Twin-screw extrusion production equipment for stuffing-containing noodles

A technology of twin-screw extrusion and production equipment, which is applied in the direction of dough processing, dough extruder, baking, etc., can solve the problems of increasing labor intensity in the cooking process, noodle product variety and single nutritional value, etc., to save cooking procedures, The effect of enriching taste and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technology will be further described below in conjunction with the accompanying drawings.

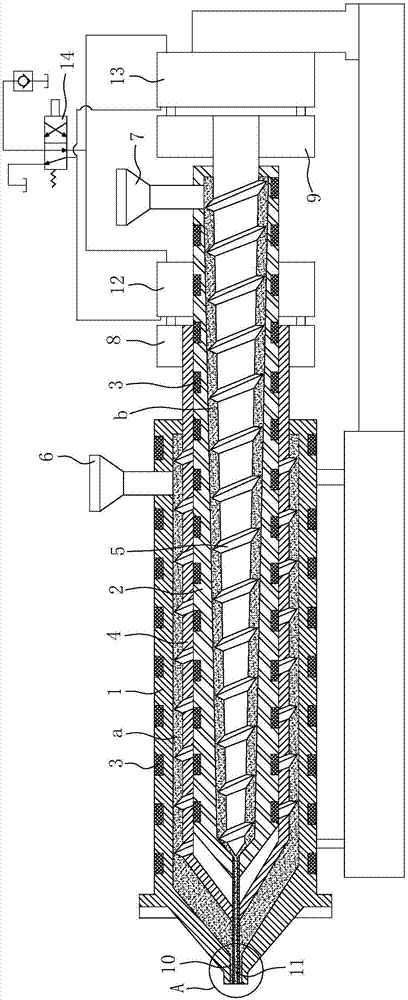

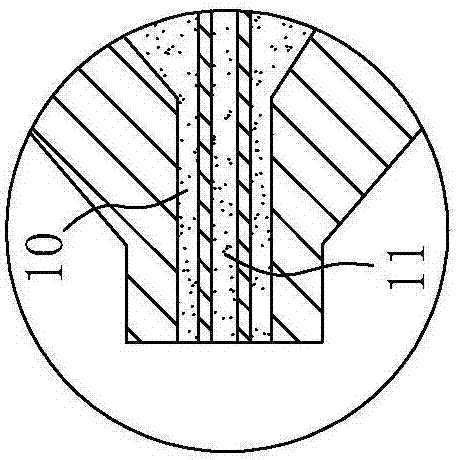

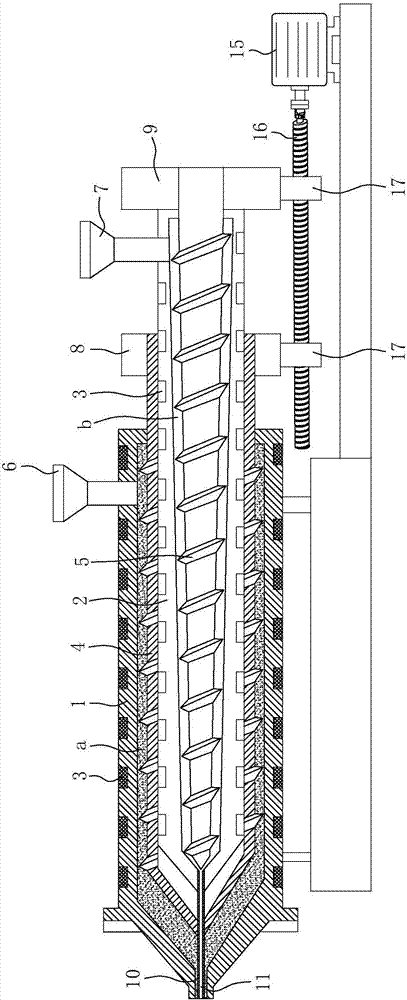

[0017] The noodle production equipment with fillings contained in the twin-screw extrusion of this embodiment includes a barrel and a screw. The barrel includes an outer barrel 1 and an inner barrel 2. Both barrels are fixed, and the barrel inside Both are embedded with heating wire 3, the inner barrel 2 is inserted into the outer barrel 1, the screw is divided into a large screw 4 and a small screw 5, the large screw 4 is a hollow rod body, the large screw 4 is inserted into the outer barrel 1, and the inner The barrel 2 is inserted into the large screw 4, the small screw 5 is inserted into the inner barrel 2, and the outer barrel 1 is provided with a flour feeding funnel 6 that feeds the large screw 4, and the tail of the large screw extends from the outer barrel 1. Out, the tail of the inner material cylinder protrudes from the large screw 4, the tail of the small screw pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com