Salty milky tea and process for preparation thereof

A technology of milk tea and salty taste, which is applied in the field of salty milk tea and its preparation, to achieve the effect of reducing component loss, smooth taste and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

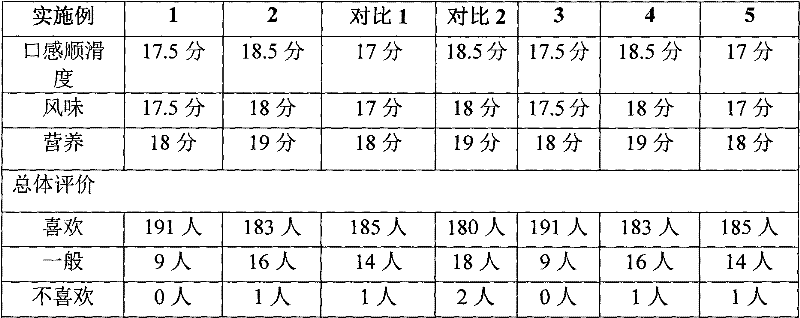

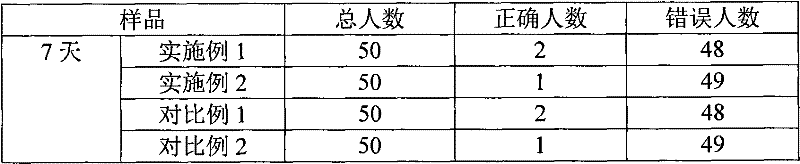

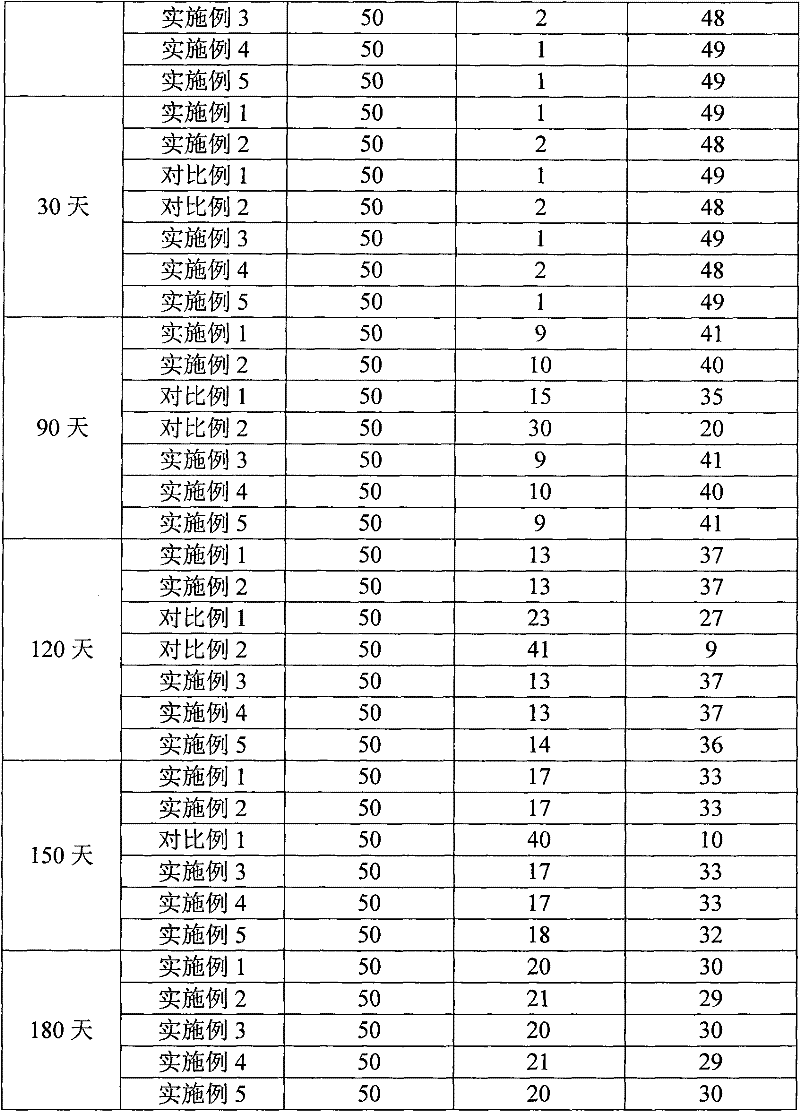

Examples

Embodiment 1

[0028] The salty milk tea formula of the present embodiment is (calculated by one ton of product)

[0029] Milk 800kg

[0030] 1.0 kg iodized salt

[0031] Microcrystalline cellulose 1.0 kg

[0032] Carrageenan 0.06 kg

[0033] Sodium alginate 0.4 kg

[0034] Glyceryl monostearate 0.8 kg

[0035] Sucrose fatty acid lipid 0.3 kg

[0036] Brewed tea juice (Chuanzi brick tea) 10kg

[0037] Anhydrous butter 7kg

[0038] Food flavor 1.1 kg

[0039] water balance

[0040] Raw material standards: tea juice is made of Chuanzi brick tea: water = 1:100, boiled at 80-90°C for 10-20 minutes, then cooled, and the performance indicators of the remaining raw materials meet the requirements of relevant quality standards. The stabilizer, anhydrous butter Or cream or butter, etc. are evenly added to the batching tank, mixed with milk, put tea soup into the batching tank, and mixed with milk; preheat the obtained material liquid to 50°C, and then homogenize, the homogenization pressure ...

Embodiment 2

[0043] The salty milk tea formula of the present embodiment is (calculated by one ton of product)

[0044] Milk 900kg

[0045] 2.5 kg iodized salt

[0046] Microcrystalline cellulose 0.8 kg

[0047] Carrageenan 0.1 kg

[0048] Sodium alginate 0.15 kg

[0049] Glyceryl monostearate 0.3 kg

[0050] Sucrose fatty acid lipid 0.5 kg

[0051] Black tea powder (Indian Assam black tea leaves) 2.5 kg

[0052] Butter 4 kg

[0053] Food flavor 1.1 kg

[0054] water balance

[0055] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0056] Add the stabilizer, anhydrous cream or cream or butter evenly into the ingredient tank, mix well with the milk, put the instant tea powder into the ingredient tank, and mix well with the milk; preheat the material liquid to 70°C, and then Homogenization, the homogenization pressure is 25MPa, and the temperature is 70°C; then sterilized and filled.

[0057]The product feature of the salty mil...

Embodiment 3

[0085] The salty milk tea formula of the present embodiment is (calculated by one ton of product)

[0086] Milk 936.4 kg

[0087] 0.4 kg iodized salt

[0088] Microcrystalline cellulose 0.5 kg

[0089] Carrageenan 0.08 kg

[0090] Sodium alginate 0.3 kg

[0091] Glyceryl monostearate 0.6 kg

[0092] Sucrose fatty acid lipid 0.4 kg

[0093] Tea juice (green tea) 7kg

[0094] Butter 4 kg

[0095] water balance

[0096] Raw material standards: tea juice is made of green tea: water = 1:100, boiled at 80-90°C for 10-20 minutes, then cooled, and the performance indicators of other raw materials meet the requirements of relevant quality standards, and stabilizers, butter, etc. are evenly added In the batching tank, fully mix with milk, put the tea soup into the batching tank, and fully mix with milk; preheat the obtained feed liquid to 60°C, and then homogenize, the homogenization pressure is 20MPa, and the temperature is 60°C; then Sterile filling.

[0097] The product cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com