Dye dissolving and adding device

A technology for dyes and dye barrels, which is applied in the direction of cleaning devices for processing textile materials, equipment configuration for processing textile materials, and processing of textile materials. Miscasting and other problems to achieve the effect of avoiding cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

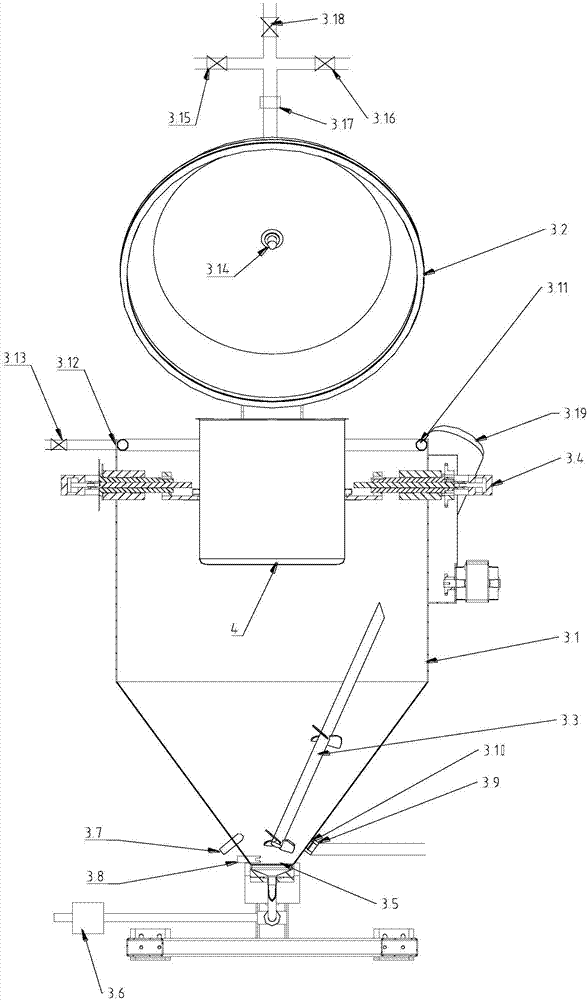

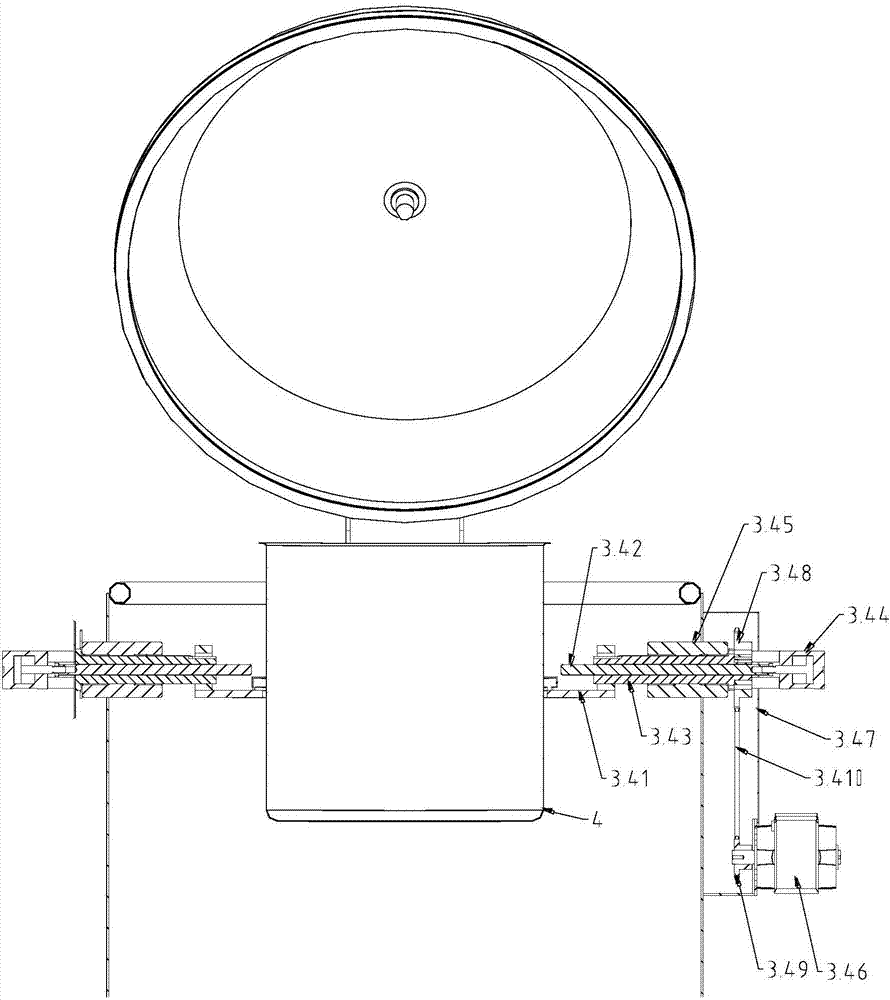

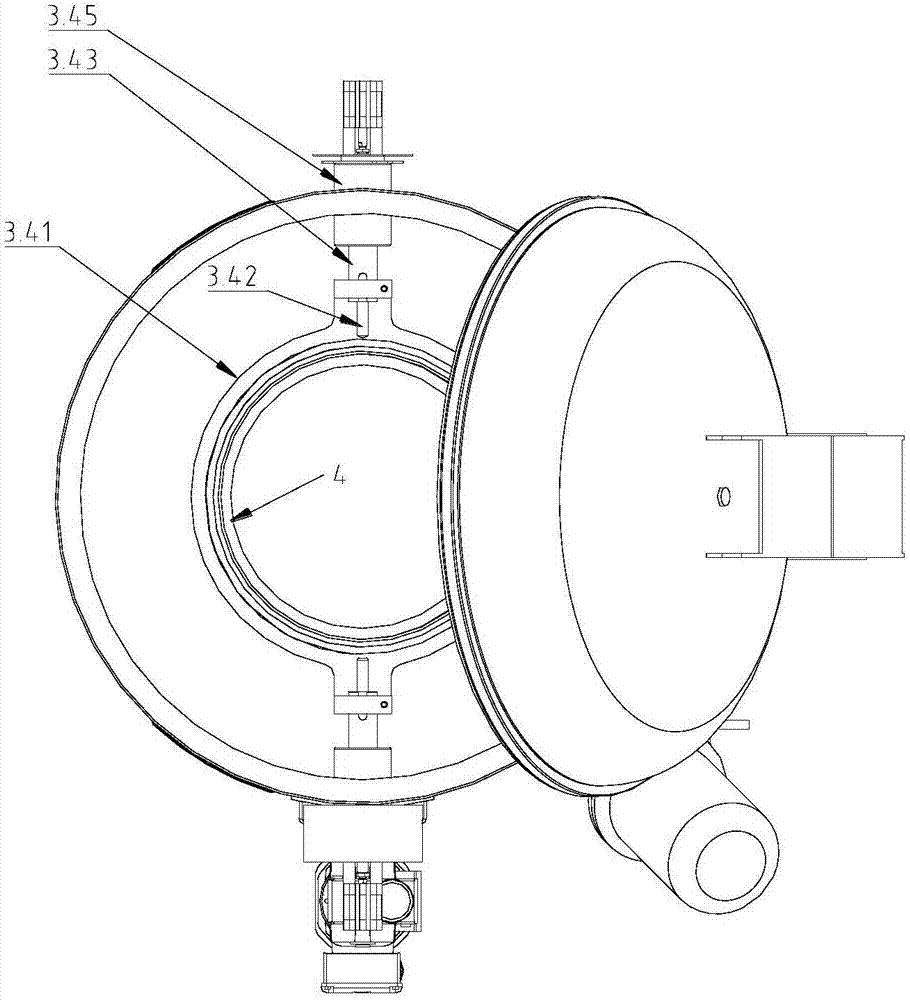

[0034] A kind of dye chemical material device, see attached Figure 1-3, the dye chemical material device comprises a chemical material tank body 3.1, a tank cover 3.2, a stirring paddle 3.3, and a clamping turning mechanism 3.4, and the tank cover is arranged on the upper mouth of the chemical material tank body through a pneumatic uncapping mechanism, and the diameter of the chemical material tank body is 1m, the bottom of the chemical material tank is conical, and the cone angle is 45 degrees. There is a discharge port 3.5 at the bottom of the tank, and the discharge port is externally connected to the discharge pipeline. A temperature sensor 3.7 is installed on the cone wall, a tuning fork switch 3.8 (detecting the liquid level signal) is installed at the discharge port of the chemical material tank, and at least one steam inlet 3.9 is also ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com