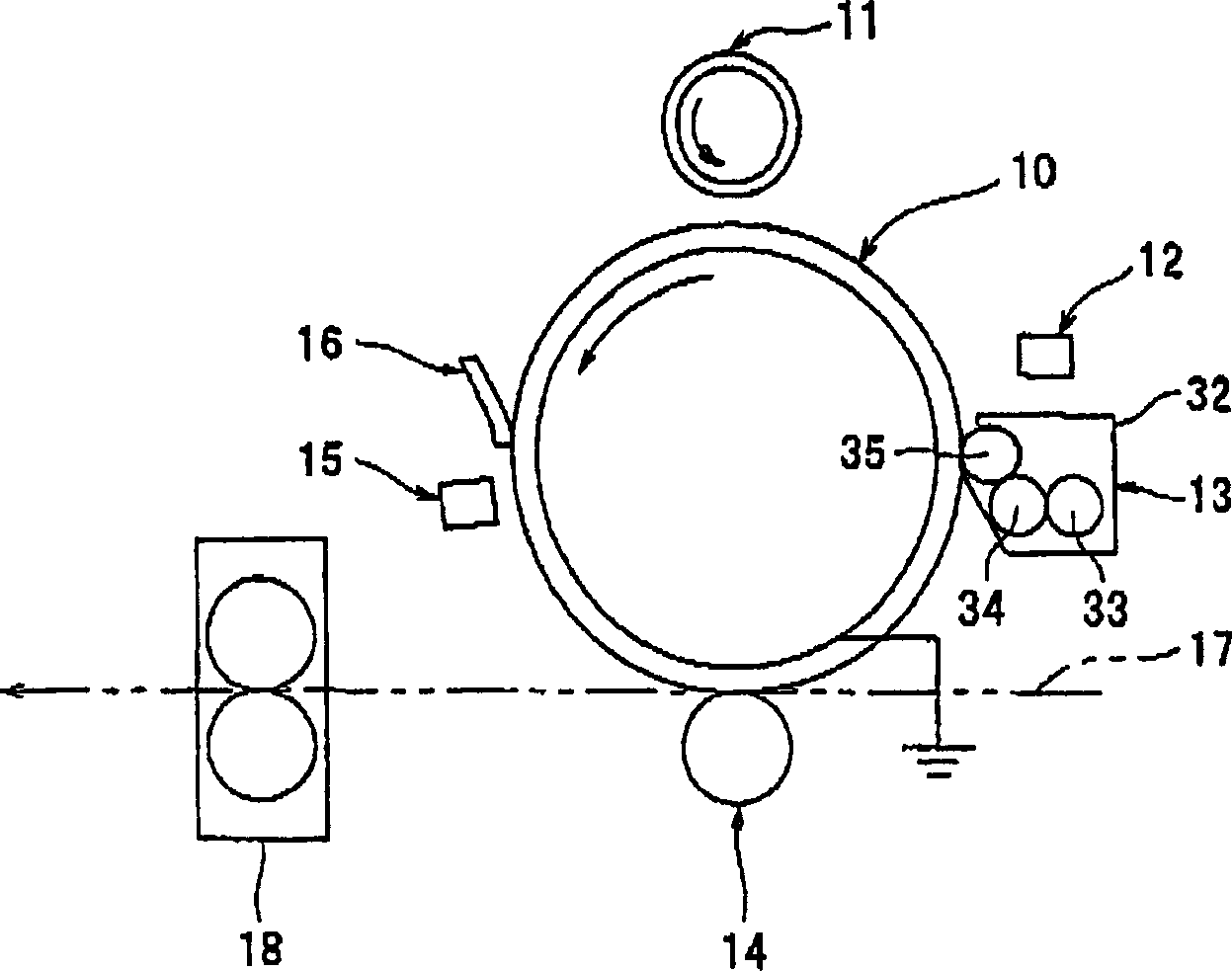

Cleaning device, process cartridge, and image forming apparatus

A cleaning device and image technology, which is applied in electrography, optics, instruments, etc., can solve the problem of cleaning structure without small particles and spherical toner, and achieve the effect of increasing line pressure, improving surface pressure, and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

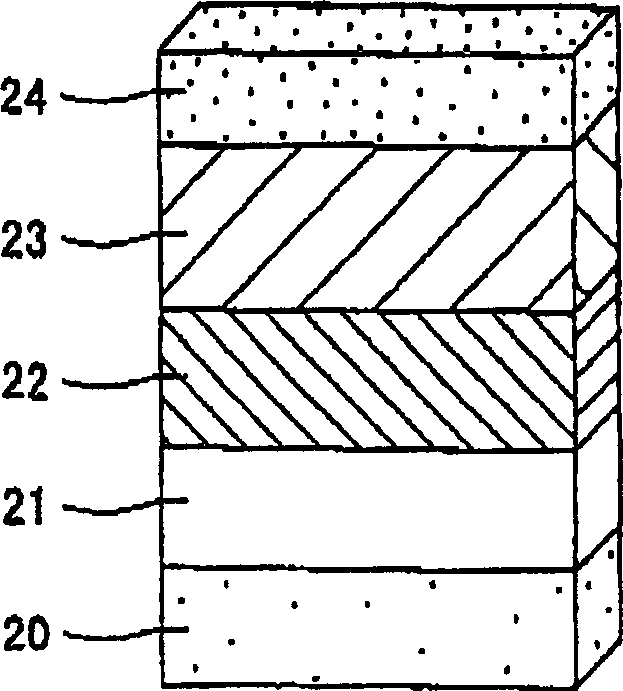

Method used

Image

Examples

Embodiment 2

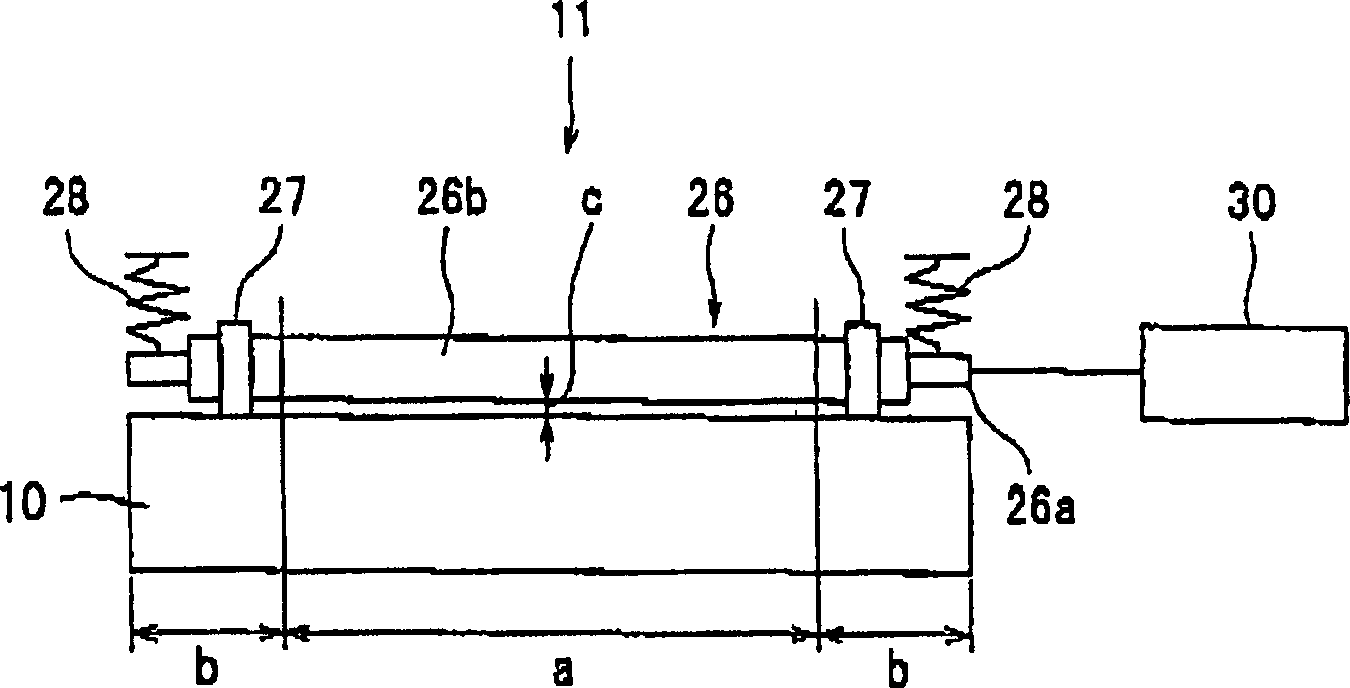

[0243] In the image forming process of the AC superimposed roller charging method, the transition between the cleaning blade 38 and the image carrier 10 is performed when zinc stearate is coated on the surface of the image carrier 10 and when zinc stearate is not coated. moment.

[0244] (experimental conditions)

[0245] Cleaning blade 38 : A cleaning blade (thickness 2mm, free length 7mm) using the existing powder block toner

[0246] (Length in the longitudinal direction of the cleaning blade: 325mm)

[0247] When measuring the cleaning action using a Jupiter machine, compare the average values.

[0248] The diameter of the image carrier 10: φ30

[0249] (result)

[0250] condition

Torque (kg·cm)

1.3

Zinc stearate coated with

1.9

[0251] As shown in the table, when zinc stearate was applied as a lubricant, the torque increased on the contrary. The reason for this is that when a lubricant is ...

Embodiment 3

[0256] In this experiment, torque values generated during the cleaning operation were measured under the following conditions 1 to 3, and their magnitude relationships were compared.

[0257] (experimental conditions)

[0258] Cleaning blade A: A cleaning blade (thickness 2 mm, free length 7 mm, shape: Figure 8 (C))

[0259] Cleaning scraper B: front end obtuse scraper (shaped as Figure 13 (A))

[0260] Cleaning scraper C: The obtuse angle scraper at the front end reduces the friction coefficient of the front end (the shape is Figure 13 (B))

[0261] (Note: The length of the cleaning blades of A, B, and C in the length direction: 325mm)

[0262] Image carrier: φ30

[0263] (result)

[0264] toner

piece

line pressure

(N / cm)

torque

(kgf cm)

Condition 1

powder block toner

Scraper A (for powder block)

0.2

1.8

Condition 2

spherical toner

Scraper B

0.95

3.8

Condition 3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com