Patents

Literature

125 results about "Dynamic Tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

"Dynamic Tension" is the name Charles Atlas gave to the system of physical exercises that he first popularized in the 1920s. Dynamic Tension is a self-resistance exercise method which pits muscle against muscle. The practitioner tenses the muscles of a given body part and then moves the body part against the tension as if a heavy weight were being lifted. Dynamic Tension exercises are not merely isometrics, since they call for movement. Instead, the method comprises a combination of exercises in three disciplines: isotonic, isokinetic, and some exercises in the isometric discipline.

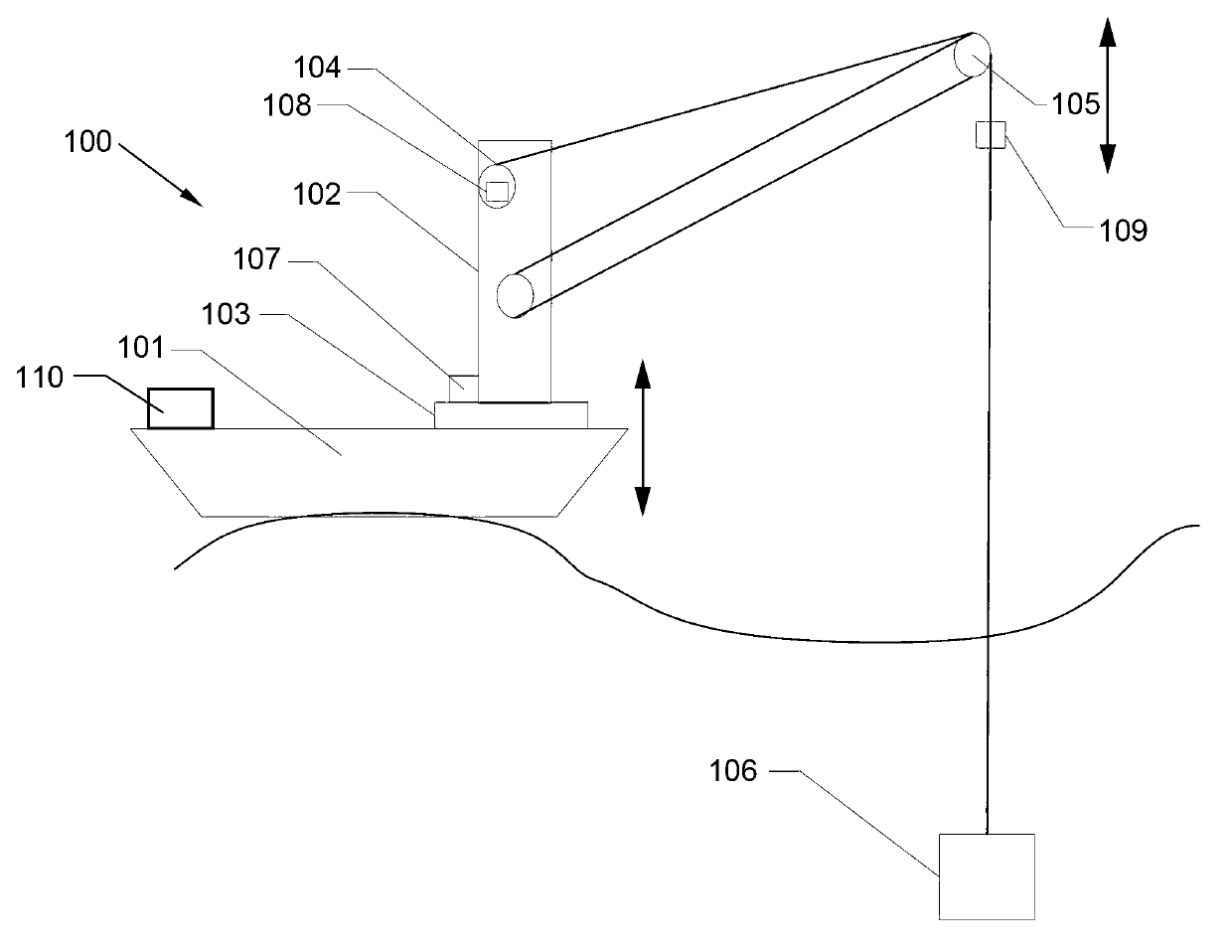

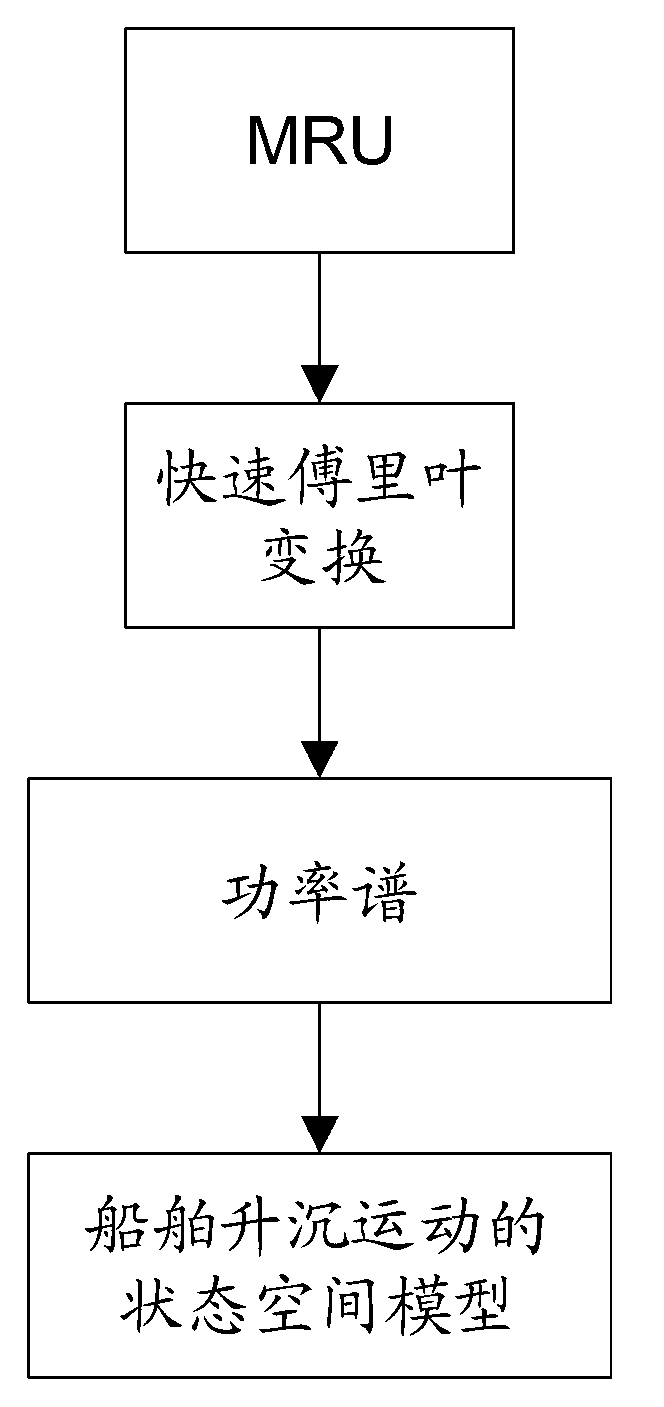

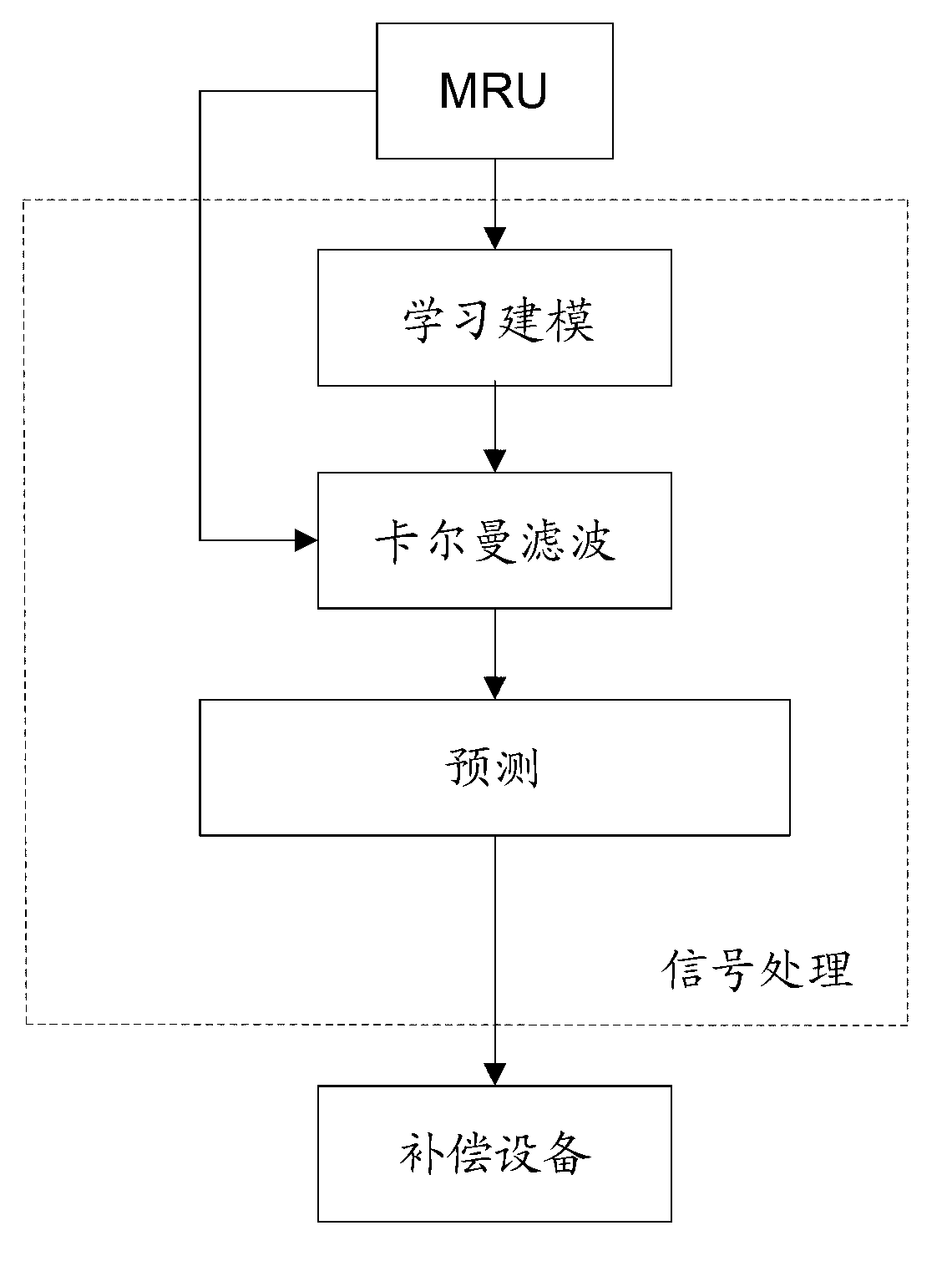

Active heave compensation control system and control method thereof

ActiveCN103318776ARealization of active heave compensationCranesReal-time dataActive heave compensation

The invention discloses an active heave compensation control system comprising a lifting reel, a ship attitude motion sensor, an absolute value encoder, a tension sensor and a compensation unit. The lifting reel is arranged on an offshore crane, a load is suspended by a wire rope which stretches from the lifting reel and goes across a suspension fulcrum at the front end of a support arm, and the load in immersed in water. Real-time detection of heave movement of the ship is performed by the ship attitude motion sensor. Real-time detection of movement of the lifting reel is performed by the absolute value encoder. Real-time detection of dynamic tension of the wire rope is performed by the tension sensor. The compensation unit is connected to the ship attitude motion sensor, the absolute value encoder and the tension sensor. Predictive parameters are calculated by the compensation unit based on historical data and real-time data of the heave moment of the ship, the movement of the lifting reel and the dynamic tension of the wire rope; and compensation voltage is provided for the lifting reel based on the predictive parameters. The invention also discloses an active heave compensation control method.

Owner:SHANGHAI ZHENHUA HEAVY IND

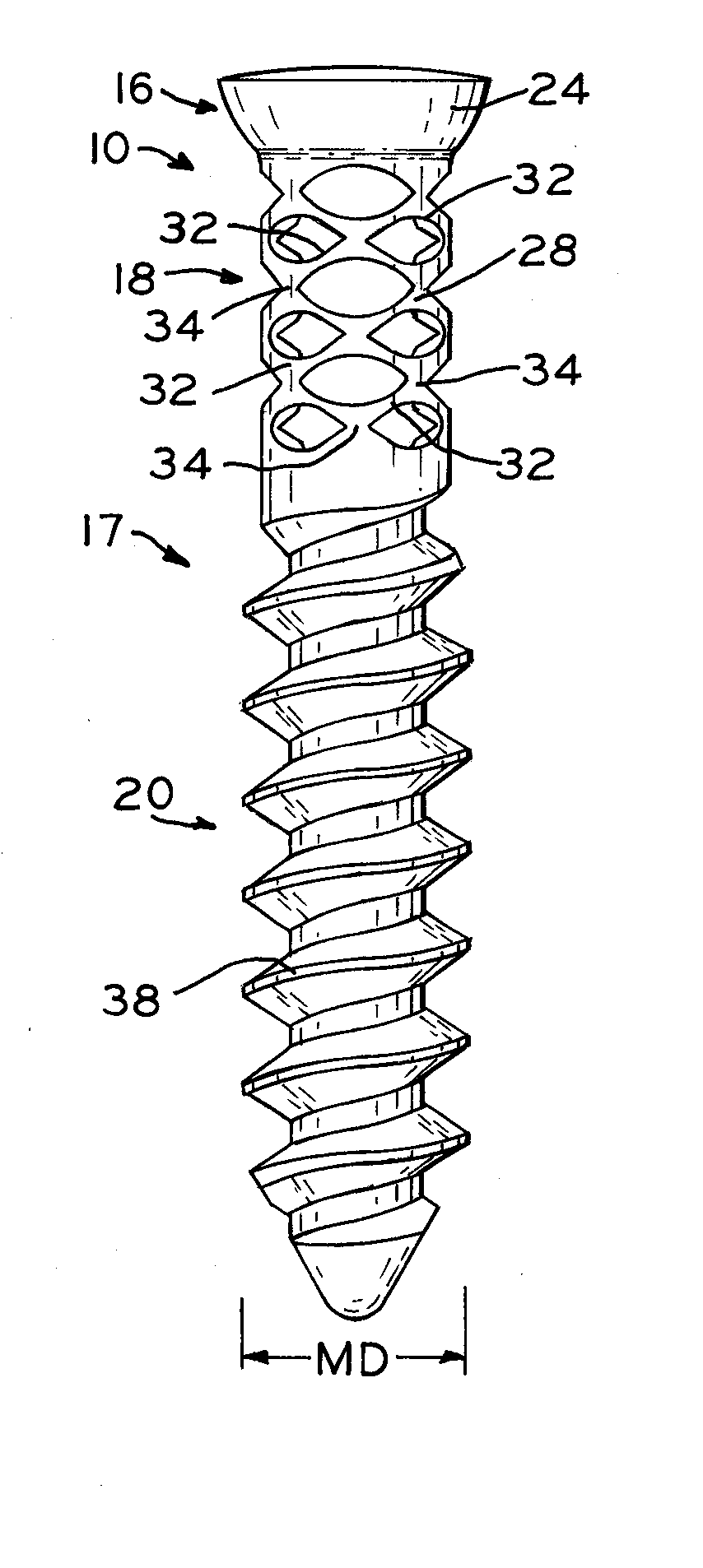

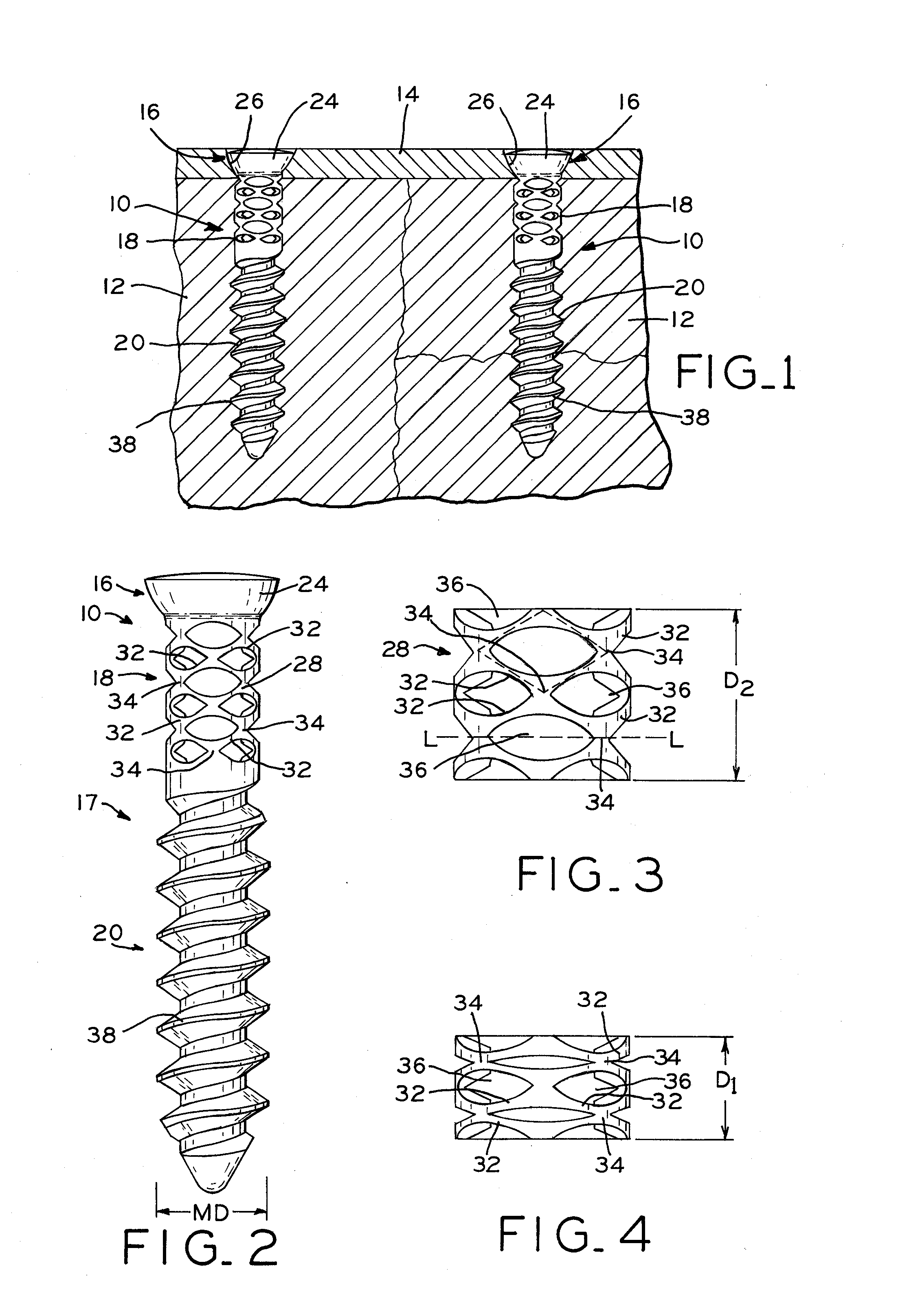

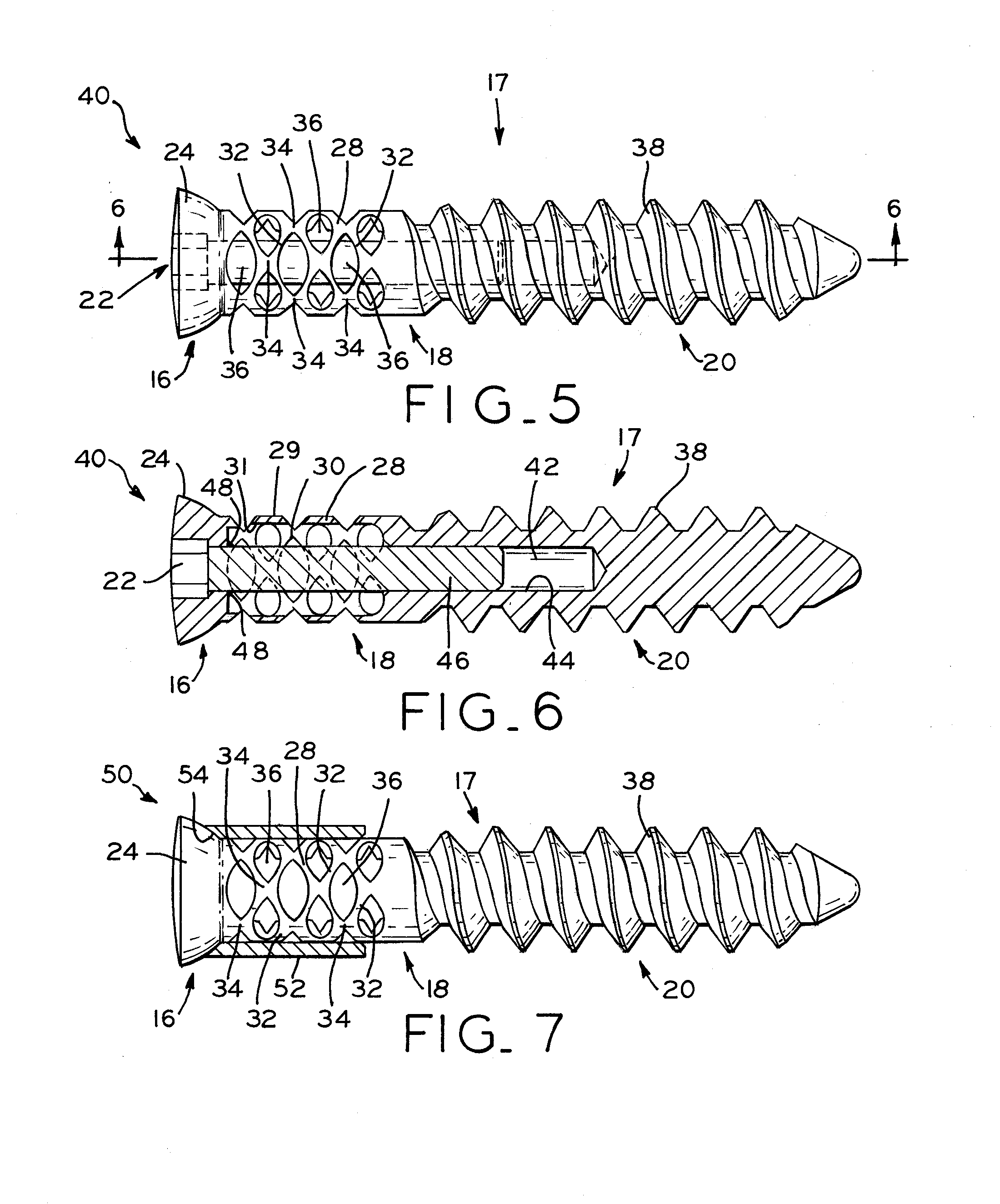

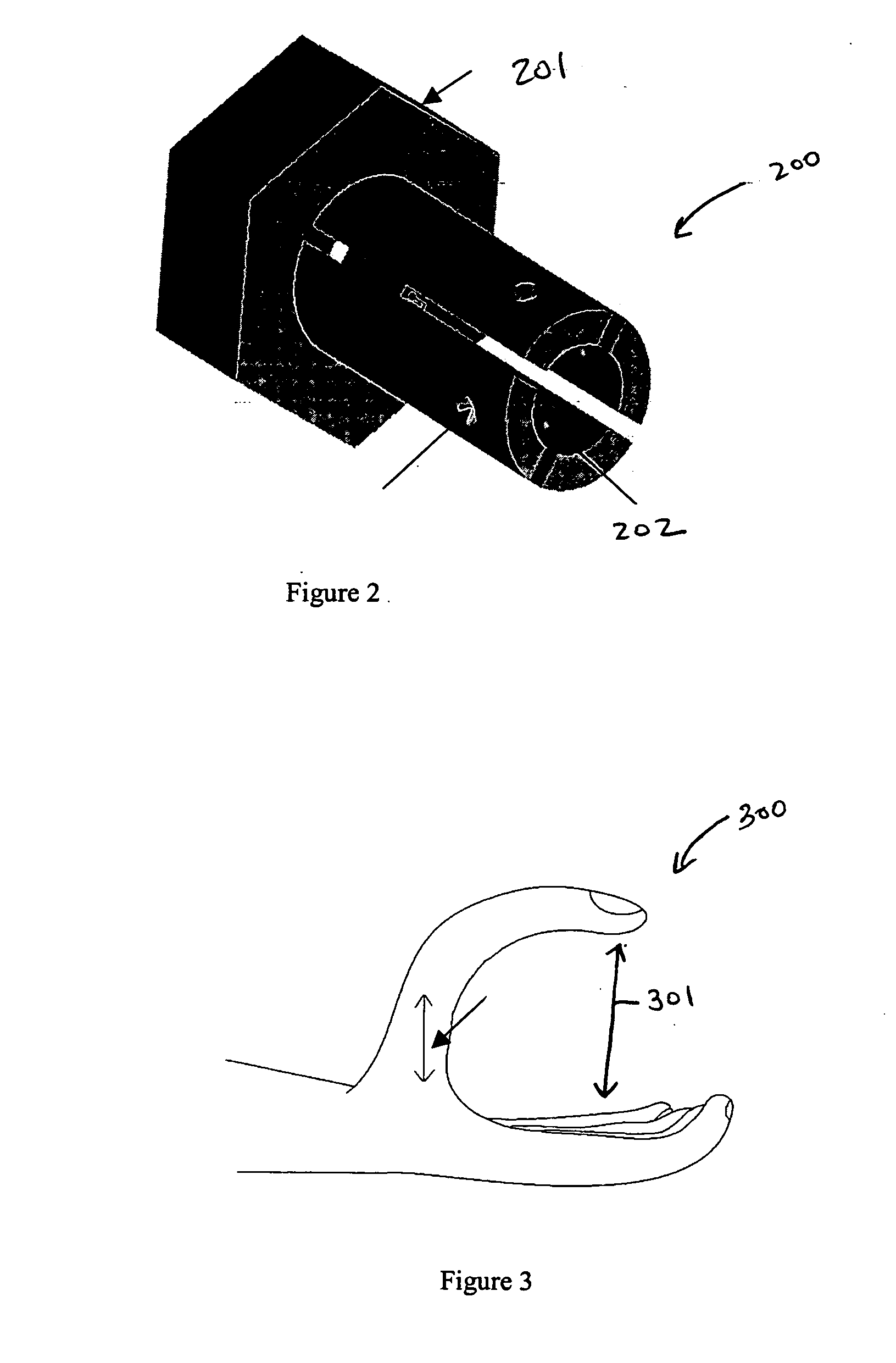

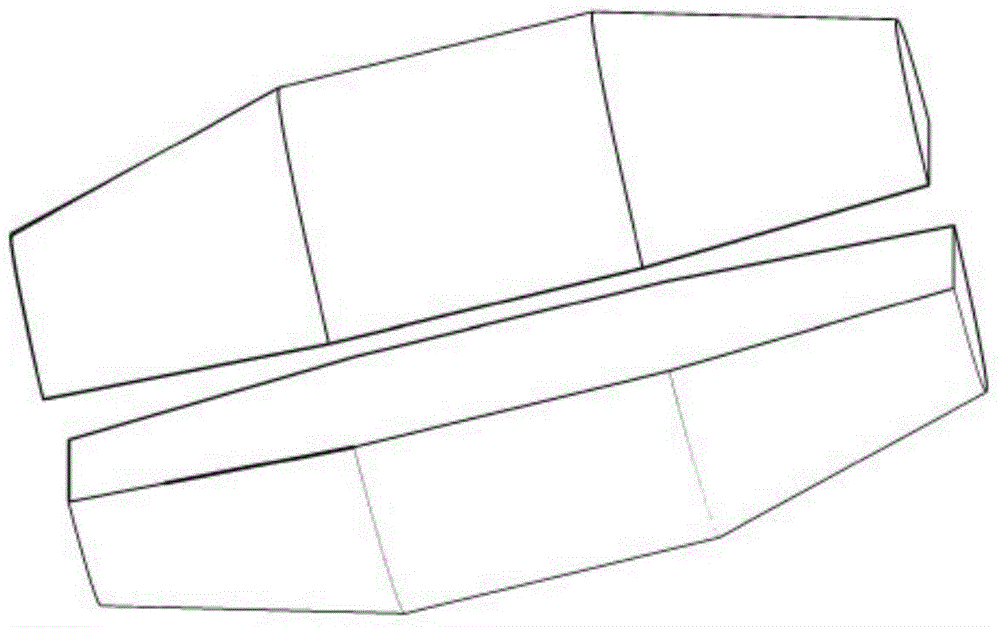

Bone screw for providing dynamic tension

InactiveUS20090264937A1High torqueIncrease or decrease lengthSuture equipmentsLigamentsLaser cuttingEngineering

A bone screw including a head portion, an intermediate portion, and a threaded portion. The intermediate portion further includes a wave-type spring formed therein. In one exemplary embodiment, the wave-type spring is formed to have a lattice structure. In one exemplary embodiment, the wave-type spring of the intermediate portion is formed by laser cutting. By providing a wave-type spring in the intermediate portion of the bone screw of the present invention, the bone screw provides dynamic tension to maintain a bone plate or other orthopedic device in its desired position substantially adjacent a bone.

Owner:ZIMMER INC

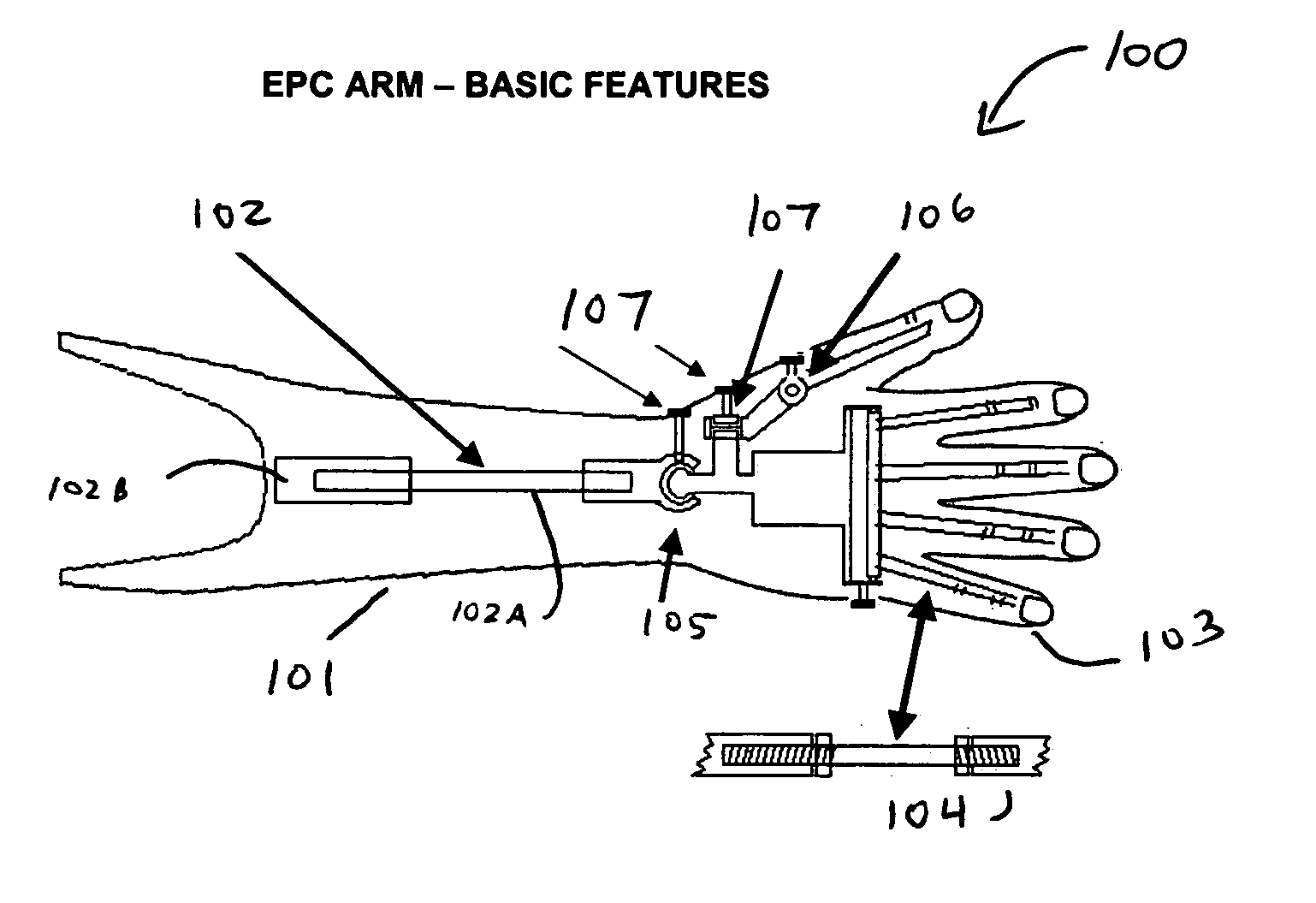

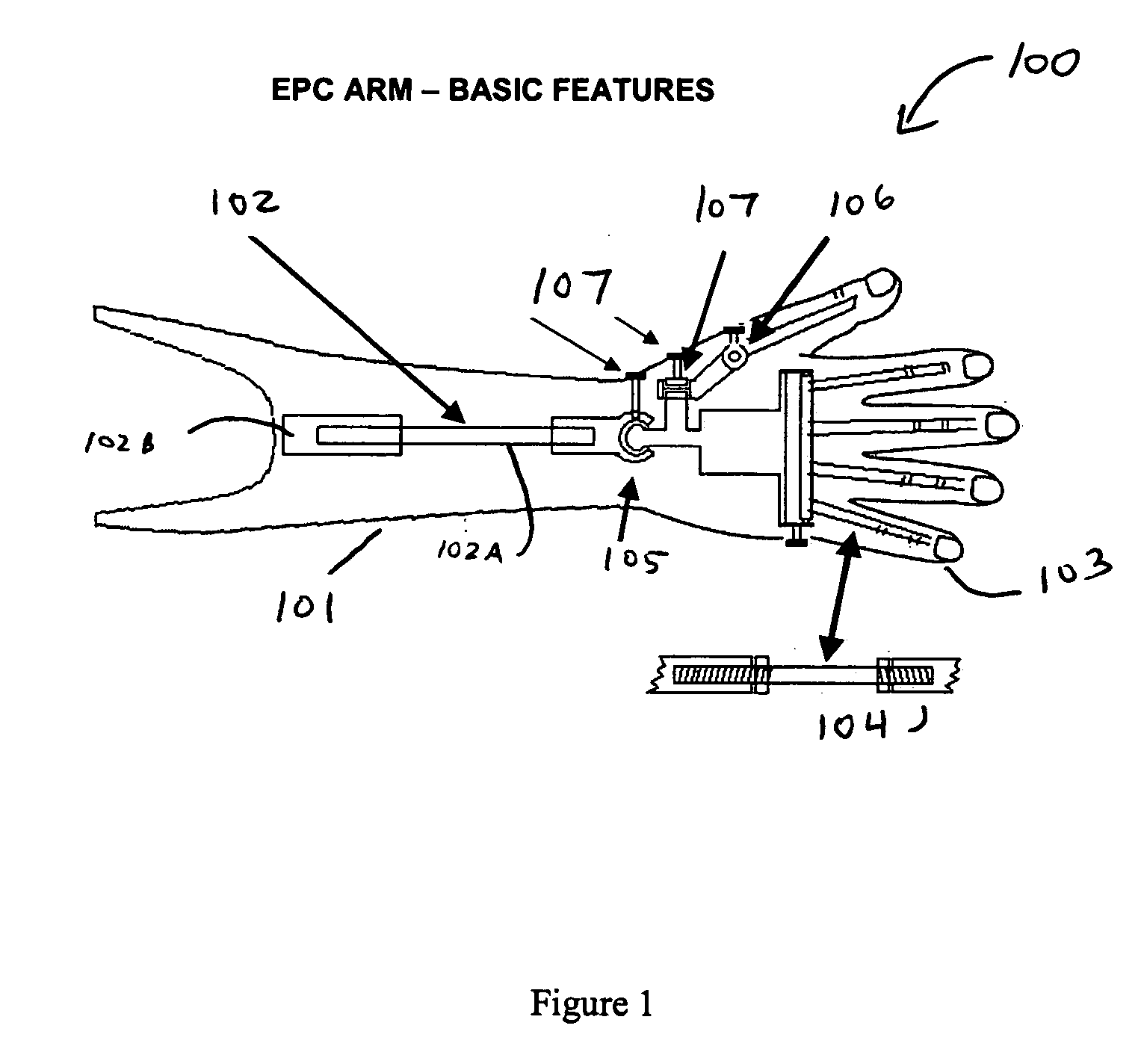

Enhanced-functionality prosthetic limb

InactiveUS20050234564A1Many functionsLong lastingArtificial handsPhysical medicine and rehabilitationThree degrees of freedom

An enhanced-functionality prosthetic limb is disclosed, comprising a prosthetic hand or gripping device, and forearm, which may be body-powered or motor-powered, targeted primarily for pediatric use, attachable to the arm stump of a below-elbow, or above-elbow, with the inclusion of a prosthetic elbow, amputee individual, with incorporation of one or more of the following features: expandability in length or size to accommodate child growth or other expandability needs, grasp locking capability, individual finger locking capability, three degree of freedom wrist joint, dynamic tensional rotation control of wrist, dynamic grasp control to allow grasping of irregular objects, extended grasp for gripping larger objects, excessive force breakaway, and algorithms to support by user of care-provider adjustment of the prosthesis.

Owner:FINK RAINER +5

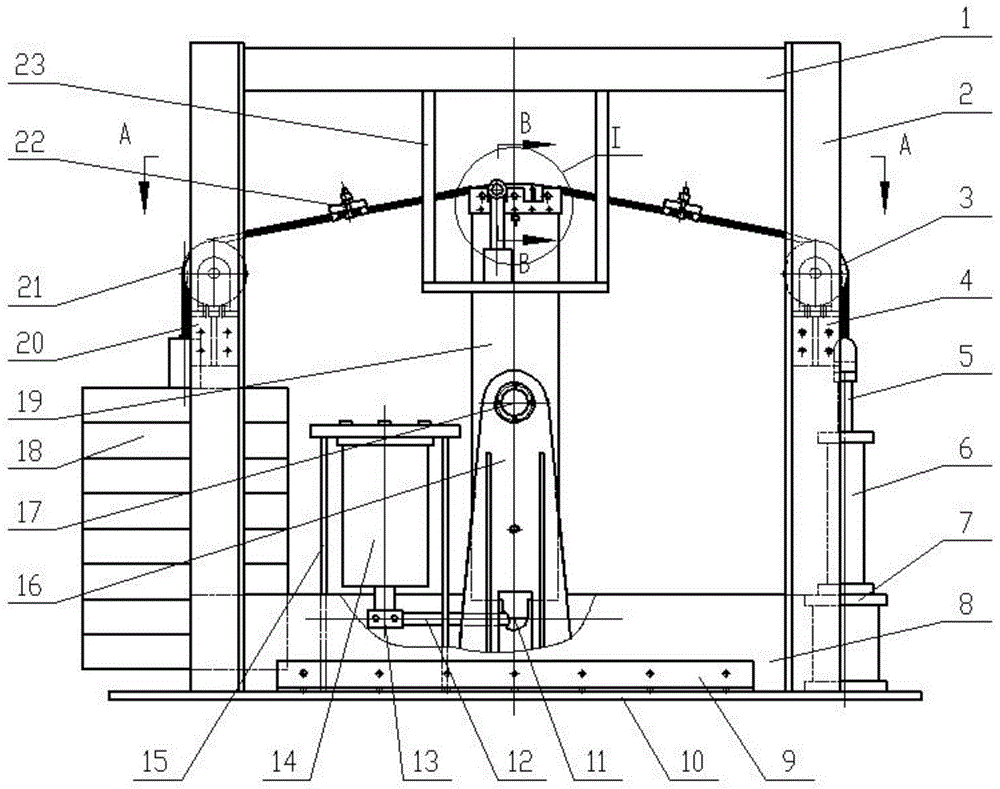

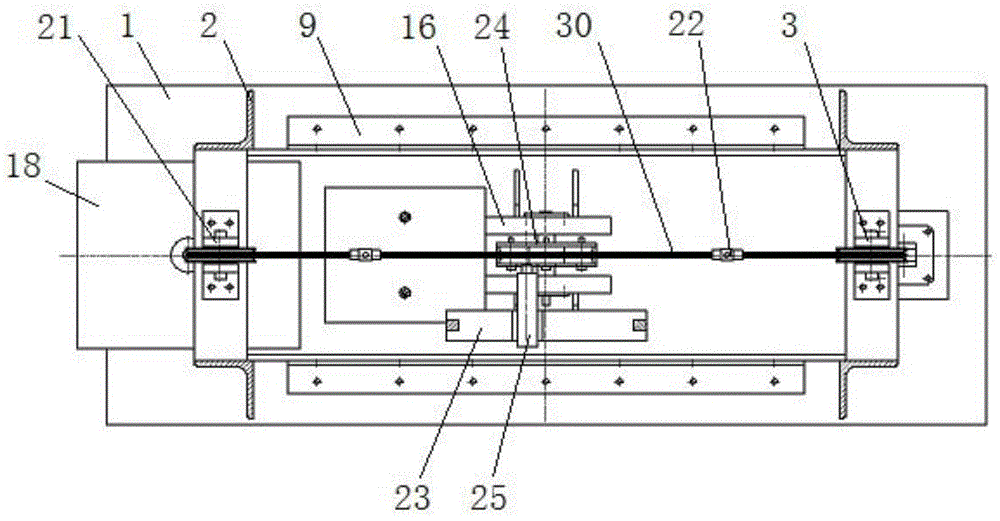

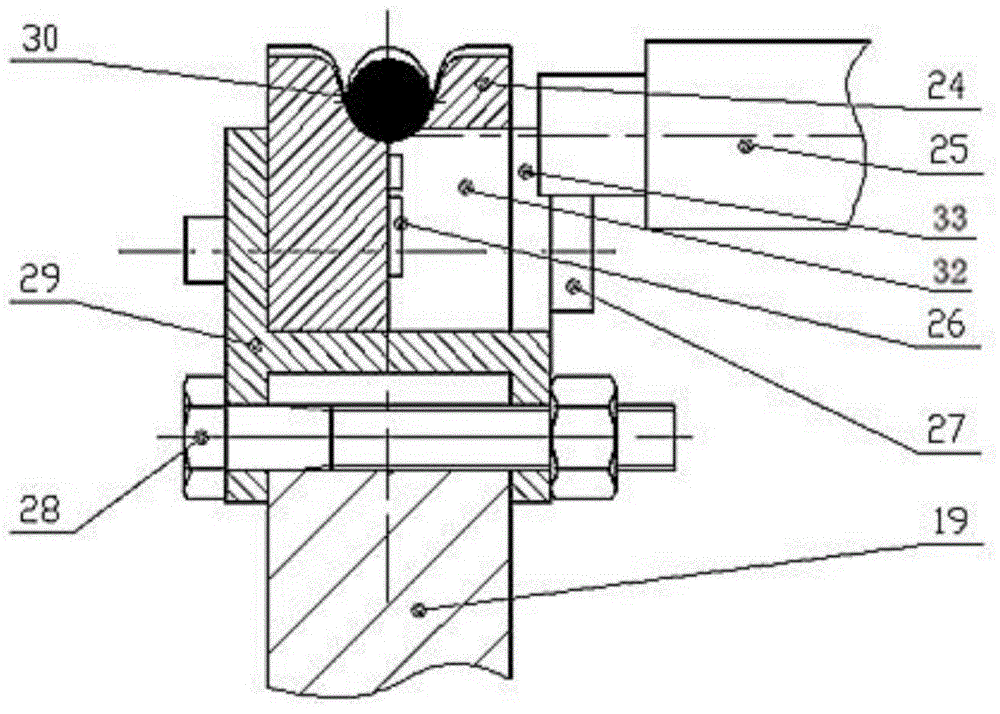

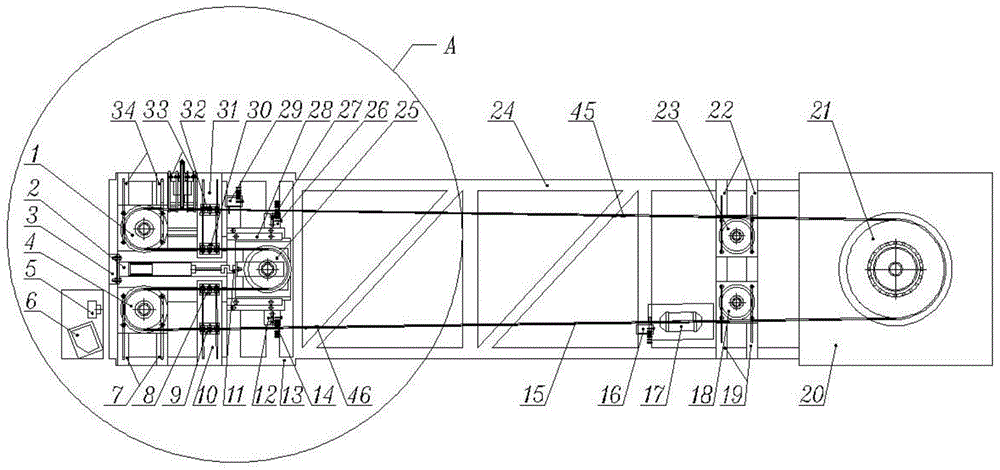

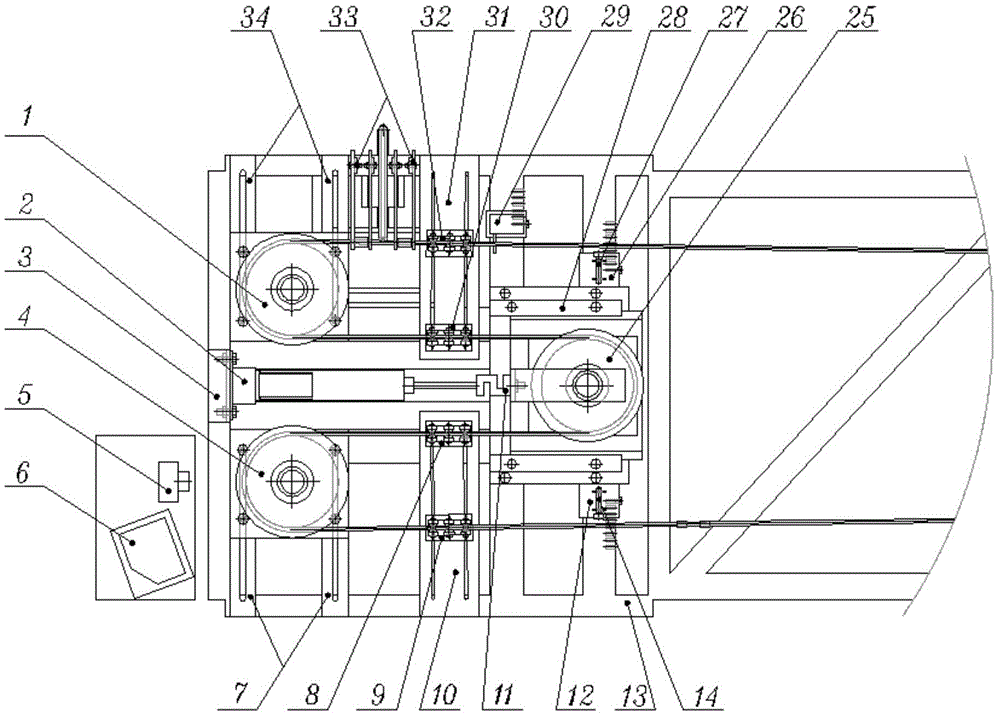

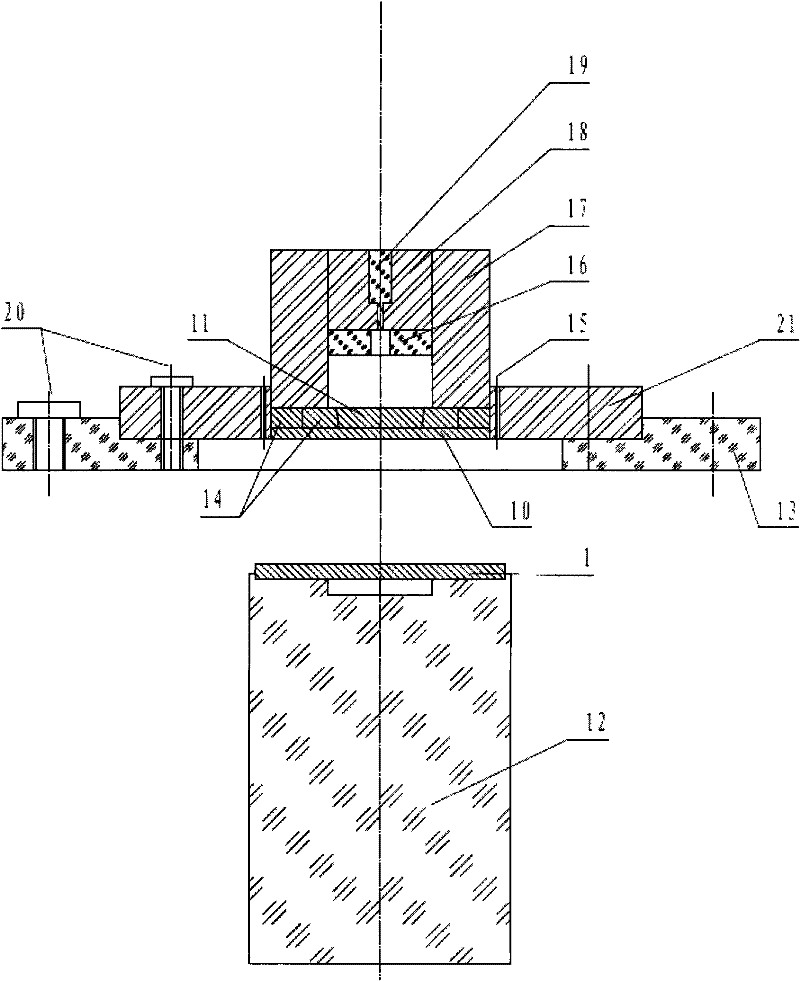

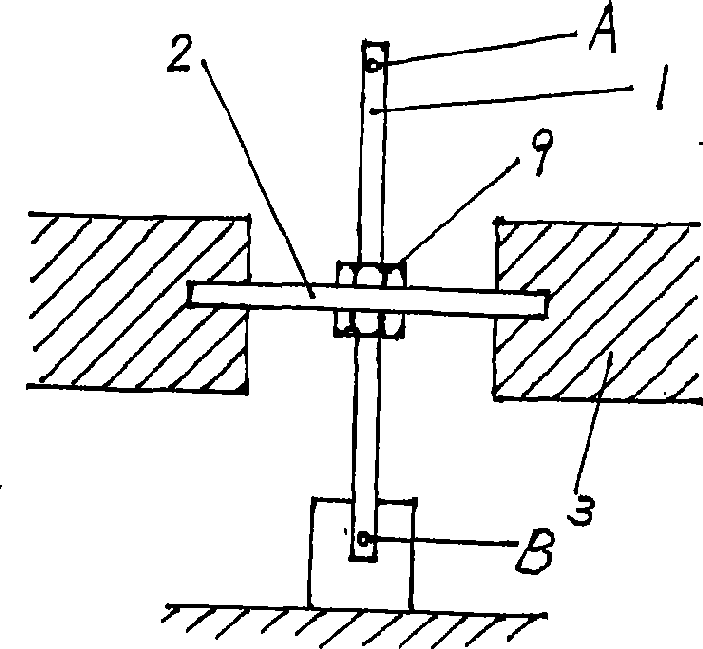

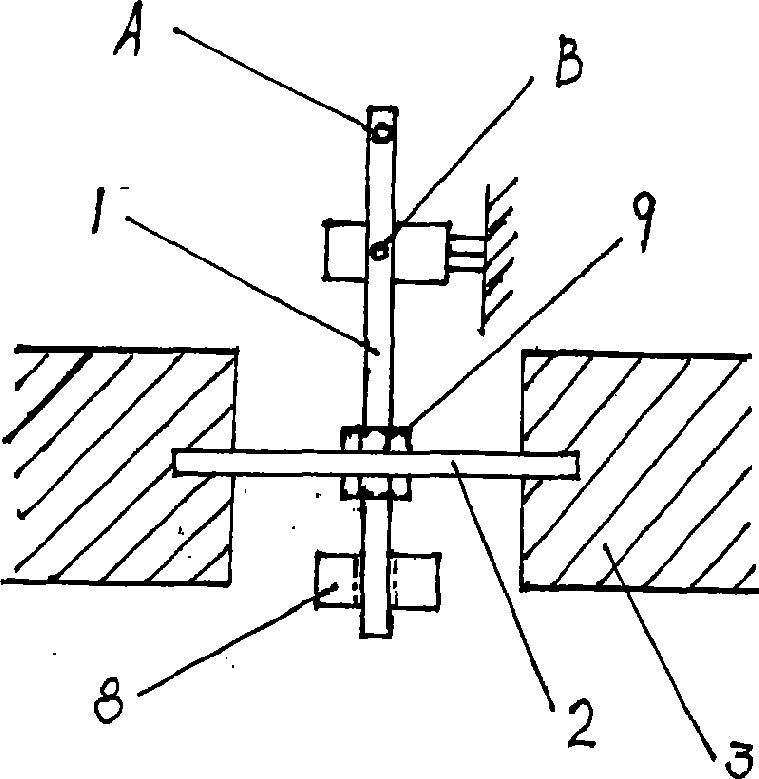

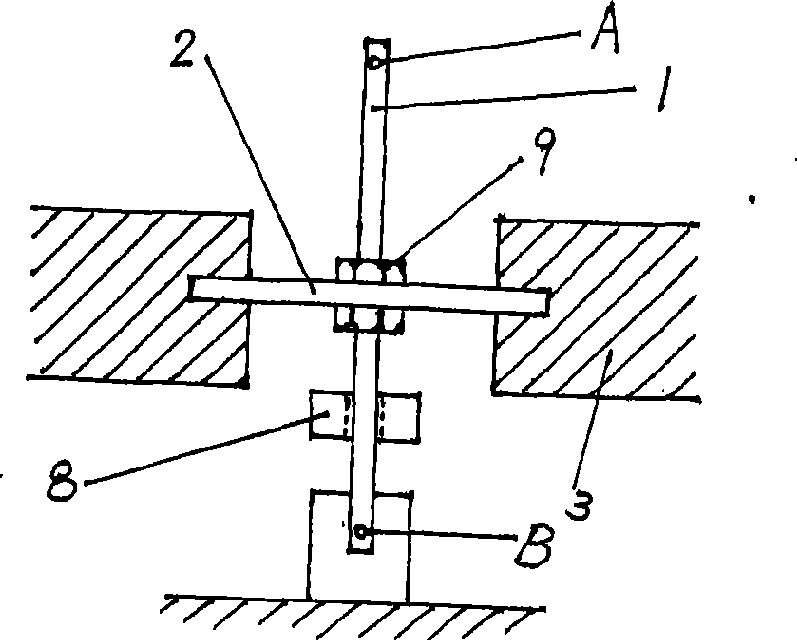

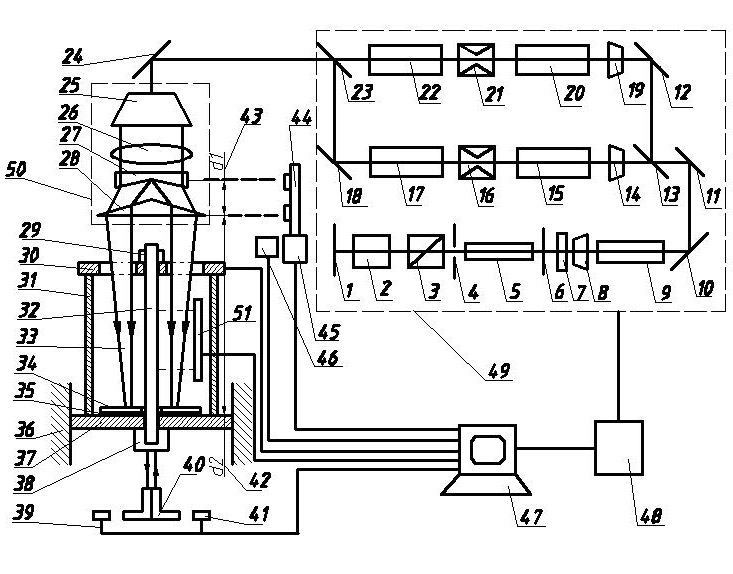

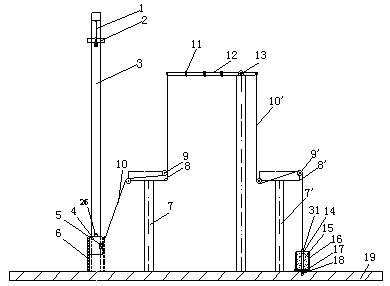

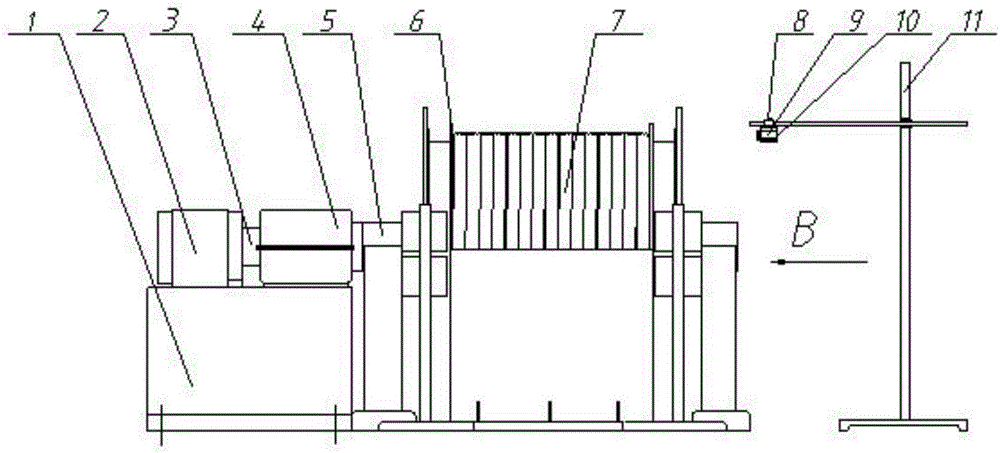

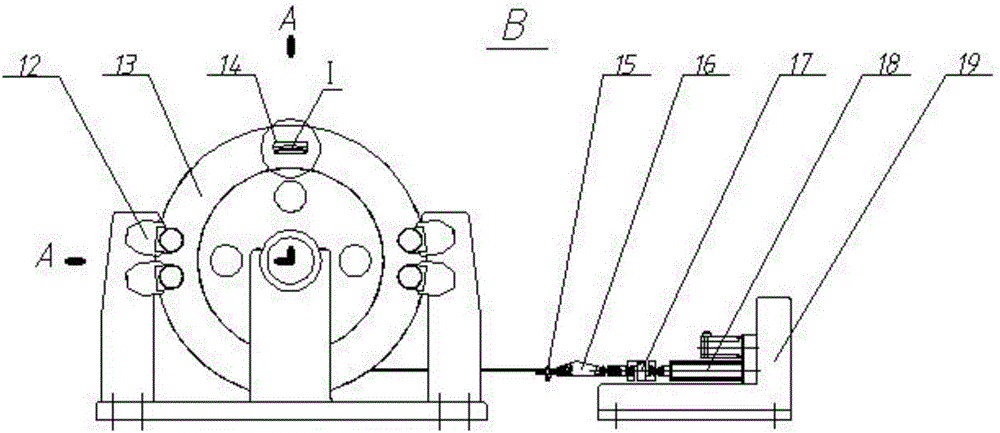

Testing device and method for monitoring steel wire rope-friction pad dynamic micro-friction state

ActiveCN103954553AReal-time measurement of dynamic tension evolutionSimple structureUsing mechanical meansMaterial analysisEngineeringDynamic Tension

The invention discloses a testing device and a testing method for monitoring steel wire rope-friction pad dynamic micro-friction state. The testing device comprises a base frame, a loading system, a micro-slip system and a state monitoring system, wherein the loading system comprises a weight loading system, a hydraulic loading system and a steel wire rope; the micro-slip system comprises a support system, a drive system and a friction transmission system; the state monitoring system comprises a dynamic tension monitoring system, a pad stress measuring system, a friction force measuring system and a micro-slip monitoring system. By utilizing the testing device and the testing method, dynamic alternating tension can be applied to the steel wire rope and dynamic micro-friction can be applied between the steel wire rope and a friction pad simultaneously, and dynamic tension evolution of the steel wire ropes at both sides of the friction pad, micro-slip amplitudes of different sections of a contact arc of the steel wire rope and the friction pad, stress change of the friction pad near the contact zone of the steel wire rope and the friction pad and dynamic friction force between the steep wire rope and the friction pad can be measured in real time.

Owner:CHINA UNIV OF MINING & TECH

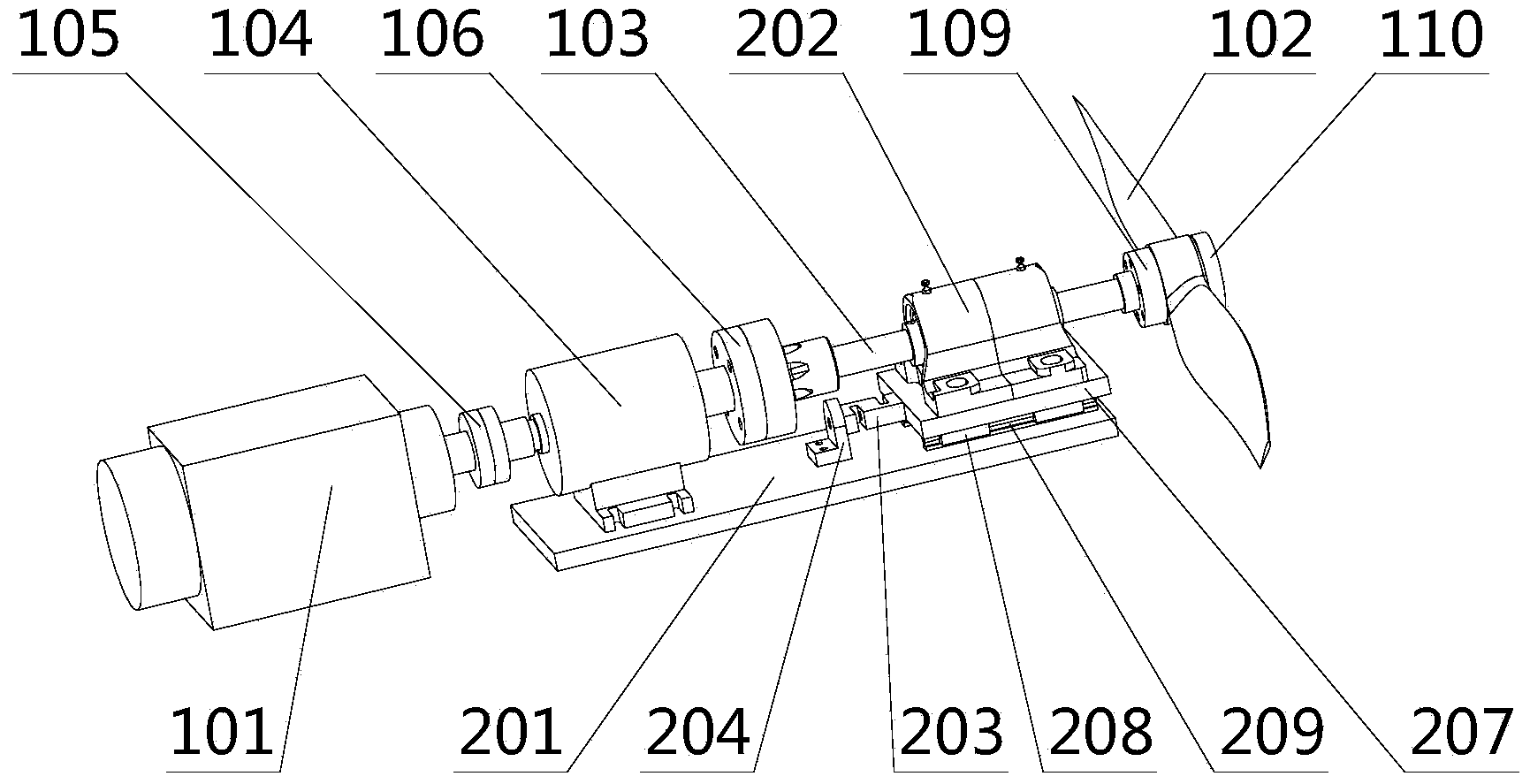

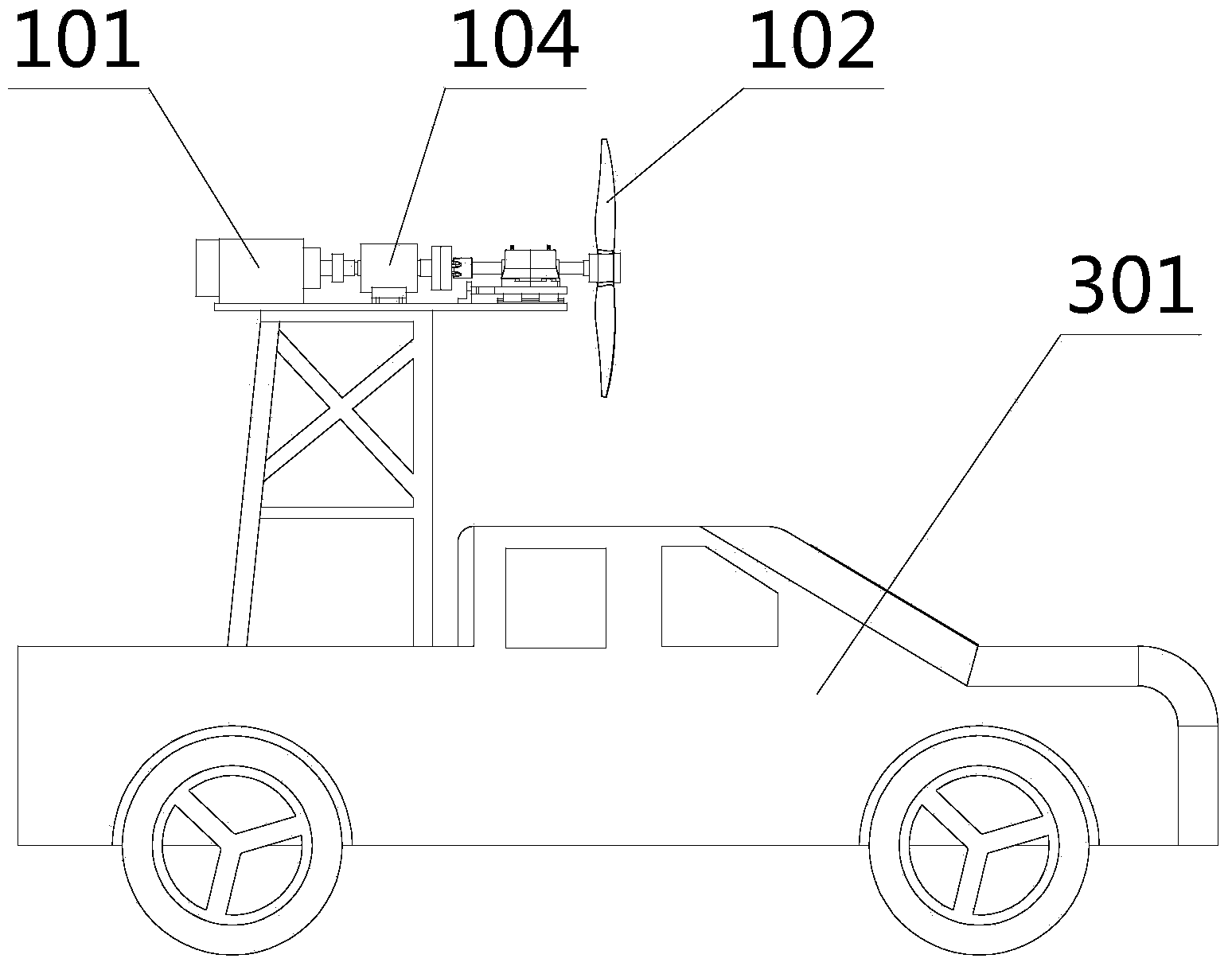

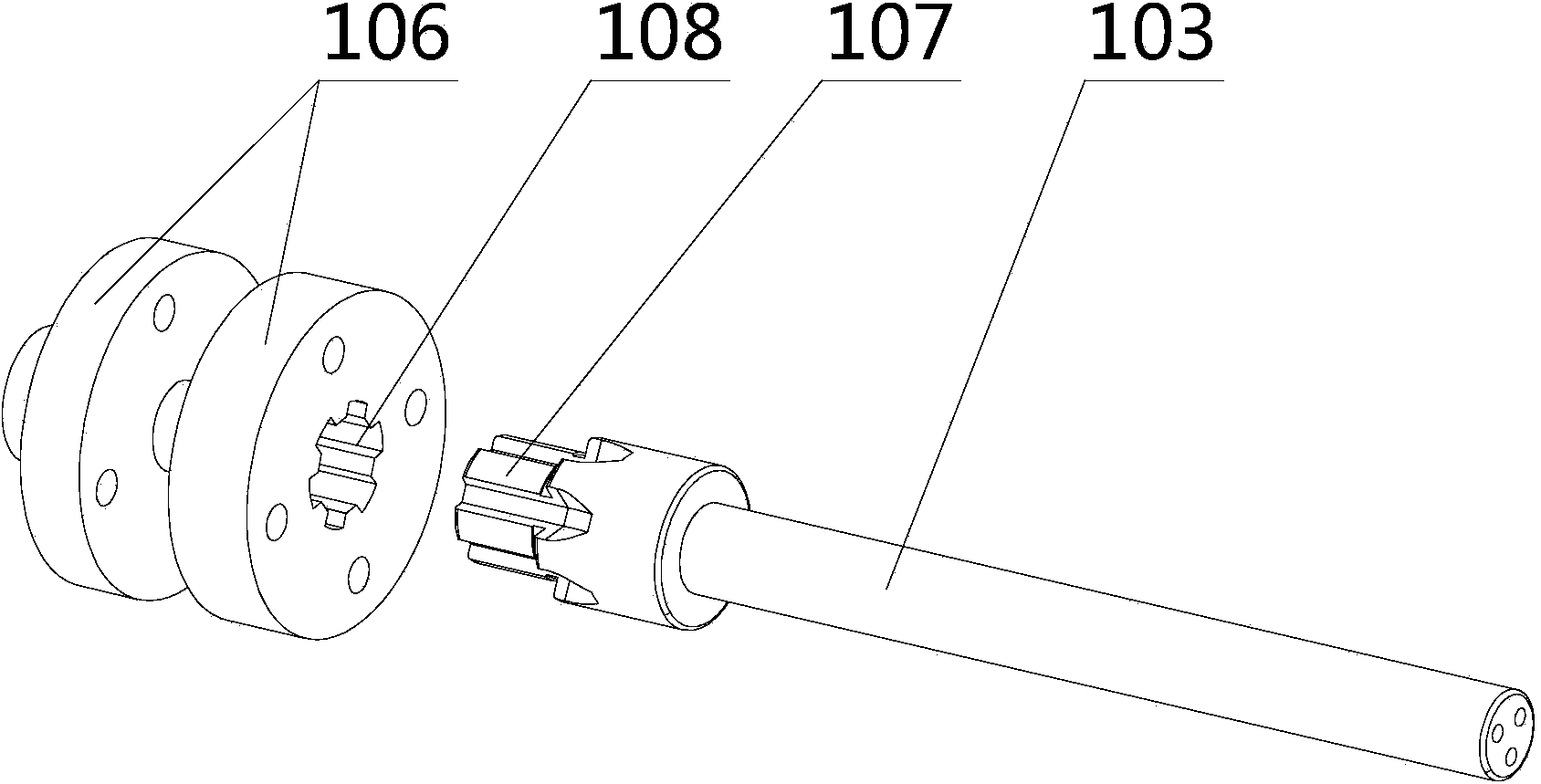

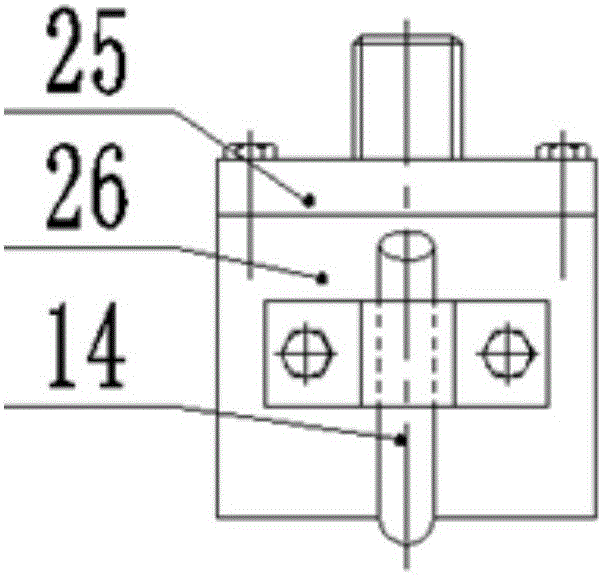

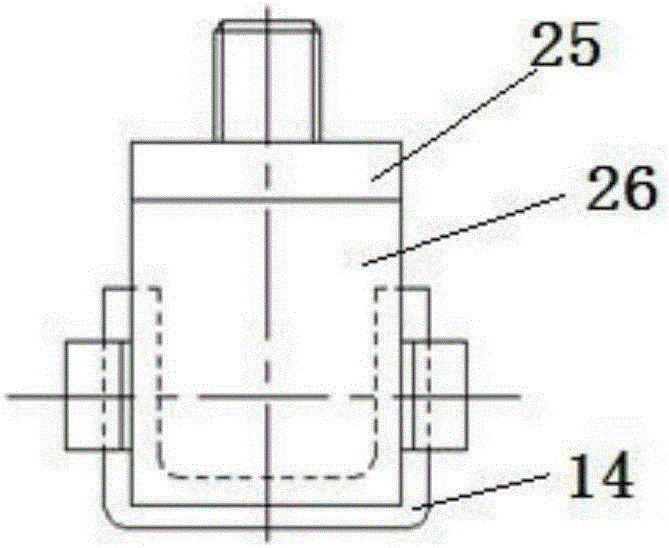

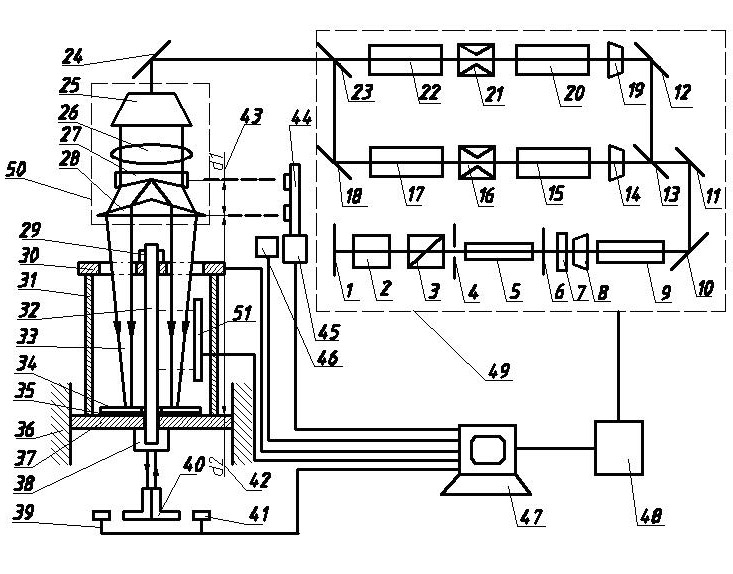

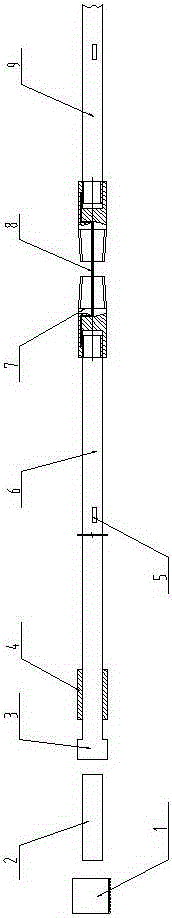

Propeller dynamic tension and torque duplex measuring device

ActiveCN104316229ALow costHigh accuracy of measurement resultsForce measurementWork measurementPull forcePropeller

The invention provides a propeller dynamic tension and torque duplex measuring device and belongs to the technical field of force measurement. The propeller dynamic tension and torque duplex measuring device comprises a drive motor, a propeller, a bottom plate and a bearing seat. The propeller is provided with a spindle. The end, far from the propeller, of the spindle penetrates through the bearing seat and is in coaxial transmission connection with an output shaft of the drive motor through a dynamic torque sensor. The dynamic torque sensor is fixedly connected with the bottom plate. The bearing seat is provided with a tension and pressure senor. The tension and pressure sensor is connected with the bottom plate through a connecting part. The bearing seat is connected with the bottom plate in a sliding mode. The propeller dynamic tension and torque duplex measuring device can simultaneously measure dynamic tension and torque generated during rotation of the propeller, and is simple in structure, low in cost, high in measurement accuracy and convenient to install and maintain.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

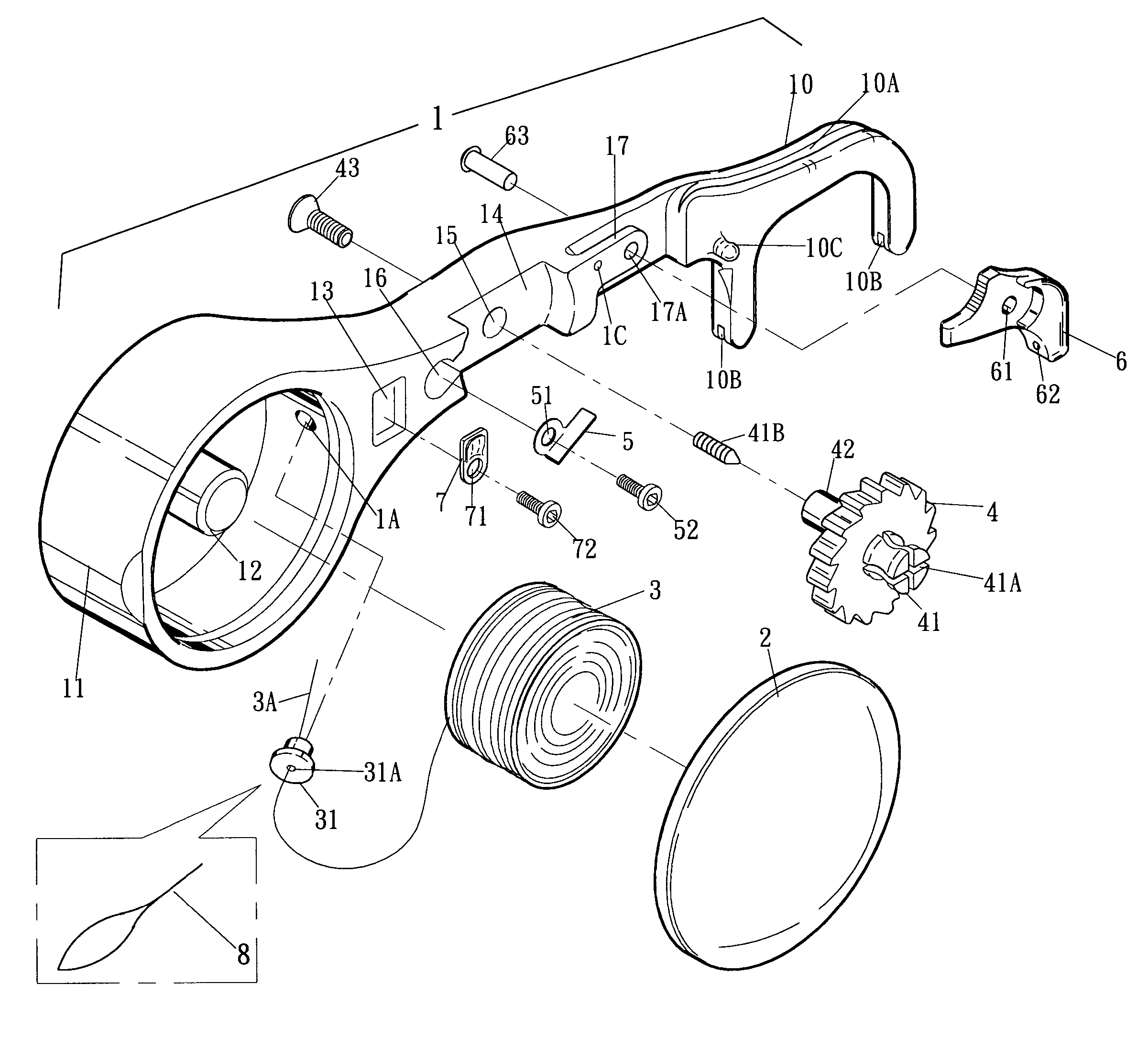

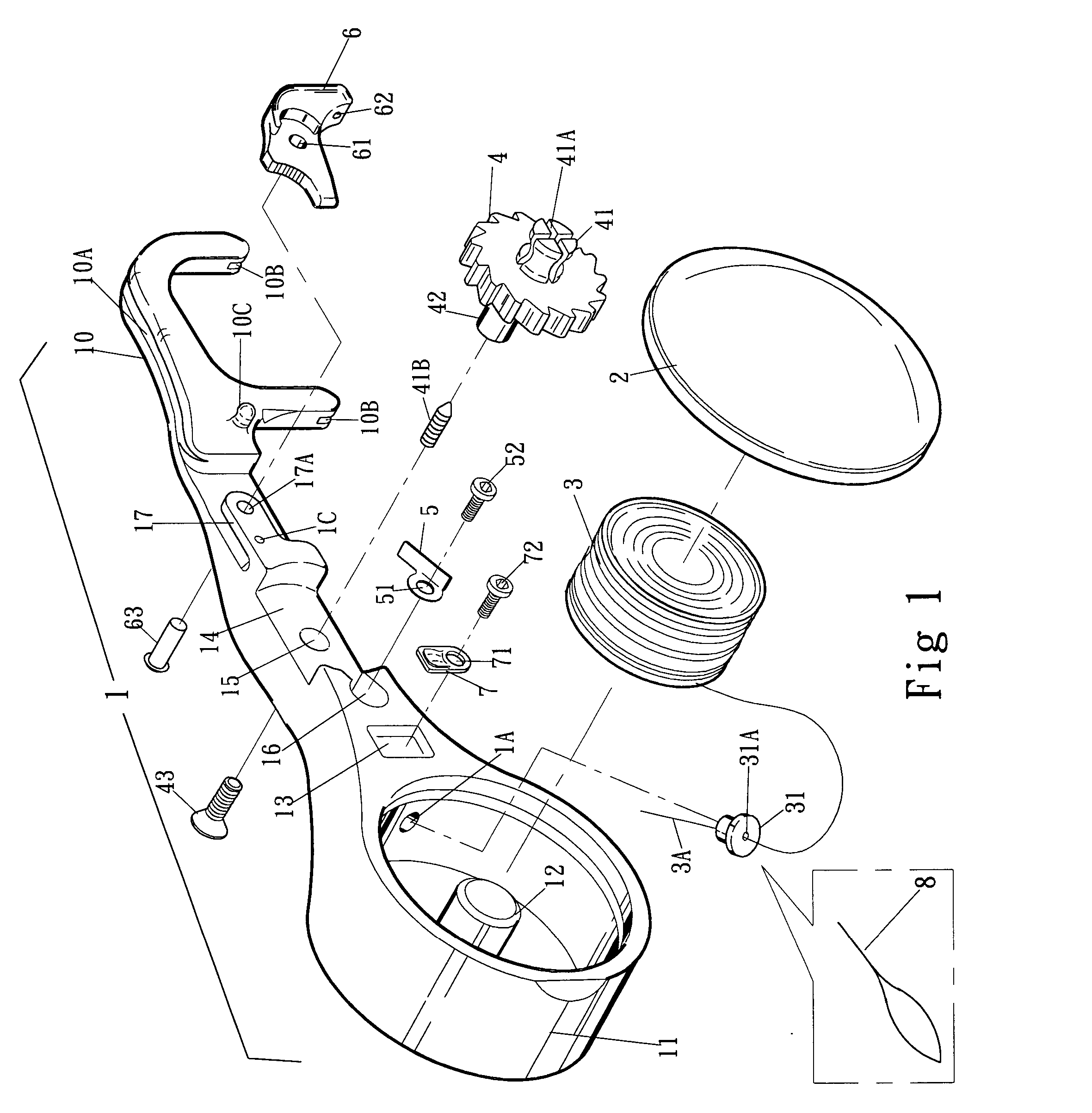

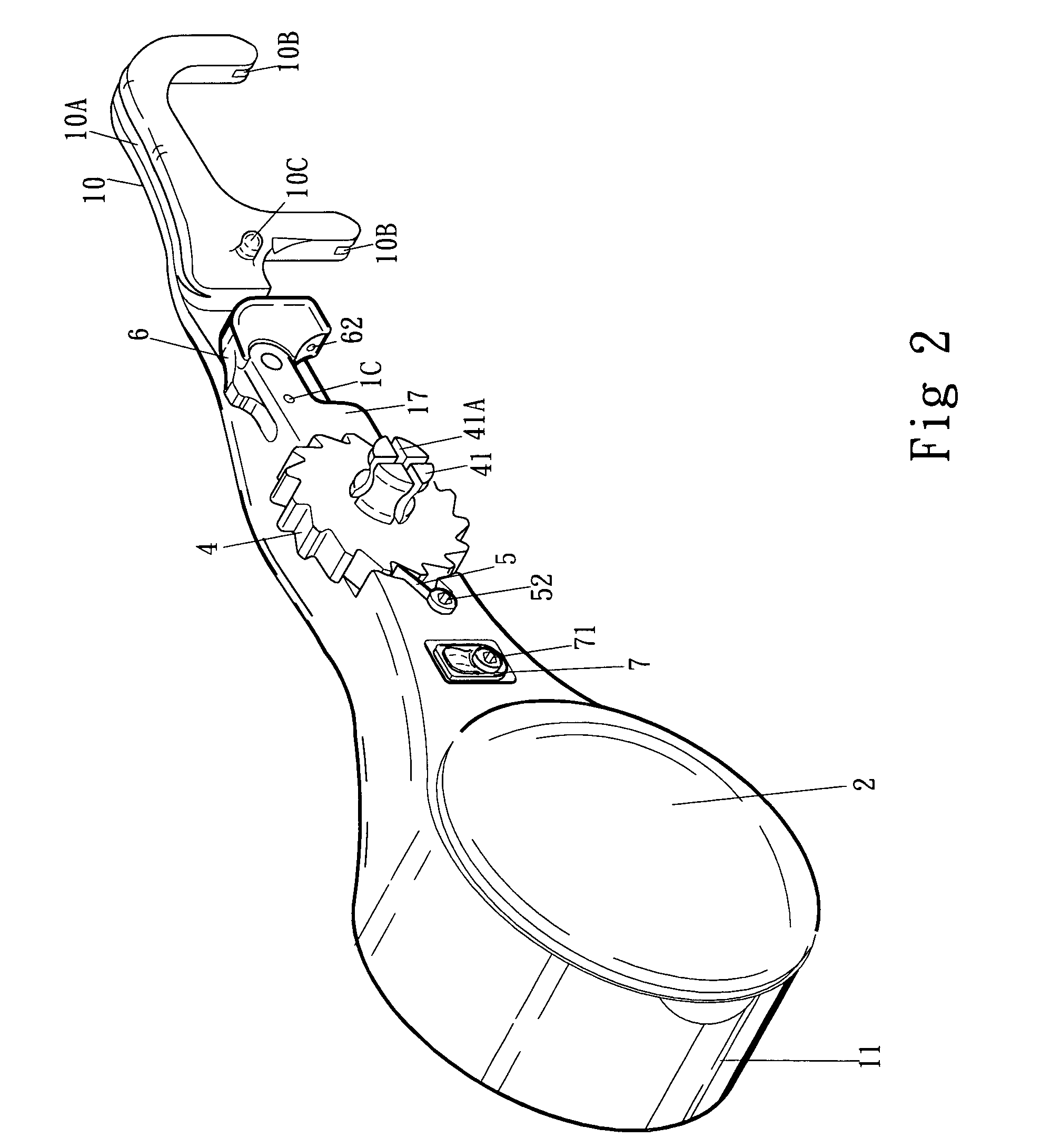

Floss dispenser with dynamic tension control

Provided is a floss dispenser comprises a housing defining at least a receiving chamber with a floss bobbin rotationally received therein. A floss fork is arranged at an end of the housing for bracing a section of floss thereon. A first tension-controlling device is arranged on the housing controlling a tension of the floss after the floss fork. And a tensioner is arranged adjacent to the feeding device controlling the tension between the floss bobbin and the floss fork. By the provision of the tensioner, the tension of the floss can be properly controlled during the flossing process, and the tension of the floss can be released after the flossing process.

Owner:CHEN CHIA CHING

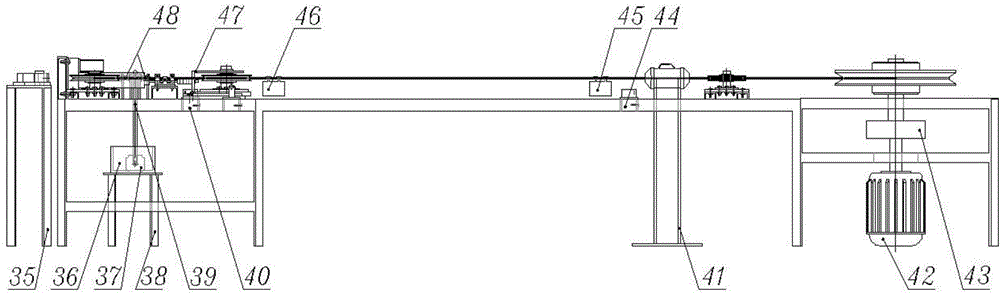

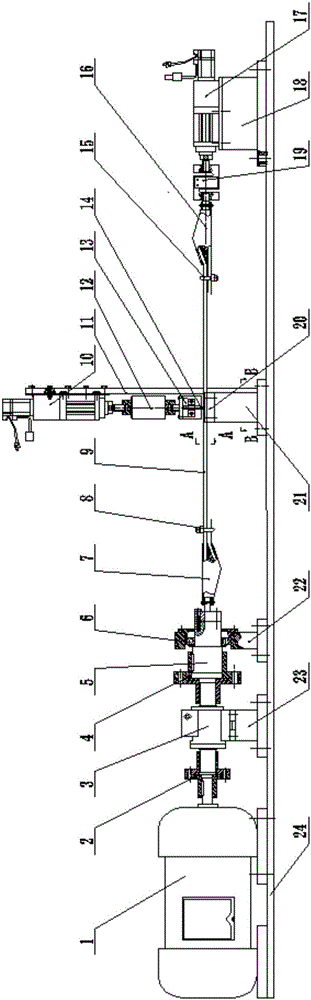

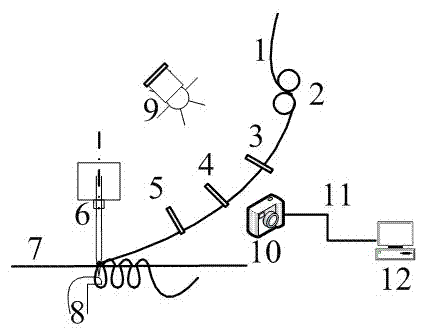

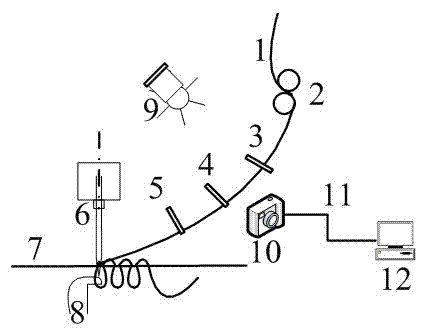

Bending fatigue damage monitoring system for steel wire under action of corrosion-alternating load coupling

InactiveCN104614261ASimple and fast operationVersatileWeather/light/corrosion resistanceMaterial strength using steady bending forcesFatigue damageControl system

The invention discloses a bending fatigue damage monitoring system for a steel wire under action of corrosion-alternating load coupling. The bending fatigue damage monitoring system comprises a driving system, an alternating force loading system, a reversing control system, a surrounding angle adjusting system, a corrosion liquid addition system, a steel wire and a steel wire status monitoring system. According to the bending fatigue damage monitoring system, the bending fatigue test for the steel wire under the action of corrosion-alternating load coupling can be realized, and the quantitative monitoring on the internal damage of the steel wire and the disclosure on the bending fatigue damage failure mechanism can be achieved. The bending fatigue damage monitoring system can be used for exploring the dynamic contact between the steel wire rope and a friction liner of a friction wheel under the working condition of simulating mine hoisting, local microslip amplitude and the dynamic tension evolution of the steel wire rope. The bending fatigue damage monitoring system can provide effective experimental equipment for the quantitative analysis of the bending fatigue failure characteristic of the steel wire under action of corrosion-alternating load coupling; and the bending fatigue damage monitoring system is simple and convenient to operate, complete in functions, good in effect, and has wide practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

Ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device and method

InactiveCN105823696AWide applicabilityUsing mechanical meansMaterial strength using repeated/pulsating forcesFatigue damageLow speed

The invention discloses an ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device .The monitoring device comprises a tension-torsional fatigue system and a dynamic loading monitoring system which are arranged on a supporting system; the tension-torsional fatigue system comprises a low-speed large-torque motor and a servo electric cylinder A, the low-speed large-torque motor is connected with one end of a fatigue steel cable through a coupling A, a torque sensor, a coupling B, a shaft and a steel cable fixture A, and a threaded rod of the servo electric cylinder A is connected with the other end of the fatigue steel cable through a tension sensor and a steel cable fixture B; the dynamic loading monitoring system comprises a servo electric cylinder B, a threaded rod of the servo electric cylinder B is connected with a loading steel cable fixture through a two-dimension force sensor, a fixture block is arranged on a fixture rotary table of the loading steel cable fixture, and the loading steel cable is fixed on the fixture block .According to the ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device, cable multi-axial friction fatigue properties among steel cables under the dynamic tension-torsional combined fatigue loading action and dynamic contact and creep properties between the steel cables and a friction liner can be researched.

Owner:CHINA UNIV OF MINING & TECH

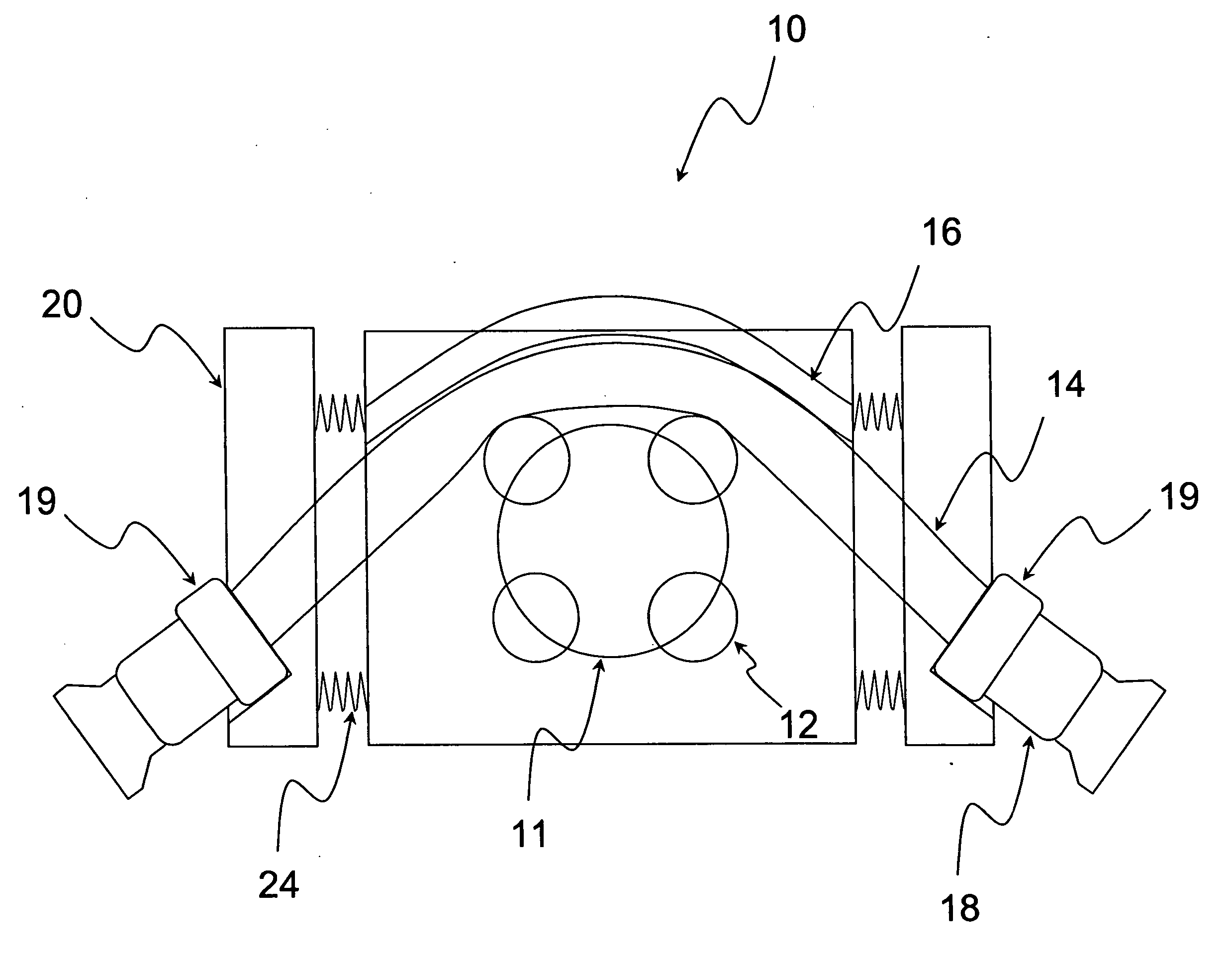

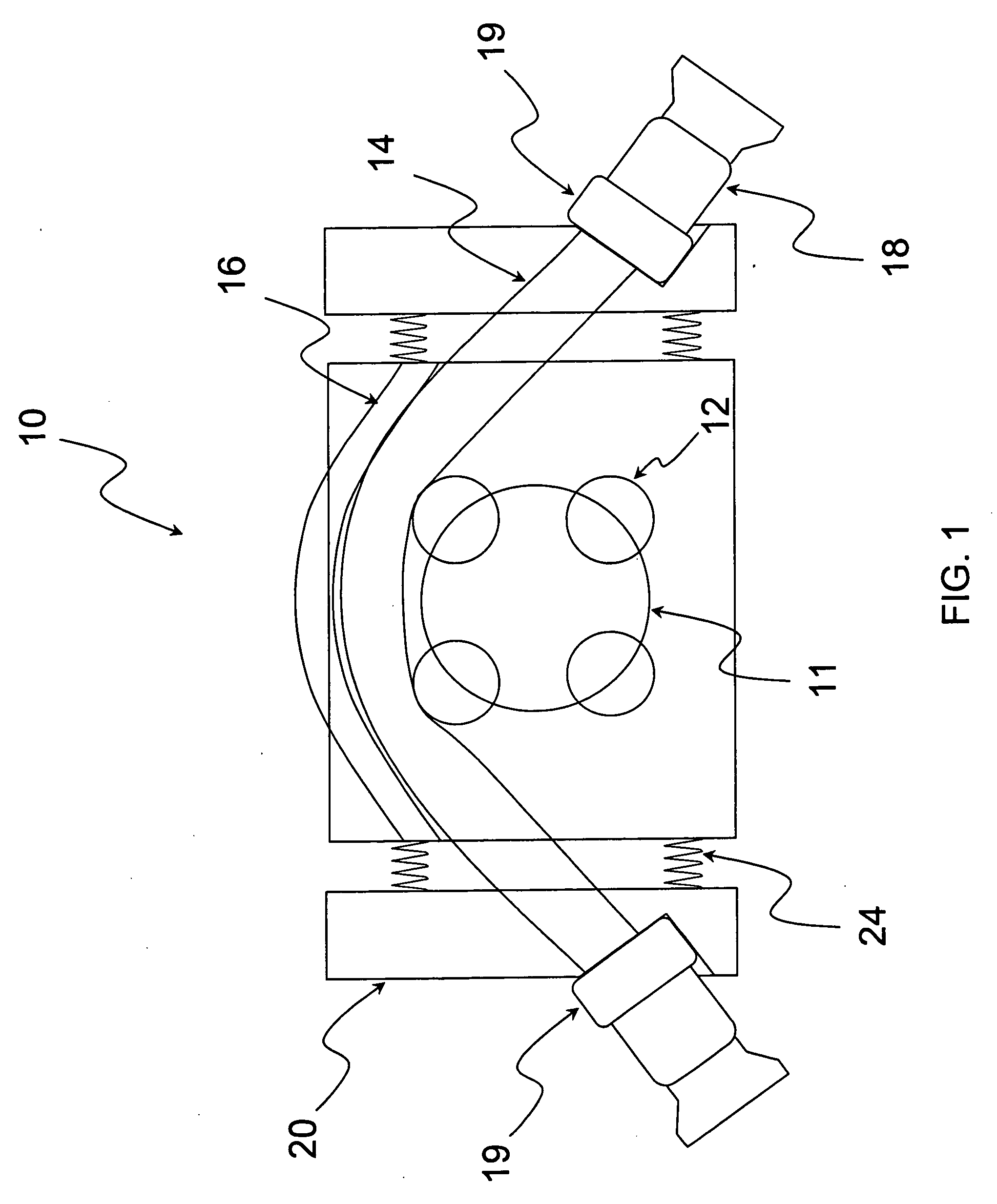

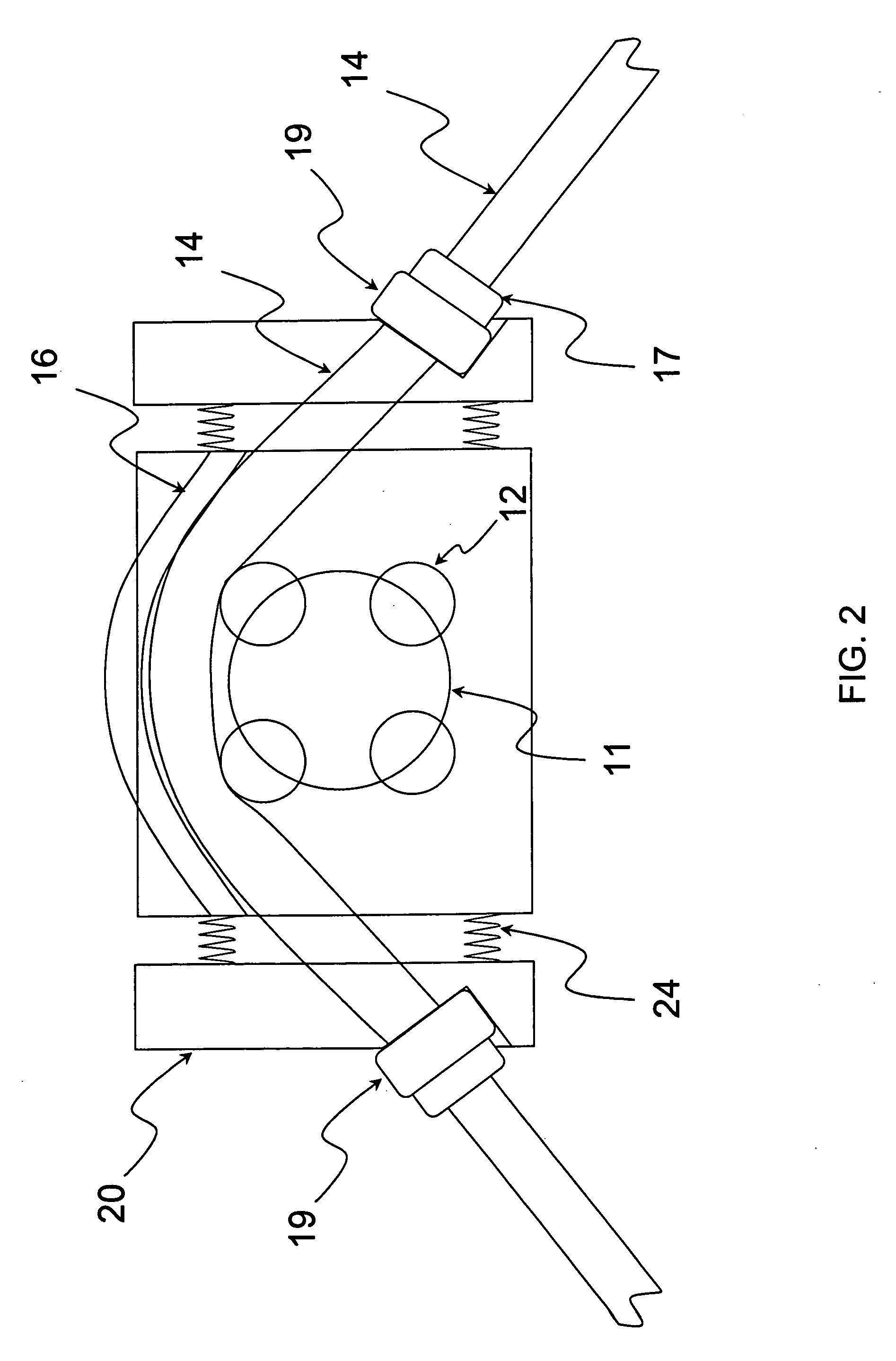

Dynamically tensioned peristaltic tubing pump

InactiveUS20060083644A1Low costReduce adverse effectsFlexible member pumpsPiston pumpsPeristaltic pumpPliability

An improved peristaltic pump whereby the elastomeric tubing communicates with the peristaltic pump in a way that allows for axial movement of the tubing thereby extending the flex life of the pump tubing. A tubing element is fitted with a flange that allows tension to be applied to the tubing in a way that changes depending upon the location of the rotor at any given time. The tension can be applied via an elastic material located between the flange and the housing or between the housing and a device that communicates with the flange. The dynamic tension reduces the amount of stress on the tubing material when the rollers first engage the tubing on the suction side of the pump and when they depart the tubing on the discharge side of the pump. The invention is particularly useful for materials that have limited axial flexibility and for those with very large axial flexibility.

Owner:MAZTECH

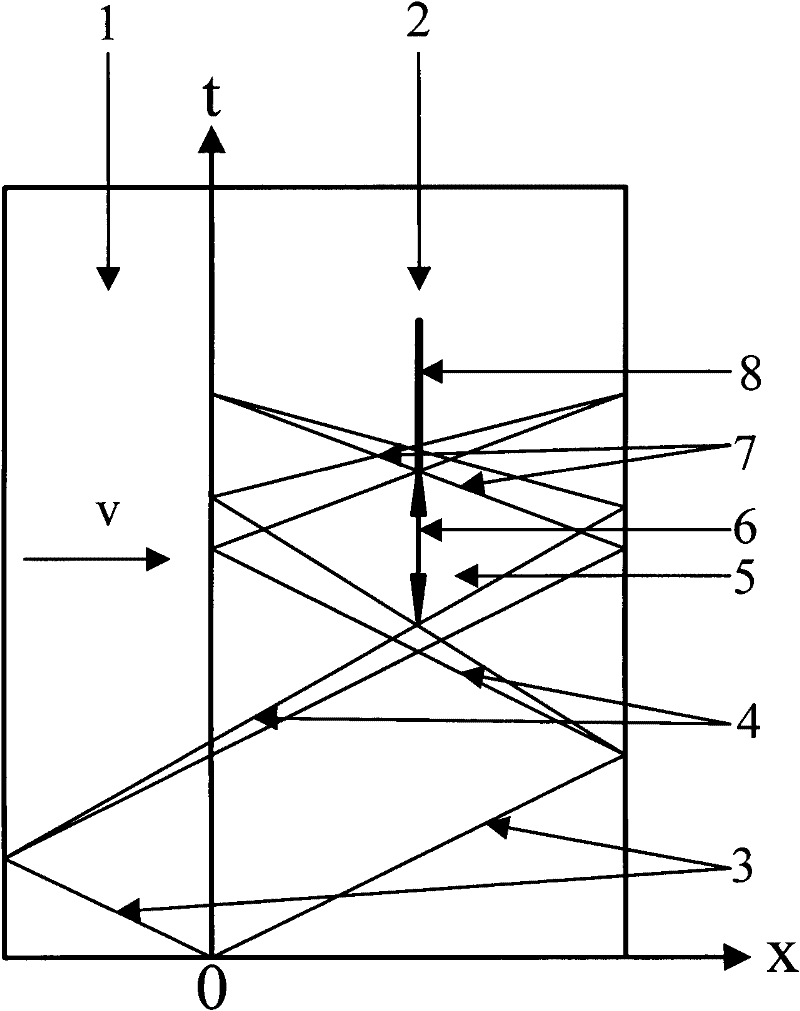

Dynamic tension fracture experiment method of material

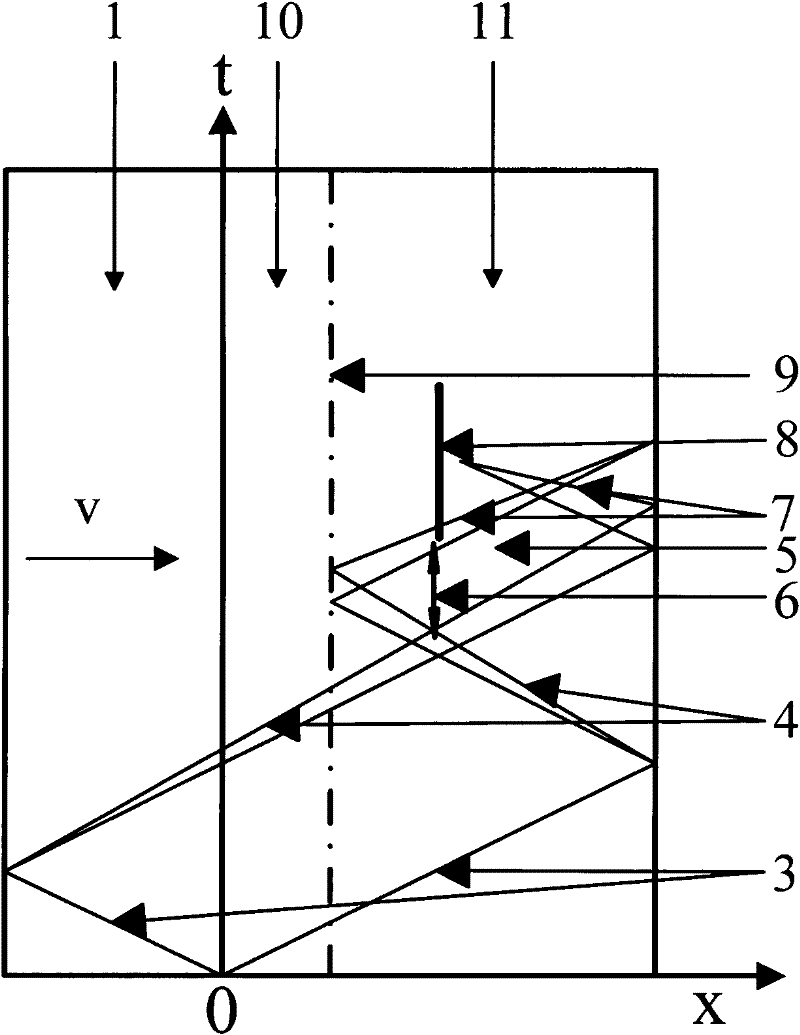

InactiveCN102507346AGuaranteed impact hardening effectEasy to implementMaterial strength using single impulsive forceEngineeringDynamic Tension

The invention relates to a dynamic tension fracture experiment method of a material, which is a manner of striking a target plate (2) with a flying sheet (1) to make the target plate (2) generate lamination crack or damage and is characterized in that the target plate (2) is a double-layer target comprising a first-layer target plate (10) and a second-layer target plate (11) which are clung together and prepared from an identical material; after the flying sheet (1) strikes the first-layer target plate (10), impact waves (3) are respectively generated to the flying sheet (1) and the first-layer target plate (10), when the impact waves arrive at the free surface of the flying sheet (1) and the free surface of the second-layer target plate (11), the impact waves are reflected to form rarefaction waves (4), and two bundles of rarefaction waves (4) move oppositely and encounter in the second-layer target plate (11) or the first-layer target plate (10) so as to generate enough strong tensile stress; and after a certain incubation time, a stress tensile region (5) generates lamination crack or damage to form a lamination crack surface or a maximal damage surface (8).

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Non-contact yarn tension testing device by utilization of CCD technology

InactiveCN102517812AAccurate detectionHigh-resolutionTufting apparatusTension measurementEngineeringDynamic Tension

The invention relates to a non-contact yarn tension testing device, which contains a constant tension thread guide roller, an auxiliary light source and a CCD image sensor. The invention is characterized in that the auxiliary light source and the CCD image sensor are respectively arranged at two sides of a yarn transport path between the constant tension thread guide roller and a tufting needle of a carpet tufting machine, and the CCD image sensor is connected to a computer through a USB interface data transmission device. The non-contact yarn tension testing device provided by the invention can be used to realize accurate detection of dynamic tension and raise carpet resolution, and is of great significance for dynamic tension measurement of yarn during operation.

Owner:DONGHUA UNIV

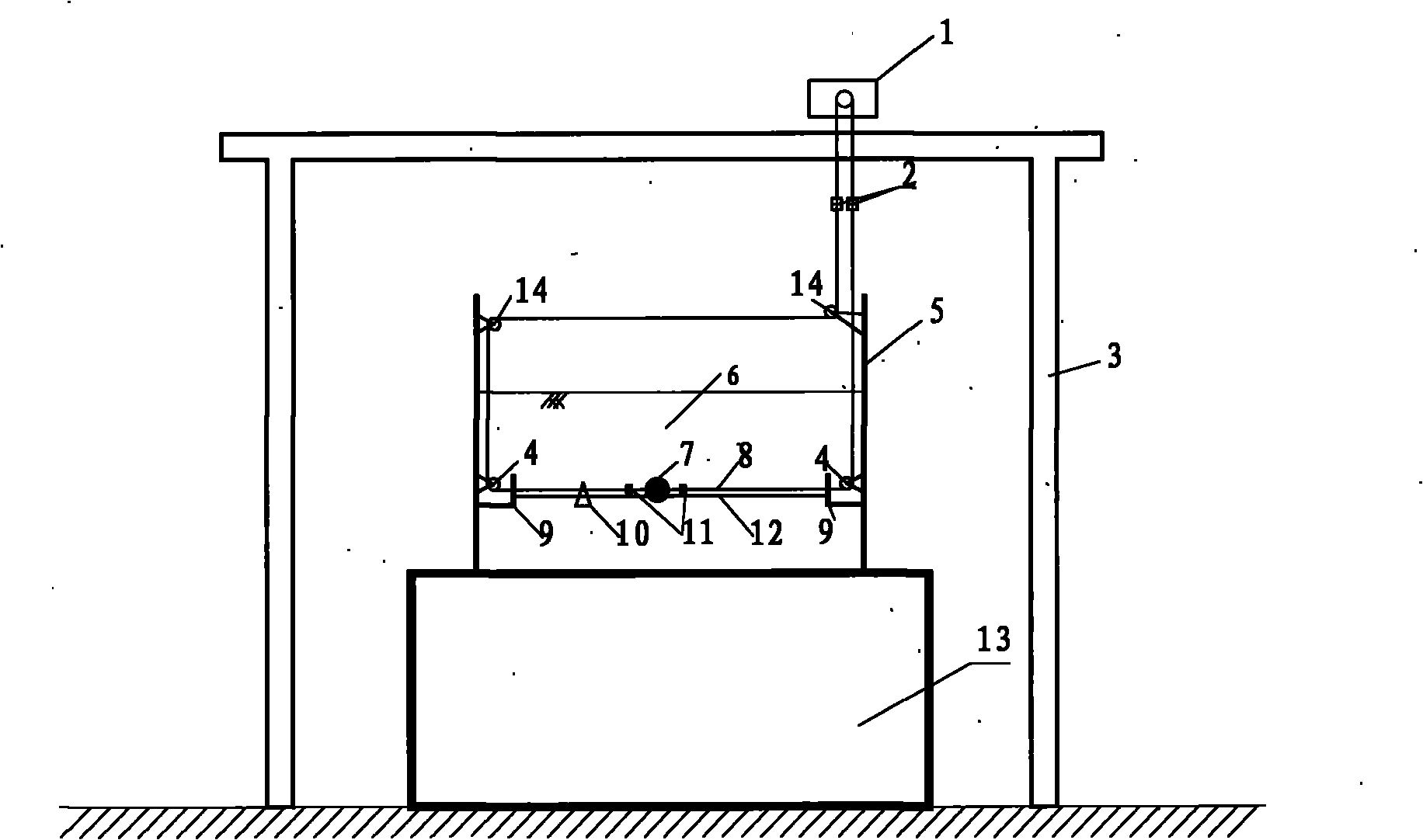

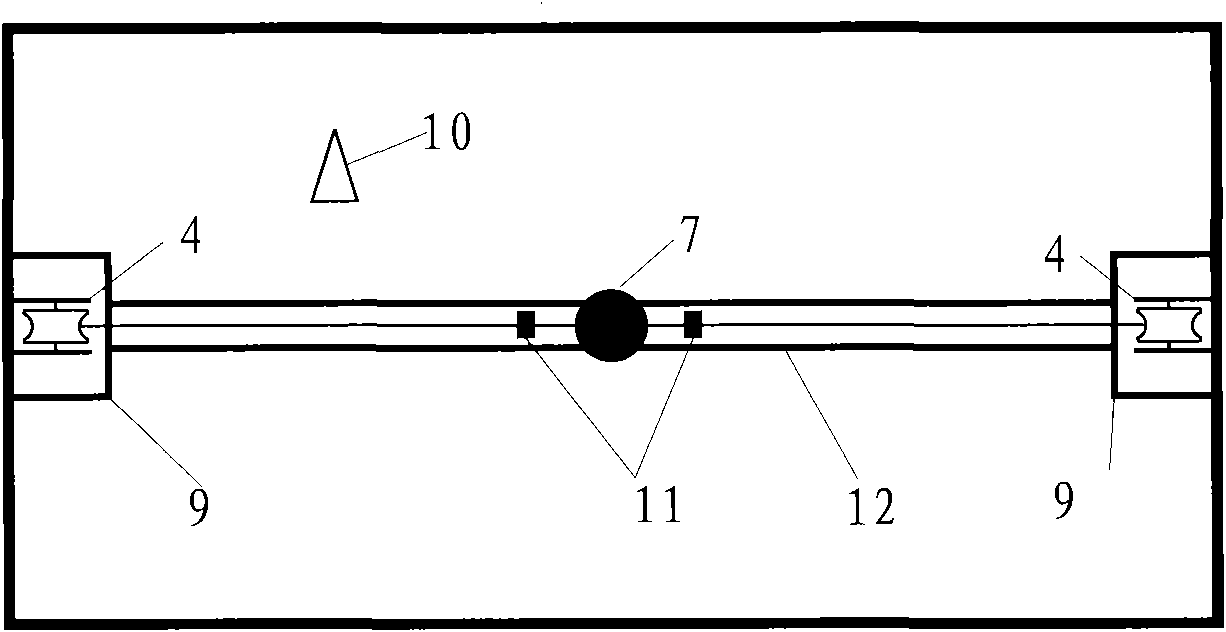

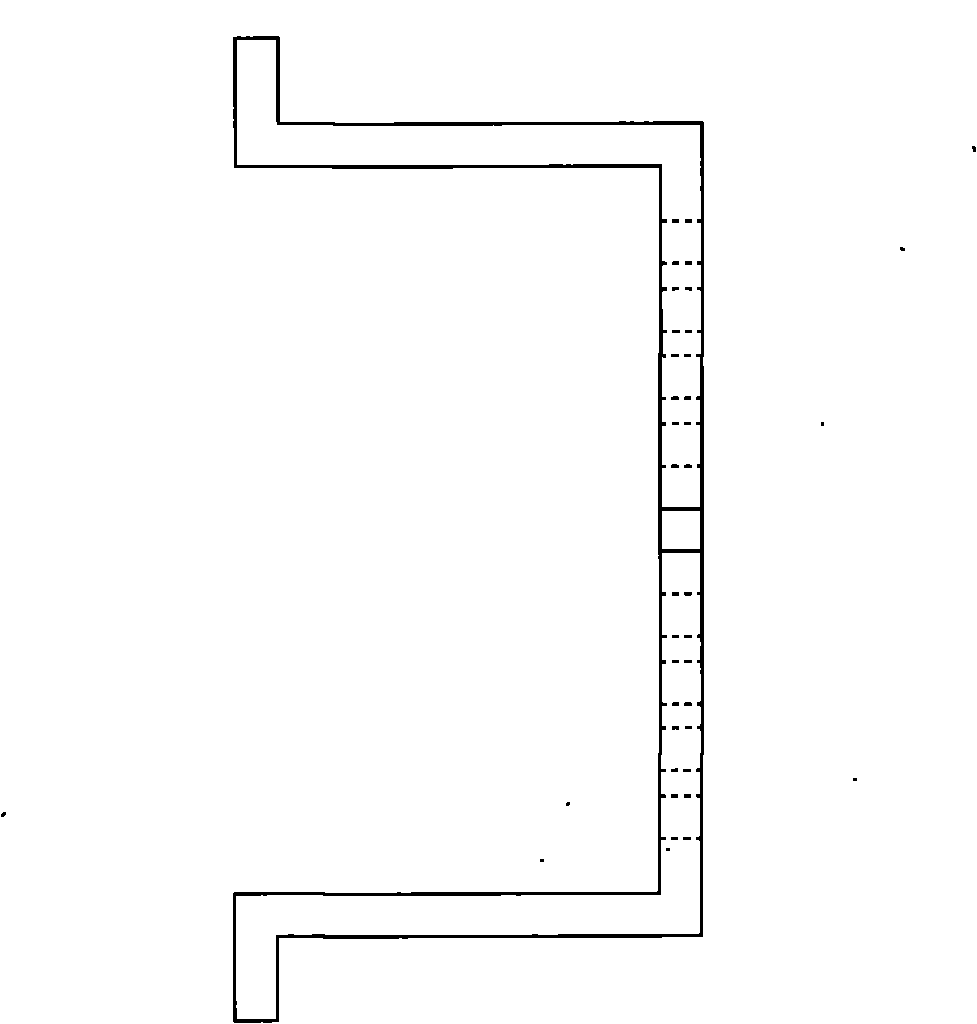

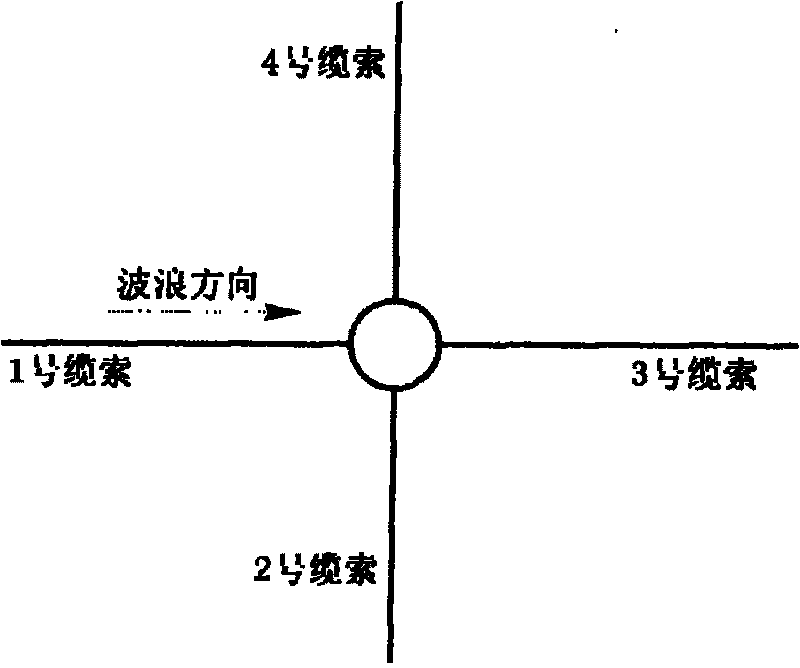

Device for measuring apparent viscosity of liquefied sand and method therefor

InactiveCN101788444AImprove test efficiencyAvoid border effectsFlow propertiesTest efficiencyApparent viscosity

The invention relates to a device for measuring apparent viscosity of liquefied sand and a method therefor. The device comprises a vibration table and a model box, wherein a horizontal track is arranged in the model box; a rigid ball is placed on the track; both ends of the rigid ball are respectively connected with dynamic tension sensors which are pulled by traction ropes; the traction ropes are led out of the model box through a fixed pulley set and connected with two dynamic displacement sensors and then connected on a reversible regulating motor; and a dynamic pore pressure sensor is arranged at the equal height with the rigid ball in the model box. The saturated sand in the model box can be in the liquefaction state through the vibration table, the motor drives the rigid ball to do horizontal movement on the track, the speed and resistance of the rigid ball are measured, and the apparent viscosity of the liquefied sand is calculated. The invention solves the technical problems of apparent viscosity measurement of the liquefied sand, can perform parallel test in the same test and has the advantages of high test efficiency and small boundary effect.

Owner:HOHAI UNIV

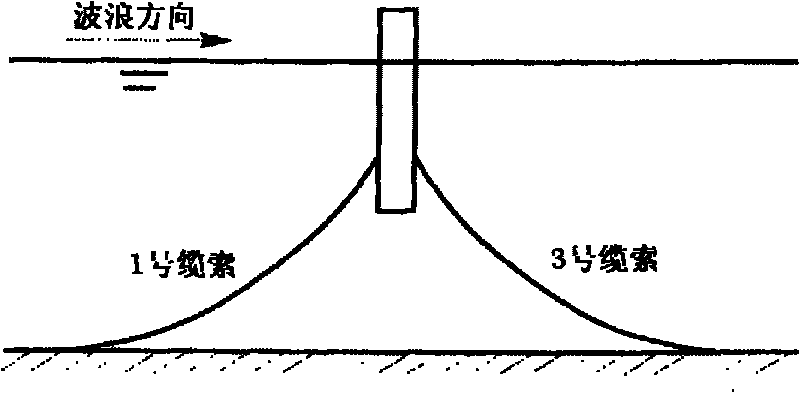

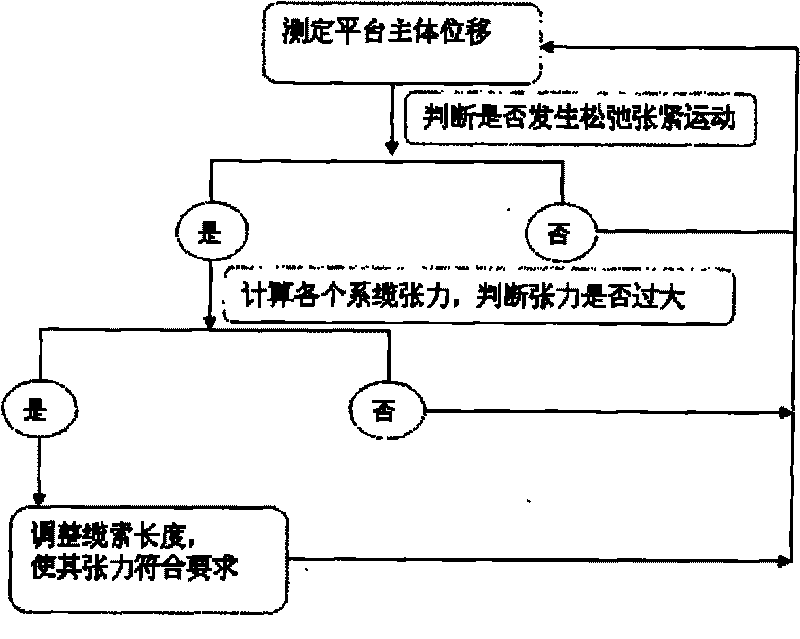

Method for monitoring anchoring line of deep-sea terrace

InactiveCN101710242AEasy to controlImprove securityTotal factory controlProgramme total factory controlSurface oceanRisk Control

The invention belongs to the technical field of offshore oil and natural gas exploitation equipment safety monitoring and risk control, and relates to a method for monitoring anchoring line of deep-sea terrace. The method comprises the following steps: (1) installing a displacement transducer on the position of height of gravitational center of the terrace to monitor the motion displacement U0 of the terrace main body in real time, arranging a strain transducer on the anchoring line to monitor the strain of the anchoring line in real time and transmitting the monitoring data to a central computer; (2) calculating and analyzing whether the anchoring line appears relaxed-tensioned state; (3) calculating and analyzing dynamic tension; (4) comparing the calculated dynamic tension with the fracture tension of the anchoring line, judging whether the tension of the anchoring line is within the safe range, if not, implementing adjustment; (5) if needing adjustment, commanding the adjustment value of the anchoring line to each anchor gear, starting and controlling each anchor gear, adjusting the length of the anchoring line, and calculating whether the adjusted length of the anchoring line meets the requirement, if not, repeating the step. The invention can realize control on state and tension of the terrace anchoring line, can enhance the safety level of the terrace system and can reduce occurrence of grave accidents.

Owner:TIANJIN UNIV

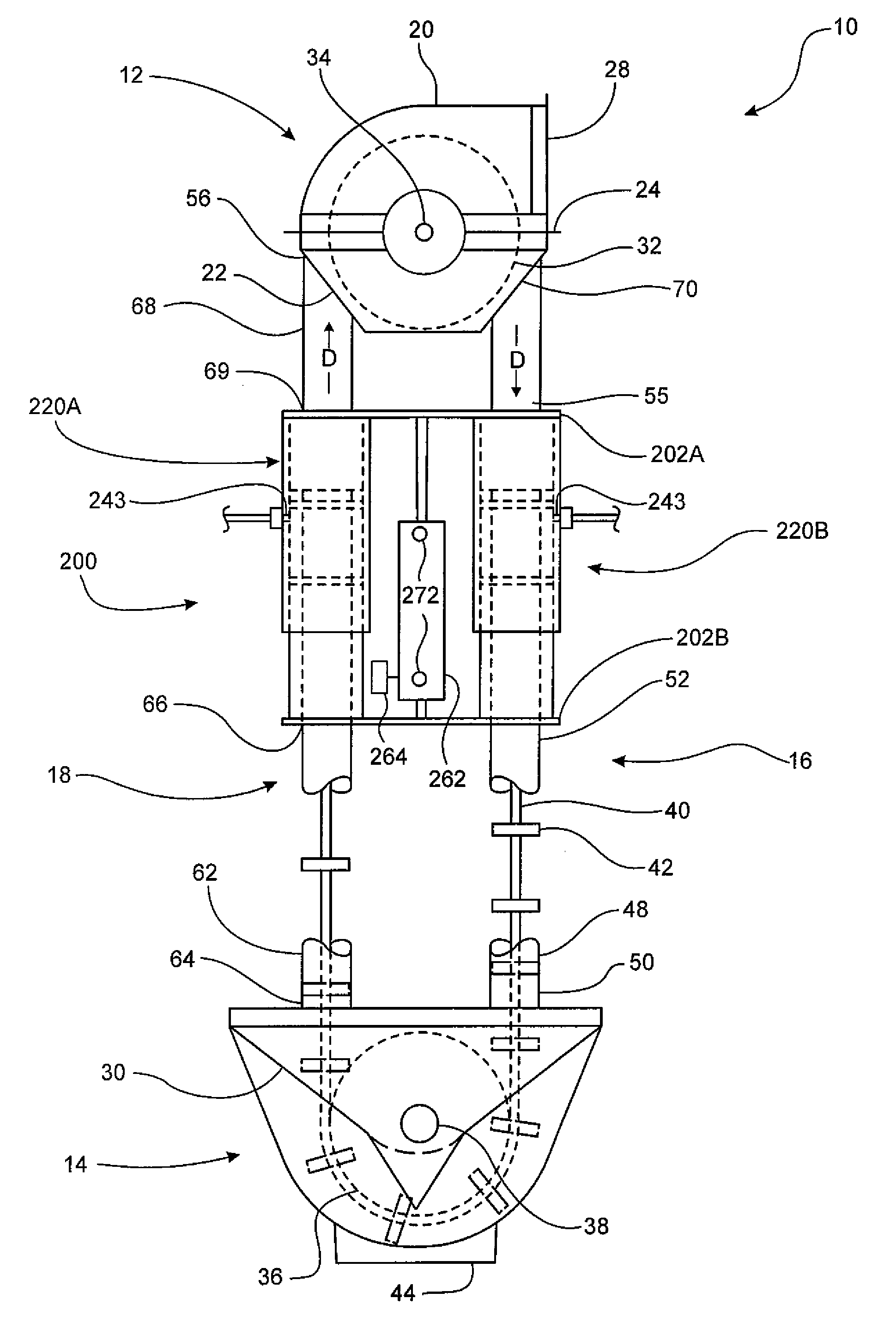

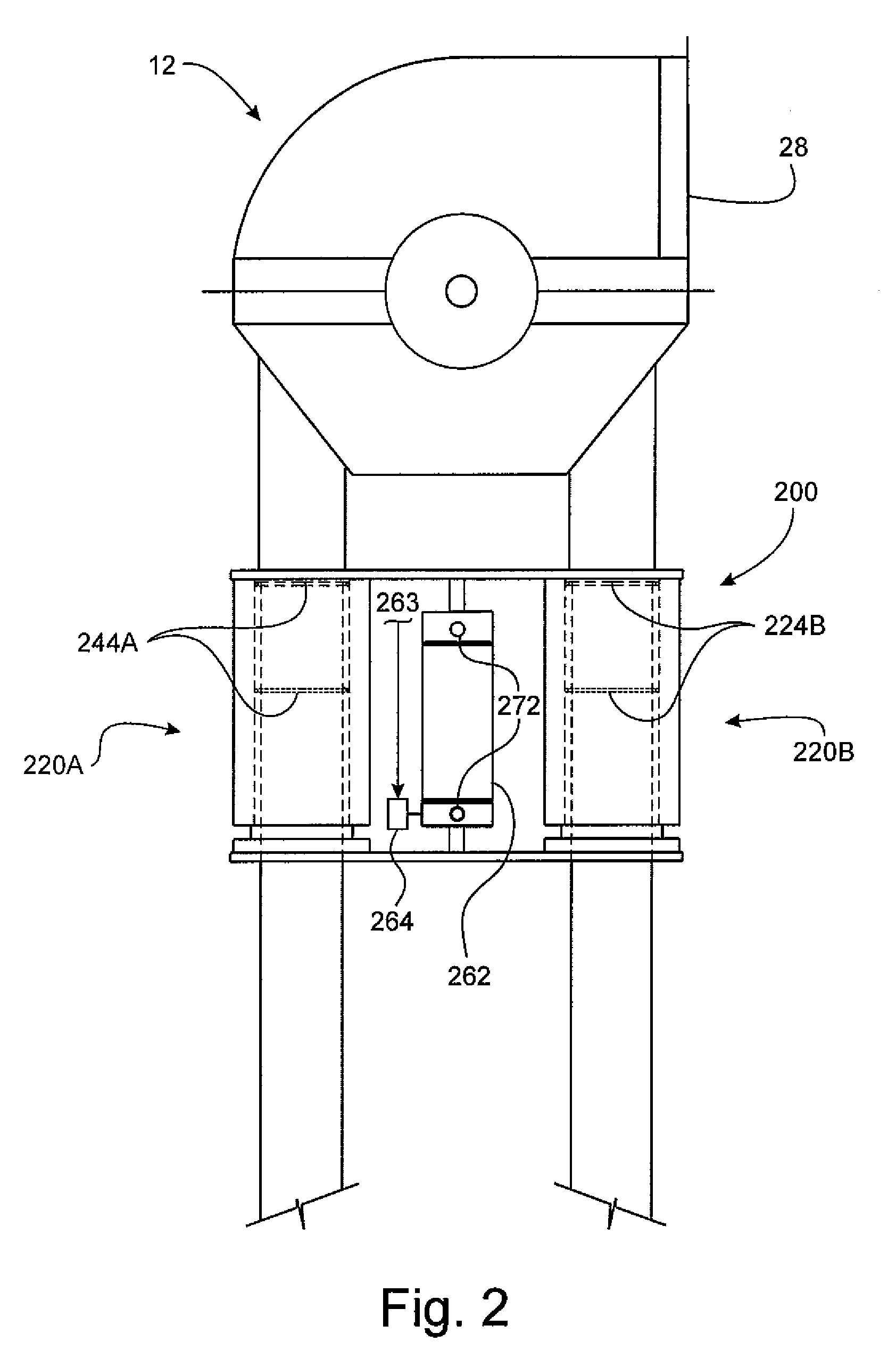

Dynamic tension control apparatus and method for aero-mechanical conveyor

A tensioning assembly for use in an aero-mechanical conveyor for moving bulk materials. The conveyor includes upper and lower housings having head and tail pulley assemblies mounted therein. The tensioning assembly includes first and second extendable tubes that define sections of inflow and outflow conveyor tubes that interconnect the upper and lower housings. An endless rope assembly is disposed within the conveyor tubes and around the head and tail pulleys. An adjustable actuator is positioned in cooperative engagement with the first and second extendable tubes. When the actuator is in a first position, the extendable tubes have a first length and when the actuator is in a second position, the extendable tubes have a second length. The actuator is configured to move between the first position and the second position in response to changes in tension within the endless rope assembly as indicated by a signal from a tension measuring device.

Owner:SPIROFLOW SYST

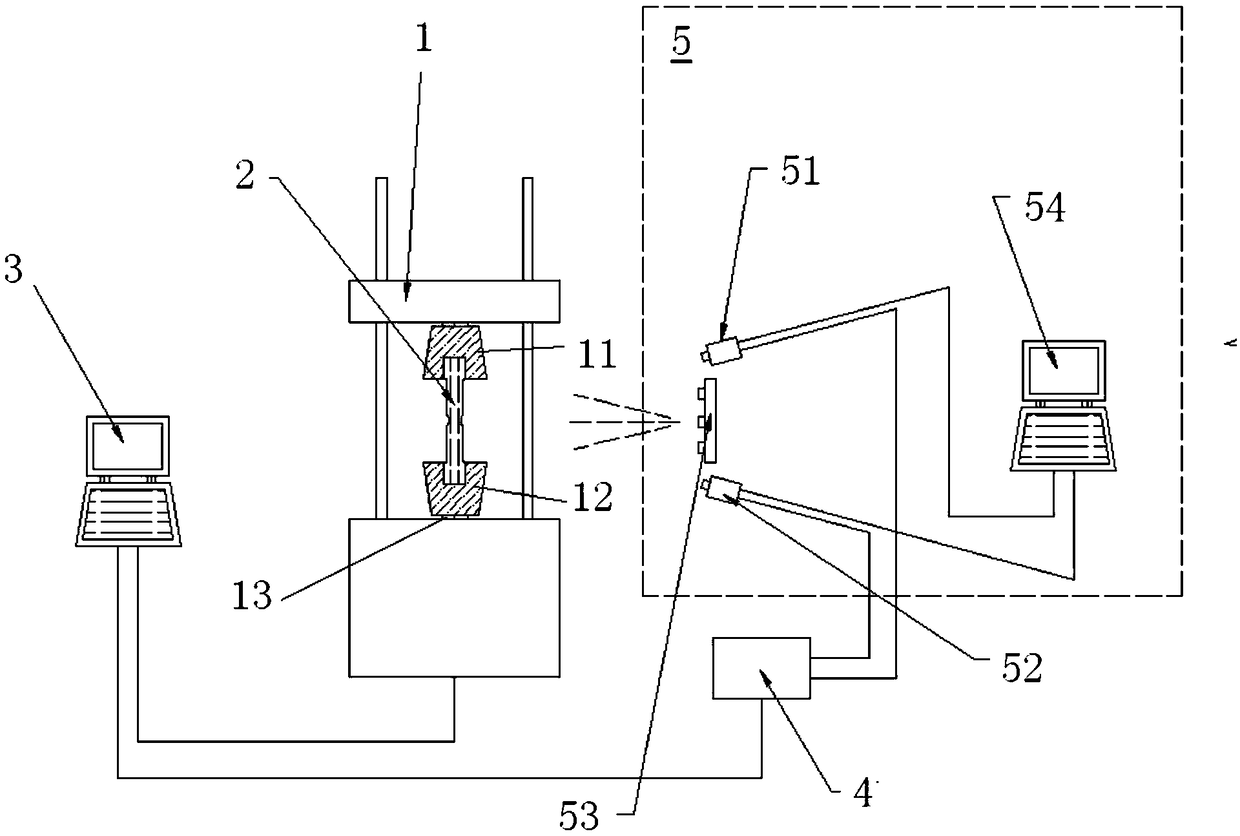

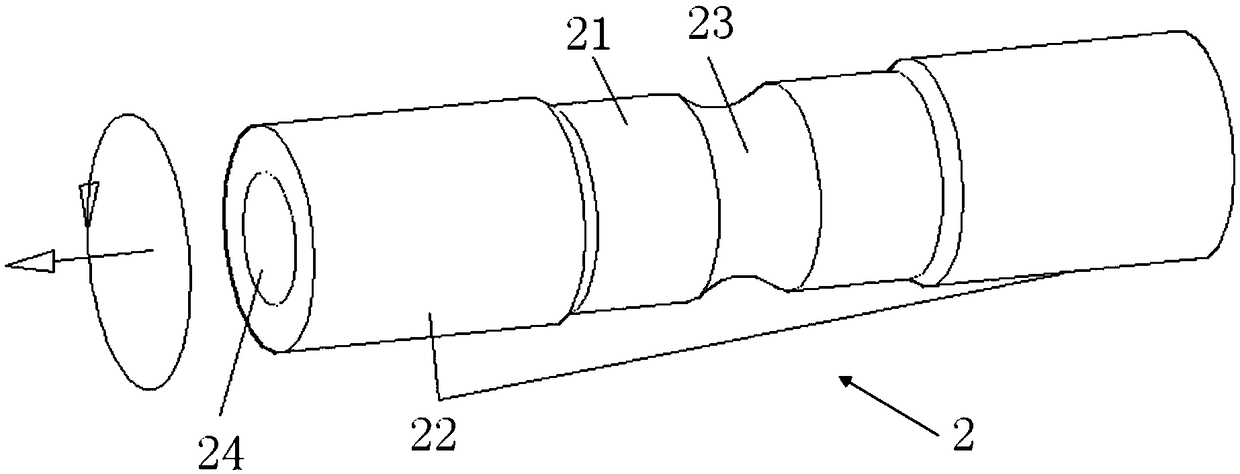

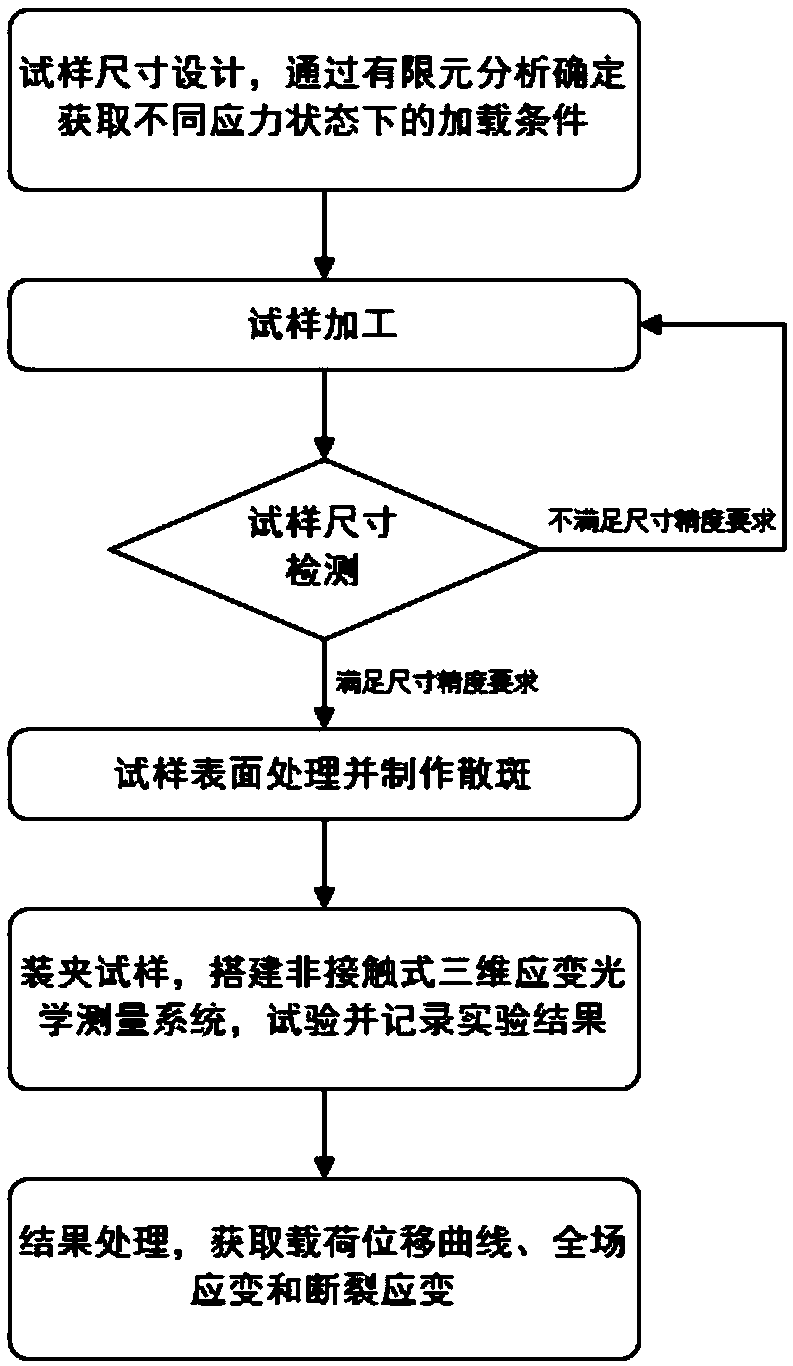

Combined tension-torsion multi-axis fracture experimental system and experimental method

ActiveCN109342189ARealize measurementMaterial analysis by optical meansMaterial strength using tensile/compressive forcesEngineeringDynamic Tension

The invention provides a combined tension-torsion multi-axis fracture experimental system. The experimental system comprises a dynamic tension-torsion testing machine and a control device connected with the dynamic tension-torsion testing machine. The dynamic tension-torsion testing machine has an upper chuck, a lower chuck and a force sensor, and is clamped with a sample through the upper chuck and the lower chuck. The sample is a thin-walled tube with a notch, and is provided with a speckle. A deformation measurement system comprises a non-contact three-dimensional strain optical measurementsystem connected with the control device through a synchronous trigger device which comprises two cameras connected with the synchronous trigger device and an image acquisition and data processing device connected with the two cameras respectively. The invention also provides a combined tension-torsion multi-axis fracture experimental method. The invention adopts a sample of a thin-walled tube with a notch, which can obtain a low-stress triaxial level and different Rhodes parameter levels by changing different combined tension-torsion loading ratios. In addition, since the experimental systemcomprises a non-contact three-dimensional strain optical measurement system, measurement of full field strain can be achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

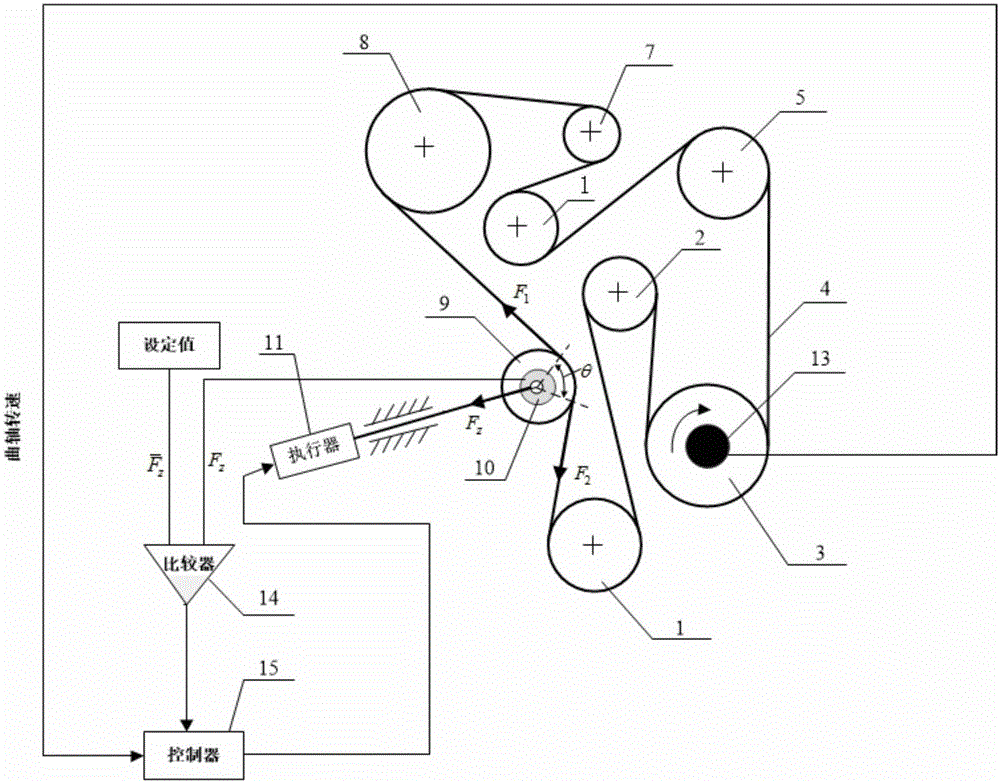

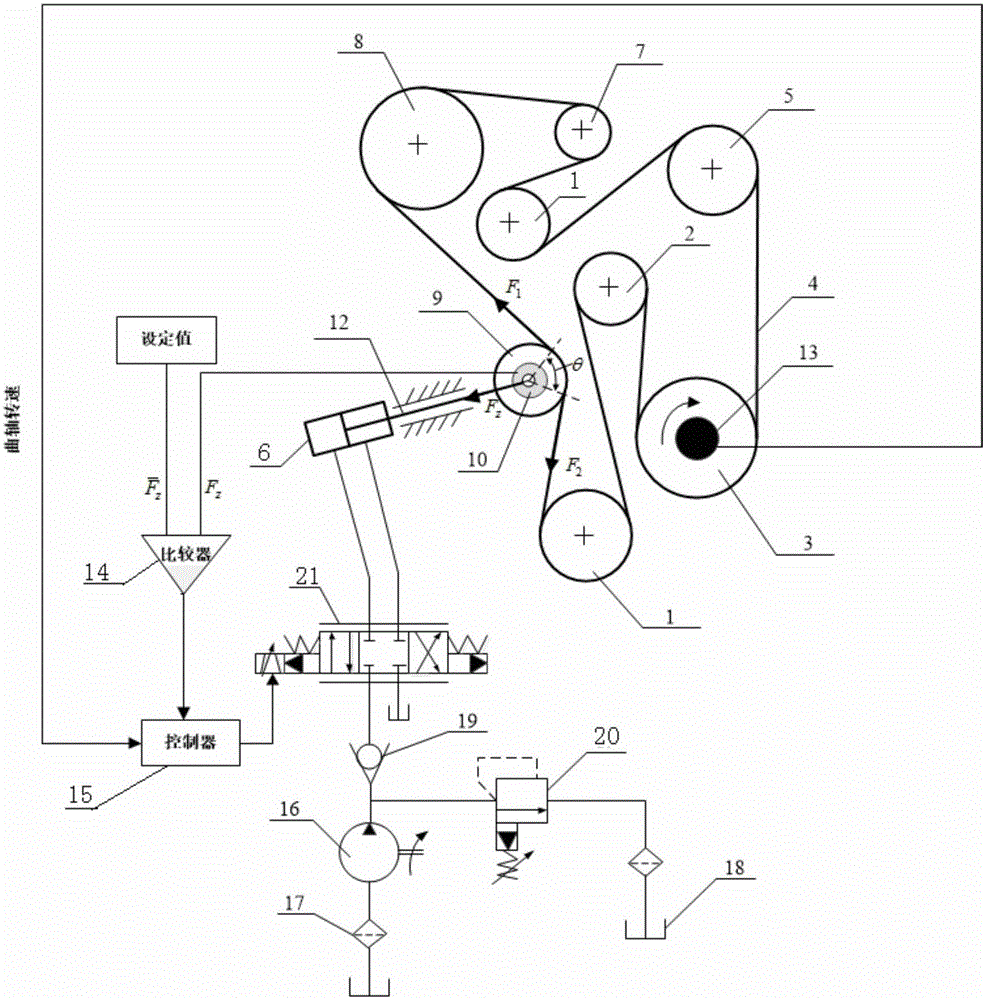

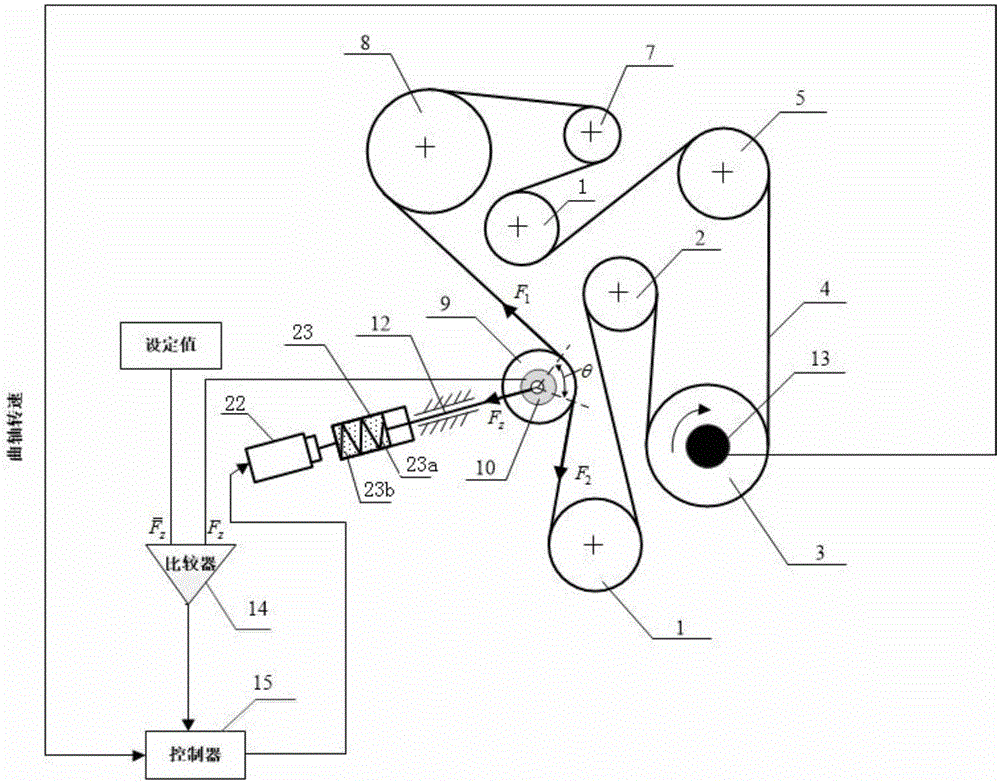

Tension adjusting device for self-adaptive engine front end accessory gear train

InactiveCN105179083AExtended service lifeGood transmission effectGearingMachines/enginesElectricityControl system

The invention discloses a tension adjusting device for a self-adaptive engine front end accessory gear train. The tension adjusting device comprises the engine front end accessory gear train and a belt tension control system. The belt tension control system comprises a piezoelectric sensor, an angle encoder, a comparator, a controller and an actuator. When the rotation speed of a crankshaft of an engine is zero, a tensioning wheel is in the preset position where the belt tension is smaller all the time; when the engine is started, the rotation speed of the crankshaft is gradually increased from zero, and the controller immediately controls the actuator to act, so that the tensioning wheel moves to the preset position where the belt tension is larger; and after the rotation speed of the crankshaft is stable, a tension value obtained by the piezoelectric sensor is compared with a preset tension value through the comparator, then the controller controls the actuator to act to adjust the position of the tensioning wheel so that the tension can be kept in a constant state. According to the tension adjusting device, the rotation speed of the crankshaft of the engine and the dynamic tension applied to the ribbed belt can be measured in real time, and the position of the tensioning wheel can be adjusted actively, so that the purpose that the tension of the belt is adjusted according to the running state of the self-adaptive engine is achieved.

Owner:CHONGQING UNIV

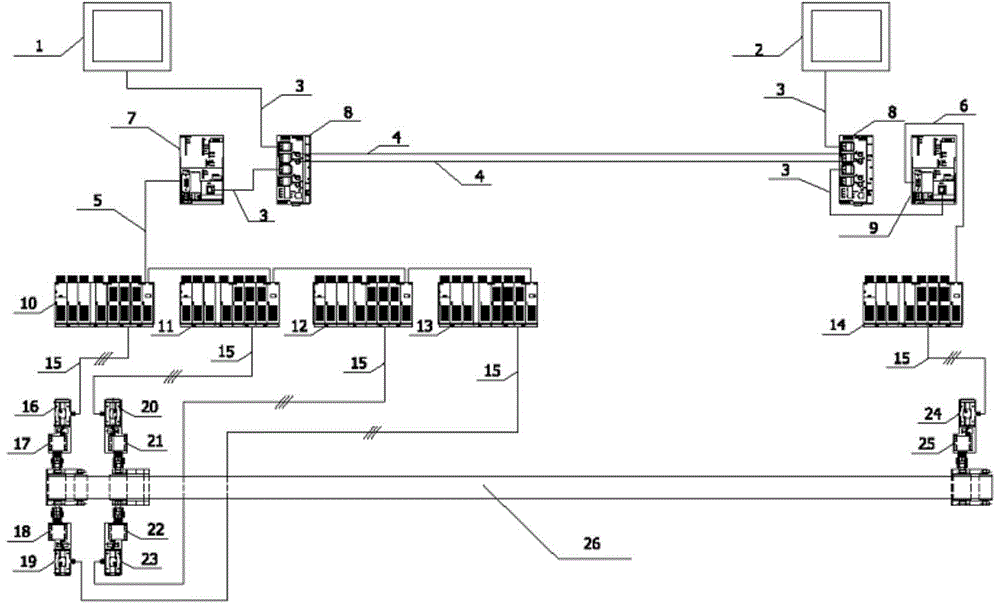

Synchronizing system of multi-transmission rubber belt conveyor

ActiveCN104097915AGuaranteed uptimeExtended service lifeControl devices for conveyorsDynamic TensionEngineering

The invention relates to a synchronizing system of a multi-transmission rubber belt conveyor and belongs to the technical field of metallurgical mines. The synchronizing system has the advantages that the computer synchronizing control technology is improved, four motors at the head drive a rubber belt conveyor in a balanced manner while the current and frequency of the drive motor at the tail are synchronously calculated and adjusted in real time to allow the output power and the operation speed of all the motors at the head and at the tail to be balanced so as to guarantee stable operation of the rubber belt conveyor, impact on machinery and an electric system during fast starting / fast shutdown is lowered, belt overlapping is avoided, possible harm, caused by rubber belt conveyor dynamic tension waves, to a rubber belt and mechanical equipment is restrained effectively, the service life of the rubber belt conveyor is prolonged, and safety and reliability of a conveying system are increased.

Owner:WANBAO MINING

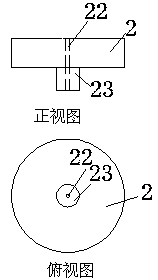

Dynamic tension sensor

InactiveCN101382465AReasonable structureEliminate the effects ofTension measurementLinear relationshipEngineering

The invention relates to a dynamic tension sensor applicable to linear, rope-shaped, beam-shaped, strip and sheet materials, comprising a flexure strip with uniform section, with the two ends fixed on a slab, and a torsion shaft which passes through the centers of the slab and the flexure strip; one end of the torsion shaft is a detecting end and is fixed with two groups of magnetic bodies, one side or two sides of the detecting end is / are provided conductive component of a tested object, and the other end of the torsion shaft is provided with two magneto-dependent sensors of the same class in the magnetic field of the two groups of the magnetic bodies; the influence of temperature shift can be eliminated by utilizing the dual sensors, and the gravity influence of the other side can be eliminated by the adjustment of one side of the flexure strip; the dynamic tension sensor has the advantages that the function of the flexure strip and the torsion shaft is combined and utilized to convert the tension change of the tested material into the corresponding displacement of the torsion shaft, and the displacement is corresponding to the magnetic-field strength change of the tail end of the torsion shaft and has linear relationship with the output voltage of a magneto sensor, therefore, automatic online detection can be carried out to the tension change of the tested material.

Owner:杨金保 +2

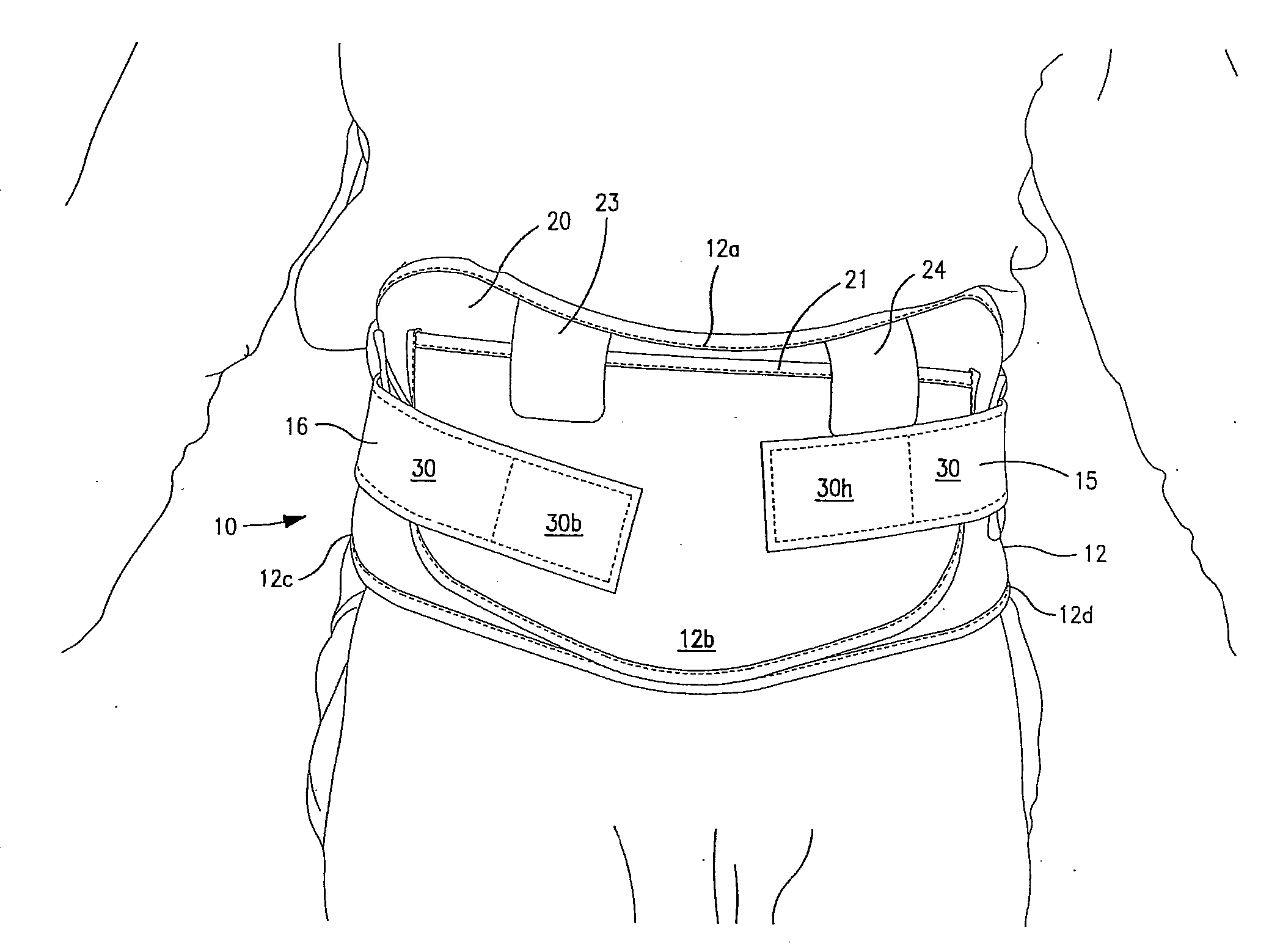

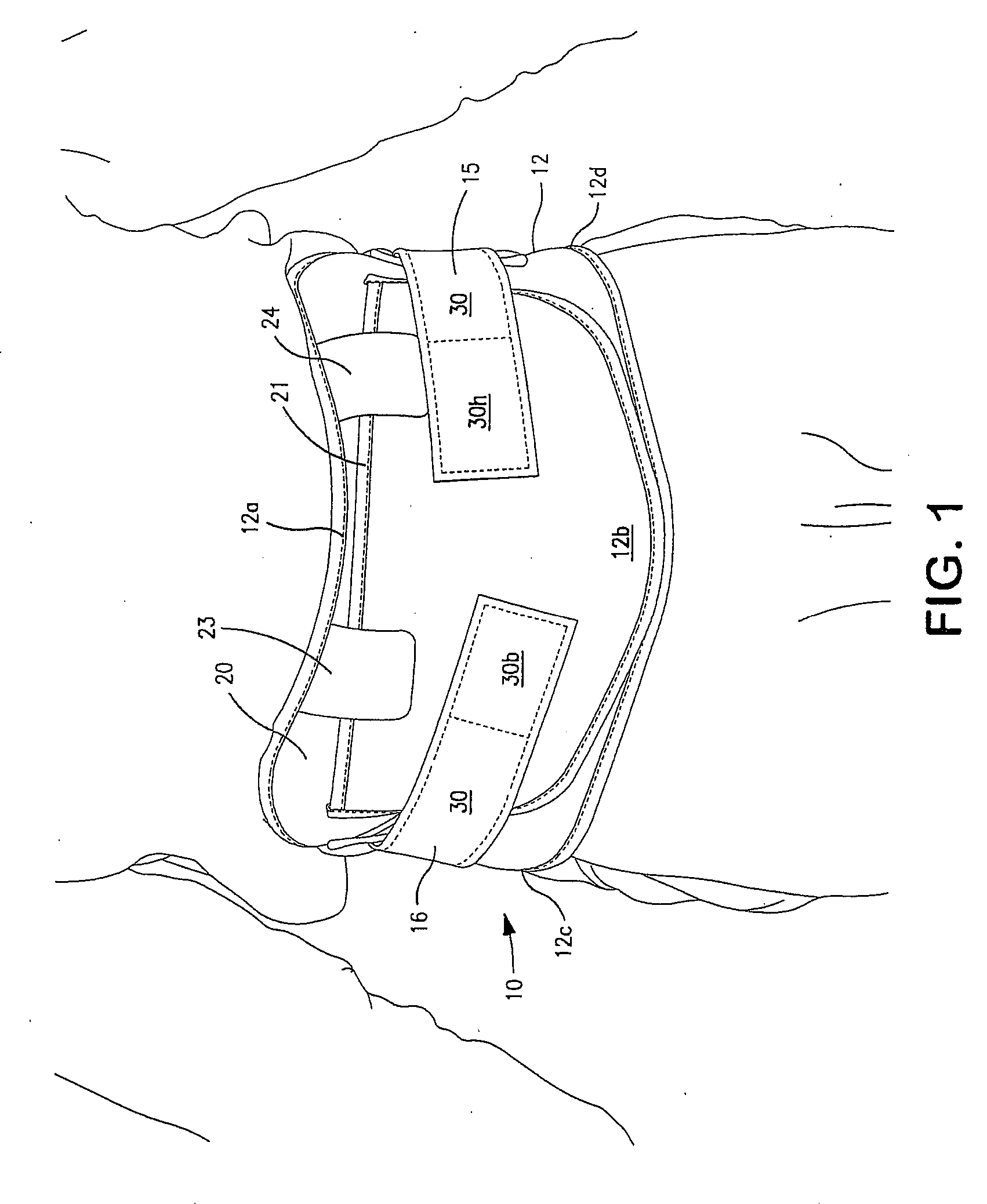

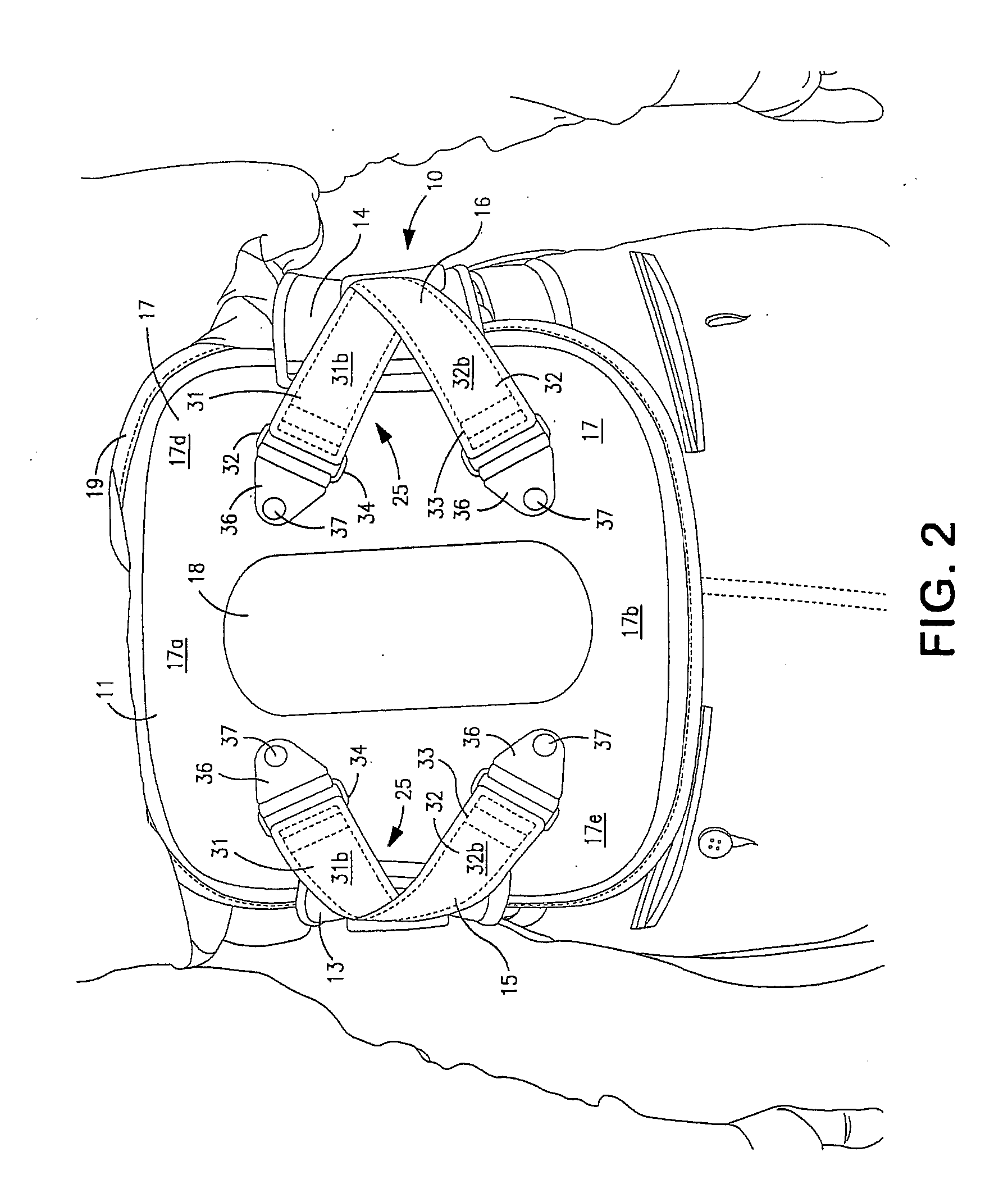

Back brace

The invention is a back brace including a back panel, a front panel, and at least one dynamic tension strap for connecting the front panel to the back panel.

Owner:X BACK BRACING SERVICES

Impact dynamic tension test method and device thereof of ring laser

InactiveCN102072841AEasy clampingThe testing process is simpleStrength propertiesRing laserEngineering

The invention relates to an impact dynamic tension test method and a device thereof of a ring laser, relating to the technical field of dynamic tension mechanics performance test of materials. In the invention, a high power ring pulse laser is adopted to contain a test-piece in a hollow part of a laser beam; and a ring pulse laser gets through the test-piece via the hollow part and impacts a target, so that the test-piece arranged between a bracket and the target acquires instant tension so as to complete the impact dynamic tension test of the test-piece. The method and the device of the invention are used for for measuring dynamic stress strain relation of the materials under ultrahigh strain state, the device has simple structure, simple and convenient test process, and can perform direct dynamic tension test; and the method and the device can perform the dynamic tension test of the materials under the conditions of different high strain rates and ultrahigh strain rates, thereby having low cost and good application prospect.

Owner:JIANGSU UNIV

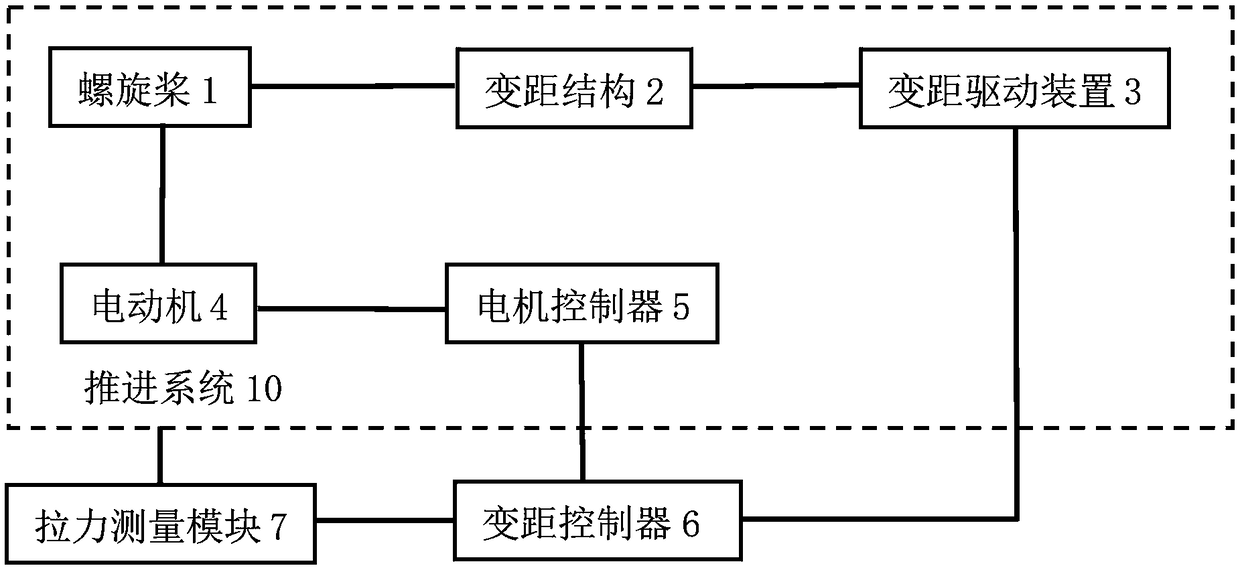

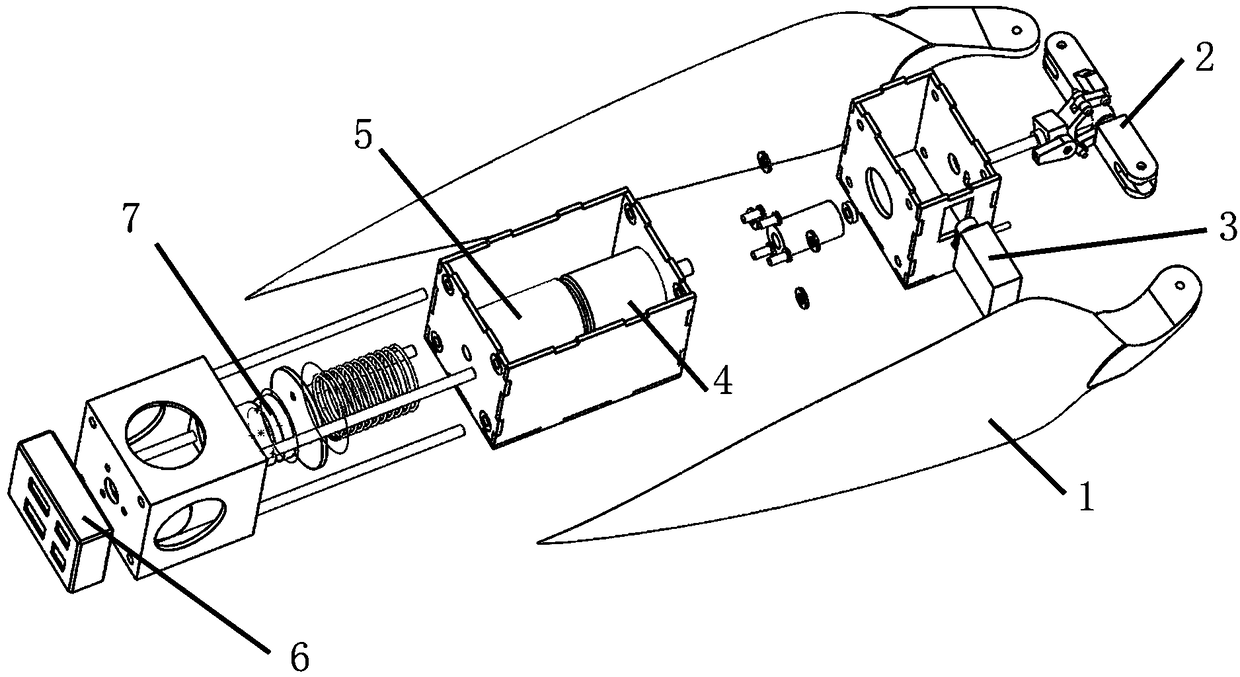

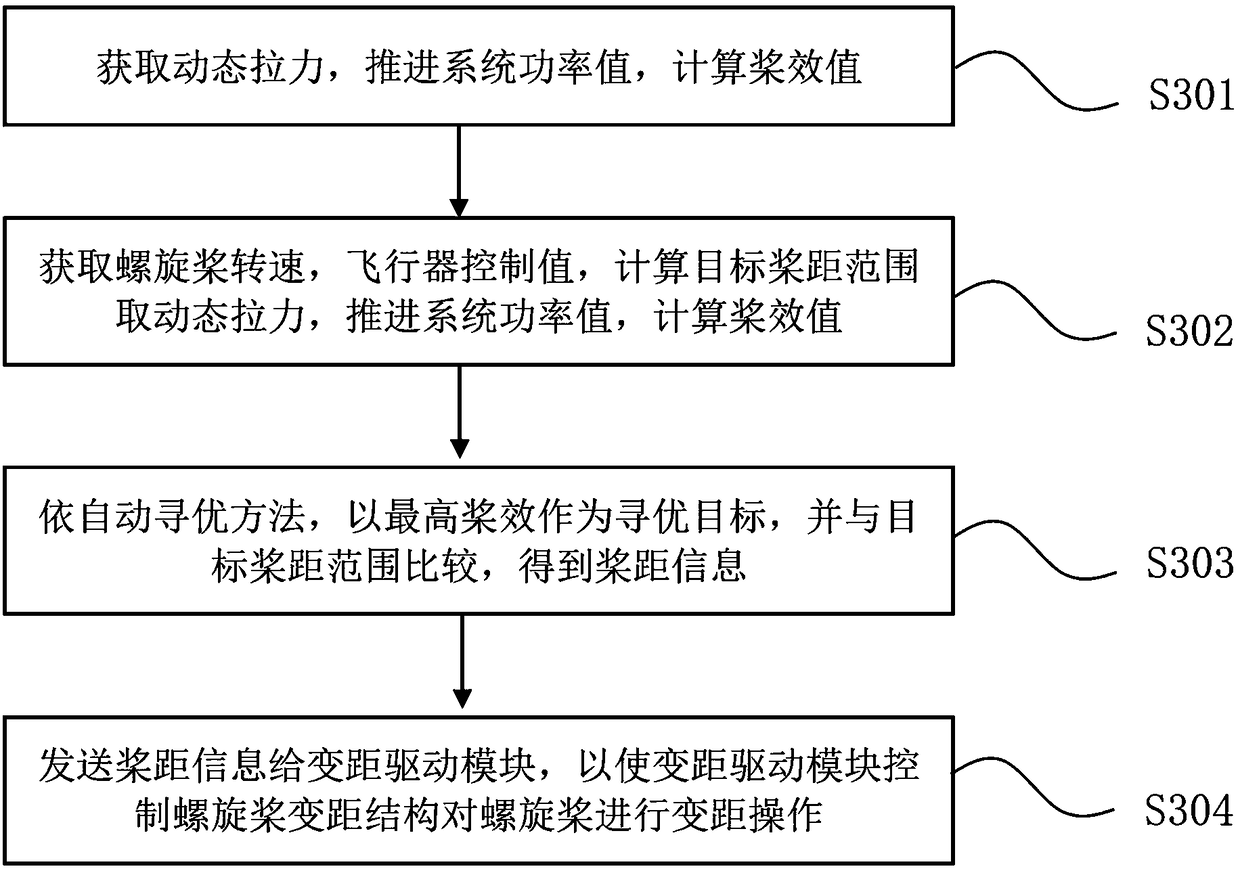

Automatic variable-pitch propeller device, control method thereof and aircraft

The invention discloses an automatic variable-pitch propeller device, a control method thereof and an aircraft. A variable-pitch driving device is connected with a propeller through a variable-pitch structure, and the pitch of the propeller is adjusted by operating the variable-pitch structure; a tension measuring module is connected with a propulsion system and is used for measuring the dynamic tension of the propulsion system; a variable pitch controller determines real-time propeller efficacy value information according to the dynamic tension and input power, determines a target pitch rangeaccording to the propeller rotating speed and airspeed information, and provides a pitch value in the target pitch range by using an automatic optimization method according to the propeller efficacydata, and the propeller performs variable pitch operation. The device can calculate the propeller efficacy value of the propulsion system in real time, automatically optimizes and matches the optimalpitch based on propeller efficacy, and improves the efficiency of the propulsion system of the aircraft.

Owner:陈俊胤

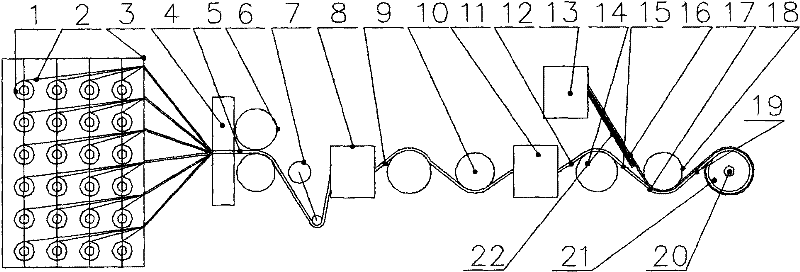

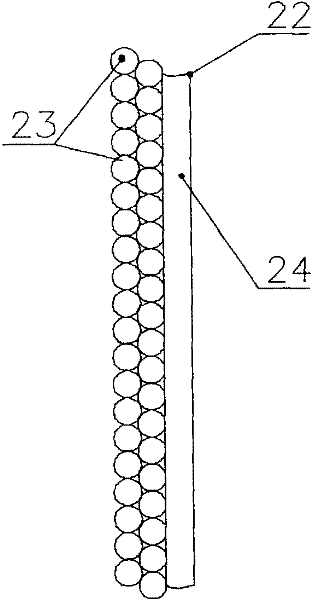

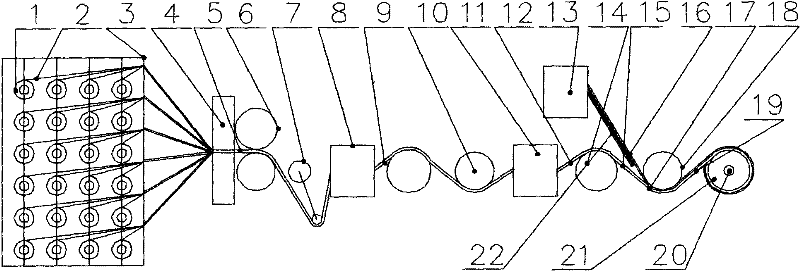

Process for manufacturing continuous non-woven cloth and cross cloth with more than two layers

InactiveCN102535021AWide adaptabilityImprove fullyLaminationLamination apparatusFiber bundleDynamic Tension

A process for manufacturing continuous non-woven cloth and cross cloth with more than two layers relates to the technique of manufacture process of the non-woven cloth. The process for manufacturing the non-woven cloth comprises installing a fiber tube; enabling dynamic tension of fiber bundles to be consistent; forming fibers parallelly arranged at equal intervals and accurately positioned; drawing the fibers into a main machine; enabling fibers entering the main machine and accurately positioned to enter a first silk spreading mechanism through a tension evening mechanism and enabling the whole fibers to be drawn to form even seamless fiber pieces; forming even seamless fibers with tension adjustable; forming fiber pieces evenly coated by binding agents; forming non-woven cloth without being dried and sized; forming even seamless dried and sized non-woven cloth or orthogonal cloth; forming coiled non-woven cloth or multilayer orthogonal cloth; and breaking the cloth and uncoiling the cloth to successfully finish the manufacture. The invention further provides the process for manufacturing the cross cloth with more than two layers. The process for manufacturing the continuous non-woven cloth and the cross cloth with more than two layers solves the problems that existing efficiency is low, quality is not up to requirements, fiber trace is visible, and strength of the cross cloth is reduced because of additionally coating one layer of the binding agents.

Owner:宋锋

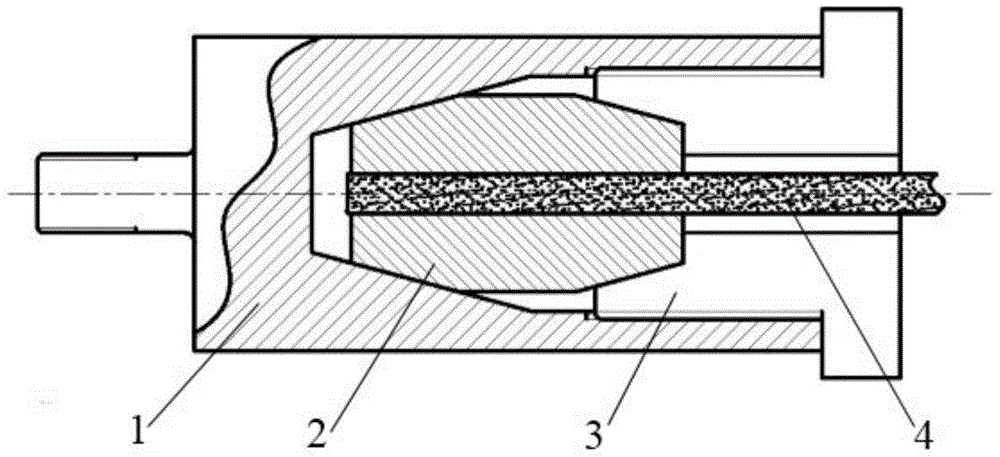

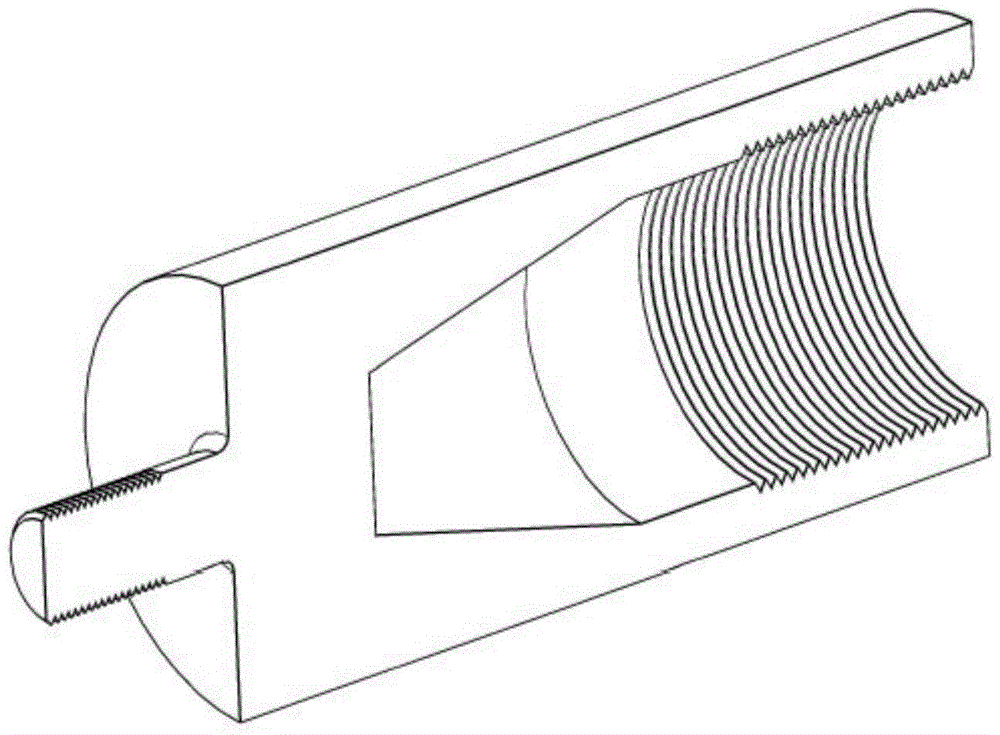

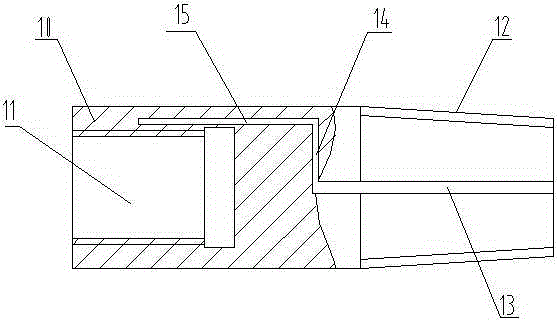

Dynamic tension experiment fixture

InactiveCN104897461AAvoid concentrationSimple processing technologyStrength propertiesDynamic TensionScrew thread

The invention discloses a dynamic tension experiment fixture. The dynamic tension experiment fixture comprises a main fixture, clamping pieces and a thread fixing fixture, wherein a hole is formed in one end of the main fixture; an internal thread and an internal conical surface are sequentially formed on the inner wall of the hole from outside to inside; an external thread matched with the internal thread of the main fixture is formed on the periphery of one end of the thread fixing fixture; a center hole allowing a lath-shaped test piece to pass through is formed along an axis of the thread fixing fixture, a taper hole coaxial with the center hole is formed in one end, extending into the main fixture, of the thread fixing fixture, and the minimum aperture of the taper hole is larger than the center hole; the two symmetric clamping pieces are configured and used for clamping the lath-shaped test piece, and shapes of two ends of each clamping piece are matched with the shape of the internal conical surface of the main fixture and the shape of taper hole of the thread fixing fixture respectively. The test piece is simple to process, the clamping operation is convenient, the experiment efficiency is high, and the dynamic tension experiment fixture can be applicable to test pieces with different thicknesses.

Owner:NANJING UNIV OF SCI & TECH

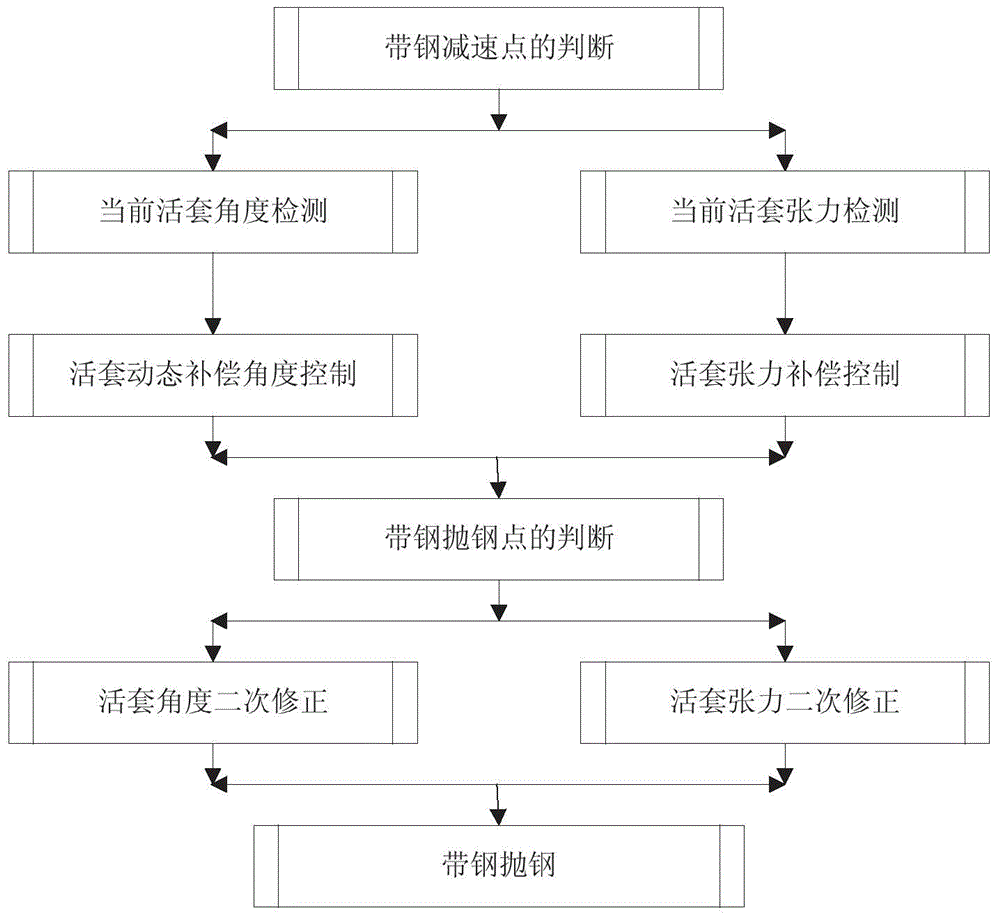

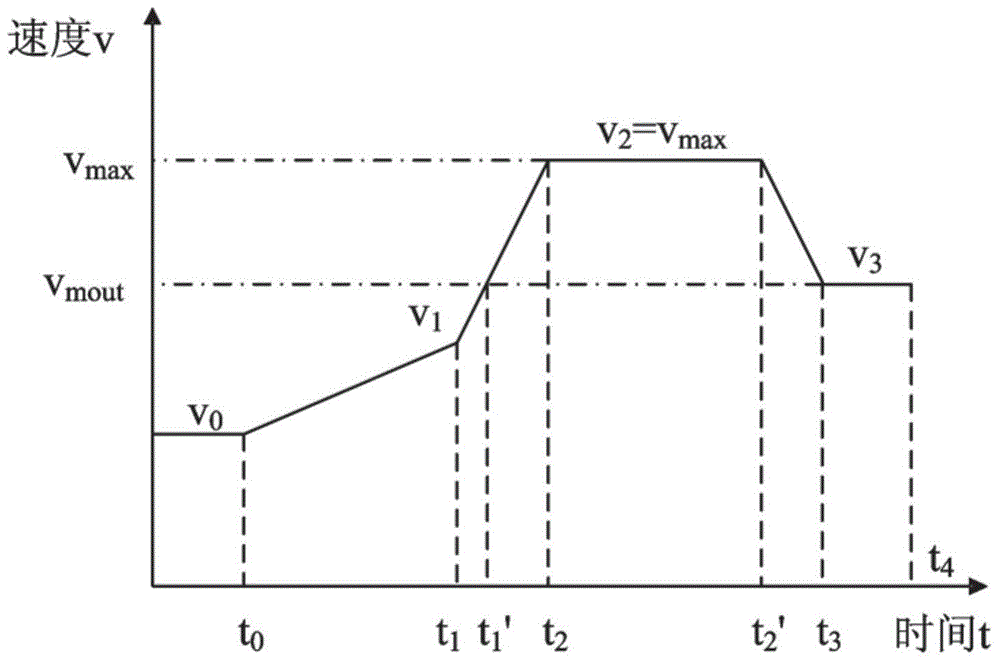

Method for dynamically controlling loop angle of hot continuous rolling mill

ActiveCN104801547AImplementation angleAchieve tension controlRoll mill control devicesFlexible work arrangmentsEngineeringDynamic Tension

A method for dynamically controlling a loop angle of a hot continuous rolling mill adopts a strip steel rolling force detector, a strip steel speed detector, a loop angle detector, a strip steel tension detector, a basic automatic level control machine and a process control machine to conduct dynamic control on angles of six loops among seven continuous rolling mills according to the set process requirements, accordingly the stability of the loops during strip steel throwing is improved, specifically variable-angle control before strip steel throwing and a unary function loop angle compensation method are adopted to achieve continuous dynamic control in the control process according to change of angle and tension control, meanwhile synchronous and dynamic tension control is achieved in the tension control process according to angle change, and the stability of the loops in the strip steel throwing process is improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

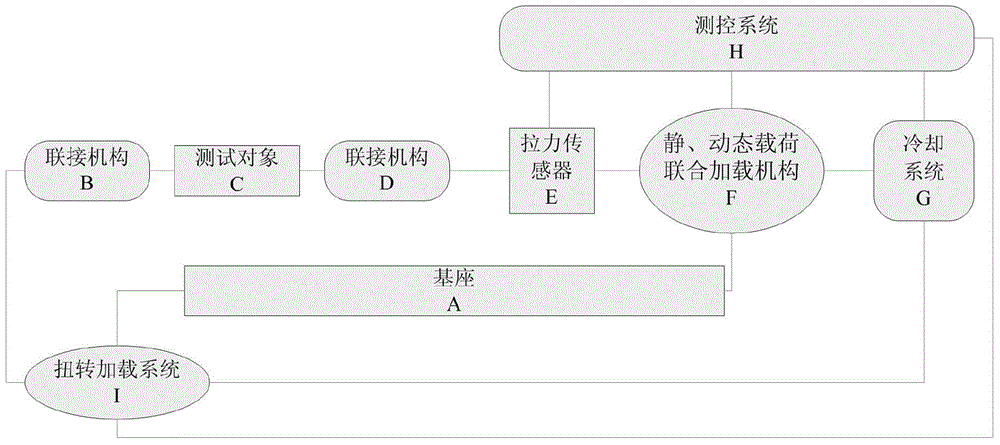

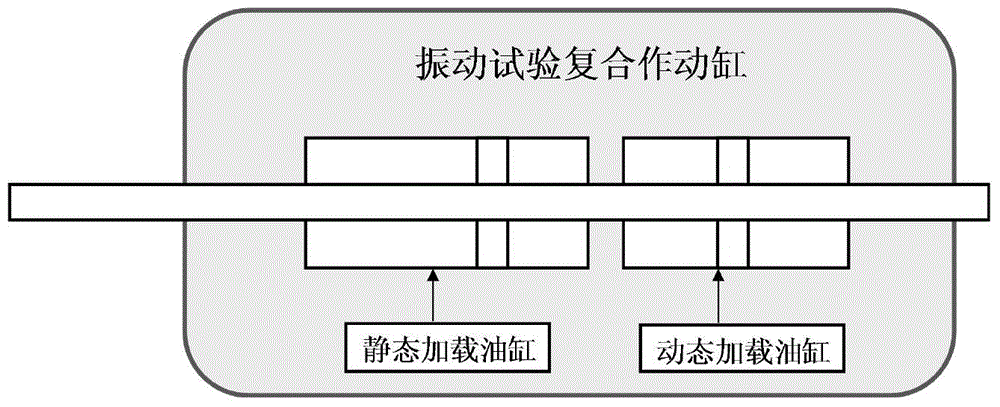

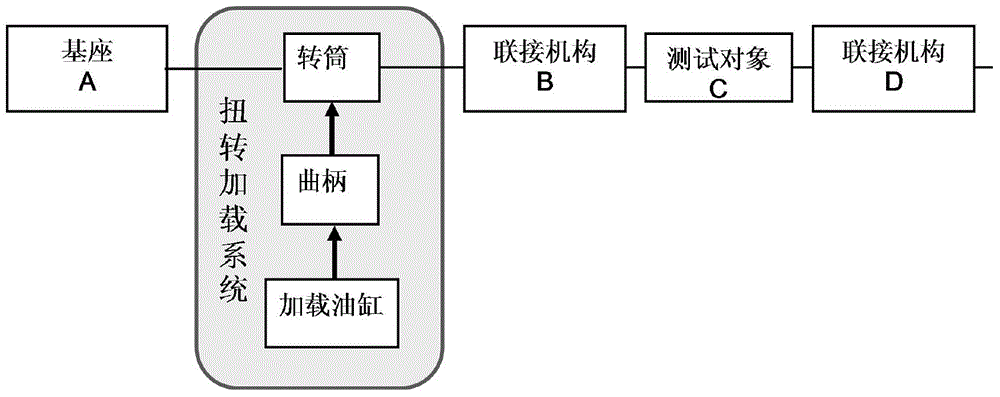

Synthetical fatigue testing system and method for extensional vibration and torsion of composite insulator

InactiveCN104677756AReduce stretching vibrationShorten the timeMaterial strength using repeated/pulsating forcesComposite insulatorsPull force

The invention relates to a synthetical fatigue testing system and a synthetical fatigue testing method for extensional vibration and torsion of a composite insulator. The system comprises a linkage mechanism, a tension sensor, a static and dynamic load linkage loading mechanism, a cooling system and a torsion loading mechanism which are connected end to end, wherein the tension sensor, the static and dynamic load linkage loading mechanism, the cooling system and the torsion loading mechanism are respectively connected with a measurement control system; the static and dynamic load linkage loading mechanism and the torsion loading mechanism are respectively connected with a base. According to the system, one end of the composite insulator is applied with static tension along the axial direction and the dynamic tension with adjustable frequency, and the other end of the composite insulator is applied with the torsion tension with adjustable frequency by the measurement control system; a testing condition is provided for the fatigue property research of the composite insulation under the comprehensive effects of static load, dynamic extensional vibration load and the torsion load.

Owner:STATE GRID CORP OF CHINA +2

Anchor solid dynamic tensile testing device and method

InactiveCN105510158ARealize dynamic drawingEnables dynamic tensile testingMaterial strength using repeated/pulsating forcesEngineeringDynamic Tension

The invention discloses an anchor solid dynamic tensile testing device and method. A heavy hammer-lever device is applied, impact loads generated when a heavy hammer freely falls are converted and amplified into impact loads acting on an anchor rod, the quantity values of tensile loads borne by the anchor rod are changed by adjusting the position of a lever fulcrum, and a response rule on an anchor solid interface under different loads and different tensile speeds is researched. By the adoption of a guide device and a lever amplification device, dynamic tension of the anchor rod is achieved, and a first researched interface debonding failure rule and a second researched interface debonding failure rule have certain engineering significance in a rock burst anchoring roadway anchor solid failure mechanism.

Owner:HENAN POLYTECHNIC UNIV

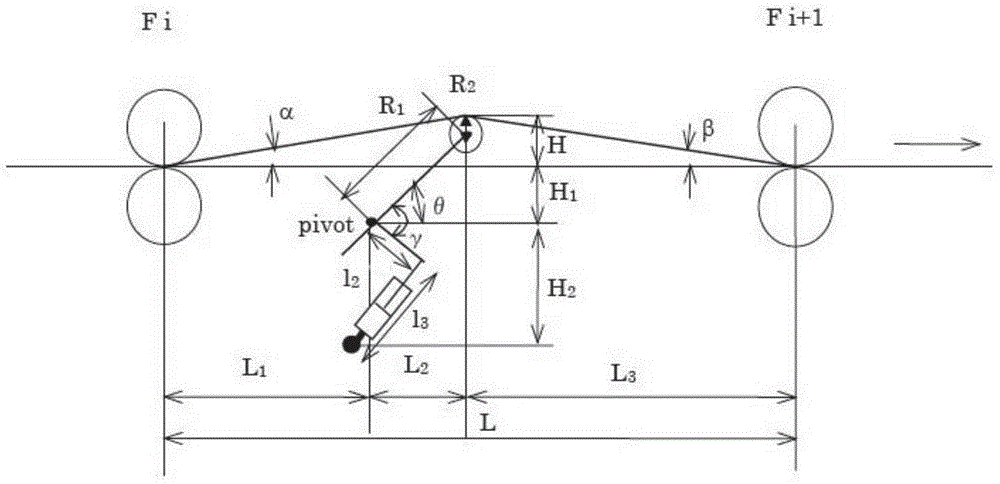

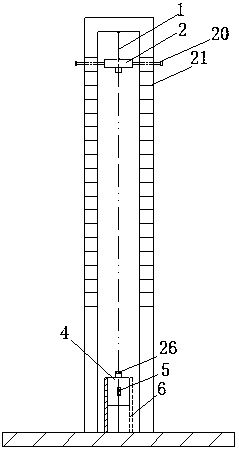

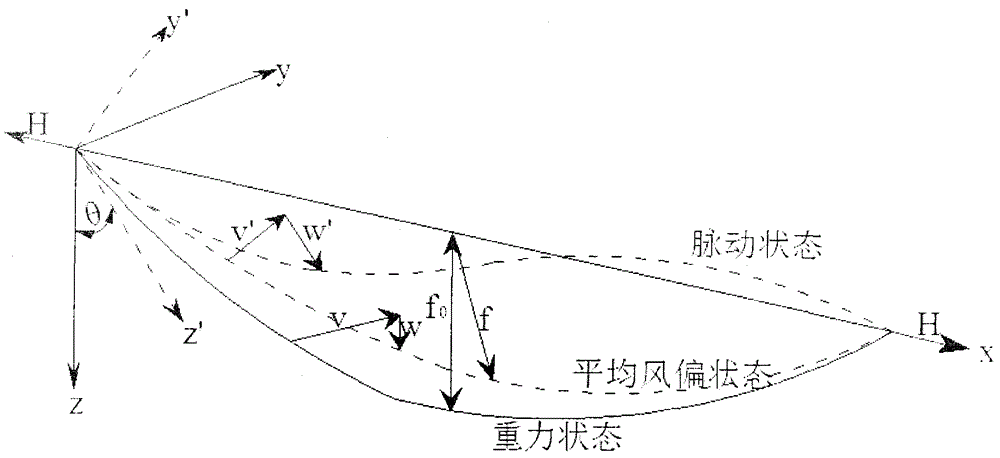

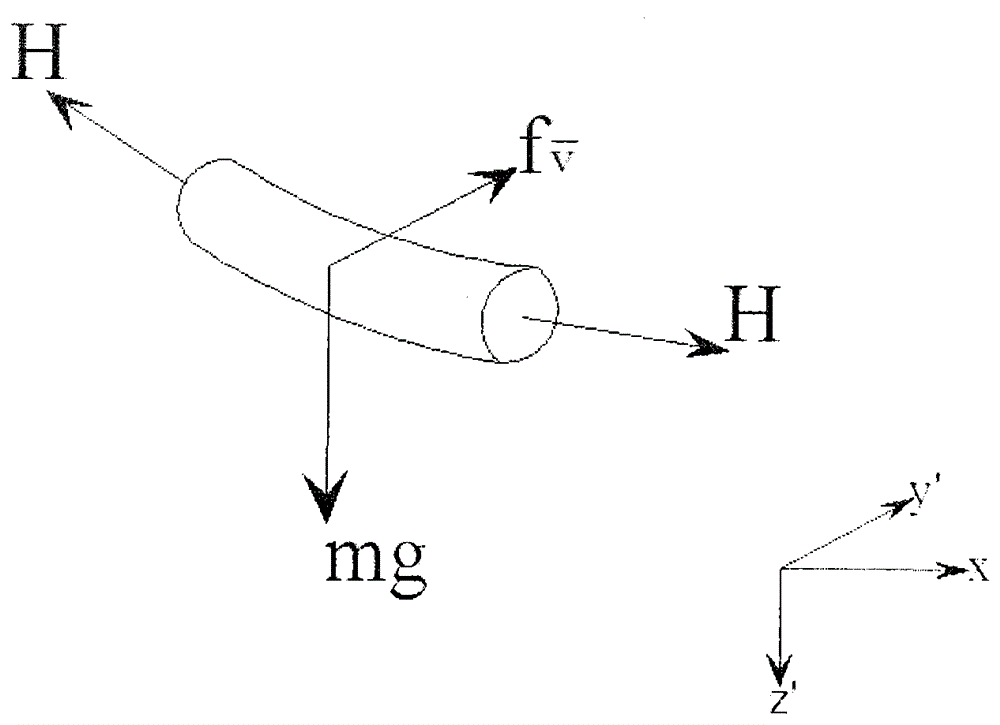

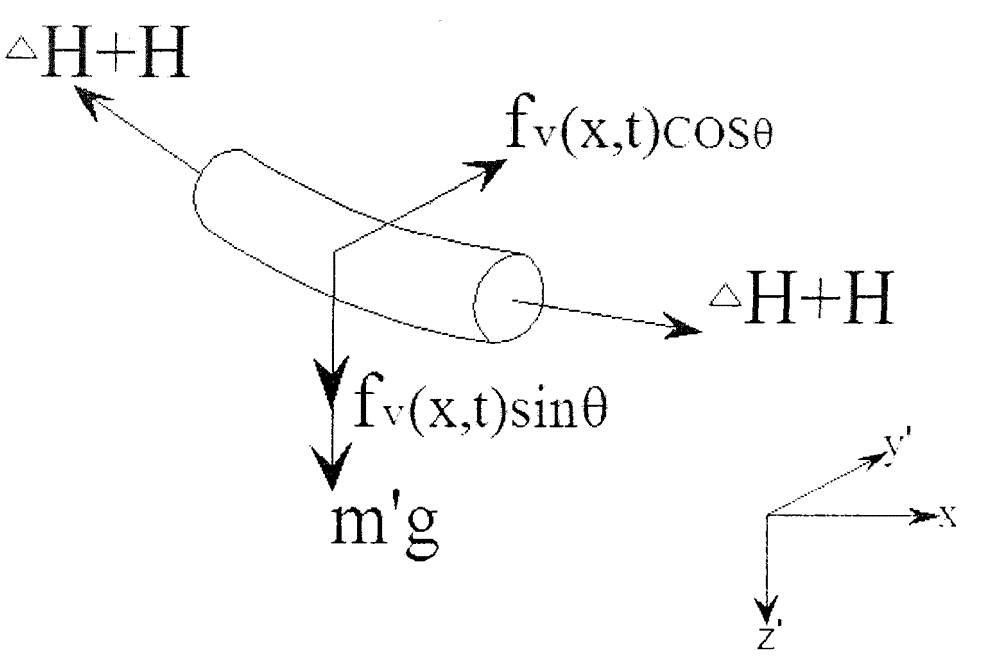

Cross arm hanging point load calculating method under fluctuating wind effect during transmission line windage yaw

InactiveCN104362570AImprove carrying capacityGuaranteed safe operationSpatial arrangements/dispositions of cablesTransmission towerPower grid

The invention discloses a cross arm hanging point load calculating method under the fluctuating wind effect during transmission line windage yaw. The method comprises the following steps: 1, solving the chordwise tension H of a power transmission line under the average windage yaw state through iteration; 2, solving the dynamic tension DH under the fluctuating wind effect; 3, solving the end tension of the power transmission line. By means of the Cross arm hanging point load calculating method under the fluctuating wind effect during transmission line windage yaw, the influence of the dynamic tension caused by fluctuating wind to the two ends of the power transmission line can be considered during tower structure load calculation in transmission tower design, and it is of great significance in enhancing the tower bearing capacity and ensuring safety operation of a power grid.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

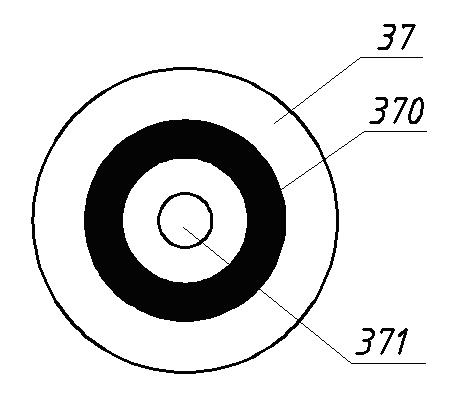

Dynamic radial deformation and dynamic tension monitoring device of deep-well double-broken-line-type multi-layer winding elevator steel wire rope and method thereof

ActiveCN106482782AAccurate detection of deformationPrecise detection of tensionMeasurement devicesTension compressionPull force

The invention discloses a dynamic radial deformation and dynamic tension monitoring device of a deep-well double-broken-line-type multi-layer winding elevator steel wire rope. The device comprises a pedestal, a driving system, a tension-compression detection system and a dynamic deformation monitoring system. The driving system comprises an electromotor. The electromotor is connected to a roller through a shaft coupling A, a speed reducer and a shaft coupling B. An outer side of a roller baffle plate is tightly contacted with a brake disc. The tension-compression detection system comprises a servo electric cylinder. A S-type tension sensor is connected to the servo electric cylinder and a steel wire rope clamp respectively. A roller surface is provided with a friction liner. A steel wire rope winds a double-broken-line rope groove of a friction liner surface. One end of the steel wire rope clamp is locked through the steel wire rope clamp. A back side of the friction liner is axially provided with a plurality of sensor installation grooves along the roller. A weighing-type pressure sensor is arranged in one sensor installation groove. The dynamic deformation monitoring system comprises a two-dimensional laser sensor. In the invention, tension characteristics of a steel wire rope under various kinds of work conditions can be simulated and a deformation quantity and a tension force of each layer of the steel wire rope can be accurately detected.

Owner:CHINA UNIV OF MINING & TECH

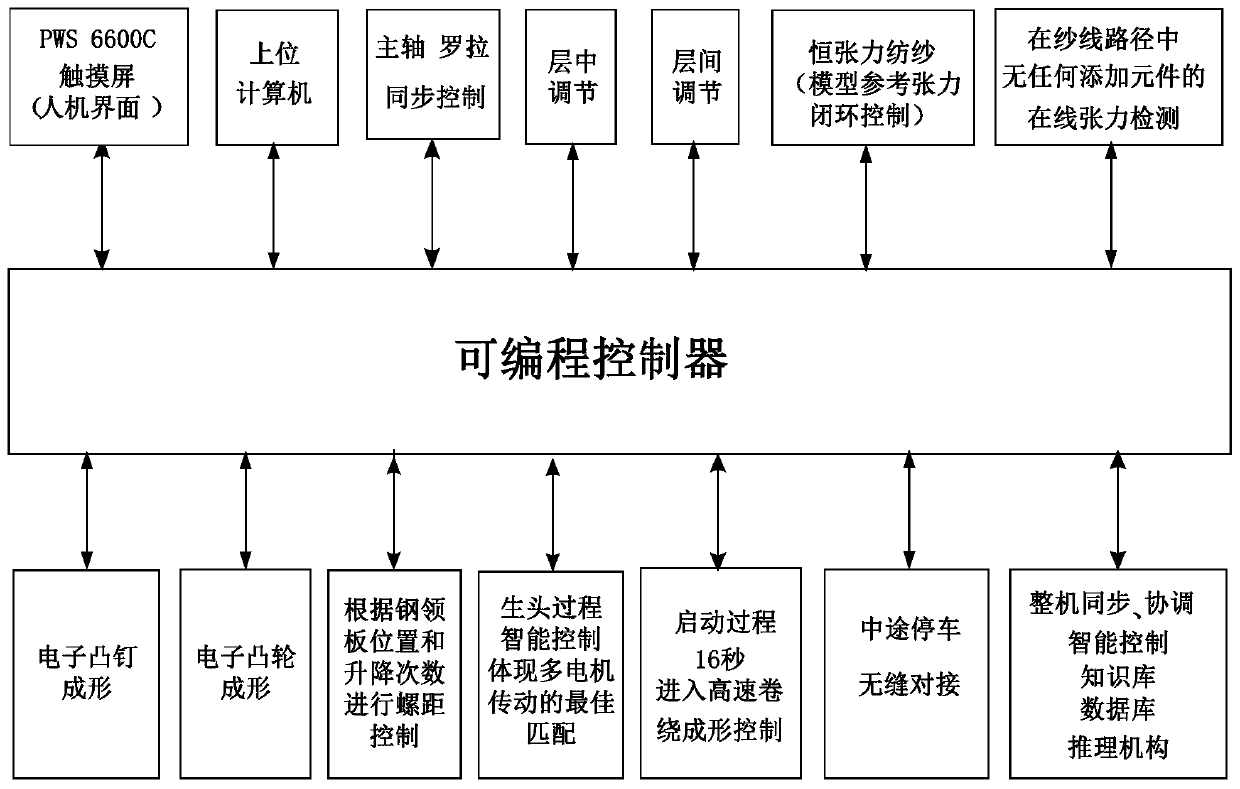

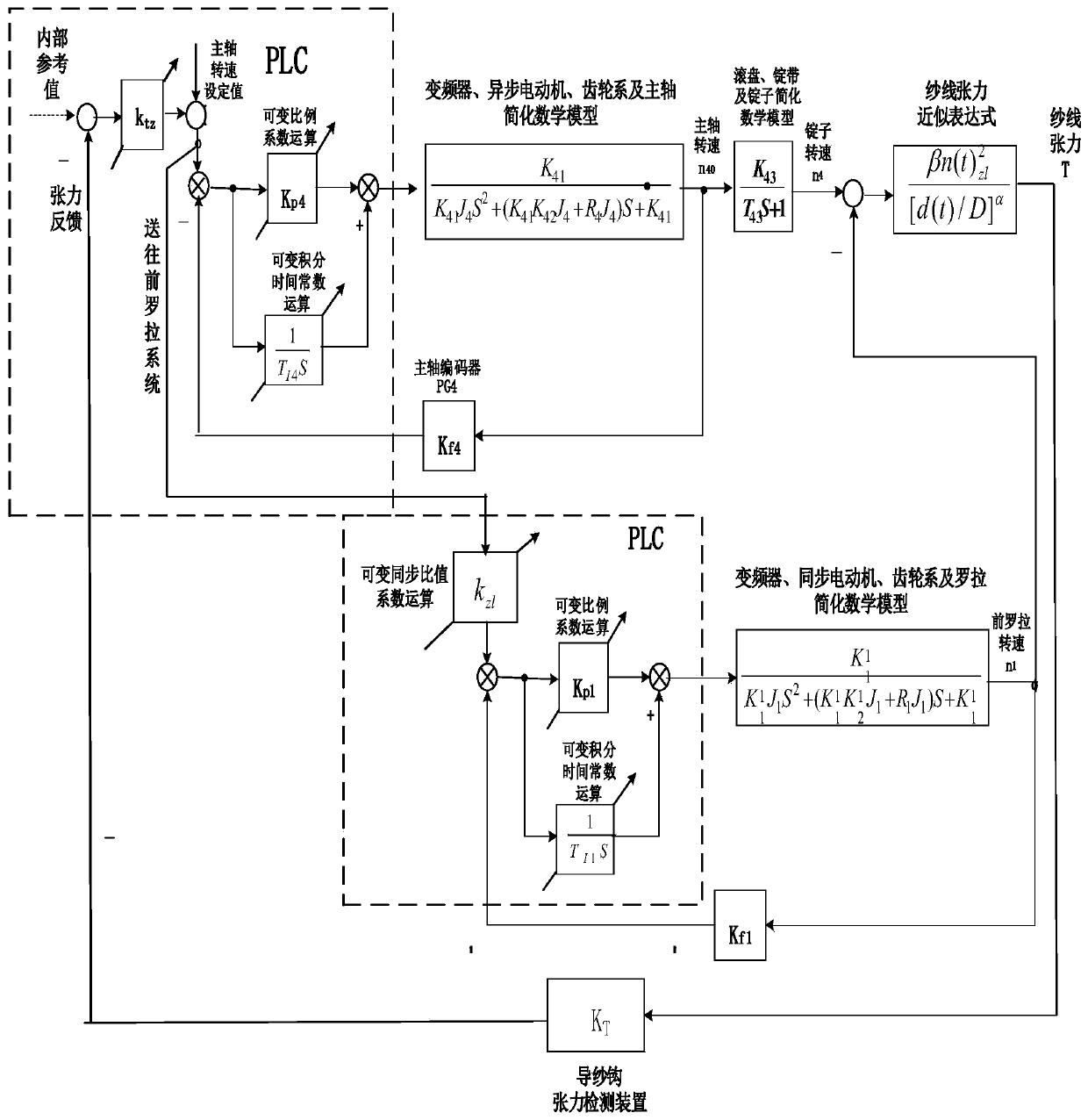

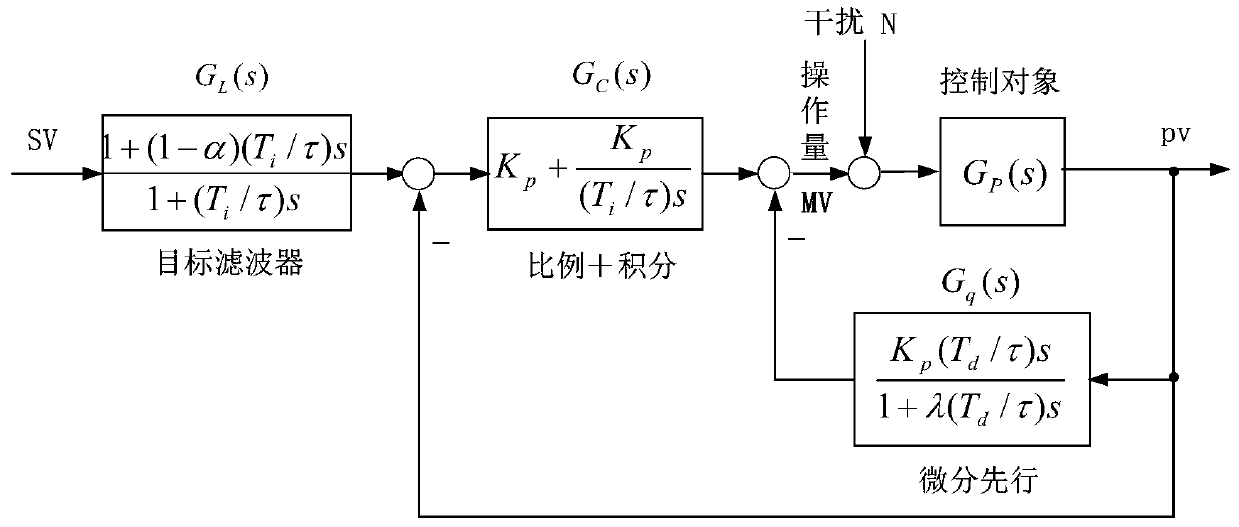

Intelligent control method and intelligent control system for ring spinning frame

The invention discloses an intelligent control method and an intelligent control system for a ring spinning frame. The intelligent control method includes collecting online-detected dynamic tension signals of the ring spinning frame, and establishing a knowledge base, a database and an inference mechanism; according to on-site online-detected tension data as well as the ascending and descending frequency and specific location of a steel collar plate, through the inference mechanism, outputting specific data of intra-layer adjustment and interlayer adjustment on the basis of the established knowledge base and database; according to the outputted specific data of intra-layer adjustment and interlayer adjustment, adjusting the frequency of a frequency converter of a main shaft to adjust the spindle speed, and implementing intra-layer adjustment and interlayer adjustment to further realize constant tension control. The intelligent control method and the intelligent control system have theadvantages that the tension of yarns is stabilized, high-efficiency spinning is realized, economic benefits are increased, and the amount of labor used is reduced.

Owner:宣向斌

Clamping device of Hopkinson pull bar test-piece and experimental method

ActiveCN105300792AShorten experiment timeEasy to installStrength propertiesShock waveConnection type

The invention discloses a clamping device of a Hopkinson pull bar test-piece and an experimental method and belongs to the field of shock dynamics experiment. The experimental device is used in pairs. One end of an adapter is in threaded connection with an incident bar or transmission bar, and the threaded clearance is filled with thread seal tape so as to avoid the damage of shock wave to connecting thread; and the other end of the adapter is provided with a square groove to be connected to a flat test-piece. The square groove which matches the test-piece undergoes plane machining into tiny serrated teeth so as to increase frictional force during clamping. The outer rim of the adapter is processed into taper thread which matches a nut. When the clamping device is in use, clamping force perpendicular to the groove surface is provided by screwing-in the nut. According to the invention, the problem that screw thread is not easy to process in a composite material and high-strength glue is nonuniform during gluing process can be greatly avoided, connection type of a fibrous composite material under dynamic tension is studied, and a forceful foundation is laid for the constitutive relation of the fibrous composite material under dynamic tension.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com