Patents

Literature

126results about How to "Reduce pollution control costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tobacco remanufacturing process by spinning method

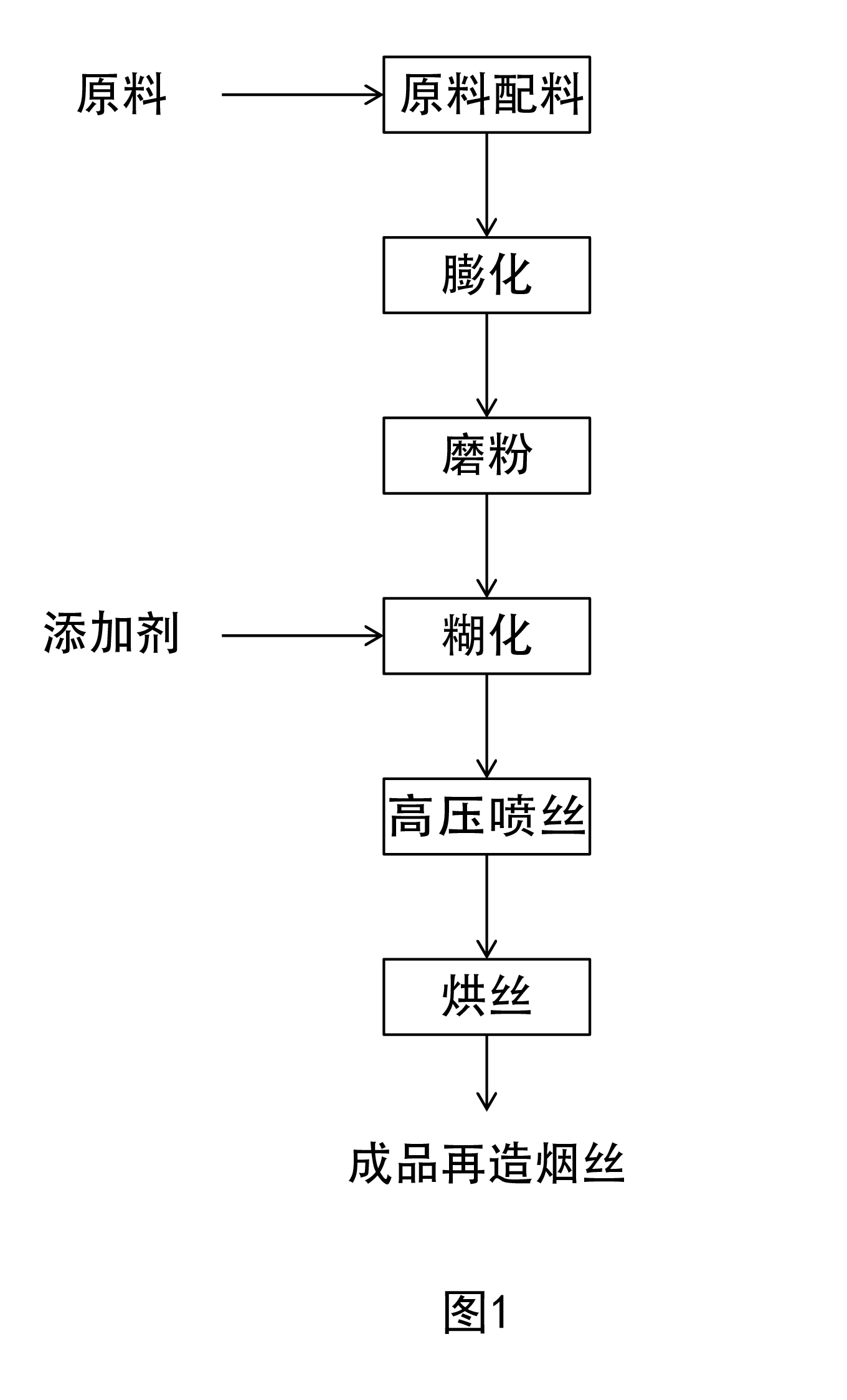

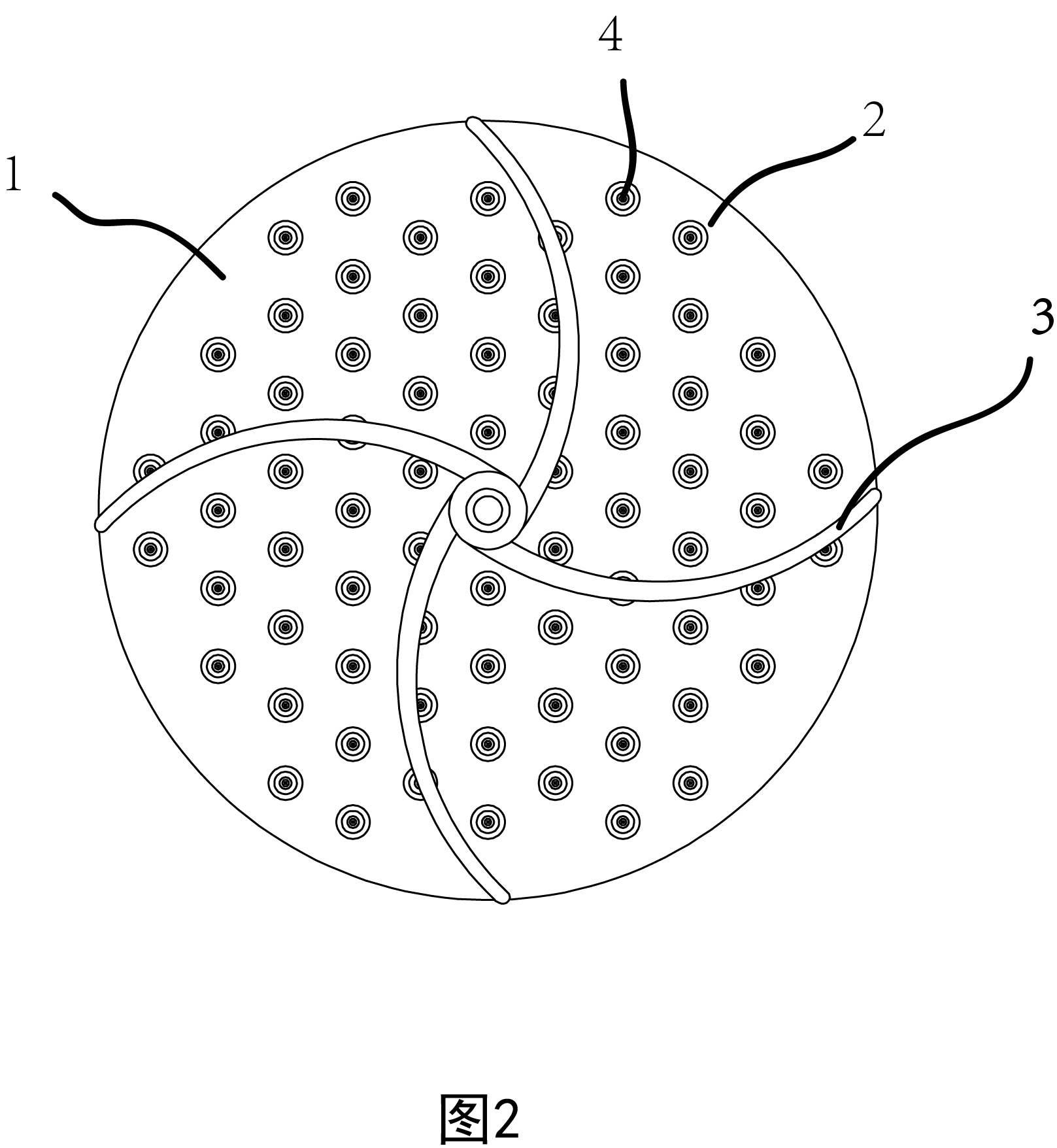

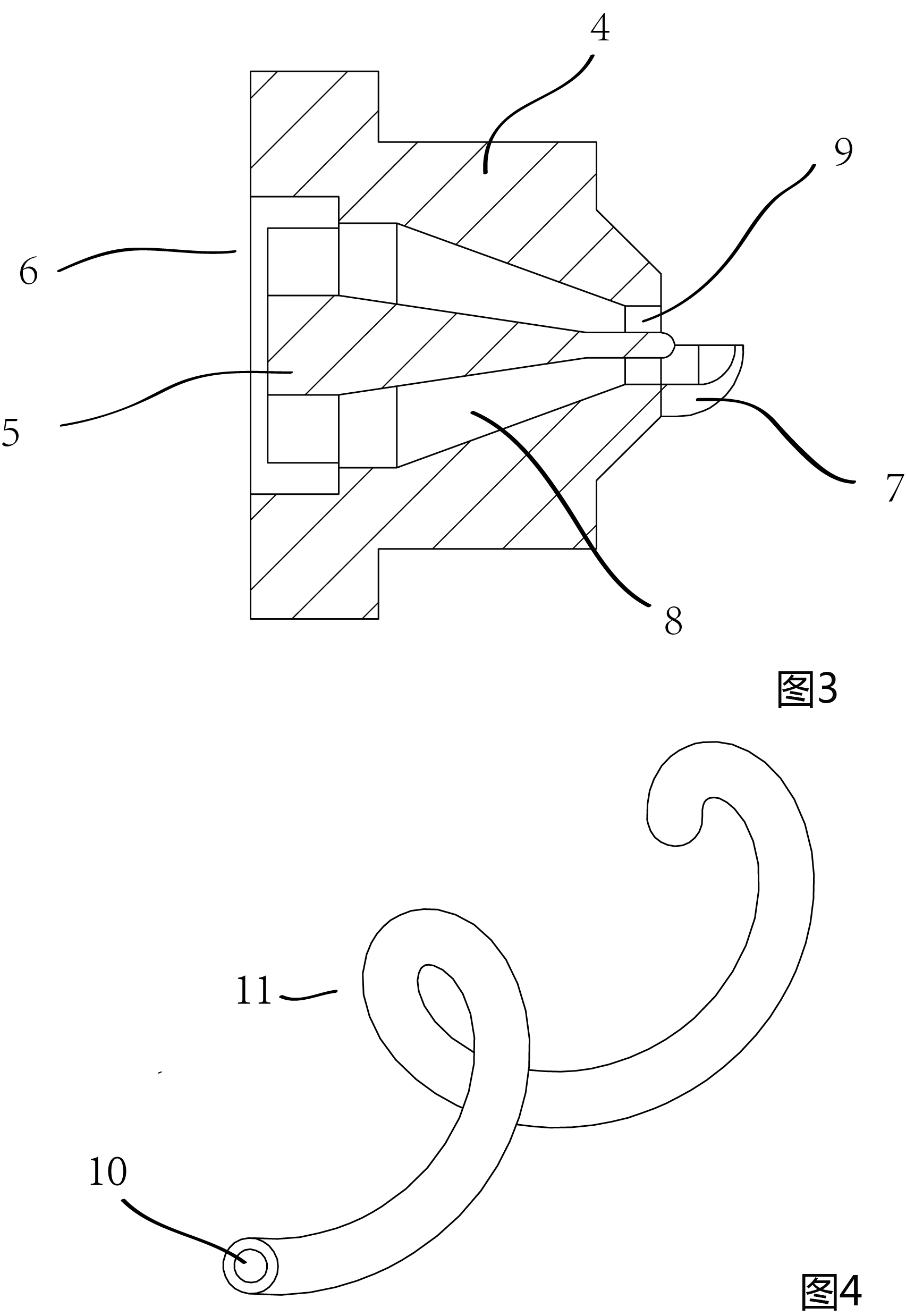

The invention relates to a tobacco remanufacturing process by a spinning method, belonging to the chemical technology of tobacco, in particular to a tobacco remanufacturing process for remanufacturing the tobacco and tobacco shreds by utilizing smoked sheets, tobacco waste and tobacco stalks. The tobacco remanufacturing process is characterized in that the remanufactured tobacco shreds with different shapes and structures are produced by carrying out the procedures of blending, bulking, grinding, gelatinizing, high-pressure spinning and shred baking on raw materials, and comprise hollow remanufactured tobacco shreds. Compared with the traditional processes such as a thick slurry method, a rolling method and a papermaking method, the tobacco remanufacturing process has the benefits that the utilization ratio of the tobacco is improved from 85%-95% to be close to 100%, no sewage and waste are discharged, the quality of the tobacco shreds is improved, the application range of the remanufactured tobacco shreds is expanded, the process flow is simple and easy to control, the automatic production is easy to be realized and the sensing quality and the production efficiency are improved.

Owner:侯明

Blue algae bloom activated char and preparation thereof

The invention relates to a blue algae water bloom active carbon and a preparation method thereof. The active carbon is produced by drying the blue algae water bloom alga mud at the hign temperature of 250 to 600 DEG C for 0.5 to 2 hours. The invention starts a new trail for utilizing the blue algae water bloom as a resource. The method can effectively produce active carbon with blue algae water bloom, which can not only save resources but also is favorable to protect the ecological environment and finally the purpose of treating pollution and reducing the pollution treatment cost can be realized.

Owner:YUNNAN UNIV

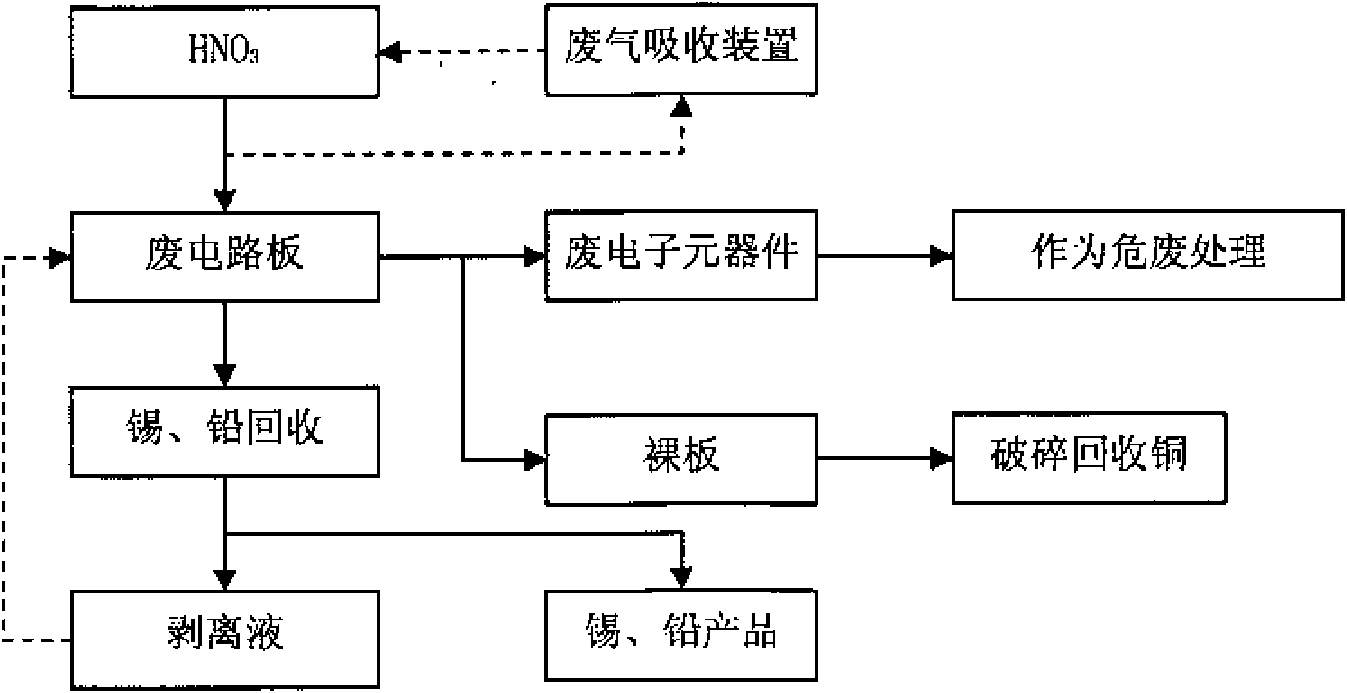

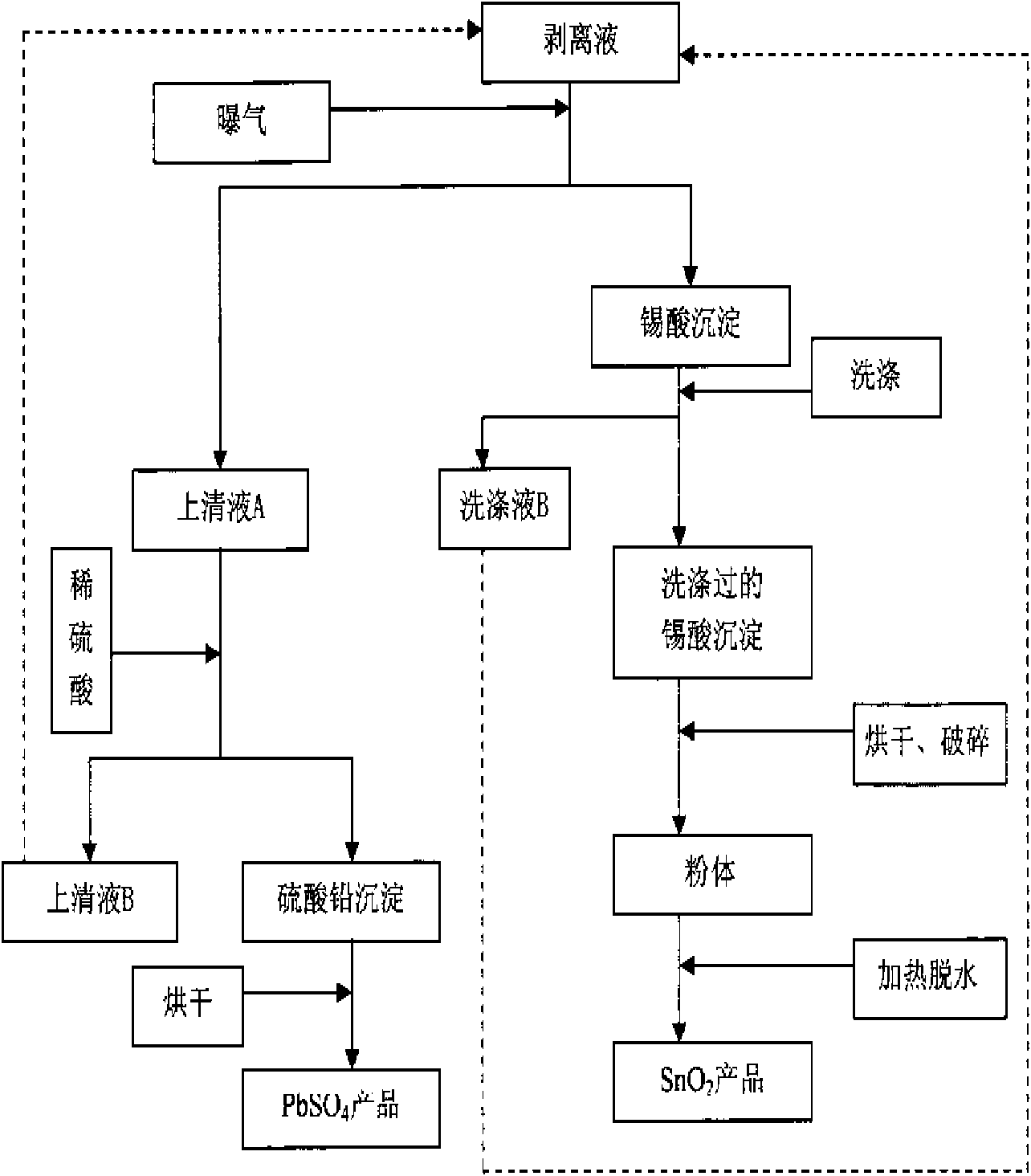

Tin-lead recovery method in waste circuit board

InactiveCN101665875ARealize classification precipitationExpand resource profit marginsLiquid wasteRecovery method

The invention provides a tin-lead recovery method in a waste circuit board. The method comprises the following steps of: wet-stripping electronic components on a waste circuit board, carrying out classified deposition and recovery of tin and lead in the waste circuit board, and reusing waste gas and waste liquid generated in the recovery process into the recovery process. The method can effectively prevent the pollution of waste acid, waste gas and waste metal generated in the recovery process of the waste circuit board, improve environment quality of a centralized recovery area and reduce thecost of pollution control in the recovery process.

Owner:刘景洋

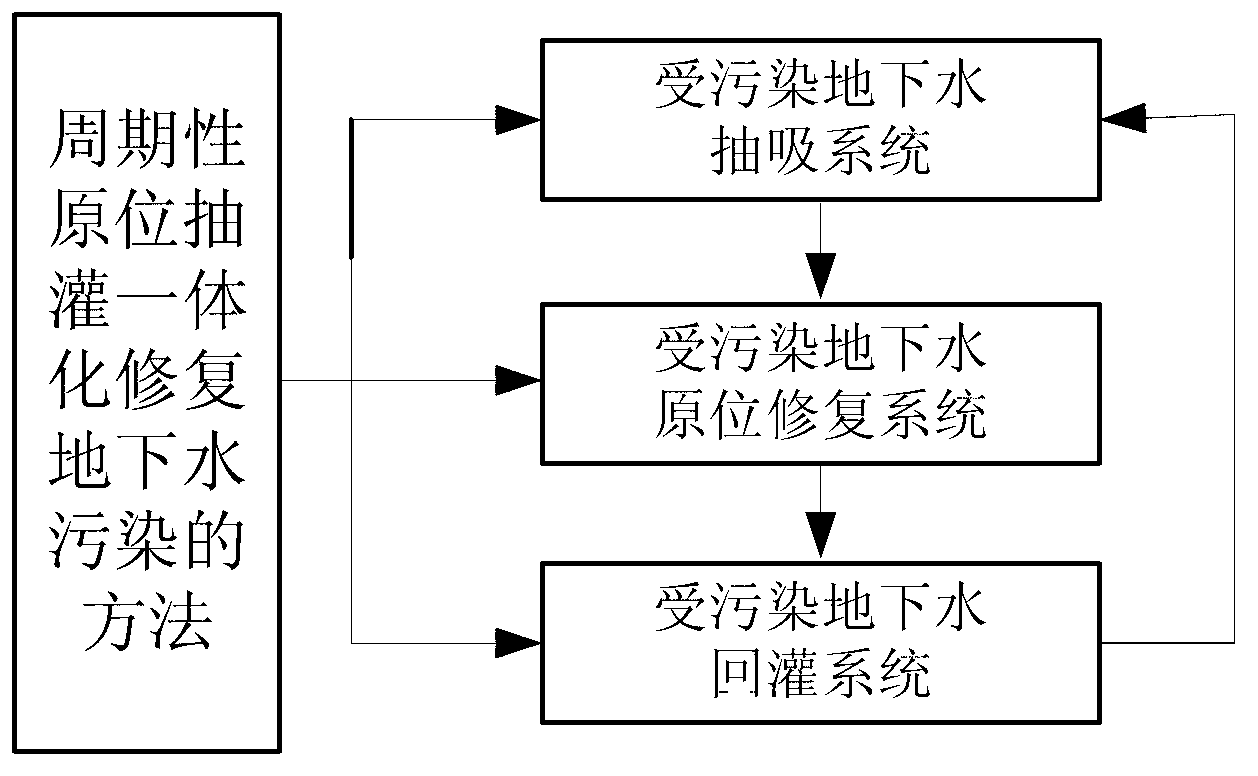

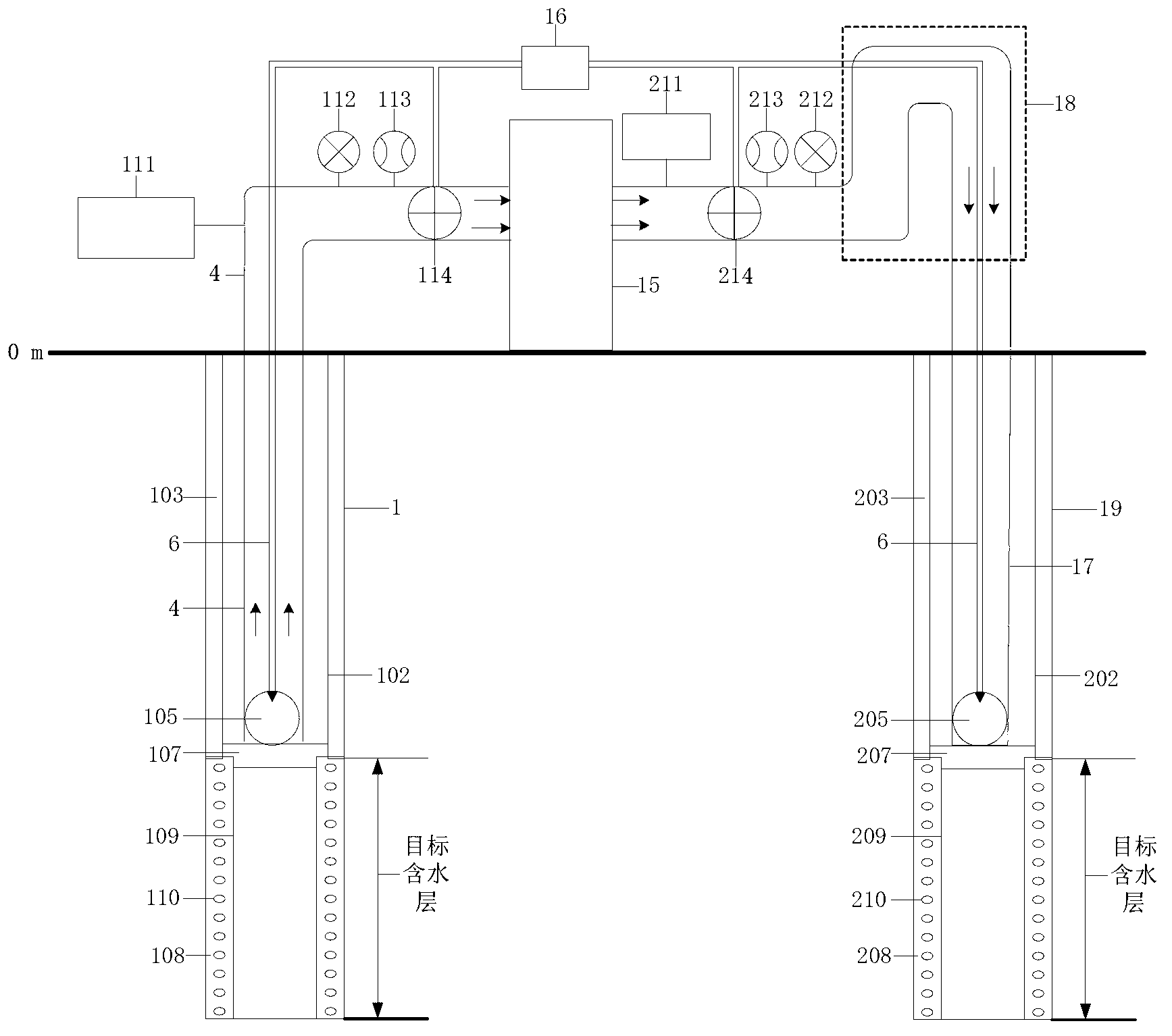

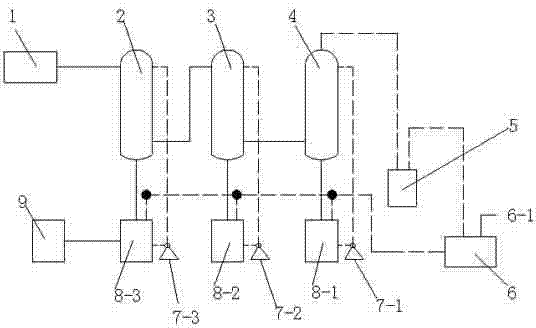

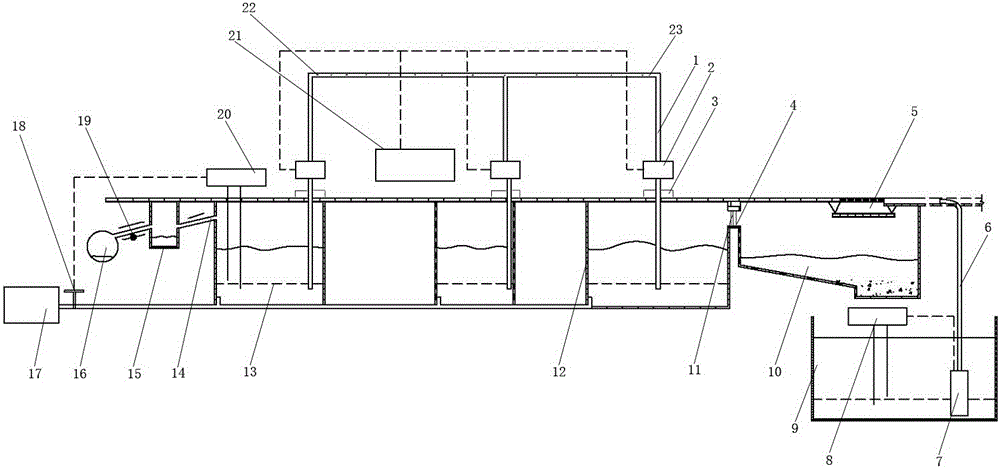

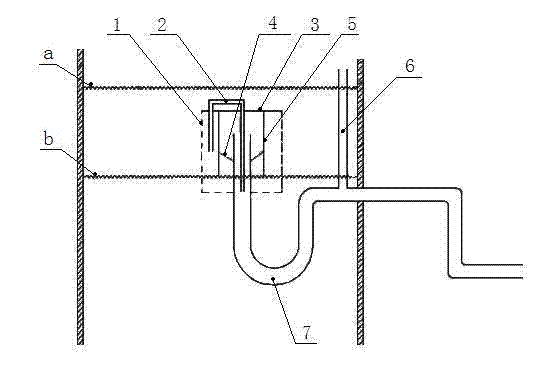

Device and method for periodic in-situ pumping based integrated repairing of groundwater pollution

ActiveCN103303986AAct as a diluentReduce concentrationContaminated soil reclamationFluid removalEnvironmental engineeringEngineering geology

The invention belongs to the technical field of in-situ preparing of polluted underground water, and particularly relates to a device and method for periodic in-situ pumping based integrated repairing of groundwater pollution. The device comprises a polluted underground water pumping system, an in-situ repairing system and a recharge system, wherein the pumping system is composed of a pumping well and a pumping pipeline; the pumping system is connected with the in-situ repairing system; the in-situ repairing system is connected with the recharge system; and the recharge system comprises a recharge pipeline and a recharge well. The pumping well and the recharge well are subjected to a pumping test and a recharge test before the periodic in-situ pumping based integrated repairing of the underground water pollution is carried out. By adopting the method, the processed underground water is recharged to the original polluted water layer to dilute the original polluted water layer, so that the concentration of pollutants in a target aquifer is reduced, convenience is provided for subsequent treatment, and the pollution manage cost is reduced. The processed polluted underground water is timely recharged; and the poor hydrogeololgy and engineering geology can be effectively avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

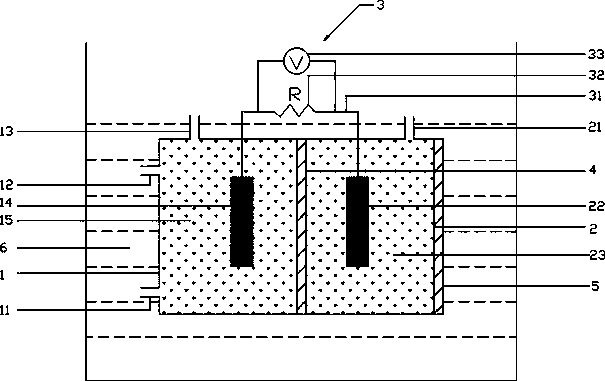

Microbial fuel cell capable of repairing nitrate polluted underground water in situ

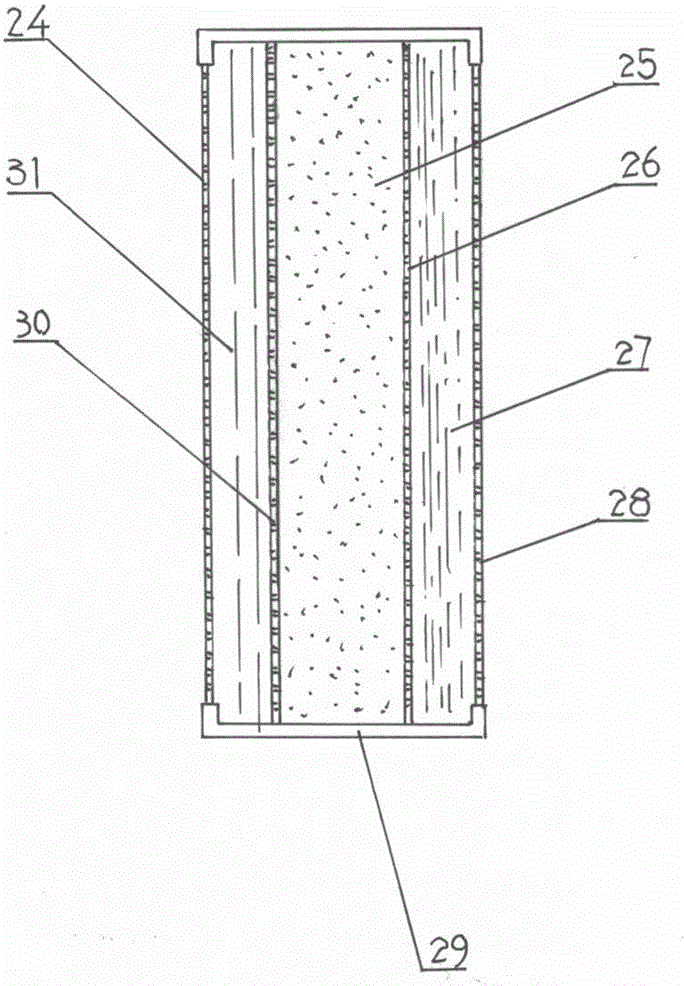

InactiveCN104064794ACompact structureLow running costTreatment by combined electrochemical biological processesFinal product manufactureIon-exchange membranesWater pipe

The invention provides a microbial fuel cell capable of repairing nitrate polluted underground water in situ. The microbial fuel cell comprises an anode chamber, a cathode chamber, anion exchange membranes at the two sides of the cathode chamber and an external circuit system, wherein the anode chamber is provided with a water inlet pipe, a water outlet pipe and an exhaust pipe and is internally provided with a biological anode, and anaerobic electro-microorganisms are attached to the biological anode; the anode chamber is fully filled with anode liquor, and efficient anaerobic digestion sludge is inoculated in the anode chamber; the cathode chamber is provided with an exhaust pipe and is internally provided with a biological cathode, and electroactive denitrifying microorganisms are attached to the biological cathode; the cathode chamber is fully filled with cathode liquor, and denitrifying sludge is inoculated in the cathode chamber; the external circuit system comprises an external resistor, a lead and an electrical signal acquisition recorder. The microbial fuel cell has three functions of organic waste water treatment, biological electricity production and in-situ repair of nitrate polluted underground water, solves the problem of secondary pollution, caused by organic matter, microorganisms and the like, on underground water in the in-situ repair process and is compact in structure and low in running cost as well as economic and efficient.

Owner:OCEAN UNIV OF CHINA

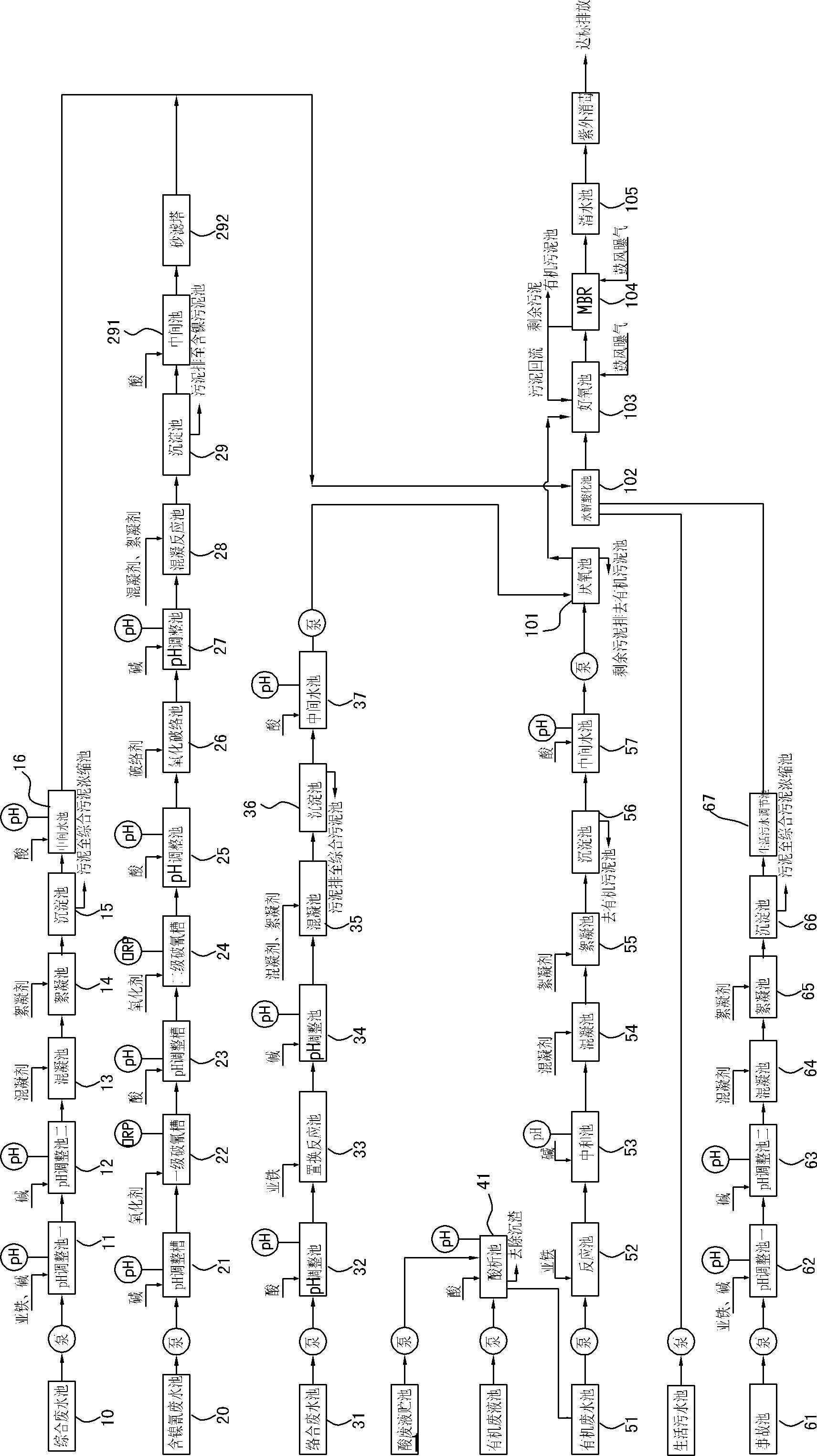

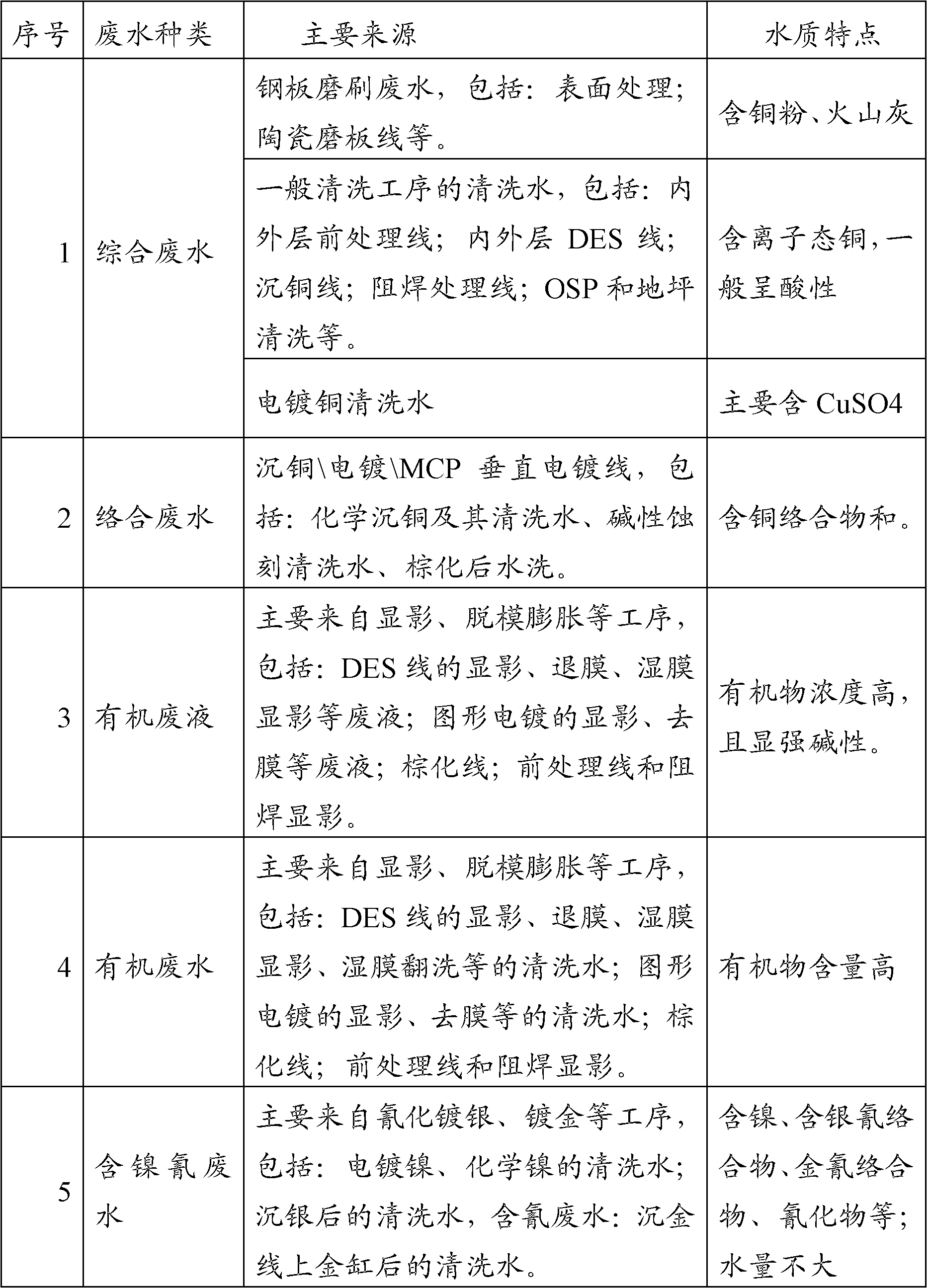

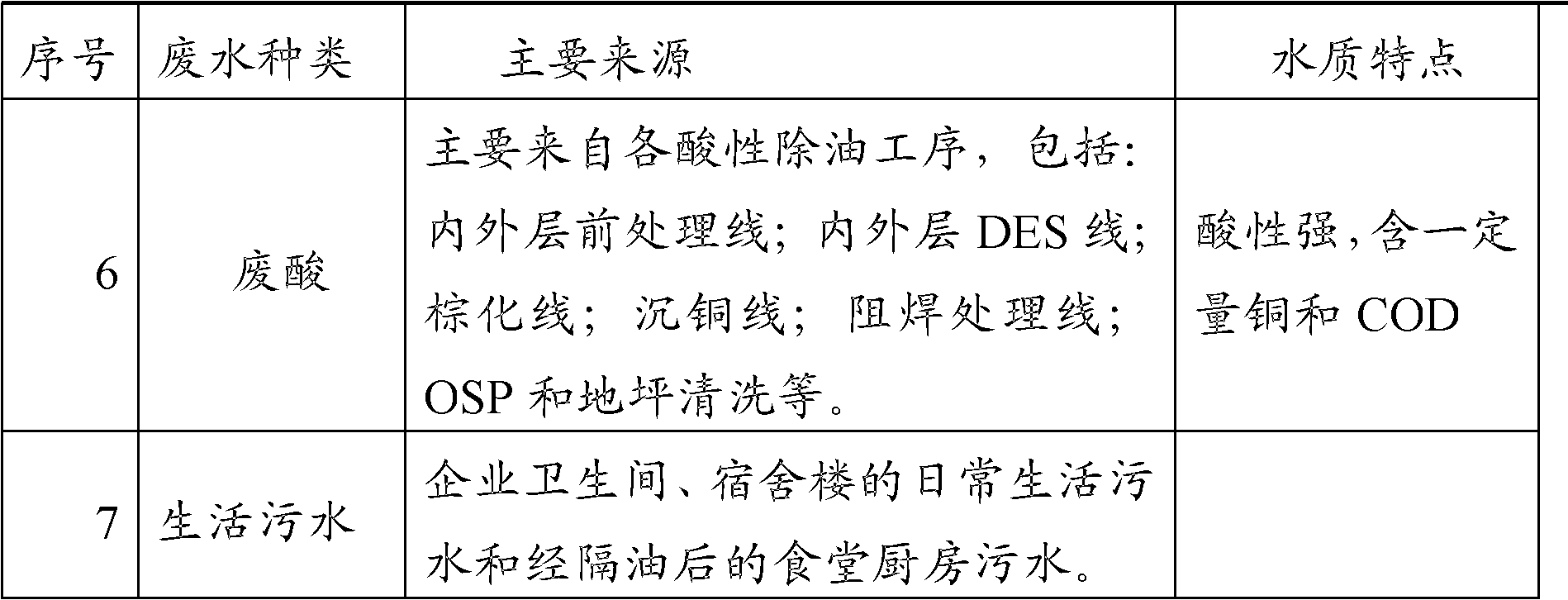

Technology for processing wastewaters in PCB (printed circuit board) industrial park

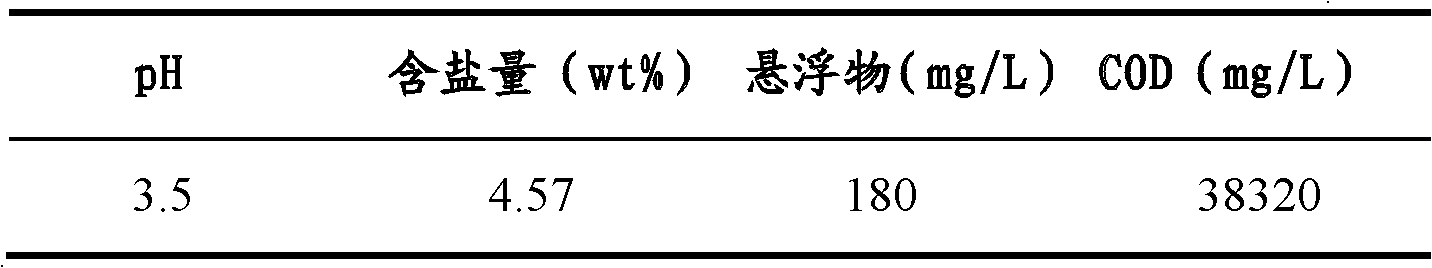

InactiveCN102515436AGood processing effectReduce processing costsMultistage water/sewage treatmentChemical oxygen demandWater quality

The invention discloses a technology for processing wastewaters in a PCB industrial park. The technology comprises the following steps: 1, dividing the wastewaters into a comprehensive wastewater, a complex wastewater, a wastewater containing nickel and cyanogen, an acid waste, an organic waste, an organic wastewater, domestic sewage, and an accident wastewater according to water qualities of various wastewaters, respectively collecting them, and allowing them to enter different wastewater collection pools; 2, respectively carrying out heavy metal removal processing through a corresponding method according to water quality characteristics of the wastewater in each wastewater collection pool, wherein there is no need to carry out the heavy metal removal processing on the domestic sewage; and 3, processing all the wastewaters according to a biochemical processing process. According to the invention, the wastewaters in the whole PCB industrial park are detailedly classified, different present wastewater processing processes are adopted to carry out the heavy metal removal processing according to the different water quality characteristics of the wastewaters, and then the biochemical processing is adopted to further remove heavy metals from the wastewaters, so the COD (chemical oxygen demand) in each obtained discharged water is less than 40mg / L.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD

Hydrogen chloride gas circulating recovery system

InactiveCN102302890AHigh recovery rateQuality improvementChlorine/hydrogen-chlorideDispersed particle separationSulfanilamideProcess engineering

The invention relates to a hydrogen chloride gas circulating recovery system, which is characterized in that: a main body comprises a hydrogen chloride tail gas tank, a first-stage falling film tower, a second-stage falling film tower and a third-stage packing tower which are parallelly arranged, and a vacuum buffer tank which participates in forming a circulating system, wherein a gas outlet of the vacuum buffer tank is connected with a gas inlet of a water ring vacuum unit; a discharge hole of the water ring vacuum unit is connected to feeding holes of a circulating tank 1, a circulating tank 2 and a circulating tank 3 respectively; and a discharge hole on the left side of the circulating tank 3 is connected with a circulating finished product tank. Hydrogen chloride tail gas generated in the process of producing industrial sulfanilamide is subjected to circulating absorption through the structure, and the obtained hydrochloric acid can be recycled, so that the resource utilization rate is fully improved, pollution-free production is promoted, production cost is reduced, and the zero emission index of hydrogen chloride gas is met.

Owner:SUZHOU WUGAN PHARMA

Method for purifying diamond concentrates through microwave oxidizing roasting

InactiveCN102381702AEmission reductionReduce pollutionEnergy based chemical/physical/physico-chemical processesChemical reactionMicrowave oven

The invention discloses a method for purifying diamond concentrates through microwave oxidizing roasting. In the method, the diamond concentrates are placed in an industrial microwave oven and subjected to oxidizing roasting in an oxidizing atmosphere for 20-120min at the roasting temperature of 300-650 DEG C, and residual graphite and amorphous carbon on surfaces of diamond and free residual graphite and amorphous carbon are removed through microwave oxidizing roasting, so that the purpose of purifying the diamond concentrates is achieved. In the invention, according to the characteristics of selective microwave heating, integral microwave heating and accelerated chemical reaction, the differences in wave absorption capacities of the graphite, the amorphous carbon and the diamond under a microwave field are utilized to rapidly oxidize the residual graphite in the diamond at the diamond oxidization temperature, meanwhile, the molecular structure of the diamond is not destroyed. Therefore, the method disclosed by the invention has many advantages of environment friendliness, simple procedures, high efficiency, reduced cost and the like.

Owner:CHANGSHA SYNO THERM

Treatment method of lignin production waste water

InactiveCN103172212AGuaranteed purityGuaranteed qualityGeneral water supply conservationDispersed particle separationElectricityInduced gas flotation

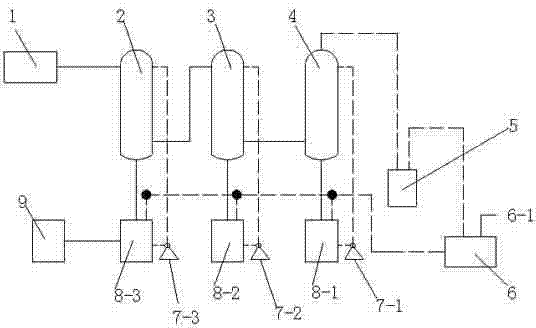

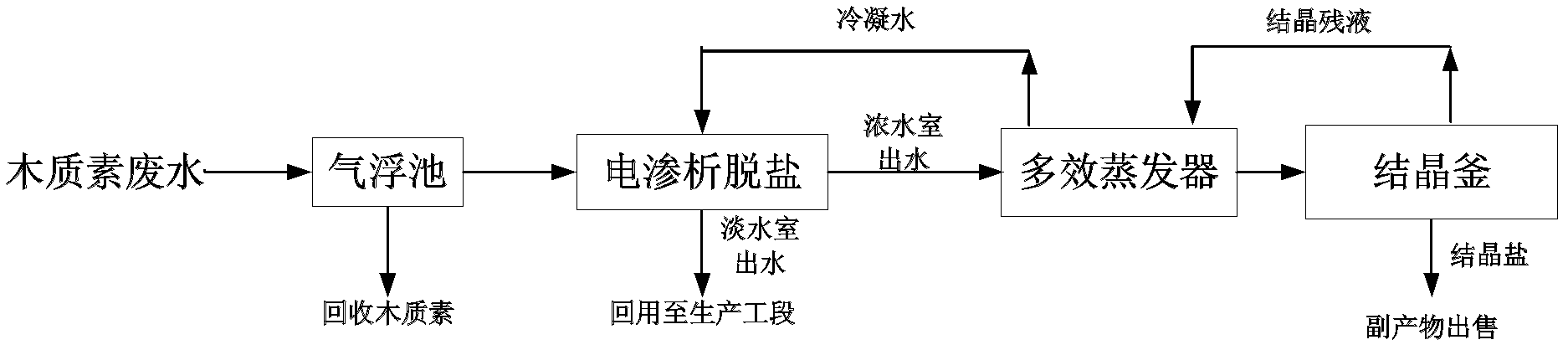

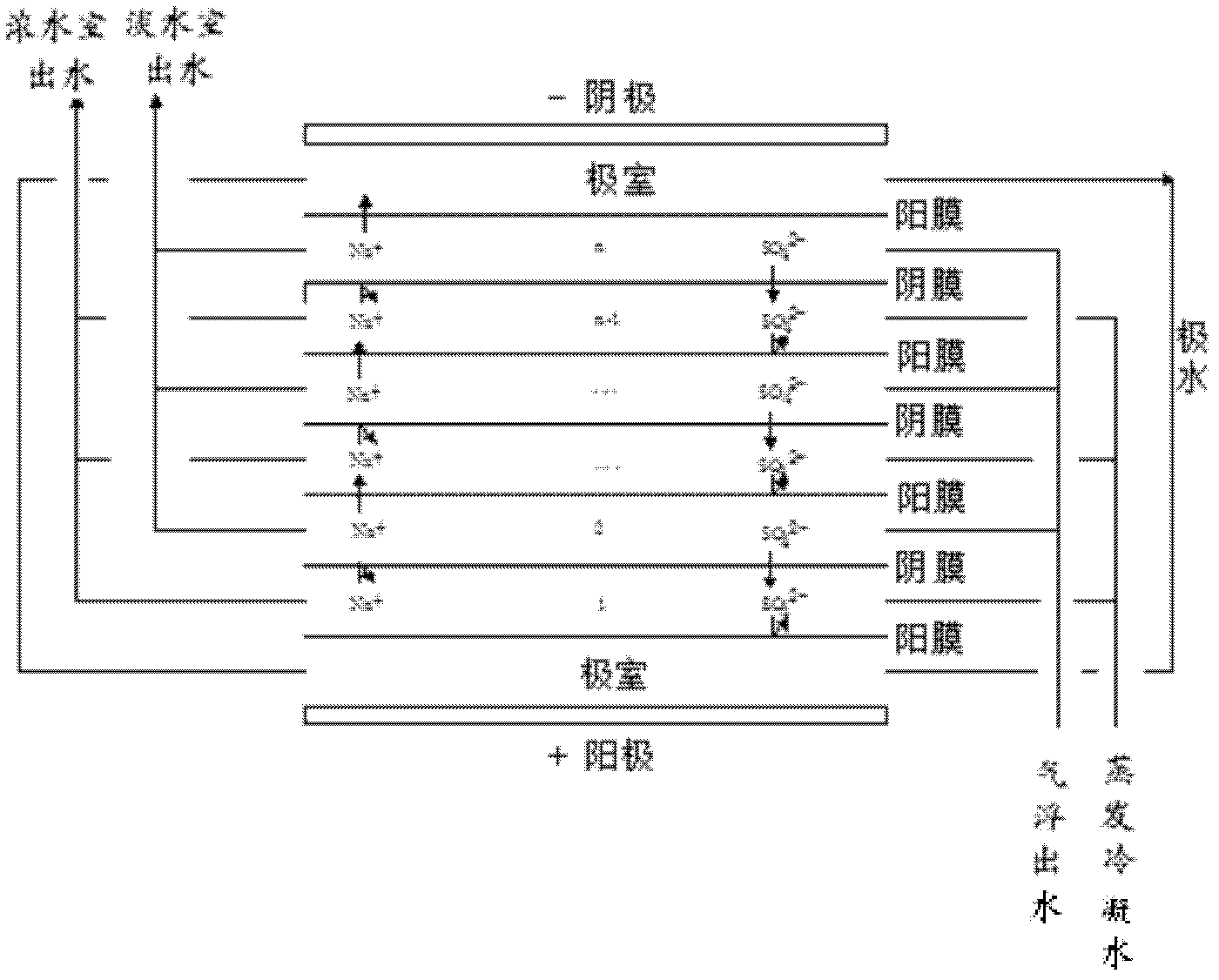

The invention relates to a treatment method of lignin production waste water, which comprises the following steps of: treating and recovering lignin residues in lignin waste water through a gas floatation method at first; respectively feeding gas floatation water and condensate water in a multi-effect evaporation stage into an electro-osmosis desalting device to obtain lignin waste water containing no salt basically and highly saline concentrated water; and recovering the lignin waste water containing no salt basically as supplementary water in the lignin production process, feeding the highly saline concentrated water into a multi-effect evaporation device to concentrate and crystallize, recovering the obtained evaporation condensate water in the electro-osmosis desalting device, and directly selling the obtained high-purity solid salt. Due to the process, resource recycling of waste water is realized; closed cycle of water is realized, so that the pollution abatement cost is reduced; organic combination of the electro-osmosis technology, multi-effect evaporation and the crystallization technology is sufficiently embodied; and the treatment method disclosed by the invention is a high-efficiency and economical treatment method.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

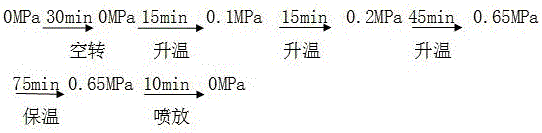

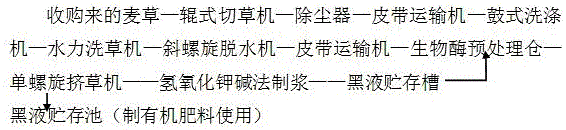

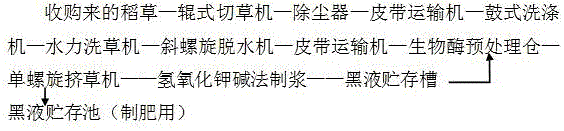

Method for producing potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction

InactiveCN106631564AImprove biological activityRetain inorganic nutrientsOrganic chemistryPulp by-products recoveryProduction lineMaterials preparation

The invention provides a method for producing a potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction, and belongs to the field of fertilizer production. The method comprises the three parts of pretreating wheat straw pretreatment black liquid by biological enzymes, extracting potassium hydroxide alkali process wheat straw boiling black liquid, and producing a finished product of the potassium fulvate organic fertilizer, wherein the process of pretreating wheat straw pretreatment black liquid by biological enzymes comprises the steps of wet process material preparation, wheat straw pretreatment by biological enzymes, and storage of black light containing rich potassium fulvic acid; the potassium hydroxide alkaline process wheat straw pulping extraction black liquid comprises extrusion of biological enzyme pretreatment wheat straws, mixing of wheat straws and potassium hydroxide medicine liquid in a pre-soaking machine, steaming ball steaming boiling spray discharging, and steamed and boiled black liquid collection and storage. The organic fertilizer production line comprises black liquid evaporation and concentration, guniting pelleting machine treatment, hot and cold sieving system treatment and organic fertilizer finished product packaging. The paper making black liquid is changed from waste into valuable materials; through biological enzyme pretreatment, the high-activity potassium fulvate organic fertilizer is produced.

Owner:宁夏同创秸科生物科技有限公司

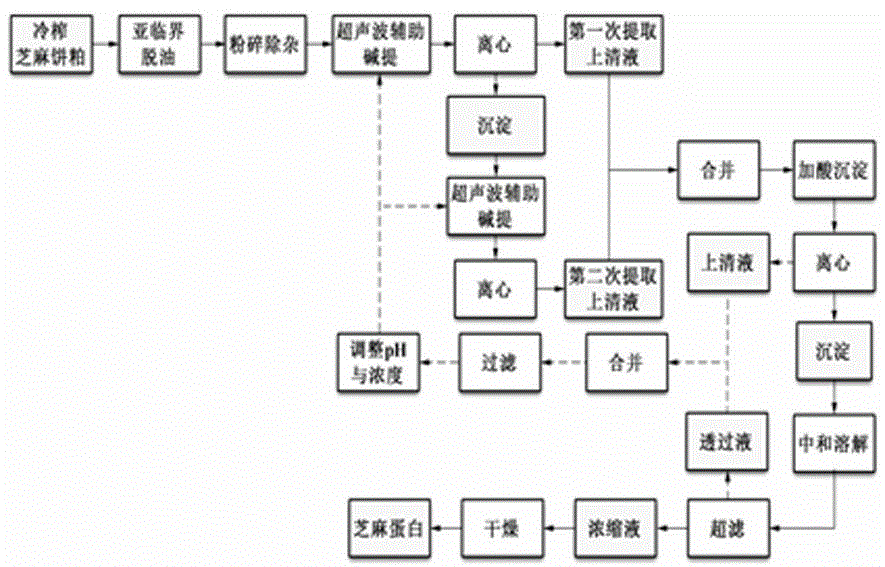

Method for ultrasonic-assisted weak base extraction of proteins in cold-pressed sesame cake meal

ActiveCN105124132AImprove qualityReduce usageProteins working-up by texturisingVegetable proteins working-upBiotechnologyUltrasonic assisted

The invention belongs to the technical field of deep processing of oil, and particularly relates to a method for ultrasonic-assisted weak base extraction of proteins in cold-pressed sesame cake meal. The method specifically comprises the following steps: recovering oil in sesame cake meal through subcritical extraction; then, crushing the sesame cake meal after oil extraction, and removing impurities; extracting sesame seed proteins through two times of ultrasonic-assisted base processes; centrifuging a protein extracting solution, taking supernatant, and acid-precipitating the proteins; performing centrifugation to obtain the precipitated proteins; and performing ultrafiltration and drying so as to obtain finished products of sesame seed proteins. Compared with a conventional alkali-solution and acid-isolation method, the method disclosed by the invention has the advantages of high quality of products, little pollution, high efficiency, and the like. Through the adoption of the method disclosed by the invention, an oil production byproduct, namely the low-temperature sesame cake meal, is produced into sesame seed proteins with a high added value, so that the comprehensive utilization of resources is realized, the economic benefits are improved, and the method disclosed by the invention is of positive socioeconomic significance.

Owner:HENAN ACAD OF AGRI SCI

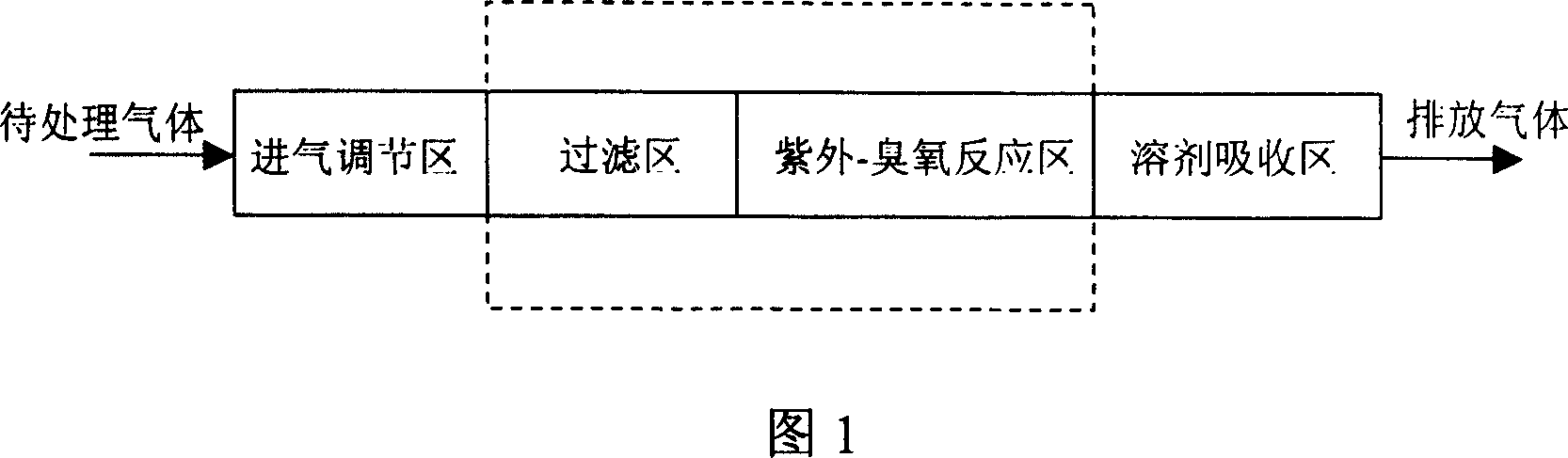

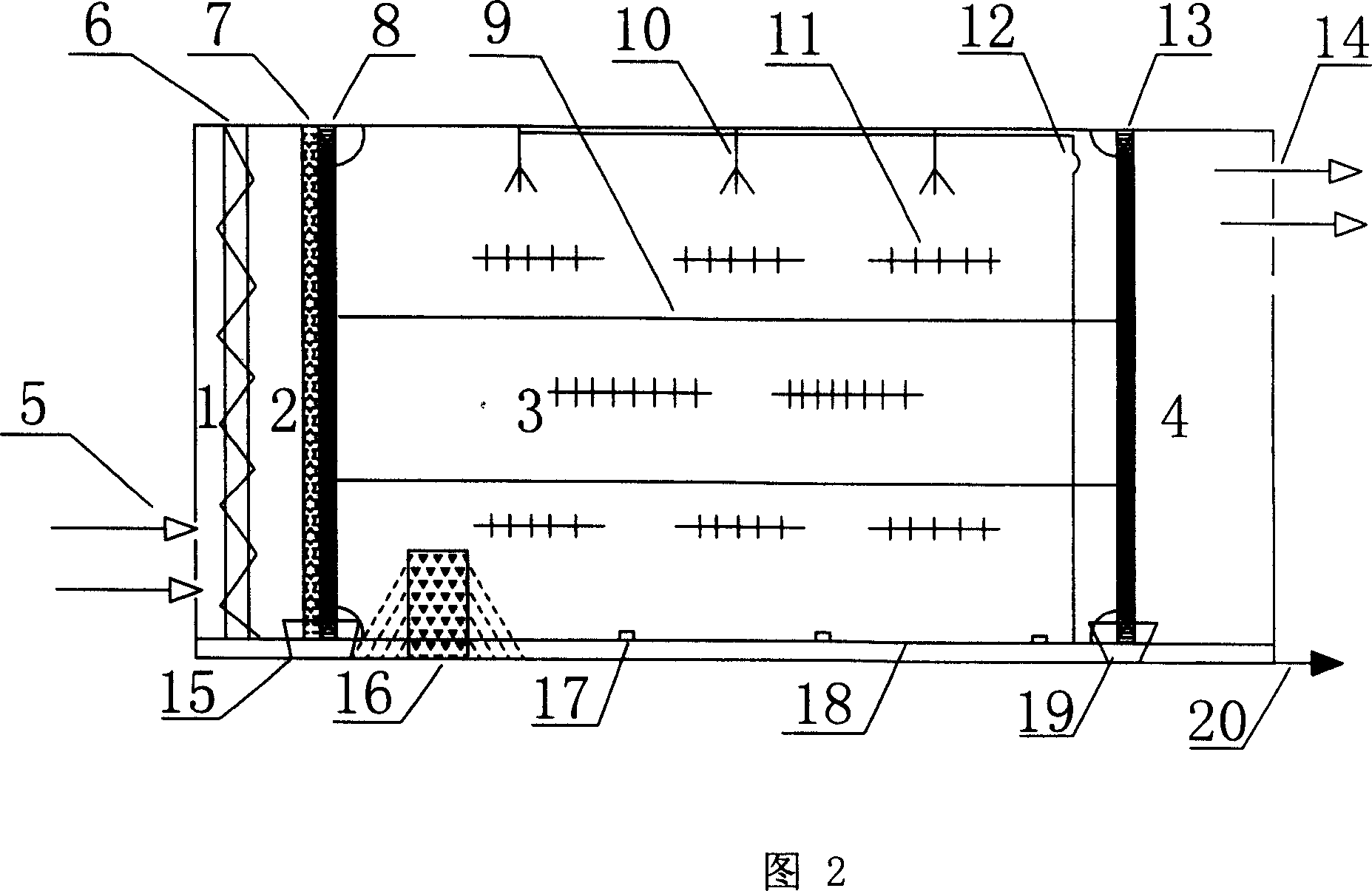

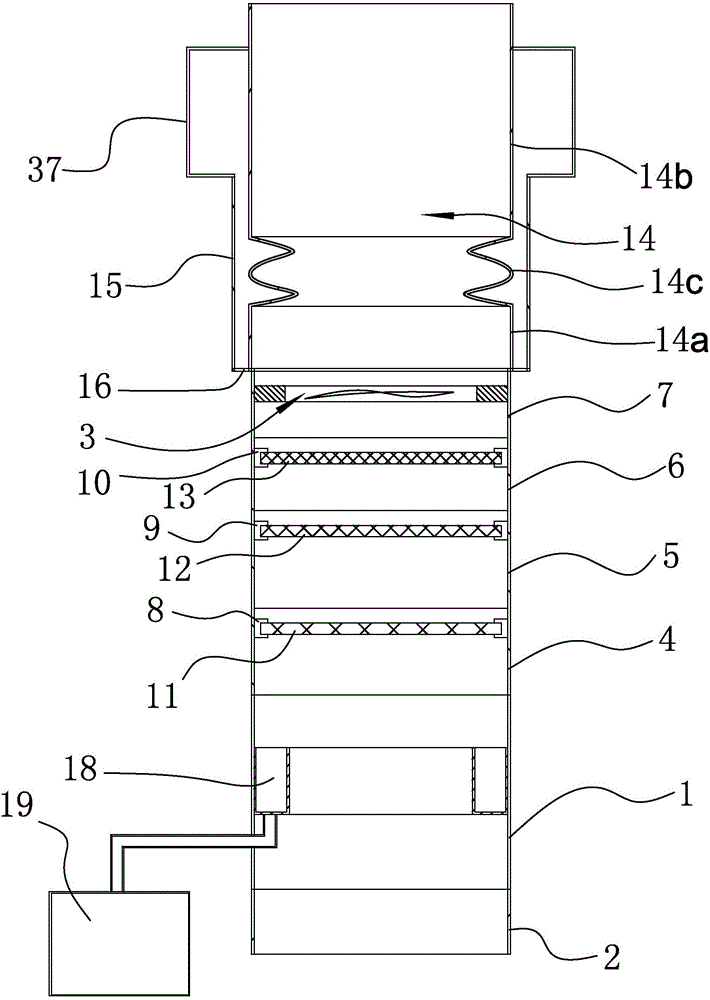

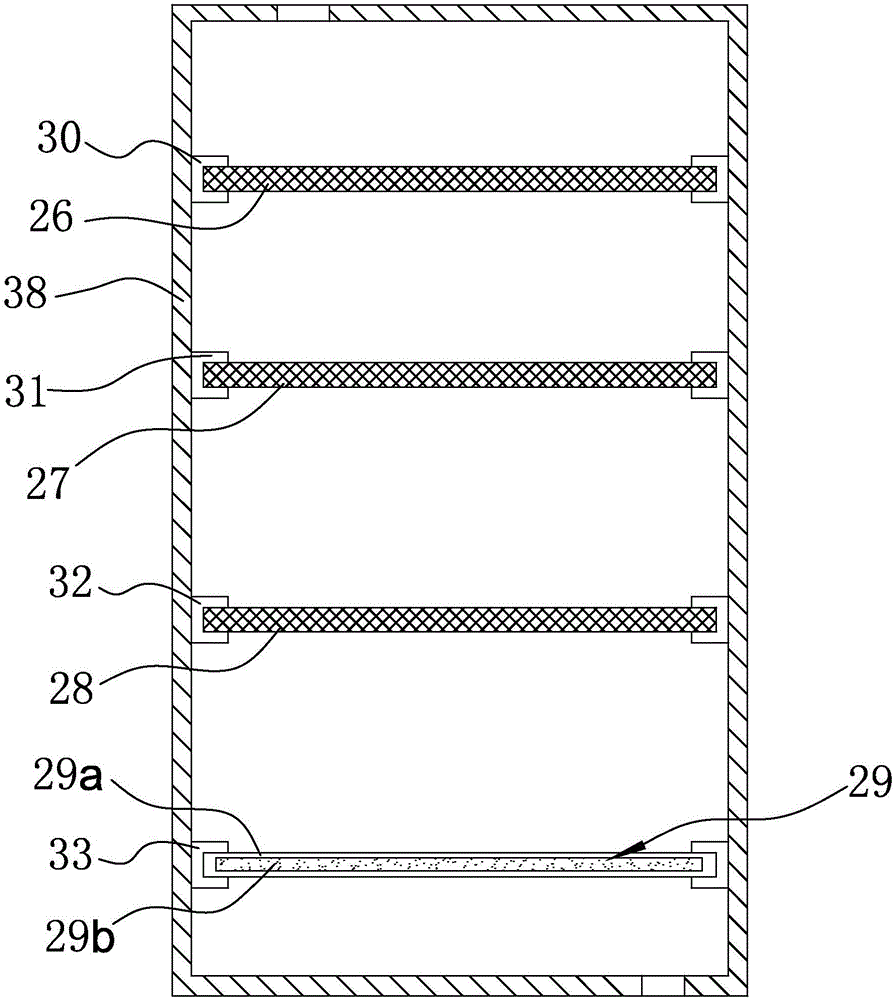

Device for photochemical degradating pollution gas

InactiveCN101053758AAchieve degradationStrong oxidation abilityDispersed particle separationEnergy based chemical/physical/physico-chemical processesBenzenePhotochemical degradation

The invention provides a device for optics degradating dusty gas, comprising a container used as a reactor characterized in that: the reactor is composed of an air inlet control zone, a filter zone, a UV-ozone reacting zone and a solution absorbing zone, wherein they need not be connected by conduit, the UV-ozone reacting zone is at least mounted with a ultraviolet light cluster each comprising at least one ultraviolet light tube, there is ozone in the UV-ozone reacting zone when the device runs, and the tail gas is completely purified by solution absorbing unit to discharge from the exhaust port after air inlet controlled. The invention can be used for the treatment of the dusty gas like 'three-benzene' discharged by the plant of shoes and furnishings, for the treatment of the exhaust gas with fetid smell discharged by effluent treatment plant, tannery, culturing plant and pharmaceutical factory, and also for the pollution gas discharged by other factories.

Owner:FUJIAN NEWLAND ENTECH CO LTD

Preparation method of industrial sewage/wastewater decolorant

InactiveCN104475036AImprove adsorption capacityReduce pollution control costsOther chemical processesWater/sewage treatment by sorptionAluminium sulfateManufacturing technology

The invention relates to the technical field of design and manufacturing of industrial sewage / wastewater decolorants, and particularly provides a preparation method of an industrial sewage / wastewater decolorant. The preparation method comprises the following steps: (1) proportionally and sequentially adding 2-8 parts of liquid dicyandiamide, 7-13 parts of formaldehyde, 1-5 parts of catalyst and 1-3 parts of aluminum sulfate into a reaction kettle, stirring for 10-15 minutes, heating to 65-80 DEG C, and keeping the temperature for 3-5 hours; and (2) after the mixed solution reaction is finished, stopping stirring, and cooling to room temperature to obtain the product decolorant, wherein the catalyst is Al2O3. The decolorant is mainly used for decolorization and decontamination of industrial sewage / wastewater.

Owner:XINJIANG DELAND

Simple automatic water-saving spraying and dedusting system of temporarily constructed road

ActiveCN105126503AEfficient dust removalSimple structureUsing liquid separation agentWater sourceEngineering

The invention belongs to a simple automatic water-saving spraying and dedusting system of a temporarily constructed road. The system is composed of a ground art and an underground part. The ground part is composed of water pumps, a dust inductor, supporting columns, a spraying water pipe and fixing bases. The hollow supporting columns are located on one side or two sides of the temporarily constructed road at intervals through the fixing bases. The upper ends of the supporting columns are fixedly provided with water pipe support grooves, and the upper ends of the water pipe support grooves support the transverse spraying water pipe. The side, towards the temporarily constructed road, of the spraying water pipe is provided with buckle type spherical spray nozzles at intervals. Water inlets of the water pumps are communicated with a water storage pond, and water outlets of the water pumps are communicated with the two ends and the middle of the spraying water pipe respectively. The dust inductor control operation of the water pumps through a controller. The underground part comprises a basement dewatering well, a drainage ditch, the water storage pond and a settlement pond. The constructed road can be effectively dedusted through the method, pollution-free construction is guaranteed, and the system has the advantages of being simple and practical in structure, capable of saving water sources, low in pollution control cost, capable of recycling sewage in site and good in use effect.

Owner:CHINA CONSTR MUNICIPAL ENG +1

Laser lapping half penetration weld method

InactiveCN103008884AAvoid color differencesReduced processLaser beam welding apparatusColor differenceTreatment costs

The invention discloses a laser lapping half penetration weld method, which is characterized in that a protection film covers a non-penetration surface to obstruct air for welding. Because the protection film covers the non-penetration surface to obstruct air for welding, the exposed non-penetration surface of a stainless steel trolley coach steel structure is reduced and prevented from being oxidized and discolored; the original color of the outer surface of the stainless steel trolley coach steel structure can be kept attractive; the operation of electrochemical corrosion to remove oxidative stain for the exposed non-penetration surface after welding is canceled and reduced; the outer surface of the stainless steel trolley coach steel structure is protected from color difference; working procedures are reduced, the time is saved, the production efficiency is improved, and the product cost is lowered; the chemical preparation discharge and the environment pollution are reduced; and the pollution treatment cost is saved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Method for utilizing biological enzyme pretreatment + potassium hydroxide alkaline process straw pulping to extract black liquor to produce potassium fulvic acid organic fertilizer

InactiveCN106699245AImprove biological activityRetain inorganic nutrientsPretreatment with alkaline reacting compoundsClimate change adaptationPotassiumPotassium hydroxide

The invention relates to a method for utilizing biological enzyme pretreatment + potassium hydroxide alkaline process straw pulping to extract black liquor to produce a potassium fulvic acid organic fertilizer and belongs to the field of organic fertilizer production. The method for producing the organic fertilizer comprises black liquor extraction after biological enzyme pretreatment, black liquor extraction after potassium hydroxide alkaline process straw cooking and production of the finished potassium fulvic acid organic fertilizer. According to the method, waste is turned into wealth, the novel biological enzyme pretreatment technology is utilized to extract the natural bioactive substance - fulvic acid which is very high in chemical activity and biological activity from the straw. Besides, inorganic nutrient such as nitrogen, potassium, calcium, magnesium, sulfur and silicon in straw stalk is reserved.

Owner:宁夏同创秸科生物科技有限公司

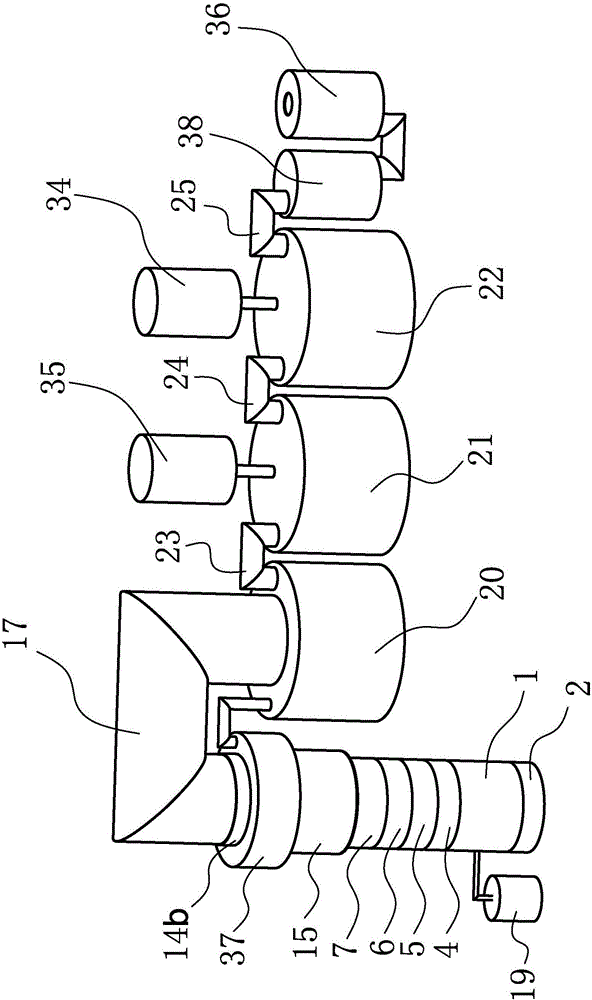

Industrial lampblack treatment device

ActiveCN105727710AImprove purification effectEfficient removalCombination devicesGas treatmentParticulatesWater storage

The invention provides an industrial lampblack treatment device, belongs to the technical field of industrial waste gas treatment, and aims to solve the technical problem that the existing industrial waste gas emission is severe in pollution. The industrial lampblack treatment device comprises a base and a connection sleeve, wherein the upper end of the connection sleeve is connected with a collection pipe in a sealing manner; a plurality of filter screens are arranged in the collection pipe; the collection pipe comprises a first collection pipe, a second collection pipe, a third collection pipe and a fourth collection pipe; the upper end of the fourth collection pipe is connected with a heat exchange pipe device in a sealing manner; at the upper end of the fourth collection pipe, the lampblack is conveyed to a water storage bucket, an alkaline liquor storage tank, an acid liquor storage tank, a treatment cylinder I and a treatment cylinder II through connection pipes, so as to filter and eliminate the hazardous matters such as acid matters, alkaline matters, dusty particulate matters and carbon monoxide gas in the lampblack layer by layer. The industrial lampblack treatment device has the advantages of being wide in range of hazardous matter filter and elimination.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

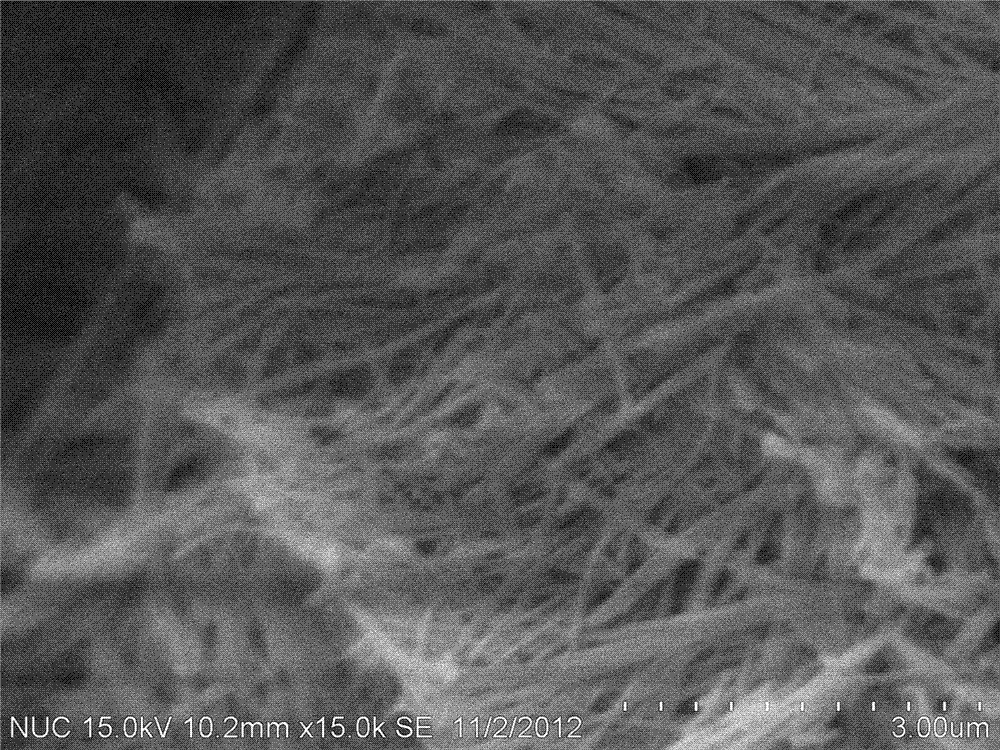

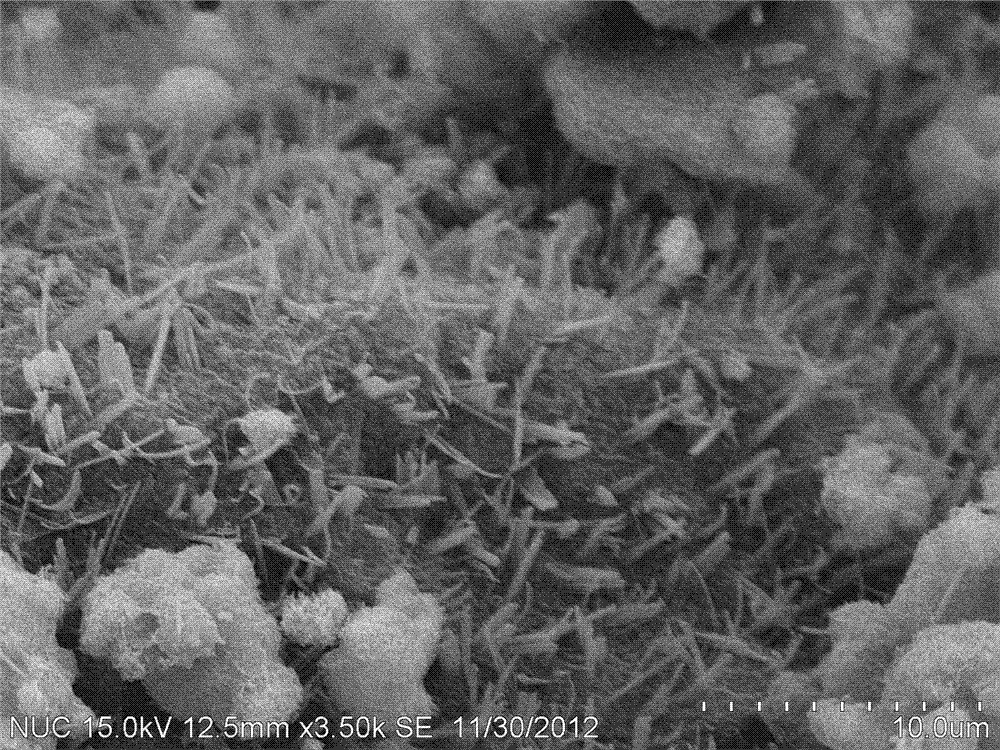

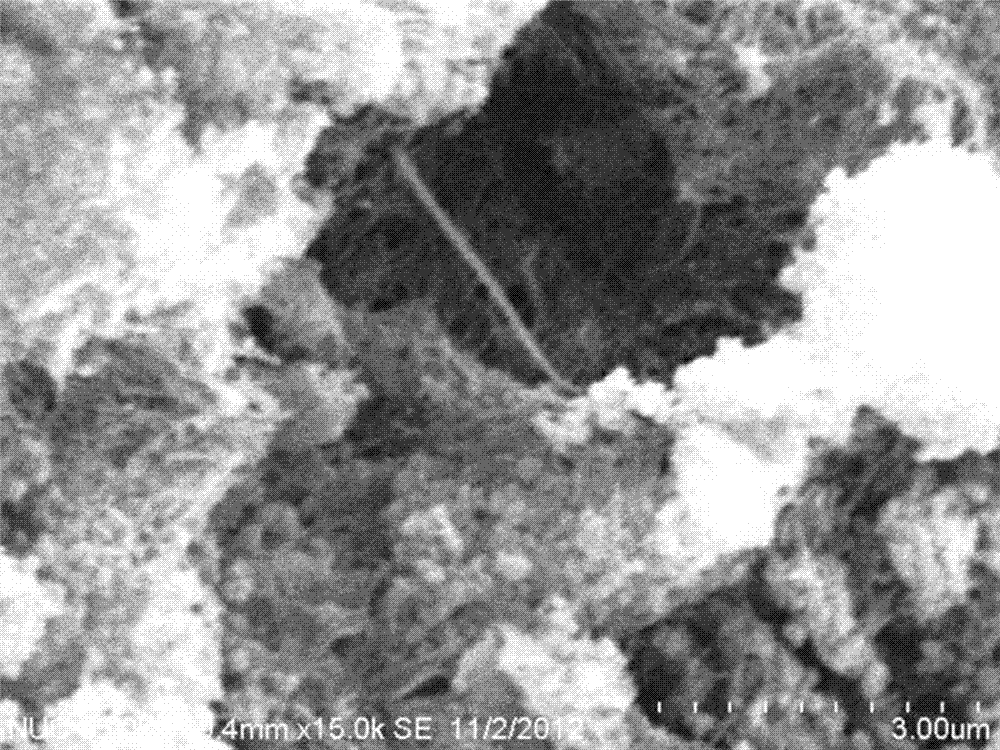

Preparation method based on photocatalytic activity for titanium dioxide nanofibers

InactiveCN103482699AAccelerate the pace of actual useReduce secondary pollutionPhysical/chemical process catalystsTitanium dioxideFiberNanofiber

The invention discloses a preparation method for titanium dioxide nanofibers on the basis of photocatalytic activity. According to the preparation method, in order to prepare uniform and slender titanium dioxide nanofibers, the charging coefficient of a reaction kettle is controlled to be 0.55 to 0.65 during the process of preparing the titanium dioxide nanofibers by adopting a hydrothermal method; the preparation method lays the foundation of mass production of the titanium dioxide nanofibers, and the actual use of the titanium dioxide nanofibers on the aspect of organic pollutant degradation through photocatalysis is quickened.

Owner:ZHONGBEI UNIV

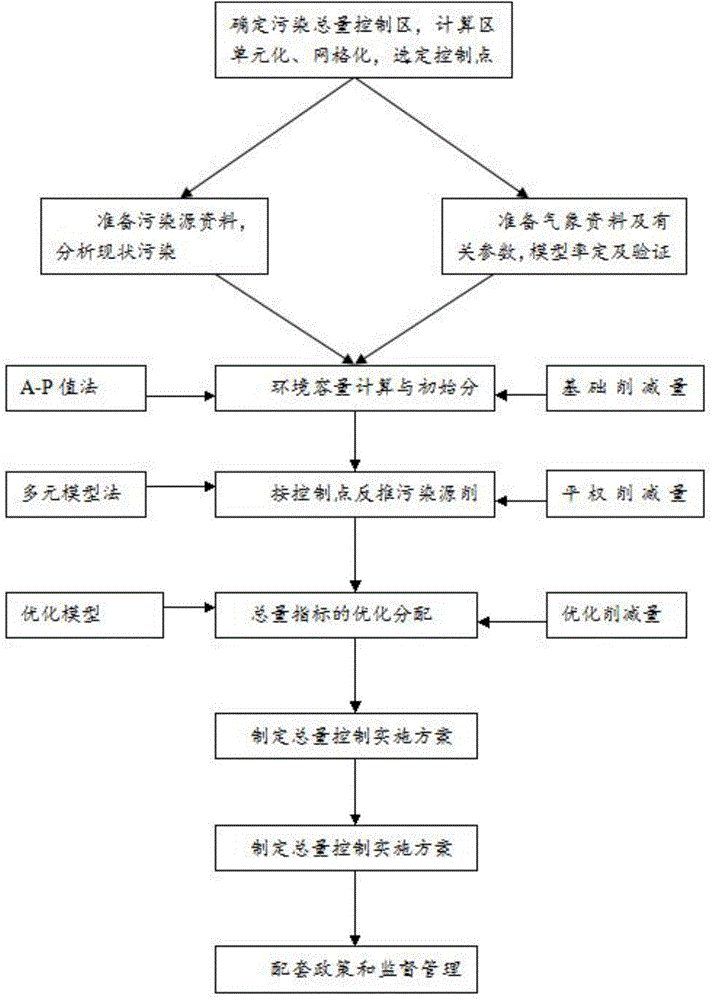

Step-by-step method for controlling total amount of air pollution

The invention discloses a step-by-step method for controlling the total amount of air pollution. The method includes: performing basic reduction quantity calculation of pollution sources; calculating affirmative reduction quantity with a multi-source model method; performing optimal allocation of total amount controlled load. An A-P value method and the multi-source model method are integrated, an optimal allocation model is introduced, and a method system which is reasonable in technology and economically feasible is formed.

Owner:SICHUAN UNIV

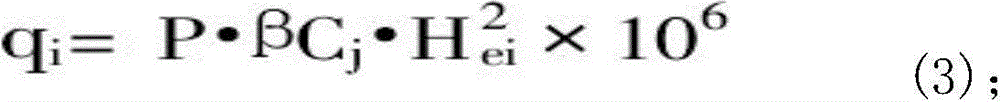

Method for flue gas desulfurization by using dyeing wastewater, and absorption tower

InactiveCN101091874AReduce pollution control costsImprove economic efficiencyDispersed particle separationWater/sewage treatmentFlue-gas desulfurizationSmoke

The invention relates to a method of desulphurization of the waste water and the absorption tower. Its desulphurization method includes: 1) printing waste water pretreatment; 2) the desulphurization about the printing waste water sprays; 3) doctor solution output and so on main steps. The absorption tower contains a tower body, an air outlet on the top of the tower body. The drawing fan is on the outside of the air outlet. The tower in vivo upper side equipped with two defogging levels with two spray levels below. The tower body breast is equipped with the smoke mouth; the tower body base is equipped with the overflow gate. The merit of the invention is that with the printing waste water removing haze in SO2, not only can meet the emission standards, but also can save the sulfuric acid in the printing waste water. Also it can largely reduce chemistry oxygen consumption, which is advantageous in further processing in water disposal plant, and makes the waste water and the waste gas under the comprehensive program of public order. The invention greatly reduces the anti-pollution cost, promotes the business economic benefit, promotes enterprise to implement the waste water and gas governing.

Owner:JIANGSU ZHENGTONG HONGTAI INC

Preparation process of bovine blue wet leather

ActiveCN109628663AGood emulsifying and moisturizing effectImprove uniformityLeather manufacturingLeather clicking/perforating/clickingHair removalSalt free

The invention relates to the technical field of leather processing and provides a preparation process of bovine blue wet leather with a large leather area, broad growth patterns, great comprehensive performance and small environmental pollution. The bovine blue wet leather prepared by the preparation process of the bovine blue wet leather is large in width, broad in pattern, compact and fine in grain surfaces, consistent in color, uniform in thickness, soft, plump and elastic in leather body and high in physical strength. Moreover, the production process flow is simple and easy to implement, and the production cost is proper; in an implementation process, recycling of wastewater, preservation and removal of hair with less ash and sulfur, ammonia-free deashing and softening, salt-free pickling chrome tanning and other clean production technologies are also adopted. The water for tanning can be saved, the pollution of tanning is obviously reduced, the pollution disposal cost is lowered,considerable benefits of energy conservation and emission reduction are provided, and the preparation process is suitable for industrial production and use. The preparation process of the bovine bluewet leather specifically comprises the following steps of batching of bovine raw material leather, soaking in water, hair removal and expansion, beef removal, splitting, ash removal and softening, pretreatment, dewatering and peeling, soaking in acid and tanning with chrome and washing with water and discharging.

Owner:XUZHOU XINGNING LEATHER CO LTD

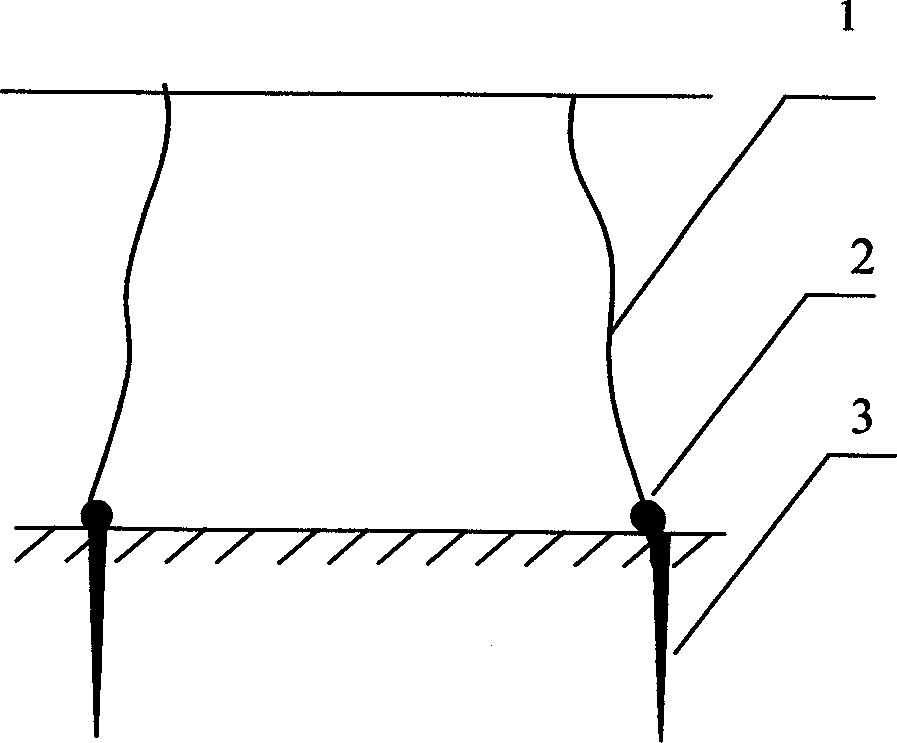

Anti-pollution and pollution reducing method for large water area

InactiveCN1458344AImprove pollution control effectImprove water qualityWater cleaningWater flowSewage

The present invention discloses one simple, unique, efficient and cheap large area water pollution preventing and reducing isolation method. The technological scheme is to separate water of different pollution degree with mixing. Sewage is controlled to flow through separated water flow belt and has no pollution to large area water. The said method needs no biological and chemical additive added.

Owner:杨树清

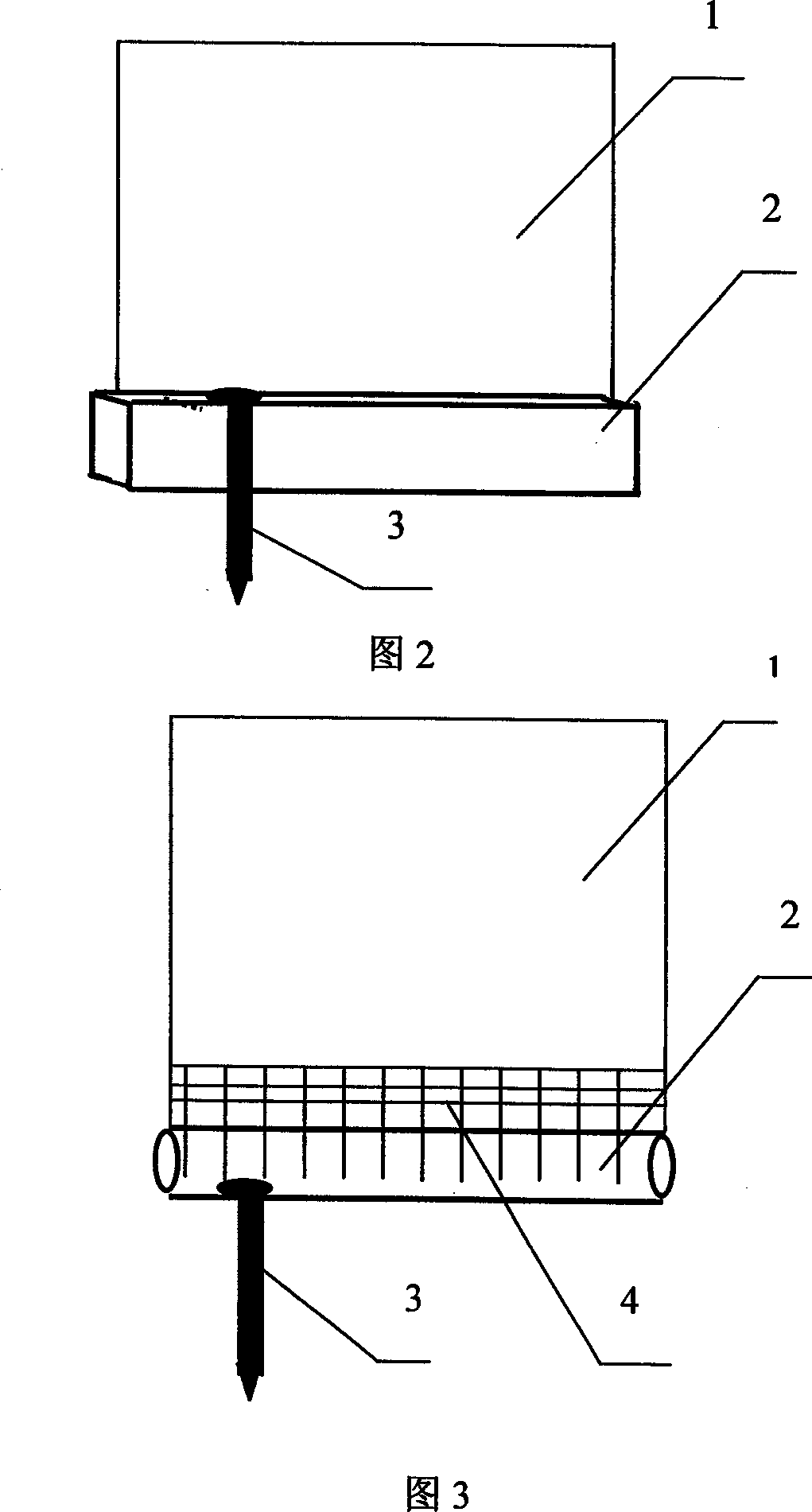

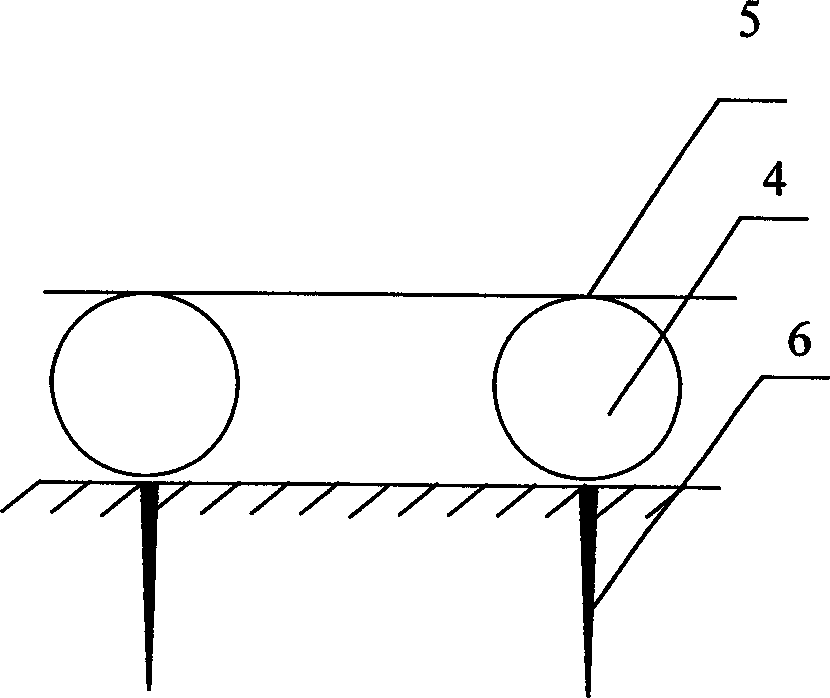

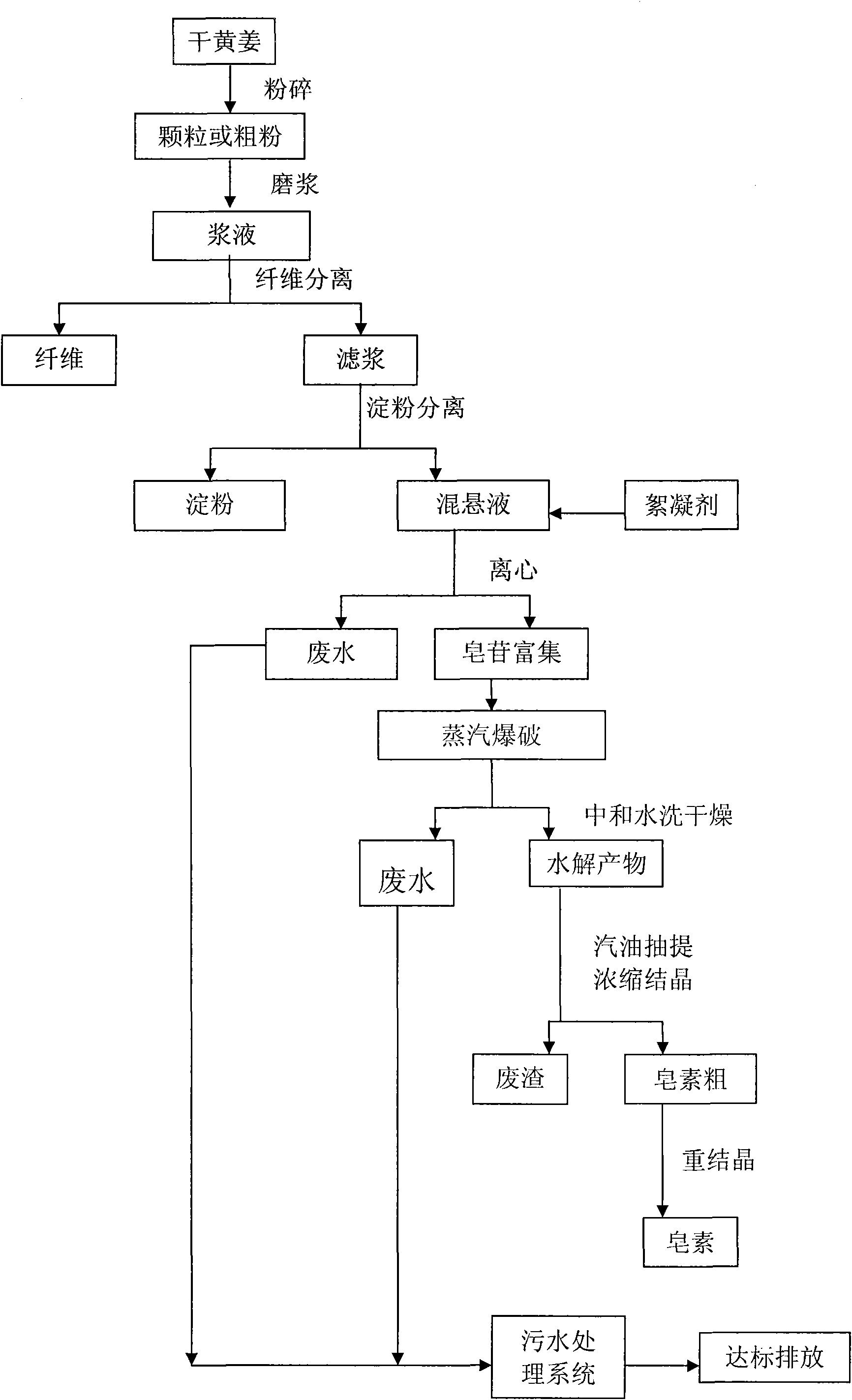

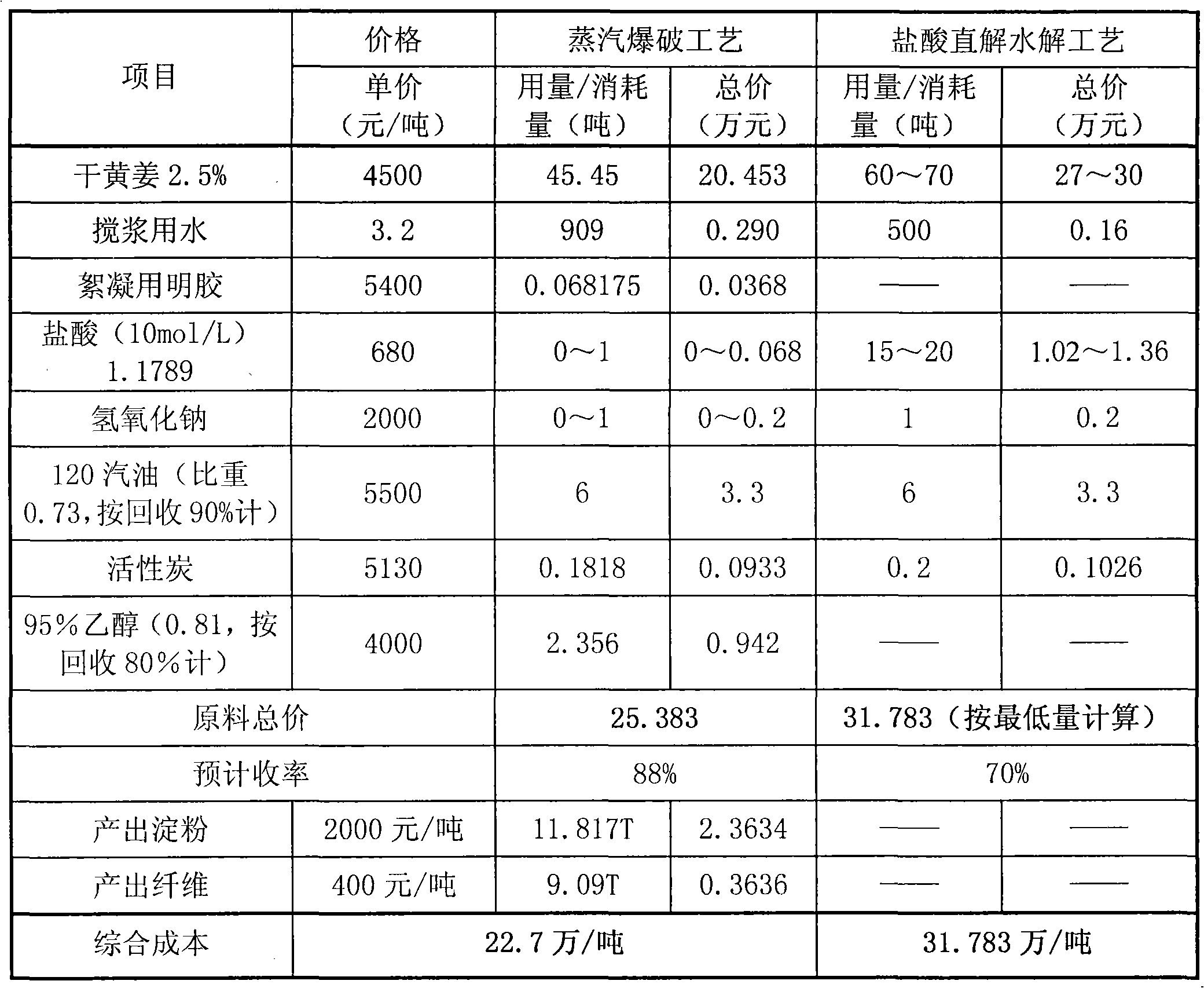

Method for extraction of diosgenin via steam explosion

The invention relates to a production process for extraction of diosgenin via steam explosion. The high-purity diosgenin is prepared via preparation of pulp with a dioscoreaceae plant turmeric, preparation of a solid substance via flocculation and sedimentation, hydrolysis by adopting the steam explosion technology, extraction of hydrolysis products with organic solvents and then recrystallization. The process needs no large amount of acid, the wastewater discharge can be reduced, the environmental protection can be facilitated, the energy consumption and production cost can be reduced, and the process is suitable for industrial production.

Owner:CHONGQING HUAPONT PHARMA

Nano-silver honeycomb-type purification activated carbon and preparation method thereof

ActiveCN103432991AThe method is simple and feasibleReduce pollution control costsOther chemical processesAlkali metal oxides/hydroxidesChemistryPollution

The invention relates to nano-silver honeycomb-type purification activated carbon and a preparation method thereof. The nano-silver honeycomb-type purification activated carbon uses the following raw materials in part by weight: 32 to 38 parts of chemical activated carbon, 25 to 30 parts of granular activated carbon from coal, 35 to 42 parts of cocoanut active charcoal, 4 to 6 parts of nano-silver with purity of 99 percent, 1 to 2 parts of methylcellulose and 1 to 2 parts of talcum powder. The method comprises the following steps: carrying out ball milling, mixing the raw materials with uniformly stirring to obtain a product material; carrying out vacuum pugging, extrusion forming, air-drying and sintering to obtain the nano-silver honeycomb-type purification activated carbon. According to the invention, the activated carbon can be guaranteed to have an excellent dirt adsorption function, also can have an excellent effect of killing and inhibiting microorganisms which are pathogenic for people, is suitable for the environment such as a hospital and the like, and also has the advantages of firmness for sizing, durability, simple and practicable method, low pollution control cost, low carbon, energy saving and good treatment effect.

Owner:台州绿之源环保股份有限公司

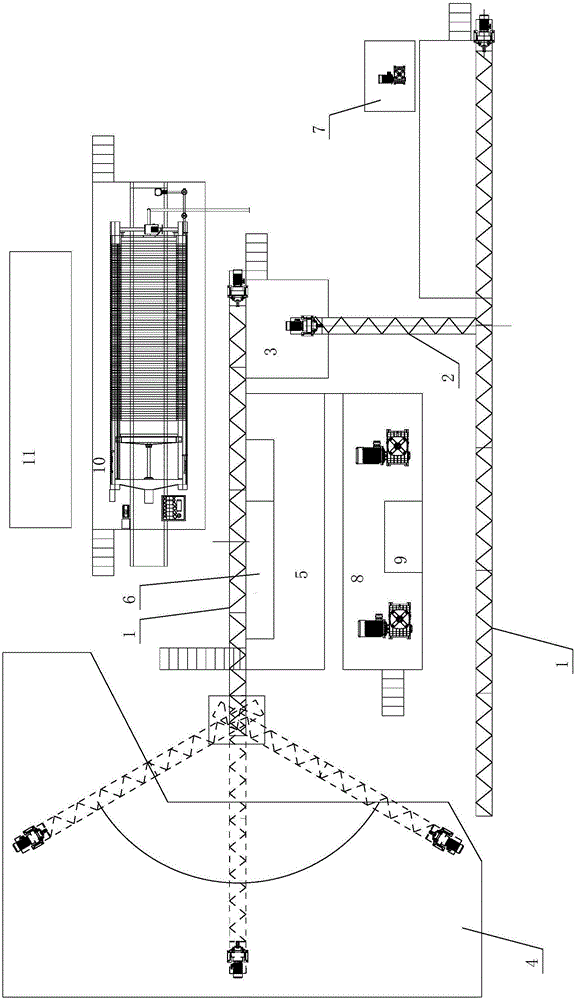

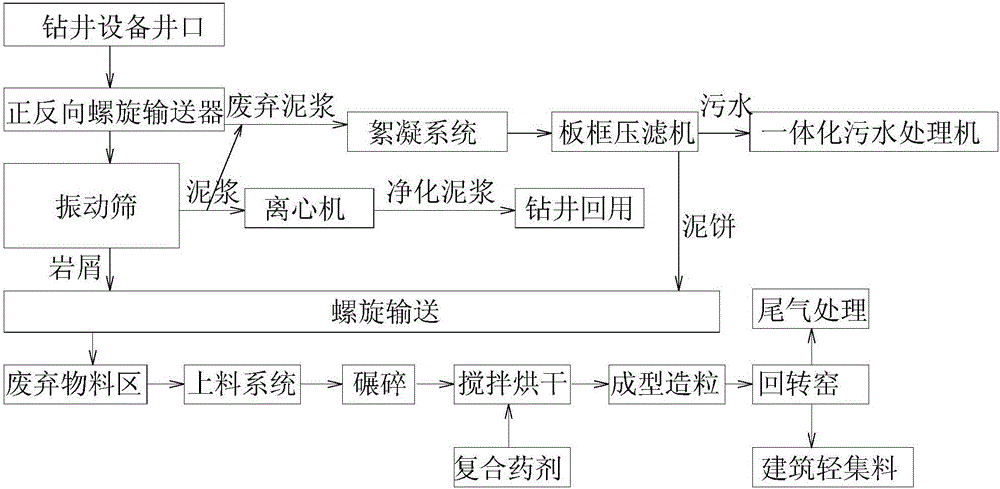

Petroleum drilling waste mud reduction zero-release recycling system and method

PendingCN106082581AAvoid increasing the amountReduce generationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWell drillingSludge

The invention relates to the technical field of petroleum drilling waste mud recycling treatment, in particular to a petroleum drilling waste mud reduction zero-release recycling system and method. The system comprises a forward and reverse spiral conveyor arranged at the mouth of a well of drilling equipment, the forward and reverse spiral conveyor is connected with a vibration sieve through a non-shaft spiral conveyor, the vibration sieve is connected with a waste material region through the forward and reverse spiral conveyor, the vibration sieve is connected with a mud storage tank through a pipeline, the mud storage tank is connected with a horizontal type centrifugal machine through a submersible slurry pump, the horizontal type centrifugal machine is connected with the waste material region through the forward and reverse spiral conveyor, the waste material region is connected with a movable prying type organic sludge recycling rotary kiln through a conveyor belt. According to the petroleum drilling waste mud reduction zero-release recycling system and method, mud non-grounding equipment is adopted, and waste mud reduction and recycling are achieved; in addition, waste mud and debris mud-water separation recycling can be achieved.

Owner:TIANJIN FANYINDETAI PETROLEUM ENVIRONMENTAL PROTECTION TECH DEV INC

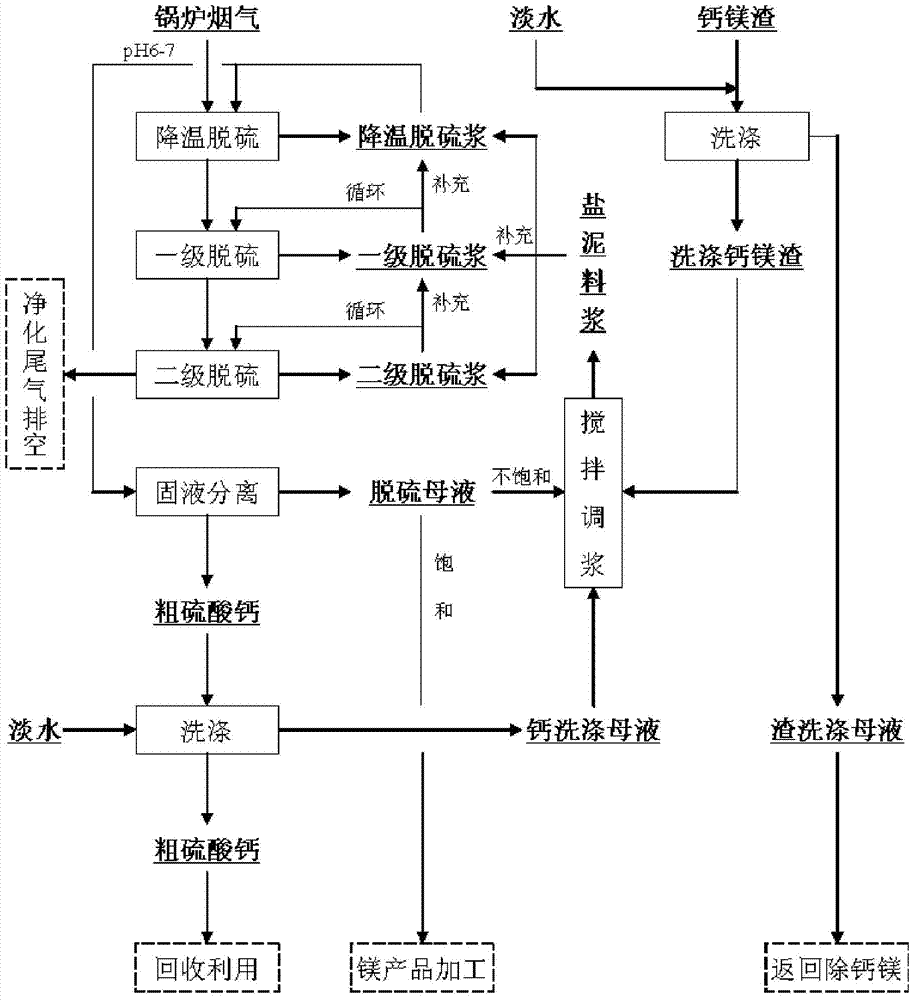

Flue gas desulfurization method

The invention provides a flue gas desulfurization method which comprises the following steps: calcium and magnesium slag is configured to salty mud slurry after washed by water; coal-fired flue gas and the salty mud slurry or primary desulfurized circulatory slurry are subjected to parallel-flow cooling, and simultaneously, part of sulfur dioxide in the coal-fired flue gas is absorbed to obtain primary flue gas and cooled desulfurization slurry; the cooled desulfurization slurry and the coal-fired flue gas are subjected to parallel-flow cooling repeatedly until the pH (potential of hydrogen) value of the cooled desulfurization slurry is 6-7, and solid-liquid separation is performed to obtain calcium sulfate and a desulfurization mother liquid; the primary flue gas and the salty mud slurry or secondary desulfurized circulatory slurry are subjected to reversed-flow desulfurization to obtain secondary flue gas and primary desulfurized circulatory slurry; and the secondary flue gas and the salty mud slurry are subjected to reversed-flow desulfurization to obtain purified flue gas and secondary desulfurized circulatory slurry. With the adoption of the flue gas desulfurization method, the waste calcium and magnesium slag is recycled, the pollution treatment cost of an enterprise is reduced, moreover, sulfur dioxide is effectively removed, and cleanness and environmental protection are achieved.

Owner:DAZHOU HENGCHENG ENERGY GROUP

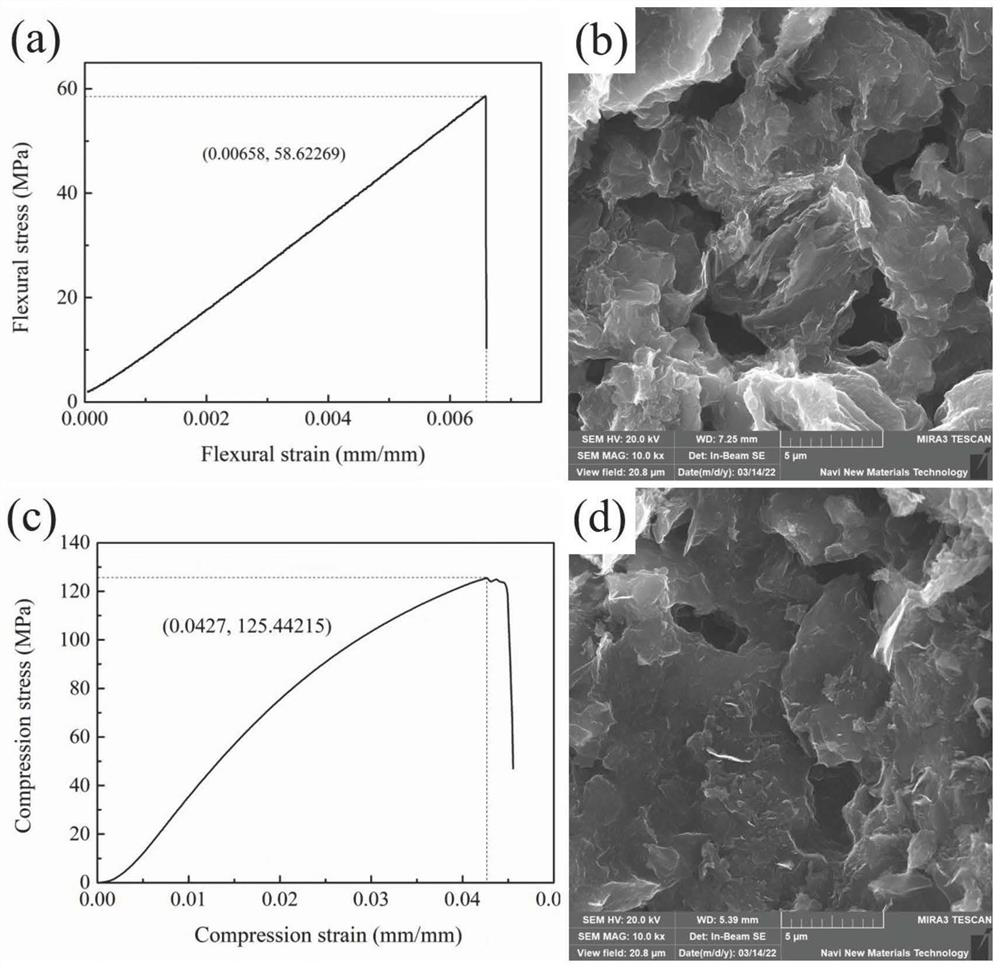

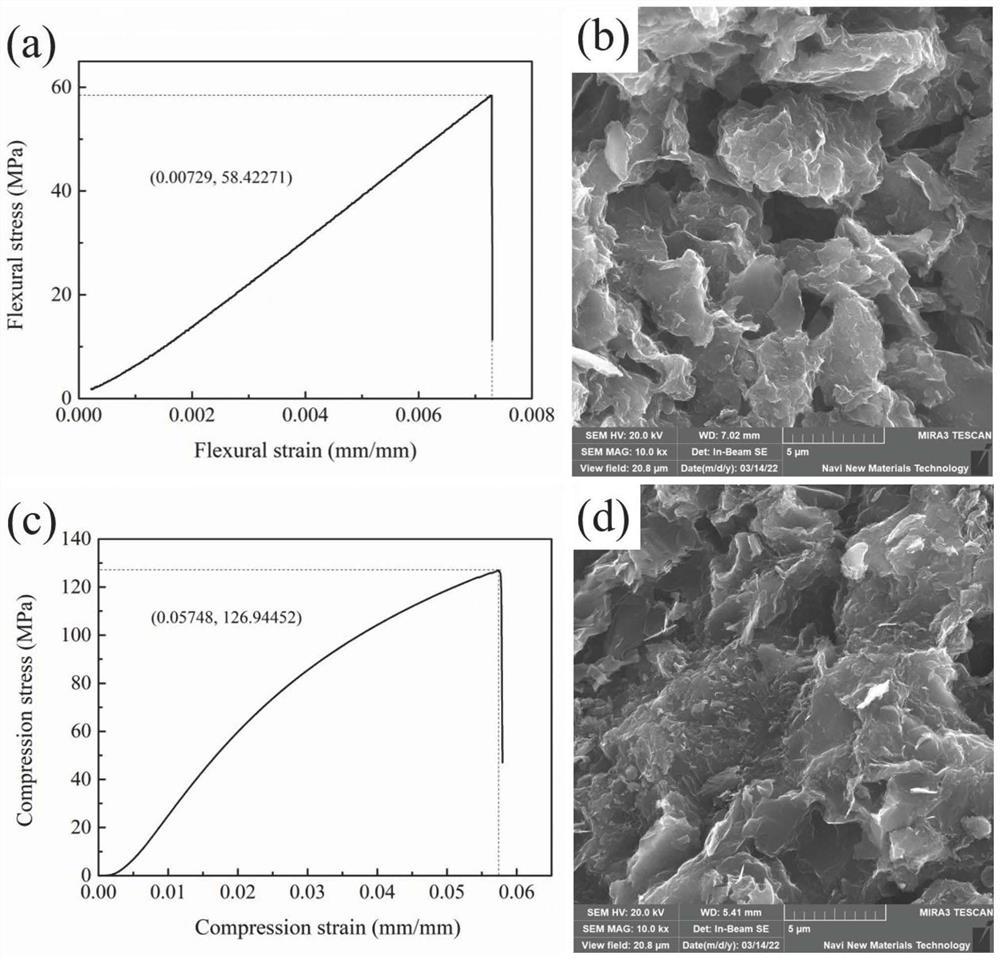

Preparation method and application of low-cost high-purity graphite material

The invention discloses a preparation method and application of a low-cost high-purity graphite material. The preparation method comprises the following steps: pretreating waste graphite powder to obtain graphite powder of which D50 is less than or equal to 10 microns; the preparation method comprises the following steps: preparing active powder A from graphite powder, carbon / carbon powder and asphalt; then preparing active powder B from green coke and asphalt; mixing the active powder A, the active powder B and high-temperature asphalt to prepare pressed powder; a green body block is obtained through a pre-mold pressing-gradient isostatic pressing forming process; roasting the green block at 800-1200 DEG C for 2-4 hours, cooling to 200-300 DEG C, and naturally cooling to room temperature to obtain a roasted block; and placing the roasted block in a vacuum graphitization furnace for atmosphere protection, treating at 2500-2800 DEG C for 2 hours, cooling to 200-300 DEG C, and naturally cooling to room temperature to obtain the high-purity graphite material. According to the preparation method, the graphite waste powder is adopted as the aggregate, so that the raw material cost can be effectively reduced, the additional value of the high-purity graphite waste powder can be improved, dipping and repeated roasting are not needed, the preparation process is simple, the production period can be effectively shortened, and the production cost can be reduced.

Owner:重庆东攀碳材料科技有限公司

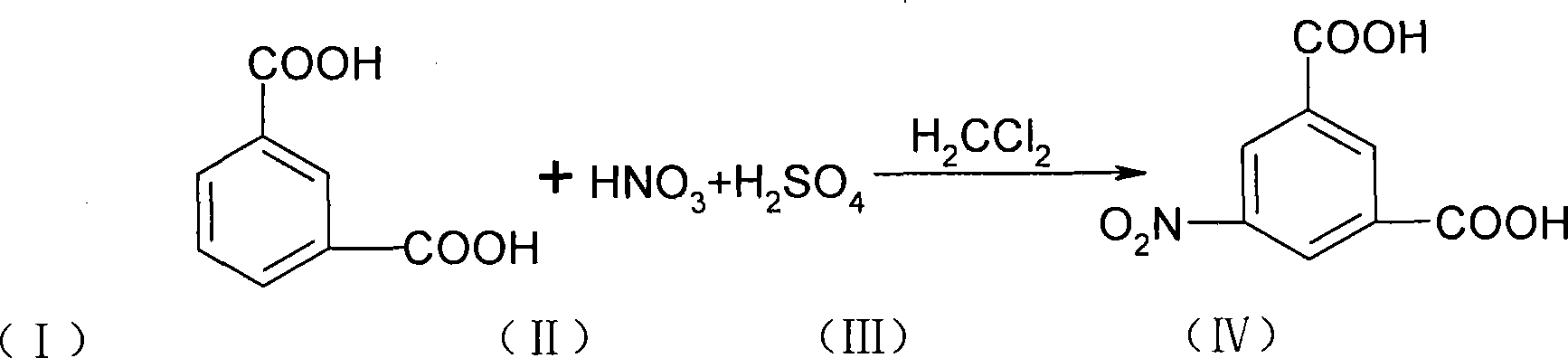

Method for producing 5-nitryl isophthalic acid

InactiveCN101219958AReduce dosageReduce generationNitro compound preparationRoom temperatureIsophthalic acid

A method for preparing a 5-nitroisophthalic acid dissolves an isophthalic acid into a dichloromethane, stirs and heats to reflux, and then slowly drops a mixed acid of fuming nitric acid and sulfate to continue the refluxing reaction for 5 hours with a used account of the mixed acid for 2.4 to 3 times of the quality of the isophthalic acid. When the reaction is finished, a solvent is evaporated, and the nitro products are put into cold water to stay for being cooled to a room temperature and then filtered; the nitro products are then added a proper amount of water for immersion cleaning, leached by cold water, dried under a temperature of 105 DEG C for a plurality of hours to get the final product 5-nitroisophthalic acid. Adopting the method of the invention can get the 5-nitroisophthalic acid with a theoretical yield of 93 percent and a purity to be equal to or higher than 99 percent.

Owner:潘健

Automatic water distribution system for siphon water tank

InactiveCN103172128AAutomatic even water intakeUniform water inflowGravity filtersWater/sewage treatment by sorptionSiphonEngineering

The invention discloses an automatic water distribution system for a siphon water tank. The automatic water distribution system for the siphon water tank comprises a siphon pipe, a siphon cover, a gas-guide pipe and a filtering cover, wherein the siphon pipe is of a U-shaped structure, one end of the siphon pipe is a water inlet end, the other end of the siphon pipe is bent and then connected with one T-shaped pipe, the vertical end of the T-shaped pipe is an overflow pipe higher than a high water level, and the horizontal end of the T-shaped pipe is a water outlet pipe; the siphon cover is a cylinder with an opening formed at the lower bottom, and the siphon cover is inverted at the water inlet end of the siphon pipe; the gas-guide pipe is of an inverted U-shaped structure with the two ends in different lengths, and the long end of the gas-guide pipe penetrates through the bottom of the siphon cover to be inserted into the water inlet end of the siphon pipe; the filtering cover of a grid structure covers the siphon cover outside; and supporting rods are arranged between the siphon pipe and the siphon cover. According to the invention, zero-energy-consumption automatic uniform water distribution is realized by adopting a siphon principle, uniform water inflow of a subsequent sewage soil adsorption bed can be realized by adopting the water charging system, energy is saved, and pollution control cost is reduced, so that the automatic water distribution system for the siphon water tank has a broad market prospect.

Owner:恒蓝水务有限公司

Method for preparing 4,4'-butylidene bis(6-tert-butyl m-cresol) through one-pot process

ActiveCN108586206AReduce usageBig economic interestsOrganic chemistryOrganic compound preparationOrganic layerSolvent

The invention relates to a method for preparing 4,4'-butylidene bis(6-tert-butyl m-cresol) through a one-pot process. In the method for preparing the 4,4'-butylidene bis(6-tert-butyl m-cresol) by using 6-tert-butyl m-cresol and n-butyraldehyde as raw materials, methanol as a solvent and hydrochloric acid as a catalyst, an aromatic hydrocarbon solvent is added after a condensation reaction is completed, and a reaction mixture is completely dissolved and layered at a reflux temperature of the methanol through a mixed solvent composed of a methanol solvent and the aromatic hydrocarbon solvent, wherein an acid water layer is separated; an organic layer is heated to evaporate remaining methanol; and a crystallized product is obtained through after-treatment. The method provided by the inventionsolves the problem that a large amount of acid water needs to be neutralized in the production process, avoids the use of a large amount of an alkali liquid, and avoids the problem of pollution to aneutralized product due to the use of the alkali liquid. The process of acid-water separation facilitates improving the melting point and light transmittance indexes of a product, and separated acid water can be partially or completely reused, so the cost of pollution treatment is reduced.

Owner:淄博万科化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com