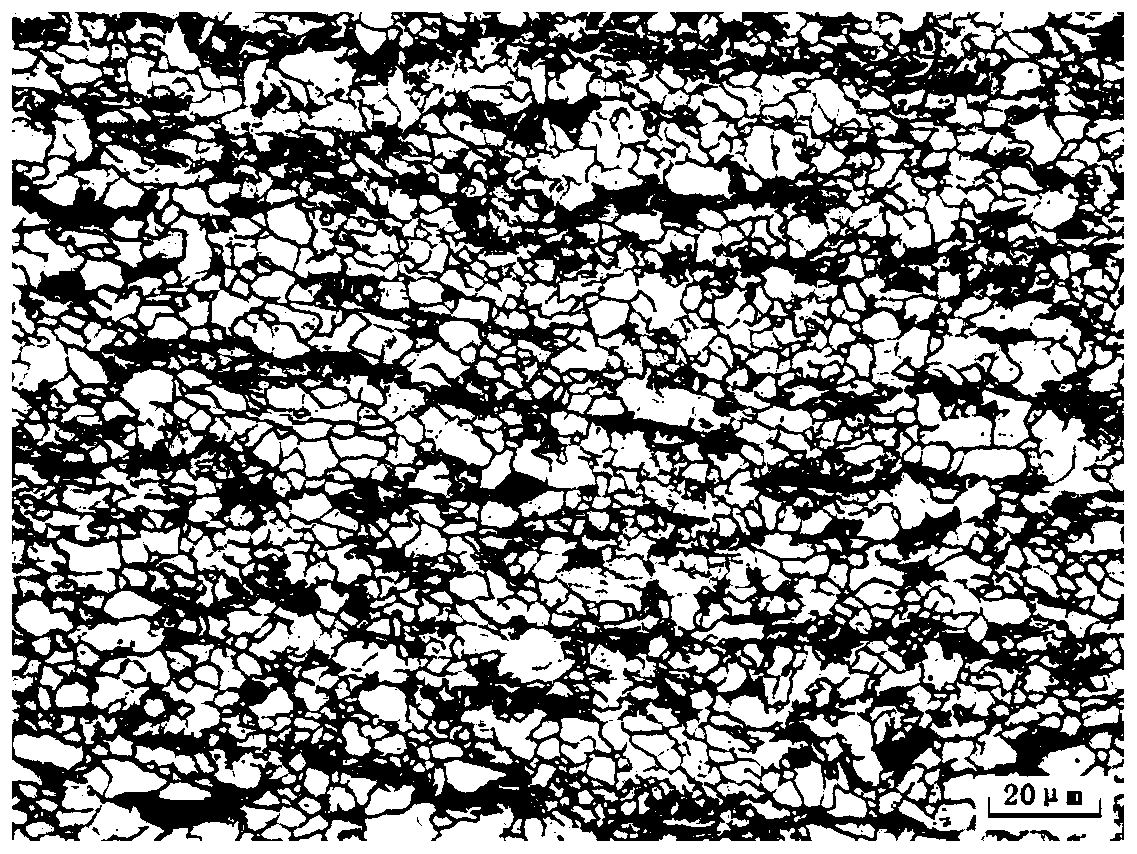

Manufacturing method of pipeline steel with high strength and toughness and high deformability

ActiveCN103160756AImprove toughnessImprove deformation abilityRoll mill control devicesMetal rolling arrangementsLine tubingYield ratio

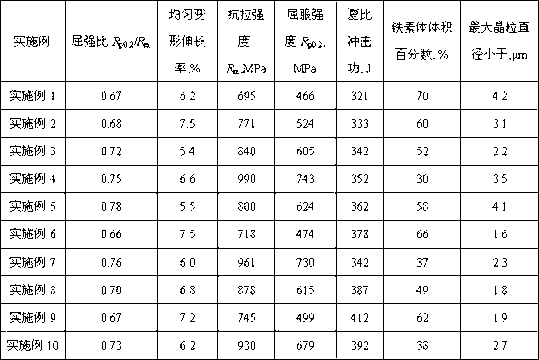

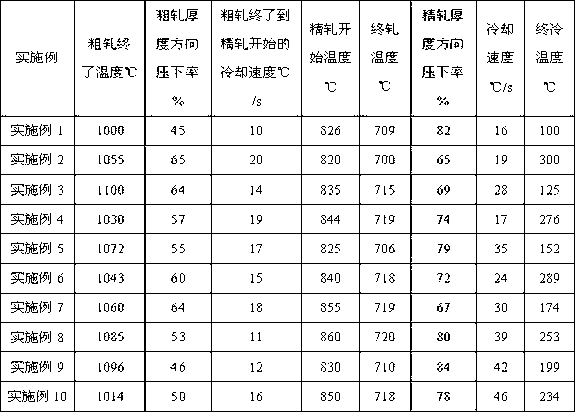

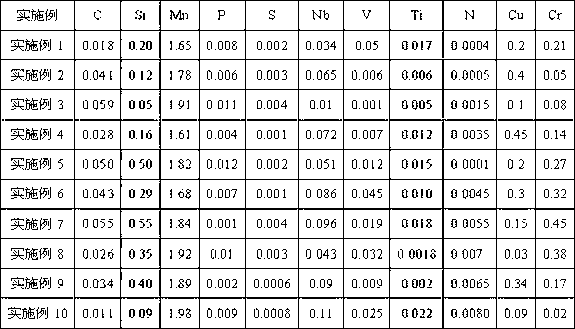

The invention discloses a manufacturing method of pipeline steel with high strength and toughness and high deformability. The steel comprises the following components in percentage by weight: 0.01-0.06% of C, 0.05-0.55% of Si, 1.60-2.00% of Mn, not more than 0.012% of P, not more than 0.005% of S, not more than 0.11% of Nb, not more than 0.06% of V, not more than 0.025% of Ti, not more than 0.0080% of N, not more than 0.50% of Cu, not more than 0.50% of Cr and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing pretreatment of molten iron, smelting, refining and continuous casting to prepare a plate blank comprising the components in percentage by weight, being in line with the requirements; and manufacturing a steel plate through thermal mechanical control of rolling and control of cooling process so as to get the pipeline steel. The pipeline steel disclosed by the invention is very small in crystal grains and appropriate in soft phase-hard phase proportion and can get higher strength and toughness and excellent deformability under the situation of not containing Ni, Mo and other alloy elements and containing lower C content. The tensile strength Rm is not less than 695 and not more than 990, the yield ratio Rp0.2 / Rm is not more than 0.8, the uniform deformation elongation rate is not less than 5%, and the Charpy impact energy is not less than 300J. The pipeline steel disclosed by the invention is low in cost, and the obtained steel plate has the advantages of excellent deformability, strength, toughness and excellent welding performance.

Owner:NANJING IRON & STEEL CO LTD

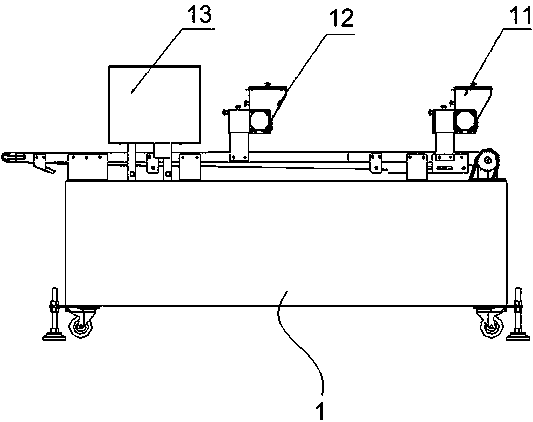

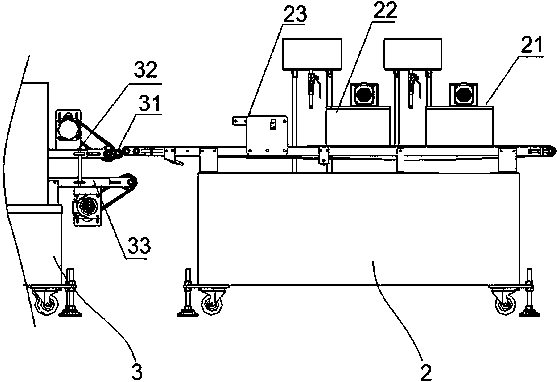

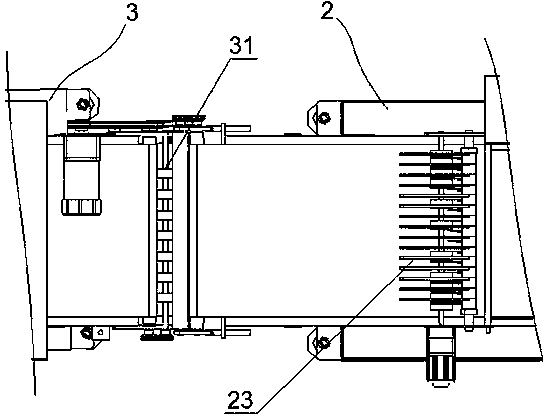

Imitating handmade full-automatic raw twisted cruller production line

ActiveCN111374155AReduce stressOvercome partial shrinkageDough-sheeters/rolling-machines/rolling-pinsDough dividingMechanical engineeringFully automated

The invention discloses an imitating handmade full-automatic raw twisted cruller production line which at least includes a horizontal reciprocating dough rolling device, an interval oil-water brushingcutting device, a stacking creasing device, a stretching device and a cutting device. A reciprocating dough rolling mechanism applies reciprocating rolling non-parallel to the conveying direction ona dough material to form a dough strip; the interval oil-water brushing cutting device brushes water and oil at intervals along the dough strip conveying direction and divides the dough strip into a plurality of dough strips; stacked two-layer dough strips are pressed for creasing through the stacking creasing device; the stretching device elongates the dough strips; and the cutting device cuts the elongated dough strips to form raw twisted cruller. According to the structural design of the imitating handmade full-automatic raw twisted cruller production line, full-automatic production is realized, the quality that the produced raw twisted cruller imitates hand-made raw twisted cruller is achieved, the produced raw twisted cruller are better than hand-made, the taste of the fried raw twisted cruller is the same as that of the hand-made, even better, and efficiency and high-quality production are achieved.

Owner:SUZHOU GUOEN FOOD MACHINERY

Preparation method of J55-grade steel ERW (electric resistance welding) expansion pipe with high diameter expansion performance

InactiveCN102534166AEasy to prepareGood benefitDrilling rodsFurnace typesMetallic materialsEngineering

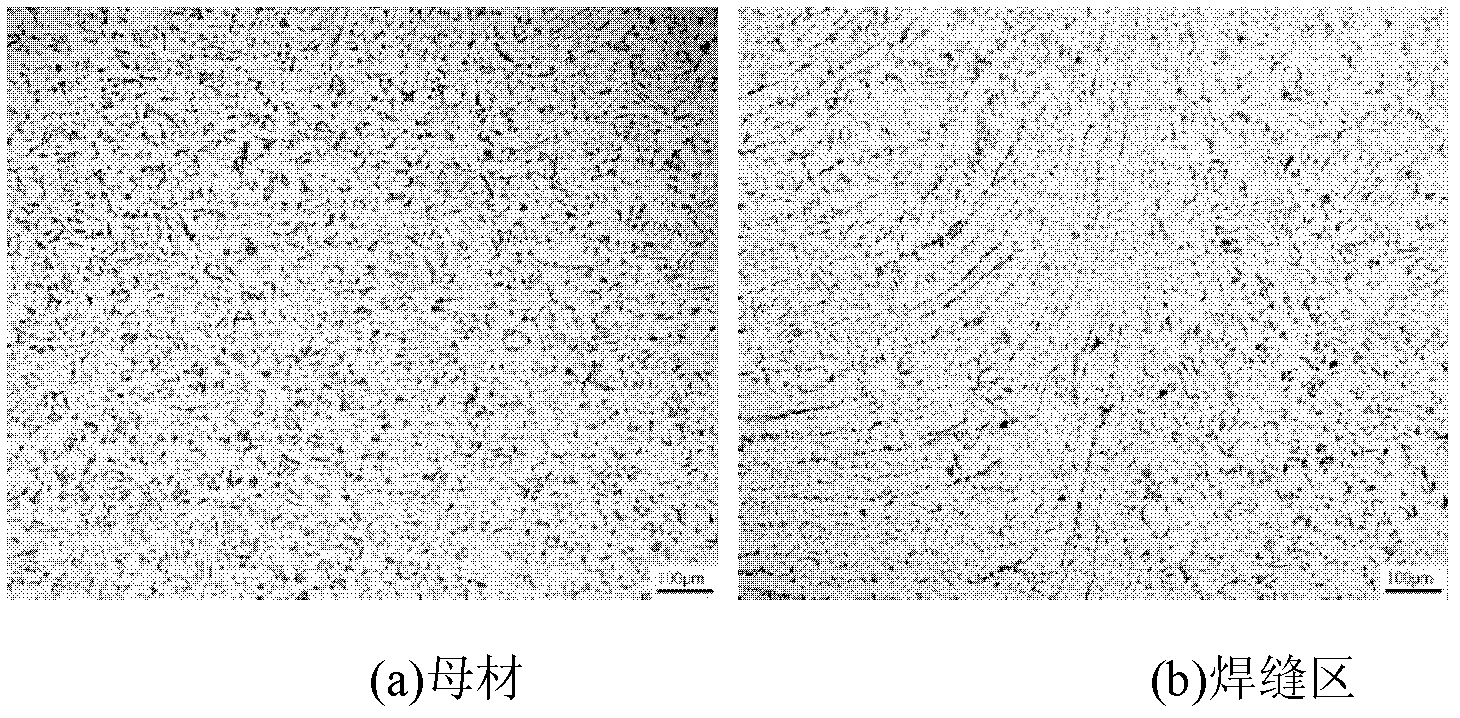

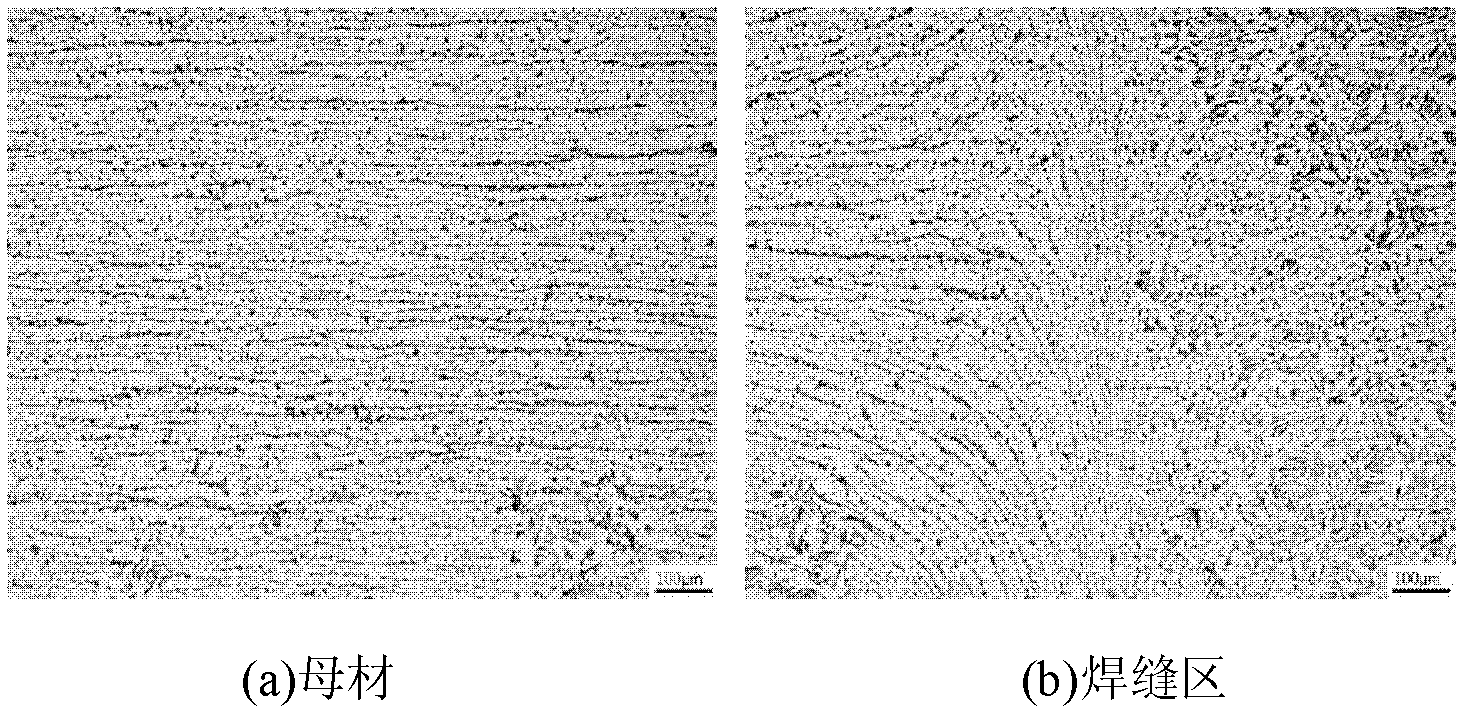

The invention relates to a preparation method of a J55-grade steel ERW (electric resistance welding) expansion pipe with high diameter expansion performance, belonging to the field of metal materials. The invention is characterized in that J55-grade steel expansion pipe steel is acquired at low production cost through reasonable alloy design, and is welded to make the pipe instead of the seamlesssteel pipe. The method comprises the following steps: heating a J55-grade steel expansion pipe to 1000-1150 DEG C, keeping the temperature for 30-60 minutes, and cooling in air to room temperature; heating the J55-grade steel expansion pipe to the temperature of 50-100 DEG C higher than the J55-grade steel expansion pipe steel AC3 point, keeping the temperature for 30-60 minutes, and cooling in air to room temperature; and finally keeping the steel plate at the two-phase region temperature of 700-750 DEG C for 30-60 minutes. The invention eliminates the microstructure difference between the base material and the weld zone, implements substantial conformity of properties at all parts of the pipe body, and acquires a uniform distribution ferrite. The content of the ferrite is high, and is approximate to the critical value under such conditions. The method is beneficial to eliminating the zonal structure of the material so as to refine the structure, eliminate some defects (such as voidsand the like) and enhance the uniform elongation rate, so that the J55-grade steel ERW expansion pipe has higher overall diameter expansion performance. The preparation method provided by the invention is simple; and the ERW expansion pipe is practical and economical.

Owner:UNIV OF SCI & TECH BEIJING

24-30% Mn-containing alloy pipe material and manufacture method thereof

ActiveCN101798658AHigh uniform elongationUniform elongationTemperature control deviceFurnace typesElectrical resistance and conductanceAlloy

The invention relates to a 24-30% Mn-containing alloy pipe material and a manufacture method thereof. The pipe material comprises the following components of: 0.001-0.35% of C, 24-30% of Mn, 0-5% of Si, 1.0-3.5% of Al, P which is less than and equal to 0.015%, S which is less than and equal to 0.010%, and Fe in balance amount, or one or two of 1-6% of Cr, 0.1-0.5% of Cu, 0.01-0.9% of Nb, 0.01-0.1% of Ti and 0.01-0.3% of V. The manufacture method comprises the following steps of: vacuum smelting and casting, annealing in a homogenizing way, hot rolling to obtain a steel plate or a bar material, electric resistance welding or hot rolling to obtain a pipe blank, and performing solid solution and aging treatment to obtain the alloy pipe material with good expansibility performance. The even elongation coefficient is more than or equal to 60%, and the yield strength is 250-400MPa. After performing 30-40% of plastic deformation, the even elongation coefficient is more than or equal to 25%, and the yield strength is 500-630MPa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oil well pipe for expansion in well and two-phase stainless steel for use as oil well pipe for expansion

An oil well pipe for expansion which is expanded in a well. The oil well pipe is made of a two-phase stainless steel which has a chemical composition containing, in terms of mass%, 0.005-0.03% carbon, 0.1-1.0% silicon, 0.2-2.0% manganese, up to 0.04% phosphorus, up to 0.015% sulfur, 18.0-27.0% chromium, 4.0-9.0% nickel, up to 0.040% aluminum, and 0.05-0.40% nitrogen, with the remainder being iron and impurities, and has a structure having an austenite content of 40-90%. The oil well pipe for expansion has a yield strength of 276-655 MPa and a uniform elongation more than 20%. The oil well pipe has excellent expansibility.

Owner:SUMITOMO METAL IND LTD

Hot press member and method for producing same

InactiveCN108138289AHigh strengthImprove ductilityHot-dipping/immersion processesFurnace typesVolumetric Mass DensityHigh intensity

Provided is a hot press member that is provided with all of the following properties: high strength, with tensile strength TS being 1,500 MPa or higher; high ductility, with uniform elongation uEL being 6.0% or higher; and excellent heat treatment curability, with yield stress YS increasing 150 MPa or more upon execution of a heat treatment (baking finish treatment). This hot press member is characterized by having a structure containing a prescribed component composition (specifically, a low C content of at least 0.090% and less than 0.30%, and a high Mn content of at least 3.5% and less than11.0%), a martensitic phase comprising 70.0 vol% or more, and a retained austenitic phase comprising 3.0-30.0 vol%, inclusive, and in that the dislocation density thereof is 1.0x10<16> m<2> or higher.

Owner:JFE STEEL CORP

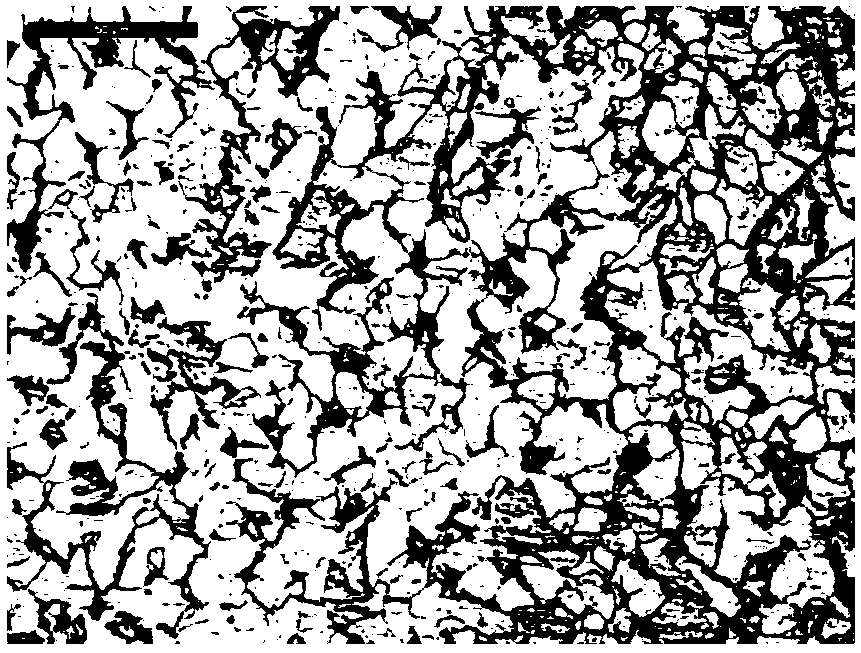

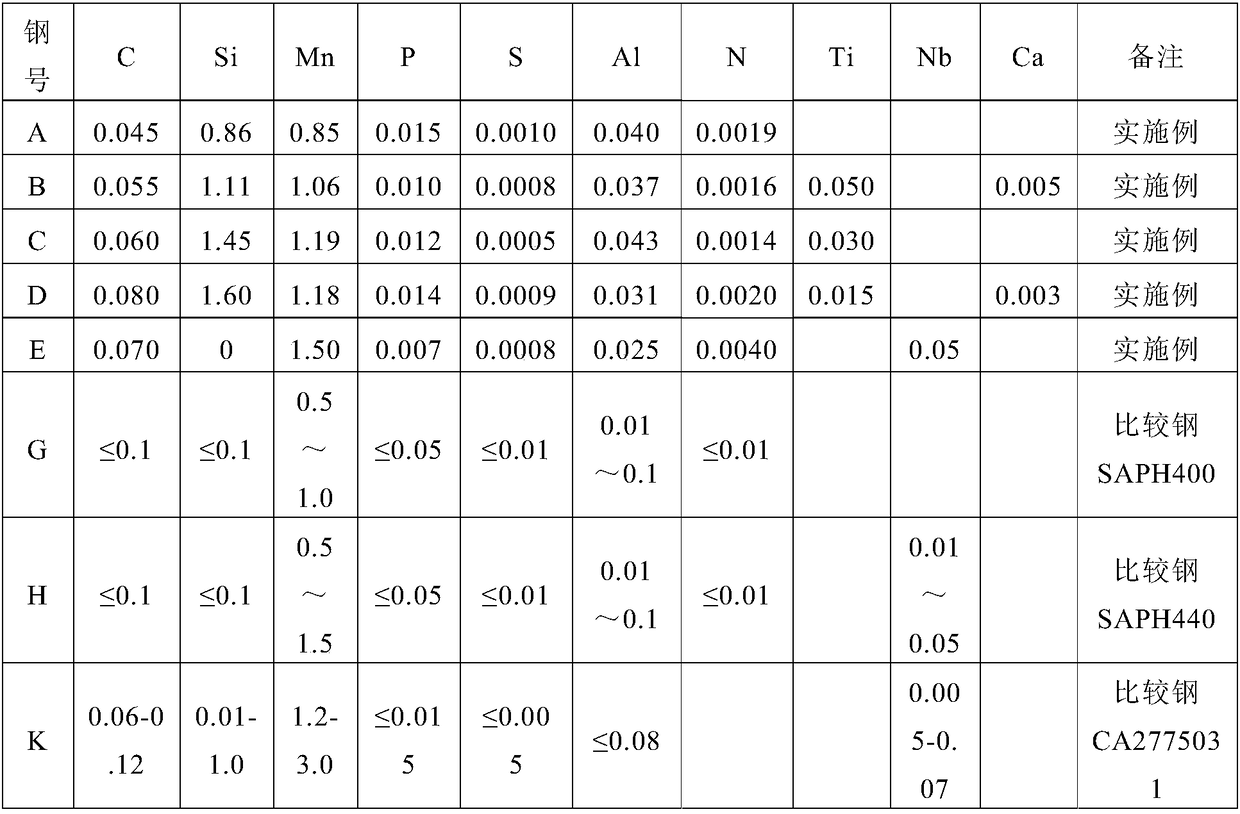

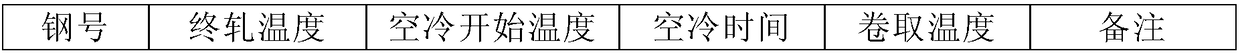

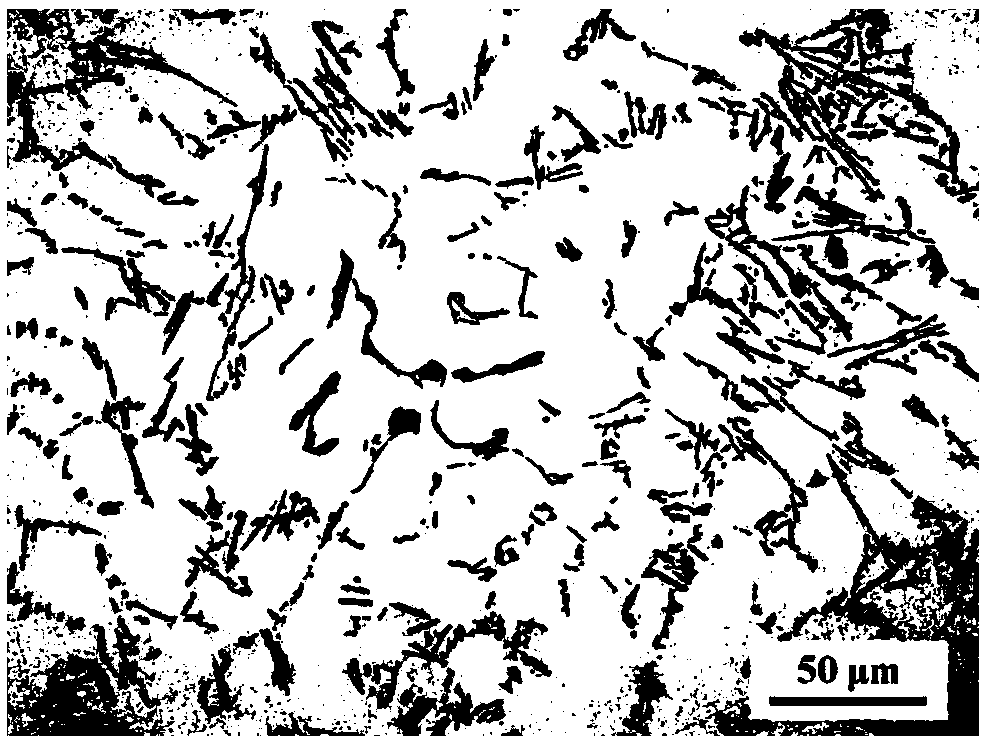

400-500Mpa grade high-uniform elongation hot rolled steel sheet and manufacturing method thereof

The invention discloses a 400-500Mpa grade high-uniform elongationhot rolled steel sheet and a manufacturing method thereof. The 400-500Mpa grade high-uniform elongationhot rolled steel sheet is prepared from the following components in percentage by weight: 0.04-0.08 percent of C, 0-1.6 percent of Si, 0.8-1.5 percent of Mn, smaller than or equal to 0.035 percent of P, smaller than or equal to 0.001 percent of S, 0.025-0.060 percent of Al, smaller than or equal to 0.0060 percent of N, more than one of smaller than or equal to 0.03 percent of Ti, smaller than or equal to 0.05 percent of Nb andsmaller than or equal to 0.0050 percent of Ca and the balance of Fe and inevitable impurities. The steel sheet provided by the invention does not need to be subjected to heat treatment, is directly manufactured on a conventional hot rolling production line, is thin in specification (smaller than or equal to 12 mm), has the tensile strength being in a 400 Mpa grade or above and has the uniform elongation being the high uniform elongation of 20 percent or above; and after hot rolling, the steel sheet is relatively simple in cooling technology, uniform in performance and good in sheet shape, hasgood cold processing performance and welding performance, is low in production cost and can meet the requirements for formation performance of complex-shaped parts including an automotive chassis anda structural member.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum-silicon alloy high-pressure heat treatment method and obtained product

The invention provides an aluminum-silicon alloy high-pressure heat treatment method. The aluminum-silicon alloy high-pressure heat treatment method comprises the steps of 1, alloy smelting, wherein after aluminum and other raw materials are molten in a smelting furnace at high temperature, casting is carried out, and the other raw materials comprise one or more of silicon, magnesium and copper; 2, high-pressure solid solution treatment, wherein the pressure of 1-10 GPa and the temperature of 600 DEG C to 750 DEG C are exerted to a casting, and quasi-hydrostatic pressure heat treatment is carried out; and 3, aging treatment, wherein aging treatment is carried out for 0.1 h to 10 h at the temperature of 150 DEG C to 200 DEG C. The invention further provides a product obtained through the aluminum-silicon alloy high-pressure heat treatment method. Silicon in an aluminum-silicon alloy obtained through the heat treatment method is evenly dispersed nano-particles; the obtained aluminum-silicon alloy has good plasticity; and the size of silicon in the aluminum-silicon alloy can be regulated and controlled through the aging temperature and time, and the alloy with different kinds of yieldstrength and even ductility can be obtained by reasonably changing the aging parameters.

Owner:BEIHANG UNIV

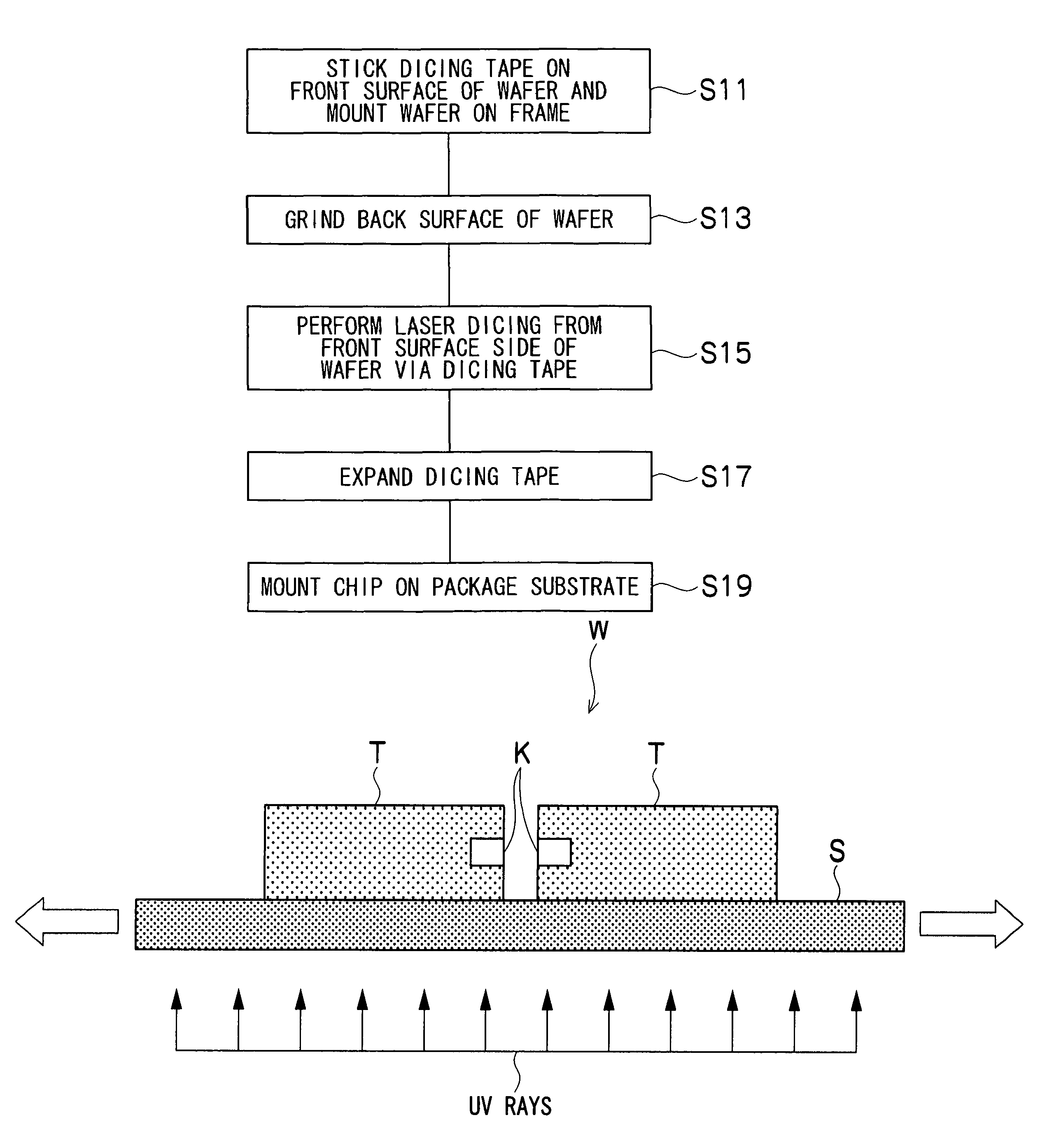

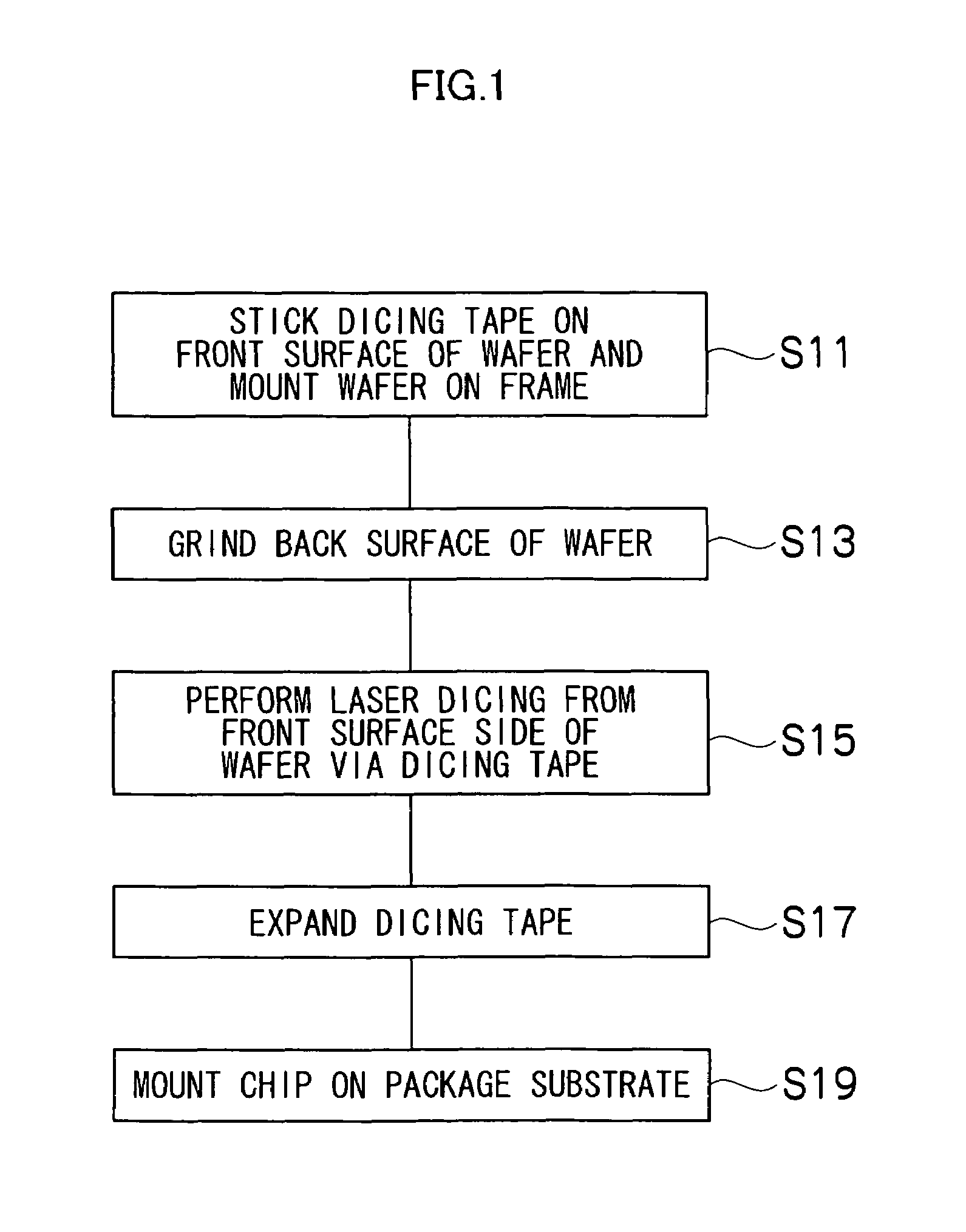

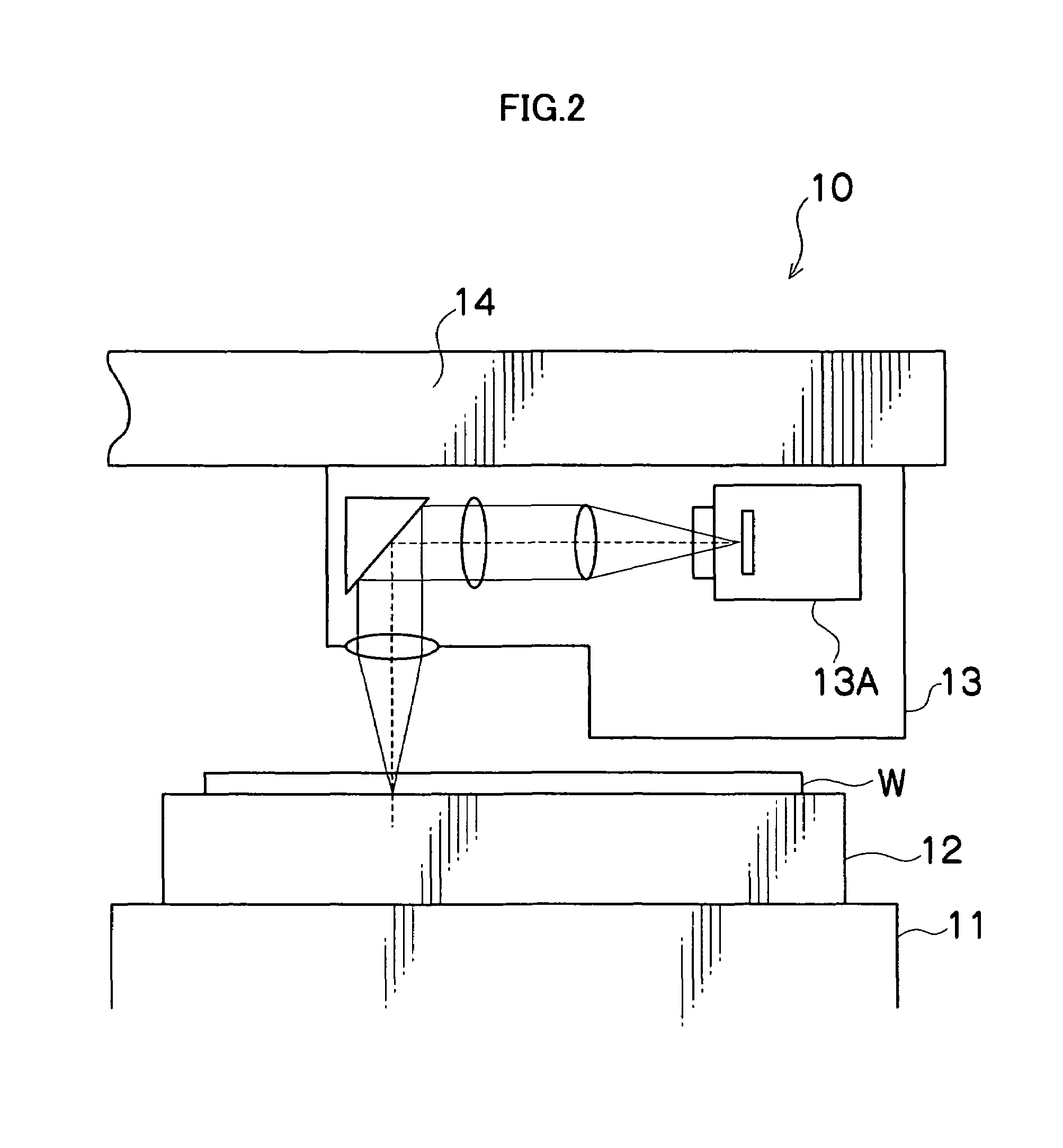

Method and device for dividing plate-like member

InactiveUS7410831B2Good end-face shapePositively manufacture an ultrathin chipSemiconductor/solid-state device manufacturingFine working devicesEngineeringFace shape

Owner:TOKYO SEIMITSU

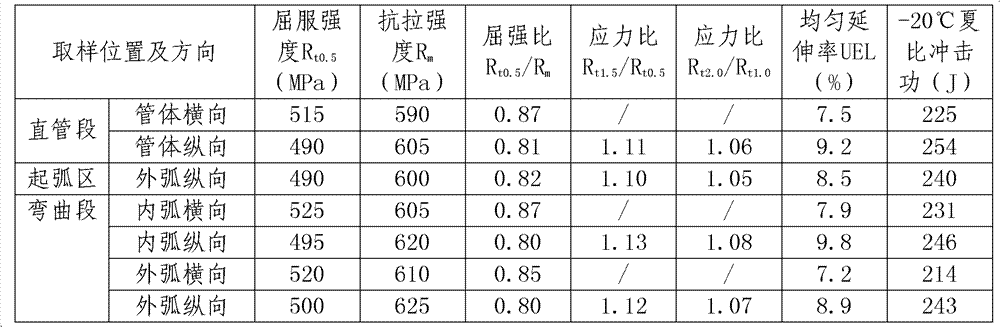

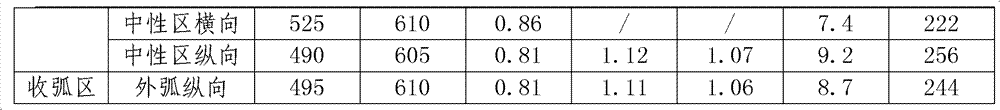

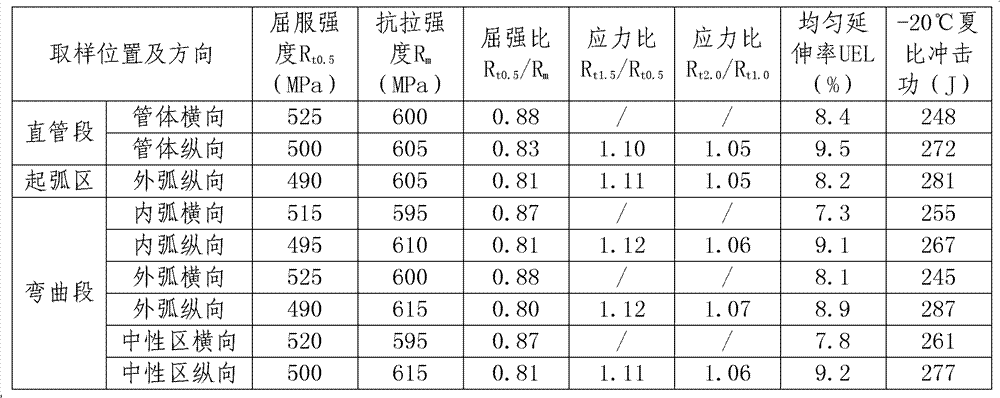

Marine high-strain welded steel pipe based on double-phase structure and preparing method thereof

ActiveCN110000517AWith mechanical propertiesCorrosion resistanceArc welding apparatusDouble phaseHigh intensity

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Steel sheet

InactiveUS20190211427A1Improve solderabilityTensile strength highHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

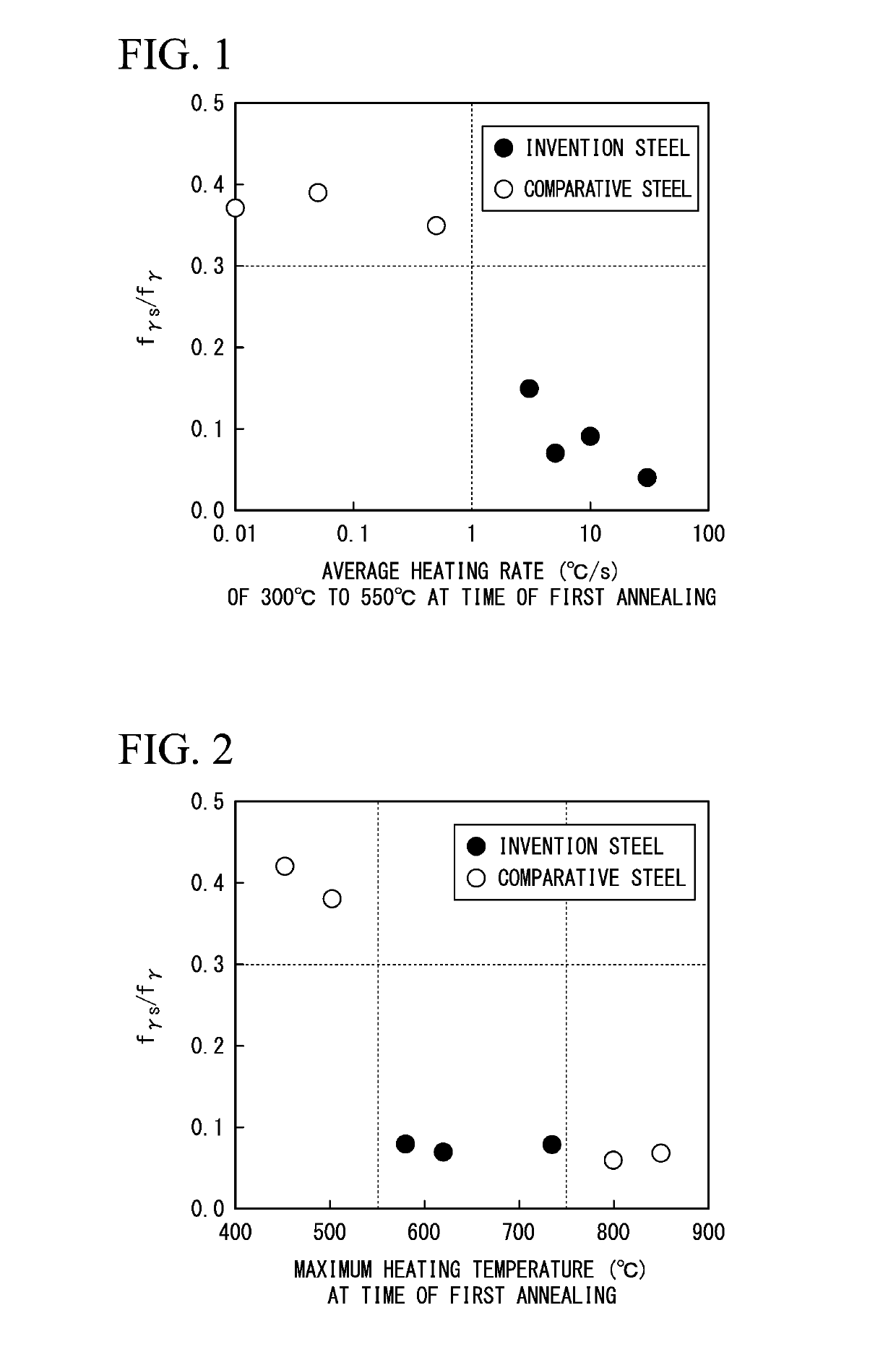

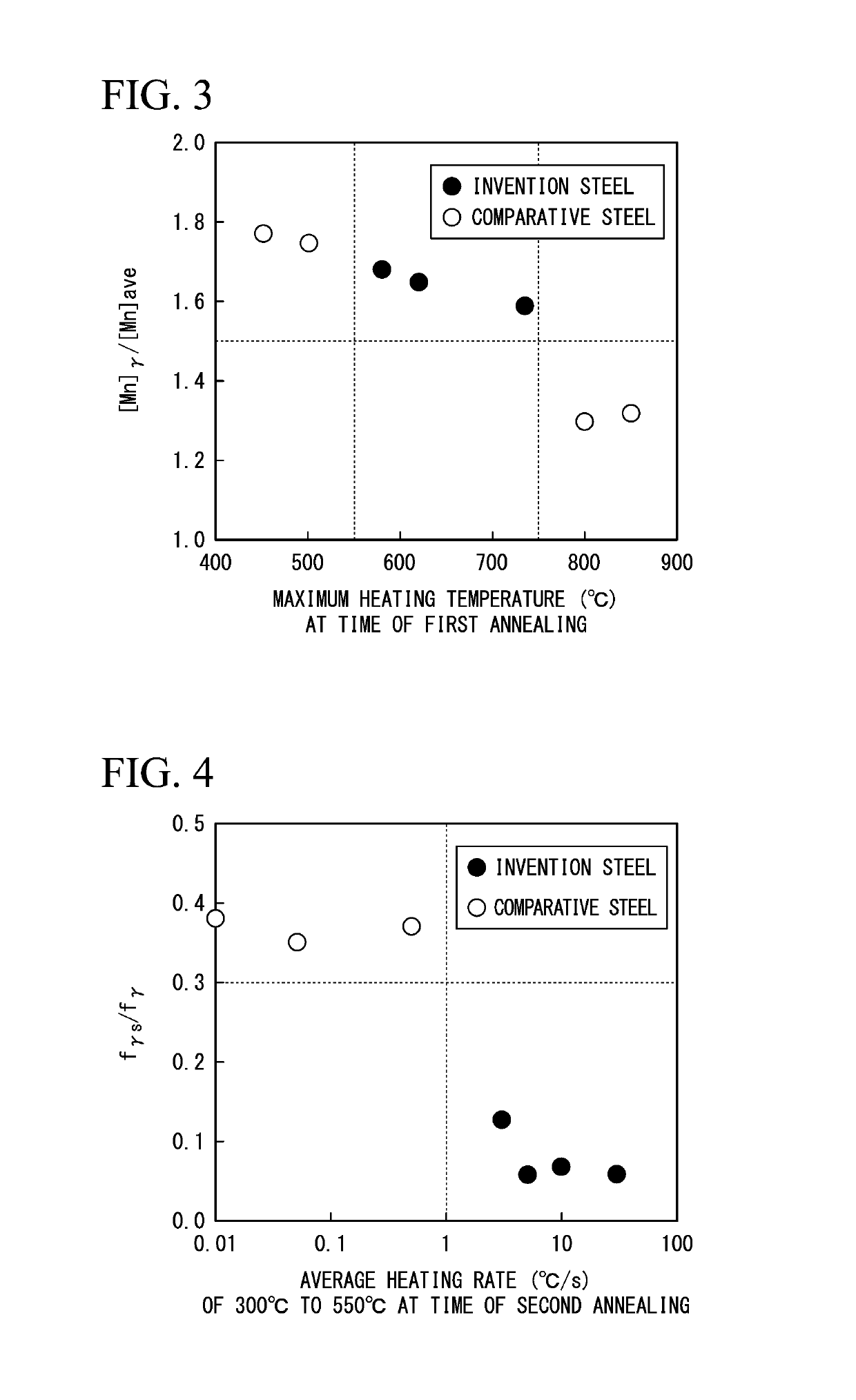

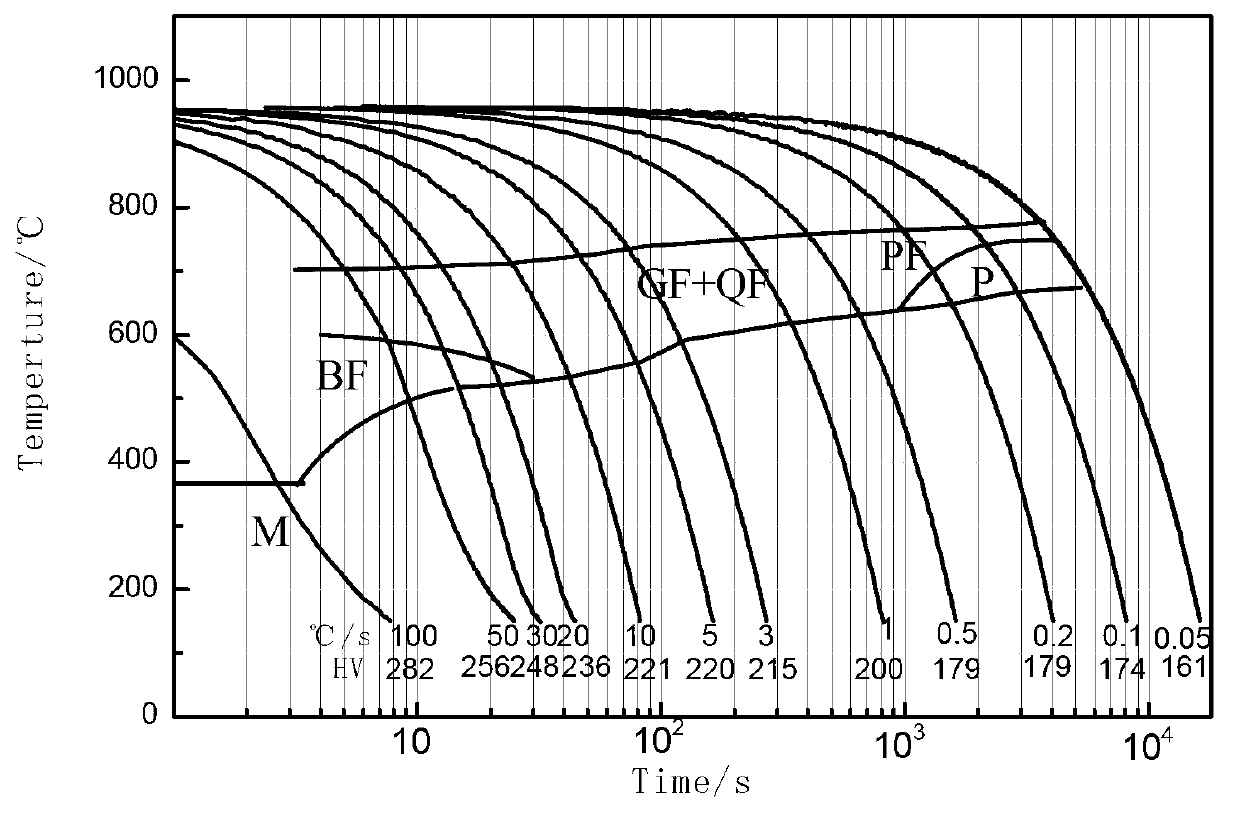

A steel sheet according to an aspect of the present invention includes a predetermined chemical composition; in which a metallographic structure in a ¼ t portion contains residual austenite of 4 volume % to 70 volume %; [Mn]γ / [Mn]ave>1.5 is satisfied in the ¼ t portion; fγs / fγ≤0.30 and [C]×[Mn]≥0.15 are satisfied in the ¼ t portion.

Owner:NIPPON STEEL CORP

Method of obtaining X80 steel grade two phase organization large deformation pipeline steel

InactiveCN103131833AAbility to meet large deformationCapable of large deformationHeat treatment process controlThermodynamicsEngineering

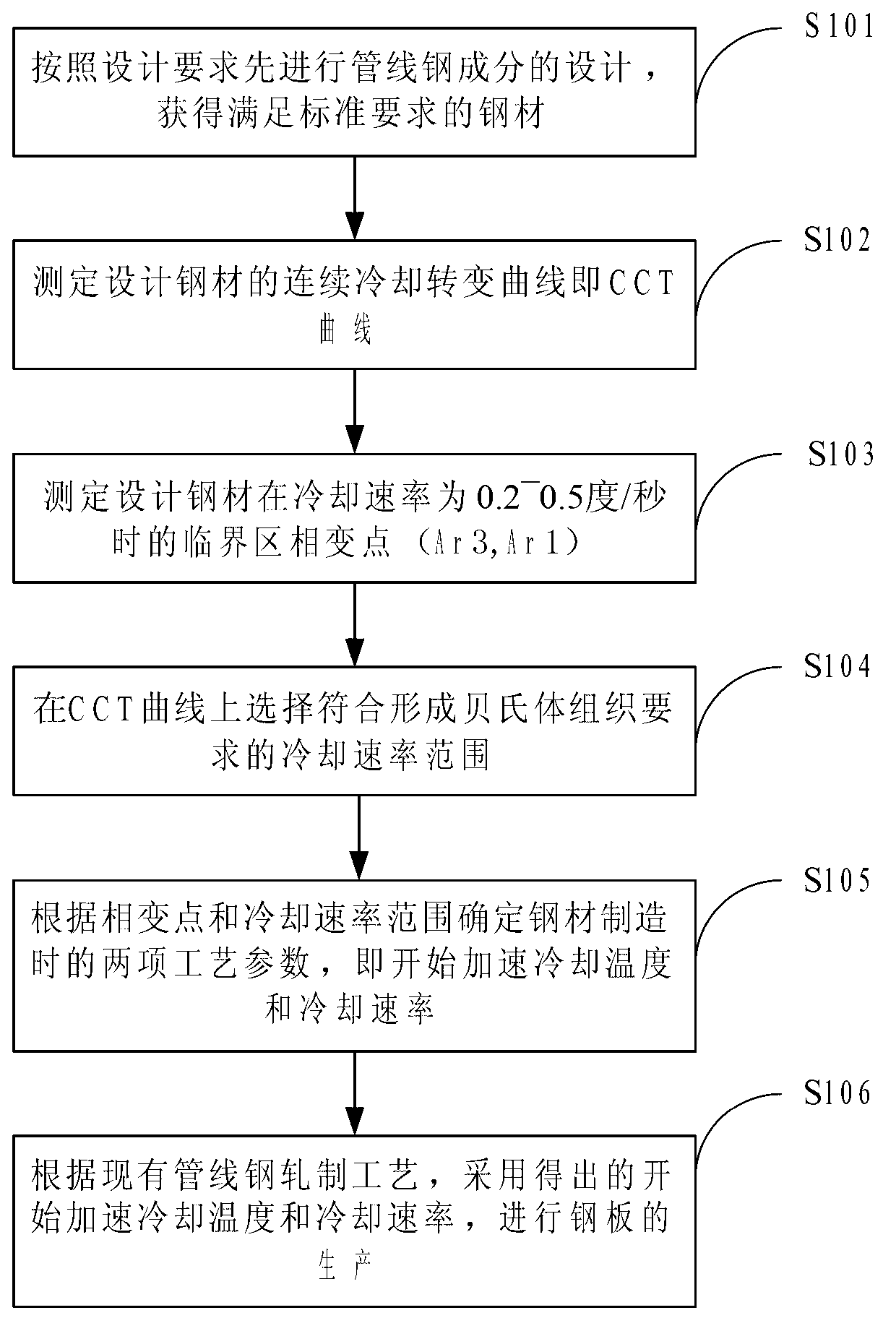

The invention belongs to the large deformation pipeline steel machine technical field, and provides a method of obtaining X80 steel grade two phase organization large deformation pipeline steel. The method of obtaining X80 steel grade two phase organization large deformation pipeline steel comprises the following steps: firstly conducting design of pipeline steel component, obtaining steel component meeting standard requirement; determining CCT curve of designed steel; determining a critical zone (Ar3,Ar1) of the designed steel when cooling rate is 0.2-0.5 degree / second; choosing cooling rate ranged conforming to forming bainite structure requirement in the CCT curve; determining beginning accelerated cooling temperature and cooling speed in manufacture of the steel according to phase transformation point and cooling rate range, and conducting production of steel plates. The method of obtaining X80 steel grade two phase organization large deformation pipeline steel obtains a two phase organization composed of the bainite and territe through critical zone accelerated cooling, the pipeline steel has large deformation capability, large uniform elongation, high strain strengthening index and low yield ratio, practical use requirement of large deformation pipeline steel is met, practicability if strong, and strong population and application value are possessed.

Owner:XI'AN PETROLEUM UNIVERSITY

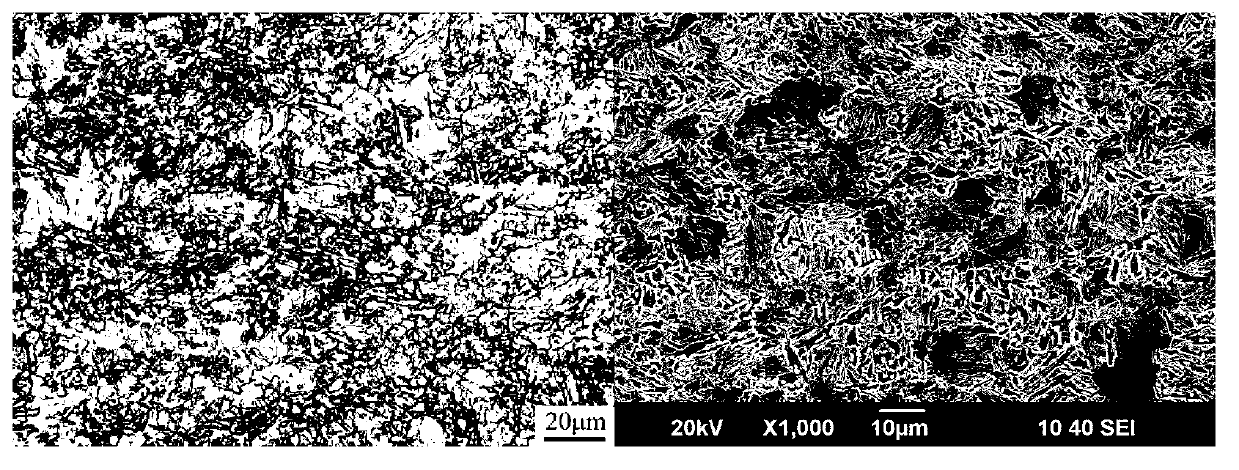

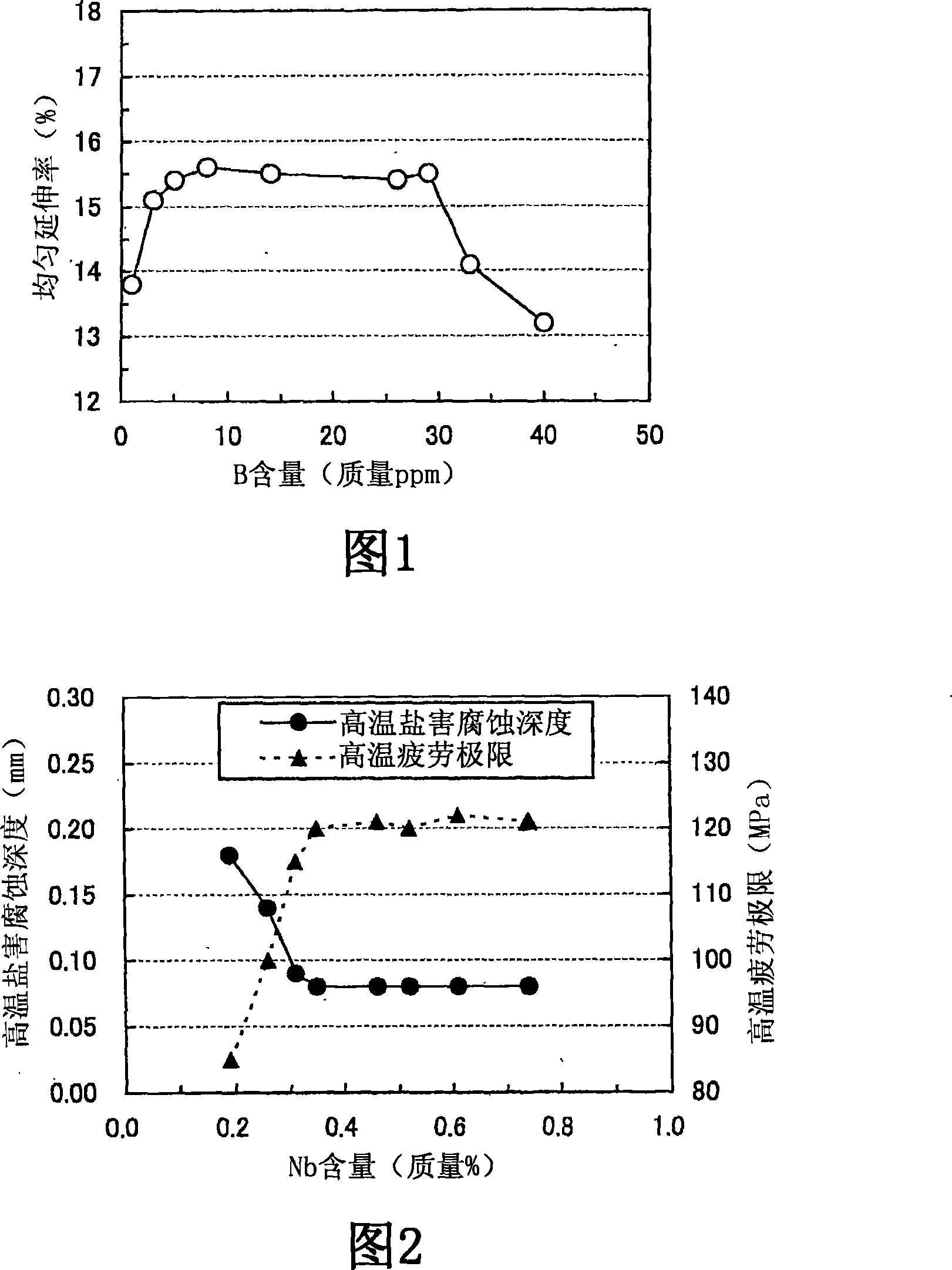

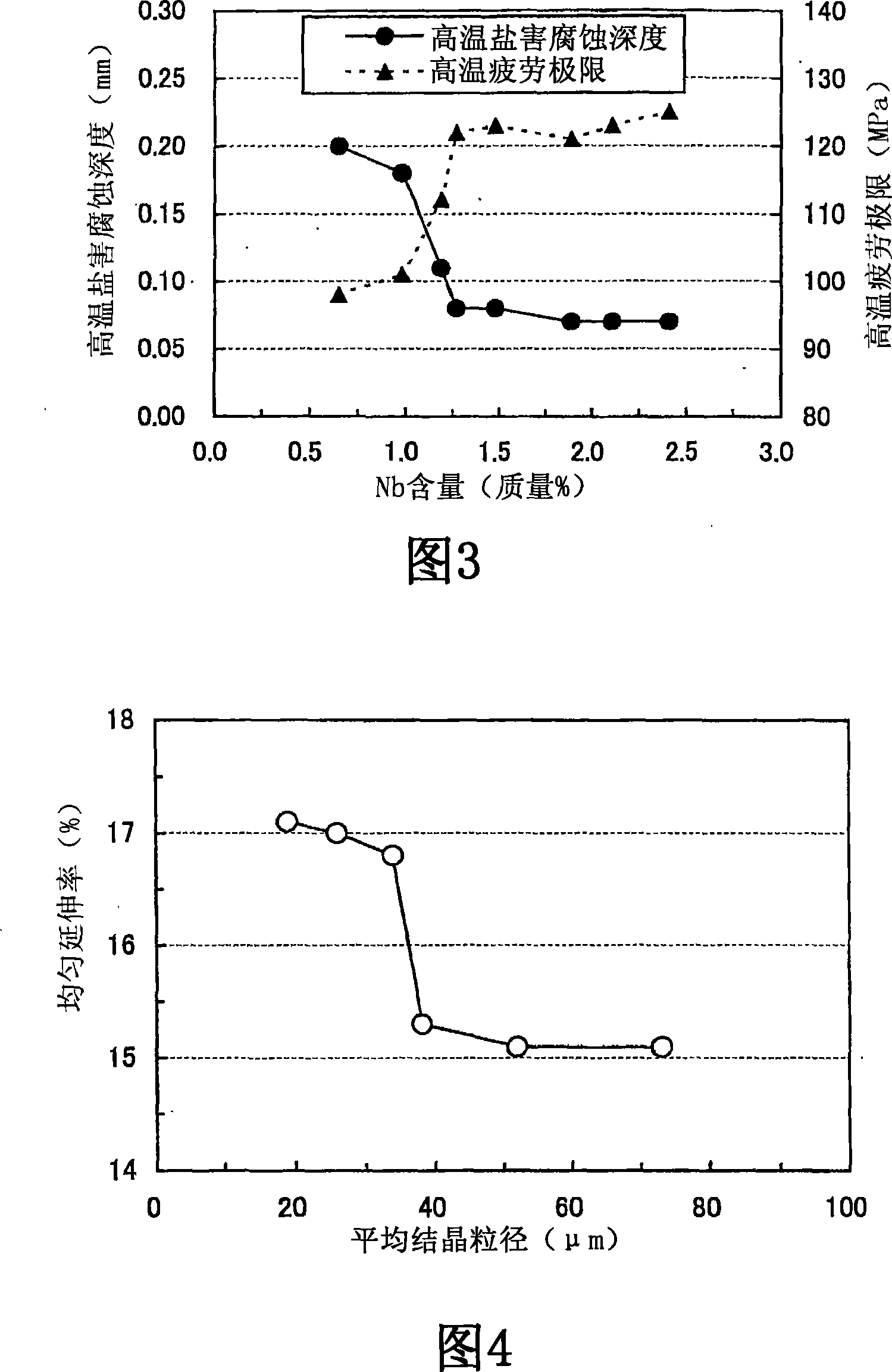

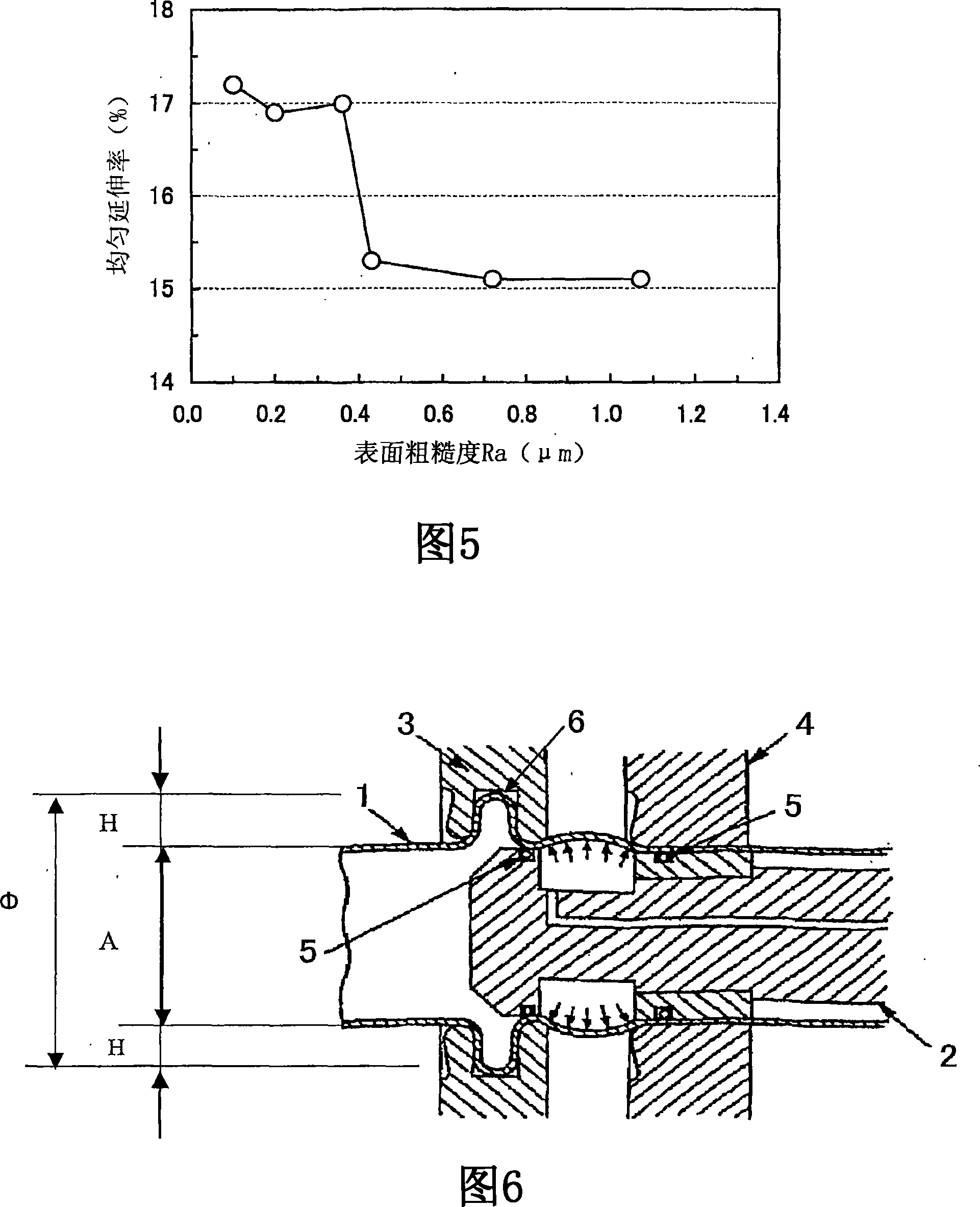

Ferritic stainless steel sheet for original pipe of bellows

A ferrite stainless steel sheet for bellows stock pipe that simultaneously attains excellent workability and excellent high-temperature properties (high-temperature salt erosion resistance and high-temperature fatigue performance). In particular, there is provided a ferrite stainless steel sheet for bellows stock pipe comprising 0.015 mass% or less C, 1.0 mass% or less Si, 1.0 mass% or less Mn, 0.04 mass% or less P, 0.010 mass% or less S, 11 to 19 mass% Cr, 0.015 mass% or less N, 0.15 mass% or less Al, 1.25 to 2.5 mass% Mo, 0.3 to 0.7 mass% Nb, 0.0003 to 0.003 mass% B and the balance Fe and unavoidable impurities. In preferred form, there is provided a ferrite stainless steel sheet for bellows stock pipe whose average crystal grain diameter (D) is 35 mum or less, or whose surface roughness in terms of Ra is 0.40 mum or less.

Owner:JFE STEEL CORP

Efficient in-vitro plant regeneration method of adult high-quality single-plant Xiaoqiao oriental cherry of cerasus lannesiana var. speciosa

ActiveCN105379621AStrong elongation fast growthShort generation cycleHorticulture methodsPlant tissue cultureHormoneAxillary bud

The invention discloses an efficient in-vitro plant regeneration method of an adult high-quality single-plant Xiaoqiao oriental cherry of cerasus lannesiana var. speciosa. According to the efficient in-vitro plant regeneration method, a basic culture medium is set, and different hormone components and concentration level ratios are optimized; annual young sprouts of the adult plant are used as explants, and complete plants are formed by axillary bud induction, axillary bud multiplication and rooting culture; and after the complete plants are transplanted to a base material, healthy and strong nursery stocks which grow orderly and have consistent appearance are obtained. The efficient in-vitro plant regeneration method has the advantages that the growth speed of axillary buds of the explants is high; the induction rate is high and is up to be 100%; the multiplication coefficient is great and is up to be more than 4.5; the elongation growth of multiplied buds is rapid and the buds are 3cm-4cm high after being cultured for 15 days; the rooting rate can be up to be 100% and each plant has more than 5 roots; and tissue culture rooting seedlings are healthy and strong and have high transplanting survival rate. In actual production and application, annual large-scale rapid seedling growing can be carried out to produce young Xiaoqiao oriental cherry seedlings which are healthy and strong, and ordered and consistent, so that the efficient in-vitro plant regeneration method has a wide application prospect.

Owner:SOUTH CHINA AGRI UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com