Technology for producing compound protein concentrates

A technology of concentrated protein powder and process technology, which is applied in the field of deep processing of oil crops, can solve the problems of limited development and application, weak functionality, yellowish color, etc., and achieves the effects of high equipment configuration efficiency, pollution prevention, and comprehensive nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

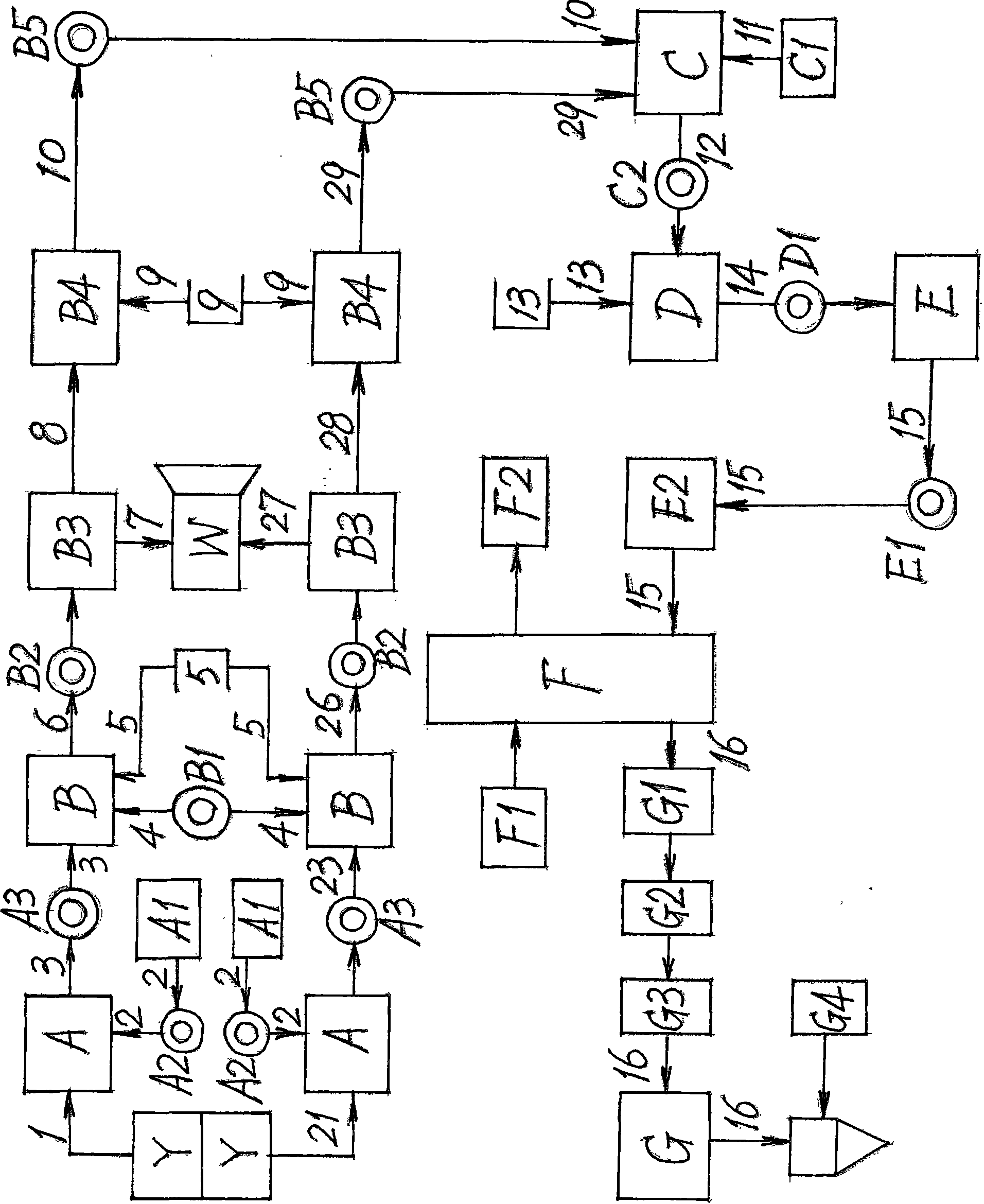

[0008] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] In the batching stage and the acid precipitation stage, soybean low-temperature meal 1 and peanut powder 21 are used as raw materials, respectively, and are prepared on production line equipment according to the process. The process of making soybean acid precipitation emulsion 10 from soybean low-temperature meal 1 is as follows: firstly, 48-52°C hot water 2 is added to batching tank A from hot water tank A1 through hot water pump A2, and 1.75 tons of soybean low-temperature meal 1 is put into each batch, and Add 14 tons of hot water 2 at a material-to-water ratio of 1:8, stir evenly, and make soybean feed liquid 3, pump it into acid sink B with slurry pump A3, and add it into acid sink B from acid metering pump B1 Acid solution 4, then add appropriate amount of defoamer 5, mix and stir to make soybean acid precipitation liquid 6, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com