Minced penaeus vannamei preparation method

A technology for white prawn and minced meat is applied in the field of preparation of minced meat of Penaeus vannamei, which can solve the problems of reducing fish resources and failing to meet market demands, and achieves the effects of improving protein denaturation and dry consumption, meeting consumer needs and having high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Below in conjunction with embodiment the present invention is described in further detail:

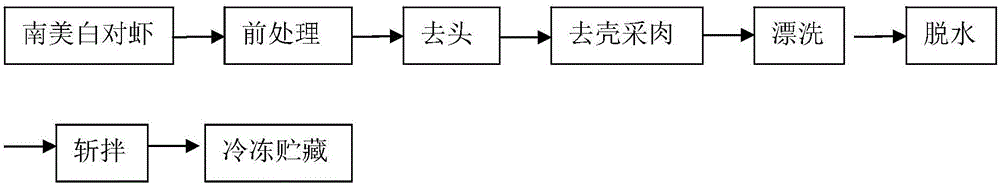

[0025] A preparation method for minced meat of Penaeus vannamei comprises the following steps:

[0026] (1) Pre-treatment: 35kg of fresh and alive Penaeus vannamei was washed with water at 4°C to remove sediment and shocked with crushed ice;

[0027] (2) Head removal: remove the head of the shocked Penaeus vannamei from the first abdominal segment, and then wash it with water at 4°C;

[0028] (3) Shelling and meat harvesting: adopt surimi meat harvester to harvest the meat of the Penaeus vannamei after head removal, the aperture of the meat harvester is 3mm, fully remove the shrimp shell;

[0029] (4) Rinse: Rinse the harvested Penaeus vannamei meat twice with clear water at 4°C, the weight of clear water used for each rinse is 4 times that of the shrimp meat, and the rinse time is 20 minutes each time;

[0030] (5) Dehydration: the vannamei meat after rinsing is centrifugally...

Embodiment 2

[0035] (1) Pre-treatment: wash 35kg of fresh and live Penaeus vannamei with water at 8°C, remove sediment, and shock with crushed ice;

[0036] (2) Head removal: remove the head of the Shocked Penaeus vannamei from the first abdominal segment, remove the catgut, and wash it with water at 8°C;

[0037] (3) Shelling and meat harvesting: adopt a surimi meat harvester to process the meat of the Penaeus vannamei after the head has been removed, the aperture of the meat harvester is 3mm, and the shrimp shells are fully removed;

[0038] (4) Rinsing: Rinse the harvested Penaeus vannamei meat once with clear water at 5°C, the weight of clear water used for rinsing is 5 times the weight of the shrimp meat, and the rinsing time is 20-30min;

[0039] (5) Dehydration: Centrifugal dehydration of the vannamei meat after rinsing, the centrifugal speed is 2900r / min, and the centrifugation time is 4min to obtain minced meat of Penaeus vannamei;

Embodiment 3

[0045] (1) Pre-treatment: 35kg of fresh and alive Penaeus vannamei was washed with clear water at 0°C to remove sediment, and the live shrimp was ice-shocked with crushed ice;

[0046] (2) Head removal: the head of the shocked Penaeus vannamei was removed from the first abdominal segment, and then washed with clean water at 0°C.

[0047] (3) Shelling and meat harvesting: the meat harvester of surimi is used to harvest the meat of the Penaeus vannamei after the head has been removed, the aperture of the meat harvester is 3mm, and the shrimp shells are fully removed;

[0048] (4) Rinse: Rinse the harvested Penaeus vannamei meat twice with clear water at 0°C, the weight of clear water used for each rinse is 4 times that of the shrimp meat, and the rinse time is 20 minutes each time;

[0049] (5) Dehydration: the vannamei meat after rinsing is centrifugally dehydrated, the centrifugal speed is 2800r / min, and the centrifugation time is 3min to obtain minced shrimp;

[0050] (6) Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com