Method for dynamically controlling loop angle of hot continuous rolling mill

A technology of dynamic control and hot continuous rolling mill, applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of unfavorable looper tail, looper drop, and failure to realize smooth steel throwing, etc., and achieve looper stability sex improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

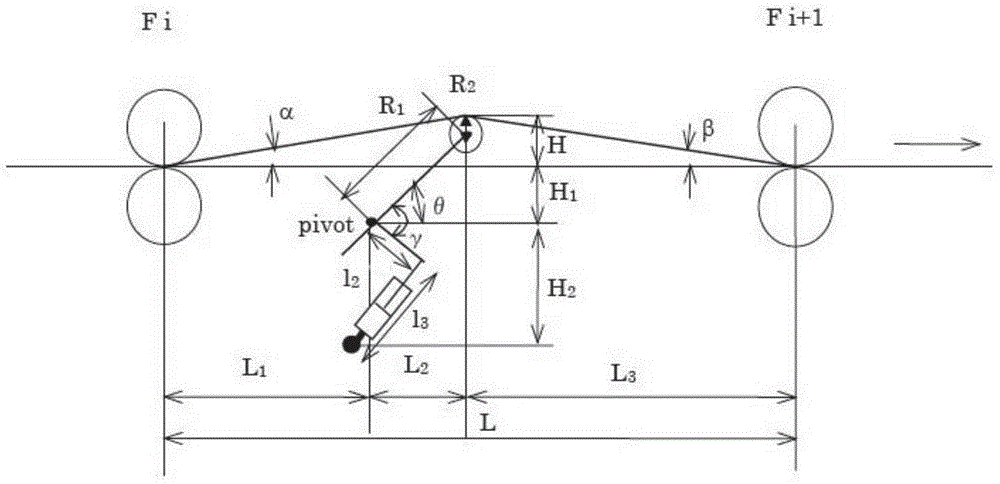

[0049] In the following, a method for dynamically controlling the looper angle of a hot continuous rolling mill according to the present invention will be further specifically described according to the accompanying drawings and specific implementation methods.

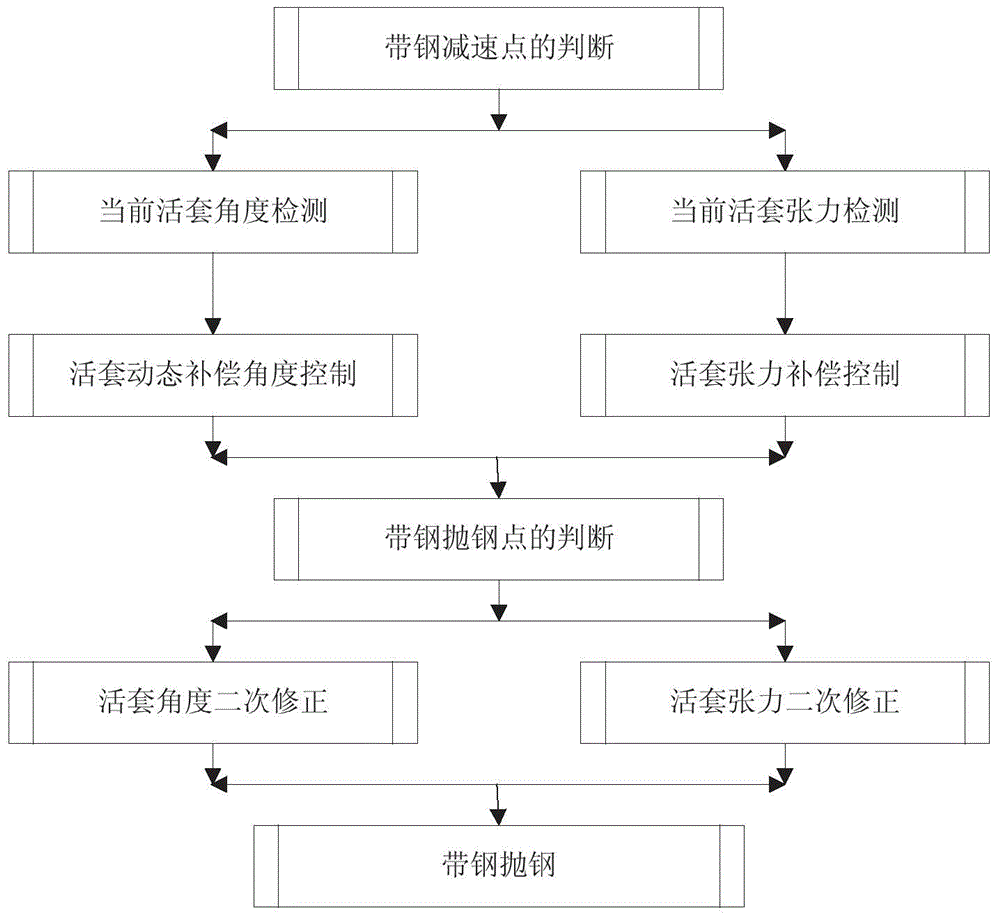

[0050] Such as figure 1 A method for dynamically controlling the looper angle of a hot continuous rolling mill is shown, through a strip rolling force detector, a strip speed detector, a looper angle detector, a strip tension detector, and a basic automation level control machine and process The control machine dynamically controls the angles of the 6 loops between the 7 continuous rolling mills during the strip rolling process according to the requirements set by the process, so as to enhance the stability of the loops when the strip is cast, including the following steps:

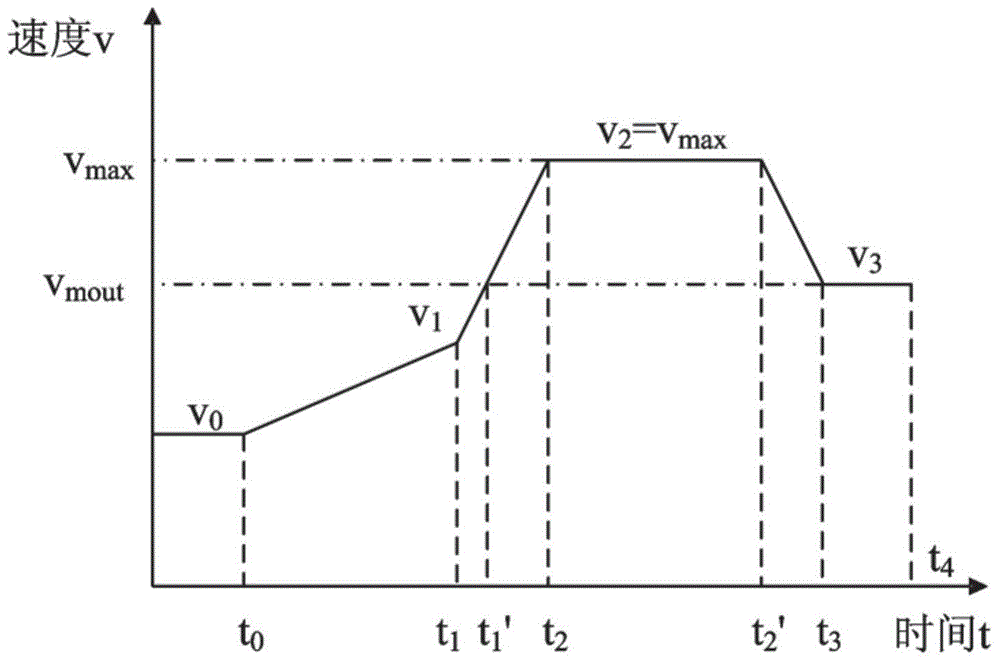

[0051] S1: The strip speed value is detected in real time by the strip speed detector, and transmitted to the basic automation level control mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com