Manufacturing method of porous anodised aluminum oxide biochip

A porous anode and biochip technology, applied in the field of biochip research, can solve problems such as complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

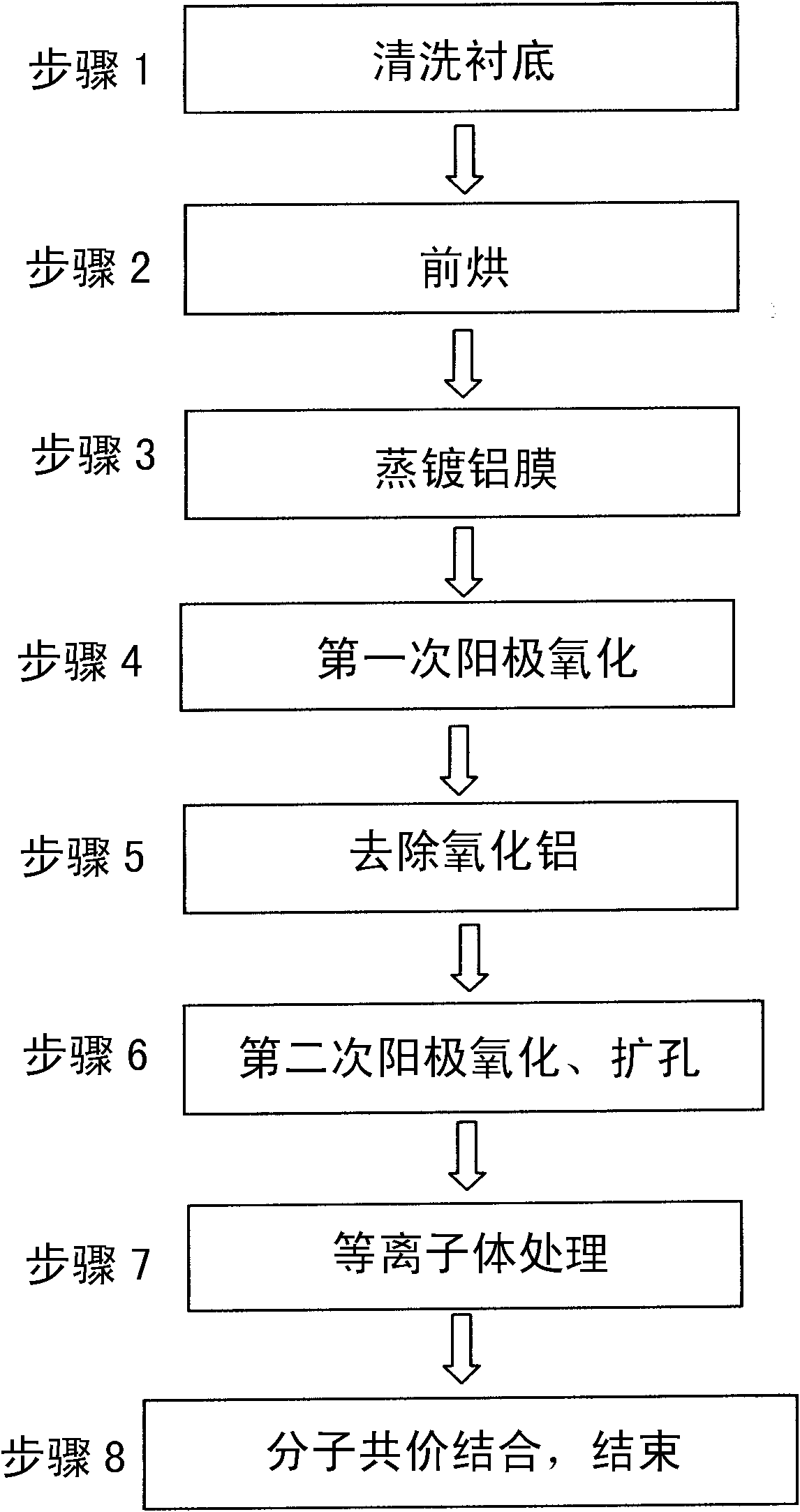

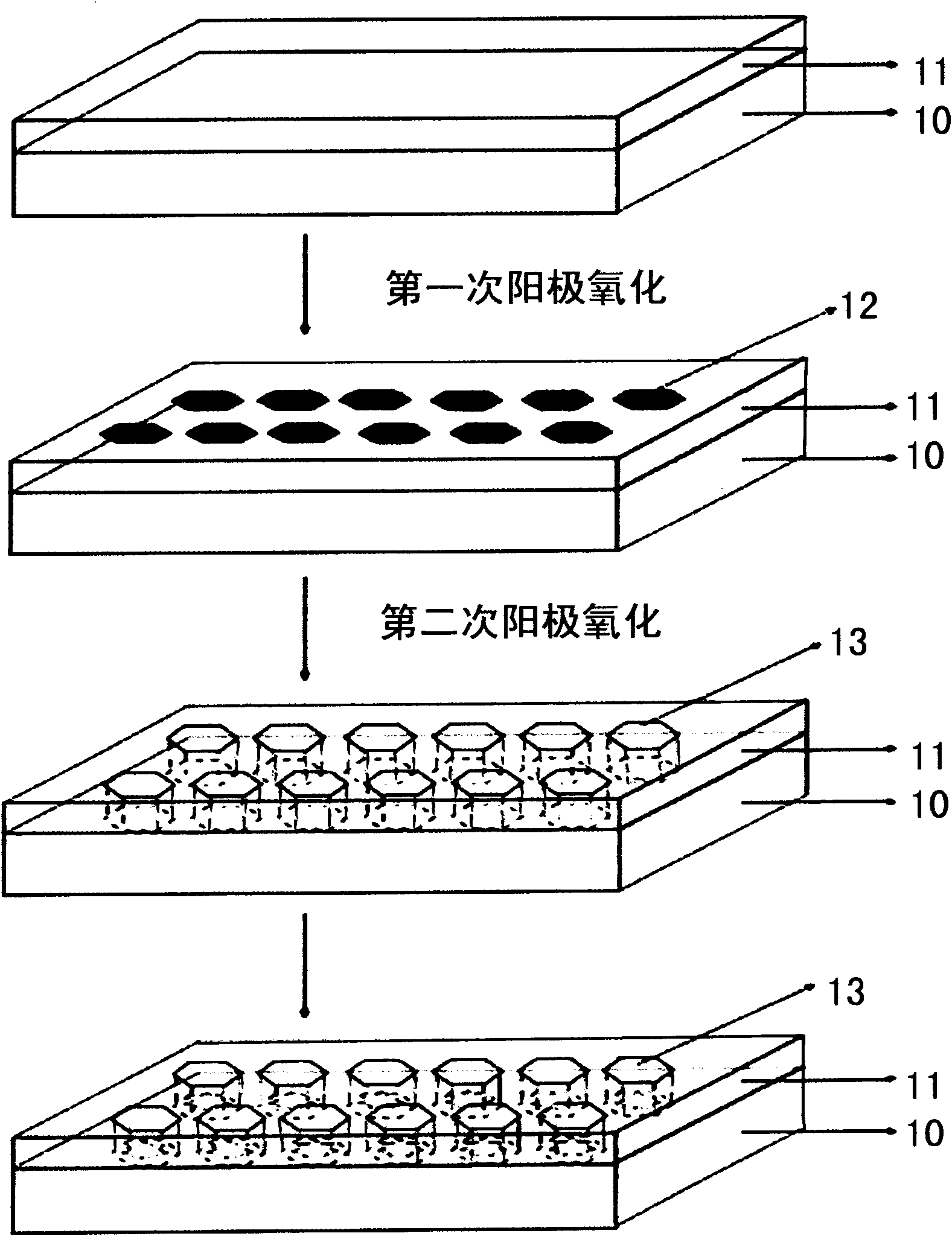

[0030] see figure 1 combined reference figure 2 As shown, the present invention is a method for making an anodized aluminum sequencing chip, comprising the following steps:

[0031] Step 1: Take a substrate 10, clean it, and remove organic and inorganic impurities. The material of the substrate 10 is glass, pottery, organic thin film material or silicon-based semiconductor material substrate. Cleaning is to use ultrasonic waves in order to analyze pure acetone, Cleaning with absolute ethanol and deionized water to remove organic impurities on the surface of the substrate 10, then heating and boiling the substrate 10 with a mixture of sulfuric acid and hydrogen peroxide, and rinsing with deionized water to remove inorganic impurities on the surface of the substrate 10. The method can remove organic attachments and inorganic particles on the surface of the substrate 10, and improve the film-forming quality of the aluminum film 11;

[0032] Step 2: pre-baking, vacuum-drying th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com