Patents

Literature

80results about How to "Avoid sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV-oxide hybrid drying type engraving intaglio printing ink

ActiveCN101250354AAchieve dryingWell mixedInksOther printing apparatusPulp and paper industryPrinting ink

The invention relates to UV-oxidation mixing drying type incising gravure printing ink, which is prepared through firstly producing by rolling UV drying components and oxidation drying components assisting volatilization drying, penetration drying and complex drying effect, and evenly mixing according to 1%-99% proportion of UV drying component and 99%-1% oxidation drying components assisting volatilization drying, penetration drying and complex drying effect. The printing ink of the invention conducts UV drying in the process of printing, instantly realizes partial drying of printing ink to form a drying ink film, can finish oxidation drying and assisting volatilization drying, penetration drying and complex drying effect to achieve the complete drying of printing ink. The printing ink solves the technical problems that thick ink film existing in current UV drying incising gravure printing ink is incomplete, complete drying can not be realized in the natural storage process, and has the advantages of economical, energy-saving and environment-friendly.

Owner:CHINA BANKNOTE PRINTING & MINTING

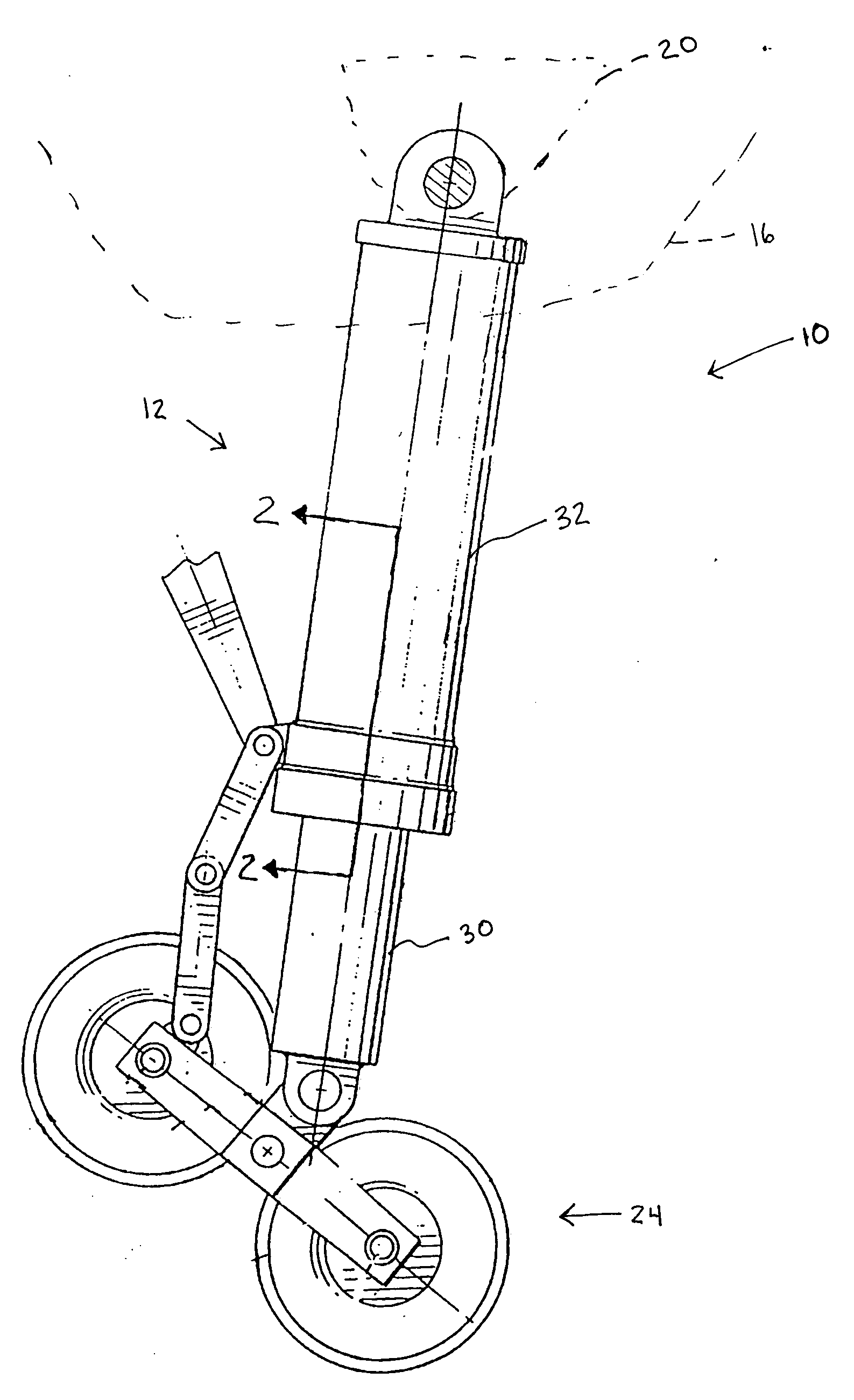

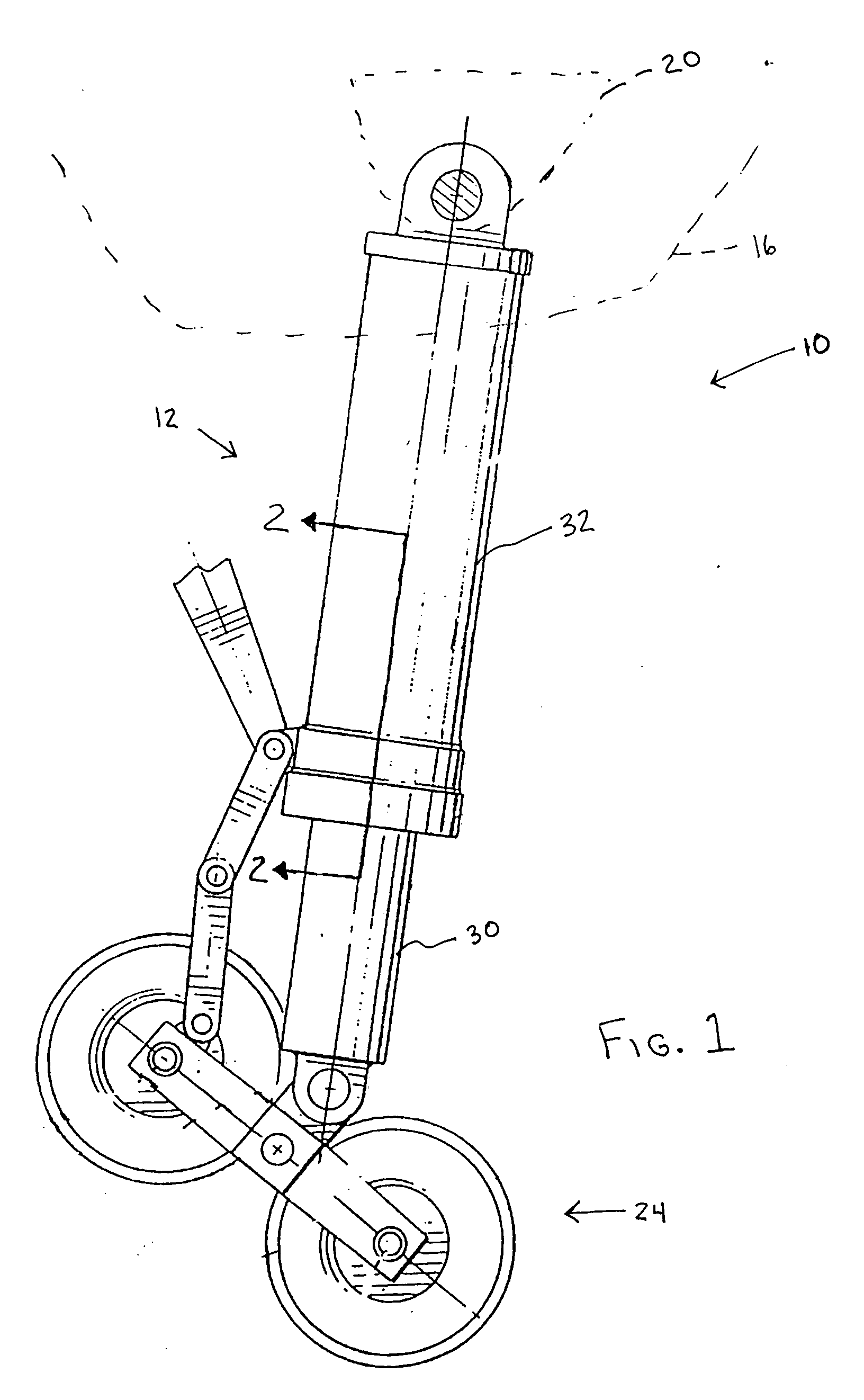

Aircraft shock strut and improved bearings therefor

An aircraft shock strut includes a cylinder and a piston telescopically movable within the cylinder. A first bearing is mounted to one of the cylinder and the piston. The first bearing includes a support structure and a first bearing surface formed by a lead-free PTFE material layer for providing sliding engagement with the other of the cylinder and the piston.

Owner:THE BF GOODRICH CO

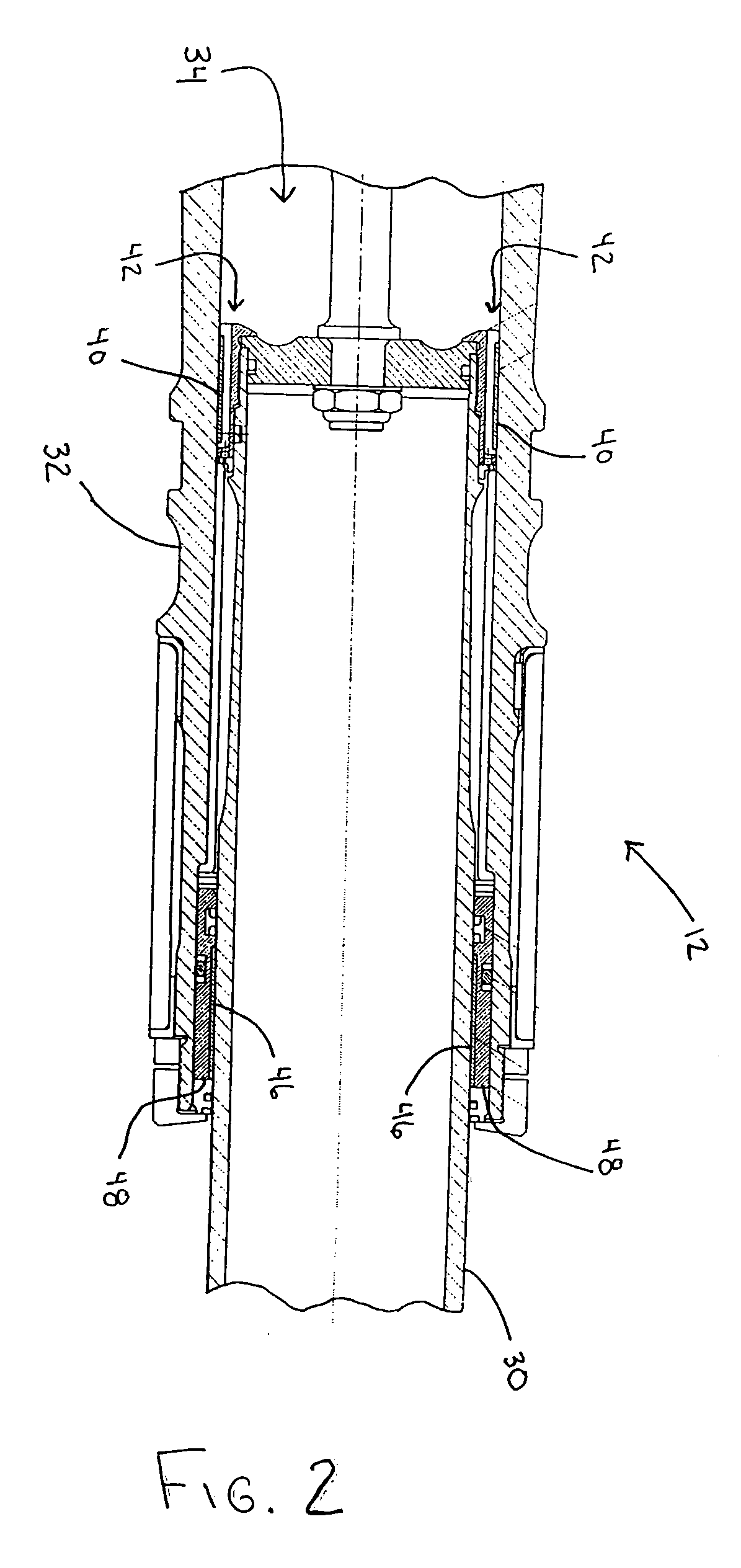

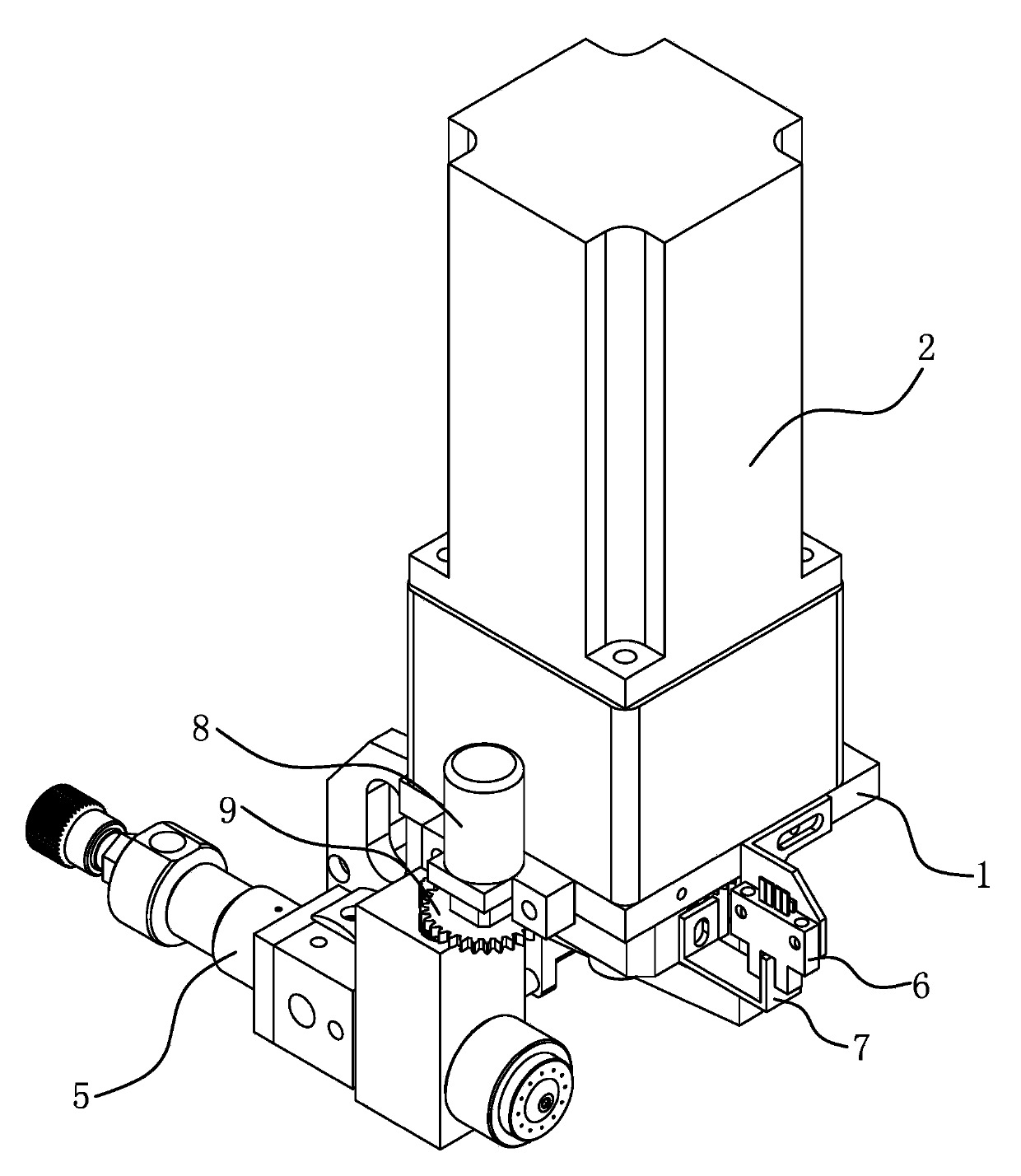

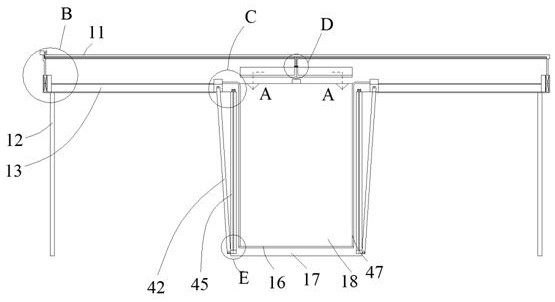

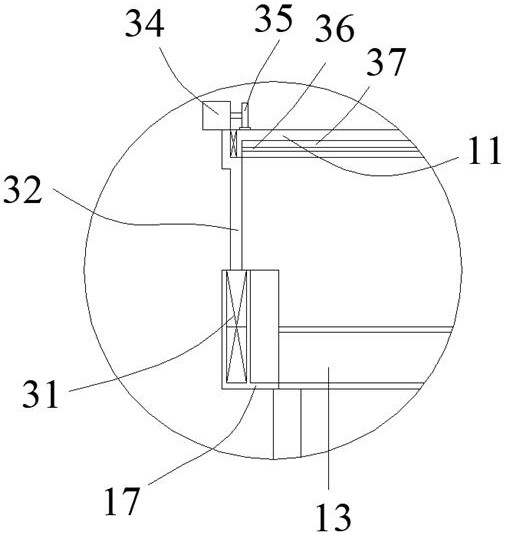

Automatic upper glue spraying component and automatic upper glue spraying machine

The invention provides an automatic upper glue spraying component and an automatic upper glue spraying machine, belongs to the technical field of operation, and solves the problem that spraying nozzles of existing glue spraying machines cannot be kept in the same direction with any positions of shoe outsoles. The automatic upper glue spraying component comprises a first motor, a glue spraying gun, a second motor and a connecting piece. A rotating shaft of the first motor and a shell of the second motor are fixedly connected through the connecting piece. The glue spraying gun is fixedly connected with a rotating shaft of the second motor. The direction of the axis of the rotating shaft of the first motor is different from that of the axis of the rotating shaft of the second motor. According to the automatic upper glue spraying component, the direction of a nozzle of the glue spraying gun and the distance between the glue spraying gun and the rotating shaft of the first motor can be adjusted, and can be automatically adjusted according to program settings during glue spraying, so that the glue spraying gun can be ensured to face to-be-sprayed points in the optimal direction, and intervals between the nozzle of the glue spraying gun and to-be-sprayed surfaces are ensured to be uniform. The automatic upper glue spraying component used for spraying glue to uppers has the advantage of improving product quality.

Owner:曹县雅天工艺品有限公司

Offset printing ink and preparation method thereof

The invention relates to the technical field of printing ink, in particular to offset printing ink and a preparation method thereof. The offset printing ink is formed by preparing printing ink base ink and components such as cerate dry vegetable oil under specific process conditions, wherein the printing ink base ink is prepared from components such as self-made quick-drying varnish as a printing ink connection substance, half-dry vegetable oil and dry vegetable oil. Compared with the prior art, the offset printing ink prepared by adopting a preparation process disclosed by the invention has significantly improved comprehensive performance, has the advantages of good wear-resisting property, quick drying speed, strong adhesion, and good in adaptation to various types of paper, and the problems of dirt attachment, slow drying, fading and the like of a printed product can be effectively avoided.

Owner:茂名阪田油墨有限公司

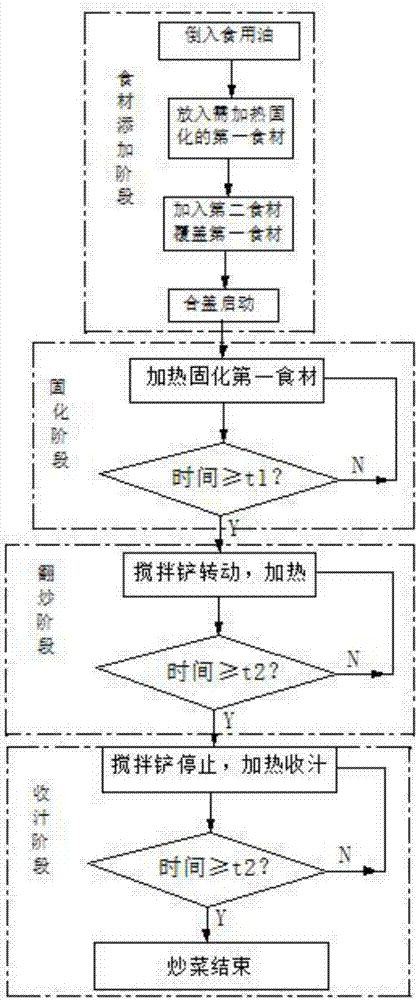

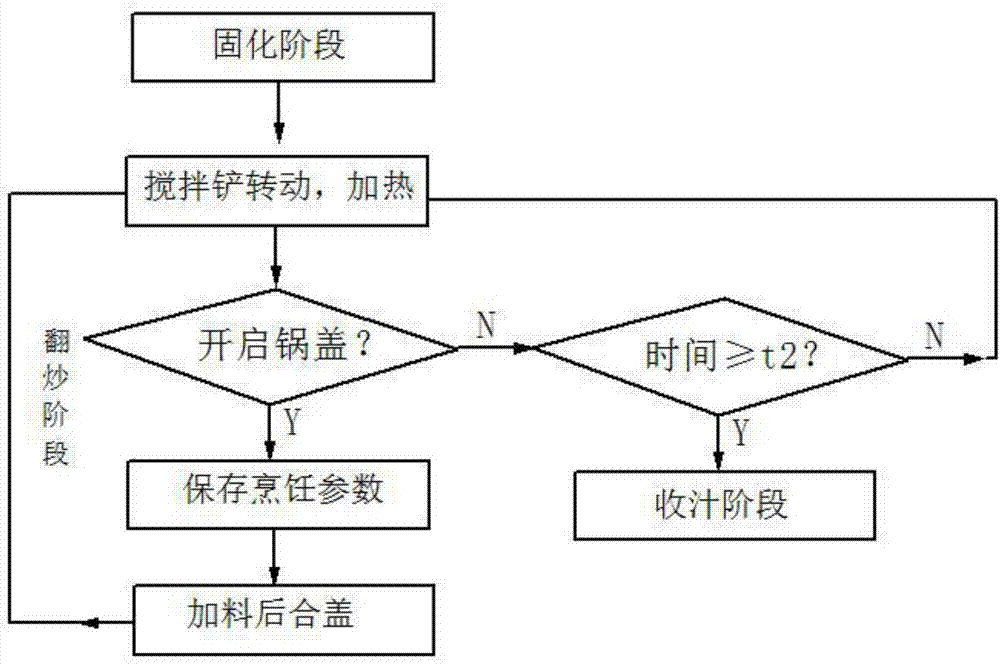

Cooking method of automatic cooking machine

InactiveCN107996946AGuaranteed absorptionGreat tasteCooking vesselsFood scienceFood materialEngineering

The invention relates to a cooking method of an automatic cooking machine. The automatic cooking machine comprises a pot body, a wok and a pot cover, wherein a stirring slice is arranged on the pot cover and extends into the wok so as to stir-fry food materials, and a heating device for heating the wok is arranged in the pot body. The cooking method mainly comprises a food material adding stage, asolidifying stage, a stir-frying stage and a thickening stage. The method provided by the invention can ensure food material juice absorption and improve dish taste.

Owner:JOYOUNG CO LTD

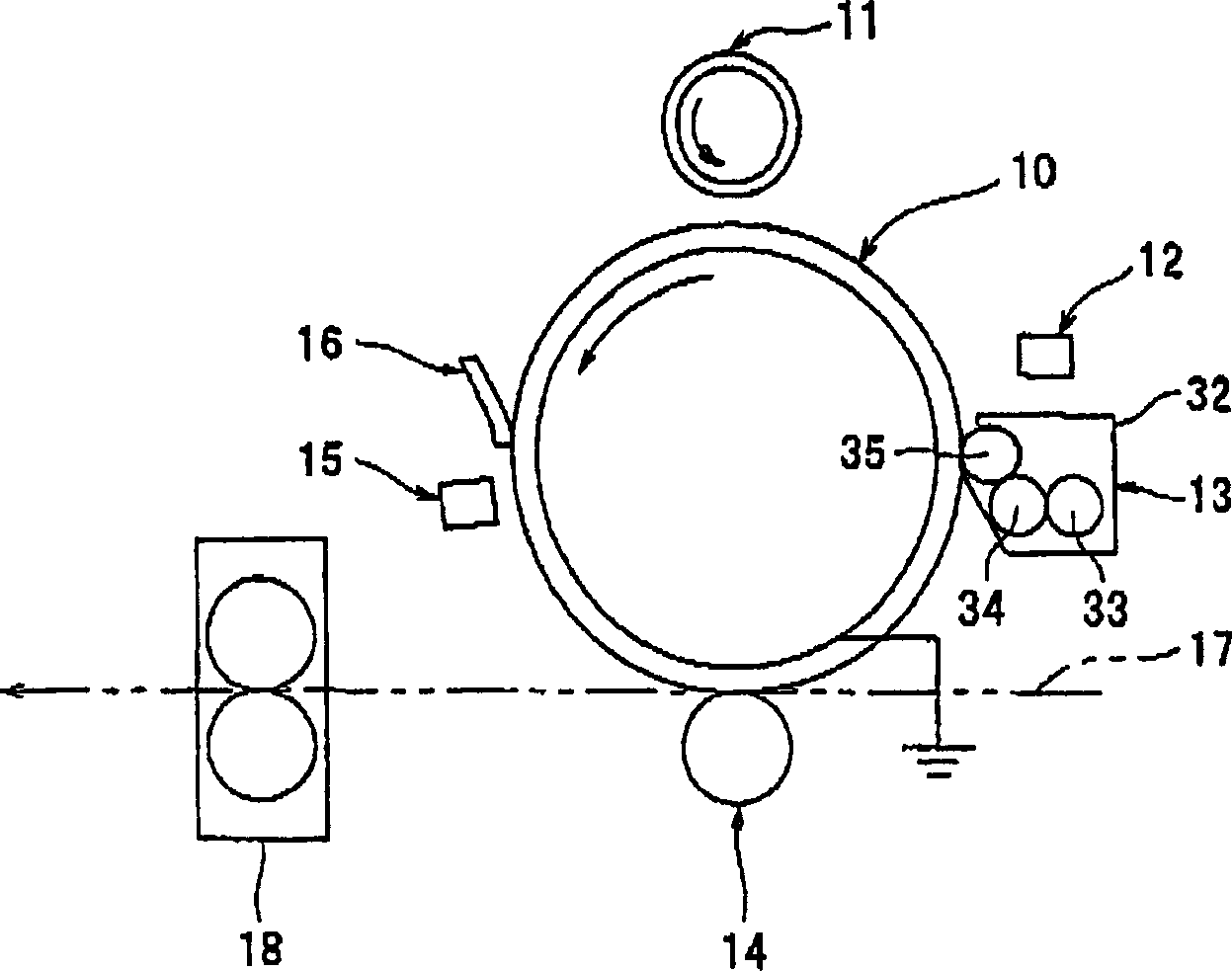

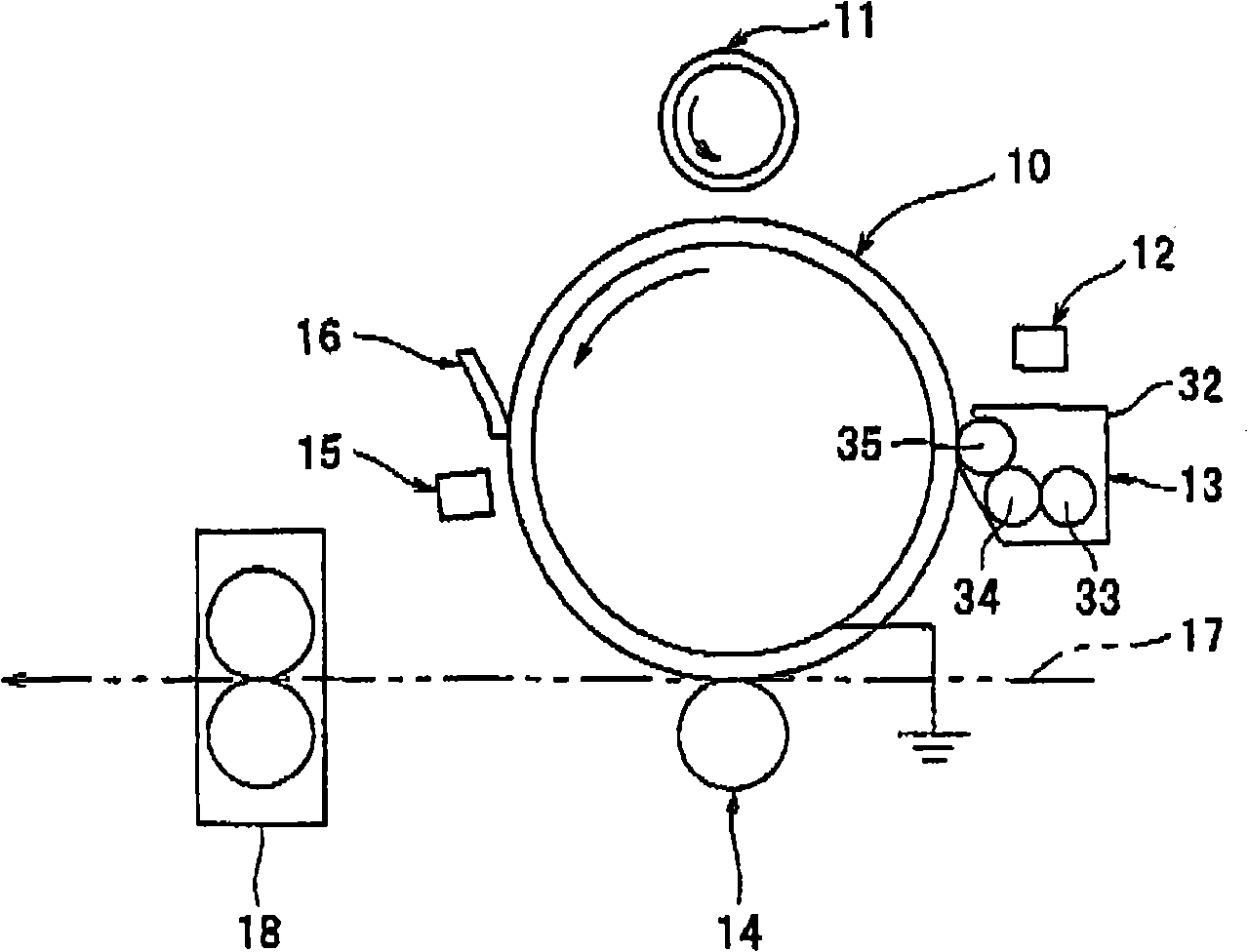

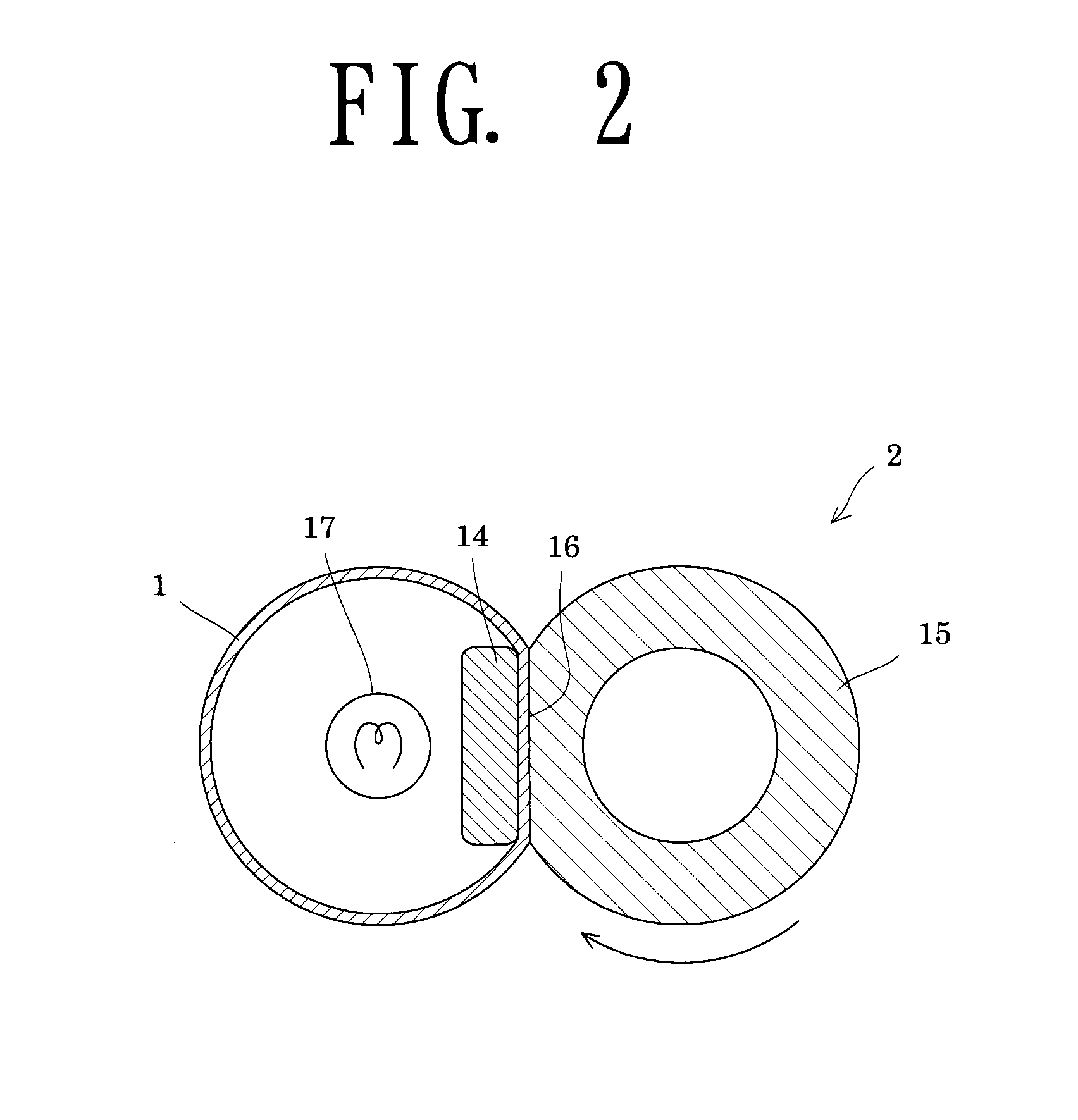

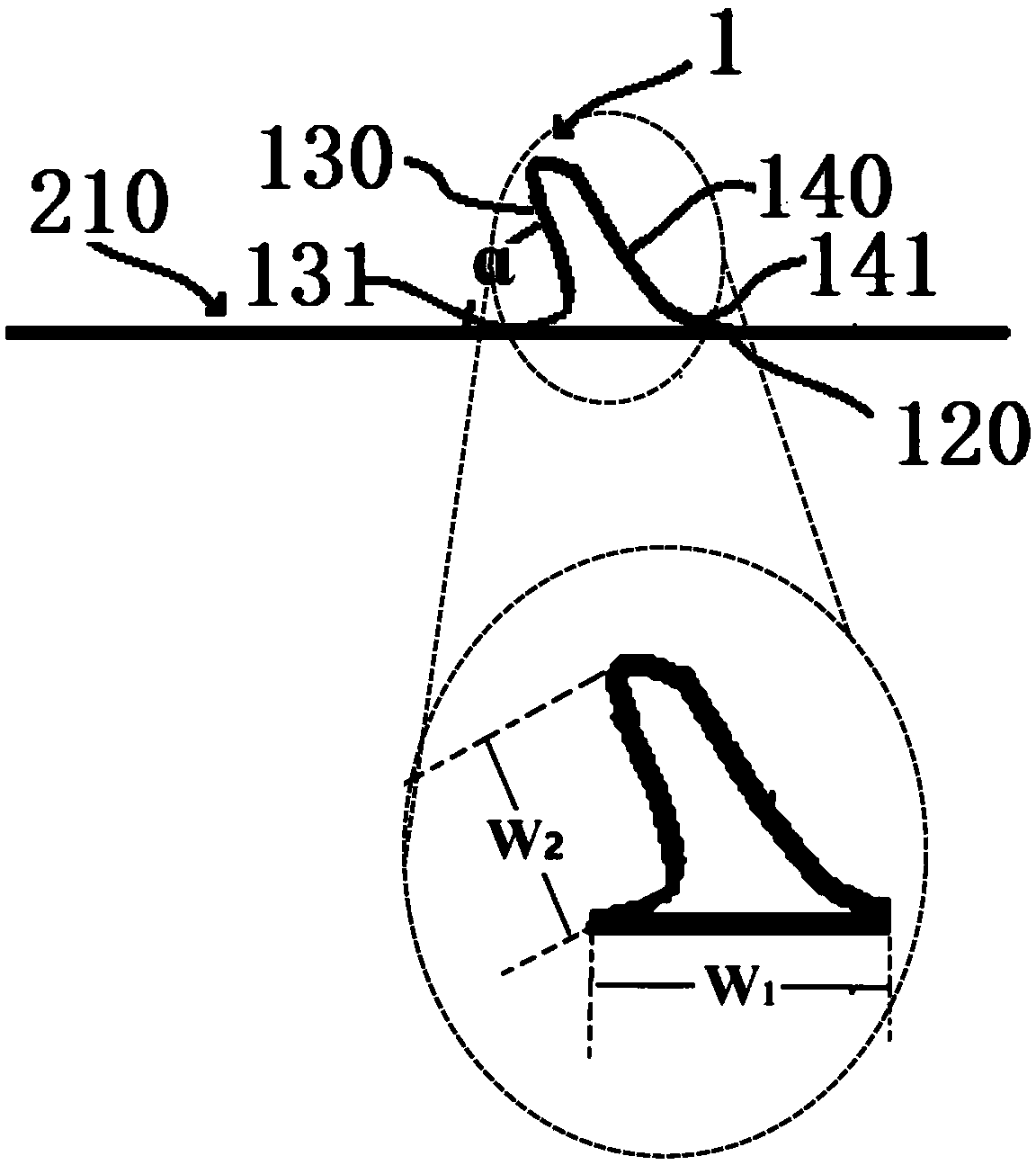

Cleaning device, process cartridge, and image forming apparatus

ActiveCN1770041ANo reduction in contact widthIncrease line pressureElectrography/magnetographyBand shapeImage formation

In cleaning devices, process cartridges and image forming devices, a cleaning structure with low linear pressure and high surface pressure can be obtained by specifying the material, shape and support structure of the cleaning blade. Press the front end corners of the elastic cleaning blade (38) supported by the so-called sheet holder, that is, the supporting member (37), on the roller-shaped and belt-shaped image carrier (10), and remove the residue remaining on the image carrier after image transfer. body toner. In such a cleaning device (16), the angle (θ) forming the front end corner line portion (36) of the cleaning blade is formed as an obtuse angle, and the front end corner line portion is formed at a surface pressure greater than or equal to 2.0 g / mm2. Press on the image carrier. The so-called surface pressure refers to the value obtained by dividing the total load applied to the cleaning blade by the contact area of the cleaning blade with respect to the member to be cleaned.

Owner:RICOH KK

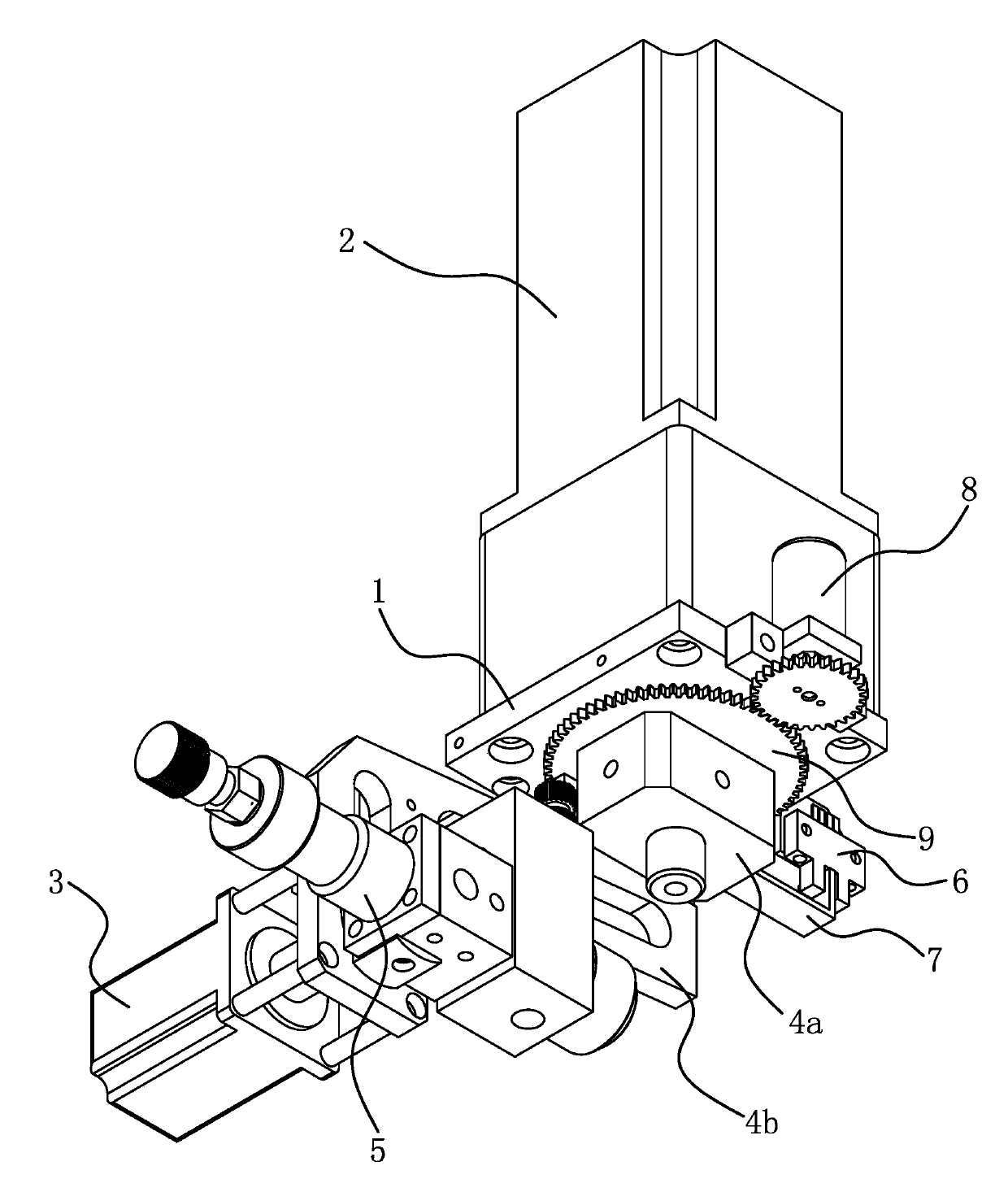

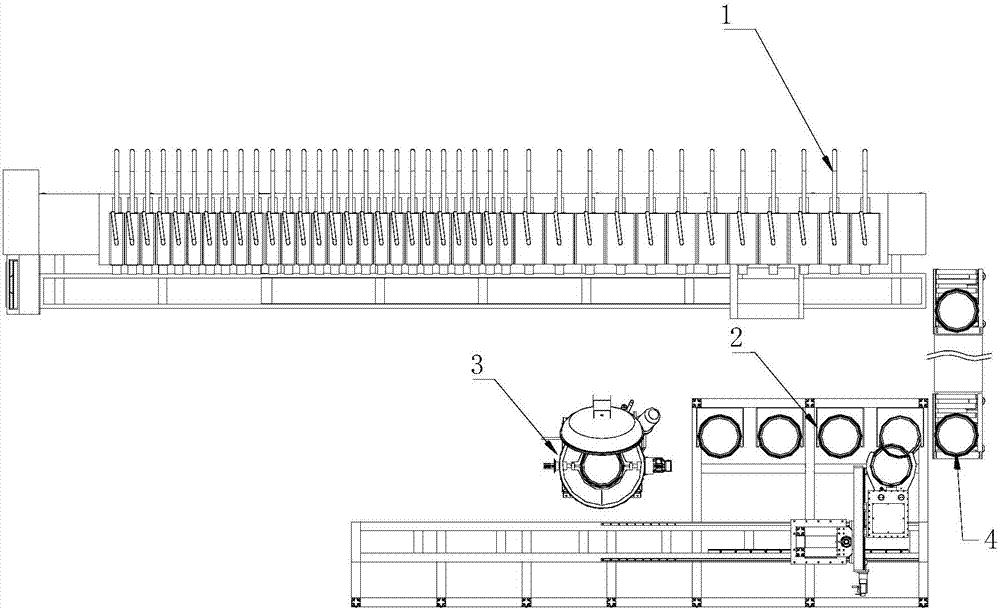

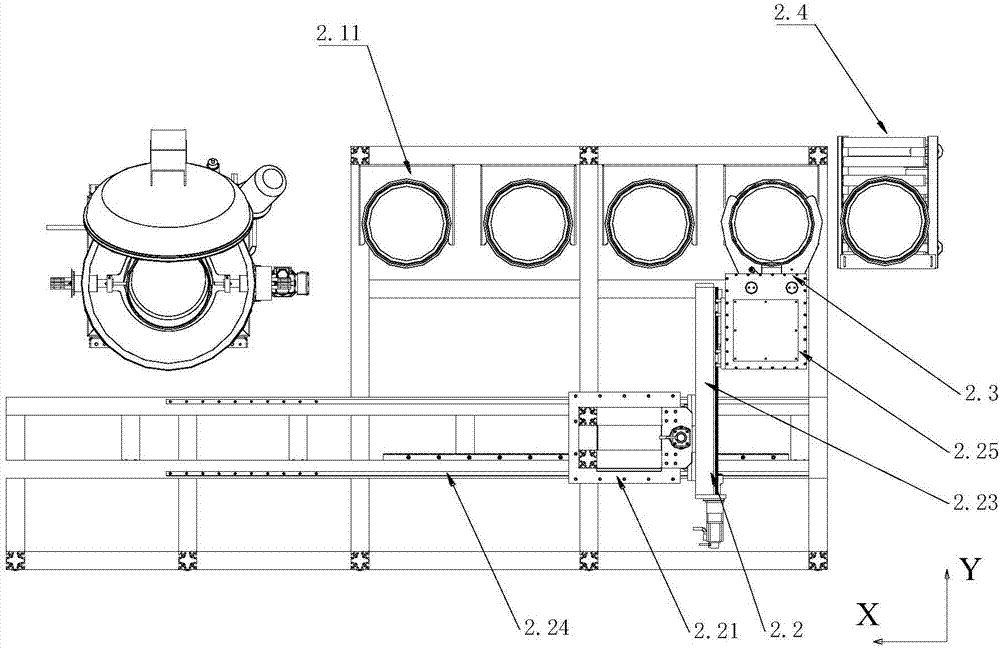

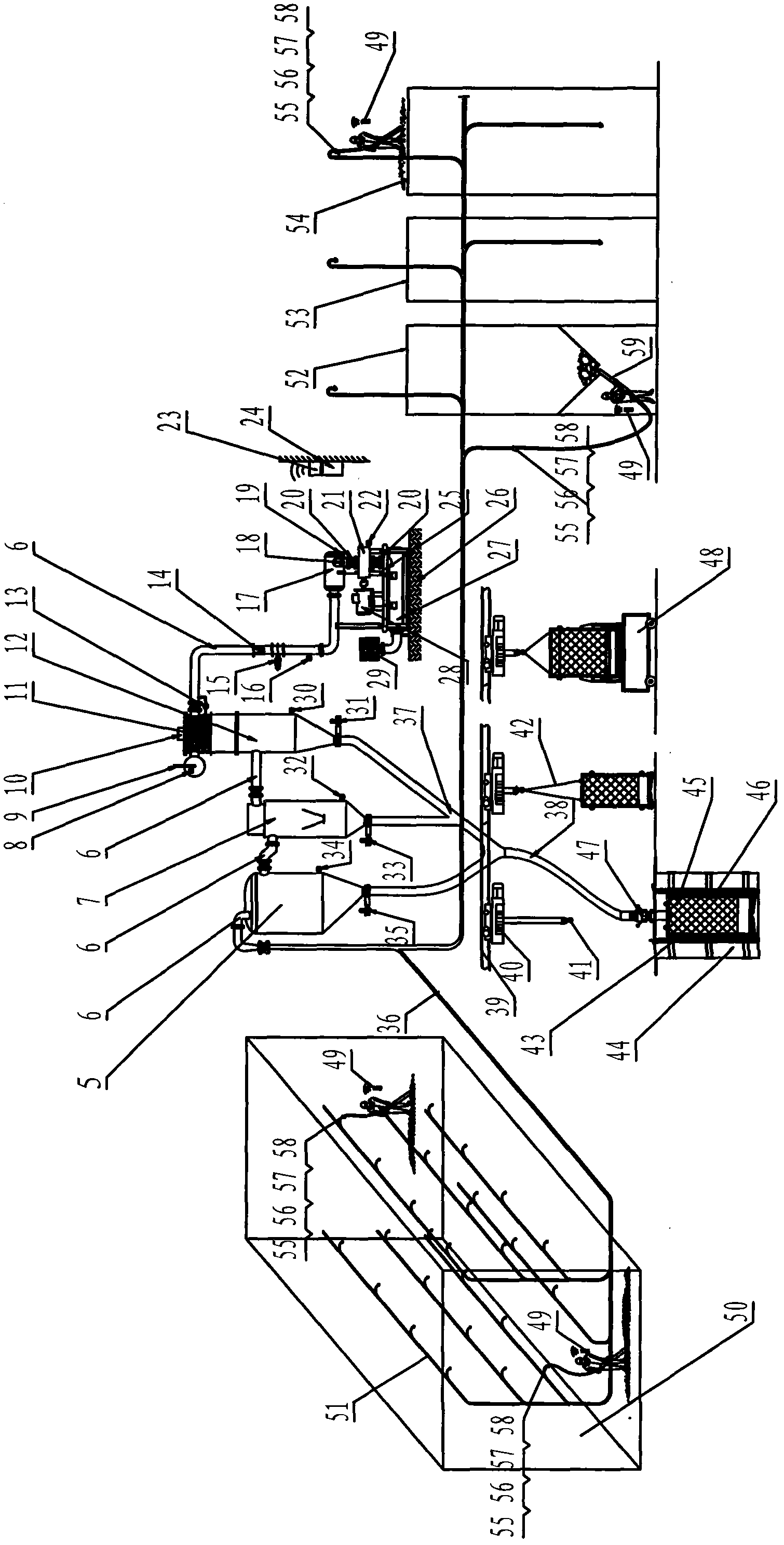

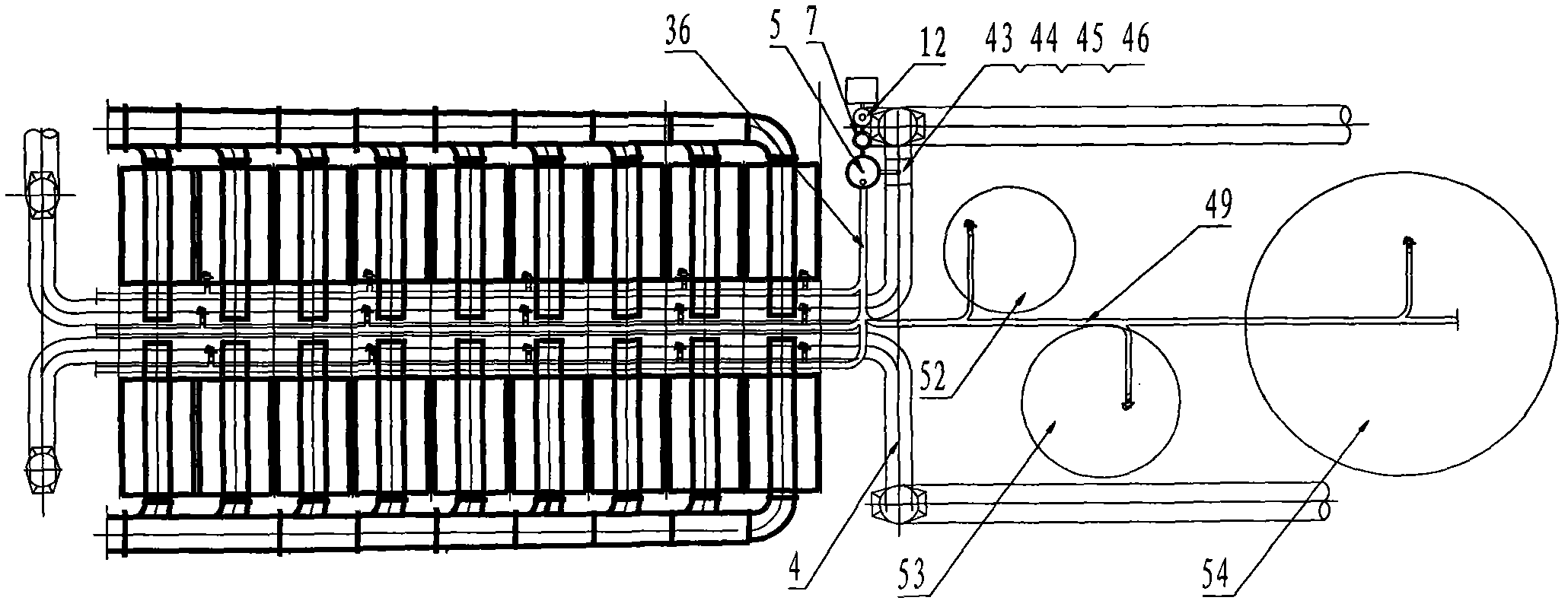

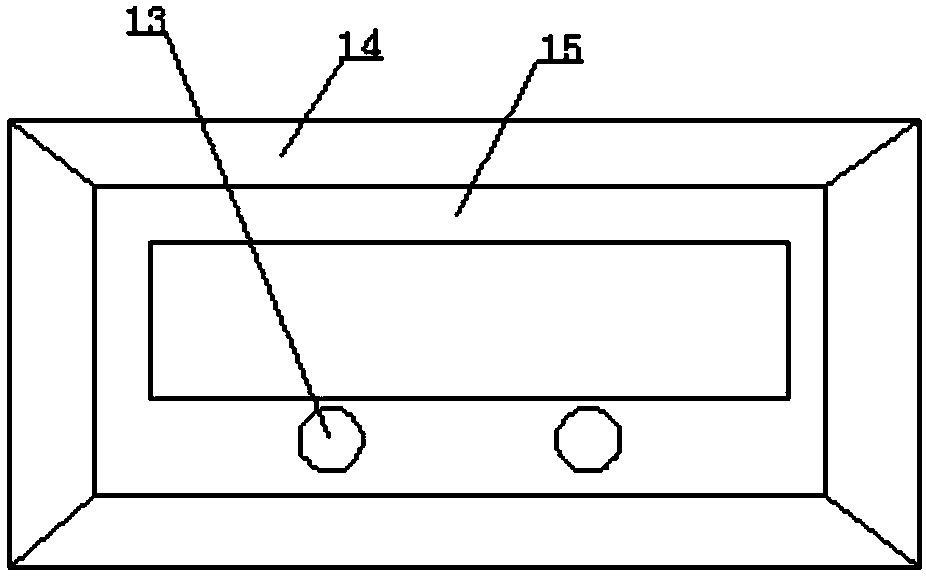

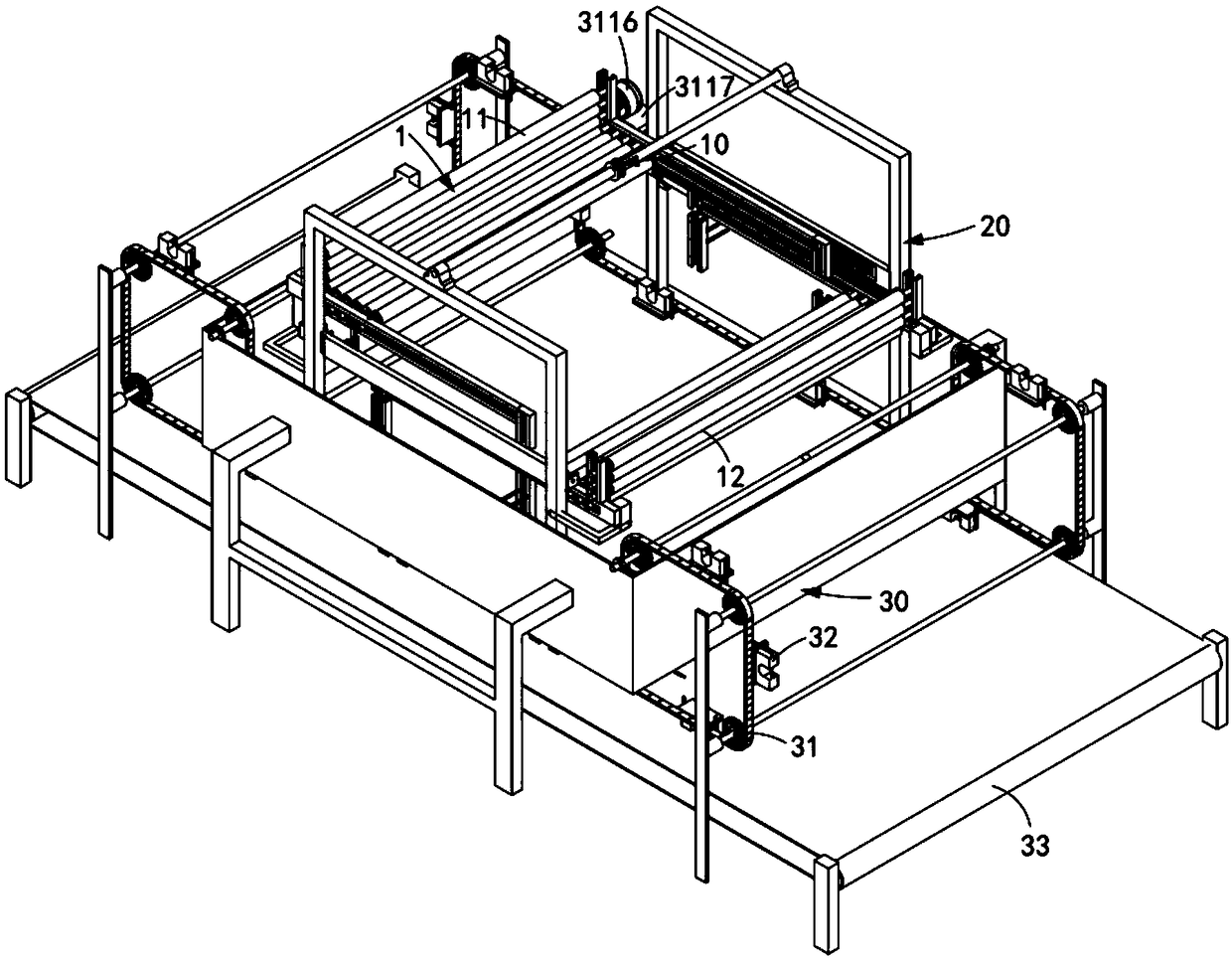

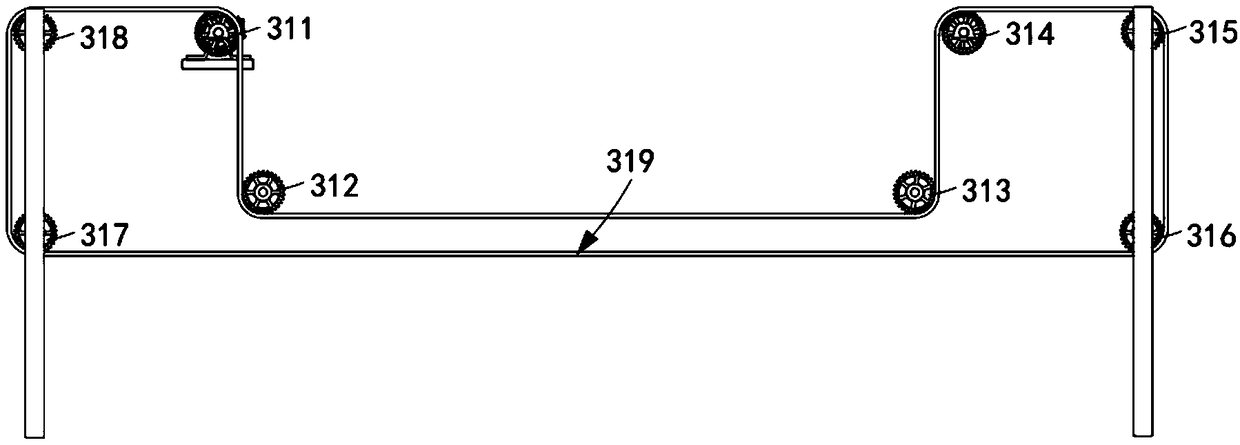

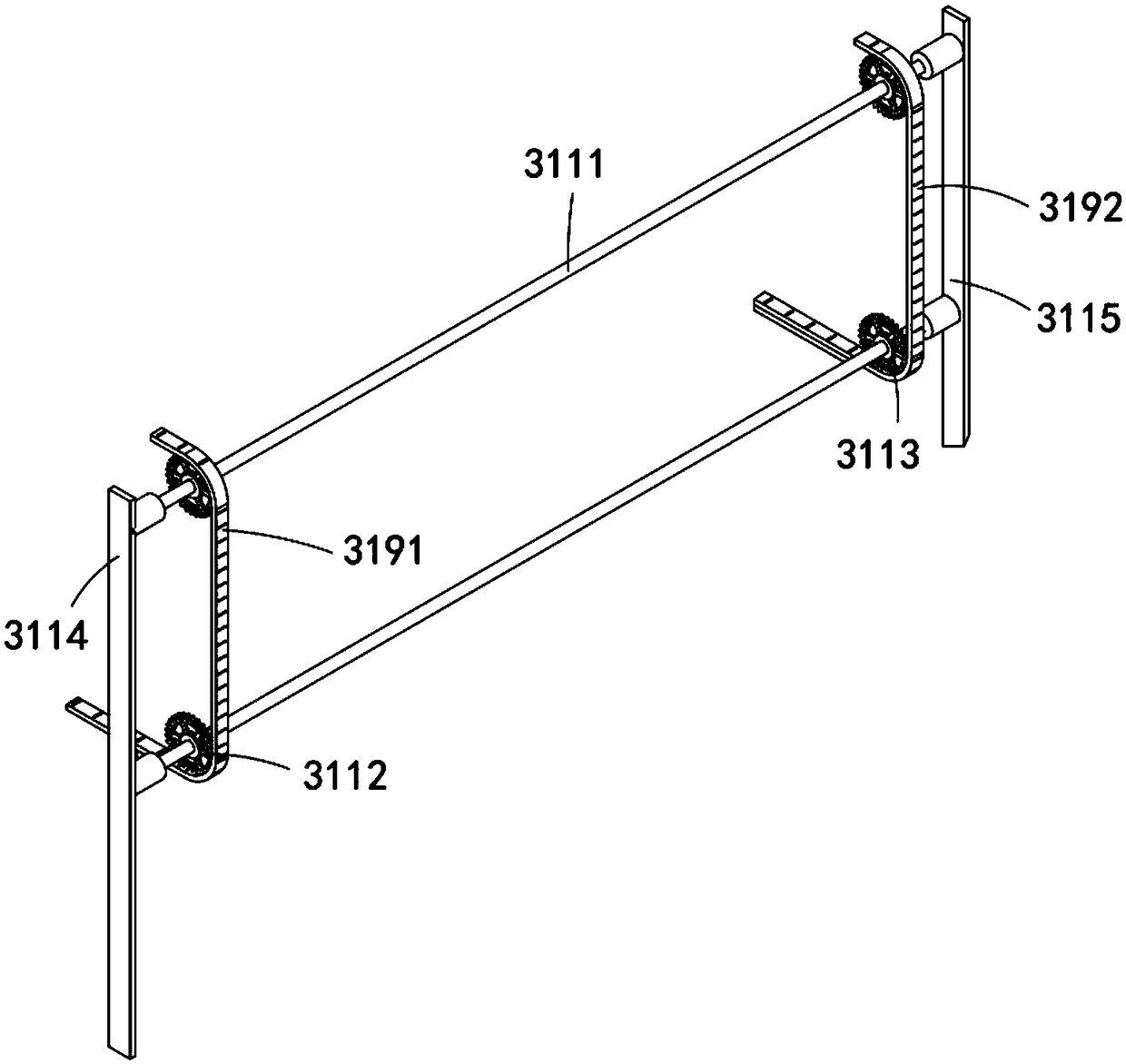

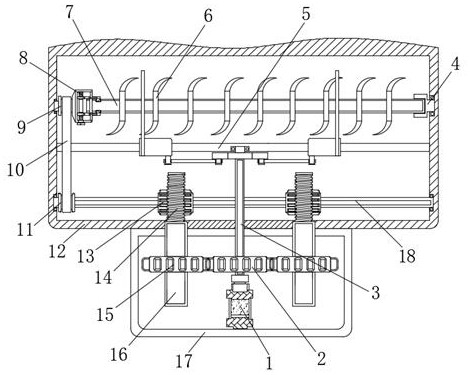

Full-automatic dye weighing and dissolving equipment

PendingCN107059303AVersatileHigh degree of automationTextile treatment machine arrangementsManipulatorEngineering

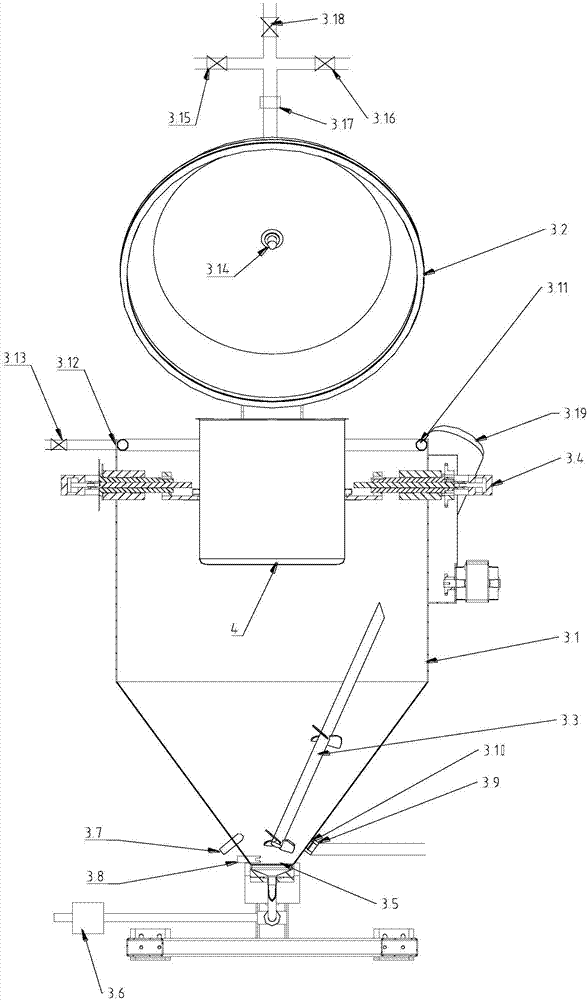

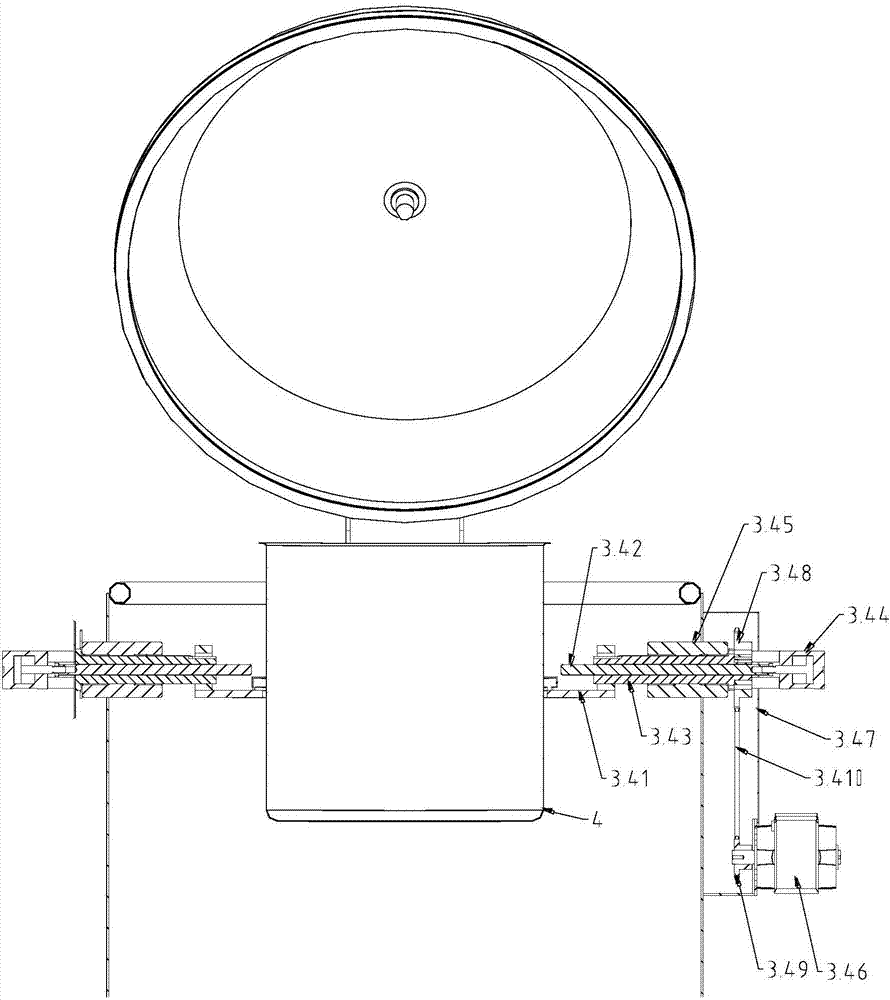

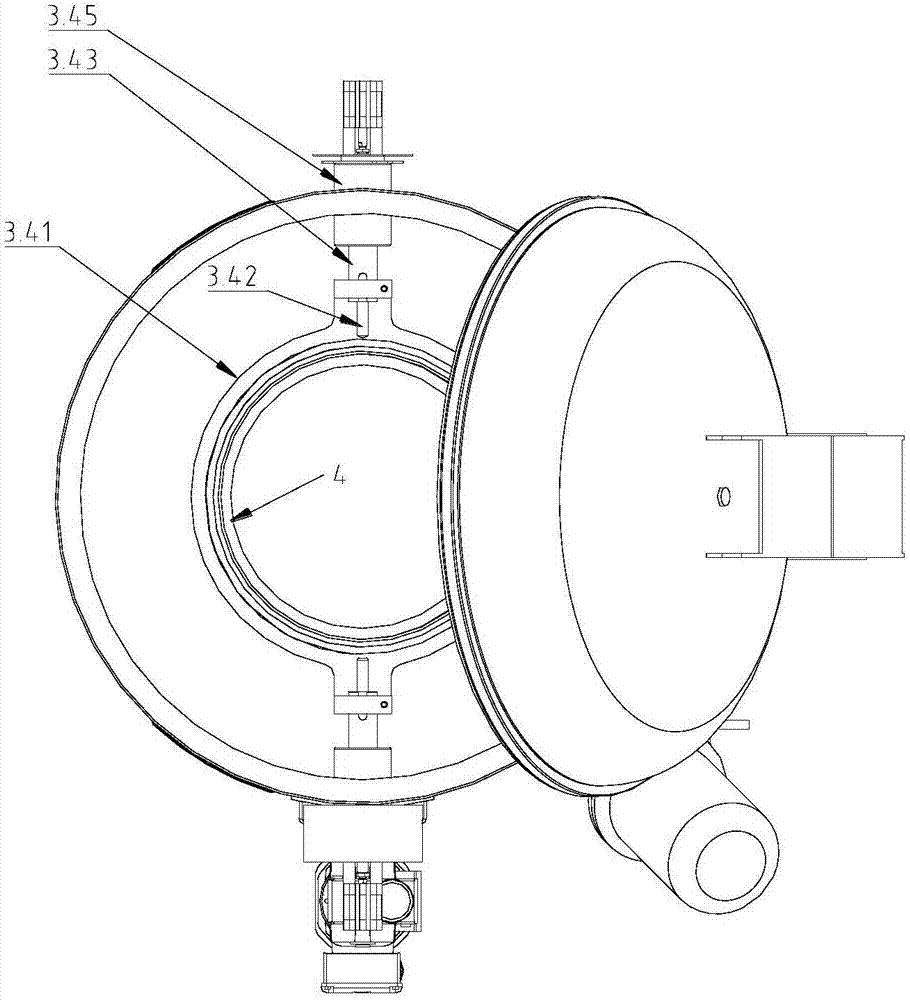

The invention discloses full-automatic dye weighing and dissolving equipment. The full-automatic dye weighing and dissolving equipment comprises a dye weighing system, an automatic grabbing stereoscopic storehouse, a dye dissolving device and a special dye barrel, wherein a discharge platform of the automatic powdery dye weighing system is connected with a feed platform of the automatic grabbing stereoscopic storehouse, and the dye dissolving device is arranged at one side of the automatic grabbing stereoscopic storehouse; the automatic grabbing stereoscopic storehouse comprises a stereoscopic frame used for placing a dye barrel, a triaxial moving platform and a mechanical hand used for grabbing the dye barrel, the mechanical hand is installed on the triaxial moving platform to achieve motion along the X,Y and Z space, and therefore the mechanical hand can grab and conveying the dye barrel at any position of the stereoscopic frame; the dye dissolving device comprises a dye dissolving tank, a tank cover and a clamping and turnover mechanism. The dye weighing system, the automatic grabbing stereoscopic storehouse and the dye dissolving device are organically combined, and the full-automatic dye weighing and dissolving equipment integrates dye weighing, dissolving and conveying functions and is rich in function and high in automation degree.

Owner:杭州三拓科技有限公司

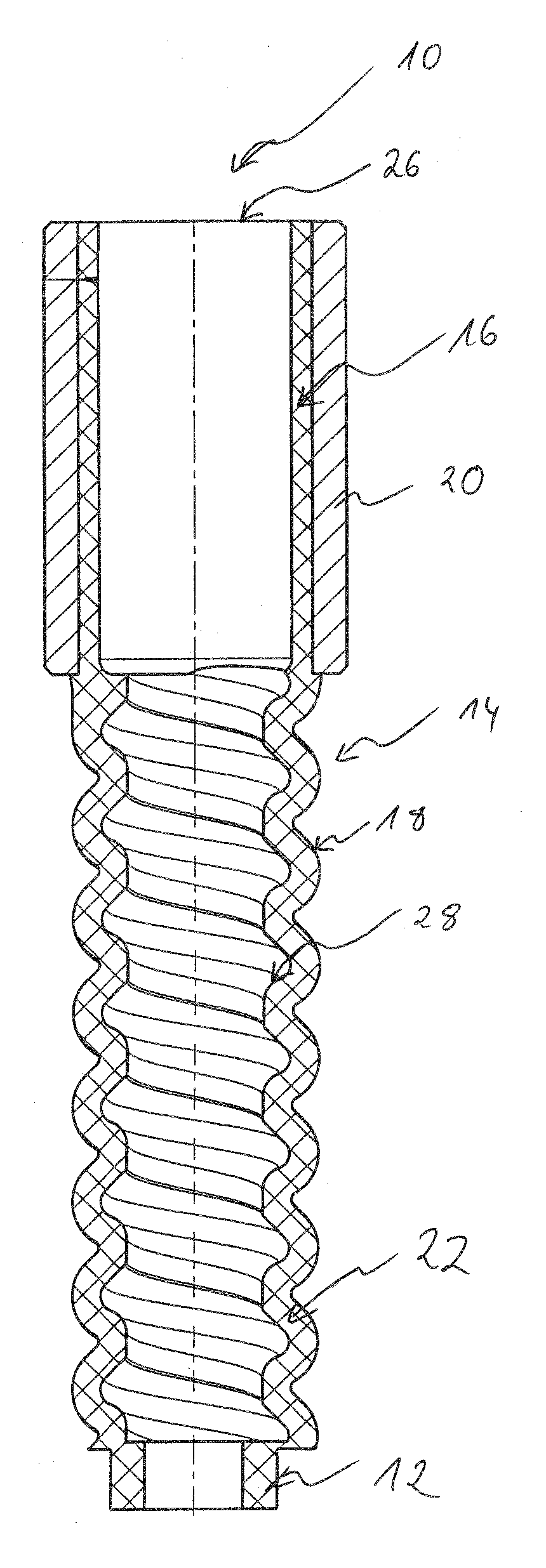

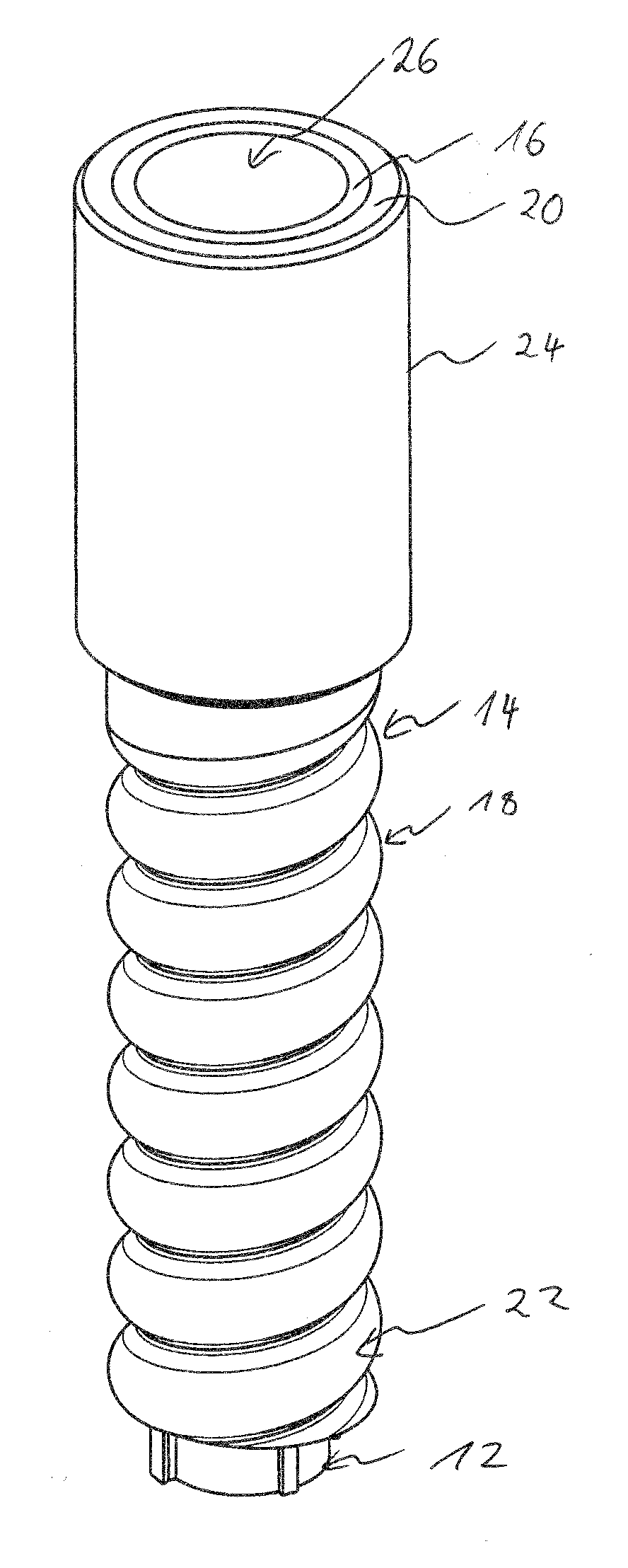

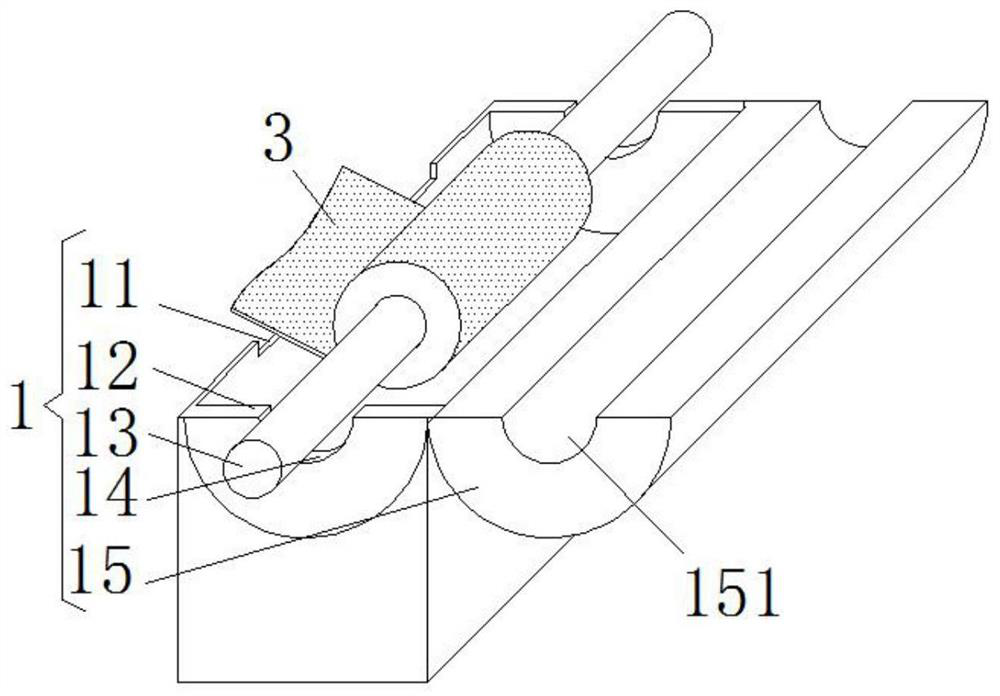

Screw dowel for fastening rails

InactiveCN103314157AExtended service lifeReduce crackingRail fastenersDowelsClassical mechanicsEngineering

Screw dowel for concreting into a railway sleeper or ballastless track and frictionally connecting to a sleeper screw, comprising a threaded portion (14) with external thread flights (18) arranged on the outside of the screw dowel (10) and with internal thread flights (19) arranged on the inside of the screw dowel; and an upper subportion (16) without external thread that is situated close to the dowel opening (26) in the installed state; the screw dowel comprises two constituent parts made of different materials, namely a basic body made of plastic and a cylindrical ring (20) made of a steel material and mounted with a form fit and / or force fit.

Owner:福斯洛工厂有限责任公司

Aluminum oxide recycling and material jam treatment method of electrolytic aluminum flue gas purification system

The invention relates to an aluminum oxide recycling and material jam treatment method of an electrolytic aluminum flue gas purification system. The possible material jam and leakage problems as well as the environmental factors of the electrolytic aluminum flue gas purification system are fully considered; negative-pressure dust collection is adopted to recycle aluminum oxide, the aluminum oxide is delivered into a cage-shaped material separation device arranged in the flue of the electrolytic flue gas purification system; the negative pressure of the flue of the electrolytic flue gas purification system performs winnowing separation on the material which is thrown from top to bottom; and the aluminum oxide and small particles of aluminum oxide are separated from the flue, then enter the electrolytic flue gas purification system and is recycled by a deduster before entering a production cycle. The method has the following advantages: the process flow is short, on-site recycling and on-site separation are realized, the recycled material is switch to production cycle on site; the power is high, the efficiency is high, the working environment of workers can be greatly improved, and the labor intensity can be reduced; the antimagnetic design is improved, and reliable operation in a strong magnetic field environment can be ensured; and due to the remote control opening and closing design, the labor intensity of the workers is reduced, and the method is safer.

Owner:傅文渊

Shoe manufacturing process

The invention discloses a shoe manufacturing process. The shoe manufacturing process comprises the following steps: (1) molding a sole: preparing the sole in a mold; (2) preparing an upper material: compounding and molding a vamp and a lining through gluing; (3) cutting the upper material: cutting the upper material prepared by the step (2) into an upper matched with the sole; (4) gluing or sewing the upper prepared by the step (3) onto the sole; (5) carrying out paint spraying and waxing treatment on the vamp, and naturally airing; and (6) correcting a shoe edge. By setting a shoe edge correction step, burrs and gluing at the shoe edge of a prepared shoe are treated by adopting a correction tool and the problems of the burrs and the gluing of the shoe edge of the finished-product shoe are avoided.

Owner:CHENGDU LIXIN SCI & TECH

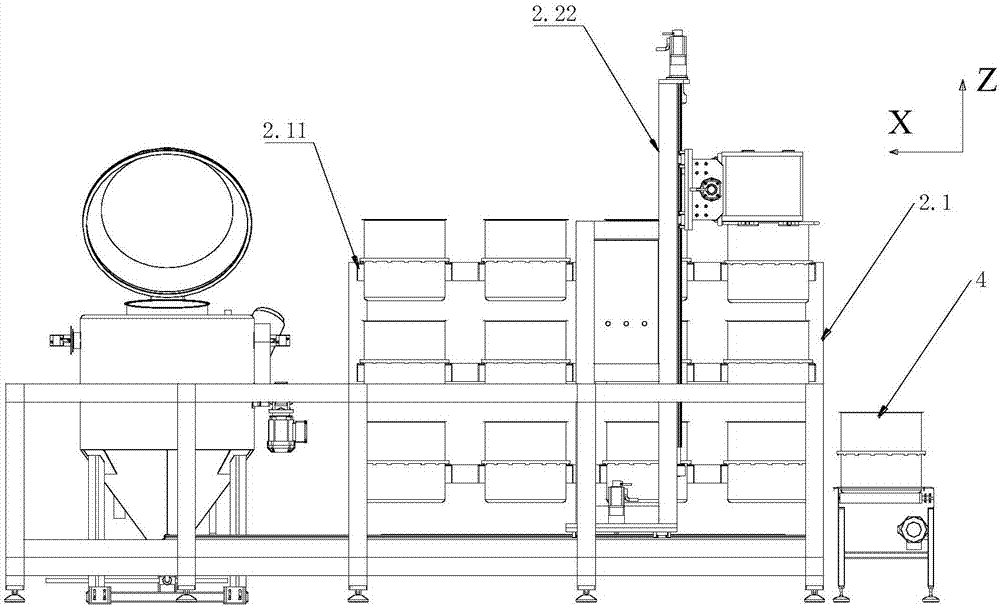

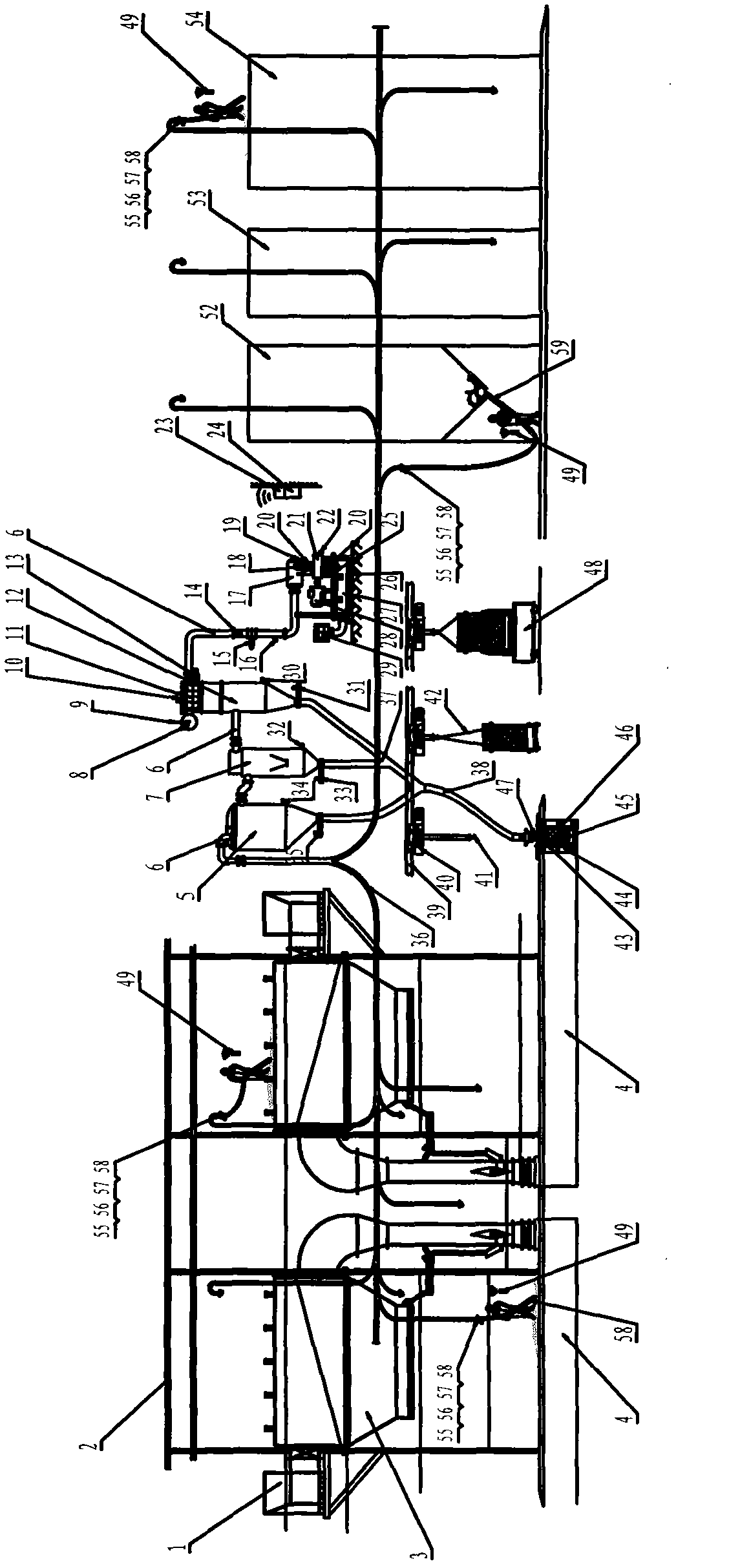

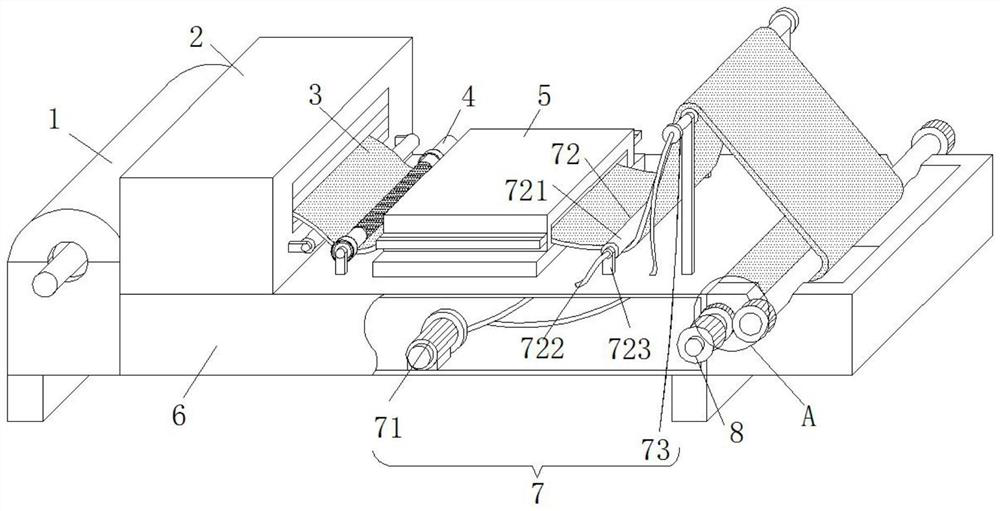

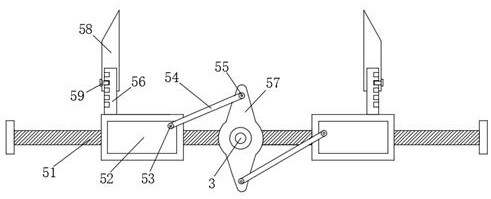

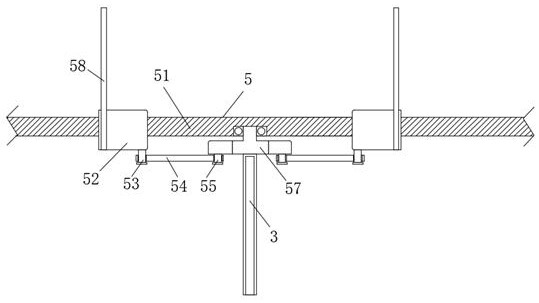

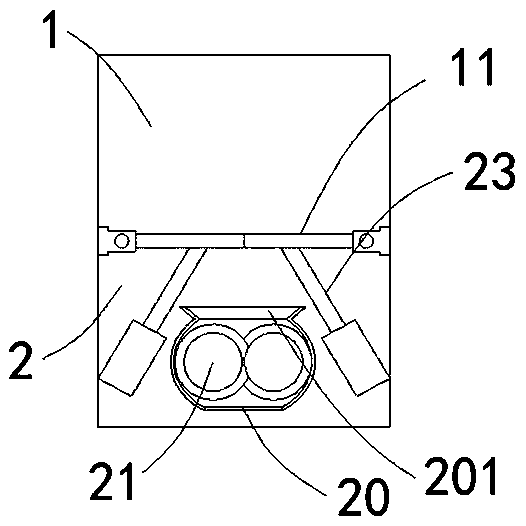

Dye dissolving and adding device

PendingCN107366115AAvoid stickyImplementation angleTextile treatment containersTextile treatment machine arrangementsThermodynamicsSprayer

The invention discloses a dye dissolving and adding device. The device comprises a dissolving and adding tank, a tank cover and a clamp turnover mechanism. The tank cover is arranged on an upper opening in the dissolving and adding tank through a pneumatic cover-opening mechanism. The bottom surface of the dissolving and adding tank is of a conical structure to prevent dye solutions from leaving on the tank bottom. The dye dissolving and adding device is provided with a steam inlet. Water temperature is increased by high-temperature steam such that the device reaches the optimal dissolving and adding temperature. The tank top of the dye dissolving and adding device adopts a sprayer capable of rotating 360 degrees such that the dissolving and adding tank allows water ingress and can be cleaned at a full angle. The sprayer is externally connected with a main water inlet / air pipeline which is connected with a cold water inlet branch, a cold water inlet branch and a high-pressure air inlet branch. The 360-degree rotary sprayer allows water and air ingress. Therefore, the cleaning and drying functions of the tank are realized. The clamp turnover mechanism of the dye dissolving and adding device matches a special-purpose dye barrel. As a result, the dye barrel freely turns over in the dissolving and adding tank.

Owner:杭州三拓科技有限公司

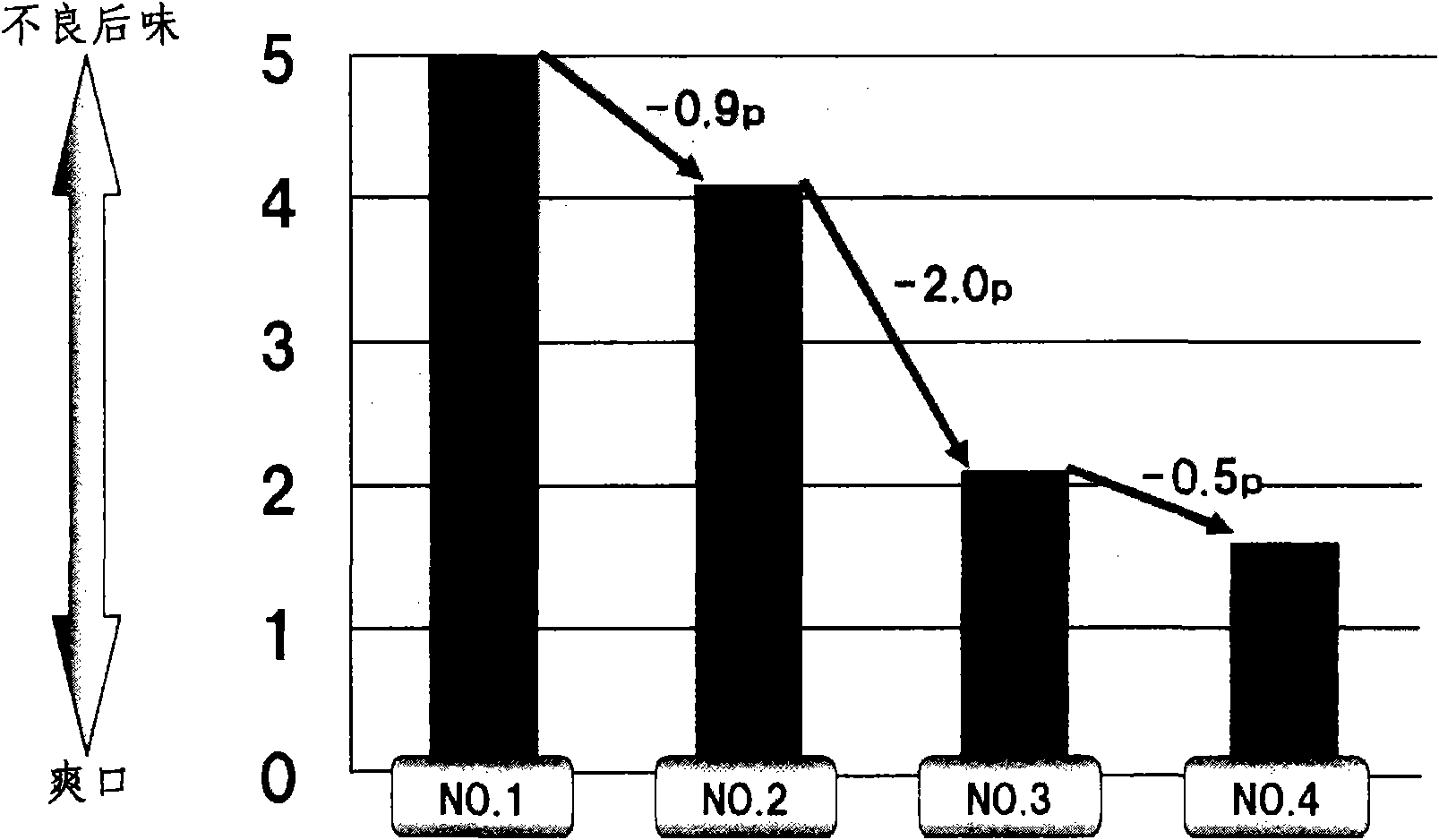

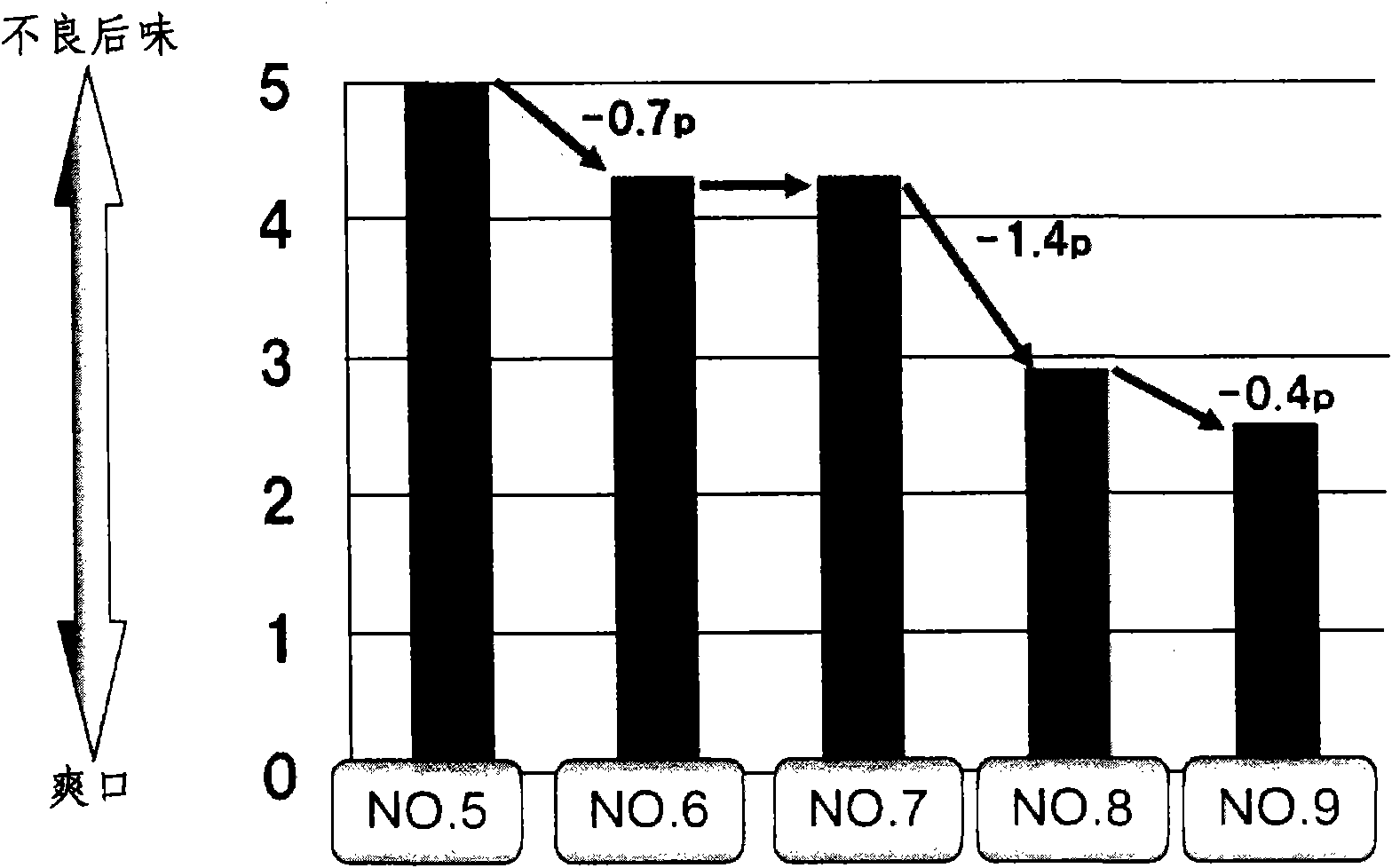

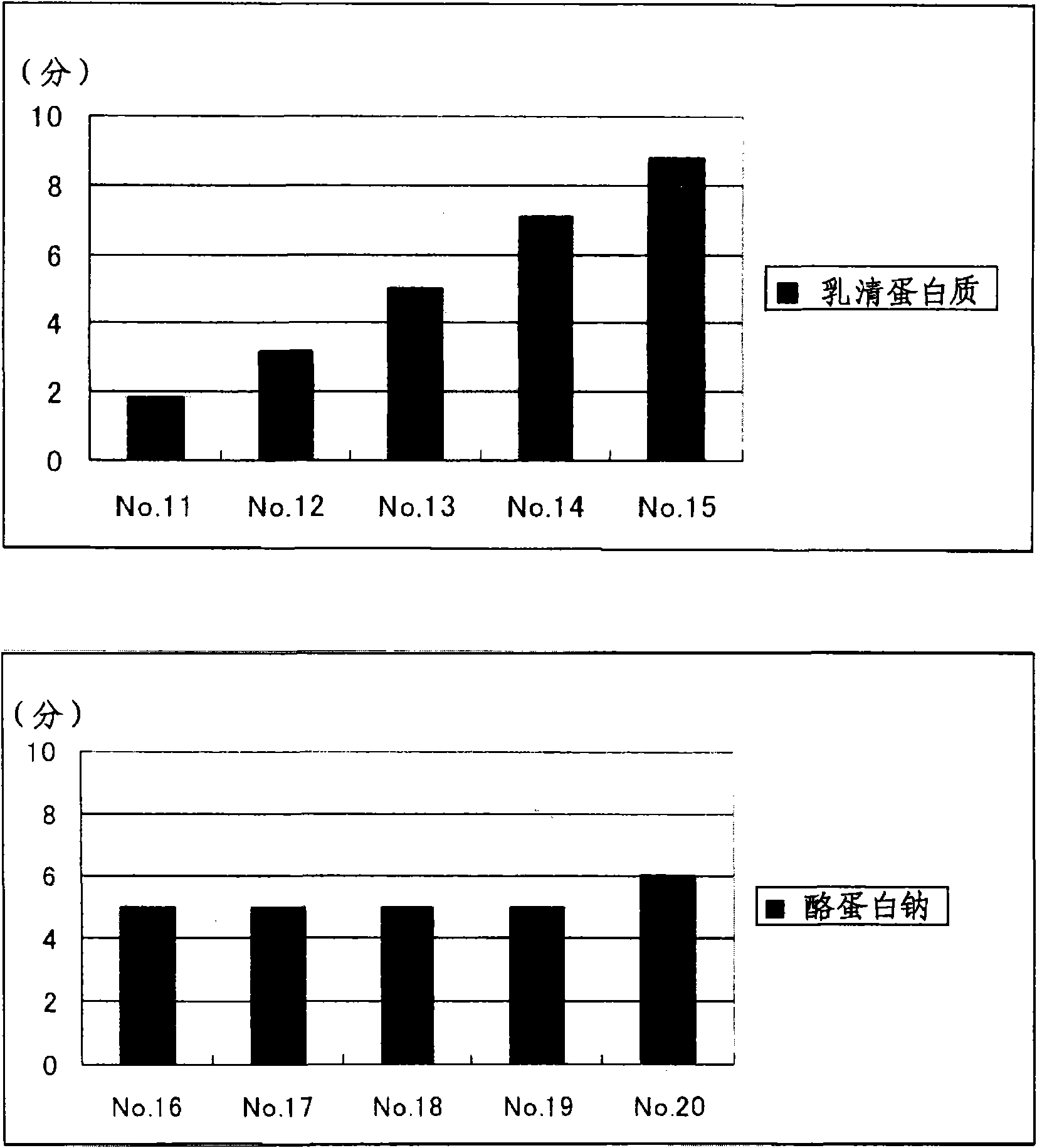

Milk-containing drink and milk composition having reduced milk serum protein content

InactiveCN101664062AReduce contentAdd flavorMilk preparationCoffee extractionBiotechnologyMilk Serum

Provided is a novel means of preventing the characteristic post-pasteurization sliminess and non-crispy flavor of milk-containing drinks, in particular milk-containing coffee drinks. A milk composition wherein the milk serum protein / milk protein ratio is reduced; and a milk drink wherein the milk serum protein content is reduced.

Owner:SUNTORY HLDG LTD

Method for detecting drying performance change of ink

InactiveCN101620216AChanges in drying performance truly reflectAvoid stickyColor measuring devicesMaterial testing goodsEngineering

The invention relates to a method for detecting the drying performance change of ink, which is characterized by comprising the following steps: a plurality of kinds of ink is placed on a smooth substrate, wherein the variables of the single printing condition of the ink are changed, a plurality of rectangular frames are left on the substrate, printing stocks are padded below the substrate, the ink is placed above the rectangular frames, and a plurality of ink is uniformly scraped into the rectangular frames from top to bottom, the substrate is taken away, and a plurality of ink contrast blocks are left on the printing stocks. The invention has the advantages that firstly, the change condition of the drying performance of the ink along with the change of printing conditions can be predicted, and reference for the adjustment of the ink and the printing conditions is provided; secondly, the drying performance of the ink can be sorted so as to choose the ink with appropriate drying performance and avoid the phenomenon that the ink is pulled up from paper; and thirdly, the method consumes less ink, and detected ink can truly reflect the drying performance change of the ink in the process of printing, therefore, printing work efficiency is improved.

Owner:CHINA BANKNOTE PRINTING & MINTING

Adhesive viscosity detecting apparatus for building wood bonding process

ActiveCN109100302AStrong construction glueShorten detection timeUsing mechanical meansMaterial analysisAdhesiveCoil spring

The invention aims to solve the existing problem of the inconvenience of quickly detecting the viscosity of an adhesive, and disclose an adhesive viscosity detecting apparatus for building wood bonding process. The apparatus comprises a first positioning ring, a first rotating ring, a first collar, first mounting frames, first fastening screws, a first rotating shaft, a first rocking handle, a first supporting rod, a spiral spring, a sliding block, a third fastening screw, a guide groove, heating rods, a base, a storage box, second fastening screws, second mounting frames, a second supportingrod, a second positioning ring, a second rotating ring, a second collar, a second rotating shaft, a second rocking handle, and positioning rods. According to the adhesive viscosity detecting apparatusfor the building wood bonding process, various types of wood separately placed can be detected by using the first mounting frames and the second mounting frames, and the woods of different thicknesscan be tightened by the first fastening screws and the second fastening screws; a bonding between the woods is not strengthened during building construction is avoided by detecting the adhesion between various woods, and the requirement is met.

Owner:NANJING INST OF MECHATRONIC TECH

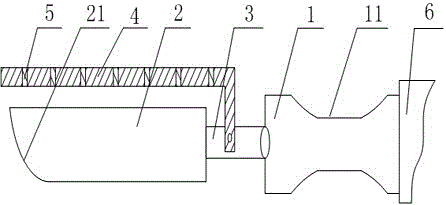

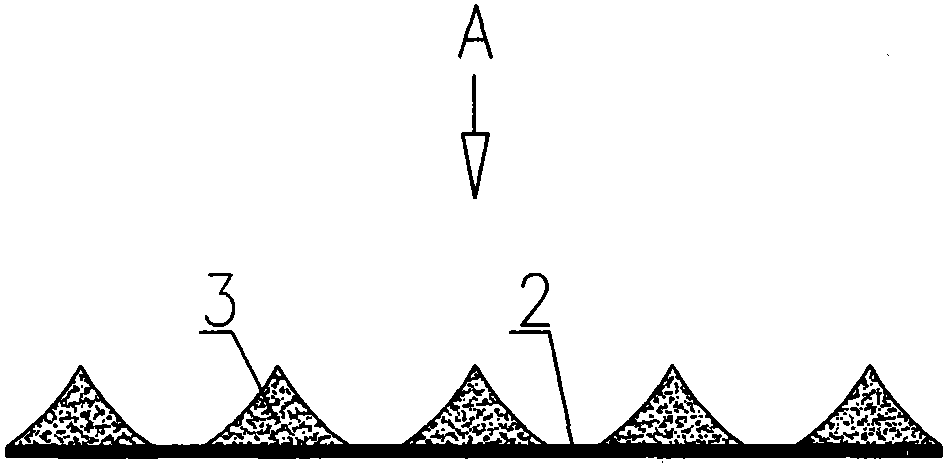

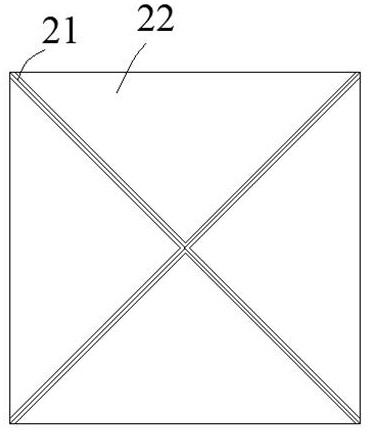

Method for adhering face brick of building

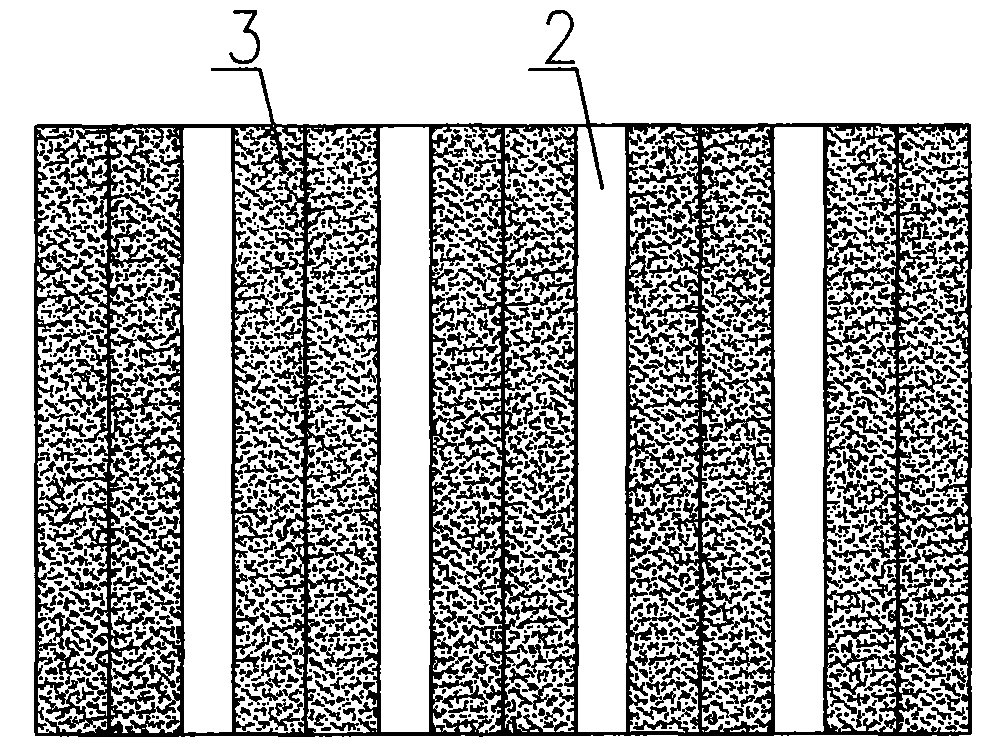

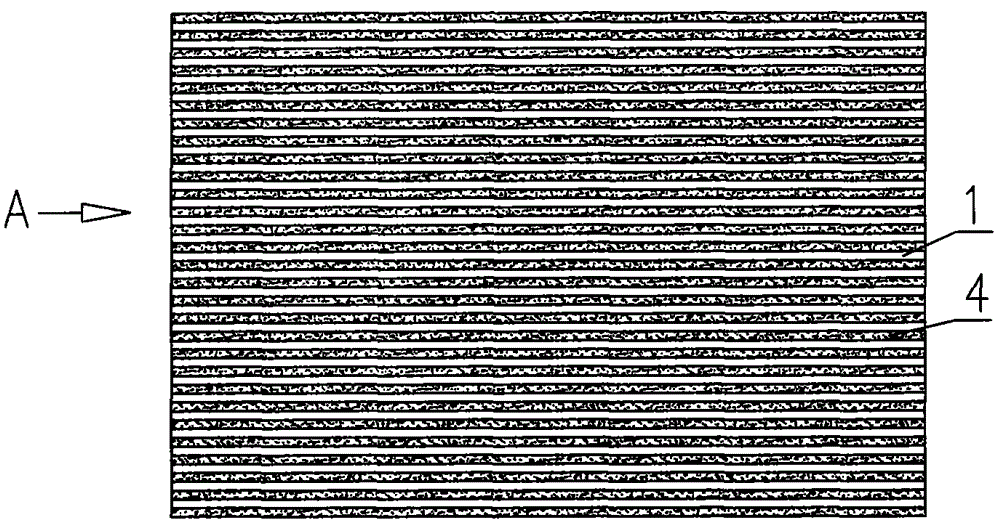

The invention provides a method for adhering wall bricks with relatively large specification and weight or vitreous bricks with extremely low water absorbing rate, and specifically provides a method for adhering a face brick of a building. The method comprises the steps of fully coating prepared adhering materials on a wall base layer (1); pressing the adhering materials on the rear surface of the face brick (2) into furrow shape, wherein each adhering material in the furrow shape is vertical to the ground; transversely combing the adhering materials on the wall base layer through a saw-tooth render to form an adhering material layer (4) of a strip-shaped structure through the adhering materials on the surface of the wall base layer; adhering and pressing the face brick of which the rear surface is provided with the furrow-shaped adhering material on the wall bas layer fully adhered with adhering material, wherein a transverse strip-shaped structural adhering material layer (4) and a vertical similar furrow shaped adhering material layer (3A) are arranged between the wall base layer (1) and the face brick (2). The method has the advantages that the adhering strength is improved, and the construction is convenient.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Cleaning device, process cartridge, and image forming apparatus

ActiveCN101339396ANo reduction in contact widthIncrease line pressureElectrographic process apparatusBand shapeImage transfer

A low linear pressure and high surface pressure cleaning structure by specifying the material, shape and support structure of a cleaning blade in a cleaning device, a process cartridge and an image forming apparatus is obtained. A tip portion of an elastic cleaning blade 38 supported by a support member 37 which is a so-called blade holder is pressed against a drum-shaped or belt-like image bearing member 10 to remove a residual toner remaining on the image bearing member after image transfer. In such a cleaning device 16, an angle [theta] forming a front edge portion 36 of the cleaning blade is made obtuse and the front edge portion is pressed against the image bearing member at a surface pressure of 2.0g / mm<2> or larger. The surface pressure is a value given by dividing total load applied on the cleaning blade by a contact area of the cleaning blade to the image bearing member.

Owner:RICOH KK

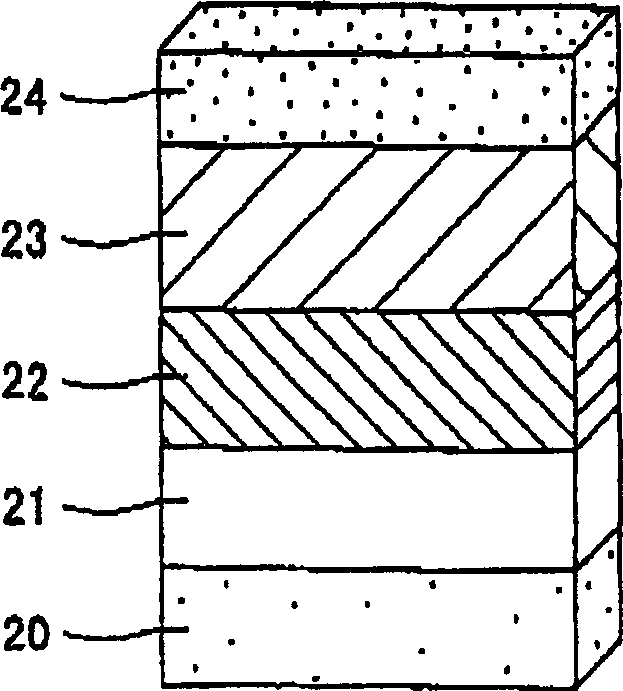

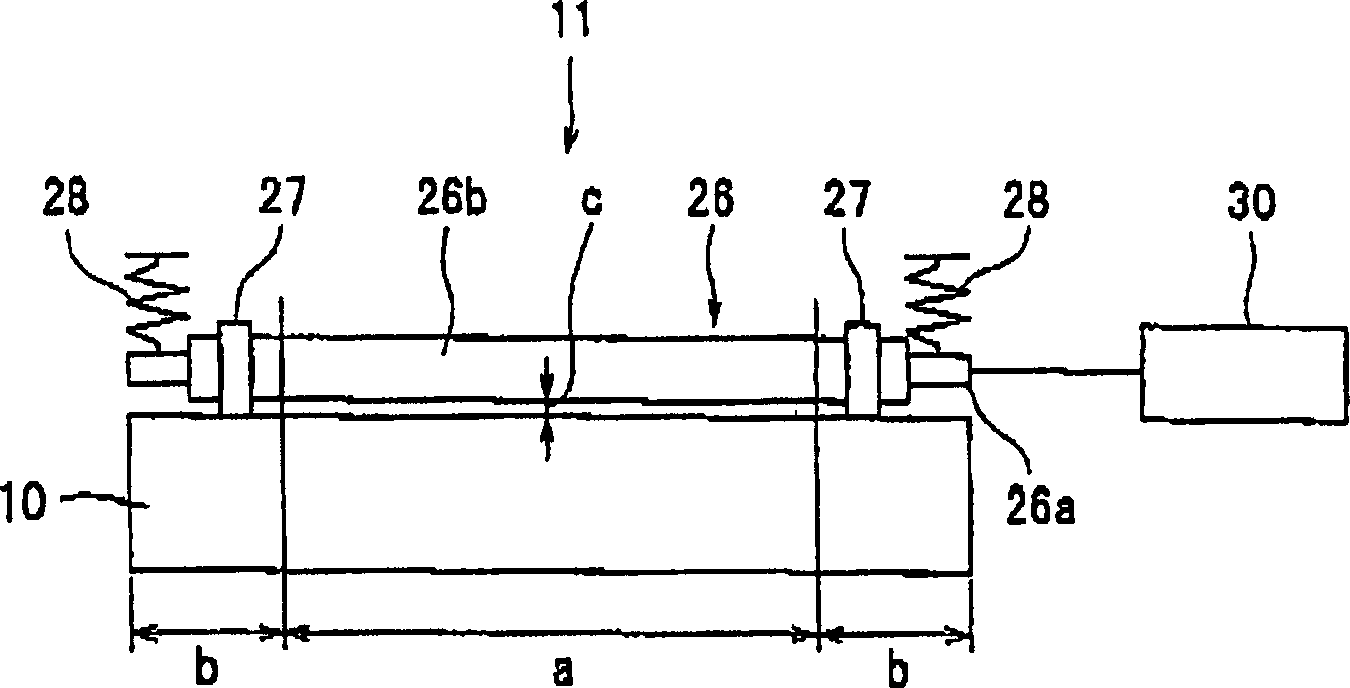

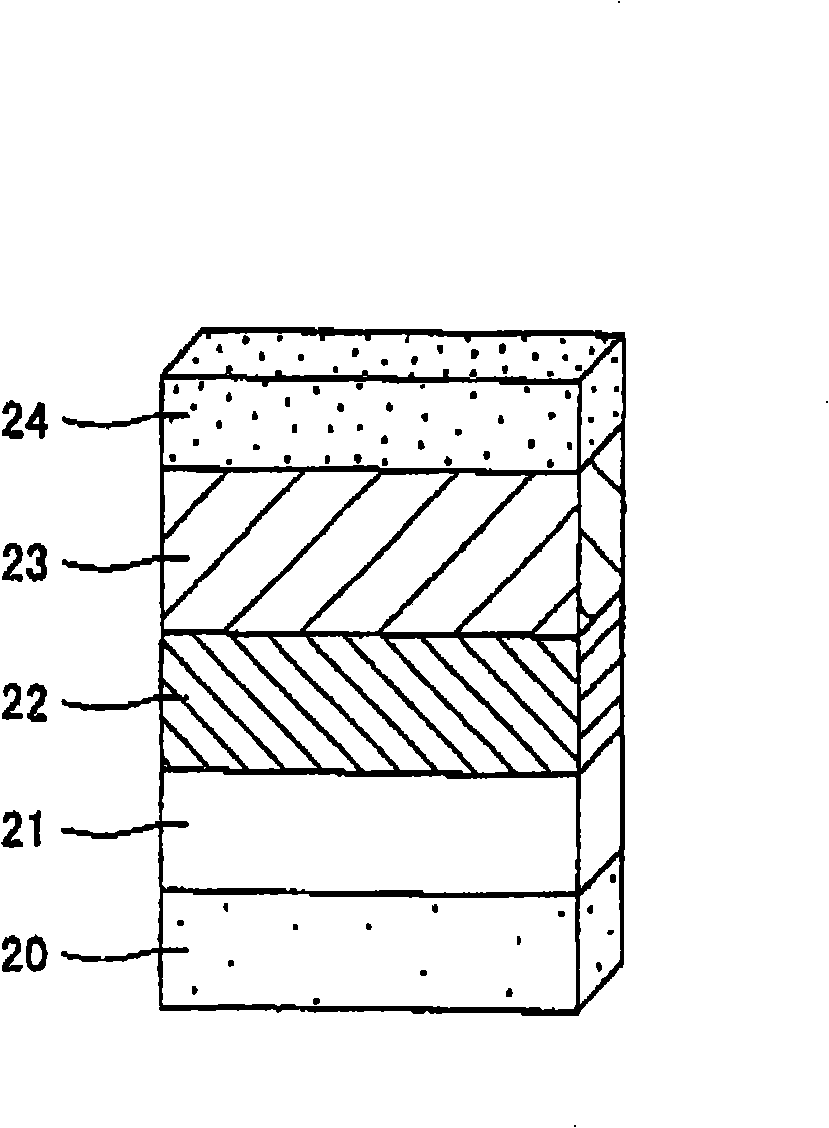

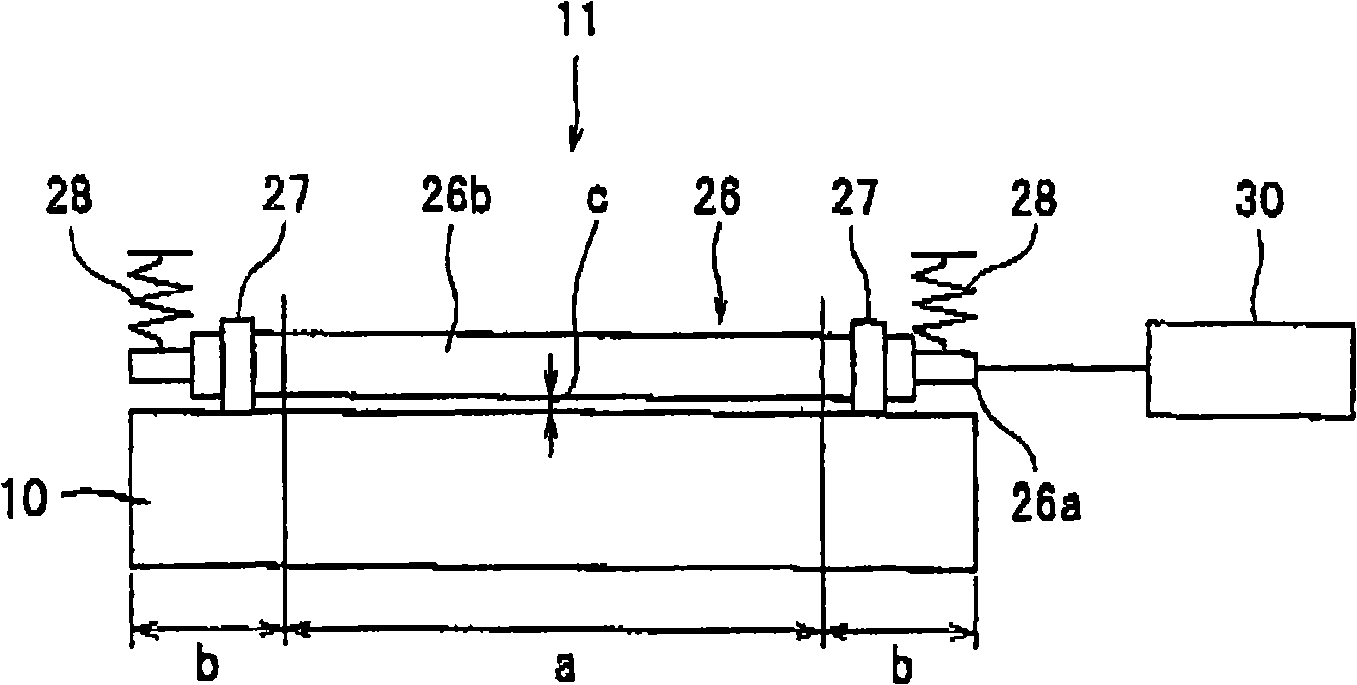

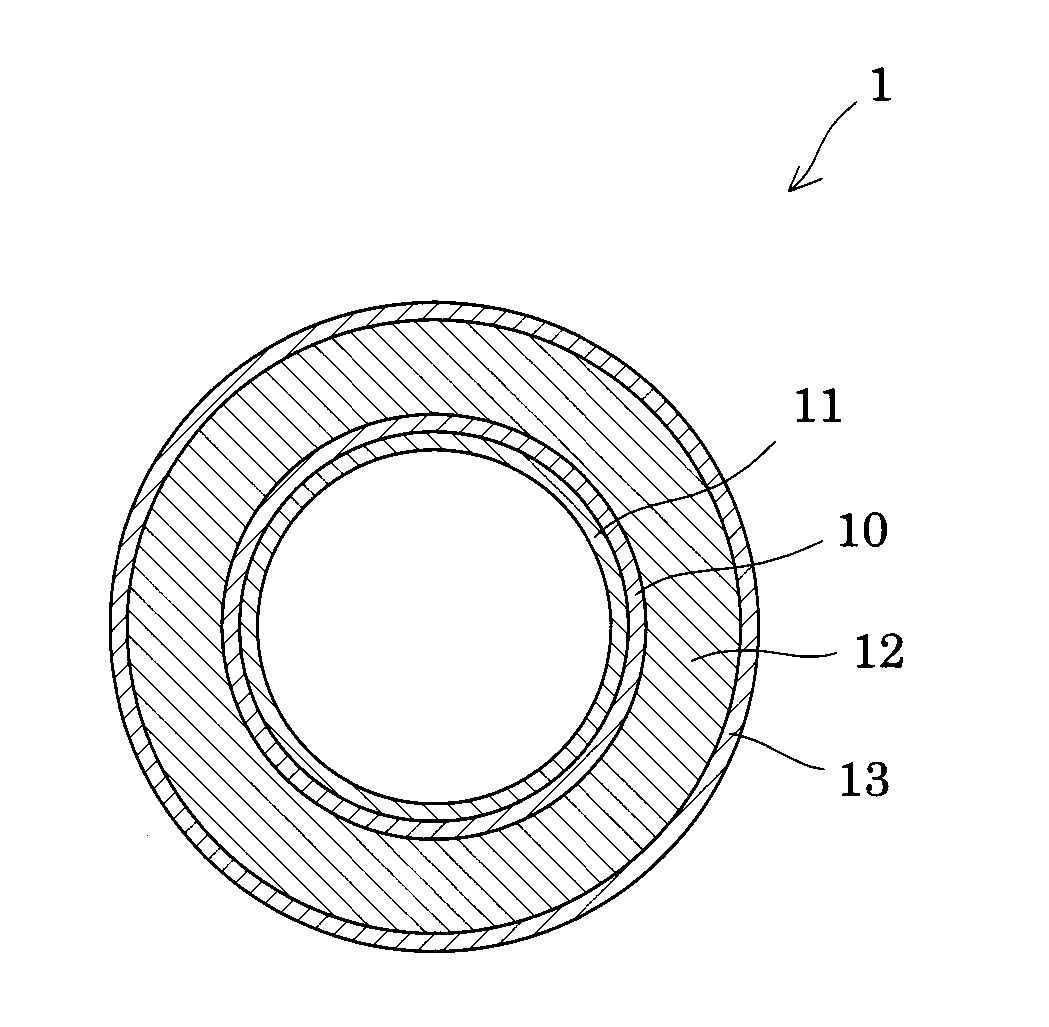

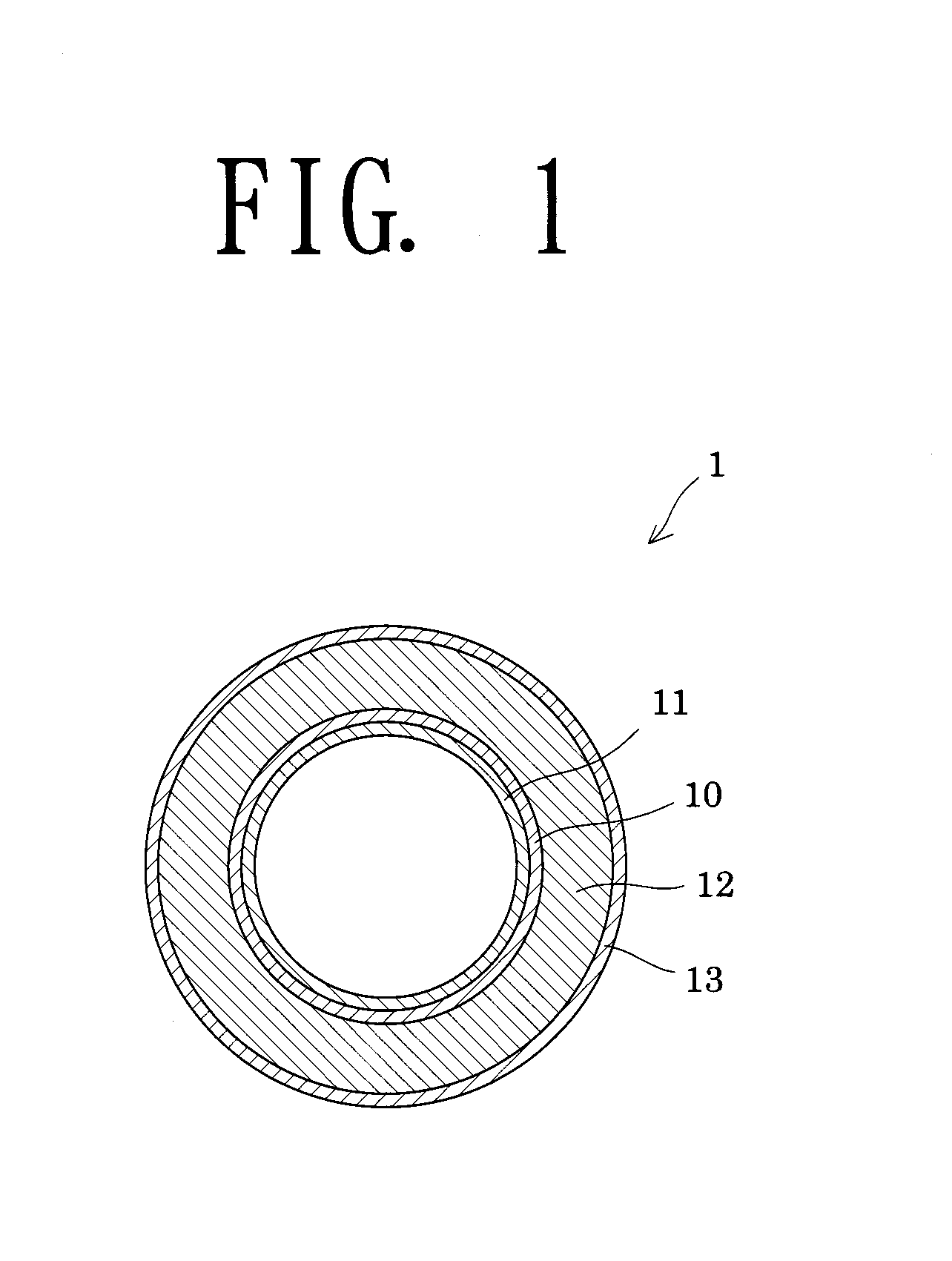

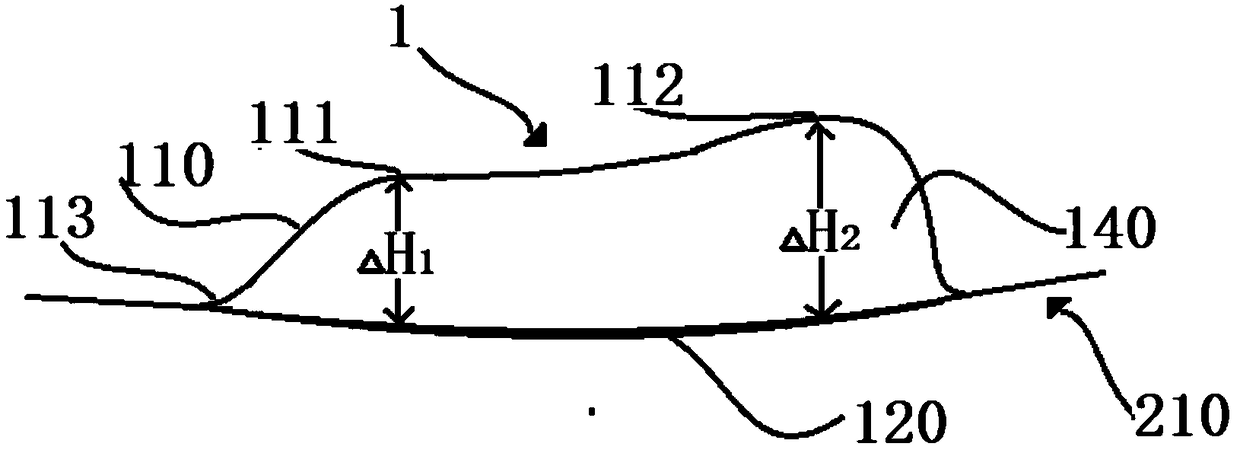

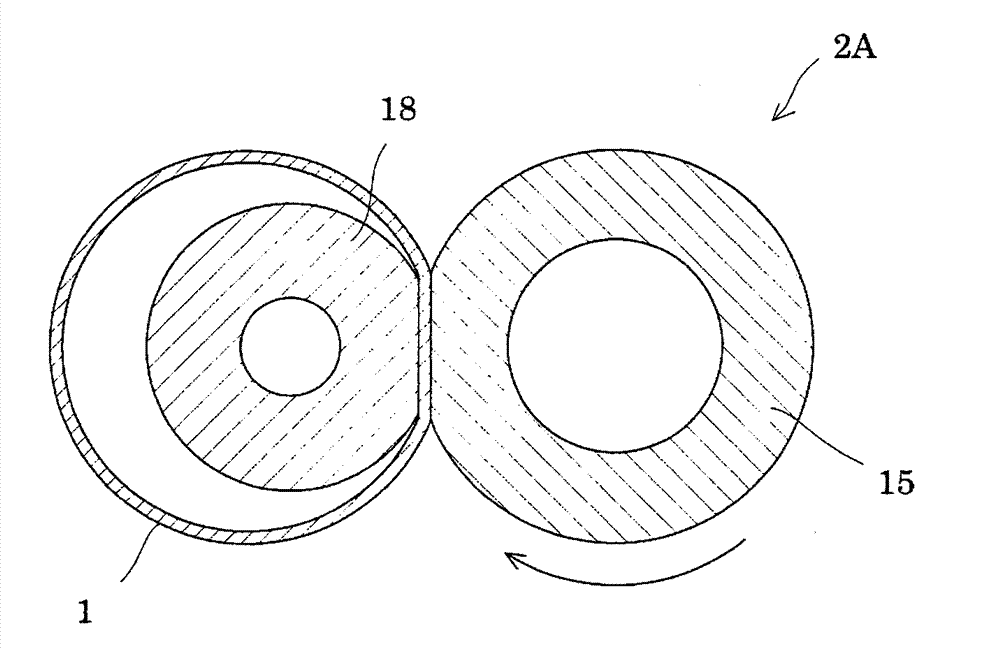

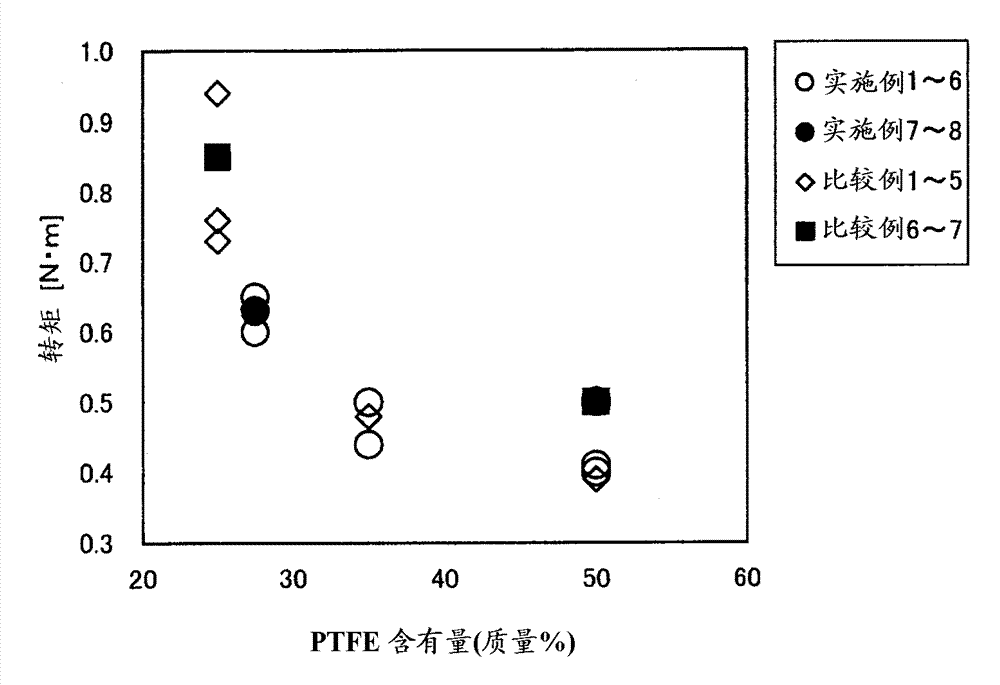

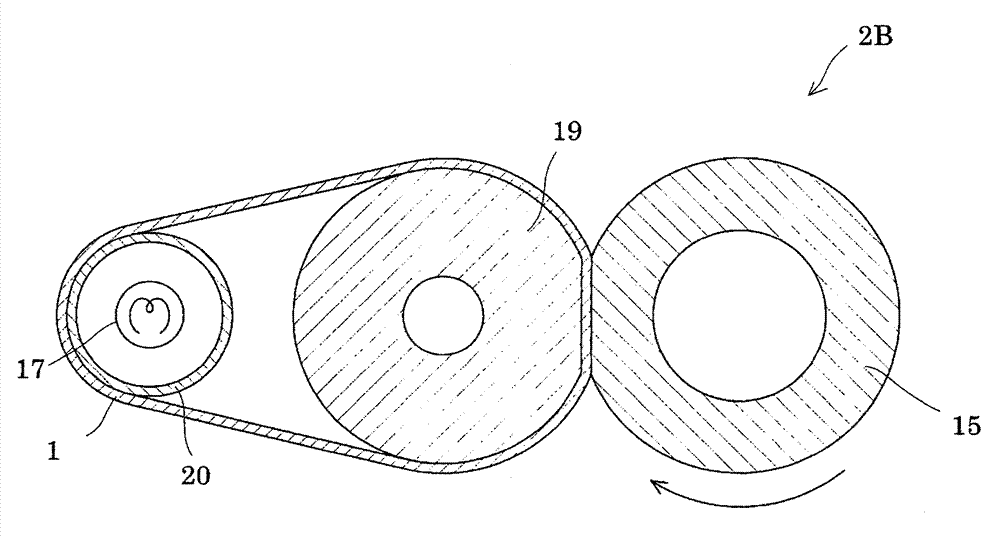

Fixation member and fixation apparatus having the fixation member

InactiveUS20140086652A1Easy to wearReduce driving torqueElectrographic process apparatusPolyamide-imideSurface roughness

The present invention provides a fixation member which exhibits enhanced wear resistance and sliding property between the peripheral surface of the fixation member and a pressure member, which can reduce driving torque at a fixation unit, and which does not cause stick slipping even in a high-load operational mode, and a fixation apparatus having the fixation member. The fixation member employed in a fixation unit of the fixation apparatus has a metallic substrate having at least one layer of an electrocast seamless belt, and a slide layer disposed on the inner peripheral surface of the metallic substrate, wherein the slide layer is formed of at least one species of the group consisting of a polyamide-imide resin and a polyimide resin, and a fluororesin; the slide layer has a fluororesin content of 27.5 mass % to 50 mass %; and the slide layer has a surface roughness Ra of 0.4 μm or less.

Owner:SYNZTEC +2

Continuous automatic output vermicelli cooking device

The invention relates to a continuous automatic output vermicelli cooking device. The device comprises a sheet jelly conveying belt which is erected at the top of a machine frame, a cooking box is arranged at the bottom of the sheet jelly conveying belt, the cooking box comprises a material holding mechanism, a driving mechanism and a transmission mechanism, the material holding mechanism is fixedly arranged below the sheet jelly conveying belt and is arranged on the machine frame, the material holding mechanism is used for supporting the sheet jelly which is vertically output by the sheet jelly conveying belt and outputting the sheet jelly in an S shape, the material holding mechanism comprises a first material holding assembly and a second material holding assembly, the first holding assembly and the second holding assembly are arranged in parallel in a staggered mode; the driving mechanism are symmetrically arranged below the sheet jelly conveying belt and is arranged between the first holding assembly and the second holding assembly, the transmission mechanism is arranged below the material holding mechanism and is arranged in a circuitous manner along the length direction of the cooking box, the transmission mechanism comprises a transmission component, a material receiving component and a discharging component. According to the continuous automatic output vermicelli cooking device, the technical problem that the sheet jelly cannot be transmitted out in time is solved.

Owner:赵长春

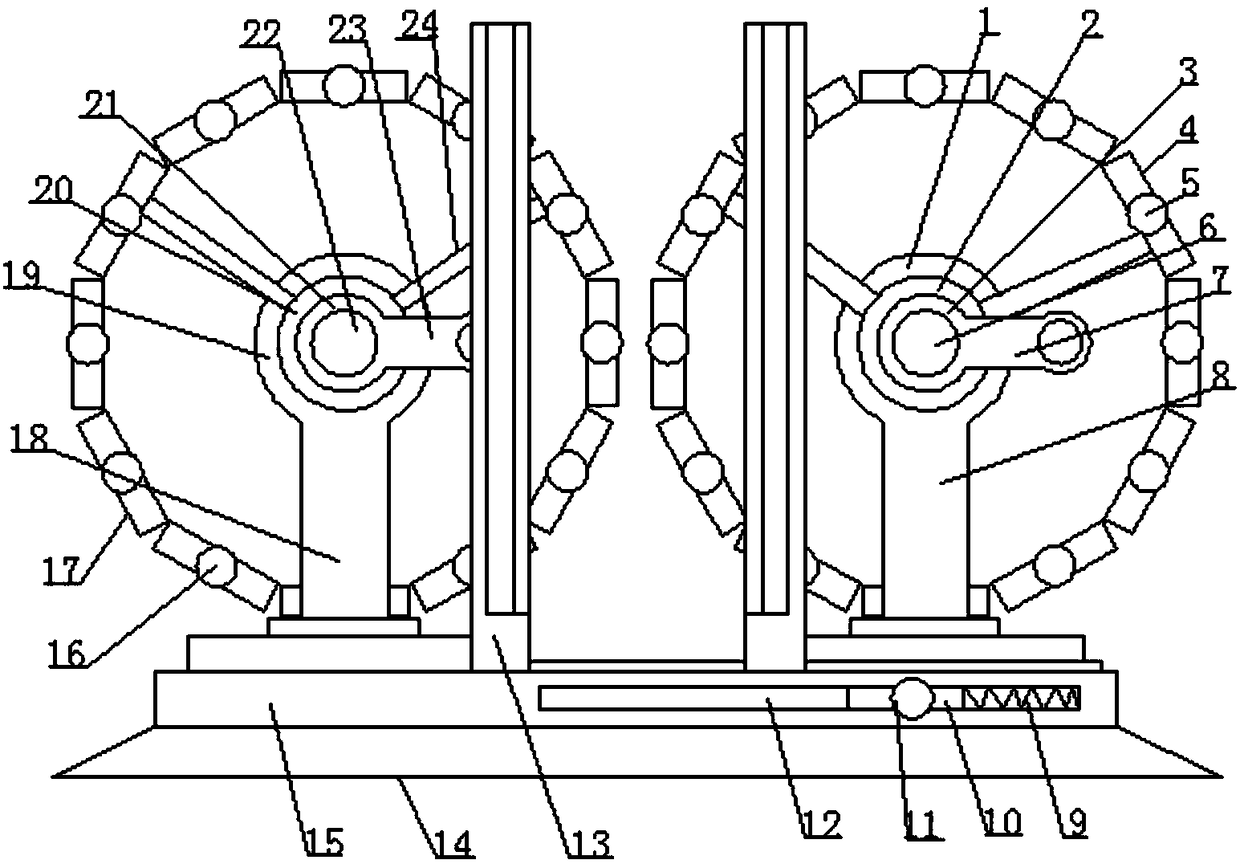

A double-sided printing device for plastic film

ActiveCN109532220BPrevent fallingEasy accessRotary pressesPrinting press partsEngineeringPlastic film

The invention relates to the technical field of plastic film printing, in particular to a plastic film double-sided printing device, including an unwinding mechanism, a pre-printing room, a plastic film, a pressure roller, a double-sided printing room, a base, a cooling mechanism and a winding mechanism , the end of the base is fixed with an unwinding mechanism, and the plastic film in rolls is placed inside the unwinding mechanism; the plastic film passes through the pre-printing chamber, and the end of the pre-printing chamber Two parallel press rollers are fixed; the top of the base fixes the double-sided printing chamber, and the inside of the double-sided printing chamber runs through the plastic film; the plastic film passes through the cooling mechanism, and the The end of the plastic film is connected to the winding mechanism. The invention has flexible operation, can realize cooling of the plastic film after printing, avoids smudging and sticking, and improves printing quality.

Owner:广东恒利新包装材料有限公司

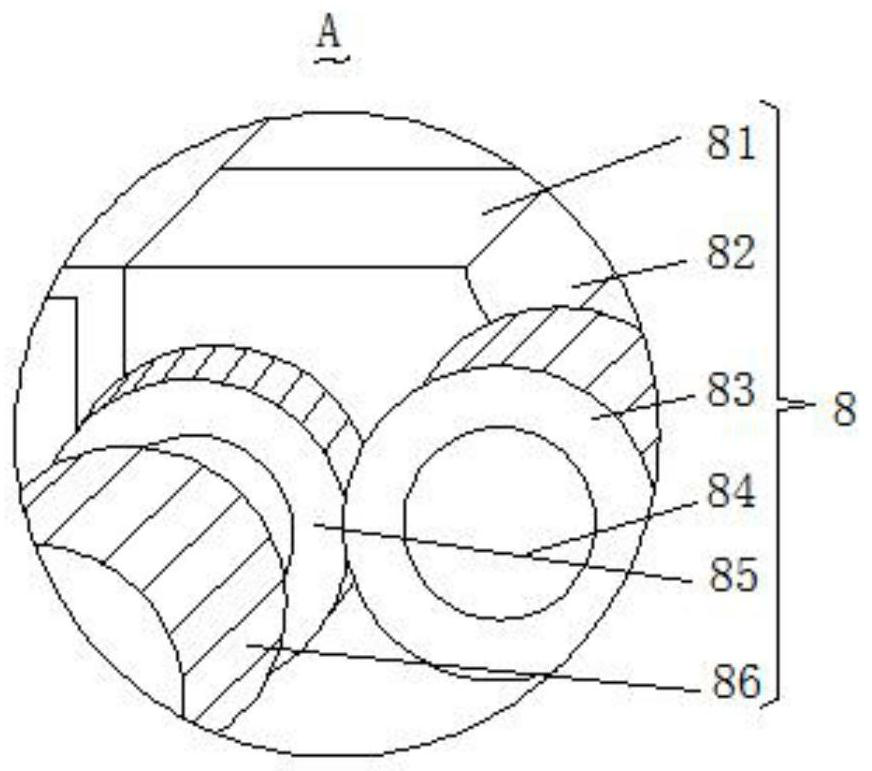

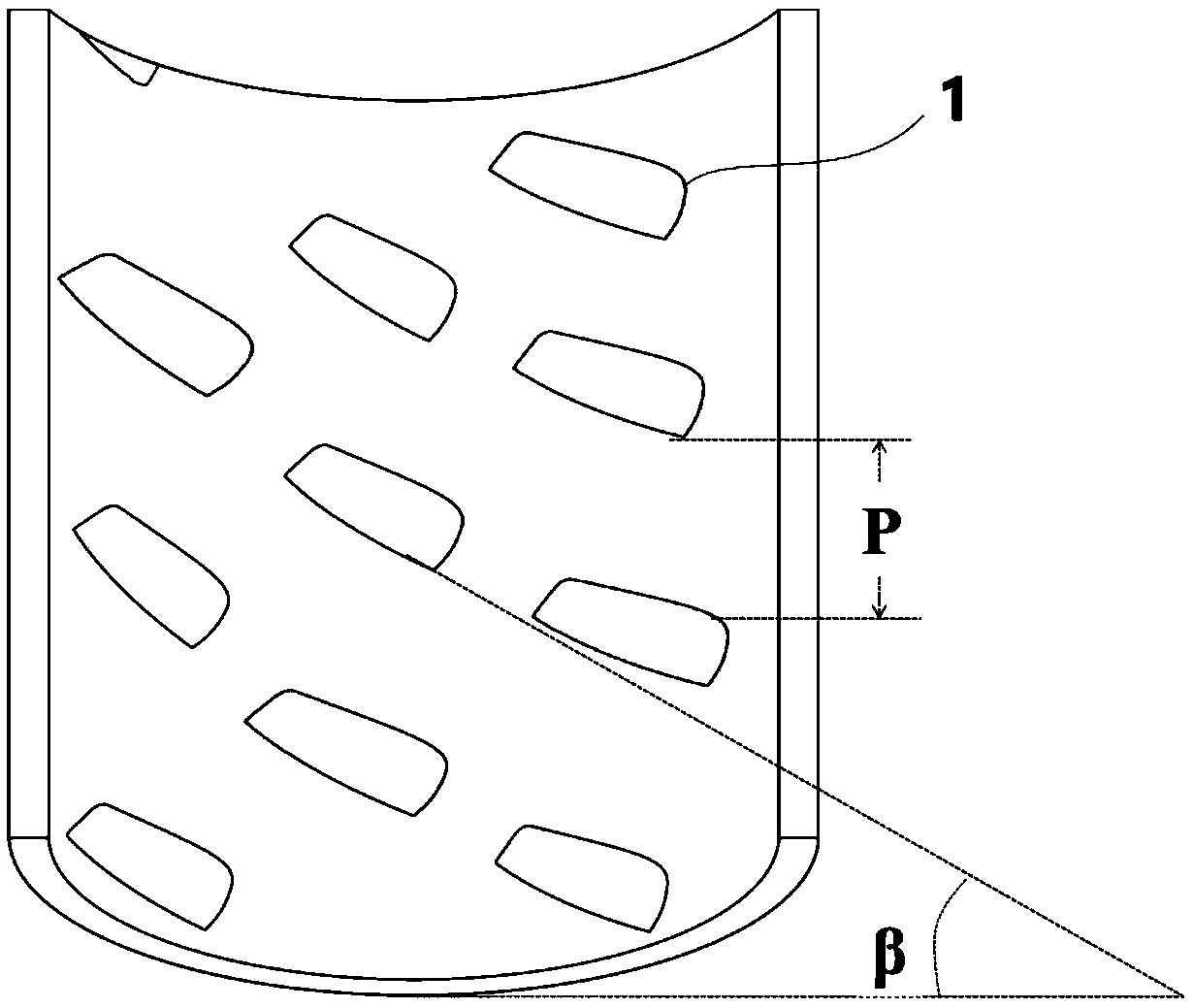

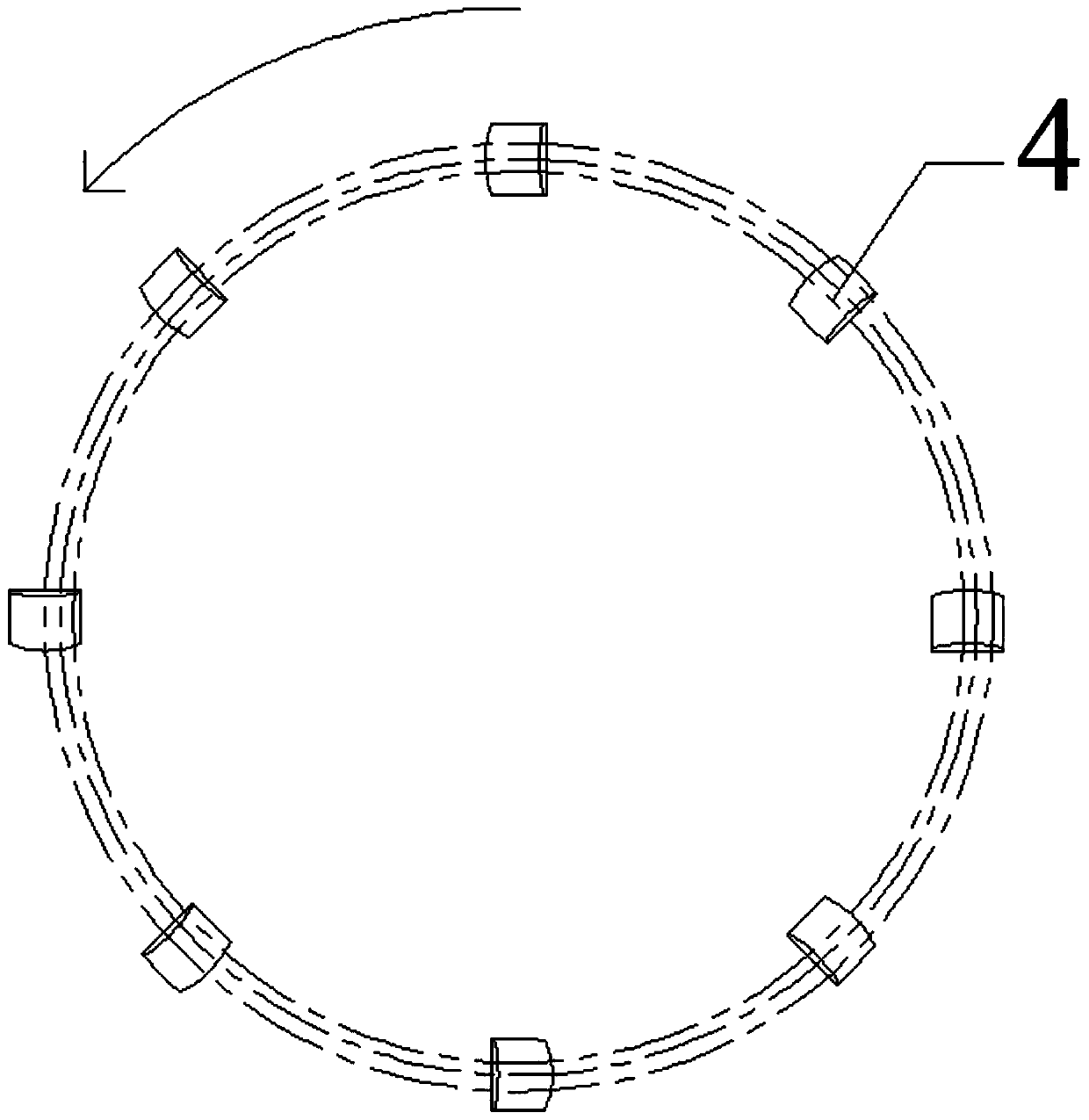

Buffering rib of rotary drum screen and rotary drum screening machine

The invention discloses buffering ribs of a rotary drum screen and a rotary drum screening machine and belongs to the field of material screening equipment. Each buffering rib comprises a bottom surface and a first side surface, wherein the bottom surface is matched and connected with the inner side wall of a screen mesh; the first side surface is connected with the bottom surface, the first sidesurface is opposite to the feed end of the screen mesh, and a certain included angle is formed between the first side surface and the inner side wall of the screen mesh; the buffering ribs are uniformly distributed on the inner side wall of the screen mesh, and longitudinal extending directions of the buffering ribs are at certain inclined angles relative to a longitudinal central axis of the screen mesh; and finally, the buffering ribs are uniformly distributed in a circumferential spiral connection state in the screen mesh. According to the buffering ribs disclosed by the invention, materials can be stirred and propelled, the work area of the screen mesh of the rotary drum screening machine is effectively enlarged, and the blocking rate of the screen mesh is greatly reduced, so that thescreening quantity of the rotary drum screening machine is indirectly increased, and the work efficiency is improved. Besides, the rotary drum screening machine disclosed by the invention has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:安徽马钢嘉华新型建材有限公司

Fixation member and fixation apparatus having the fixation member

InactiveCN103676576AReduce drive torqueAvoid stickyElectrographic process apparatusPolyamide-imideSurface roughness

The present invention relates to a fixation member and a fixation apparatus having the fixation member. The present invention provides a fixation member which exhibits enhanced wear resistance and sliding property between the peripheral surface of the fixation member and a pressure member, which can reduce driving torque at a fixation unit, and which does not cause stick slipping even in a high-load operational mode, and a fixation apparatus having the fixation member. The fixation member (1) employed in a fixation unit of the fixation apparatus has a metallic substrate (10) having at least one layer of an electrocast seamless belt, and a slide layer (11) disposed on the inner peripheral surface of the metallic substrate (10), wherein the slide layer (11) is formed of at least one species of the group consisting of a polyamide-imide resin and a polyimide resin, and a fluororesin; the slide layer (11) has a fluororesin content of 27.5 mass% to 50 mass%; and the slide layer (11) has a surface roughness Ra of 0.4 [mu]m or less.

Owner:NOK CORP +2

Agricultural seeding soil turning device with automatic soil covering mechanism

InactiveCN111615872ARealize automatic soil turningImprove tillage efficiencyAgricultural machinesTilling equipmentsGear wheelAgricultural engineering

The invention discloses an agricultural seeding soil turning device with an automatic soil covering mechanism. The soil turning device comprises a motor, wherein the top of the motor is fixedly connected with a first rotating shaft, the top of the first rotating shaft is fixedly connected with a scraping mechanism through a bearing seat, and a scraper blade is arranged on the scraping mechanism; afirst gear is fixedly connected to the position, close to the motor, of the surface of the first rotating shaft, the left side and right side of the first gear are meshed with the surface of a thirdgear, and the inner center of the third gear is fixedly connected with second connecting shafts; and threaded rods are fixedly connected to the tops of the second connecting shafts. The first gear andthe third gear are arranged, a fixing mechanism is driven by a first runner so as to realize rotation of a roll shaft, so that the work of automatic soil turning is achieved; and the inner wall of the casing of the device can be scraped through movement of a first sliding sleeve on the surface of a first connecting rod, and dirt on the inner wall of the casing of the device can be removed.

Owner:蒋彩霞

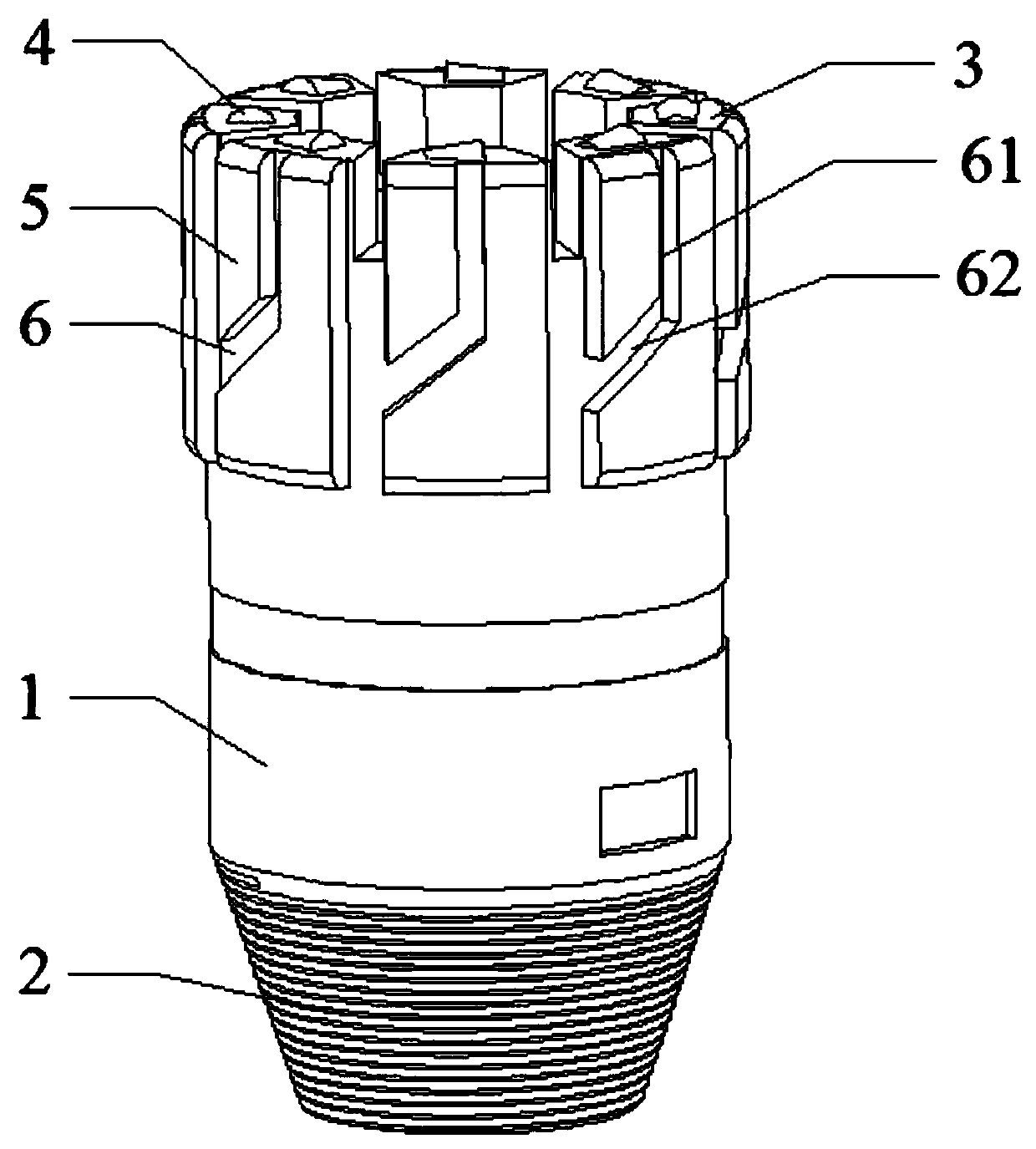

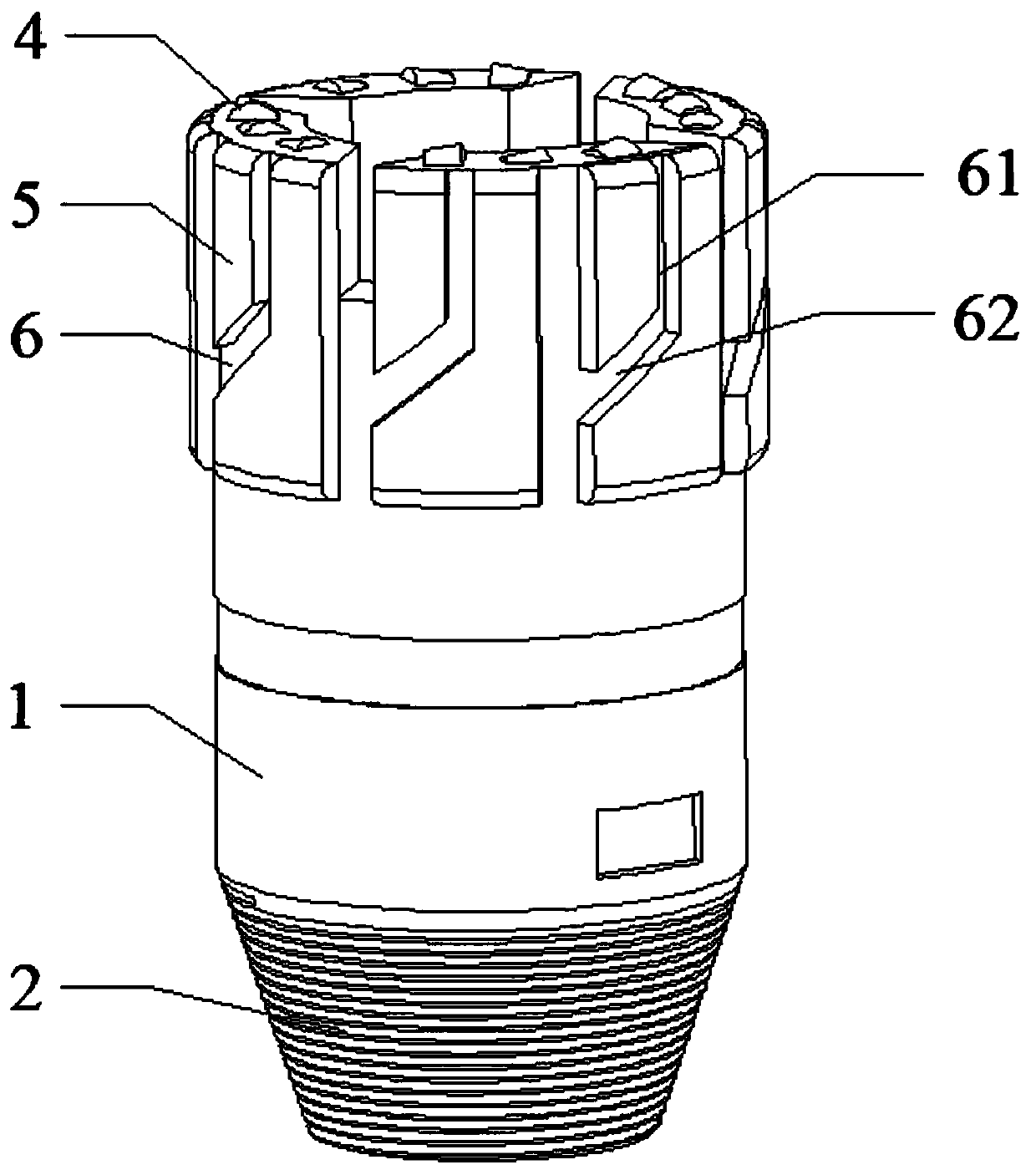

Drill bit for ultra-high rotating speed drilling of deep hard stratum

PendingCN109989714AHeat dissipation fastQuick release powderDrill bitsConstructionsWater channelPolycrystalline diamond

The invention relates to a tool for deep geological exploration coring, in particular to a drill bit for ultra-high rotating speed drilling of a deep hard stratum. The drill bit for ultra-high rotating speed drilling of the deep hard stratum comprises a drill bit body, one end of the drill bit body is fixedly connected with a connector, the other end of the drill bit body is fixedly provided witha plurality of drill bit matrixes which are evenly distributed along the circumference, an interval is formed between every two adjacent drill bit matrixes, and reinforced polycrystalline diamond cutting teeth are fixedly arranged on the working face of the drill bit matrixes. The drill bit for ultra-high rotating speed drilling of the deep hard stratum further comprises a plurality of gauge protectors fixedly connected with the side walls of the drill bit matrixes and the side wall of a rotary head body, the gauge protectors correspond to the drill bit matrixes one to one, the top ends of thegauge protectors are flush with the working faces of the drill bit matrixes, an interval is formed between every two adjacent gauge protectors, and a diversion water channel is further formed in eachgauge protector, and the top ends of the diversion water channels are flush with the gauge protectors. The drill bit for ultra-high rotating speed drilling of the deep hard stratum is rapid in heat dissipation, rapid in powder discharging, small in vibration and preventing stick-slip.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

UV-oxide hybrid drying type engraving intaglio printing ink

ActiveCN101250354BAchieve dryingWell mixedInksOther printing apparatusPrinting inkComposite material

The invention relates to UV-oxidation mixing drying type incising gravure printing ink, which is prepared through firstly producing by rolling UV drying components and oxidation drying components assisting volatilization drying, penetration drying and complex drying effect, and evenly mixing according to 1%-99% proportion of UV drying component and 99%-1% oxidation drying components assisting volatilization drying, penetration drying and complex drying effect. The printing ink of the invention conducts UV drying in the process of printing, instantly realizes partial drying of printing ink to form a drying ink film, can finish oxidation drying and assisting volatilization drying, penetration drying and complex drying effect to achieve the complete drying of printing ink. The printing ink solves the technical problems that thick ink film existing in current UV drying incising gravure printing ink is incomplete, complete drying can not be realized in the natural storage process, and has the advantages of economical, energy-saving and environment-friendly.

Owner:CHINA BANKNOTE PRINTING & MINTING

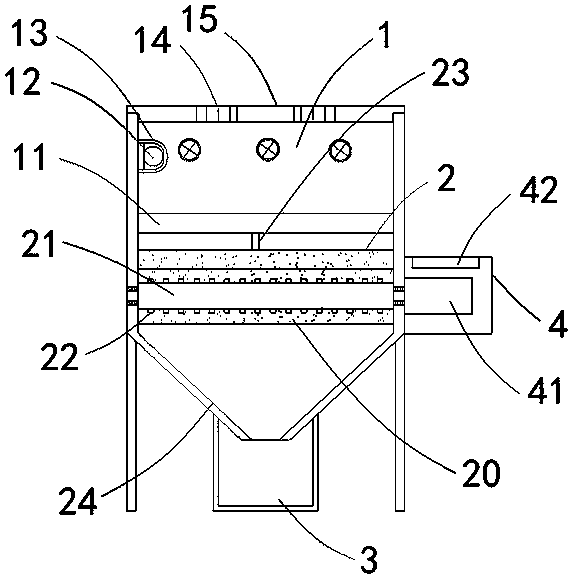

Soil grinding device with soil drying function

PendingCN111504744AAvoid stickyAvoid it happening againPreparing sample for investigationDirt cleaningAgricultural engineeringSoil drying

The invention discloses a soil grinding device with a soil drying function. The device comprises an equipment box, a support frame is arranged at the bottom end of the equipment box; the equipment boxis sequentially divided into a drying area used for soil drying and a grinding area used for soil grinding in the direction from a top end opening to a bottom end opening. The drying area and the grinding area are separated through a double door. A plurality of baking lamps are arranged on the side wall of the drying area; a detachable lampshade is arranged on each baking lamp in a sleeving manner; the soil grinding device is easy to operate and has the soil drying capacity, meanwhile, the whole soil grinding process is carried out in a closed space, dust is prevented from being generated inthe grinding process, the working environment of operators is guaranteed, meanwhile, the device can be directly washed, and equipment cleaning is facilitated.

Owner:西藏净源科技有限公司

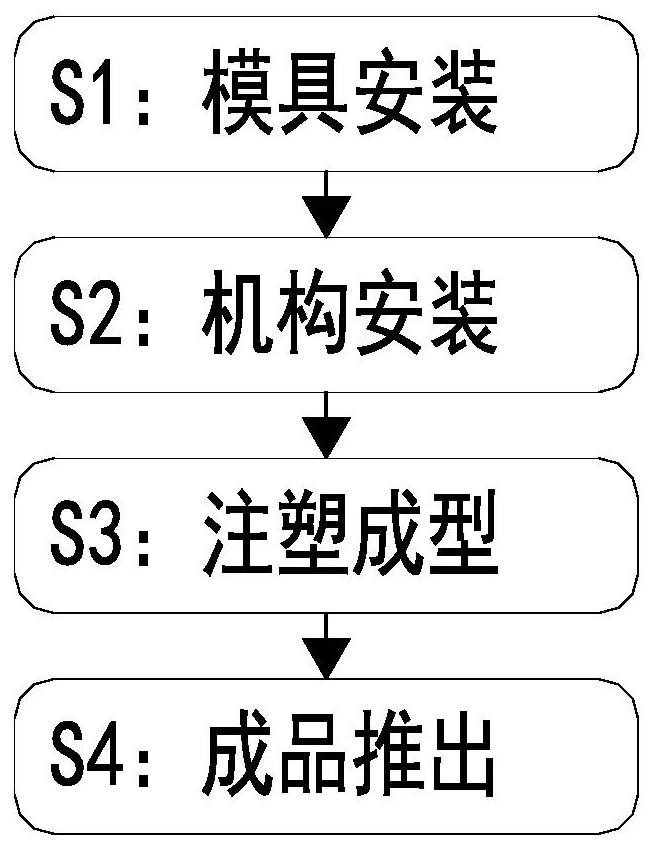

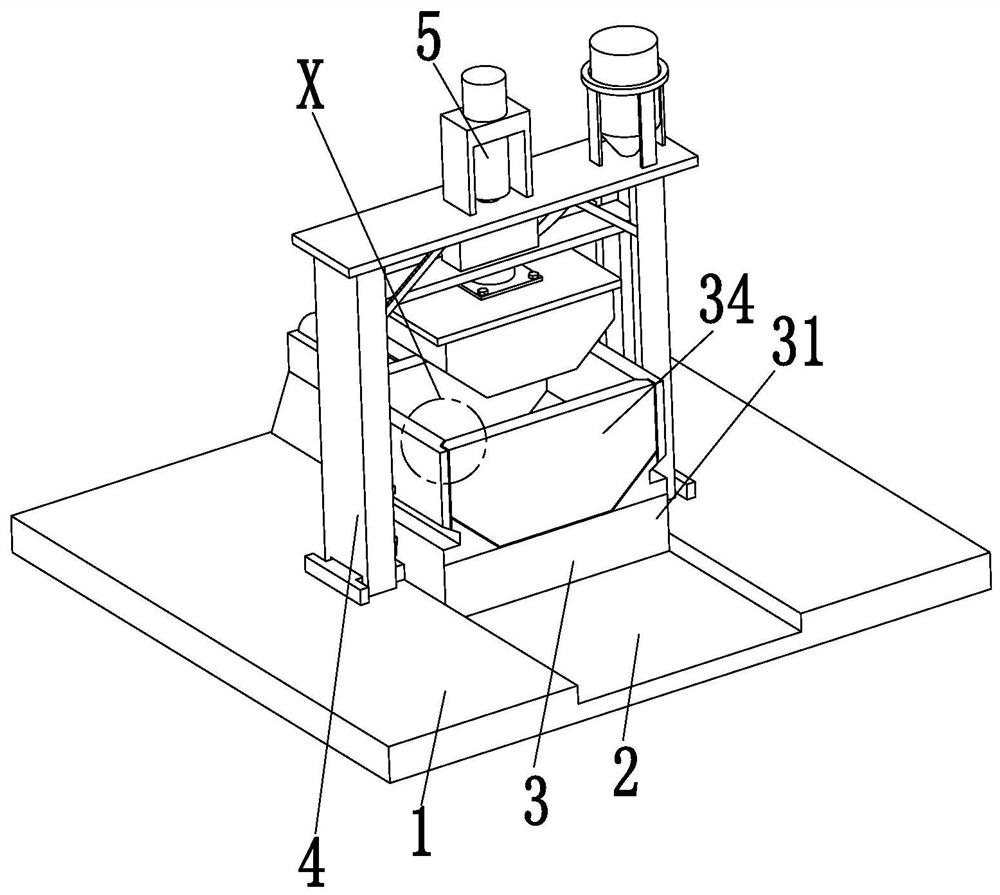

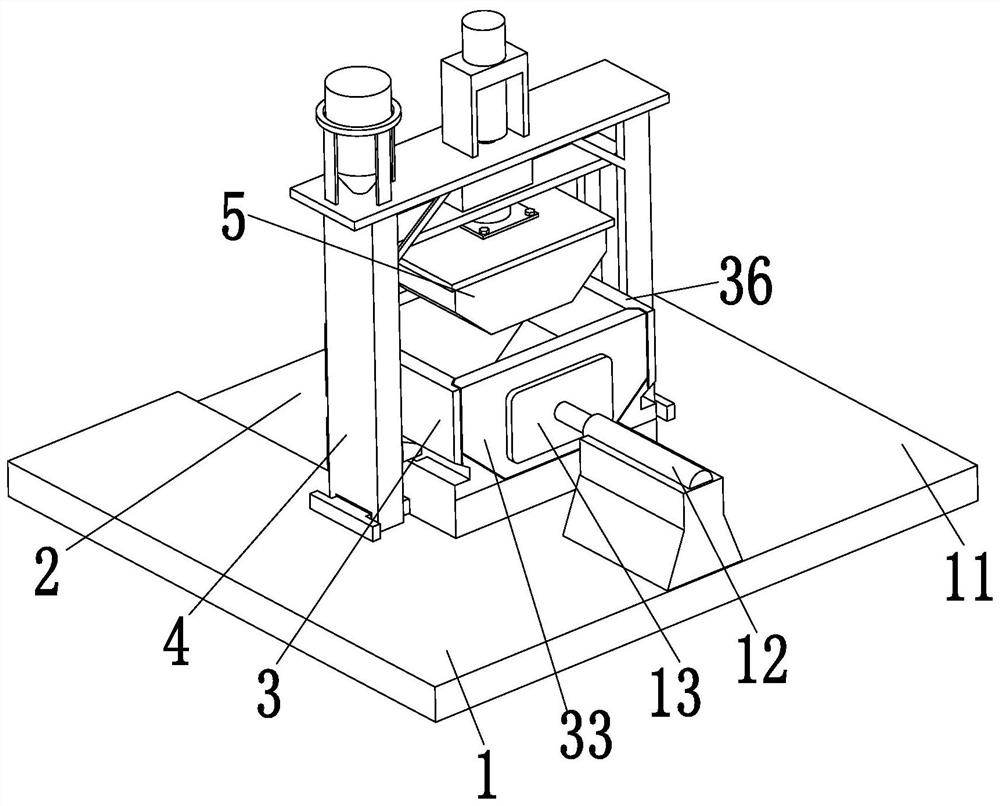

Electric meter box transparent plastic shell injection molding method

The invention relates to an electric meter box transparent plastic shell injection molding method. The method mainly comprises the following steps following steps of: mold mounting, mechanism mounting, injection molding, finished product pushing and the like. A used injection molding machine comprises a fixed base, a sliding groove, a molding device, a supporting bottom plate and an injection molding device. The sliding groove is formed in the front side of the upper end of the fixed base, the molding device is slidably arranged in the sliding groove, supporting bottom plates are symmetricallyarranged on the left side and the right side of the upper end of the fixed base, and the injection molding device is installed at the upper ends of the supporting bottom plates. The problems that according to a traditional electric meter box transparent plastic shell injection molding method, when electric meter box transparent plastic shells of different specifications need to be subjected to injection molding, injection molding equipment needs to be replaced, inconvenience is caused, and due to the fact that the side walls of part of the transparent plastic shells are prone to adhering to an injection molding mechanism and difficult to push out, the damage to the transparent plastic shells is possibly caused by forcible push-out can be solved.

Owner:许丽

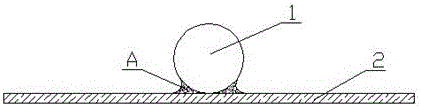

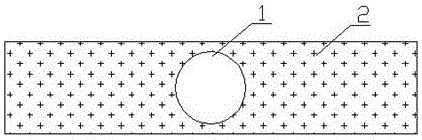

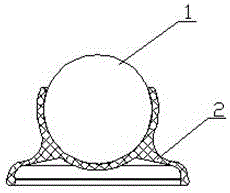

Medical image in-vitro positioning identification point with compatibility

InactiveCN106388849ACompatibleVersatilityComputerised tomographsDiagnostic recording/measuringDiagnostic Radiology ModalityMedical equipment

The invention discloses a medical image in-vitro positioning identification point with compatibility, which belongs to the technical field of medical equipment and medical treatment and public health. The positioning identification point comprises an imaging portion and a fixing portion capable of fixing the imaging portion at the surface of a human body, wherein the imaging portion is a hollow body which is made of an imaging material with density greater than the tissue density of the human body, and the hollow body can be imaged by using a secondary refraction principle; the imaging portion is a hollow sphere; the imaging material is glass, ceramics or zirconium oxide. The hollow body made of the imaging material with the density greater than the tissue density of the human body is used as the imaging portion, the hollow imaging portion can be imaged by using the secondary refraction principle of the hollow structure when in CT / MRI and MRI imaging, so that the medical image in-vitro positioning identification point is more compatible with the existing multi-mode image fusion imaging device, has universality, is unnecessary to replace when different modes are changed for scanning, more precise in positioning and more convenient to use.

Owner:ANHUI YOUNIKE MEDICAL TECH CO LTD

Traditional Chinese medicine processing and airing equipment

InactiveCN112696893AEfficient deploymentEfficient storagePharmaceutical product form changeDrying chambers/containersGear wheelChinese herbology

The invention discloses traditional Chinese medicine processing and airing equipment which comprises a box body. A loading inner cavity is formed in the box body, a plurality of bottom supports are arranged on the lower side of the box body, a plurality of sliding cavities are formed in the two sides of the loading inner cavity, the sliding cavity is located in the box body, the sliding cavity is able to be opened, a plurality of pushing air cylinders are arranged in the box body, a matching air cylinder rod is arranged in the pushing air cylinder in a power connection mode, a top box body is arranged in the matching air cylinder rod in a rotating mode, a connecting motor is arranged at the top of the matching air cylinder rod, a rotating gear is arranged on one side of the connecting motor in a power connection mode, the rotating gear is engaged with the top of the top box body, and a bearing device capable of bearing traditional Chinese medicinal materials in a swinging mode and flatly spreading the traditional Chinese medicinal materials is arranged in the top box body. The traditional Chinese medicinal materials can be efficiently spread and stored in the equipment, and then the traditional Chinese medicinal materials can be prevented from being wetted by rainwater in an external space in time.

Owner:齐卢虎

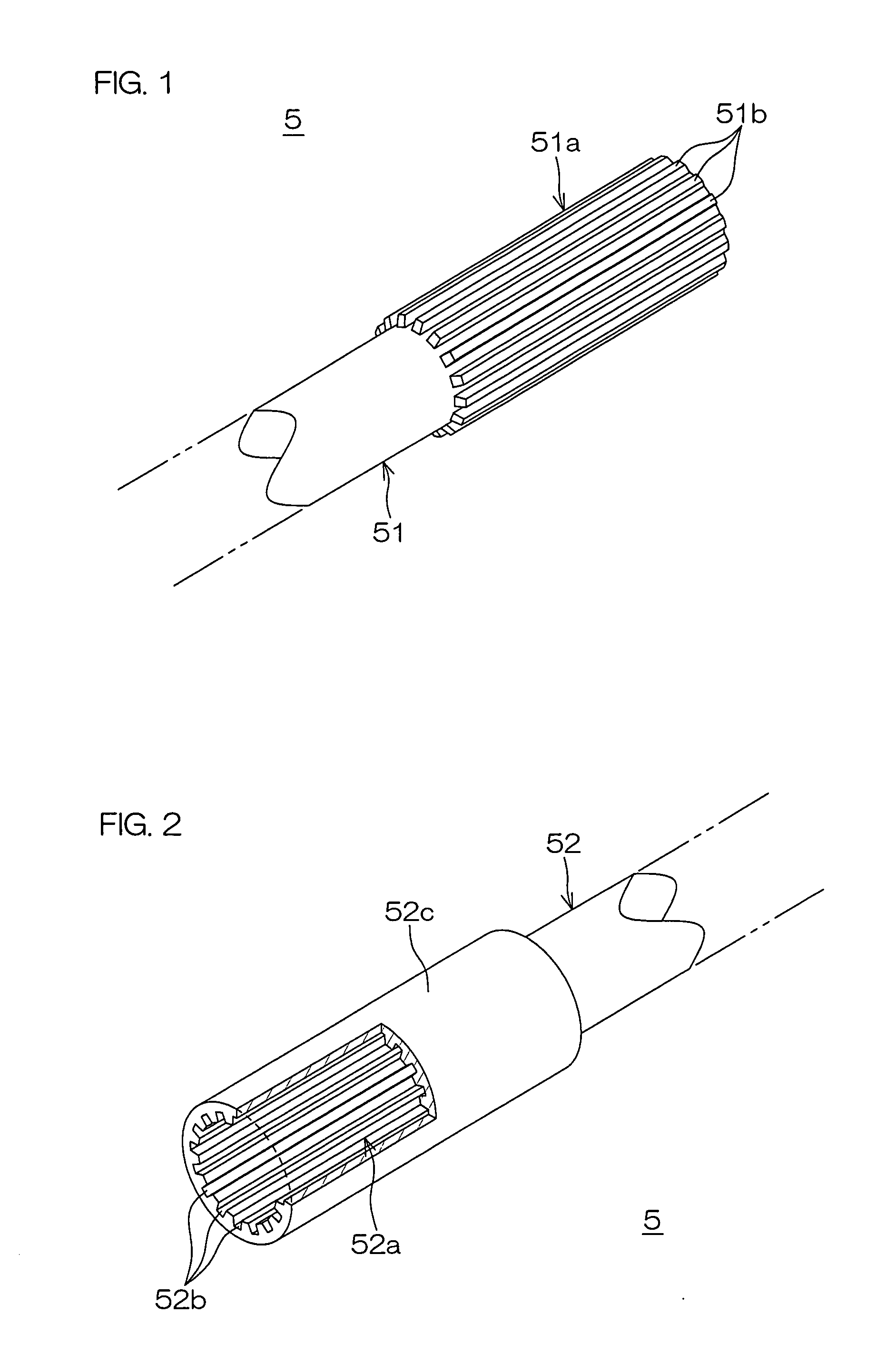

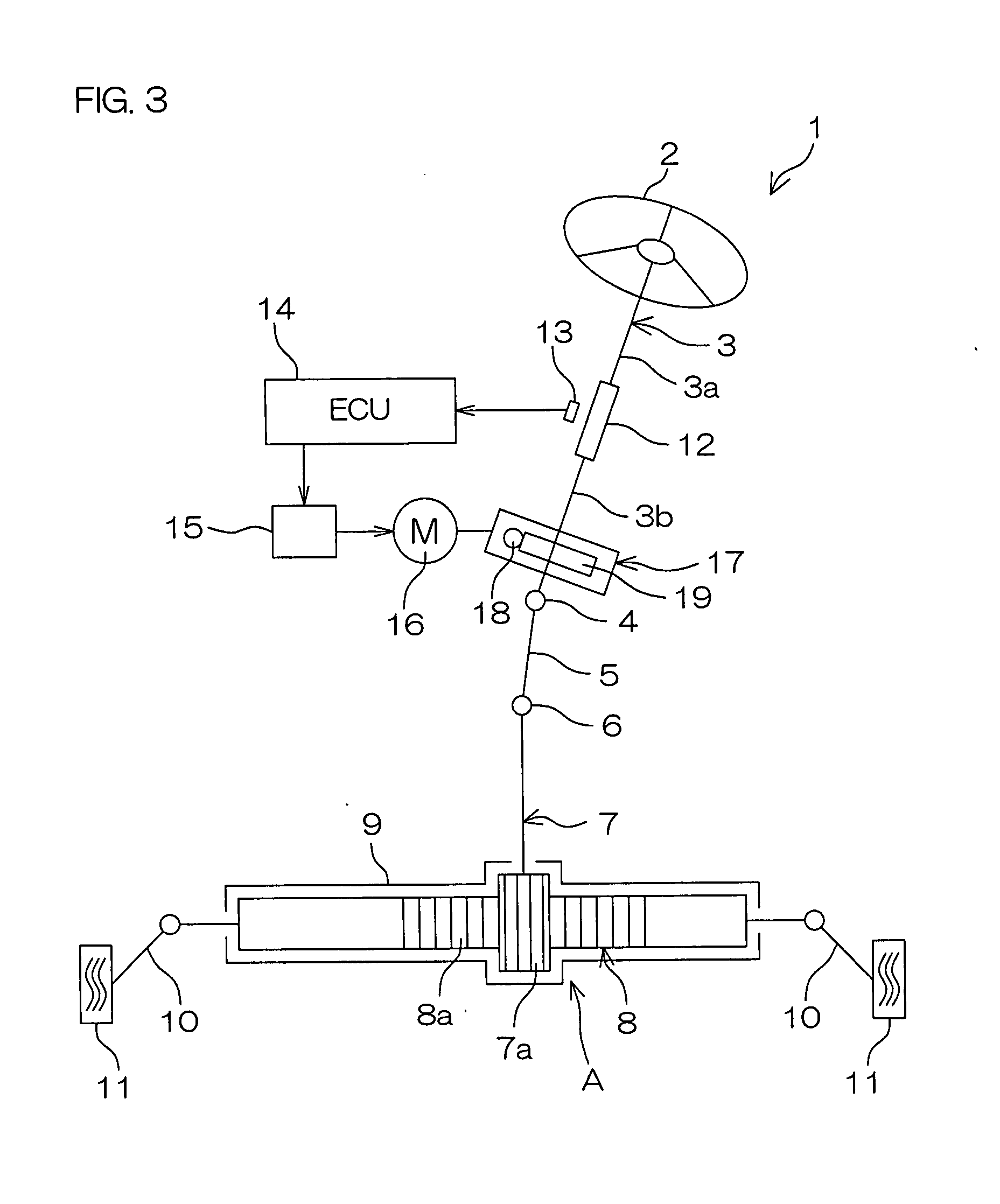

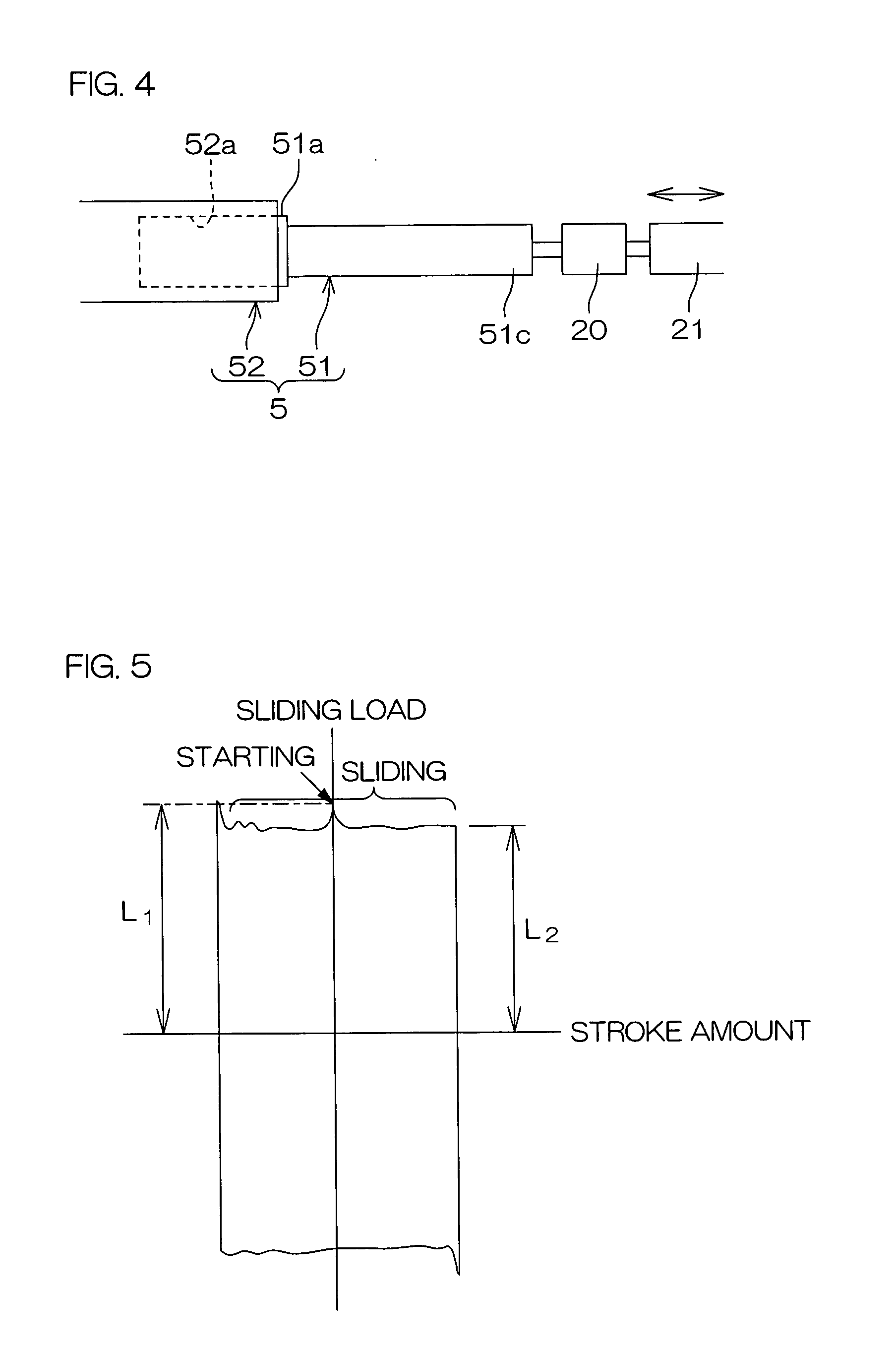

Lubricant composition, expandable shaft, and steering system using the same

InactiveUS20070209863A1Improve the lubrication effectImprove performanceClutchesYielding couplingHigh surfaceEngineering

A lubricant composition contains a base oil having a kinematic viscosity of 1500 to 13000 mm2 / s (40° C.) and polytetrafluoroethylene serving as a thickener, and is used for lubricating an expandable shaft to prevent stick-slip from occurring when a high surface pressure is applied thereto, thereby allowing to maintain a good lubricating performance consistently. The expandable shaft 5 has a pair of shaft members 51 and 52 filled with the lubricant composition. In a steering system 1, the expandable shaft 5 is incorporated as an intermediate shaft into an area between a steering shaft 3 and a rack-and-pinion mechanism A.

Owner:JTEKT CORP

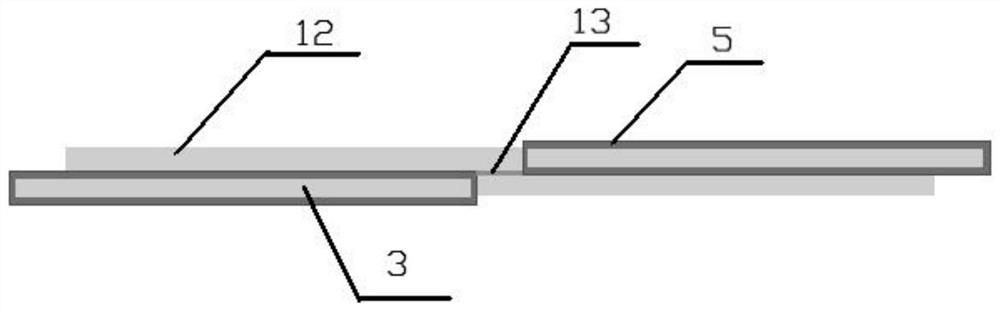

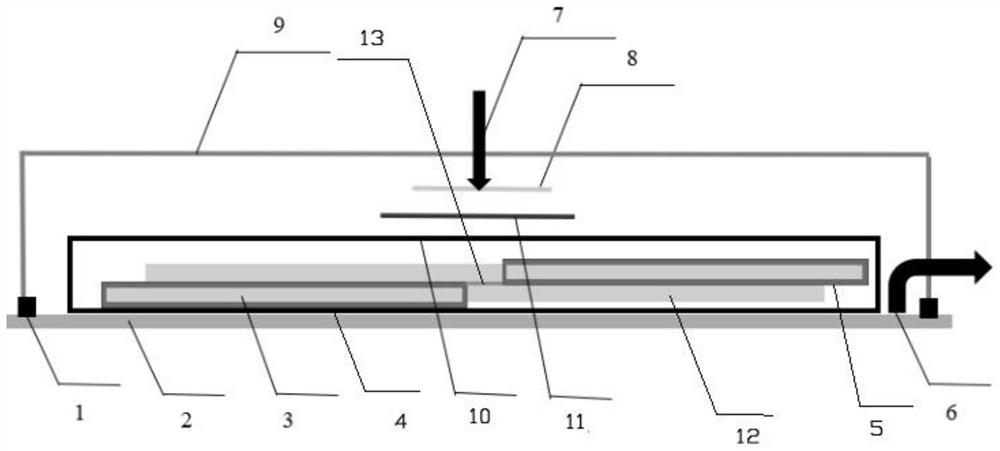

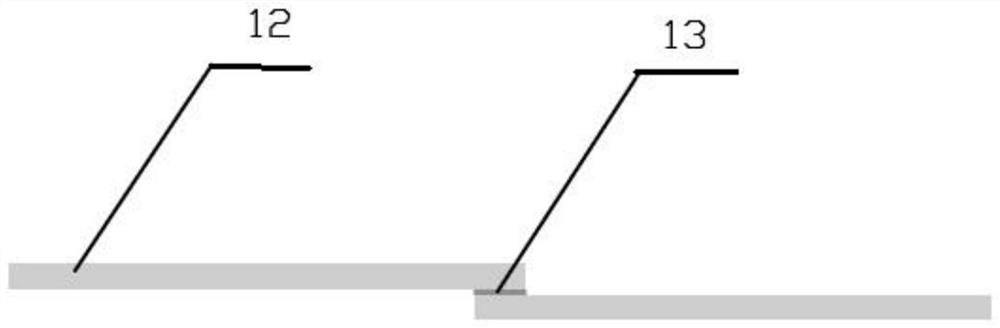

Production method of carbon-pultrued-plate single-lap tensile shearing specimen

PendingCN112743873ASolve preparation difficultiesReduce the probability of air bubblesPreparing sample for investigationIsolation membraneResin adhesive

The invention provides a production method of a carbon-pultrued-plate single-lap tensile shearing specimen. The production method of the carbon-pultrued-plate single-lap tensile shearing specimen comprises the following steps: (1) cutting a carbon pultrued plate into four specimen pieces with the same length, and covering both specimen pieces in the four specimen pieces with first isolation films; (2) laying devices for the carbon-pultrued-plate single-lap tensile shearing specimen; (3) turning on a vacuum pump, and conducting vacuum operation; (4) conducting resin infusion; (5) after resin infusion is completed, conducting heat preservation and curing operation; and (6) after heat preservation is completed, conducting demoulding. According to the production method of the carbon-pultrued-plate single-lap tensile shearing specimen, a vacuum infusion mode is adopted for producing the carbon-pultrued-plate single-lap tensile shearing specimen, the problem that production of single-lap-interface specimens through glue joint of fluid resin is difficult is solved, an actual product production technology is simulated, a bubble rate of a lap interface of the produced specimen is low, the quality is higher, and the product performance is elevated more accurately.

Owner:东方电气(天津)风电叶片工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com