Method for extraction of diosgenin via steam explosion

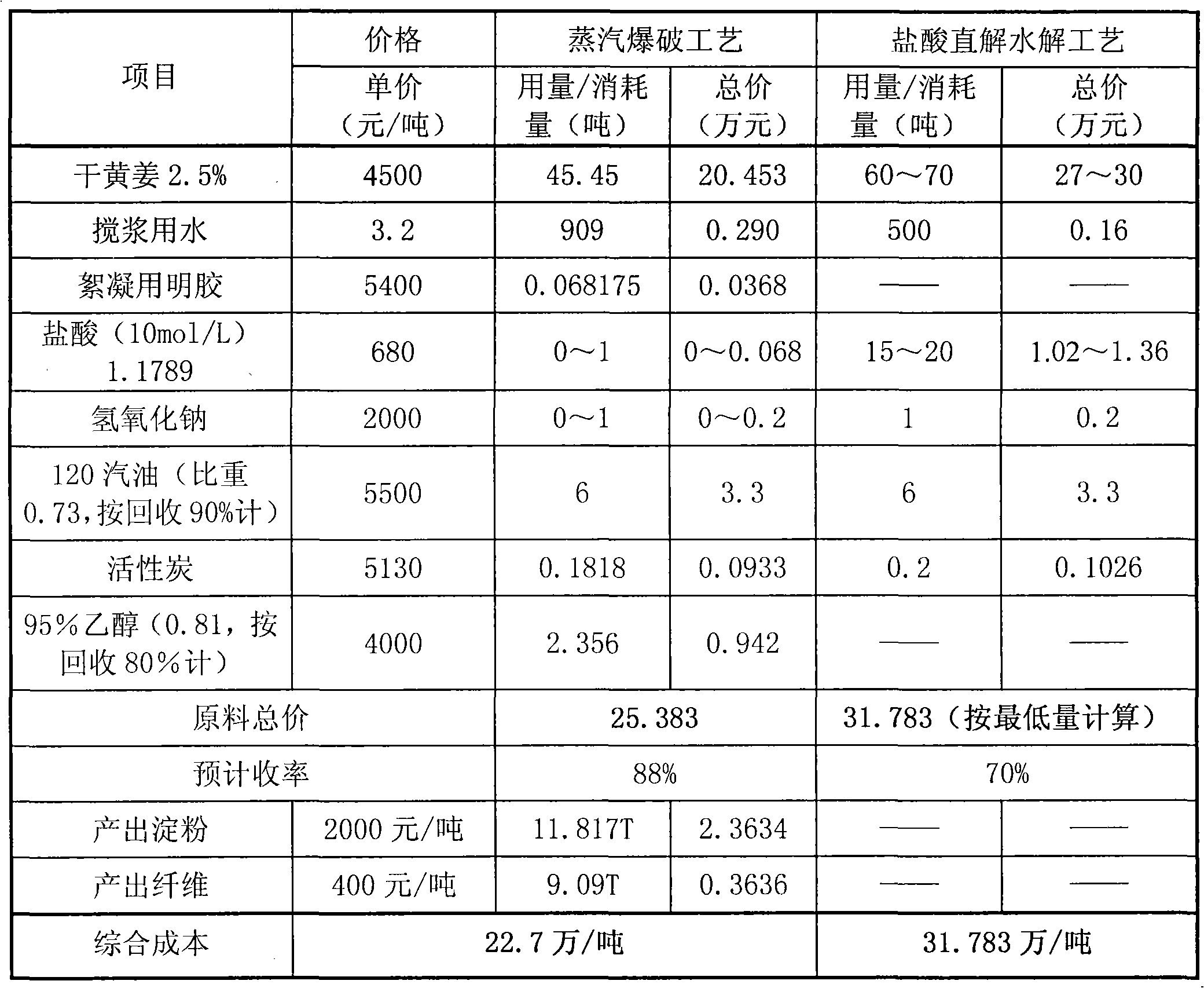

A technology of diosgenin and diosgenaceae, which is applied in the field of production technology of extracting diosgenin by steam explosion method, can solve the problems of large time and energy consumption, low yield, incomplete cracking, etc., and achieves reduction of production cost and saving Effects of solvent cost and pollution load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

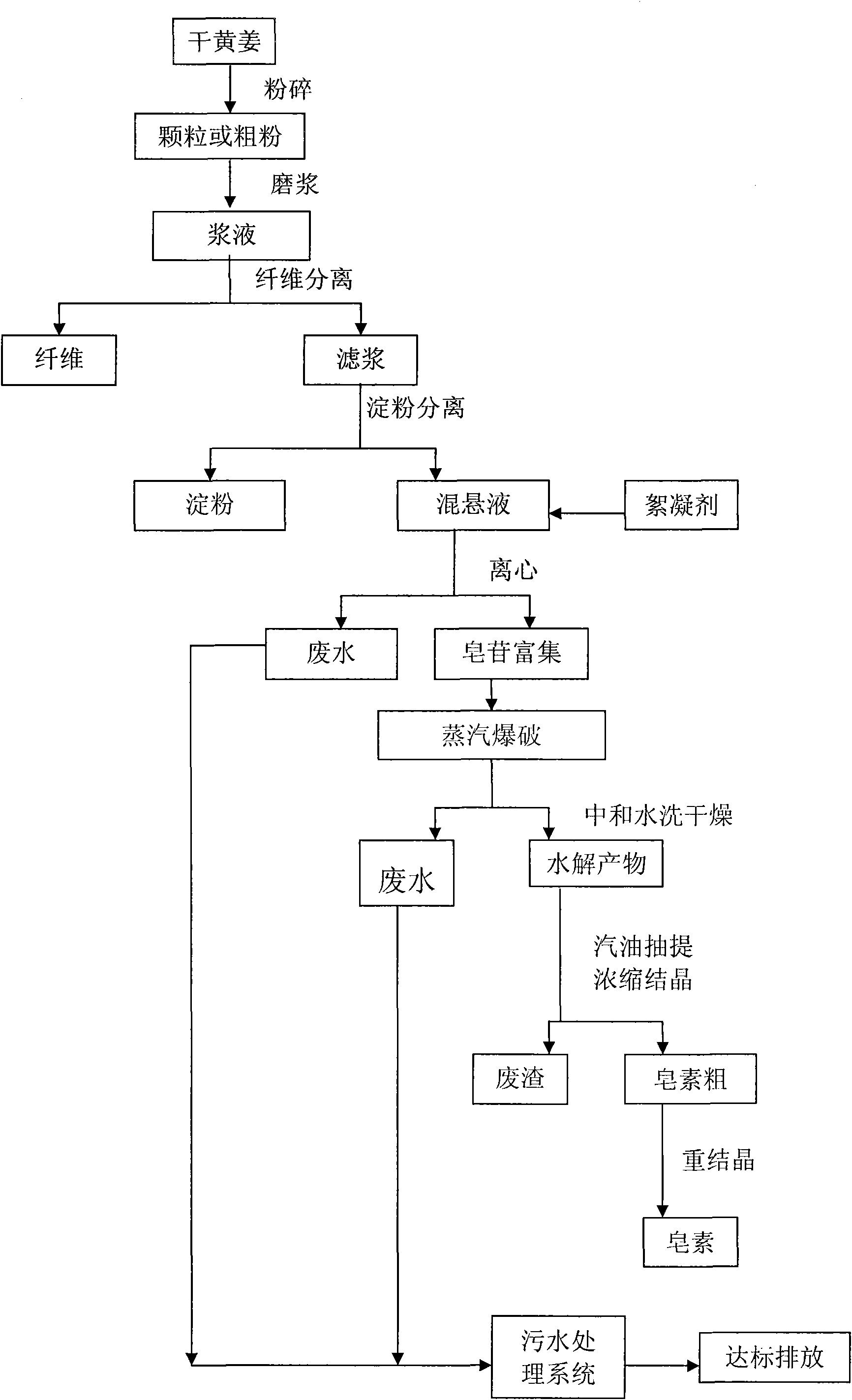

Method used

Image

Examples

Embodiment 1

[0065] Take 5,000 grams of dried turmeric, coarsely crush it, grind it with water to separate fibers and starch, flocculate it with 3 L of 0.1% gelatin solution, and dry it by centrifugation to obtain a saponin-enriched product. Put the saponin-enriched material into the steam explosion tank, then raise the temperature to 140°C, and then quickly pass steam until the pressure in the steam explosion tank is 2.4Mpa, steam explosion treatment for 1.5 minutes, open the discharge valve, and spray the material to normal pressure for release In the tank, the product was washed with water and centrifuged, dried at 80°C, then extracted with 10 times of No. 120 solvent oil and 6% of activated carbon for 6 hours, concentrated and crystallized, added 20 times of 95% ethanol and 3% of activated carbon to the crude product, and dissolved at 90°C for 15 minutes After suction filtration, the filtrate was added with 1.2 times of water and cooled for recrystallization to obtain 80.4 g of finished...

Embodiment 2

[0067] Take 5,000 grams of dried turmeric, coarsely crush it, grind it with water to separate fibers and starch, flocculate it with 2.5 L of 0.06% gelatin solution, and dry it centrifugally to obtain a saponin-enriched product. Put the saponin-enriched material into the steam explosion tank, then raise the temperature to 160°C, and then quickly introduce steam until the pressure in the steam explosion tank is 2.8Mpa, steam explosion treatment for 2.0 minutes, open the discharge valve, and spray the material to normal pressure for release In the tank, the product was washed with water and centrifuged, dried at 80°C, then extracted with 10 times of No. 120 solvent oil and 6% of activated carbon for 6 hours, concentrated and crystallized, added 20 times of 90% ethanol and 3% of activated carbon to the crude product, and dissolved at 90°C for 15 minutes After suction filtration, the filtrate was added with 1.2 times of water and cooled for recrystallization to obtain 82.6 grams of ...

Embodiment 3

[0069] Take 5,000 grams of dried turmeric, coarsely crush it, grind it with water to separate fibers and starch, flocculate it with 12.5 L of 0.04% gelatin solution, and dry it by centrifugation to obtain a saponin-enriched product. Put the saponin-enriched material into the steam explosion tank, then raise the temperature to 180°C, and then quickly introduce steam until the pressure in the steam explosion tank is 3.5Mpa, steam explosion treatment for 0.5 minutes, open the discharge valve, and spray the material to normal pressure for release In the tank, the product was washed with water and centrifuged, dried at 85°C, then extracted with 10 times of No. 120 solvent oil and 6% of activated carbon for 6 hours, concentrated and crystallized, added 20 times of 92% ethanol and 3% of activated carbon to the crude product, and dissolved at 90°C for 15 minutes After suction filtration, the filtrate was added with 1.2 times of water and cooled for recrystallization to obtain 81.3 gram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com