Parts washer

A technology for cleaning machines and parts, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high labor costs, low cleaning efficiency, heavy workload, etc., and achieve a high degree of automation, High cleaning efficiency and comprehensive cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

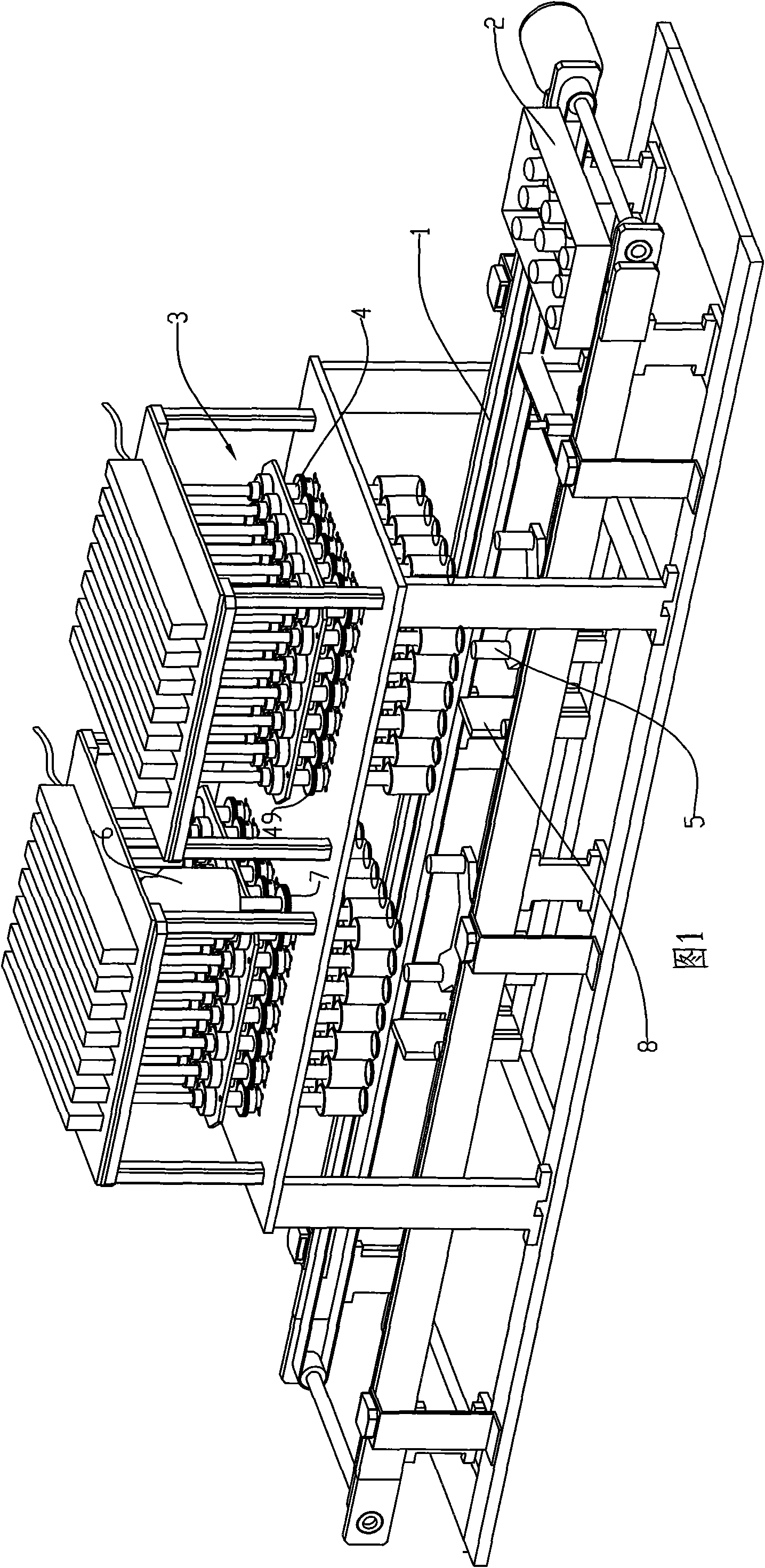

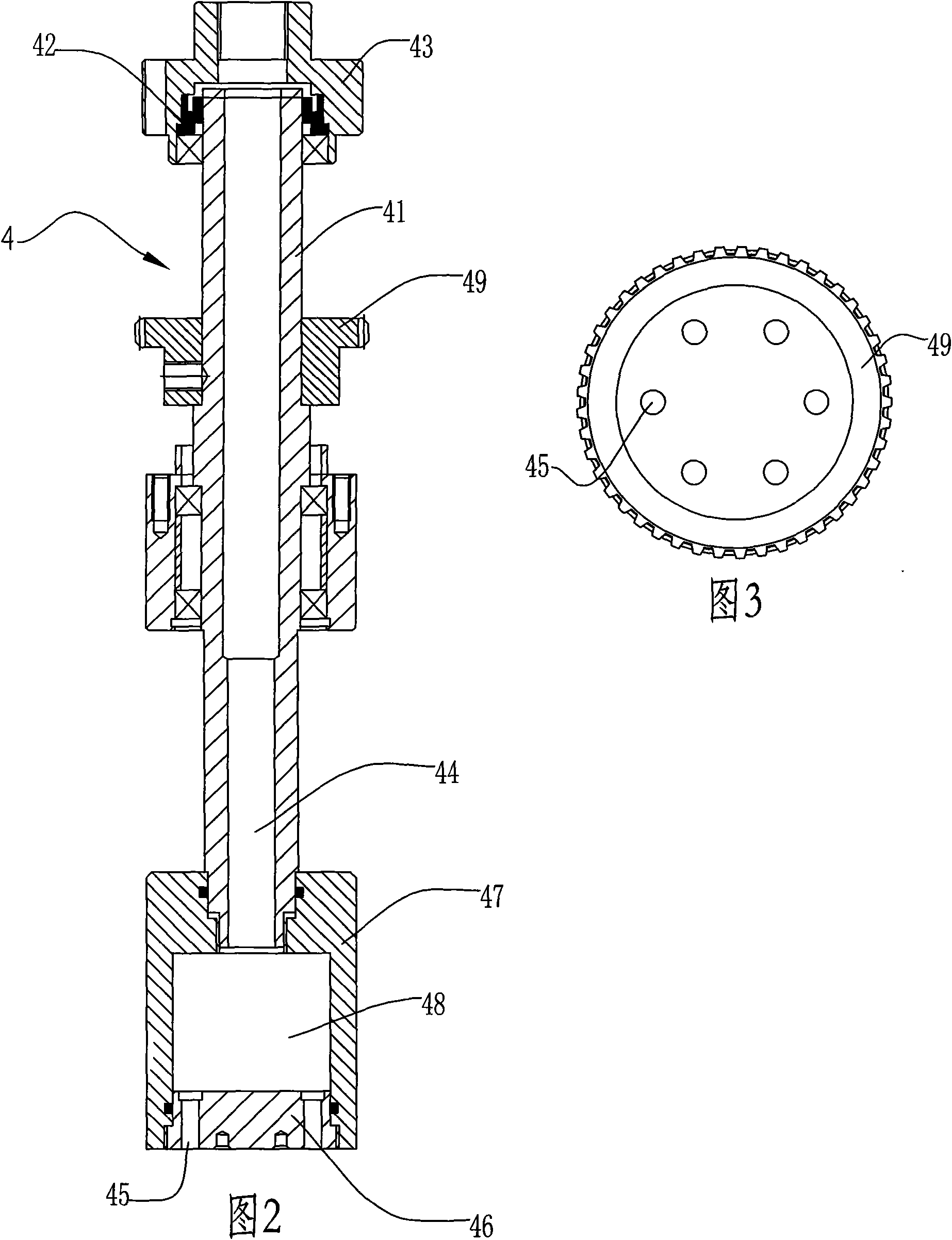

[0009] A parts washer such as figure 1 , there is a conveyor belt 1, on which a feed tray 2 can be placed for conveying, and a spray washing device 3 is installed above the conveyor belt, and the spray cleaning device includes a plurality of vertically fixed nozzle assemblies 4, each nozzle assembly 4, Such as figure 2 , including the nozzle 41, the cover connected to the liquid inlet pipe on the top of the nozzle 41, the nozzle cap 43 sealed by the gasket 42 with the nozzle, and the bottom end of the nozzle, which has a plurality of holes 44 communicating with the nozzle The nozzle 46 of the spray hole 45; each nozzle assembly closes up to each other, and the same position of the nozzle is fixedly connected with a gear 49, and each adjacent gear 49 meshes with each other, and is in phase with another gear 7 driven by the motor 6. Engagement; the pressure cylinder 5 is arranged under the conveyor belt directly below the spray washing device 3, and the pressure cylinder 5 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com