Patents

Literature

31results about How to "Not easy to pull off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

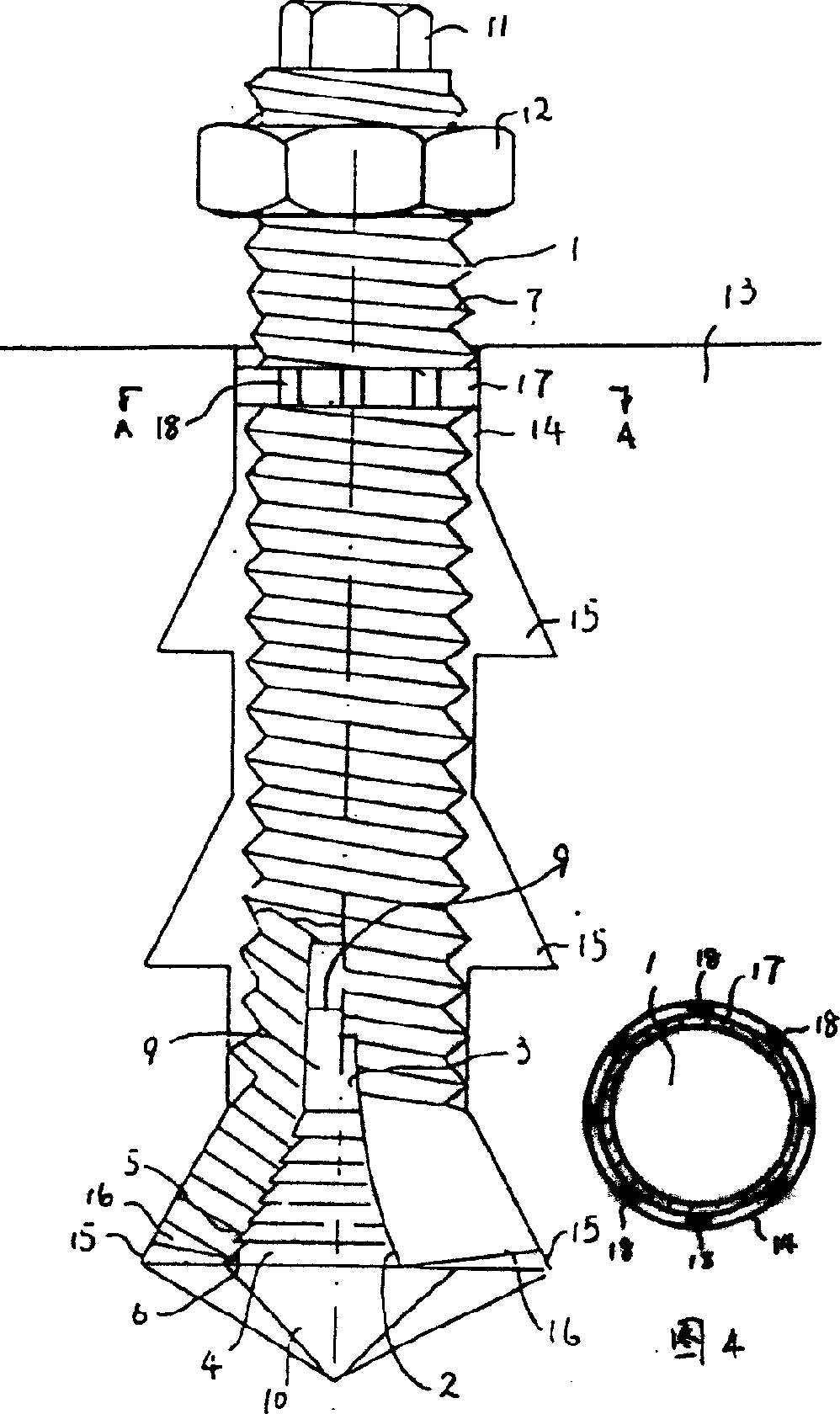

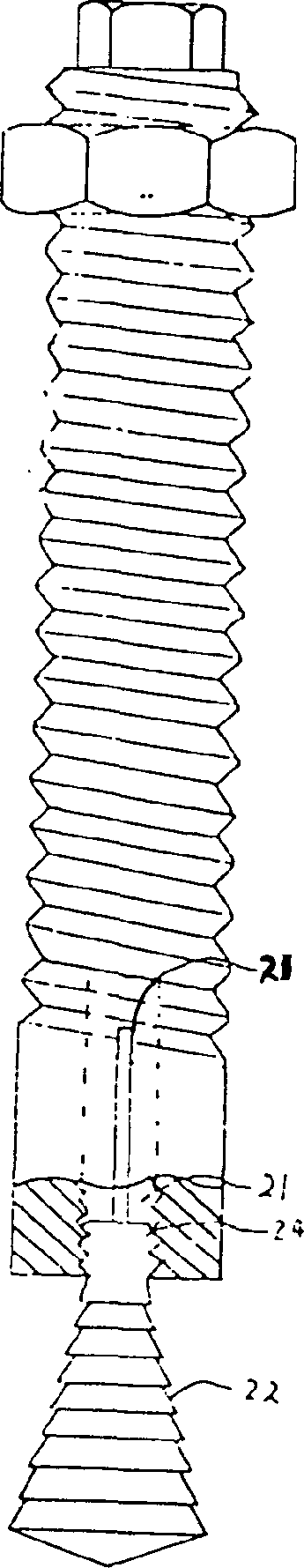

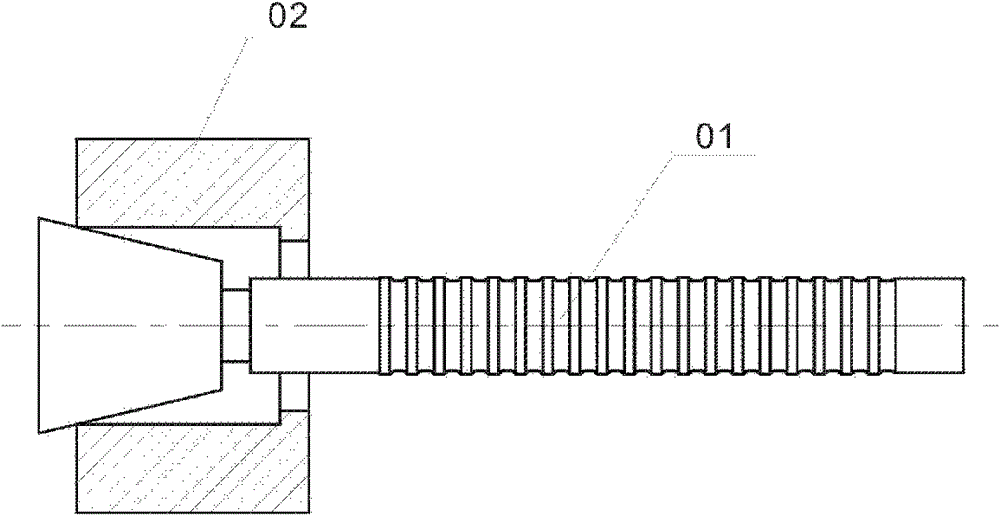

After-planting expansion piece

InactiveCN1587578AThe main structure is firm and strongHigh strengthBuilding reinforcementsEngineeringExpansion joint

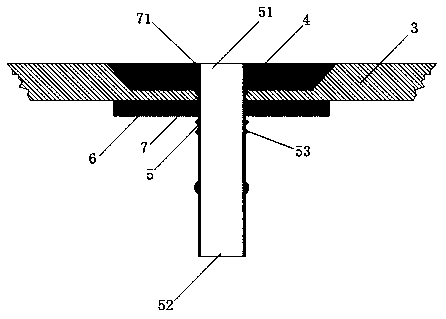

The post-mounted expansion unit includes an expansion rod, and an expansion mechanism in the lower part of the expansion rod, and the expansion mechanism includes the expansion hole in the lower part of the expansion rod, expansion slot and conic push head with guide section and matching the expansion hole. The said technological scheme has strong and firm expansion rod, and expansion mechanism with obviously raised connection strength between the post-mounted part and the deep hole. In addition, the expansion hole wall and the conic push head have anti-skid thread to further raise the connected strength.

Owner:徐洁媛

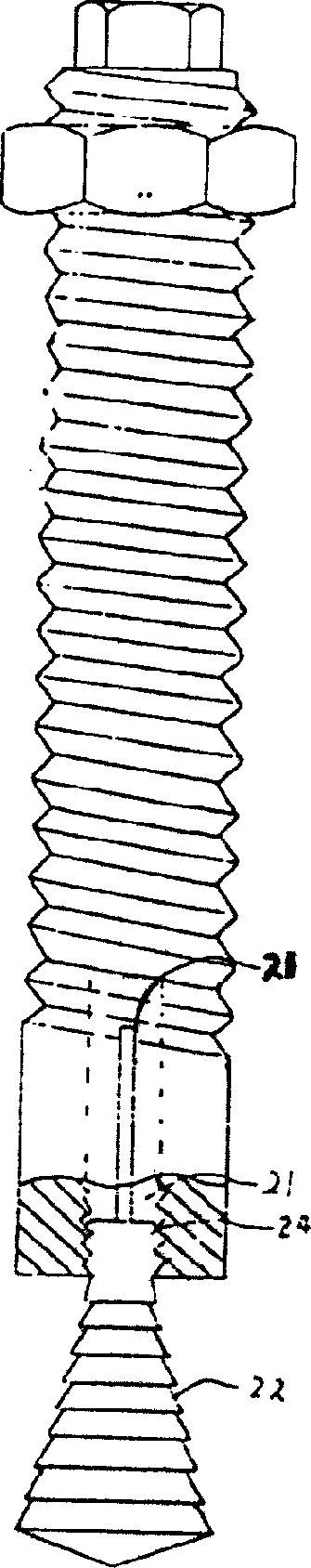

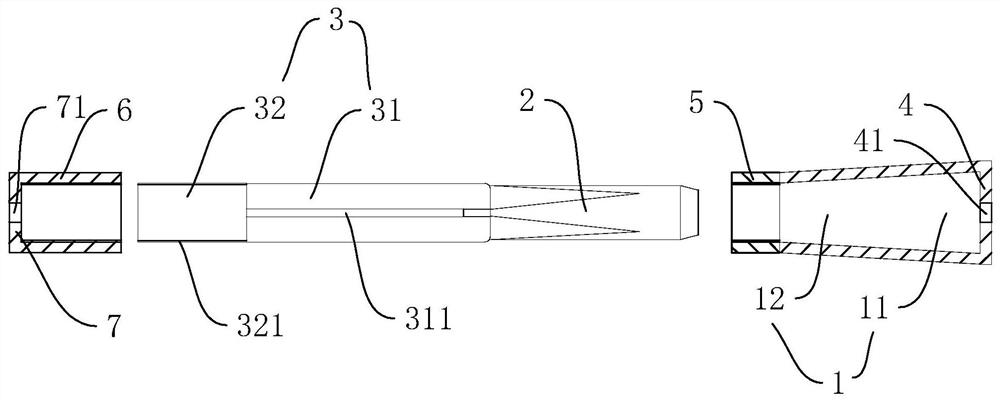

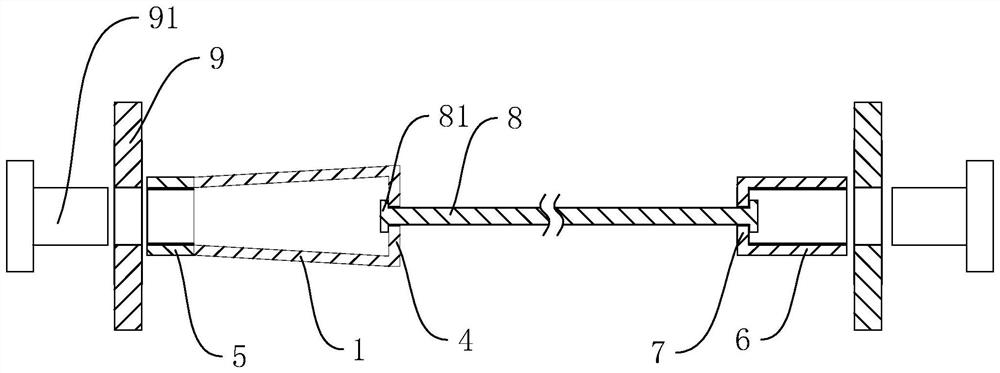

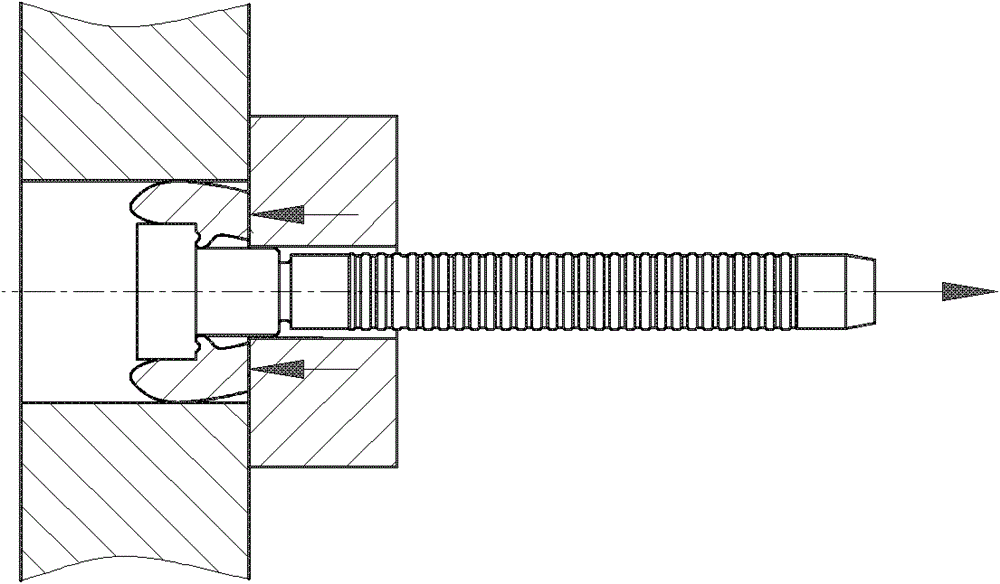

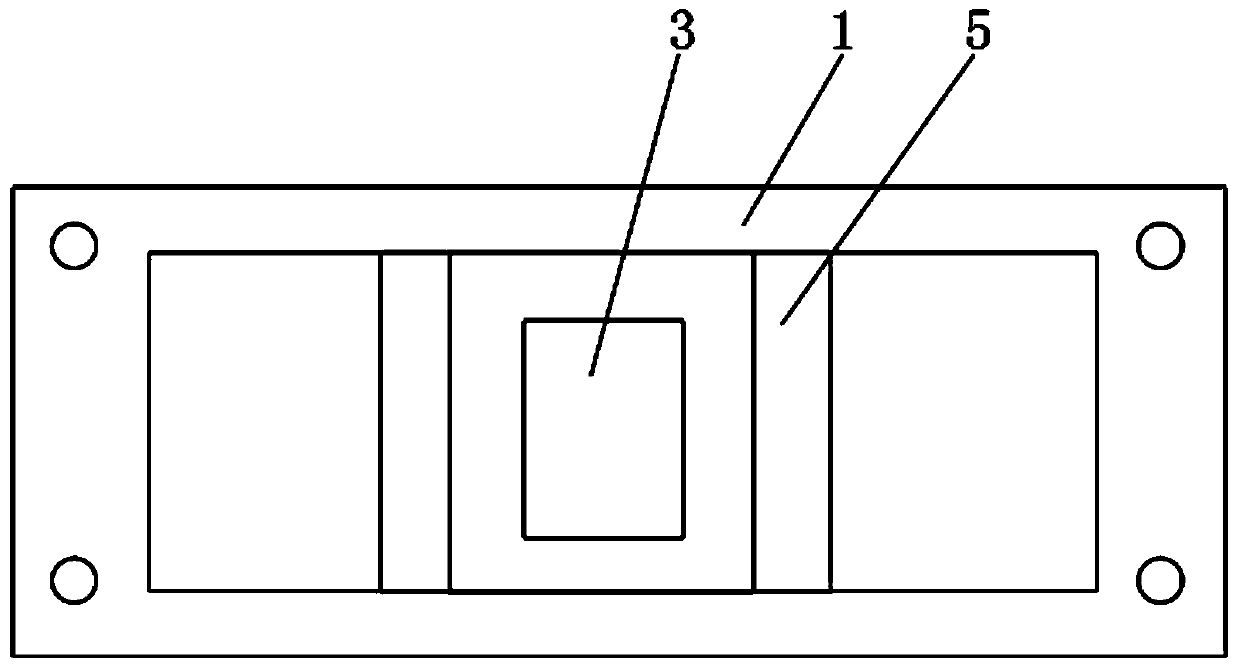

Pre-stressed concrete compression pipe pile tension connector without end plate and pipe pile

The invention discloses a pre-stressed concrete compression pipe pile tension connector without an end plate. The pre-stressed concrete compression pipe pile tension connector without an end plate comprises an expansion shell, a first sealing cover, an expansion connecting pin and a wedge-shaped part, wherein a through groove penetrating through both ends is formed in the expansion shell, the through groove comprises an extending section and a clamping section, the inner diameter of the clamping section is larger than that of the extending section, a first sleeve is arranged at the end, corresponding to the extending section, of the expansion shell, and an inner thread is arranged on the first sleeve; the first sealing cover is fixed to the end, corresponding to the clamping section, outside the expansion shell, and a first through hole is formed in the first sealing cover; the expansion connecting pin comprises a connecting section and an expansion section, an expansion groove is formed in the expansion section, the expansion groove extends axially from the end part of the expansion part to the connecting section, the expansion section is divided into at least two parts through the expansion groove, and the expansion section extends into the expansion shell; and the wedge-shaped part comprises a head part and a tail part, the outer surface of the wedge-shaped part is graduallyclosed inward from the head part to the tail part, and the wedge-shaped part extends into the expansion section along the expansion groove from the tail part to expand the expansion section. According to the pre-stressed concrete compression pipe pile tension connector without the end plate, materials are saved, the structure is simple, but connection is more reliable, and use is more convenient.

Owner:JIAXING WEIKAI MACHINERY CO LTD

Automobile temperature sensor

InactiveCN106813800AExtended service lifeImprove stabilityThermometers using electric/magnetic elementsUsing electrical meansThermistorReaction speed

The invention discloses an automobile temperature sensor, comprising a protective cover, a bracket is arranged inside the protective cover, a sensor is clamped in the middle of the bracket, an electric wire is arranged inside the sensor, and one end of the electric wire is connected to a thermosensitive resistance, the other end of the electric wire is connected to the tongue, the upper part of the protective cover is provided with a plug connector, the connection between the protective cover and the plug connector is provided with a sealing cover, and one side of the protective cover connects the wire body Injection connection with sensor. This kind of temperature sensor increases the service life of the temperature sensor, improves the stability between the temperature sensor and the wire body, reduces the cost, makes the overall use effect of the temperature sensor more obvious, and improves the response speed of the sensor head. It is simple and easy to install, and at the same time reduces the safety hazards existing in the car.

Owner:鼎佳(天津)汽车电子有限公司

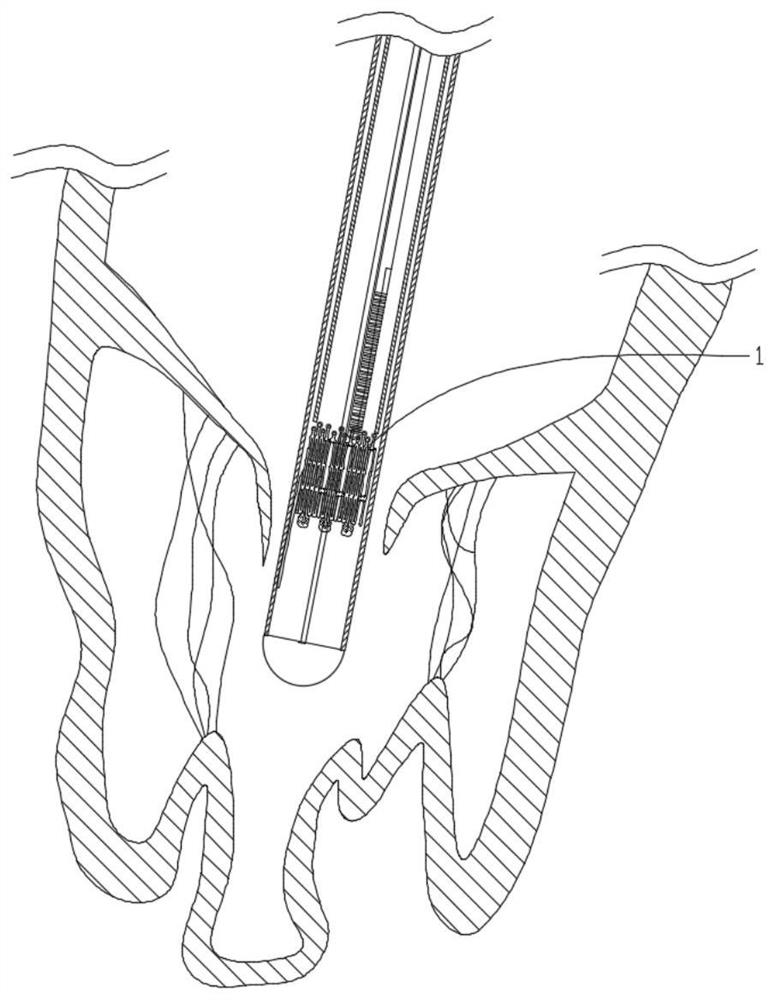

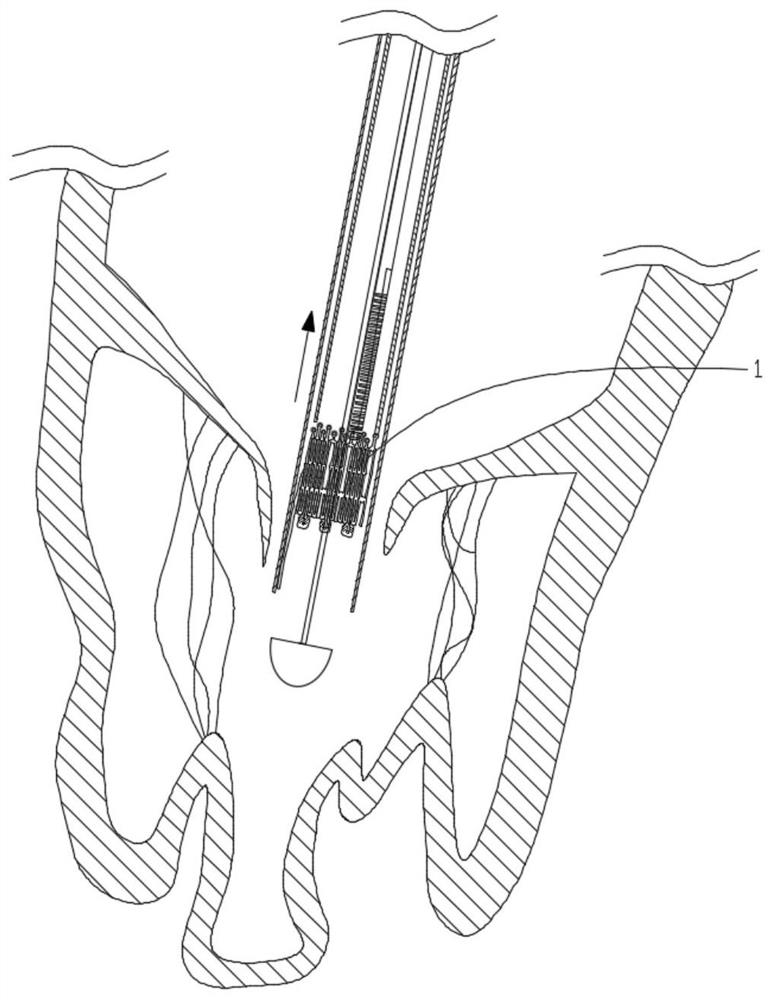

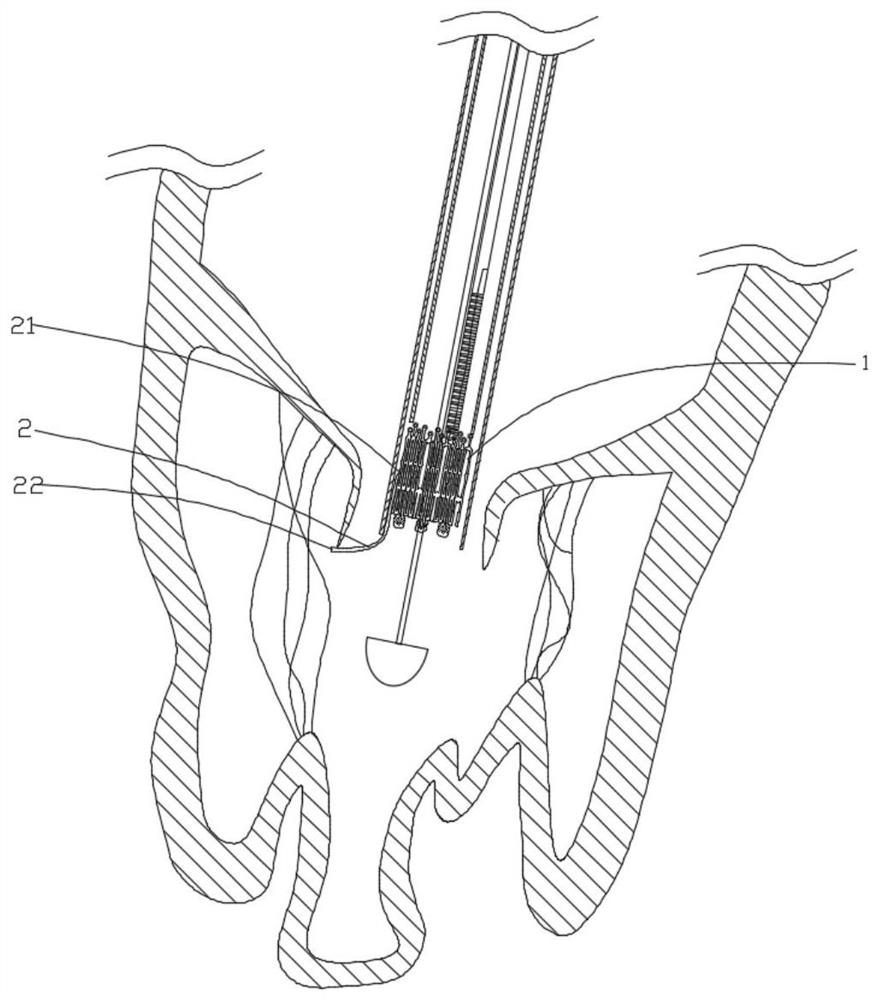

Multi-dimensional fixed heart valve prosthesis

The invention relates to the field of medical instruments, in particular to a multi-dimensional fixed heart valve prosthesis which comprises a support and a valve, the support comprises a valve sewing section and an atrium section, the valve is fixedly connected to the valve sewing section, the valve sewing section is connected with the atrium section in a matched mode, a valve leaflet clamping piece is arranged on the valve sewing section, an anti-falling anchoring mechanism is arranged on the atrium section, after the heart valve prosthesis is released, the valve leaflet clamping piece is connected with a front heart valve leaflet of a patient in a matched mode, and the anti-falling anchoring mechanism penetrates through the atrium section and is fixedly connected with the back valve tissue of the patient. The physiologico-anatomical structure of the heart is used skillful, the valve leaflet clamping piece is arranged in the front valve area, and is used for fixing the front valve; a two-way anchoring device is arranged in the back valve area, so that the back valve area of the patient is fixed; the combination of the two enables the valve prosthesis to have multi-dimensional anchoring force, and the anchoring effect of the valve prosthesis in the heart is ensured.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

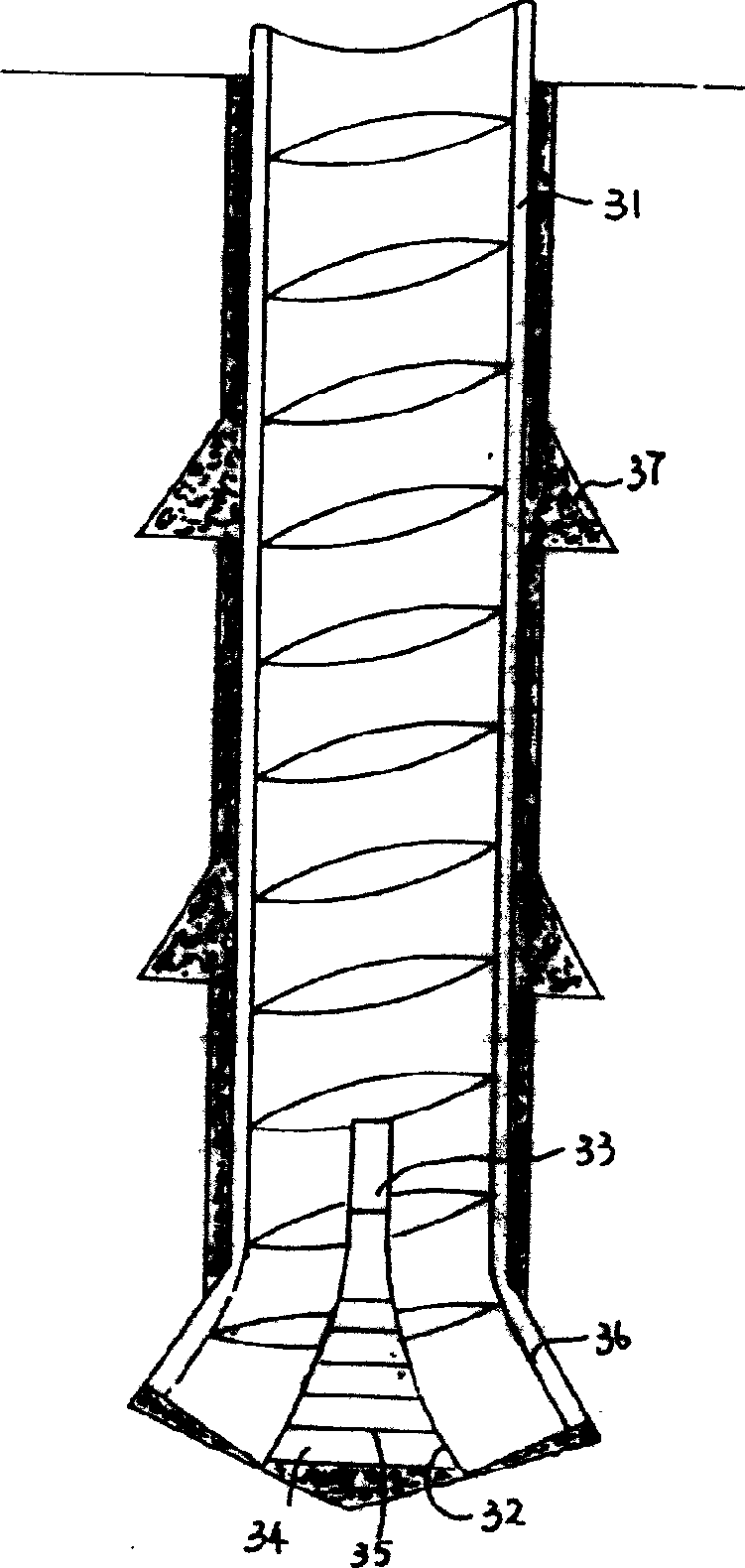

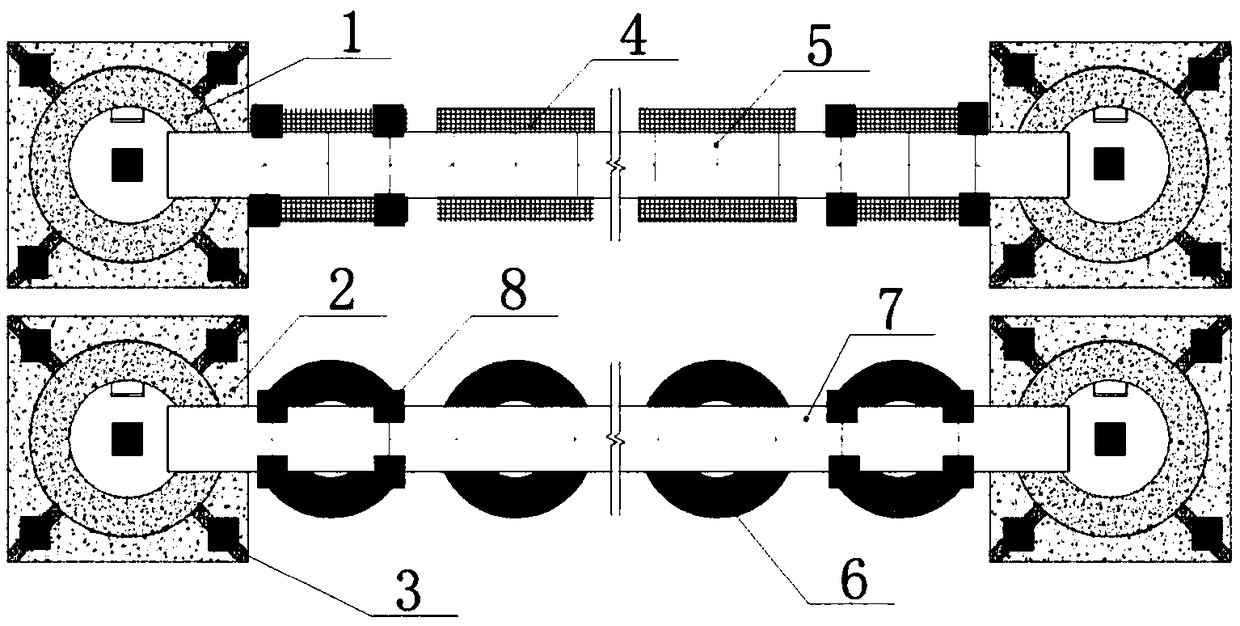

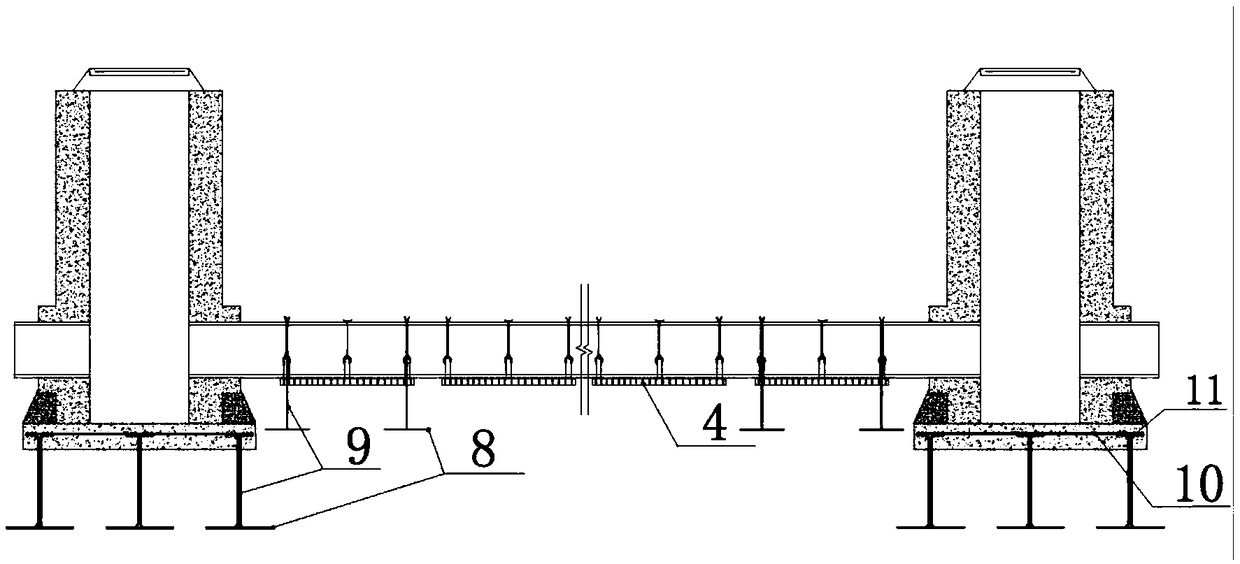

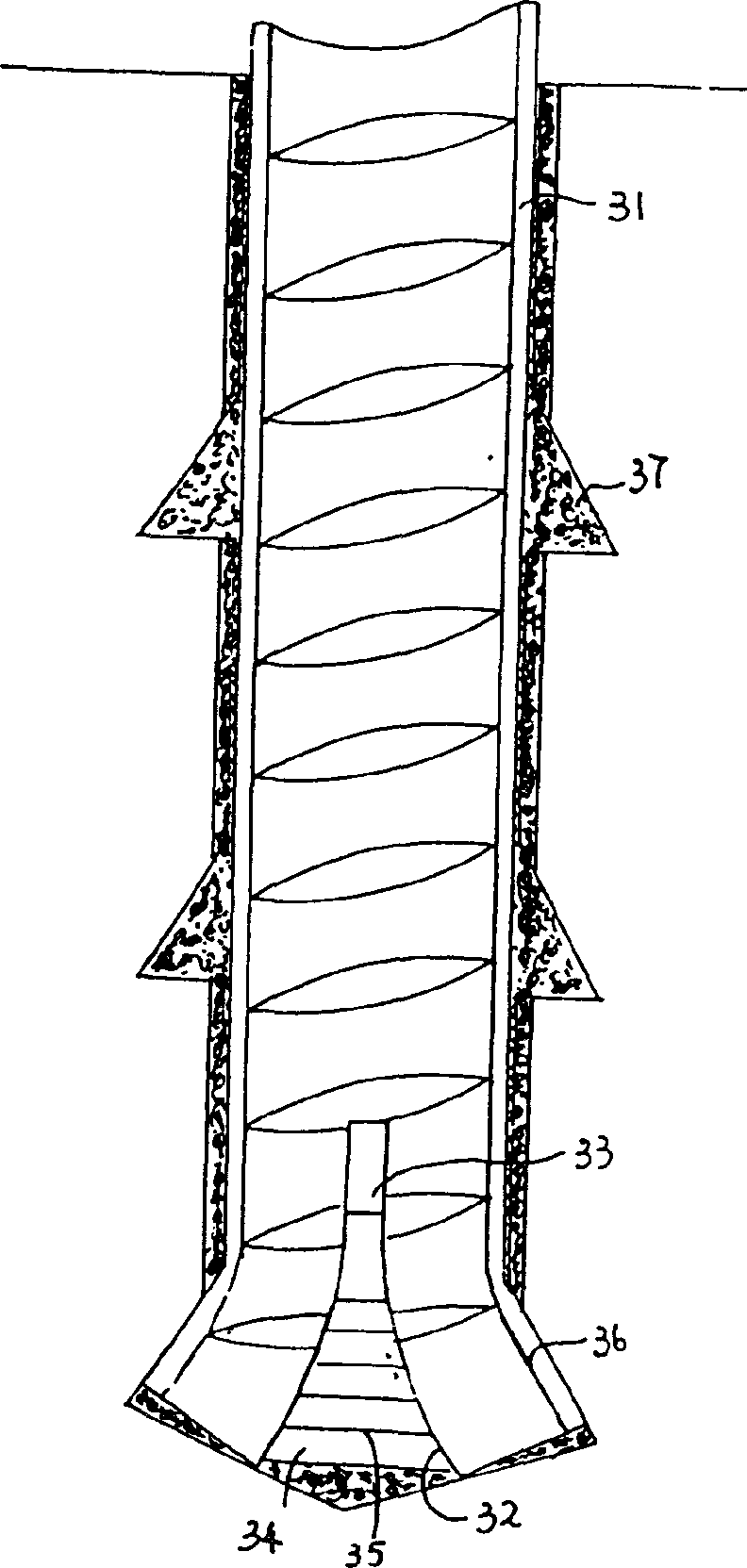

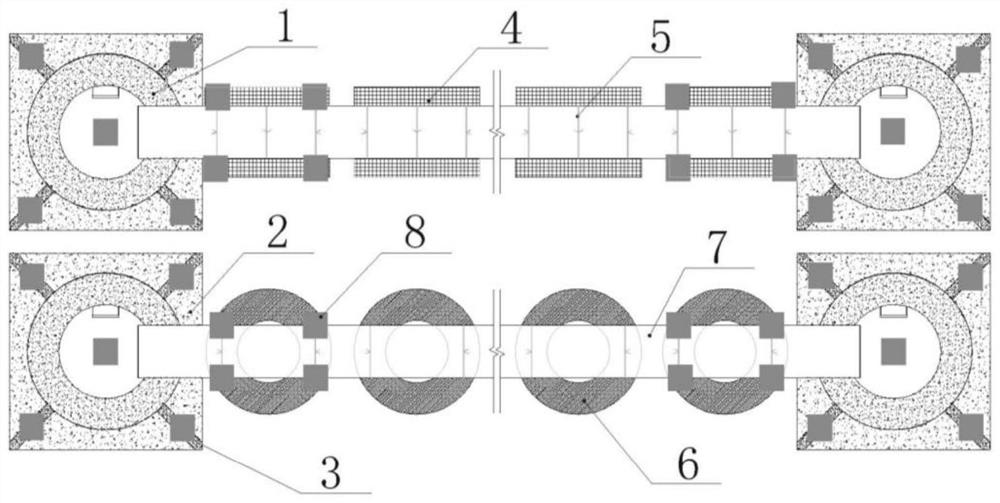

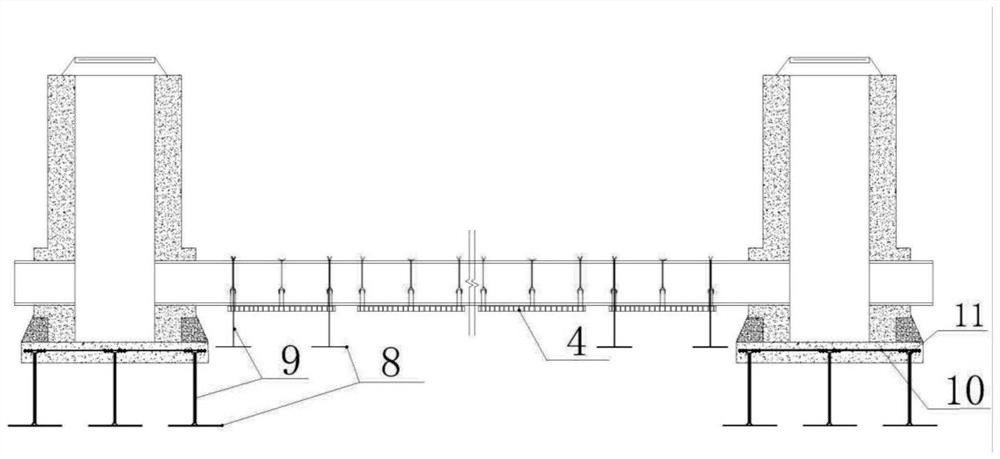

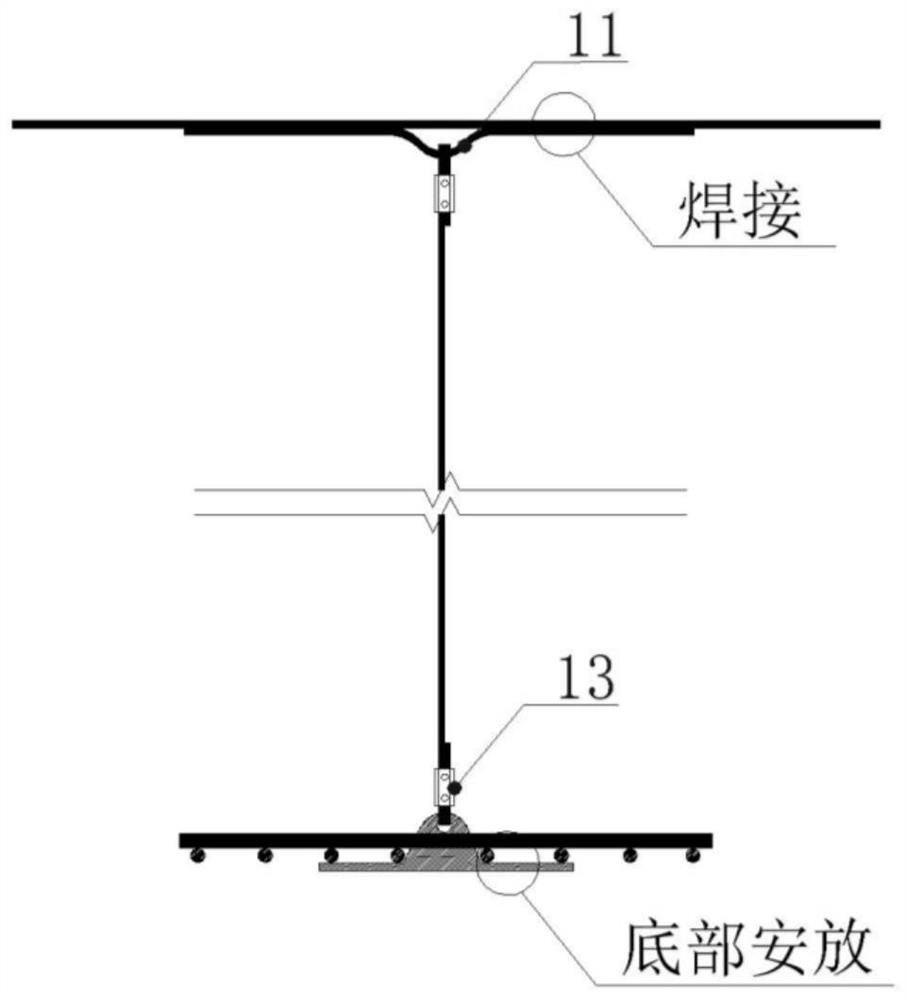

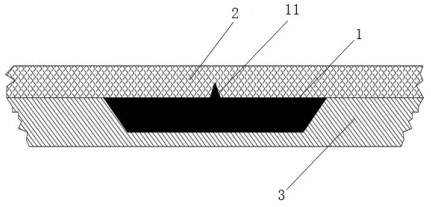

Anti-floating system and construction method of sandbar sewage pipe, well

ActiveCN108894206AEliminate buoyancyAvoid deformationProtective foundationSoil preservationArchitectural engineeringSewage

The invention discloses a sandbar sewage pipe, well anti-floating system, include anti-float plates, Bundle wire, clip rib, steel mesh, U-groove ribs, steel plate fasteners, Staples, bracing ropes, Anti-float plate are arranged at that bottom of the pipeline and bind to the pipeline through bundle wires, A loc wire rib is inserted into that inn side of the bundle wire, and a binding surface with the pipe is added. The steel bar mesh sheet is arranged below the pipe and below the sewage well. The steel bar mesh sheet is welded with U-groove reinforcement or steel plate buckle, and the U-groovereinforcement is not only welded with the mesh surface of the steel bar mesh sheet, but also bound or welded with the reinforcement of the bottom plate foundation; The steel plate buckle is welded onthe reinforcing bar mesh sheet or pierced from the bottom of the reinforcing bar mesh sheet; The clasp binds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The claspbinds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The invention also discloses a construction method of the sandbar sewage pipe and the well anti-floating system. The invention changes the traditional method of deep burying, increasing dead weight and increasing fixed foundation, and provides a stable and safe anti-floating system and construction method forsandbar high-water-level pipe and well construction.

Owner:CHINA FIRST METALLURGICAL GROUP

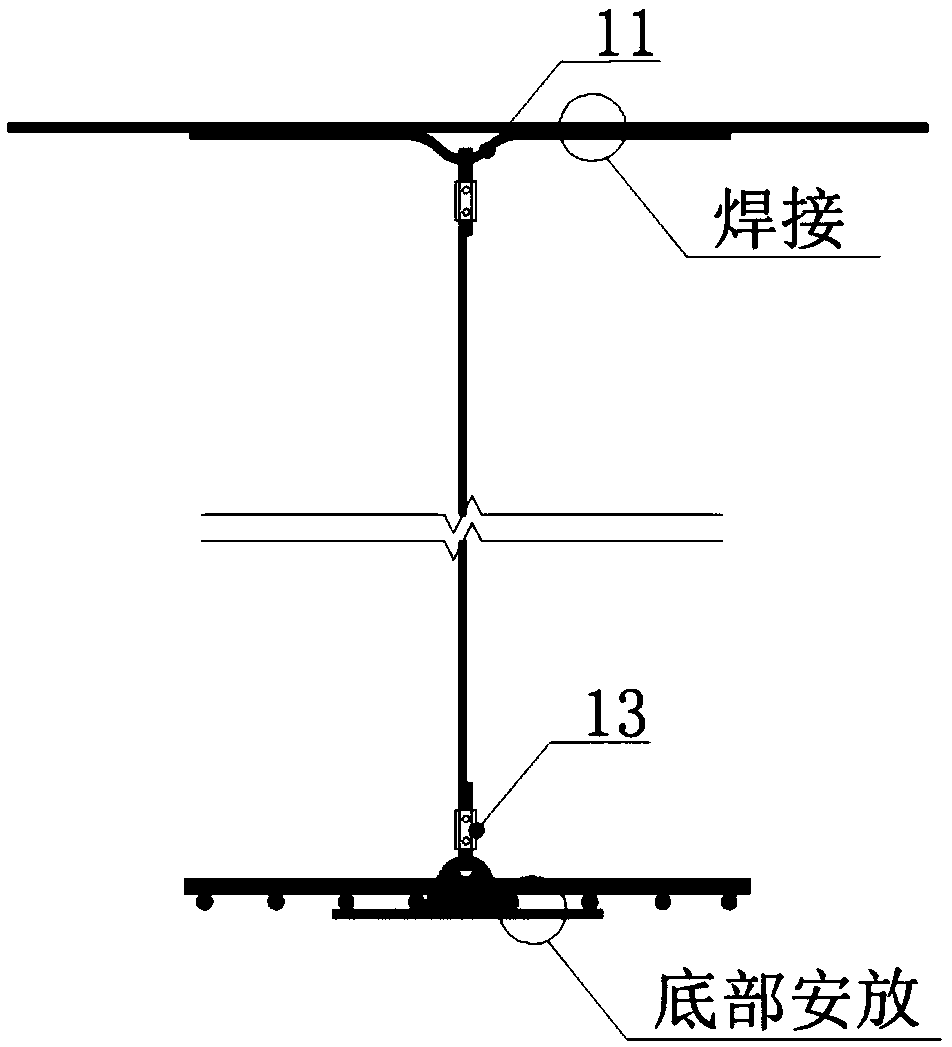

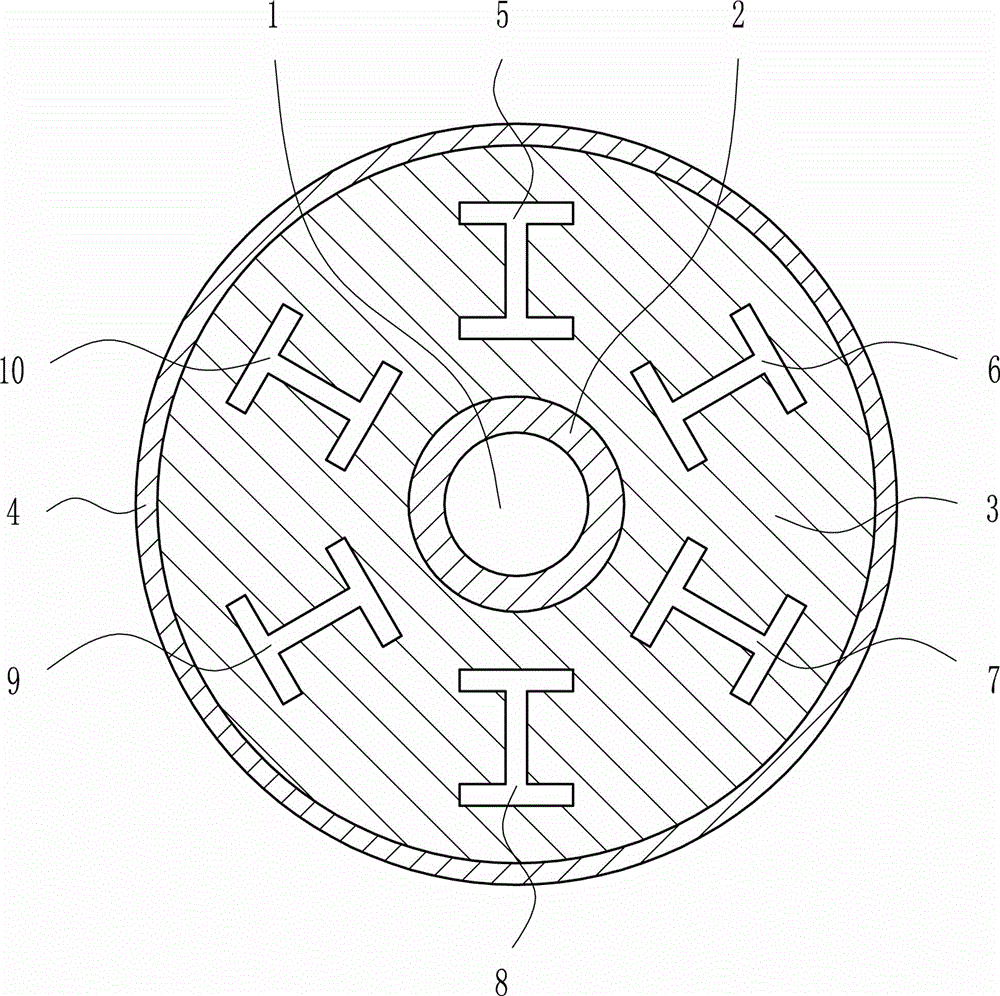

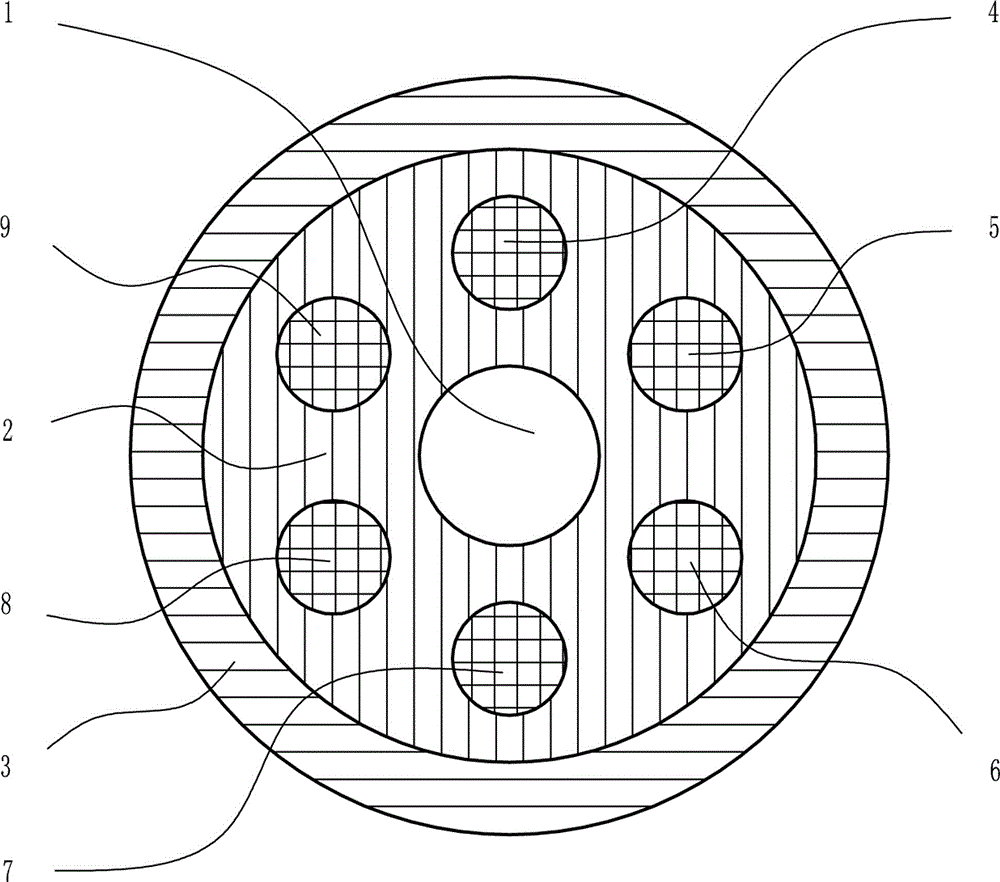

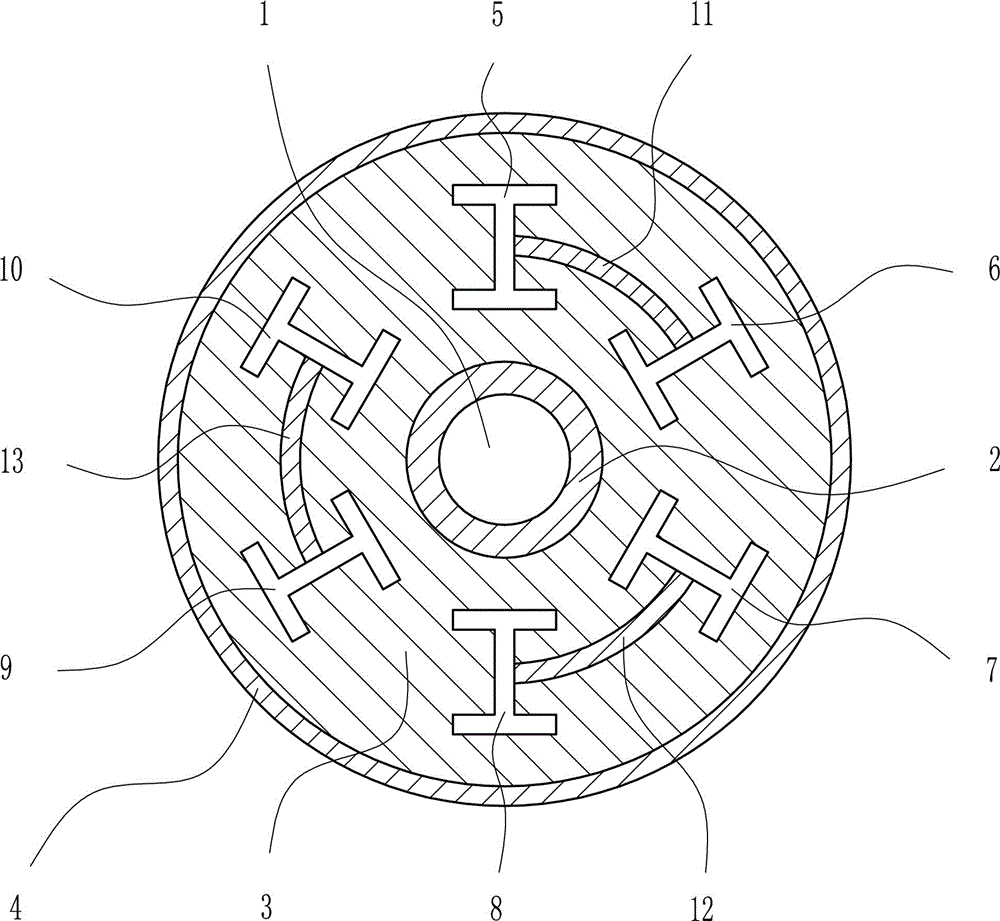

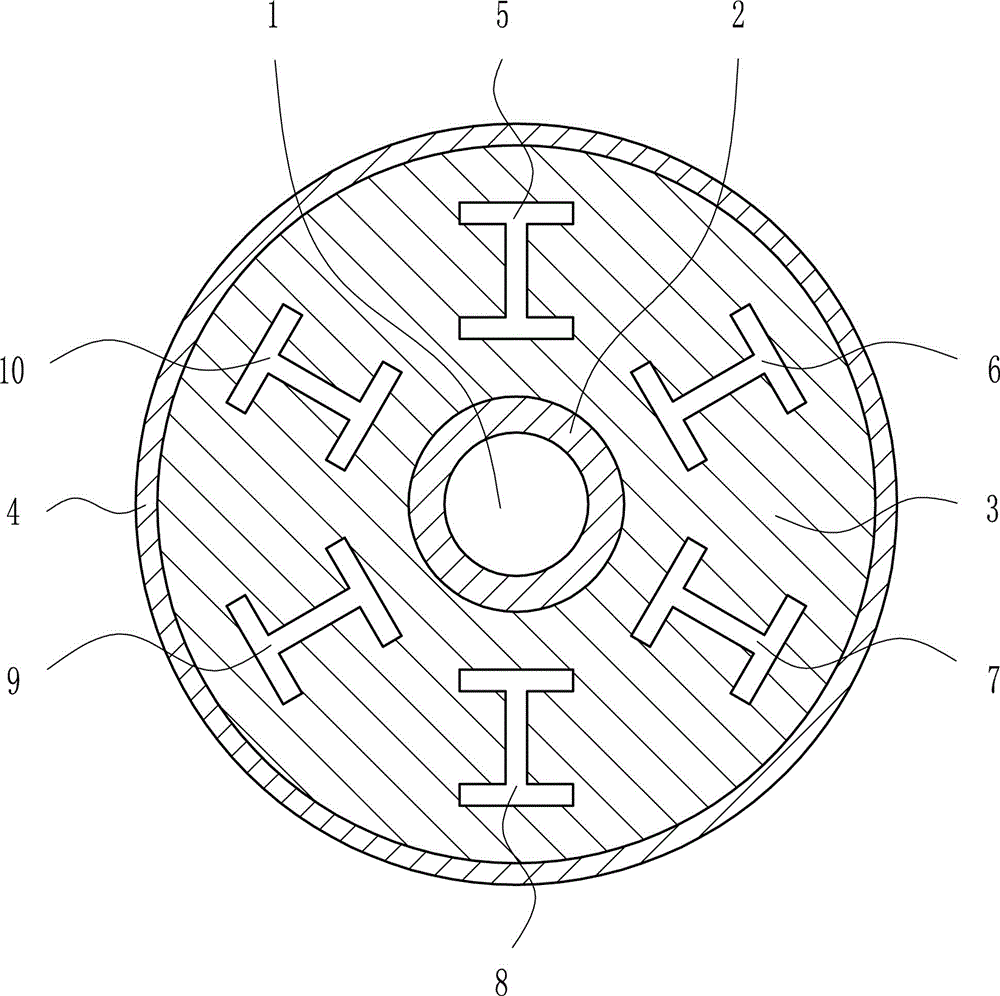

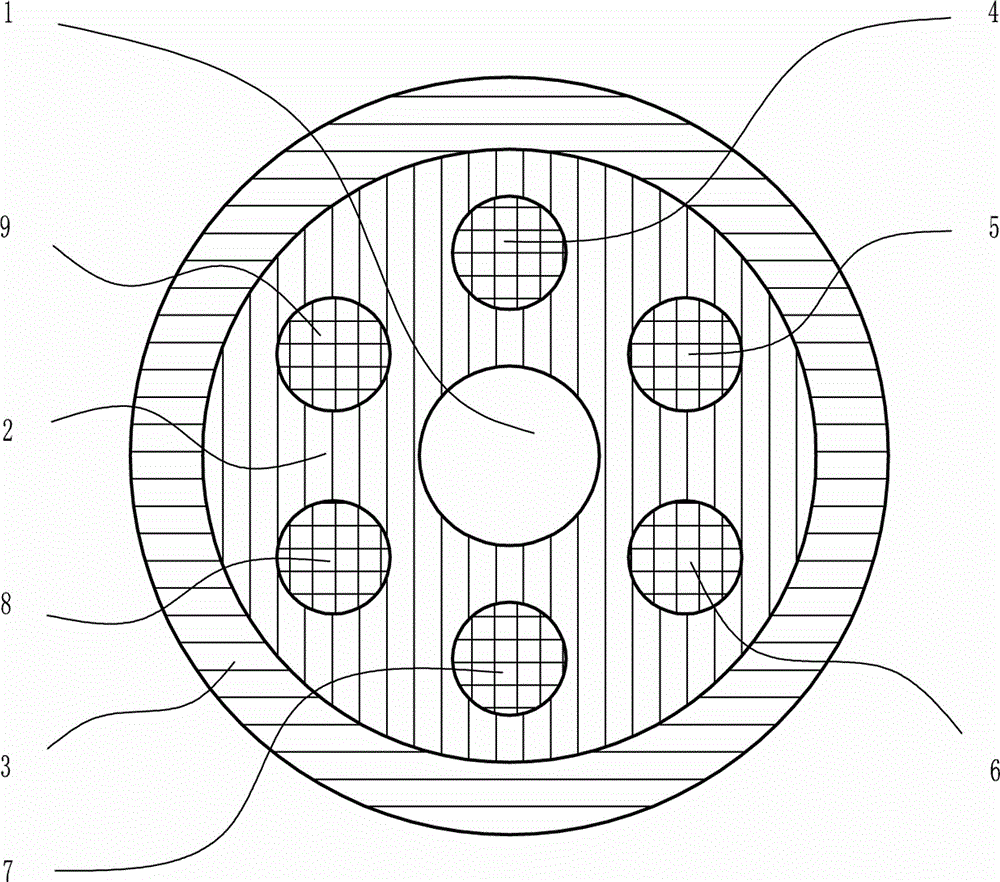

High-tensile copper-clad steel wire rod

ActiveCN104681119AImprove tensile propertiesImprove deformation resistanceMetal/alloy conductorsWire rodEconomic benefits

The invention belongs to the technical field of copper-clad steel and in particular relates to a high-tensile copper-clad steel wire rod. The high-tensile copper-clad steel wire rod provided by the invention comprises a low-carbon steel layer, a pure iron layer and a copper-clad layer, a low-carbon I-beam I, a low-carbon I-beam II, a low-carbon I-beam III, a low-carbon I-beam IV, a low-carbon I-beam V and a low-carbon I-beam VI are evenly arranged in the pure iron layer in the circumferential direction, the carbon content of the low-carbon steel layer is 0.15% to 0.2 %, the carbon content of the pure iron layer is 0.02% to 0.04 %, and the carbon content of the low-carbon I-beam I, the carbon content of the low-carbon I-beam II, the carbon content of the low-carbon I-beam III, the carbon content of the low-carbon I-beam IV, the carbon content of the low-carbon I-beam V and the carbon content of the low-carbon I-beam VI are all 0.2% to 0.25%. The high-tensile copper-clad steel wire rod comprises a plurality of low-carbon I-beams, so that the tensile property is improved, the service life is prolonged, and considerable economic benefits can be obtained.

Owner:JINGGANGSHAN JIDA METAL

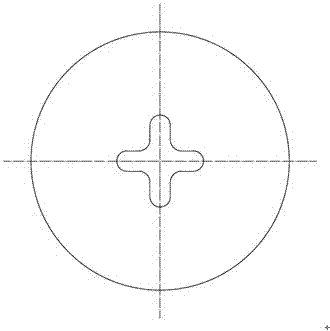

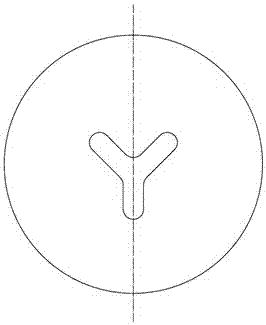

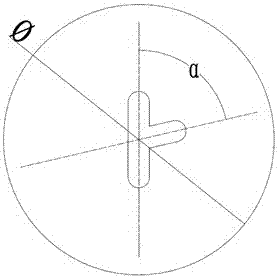

A seeding method for growing sapphire crystals by Kyropoulos method

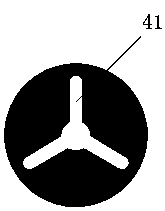

InactiveCN105019023BEasily brokenImprove yieldPolycrystalline material growthUsing seed in meltEngineeringSymmetric structure

The invention relates to a seeding method for growth of sapphire crystal with a KY (Kyropoulos) method. A non-rotating symmetric structure of a radiation heat dissipation opening of seed crystal is used, and the seeding method comprises following steps during seeding: (1), the seed crystal is immersed 3-5 mm below the liquid level of melt; (2), a crystal plate grows out from the seed crystal preferentially towards one side after the heat dissipation opening adopting the non-rotating symmetric structure dissipates heat; (3), the seed crystal is lifted and pulled at an average lifting and pulling speed being 3-12 mm / h, alternate instant lifting is adopted in the lifting and pulling process, the seed crystal is rotated by a given angle, and a crystal plate grows out again in the heat dissipation direction after alternate instant lifting, so that next instant lifting is facilitated; (4), the step (3) is carried out repeatedly until the length of a crystal section reaches 60-80 mm, the crystal section adopting a spiral structure is formed, and when the equivalent diameter of the cross section of a solid-liquid interface reaches 40-60 mm, seeding is finished. The seeding method has the advantages as follows: the spiral seeding structure can be obtained, defects and dislocation of the seed crystal can be eliminated to the largest extent, breaking cannot be caused easily, the yield of crystal can be increased, and industrial production is facilitated.

Owner:JIANGSU CEC ZHENHUA CRYSTAL TECH

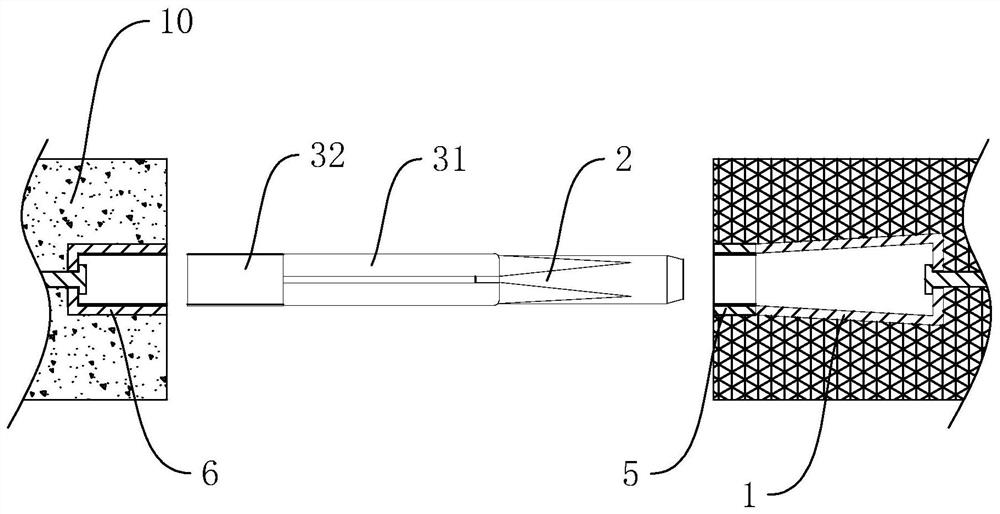

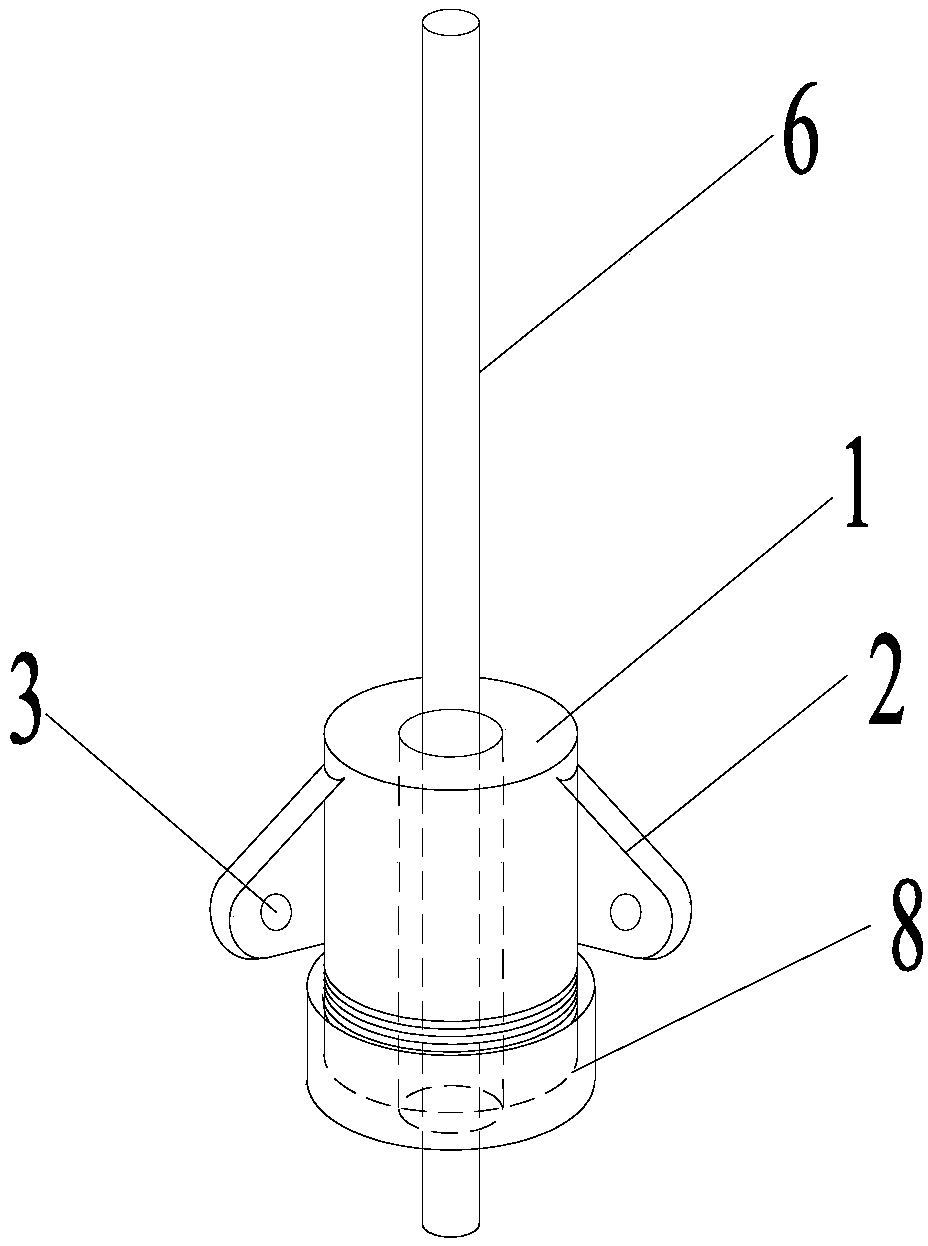

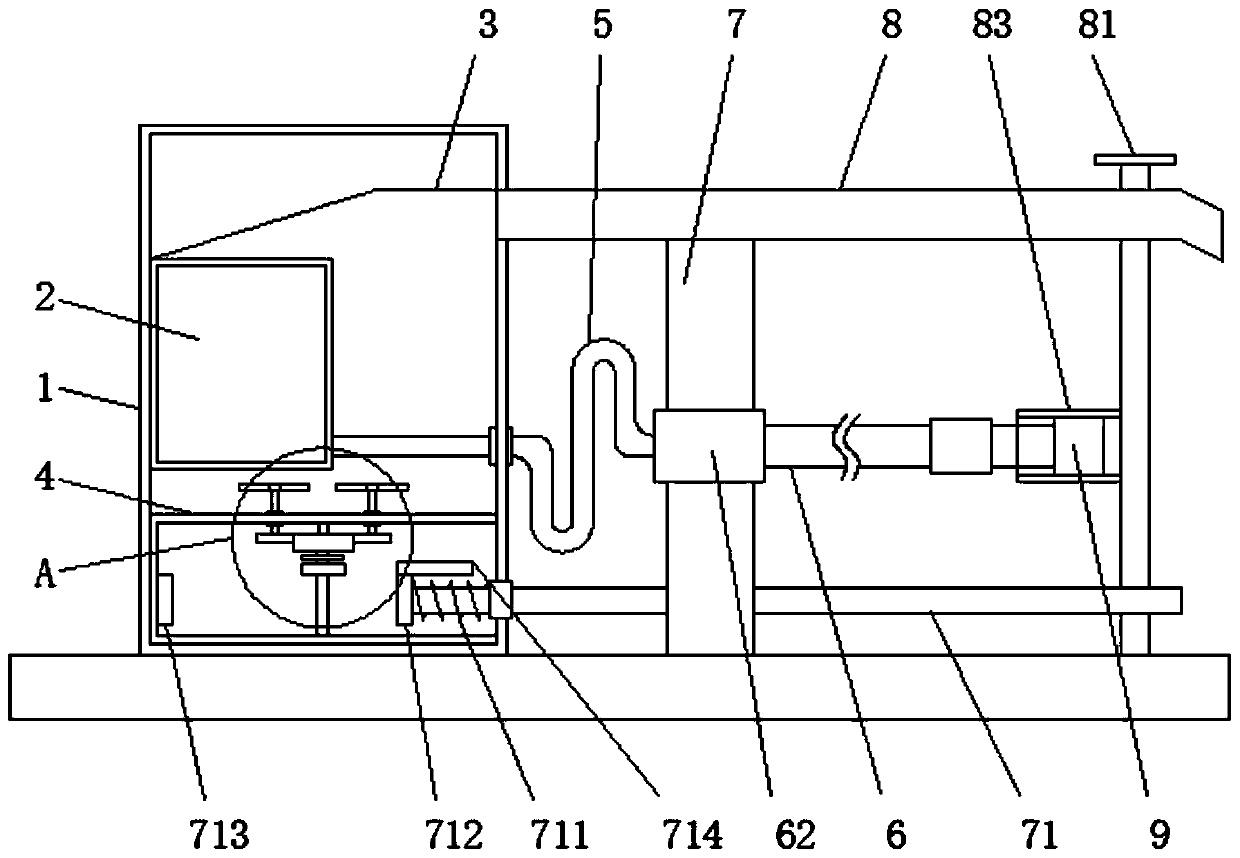

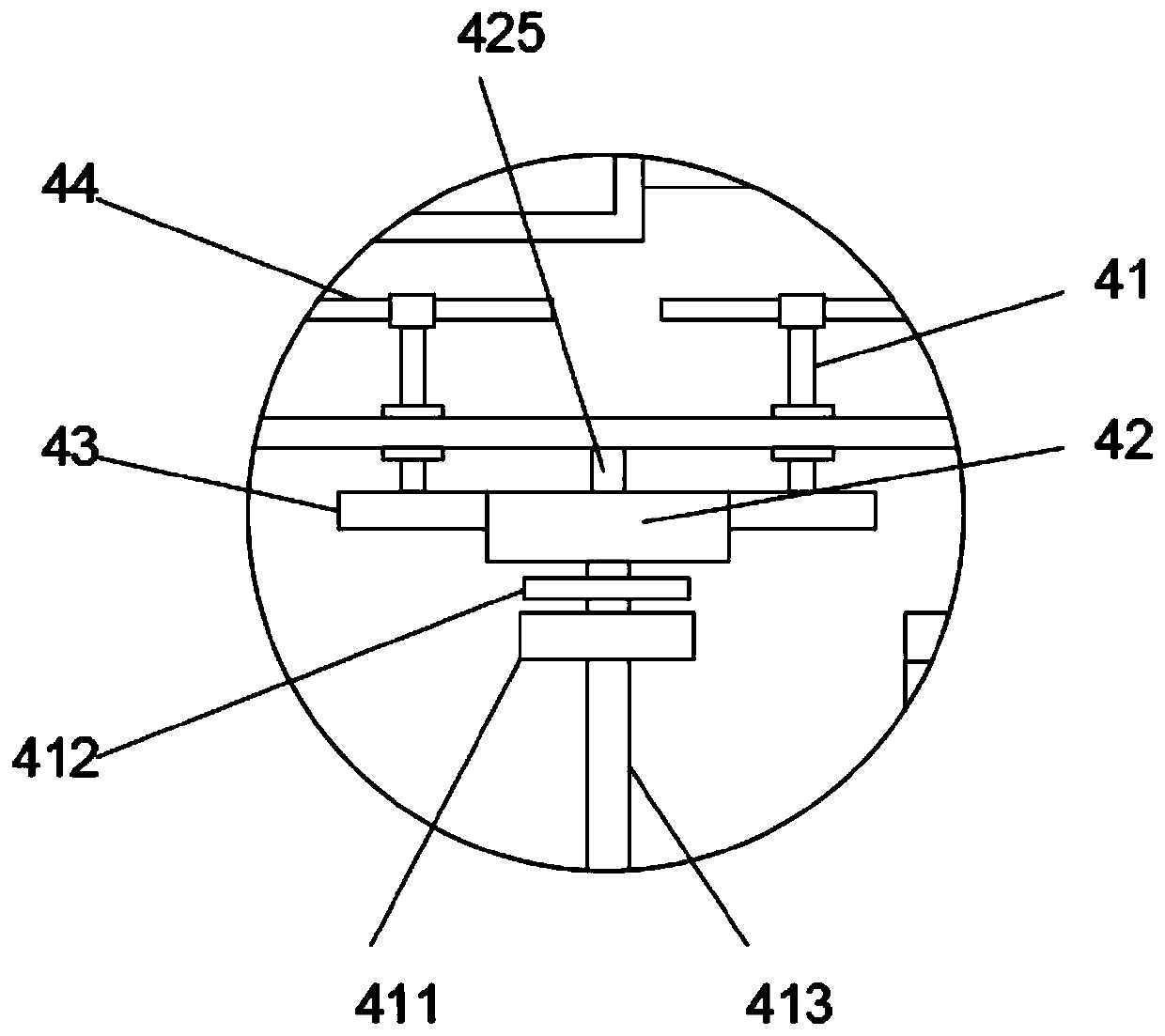

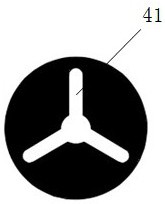

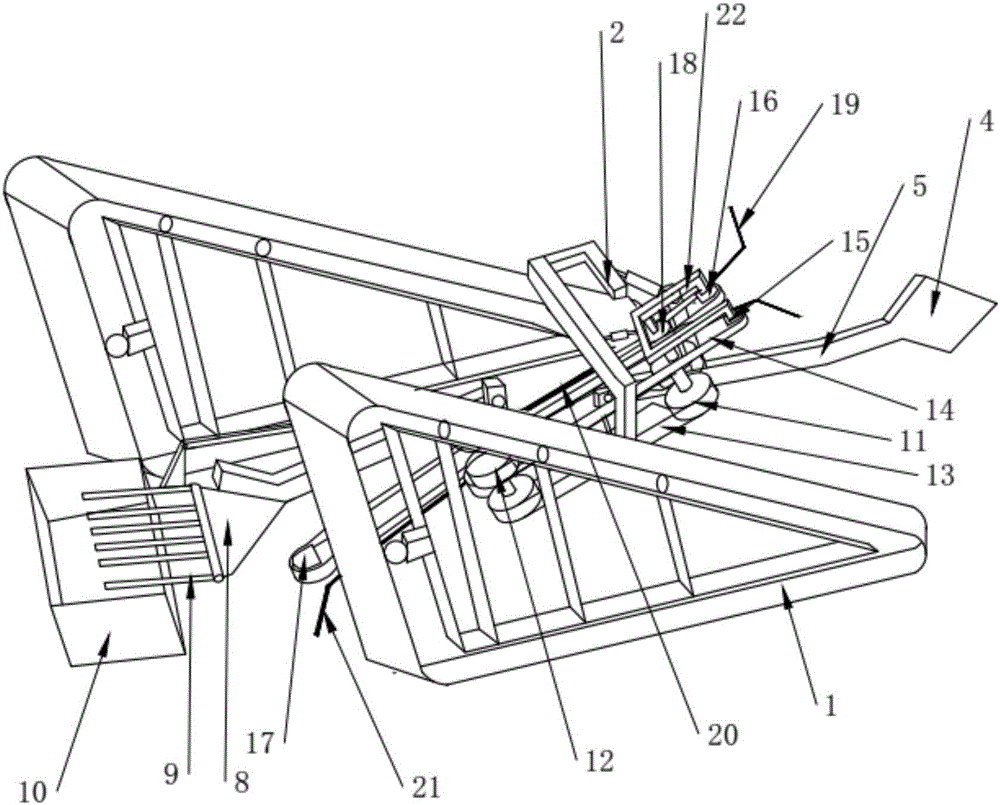

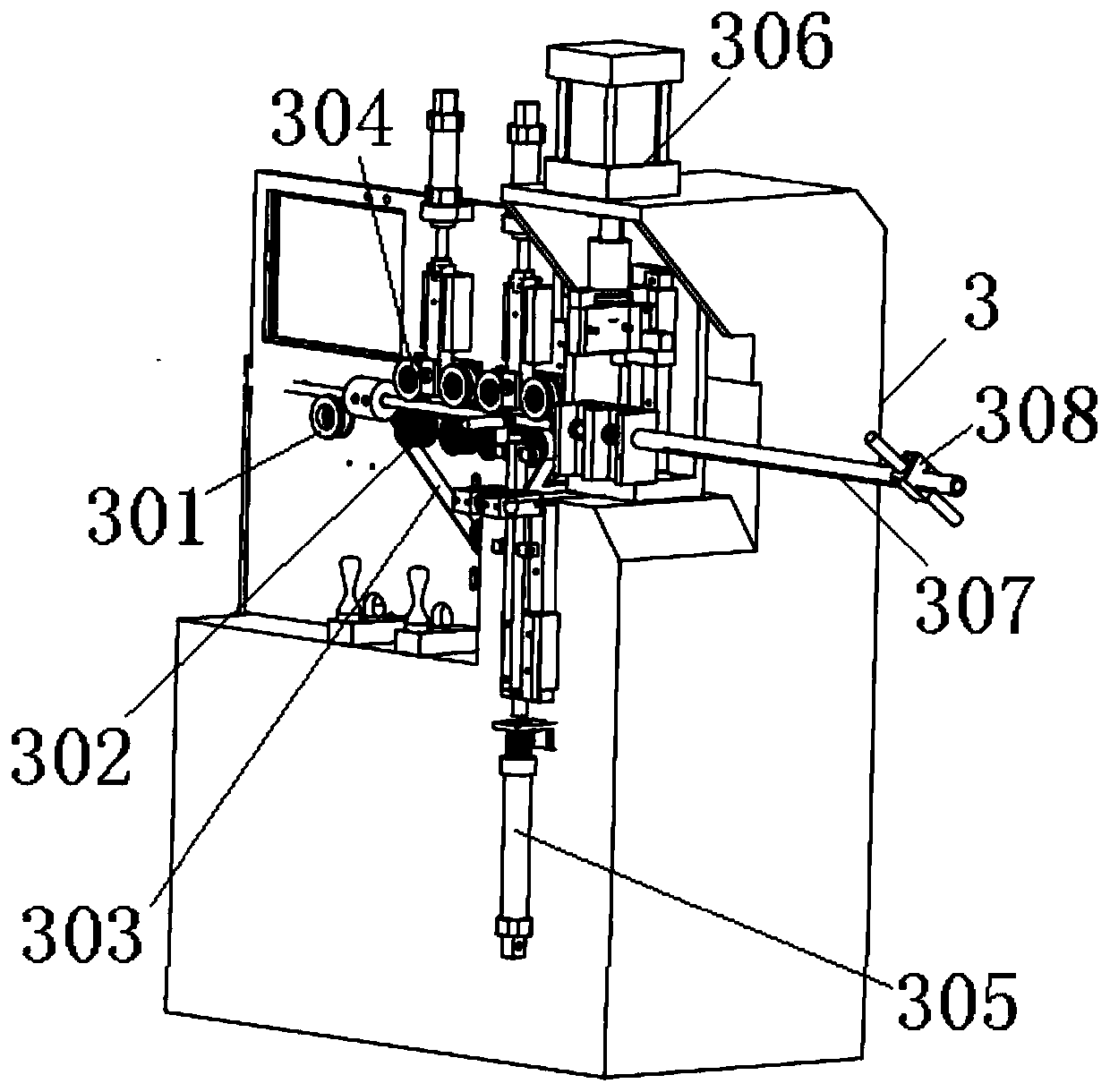

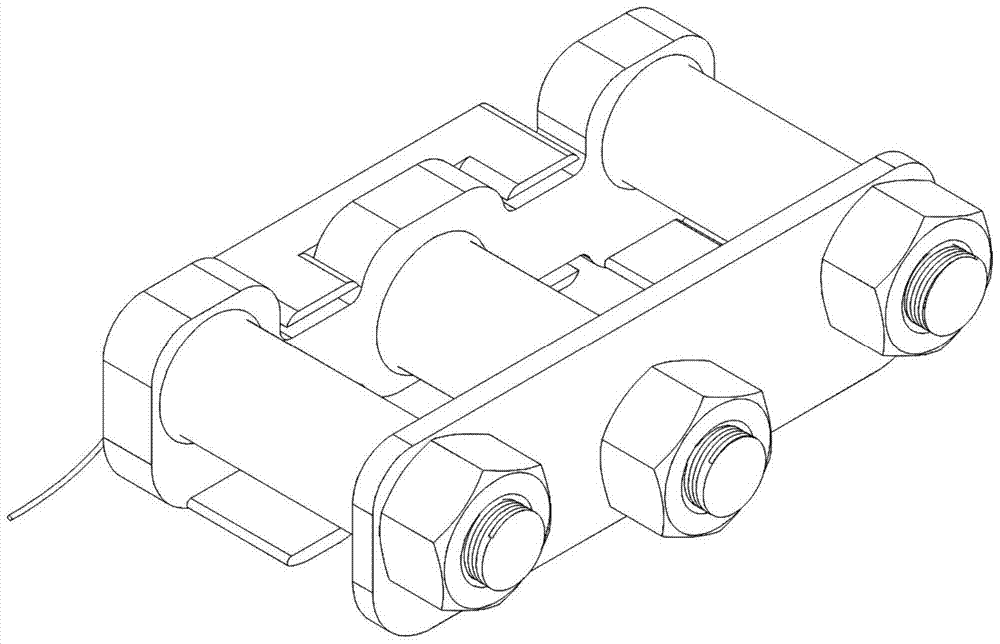

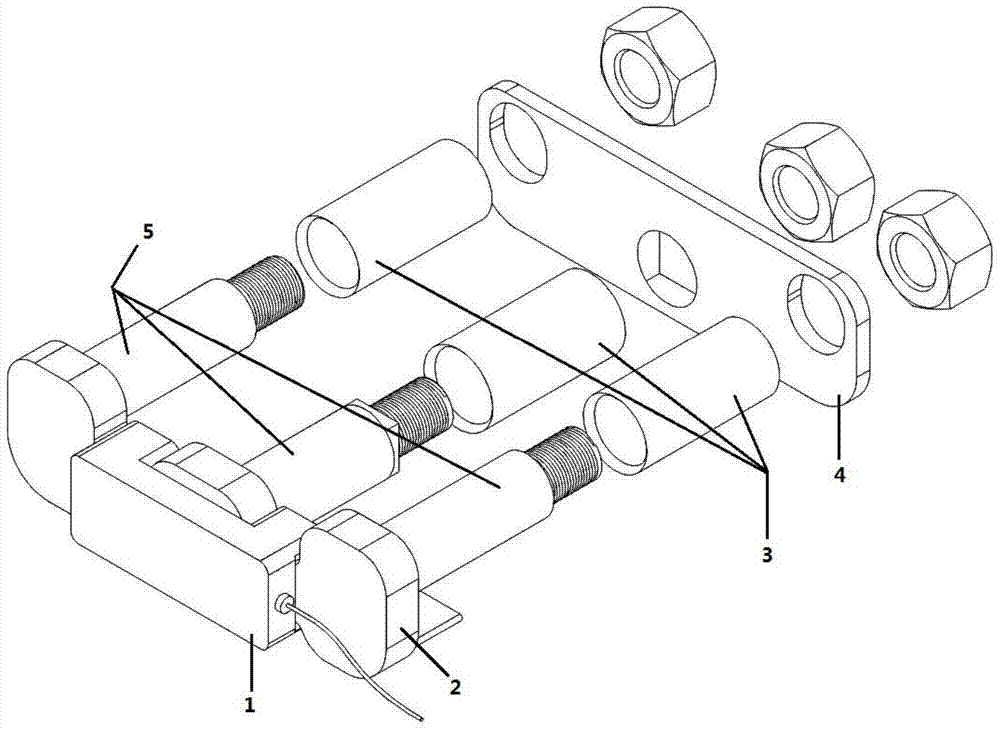

Coal mine thread jamming machine and using method thereof

PendingCN108975150AEasy to assemble and disassembleLight weightRopes and cables for vehicles/pulleyLoad-engaging elementsEar shapingEngineering

The invention provides a coal mine thread jamming machine and a using method thereof. The coal mine thread jamming machine can be applicable to underground coal mine. The coal mine thread jamming machine comprises a tapered sleeve, the tapered sleeve is of a cylindrical structure, the interior of the tapered sleeve is provided with a tapered opening hole allowing an anchor cable to penetrate through, the two sides of the tapered sleeve are provided with two ear-shaped structures respectively, each ear-shaped structure is provided with a connection hole, the two ear-shaped structures are provided with unloading buckles through threaded nuts respectively, the two unloading buckles are provided with lifting ropes in a quality testing mode, a fastening clamping sheet is arranged between the anchor cable and a tapered sleeve through hole, the tapered sleeve is provided with a lid-shaped separator which fixes the clamping sheet into the tapered sleeve through hole, the middle of the lid-shaped separator is provided with a round hole allowing the anchor cable to penetrate through, and the separator is in threaded matching with the lower part of the tapered sleeve. The coal mine thread jamming machine is simple in structure, easy to use, low in cost, high in reliability and convenient to dismount.

Owner:徐州和盛矿业科技有限公司 +1

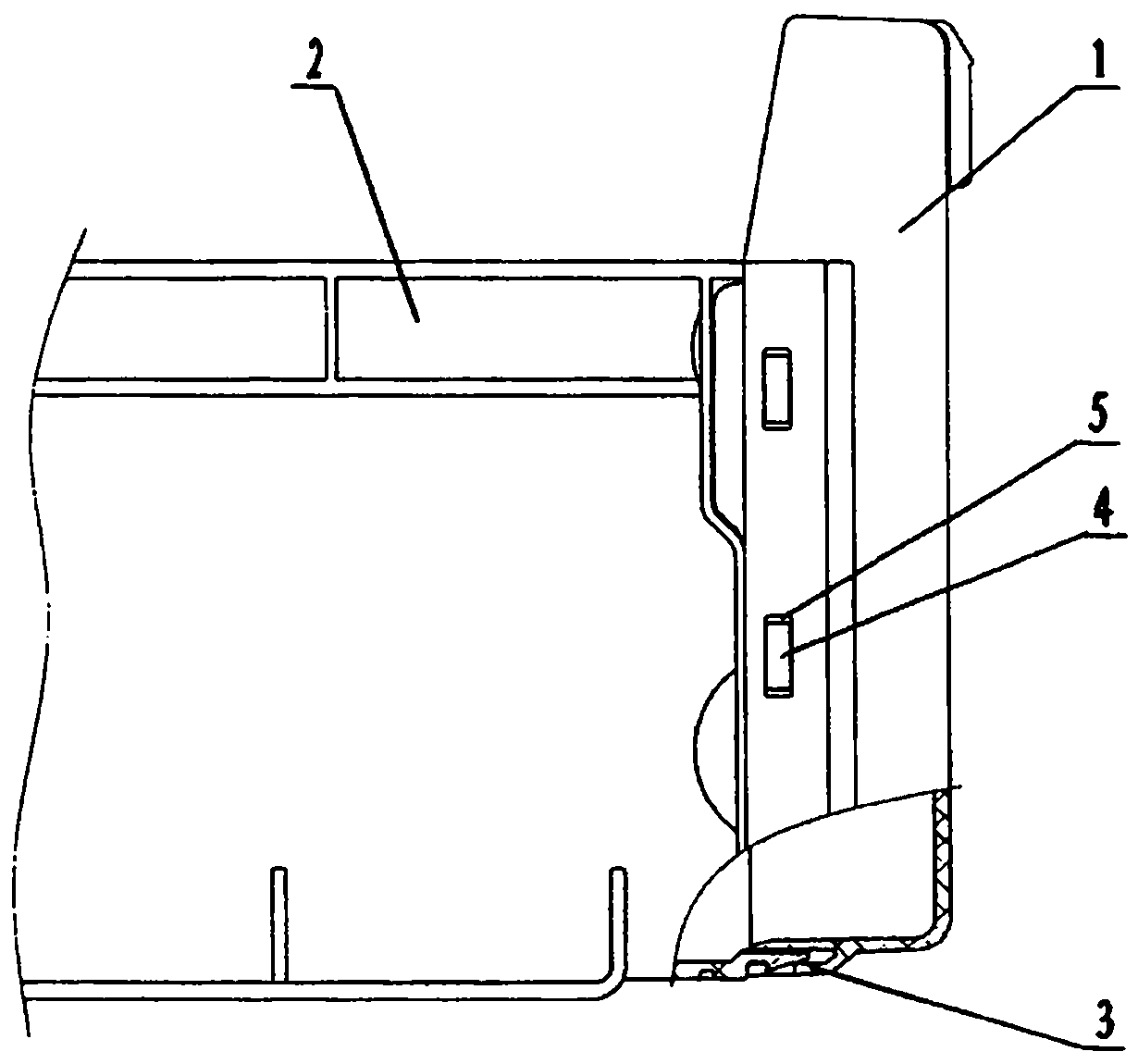

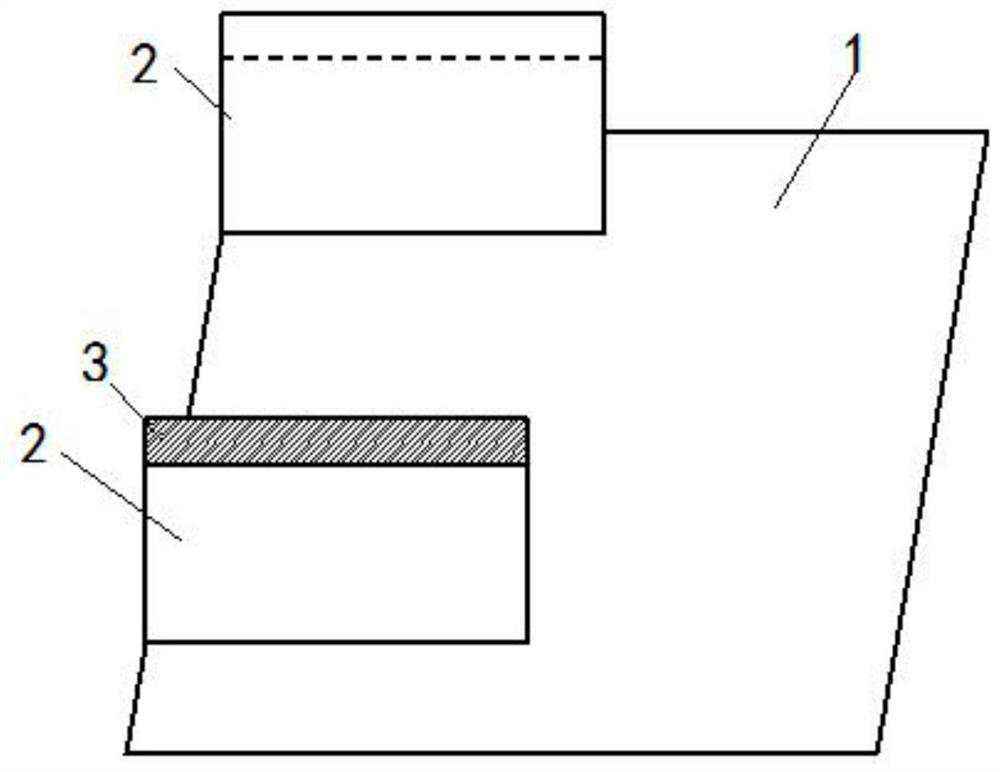

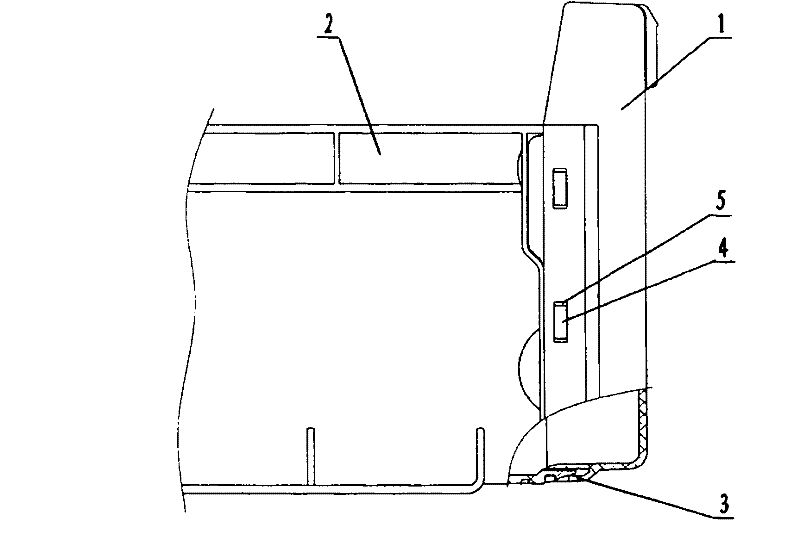

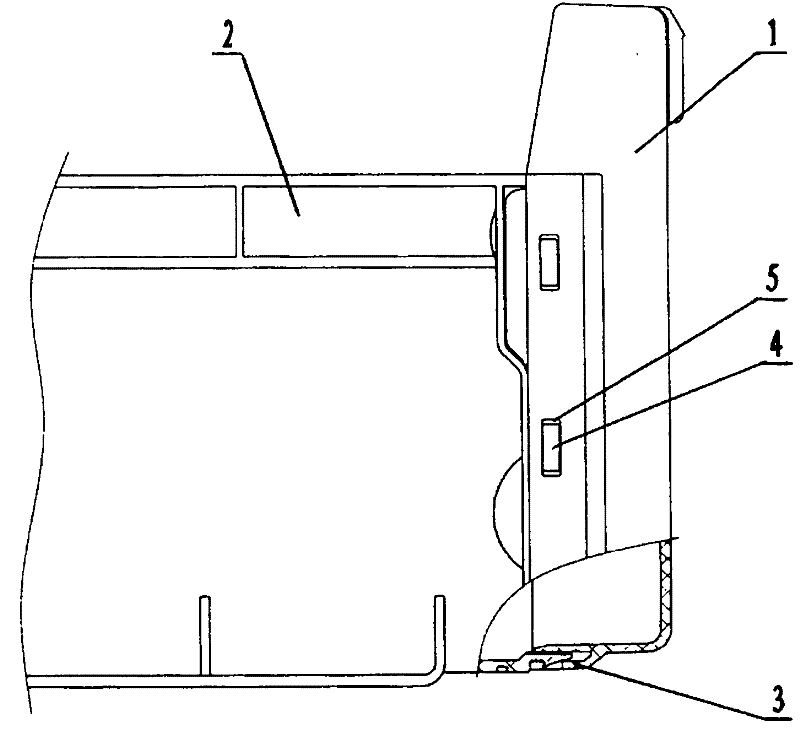

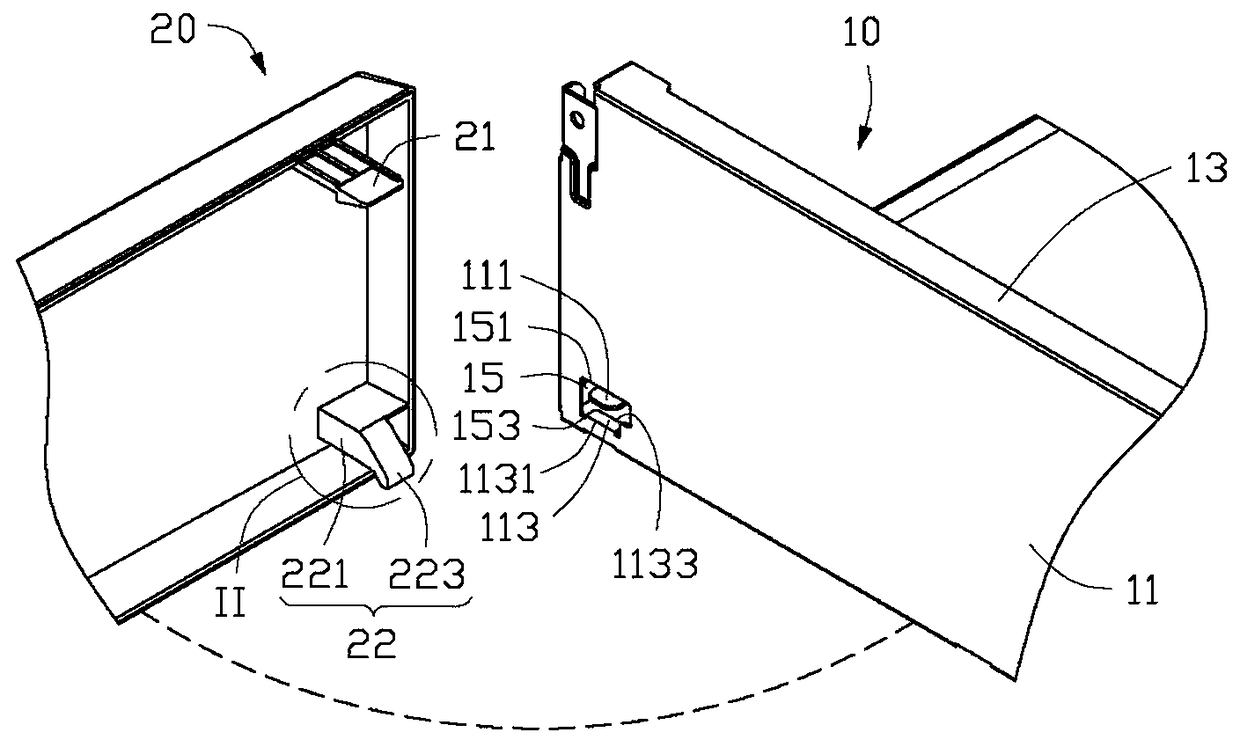

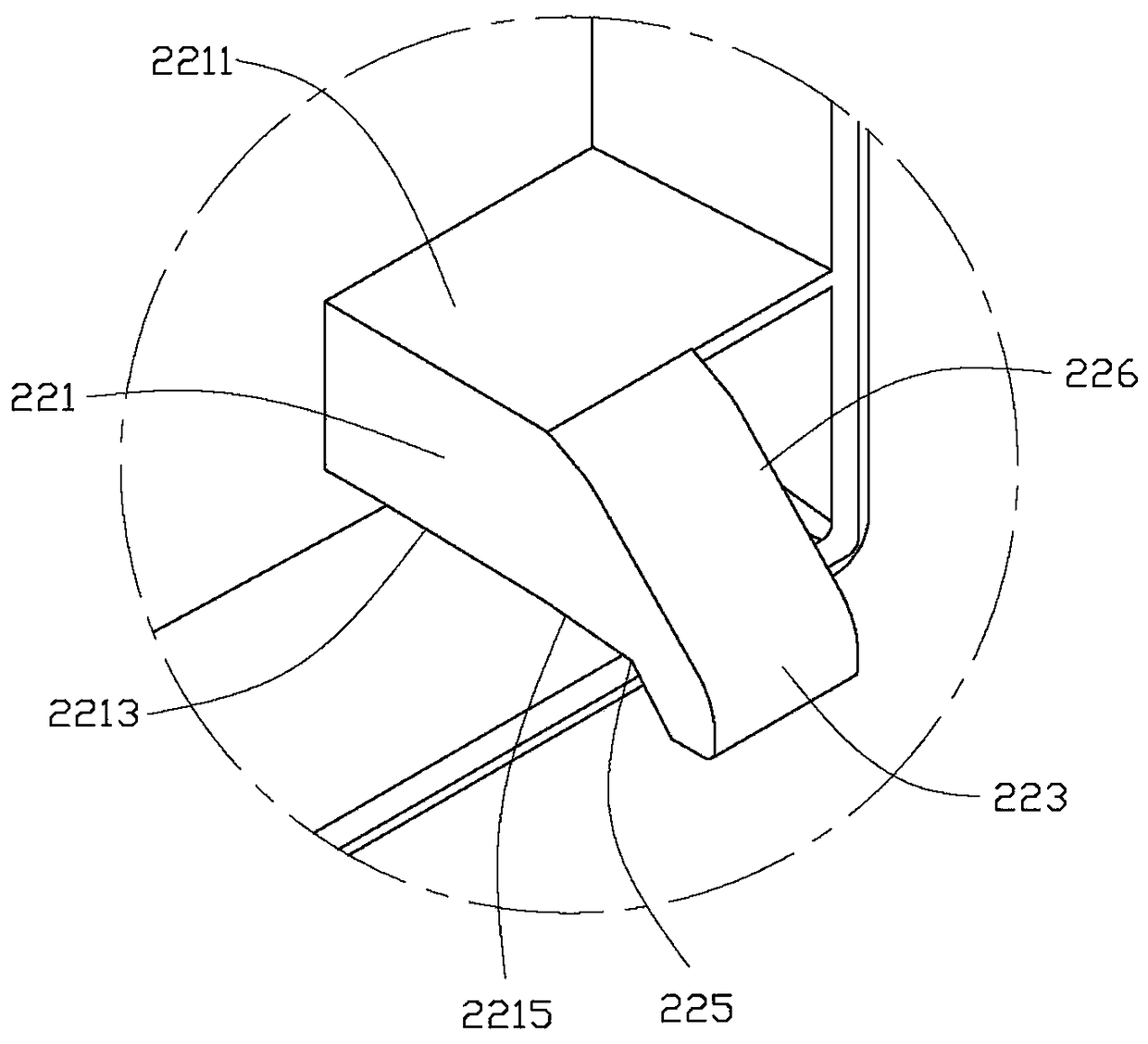

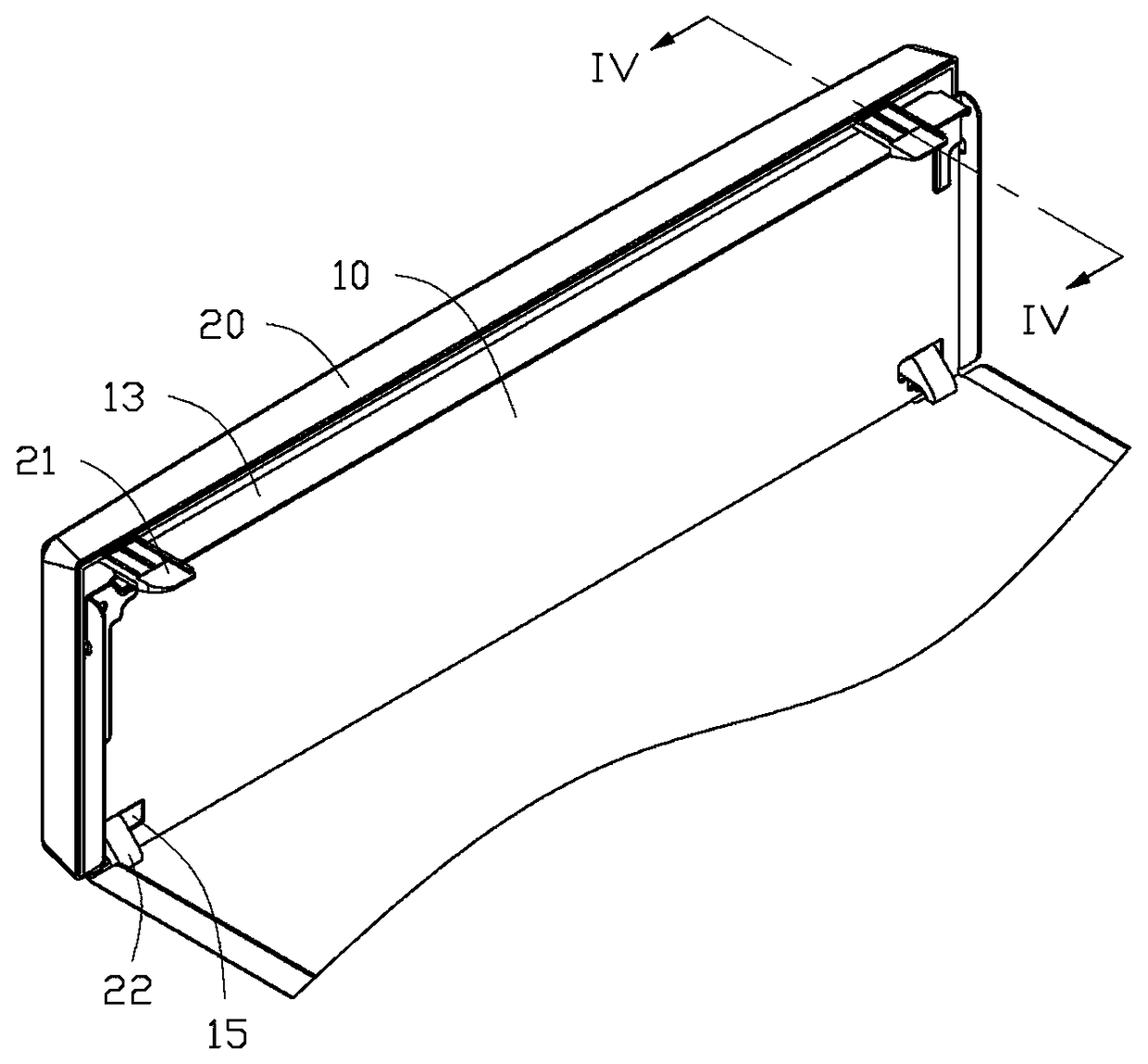

Refrigerator drawer with transparent drawer head

InactiveCN111306881AIncrease the bearing surfaceEven by forceLighting and heating apparatusSupportIceboxEngineering

Owner:王伍仪

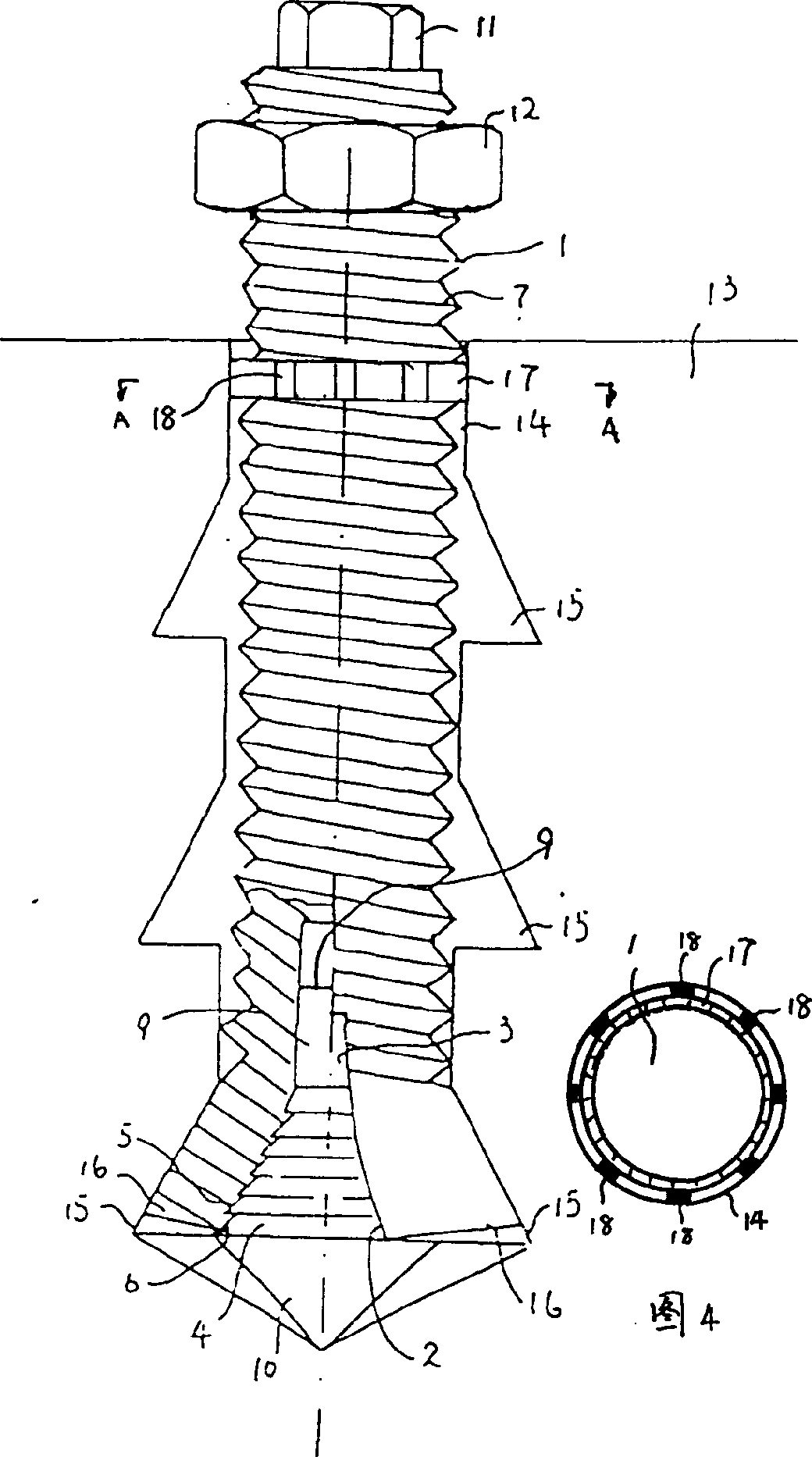

After-planting expansion piece

InactiveCN1273709CThe main structure is firm and strongHigh strengthBuilding reinforcementsEngineeringExpansion joint

The post-mounted expansion unit includes an expansion rod, and an expansion mechanism in the lower part of the expansion rod, and the expansion mechanism includes the expansion hole in the lower part of the expansion rod, expansion slot and conic push head with guide section and matching the expansion hole. The said technological scheme has strong and firm expansion rod, and expansion mechanism with obviously raised connection strength between the post-mounted part and the deep hole. In addition, the expansion hole wall and the conic push head have anti-skid thread to further raise the connected strength.

Owner:徐洁媛

A heat-dissipating new energy charging pile with the function of protecting cables

ActiveCN108705940BTo achieve the purpose of heat dissipationImprove cooling effectCharging stationsElectric vehicle charging technologyNew energyElectric power

The invention discloses a heat radiating type new energy charging pile with a cable protecting function. The heat radiating type new energy charging pile with the cable protecting function comprises ashell, a heat radiating box body, a charging cable, a protective sleeve and a fixed cross plate; a power supply module box is arranged in the shell; the heat radiating box body is arranged under thebottom end of the power supply module box; a flow guide plate is arranged at the top end of the power supply module box; the flow guide plate is connected with the internal wall of the shell; one endof the charging cable is electrically connected with the power supply module box; the other end of the charging cable is connected with a charging gun head through the protective sleeve; and a fixingcolumn and the fixed cross plate are integrally welded together. According to the heat radiating type new energy charging pile with the cable protecting function, as a mobile rod is arranged, the mobile rod can move back and forth for multiple times; and therefore, a heat radiating fan can rotate for multiple times to improve the heat radiating effect; the heat radiating mode does not need to be driven by power so that energy is saved; and meanwhile, the temperature of the equipment can be kept stable as long as the use frequency of the equipment every day reaches a certain time number.

Owner:QINGDAO SONLI SOFTWARE INFORMATION TECH

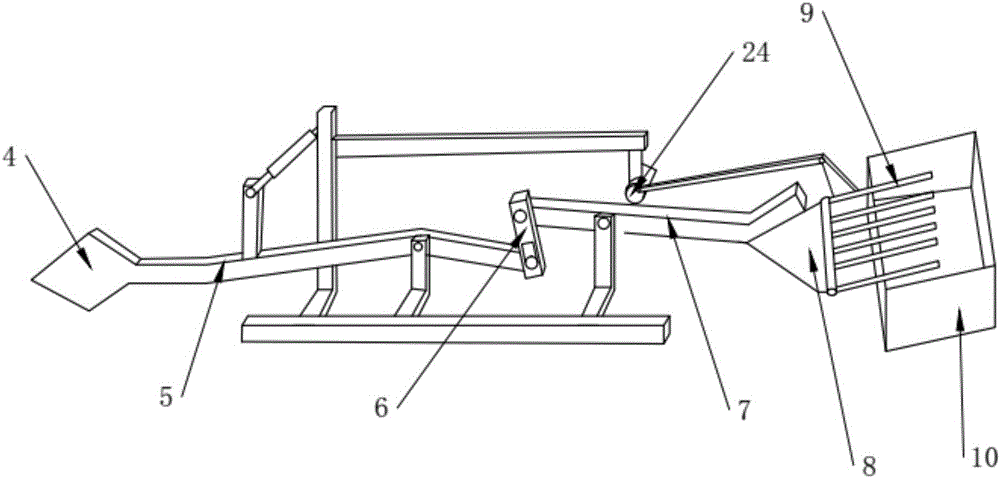

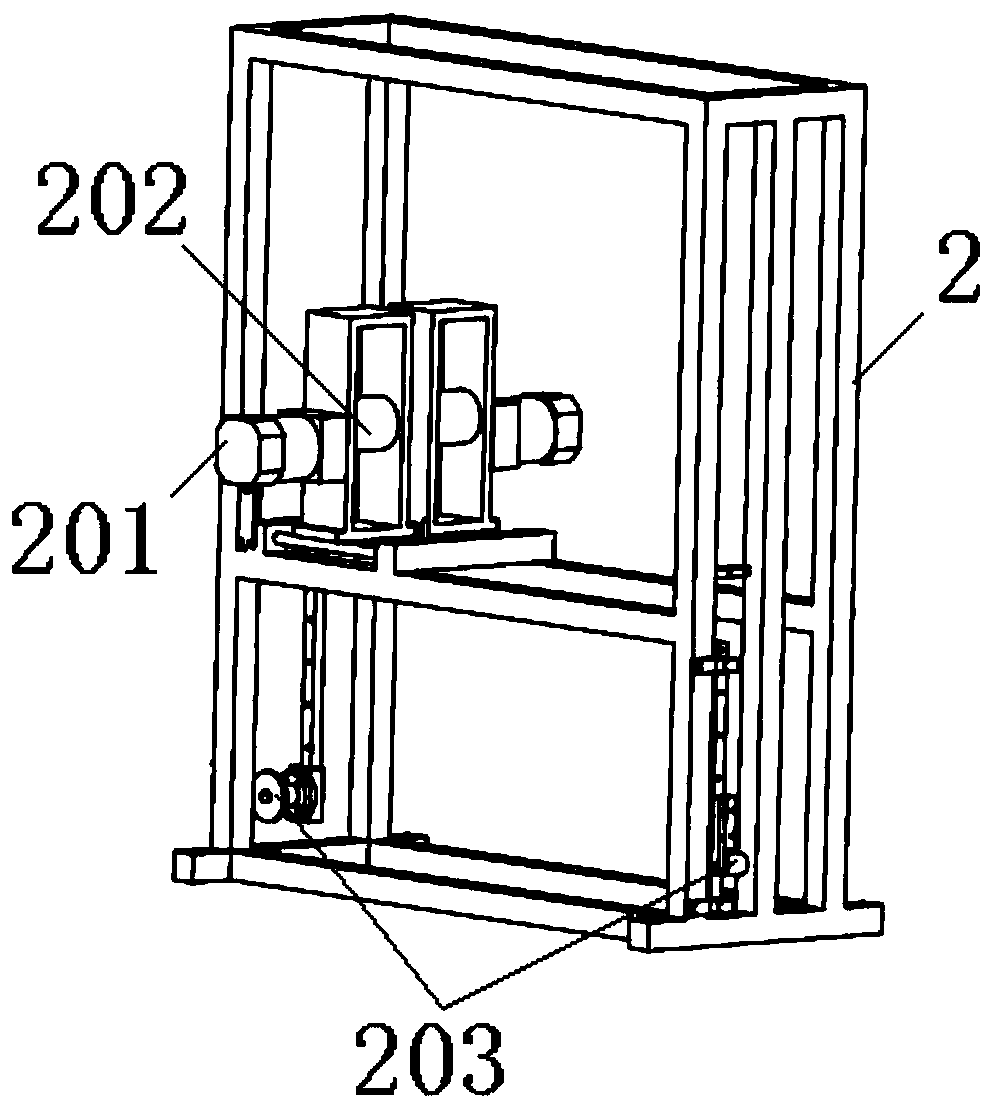

Rubber pipe discharging device

ActiveCN106744018AReasonable structural designIncrease contact surfaceFilament handlingEngineeringLaser sensor

The invention discloses a rubber pipe discharging device. The rubber pipe discharging device comprises a feeding disc and a rubber pipe cut-off and discharging machine which are sequentially arranged. The rubber pipe cut-off and discharging machine comprises a conveying wheel set, a rubber pipe cut-off mechanism and a guide pipe for a rubber pipe to penetrate. The conveying wheel set is internally provided with a rubber pipe penetrating gap. The guide pipe comprises two sections, a cutter is correspondingly arranged between the two sections, an opening is formed in the pipe wall of the guide pipe in the axial direction, and the part, corresponding to the opening, of the guide pipe is provided with a laser sensor used for detecting the end portion of the rubber pipe. The rubber pipe discharging device is reasonable in structural design, feeding is conducted through double power sources, and it is guaranteed that the end portion of the rubber pipe is not prone to being pulled; belt conveying is adopted, the contact area is large, skidding is not likely to happen, and the rubber pipe cannot be subjected to extrusion deformation; the laser sensor is used for controlling the cut-off length of the rubber pipe, precision is high, and accuracy and reliability are achieved; and automatic rubber pipe cutting-off and discharging are achieved, the production efficiency is high, and cost is reduced.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

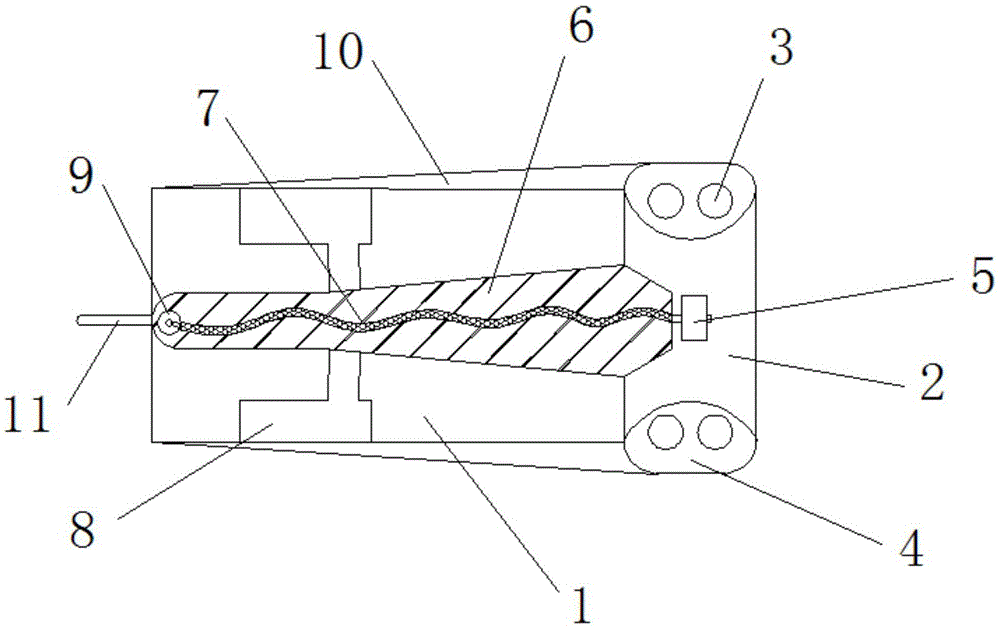

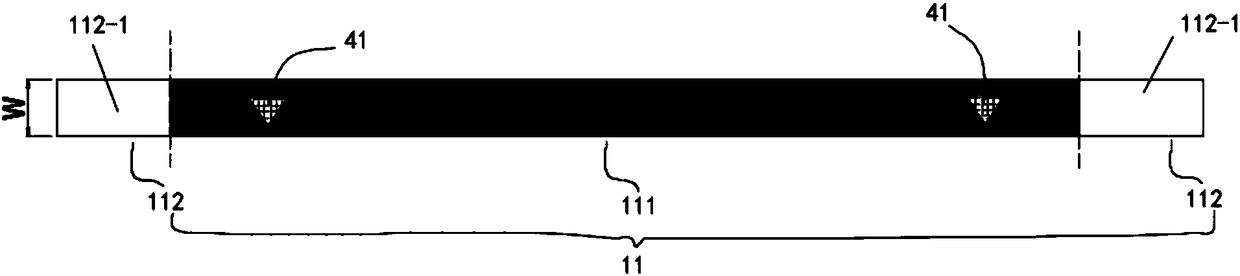

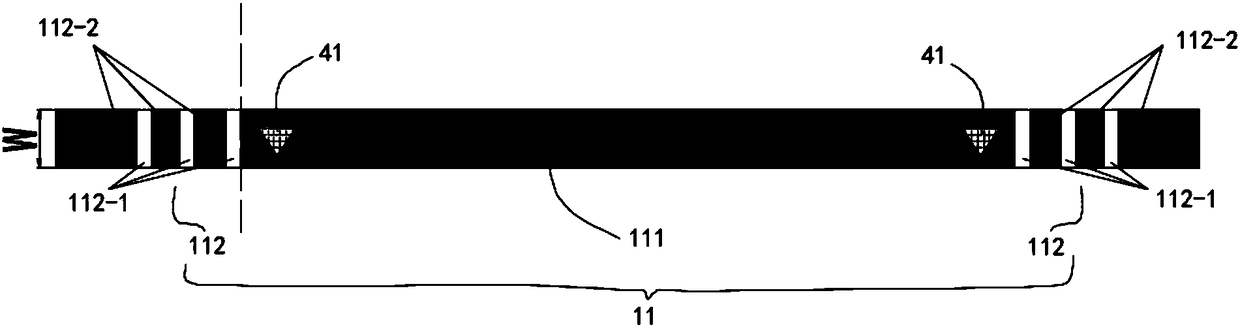

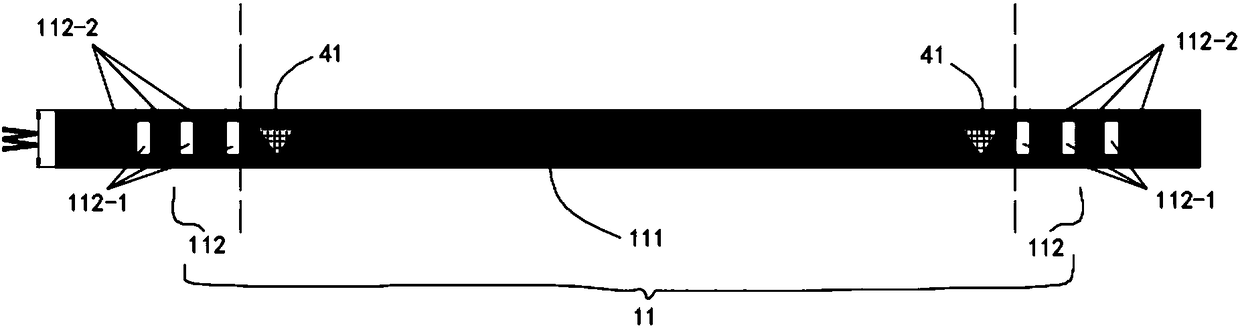

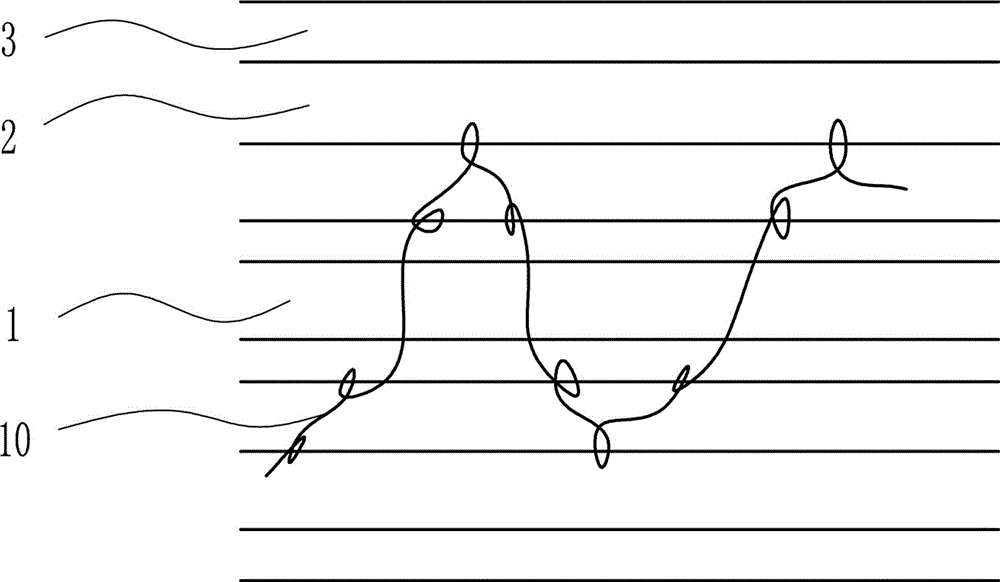

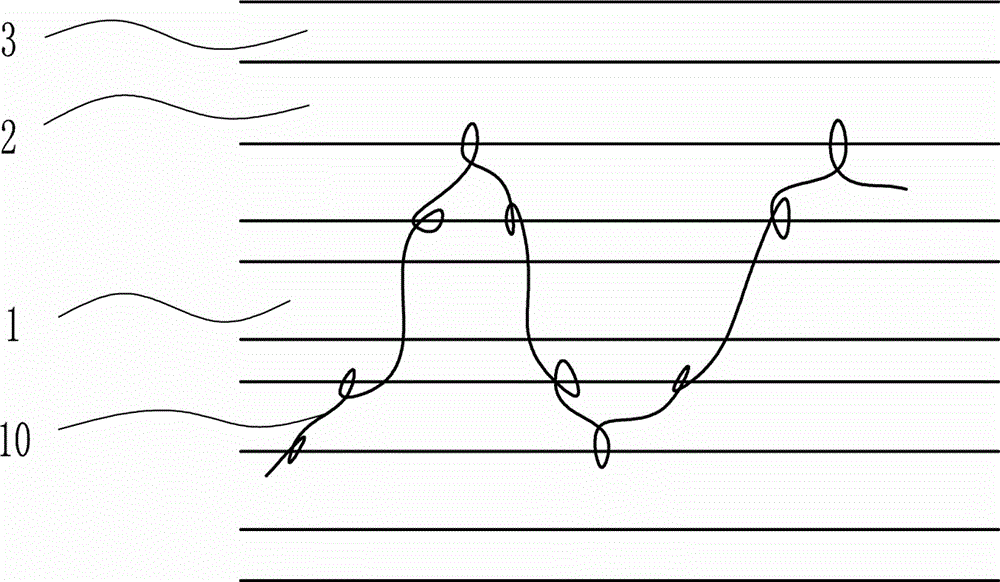

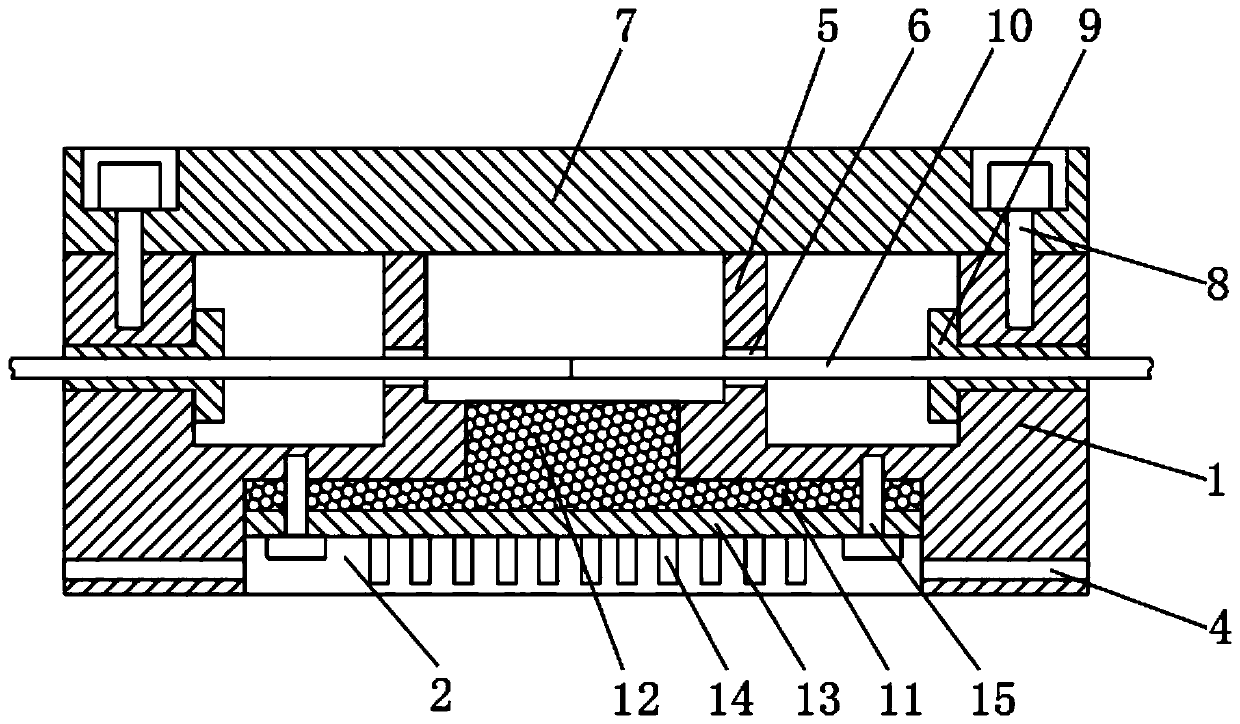

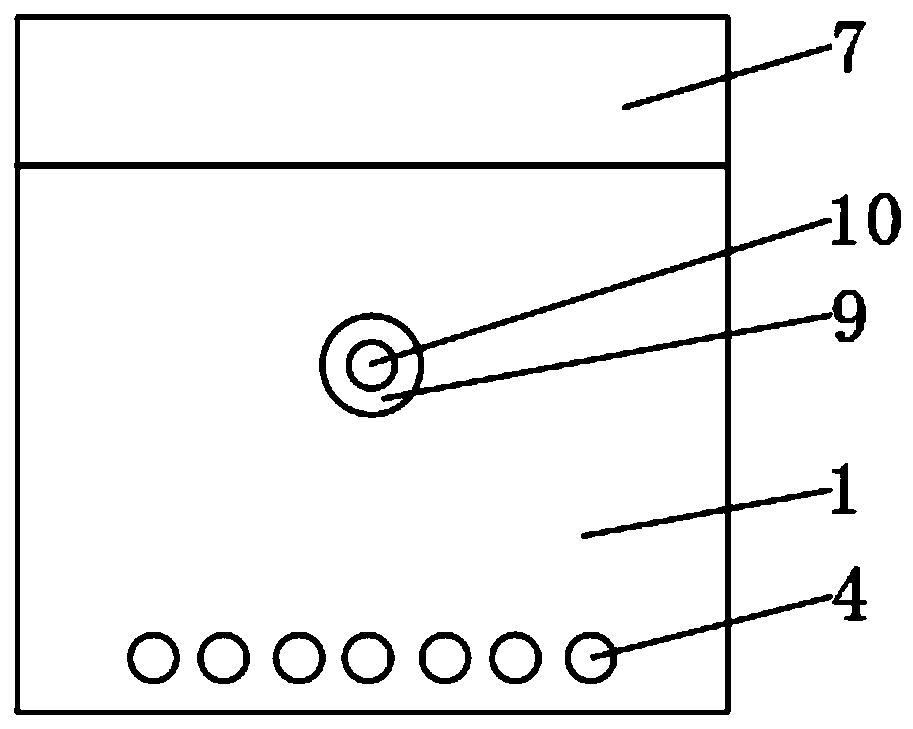

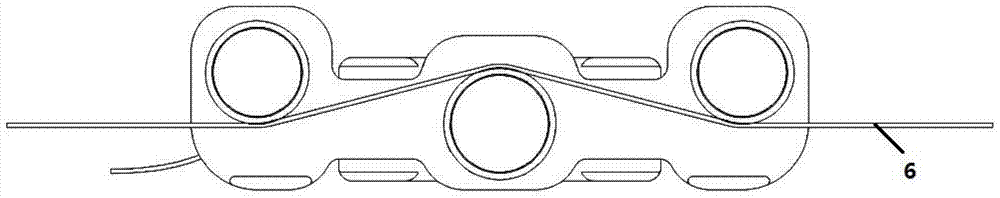

Banknote rolling band and banknote rolling mechanism

InactiveCN108597094AHigh strengthNot easy to pull offCoin/currency accepting devicesArticle deliveryTransmittanceEngineering

The present invention discloses a banknote rolling band, comprising a band body having a first width. The band body comprises a first portion having a certain length of light shielding and second portions located at both ends of the first portion and varying relative to the light shielding degree of the first portion. The invention also discloses a banknote rolling mechanism, comprising a roller rotatable about an axis, a pair of rolling wheels respectively disposed on both sides in the axial direction of the roller and rotatable about respective axes, a pair of banknote rolling bands respectively winding the rolling wheels and the roller and used for tightening or releasing a medium, and a sensor arranged between the rolling wheels and the roller. The sensor is used for monitoring the transmittance of the banknote rolling band passing through the sensor, the banknote rolling band comprises a band body having a first width, the band body comprises a first portion having a certain length of light shielding and second portions located at both ends of the first portion and varying relative to the light shielding degree of the first portion. The banknote rolling band and the banknote rolling mechanism solve the problem that the sensor monitoring is inaccurate after the banknote rolling band is contaminated.

Owner:SHENZHEN YIHUA COMP +2

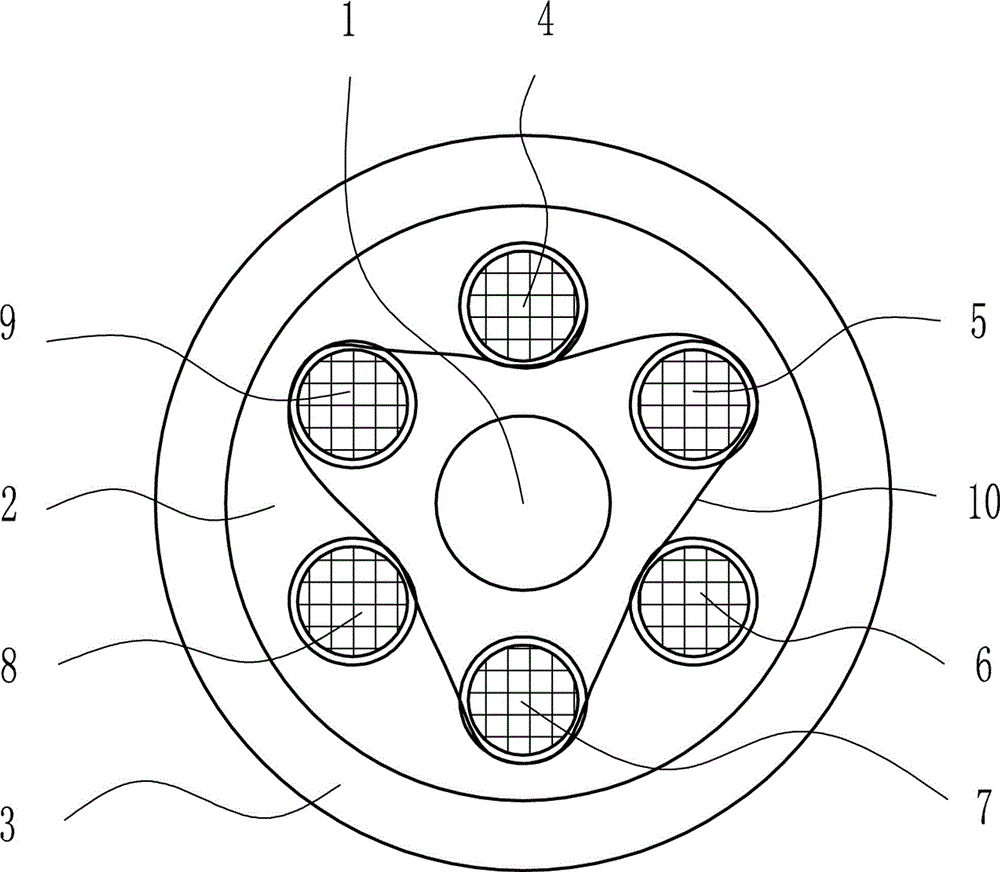

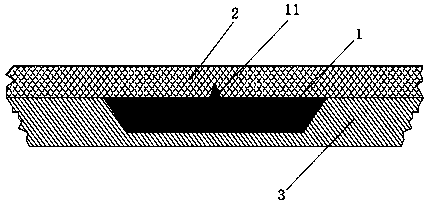

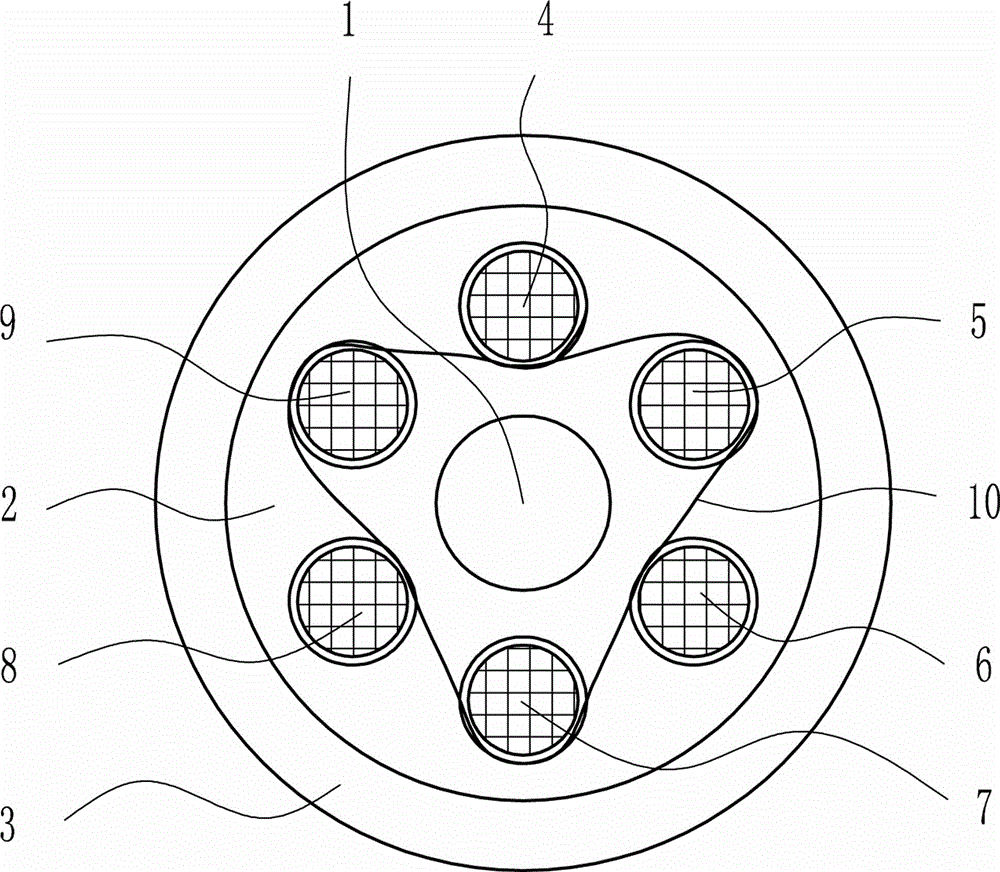

A high-strength copper-clad steel wire

ActiveCN104658636BHigh strengthImprove tensile propertiesSingle bars/rods/wires/strips conductorsSocial benefitsEconomic benefits

The invention belongs to the technical field of copper-clad steel and specifically relates to a high-strength copper-clad steel wire. The invention aims at providing a high-strength copper-clad steel wire. The high-strength copper-clad steel wire comprises a soft iron layer, a copper-plated layer and the like, wherein the carbon content in the soft iron layer is 0.02%-0.03%; a steel wire I, a steel wire II, a steel wire III, a steel wire IV, a steel wire V and a steel wire VI are uniformly arranged in the soft iron layer in the circumferential direction; the carbon content in each of the steel wire I, the steel wire II, the steel wire III, the steel wire IV, the steel wire V and the steel wire VI is 0.15%-0.2%; the copper-plated layer is arranged outside the soft iron layer, and the soft iron layer is wrapped with the copper-plated layer. The high-strength copper-clad steel wire provided by the invention is embedded with a plurality of steel wires, so that strength and tensile strength are improved, the high-strength copper-clad steel wire is less liable to being broken by pulling in mounting and using processes, the structure is simple, the use is convenient, the service life is prolonged and social benefits and economic benefits are good.

Owner:JINGGANGSHAN JIDA METAL

Shazhou sewage pipe, well anti-floating system and construction method

ActiveCN108894206BEliminate buoyancyAvoid deformationProtective foundationSoil preservationMesh reinforcementSewage

The invention discloses a sandbar sewage pipe, well anti-floating system, include anti-float plates, Bundle wire, clip rib, steel mesh, U-groove ribs, steel plate fasteners, Staples, bracing ropes, Anti-float plate are arranged at that bottom of the pipeline and bind to the pipeline through bundle wires, A loc wire rib is inserted into that inn side of the bundle wire, and a binding surface with the pipe is added. The steel bar mesh sheet is arranged below the pipe and below the sewage well. The steel bar mesh sheet is welded with U-groove reinforcement or steel plate buckle, and the U-groovereinforcement is not only welded with the mesh surface of the steel bar mesh sheet, but also bound or welded with the reinforcement of the bottom plate foundation; The steel plate buckle is welded onthe reinforcing bar mesh sheet or pierced from the bottom of the reinforcing bar mesh sheet; The clasp binds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The claspbinds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The invention also discloses a construction method of the sandbar sewage pipe and the well anti-floating system. The invention changes the traditional method of deep burying, increasing dead weight and increasing fixed foundation, and provides a stable and safe anti-floating system and construction method forsandbar high-water-level pipe and well construction.

Owner:CHINA FIRST METALLURGICAL GROUP

Anti-extubation quilt

PendingCN112754239APrevent accidental extubationReduce usageBlanketBed linenHuman bodyMechanical engineering

The invention discloses an anti-extubation quilt, and relates to the technical field of medical supplies, the anti-extubation quilt comprises a quilt body and two widened edges, the quilt body can cover the body of a user and keep the body temperature of the user, the widened edges can separate the two arms of the user from a postoperative drainage tube, and one end of each widened edge is fixedly connected with the surface of the quilt body through a connecting part. During use, the two widened edges are located at the end, close to the head of the user, of the quilt body and located on the left side and the right side of the human body respectively, the width of each widened edge is larger than the distance between each connecting part and the edge of the quilt body, each connecting part is parallel to the body of the user, and a fixing device is arranged at the free end of each widened edge. And the widened edges can be fixed on the bed body by the fixing devices. According to the invention, the widened edges and the fixing devices are arranged, so that the restraint on the thoracic and abdominal postoperative patient is safe and effective, the patient can accept the restraint easily, and the comfort of the patient is improved.

Owner:南京市中西医结合医院

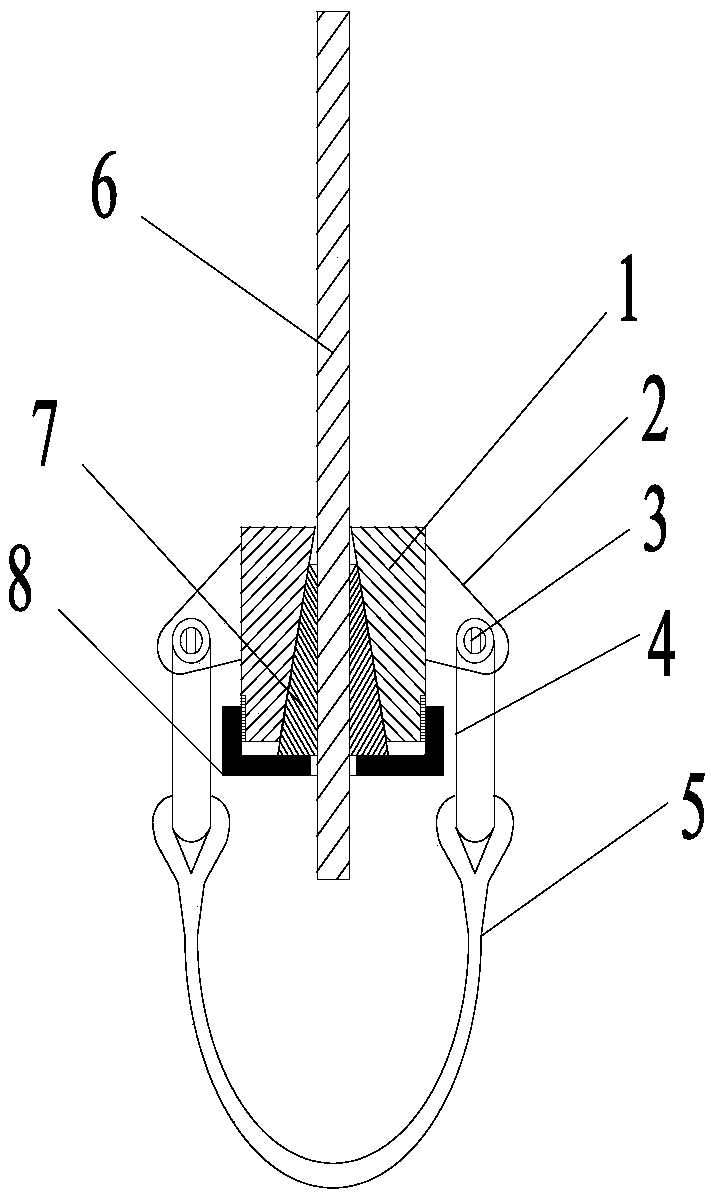

Refrigerator drawers with transparent drawer heads

InactiveCN102278858AIncrease the bearing surfaceEven by forceLighting and heating apparatusSupportRefrigerator carSpacing tooth

The invention relates to a refrigerator drawer with a transparent drawer head, which comprises a drawer head and a drawer bucket which are connected to each other. The drawer head is made of transparent material, and U-shaped sockets are arranged on both sides and the bottom edge of the drawer head. The whole is inserted into the U-shaped socket, and the corresponding positions of the drawer head and the drawer bucket are spaced with hanging teeth and tooth slots for mutual hooking. The beneficial effects of the invention are as follows: the force bearing surface is large, the force bearing is uniform, the connection is firm, it is not easy to be pulled off, and the appearance is beautiful.

Owner:王红亚

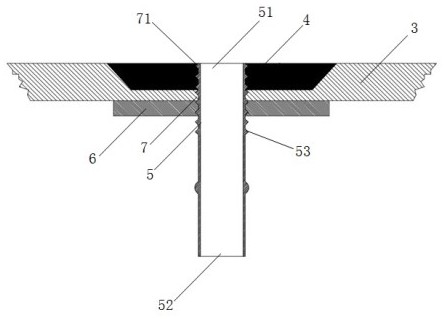

A method for making a vacuum port of a composite material mold

The invention relates to a method for manufacturing a vacuum port of a composite material mold, comprising the following steps: placing an embedded part on a master mold; The position of the embedded part; the support part is opened, and the connecting end is screwed into the vacuum port base through the fastener. The manufacturing method of a vacuum port of a composite material mold according to the present invention can form a split-type vacuum port, which has low manufacturing cost, simple maintenance in the later stage, partial replacement, and reduced maintenance cost and cycle; precise positioning is realized through embedded parts with protrusions, The base of the metal vacuum port is glued and bonded to the glass fiber reinforced plastic support, so the base of the vacuum port is not easy to be pulled off; if there is a problem with the thread of the through hole of the vacuum port base, only the through hole bushing needs to be replaced, and there is no need to replace the entire base.

Owner:TPI COMPOSITES (TAICANG) CO LTD

A high tensile copper clad steel wire

ActiveCN104681119BImprove tensile propertiesImprove deformation resistanceMetal/alloy conductorsWire rodEconomic benefits

Owner:JINGGANGSHAN JIDA METAL

Panel engaging device and housing

ActiveCN104951016BNot easy to pull offFit firmlyDigital processing power distributionArchitectural engineeringFront panel

A panel clamping and closing device comprises a panel and a shell fixed to the panel. The panel is provided with a front plate. The two opposite sides of the panel are provided with a first buckle piece and a second buckle piece respectively, and the front panel is provided with a side plate for the first buckle piece to be buckled and a clamping groove for the second buckle piece to be clamped. The clamping groove comprises a top wall, the front panel is bent and extends towards the exterior of the shell from the top wall so that a limiting piece can be formed, and the limiting piece is used for guiding the second buckle piece to be rotationally clamped into the clamping groove and can abut against the second buckle piece. The embodiment of the invention further relates to the shell. The panel clamping and closing device is additionally provided with the limiting piece through the clamping groove in the shell, when the panel is pulled, the limiting piece can abut against the second buckle piece so that the panel cannot be pulled to disengage from the shell easily, and the panel and the shell are stably matched.

Owner:海宁经开产业园区开发建设有限公司

Preparation method of high-toughness plastic housing for temperature sensor

The invention discloses a preparation method of a high-toughness plastic housing for a temperature sensor. The method comprises the following steps: uniformly mixing an acrylonitrile-butadiene-styrenecopolymer and nanometer titania; adding poly (p-benzamide), phenolic resin and an antiaging agent; uniformly stirring; extruding and pelletizing to obtain a first material; stirring lignin and a silver nitrate solution; filtering; drying; calcining; cooling; crushing to obtain a second material; stirring sepiolite, a carbon nano tube, the second material, dicumyl peroxide, 3-methyl-2-butenal, zeolite powder, disproportionated rosin and C9 petroleum resin to obtain a third material; mixing the first material and the third material; increasing the temperature and uniformly stirring; and feedinginto a twin-screw extruder for extruding and pelletizing, and then modeling to obtain the high-toughness plastic housing for the temperature sensor. The prepared plastic housing is good in antibacterial effect, high in density, and extremely high in toughness and stretching resistance, and the service life of the temperature sensor is prolonged.

Owner:ANHUI RUIXIN AUTOMATION INSTR

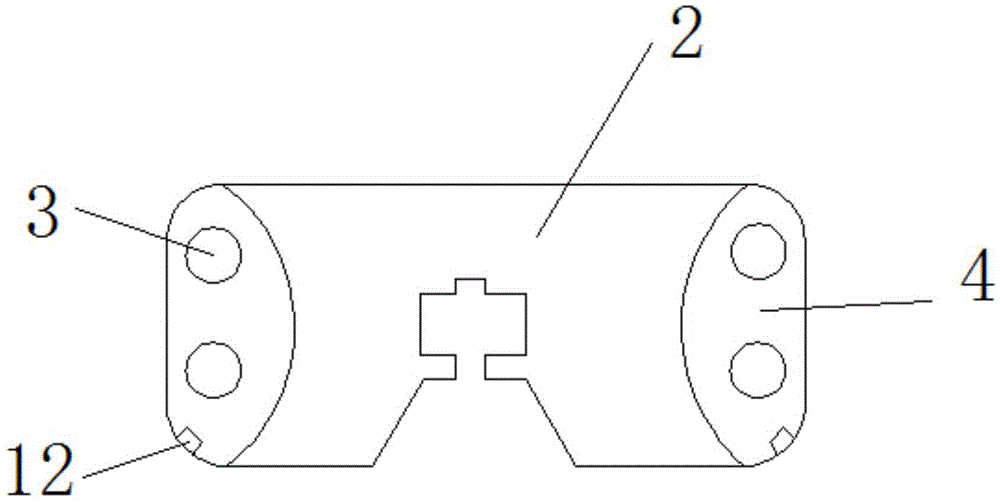

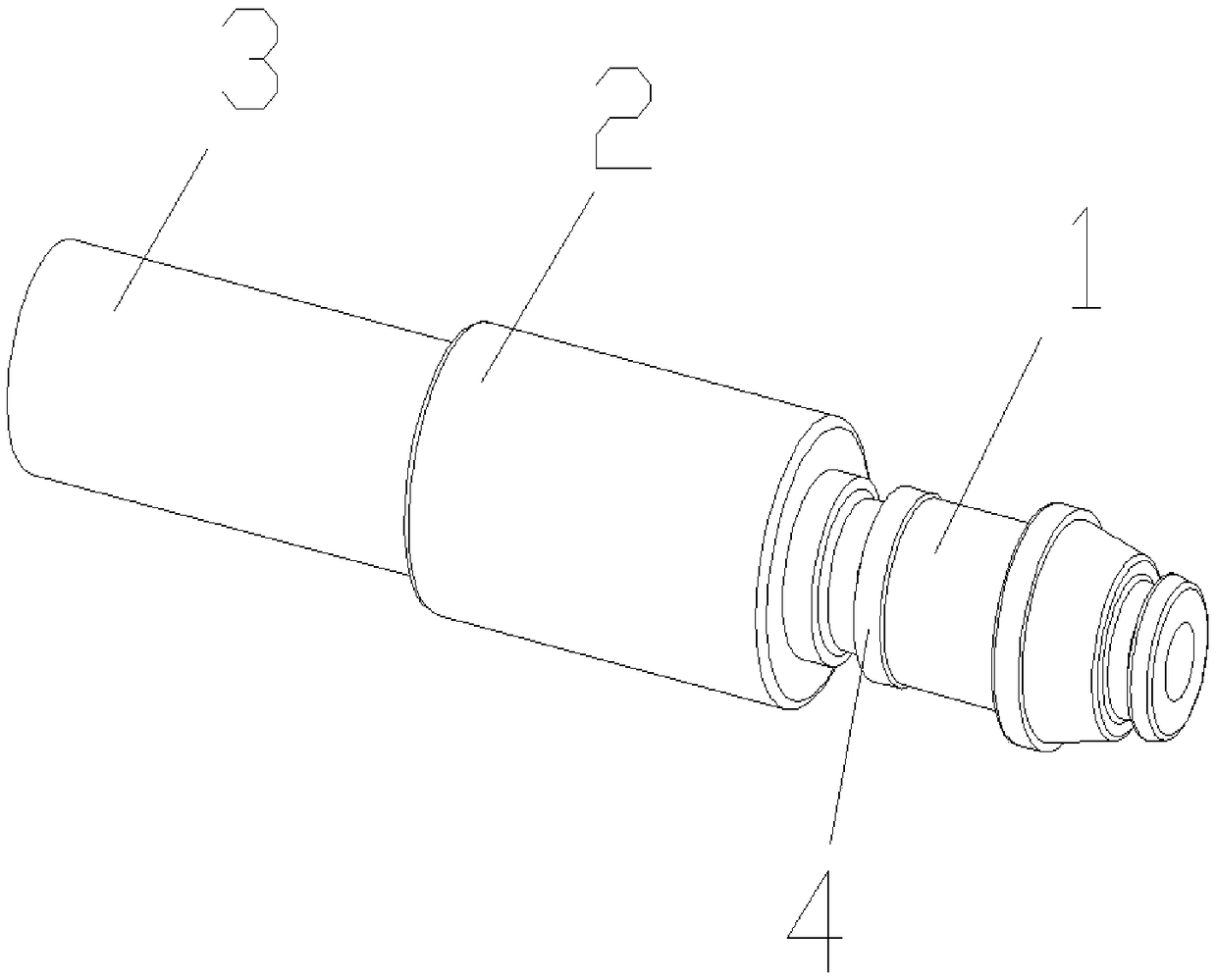

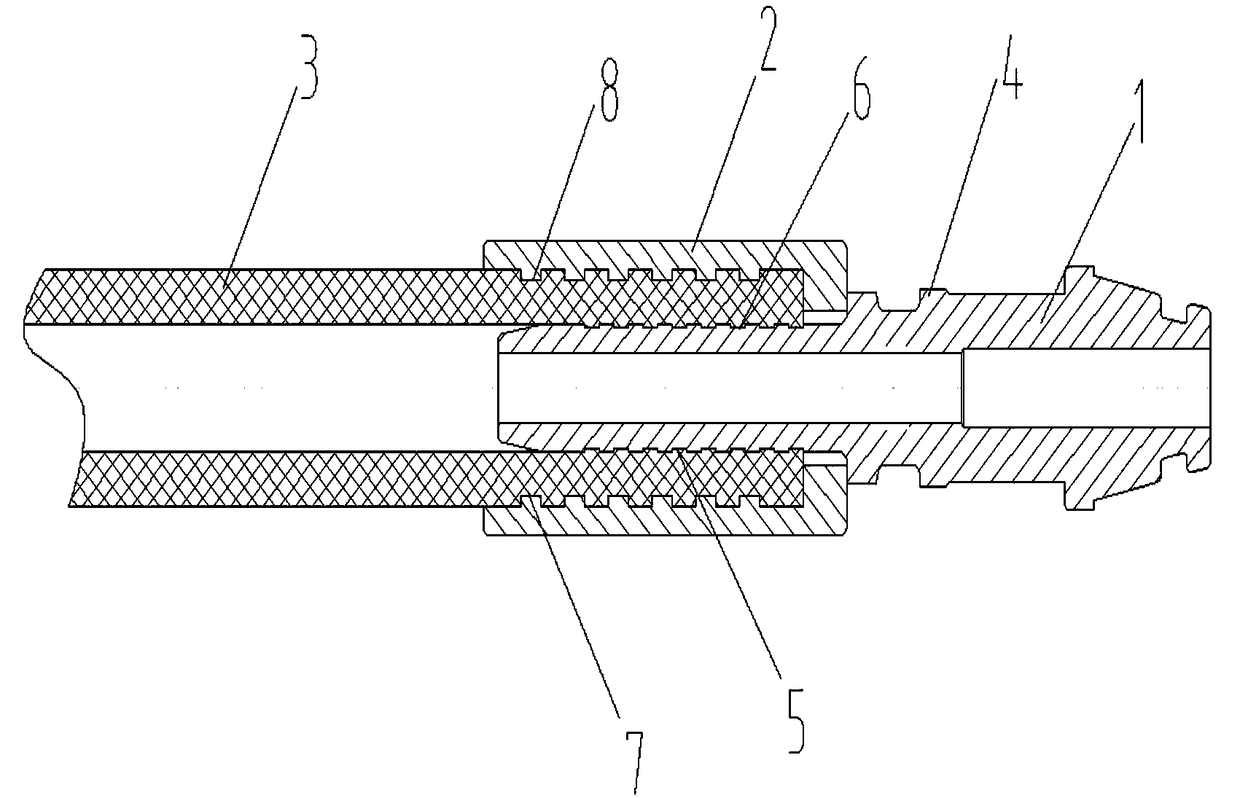

A plug for sealing holes

ActiveCN102261469BNot easy to pull offStop the flowEngine sealsPipe elementsEngineeringRetaining ring

The invention relates to a hole plugging part, in particular to a plug used for sealing a hole, which comprises a mandrel rod, a sleeve of the mandrel rod, and is arranged in a breaking groove of the mandrel rod, and is characterized in that the mandrel rod head The axial section of the shaft is stepped, and the step adjacent to the rod is a spherical or conical surface, and an anti-retraction ring groove is provided at the joint between the mandrel rod and the step. The inner hole of the casing is matched with the mandrel rod, and is assembled at the step near the spherical or conical surface of the mandrel rod. The plugging structure of the present invention is simple and reasonable, and the mandrel rod is not easy to be pulled off from the casing during installation. Compared with the plugging of the existing structure, the plugging force required for plugging holes is smaller, and the reliability of the sealing is also improved. improve.

Owner:HANGZHOU XZB TECH

Manufacturing method for vacuum port of composite material mould

InactiveCN109514890ANot easy to pull offReduce manufacturing costEngineeringFibre-reinforced plastic

The invention relates to a manufacturing method for a vacuum port of a composite material mould. The manufacturing method comprises the following steps: placing a pre-embedded part onto a female mould; removing the pre-embedded part after a supporting part of the composite material mould is manufactured, and putting a vacuum port base into the original pre-embedded part position; and breaking through the supporting part, and enabling a connecting end head to pass through a fastening part to screw into the vacuum port base. The manufacturing method for the vacuum port of the composite materialmould can form a split type vacuum port, is low in manufacturing cost, is simple in later-stage maintenance, can be locally replaced, reduces maintenance cost and shortens a maintenance period; precise positioning is realized through the pre-embedded part with a bulge, and the metal vacuum port base is adhered with glue and is bonded with a glass fibre reinforced plastic supporting part, so that the vacuum port base is not easily dropped by pulling; and if threads of a through hole of the vacuum port base have problems, only a through hole lining needs to replace, and the whole base does not need to replace.

Owner:TPI COMPOSITES (TAICANG) CO LTD

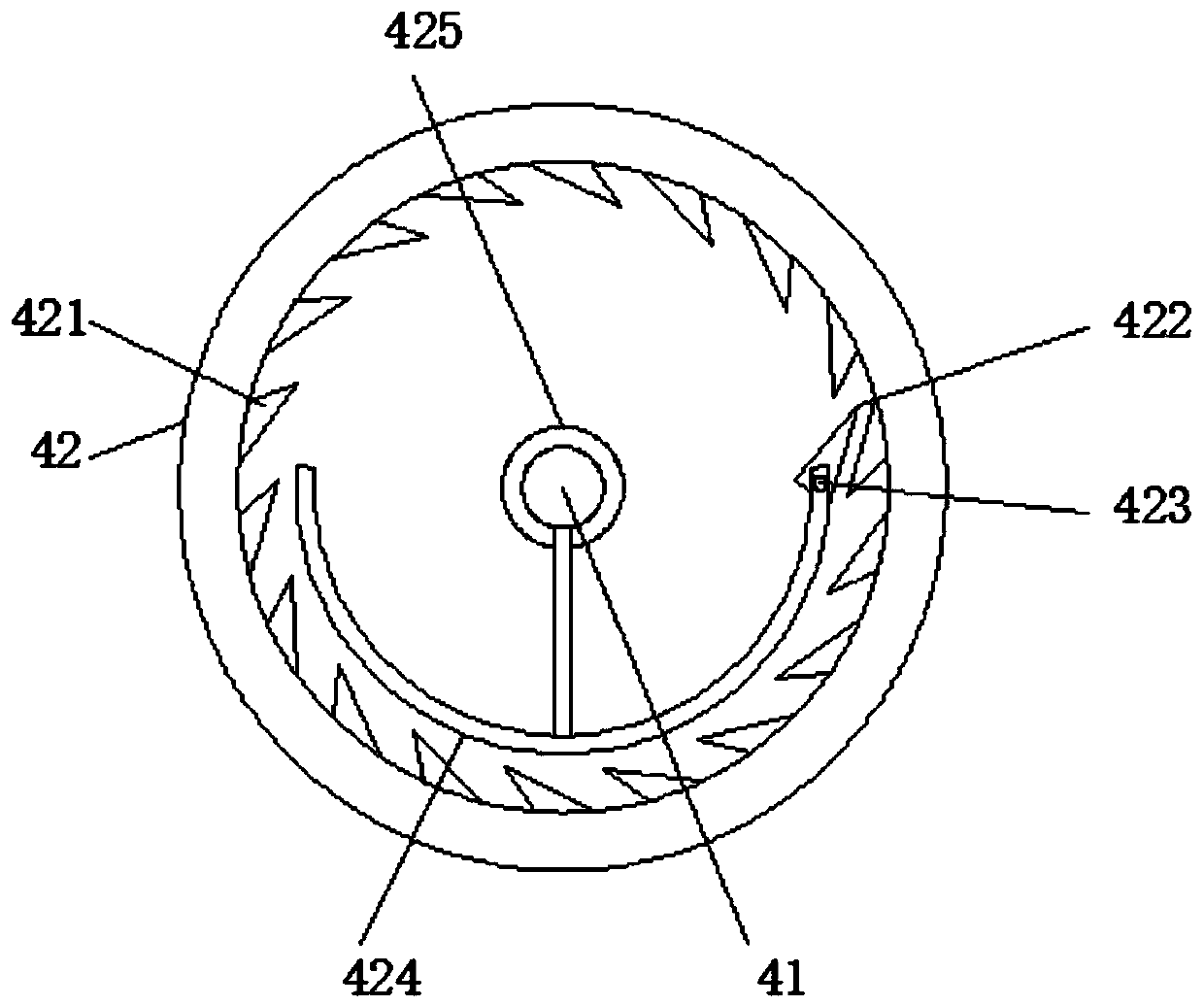

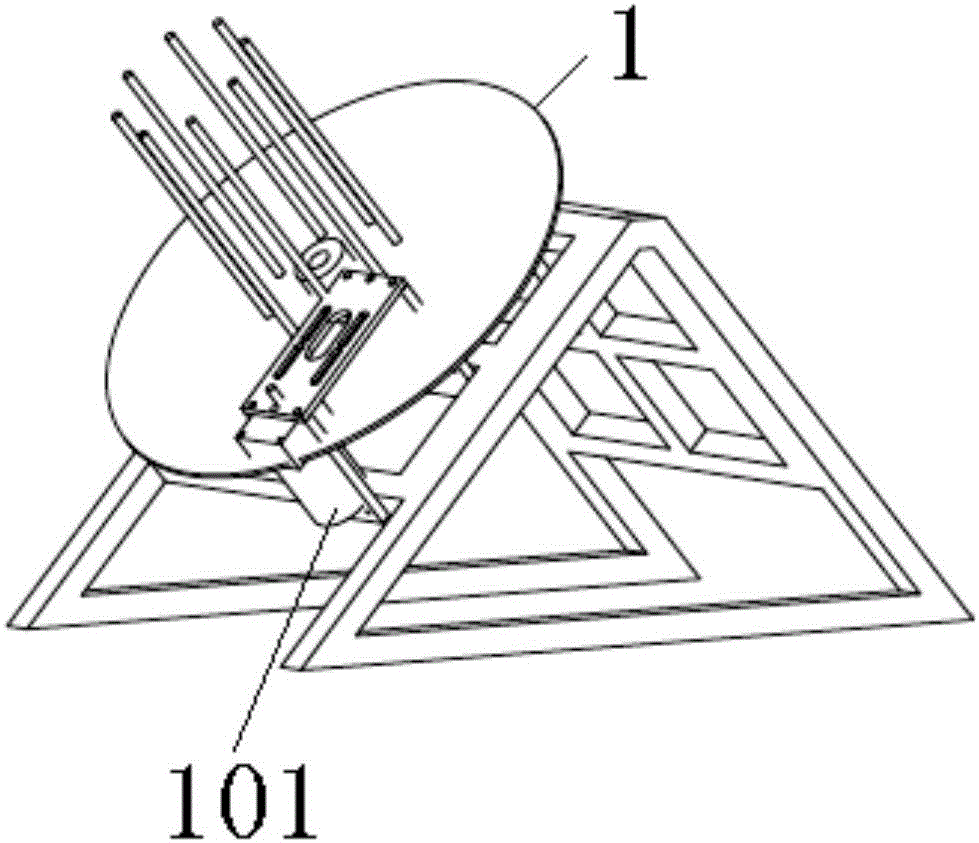

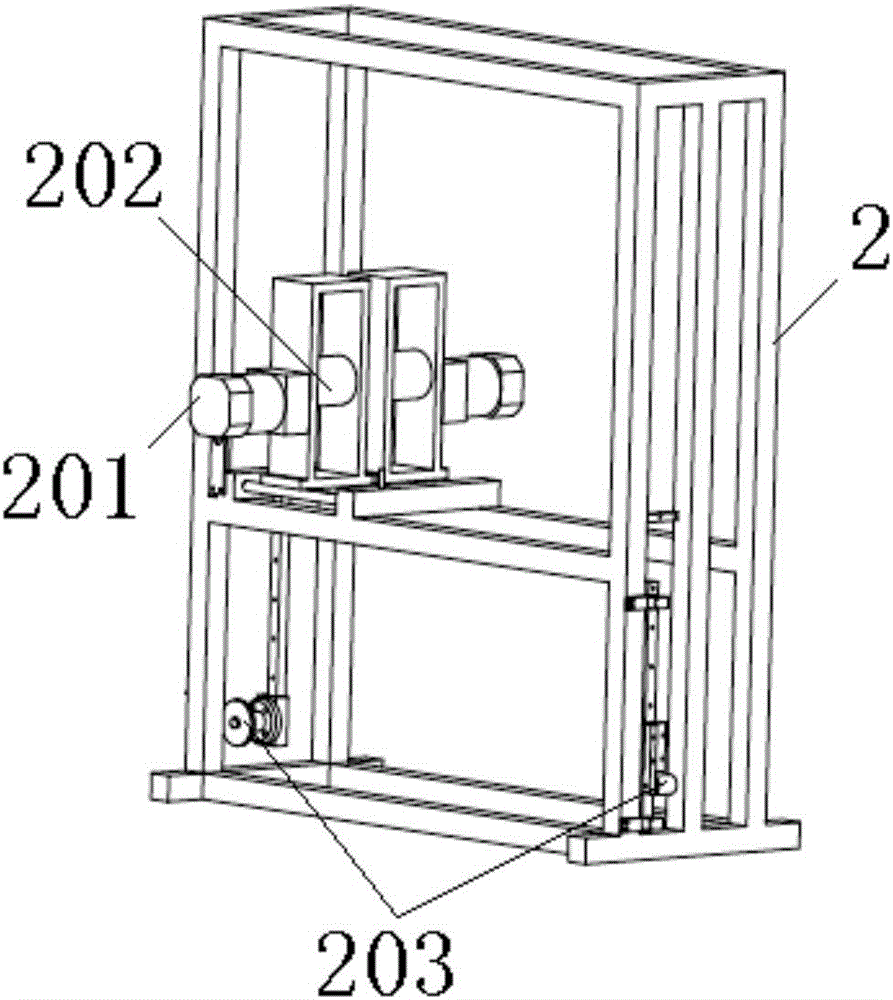

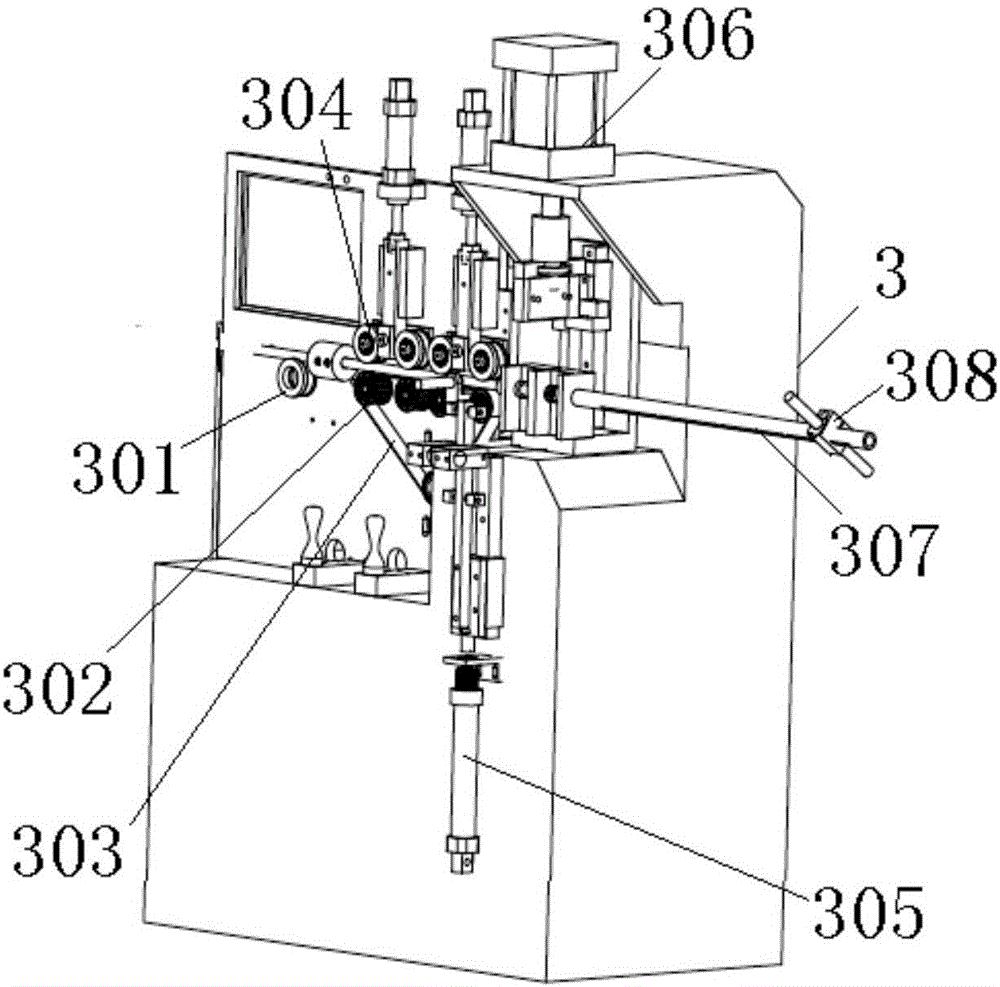

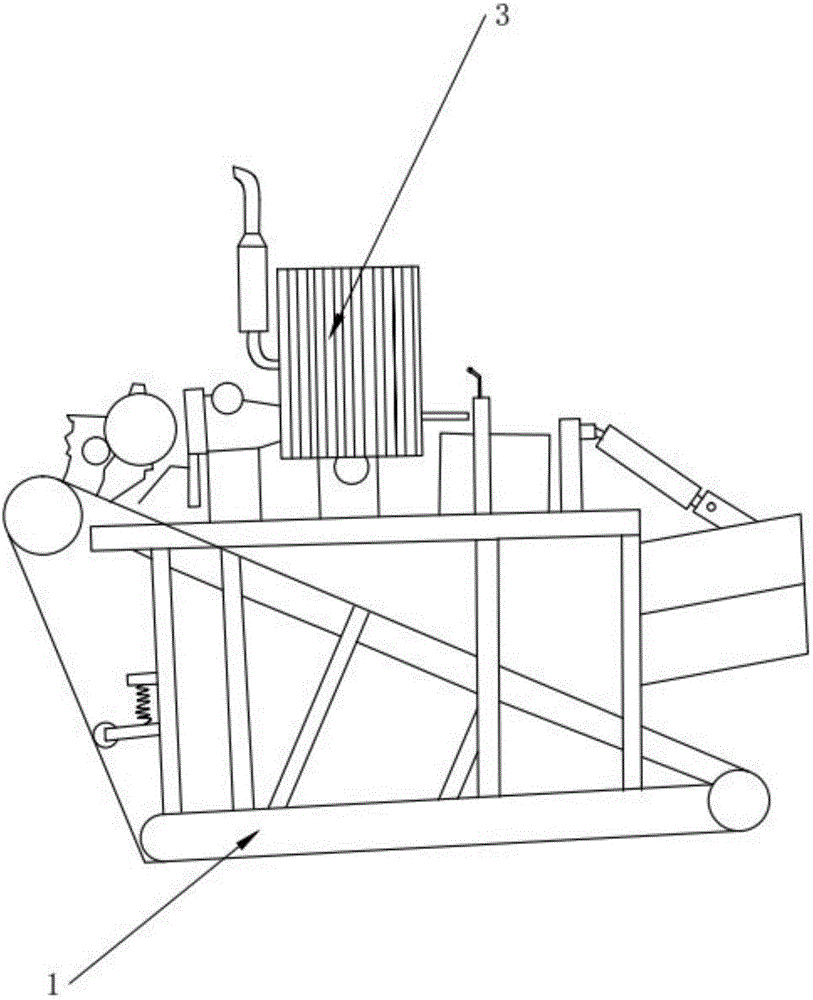

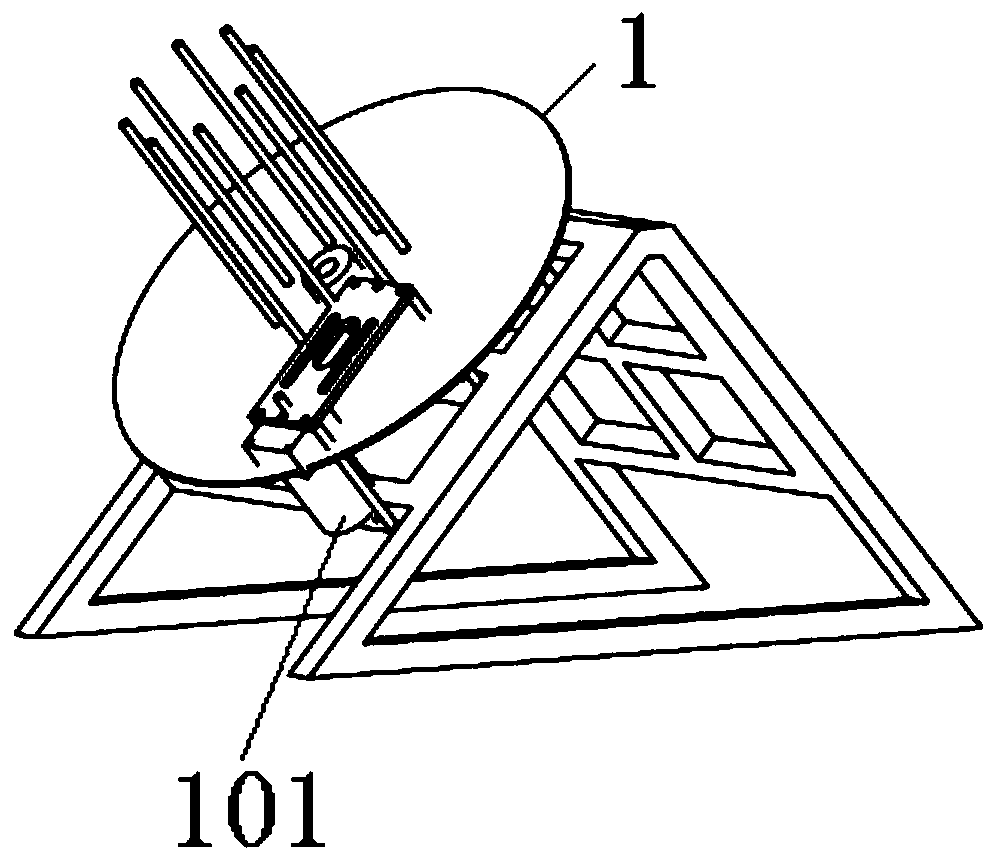

Fresh ginger harvester

The invention discloses a fresh ginger harvester, and relates to the technical field of agricultural machinery. The fresh ginger harvester comprises a frame, traveling devices, power device and a ginger discharging device, the traveling devices are positioned on two sides of the frame, the power device is mounted on the frame and provides power for the traveling devices and the ginger discharging device, and the ginger discharging device comprises a repeatedly harvesting mechanism, a soil digging mechanism and ginger drawing mechanism. The fresh ginger harvester has the advantages that the ginger discharging device is obliquely arranged along the traveling direction, fresh ginger does not easily fractured in a drawing manner and can be orderly placed, a plowshare cutter drives a repeatedly harvesting cutter to work, and falling fresh ginger can be picked out.

Owner:李曙光

High-strength copper-clad steel wire

ActiveCN104658636AHigh strengthImprove tensile propertiesSingle bars/rods/wires/strips conductorsSocial benefitsMetallurgy

The invention belongs to the technical field of copper-clad steel and specifically relates to a high-strength copper-clad steel wire. The invention aims at providing a high-strength copper-clad steel wire. The high-strength copper-clad steel wire comprises a soft iron layer, a copper-plated layer and the like, wherein the carbon content in the soft iron layer is 0.02%-0.03%; a steel wire I, a steel wire II, a steel wire III, a steel wire IV, a steel wire V and a steel wire VI are uniformly arranged in the soft iron layer in the circumferential direction; the carbon content in each of the steel wire I, the steel wire II, the steel wire III, the steel wire IV, the steel wire V and the steel wire VI is 0.15%-0.2%; the copper-plated layer is arranged outside the soft iron layer, and the soft iron layer is wrapped with the copper-plated layer. The high-strength copper-clad steel wire provided by the invention is embedded with a plurality of steel wires, so that strength and tensile strength are improved, the high-strength copper-clad steel wire is less liable to being broken by pulling in mounting and using processes, the structure is simple, the use is convenient, the service life is prolonged and social benefits and economic benefits are good.

Owner:JINGGANGSHAN JIDA METAL

High-stability optical fiber coupler packaging member

PendingCN110632707AReliable connectionGood cooling effectCoupling light guidesFiberOptical fiber coupler

The invention belongs to the field of optical fiber couplers, and particularly relates to a high-stability optical fiber coupler packaging member. The high-stability optical fiber coupler packaging member comprises a packaging shell, a groove is formed in a lower end of the packaging shell, a heat dissipation hole is formed in the bottom of the packaging shell, a connection seat is arranged in thepackaging shell, a sealing cover is installed at an upper end of the packaging shell, a fastening sleeve is connected in the packaging shell through threads, an optical fiber is bonded in the fastening sleeve through glue, a heat conduction pad is attached to the lower part of the packaging shell, a heat conduction block is arranged at an upper end of the heat conduction pad, the heat conductionblock and the heat conduction pad are of an integrated structure, and a heat dissipation plate is connected to a lower end of the heat conduction pad in a contact manner. According to the high-stability optical fiber coupler packaging member provided by the invention, the fastening sleeve is installed in the packaging shell, the optical fiber is bonded in the fastening sleeve through glue, and theoptical fiber is fixed, so that the optical fiber is not easy to be pulled off, and the connection of the optical fiber in the packaging shell is more stable and reliable.

Owner:昆山准超五金科技有限公司

Hose unloading device

ActiveCN106744018BNot easy to squeeze and deformRealize automatic cutting and cuttingFilament handlingLaser sensorGuide tube

The invention discloses a rubber pipe discharging device. The rubber pipe discharging device comprises a feeding disc and a rubber pipe cut-off and discharging machine which are sequentially arranged. The rubber pipe cut-off and discharging machine comprises a conveying wheel set, a rubber pipe cut-off mechanism and a guide pipe for a rubber pipe to penetrate. The conveying wheel set is internally provided with a rubber pipe penetrating gap. The guide pipe comprises two sections, a cutter is correspondingly arranged between the two sections, an opening is formed in the pipe wall of the guide pipe in the axial direction, and the part, corresponding to the opening, of the guide pipe is provided with a laser sensor used for detecting the end portion of the rubber pipe. The rubber pipe discharging device is reasonable in structural design, feeding is conducted through double power sources, and it is guaranteed that the end portion of the rubber pipe is not prone to being pulled; belt conveying is adopted, the contact area is large, skidding is not likely to happen, and the rubber pipe cannot be subjected to extrusion deformation; the laser sensor is used for controlling the cut-off length of the rubber pipe, precision is high, and accuracy and reliability are achieved; and automatic rubber pipe cutting-off and discharging are achieved, the production efficiency is high, and cost is reduced.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

A Suspended Unbalanced Dynamic Tension Sensor

InactiveCN105203239BNo fixed installation requiredAvoid ablationForce measurementCantilevered beamDynamic Tension

The invention discloses a suspension type unbalanced dynamic tension sensor, which adopts a double cantilever beam structure, uses strain gauges for indirect measurement, and adopts the design of a roller at the same time, so that the friction can be reduced when the instantaneous large tension is measured, and the measured rope can be effectively prevented from being damaged. The heating ablation phenomenon of the belt; in addition, it adopts an unbalanced suspension structure design, which does not need to be fixed on the base during measurement. On the one hand, it ensures that the rope will not fall off during the measurement process and make the measurement invalid; The adverse effect of non-uniform force ensures the accuracy of dynamic measurement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

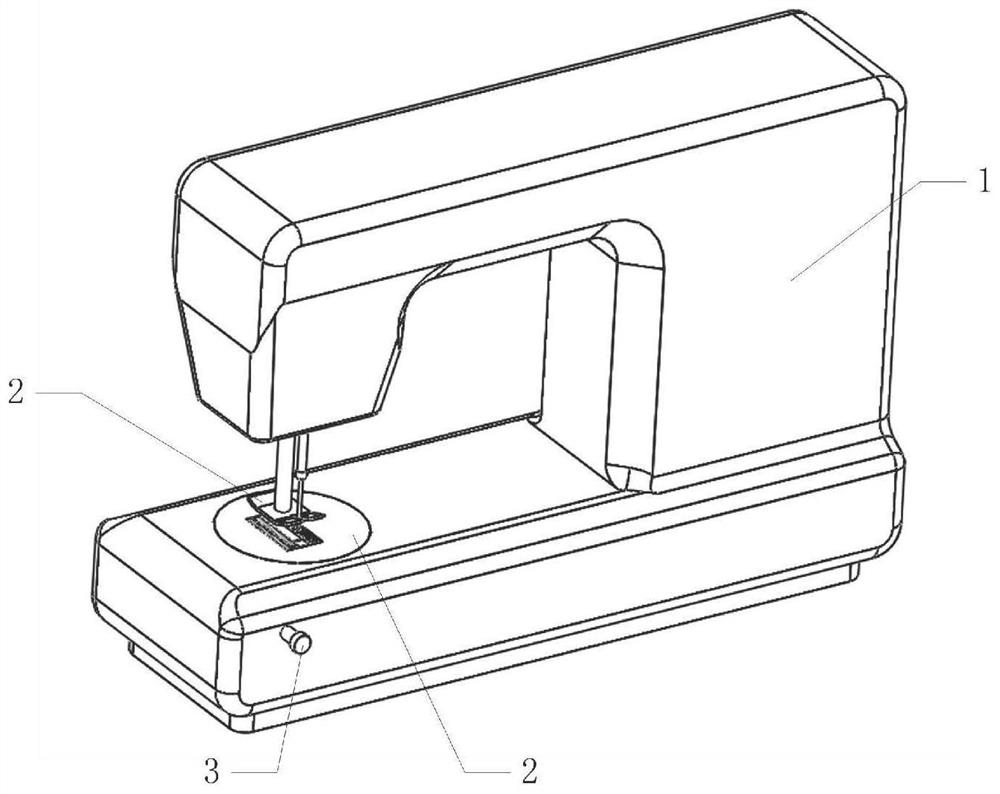

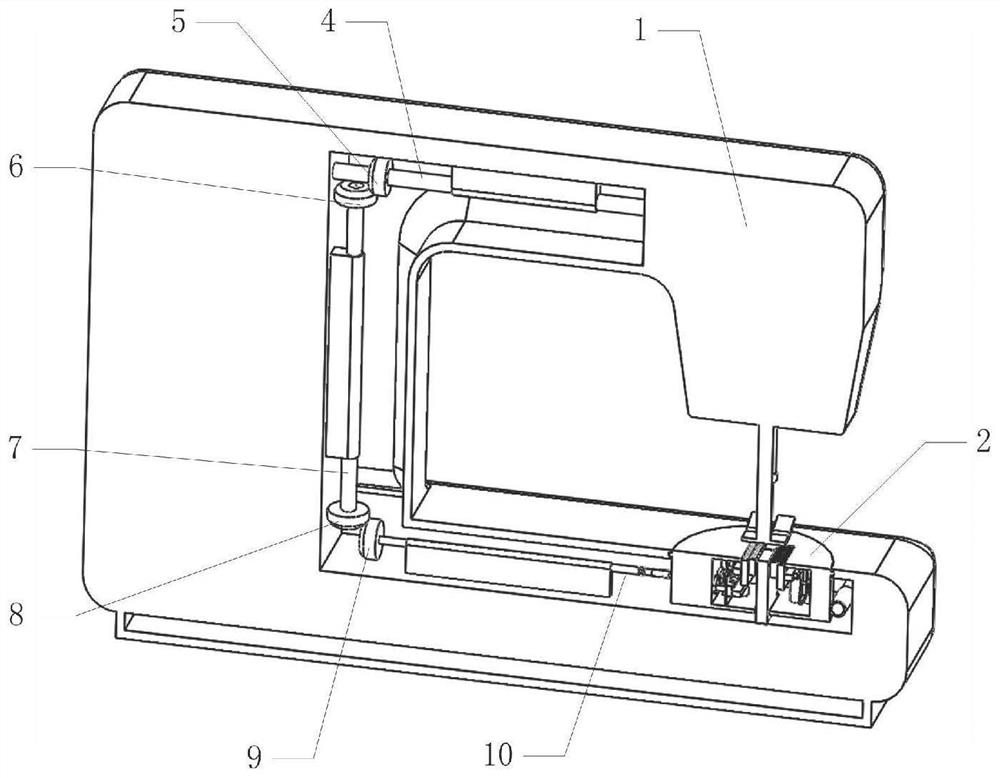

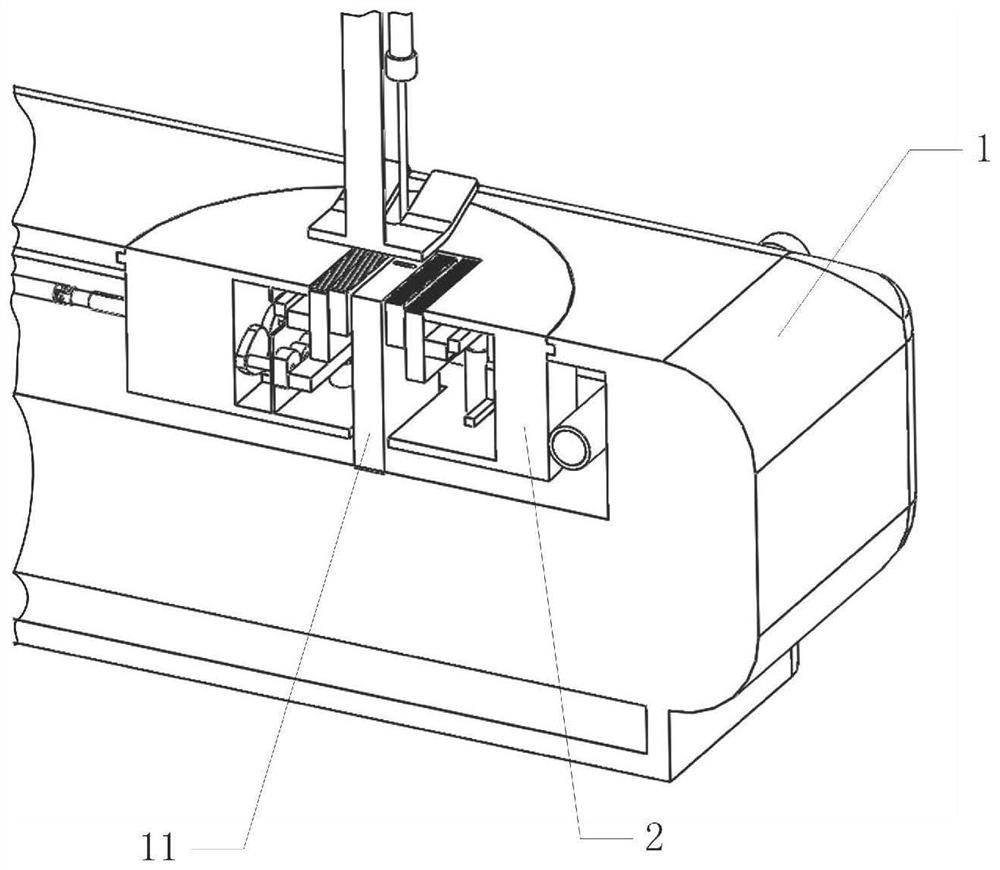

Fabric correction equipment of sewing machine

InactiveCN113818154AEasy to operatePlay a clamping roleWork-feeding meansPressersEngineeringCounter rotation

The invention belongs to the technical field of sewing machine correction, and particularly relates to fabric correction equipment of a sewing machine. The fabric correction equipment of the sewing machine comprises a machine body, a rotary mounting shell, an adjusting rod, a wire drawing wheel module, a worm, a main cloth moving toothed plate and an auxiliary cloth moving toothed plate. In the working process of the fabric correction equipment of the sewing machine provided by the invention, when cloth deviates, the adjusting rod is manually rotated to drive the worm installed on the adjusting rod to rotate, the worm rotates to drive the rotary mounting shell to rotate through cooperation with worm teeth on the rotary mounting shell, the rotary mounting shell can drive the main cloth moving toothed plate and the auxiliary cloth moving toothed plate which are mounted on the rotary mounting shell to rotate reversely in the rotating process, and deviation of the cloth is counteracted through rotation, namely, the clamped cloth is corrected in the rotating process; and after the cloth is corrected and a lower needle sews the cloth for several stitches, the rotary mounting shell drives the main cloth moving toothed plate and the auxiliary cloth moving toothed plate to reversely rotate and reset through the adjusting rod, so that compared with traditional correcting operation, the fabric correction equipment of the sewing machine is convenient to operate.

Owner:杨素

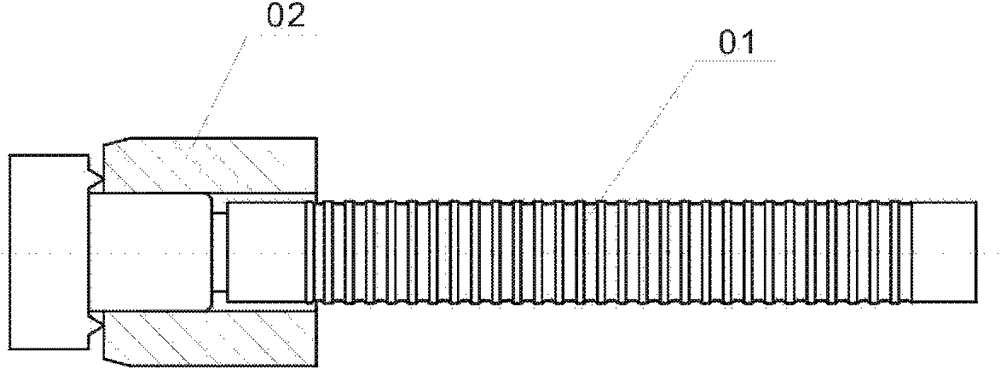

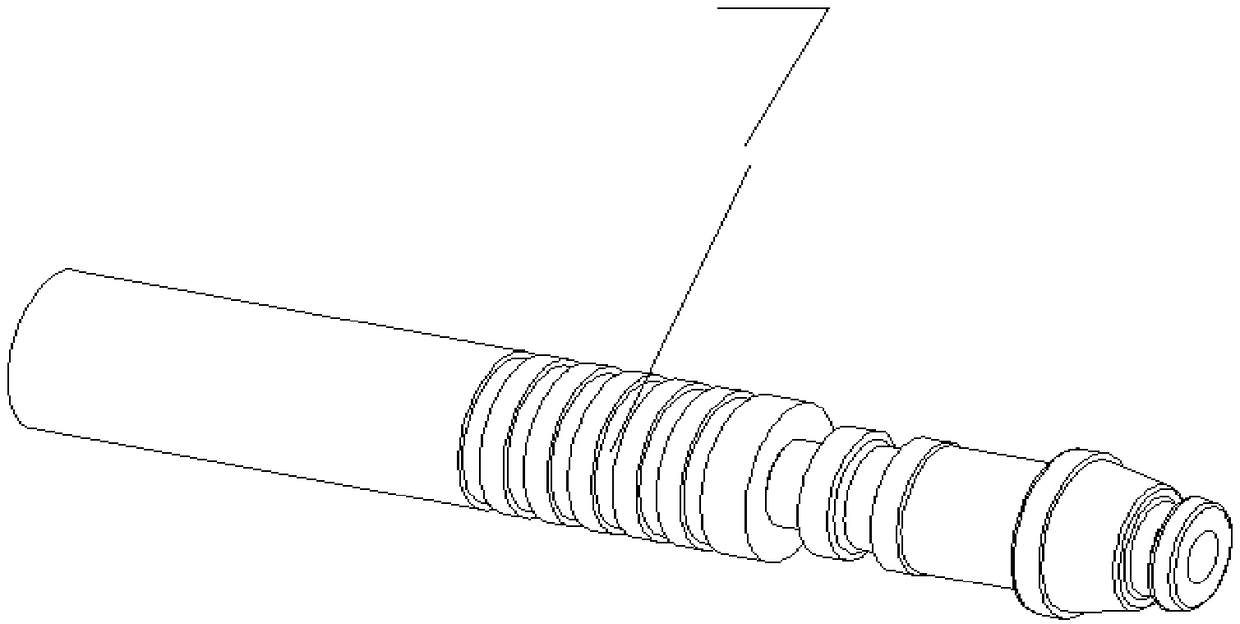

Brake oil tube

InactiveCN109185584AAvoid damageNot easy to pull offFlexible pipesHose connectionsScrew threadPetroleum engineering

The invention discloses a brake oil tube. The brake oil tube comprises a joint core, a sleeve and a hose; a first square internal thread is arranged on at least a part of the outer side face of the joint core; a first square external thread cooperating with the first square internal thread is arranged on at least a part of the inner side face of the hose so that the hose is able to be connected with the joint core mutually; a second square internal thread is arranged on at least a part of the outer side face of the hose; a second square external thread is arranged on at least a part of the inner side face of the sleeve; the second square internal thread cooperates with the second square external thread so that the sleeve is able to be connected with the hose mutually; and thread teeth of the first square internal thread, the first square external thread, the second square internal thread and the second square external thread are square teeth. The brake oil tube can be convenient to dismount and can effectively reduce a risk of oil leakage.

Owner:WUHU SHUANGYI HYDRAULIC COMPONENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com