Patents

Literature

38results about How to "Increase product variety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salty milky tea and process for preparation thereof

ActiveCN101692852AIncrease product varietyReduce ingredient lossMilk preparationInstant teaSalty taste

The invention relates to the field of liquid milk, in particular to salty milky tea and a process for preparation thereof. The salty milky tea based on 1000 parts by weight comprises 800-936.4 parts by weight of milk, 7-10 parts by weight of tea extract or 0.8-4 parts by weight of instant tea powder, 1.26-3.3 parts by weight of stabilizer, 4-7 parts by weight of waterless cream or single cream or butter, 0.4-3 parts by weight of salt and 0-193.54 parts by weight of water, wherein the stabilizer comprises thickener and emulsifier. The salty milky tea prepared by the process contains healthcare components of tea but remains natural nutrition component in milk and is a liquid drink with smooth taste and heavy aroma. By utilizing the process, the loss of components of milk and tea is decreased to the utmost extent, and distinctive characteristics of full fresh and salty taste of the milky tea are remained.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

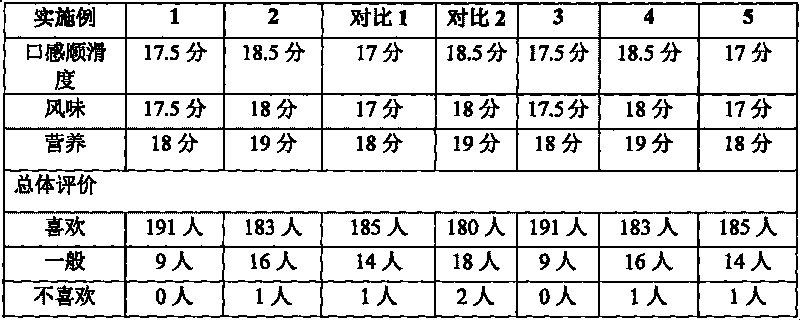

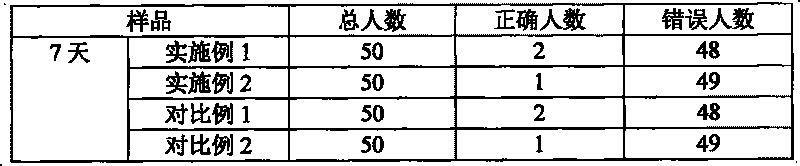

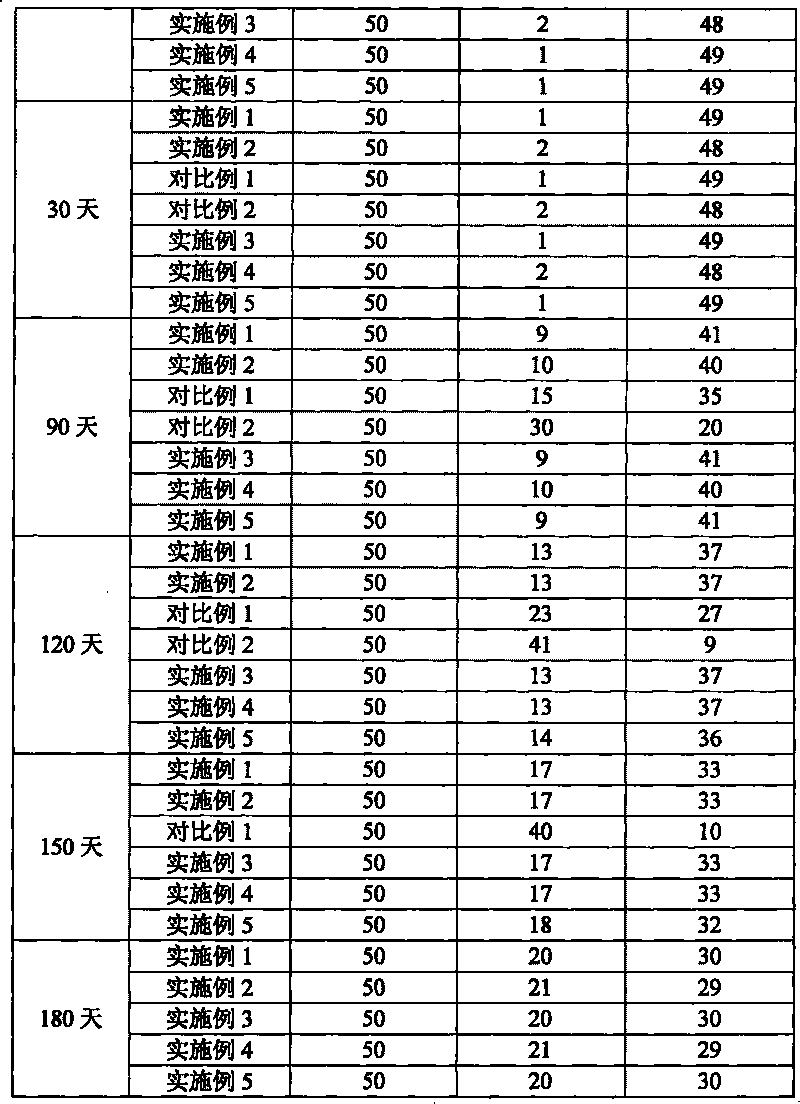

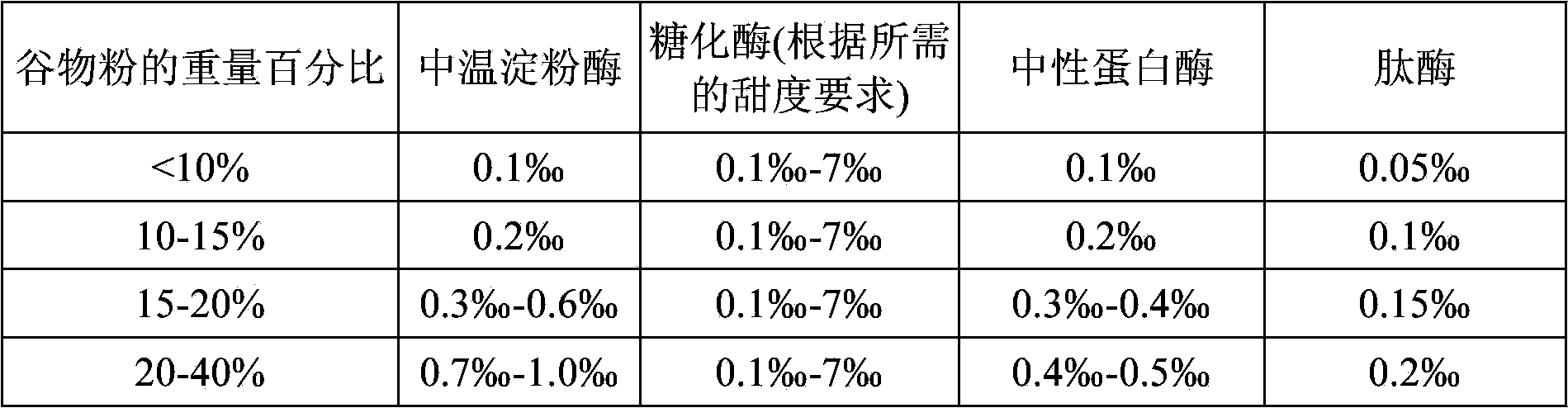

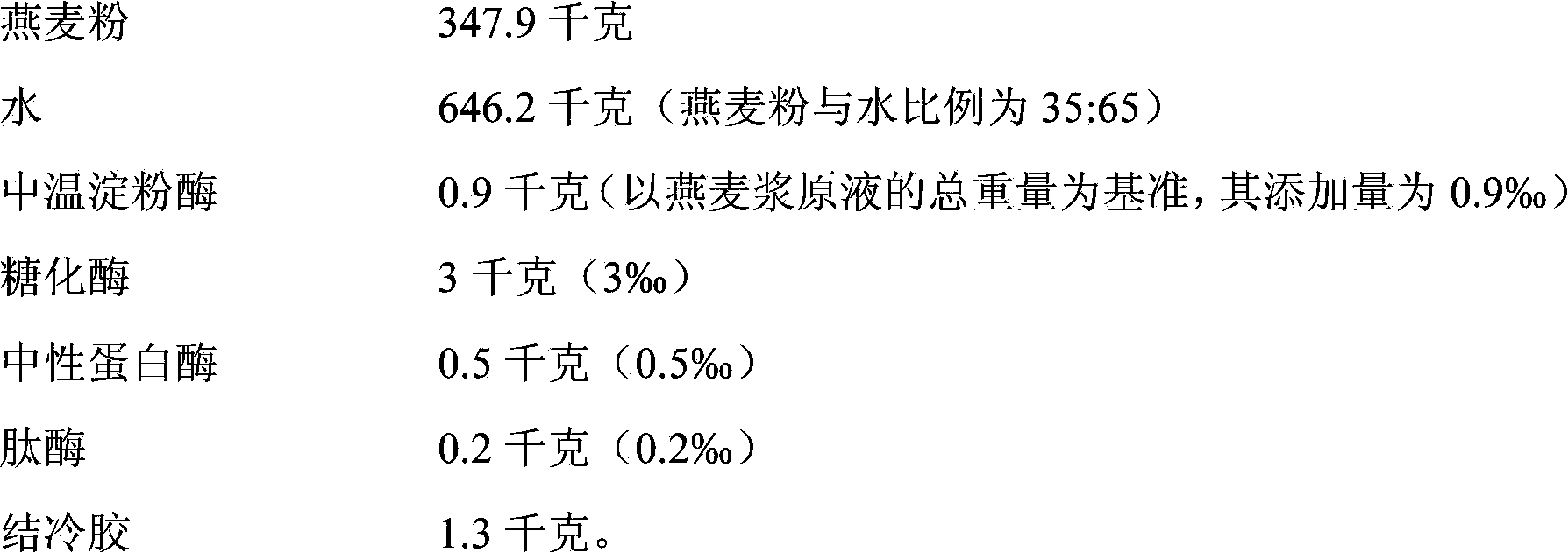

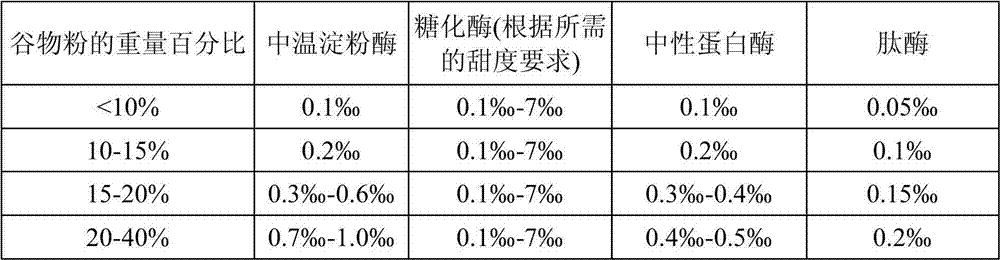

Cereal beverage and preparation method thereof

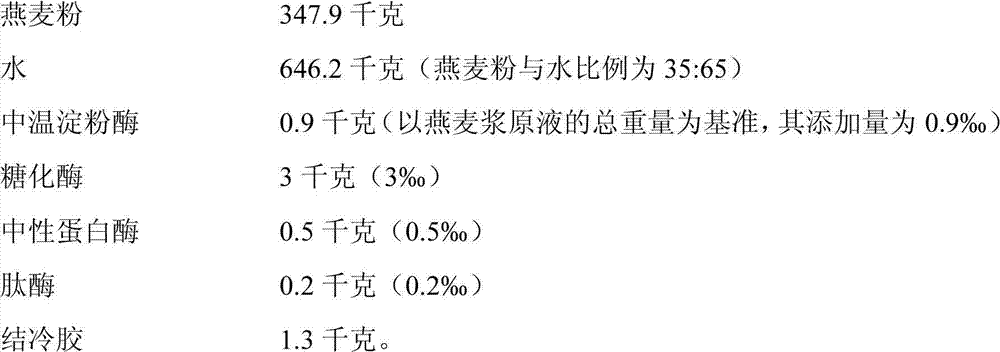

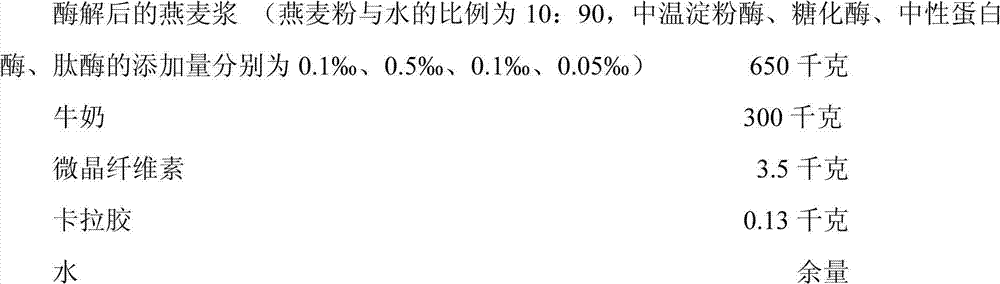

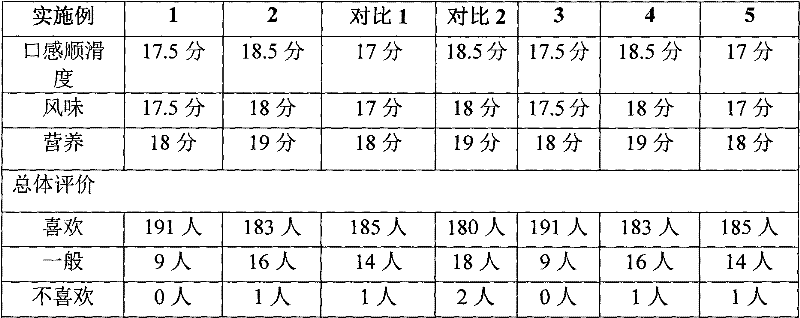

The invention provides a cereal beverage and a preparation method thereof. The preparation method of the cereal beverage comprises: adding medium temperature amylase, glucoamylase, neutral protease and peptidase into one or more kinds of cereal pulp original solutions to perform enzymatic hydrolysis reaction, and obtaining one or more kinds of cereal pulps subjected to enzymatic hydrolysis after the reaction is finished; when one cereal pulp original solution is subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the cereal pulp subjected to enzymatic hydrolysis, so as to obtain the cereal beverage; and when multiple kinds of cereal pulp original solutions are subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the multiple kinds of cereal pulps subjected to enzymatic hydrolysis, so as to obtain the cereal beverage. The invention also provides the cereal beverage which is prepared by employing the above preparation method. The cereal beverage provided by the invention is capable of completely keeping nutritional components of the cereal raw materials, is relatively beneficial for digestion and absorption of human, and has the characteristics of being smooth in mouthfeel and refreshing in flavor.

Owner:INNER MONGOLIA DAIRY TECH RES INST CO LTD

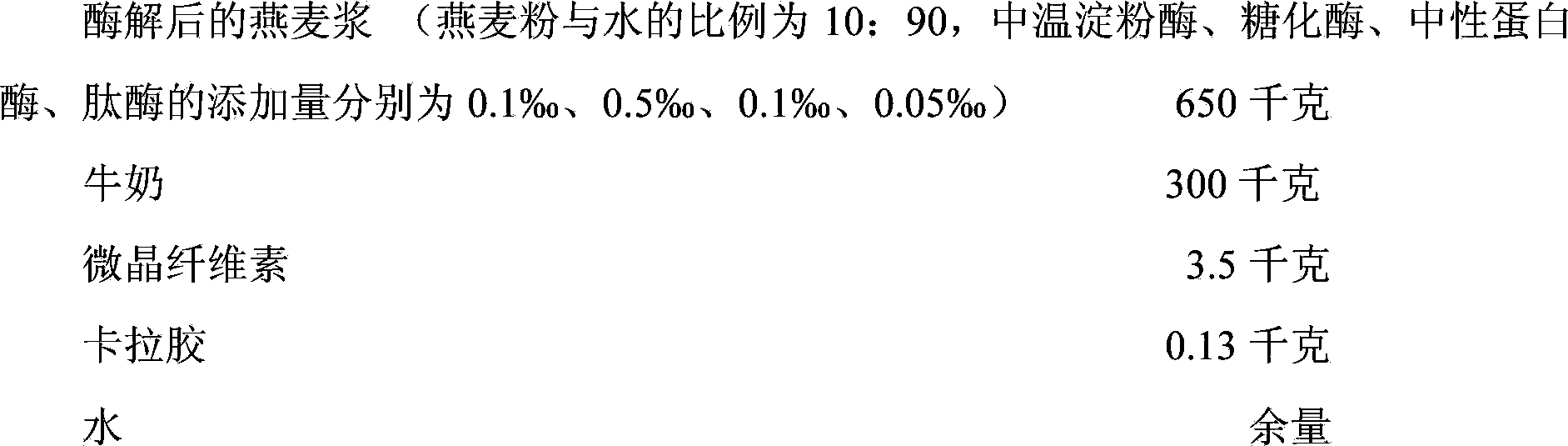

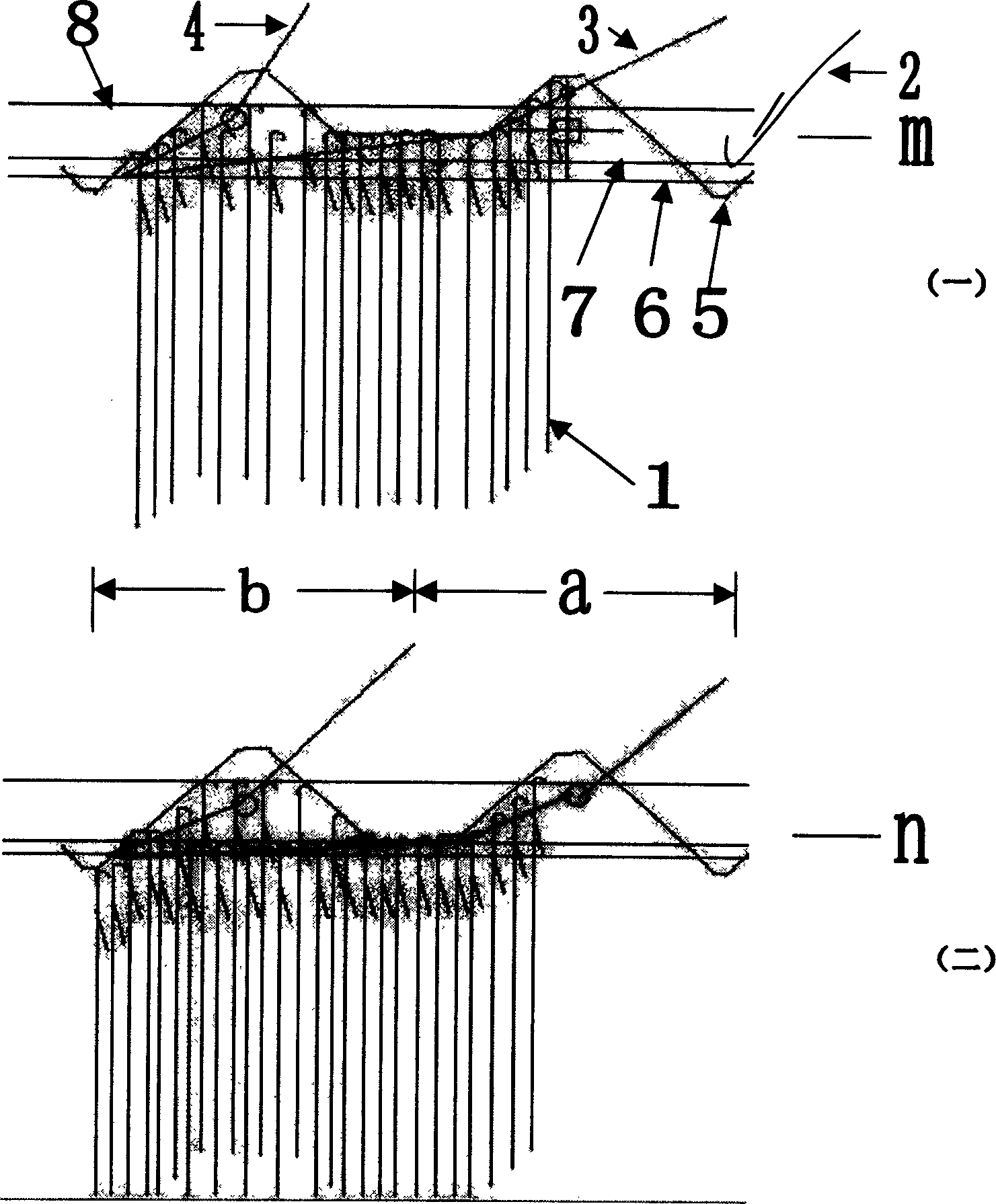

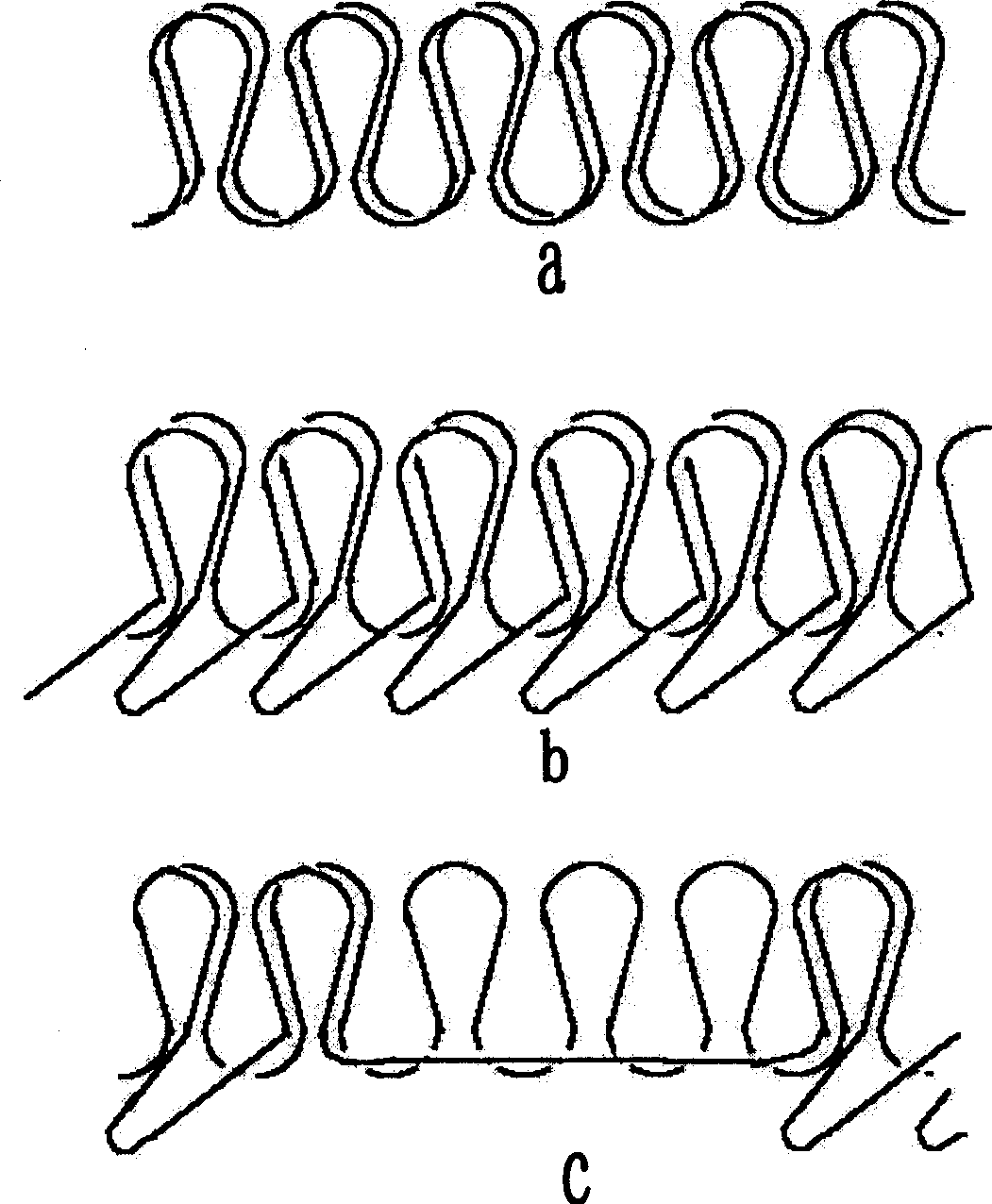

Weaving method for knitting fleece imitating effect of burnt-out print

A jacquard loop weaving method simulating burnt-out effect on a double-side knitting weft machine is to arrange every two groups of loops in a full-flat-row on the machine. In first group, all disk needles do not go out and all cylinder needles feed the ground bear yarns after quiting from loops, then the knitting needless fall down but don't unhook and all hooks of the cylinder hold the ground yarns, then in the second group, some cylinder needles are selected again to feed loop bear yarns, and all disk needles go out to hold the loop threads, the selected needles hook the ground yarns on the first group bearing and loop yarns on the second to fall down quiting and looping, at the brnt-out simulation effect spots without loops their corresponding cylinder needles are not selected and remain at the height of the first group fall down but not catch the loop yarns which are at the back of the texture in suspension.

Owner:JIANGNAN UNIV

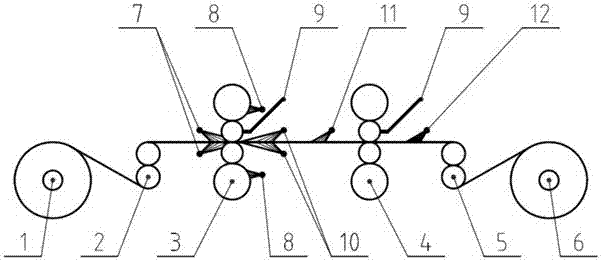

Ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and method

PendingCN107309272AImprove deformationFulfil requirementsWork cleaning devicesMetal rolling arrangementsTinningEmulsion

The invention provides ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and a method. By arranging a leveling liquid system taking a low-concentration emulsion as a medium in a two-stand leveling unit, the wet leveling elongation percentage of strip steel is raised substantially; by reasonably arranging a splashing prevention device, the splashing of leveling liquid is effectively prevented; equipped with an alkali liquor washing system and a strip steel cleaning system, the surface of the strip steel is subjected to alkali liquor washing and soft water cleaning, so that the leveling liquid remained on the surface of the strip steel is cleaned, and spots of the leveling liquid are effectively controlled; by adopting a curtain wall air knife type air knife blowing system, high-output and low-noise efficient blowing is realized; and equipped with a hot air drying system, surface cleanness and dryness of the strip steel are guaranteed. By adopting the leveling liquid system taking the low-concentration emulsion with the concentration being 0.5-1.5% as the medium, the elongation percentage and the antirust capability of the strip steel are raised and improved significantly, steel plate deformation is improved substantially and the elongation percentage can reach 5-10%, the high elongation percentage wet leveling can repair and cover a part of surface defects, and thus the plate surface quality and the product overall quality are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

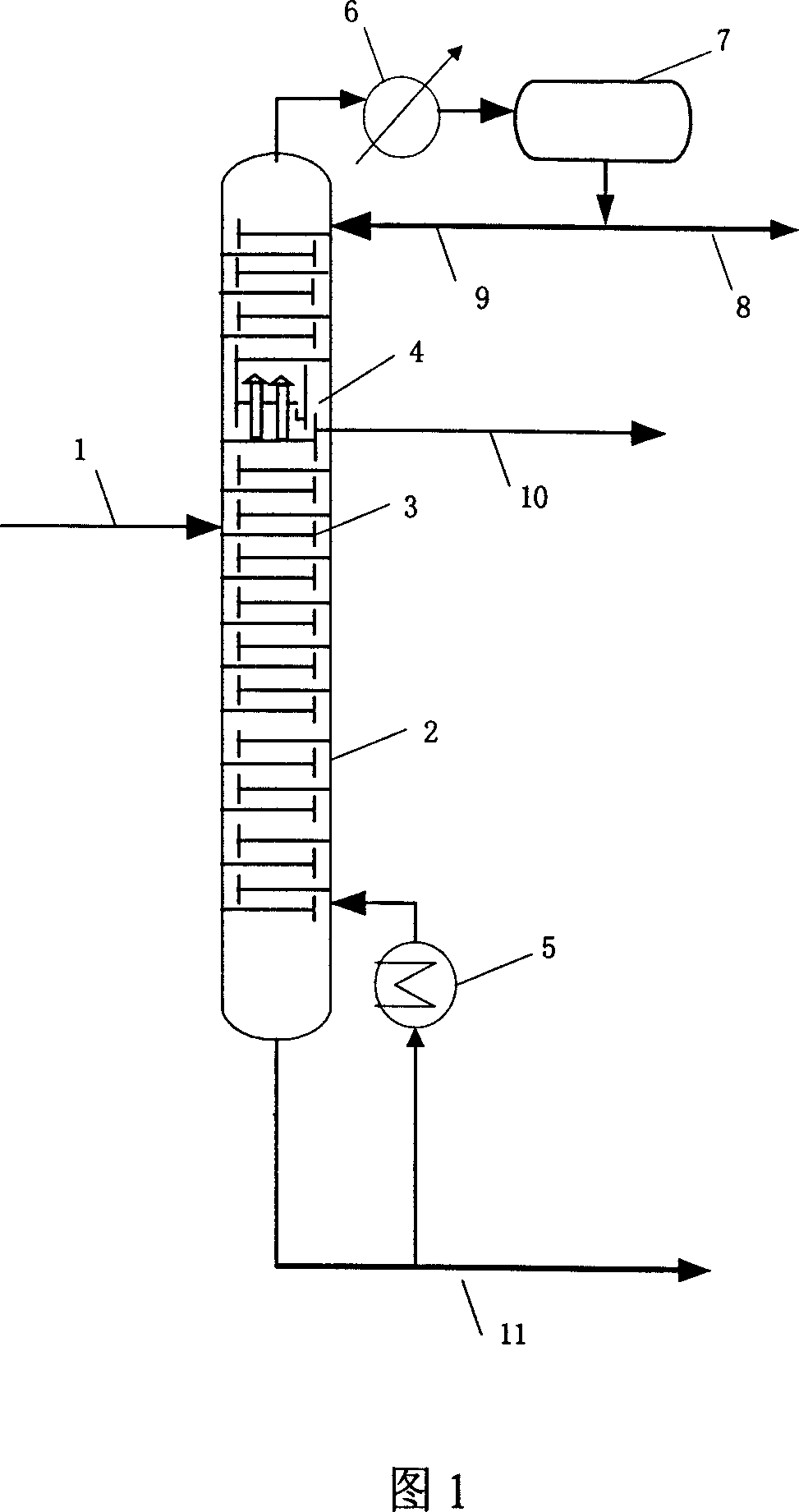

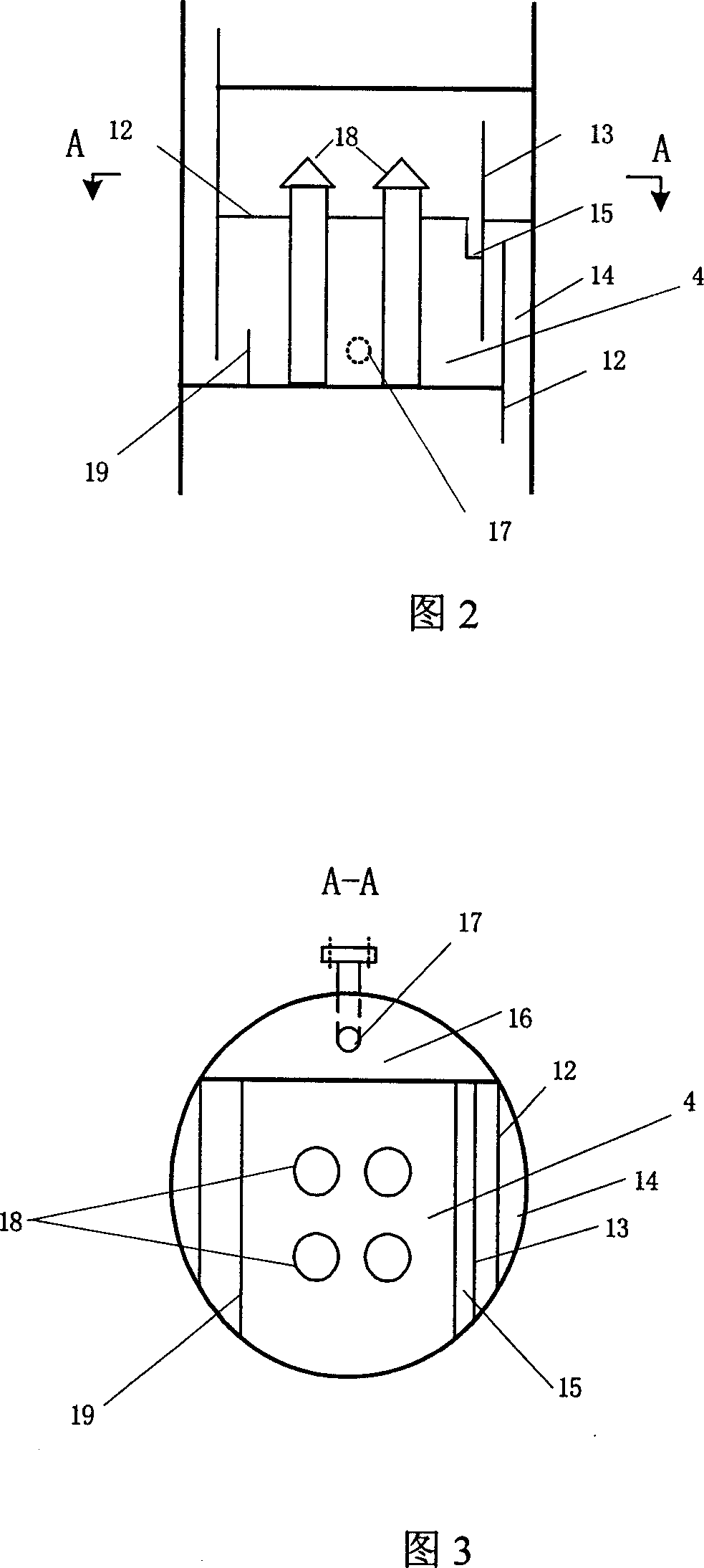

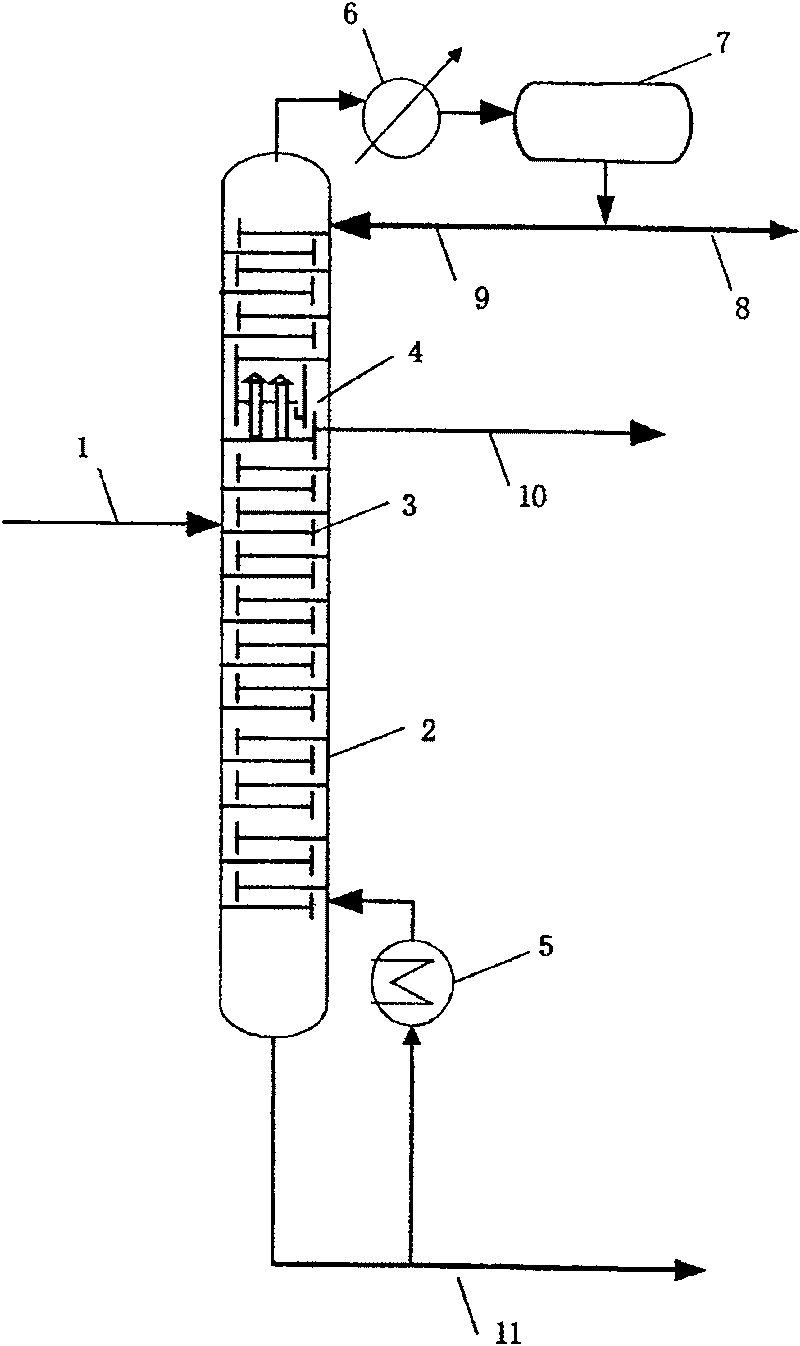

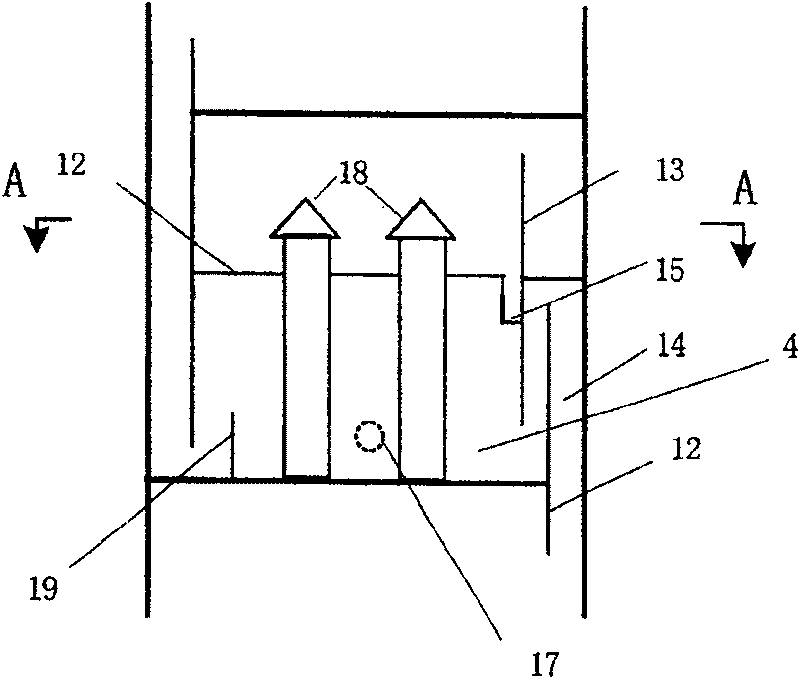

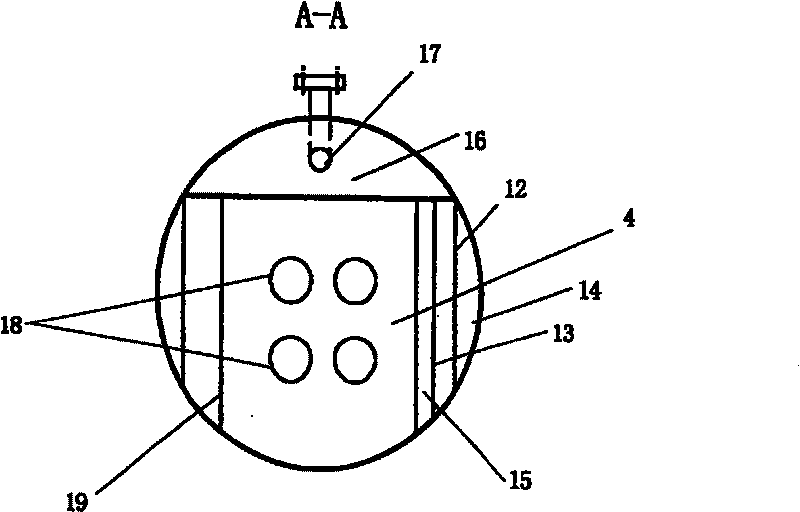

Rectifying tower forrecovering oxygen-bearing organic matter inwater for Fischer-Tropsch synthesis

ActiveCN1935305ASolve the economySolve the pollution of the environmentHydrocarbon from carbon oxidesDistillation purification/separationGas phaseOil phase

The present invention relates to a fractionating tower for recovery oxygen-containing organics from Fischer-Tropsch synthesis reaction water. It is characterized by that said fractionating tower adopts a specially-designed chimney tray, said chimney tray can ensure the effective separation of water phase and oil phase richly containing oxygen-containing organics. Said invention also provides the concrete structure of said specially-designed chimney tray, and its concrete working principle and concrete operation method.

Owner:YANKUANG ENERGY R&D CO LTD

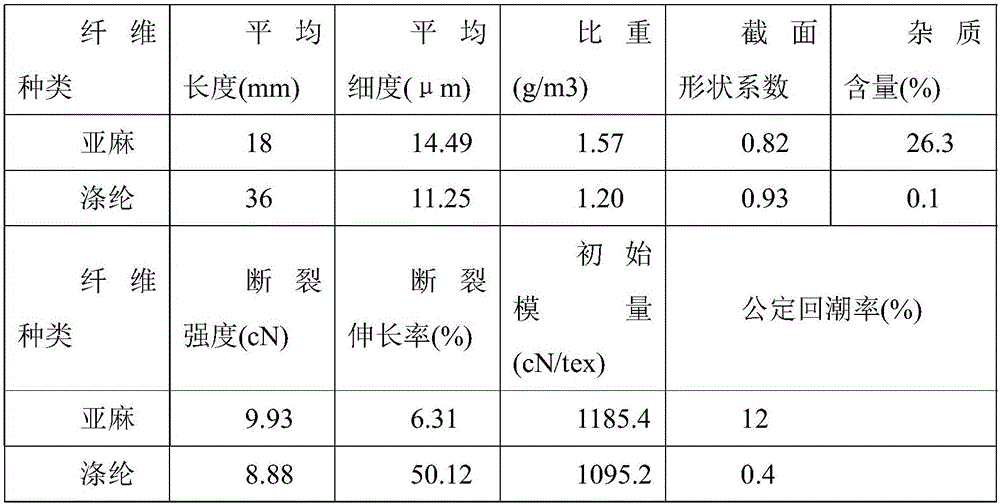

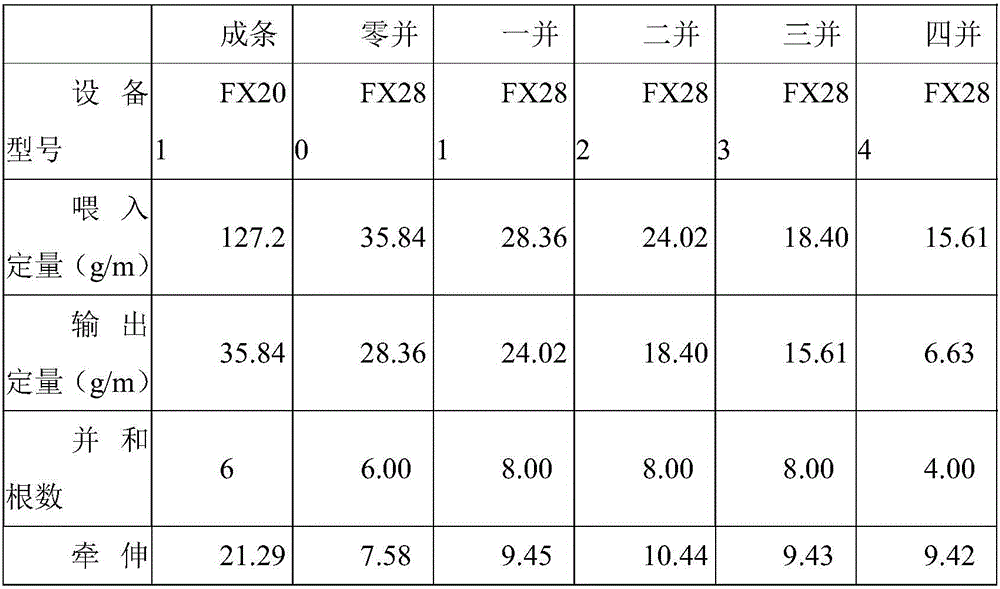

Biological enzymatic production method of breathable polyester fiber and flax fiber blended yarn

ActiveCN106087167AGood moisture absorptionImprove perspirationBiochemical treatment with enzymes/microorganismsYarnPolyesterYarn

The present invention discloses a production method of a breathable polyester fiber and flax fiber blended yarn, flax fiber is 40-80% by weight, and the balance is polyester fiber. The method comprises the steps of pretreating, cleaning, carding, drawing, roving and spinning. The production method provided herein allows for the production of the polyester fiber and flax fiber blended yarn that is hygroscopic, light and thin, glossy, breathable, antibacterial and mite-proof. The flax fiber is degummed by using a composite enzyme solution, with a degumming rate higher than and equal to 98%. In the case where enzyme usage is 15%, enzyme soaking temperature is 50 DEG C, enzyme soaking time is 1 h and stacking time is 16 h, gum residual rate of the flax fiber is only 1.83%. Fission rate of the flax fiber reaches 3.78 / dtex, with strength being 3.97 / CN per tex<-1>.

Owner:JIANGSU HUAXIN LINEN TEXTILE

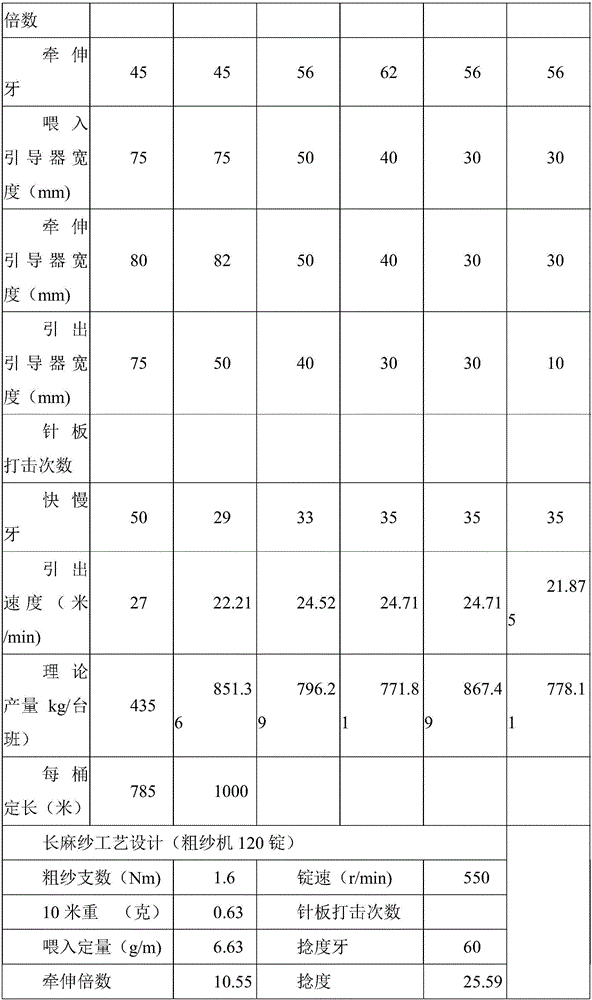

Liquid nitrogen washing device with function of producing natural gas

ActiveCN103043609AEnsure safe productionAvoid solidified iceHydrogen separation using liquid contactSyngasNitrogen

The invention discloses a liquid nitrogen washing device with a function of producing natural gas, which comprises a first feed gas cooler 1, a second feed gas cooler 2, a nitrogen washing tower 3, a purifying synthesis gas pipe and a demethanizer 3, wherein the purifying synthesis gas pipe runs through the first feed gas cooler 1 and the second feed gas cooler 2 in sequence; the demethanizer 3 is provided with an air inlet end, an air outlet end and a fraction output end; the purifying synthesis gas pipe is communicated with the air inlet end after running through the second feed gas cooler; and the air outlet end is communicated with the nitrogen washing tower 3 through a pipe. The liquid nitrogen washing device with the function of producing natural gas is capable of recycling methane generated during the process of coal gasification and manufacturing the methane into natural gas, which not only realizes the goal of obtaining clean natural gas containing about 99% of methane while producing refined ammonia synthesis gas, but also adds a new product variety and increases the business opportunity of a factory.

Owner:李红凯 +1

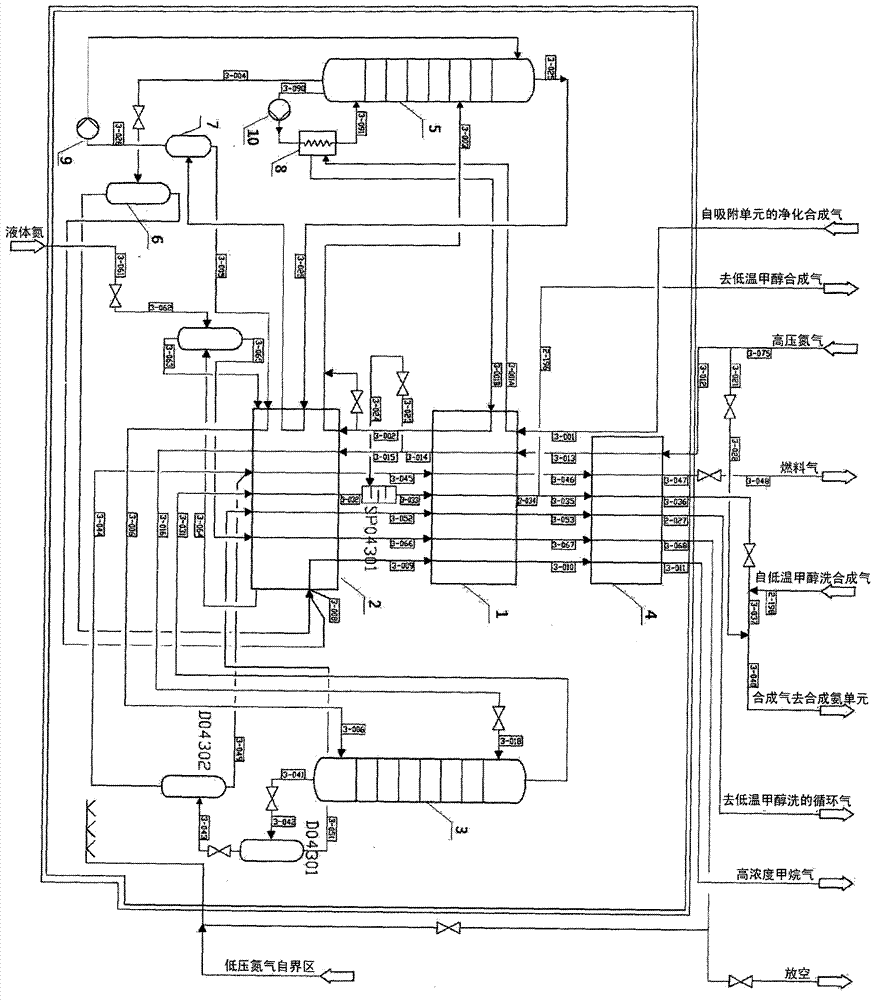

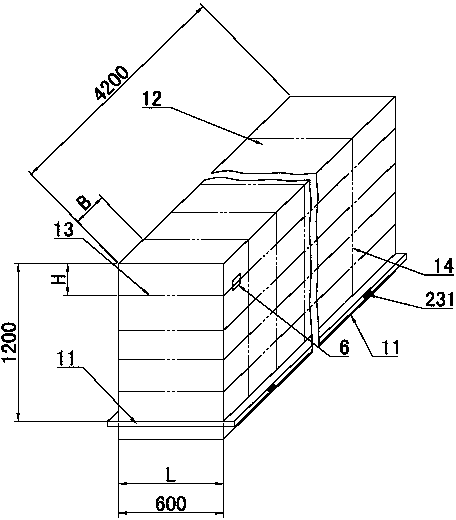

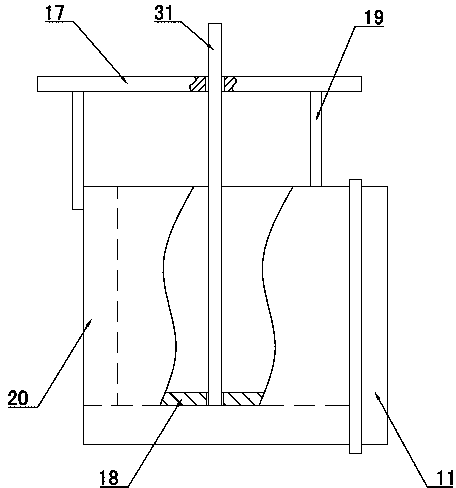

Device and method for manufacturing aerated concrete blocks with holes and grooves in core pulling mode

InactiveCN103817774AFast installationIncrease the rate of heatingMouldsMould auxillary partsFoam concreteBuilding energy

The invention relates to a device and method for manufacturing aerated concrete blocks with holes and grooves in a core pulling mode, and belongs to the field of building energy conservation. A core rod (31) is fixed inside a mould (20) through a fixing frame (30), and inserting holes or locking pairs capable of locking the core rod (31) are formed in the fixing frame (30). The method for manufacturing the aerated concrete blocks comprises the following steps that (1) before or after grout is poured into the mould (20), the core rod (31) is inserted into a mould cavity of the mould (20) and is fixed; (2) after a blank is formed and before the blank is cut, the core rod (31) is pulled out; (3) according to the cutting scheme corresponding to the position of the core rod (31), cutting of the blank is completed, and a combination of block blanks stacked together is formed; (4) the combination of the block blanks is maintained and detached, and then the steamed and pressed aerated concrete blocks or foam concrete blocks with the inner holes and the grooves are formed. According to the device and method for manufacturing the aerated concrete blocks with the holes and the grooves in the core pulling mode, subsequent cutting processing is not needed, and the blocks are provided with the neat grooves or the inner holes before the maintenance of the block blanks.

Owner:FUZHOU NO 1 CONSTR ENG +2

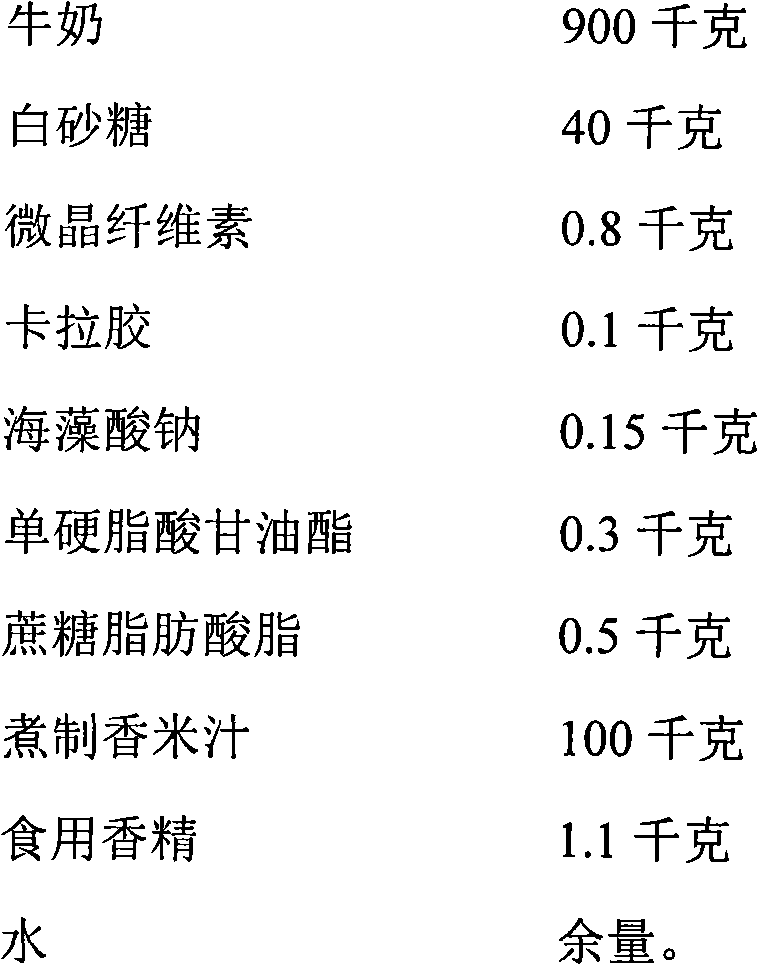

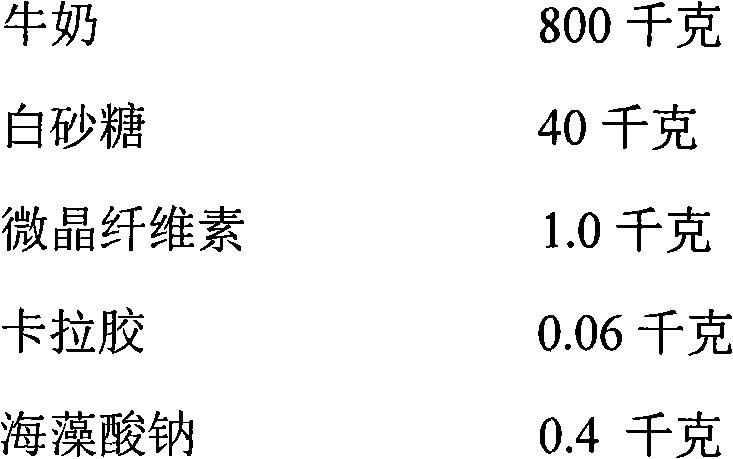

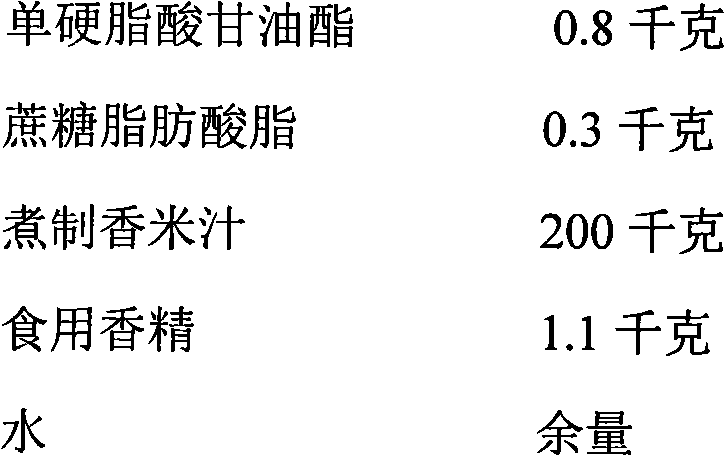

Liquid milk product containing boiled fragrant rice juice and preparation method thereof

ActiveCN102067910AIncrease product varietyReasonable nutritional valueMilk preparationFlavorAromatic rice

The invention relates to the field of milk products, in particular to a liquid milk product containing boiled fragrant rice juice and a preparation method thereof. The liquid milk product containing boiled fragrant rice juice can be flavor milk and comprises the components in parts by weight in the terms of 100 parts: 80-90 parts of milk, 0.156-0.28 part of stabilizing agent, 10-20 parts of fragrant rice juice and the balance of water; or the liquid milk product containing boiled fragrant rice juice can be flavor milk drink and comprises the components in parts by weight: 30-80 parts of milk,0.21-0.36 part of stabilizing agent, 10-40 parts of fragrant rice juice and the balance of water, wherein the fragrant rice juice is prepared by the steps of: mixing the fragrant rice and water in the ratio of 7:100-8.5:100, boiling for 16-25min and pulping and filtering after naturally cooling. The liquid milk product containing boiled fragrant rice juice, prepared in the invention, is smooth inmouthfeel and good in stability during the shelf period.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

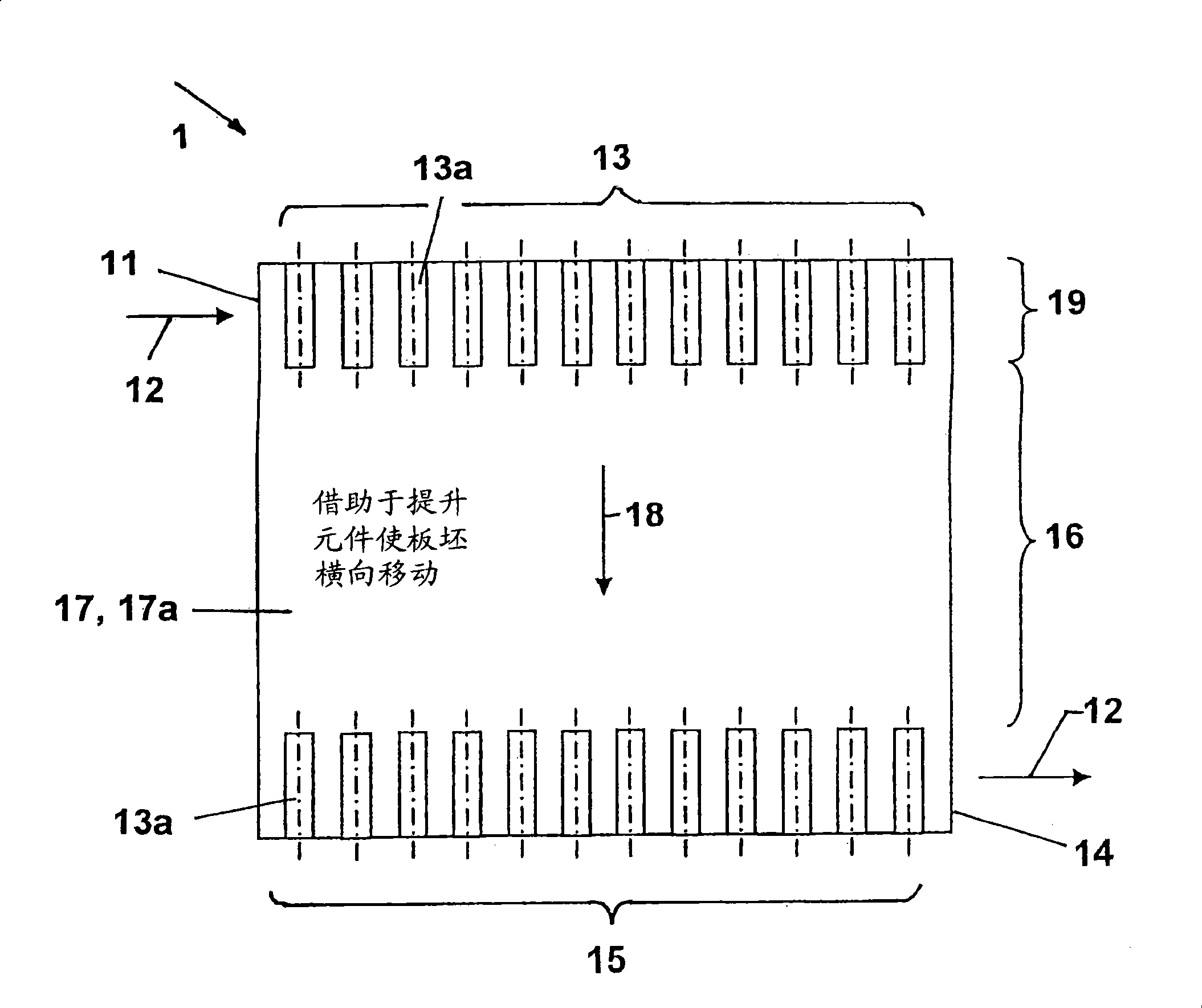

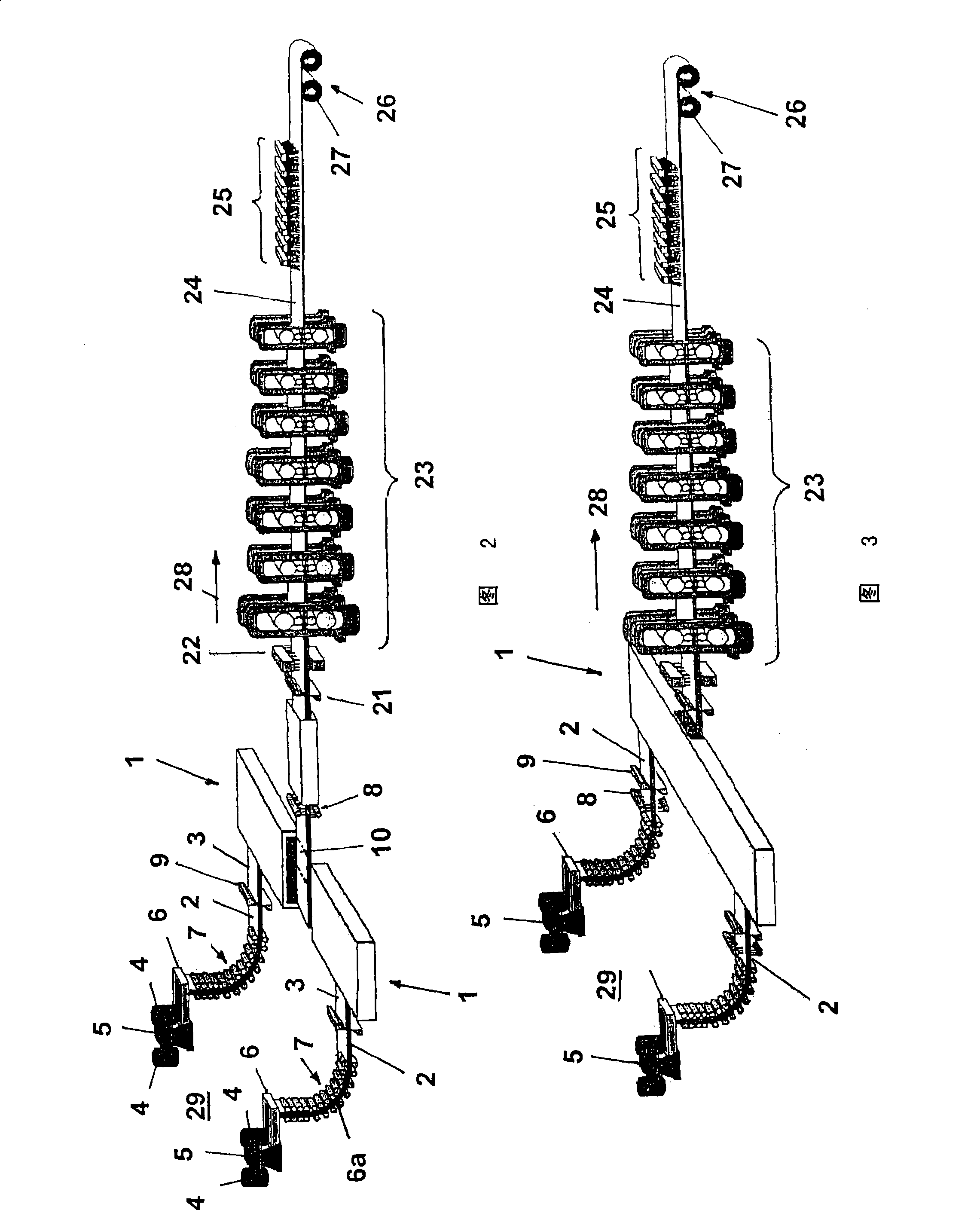

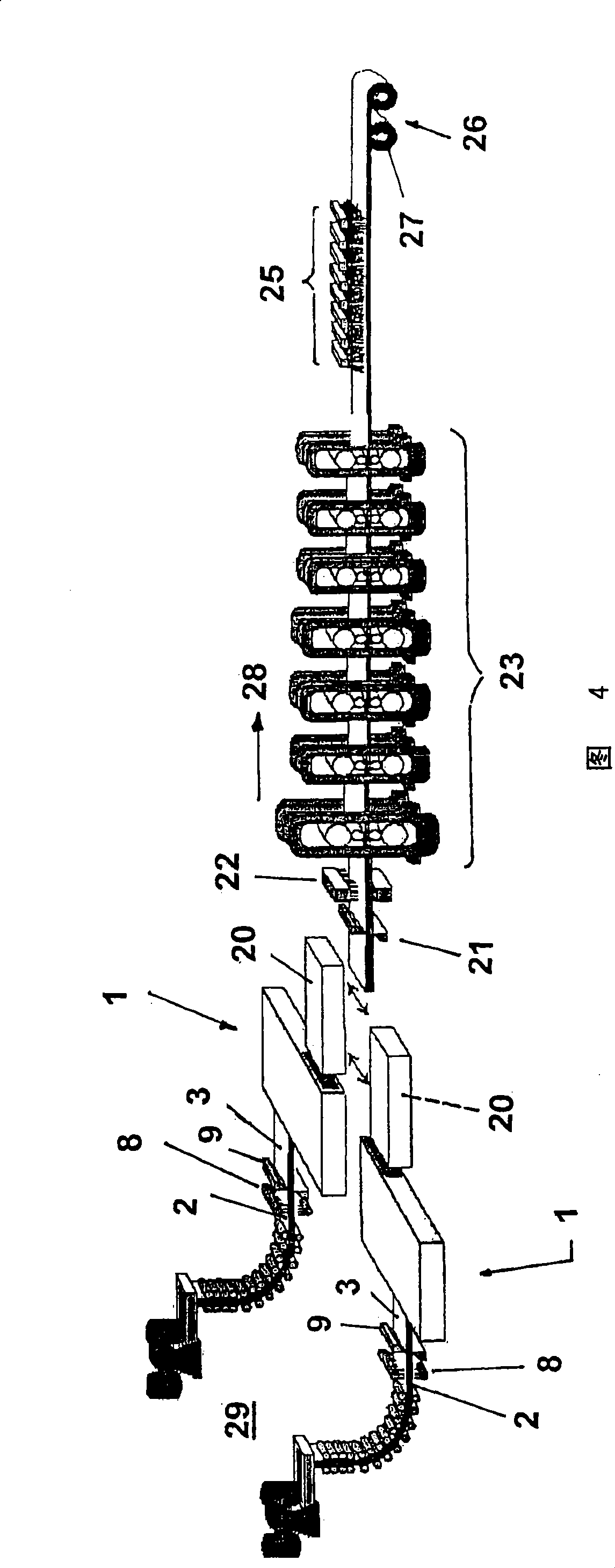

Roller hearth furnace for heating and/or temperature equalisation of steel or steel alloy continuous cast products and arrangement thereof before a hot strip final rolling mill

ActiveCN101365918AIncrease product varietyImprove thermal efficiencyFurnace typesWork heating devicesHeating furnaceIndustrial engineering

The invention relates to a roller hearth furnace (1) for heating and / or temperature equilibration of continuous cast products (2), comprising a first series of rollers (13) running in the longitudinal direction (12) and a second parallel series of rollers (15) on the outlet side (14), wherein a buffer zone (16) with lifting elements (17) for the perpendicular transport of the continuous cast product (2) is arranged between the series of rollers (13, 15). Furthermore, alternative arrangements for a further process route (28) are provided.

Owner:SMS DEMAG AG

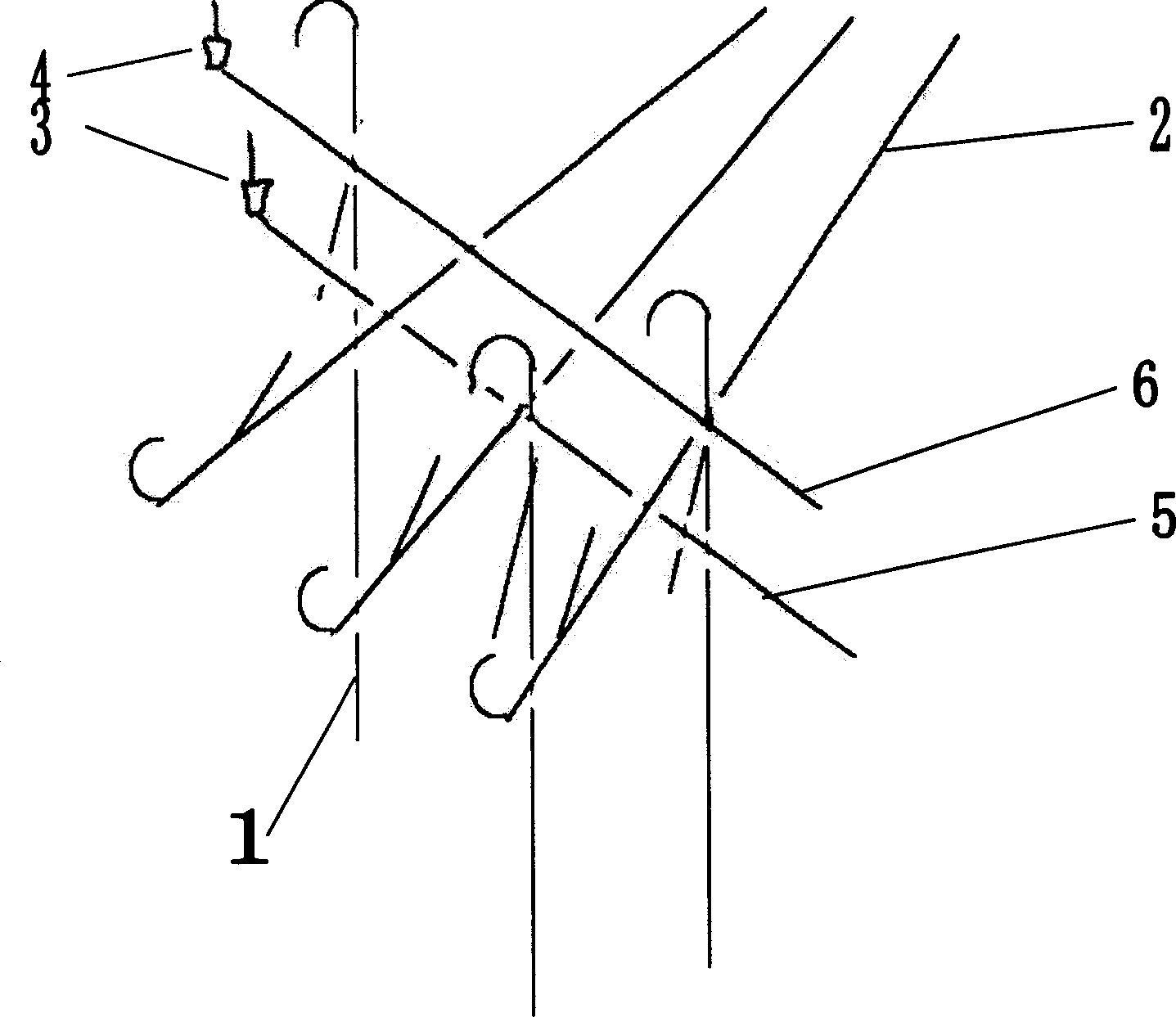

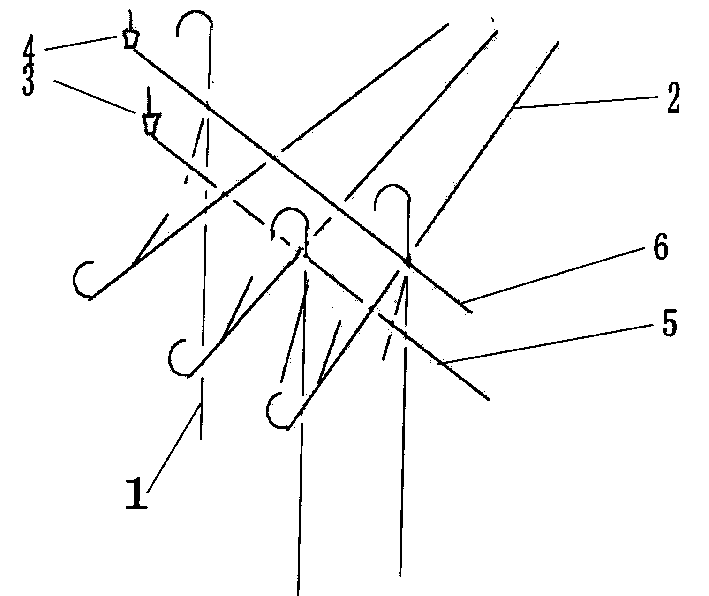

Process for weaving upper weft float hollow jacquard terry on warp-knitting circular weaving machine

InactiveCN1523149AIncrease product varietyControl changesCircular knitting machinesEngineeringWarp knitting

The present invention relates to a knitting method of welt stencil jacquard looped pile by using two-faced circular weft knitting machine. It is characterized by that on the two-faced circular weft knitting machine using cylinder needle and dial needle, in the loop-forming knitting process of every line, after having been cleared the cylinder needle can selectively form two heights of high and low, and has two yarn guide positions of high and low. The ground yarn position is lower, the ground yarn is laid in the needle hole of all the cylinder needles under the dial needle, and the terry yarn position is higher, the terry yarn is laid on the dial needle and before high-position cylinder needle, in the process of laid sinking loop-formation the ground yarn and terry yarn are laid on the high-position cylinder needle, and under the division of that the dial needle holds terry yarn and does not act on ground yarn the terry pile structure can be formed, and the ground yarn only is laid on low-position cylinder needle, the loop formation can be formed into weft plain structure with single ground yarn, and the terry yarn is position on the back side of fabric texture and formed into welt state.

Owner:JIANGNAN UNIV

Production method for low-iron low-silicon fire-resistant material grade chromium oxide green

The invention discloses a production method for low-iron low-silicon fire-resistant material grade chromium oxide green. The production method comprises the following steps: (1), selecting premium-grade chromic anhydride, wherein the silicon content and the iron content are less than 0.02%; (2), adding the chromic anhydride in a rotary kiln, wherein the kiln head sealing cover of the rotary kiln adopts a stainless steel sealing cover, the kiln head refractory bricks are made of zirconia refractory, and the kiln tail is made of normal refractory material; (3), heating the rotary kiln, controlling the temperature of the kiln head to 1000-1200 DEG C, controlling the temperature of the kiln tail to 400-600 DEG C, and enabling the material to stay for 2-4 h in the rotary kiln; (4), after roasting, performing natural cooling to the room temperature, mixing material, screening, grinding and packaging, so as to obtain the low-iron low-silicon fire-resistant material grade chromium oxide green. According to the invention, through improvement and process optimizing control, the content of the silicon and iron meets the requirements of the fire-resistant material grade chromium oxide green, the product meeting the requirements of customers are produced, the product market is expanded, and the additional value of the low-iron low-silicon fire-resistant material grade chromium oxide green is increased.

Owner:GANSU JINSHI CHEM

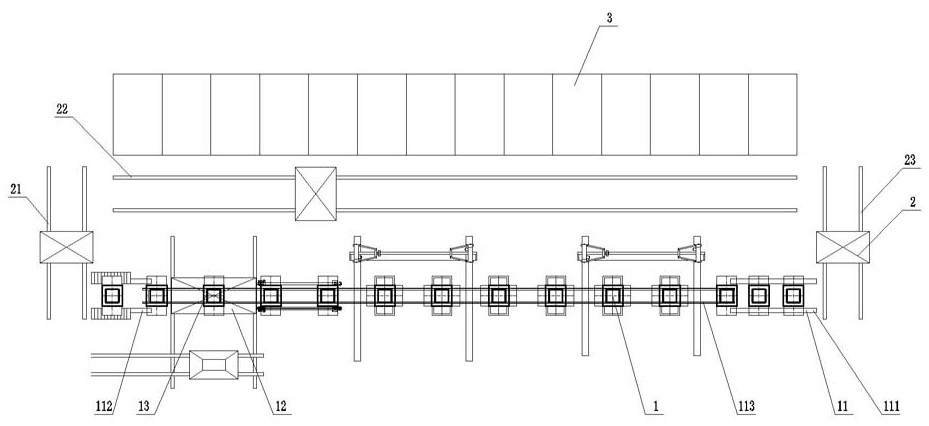

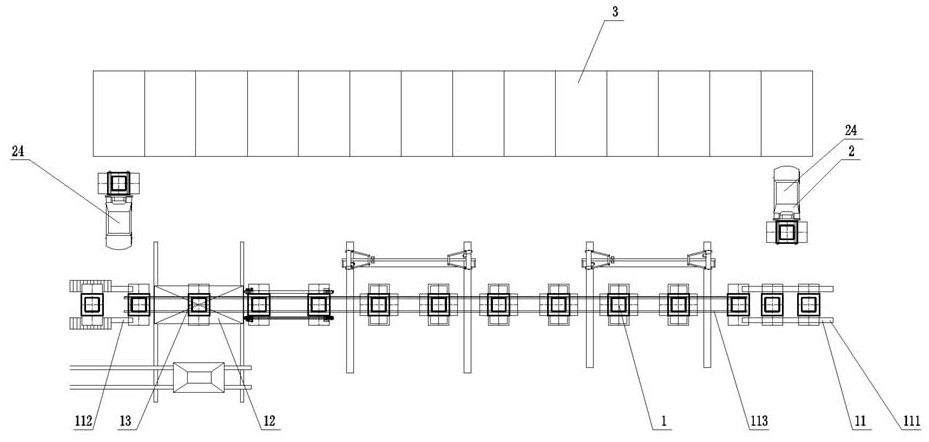

Prefabricated concrete component production line

PendingCN114179210AReliability impactSimple structureCeramic shaping plantsFeeding arrangmentsTransport systemChain type

The precast concrete component production line comprises an operation system, a ferry system and a maintenance system, and materials flow between the operation system and the maintenance system through the ferry system; the operation system comprises a conveying system, a material distribution system and a vibration system; the conveying system comprises a front-end chain type conveying system, a tail-end chain type conveying system and a stepping conveying system; the stepping conveying system comprises a lifting mechanism and a transmission bracket; the front-end chain type conveying system and the tail-end chain type conveying system are each provided with a deviation rectifying device. The production line has the beneficial effects of simple structure, small investment and flexible production; production capacity and production efficiency of a production line can be improved, and labor intensity of workers is reduced; the pouring efficiency and the pouring quality can be improved; the U-shaped prefabricated part ensures the flatness in the foundation pit and improves the installation precision of the operation line. And the deviation rectifying device timely adjusts to ensure the accuracy of the mold position and ensure the mold assembly line working procedure.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Coconut milk ice cream and manufacturing method thereof

InactiveCN102948595AIncrease product varietyImprove economic efficiencyFrozen sweetsChemistrySucrose

The invention relates to coconut milk ice cream, which comprises the following components: 30-35% of vegetable cream, 10-12% of milk powder, 8-10% of white sugar, 5-7% of coconut powder, 0.2-0.3% of sucrose fatty acid ester, 0.1-0.2% of xanthan gum, 0.1-0.15% of coconut milk essence and the balance of water. A manufacturing method of the coconut milk ice cream comprises the following steps of: uniformly mixing the white sugar, the sucrose fatty acid ester and the xanthan gum; during mixing, slowly adding the mixture into the water at the temperature of 30-35 DEG C, and adding the milk powder and the coconut powder after the mixture is dissolved; dissolving and uniformly mixing, heating to the temperature of 80+ / -2 DEG C, keeping the temperature for 15min, cooling to the room temperature, then adding the coconut milk essence, and uniformly mixing; and whipping the vegetable cream until the volume is increased by 3.0-3.5 times at the temperature of 10-15 DEG C, during slowly mixing, slowly adding the mixture into the whipped vegetable cream, uniformly mixing, standing at the temperature of minus 18-minus 22 DEG C, and refrigerating for over 12h, so as to obtain the coconut milk ice cream. The invention is especially suitable for cake shops, bakeries and other baking shops.

Owner:HARBIN PATERNA BIOTECH DEV

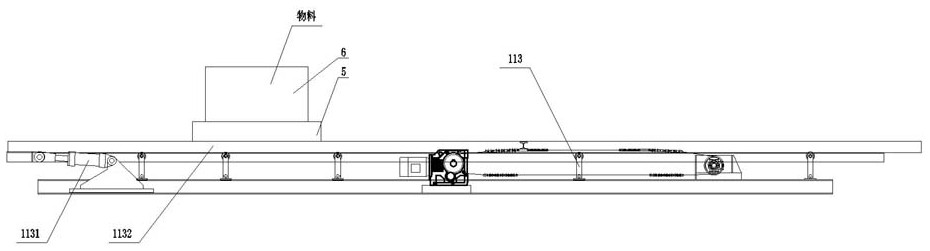

Minced penaeus vannamei preparation method

InactiveCN106262011AIncrease product varietyIncrease profitFood scienceSodium triphosphateGel strength

The invention provides a minced penaeus vannamei preparation method. The method includes the steps that fresh alive penaeus vannamei is cleaned with clean water of 0-10 DEG C, silt is removed, and penaeus vannamei is shocked; secondly, the head of the shocked penaeus vannamei is removed from the first urite, and the penaeus vannamei is cleaned with clean water of 0-10 DEG C; thirdly, meat is obtained from the penaeus vannamei without head, and shrimp shells are fully removed; fourthly, the obtained penaeus vannamei meat is washed 1-3 times with clean water of 0-10 DEG C; fifthly, the washed penaeus vannamei meat is centrifugally dewatered to obtain minced penaeus vannamei; sixthly, the centrifuged minced penaeus vannamei is chopped and stirred for 15-20 min by means of cane sugar, sorbitol, sodium pyrophosphate and sodium tripolyphosphate; seventhly, the chopped and mixed minced penaeus vannamei is packaged quantitatively and placed in the environment at temperature not higher than -20 DEG C to be stored. The prepared frozen minced penaeus vannamei is high in quality, gel strength is about 260g.cm after 6 months of storage, different minced penaeus vannamei products can be processed and manufactured according to needs, and consumption requirements of people are met.

Owner:SHANGHAI OCEAN UNIV

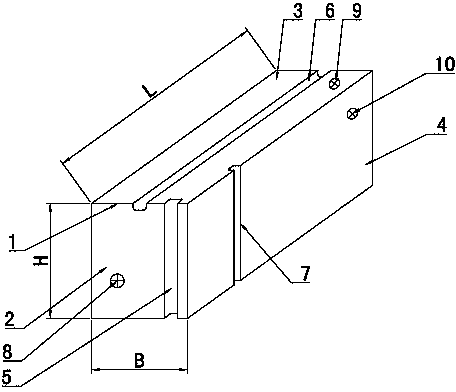

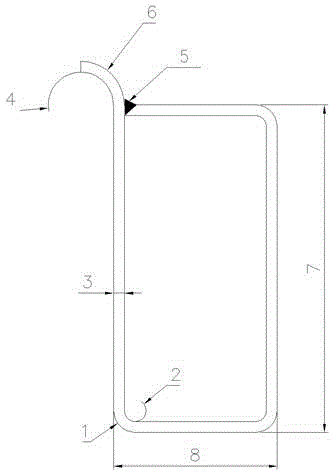

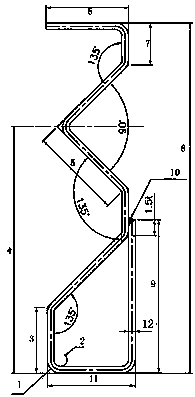

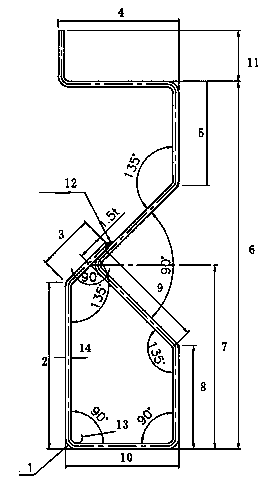

Special D-shaped support pipe

The invention discloses a specially-shaped square pipe which is produced by a cold bending online continuous production process and bending a single plate and is used for supporting commercial vehicles. By the specially-shaped square pipe, the problems of simple structure, small section inertia moment, limited section performance, a plurality of processing and welding processes, low yield and complex mounting process of the existing ordinary profiles are solved. The specially-shaped square pipe comprises a steel plate which is coldly and wholly bent to be D-shaped, wherein a welding seam (5) is arranged in a butt joint connector of the steel plate; the section of the steel plate is D-shaped. According to the specially-shaped square pipe, the continuous roll bending forming of a cold bending and welding pipe unit is adopted, and the production processes of online welding and shaping, and online sawing, bending a single plate and offline welding and shaping by a bending machine are adopted.

Owner:杜伟

A fruit marc papier-mache food and method of preparing the same

InactiveCN101548758BIncrease market valueSolve pollutionFood shapingFood preparationAdditive ingredientSlurry

Owner:JINAN UNIVERSITY

Dried Chinese cherry making method

InactiveCN105639523AIncrease product varietyAvoid short maturation cyclesFood thermal treatmentFood dryingWater contentChemistry

A dried Chinese cherry making method includes the following steps that firstly, fresh and ripe Chinese cherries which are not rotted and free of disease and pest damage are selected, placed into a cleaning solution to be soaked and cleaned, the temperature of the cleaning solution is kept to be 35-45 DEG C, the Chinese cherries are soaked for 35-40 min, then cleaned and taken out from the water, water on the surfaces of the Chinese cherries is drained, and the Chinese cherries are placed in a fresh-keeping storehouse with the temperature being 6-8 DEG C and the humidity being 78-83% and stored for at least 4 hours; secondly, the Chinese cherries are taken out of the fresh-keeping storehouse and put into hot water with the temperature of 96-100 DEG C to be heated for 6 min, the mass ratio of the Chinese cherries to the water is 1:4.5, and the Chinese cherries are quickly cooled with cold water after being heated; thirdly, the cooled Chinese cherries are taken out and placed in a vacuum low-temperature cold air drying machine and kept for 20-30 min at the temperature of 40-50 DEG C; fourthly, the dried Chinese cherries are placed in a fresh-keeping storehouse with the temperature being 4-6 DEG C and the humidity being 65-70% and stored for at least 4 hours; fifthly, the preserved Chinese cherries are placed in a drying device to be dried until the water content is lower than 9%, and the Chinese cherries are packaged and put in a storehouse after being inspected qualified.

Owner:GUANGDE YUANYE FRUIT GROWING FAMILY FARM

Method for preparing almond nuts

InactiveCN105685922AFully retain nutrientsRetain nutrientsFood ingredient functionsConstipationNutrients substances

The invention discloses a method for preparing almond nuts. The method includes the following steps that fresh apricots are collected and washed, then fruit pulp is smashed and softened in a cold-and-hot mode till the fruit pulp is removed, sterilizing, drying and preparing are carried out, and the almond nuts can be obtained. The method has the advantages that according to the almond products produced with the method, nutrient substances of almonds can be fully retained, the types of extended products of apricots are increased, and resource waste, caused by the short maturation period and the perishable defect, of the apricots is avoided. The method is easy to operate and grasp, and the finished product is convenient to eat, has the effects of moistening the lung, eliminating phlegm, relieving coughing and asthma, smoothing the intestine, relieving constipation and the like, and is suitable for eating for a long time.

Owner:HEXIAN ZHUHAN MELON & FRUIT PLANTING FAMILY FARM

Method for efficiently extracting maitake mycelia polysaccharides through submerged fermentation production

The invention discloses a method for efficiently extracting maitake mycelia polysaccharides through submerged fermentation production. The method is that mycelia separated from a maitake fermentation liquor is processed and separated through ultrasonic waves and composite enzymatic hydrolysis to obtain maitake polysaccharides. According to the invention, the conventional 'water extraction and alcohol precipitation' extraction method of polysaccharides is changed, the extraction yield and the product quality of maitake polysaccharides are improved, the consumption of purified water and energy consumption are reduced during production, and the economic benefits are increased.

Owner:江苏阜丰生物科技有限公司

OM-shaped pipe for supporting

The invention discloses a special-shaped rectangular pipe. The pipe with a function of supporting is applied to commercial vehicles and produced by means of online continuous cold-bending process and single-pipe bending process. The problems of simple structure, small second moment of area, limited section performance, excessive machining and welding procedures, low yield and complexity in installation process of existing normal sections are solved. The pipe comprises a steel plate integrally forming an OM shape by cold bending, a weld seam (10) is reserved at the butt joint of the steel plate, and the cross section of the steel plate is in the OM shape. A cold-bending pipe welding set is adopted for continuous roll bending, online welding shaping, online saw cutting, single-plate bending and offline welding shaping of a bending machine.

Owner:宋宇光

Rectifying tower forrecovering oxygen-bearing organic matter inwater for Fischer-Tropsch synthesis

ActiveCN1935305BSolve the economySolve the pollution of the environmentHydrocarbon from carbon oxidesDistillation purification/separationGas phaseOil phase

The present invention relates to a fractionating tower for recovery oxygen-containing organics from Fischer-Tropsch synthesis reaction water. It is characterized by that said fractionating tower adopts a specially-designed chimney tray, said chimney tray can ensure the effective separation of water phase and oil phase richly containing oxygen-containing organics. Said invention also provides the concrete structure of said specially-designed chimney tray, and its concrete working principle and concrete operation method.

Owner:YANKUANG ENERGY R&D CO LTD

Irregular supporting ON type pipe

The invention discloses an irregular rectangular pipe which is produced by using a cold-bending on-line continuous technique, is bent and singly produced and is used for supporting a commercial vehicle. The problems of the present common section bar of simple structure, small section inertia moment, limited section performance, many processing welding links, low yield and complex mounting technique are solved. The irregular rectangular pipe comprises an integrated cold-bent ON shaped steel plate, wherein a welding joint (12) is arranged at a butt-joint connector of the steel plate, and the cross section is of ON shape. According to the invention, a cold-bending welding pipe unit is used for continuously rolling, bending and forming. Online welding reshaping, online sawing production technique, single plate bending and offline welding reshaping technique of a bending machine are adopted.

Owner:杜伟

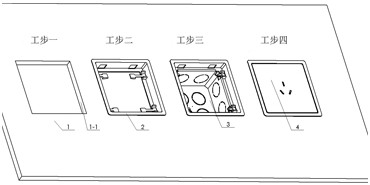

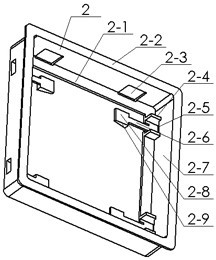

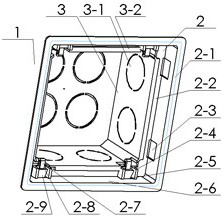

Electric appliance accessory and installation method thereof

PendingCN112952694ASolve the problem of installing wall switch socketEasy to installElectrical apparatusEngineeringPhysics

An electric appliance accessory comprises a wall switch, a socket, a junction box and a mounting frame. The accessory is characterized in that the mounting frame is placed in a mounting hole in a wall panel, the top of the mounting frame is larger than the mounting hole, and a plurality of lockers, bosses and lock holes are arranged at the bottom of the mounting frame; the locking device is connected with the bottom of the mounting frame through a flexible foldable thin connector, the locking device is provided with an inclined surface which is plugged into a corresponding lock hole, and the inclined surface is clamped on a wall panel of the mounting hole, so the mounting frame is fixed on the wall panel; and a wall switch socket is placed in the mounting frame.

Owner:上海岭帜电器科技有限公司

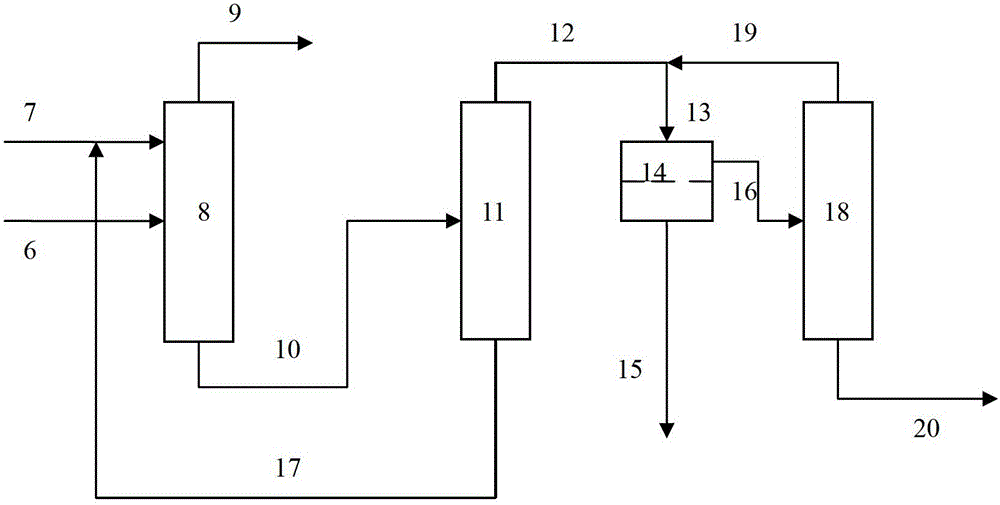

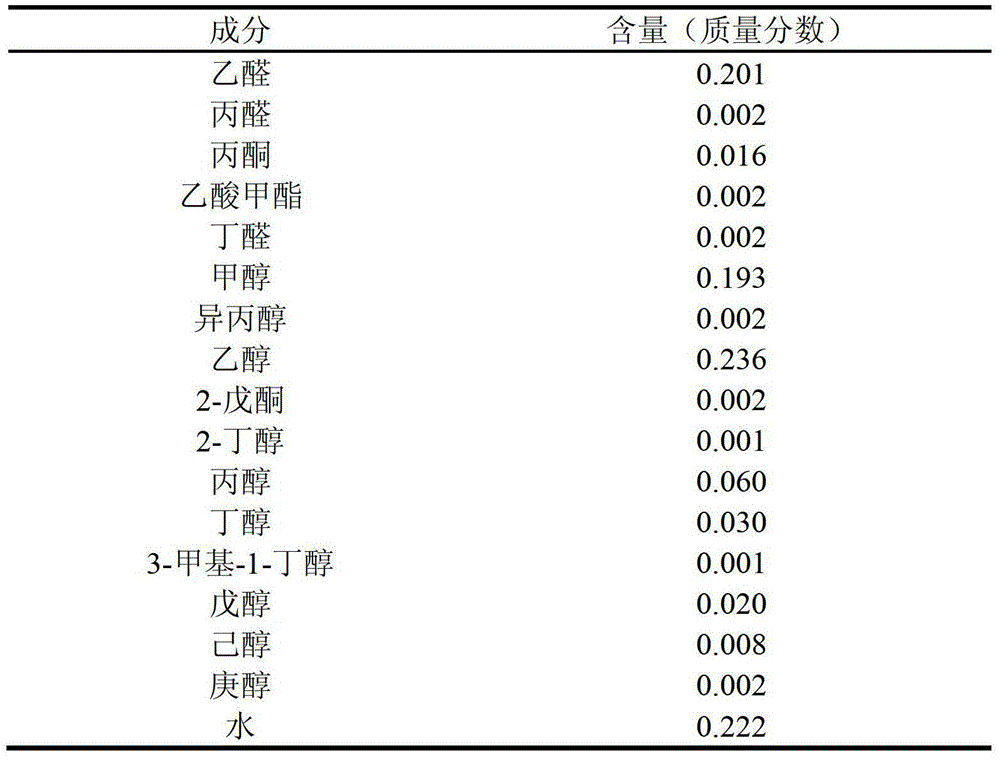

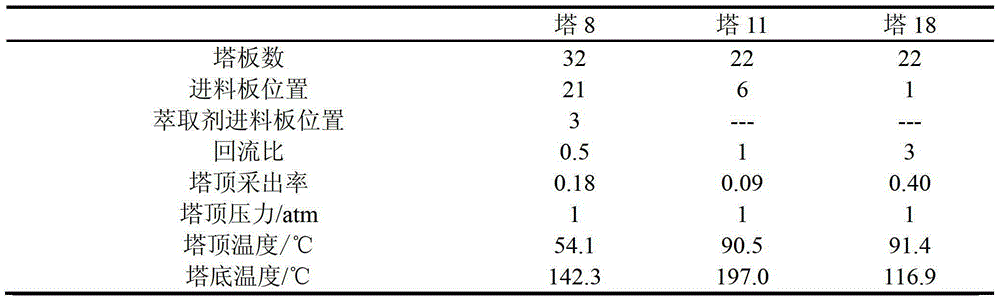

A method for dehydration recovery of non-acid oxygen-containing organic matter in Fischer-Tropsch synthesis water

ActiveCN103483148BIncrease product varietyIncrease varietyOrganic compound preparationWater contaminantsRecovery methodExtractive distillation

The invention discloses a dehydration recovery method of non-acid oxygen-containing organic substances in Fischer-Tropsch synthesis water. The method comprises the following steps: carrying out extractive distillation on non-acid oxygen-containing organic substances to obtain a light mixed alcohol product at the tower top and obtain a water solution containing heavy mixed alcohols and extractant at the tower bottom, wherein the non-acid oxygen-containing organic substances are oxygen-containing organic substances obtained by deacidifying and rectifying Fischer-Tropsch synthesis water; (2) rectifying the water solution containing heavy mixed alcohols and extractant to obtain a water solution containing heavy mixed alcohols at the tower top and obtain reclaimed extractant at the tower bottom; and (3) carrying out non-homogeneous phase stratification on the water solution containing heavy mixed alcohols to obtain an organic phase solution on the upper layer and obtain a water phase solution on the lower layer; and (4) rectifying the organic phase solution to obtain the heavy mixed alcohol product at the tower bottom. The mixed alcohol product is obtained through a plurality of rectifying operating units; and the product has the advantages of high purity and higher heat value, can be used as a fuel, and can also be subjected to deep processing to obtain different oxygen-containing compounds, thereby greatly increasing the product varieties of the solid fuel liquefying oil producer.

Owner:SYNFUELS CHINA TECH CO LTD

Cereal drink and preparation method thereof

The invention provides a cereal beverage and a preparation method thereof. The preparation method of the cereal beverage comprises: adding medium temperature amylase, glucoamylase, neutral protease and peptidase into one or more kinds of cereal pulp original solutions to perform enzymatic hydrolysis reaction, and obtaining one or more kinds of cereal pulps subjected to enzymatic hydrolysis after the reaction is finished; when one cereal pulp original solution is subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the cereal pulp subjected to enzymatic hydrolysis, so as to obtain the cereal beverage; and when multiple kinds of cereal pulp original solutions are subjected to the enzymatic hydrolysis reaction, successively performing volume metering, homogenizing, enzyme deactivation and sterilization and loading on the multiple kinds of cereal pulps subjected to enzymatic hydrolysis, so as to obtain the cereal beverage. The invention also provides the cereal beverage which is prepared by employing the above preparation method. The cereal beverage provided by the invention is capable of completely keeping nutritional components of the cereal raw materials, is relatively beneficial for digestion and absorption of human, and has the characteristics of being smooth in mouthfeel and refreshing in flavor.

Owner:INNER MONGOLIA DAIRY TECH RES INST CO LTD

A method for efficiently extracting polysaccharides produced by submerged liquid-state fermentation of P.

ActiveCN104087635BEmission reductionReduce pollution control costsFermentationPrecipitationFungal mycelium

Owner:JIANGSU SHENHUA PHARMA

A method for efficiently extracting and producing Wulingshen mycelium polysaccharides by submerged liquid fermentation

The invention discloses a method for efficiently extracting xylariasp mycelium polysaccharide produced through submerged fermentation. According to the method, mycelium separated by xylariasp fermentation liquid is treated by ultrasonic waves and composite enzymatic hydrolysis and is separated to obtain the xylariasp polysaccharide. By means of the method, a conventional water extraction and alcohol precipitation method for extracting polysaccharide is changed, the extraction yield of the xylariasp polysaccharide and the product quality are improved, the use amount of purified water and energy consumption during production are reduced, and the economic benefits are increased.

Owner:JIANGSU SHENHUA PHARMA

Salty milky tea and process for preparation thereof

ActiveCN101692852BIncrease product varietyReduce ingredient lossMilk preparationInstant teaSalty taste

The invention relates to the field of liquid milk, in particular to salty milky tea and a process for preparation thereof. The salty milky tea based on 1000 parts by weight comprises 800-936.4 parts by weight of milk, 7-10 parts by weight of tea extract or 0.8-4 parts by weight of instant tea powder, 1.26-3.3 parts by weight of stabilizer, 4-7 parts by weight of waterless cream or single cream orbutter, 0.4-3 parts by weight of salt and 0-193.54 parts by weight of water, wherein the stabilizer comprises thickener and emulsifier. The salty milky tea prepared by the process contains healthcarecomponents of tea but remains natural nutrition component in milk and is a liquid drink with smooth taste and heavy aroma. By utilizing the process, the loss of components of milk and tea is decreased to the utmost extent, and distinctive characteristics of full fresh and salty taste of the milky tea are remained.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method for dried yellow peach kernel product having shell

The invention provides a preparation method for a dried yellow peach kernel product having shell. The preparation method comprises: collecting fresh yellow peach, washing, rotting the pulp until the pulp is removed, disinfecting and sterilizing, and drying so as to obtain the product. According to the present invention, the yellow peach kernel produced by using the method can completely retain the nutrients of the yellow peach kernel, improve the extension product types of the yellow peach, and avoid the waste of the resource due to the short mature period and the easy rotting of the yellow peach; and the method has characteristics of simple operation and easy mastering, and the finished product is easy to eat, has effects of lung moisturizing, phlegm removing, cough stopping, asthma relieving, intestine smoothing, constipation relieving and the like, and is suitable for long-term consumption.

Owner:石台县小菜一碟农产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com