After-planting expansion piece

A technology of expansion and post-planting, which is applied in the direction of building components, building reinforcements, structural elements, etc., and can solve problems such as loosening, fitting, and pull-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

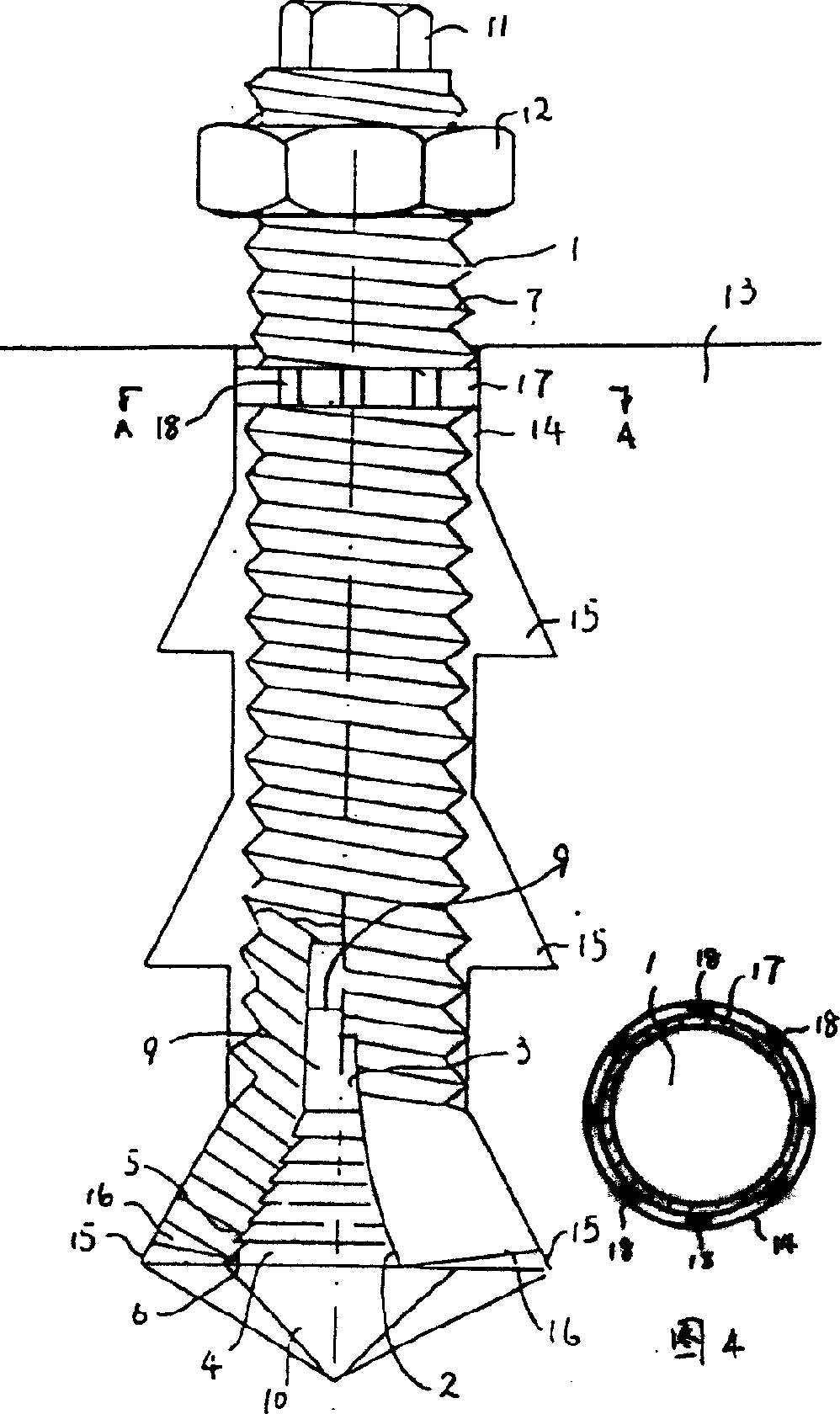

[0018] Refer to attached figure 1 . The present invention comprises expansion rod 1, and the lower end of expansion rod is provided with expansion mechanism, and expansion mechanism comprises expansion hole 2 at the lower end of expansion rod, and the expansion part of expansion hole is provided with expansion slot 3, and it is also provided with the upper end that cooperates with expansion hole. Conical head 4 with guide section 9 .

[0019] The surface of the expansion hole wall is provided with anti-slip lines 5, and the conical surface of the conical plug is provided with anti-slip lines 6 matching the aforementioned anti-slip lines. The anti-slip lines on the surface of the hole wall are anti-slip teeth, and correspondingly, the anti-slip lines on the conical surface of the plug are matched anti-slip teeth.

[0020] Refer to attached figure 1 , 4 The upper part of the expansion rod is covered with a ring 17, and several protrusions 18 are distributed on the surface of ...

Embodiment 2

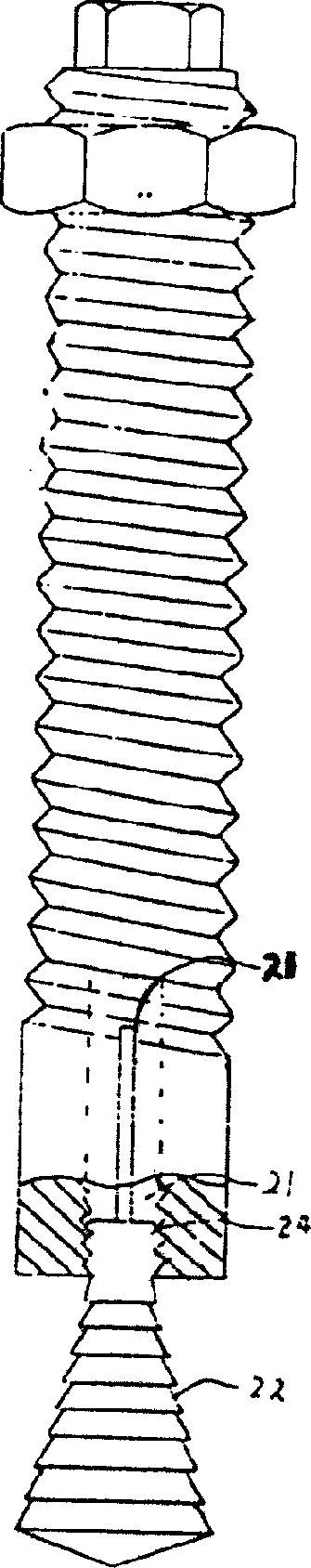

[0027] Refer to attached figure 2 . In this embodiment, the guide section 22 of the plug is threadedly matched with the expansion hole 21, and the reference number 23 is the expansion hole. Others are with embodiment 1.

Embodiment 3

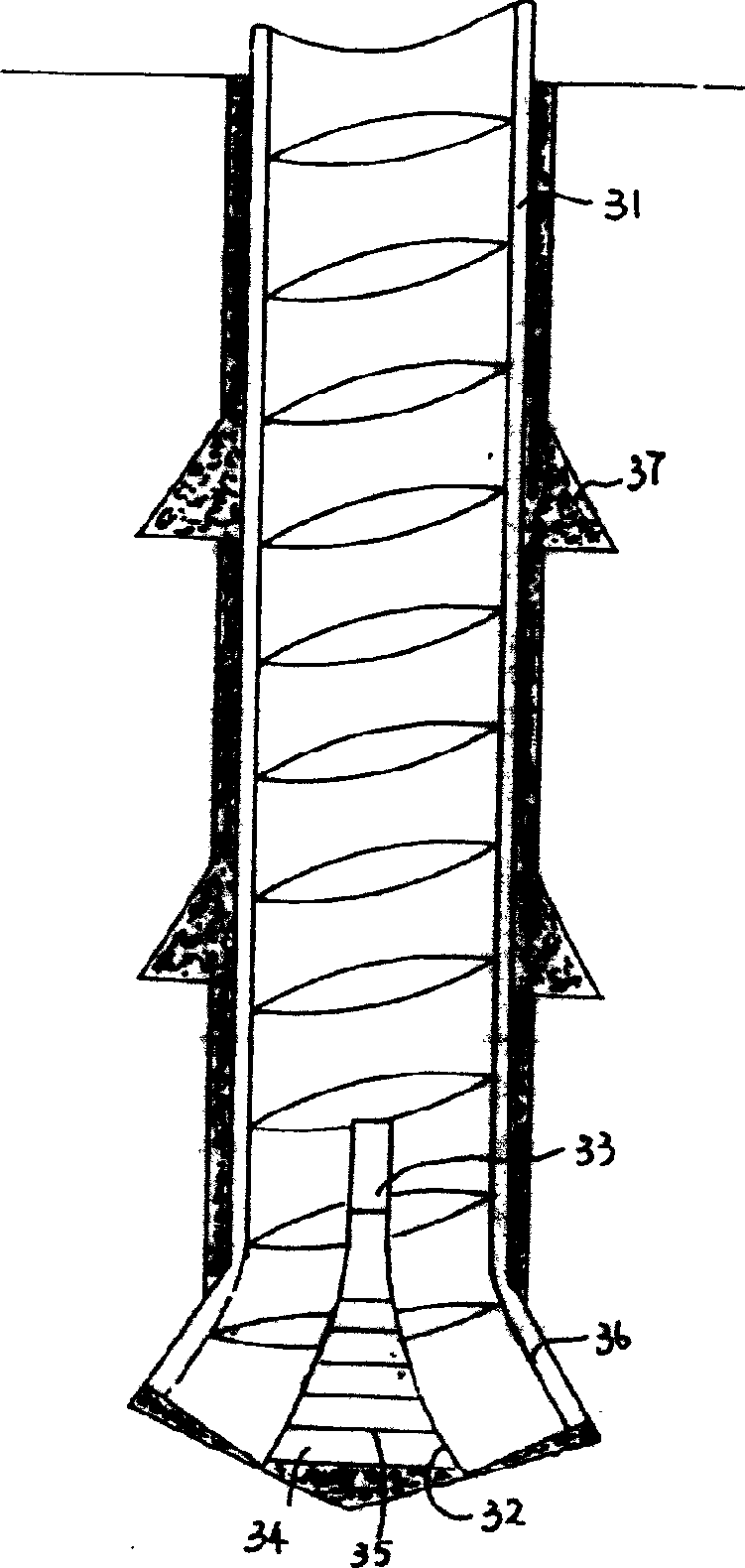

[0029] Refer to attached image 3 . The expansion rod 31 of the present embodiment is a threaded steel bar, and the lower end of the expansion rod is provided with an expansion hole 32, and the expansion part of the expansion hole is provided with an expansion slot 33, and it is also provided with a tapered top 34 cooperating with the expansion hole.

[0030] The surface of the expansion hole wall is provided with anti-slip lines, and the conical surface of the conical plug is provided with anti-slip lines 35 matching the aforementioned anti-slip lines. The anti-slip lines on the surface of the hole wall are anti-slip teeth, and correspondingly, the anti-slip lines on the conical surface of the plug are matched anti-slip teeth.

[0031] Reference number 36 is the expansion part of the expansion rod. Reference numeral 37 is cement slurry or construction adhesive etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com