Oil well pipe for expansion in well and two-phase stainless steel for use as oil well pipe for expansion

A technology of duplex stainless steel and oil well pipe, applied in the field of duplex stainless steel, can solve problems such as uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

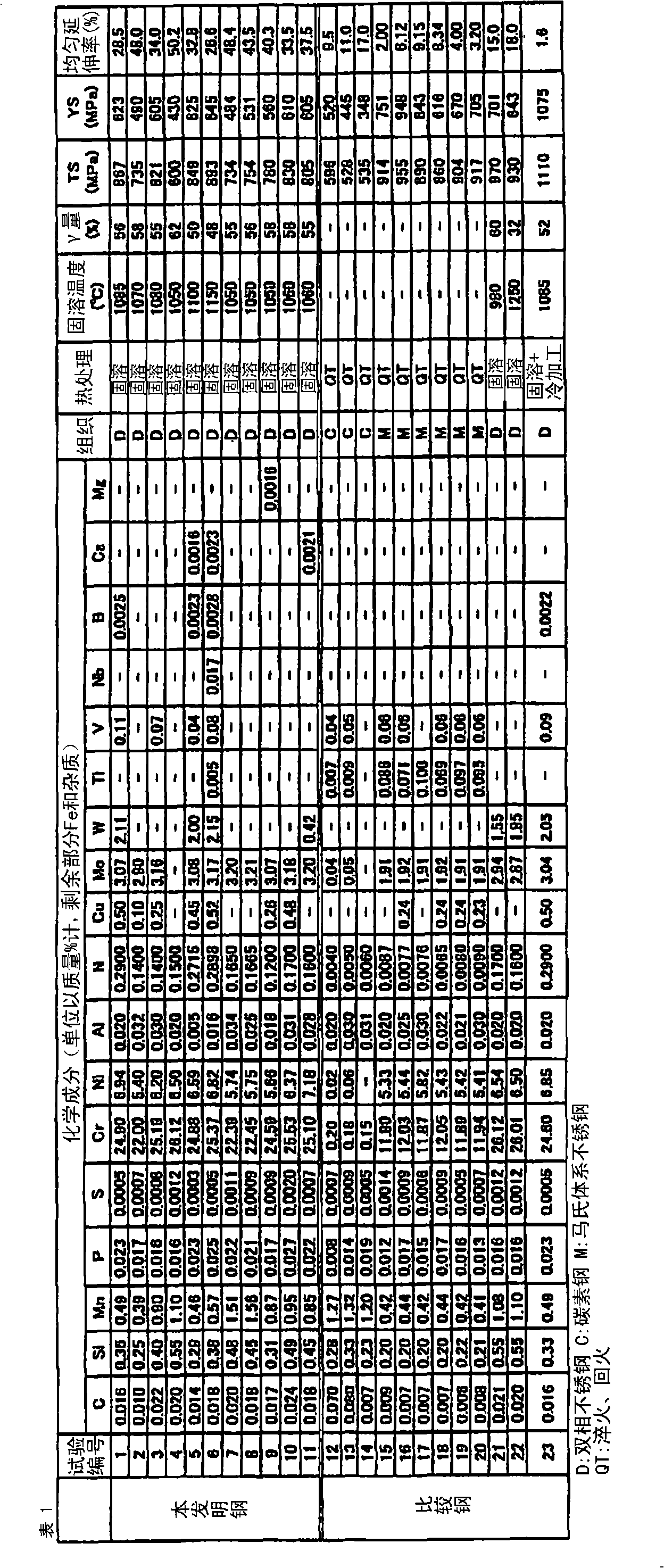

[0068] A plurality of steels having the chemical compositions shown in Table 1 were melted to produce billets. Hot forging and hot rolling were performed on the produced billets to form a plurality of test steel plates having a thickness of 30 mm, a width of 120 mm, and a length of 300 mm.

[0069] Table 1

[0070]

[0071] The "Organization" column in Table 1 indicates the steel type of each test number. "D" means duplex stainless steel, "C" means carbon steel. "M" indicates martensitic stainless steel. Referring to Table 1, test numbers 1 to 11 and 21 to 23 are duplex stainless steels. Numbers 12 to 14 are carbon steels, and test numbers 15 to 20 are martensitic stainless steels.

[0072] The steel plates of test numbers 1 to 23 were subjected to the heat treatment and cold working described in the "heat treatment" column in Table 1. Specifically, the steel sheets of test numbers 1 to 11 were subjected to solution treatment in a temperature range of 1050° C. to 1150°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com