A plug for sealing holes

A technology for sealing holes and nail cores, which is applied in the field of hole plugging parts. It can solve the problems of high plugging force, unsatisfactory sealing, and the inability of the casing to fully fit the hole wall, etc., to achieve good sealing performance and high plugging force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

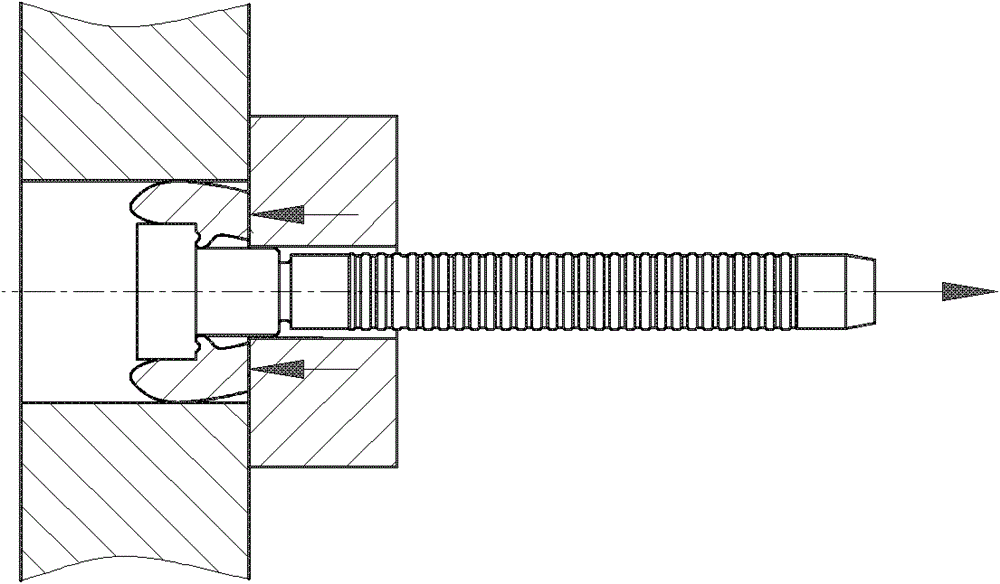

[0029] Below in conjunction with accompanying drawing, the specific embodiment of the novel blocking of the present invention will be further described:

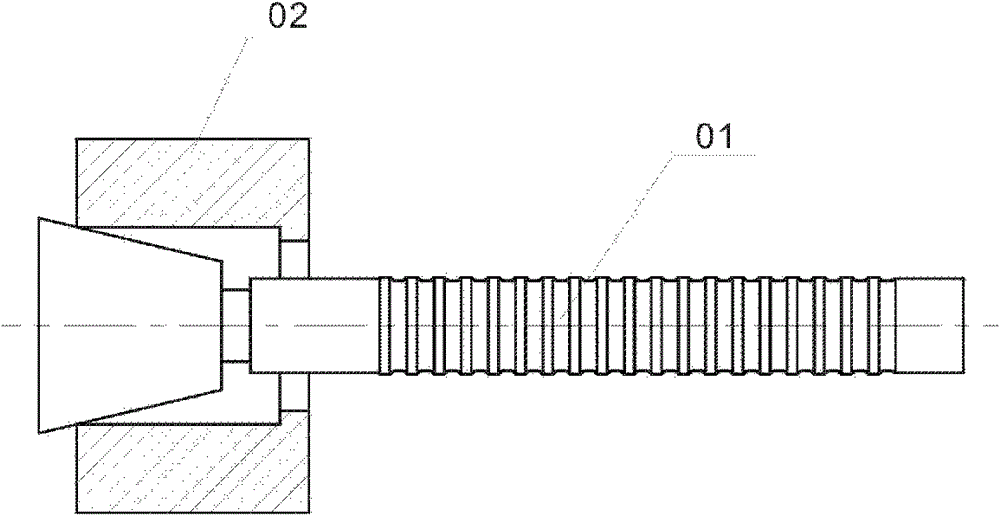

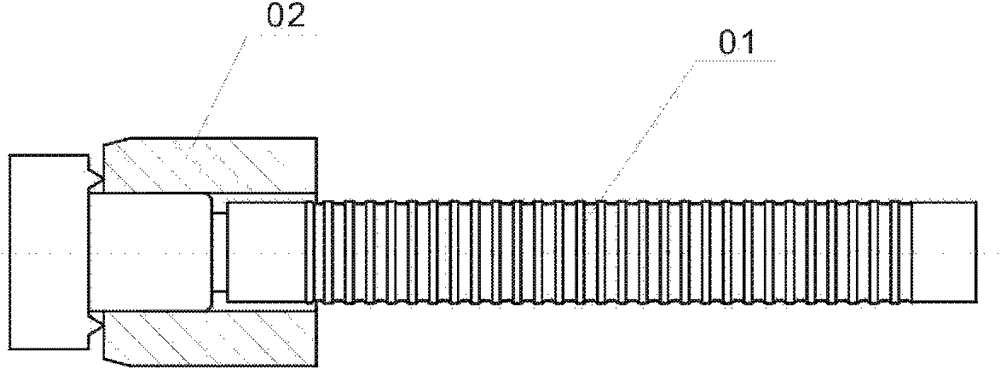

[0030] Figure 5 Shown is an embodiment of the plugging of the present invention, the plugging includes a mandrel rod 1, a sleeve 2 installed outside the mandrel rod 1, a pull-off groove 10 is provided on the mandrel rod 1, and the outer periphery of the mandrel rod 1 is arranged Anti-skid groove 15. The mandrel 1 has a stepped head 12 , that is, the axial section of the head 12 is stepped, and the outer end surface of the head is a spherical concave surface 14 . Wherein, the step 121 adjacent to the rod is spherical (see Figure 5 Enlarged part in the middle), a stop ring groove 13 is provided at the junction of the mandrel rod 1 and the spherical step 121 . The inner wall of the casing 2 is installed in cooperation with the mandrel 1 and is assembled near the spherical step 121 of the mandrel. The mandrel rod 1 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com