Patents

Literature

63results about How to "Adapt to the needs of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

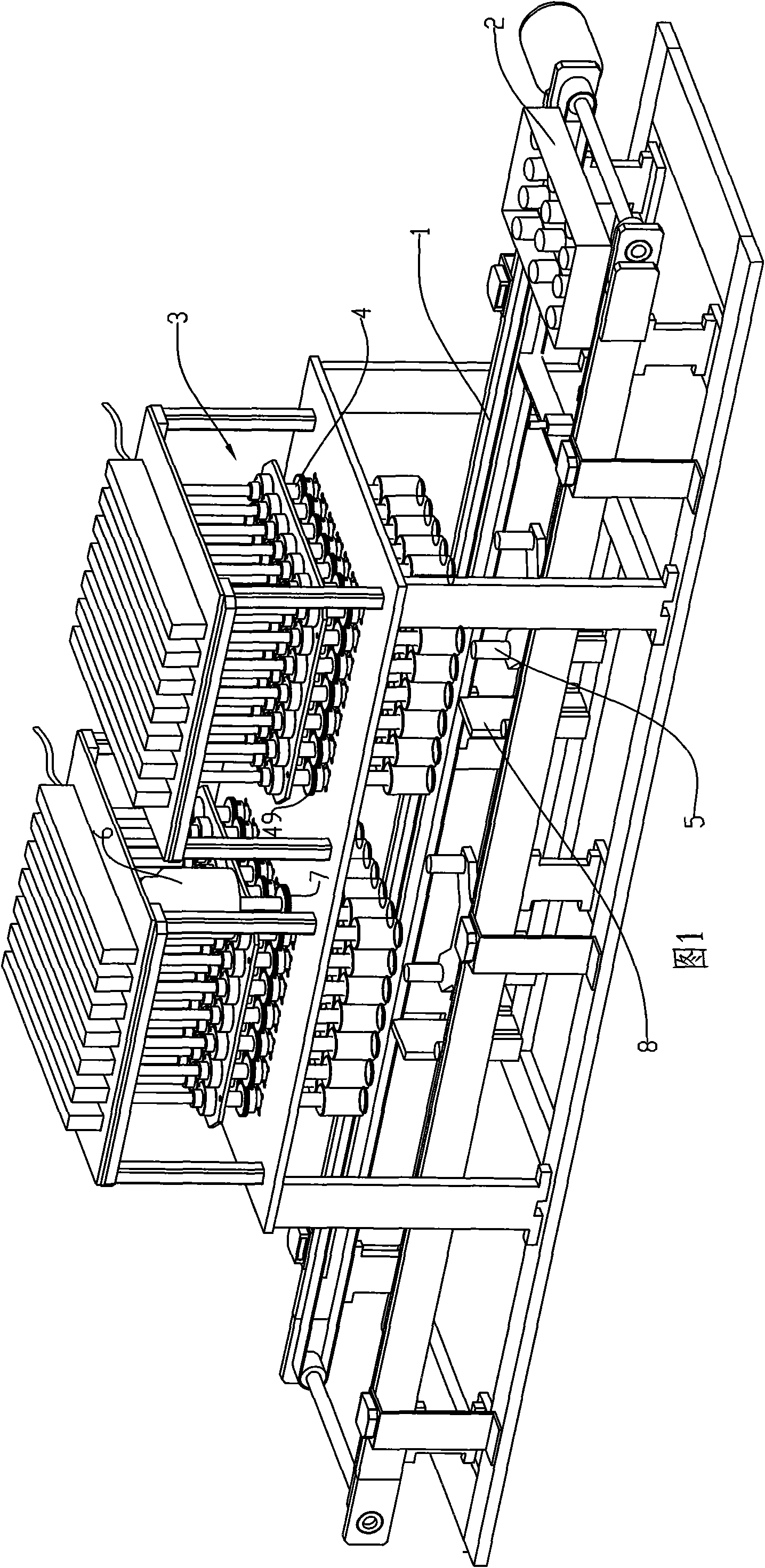

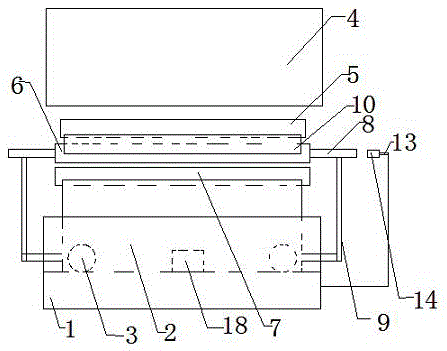

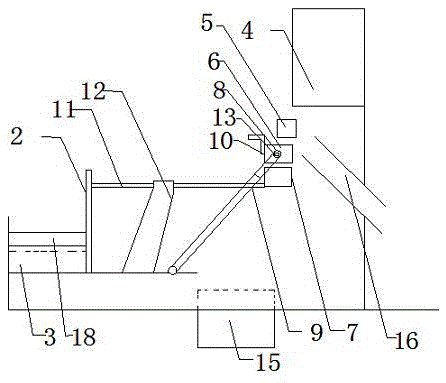

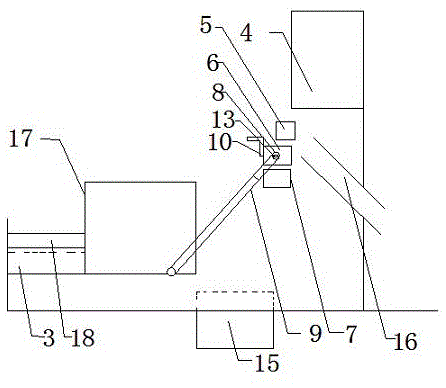

Parts washer

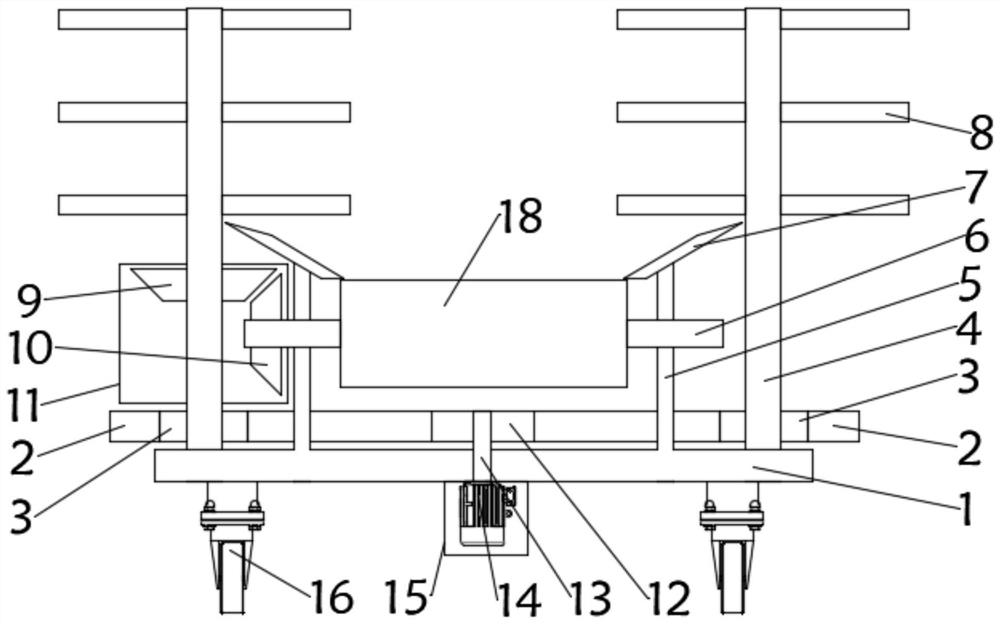

The invention discloses a parts washer. A jetter above a conveyor belt comprises a plurality of nozzle assemblies, and parts to be washed which are placed in a charging tray and conveyed to the bottom of the jetter along the conveyor belt can be propped close to the jetter by a pressure cylinder at the bottom of the conveyor belt and washed by high-pressure cleaning liquid jetted by rotation from a plurality of jet holes of jet heads at the bottom of various nozzle assemblies. The jetter is provided with a plurality of the nozzle assemblies, each nozzle assembly can be corresponding to one part and can simultaneously wash a plurality of parts, and the washing efficiency is high; the jet heads can rotate and spray liquid at the time of washing, thus the parts washer can wash the parts at various angles and in all directions, and washing is complete, reliable and has good effect.

Owner:广州市新豪精密科技有限公司

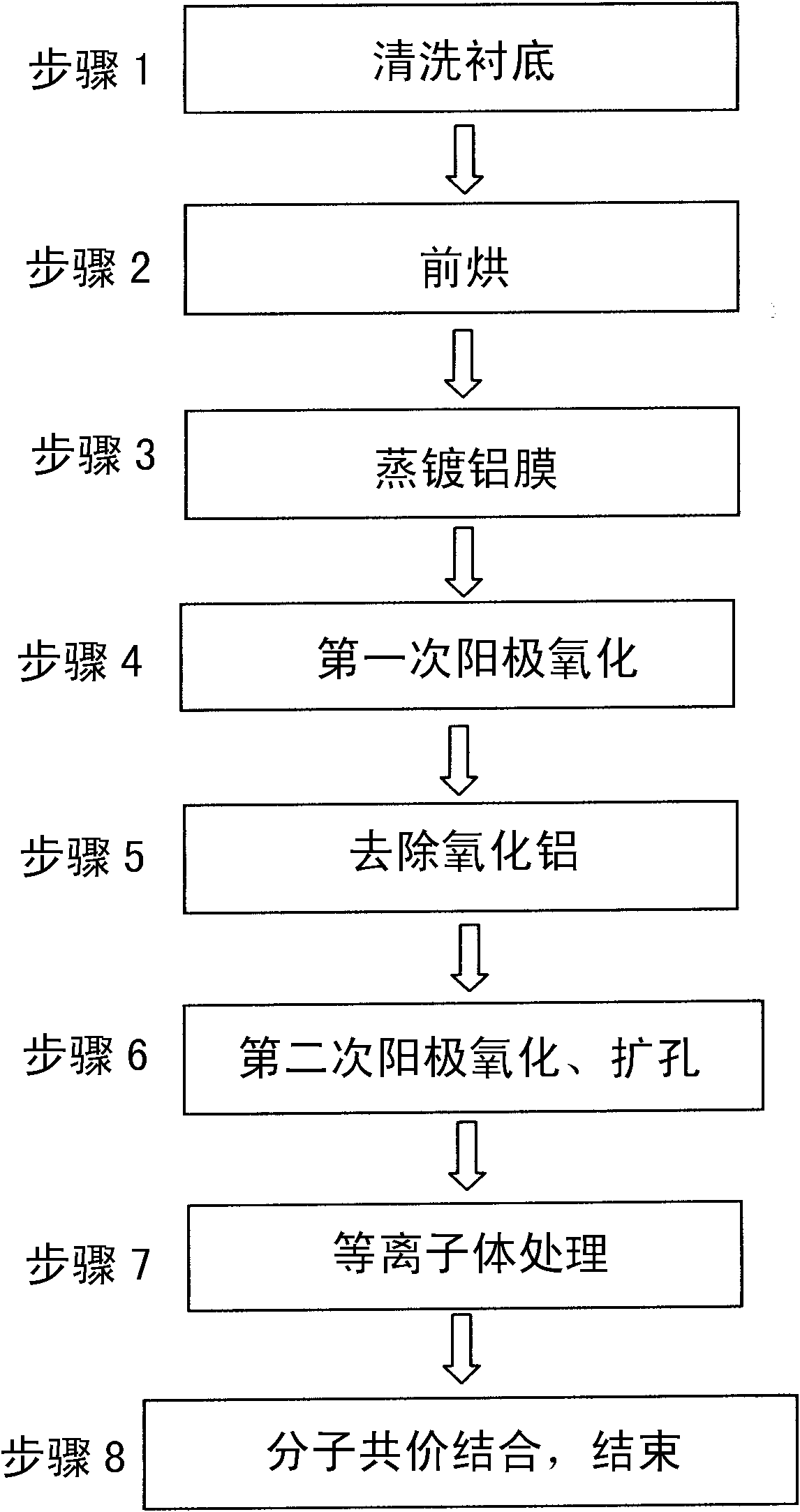

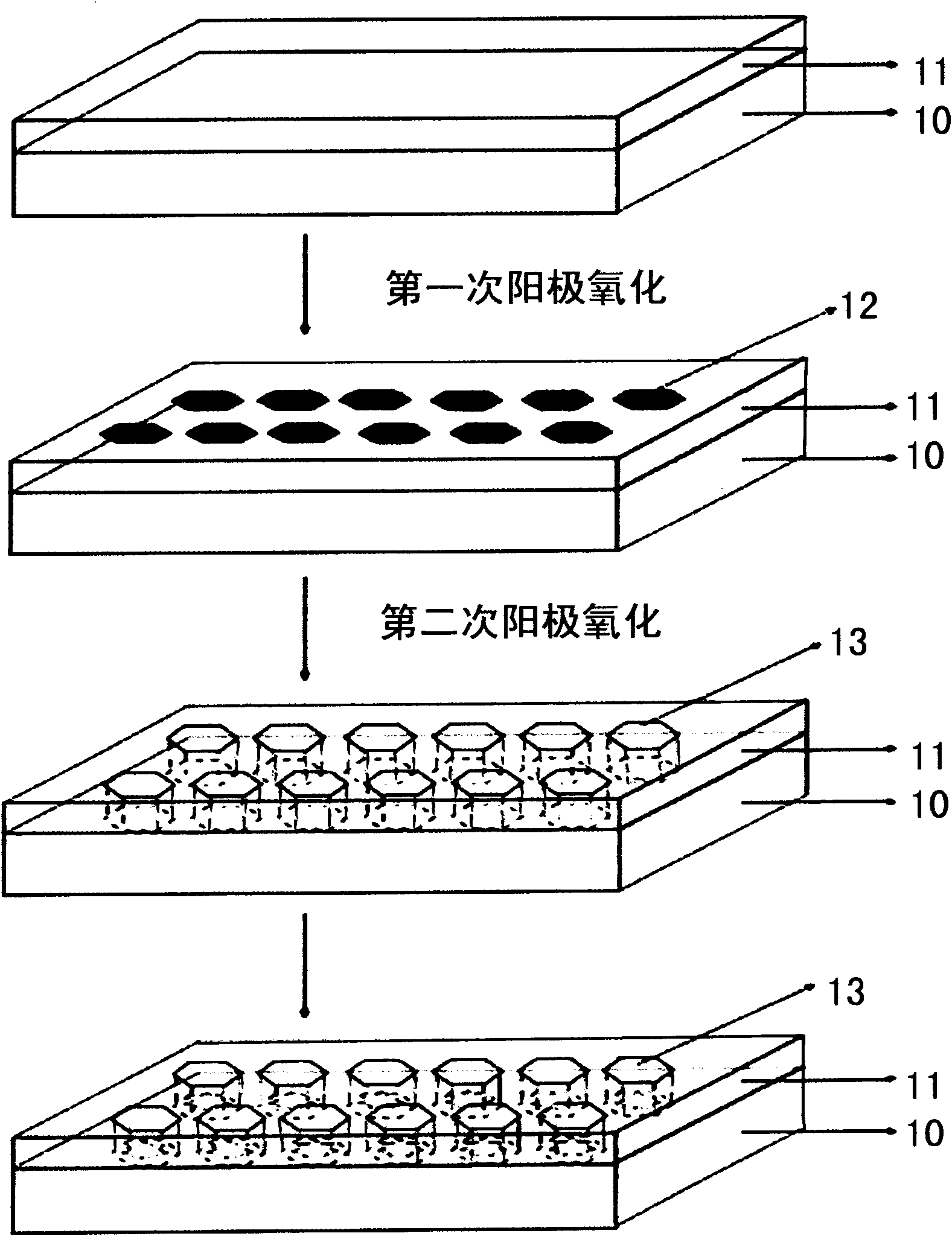

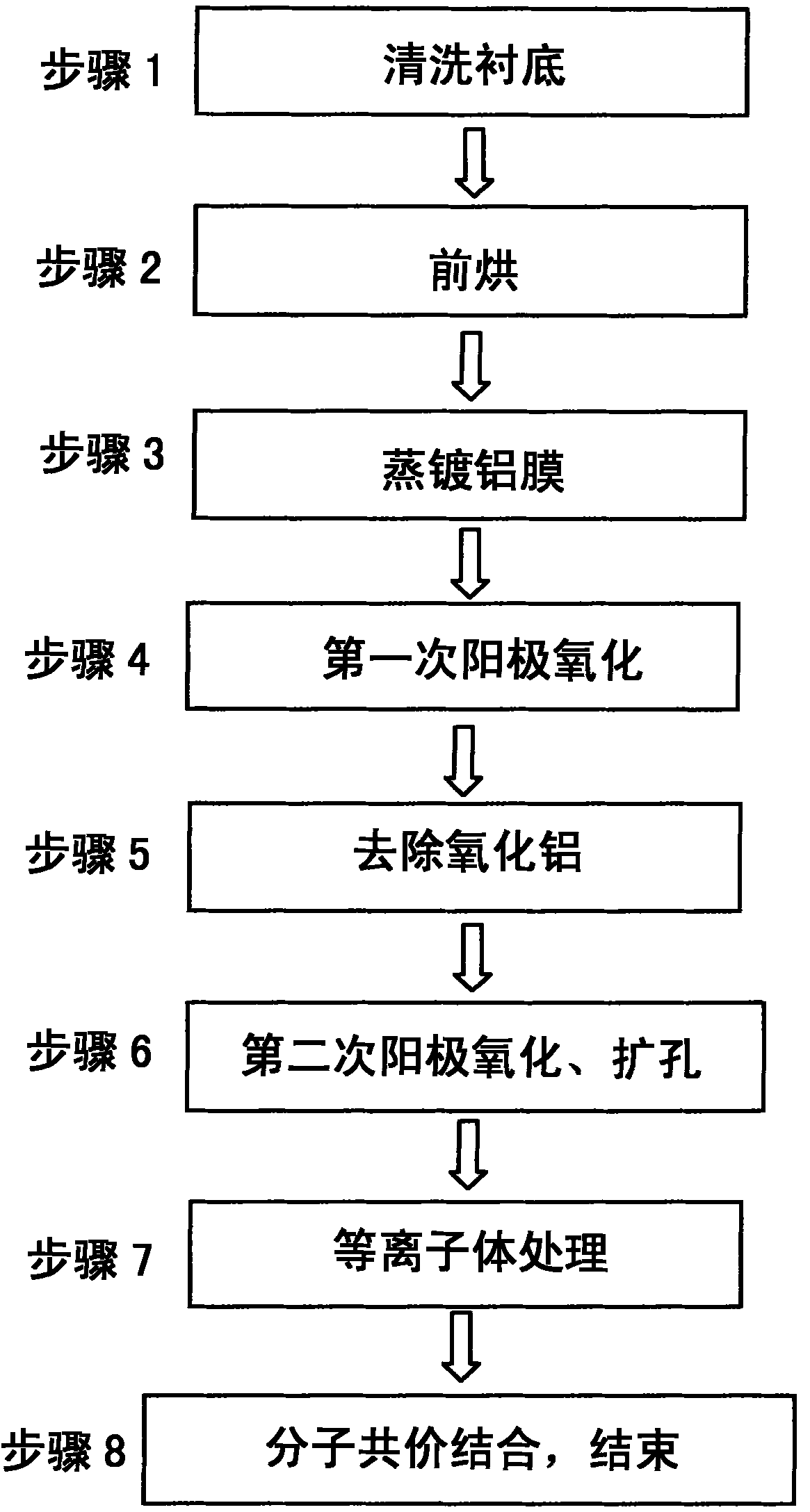

Manufacturing method of porous anodised aluminum oxide biochip

InactiveCN102183629ASimple and fast operationImprove reliabilityVacuum evaporation coatingSurface reaction electrolytic coatingPhosphoric acidVacuum drying

The invention discloses a manufacturing method of a porous anodised aluminum oxide biochip. The manufacturing method comprises the following steps of: 1, cleaning a substrate to remove organic and inorganic impurities; 2, pre-baking and drying the substrate in vacuum; 3, carrying out vapor deposition on an aluminum film on the surface of the substrate subjected to vacuum drying; 4, placing the substrate with the surface plated with the aluminum film into electrolyte to carry out primary anodic oxidation; 5, immersing the substrate subjected to the primary anodic oxidation by using a mixed solution of phosphoric acid and chromic acid to remove an aluminum oxide film generated during the primary anodic oxidation and form active spots on the surface of the aluminum film; 6, carrying out secondary anodic oxidation and reaming treatment on the aluminum film to form perforated holes on the active spots on the surface of the aluminum film so as to obtain a porous anodised aluminum oxide array chip; 7, processing the surface of the chip by using plasmas; and 8, bonding dual-functional-group molecules on the surface of the chip in a covalent way to complete the manufacturing of the porous anodised aluminum oxide biochip.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

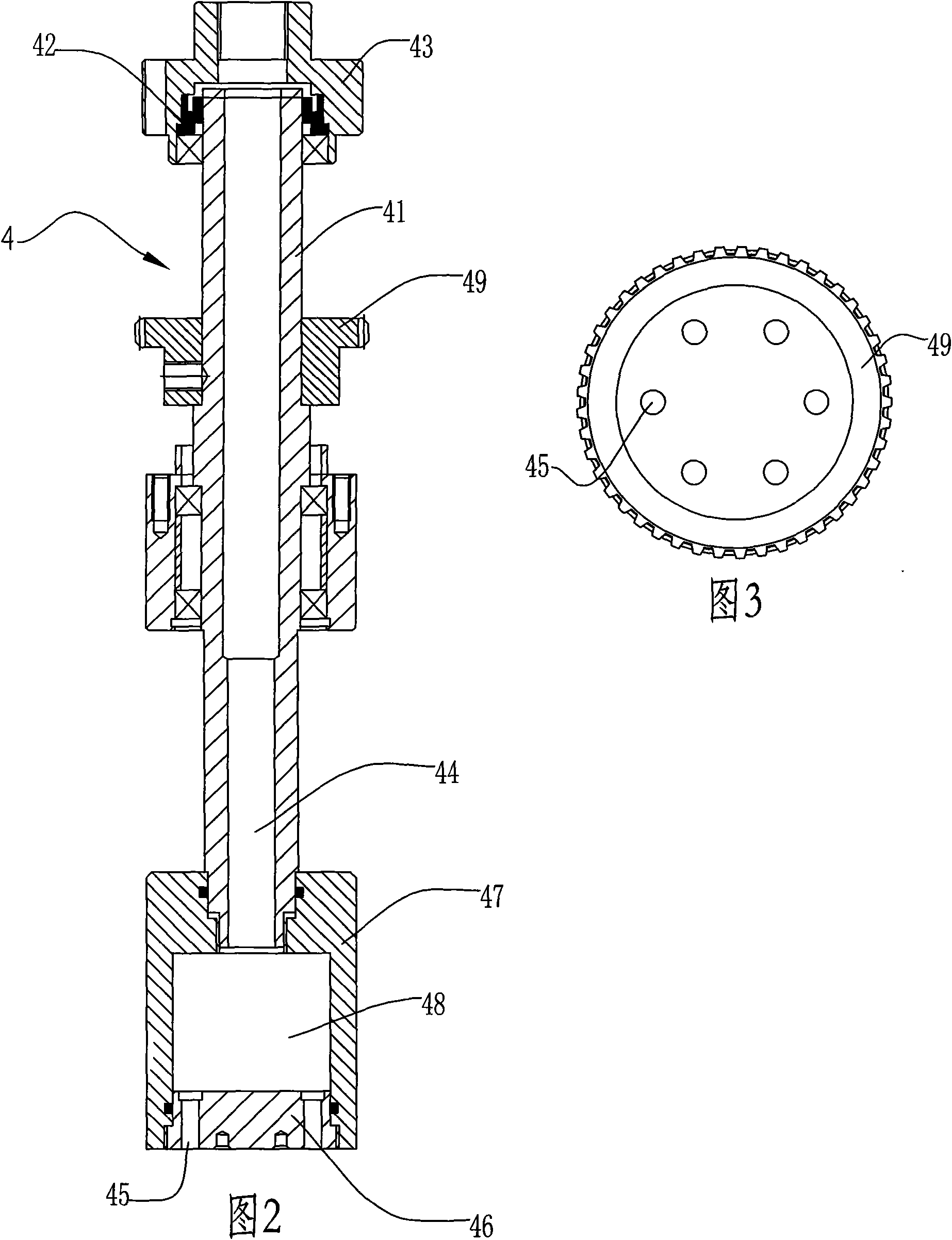

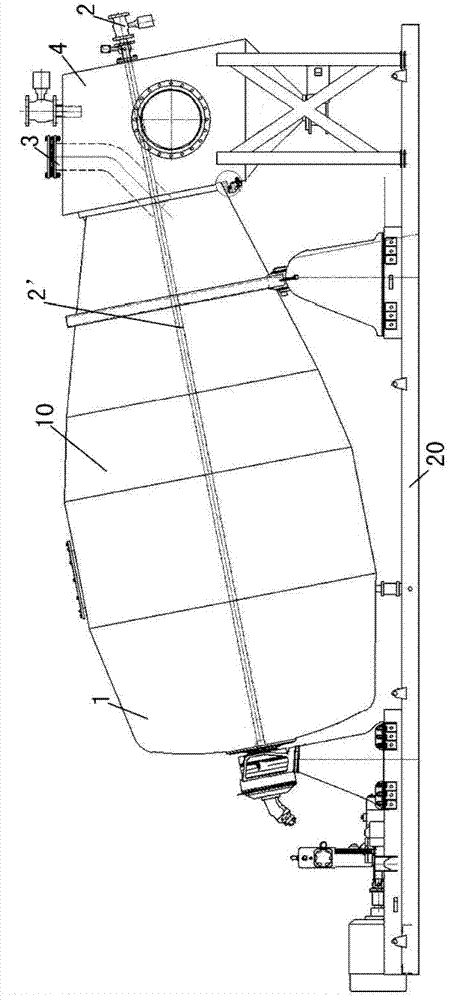

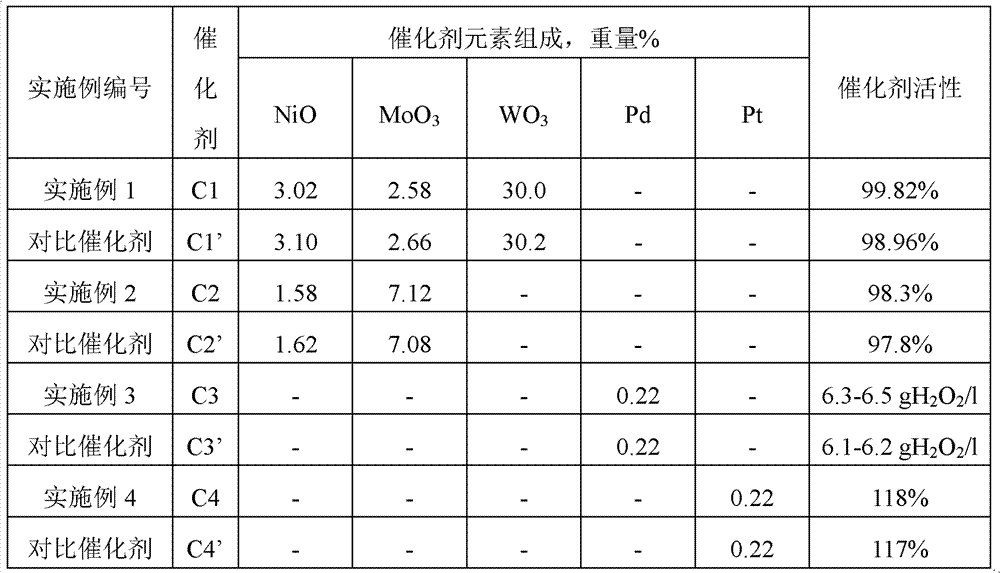

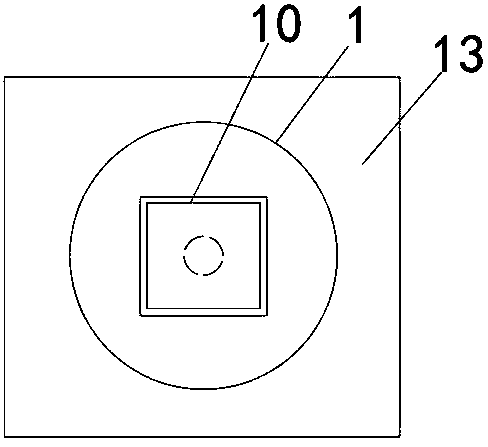

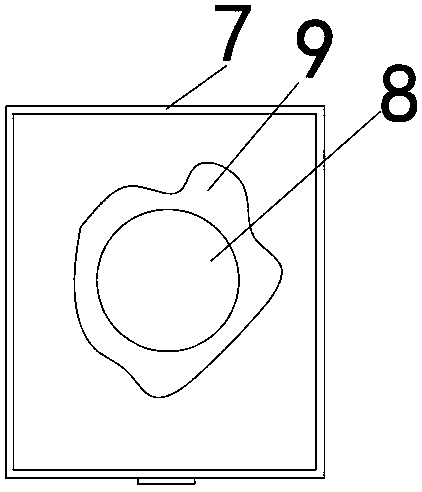

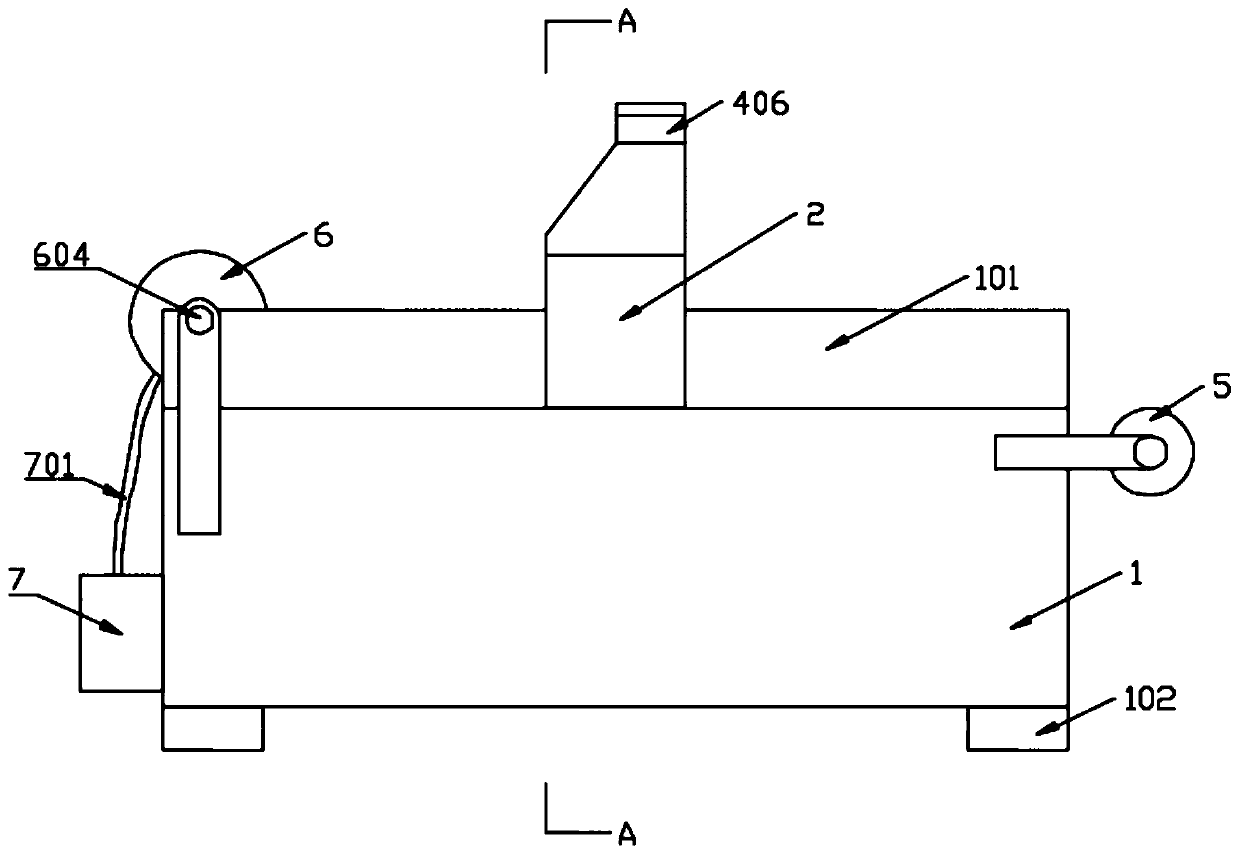

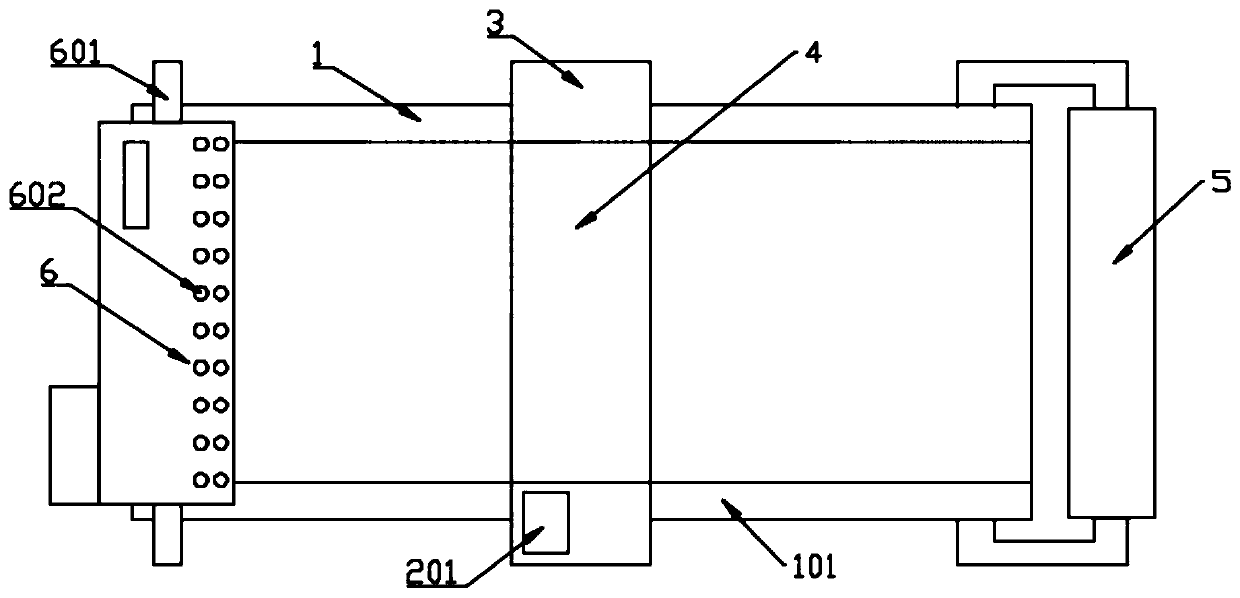

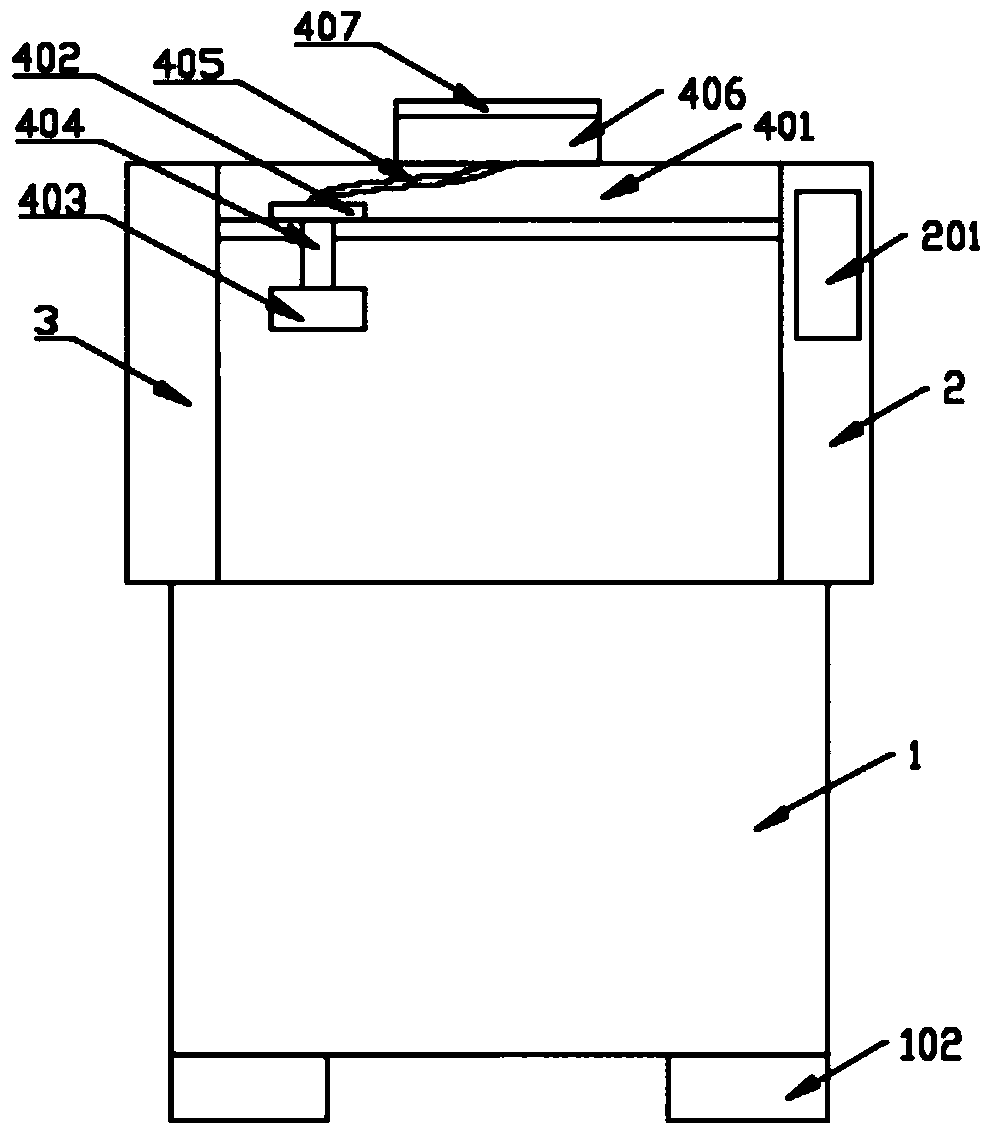

Fixed bed catalyst preparation method and fixed bed catalyst

ActiveCN103084183AReduce breakage rateImprove impregnation effectMetal/metal-oxides/metal-hydroxide catalystsAutomatic controlSpiral blade

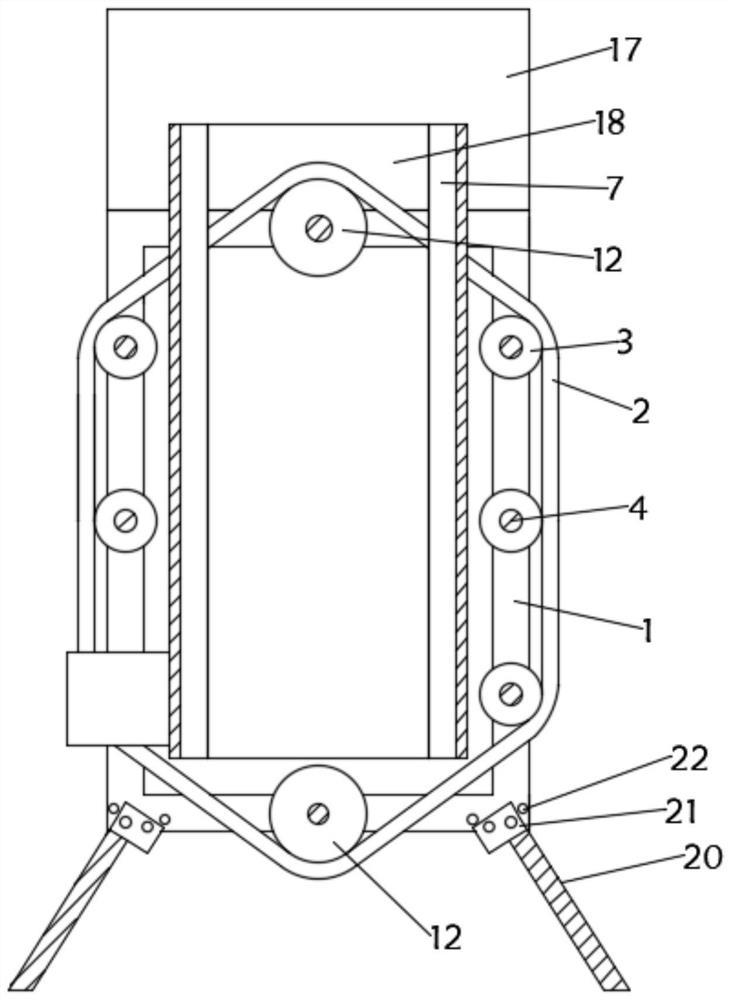

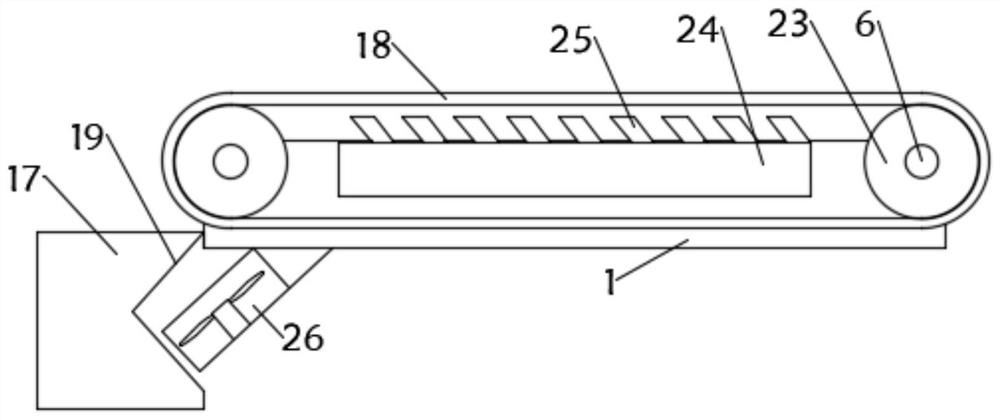

The invention discloses a fixed bed catalyst preparation method and a fixed bed catalyst. The method comprises that a molded carrier contacts a metal compound solution in an impregnation machine, and the molded carrier after contacting is dried and calcined, wherein the impregnation machine comprises an obliquely-arranged roller (10), the roller (10) comprises a rotatable cylinder (1) and a spray device (2), the inner wall of the cylinder (1) is provided with a spiral blade, and the spray device (2) is fixedly arranged and extends into the internal space of the cylinder (1). According to the method, a molded carrier is conveyed into the cylinder (1), and a metal compound solution is sprayed on the molded carrier with the spray device (2). With the method, the fixed bed catalyst with characteristics of good impregnation uniformity and low impregnation breaking rate can be obtained, automatic catalyst impregnation control can be achieved, production cost can be reduced, and requirements of large-scale industrial production can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of graphene/epoxy resin composite material for grinding and polishing

The invention discloses a preparation method of a graphene / epoxy resin composite material for grinding and polishing. The preparation method is characterized by comprising the following steps: performing reaction on a curing accelerator and an acidic reducer to generate a phase transfer agent, transferring graphene oxide from an aqueous phase to an epoxy resin phase, and after completely removingwater, performing high-temperature curing reduction to prepare a graphene / epoxy resin nanometer composite material. An organic solvent does not exist in the preparation process; and the preparation method is environment-friendly, simple to operate and moderate in condition, is suitable for epoxy resin with the conventional trade mark in the market and can adapt to the requirement of large-scale production. Nano-scale dispersion of the graphene in the epoxy resin is realized, and the graphene / epoxy resin nanometer composite material has the characteristics of high strength and high wear resistance. Meanwhile, the graphene can serve as an interface modifying agent to enhance the holding force of the epoxy resin on inorganic fillers, so that great market application value in the field of grinding and polishing tools is achieved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

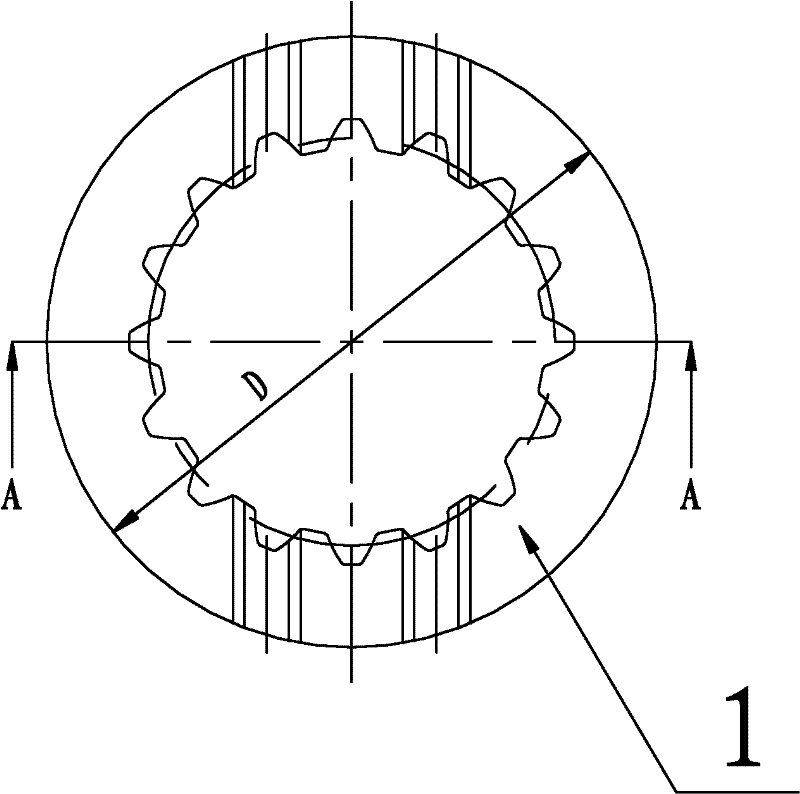

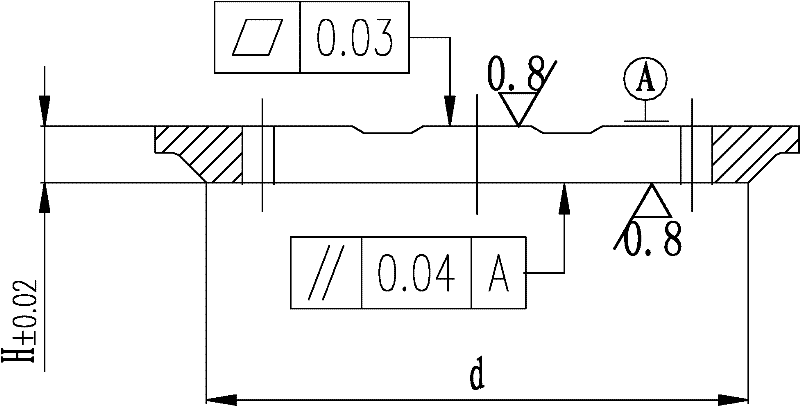

High-precision double-sided grinding method and machine of annular parts with unequal areas of two end surfaces

ActiveCN102229077ARealize mass productionStable at or above thicknessPlane surface grinding machinesHigh volume manufacturingFrequency ratio

The invention relates to a high-precision double-sided grinding method and machine of annular parts with unequal areas of two end surfaces. According to a rule that the rotating speed and the grinding amount of a grinding wheel of a grinding machine are proportionable, a motor transducer is additionally arranged on a circuit of an assisted grinding system of the grinding machine, the area ratios of two different end surfaces of different parts are converted into different grinding amount ratios so that the frequency ratio and the rotating speed ratio are further adjusted; an appropriate rotating speed ratio of a reference grinding wheel and an assisted grinding wheel is reached by changing and controlling the frequency of the assisted grinding wheel circuit; requirements on thickness, roughness, planarity, parallelism and the like can be stably reached or exceeded finally; the production efficiency is greatly increased and is 28 times that of the common M7160; the production cost is effectively reduced; and the batch production of the parts is realized.

Owner:武汉华夏精冲技术有限公司

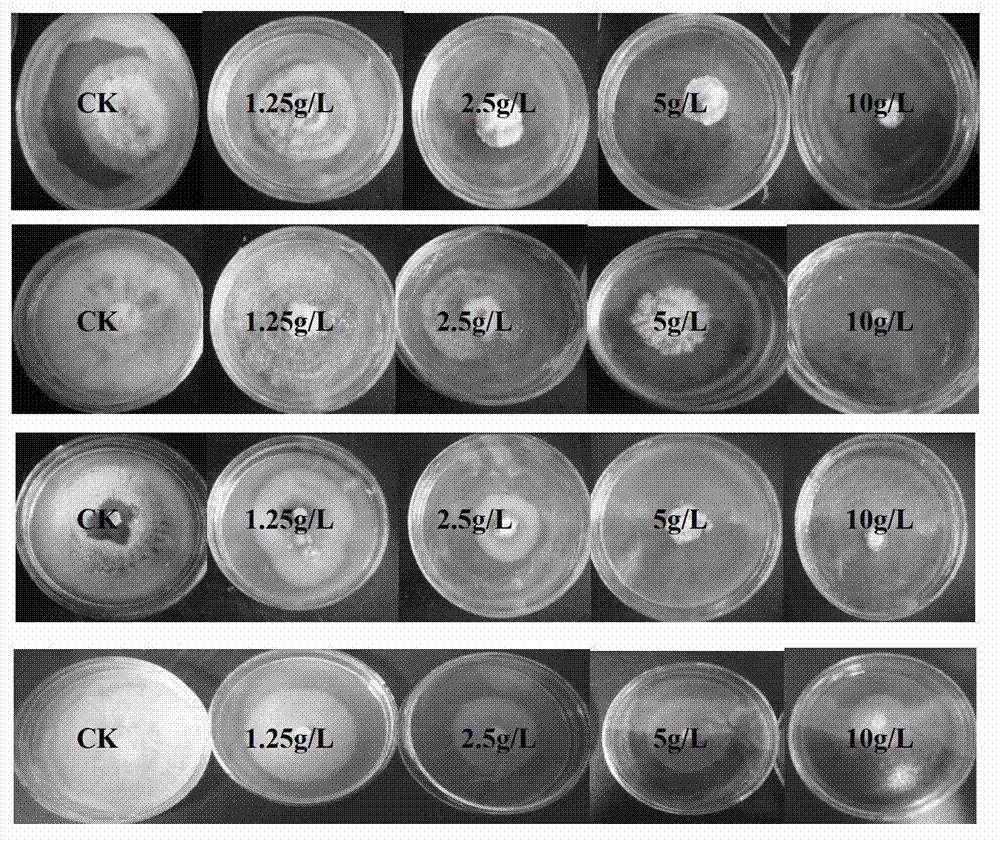

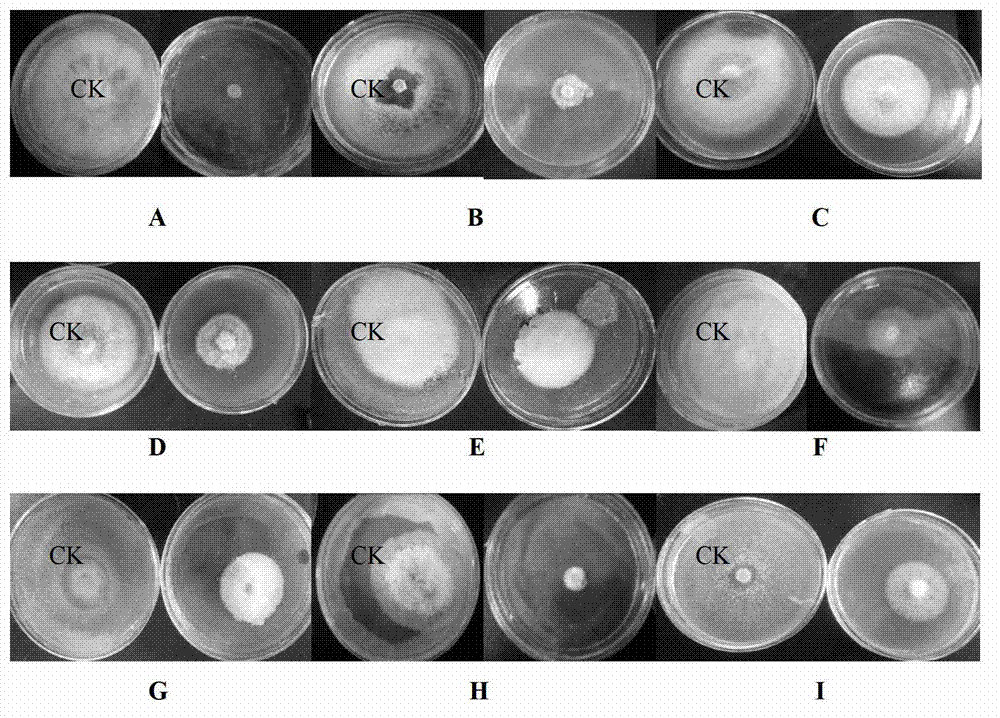

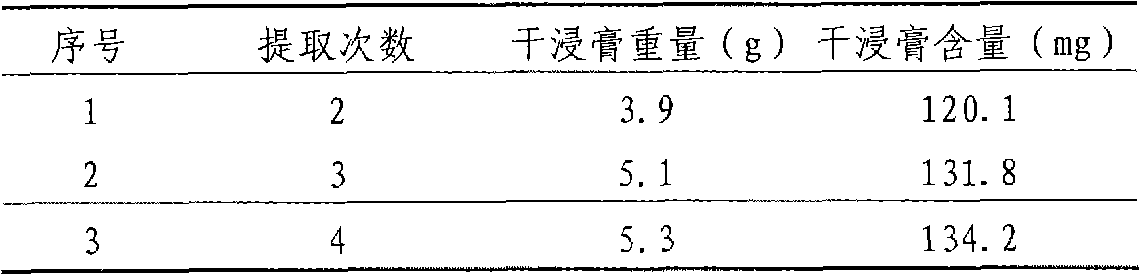

Jerusalem artichoke blade phenolic extract, as well as preparation method and application thereof

InactiveCN103109873AReduce lossesImprove extraction efficiencyBiocideFruit and vegetables preservationPlant SourcesEthyl acetate

The invention relates to a jerusalem artichoke blade phenolic extract, as well a preparation method and application of the jerusalem artichoke blade phenolic extract. The preparation method comprises the following steps of: drying fresh jerusalem artichoke blades, and crushing the fresh jerusalem artichoke blades to obtain dry powder of the jerusalem artichoke blades; putting the dry powder of the jerusalem artichoke blades into a decompression reflux extraction device, adding de-ionized water, extracting at room temperature to obtain a water phenolic extract, and concentrating or drying the water phenolic extract; or, adding an organic solvent into the decompression reflux extraction device, extracting while refluxing or decompressing and refluxing, and concentrating or drying to obtain an organic solvent phenolic extract; and extracting the water phenolic extract of the jerusalem artichoke blades or the organic solvent phenolic extract by using petroleum ether, chloroform, ethyl acetate and n-butyl alcohol respectively in turn according to the volume ratio in a stepwise manner, and finally, concentrating and drying to obtain the stepwise phenolic extract. The extract disclosed by the invention belongs to the novel plant-source (vegetative) pesticide, has specially good effects on a plurality of plant pathogenic bacteria, such as botrytis cinerea, phytophthora capsici leonian, colletotrichum gloeosporioides, rhizoctonia cerealis and gaeumannomyces graminis, and also can be used as a natural plant-source fungicide and a preservation preservative of fruits and vegetables.

Owner:北京碧青园生态环境科技有限公司

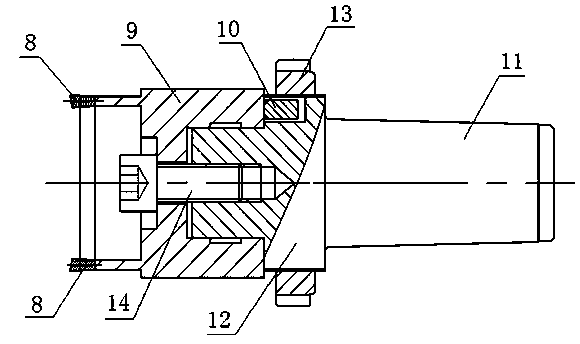

Casting method for main shaft of wind generating set

ActiveCN102921901AFast and smooth entryAvoid oxidation inclusion defectsFoundry mouldsMoulding machinesWind forceMaterials science

The invention relates to a casting method, in particular to a casting method for a main shaft of a wind generating set. The casting method provided by the invention comprises the following steps of: designing a pouring system, manufacturing a mould, shaping, manufacturing a core, assembling the mould, compounding, smelting, adopting a stokehold spheroidization process and multistage inoculation, pouring and shakeout clearing. The casting method for the main shaft of the wind generating set is unique, meets quality index requirements on size, performance, and internal and external quality, and can realize volume production for moving / fixed shafts.

Owner:KOCEL EQUIP

Culture medium and rapid propagation method for tissue culture of Vitex agnus-castus L

ActiveCN108077071AImprove reproductive efficiencyPromote growthPlant tissue cultureHorticulture methodsMethod selectionBud

The invention discloses a culture medium and a rapid propagation method for tissue culture of Vitex agnus-castus L, wherein the culture medium comprises a bud induction culture medium, a proliferationculture medium and a rooting culture medium. According to the present invention, by using the specific culture medium formula of the three components, the proliferation coefficient and the rooting rate of the tissue culture of Vitex agnus-castus L are significantly improved so as to improve the proliferation efficiency of Vitex agnus-castus L; the current growth branch of Vitex agnus-castus L isselected as the explant material, has characteristics of strong growth and strong branching ability, and does not easily produce browning during the tissue culture; and the reproductive efficiency ofVitex agnus-castus L is improved, and the culture medium and the method can meet the requirements of large-scale production.

Owner:SICHUAN COLORLINK CO LTD

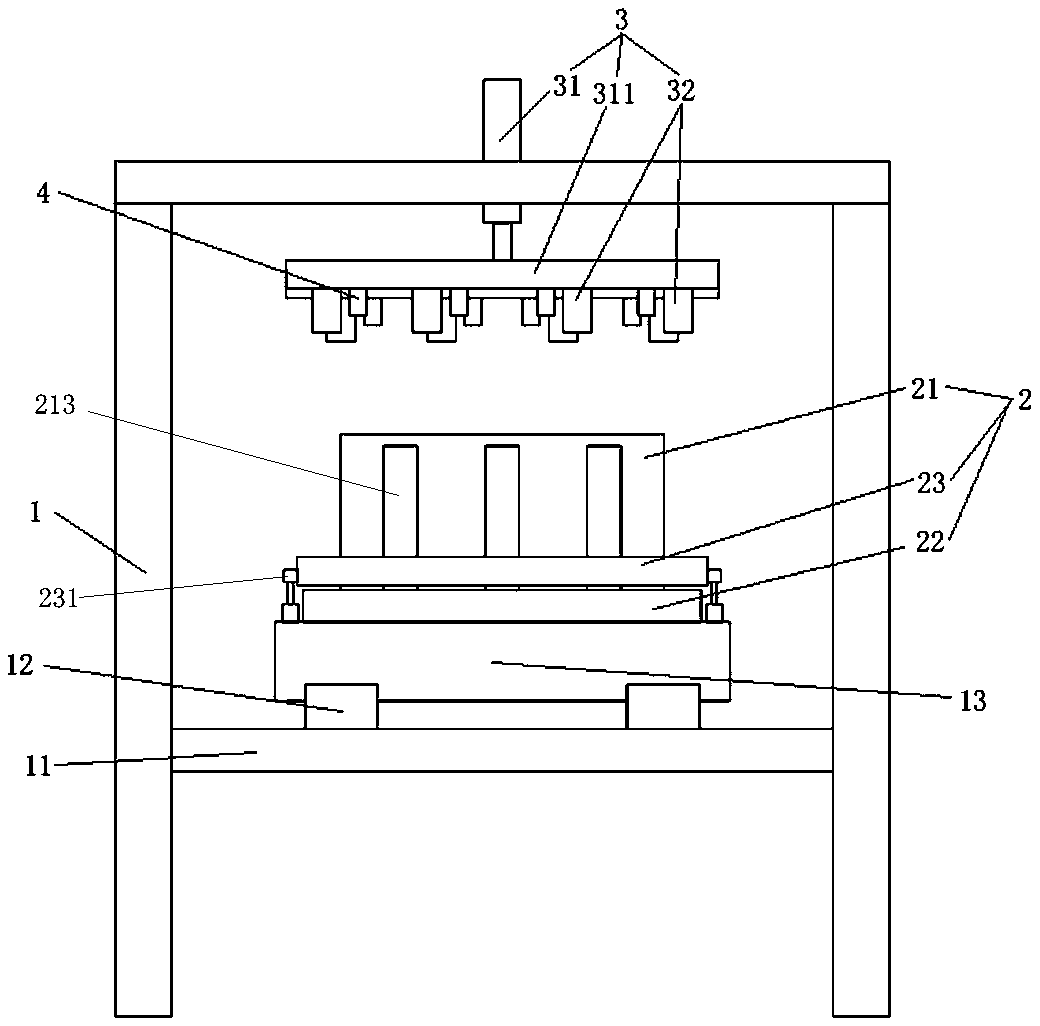

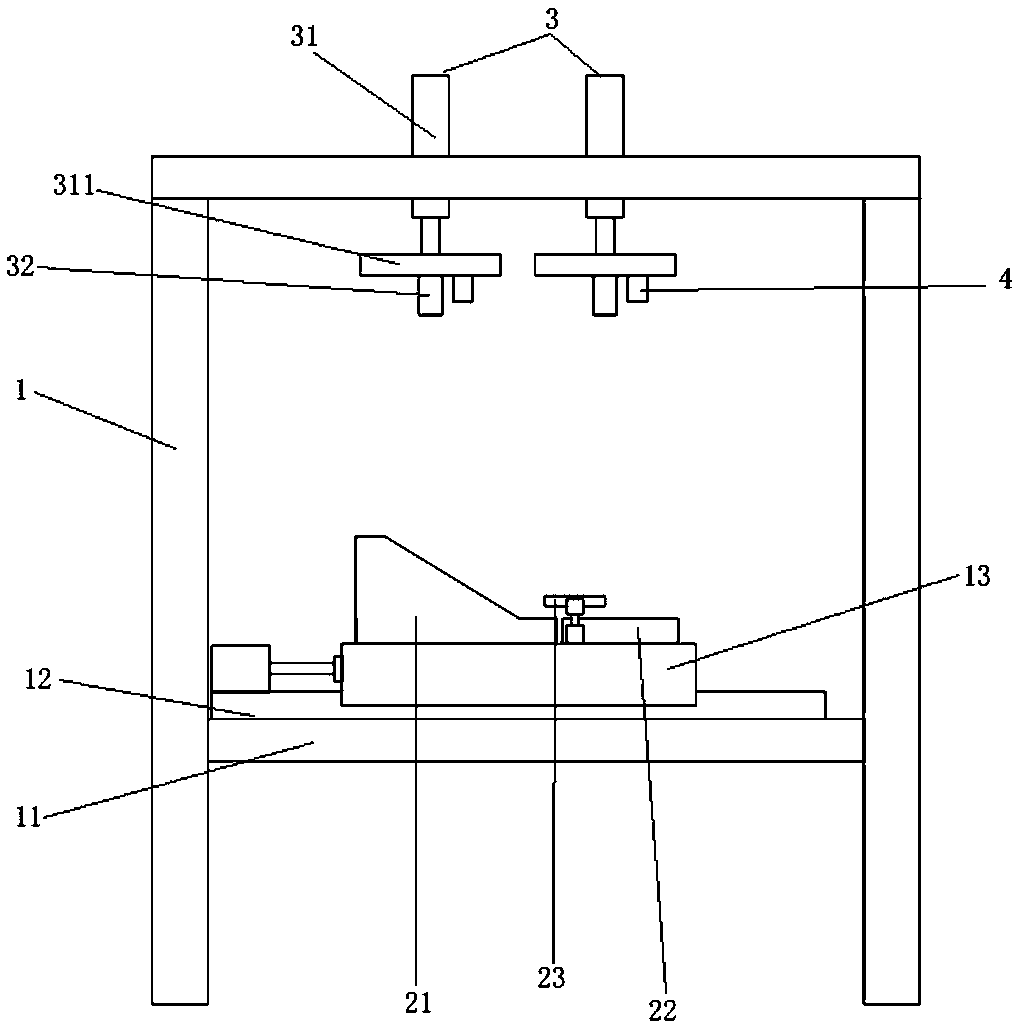

Ultrasonic welding machine assembly

PendingCN108971739AAdapt to flexible production needsEfficient weldingNon-electric welding apparatusUltrasonic weldingEngineering

The invention discloses an ultrasonic welding machine assembly and relates to the field of vehicle bumper welding machines. The ultrasonic welding machine assembly comprises a rack; a supporting boardis arranged in the middle of the rack; a slide rail is arranged on the supporting board and provided with a slide base moving along the slide rail; the slide base is provided with a supporting mold assembly; a welding assembly is arranged on the top of the rack and comprises a welding cylinder, a welding board and a plurality of welding units which are arranged from top to bottom; the welding board is arranged on the end portion of the welding cylinder; the welding units are connected with the welding board; and the supporting mold assembly comprises a first supporting base, a second supporting base and a pressure base. By means of the ultrasonic welding machine assembly, bumper parts produced one by one can be conveniently and effectively positioned and welded, and accordingly efficientproduction of separated type bumpers is achieved.

Owner:上海航天风华科技有限公司

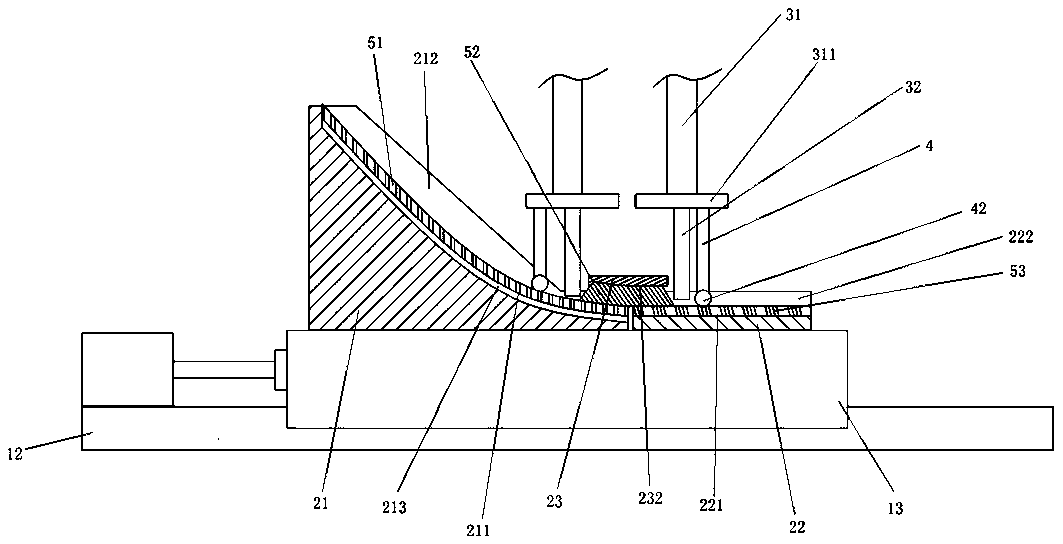

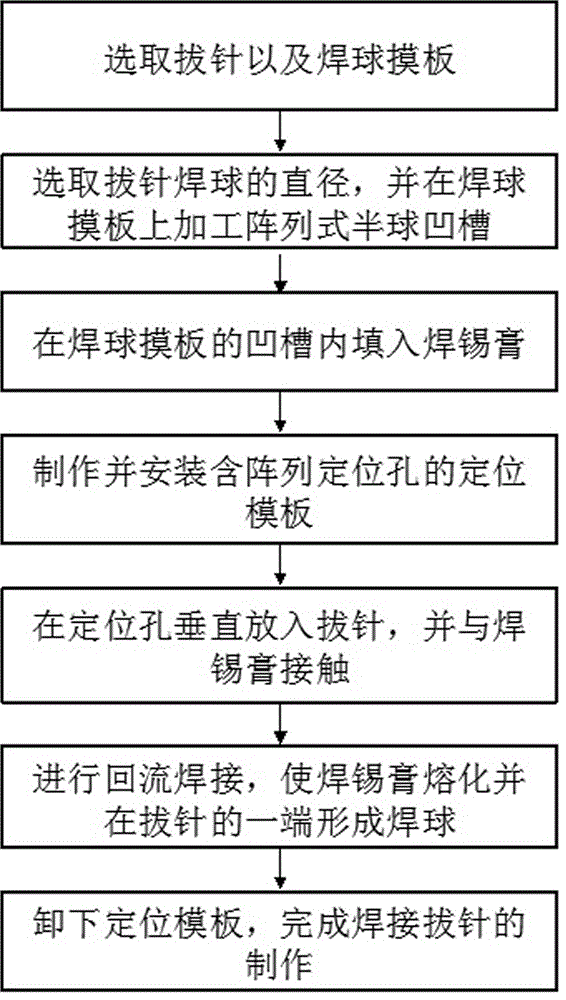

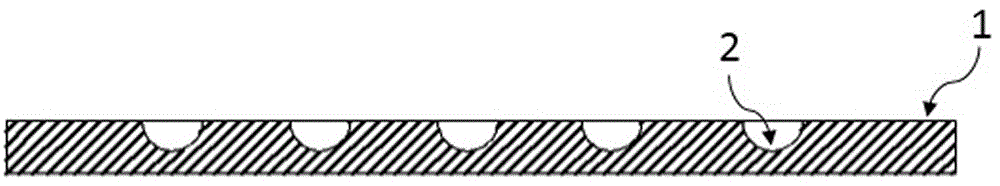

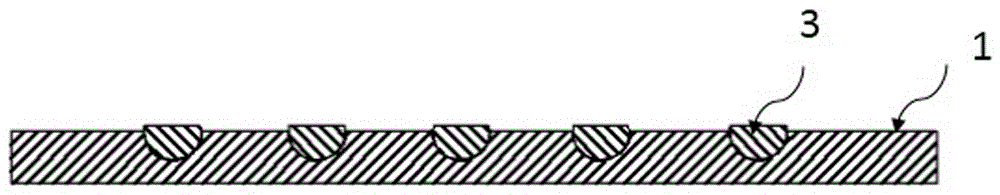

Manufacturing method of welding pull pins

ActiveCN105033387AGuaranteed repeatabilityGuarantee normativeSoldering auxillary devicesSolder ballEngineering

The invention discloses a manufacturing method of welding pull pins. The method comprises the steps that firstly, the pull pins and a welding ball template are selected; secondly, the diameter of welding balls is determined, and array type grooves matched with the welding balls in diameter are formed in the welding ball template; the grooves of the welding ball template are filled with soldering paste; fourthly, a positioning template comprising array positioning holes is manufactured, the positioning template is fixed to the portion over the welding ball template, and an upper template component and a lower template component are formed in a centering manner; fifthly, the pull pins are vertically placed in the positioning holes of the positioning template, and the lower ends of the pull pins make contact with the soldering paste with which the grooves of the welding ball template are filled; sixthly, the upper template component and the lower template component are placed in a reflux furnace, the soldering paste in the grooves of the welding ball template is molten, and the welding balls are formed at one ends of the pull pins; and seventhly, the positioning template and the welding ball template are dismounted, and the welding pull pins are obtained. According to the method, the steps are simple, pertinence is high, and the standardization and uniformity of the welding pull pins obtained through the method are good.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Thread added cigarette holder capable of reducing harmfulness of cigarettes

InactiveCN102771894AEasy to joinSolve pollutionTobacco smoke filtersPolycyclic aromatic hydrocarbonFiber

The invention discloses a thread added cigarette holder capable of reducing harmfulness of cigarettes and a production process of the thread added cigarette holder. The thread added composite cigarette holder is composed of a conventional acetic acid fiber cigarette holder A and a thread added acetic acid fiber cigarette holder B, wherein cotton threads are wrapped in the thread added acetic acid fiber cigarette holders B and infused with carbon nano tube solutions, and the weight of added carbon nano tubes in each of the thread added acetic acid fiber cigarette holders B is between 1mg and 10mg. The thread added cigarette holder capable of reducing harmfulness of the cigarettes and the production process have the advantages that the problem that indoor environments are polluted when the carbon nano tubes are added to the acetic acid fiber cigarette holders is effectively solved; by means of the control of the number of added threads, the added amount of the nano tubes in the cigarette holders can be conveniently and quantitatively adjusted; the production process is simple, capable of being combined with cigarette holder forming processes and applicable to mass production; harmful substances of polycyclic aromatic hydrocarbon, phenol and the like in cigarette smoke can be further reduced on the basis that cigarette tar is effectively reduced; and the number of the added threads and the positions of the threads in filter sticks can be controlled so that patterns with certain shapes can be structured on end surfaces of the filter sticks, and the cigarette holder is provided with anti-fake functions.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Curing kiln for prefabricated interlock pieces and curing process for curing kiln

PendingCN110434993AAdapt to the needs of mass productionImprove construction qualityCeramic shaping apparatusEngineeringIdler-wheel

The invention relates to a curing kiln for prefabricated interlock pieces and a curing process for the curing kiln. The curing kiln comprises a plurality of curing chambers, a steam generator and a first controller, wherein the steam generator is arranged on the outer sides of the curing chambers, the first controller is arranged on the outer walls of the curing chambers, each curing chamber is internally provided with a plurality of treatment chambers and a heating device, the treatment chambers comprise a plurality of sets of first idler wheels and drawer doors, and each set of the first idler wheels are symmetrically fixed to the inner walls of the curing chambers through connection parts to be used for pushing and tracting interlock piece molds. The curing process is easy to operate, accurate in control, high in mechanization degree and good in curing effect. By means of the curing kiln for the prefabricated interlock pieces and the curing process for the curing kiln, the construction quality and the production efficiency are greatly improved, meanwhile, the labor cost is saved, the whole curing process is completed in the curing kiln, the space is saved and the curing processis not affected by bad weather, the cost is reduced and the construction period is shortened, and the curing kiln for the prefabricated interlock pieces and the curing process for the curing kiln canmeet the concrete interlock block mass production requirements in construction.

Owner:CHANGJIANG WUHAN WATERWAY ENG CO

Method for producing parasitic wasps of fruit flies by means of drosophila melanogaster

The invention provides a method for mass-producing parasitic wasps of fruit flies by means of drosophila melanogaster. By fast and simply collecting pupae of the drosophila melanogaster, mass breedingand parasitism of the parasitic wasps of the fruit flies are simply completed, in a pupal stage, the parasitic wasps of the fruit flies are fast and simply separated from the unparasitized drosophilamelanogaster, and the number and a sex ratio of the parasitic wasps of the fruit flies are fast and simply regulated and controlled, so that full mating and a proper parasitism rate are ensured.

Owner:FUJIAN AGRI & FORESTRY UNIV

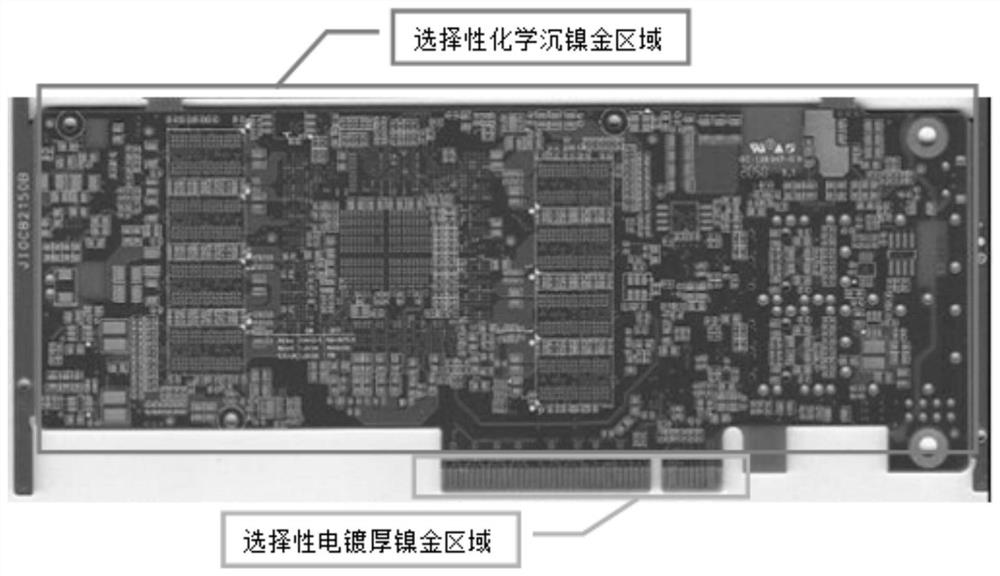

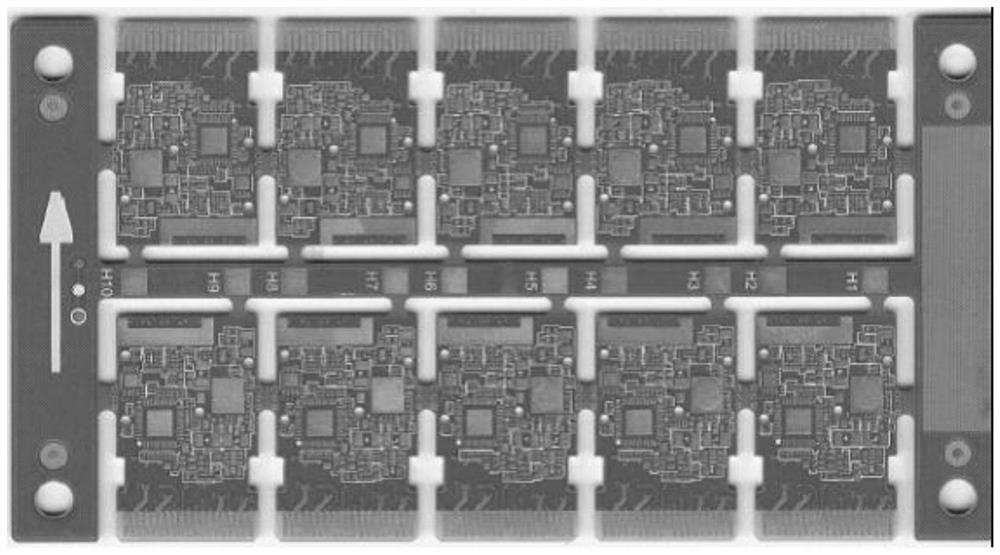

Surface treatment method of printed circuit board and application of surface treatment method

PendingCN113543487AMeet the precision requirementsSolder joint (PAD) clearance is smallConductive pattern formationManufacturing cost reductionAdhesive belt

The invention discloses a surface treatment method of a printed circuit board and application of the surface treatment method. When the gold finger area is electroplated with thick nickel gold, the chemical gold immersion area which does not need to be electroplated is protected by adopting an anti-gold-electroplating adhesive tape with the tensile strength of 1.4-1.8 kg / 10mm, the elongation of 120%-180% and the adhesive force of 0.08-0.12 kg / 25mm. The anti-gold-plating adhesive tape is tightly attached in the electroplating process, the problems of diffusion plating and ink falling of a chemical gold immersion area in the electroplating process are avoided, the anti-gold-plating adhesive tape has the characteristic of no degumming after being torn off, and the quality risk of adhesive residues is avoided. Meanwhile, the anti-gold plating adhesive tape is combined with the specific photosensitive ink, so that the surface treatment method can meet the high-precision requirement that the distance between the chemical gold immersion area and the golden finger area is larger than 6 mil, the production process is simplified, and the manufacturing cost is reduced.

Owner:广东世运电路科技股份有限公司

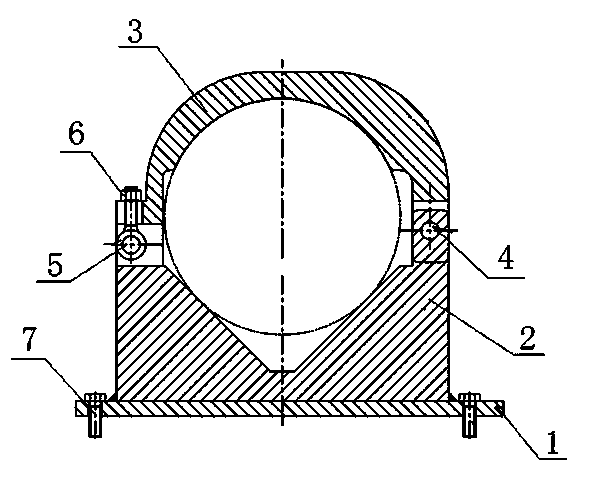

Tool manufacturing method special for radiant tube machining

InactiveCN103659356ASimple structureEasy to useTransportation and packagingPositioning apparatusTool bitScrew thread

The invention discloses a tool manufacturing method special for radiant tube machining. The manufacturing method includes the step of manufacturing a positioning mechanism and the step of manufacturing a cutting knife mechanism. In the step of manufacturing the positioning mechanism, a V-shaped base is fixed to a bottom plate through a fastening bolt, a rotating pressing plate is arranged on the V-shaped base, one side of the rotating pressing plate is connected with the V-shaped base through a rotating pin, and the other side of the rotating pressing plate is connected with the V-shaped base through a bolt and a nut. In the step of manufacturing the cutting knife mechanism, a knife sleeve is manufactured, welding grooves which are symmetrical and matched with tool bits are formed in the start end of the knife sleeve, knife sleeve rotation prevention plates are fixedly arranged on the two side faces of the tail end of the knife sleeve respectively, the tool bits are fixedly arranged on the welding grooves of the knife sleeve, a cutting knife connecting piece is manufactured, one end of the connecting piece is a cone, the other end of the connecting piece is a cylinder, the large end of the cone is connected with one end of the cylinder, the other end of the cylinder is connected with the tail end of the knife sleeve through a fastening screw, and the cylinder is sleeved with a thread bushing and matched with the thread bushing in a threaded mode. A tool manufactured through the method is simple in structure, convenient to use, high in accuracy and capable of meeting the requirement for mass production, and the efficiency can be improved by more than 5 times.

Owner:QINGDAO NPA IND

Loudspeaker assembling method

ActiveCN110381432ARealize continuous automatic assemblyIncrease productivityElectrical transducersAssembly lineLoudspeaker

The invention relates to the technical field of automation, and provides a loudspeaker assembling method. A jig is conveyed along a set direction to form an assembly line, T-shaped iron and magnets are fed on the jig at a set position at the rear section of the assembly line and assembled to form a T-shaped iron and magnet assembly, and the T-shaped iron and magnet assembly are reflowed together with the jig to the front end of the assembly line; the magnetic circuit, the basin stand and the diaphragm are assembled along an assembly line; finally, the T-shaped iron and the magnet are conveyedto the front of a T-shaped iron and magnet feeding position for discharging; the jig is continuously conveyed along the assembly line; such cycling, the interval distance, the assembly line walking speed, the assembly line pause interval and the pause duration of each assembly station can be reasonably set according to the duration required by each process, and continuous automatic assembly of theloudspeaker is realized, so that the production efficiency and the product quality are improved, the influence of labor cost and manual factors is reduced, the productivity is favorably increased, and the requirement of large-scale production is met.

Owner:深圳市久巨工业设备有限公司

Printing device used for spinning

InactiveCN110588152ANeatly ironedReasonable structural designRotary pressesOther printing apparatusComputer engineeringGas expansion

The invention relates to a spinning tool and discloses a printing device used for spinning. The printing device comprises a base, supports, a printing module, a feeding roller and a rolling roller. The supports include the first support and the second support fixedly connected to the two sides of the base correspondingly. The printing module is arranged between the first support and the second support. A controller and a battery which are connected electrically are arranged in the first support. A control panel is fixedly connected to the top of the first support. The printing module comprisesa sliding groove, a sliding block and a coating box, a control block is arranged in the sliding groove, the printing block is connected to the control block through a telescopic rod, and the printingblock is connected to the coating box through a spraying pipe. The feeding roller and the rolling roller are arranged at the two ends of the base correspondingly. A drying hole is formed in one sideof the rolling roller, a gas expansion shaft is arranged in the center of the rolling roller, and the gas expansion shaft is connected with a hot air box through a connecting pipe. The printing deviceis reasonable in structural design, fixing and drying are facilitated, textiles obtained after printing are ironed flatly, productivity is effectively improved, the labor intensity is lowered, and the printing device meets the need for large-scale production and also meets the requirement for cleanliness and sanitation.

Owner:徐州第三纺织有限公司

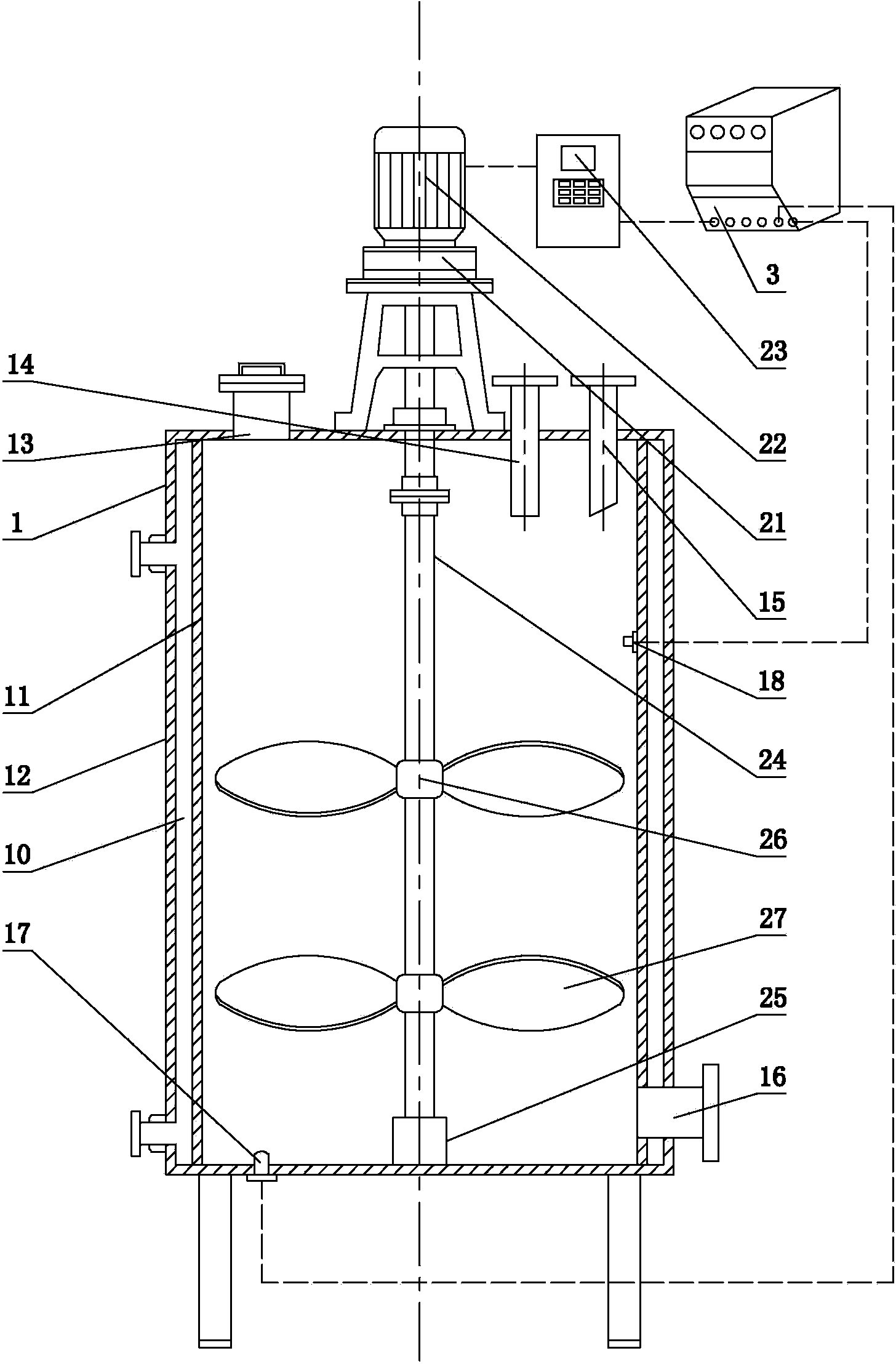

Beta-hydroxyalkyl amide synthesis process

InactiveCN103664676AHas anti-yellowing effectReasonable workmanshipOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTemperature controlSulfite salt

The invention relates to a beta-hydroxyalkyl amide synthesis process, which comprises the steps of inputting diethanol amine and silica into a reaction kettle, adding a multi-component composite catalyst into the reaction kettle, introducing argon gas for three times for gas replacement, extracting gas in the reaction kettle until the pressure reaches negative pressure, stirring and dripping dimethyl adipate into the reaction kettle, heating for two times and constantly stirring and introducing argon gas at the same time, and obtaining the finished product beta-hydroxyalkyl amide after the product cools down naturally. The beta-hydroxyalkyl amide synthesis process has the advantages of reasonable process, reliable performance and the like; under the catalytic action of the multi-component composite catalyst, ammonolysis of dimethyl adipate is realized through diethanol amine, ,and the beta-hydroxyalkyl amide is obtained, besides, sodium carbonate can accelerate the reaction, and sodium sulfite and sodium citrate have efficacy of xanthochromia resistance. The structure of the reaction kettle body for beta-hydroxyalkyl amide synthesis is reasonable, and temperature control and stirring effect are good; as reaction is performed under segmented temperature in the reaction kettle, mass production requirement can be satisfied.

Owner:HUBEI JIANGDA CHEM

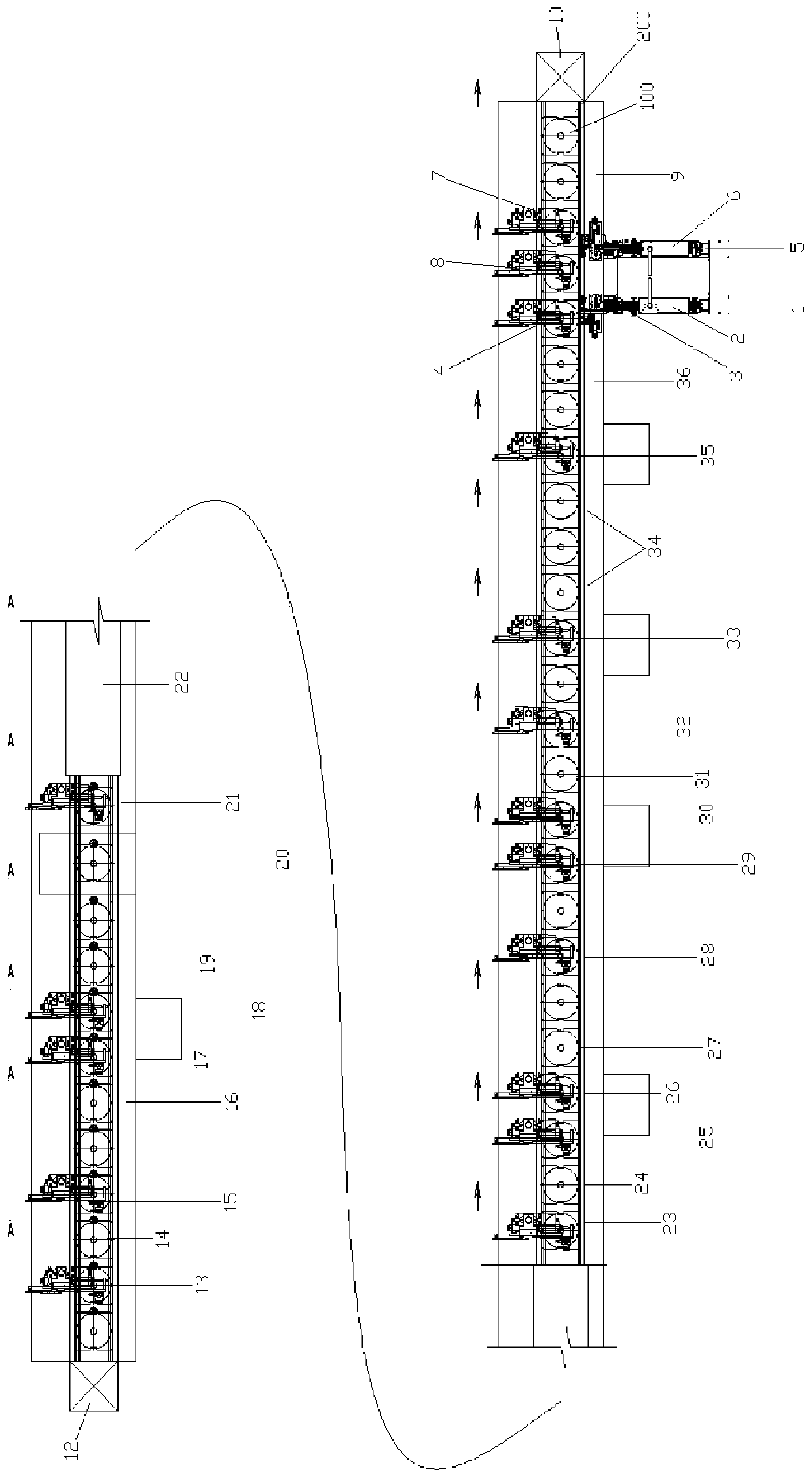

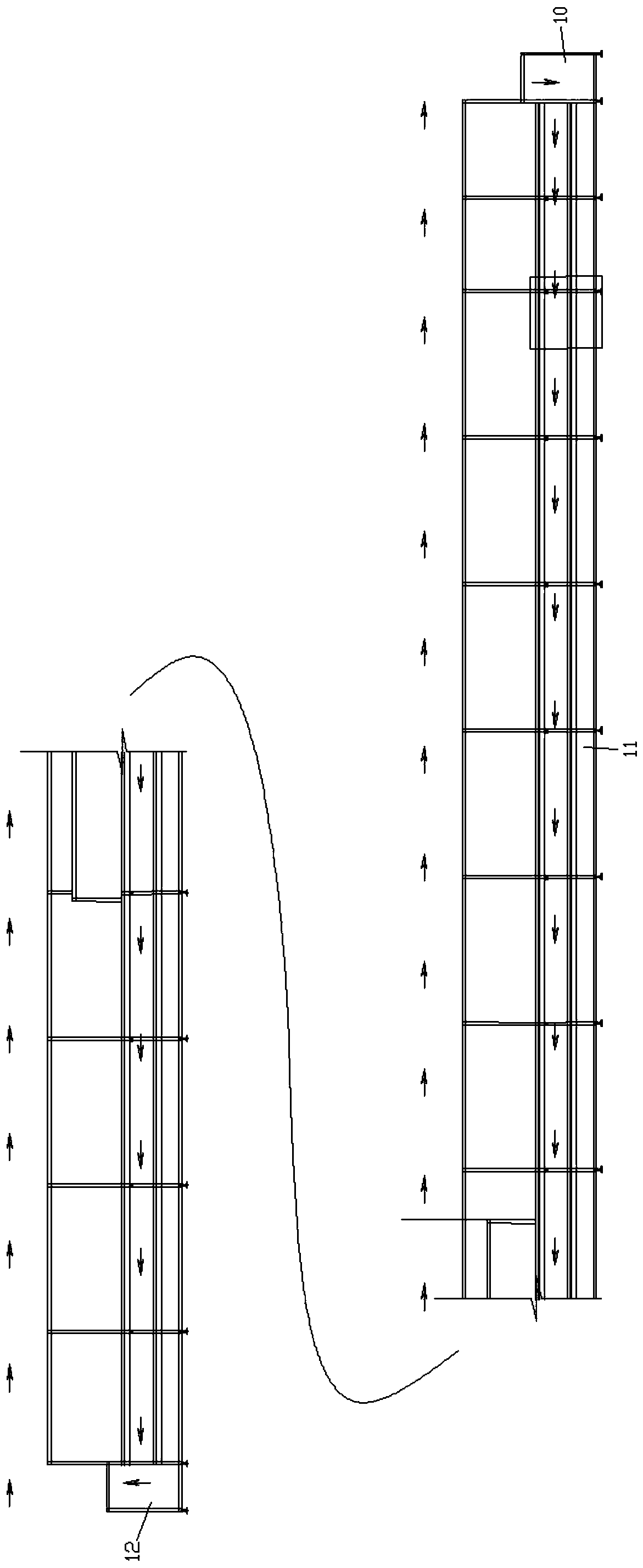

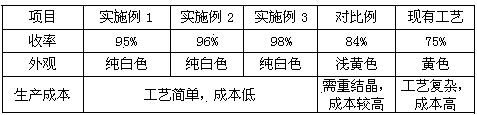

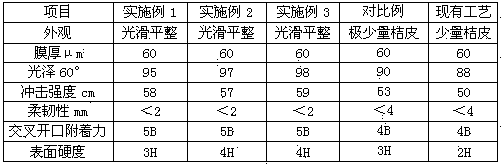

Technology for producing compound protein concentrates

ActiveCN101558815AEasy to operateEnsure hygieneProtein composition from vegetable seedsFood preparationPollutionProtein formation

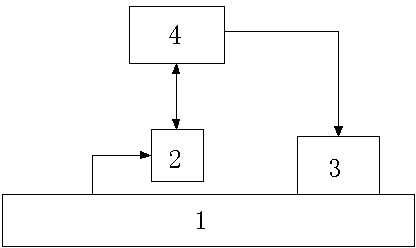

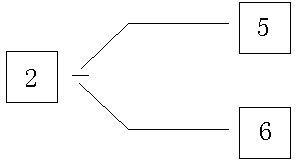

The invention relates to a technology for producing compound protein concentrates, which comprises the followings: low-temperature soybean meals (1) and peanut flour (21) are respectively prepared into soybean emulsion of acid sediment (10) and peanut emulsion of acid sediment (29) on special production lines through own batching and acid sediment stages; the soybean emulsion of acid sediment (10) and peanut emulsion of acid sediment (29) are mixed and confected based on the proportion of 65-75%:25-35% and are combined to prepare finished products of compound protein concentrates (16) with protein content more than or equal to 70% through continuously conducted neutralization stage, enzymolysis stage, sterilization stage, drying stage and packing and detecting stage. The technology features reasonable device configuration and process flows, high degree of automation of leakproof production lines, harmonious takt time, can prevent pollution can ensures safe and sanitary prepared finished products; the produced compound protein concentrates (16) have rich, comprehensive and balanced nutrition and wide application, and improve added value. The technology can fit the demand of batch production, promote the deep processing technology of the soybeans and peanuts to enhance and conduce to further improving the industrial structures and product structures of the soybeans and peanuts to realize industrialization.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

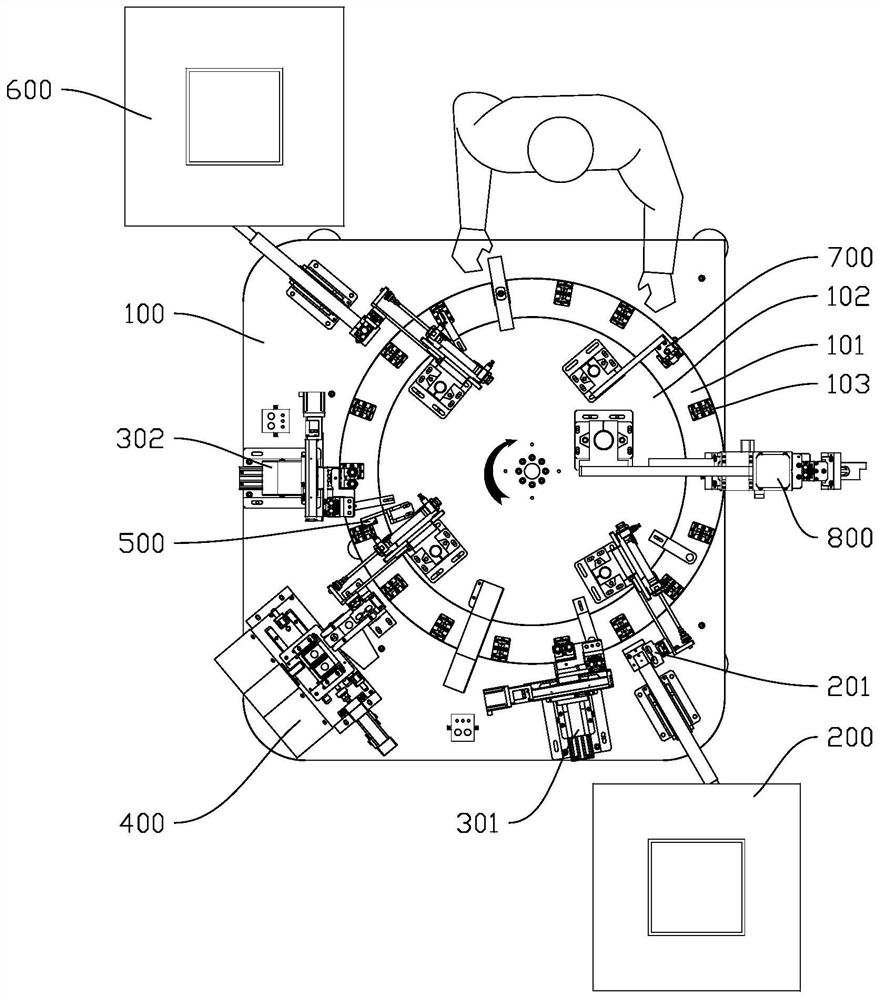

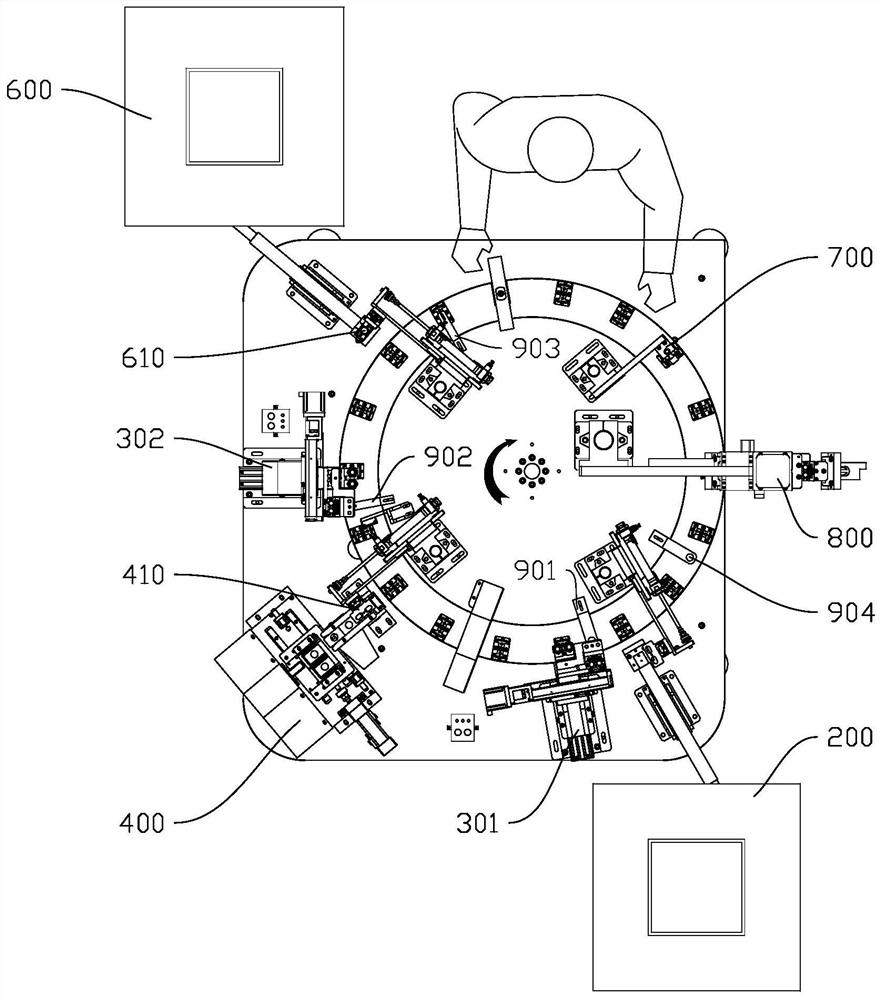

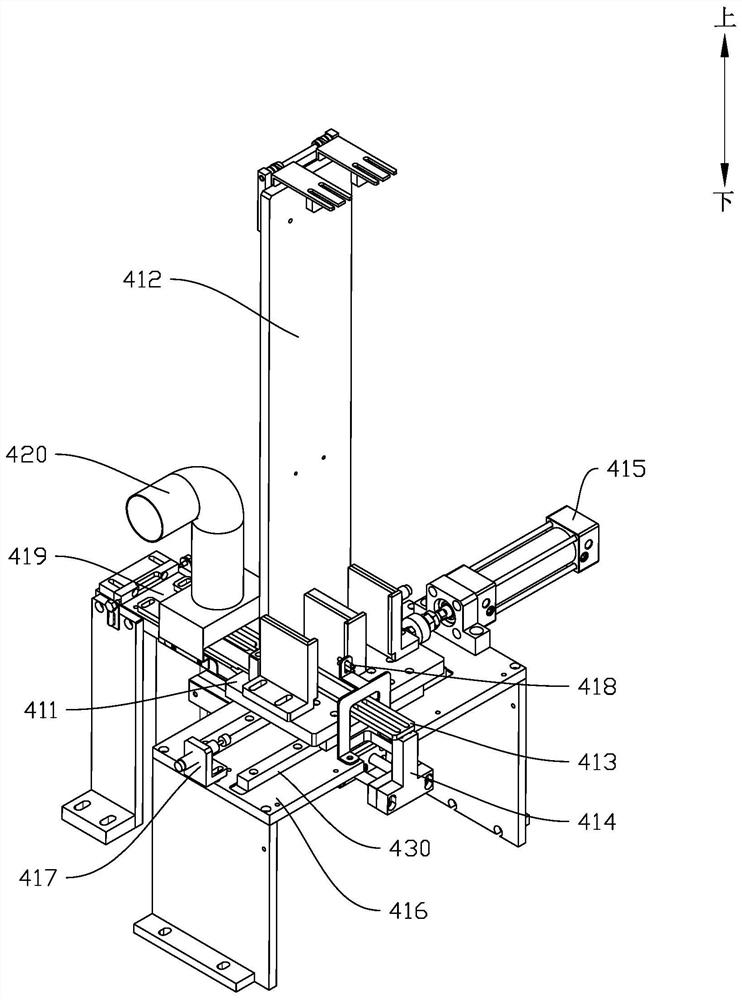

Magnetic circuit assembly system and magnetic circuit assembly method

PendingCN111843476AFully automatedRealize automated assemblyAssembly machinesMetal working apparatusProduction lineMachine

The invention discloses a magnetic circuit assembly system and a magnetic circuit assembly method. The magnetic circuit assembly system comprises a machine cabinet, a rotating disc and a fixed disc are arranged on the machine cabinet, a plurality of jig seats are arranged on the rotating disc, the rotating direction of the rotating disc is sequentially provided with a T iron feeding device, a first dispensing device, a magnet feeding device, a pressing device, a second dispensing device, a magnetic gauge feeding device, a basin pressing frame device and a discharging device, T iron feeding operation, T iron dispensing operation, magnet feeding operation, pressing magnet operation, magnet dispensing operation, magnetic gauge feeding operation, manual basin placing frame operation, basin pressing frame operation and discharging operation can be sequentially carried out, and then conveying to rest production lines is carried out. According to the system and the method, the rotating disc drives the jig seats to rotate, the jig seats can sequentially carry out various assembly operations, the automatic assembly of a magnetic circuit assembly is basically realized, the product quality and the processing efficiency are improved, the labor cost is greatly reduced, the occupied space of equipment is reduced, and the productivity is increased.

Owner:深圳市久巨工业设备有限公司

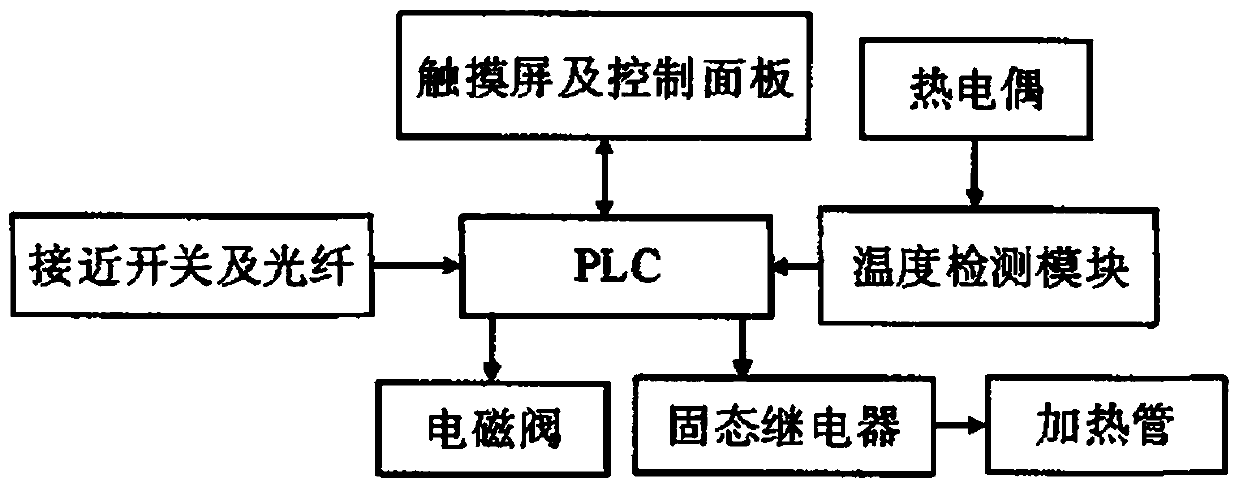

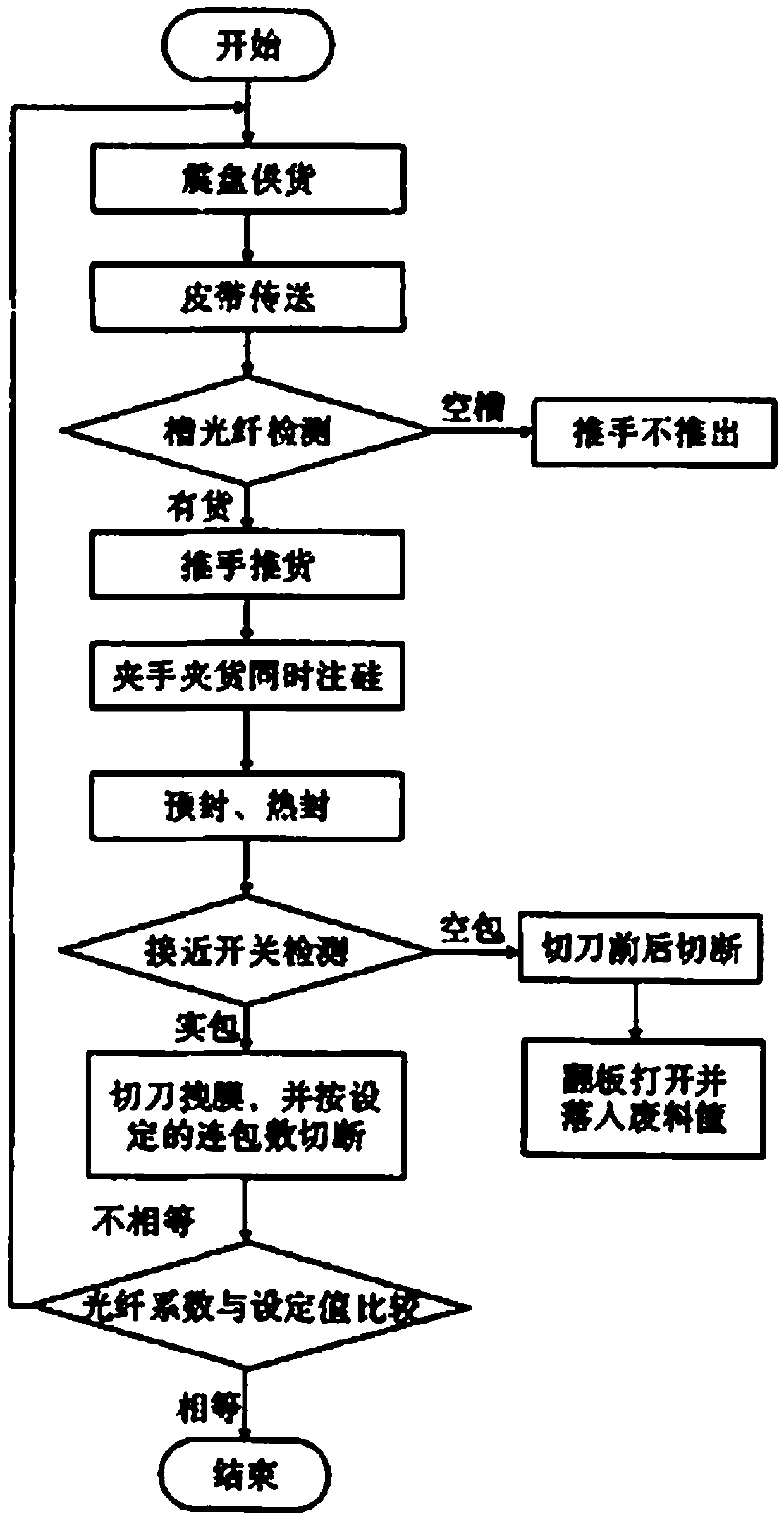

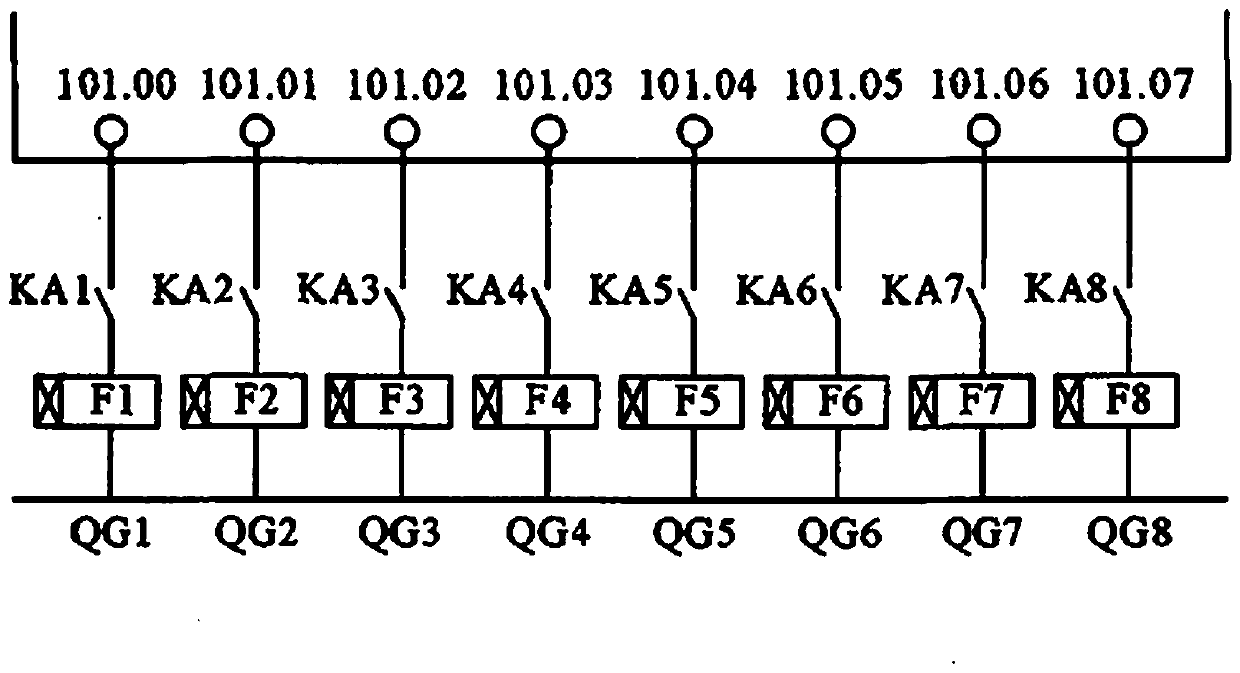

Condom packaging machine control system

InactiveCN107776990AImprove reliabilityIncrease flexibilityPackaging automatic controlSocial benefitsTemperature control

A condom packaging machine control system, involving pneumatic control system, human-computer interaction interface design, PID temperature control, etc., thereby realizing the automatic operation of the packaging machine system, and realizing the operation of the machine by the operator through the human-computer interaction interface Monitor and maintain. The control system adopts Omron PLC, which not only has high reliability, low cost, simple and convenient operation, but also improves production efficiency, meets the needs of large-scale production, and has good economic and social benefits.

Owner:赵俭

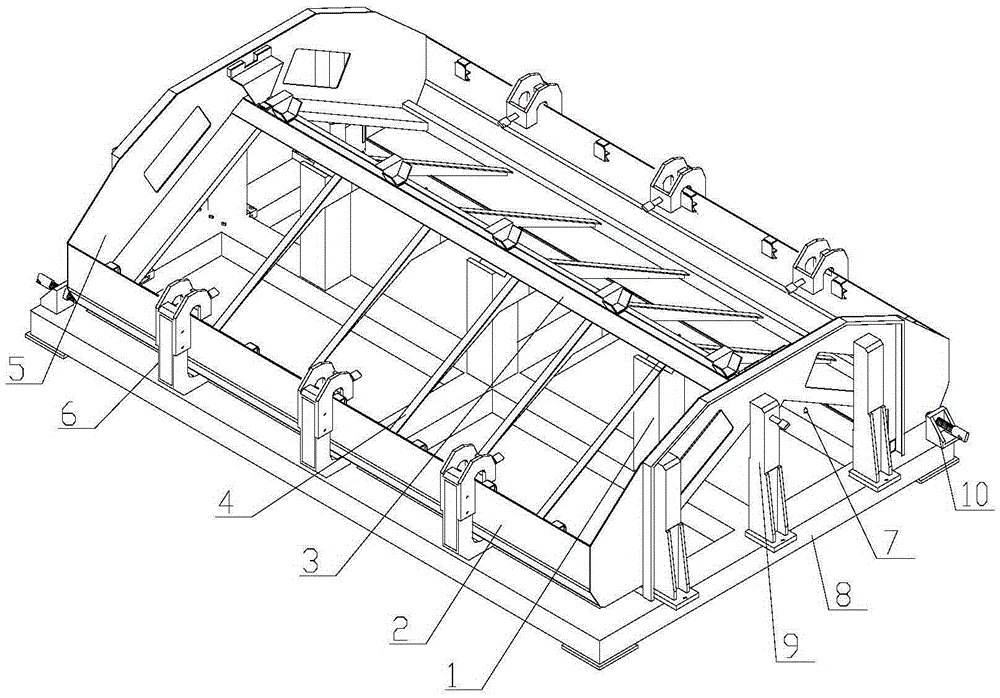

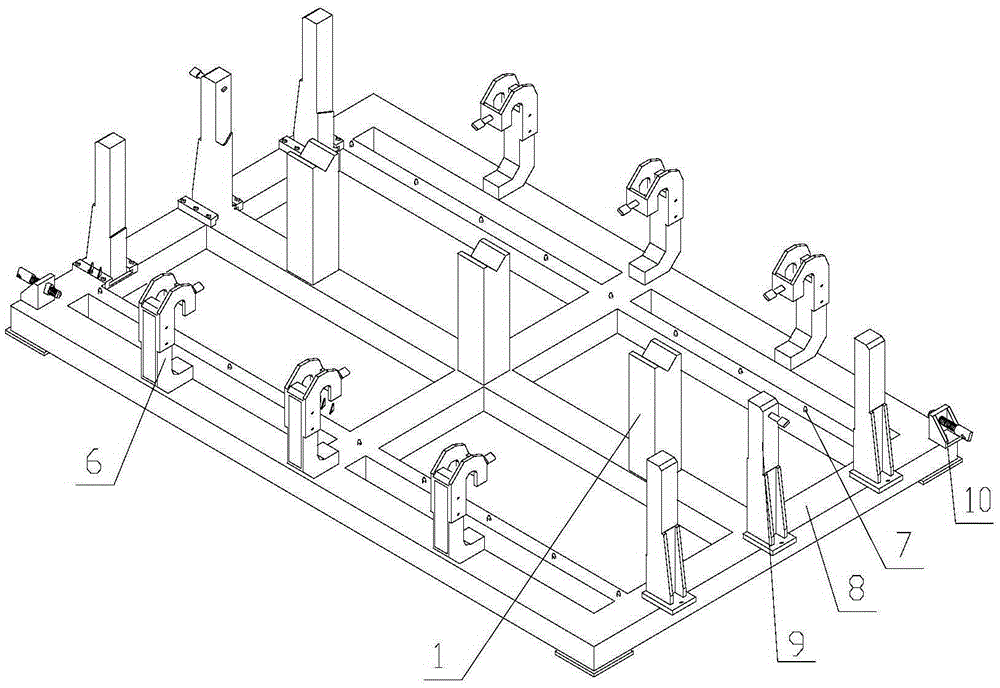

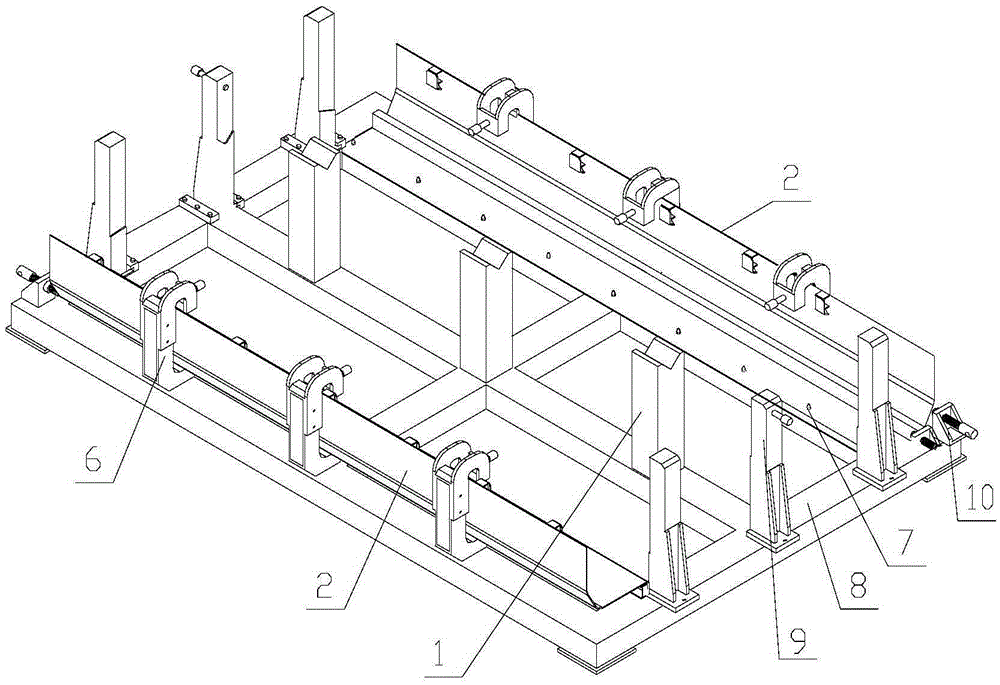

Assembly device for internal combustion locomotive cooling chamber steel structures and manufacturing method thereof

ActiveCN105397376AFull Consistency GuaranteedEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesCombustionMechanical engineering

The invention discloses an assembly device for internal combustion locomotive cooling chamber steel structures and a manufacturing method thereof. The assembly device is structurally characterized in that a base assembly is of a square frame structure with a linear beam in the center, partition locating and fastening devices are fixed to each of the left side and the right side of the base assembly, side plate locating and fastening devices shaped like hooks are installed on each of the upper side and the lower side of the base assembly, girder locating devices are fixed on a middle cross beam, locating pins are fixed to the upper plane of the base assembly, and fastening devices are installed at the opposite corners of the base assembly. By adopting the assembly device for the internal combustion locomotive cooling chamber steel structures and the manufacturing method thereof, the total uniformity of the contour dimensions of the manufactured cooling chamber steel structures is guaranteed, the interchange requirement of the cooling chamber steel structures is met, the operation is simple, convenient and fast, the requirement of mass production is met, the installation efficiency of final assemblies of locomotives is improved, the installation accuracy of the cooling chamber steel structures is guaranteed, the safety production is promoted, the labor intensity of staff is lowered, the manpower is saved, the working time is shortened, and the production efficiency is remarkably improved.

Owner:CRRC DALIAN CO LTD

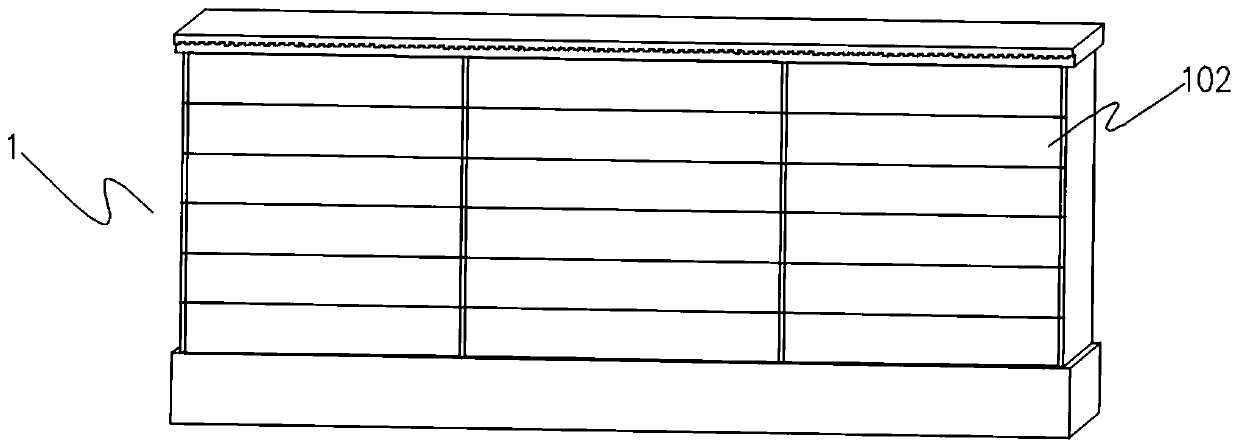

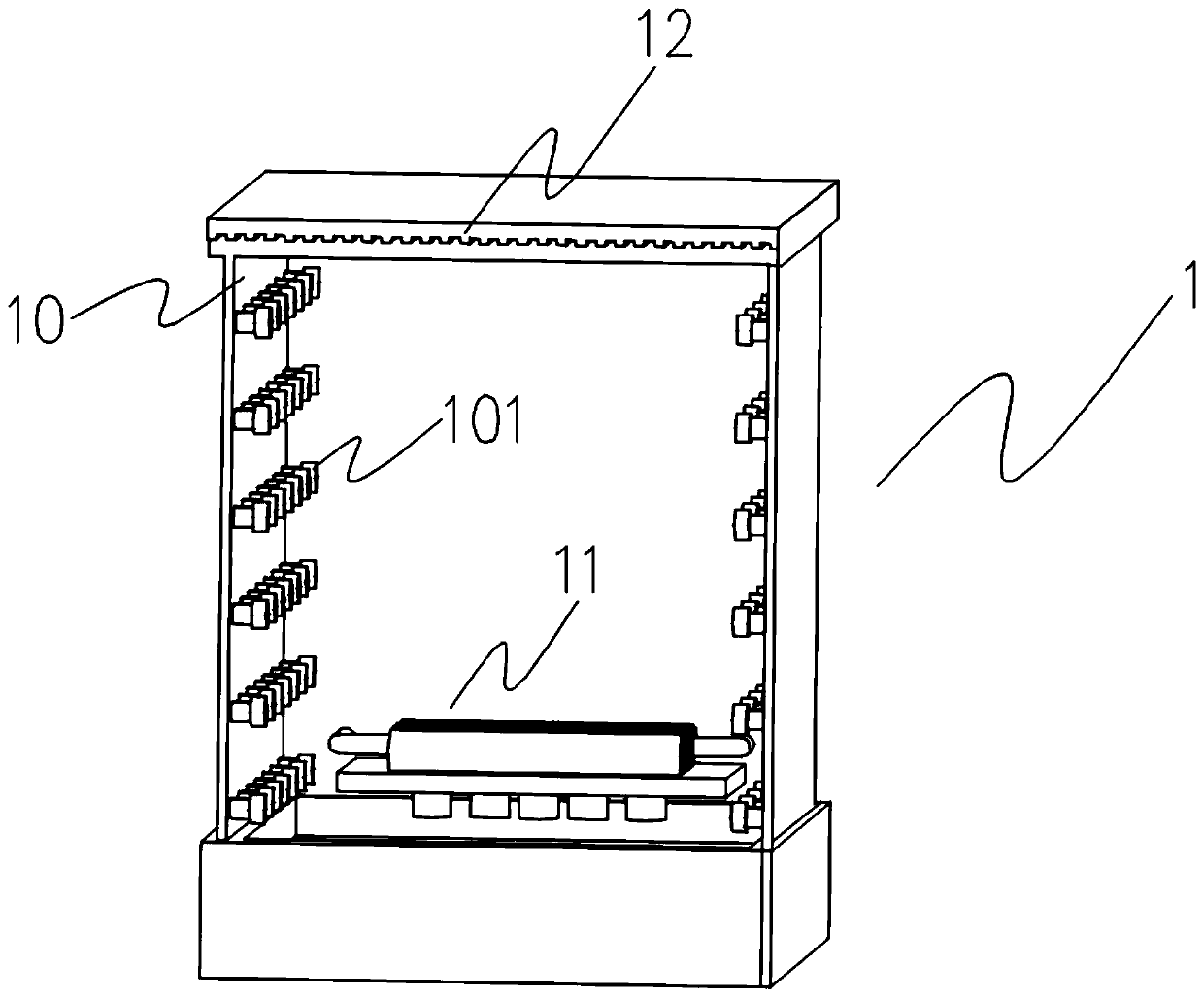

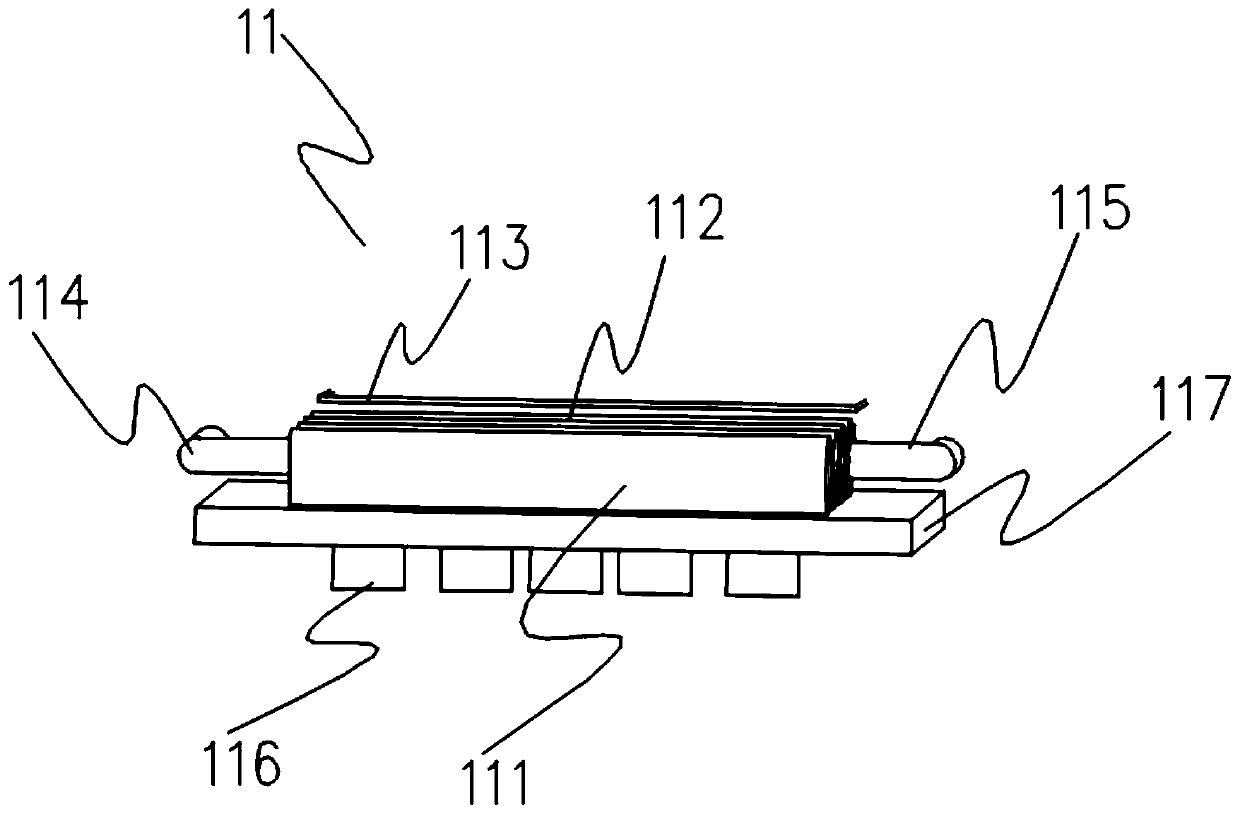

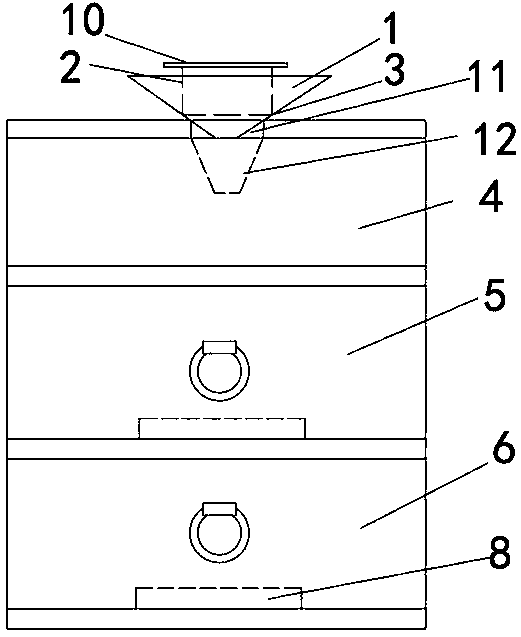

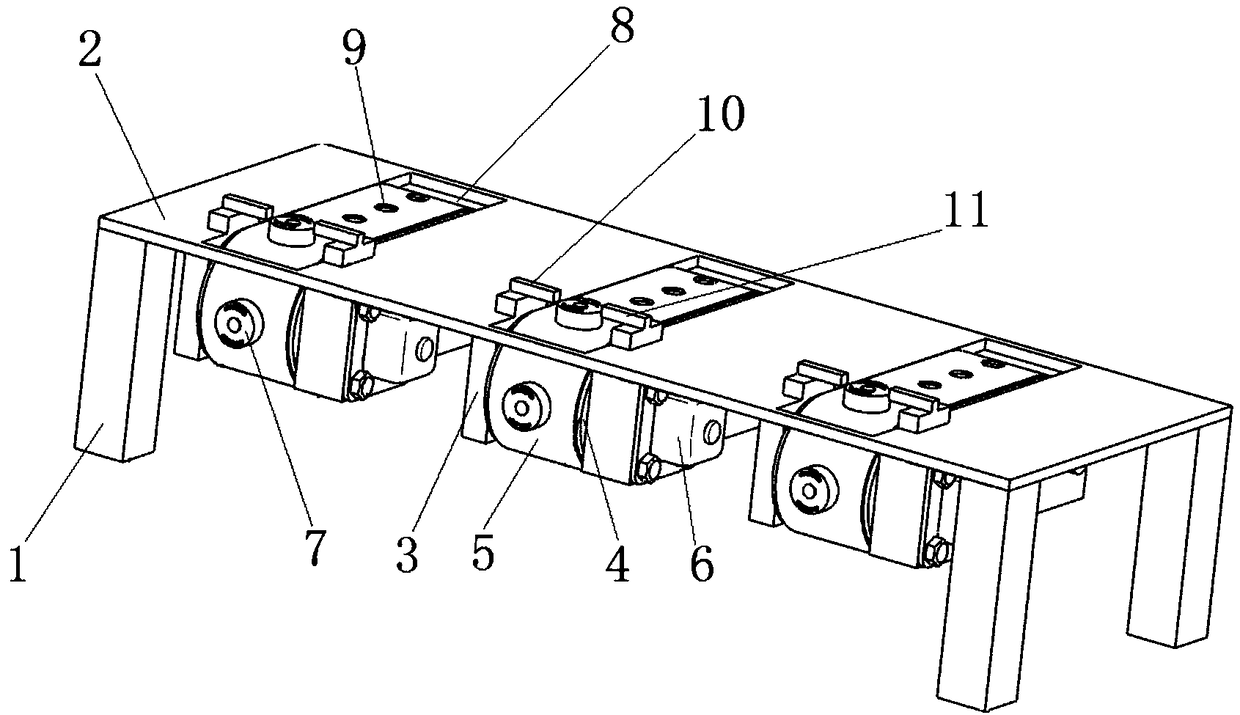

Batching disc for watch outer shells

InactiveCN108891850AImprove work efficiencyGood accuracyConveyorsEngineeringElectrical and Electronics engineering

The invention relates to a batching disc for watch outer shells. The batching disc comprises a batching disc bracket, a worktable arranged on the batching disc bracket and a plurality of batching mechanisms which are arranged on the worktable in sequence in the length direction of the worktable. The worktable is provided with a detection mechanism matched with the batching mechanisms. Compared with the prior art, the batching mechanisms sequentially arranged on the worktable in the length direction of the worktable increase the number of to-be-machined parts capable of being placed on the batching disc, then the work efficiency of machining is improved, and the batching disc meets requirements of large-scale production. Through the cooperation of the detection mechanism and the batching mechanisms, whether the watch outer shells are placed on a part tray in a grasping station or not can be recognized, so that the watch outer shells in the batching mechanisms are conveniently grasped bya mechanical arm, and the accuracy is good.

Owner:SHANGHAI UNIV OF ENG SCI

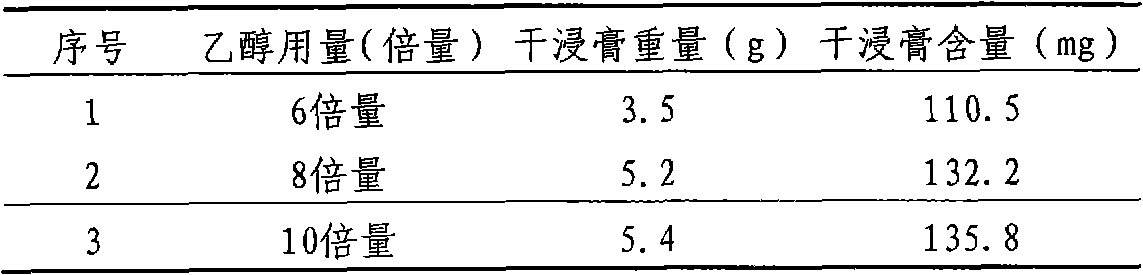

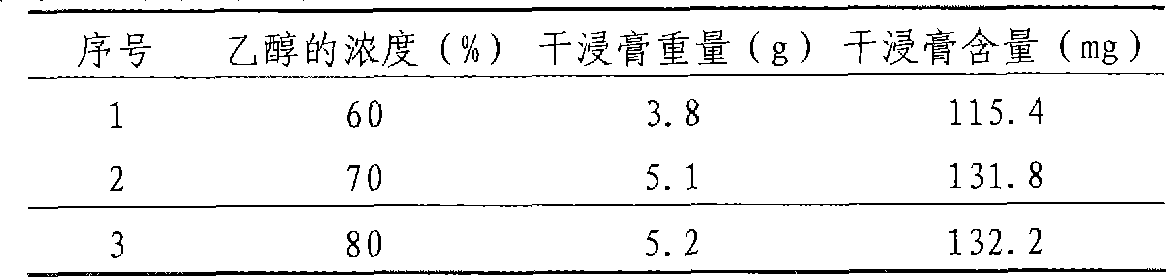

Method for preparing medicinal preparation for treating cardiovascular and cerebrovascular diseases

InactiveCN101972354AKeep intactImprove bioavailabilityCardiovascular disorderPlant ingredientsDiseaseRHODIOLA ROSEA ROOT

The invention relates to a method for preparing a medicinal preparation for treating cardiovascular and cerebrovascular diseases, which comprises the following steps of: adding 60 to 80 percent ethanol in an amount which is 6 to 10 times that of rhodiola rosea serving as medicinal materials to perform reflux extraction for 2 to 4 times and 1 to 3 hours each time, merging ethanol extracting solution, recovering the ethanol until ethanol taste does not exist to obtain extract; pulverizing American ginseng to form 80 to 100-mesh fine powder for later use; decocting medlar, root of red-rooted salvia and liquoric root in water in an amount which is 4 to 6 times that of the mixture for 2 to 4 times and 1 to 3 hours each time, merging decoction, and concentrating (the measured relative density is 1.10 at the temperature of 60 DEG C); merging the extract, concentrating under reduced pressure to form thick paste with the measured relative density of 1.25 at the temperature of 60 DEG C; adding the American ginseng fine powder, and mixing uniformly; and adding a proper amount of auxiliary materials to prepare a clinically-applied liquid preparation. The medicinal preparation has a simple preparation method and high extraction ratio of active ingredients of the medicaments, does not need specific equipment, and reduces the production cost and the load of patients, and common production equipment can meet the requirements of producing the medicinal preparation.

Owner:彭军

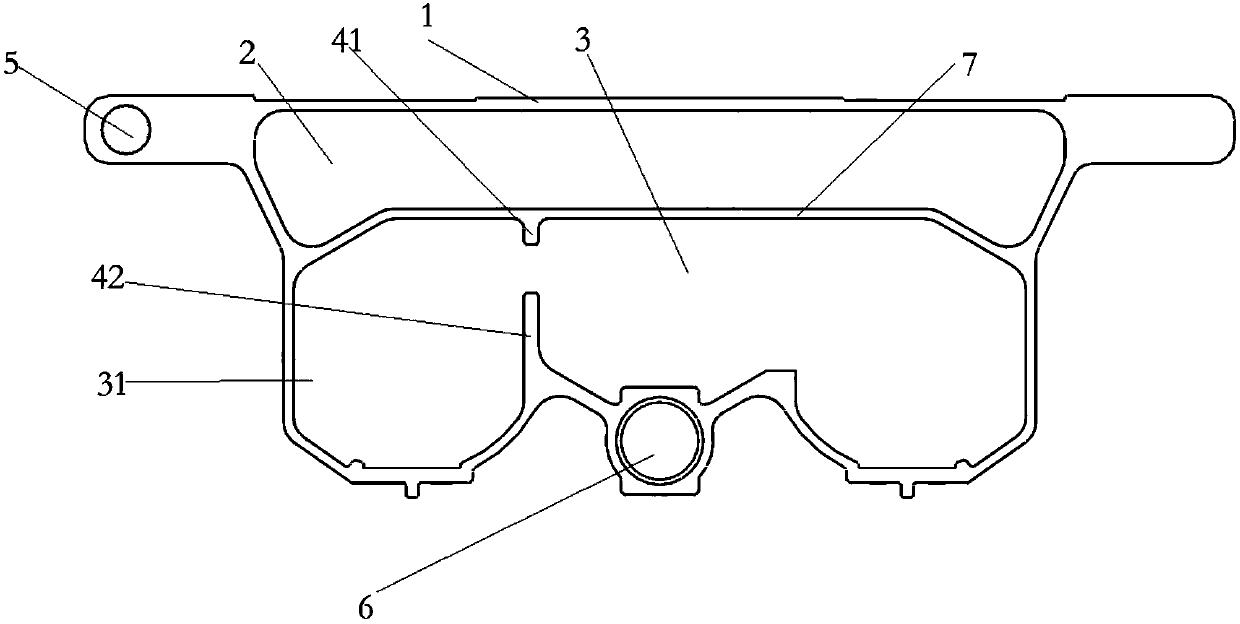

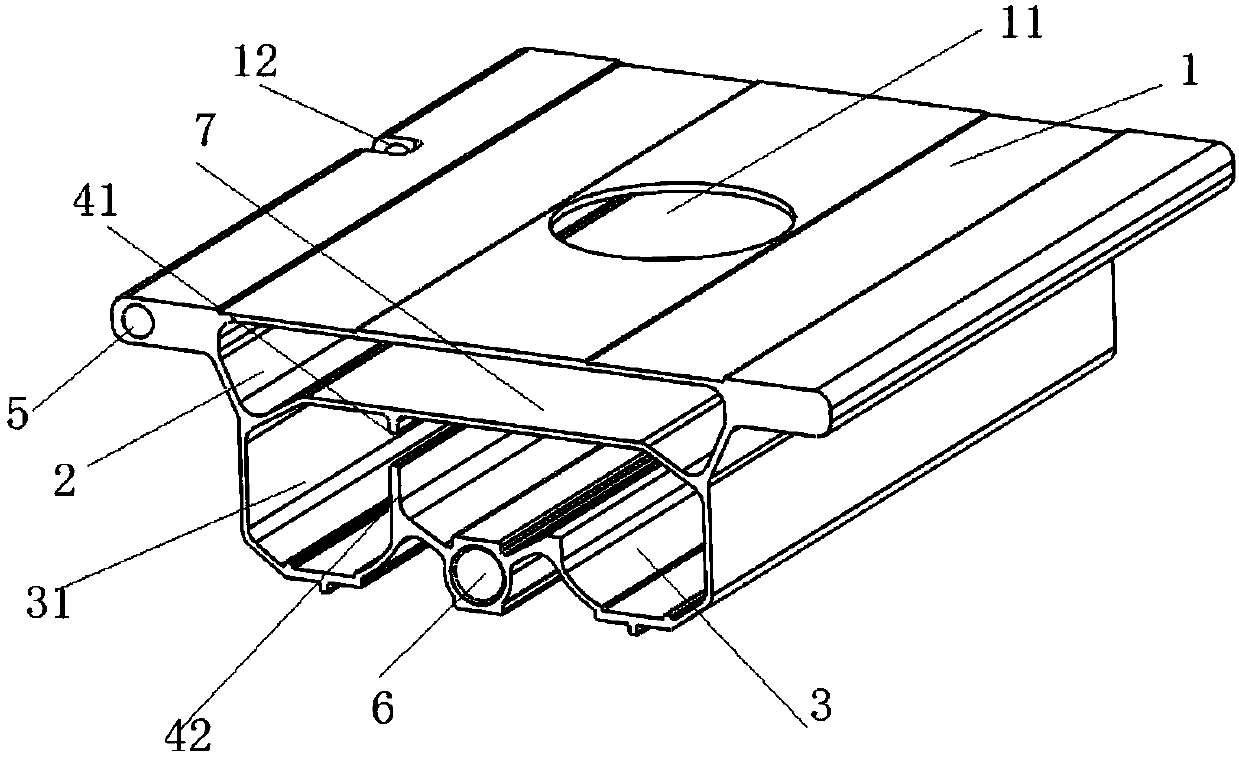

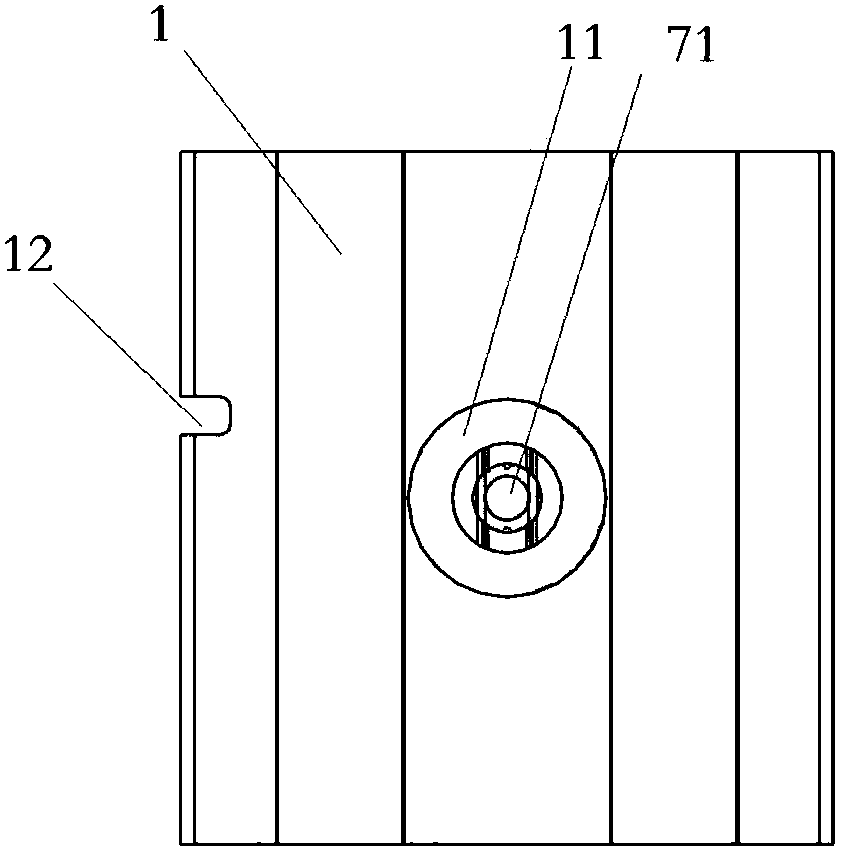

Follow-up profile and follow-up support for wheelchair and follow-up mechanism

ActiveCN107822792AReduce consumptionAdapt to the needs of mass productionWheelchairs/patient conveyanceWheelchairClassical mechanics

The invention discloses a follow-up profile and a follow-up support for a wheelchair and a follow-up mechanism. The follow-up profile comprises an upper end plate arranged in the length direction of the profile, a containing cavity formed in the lower portion of the upper end plate, a positioning rib plate, guide ribs, a connecting shaft hole and an oscillating shaft hole; the positioning rib plate is at least provided with a positioning plane parallel to the upper end plate and divides the containing cavity into an upper containing cavity and a lower containing cavity which are distributed upand down, at least one group of guide ribs are arranged on one side of the lower containing cavity, and a side containing cavity is separated out; one group of guide ribs are arranged in parallel from top to bottom and composed of upper guide ribs and lower guide ribs which have spacing between each other and extend out from the lower end face of the positioning rib plate and corresponding cavitywall surface of the containing cavity; the connecting shaft hole is formed in one side of the upper containing cavity; the swing shaft hole is formed in the lower end of the containing cavity. The follow-up support and the follow-up mechanism adopt intercepted follow-up profile equipment. According to the follow-up profile, an electric rotating mechanism and a swing mechanism are arranged simultaneously.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

Steel material texture detection method and device utilizing same

ActiveCN103357704AAvoid production safety hazardsReduce workloadMetal working apparatusNumerical controlProduction line

The invention discloses a steel material texture detection method and a device utilizing same, and is used for detecting a steel material texture of a workpiece during processing in a numerical control angle steel typing punching shearing production line / a numerical control plate material punching typing machine. The detection method includes the following steps: (1) arranging a pressure detection device on the numerical control angle steel typing punching shearing production line / the numerical control plate material punching typing machine, and employing the pressure detection device to acquire a pressure numerical value when the workpiece to be detected is punched; (2) building a standard punching pressure database of angle steel / plate materials with various textures in a microcomputer, comparing and judging the database with the acquired pressure numerical value, and displaying the judged result through a human-computer interaction interface of the microcomputer; and (3) when the judged result displayed in the human-machine interaction interface is inconsistent with the texture of the workpiece in a processing batch, starting an alarm device for alarm by the microcomputer, and reminding an operator to take out the problem workpiece. The detection method can detecting the texture of each angle steel or each plate material used in a production process, and is accurate and quick.

Owner:JINAN EVERSHINING CNC MACHINE

UV gloss oil capable of being used for rapid curing of UV-LED light source and preparation method of UV gloss oil

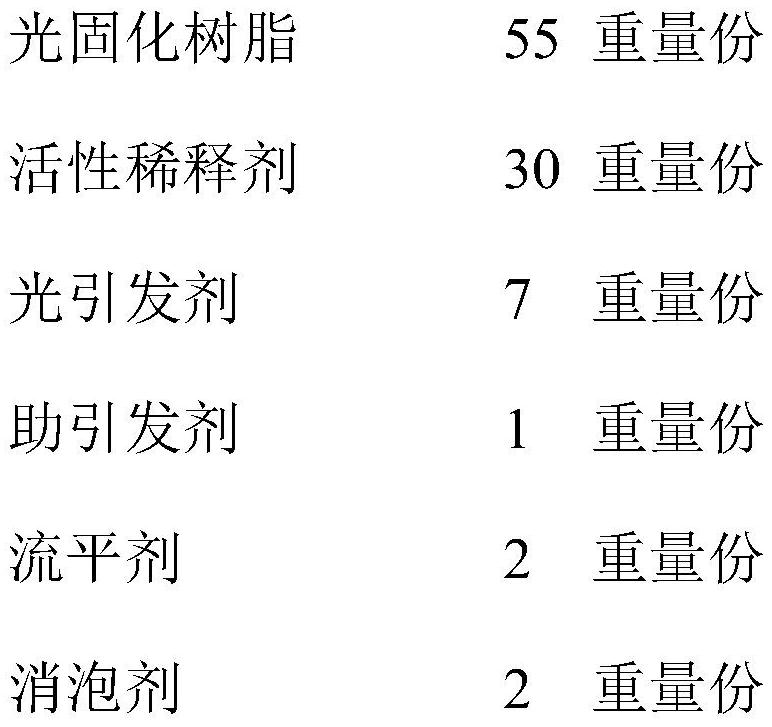

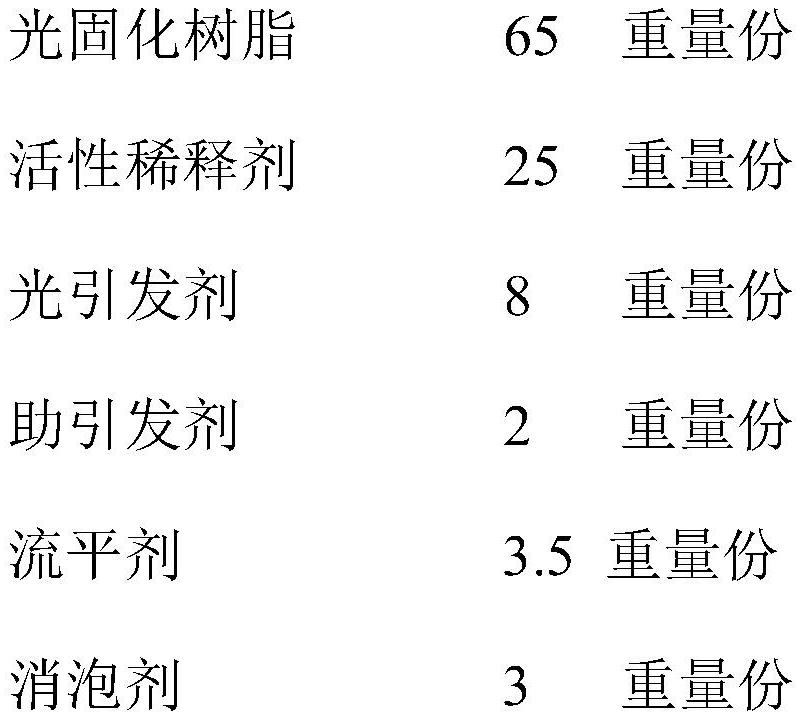

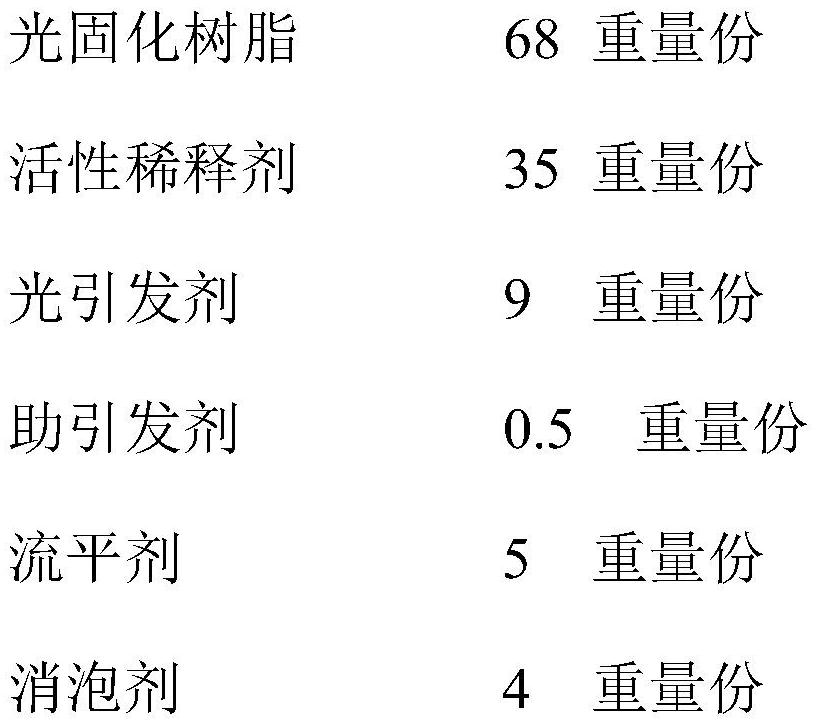

The invention relates to UV gloss oil capable of being used for UV-LED light source rapid curing and a preparation method of the UV gloss oil. The UV gloss oil comprises, in parts by weight, 55-70 parts of light-cured resin, 10-40 parts of a reactive diluent, 1-10 parts of a photoinitiator, 0.1-3 parts of a co-initiator, 0-2 parts of a flatting agent and 0-2 parts of a defoaming agent. The light-cured resin is prepared by selecting 50 to 70 parts by weight of hyperbranched acrylic resin and 0 to 20 parts by weight of organic silicon polyurethane acrylate and mixing. According to the UV gloss oil capable of being used for rapid curing of the UV-LED light source and the preparation method of the UV gloss oil, the reactive diluent with the high boiling point is adopted to replace a common organic solvent, the pollution problem of the organic solvent is solved, and complete non-toxicity is achieved; and meanwhile, the reactive diluent is hydrogen-donating ether acrylate, and oxygen inhibition can be effectively inhibited.

Owner:江门市久冠松高分子材料有限公司

Grape picking equipment

InactiveCN111758392AImprove the efficiency of grape pickingAdapt to the needs of mass productionGas current separationPicking devicesGear wheelAgricultural engineering

The invention discloses grape picking equipment. The grape picking equipment comprises a mounting frame and support plates fixedly mounted on the mounting frame; the bottom part of the mounting frameis fixedly provided with a motor and a plurality of traveling wheels; the motor is covered inside by a machine case; an output shaft of the motor passes through the mounting frame and is fixedly connected with steering gears; the mounting frame is provided with symmetric picking mechanisms; each picking mechanism includes a plurality of picking units; two drive shafts are mounted on the support plates; the two drive shafts are each provided with a conveying roller; a conveying belt for transferring grapes is arranged on the conveying rollers; and a collection box fixed onto the mounting frameis arranged at the end part of the conveying belt. Picking boards beat the grapes and beat the grapes off vines; mechanized grape picking can be realized, and the efficiency of grape picking is increased so as to meet the needs of large-scale production; and after three times of cleaning, cleaner grapes can be collected in the collection box.

Owner:黄翠云

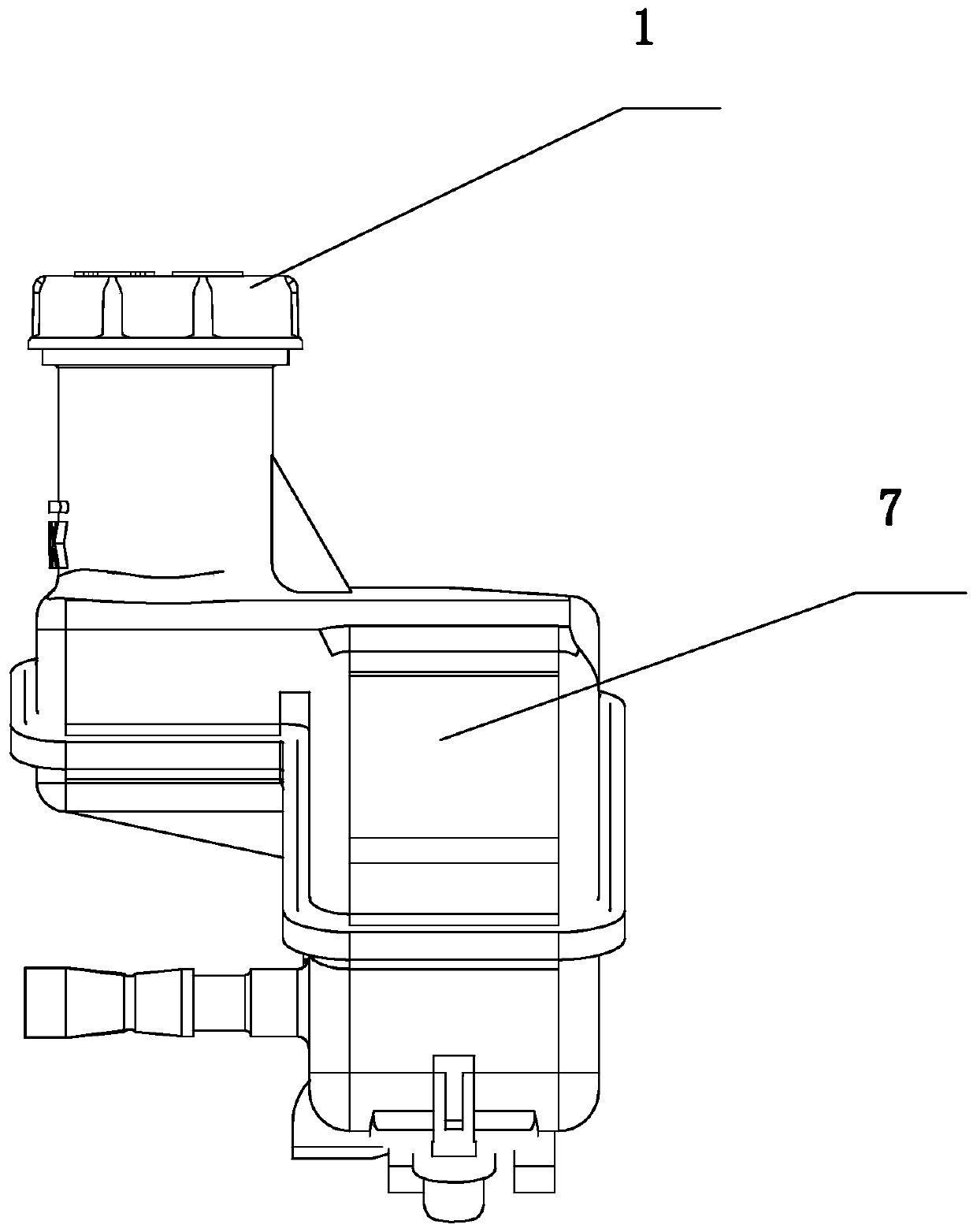

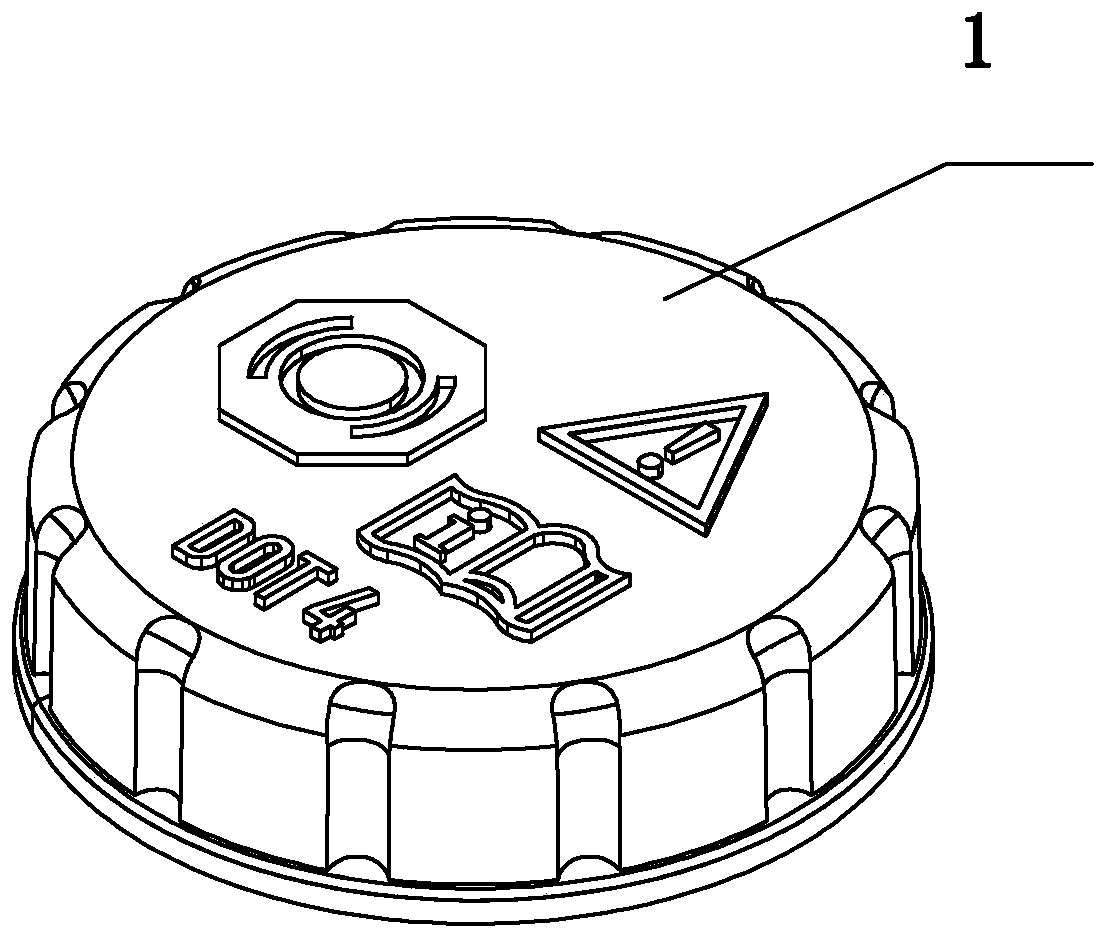

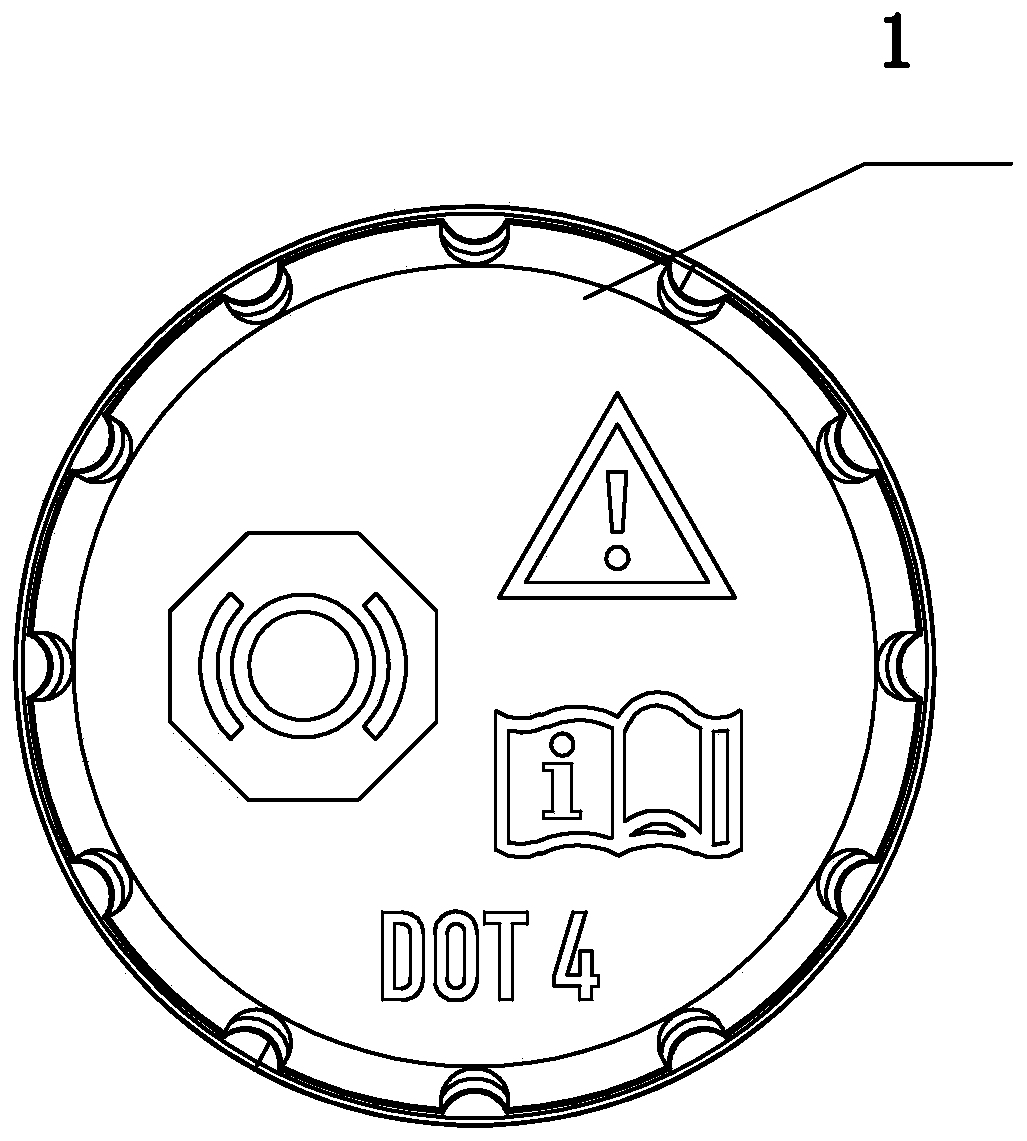

Novel oil bottle cap and automatic production line thereof

PendingCN110126802ASimple structurePrevent leakageAssembly machinesReservoir arrangementsAxis cylinderProduction line

The invention provides a novel oil bottle cap and an automatic production line thereof and belongs to the technical field of oil bottle caps and automatic production. The novel oil bottle cap comprises an oil bottle cap body, a sealing ring and a lining; the lining comprises a conical support, an annular sealing ring cover body and a connecting cylinder; an annular sealing ring cover body centralhole is formed in the center of the annular sealing ring cover body; and a vent hole is formed in one side of the conical support. The automatic production line comprises an oil bottle cap automatic gold stamping part, an automatic assembling detection part and a protective cover. The automatic assembling detection part comprises an auxiliary tooling system, a fixture turntable, a lining materialloading disc, a sealing ring material loading disc, an AirTAC three-axis cylinder with a guide rod, lining and sealing ring assembling detection equipment, a manipulator B, a lining assembling pressing cylinder, product detection equipment, an optical fiber marking machine and a product material basket; and the automatic assembling detection part further comprises stations A to N. The novel oil bottle cap has the beneficial effects that the novel oil bottle cap can breathe and can also prevent oil liquid from leaking; the production efficiency of the production line is high; the labor intensity is low; and the product quality can be guaranteed.

Owner:浙江乔士智能工业股份有限公司

An automatic production equipment for welding terminals for batteries

ActiveCN104183813BRealize mechanized productionIncrease productionSmall-sized cells cases/jacketsEngineeringConveyor belt

Owner:TIANNENG BATTERY WUHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com