Patents

Literature

334results about How to "Reliable cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

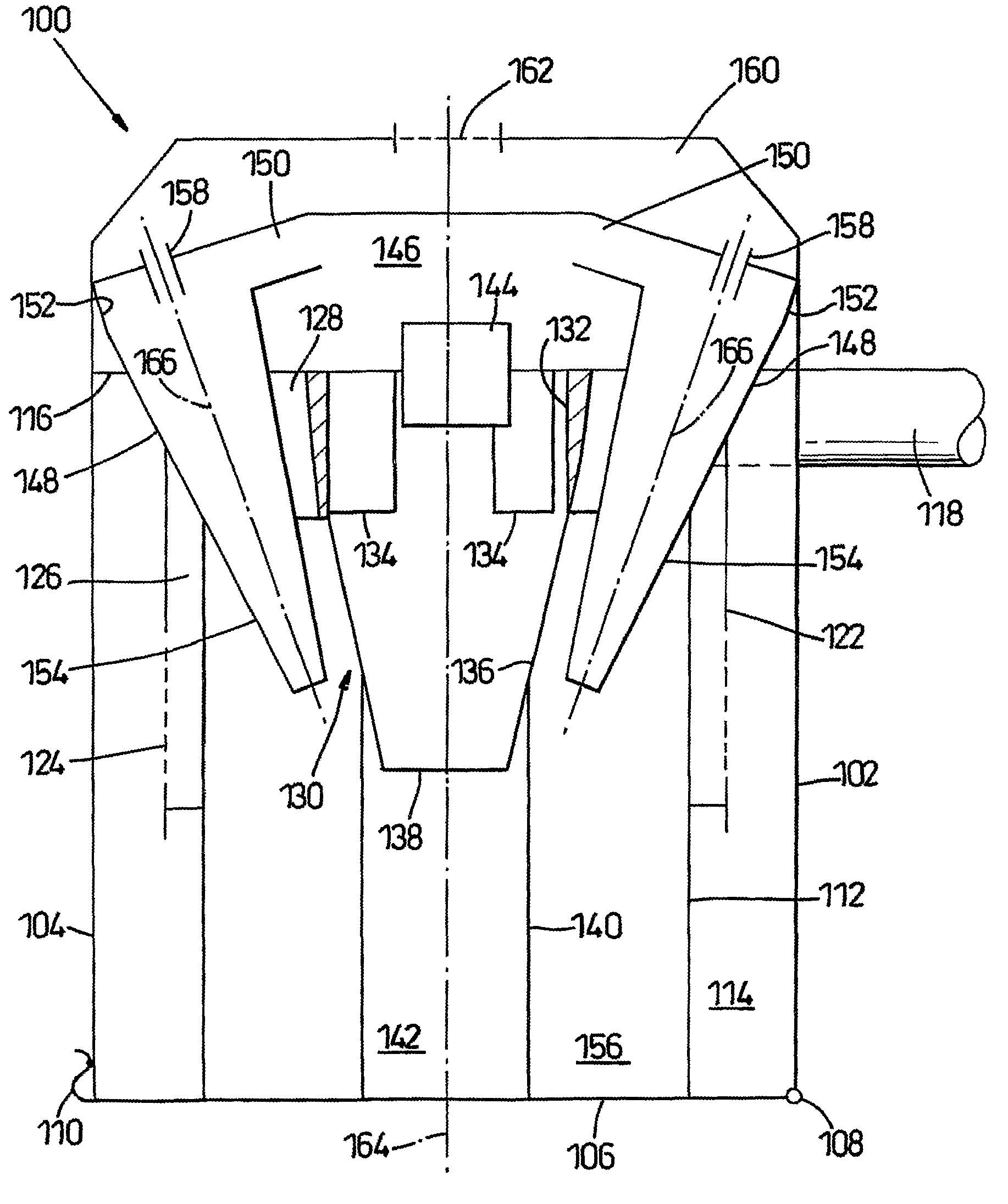

Parallel Robot

ActiveUS20120118097A1Reliable cleaningAvoid damageProgramme-controlled manipulatorMechanical apparatusParallel kinematicsDegrees of freedom

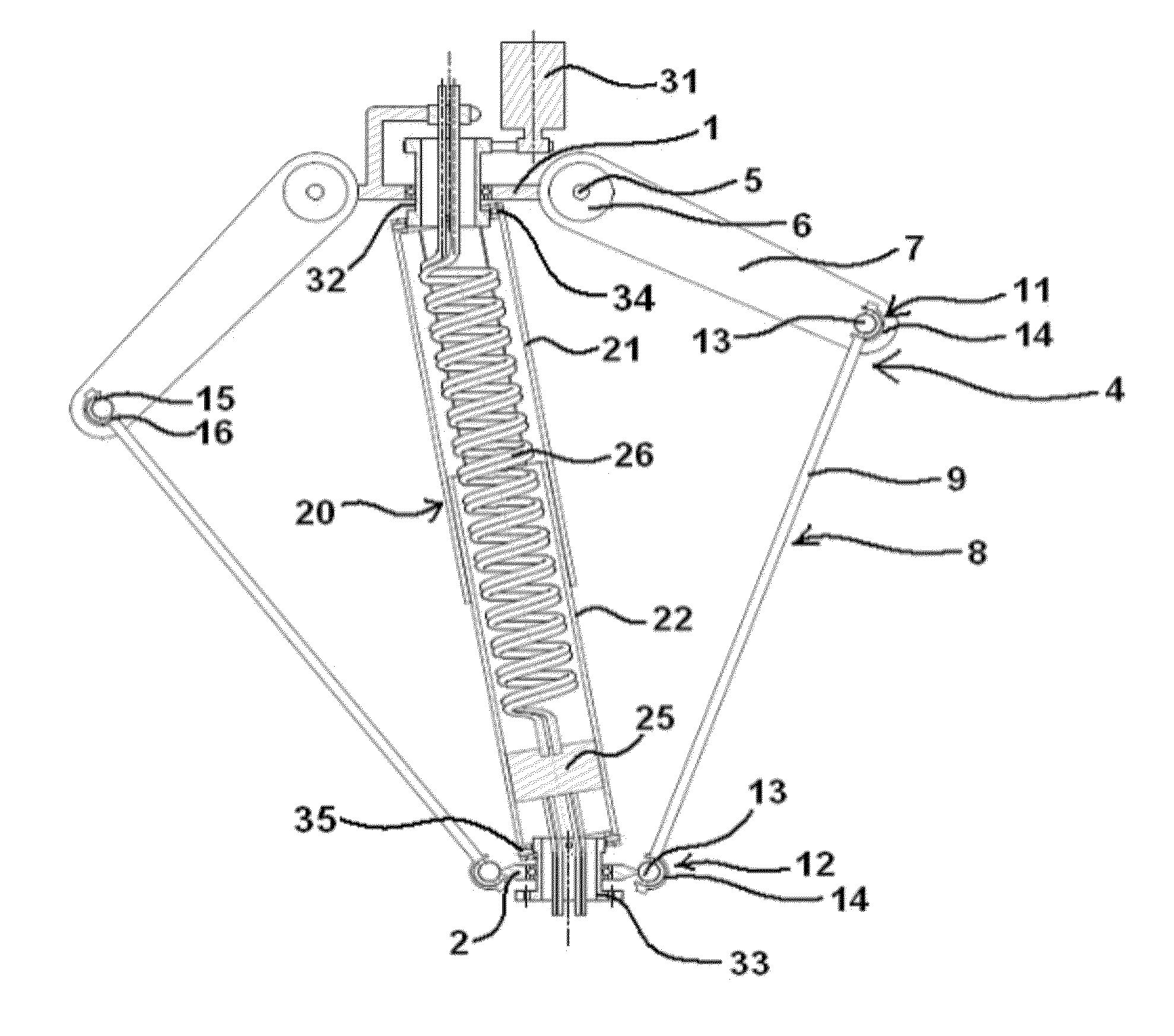

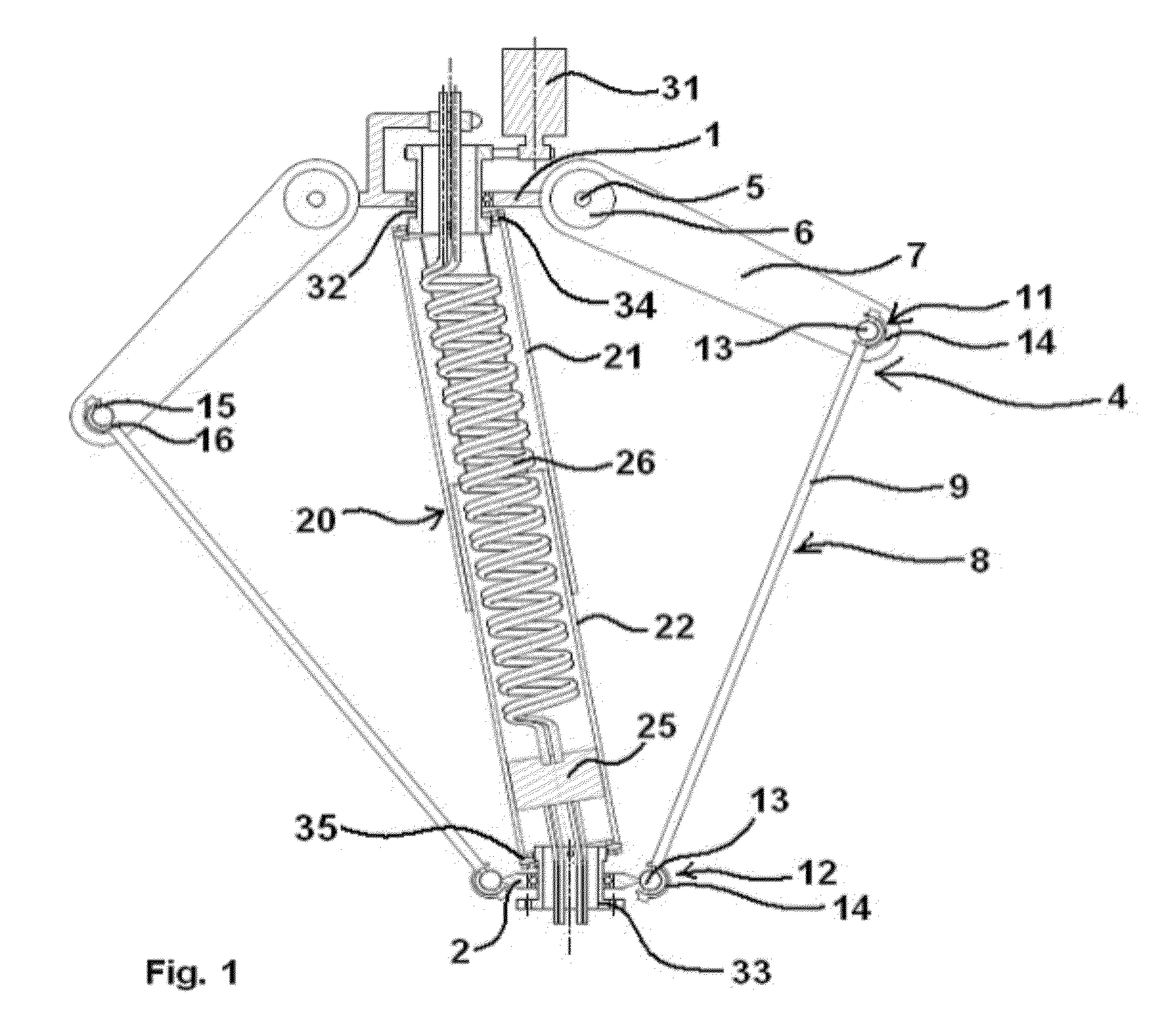

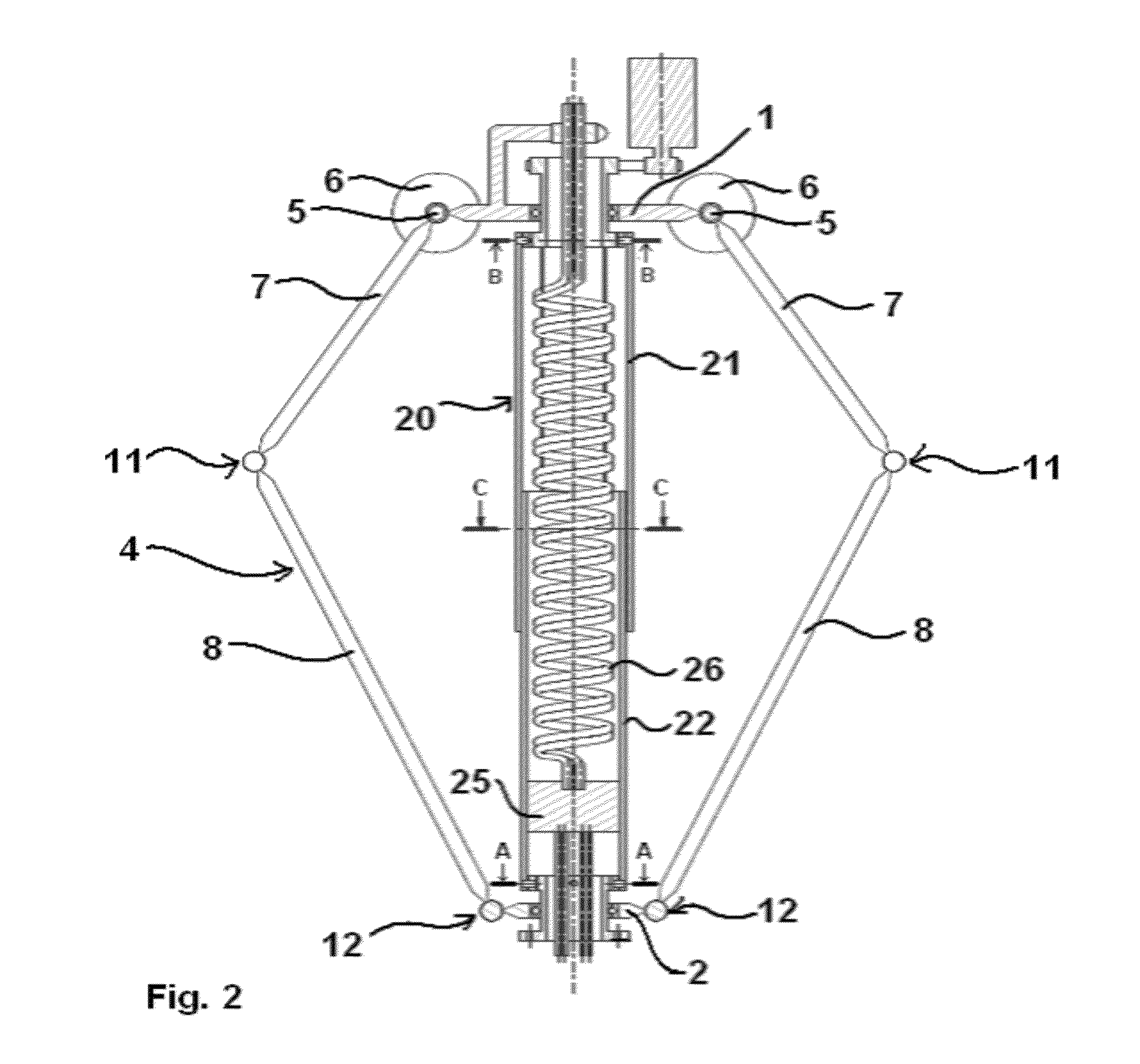

The invention relates to an industrial robot having parallel kinematics, the industrial robot, comprising a robot base (1, 38), a carrier element (2, 42) for accommodating a gripper or a tool, several movable, elongated actuating units (4,36), which are connected at one end thereof to drive units (6, 39) arranged on the robot base (1, 38), and the other end of which is movably connected to the carrier element (2, 42), an elongated hollow body (20, 43, 54), which has a continuous cavity and which is flexibly connected to the robot base (1, 38), a joint (35, 49, 65), which has a continuous cavity and which has several degrees of freedom, by means of which joint the elongated hollow body (20, 43, 54) is movably connected to the carrier element (2, 42), and at least one supply line (26, 51, 64) for a gripper arranged on the carrier element (2, 42) or a tool arranged on the carrier element (2, 42), the supply line being guided through the cavity of the elongated hollow body (20, 43, 54) and the cavity of the hollow joint (35, 49, 65) from the robot base to the carrier element (2, 42).

Owner:MAJATRONIC

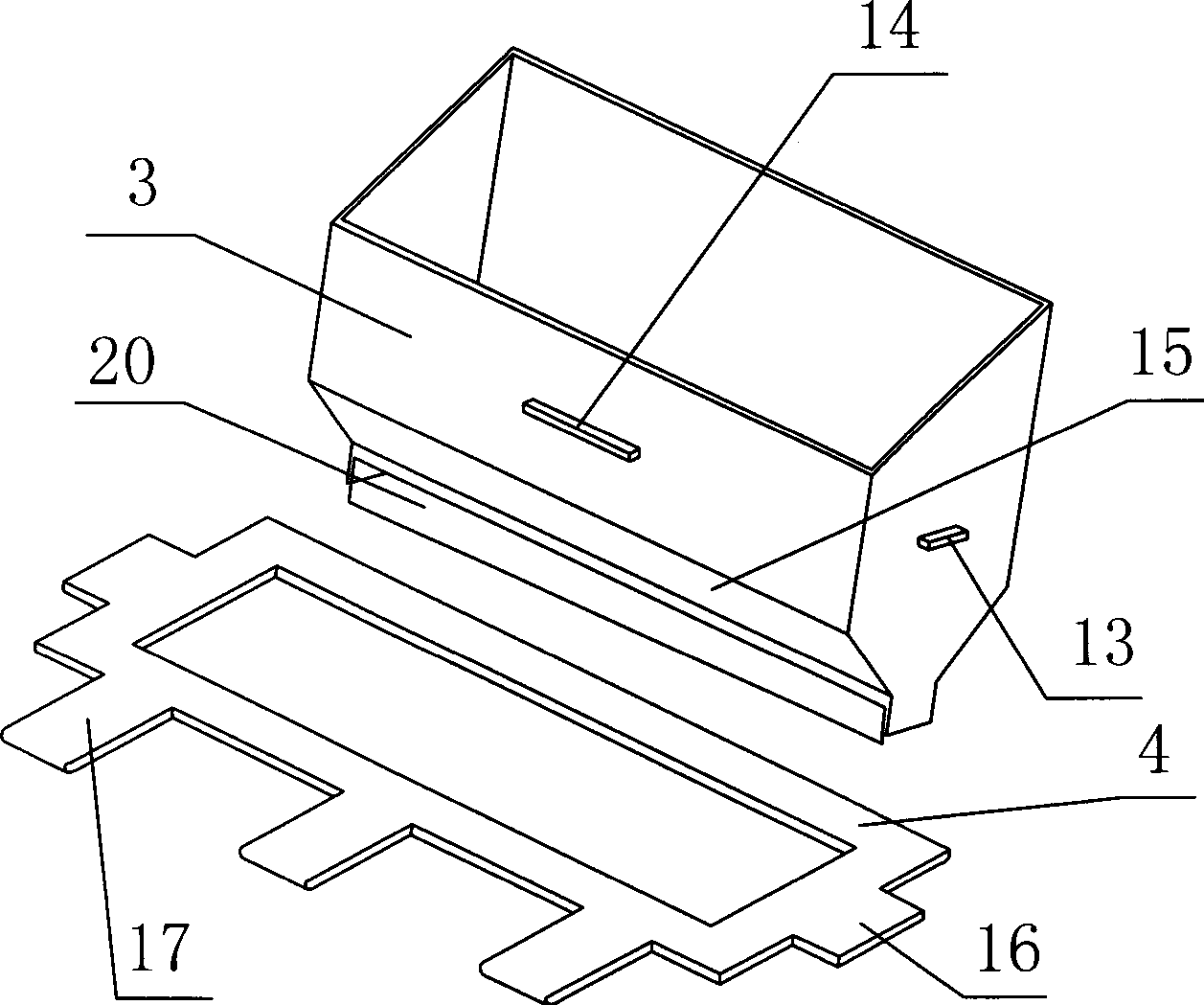

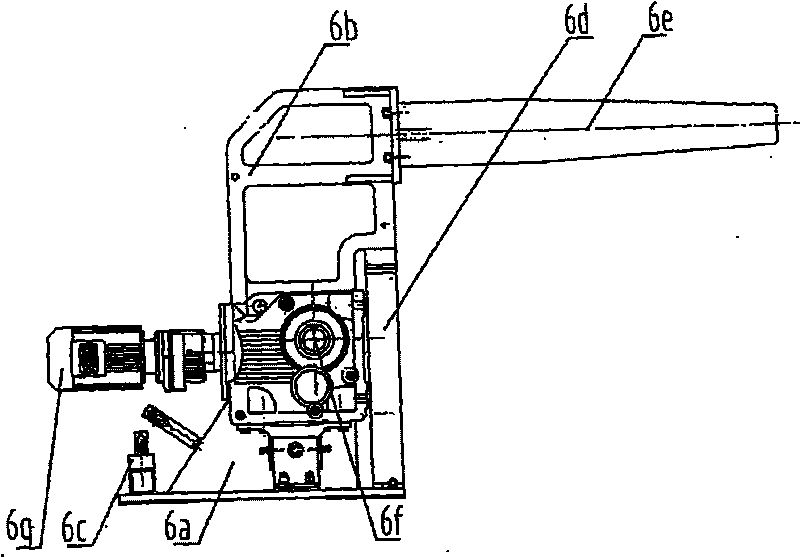

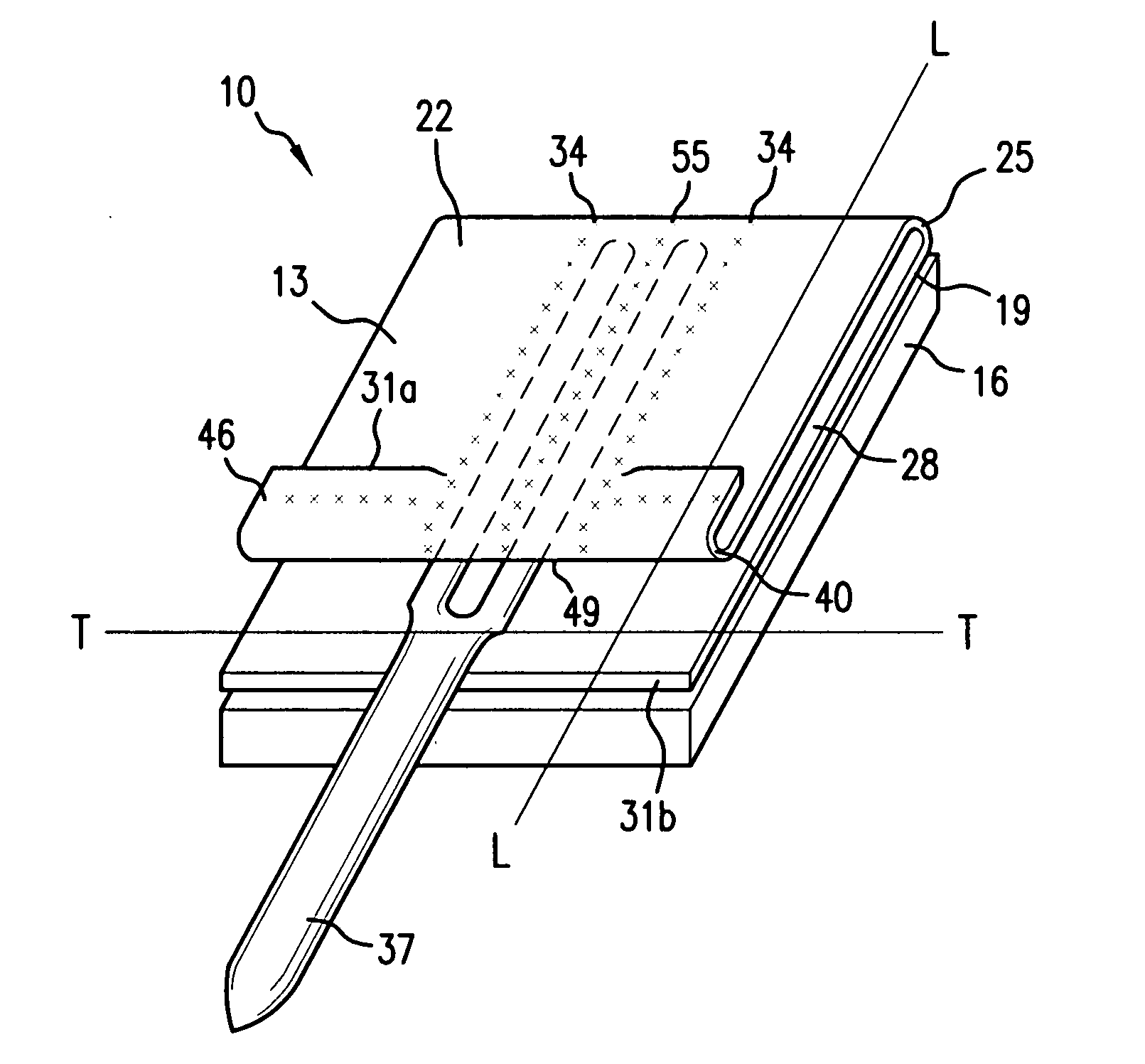

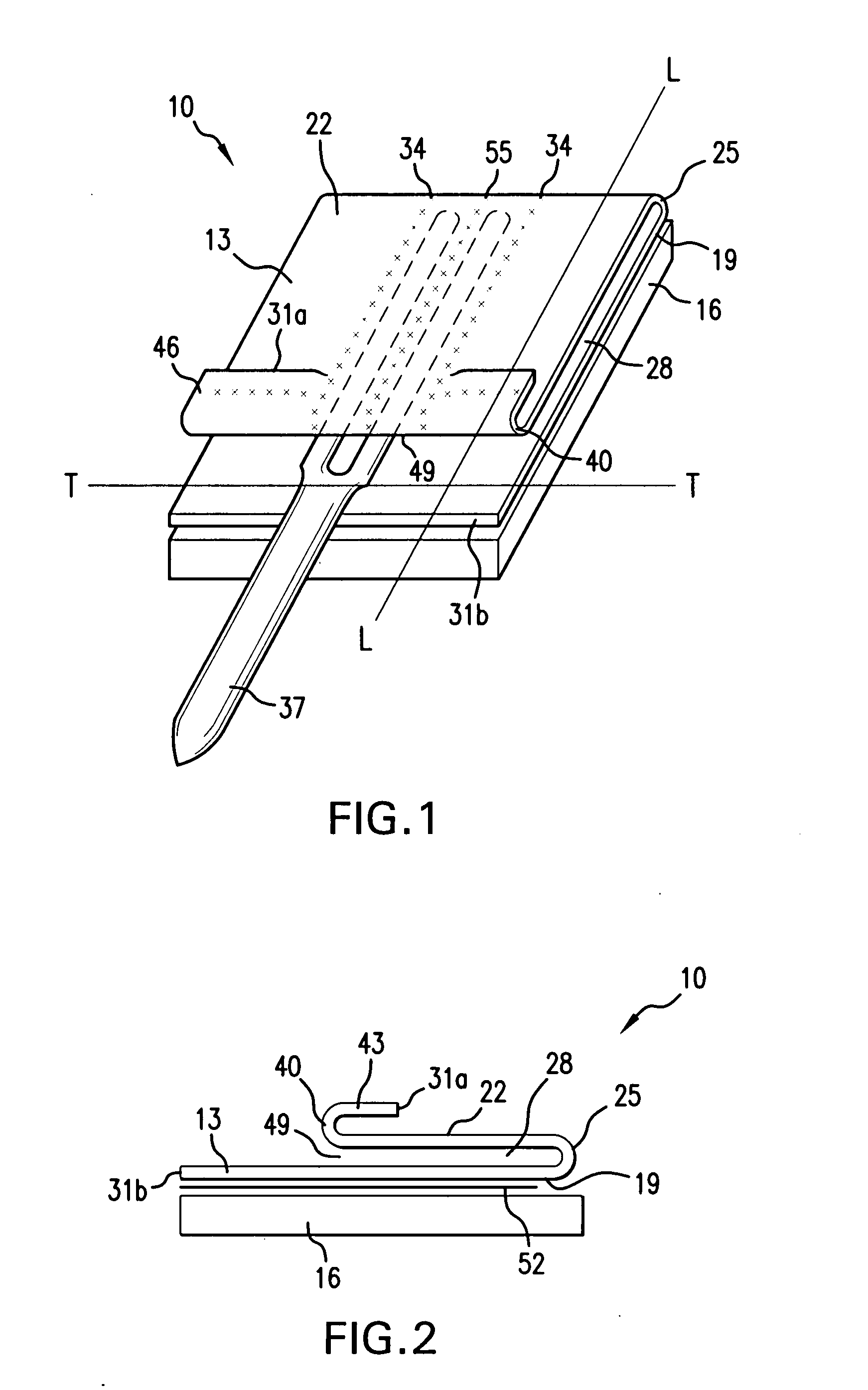

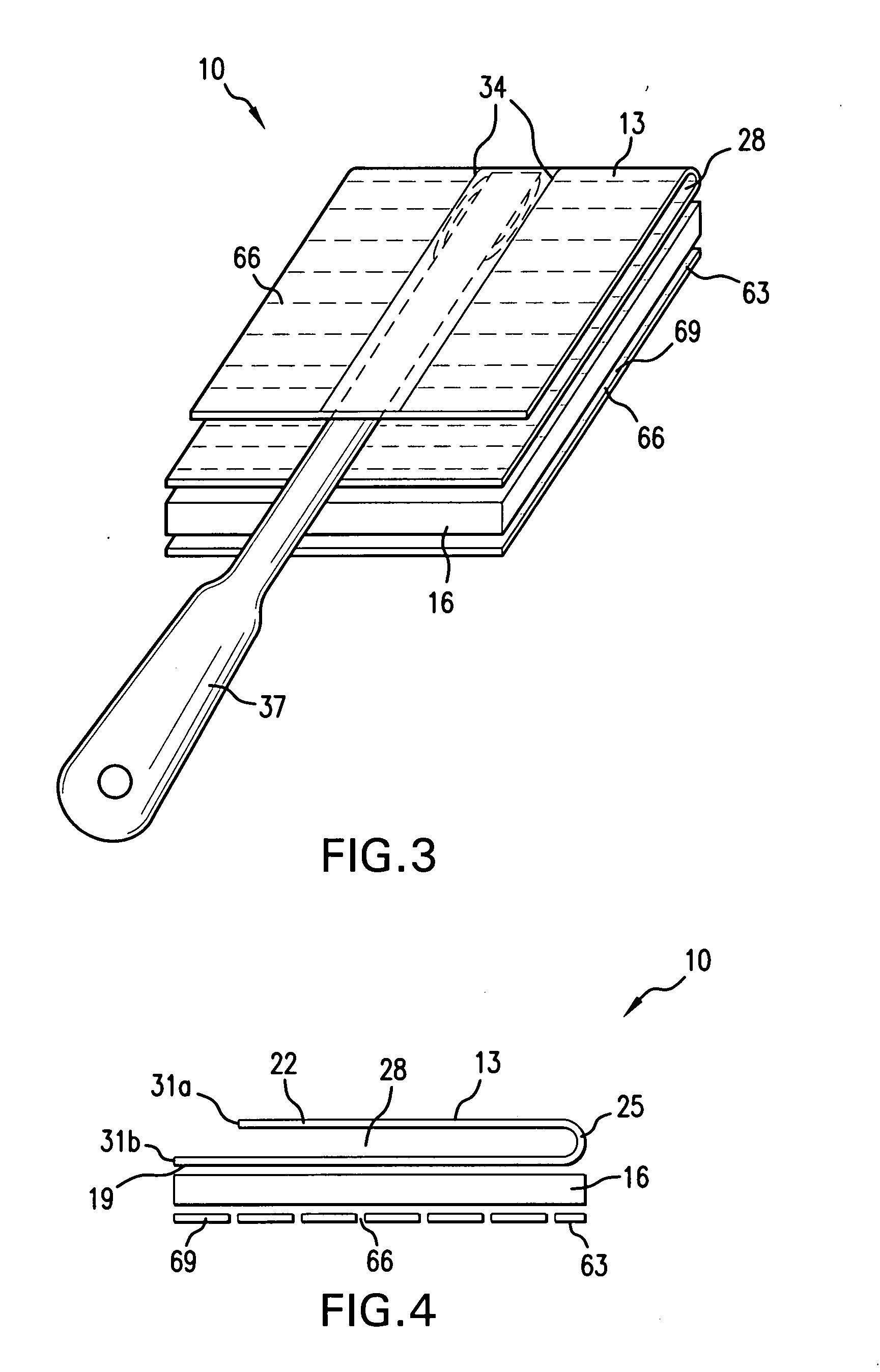

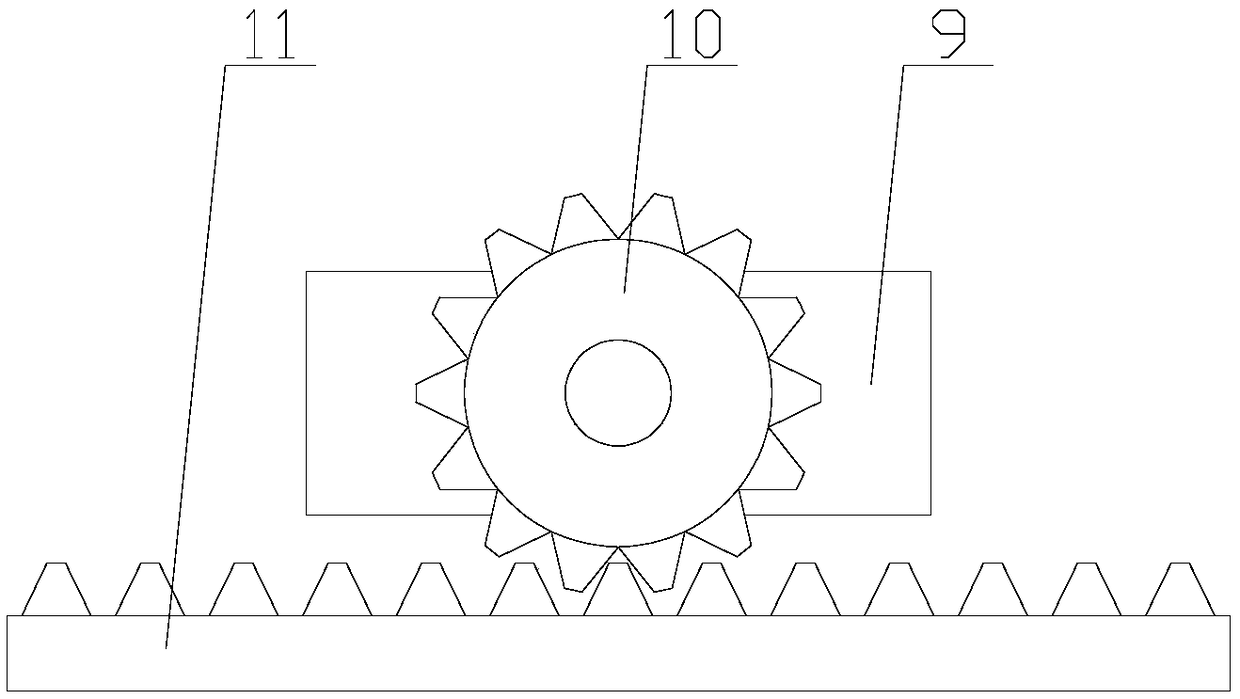

Powder sending and laying device for quickly shaping device

ActiveCN101362202APrevent dispersalAvoid wandering situationsAdditive manufacturing apparatusLoading/unloadingHigh rateReciprocating motion

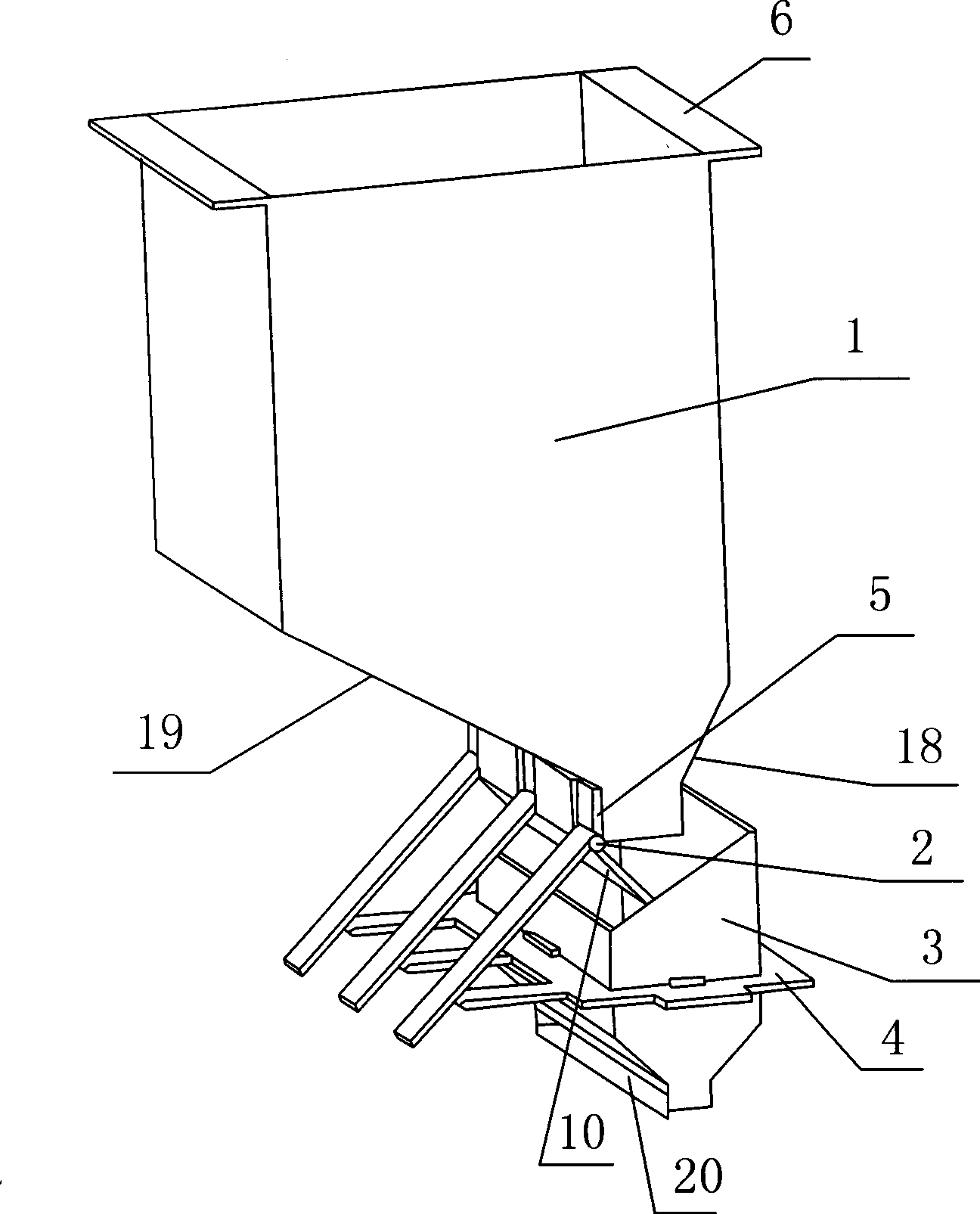

The invention discloses a powder feeding and laying device applied to a high rate former, which consists of a powder storing case and a movable hopper, wherein, the powder storing case is an upper powder storing case positioned above the movable hopper and provided with a power outlet at the bottom; the powder storing case is fixed and stable; a movable baffle capable of automatically opening and closing the powder outlet is arranged at the bottom of the powder outlet; a movable bracket is fixed outside the movable hopper which moves to and fro from left to right along a horizontal line on a forming working platform of a high rate former by a driving mechanism; an unlocking component which is matched to be used with the movable bracket is arranged on the movable baffle; a receiving port at the upper part of the movable hopper corresponds to the powder outlet; a powder laying port is arranged at the bottom of the movable hopper, which is a rectangular port enclosed by two lateral baffles in the front and the back and two flexible doctor blades on the left and the right. The powder feeding and laying device applied to a high rate former has simple structure, handy assembly and deinstallation of all parts and easy regulation and control, the capability of modular working independently, rapid powder laying, and high reliability.

Owner:西安赛隆增材技术股份有限公司

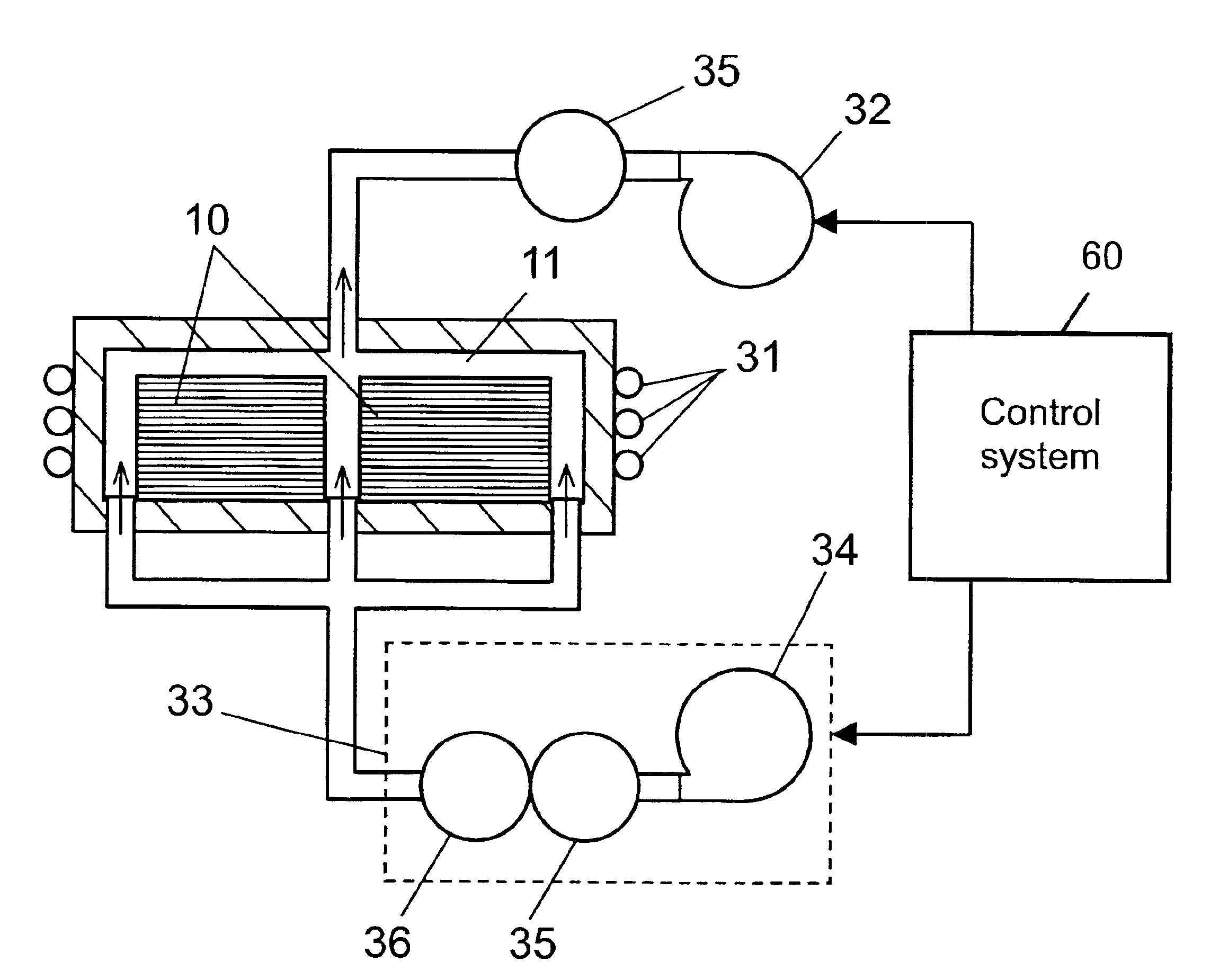

Method and system of drying materials and method of manufacturing circuit boards using the same

InactiveUS6893530B2Efficient dryingImprove reliabilityAdhesive processesDrying solid materials with heatElectricityElectrical connection

A method and system of cleaning to remove cutting dust and the like generated and adhering to a board material (1a) during drilling for electrical connection, and drying the board material, in a process of manufacturing a circuit board for small electronic equipment and the like. A large amount of board materials can be treated without receiving thermal damage by performing the steps of: placing sheets of the board material that have absorbed moisture resulting from cleaning, like a stack in a vacuum chamber (11); and drying the board material by repeating evacuation and pressurization under predetermined conditions while heating the board material.

Owner:PANASONIC CORP

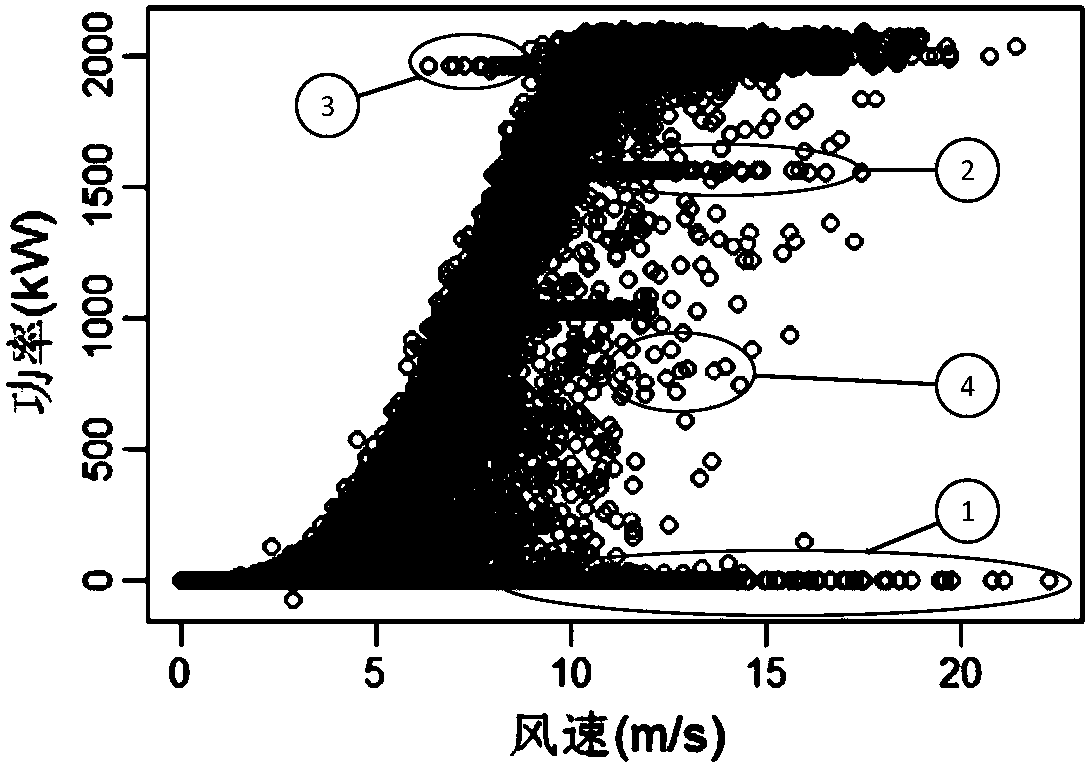

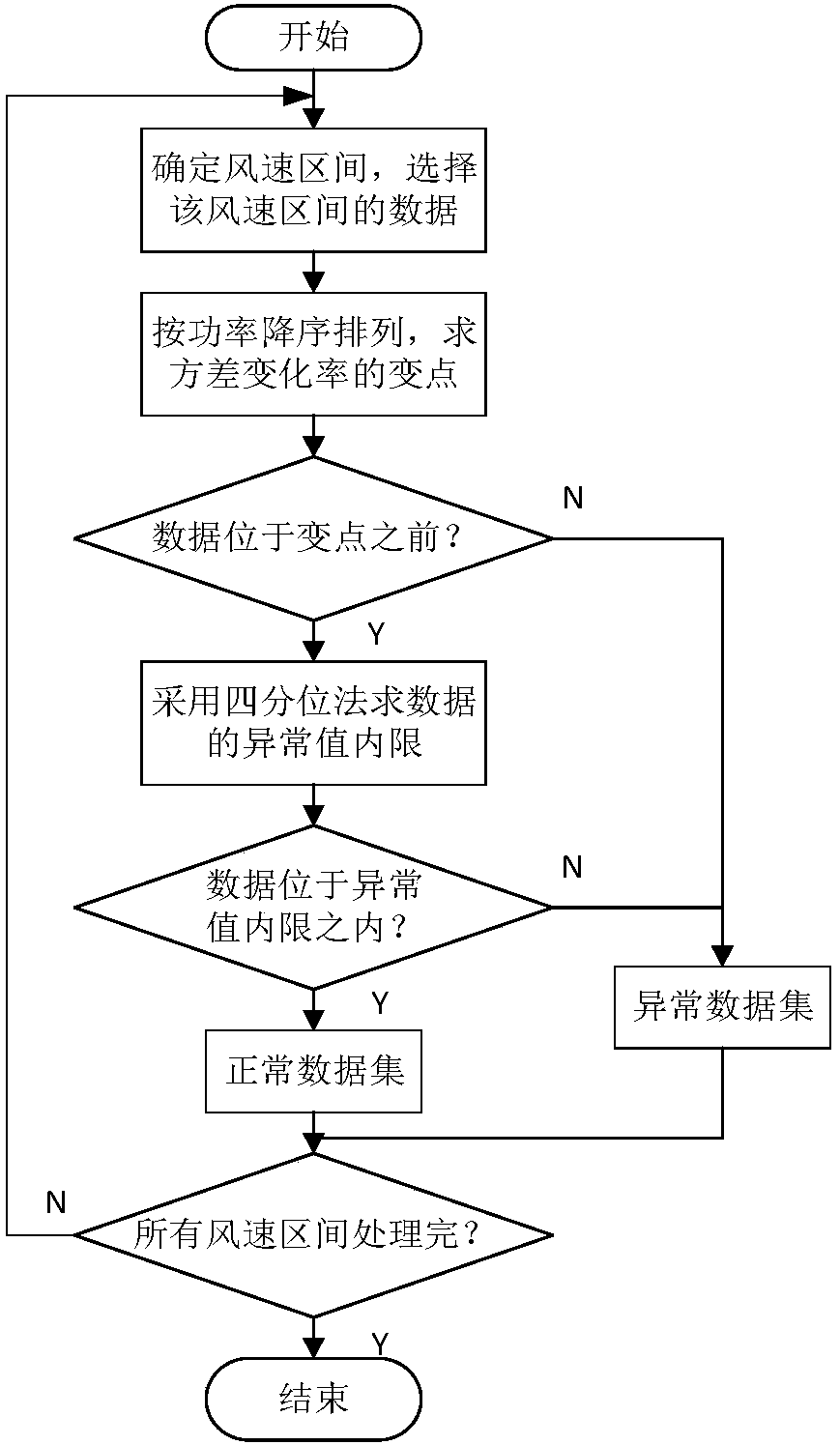

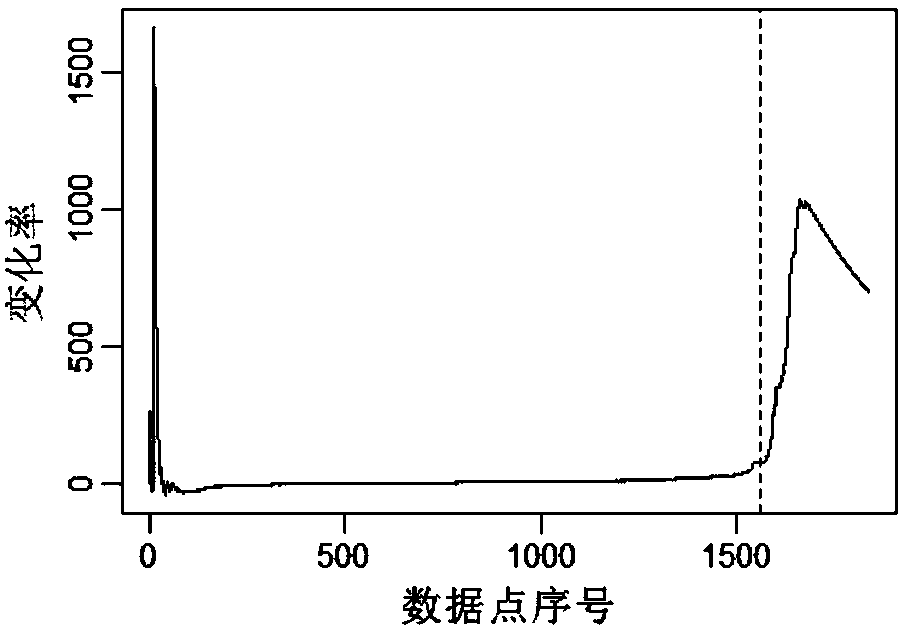

Cleaning method for wind power data of wind generating set

ActiveCN108412710AReasonable processEasy to cleanWind motor combinationsMachines/enginesElectricityCleaning methods

The invention relates to a cleaning method for the wind power data of a wind generating set. The method comprises the following steps that (1) the wind power data to be cleaned are divided into a plurality of data intervals according to the wind speed; (2) each data interval is subjected to data cleaning by adopting a variable-point grouping-quartile method, and abnormal data are removed; and (3)the cleaned data intervals are combined to obtain the cleaned wind power data. Compared with the prior art, the method has the advantages of being good in data cleaning effect, high in efficiency andhigh in universality.

Owner:TONGJI UNIV

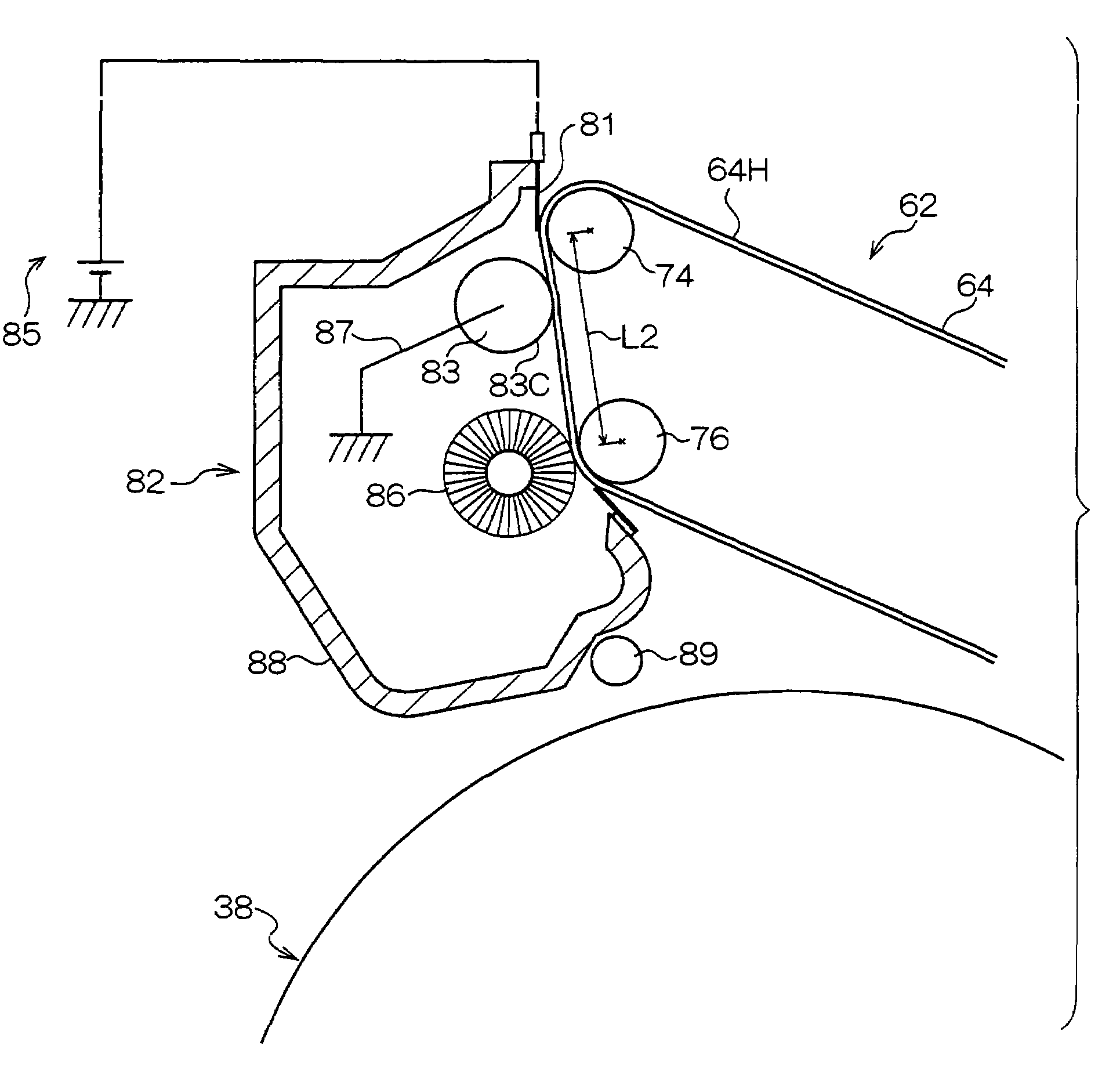

Film forming apparatus, head cleaning method, device manufacturing system, and device

ActiveUS7090728B2Reliable cleaningFlexible responseInking apparatusOptical filtersCleaning methodsEngineering

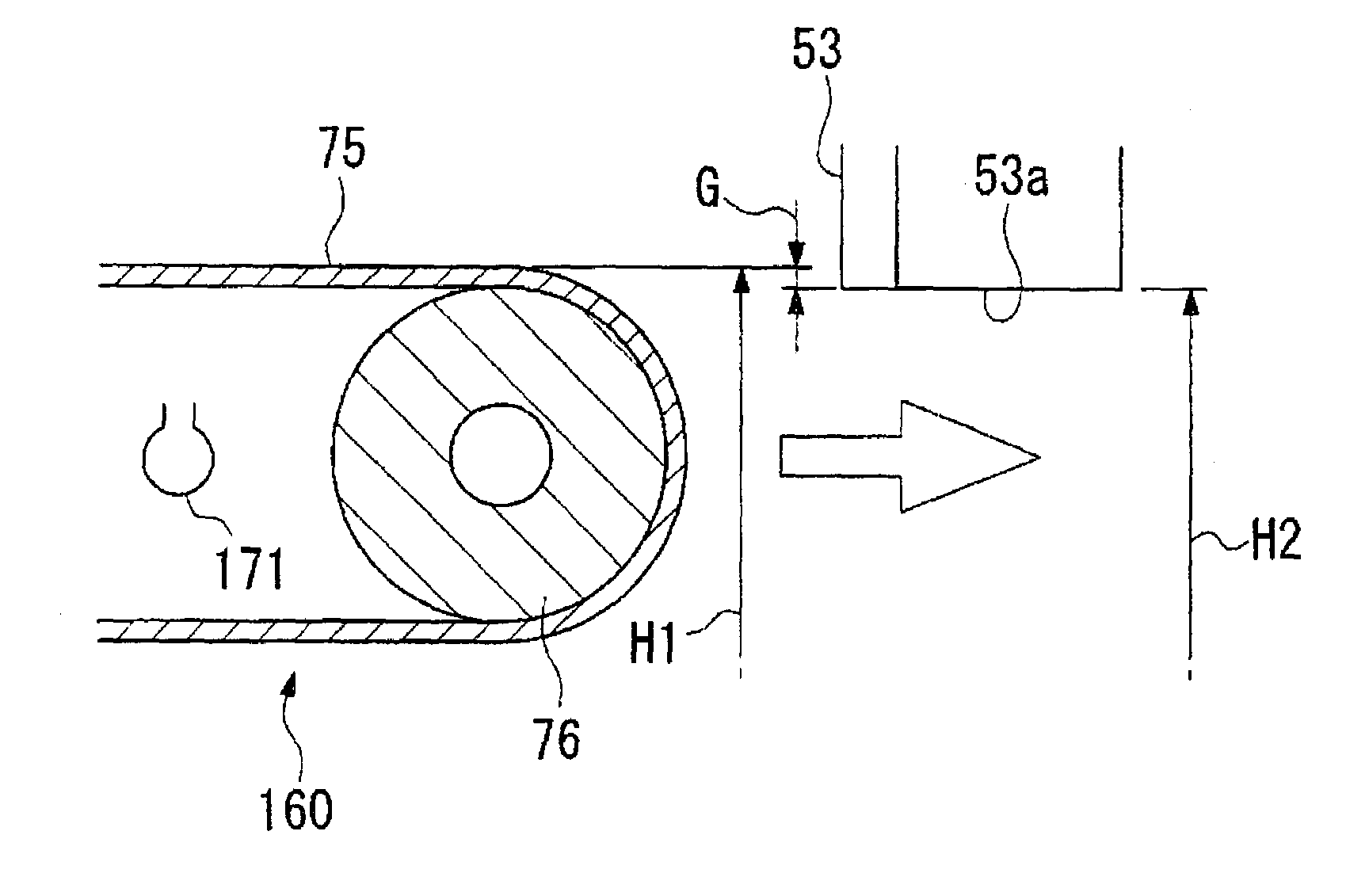

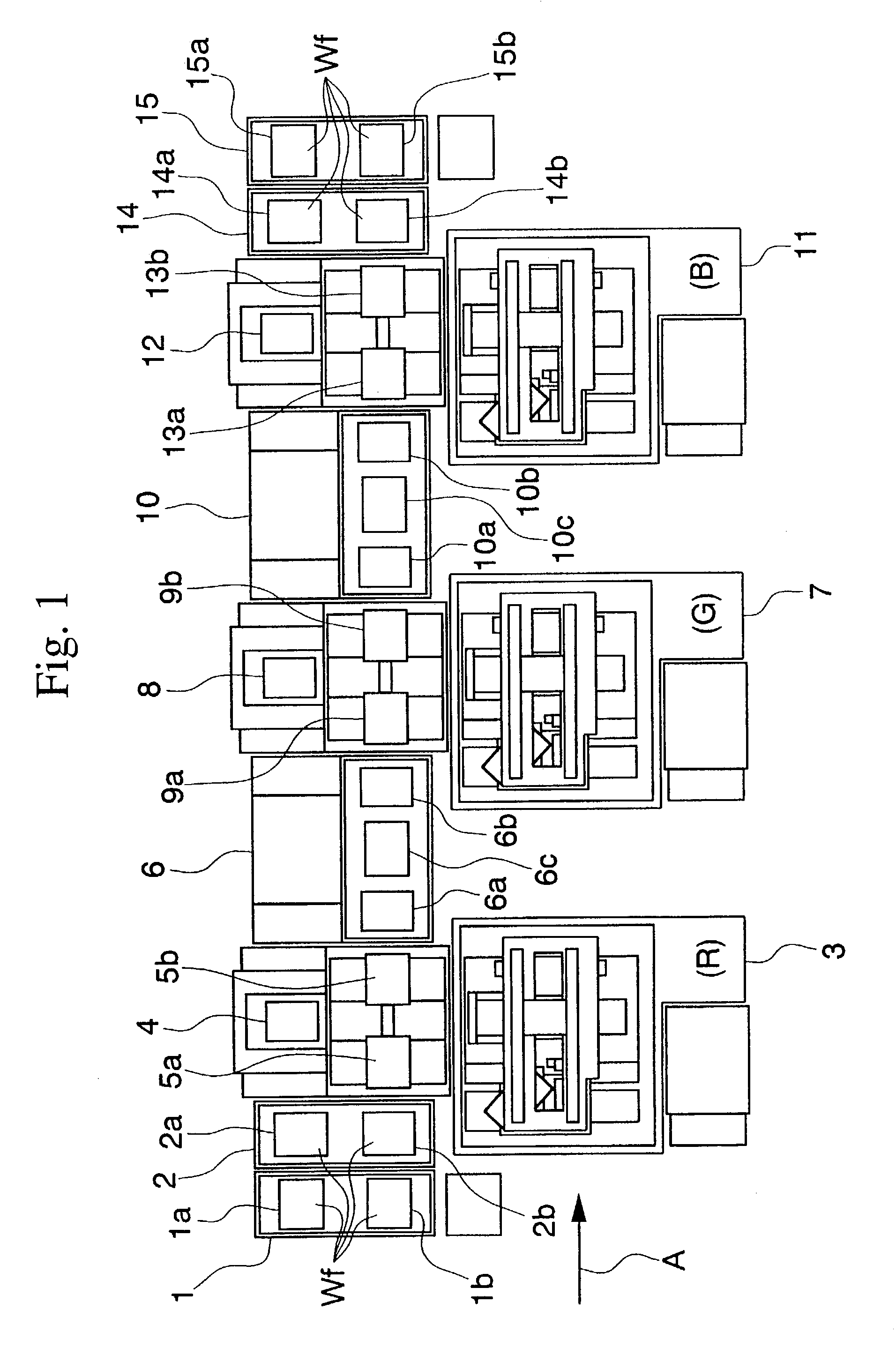

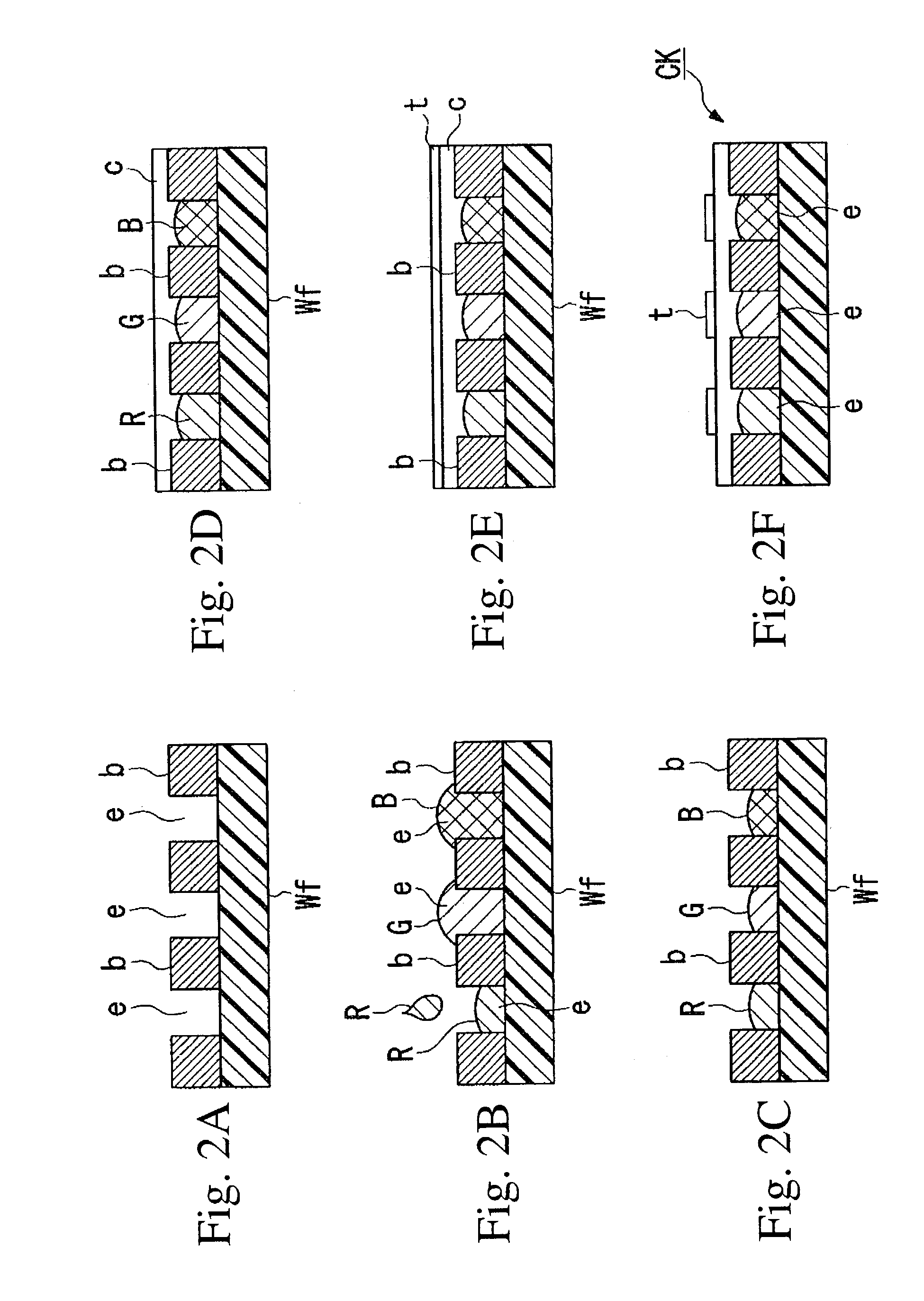

A system and method for reliably cleaning the nozzle face of each head while flexibly coping with changes in specification for a product to be manufactured. The film forming apparatus has a plurality of heads for jetting droplets, each having an nozzle in a nozzle face; and a common head cleaning mechanism for collectively cleaning the nozzle faces, so that the head cleaning mechanism is not substantially affected by a change in the pitch between the heads, or the like. Typically, the head cleaning mechanism has a wiping sheet for wiping the nozzle faces; a supply unit for feeding the wiping sheet towards the nozzle faces; and a roller for pressing the wiping sheet against the nozzle faces while the wiping sheet is fed from the supply unit, so that an unused cleaning face can always be supplied to each nozzle face.

Owner:KATEEVA

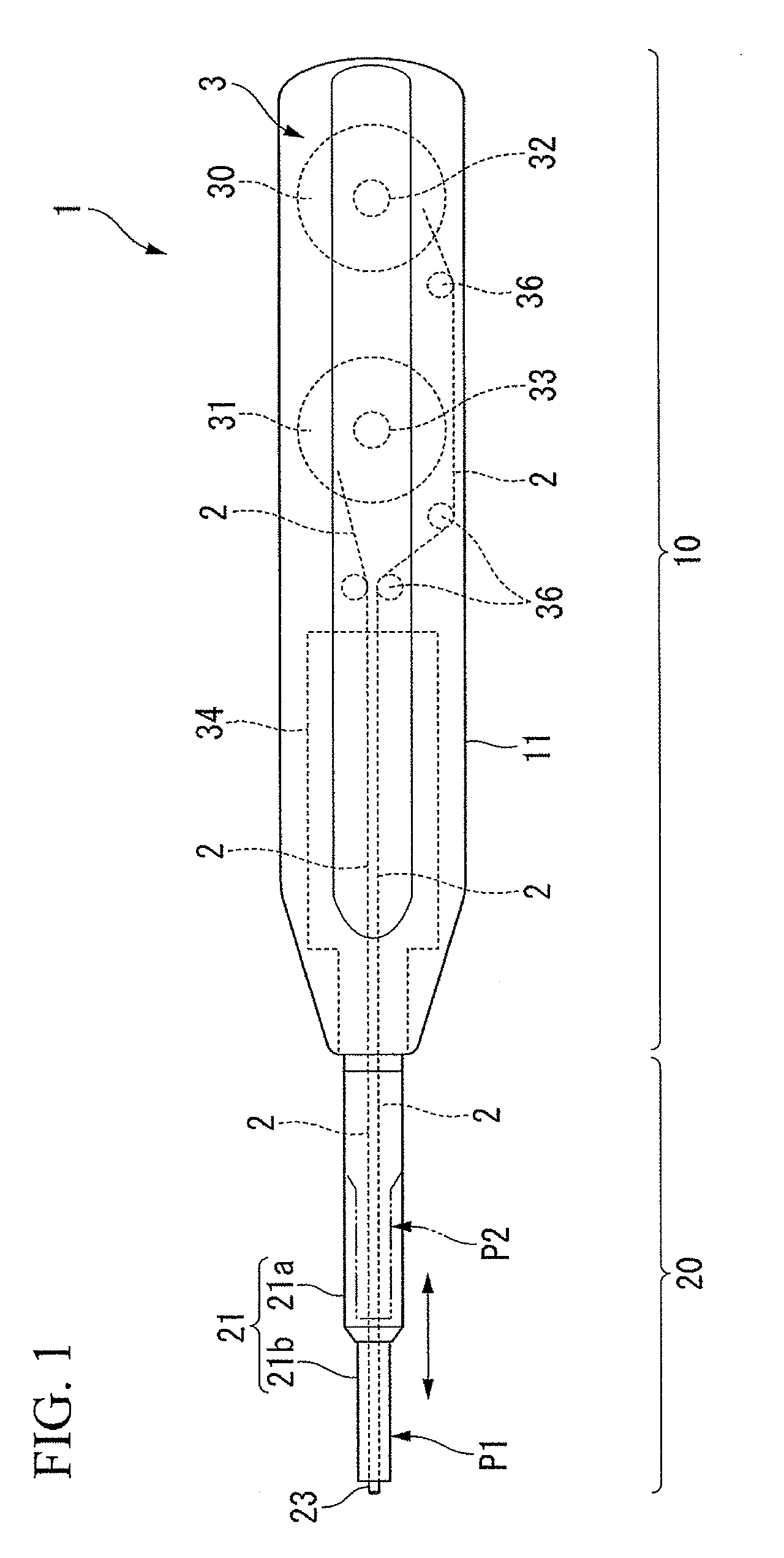

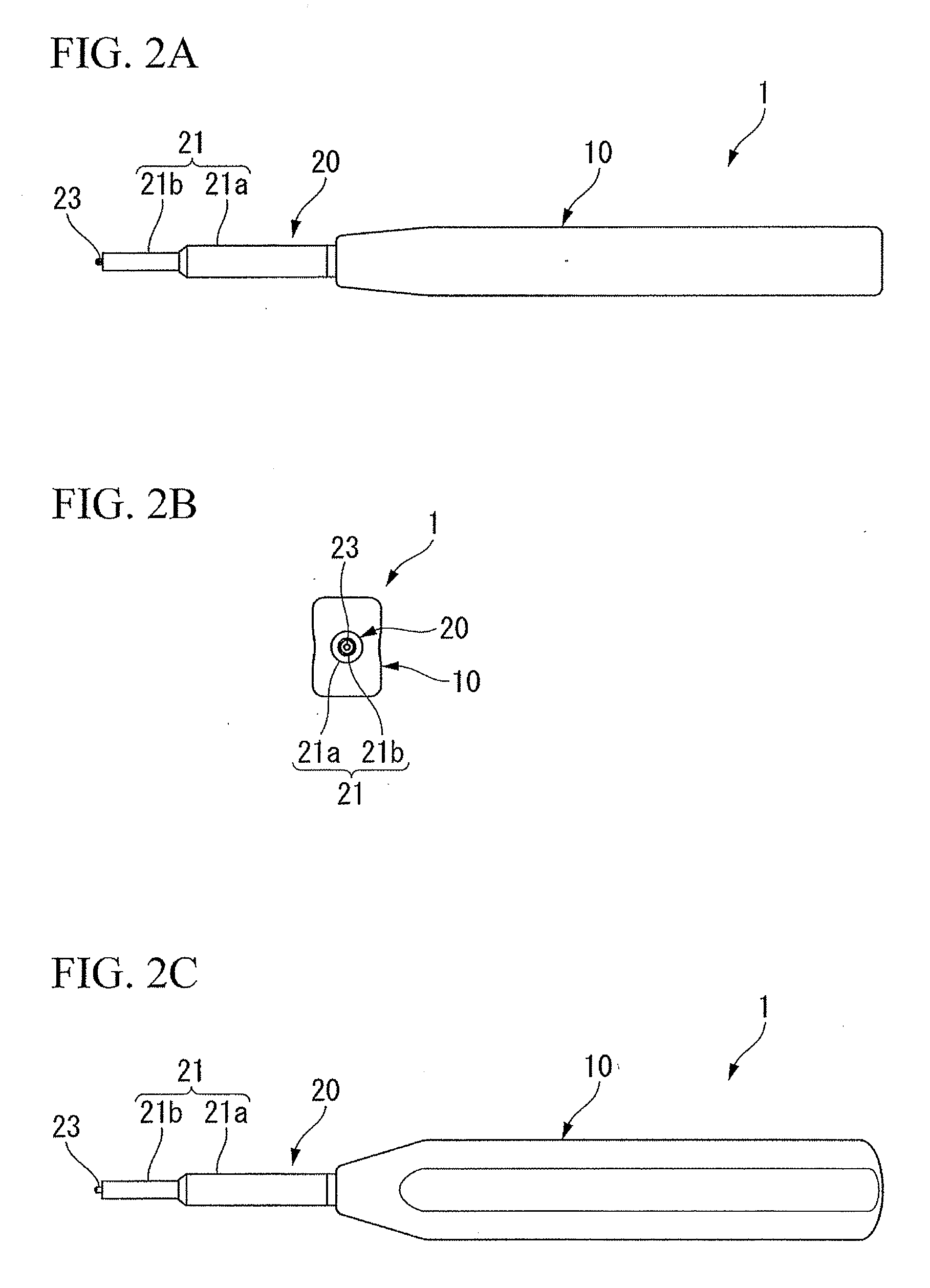

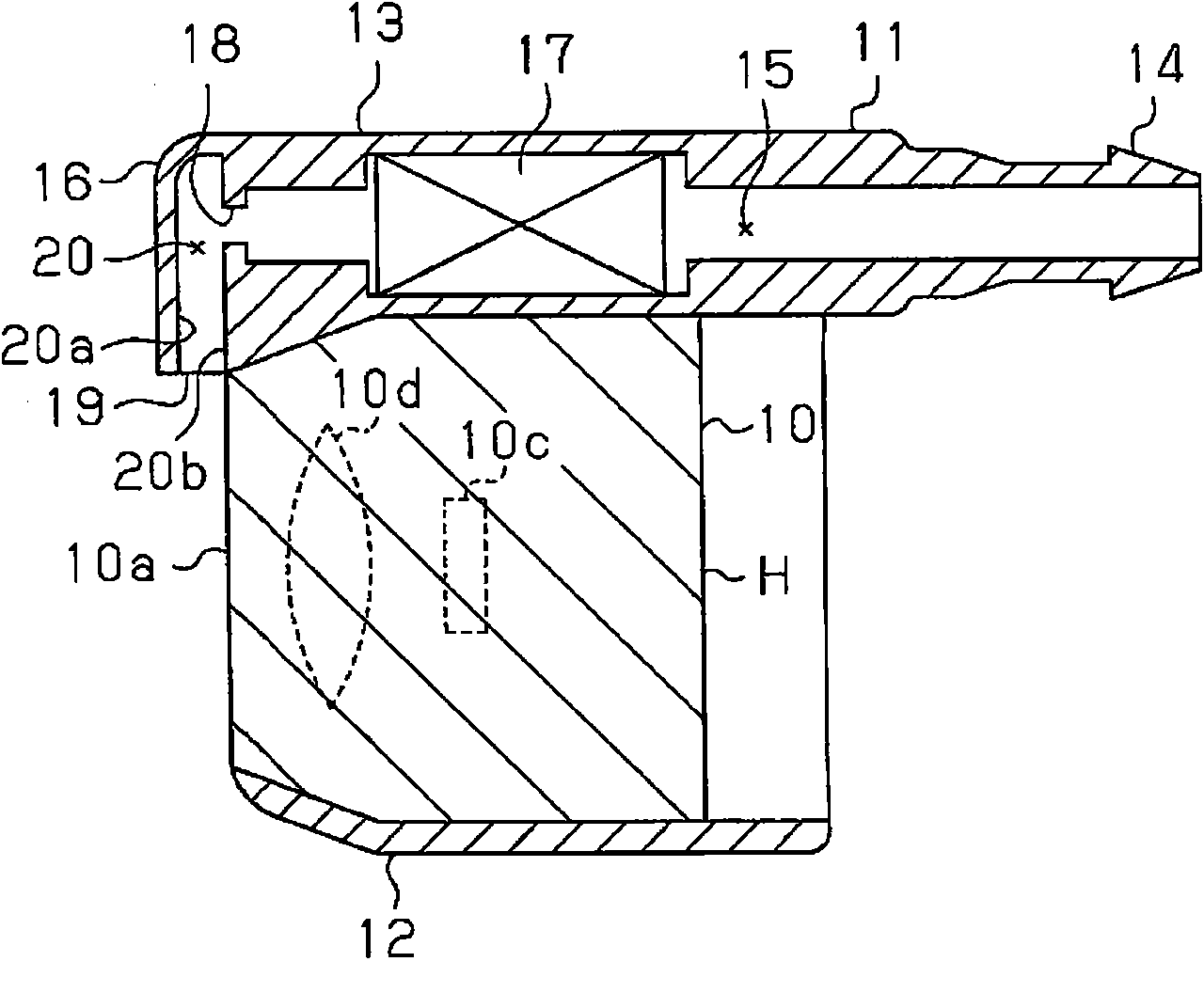

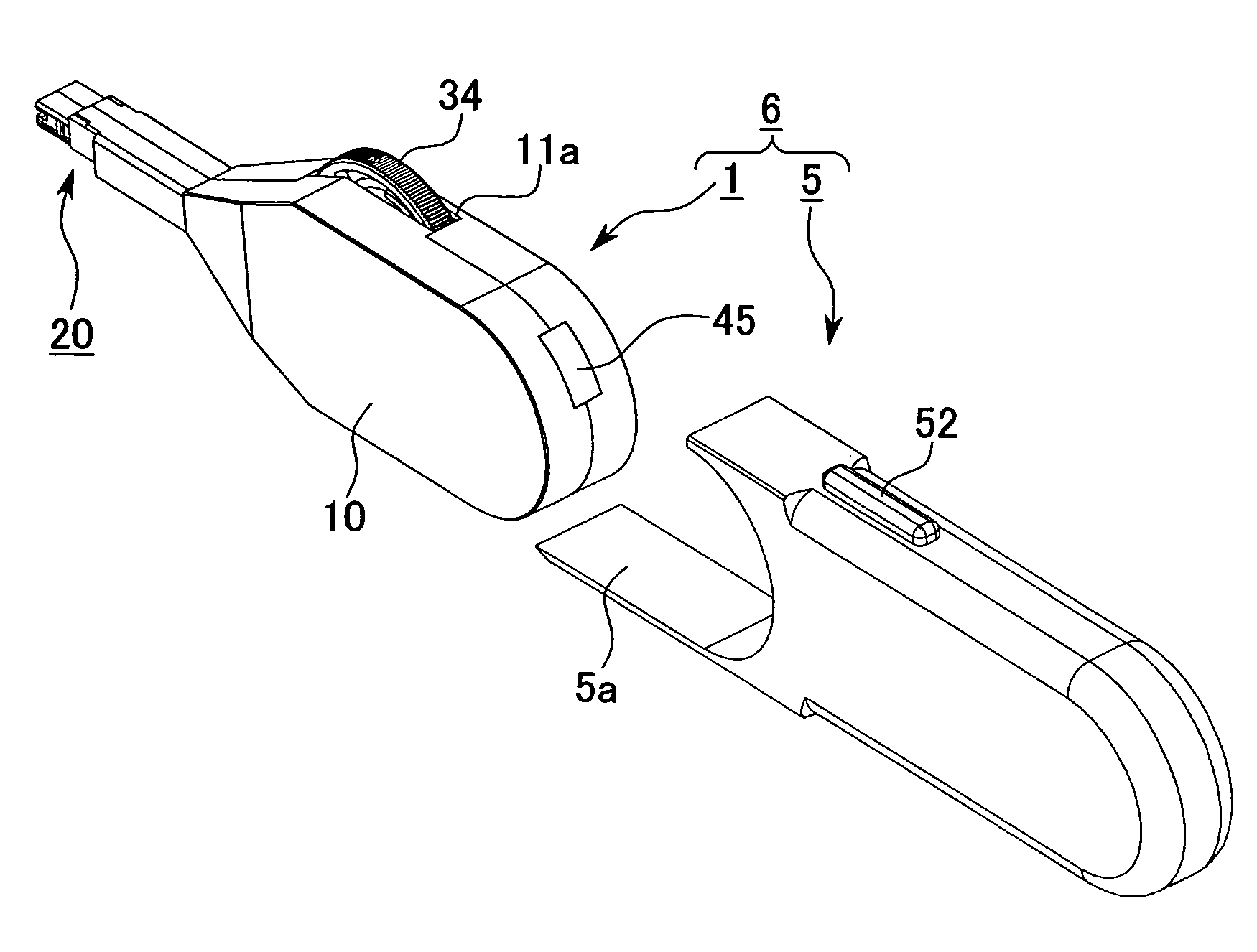

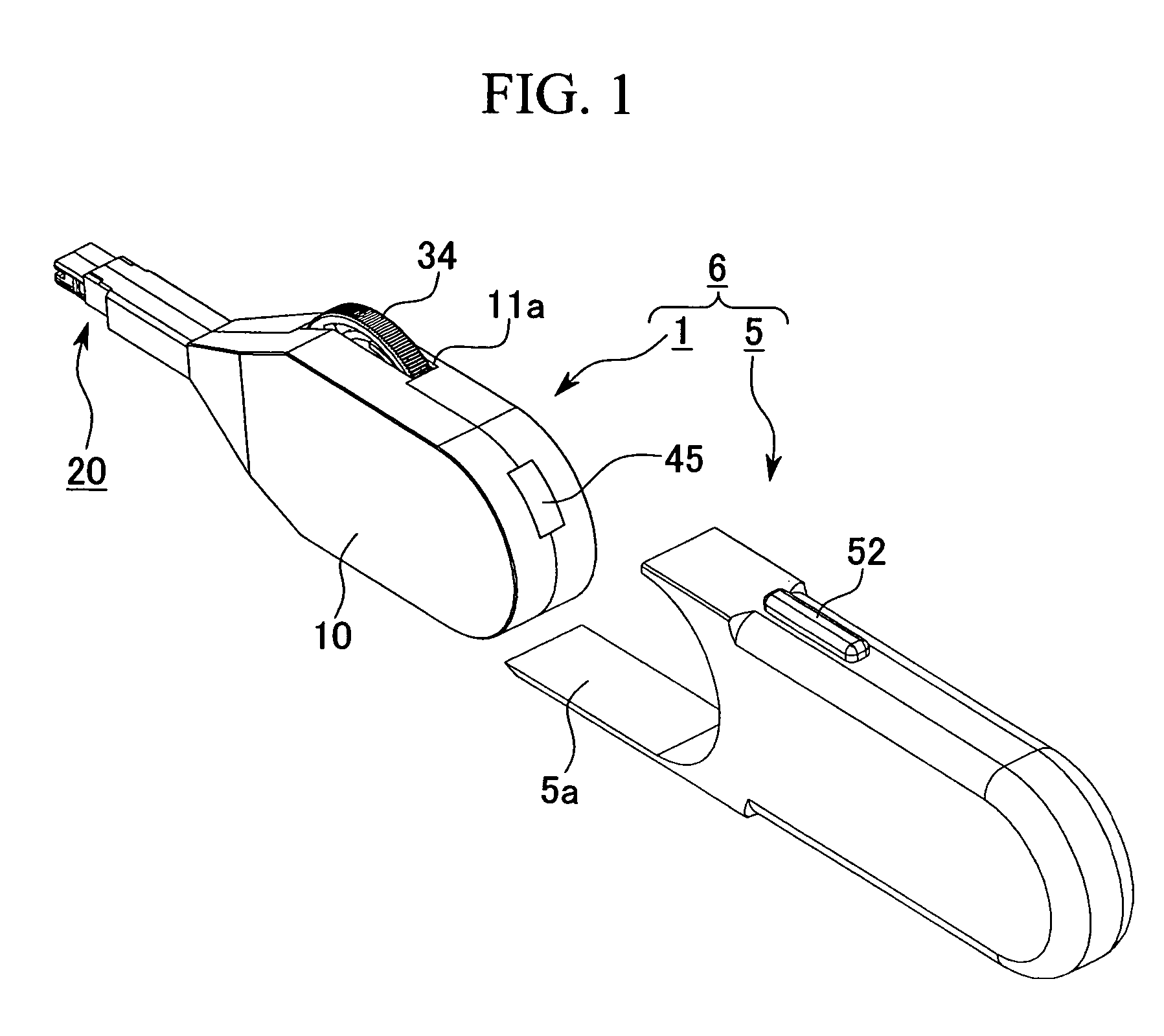

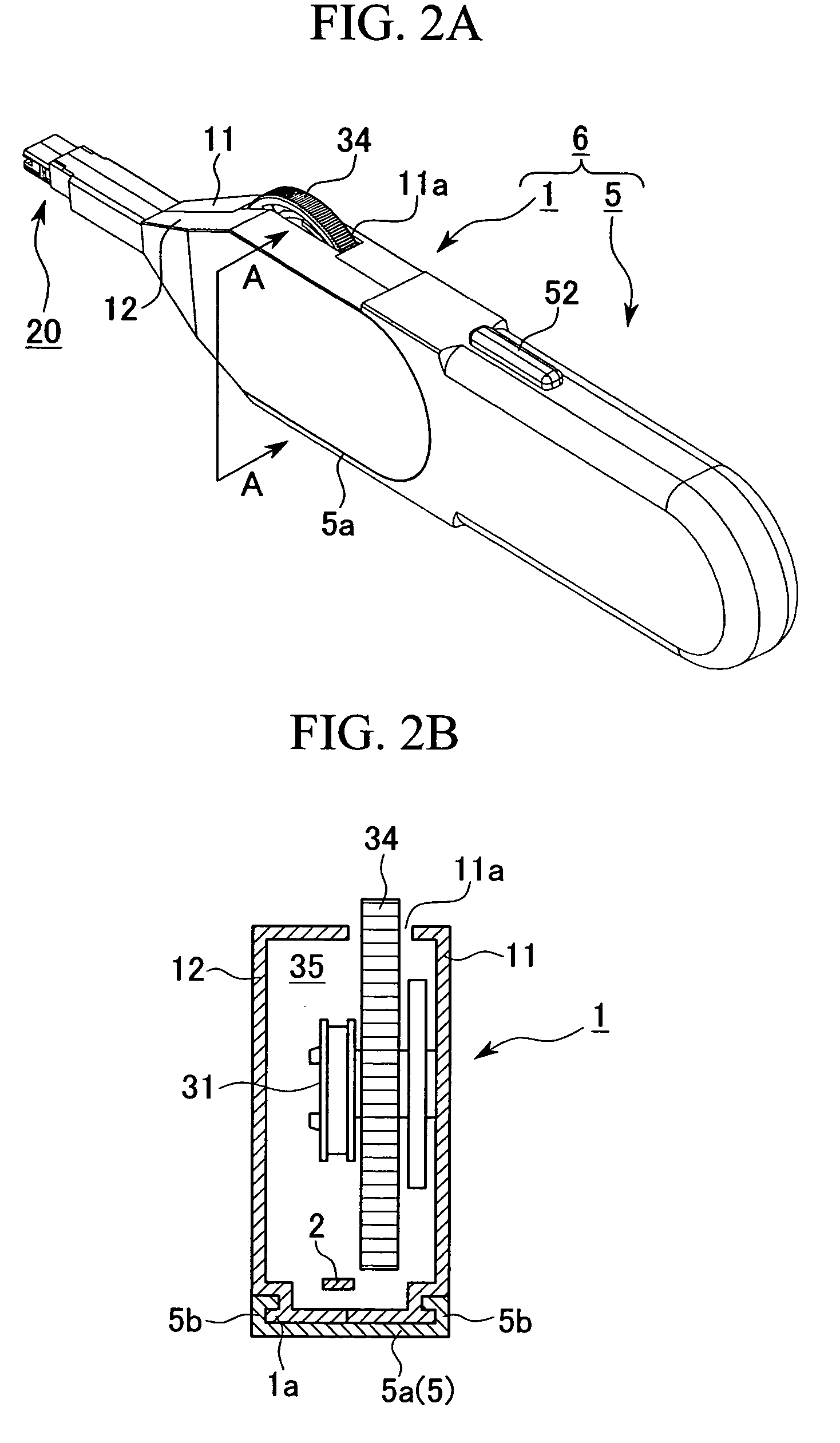

Optical connector cleaning tool

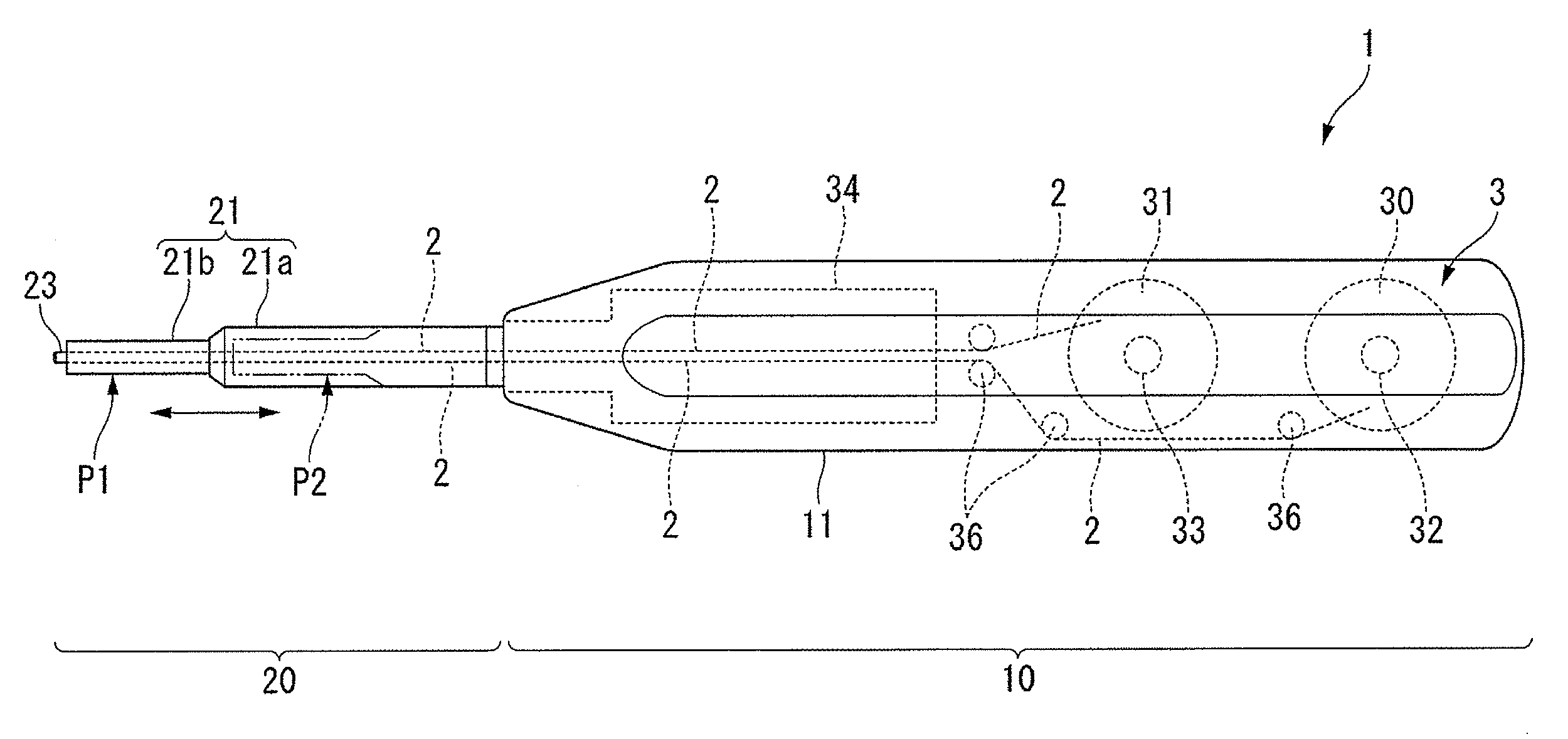

ActiveUS20100043159A1Easy to operateOptimization mechanismLiquid processingReconditioning/cleaning record carriersEngineeringMechanical engineering

An optical connector cleaning tool which wipes to clean a joining end face of an optical connector by a feeding movement of a cleaning body. It includes a tool body which incorporates a feeding mechanism that supplies and takes up the cleaning body, and an insertion part which inserts into a connector housing hole of a positioning housing for connectors. The insertion part has a head member on which is formed a pressing face that presses the cleaning body against the joining end face within the connector housing hole, and is capable of moving in a direction of extension or contraction relative to the tool body. Movement of the tool body in an insertion direction relative to the insertion part in a state where the cleaning body is in contact with the joining end face causes the head member to axially rotate while the state of contact is maintained.

Owner:THE FUJIKURA CABLE WORKS LTD

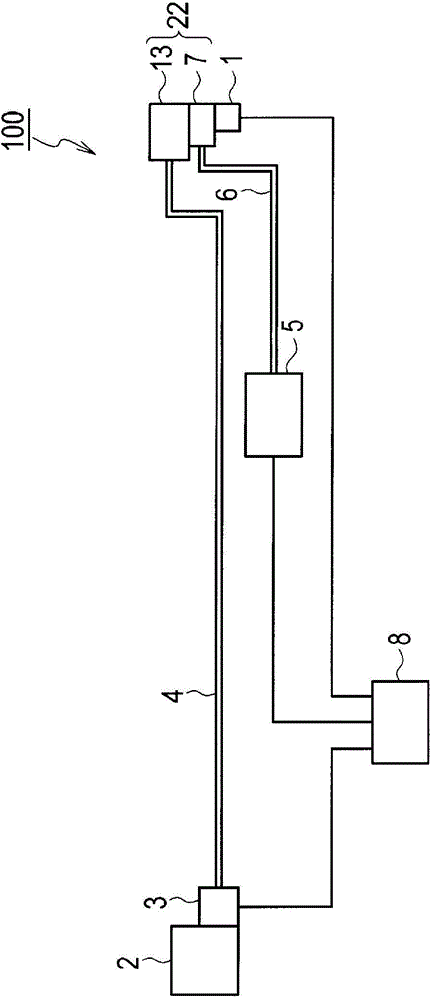

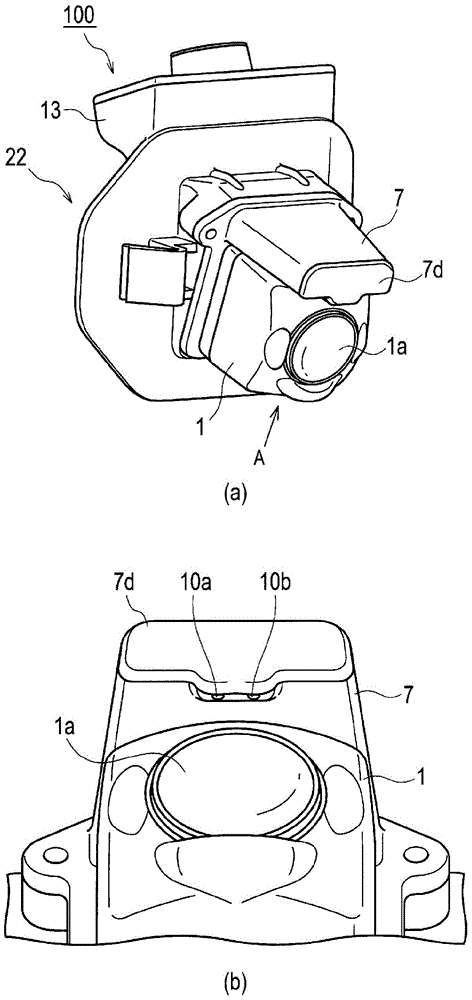

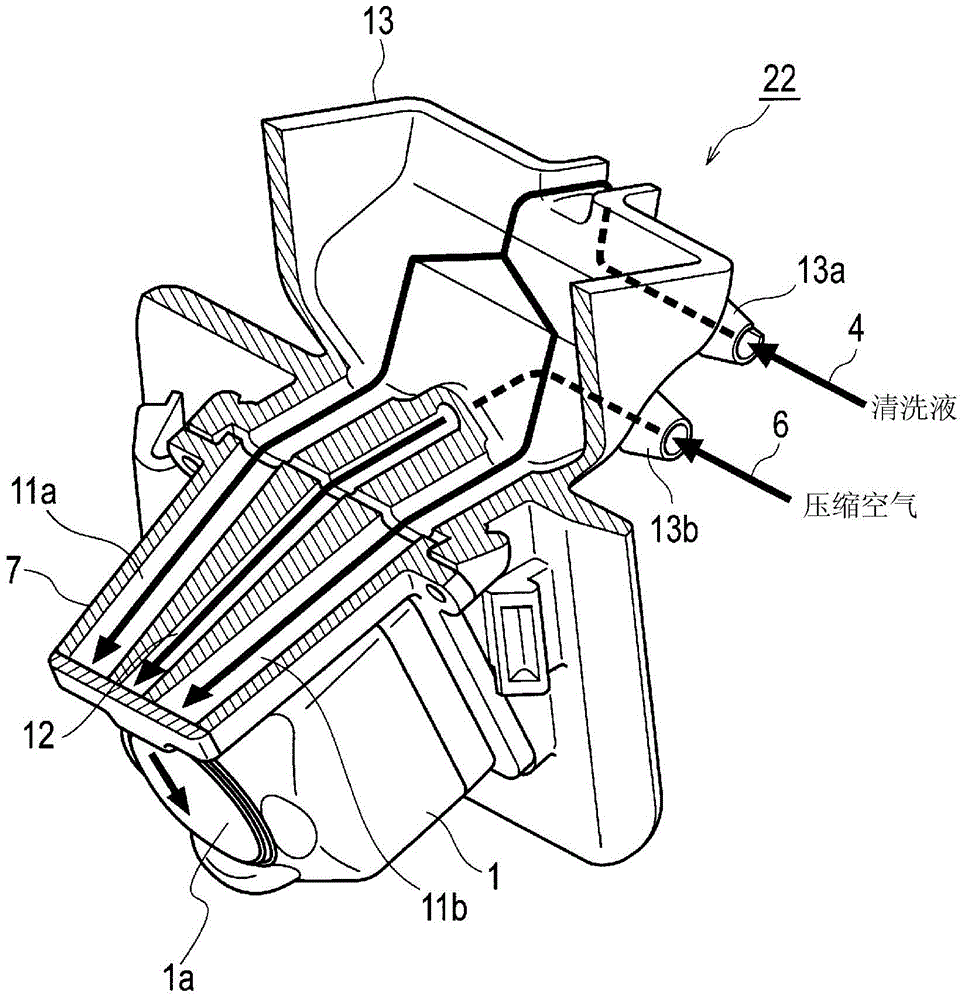

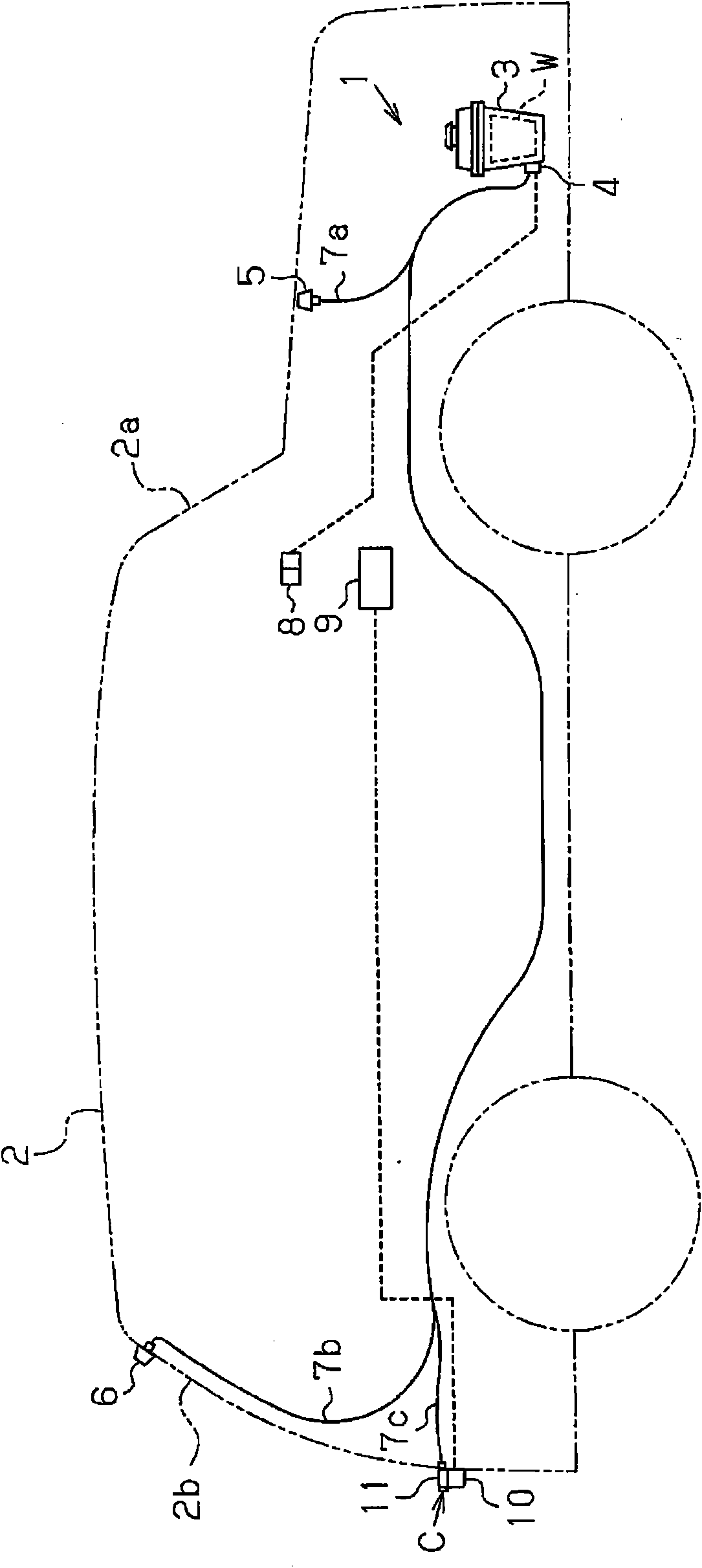

Vehicle-mounted-camera cleaning device, and vehicle-mounted-camera cleaning method

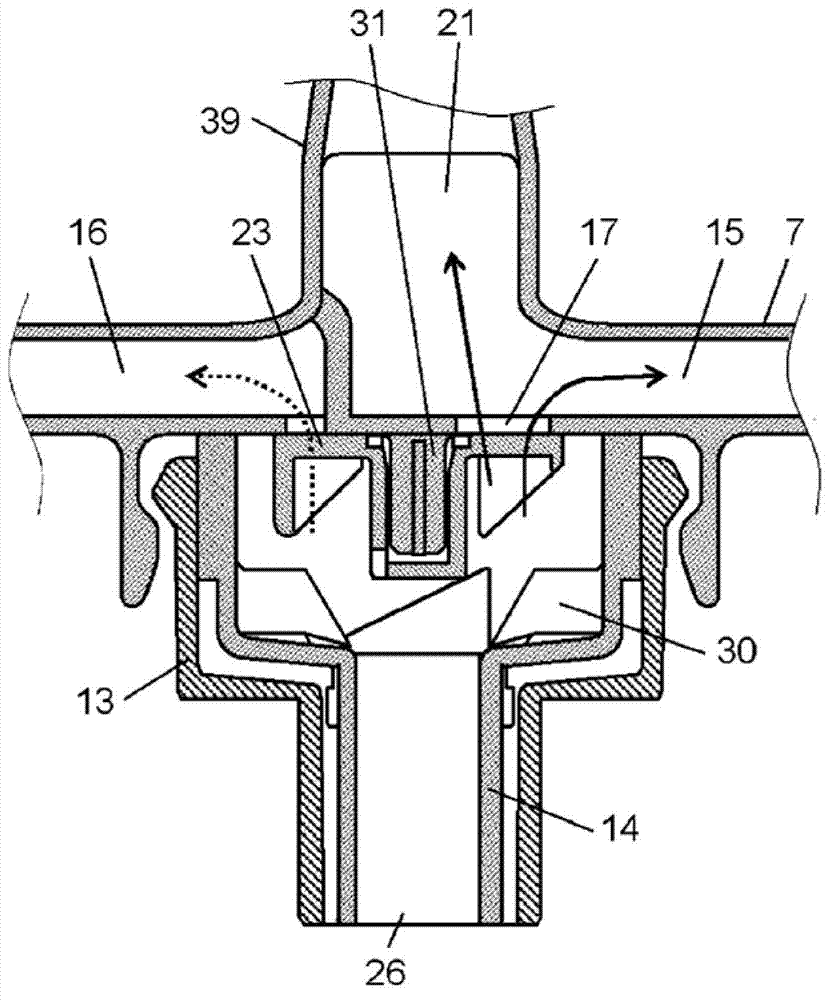

ActiveCN104470771AReliable cleaningTelevision system detailsColor television detailsEngineeringCompressed air

A nozzle (7) is provided for cleaning the lens surface (1a) of a camera (1), the nozzle (7) being equipped with cleaning-fluid channels (11a, 11b) for guiding cleaning fluid to discharge ports (10a, 10b), and an air channel (12) for guiding compressed air to the discharge ports (10a, 10b). The end sections of the cleaning-fluid channels and the end section of the air channel are positioned so as to be near one another or converge with one another. When cleaning the lens surface (1a), the lens surface (1a) is cleaned by intermittently spraying the compressed air from the discharge ports, drawing in the cleaning fluid using the negative pressure generated by spraying the compressed air, and intermittently spraying the cleaning fluid from the discharge ports.

Owner:NISSAN MOTOR CO LTD

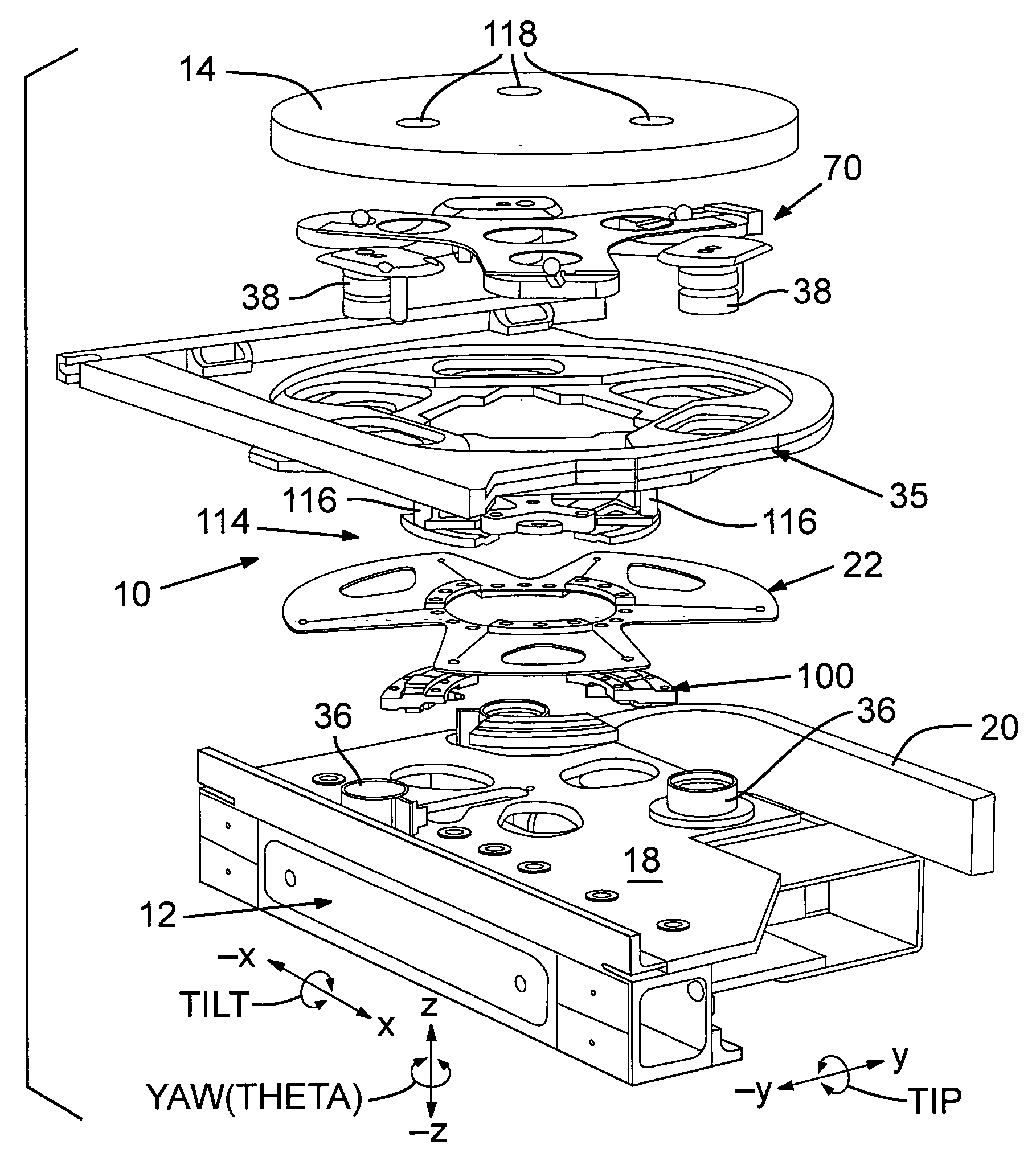

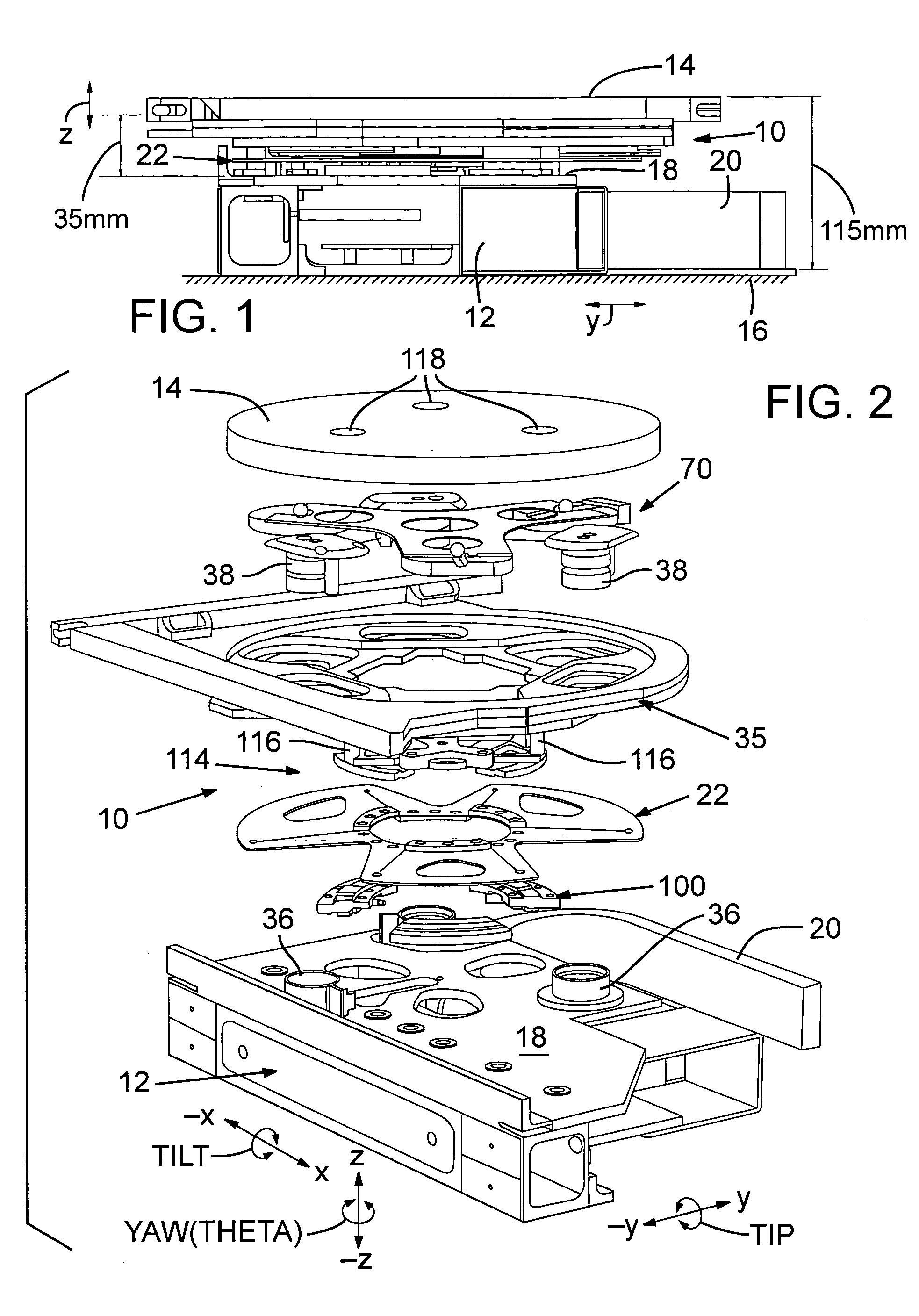

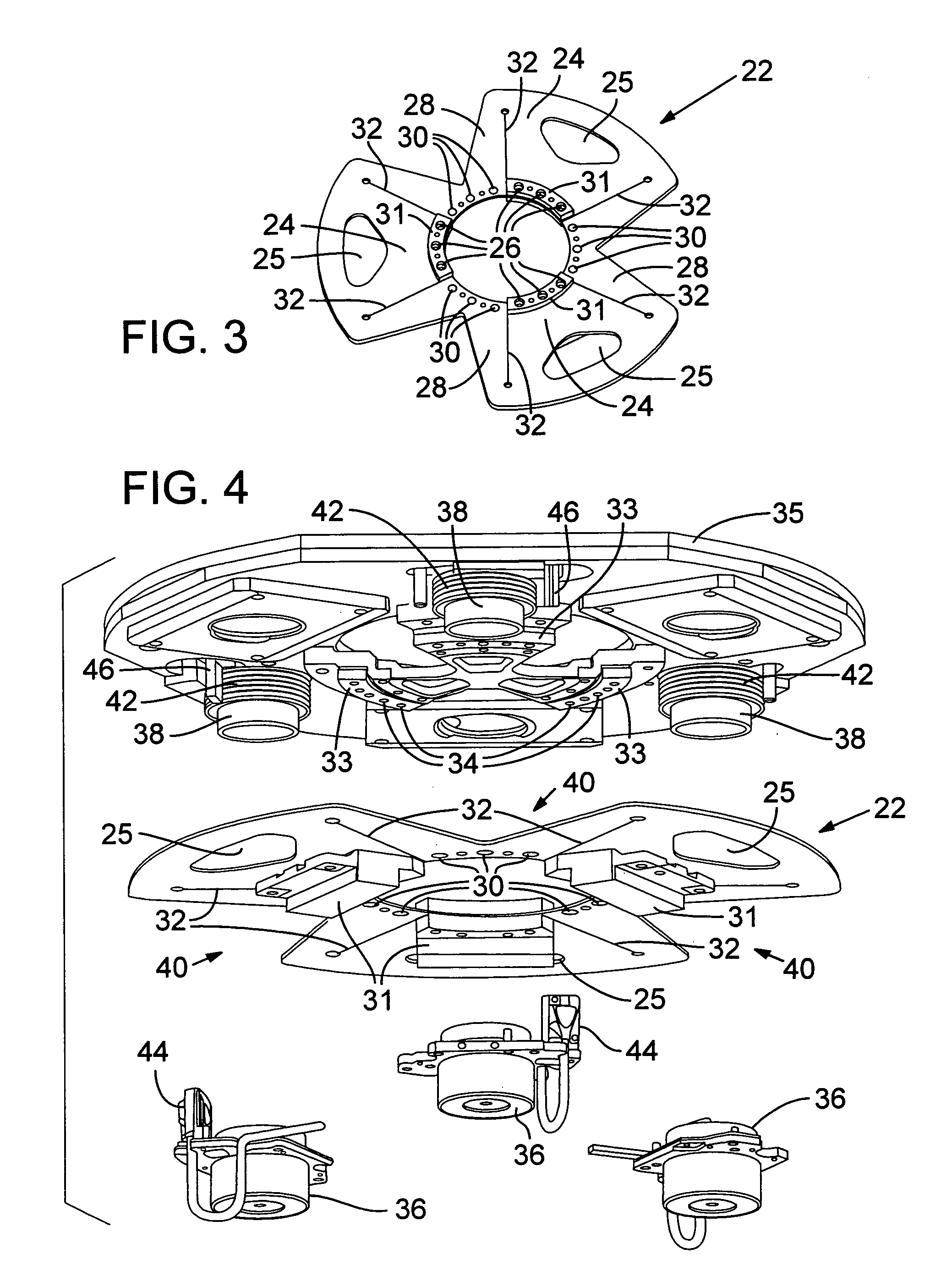

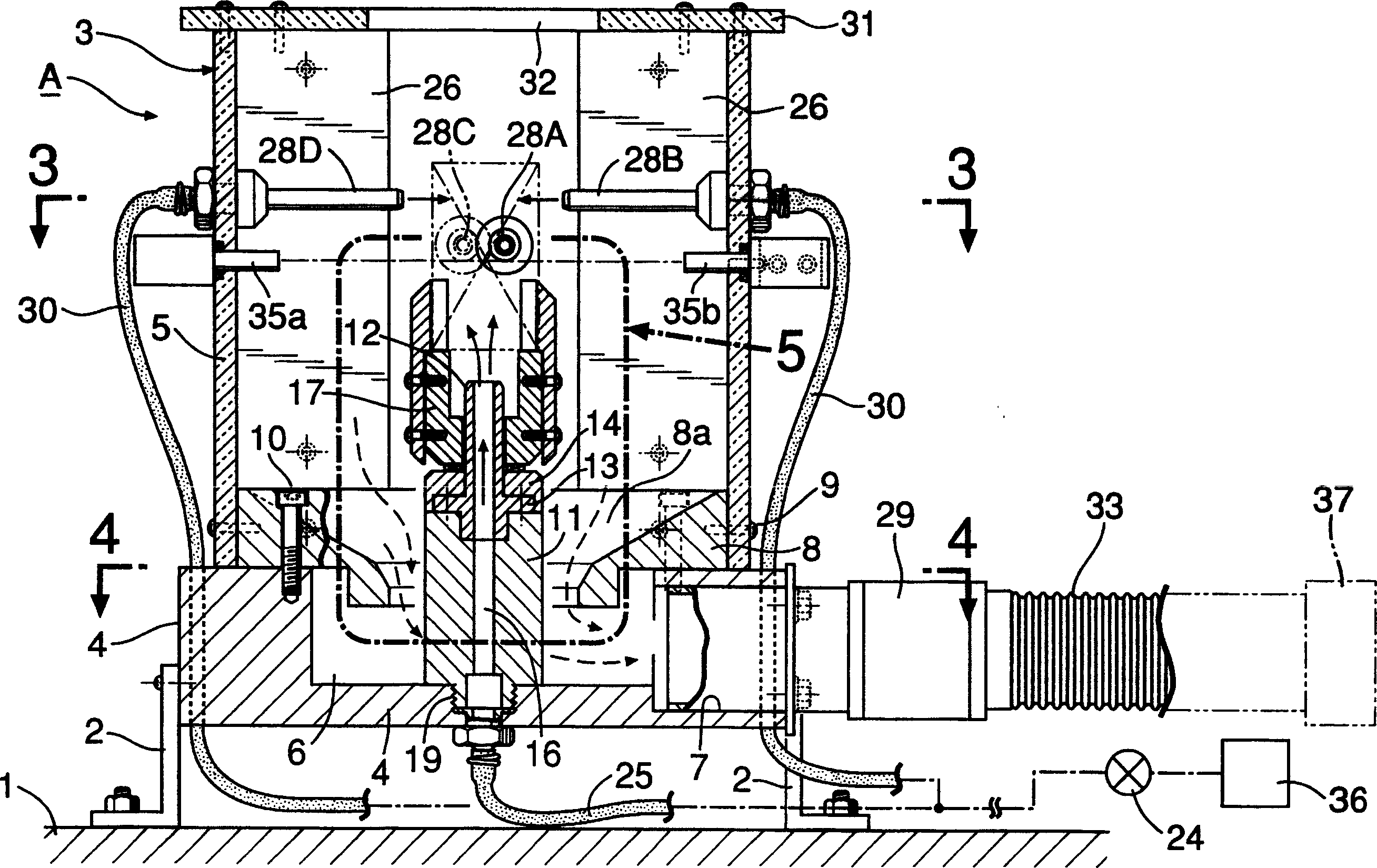

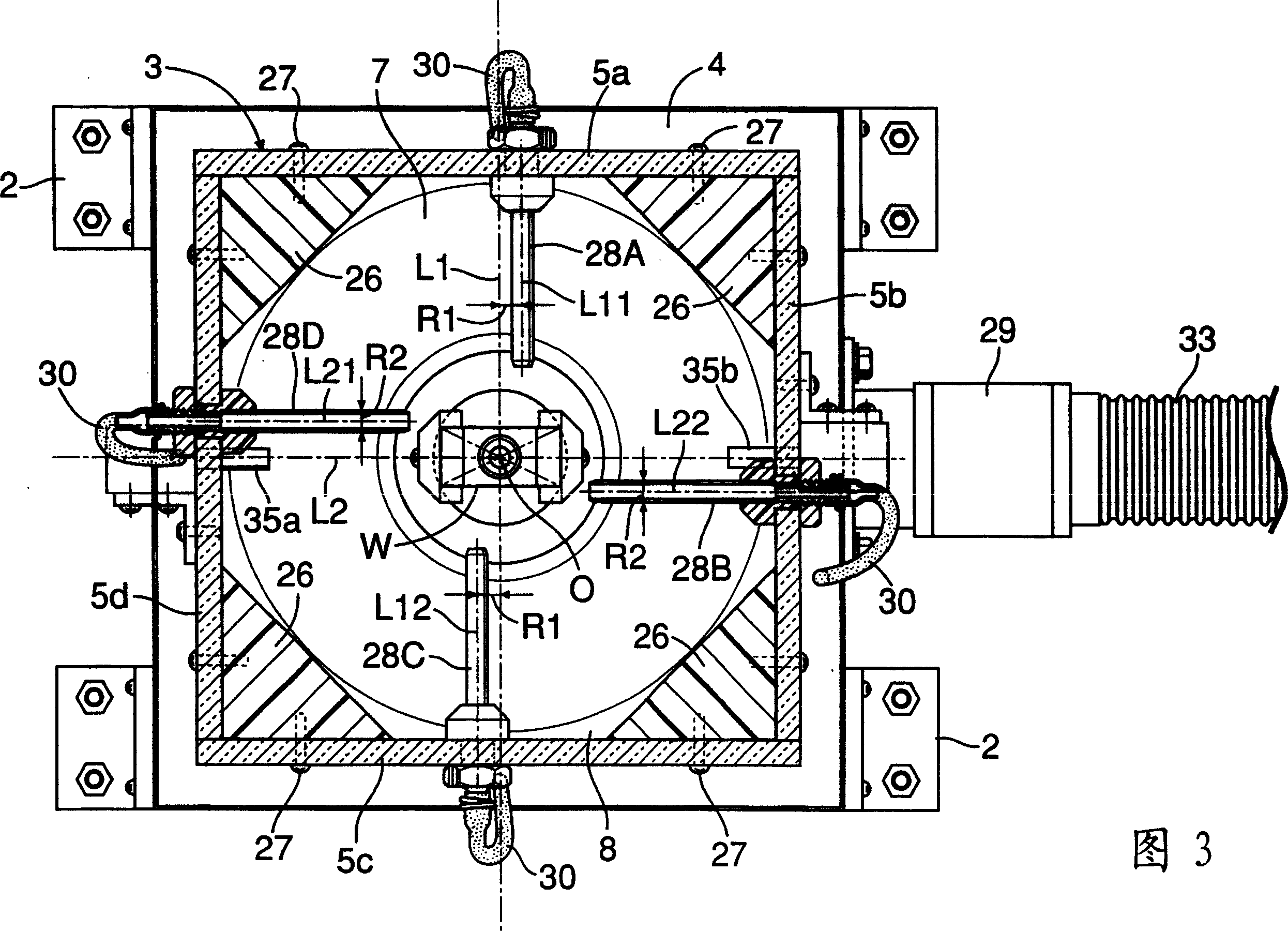

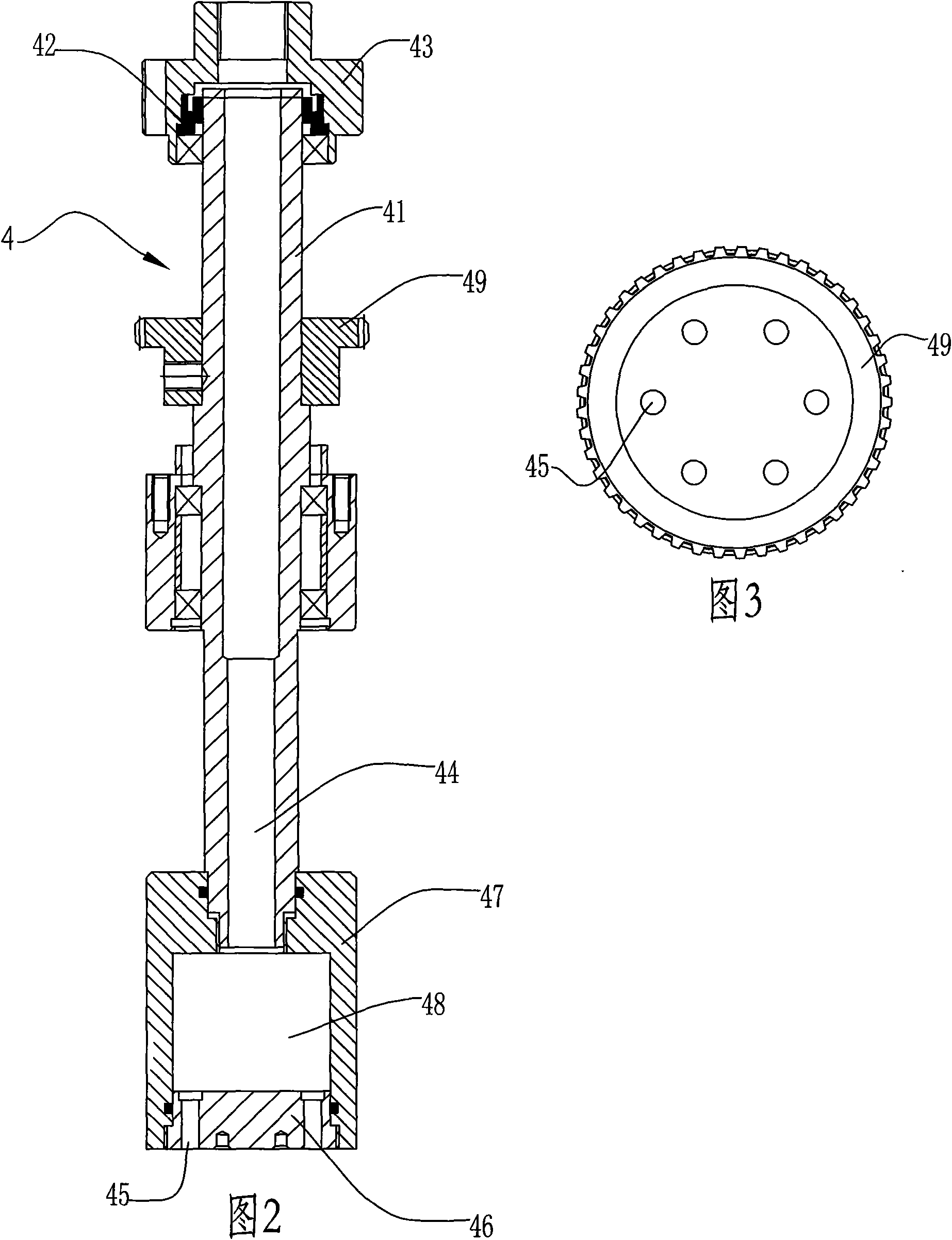

High resolution, dynamic positioning mechanism for specimen inspection and processing

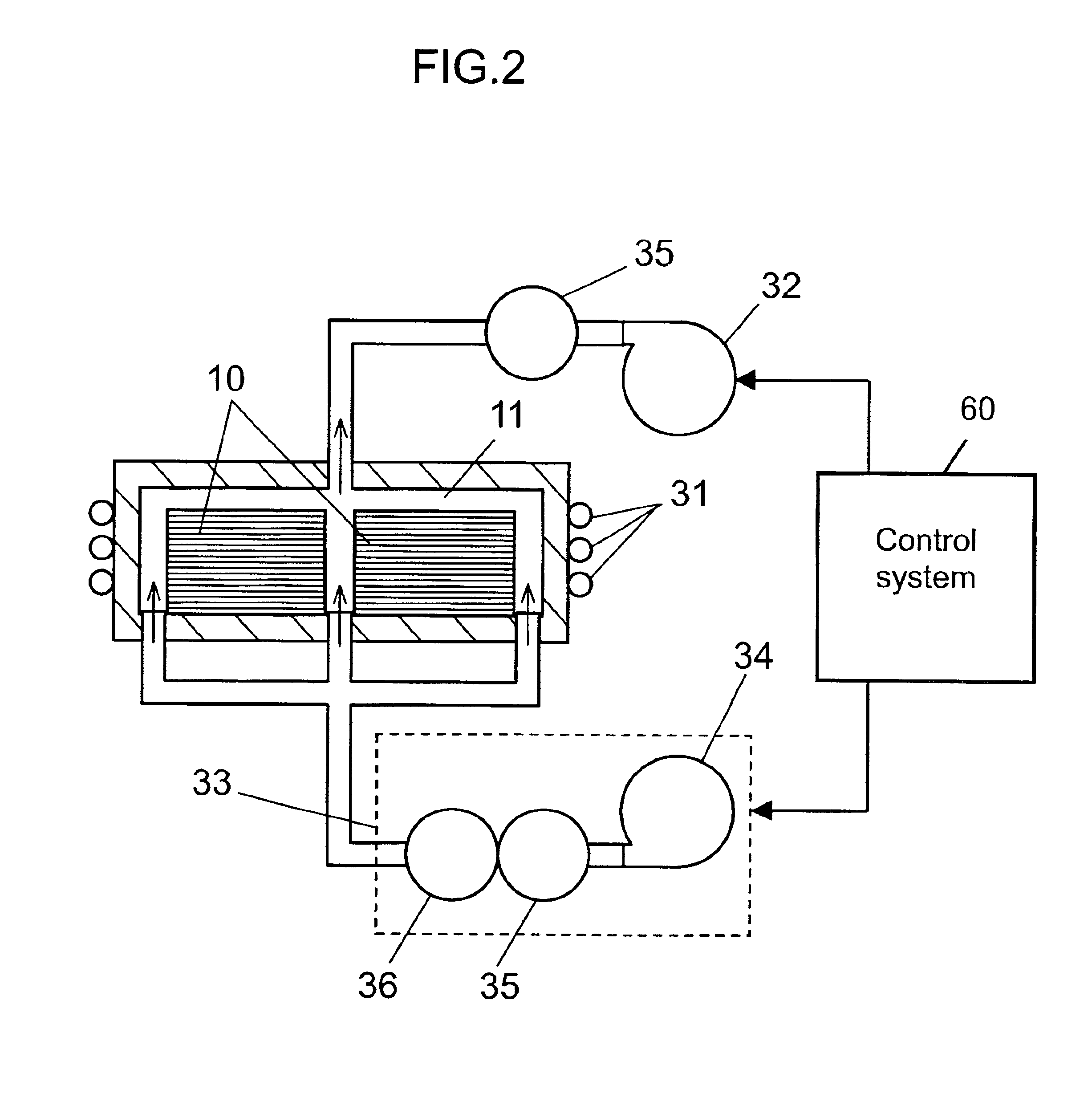

ActiveUS20050012920A1Avoid vibrationIncrease dampingMotor/generator/converter stoppersDC motor speed/torque controlEngineeringDynamic positioning

A specimen positioning mechanism (10) includes a movable stage (12) movable along multiple axes, a plate (35) connected to and supporting a specimen mounting chuck (14), multiple linear displacement mechanisms (36, 38) coupling the plate to the movable stage and mutually spaced apart at different locations between the movable stage and the plate and separately controllable to change distances between the movable stage and the plate, and a flexible member (22) coupling the movable stage and the plate. The flexible member is motion compliant in three axes of motion. The flexible member in response to linear displacements of the linear displacement mechanisms allows linear and rotational movement of the specimen mounting chuck in the three axes of motion compliance.

Owner:NEWPORT CORP

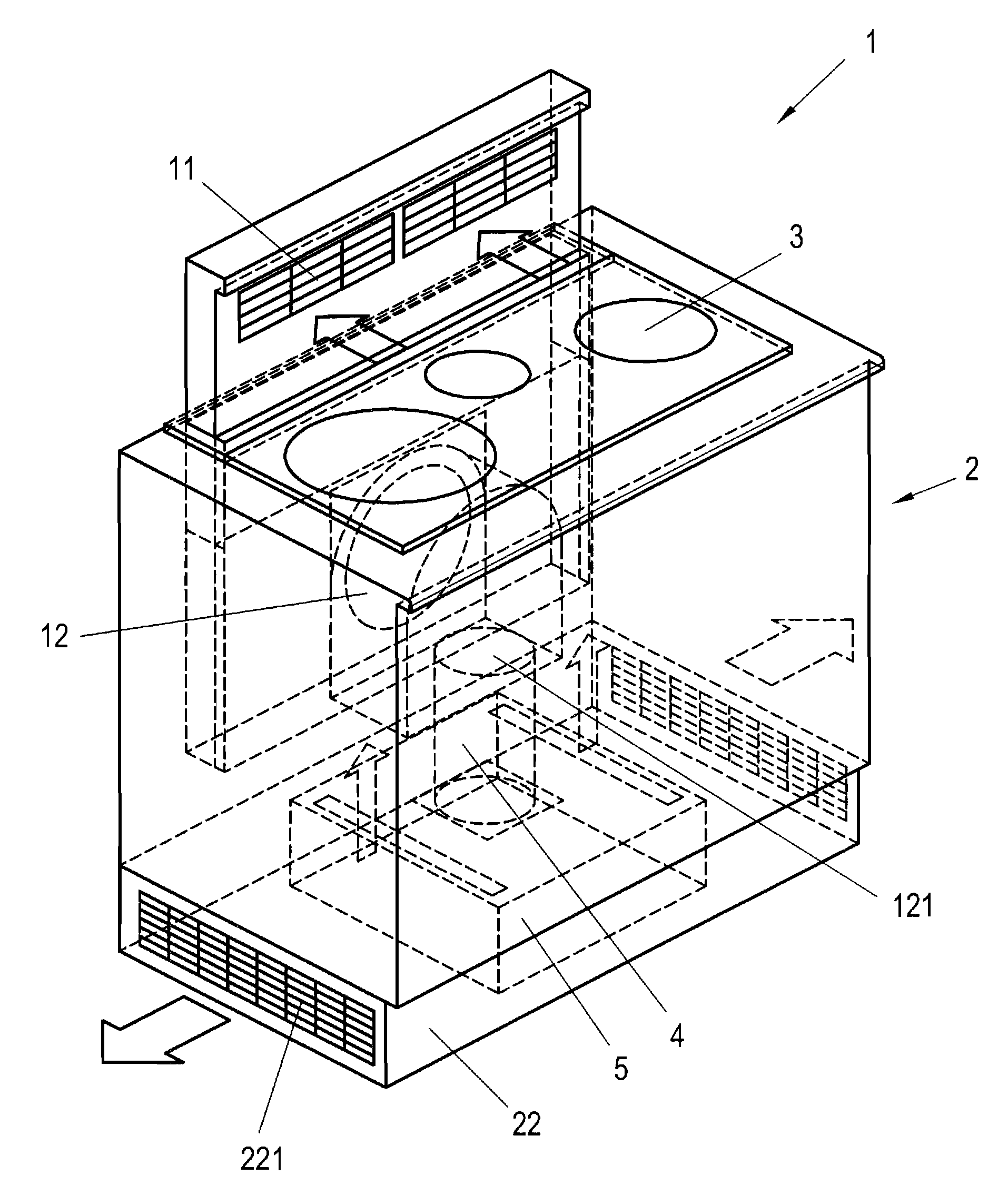

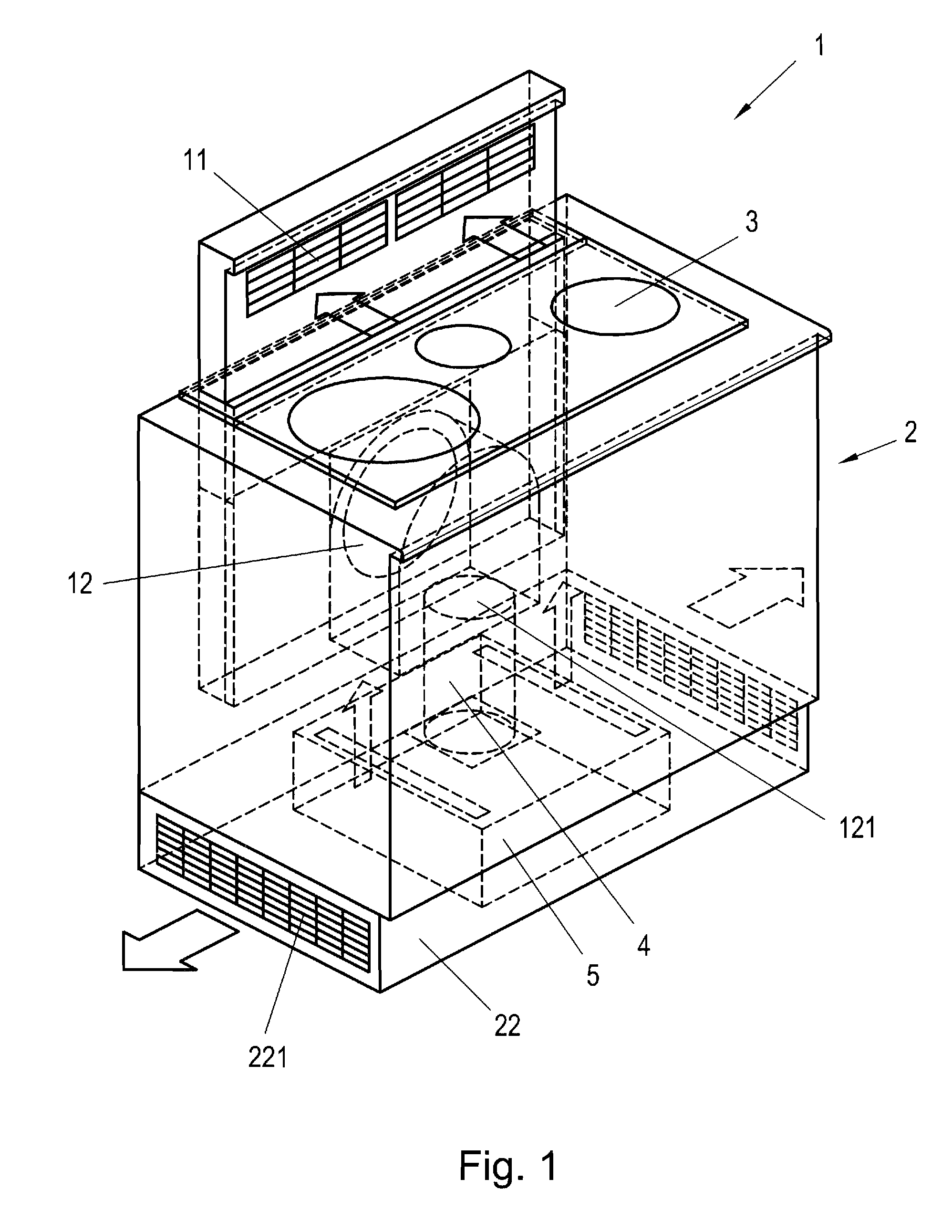

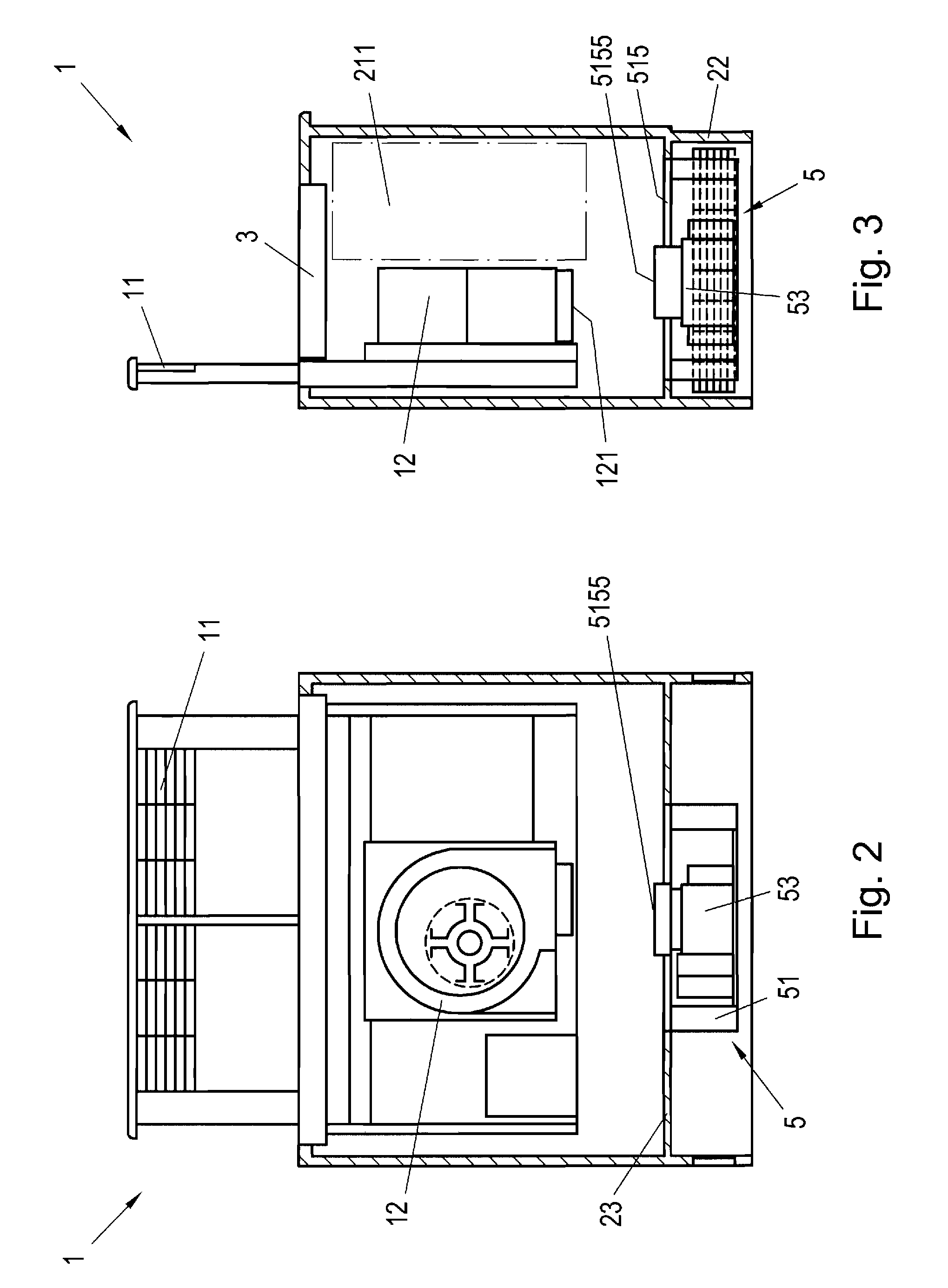

Air-circulating module and fume extraction device

InactiveUS20100012110A1Easy to assembleSimple structureLiquid surface applicatorsDomestic stoves or rangesAir cycleEngineering

An air-circulator includes an housing with an air inlet, an air outlet opening, an odor filter, and an insertion opening for inserting the odor filter. The odor filter is assigned to the air outlet opening.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

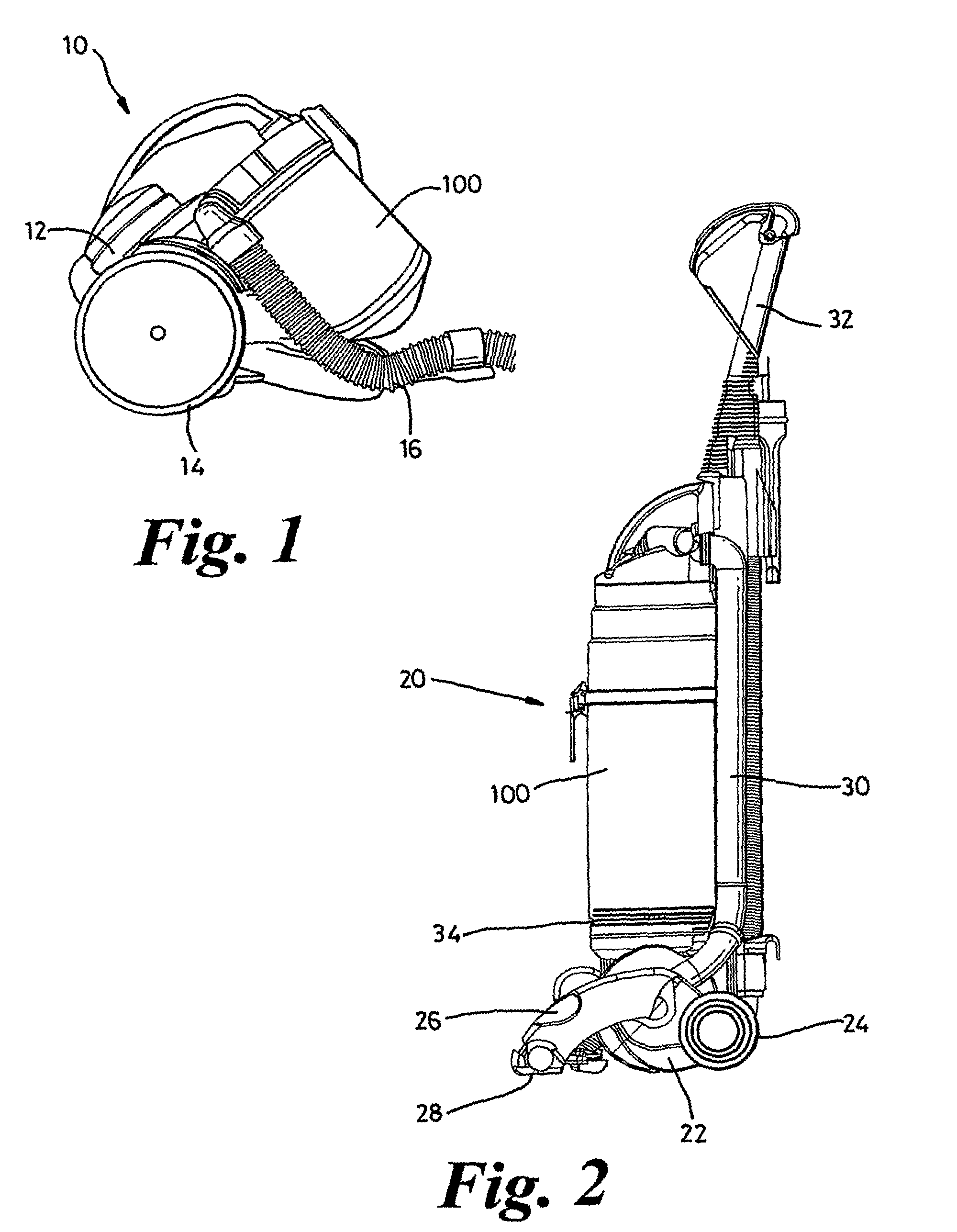

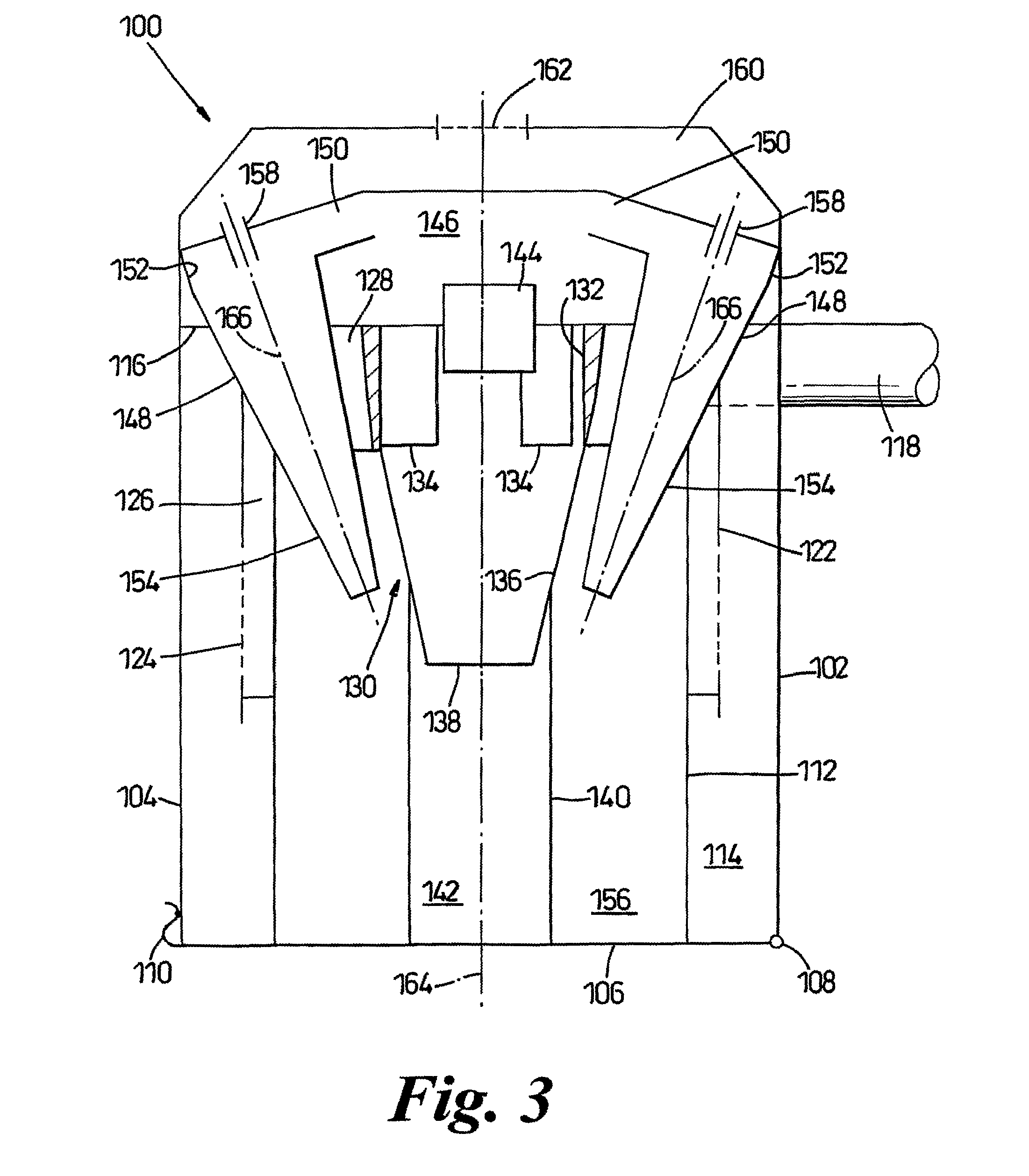

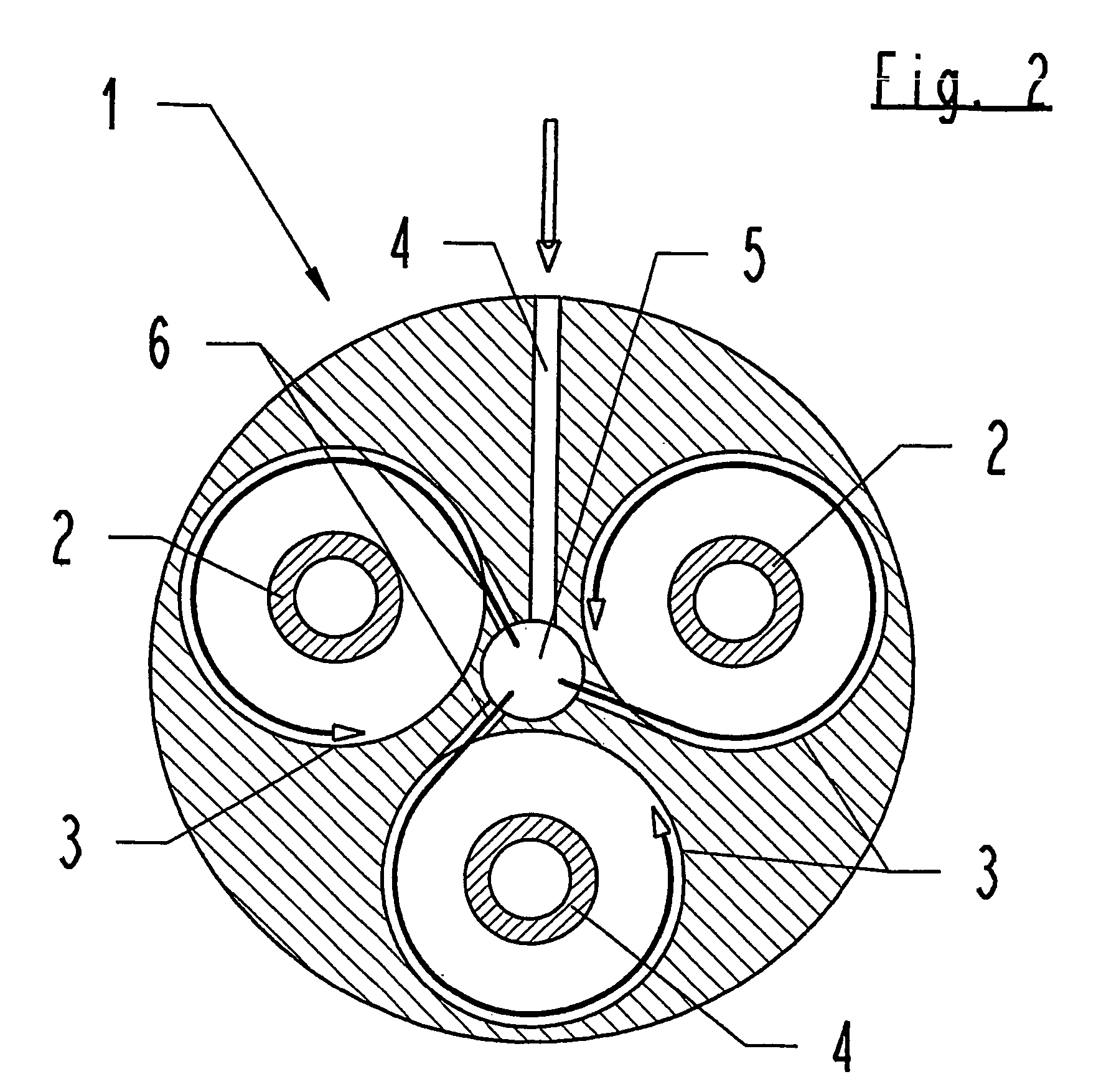

Dirt and dust cyclonic separating apparatus

InactiveUS7828866B2Improve efficiencyLow efficiencyCombination devicesSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus includes a first cyclonic separating unit including at least one first cyclone, a second cyclonic separating unit located downstream of the first cyclonic separating unit and including at least one second cyclone, and a third cyclonic separating unit located downstream of the second cyclonic separating unit and including at least one third cyclone. The separation efficiency of the second cyclonic separating unit is substantially the same as the separation efficiency of either the first cyclonic separating unit or the third separating unit, providing an apparatus which achieves a higher separation efficiency than known separation apparatus.

Owner:DYSON TECH LTD

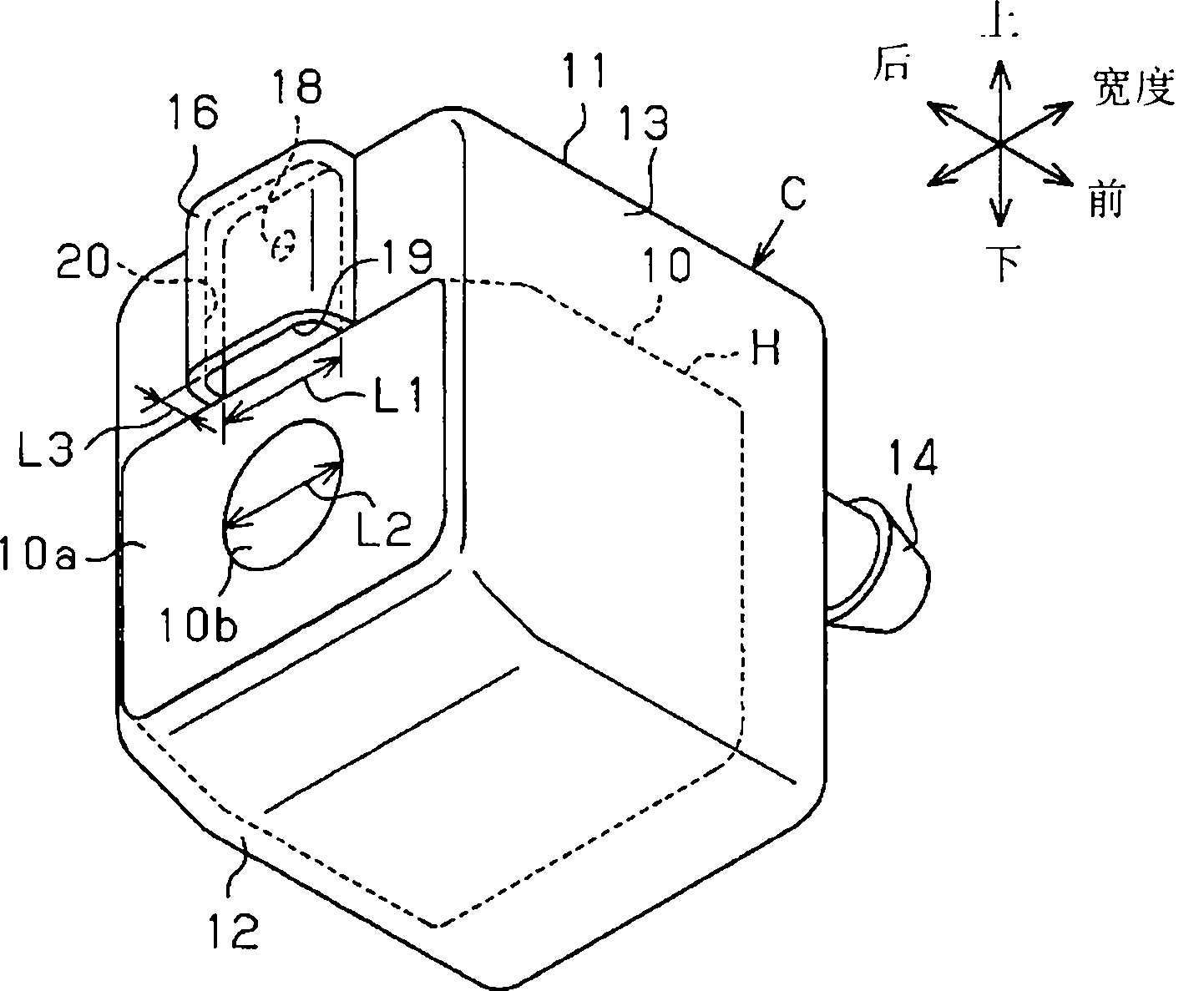

Washer nozzle for vehicle mounted camera, vehicle mounted camera, and washer device for vehicle

A washer nozzle removes foreign matter on an image capturing surface of a camera mounted to the outside of a vehicle by supplying washer fluid to the image capturing surface. The washer nozzle includes an inside spray hole and a discharge portion. The inside spray hole sprays the washer fluid introduced into the washer nozzle. The discharge portion receives washer fluid sprayed from the inside spray hole. The discharge portion has a passage extending in a direction intersecting the spray direction of the washer fluid and a discharge port connected to the passage. The discharge portion discharges, from the discharge port, washer fluid sprayed from the inside spray hole along the image capturing surface, while filling the passage with the washer fluid, thereby washing the image capturing surface.

Owner:ASMO CO LTD

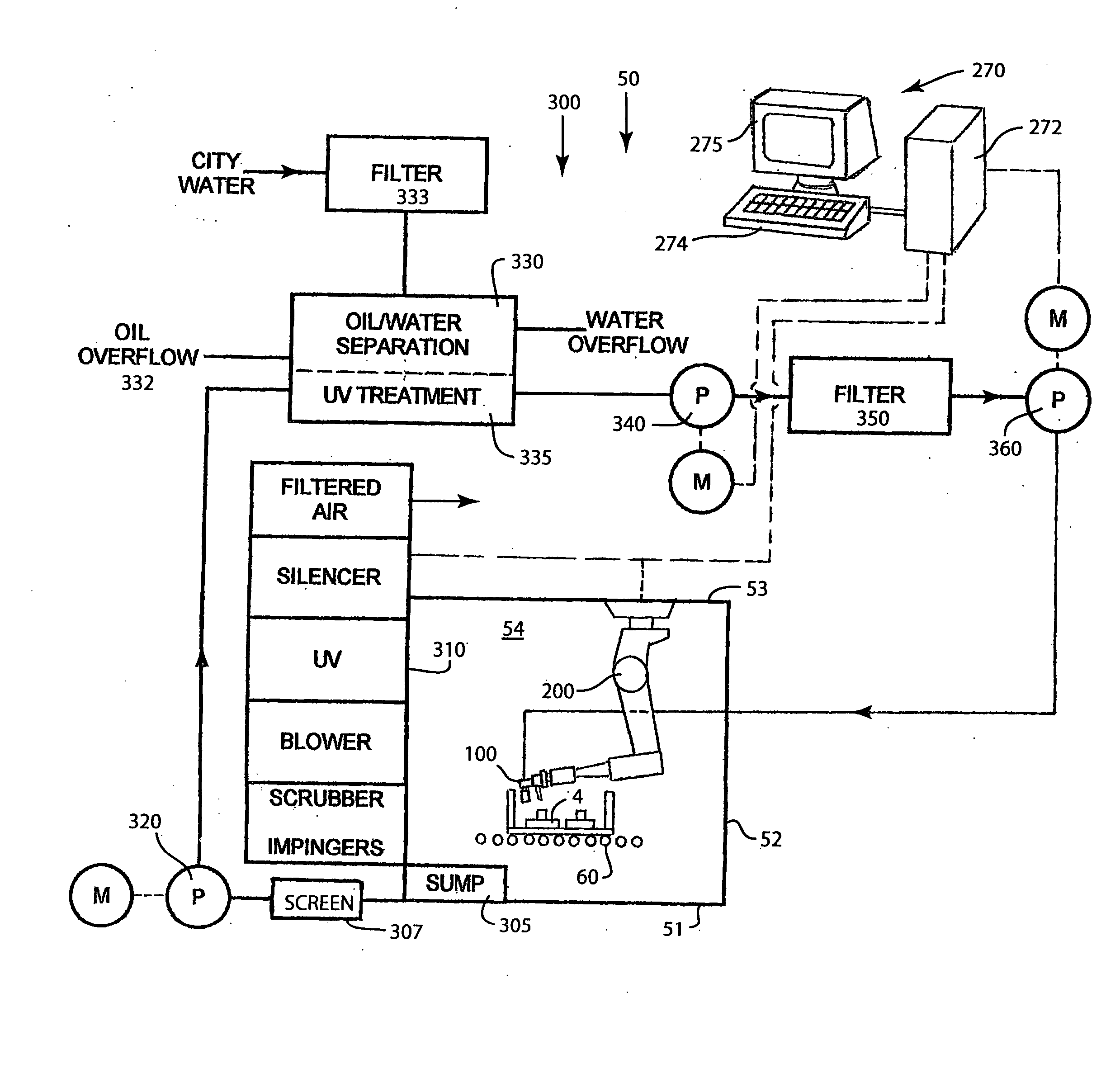

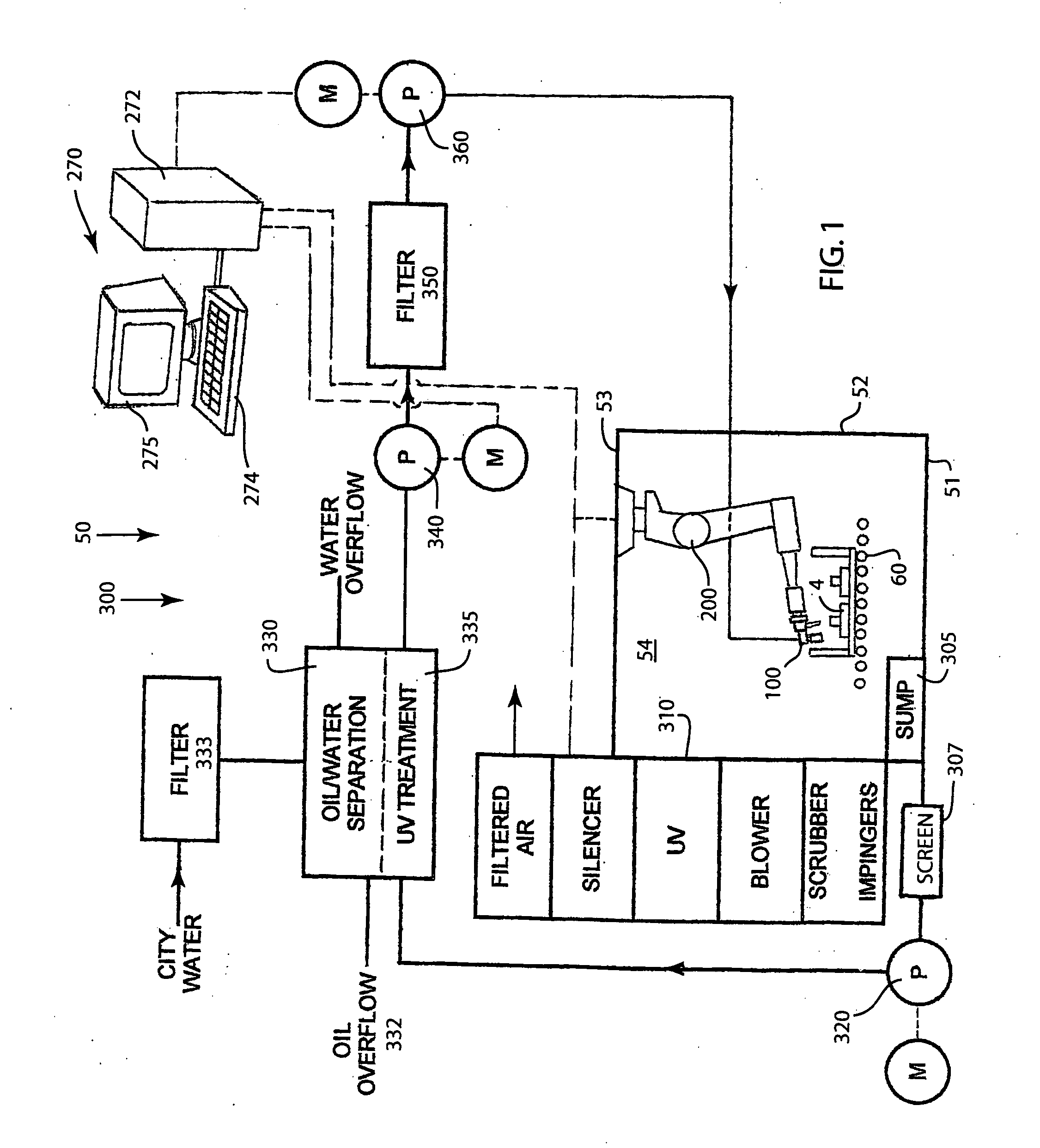

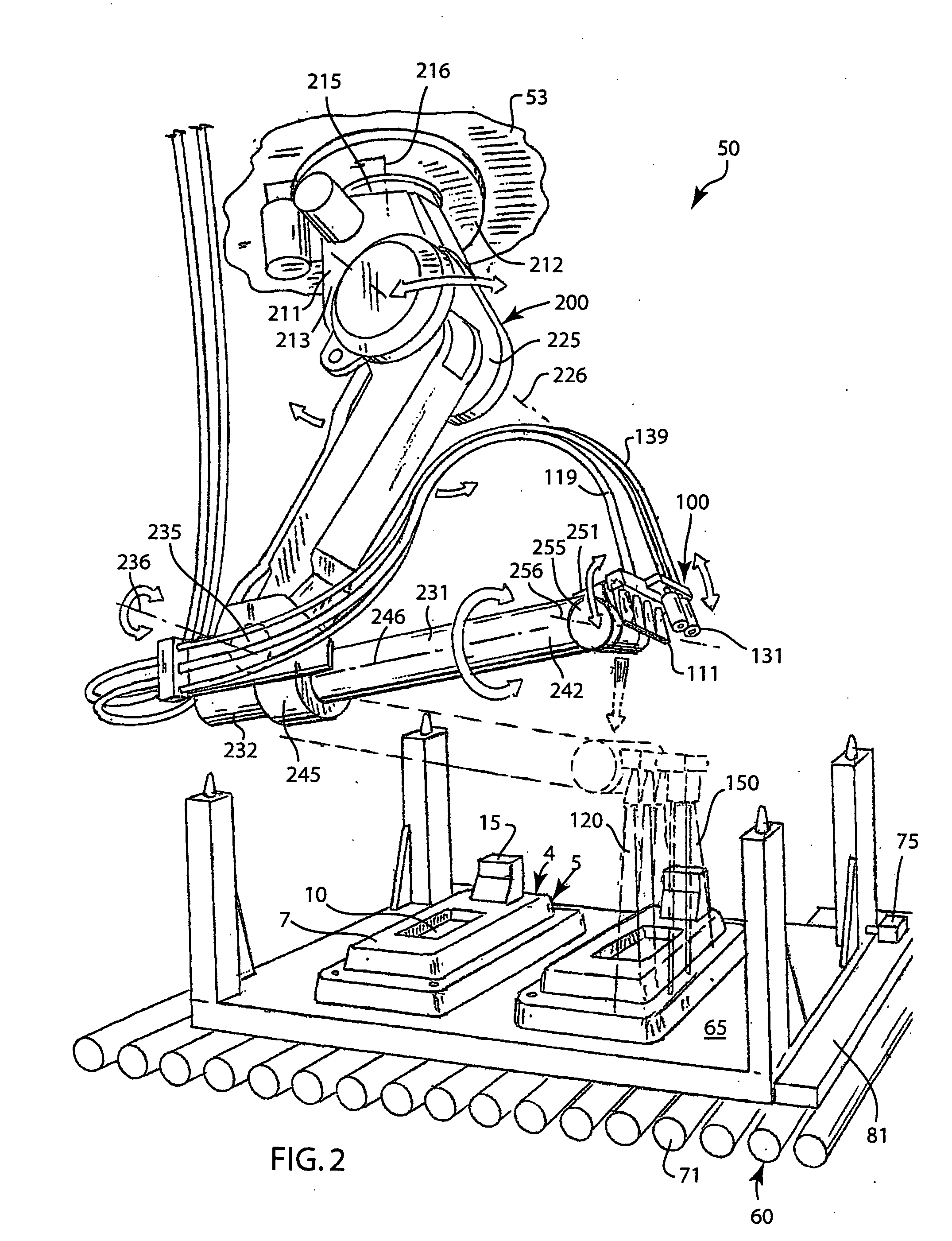

Robotic wash cell using recycled pure water

InactiveUS20050051198A1Efficiently and thoroughly cleans oil or grease from the surfaces of the item being washedReliable cleaningProgramme controlProgramme-controlled manipulatorOil and greaseRobotic arm

The present invention pertains to a robotic wash cell including a six-axis robotic arm and end effector equipped with nozzles that spray unheated, solvent free, pure water at high-pressure to clean or debur objects by maintaining the nozzles in close proximity and substantially normal to each surface being cleaned or edge being deburred. The robotic cell wash is particularly useful for cleaning contaminants such as oil and grease from items having more complex shapes. The six-axis robotic arm positions the nozzles and their sprays substantially normal to each surface being cleaned or deburred. The nozzles produce a multi-zone spray pattern with a continuous effective cleaning zone. A water recycling and pressurizing system collects the used water, separates out the oil and grease contaminants to a level of about 5 ppm, and pressurizes the pure water to about 3,000 psi for washing operations or about 6,000 psi for deburring operations.

Owner:ABB (SCHWEIZ) AG

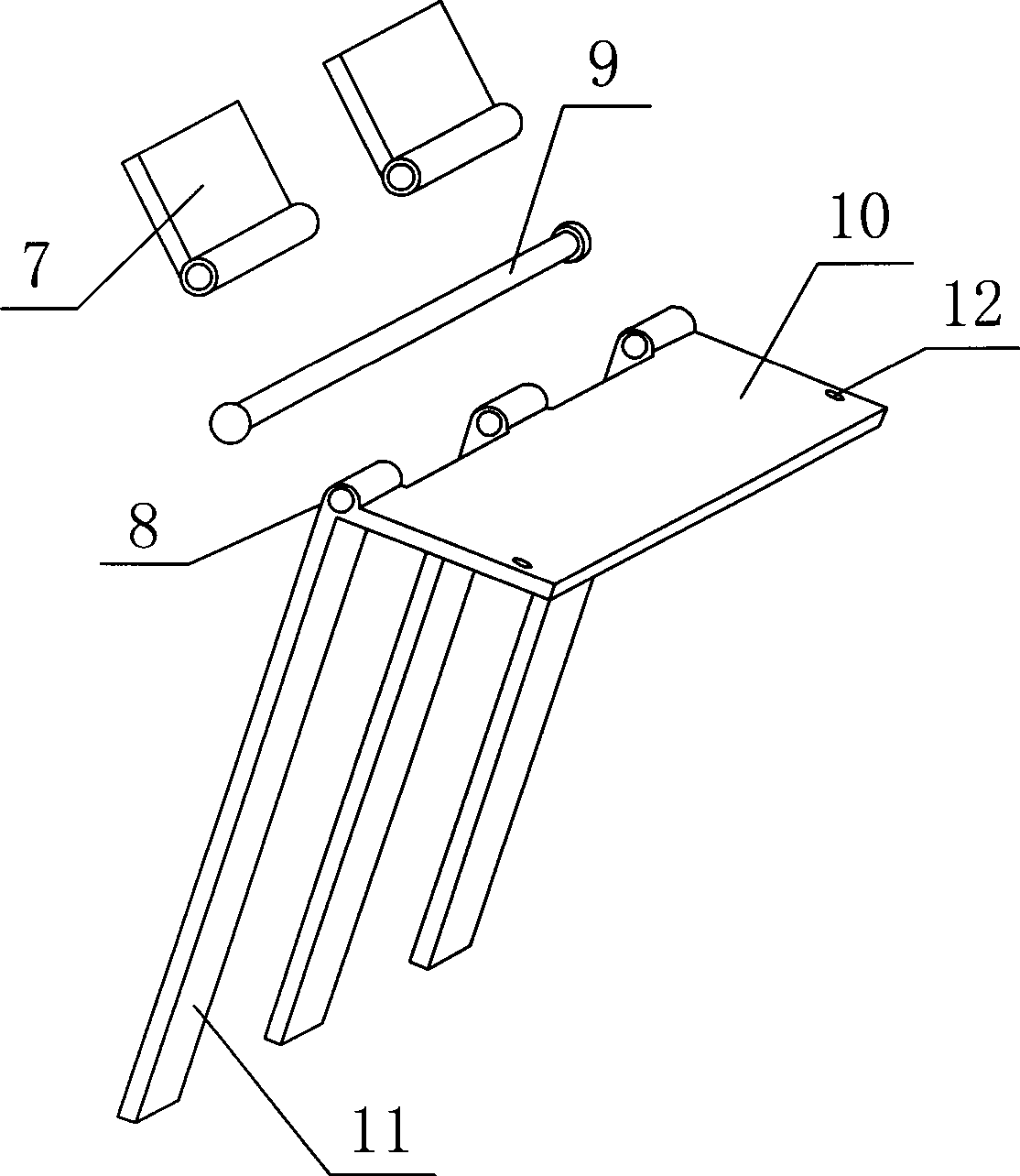

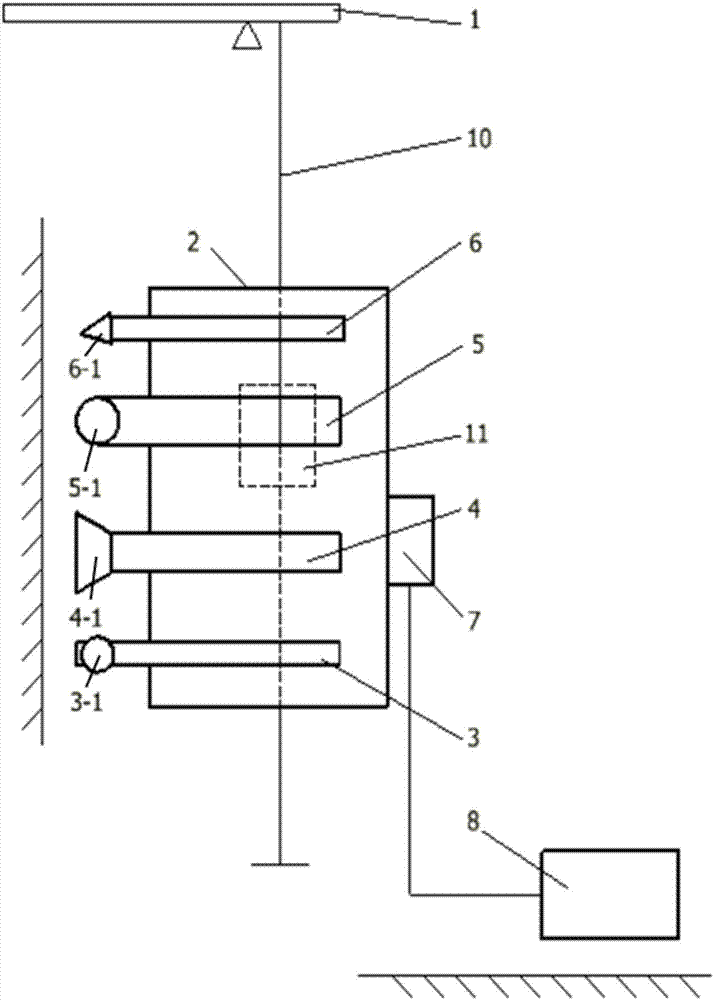

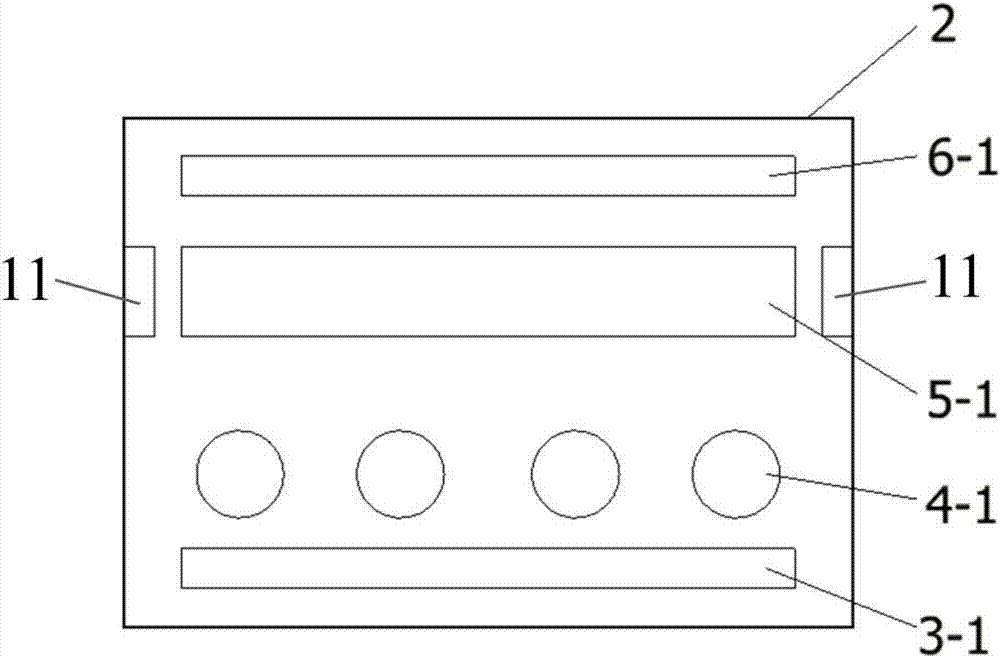

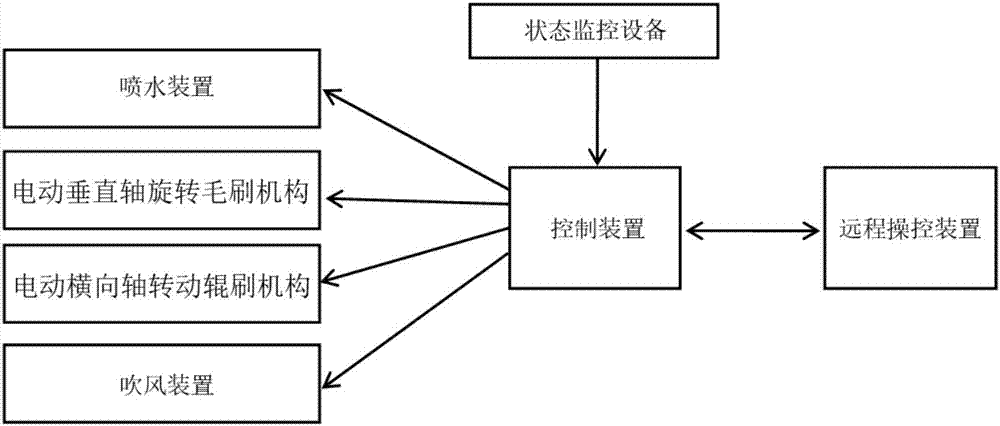

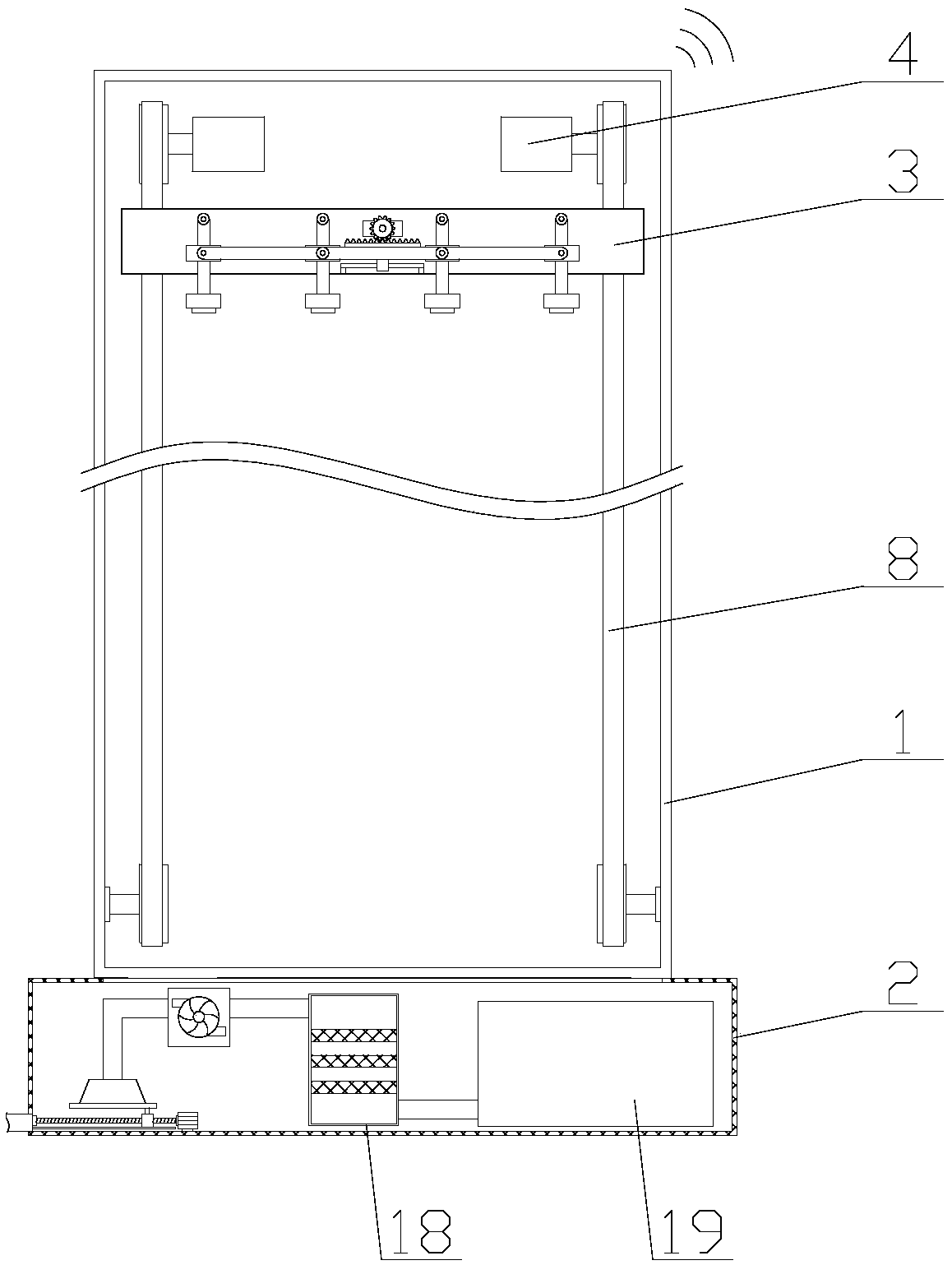

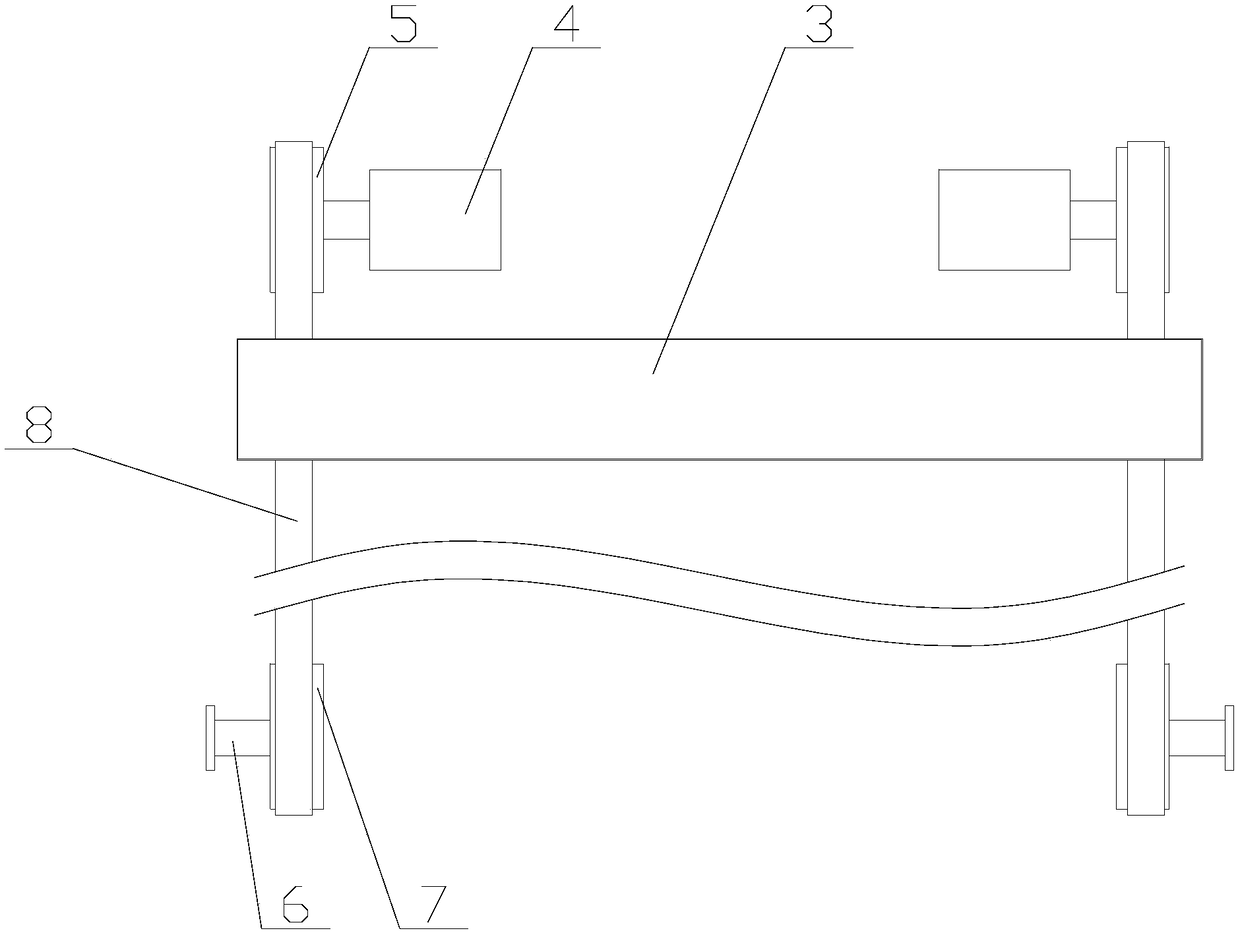

Vertical scrolling type robot system used for curtain cleaning

ActiveCN106974583ASimple structureEasy to operateCarpet cleanersCleaning action controlRobotic systemsHanging basket

The invention discloses a vertical scrolling type robot system used for curtain cleaning. The system comprises a hanging device (1) provided with a hanging basket framework (2) moving up and down, and a water injection nozzle (3-1) of a water injection device, brushes (4-1 and 5-1) of an electric rotary brush mechanism and an air blowing nozzle (6-1) of an air blowing device are sequentially located on the side, opposite to a curtain, of the hanging basket framework from bottom to top; a control device (7) is installed on the hanging basket framework, and separately in electric connection with the water injection device (3), the electric rotary brush mechanism (4) and the air blowing device (6); a remote manipulation device (8) is electrically connected with the control device. The robot system moves downward along the curtain and sequentially passes through the water injection nozzle, the brushes and the air blowing nozzle for cleaning and removal, and the remote manipulation device (8) enables ground operators to remotely control the working state in a wired or wireless mode.

Owner:汤瑞平

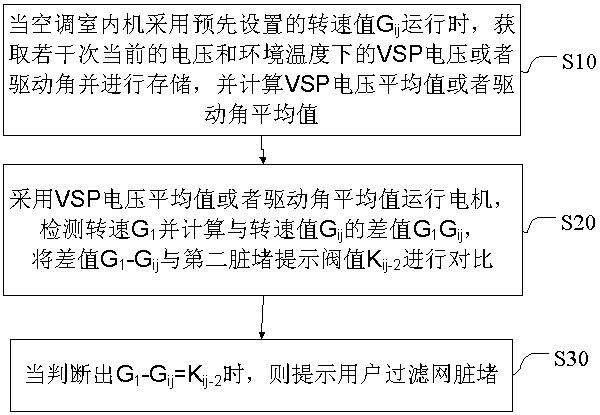

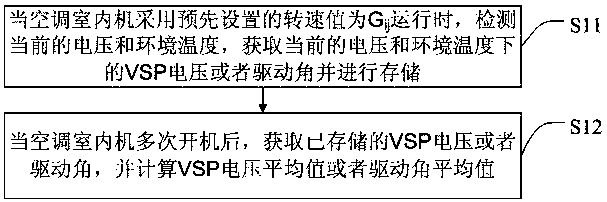

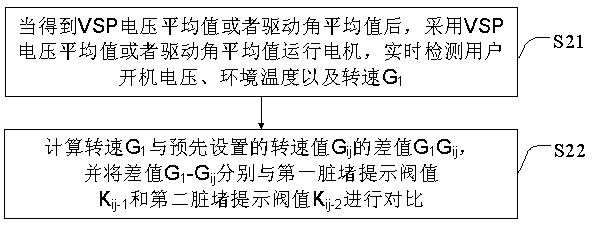

Air conditioner filter screen filth blockage prompting method, air conditioner and storage medium

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

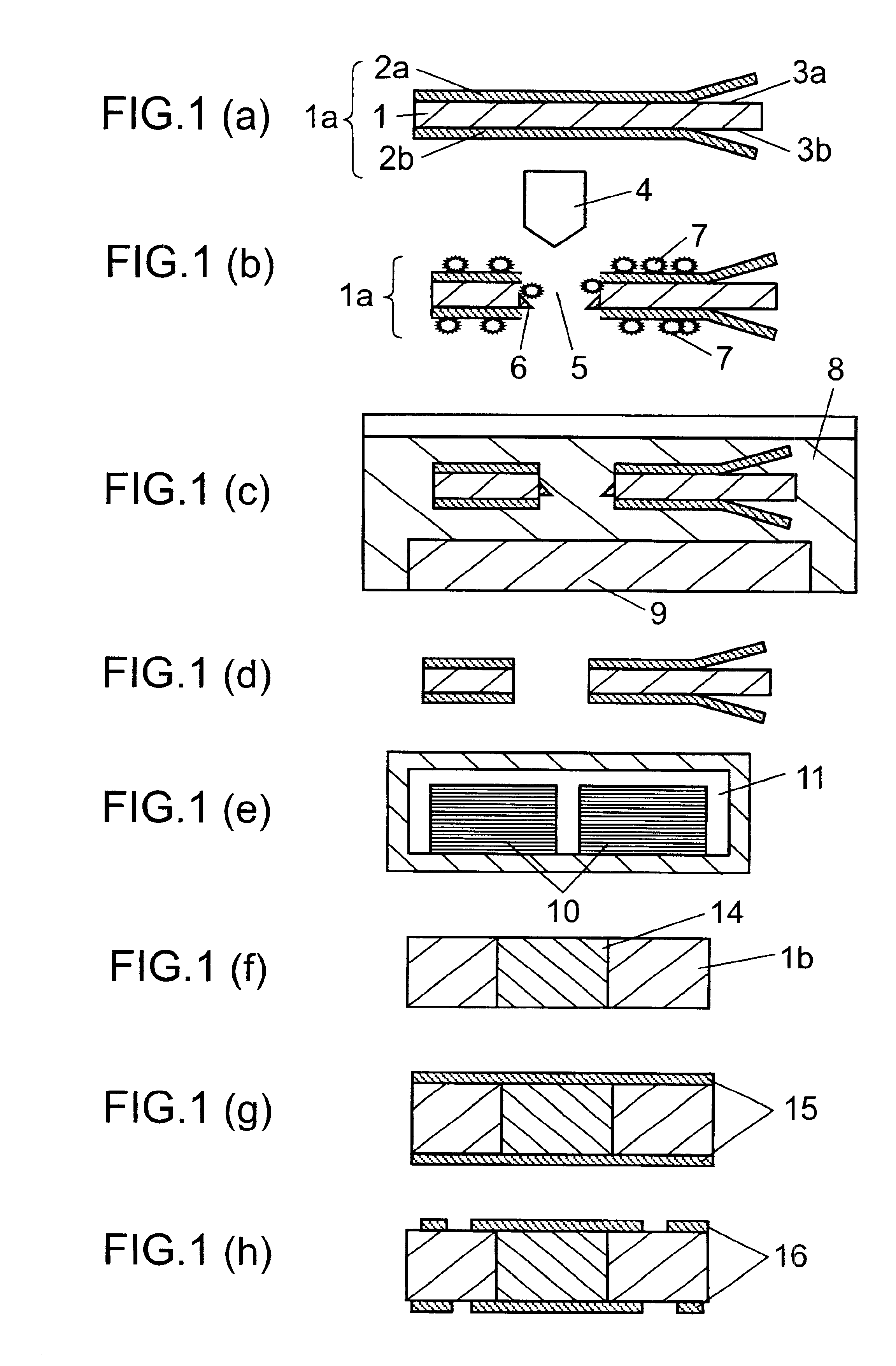

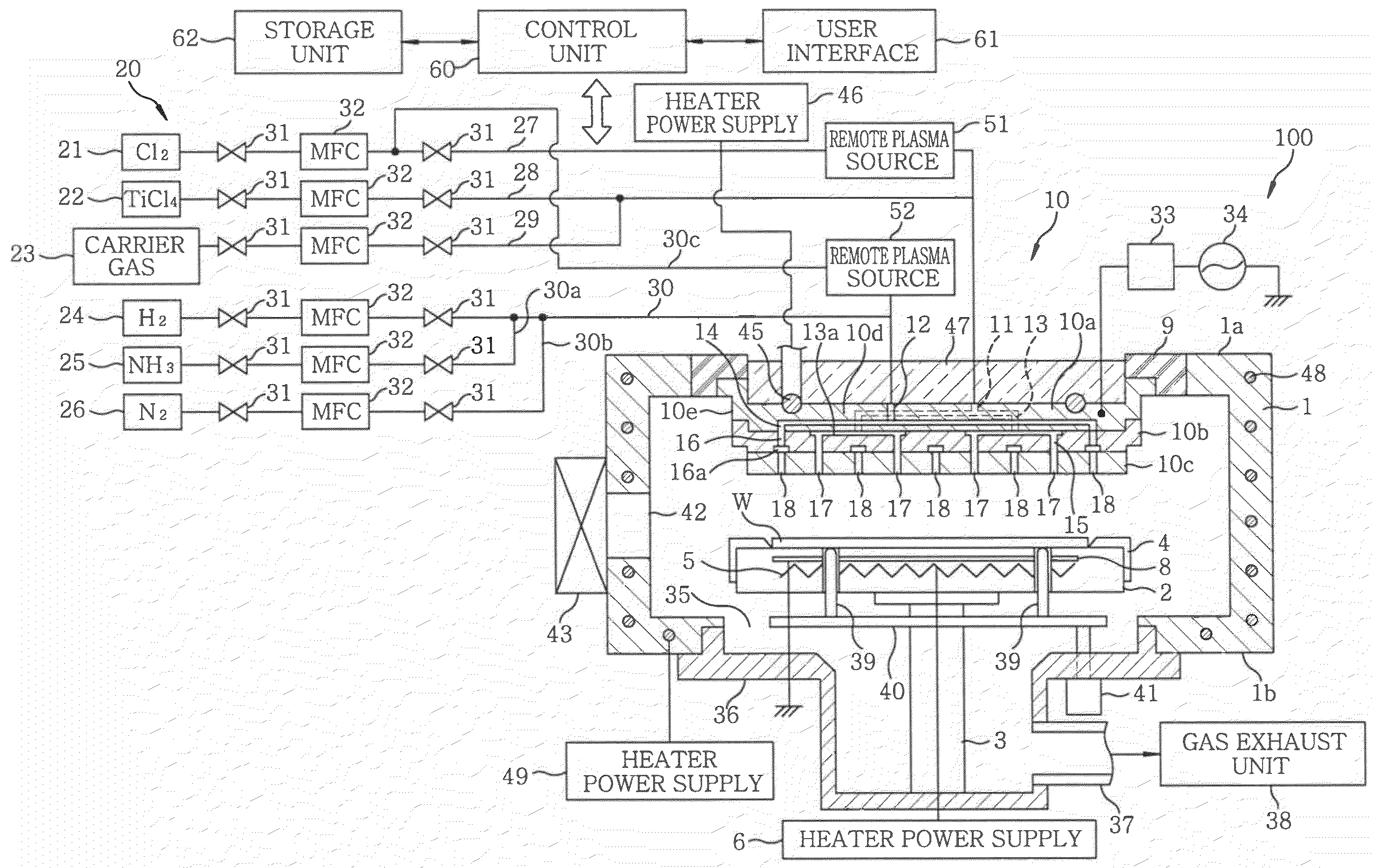

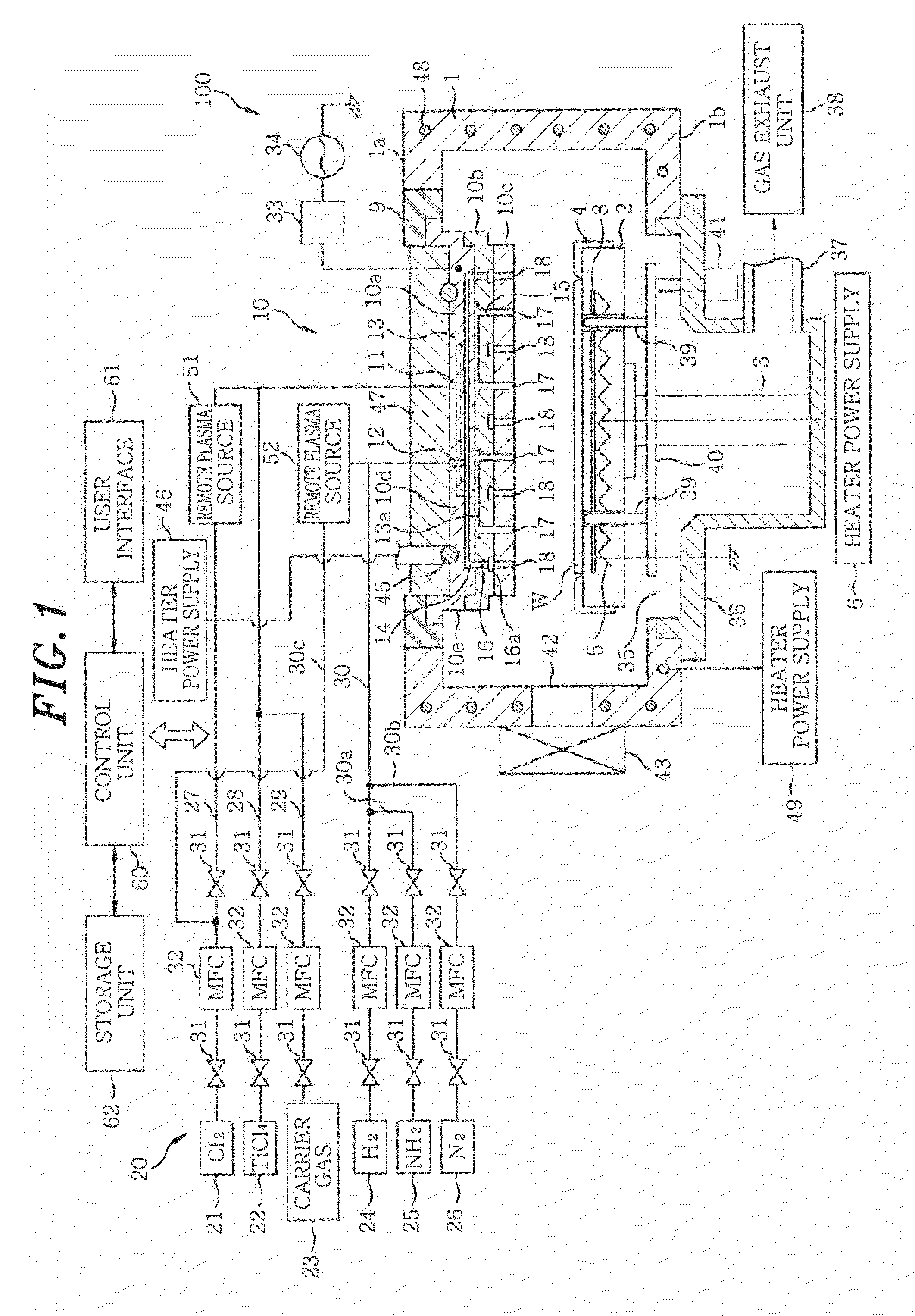

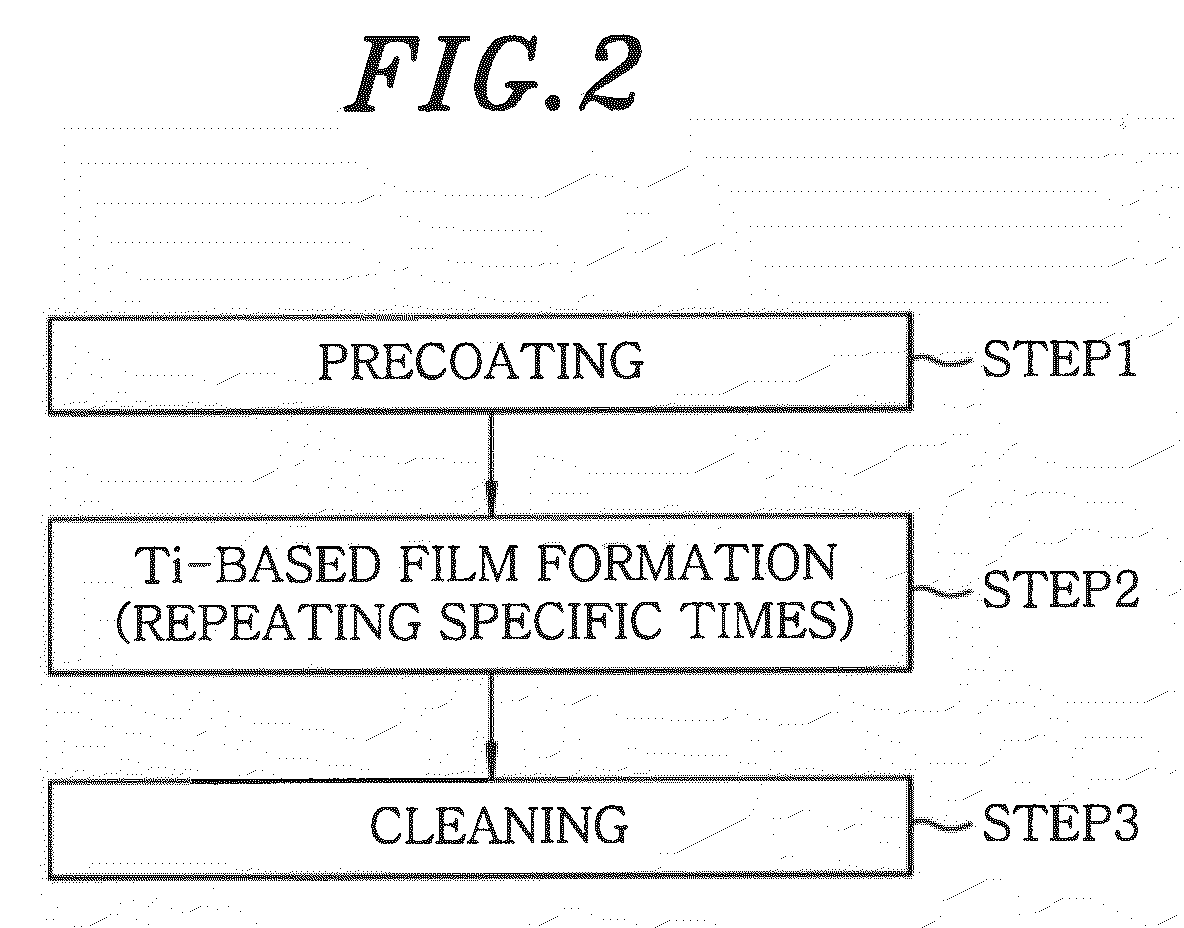

Film formation method, cleaning method and film formation apparatus

InactiveUS20090142513A1Reliably cleanClean thoroughlyLiquid surface applicatorsVacuum evaporation coatingEngineeringSusceptor

A treatment gas is supplied to form a Ti-based film on a predetermined number of wafers W while setting a temperature of a susceptor 2 in a chamber 1 to a predetermined temperature. After this, the interior of the chamber 1 containing no wafers W is cleaned by discharging Cl2 gas as a cleaning gas from a shower head 10 into the chamber 1. During this cleaning, the temperature of each of the susceptor 2, the shower head 10, and the wall portion of the chamber 1 is independently controlled so that the temperature of the susceptor 2 is not lower than the decomposition start temperature of Cl2 gas and the temperature of the shower head 10 and the wall portion of the chamber 1 is not higher than the decomposition start temperature.

Owner:TOKYO ELECTRON LTD

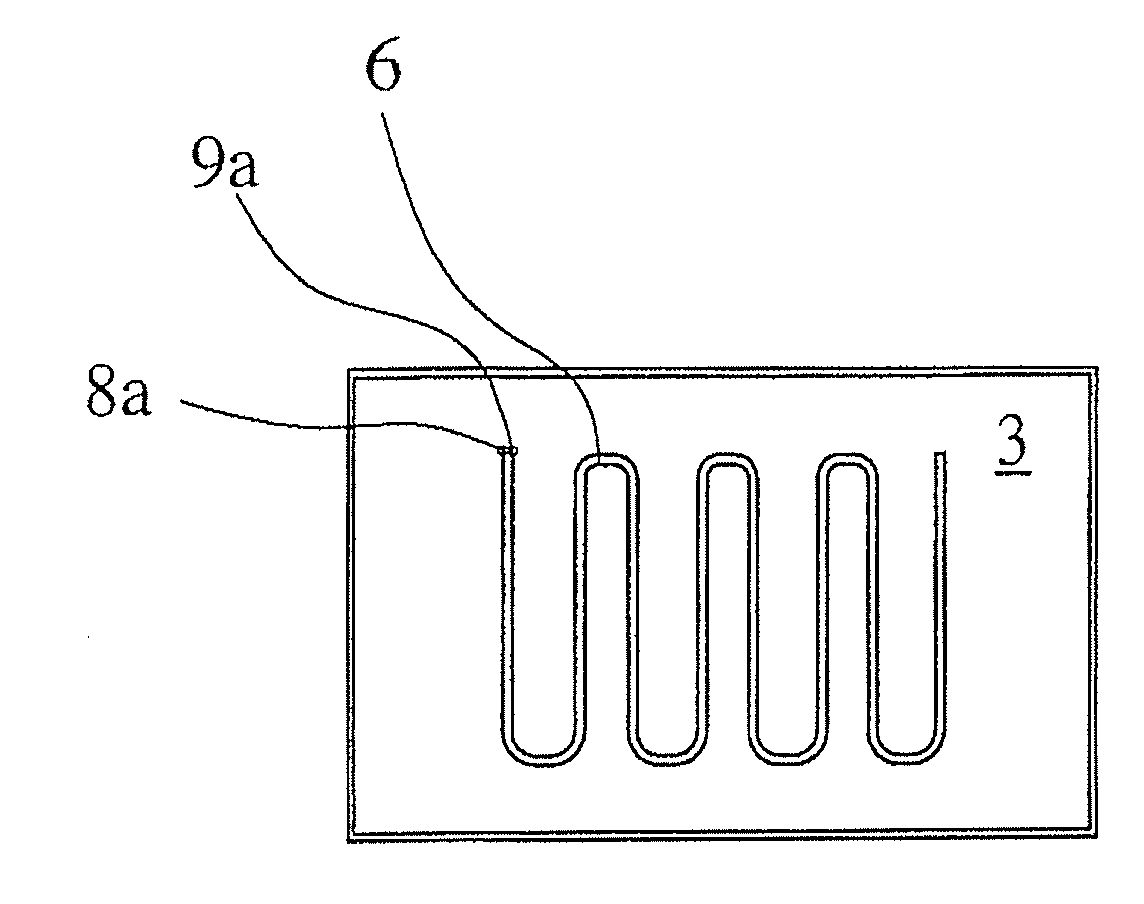

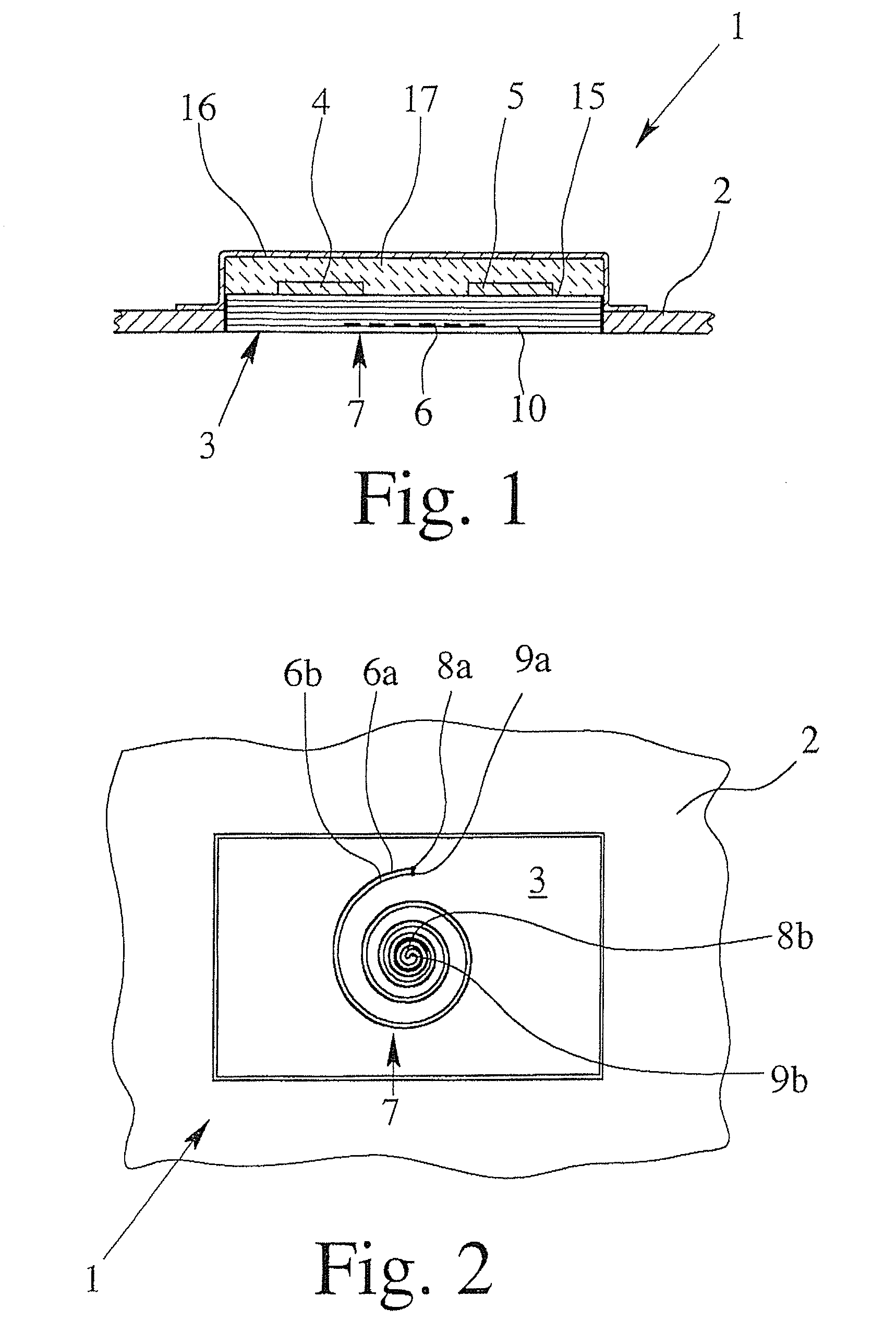

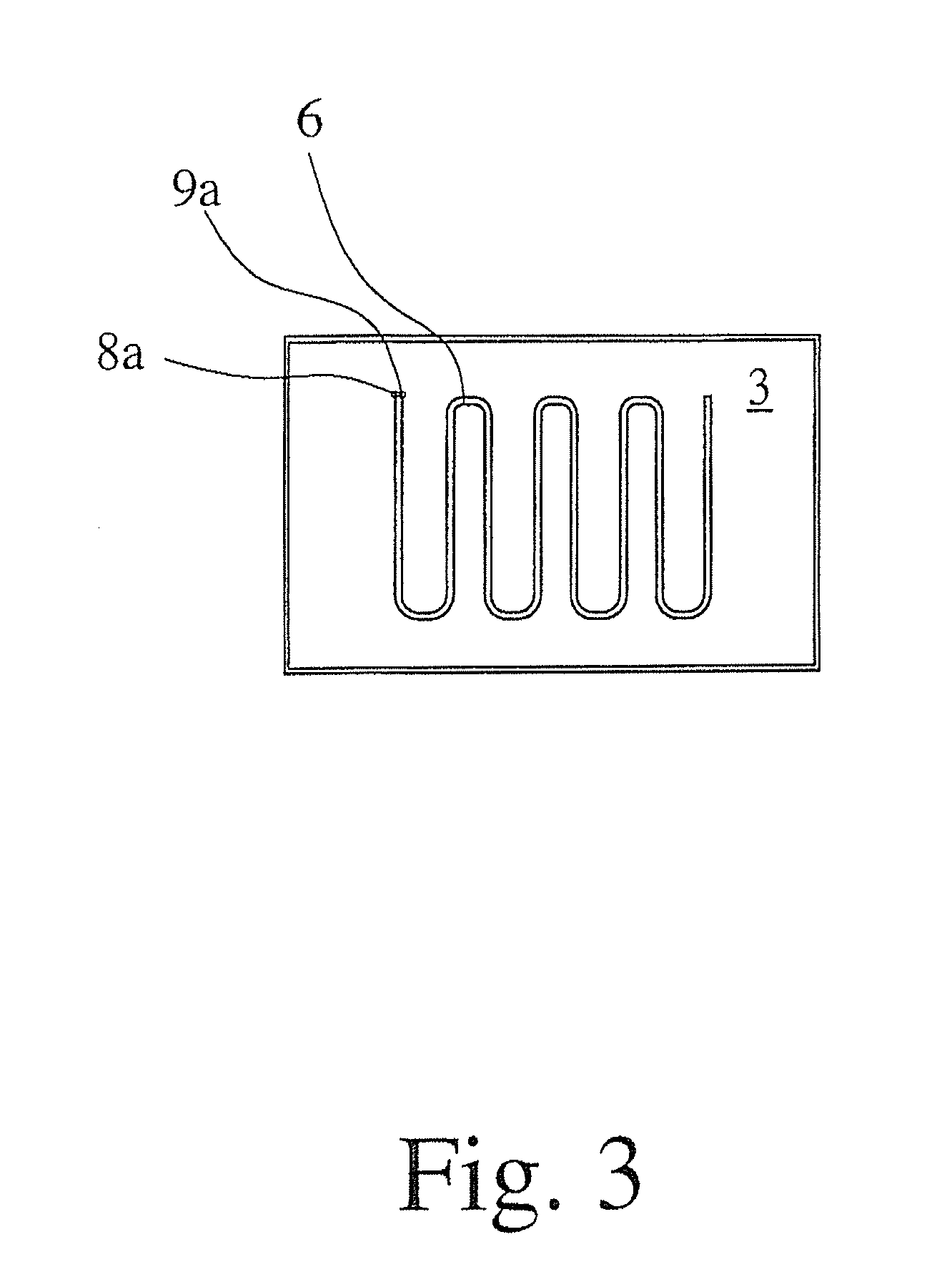

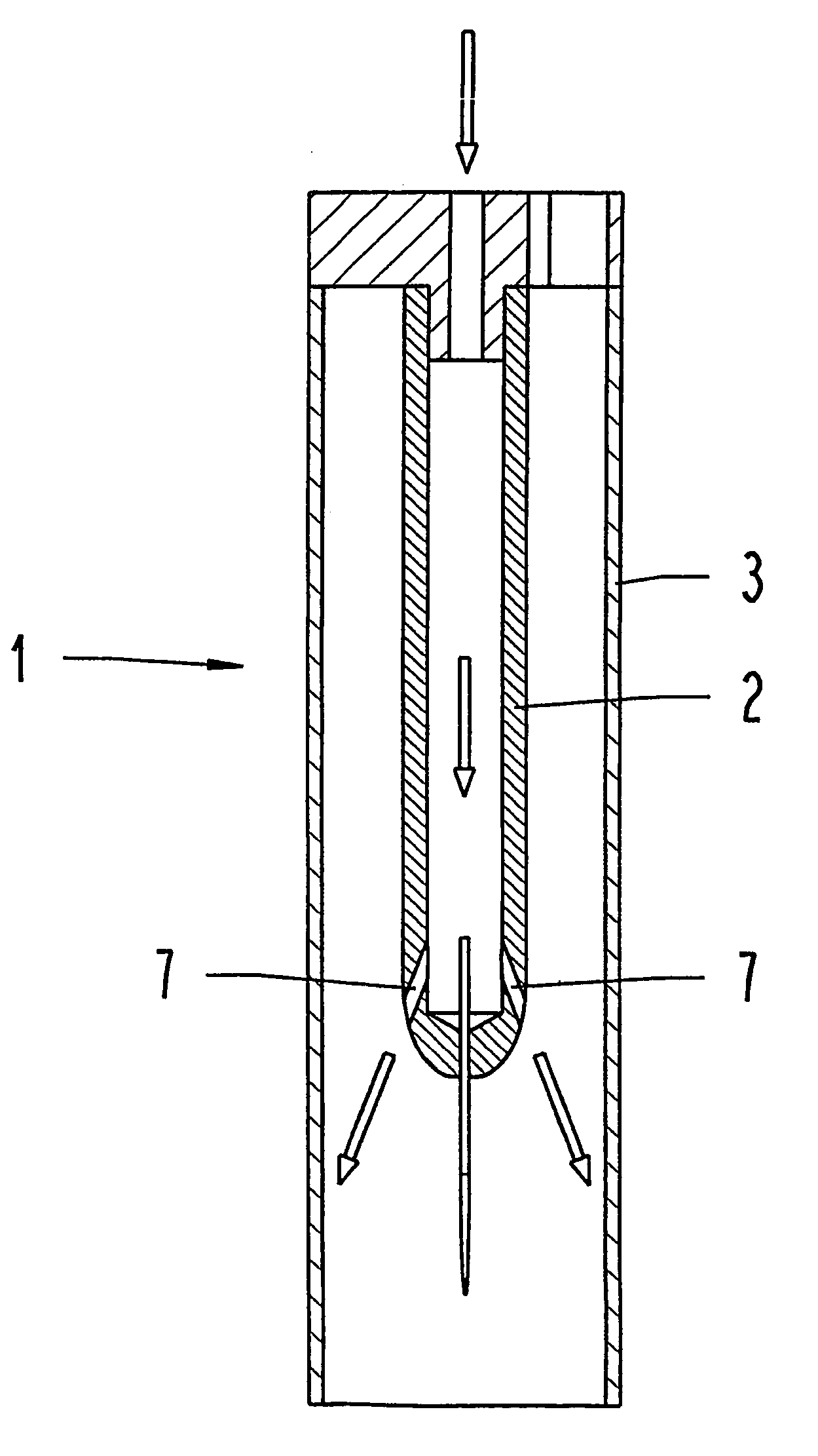

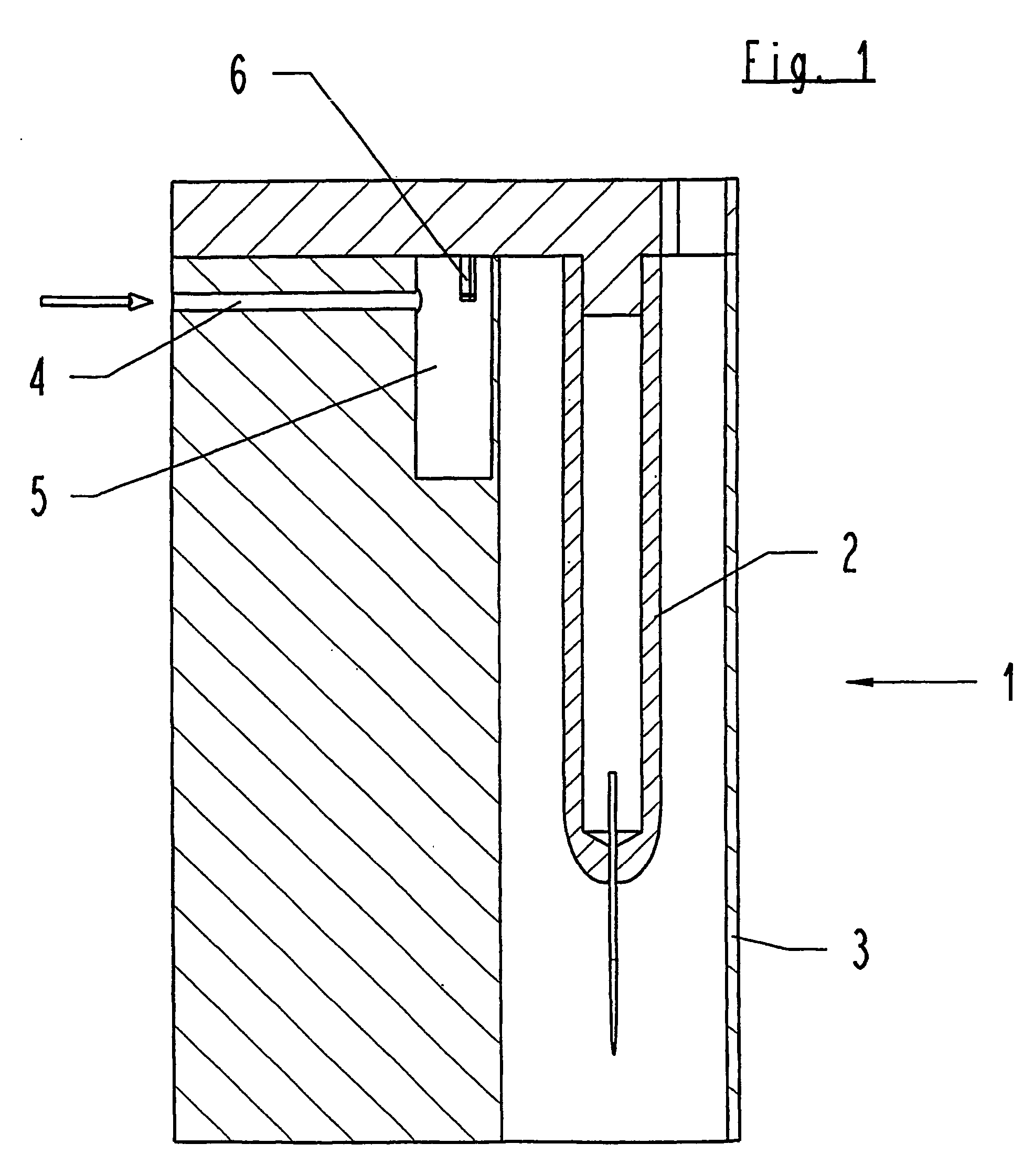

Fill level switch and sensor element for a fill level switch

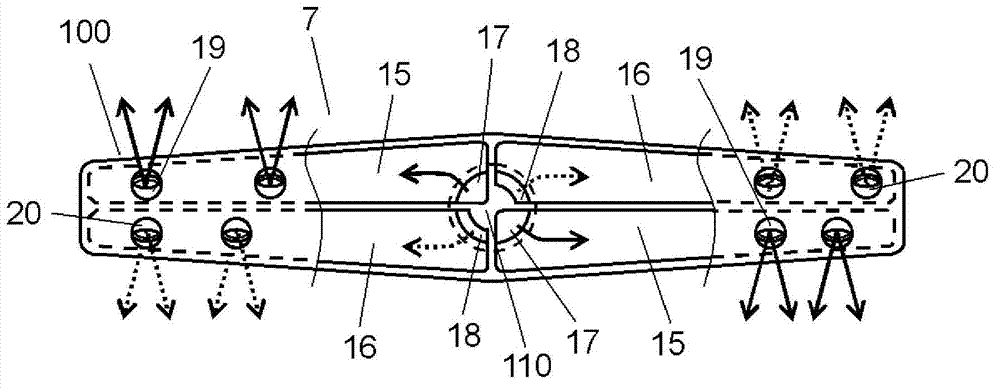

ActiveUS20110100120A1Reliable cleaningSimultaneous aerial operationsRadiating elements structural formsEngineeringElectrical and Electronics engineering

A fill level switch (1) for measuring the fill level of a medium in a container (2), having a sensor element (3) for contacting the medium, a sender (4) for applying an electromagnetic emission signal to the sensor element (3) and an evaluation unit (5) for detecting a received signal from the sensor element (3). The sensor element (3) includes at least one cable (6) for guiding the emission signal. To provide a fill level switch, which is based on a sturdy measuring principle and which allows for reliable cleaning, the fill level switch uses a delay line as the cable (6) of the sensor element (3) and the sensor element (3) has a window (7) facing the medium in the mounted position of the fill level switch and at least a part of the cable (6) can be electrically influenced by the medium via the window (7).

Owner:KROHNE MESSTECHNICK GMBH & CO KG

Vapor generator, washing system and range hood

InactiveCN104421988APrevent outflowAvoid enteringSteam generation heating methodsDomestic stoves or rangesVapor generatorChemical engineering

The invention discloses a vapor generator, a washing system and a range hood. The vapor generator comprises a body, a heating member and an eduction pipe, wherein the body is internally provided with a heating cavity, and the heating cavity is provided with an inlet and an outlet; the heating member is arranged on the body and used for heating a liquid inside the heating cavity; the eduction pipe is arranged in the heating cavity, the upper end of the eduction pipe is closed, the lower end of the eduction pipe is opened, the lower end of the eduction pipe is connected with the outlet of the heating cavity, and the eduction pipe is provided with a plurality of eduction pores. According to the vapor generator of the embodiment, generated water scale can be prevented from flowing out, the water scale can be further prevented from entering a spraying pipe, the potential danger that the spraying pipe is blocked can be eliminated, and the spraying force and washing effect of the spraying pipe can be guaranteed.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

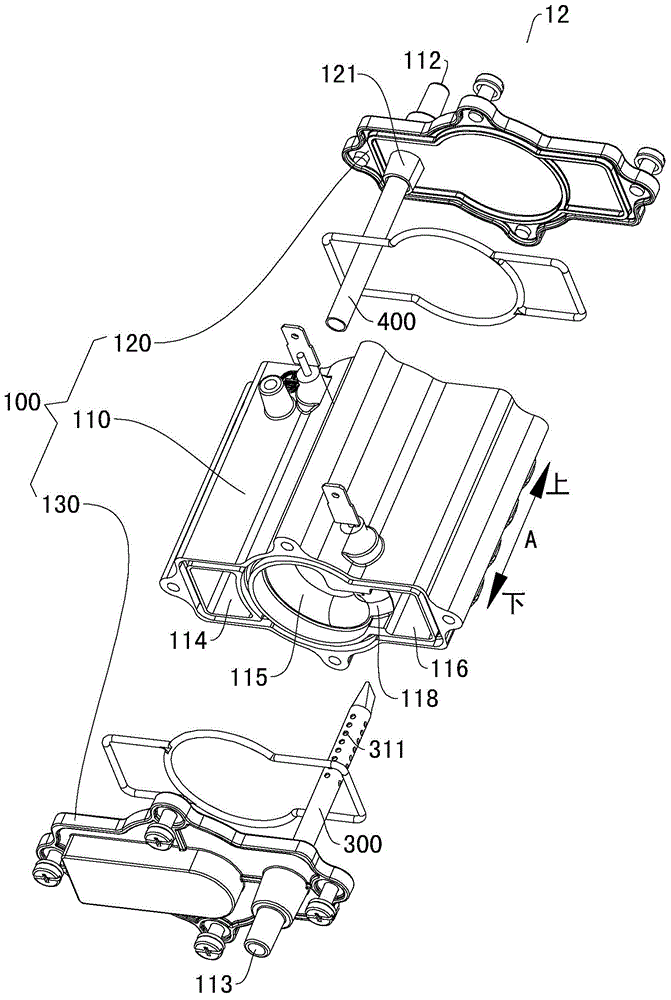

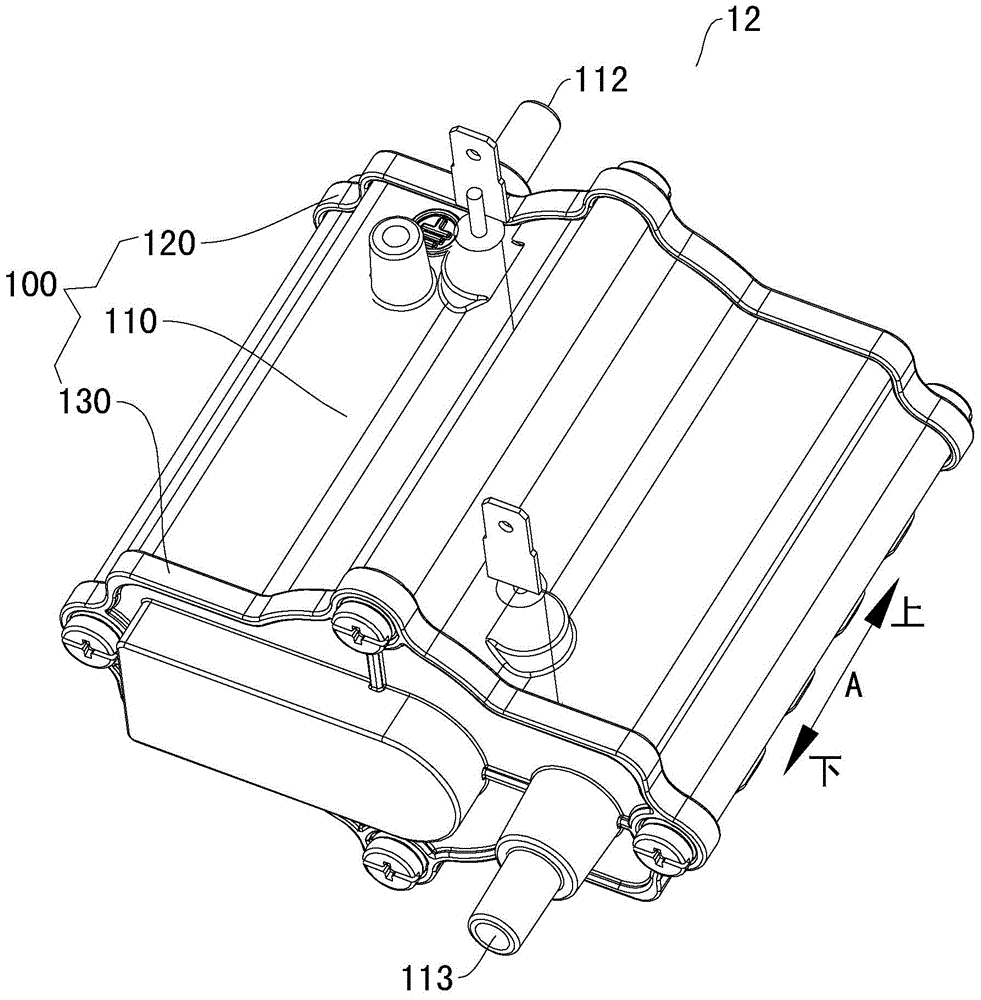

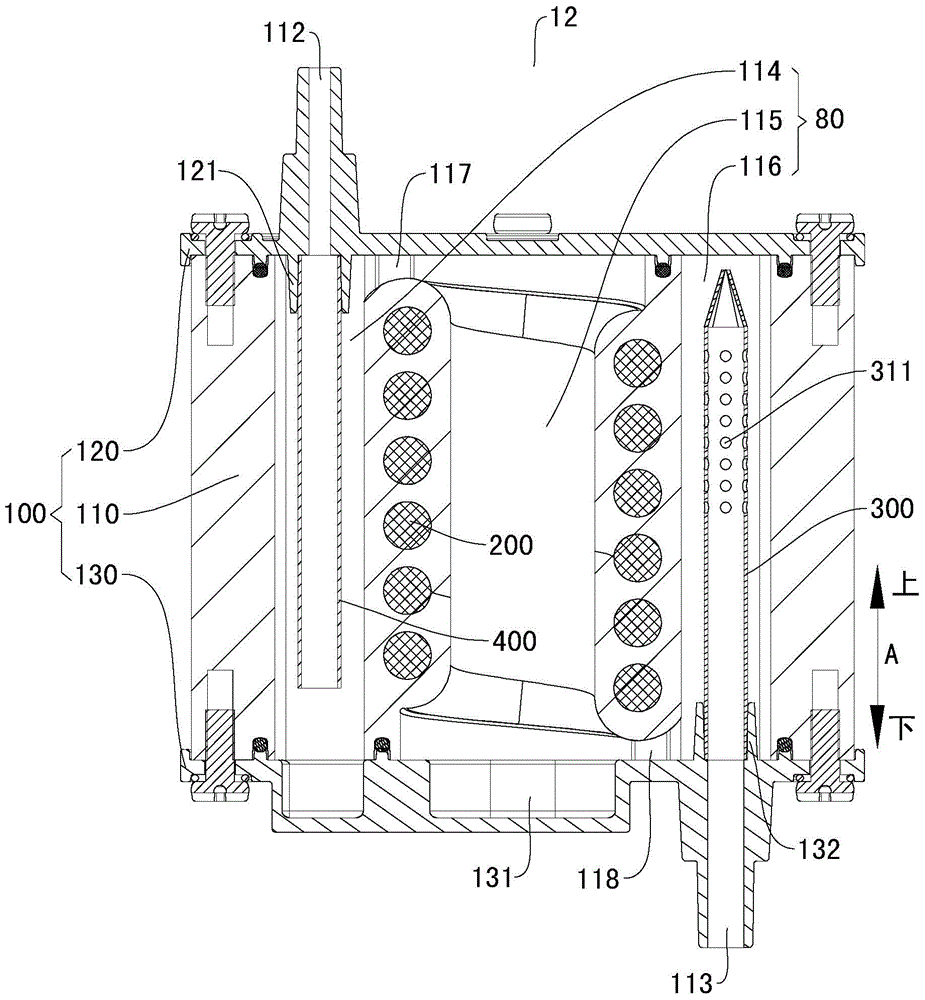

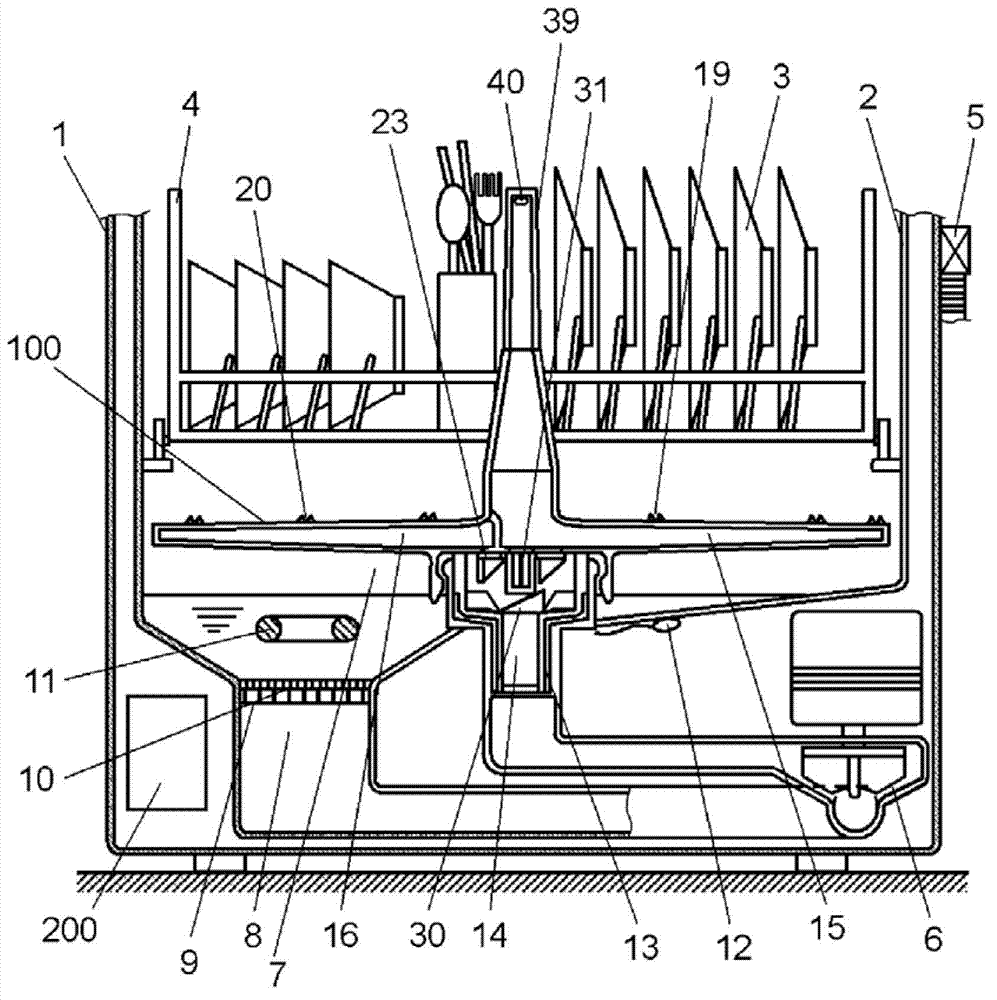

Dishwasher

InactiveCN102858221AReliable cleaningConserve waterTableware washing/rinsing machine detailsSpray nozzleEngineering

The disclosed dishwasher has a washing tub, a washing pump, a washing nozzle, and a tower nozzle. Items to be washed are placed in the washing tub. The washing pump pressurizes washing water. The washing nozzle is rotatably provided inside the washing tub and sprays washing water pressurized by the washing pump on the items to be washed. The tower nozzle protrudes vertically upward from the center of the washing nozzle and sprays washing water pressurized by the washing pump on the items to be washed. The washing nozzle has a plurality of channels and a valve body. The plurality of channels are each provided with a spray opening. The valve body switches the supply of washing water between the plurality of channels and the tower nozzle depending on changes in the pressure of the washing water supplied from the washing pump. When washing water is sprayed from the tower nozzle, washing water is sprayed from at least one of the plurality of channels in the washing nozzle, causing the washing nozzle to rotate.

Owner:PANASONIC CORP

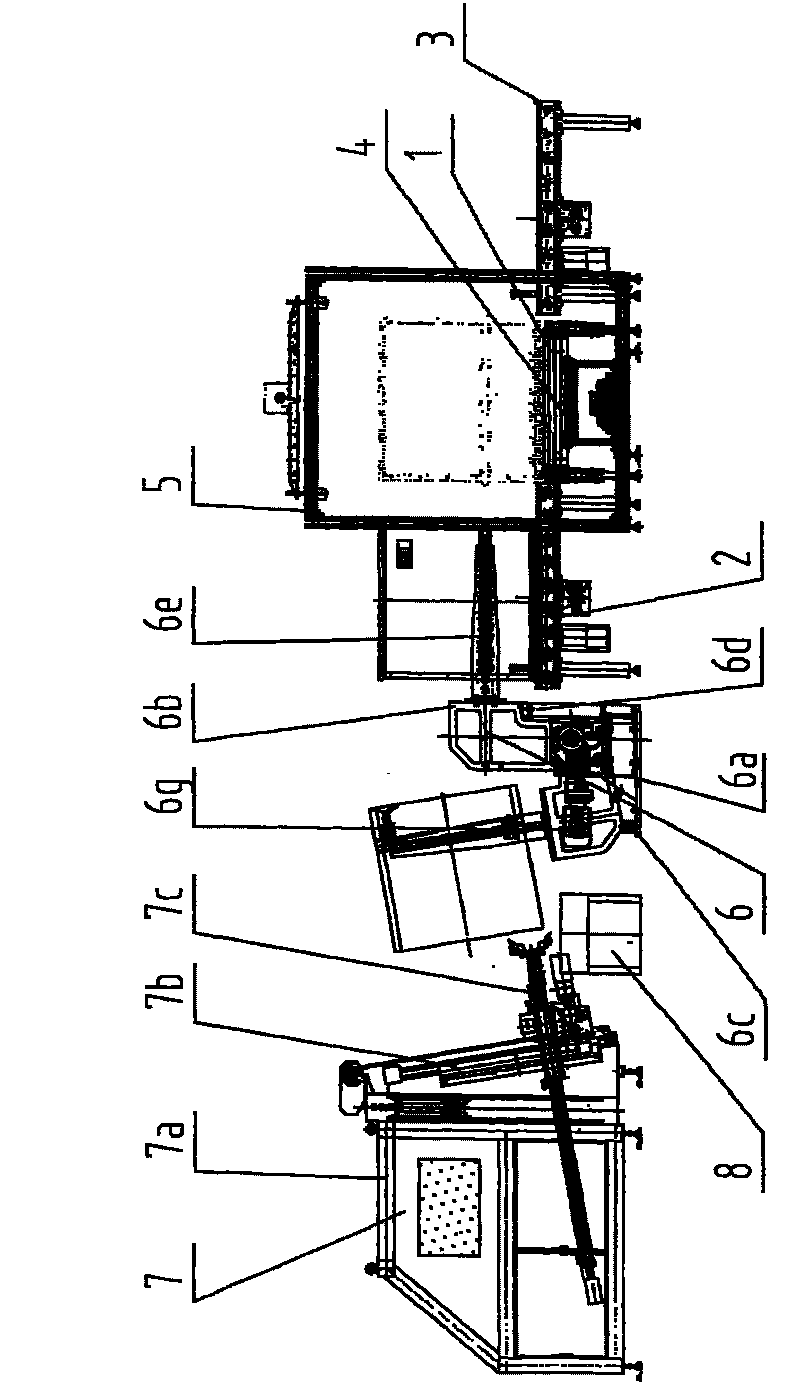

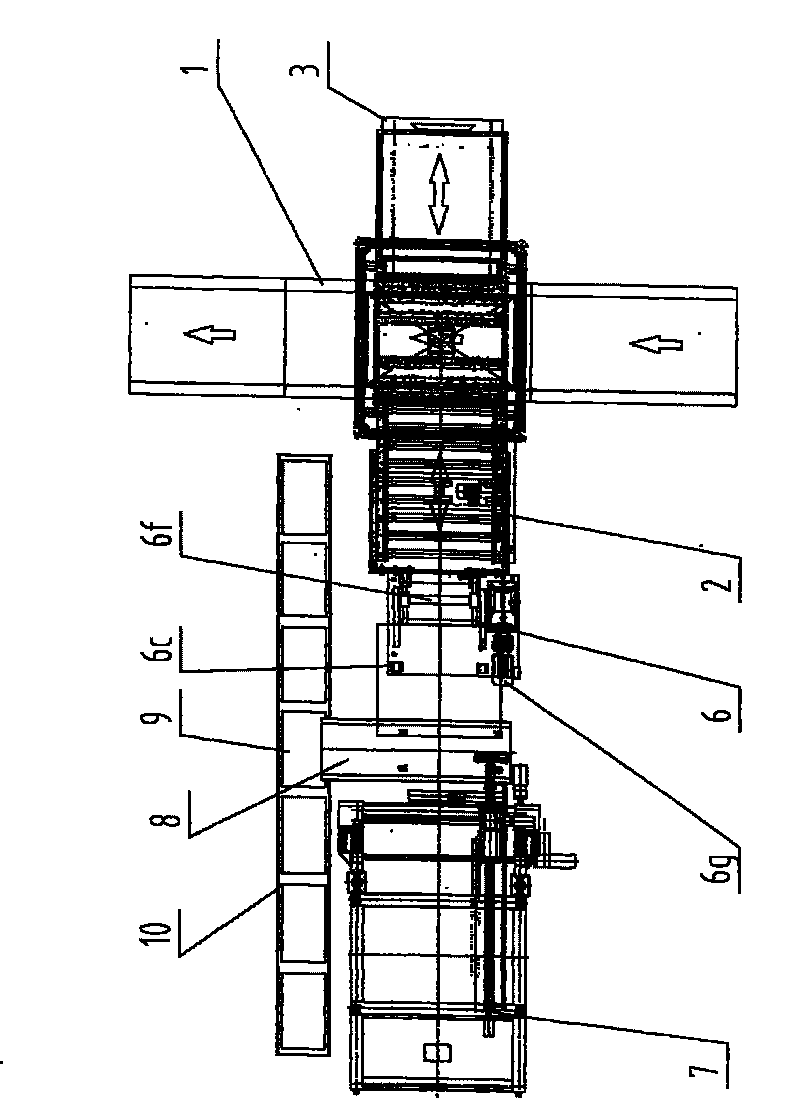

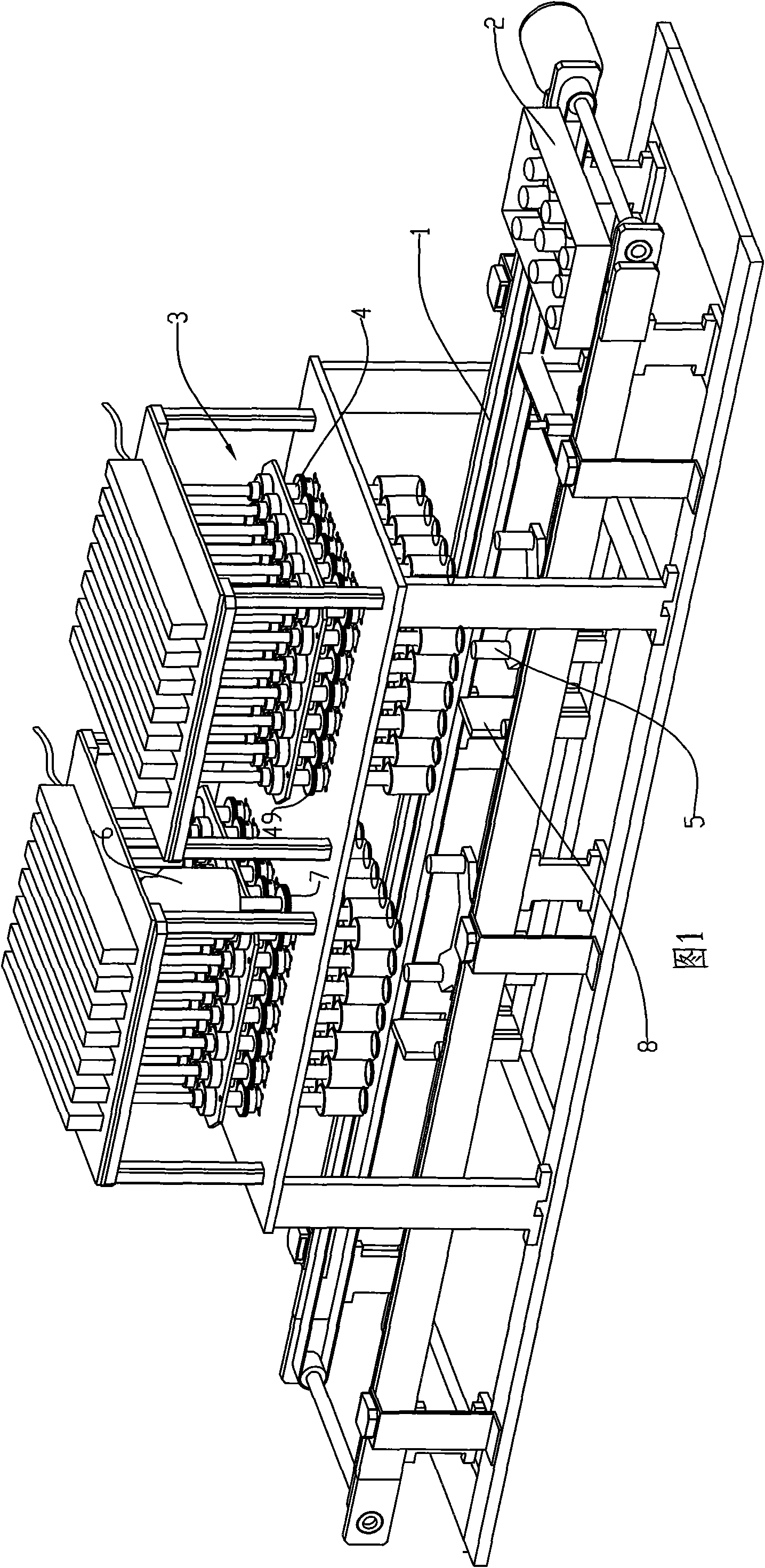

Process and system for automatically cleaning tobacco boxes

ActiveCN101722164ASatisfy classification and recyclingImprove production efficiencyProgramme-controlled manipulatorHollow article cleaningEngineeringCleaning station

The invention relates to a process and a system for automatically cleaning tobacco boxes. The process comprises the following steps of: conveying the tobacco boxes to a cleaning system, detecting the bottom of the boxes by a visual detector (5) to judge whether the tobacco boxes need cleaning or not, and identifying the positions of residual materials in the boxes; directly sending the tobacco boxes not needing cleaning out of the cleaning system, and conveying the tobacco boxes needing cleaning to a tobacco box turning station; turning the tobacco boxes by 90 to 150 DEG by a tilter (6) so that openings face a cleaning robot (7); stretching a cleaning claw (7c-2) of the cleaning robot (7) into the boxes for cleaning, cleaning the residual materials to a residual material belt conveyor (8), and then conveying the residual materials to a recycling box (9); turning and resetting the cleaned tobacco boxes by the tilter, and sending the tobacco boxes back to a visual detector station for rechecking; and sending the tobacco boxes qualified in the rechecking out of the cleaning system, and conveying unqualified tobacco boxes to the tilting station again for secondary cleaning or directly conveying the unqualified tobacco boxes to a manual cleaning station for cleaning. The process and the system can complete automatic cleaning of the tobacco boxes for storing shredded leaves and sliced leaves.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

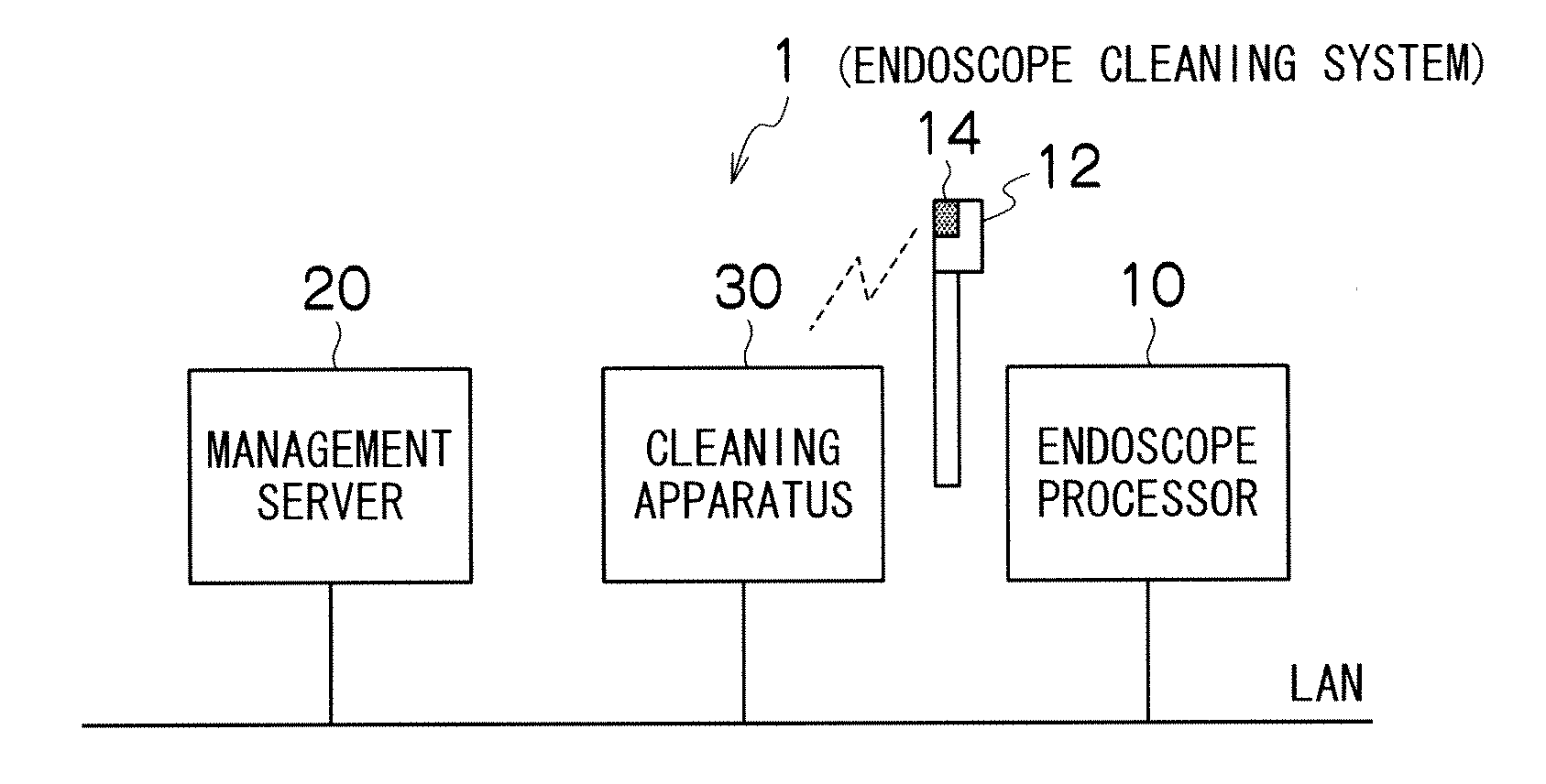

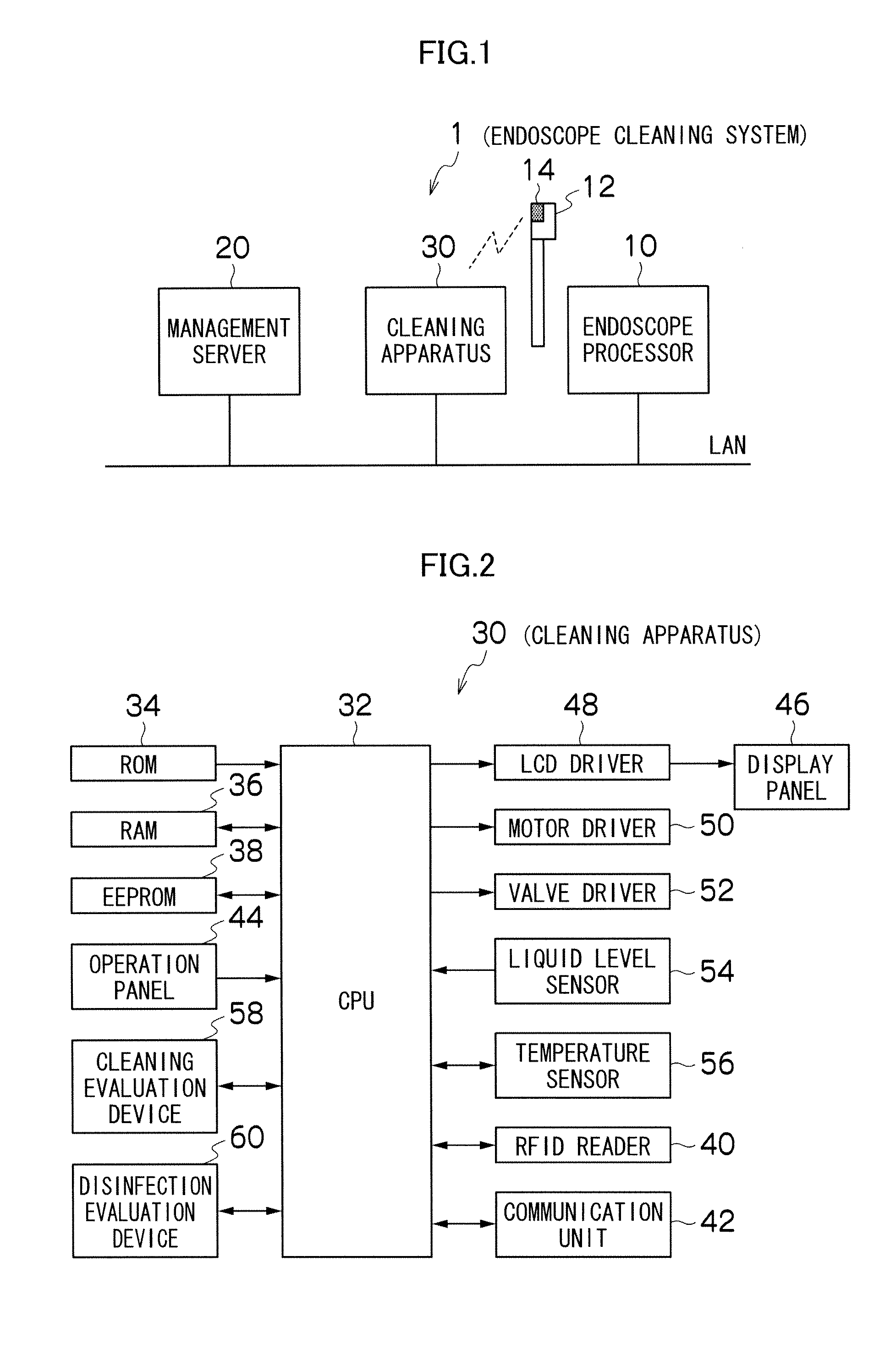

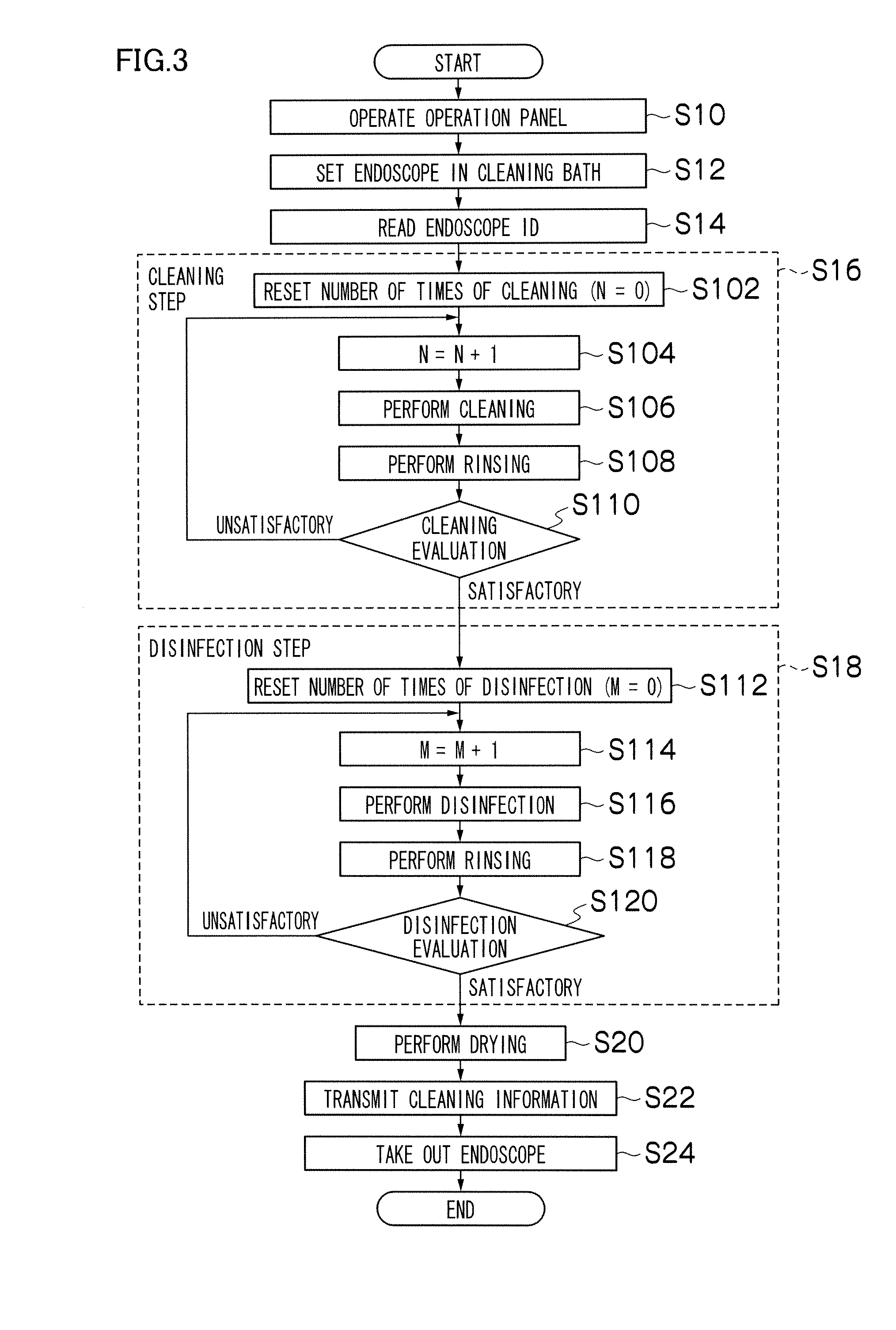

Endoscope cleaning system and endoscope cleaning method

InactiveUS20120073614A1Eliminate attachmentLess clean upEndoscopesDisinfectionSubject matterEndoscope

An endoscope cleaning system of one aspect of the subject matter includes: a first cleaning device configured to clean an endoscope; a second cleaning device configured to clean the endoscope according to a method different from that of the first cleaning device; and a cleaning evaluation device configured to determine whether or not a cleaning level of the endoscope cleaned by one of the first cleaning device and the second cleaning device satisfies a predetermined criterion, wherein one of the first cleaning device and the second cleaning device cleans the endoscope in accordance with a determination result of the cleaning evaluation device.

Owner:FUJIFILM CORP

Disposable cleaning pad

InactiveUS20080047087A1Economical and durableReliable cleaningBoard cleaning devicesCarpet cleanersFiber bundleEngineering

The present invention discloses an economical and disposable cleaning tool which may be prepared by a simplified manufacturing process involving a reduced number of steps. The cleaning tool comprises a cleaning pad and an implementing means, the cleaning pad having a pocket for receiving the implementing means. The cleaning pad may be provided with a top sheet and a fiber bundle. The top sheet is folded over and bonded to provide a cleaning portion and a back portion, and the fiber bundle is disposed on the cleaning portion. The cleaning portion and the back portion of the folded sheet are bonded together forming the pocket for a handle to be disposed therein. The handle may include a hinge to enable the handle to be repeatedly folded over for convenient storage or easily extended for use.

Owner:FIRST QUALITY RETAIL SERVICES

Electric separator with a rinsing cleaning system

InactiveUS7115153B2Reliable cleaningLow costCoupling device detailsMachines/enginesEngineeringInjection device

Owner:HENGST WALTER

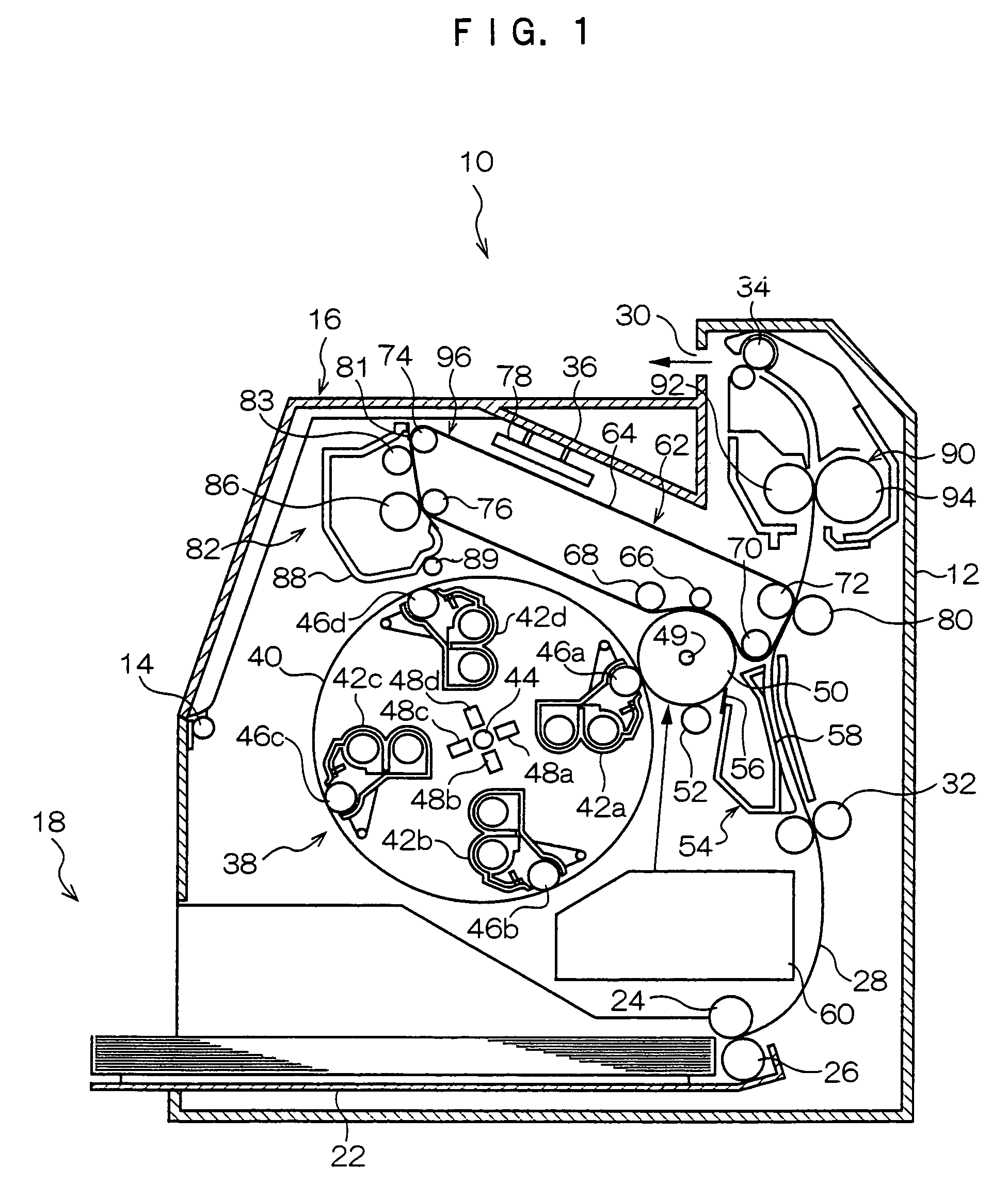

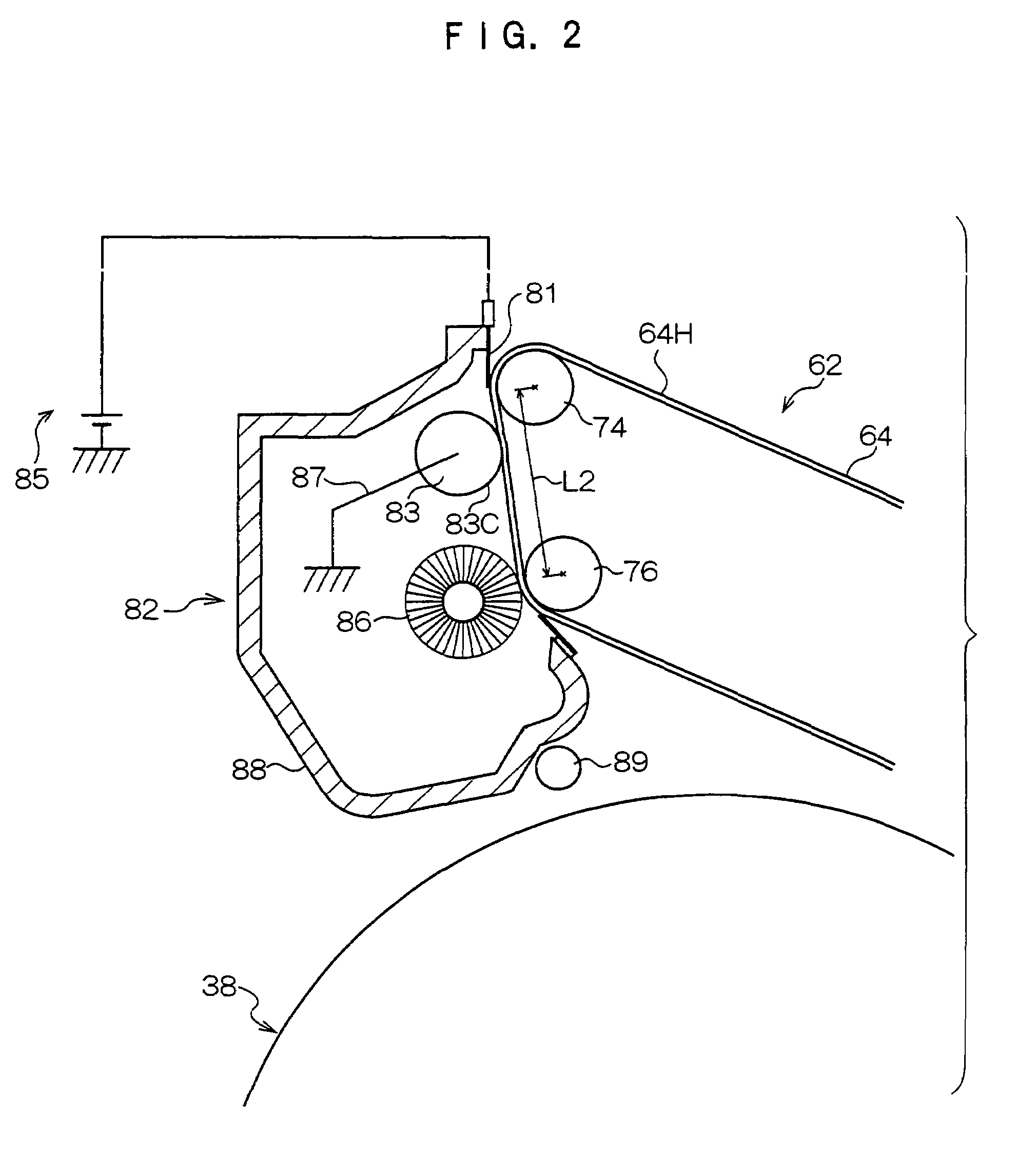

Intermediate transfer device and image forming device

InactiveUS7190919B2Reliably removedReduce mechanical stressElectrographic process apparatusEngineeringVoltage

An intermediate transfer device has: an intermediate transfer belt supported by a plurality of belt supporting mechanisms so as to be able to circulate, and having elasticity at least in a direction of circulating; a first bias applying mechanism applying a first bias voltage to toner on a toner carrier surface of the intermediate transfer belt; a layer thinning mechanism contacting the toner carrier surface and electrostatically attracting the toner which is on the toner carrier surface so as to thin a layer of the toner; a second bias applying mechanism applying a second bias voltage to the toner whose layer has been thinned; an image carrier carrying a visible image to be transferred onto the toner carrier surface, the toner on the toner carrier surface, to which the second bias voltage has been applied, being transferred onto the image carrier; and a toner removing mechanism removing the toner on the image carrier.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Cleaning unit for optical connector and cleaning tool for optical connector

InactiveUS7243390B2Easy to cleanEasy to implementLiquid processingReconditioning/cleaning record carriersRelative motionOptical connectors

A join end face of an optical connector is easily and reliably cleaned when the optical connector has been inserted into a connector housing, by using an optical connector cleaning unit comprising a cleaning member which wipes clean a join end face of an optical connector inside a connector housing by relative motion against the join end face, a drive mechanism which drives the cleaning member, and a connection section which enables a drive auxiliary mechanism for applying a moving force to the drive mechanism to be connected, and an optical connector cleaning tool in which a drive auxiliary unit comprising the drive auxiliary mechanism has been connected to the connection section of the optical connector cleaning unit.

Owner:THE FUJIKURA CABLE WORKS LTD

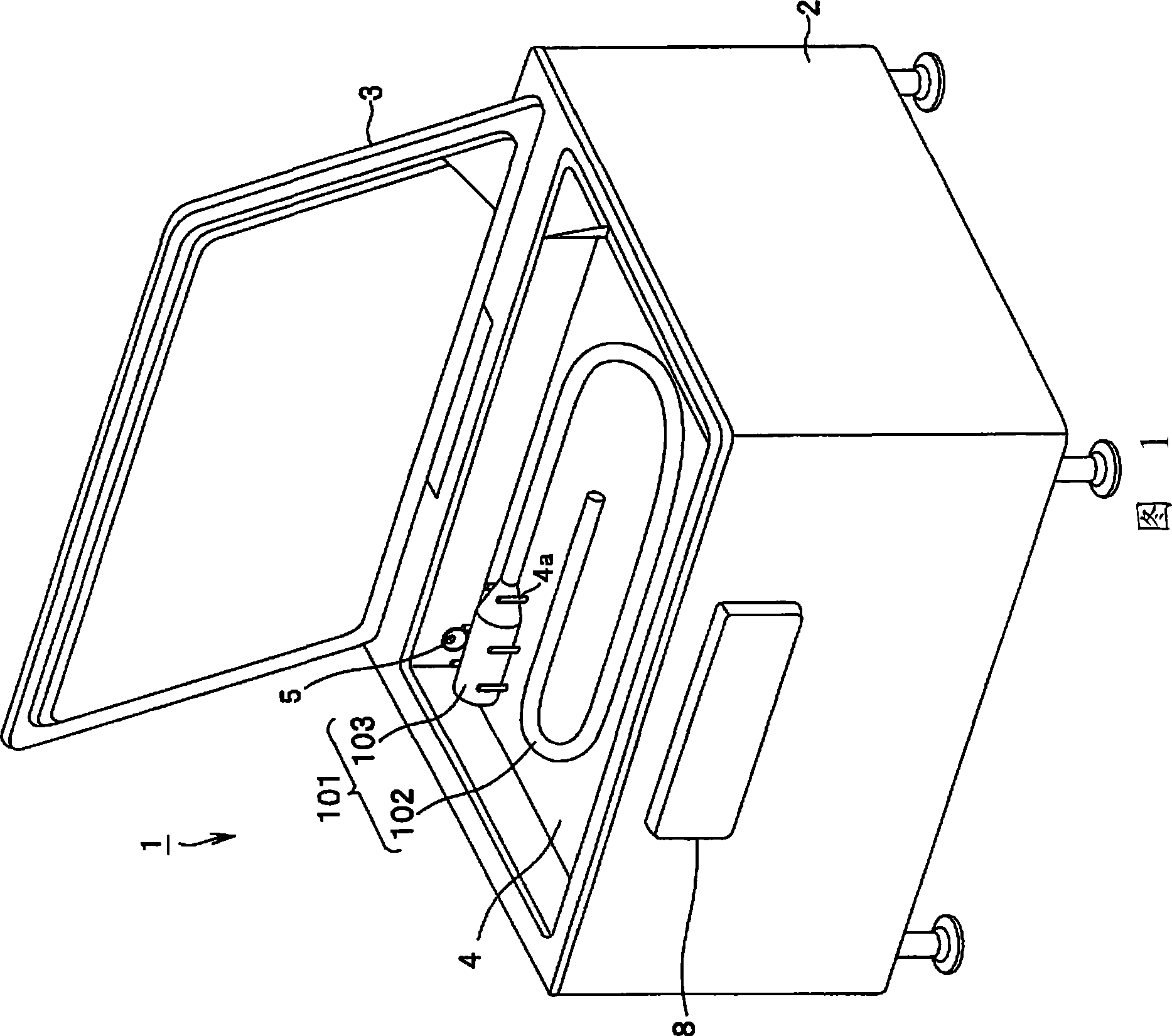

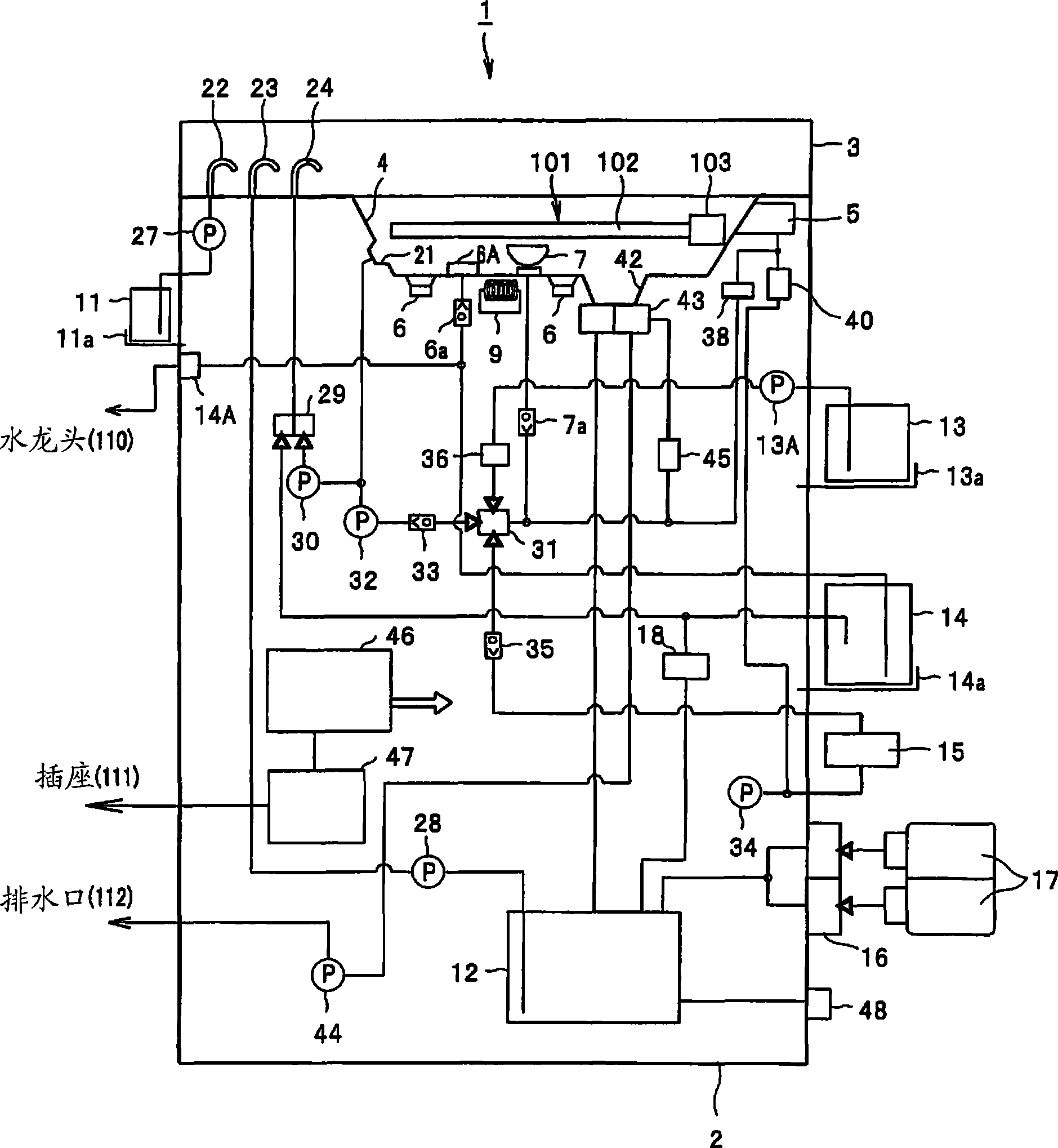

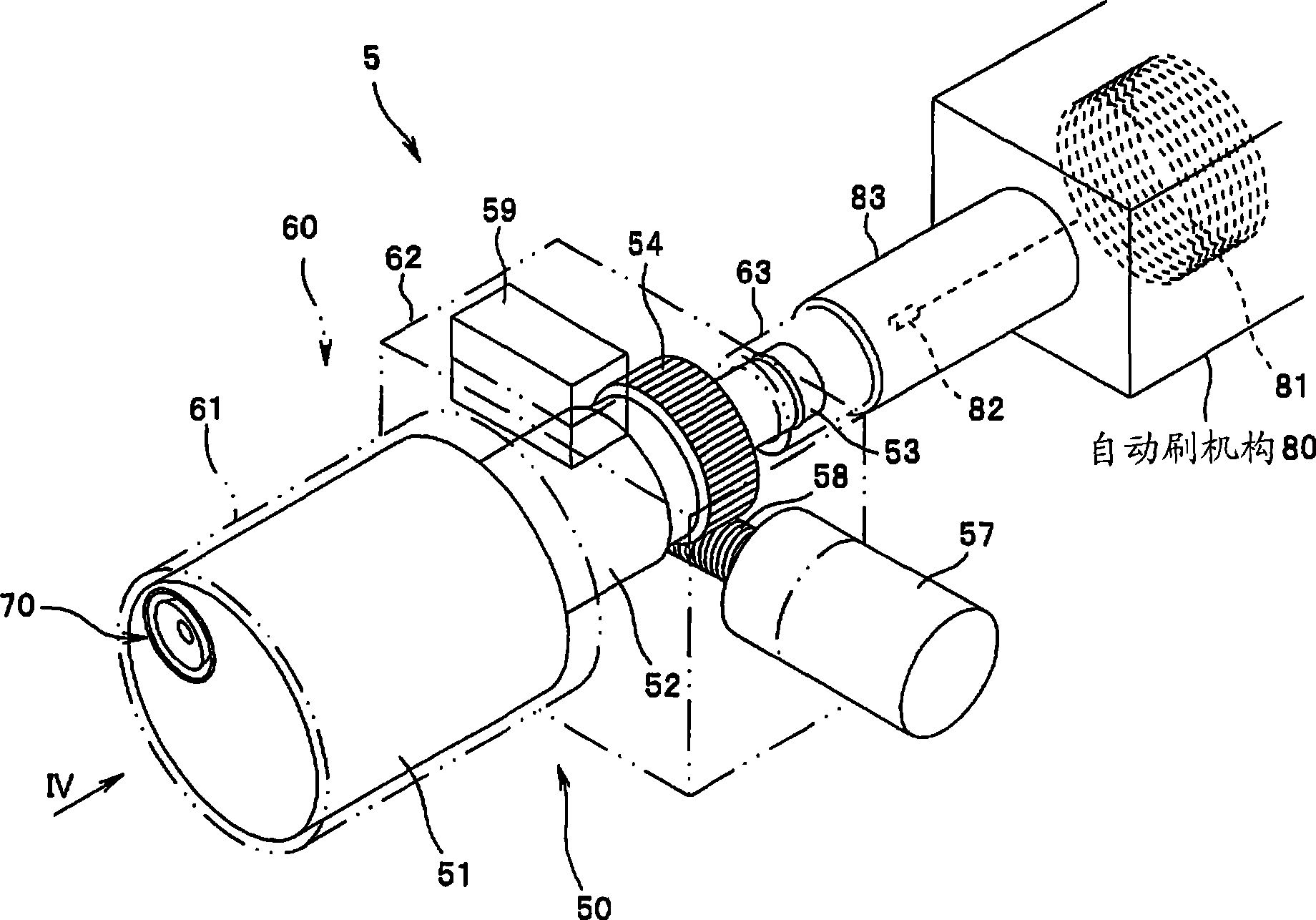

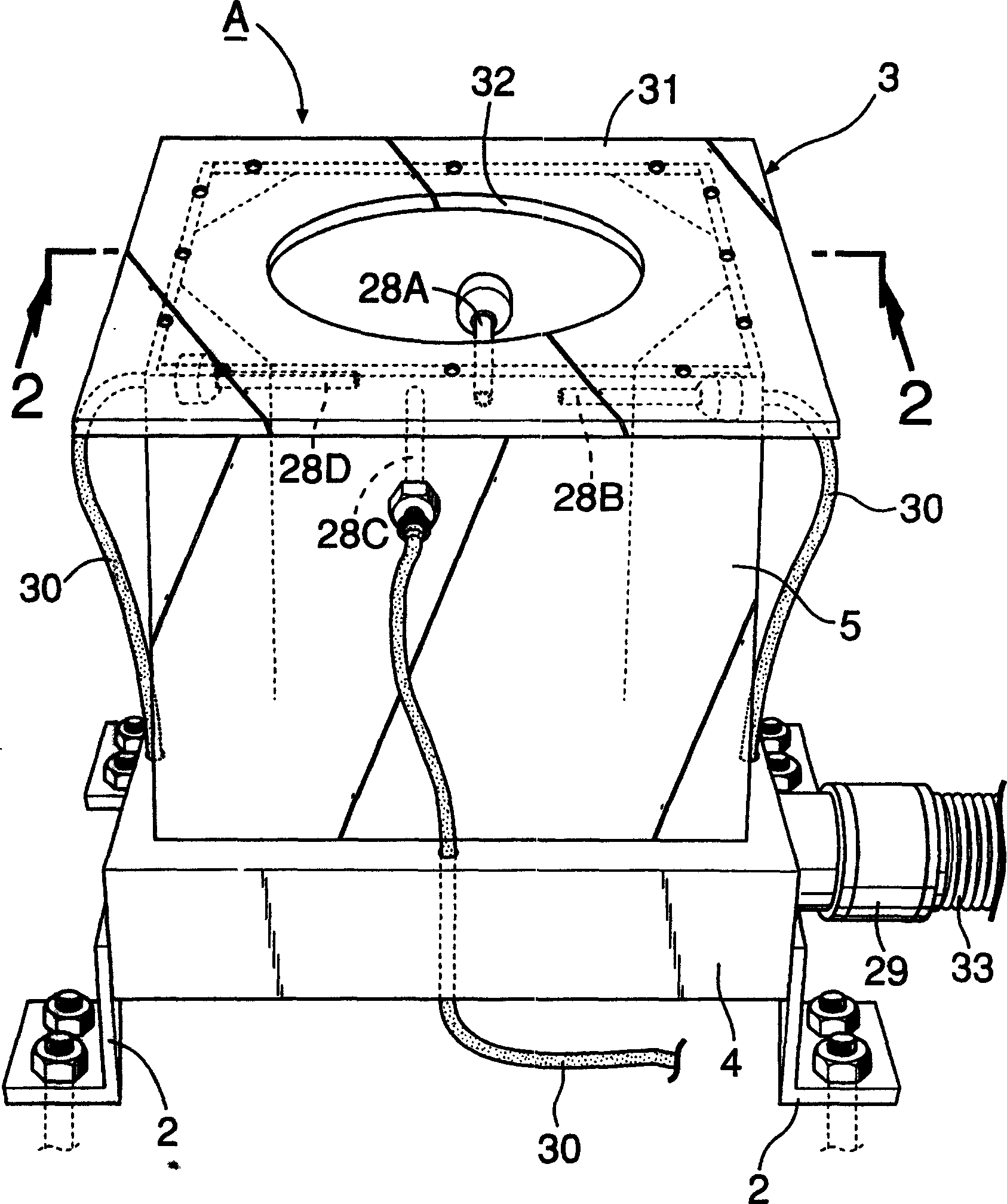

Endoscope washing and disinfecting apparatus

InactiveCN101433451AFree loading and unloadingReliable cleaningEndoscopesEndoscopic washingEndoscope

An endoscope washing and disinfecting apparatus (1) includes an apparatus main body (2) equipped with a washing bath (4) in which an endoscope (101) is mounted; a nozzle unit (70) provided so as to face a connector portion (104) of an endoscope conduit provided in the endoscope mounted in the washing bath, to which fluid within the apparatus main body is supplied so that the nozzle unit advances due to pressure of the fluid, and which supplies the fluid to inside the endoscope conduit by connecting to the connector portion; and an automatic brush mechanism (80) that is provided in the apparatus main body and that carries out brushing and cleaning within the endoscope conduit by introducing a cleaning brush (81) into the endoscope conduit through the nozzle unit and moving the cleaning brush (81) forward and rearward.

Owner:OLYMPUS MEDICAL SYST CORP

Air blowing cleaning apparatus

InactiveCN1575871AReliable cleaningReliable removalCleaning using gasesCleaning using liquidsHigh pressureNozzle

The device is provided with a housing, an air suction means connected to the housing and sucking air from the inside of the housing, a work holder for holding the work arranged rotatably in the housing, and air nozzles with which the air is supplied from a high pressure air source provided on the housing, and the air is sprayed against the work held by the work holder to clean the work.The air nozzles are arranged so as to rotate the work holder.

Owner:THAI TOYO DENSO

Parts washer

The invention discloses a parts washer. A jetter above a conveyor belt comprises a plurality of nozzle assemblies, and parts to be washed which are placed in a charging tray and conveyed to the bottom of the jetter along the conveyor belt can be propped close to the jetter by a pressure cylinder at the bottom of the conveyor belt and washed by high-pressure cleaning liquid jetted by rotation from a plurality of jet holes of jet heads at the bottom of various nozzle assemblies. The jetter is provided with a plurality of the nozzle assemblies, each nozzle assembly can be corresponding to one part and can simultaneously wash a plurality of parts, and the washing efficiency is high; the jet heads can rotate and spray liquid at the time of washing, thus the parts washer can wash the parts at various angles and in all directions, and washing is complete, reliable and has good effect.

Owner:广州市新豪精密科技有限公司

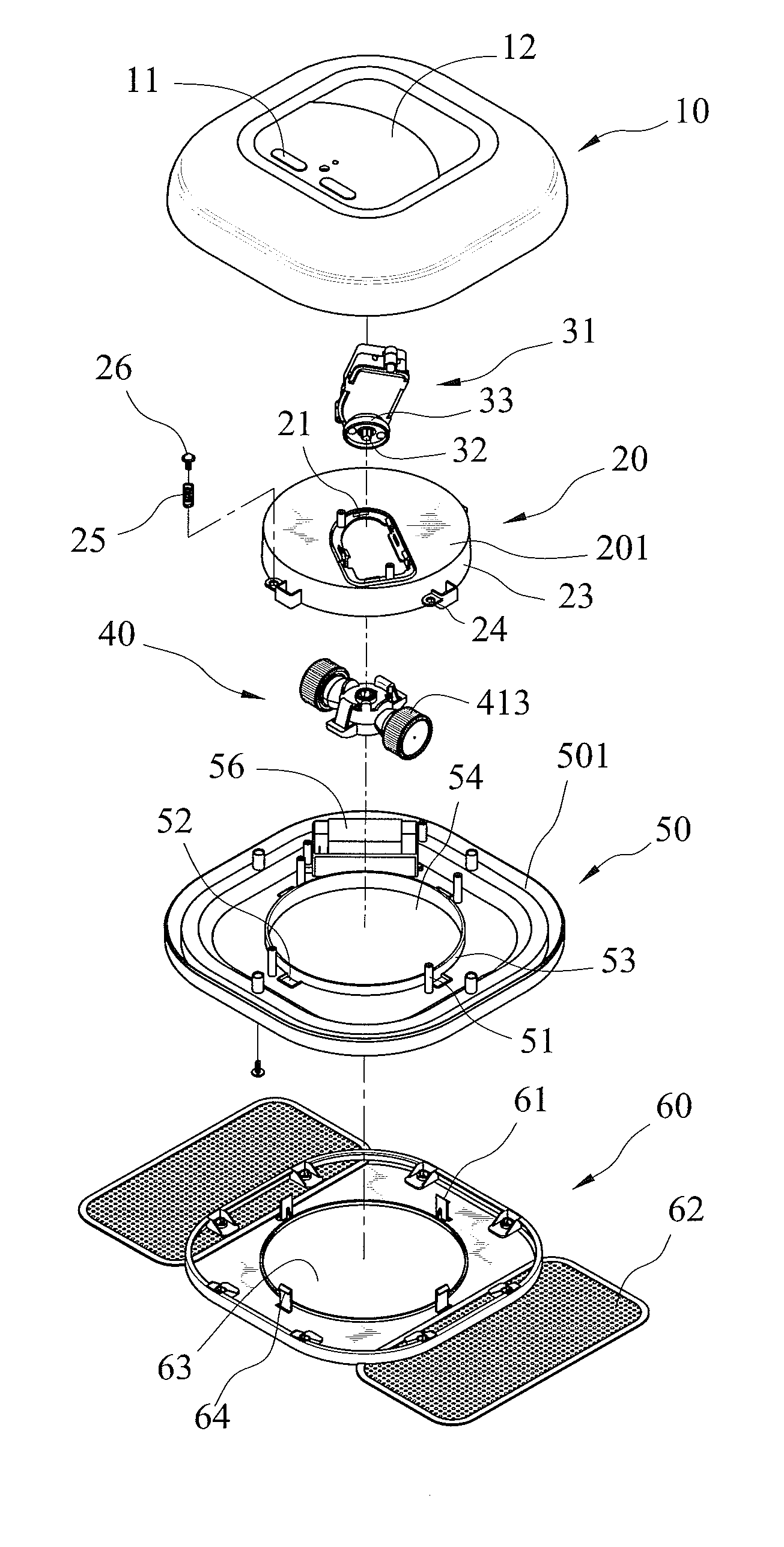

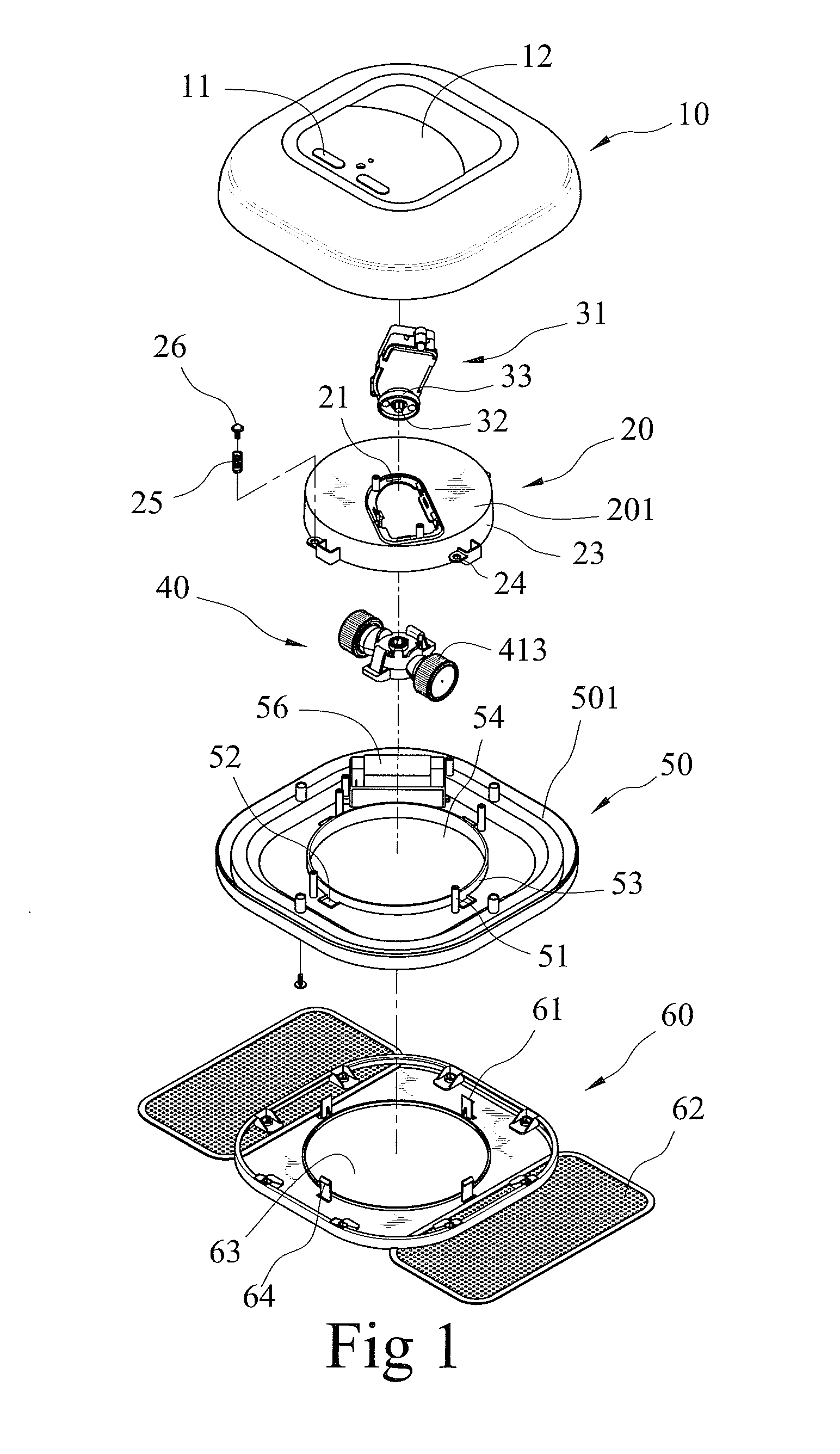

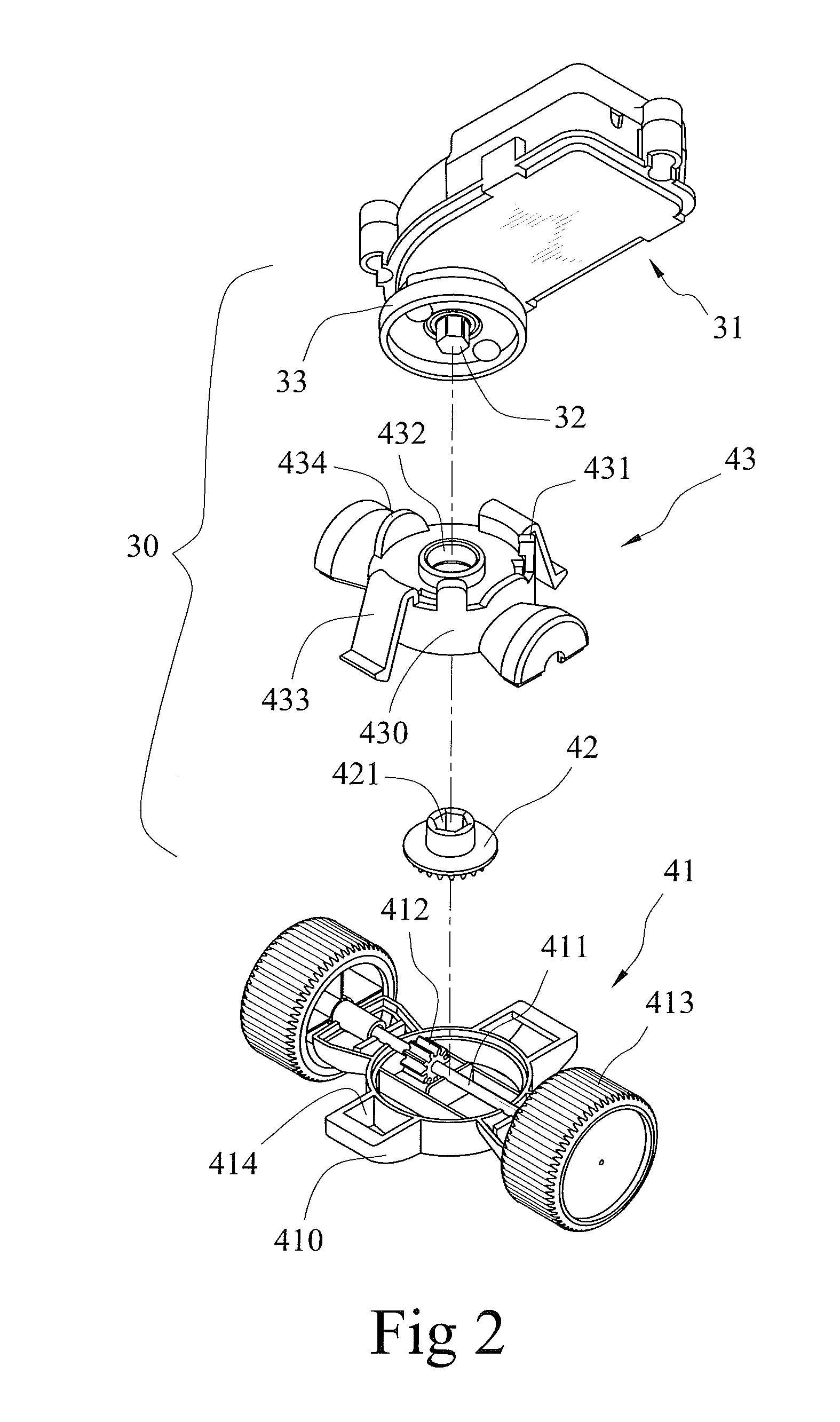

Automatic Floor Cleaning Machine

An automatic floor cleaning machine includes a base, an upper cover covering the base, a supporting seat mounted on the base, a random-turn driving unit installed on the supporting seat, and a floor cleaning plate installed on a bottom of the base. The automatic floor cleaning machine is randomly operated over a floor by the random-turn driving unit. Dedusting papers are disposed on a bottom surface of the floor cleaning plate and protruded from two sides or two corners of the base. The dedusting papers turn to sweep and kick up dust particles on the floor when the automatic floor cleaning machine is operating. Thereby, the effect of thorough cleaning of the floor can be achieved. The automatic floor cleaning machine may further include a vacuum cleaner for further enhancing the cleaning effect.

Owner:YEJEN APPLIANCES SHENZHEN +1

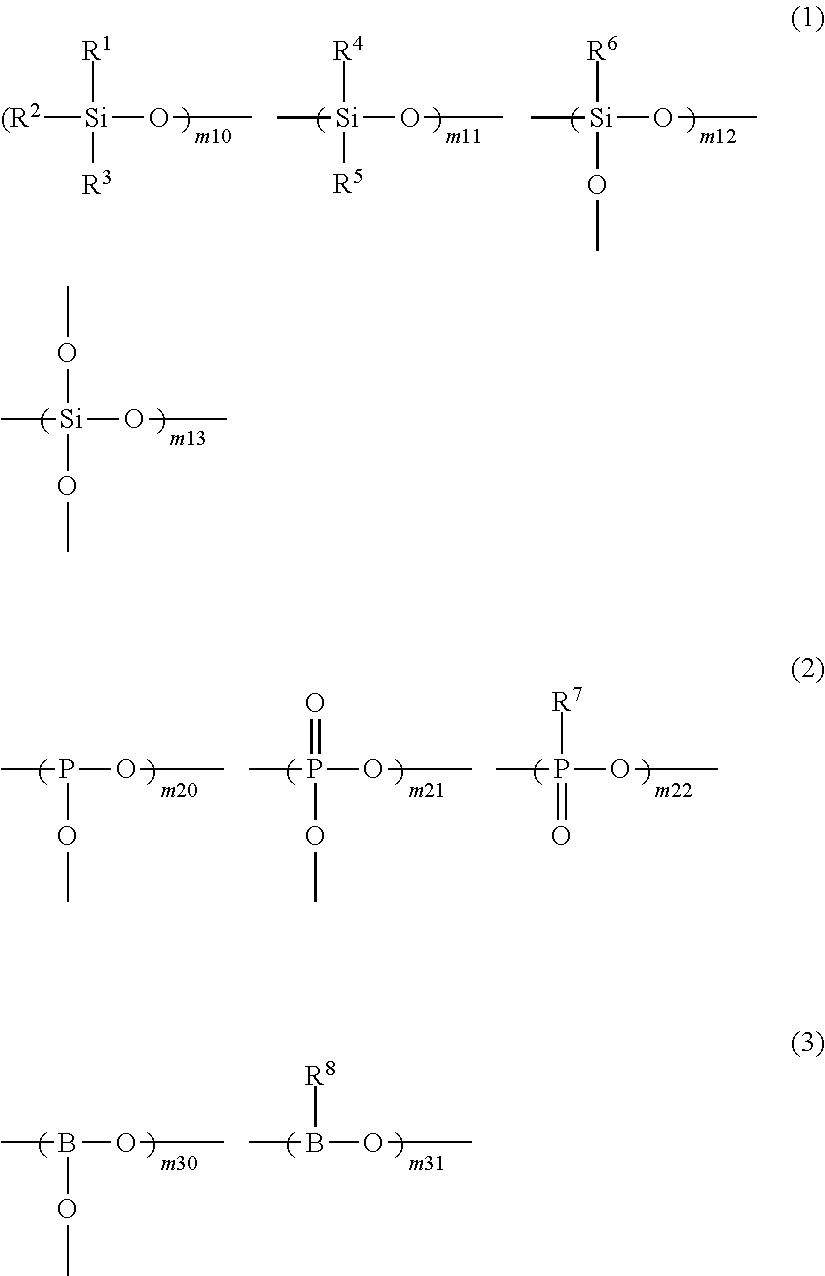

Patterning process

ActiveUS20160276152A1High dry etching selectivityEasy to disassemblePhotomechanical apparatusSemiconductor/solid-state device manufacturingResistBoron containing

The present invention provides a patterning process, which comprises step of forming a BPSG film on the under layer film by using a composition for forming a coating type BPSG film including a base polymer and an organic compound with a content of 25 parts by mass or more of the organic compound with respect to 100 parts by mass of the base polymer, the base polymer having a silicon containing unit, a boron containing unit and a phosphorus containing unit with a total content of the boron containing unit and the phosphorus containing unit being 10 mol % or more, the organic compound having two or more hydroxyl groups or carboxyl groups per one molecule. There can be provided a patterning process in which a fine mask pattern can be formed on the substrate to be processed by the multilayer resist method, and the residue of the resist under layer film on the mask pattern can be removed cleanly enough to process the substrate to be processed without causing damage to the substrate to be processed and the under layer film.

Owner:IBM CORP +1

Water-saving type solar power generation board cleaning equipment having good cleaning effect

ActiveCN108941005AClean, efficient and convenientEasy to cleanPhotovoltaicsCleaning using liquidsWater savingWater resources

The invention relates to water-saving type solar power generation board cleaning equipment having a good cleaning effect. The water-saving type solar power generation board cleaning equipment comprises a main body and a base, as well as a cleaning mechanism and a collecting mechanism; the cleaning mechanism comprises a moving assembly and a washing assembly; the moving component comprises a movingplate and two control units; the washing assembly comprises a driving unit and a washing unit; and the collecting mechanism comprises a water collection assembly and a sweeping assembly. According tothe water-saving type solar power generation board cleaning equipment having good cleaning effect, through the cleaning mechanism, multiple spray heads can be controlled to perform comprehensive washing cleaning on a solar power generation board, an omitted cleaning area is prevented, the cleaning is convenient and quick and efficient, the cleaning effect is improved, the influence from artificial improper cleaning operation is avoided, and the cleaning of the solar power generation board is more reliable; and through the collecting mechanism, sewage can be collected, purified and recycled, the consumption of water resources is reduced greatly, the cleaning cost is lowered, and the practicability and reliability of the water-saving type solar power generation board cleaning equipment areimproved.

Owner:安徽省国家电投和新电力技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com