Patents

Literature

46results about How to "Balanced nutritional value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

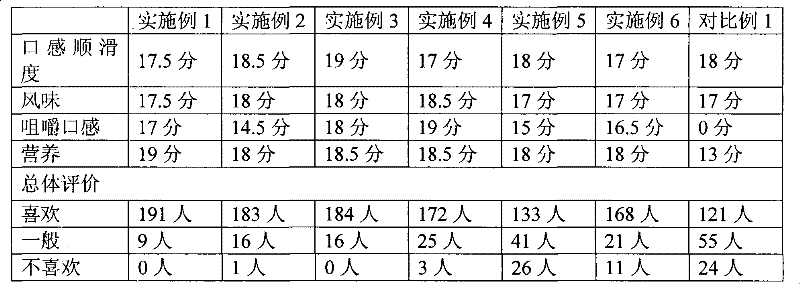

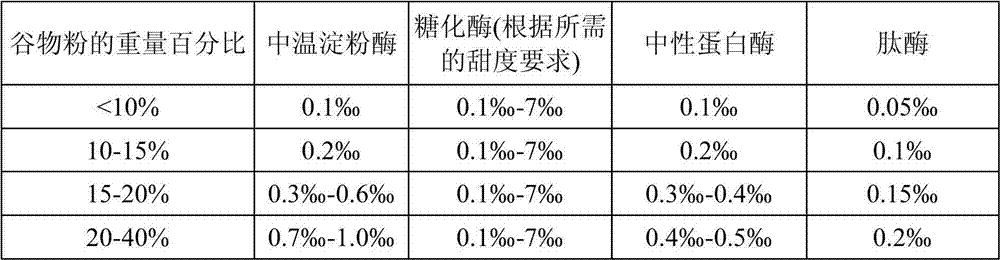

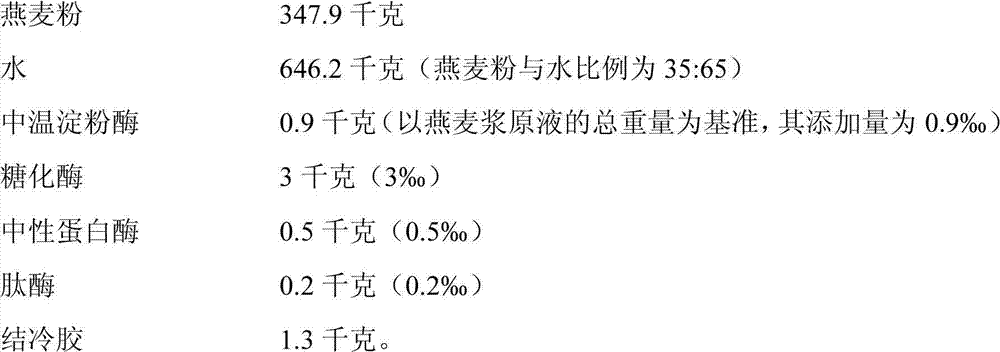

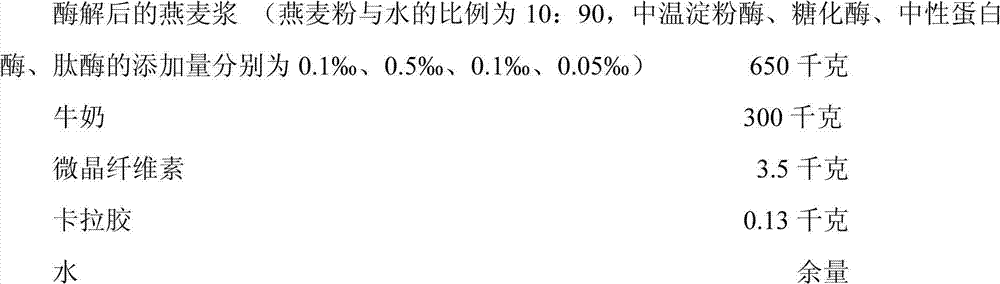

Cereal beverage and preparation method thereof

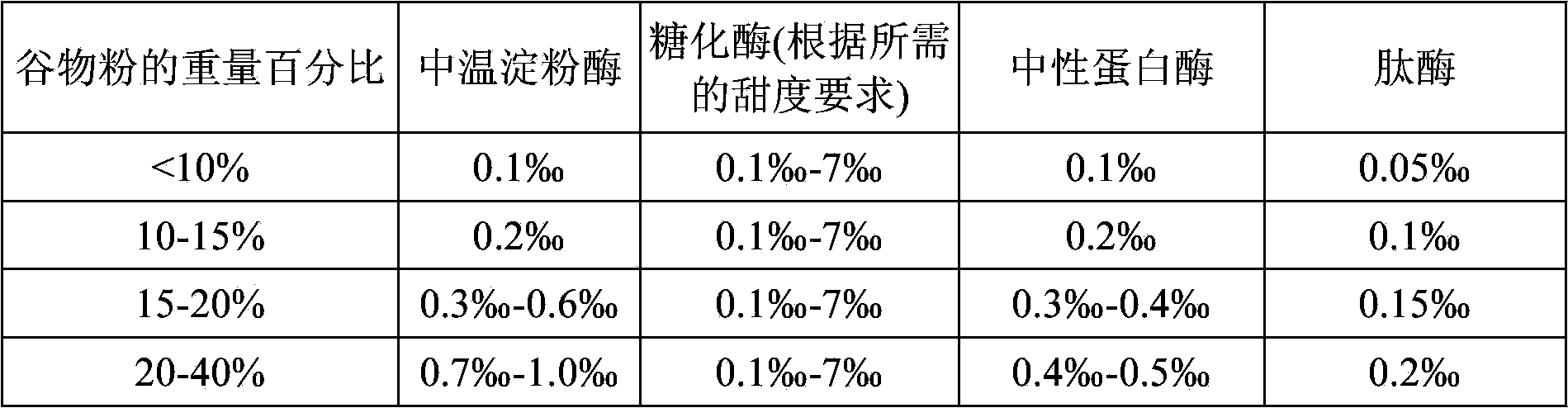

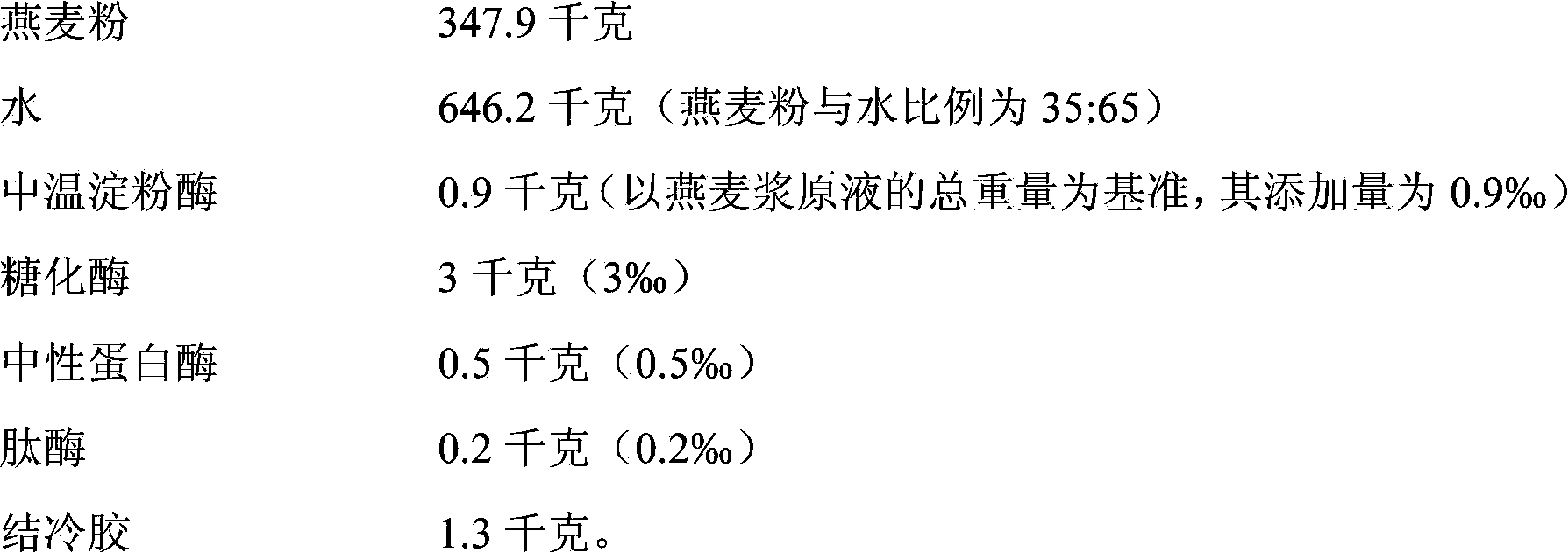

The invention provides a cereal beverage and a preparation method thereof. The preparation method of the cereal beverage comprises: adding medium temperature amylase, glucoamylase, neutral protease and peptidase into one or more kinds of cereal pulp original solutions to perform enzymatic hydrolysis reaction, and obtaining one or more kinds of cereal pulps subjected to enzymatic hydrolysis after the reaction is finished; when one cereal pulp original solution is subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the cereal pulp subjected to enzymatic hydrolysis, so as to obtain the cereal beverage; and when multiple kinds of cereal pulp original solutions are subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the multiple kinds of cereal pulps subjected to enzymatic hydrolysis, so as to obtain the cereal beverage. The invention also provides the cereal beverage which is prepared by employing the above preparation method. The cereal beverage provided by the invention is capable of completely keeping nutritional components of the cereal raw materials, is relatively beneficial for digestion and absorption of human, and has the characteristics of being smooth in mouthfeel and refreshing in flavor.

Owner:INNER MONGOLIA DAIRY TECH RES INST CO LTD

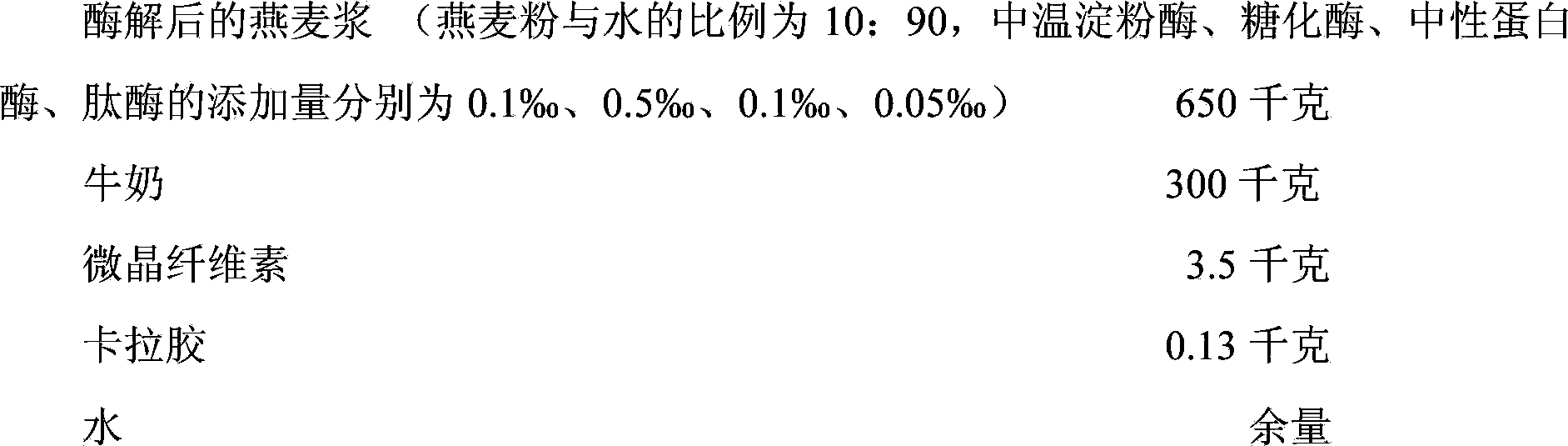

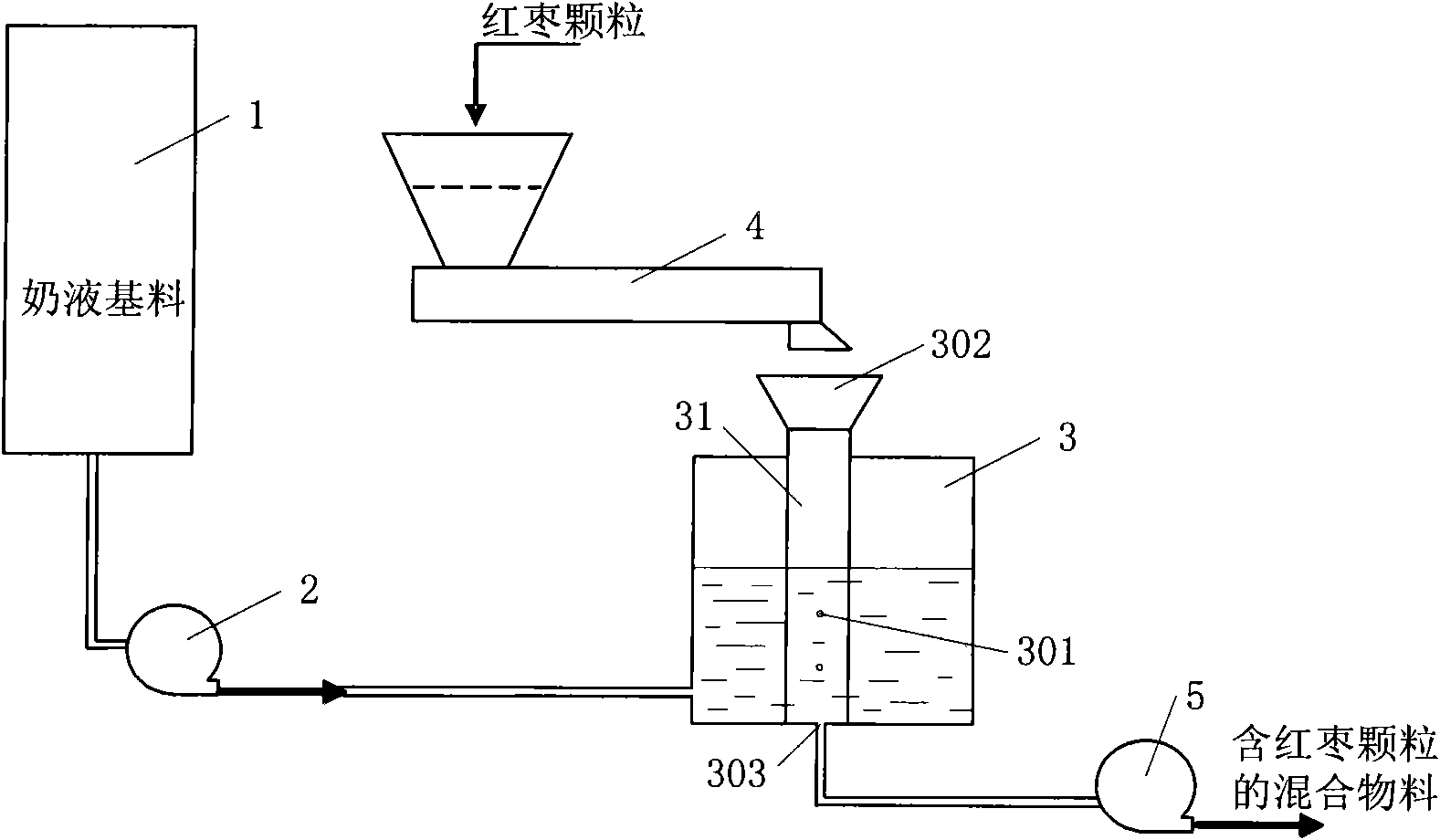

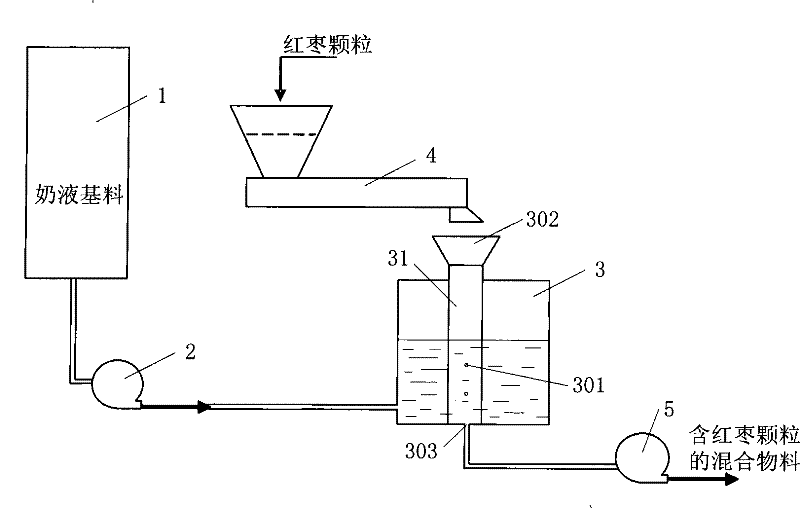

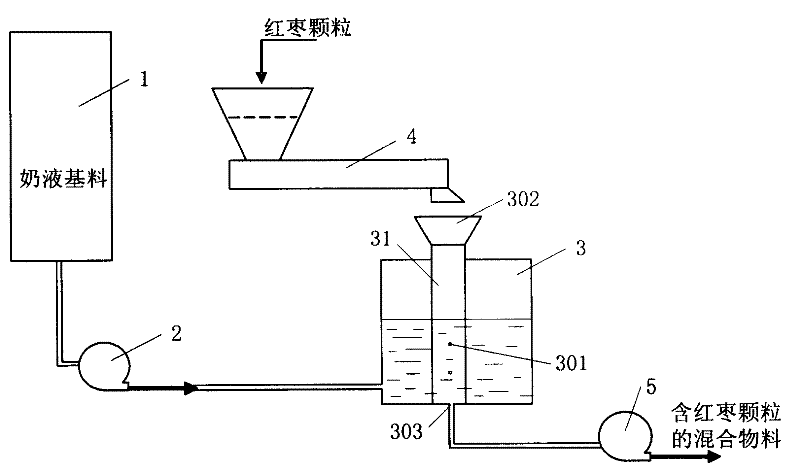

Liquid dairy product containing red jujube particles and production method thereof

ActiveCN101595921AMeeting nutritional needsIncrease varietyMilk preparationFood preparationNutritive valuesVitamin

The invention provides a liquid dairy product containing red jujube particles and a production method thereof. The total weight of a liquid dairy product is used as a reference, and raw materials comprise 1-10 percent of red jujube particles. The product adds product variety of the liquid dairy product, and the addition of the red jujube particles realizes the combination of vitamins, minerals and special activated contents in red jujubes with milk protein so that the nutritive value of the product is more reasonable and balanced. Moreover, the invention can realize the favorable stability of the product during the shelf life by the reasonable prescription and the suitable technology.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Shiitake mushroom culture medium and preparation method thereof

InactiveCN107698294AImprove qualityImprove the effect of increasing productionCalcareous fertilisersMagnesium fertilisersMonopotassium phosphateSugar

The invention discloses a shiitake mushroom culture medium and a preparation method thereof and relates to the field of culture media. The culture medium is prepared from the following components in parts by weight: 50-60 parts of cottonseed hulls, 10-30 part of rice bran, 5-15 parts of bits of wood, 10-20 parts of peanut shells, 5-10 parts of bananas, 3-5 parts of lime powder, 5-15 parts of soybean poles, 3-5 parts of white granulated sugar, 25-30 parts of ramie, 15-20 parts of chestnut shells, 18-27 parts of mulberry sawdust, 10-16 parts of chrysanthemum branches, 12-15 parts of platycodon grandiflorum stems, 1-4 parts of gypsum, 12-19 parts of bran, 2-5 parts of monopotassium phosphate, 1-4 parts of magnesium sulfate, 2-5 parts of eupolyphaga breeding wastes and a proper amount of water. The invention discloses the shiitake mushroom culture medium and the preparation method thereof. The shiitake mushroom culture medium is used for culturing shiitake mushrooms, and is high in utilization ratio of nutrients, low in cost, high in output of shiitake mushrooms and high in economical benefit.

Owner:渠县金穗农业科技有限公司

Making method of smoked chicken

InactiveCN103704746AWide variety of sourcesBalanced nutritional valueFood ingredient functionsFood preparationFlavorPhysical health

The invention discloses a making method of a smoked chicken, and solves the problem that the existing smoked chicken can not completely meet living needs of people. The making method is characterized by comprising the steps of marinating by using bittern prepared from aniseed, pepper, angelica root, galangal, amomum tsao-ko, beautiful galangal fruit, clove, magnolia flower, anise, cumin, cassia, licorice, long pepper, dried orange peel, bay leaves, murraya paniculata, cassia bark and fructus amomi rotundus, and then performing fumigation. The making method disclosed by the invention is simple in process and low in production cost, and the product is easy to preserve and convenient to carry; stewing is performed for two hours to ensure that the smoked chicken is tasty, is heated more uniformly and is tasty more thoroughly; for the appearance, the chicken skin is glossy and shiny, the surface skin is dry and tough, the meat is lean and crispy, and the color is red and bright; the chicken is more ductile, tougher and chewier, and the meat is delicious, fragrant, thick in smoked flavor, crisp in mouth and better in mouthfeel; most of the added stewing materials are medical and edible seasonings, have certain pharmacological and healthcare functions, can strengthen spleen, stimulate the appetite, resolve food stagnancy and increase the appetite, and also can prevent diseases and promote the physical health of human bodies.

Owner:刘长青

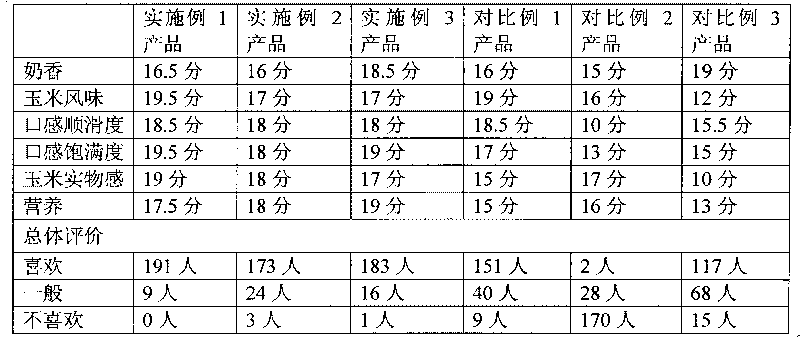

Nine precious nutrition powder food and preparation method thereof

The invention discloses a health care nutritional food with corn coarse grain flavor. The health care nutritional food comprises the following steps of: boiling and filtering corn, soybean, buckwheat, sesame, lotus seed, lily, Chinese yam, euryale seeds and longan in certain parts by weight. The preparation method provided by the invention is simple, the nine precious nutrition powder food adopts multiple first-class raw materials, the nine precious nutrition powder food is processed and refined through drying and screening and the like and is fresh, cool and tasty, the smell is spicy, and the nine precious nutrition powder food has the effect of strengthening the immunity of a human body.

Owner:安徽世茂中药股份有限公司

Multi-flavor meat floss sachima and preparation method thereof

The present invention relates to multi-flavor meat floss sachima and a preparation method thereof. A traditional fermentation process with wheat flour as a basic raw material is changed, and the wheatflour and oat powder are used as basic raw materials for mixed fermentation, thereby enriching the taste of the sachima; water and milk are adopted for dough kneading, thereby greatly improving the protein content of the sachima, increasing the nutritional ingredient content of the sachima, and better meeting the pursuit of contemporary young people for healthy diet; maltose syrup and honey are mixed in proportion to decoct syrup, so that the sachima is more unique in flavor; the surface of the sachima is sprinkled with meat floss and the meat floss is fixed by the syrup, so that the sachimais richer in taste and more balanced in nutritional value; and essences with multiple flavors are added in the syrup, so that the sachima better meets the requirements of people with different dietarypreferences.

Owner:麦肯嘉顿(江苏)食品有限公司

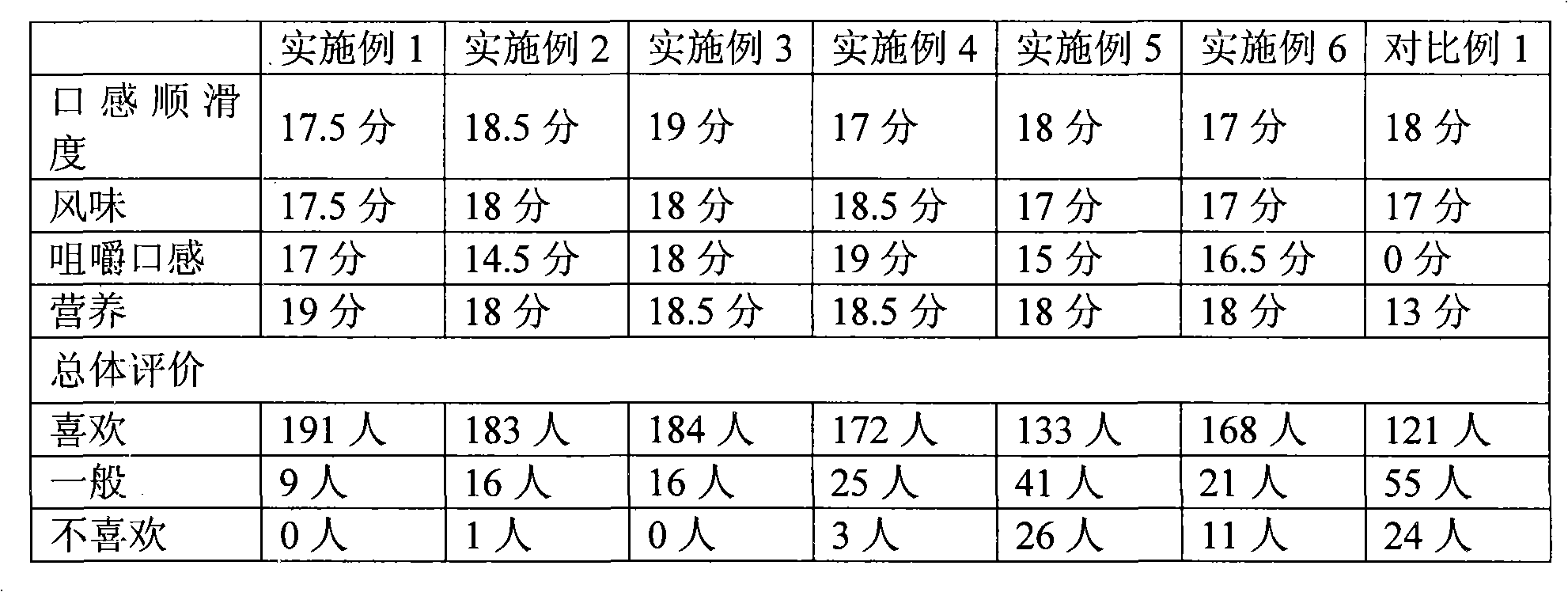

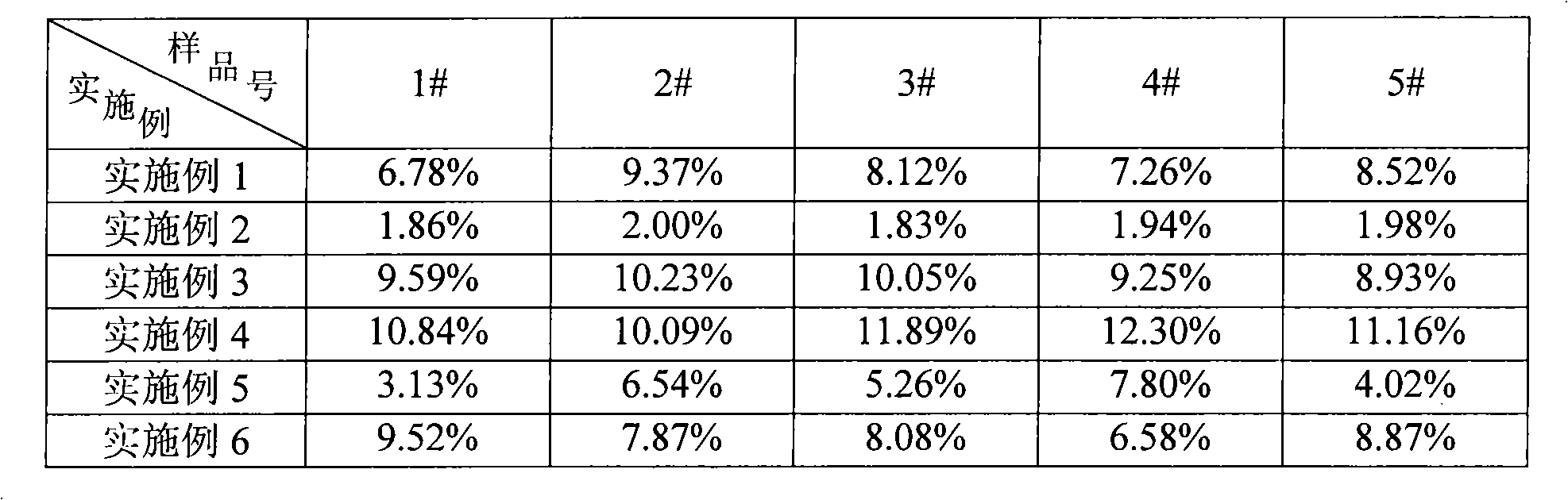

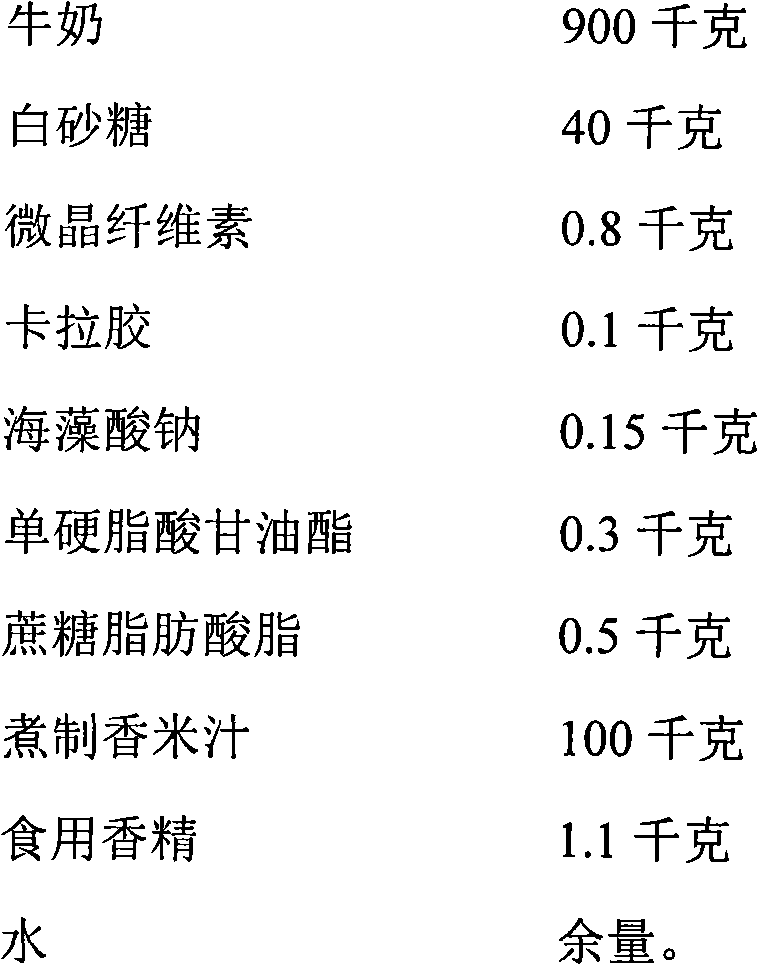

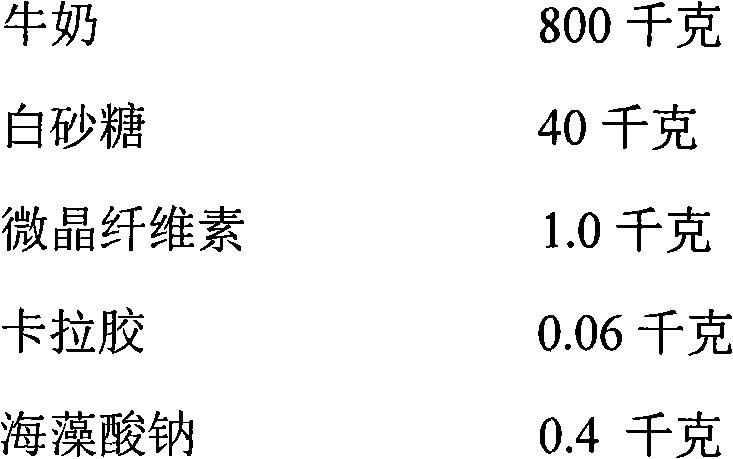

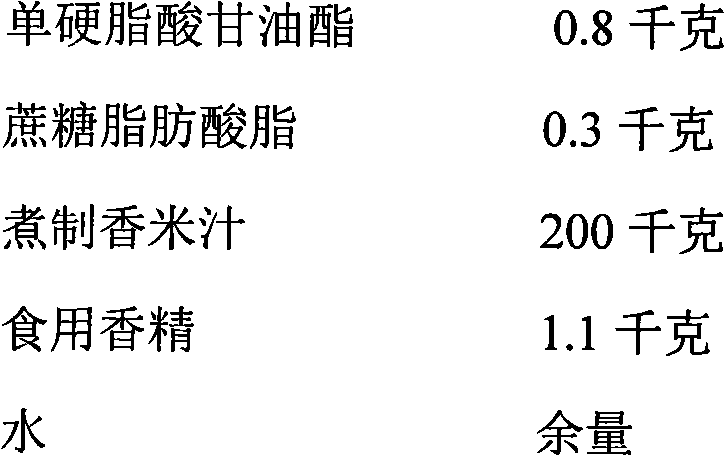

Liquid milk product containing boiled fragrant rice juice and preparation method thereof

ActiveCN102067910AIncrease product varietyReasonable nutritional valueMilk preparationFlavorAromatic rice

The invention relates to the field of milk products, in particular to a liquid milk product containing boiled fragrant rice juice and a preparation method thereof. The liquid milk product containing boiled fragrant rice juice can be flavor milk and comprises the components in parts by weight in the terms of 100 parts: 80-90 parts of milk, 0.156-0.28 part of stabilizing agent, 10-20 parts of fragrant rice juice and the balance of water; or the liquid milk product containing boiled fragrant rice juice can be flavor milk drink and comprises the components in parts by weight: 30-80 parts of milk,0.21-0.36 part of stabilizing agent, 10-40 parts of fragrant rice juice and the balance of water, wherein the fragrant rice juice is prepared by the steps of: mixing the fragrant rice and water in the ratio of 7:100-8.5:100, boiling for 16-25min and pulping and filtering after naturally cooling. The liquid milk product containing boiled fragrant rice juice, prepared in the invention, is smooth inmouthfeel and good in stability during the shelf period.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Synthetic rice applicable to diabetic patient and processing method thereof

InactiveCN107041511AImprove eating effectIncrease the degree of staple foodEdible oils/fatsFood ingredient functionsBiotechnologyBanana powder

The invention discloses a processing method of synthetic rice applicable to a diabetic patient. The processing method comprises the following steps: firstly, preparing a first raw material group, namely mashed potatoes, a second group of raw materials, namely rice flour, corn flour and soybean flour, a third group of raw materials, namely Chinese chestnut powder, Chinese yam powder and banana powder and a fourth group of raw materials, namely propolis liquid, royal jelly, custard apples, edible oil, potato starch and water; secondly, uniformly mixing the fourth group of raw materials, adding into the third group of raw materials, and uniformly mixing; thirdly, uniformly mixing the first raw material group and the second group of raw materials, then uniformly mixing with the material obtained in the step 2, and extruding into a rice-like synthetic rice primary product applicable to the diabetic patient; and fourthly, drying to obtain the synthetic rice applicable to the diabetic patient, namely firstly carrying out hot air drying at the temperature of 50-110 DEG C, then blowing with hot air at the temperature of 15-35 DEG C, then carrying out microwave drying at the power of 200-400W, then carrying out hot air drying at the temperature of 30-50 DEG C, and finally carrying out hot air drying for 1-2 minutes at the temperature of 10-20 DEG C.

Owner:钟静涛

Potato rice and processing method thereof

InactiveCN107095218AImprove eating effectIncrease the degree of staple foodFood scienceBanana powderPotato starch

The invention discloses a processing method of potato rice. The method comprises the following steps of 1, taking the raw materials in parts by weight (the first group of raw materials comprise 30 to 60 parts of potato powder; the second group of raw materials comprise 3 to 6 parts of rice powder, 10 to 20 parts of corn powder and 15 to 25 parts of soybean powder; the third group of raw materials comprise 5 to 10 parts of Chinese chestnut powder, 15 to 20 parts of yam powder and 20 to 30 parts of banana powder; the fourth group of raw materials comprise 3 to 5 parts of edible oil, 5 to 10 parts of potato starch and 80 to 100 parts of water); 2, after uniformly mixing the four groups of raw materials, adding the raw materials into the third group of raw materials; performing the uniform mixing; 3, uniformly mixing the first group and second group of raw materials; uniformly mixing the raw materials with substances obtained in the second step; extruding the materials into rice-shaped potato rice primary products; performing extrusion forming by a single-screw-rod extruding machine, wherein the first stage machine tube temperature of a single screw rod is 50 to 70 DEG C; the temperature of the second stage machine tube is 60 to 80 DEG C; the temperature of the third stage machine tube is 70 to 100 DEG C; the machine tube temperature of the fourth stage machine tube is 90 to 120 DEG C; the temperature of the fifth stage machine tube is 80 to 95 DEG C; 4, performing drying to obtain the potato rice.

Owner:钟静涛

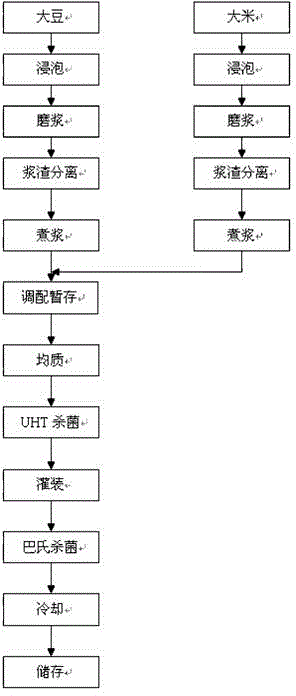

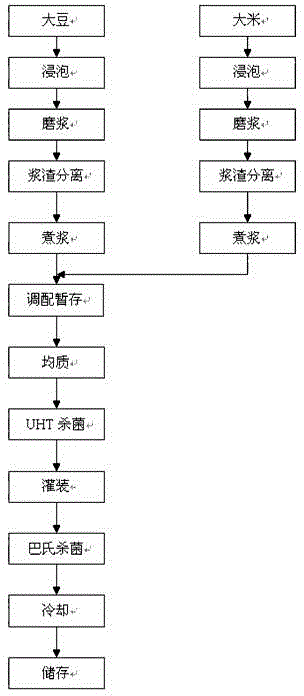

Rice-juice soybean milk and method for preparing same

InactiveCN102715243AGreat tasteImprove nutritional efficacyMilk substitutesFood scienceSoya beanChemistry

A rice-juice soybean milk and a method for preparing the same. The raw materials of the rice-juice soybean milk comprise 90 to 92 % of water, 7.5 to 8.5 % of soybeans and 1.5 to 2.5 % of rice. The method for preparing the rice-juice soybean milk comprises heating the soybean milk to 98 DEG C to 100 DEG C, heating the rice-juice to 98 DEG C to 100 DEG C, mixing the soybean milk and the rice-juice to get a mixture, homogenizing the mixture under the pressure of 10 MPa to 15 MPa to get a homogeneous liquid, and disinfecting and then cooling and setting the homogeneous liquid to form the rice-juice soybean milk. The rice-juice soybean milk perfectly combines the efficacy of the soybean milk and the rice-juice, and effectively improves taste and nutrition efficacy of the soybean milk.

Owner:SUZHOU JINJI FOODS

Preparation method for fruit-vegetable vinegar beverage containing peony extracts

InactiveCN103960719AScientific and reasonable material selectionBalanced nutritional valueMicroorganismsMicroorganism based processesKluyveromyces fragilisHealth protection

The invention provides a preparation method for a fruit-vegetable vinegar beverage containing peony extracts and relates to the field of preparation methods for fruit-vegetable vinegar beverages. The preparation method comprises the following steps: freshwatermelons, grapefruits, and pumpkins are subjected to pretreatment and juicing, so that mixed fruit-vegetable juice of the watermelons, the grapefruits, and the pumpkins is obtained; high-temperature instantaneous sterilization is performed on the mixed fruit-vegetable juice, cooling is performed, and then alcoholic fermentation is performed on the mixed fruit-vegetable juice by kluyveromyces fragilis at the temperature of 25-30 DEG C for 5-7 days; acetic acid bacteria are inoculated; acetic fermentation is performed at the temperature of 28-32 DEG C until the acetic acid content is 10-15%; the fermentation liquor, after acetic fermentation, is mixed with the mixed extracting solution of peony and rose, which is prepared in advance, and the pH value of the mixed fermentation liquor is adjusted to be 3.5-4.0; stevioside and beta-cyclodextrin are added for blending; homogenizing, filtering, sterilization and filling are performed, so that the finished product is obtained. The fruit-vegetable vinegar beverage prepared withthe preparation method provided by the invention is balanced in nutrition, has a certain health protection function, and is soft and delicious in taste, and weak in irritation.

Owner:LUOYANG CHUNKUI AGRI DEV

Capsella bursa-pastoris pill and preparation method and packaging device thereof

InactiveCN103622050ABalanced nutritional valueDeliciousFood ingredient functionsFood preparationMouthfeelFat content

Owner:河南海壹食品股份有限公司

Liquid dairy product containing corn steep liquor and making method thereof

ActiveCN101715831AFix stability issuesImprove stabilityMilk preparationLiquid productCorn steep liquor

The invention provides a liquid dairy product containing corn steep liquor and a making method thereof. The liquid dairy product containing the corn steep liquor comprises the components of 10-85% of raw milk, 3-30% of corn kernel, 0.05-1% of stabilizer and 0-86.95% of drinking water. The method for making the liquid dairy product containing the corn steep liquor comprises the following steps of: immersing the corn kernel into hot water and / or precooking in the milk to pre-sterilize and rehydrate the corn seed; then mixing the precooked corn seed with water and / or milk to carry out pulping; separating the pulped corn steep liquor into corn steep liquor juice and a corn peel, cutting the corn peel into chips; then mixing the corn steep liquor juice and the corn peel with other homogenized mixed liquor, sterilizing and canning to obtain the liquid dairy product containing the corn steep liquor. Through reasonable prescription and appropriate technique, the invention enables the product to have favorable mouth feel and rich nutrition and can realize the favorable stability of the product in shelf life.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

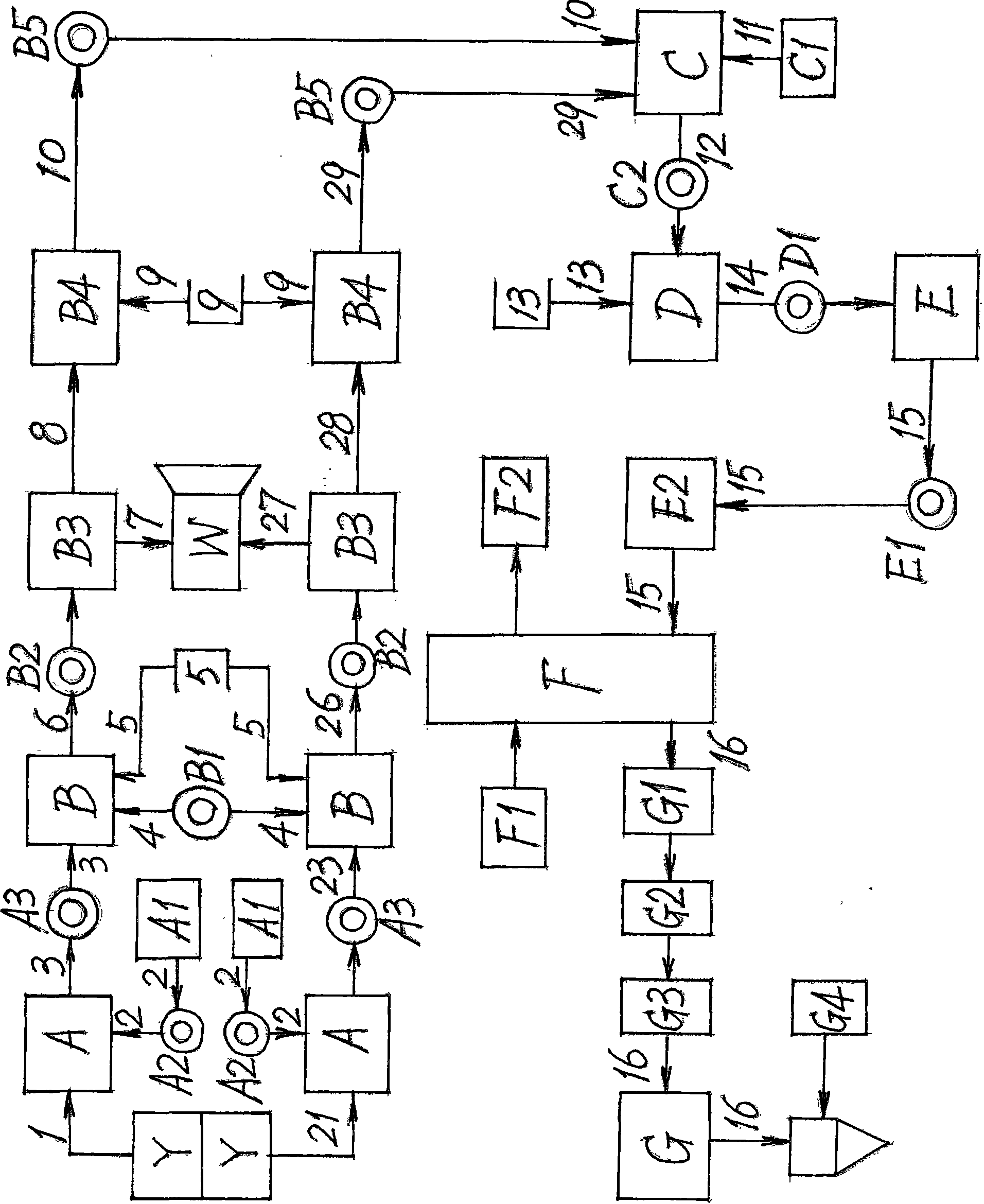

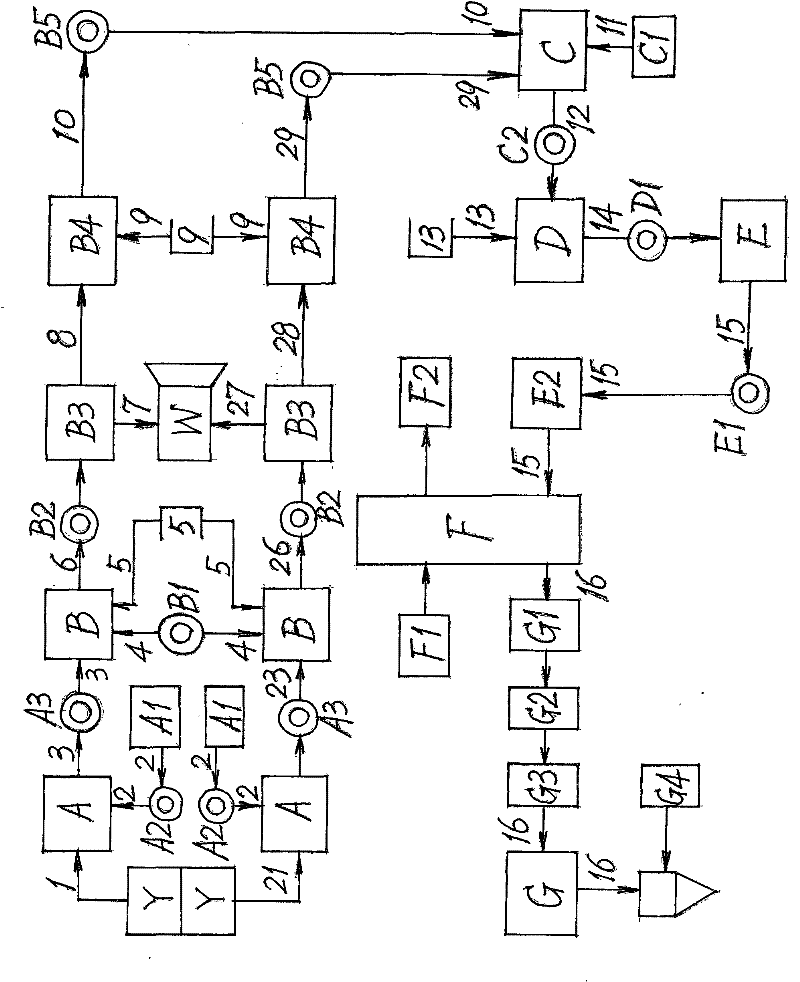

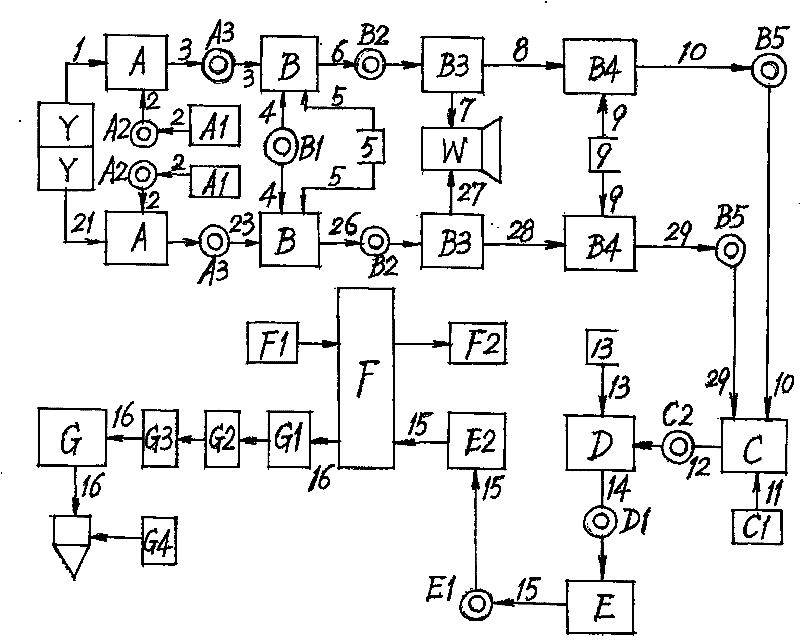

Technology for producing compound protein concentrates

ActiveCN101558815AEasy to operateEnsure hygieneProtein composition from vegetable seedsFood preparationPollutionProtein formation

The invention relates to a technology for producing compound protein concentrates, which comprises the followings: low-temperature soybean meals (1) and peanut flour (21) are respectively prepared into soybean emulsion of acid sediment (10) and peanut emulsion of acid sediment (29) on special production lines through own batching and acid sediment stages; the soybean emulsion of acid sediment (10) and peanut emulsion of acid sediment (29) are mixed and confected based on the proportion of 65-75%:25-35% and are combined to prepare finished products of compound protein concentrates (16) with protein content more than or equal to 70% through continuously conducted neutralization stage, enzymolysis stage, sterilization stage, drying stage and packing and detecting stage. The technology features reasonable device configuration and process flows, high degree of automation of leakproof production lines, harmonious takt time, can prevent pollution can ensures safe and sanitary prepared finished products; the produced compound protein concentrates (16) have rich, comprehensive and balanced nutrition and wide application, and improve added value. The technology can fit the demand of batch production, promote the deep processing technology of the soybeans and peanuts to enhance and conduce to further improving the industrial structures and product structures of the soybeans and peanuts to realize industrialization.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

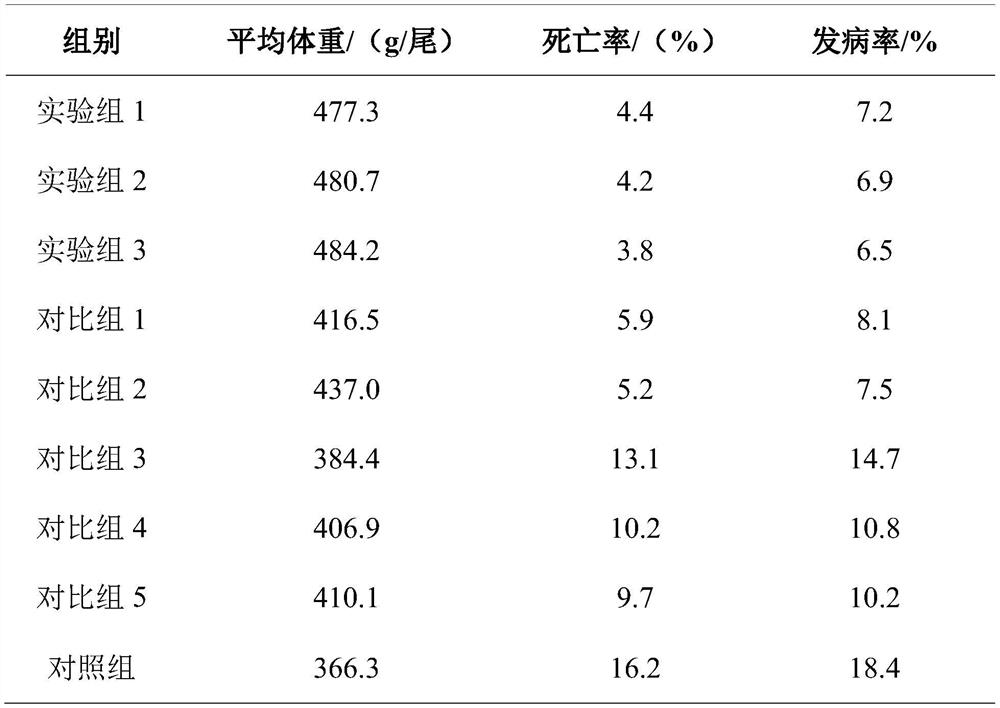

High-yield loach breeding feed

InactiveCN104782968AHigh protein contentBalanced nutritional valueFood processingAnimal feeding stuffNutritive valuesNutrition

The invention discloses high-yield loach breeding feed which comprises the following components in parts by weight: 15-25 parts of dehulled soybean meal (46% of crude protein), 6-12 parts of peanut meal, 10-18 parts of rapeseed meal, 2-6 parts of dephenolized cottonseed meal protein (50% of crude protein), 5-10 parts of fish meal, 15-20 parts of flour, 5-10 parts of bran, 6-12 parts of dried corn distiller grain containing soluble matter, 1 part of phosphatide oil, 1 part of soybean oil, 1.5 parts of calcium dihydrogen phosphate, and 1.5 parts of other additives. The loach breeding feed contains various amino acids and rich vitamins, is balanced in nutritive value, high in feeding safety, and can increase the utilization ratio of protein and amino acid. The feed provided by the invention has good effects on various loach experiments, and loaches cultivated are big in size, low in sick rate, high in nutrition absorptivity, and high in economic benefit.

Owner:江苏长寿集团南山饲料有限公司

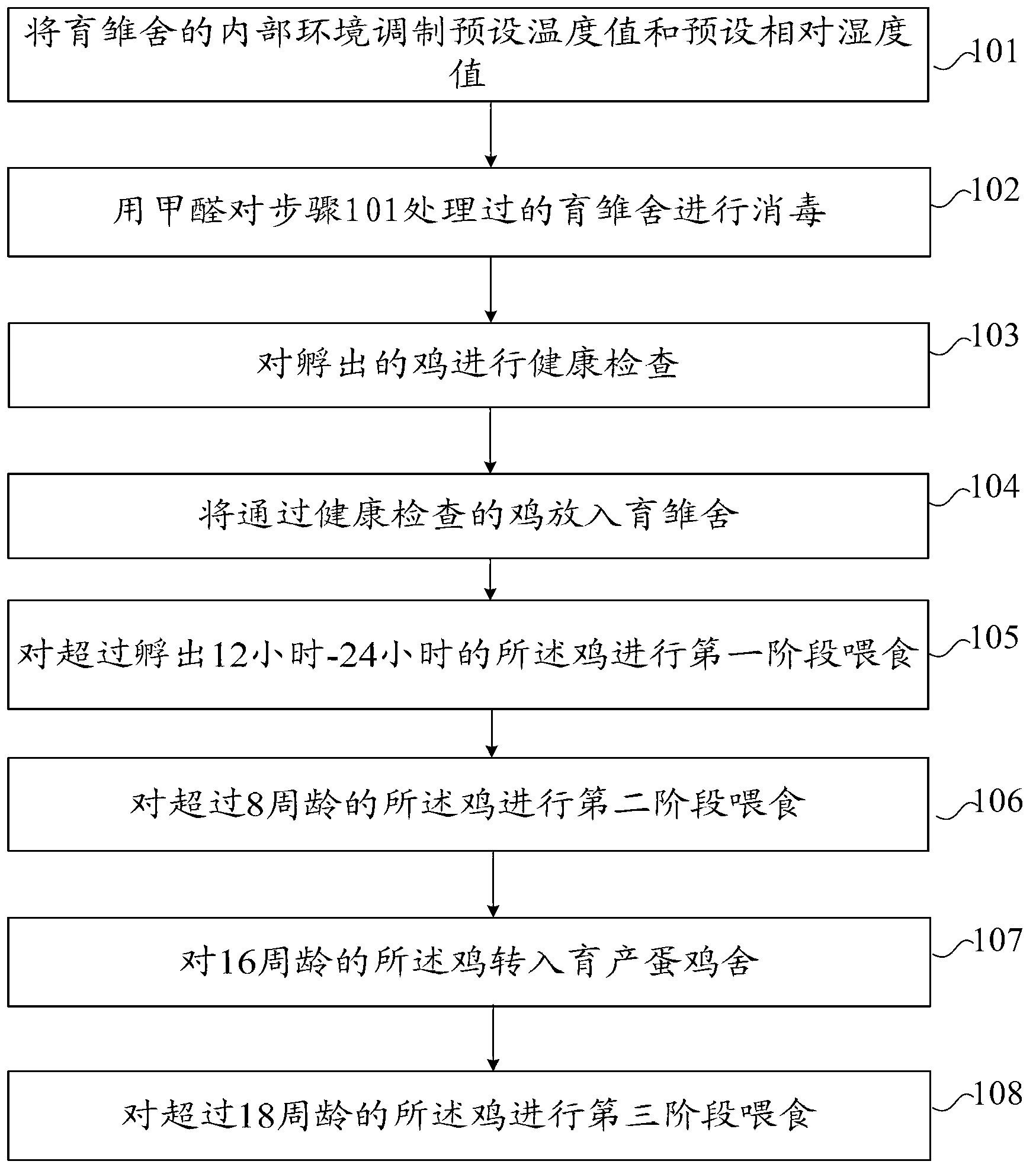

Method for cultivating chickens

InactiveCN103262825AFull of nutritionRich in nutritional valueAnimal husbandryNutritive valuesAnimal science

The invention relates to the field of cultivation, in particular to a method for cultivating chickens. The method for cultivating chickens comprises the steps of placing hatched chickens into a brooding house with the preset temperature value and the preset relative humidity value, carrying a first stage of feeding on chickens hatched for 12 hours to 24 hours, carrying out a second stage of feeding on chickens older than 8 weeks, placing chickens of 16 weeks old into a laying hen cultivating house and carrying out a third stage of feeding on chickens older than 18 weeks. The first stage of feeding comprises the step of feeding milk with the first set condensation which is 8% to 12% by mass percentage condensation, the second stage of feeding comprises the step of feeding milk with the second set condensation which is 25% to 60% by mass percentage condensation, and the third stage of feeding comprises the step of feeding milk with the third set condensation which is 70% to 90% by mass percentage condensation. The method can balance nutritive value in eggs and chickens and enables nutrition to be rich.

Owner:金德刚

Method for preparing rice-juice soybean milk

InactiveCN102715244AGreat tasteImprove nutritional efficacyMilk substitutesFood scienceSoya beanRaw material

A method for preparing rice-juice soybean milk. The raw materials of the rice-juice soybean milk comprise 90 to 92 % of water, 7.5 to 8.5 % of soybeans and 1.5 to 2.5 % of rice. The method for preparing the rice-juice soybean milk comprises heating the soybean milk to 98 DEG C to 100 DEG C, heating the rice-juice to 98 DEG C to 100 DEG C, mixing the soybean milk and the rice-juice to get a mixture, homogenizing the mixture under the pressure of 10 MPa to 15 MPa to get a homogeneous liquid, and disinfecting and then cooling and setting the homogeneous liquid to form the rice-juice soybean milk. The rice-juice soybean milk perfectly combines the efficacy of the soybean milk and the rice-juice, and effectively improves taste and nutrition efficacy of the soybean milk.

Owner:SUZHOU JINJI FOODS

Compound enzymatic hydrolysate for pet food and preparation process thereof

PendingCN113349308AFully absorbedEase the burden on digestionAnimal feeding stuffAccessory food factorsHydrolysateNutrition

The invention belongs to the technical field of enzymatic decomposition, and particularly relates to a compound enzymatic hydrolysate for pet food and a preparation process thereof. The compound enzymatic hydrolysate is obtained by adding biological enzymes into protein, starch and fat raw materials and combining with ultrasonic reaction for comprehensive enzymatic hydrolysis, wherein the comprehensive enzymatic hydrolysis comprises first-stage enzymatic hydrolysis and second-stage enzymatic hydrolysis; the first-stage enzymatic hydrolysis is to add an enzyme preparation into the raw materials, adjust the pH value, and heat for enzymatic hydrolysis reaction; the second-stage enzymatic hydrolysis is to perform ultrasonic reaction on the enzymatic hydrolysate of the first-stage enzymatic hydrolysis, then add the enzyme preparation, and heat for enzymatic hydrolysis reaction; after the reaction is finished, enzyme deactivation is performed, and impurities are screened out to obtain the enzymatic hydrolysate; and small molecular nutrient substances mainly containing rich active peptides, amino acids, fatty acids, glycerol, glucose and maltose are prepared, and the small molecules help the body to fully absorb the substances, and are used for pet food, help the body to fully absorb the substances, reduce the intestinal digestion burden and improve the nutrient digestibility.

Owner:GUANGZHOU QINGKE BIOTECHNOLOGY CO LTD

Trachinotus ovatus overwintering feed, preparation and of overwintering feed and breeding method of trachinotus ovatus

PendingCN112293615ABalanced nutritional valueEasy feedingClimate change adaptationPisciculture and aquariaBiotechnologyCellulose

The invention provides a trachinotus ovatus overwintering feed, a preparation and of the overwintering feed and a breeding method of the trachinotus ovatus. The overwintering feed comprises the components in parts by weight of 16-20 parts of fish meal, 30-40 parts of compound fermented protein powder, 6-12 parts of corn protein powder, 3-8 parts of shrimp base powder, 4-6 parts of corn oil, 2-4 parts of soybean phospholipid, 2-5 parts of carboxymethyl cellulose, 0.5-1 part of sodium dihydrogen phosphate, 0.2-0.5 part of choline chloride, 0.5-1 part of betaine, 1-2 parts of wild jujube powder,0.05-0.2 part of wormkalk extract, 0.05 to 0.15 part of curcumin, 0.5 to 0.8 part of compound vitamin premix, 0.3 to 0.6 part of compound mineral substance and 0.2 to 0.8 part of compound enzyme preparation. The overwintering feed is more suitable for autumn and winter culture of trachinotus ovatus, and the overwintering capacity of the trachinotus ovatus can be enhanced by combining a reasonableand effective culture method, so that the growth quality and the survival rate of the trachinotus ovatus cultured in winter are remarkably improved.

Owner:广东大麟洋海洋生物有限公司

Instant cranberry cookie biscuit with compound nuts, and making method thereof

PendingCN111084209AGreat tasteBalanced nutritional valueDough treatmentModified nutritive productsBiotechnologyIcing sugar

The invention discloses an instant cranberry cookie biscuit with compound nuts, and a making method thereof, and belongs to the technical field of food processing. The biscuit prepared by the invention comprises butter, powdered sugar, dried cranberry, egg, low-gluten flour, cashew kernel, walnut kernel, almond and raisin. The biscuit is made by the following steps: first crushing dried cranberry,cashew kernel, walnut kernel, almond and raisin, then sprinkling the powdered sugar on the softened butter and then adding egg liquid and performing stirring, then adding the crushed nuts and performing refrigeration, and finally performing baking to obtain the final product. The various nuts added in the biscuit not only can improve a taste of the cookie biscuit, but also have balanced nutritional value, and at the same time can also provide various trace elements necessary for the human body, so that the human body function is more balanced, the health care effect is good, and thereby the biscuit has broad market prospects.

Owner:DALIAN NATIONALITIES UNIVERSITY

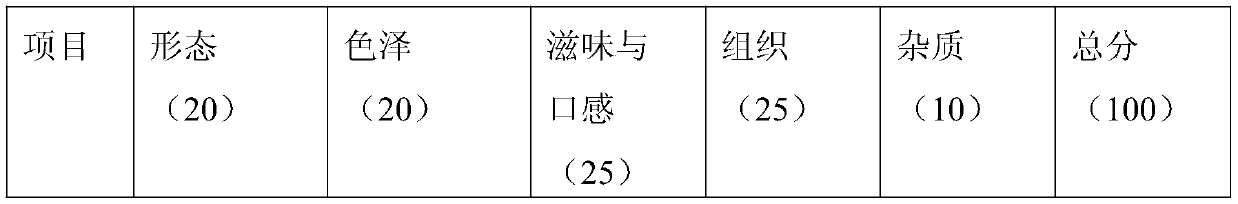

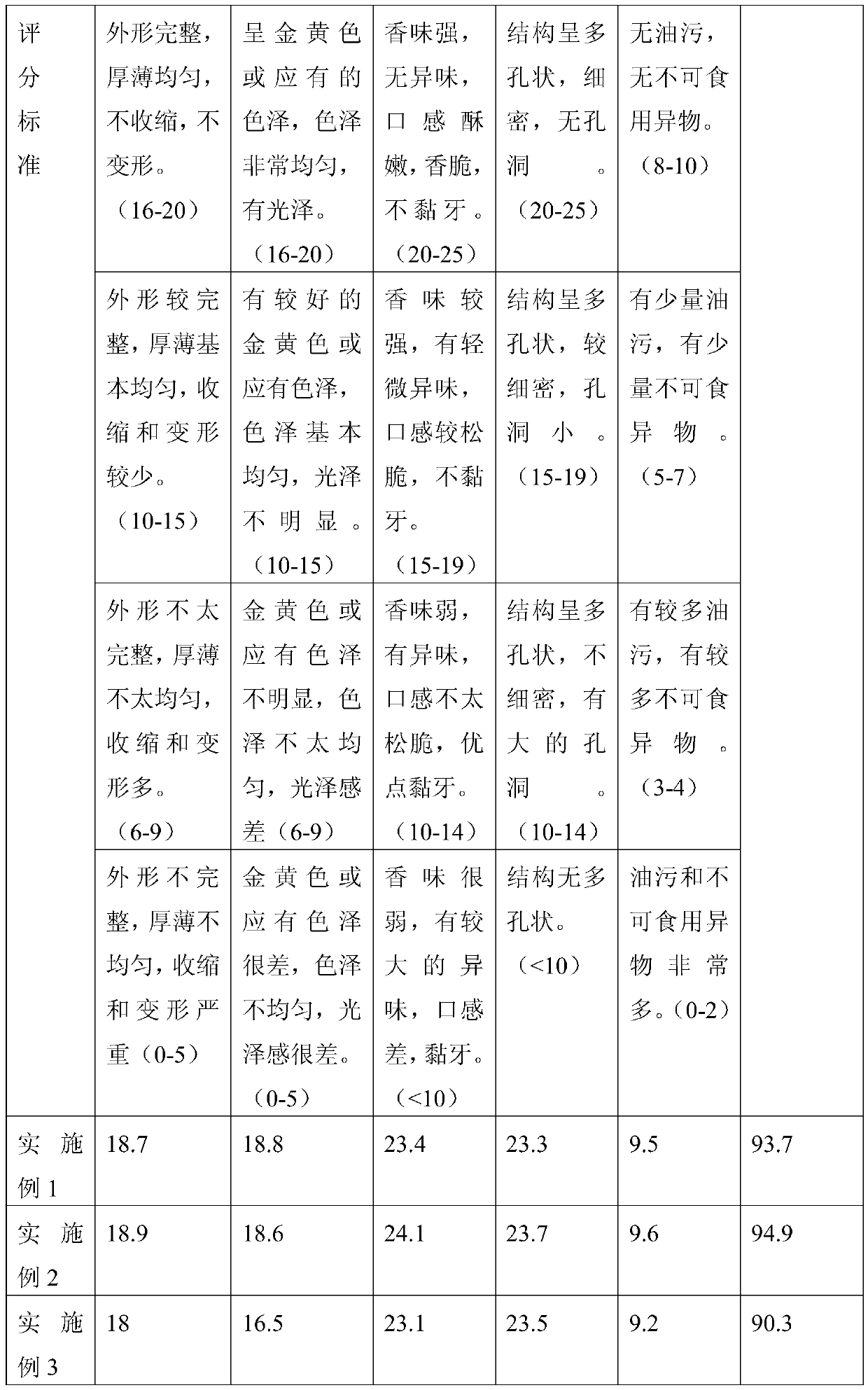

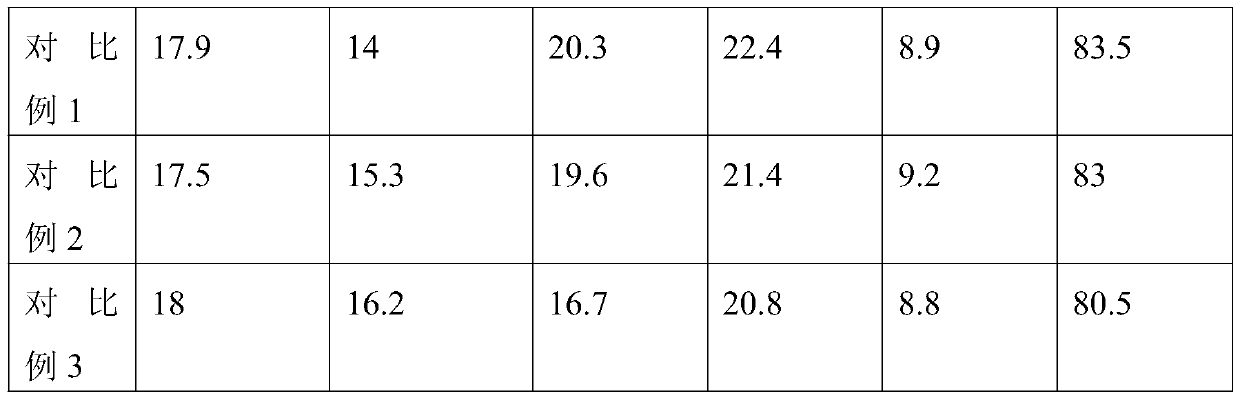

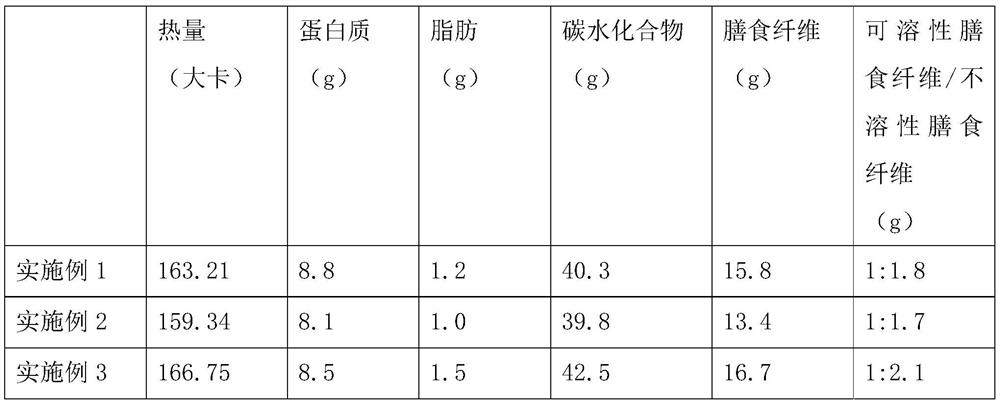

Buckwheat rice cake and preparation method thereof

The invention discloses a buckwheat rice cake and a preparation method thereof. The buckwheat rice cake comprises the following raw materials in parts by weight: 30-50 parts of polished round-grained rice, 50-70 parts of glutinous rice, 5-10 parts of buckwheat, 5-15 parts of oat, 4-8 parts of chia seeds and 8-12 parts of white granulated sugar. The preparation method comprises the following steps of: S1, grinding the buckwheat into powder; S2, squeezing oil from the chia seeds; S3, adding yeast powder into chia seed residues for fermentation; S4, soaking the polished round-grained rice, the glutinous rice and the oat; S5, dissolving the white granulated sugar; and S6, uniformly mixing the whole buckwheat powder, the chia seed powder, the polished round-grained rice, the glutinous rice and the oat, then adding cellulase for enzymolysis, then adding chia seed oil and sugar water for uniform mixing, and putting the mixture into an extrusion curing machine for extrusion curing to obtain the buckwheat rice cake. The product disclosed by the invention contains rich nutrient substances and has double effects of nutrition and health care.

Owner:CHENGDU UNIV

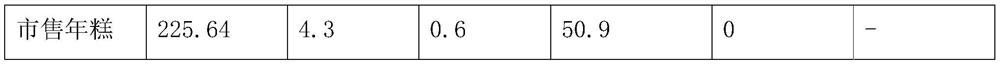

Instant artificial rice and processing method thereof

InactiveCN107048342AImprove eating effectIncrease the degree of staple foodFood scienceLevel ivBanana powder

The invention discloses a method for processing instant artificial rice. The method comprises the following steps of: step 1, obtaining raw materials, wherein a first group of raw materials comprises 30-60 parts of potato whole powder, a second group of raw materials comprises 3-6 parts of rice flour, 10-20 parts of corn flour and 15-25 parts of soybean flour, a third group of raw materials comprises 5-10 parts of chestnut powder, 15-20 parts of Chinese yam flour and 20-30 parts of banana powder, and a fourth group of raw materials comprises 3-5 parts of edible oil, 5-10 parts of potato starch and 80-100 parts of water; step 2, blending the fourth group of raw materials evenly, adding the mixture into the third group of raw materials, and blending the mixture evenly; step 3, blending the first group of raw materials and the second group of raw materials evenly, mixing the mixture evenly with material obtained in step 2, extruding the mixture to obtain primary product of rice-like artificial rice, wherein a single screw extruder is adopted for performing extrusion forming, a first-stage barrel temperature of the single screw is 50-70 DEG C, a second-stage barrel temperature is 60-80 DEG C, a third-stage barrel temperature is 70-100 DEG C, a fourth-stage barrel temperature is 90-120 DEG C, and a fifth-stage barrel temperature is 80-95 DEG C; and step 4, performing puffing-drying to obtain the instant artificial rice.

Owner:钟静涛

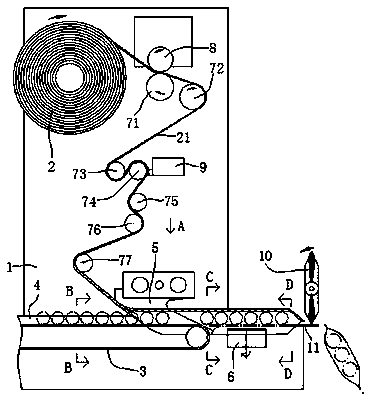

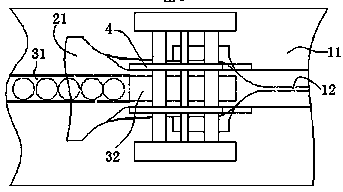

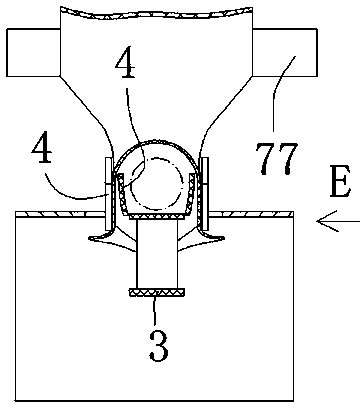

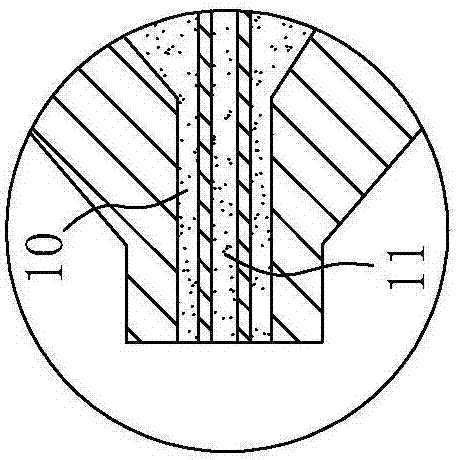

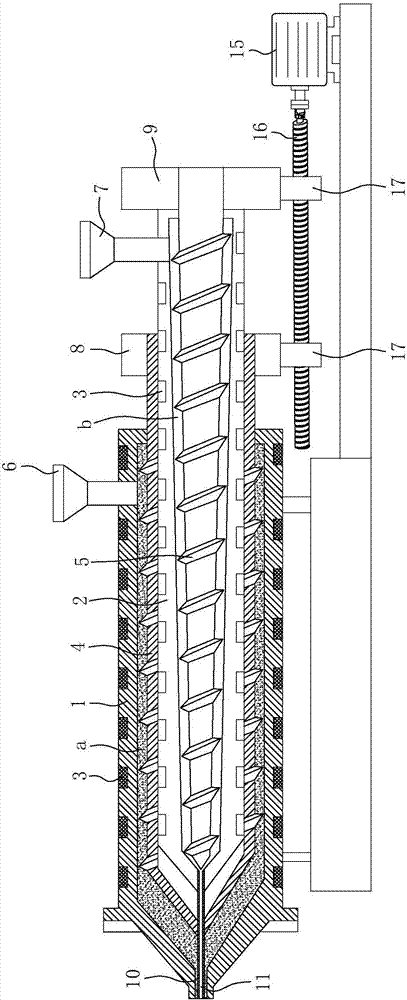

Twin-screw extrusion production equipment for stuffing-containing noodles

InactiveCN107114433ABalanced nutritional valueRich tasteDough extruding machinesDough processingReciprocating motionEngineering

The invention discloses a kind of production equipment for filling noodles with twin-screw extrusion, which includes a barrel and a screw, the barrel includes an outer barrel and an inner barrel, the inner barrel is inserted into the outer barrel, and the screw is divided into large Screw and small screw, the large screw is a hollow rod body, the large screw is inserted between the outer barrel and the inner barrel, the small screw is inserted into the inner barrel, and the flour supply to the large screw is provided on the outer barrel Funnel, the tail of the large screw protrudes from the outer barrel, the tail of the inner barrel protrudes from the large screw, the tail of the small screw protrudes from the inner barrel, and the inner barrel is provided with a filling feeding funnel, the tail of the large screw and the small screw There are rotators respectively, and the big screw and the small screw can make synchronous reciprocating motion. The discharge port is divided into an outer discharge port and an inner discharge port. The inner discharge port is placed in the outer discharge port, the outer discharge port is connected with the space formed by the outer material barrel and the large screw, and the inner discharge port is connected with the inner cavity of the inner material barrel. .

Owner:何浩然 +1

Strawberry-flavor fruit tea and preparation method thereof

The invention discloses a strawberry-flavor fruit tea and a preparation method thereof, belonging to the technical field of drink processing, and aiming at overcoming the defects that the strawberry-flavor fruit tea is complicated in processing procedures, single in nutrition and unbalanced in structure. The strawberry-flavor fruit tea comprises the following components: 42% of strawberry pulp, 7% of white granulated sugar, 2% of whole milk powder, 0.1% of citric acid and 48.9% of drinking water. The preparation method concretely comprises the following eleven steps: selecting the raw materials and carrying out primary washing, removing leaves and bases of strawberries, washing again, pulping and removing seeds, carrying out enzyme deactivation treatment, blending, homogenizing, carrying out vacuum degassing, filling, sealing and sterilizing. The strawberry-flavor fruit tea and the preparation method have the beneficial effects that the working procedures are simple, and the nutritive value is balanced; the strawberry-flavor fruit tea is moderate in sourness and sweetness, has obvious strawberry fragrance and has light pink color; the fruit tea has the soluble solid content of 14-16% and the total acid content of 0.40-0.45%; the heavy metal content of the fruit tea is in accordance with the drink standard specified in China; the total bacterial count per milliliter is less than 50, and number of coliform bacteria per 100 milliliter is less than 2; the strawberry-flavor fruit tea does not contain pathogenic bacteria.

Owner:黄振忠

Mixed rice and processing method thereof

InactiveCN107095159AImprove eating effectIncrease the degree of staple foodLipidic food ingredientsFood ingredient functionsBanana powderPotato starch

The invention discloses a processing method of mixed rice. The processing method comprises the following steps: step I, collecting raw materials, wherein a first group of raw materials comprises potato powder, peanut powder, walnut powder, red beans powder and coix seed powder, a second group of raw materials comprises rice powder, corn powder and soybean powder, a third group of raw materials comprises Chinese chestnut powder, Chinese yam powder and banana powder, and a fourth group of raw materials comprises edible oil, potato starch and water; step II, uniformly mixing the fourth group of raw materials, adding into the third group of raw materials, and uniformly mixing; step III, uniformly mixing the first group and the second group of raw materials, uniformly mixing substances obtained in the step II, extruding to obtain a rice-shaped mixed-rice primary product, extruding and molding by adopting a single-screw extruder, wherein the temperature of a primary cylinder of the single-screw extruder is 50 to 70 DEG C, the temperature of a secondary cylinder is 60 to 80 DEG C, the temperature of a tertiary cylinder is 70 to 100 DEG C, the temperature of a quaternary cylinder is 90 to 120 DEG C, and the temperature of a quintuple cylinder is 80 to 95 DEG C; and step IV, drying to obtain mixed rice.

Owner:钟静涛

Making method for hollow crisp food production

InactiveCN109874846AIngredient Component ScienceGreat tasteDough treatmentDeep-fried productsAdditive ingredientRaw material

The invention discloses a making method for hollow crisp food production. A hollow crisp food is made from, by weight, the following ingredients: 100-150 parts of flour, 0.1-0.15 part of salt, 50-70 parts of additional materials, 0.5-1 part of an additive and 100-150 parts of water. Specifically, the making method comprises the processing steps that raw materials are obtained by weight of the ingredients, salt and an additive are dissolved in water, flour and additional materials are mixed, finally the mixed flour and water are mixed to obtain dough, the dough is processed to obtain a plurality of unfinished hollow crisp bodies, and the unfinished hollow crisp bodies are fried to obtain a finished hollow crisp food. The hollow crisp food made by the hollow crisp food making method has theadvantages of containing scientific ingredients and having excellent taste and balanced nutritional value; and the flour is processed through multiple processes, so that the taste of the formed doughis guaranteed, and the taste of the finished product is guaranteed.

Owner:ANHUI PANPAN FOOD CO LTD

Technology for producing compound protein concentrates

ActiveCN101558815BEasy to operateEnsure hygieneProtein composition from vegetable seedsFood preparationPollutionProtein formation

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Liquid dairy product containing red jujube particles and production method thereof

ActiveCN101595921BMeeting nutritional needsIncrease varietyMilk preparationFood preparationNutritive valuesVitamin

The invention provides a liquid dairy product containing red jujube particles and a production method thereof. The total weight of a liquid dairy product is used as a reference, and raw materials comprise 1-10 percent of red jujube particles. The product adds product variety of the liquid dairy product, and the addition of the red jujube particles realizes the combination of vitamins, minerals and special activated contents in red jujubes with milk protein so that the nutritive value of the product is more reasonable and balanced. Moreover, the invention can realize the favorable stability ofthe product during the shelf life by the reasonable prescription and the suitable technology.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

A kind of preparation method of fruit and vegetable vinegar drink containing peony extract

InactiveCN103960719BIncrease the juice yieldAdd flavorMicroorganismsMicroorganism based processesKluyveromyces fragilisCitron melon

The invention provides a preparation method for a fruit-vegetable vinegar beverage containing peony extracts and relates to the field of preparation methods for fruit-vegetable vinegar beverages. The preparation method comprises the following steps: freshwatermelons, grapefruits, and pumpkins are subjected to pretreatment and juicing, so that mixed fruit-vegetable juice of the watermelons, the grapefruits, and the pumpkins is obtained; high-temperature instantaneous sterilization is performed on the mixed fruit-vegetable juice, cooling is performed, and then alcoholic fermentation is performed on the mixed fruit-vegetable juice by kluyveromyces fragilis at the temperature of 25-30 DEG C for 5-7 days; acetic acid bacteria are inoculated; acetic fermentation is performed at the temperature of 28-32 DEG C until the acetic acid content is 10-15%; the fermentation liquor, after acetic fermentation, is mixed with the mixed extracting solution of peony and rose, which is prepared in advance, and the pH value of the mixed fermentation liquor is adjusted to be 3.5-4.0; stevioside and beta-cyclodextrin are added for blending; homogenizing, filtering, sterilization and filling are performed, so that the finished product is obtained. The fruit-vegetable vinegar beverage prepared withthe preparation method provided by the invention is balanced in nutrition, has a certain health protection function, and is soft and delicious in taste, and weak in irritation.

Owner:LUOYANG CHUNKUI AGRI DEV

Cereal drink and preparation method thereof

The invention provides a cereal beverage and a preparation method thereof. The preparation method of the cereal beverage comprises: adding medium temperature amylase, glucoamylase, neutral protease and peptidase into one or more kinds of cereal pulp original solutions to perform enzymatic hydrolysis reaction, and obtaining one or more kinds of cereal pulps subjected to enzymatic hydrolysis after the reaction is finished; when one cereal pulp original solution is subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the cereal pulp subjected to enzymatic hydrolysis, so as to obtain the cereal beverage; and when multiple kinds of cereal pulp original solutions are subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the multiple kinds of cereal pulps subjected to enzymatic hydrolysis, so as to obtain the cereal beverage. The invention also provides the cereal beverage which is prepared by employing the above preparation method. The cereal beverage provided by the invention is capable of completely keeping nutritional components of the cereal raw materials, is relatively beneficial for digestion and absorption of human, and has the characteristics of being smooth in mouthfeel and refreshing in flavor.

Owner:INNER MONGOLIA DAIRY TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com