Treatment method of lignin production waste water

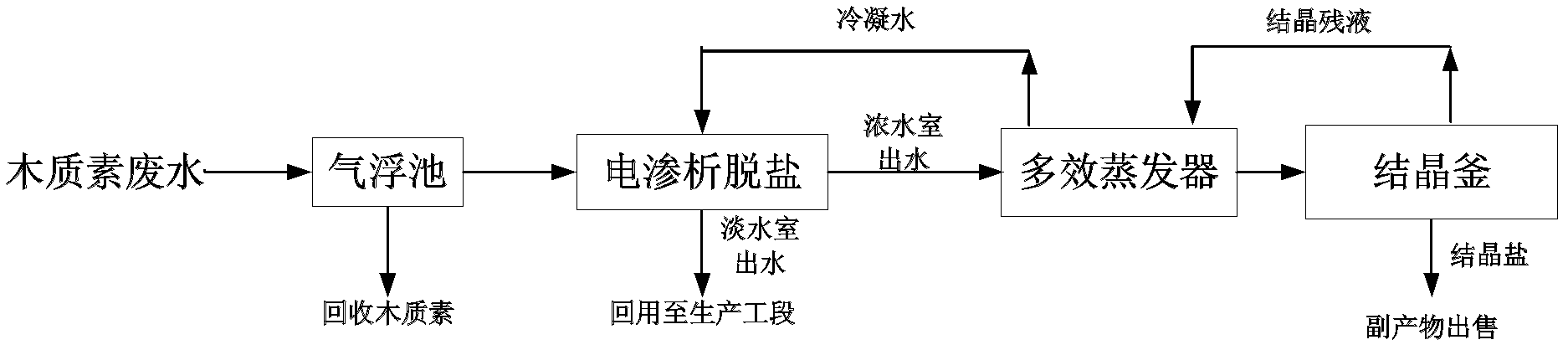

A technology for the production of waste water and treatment methods, which is applied in the directions of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low adaptability, unsuitable sulfate recovery, and electrodialysis efficiency Low-level problems, to achieve the effect of saving treatment costs, reducing pollution control costs, and overcoming low current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

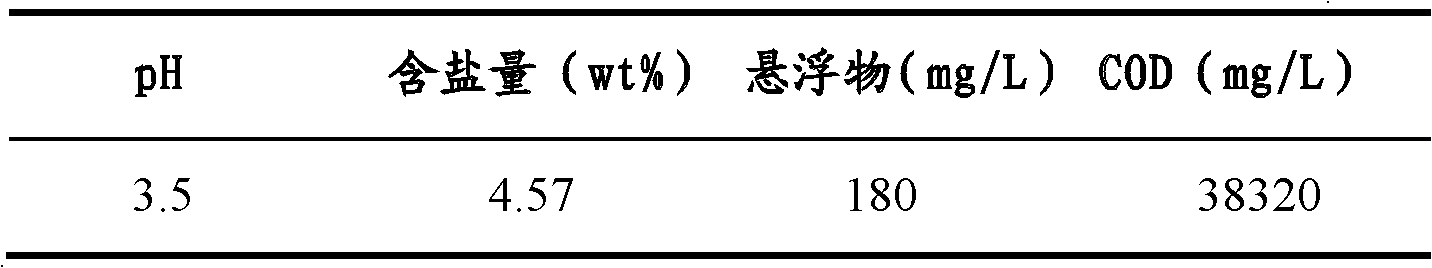

[0027] Step 1: Preprocessing

[0028] The lignin wastewater was treated by the air flotation tank to recover the lignin residue in the wastewater, so that the air flotation effluent was free of solid particles. The composition of the wastewater after air flotation treatment is shown in Table 2. The COD and salt content of wastewater remained basically the same before and after air flotation, and the concentration of suspended solids decreased from 180mg / l to 18mg / l.

[0029] Table 2 Water quality of lignin wastewater after air flotation treatment

[0030]

[0031] Step 2: Electrodialysis treatment

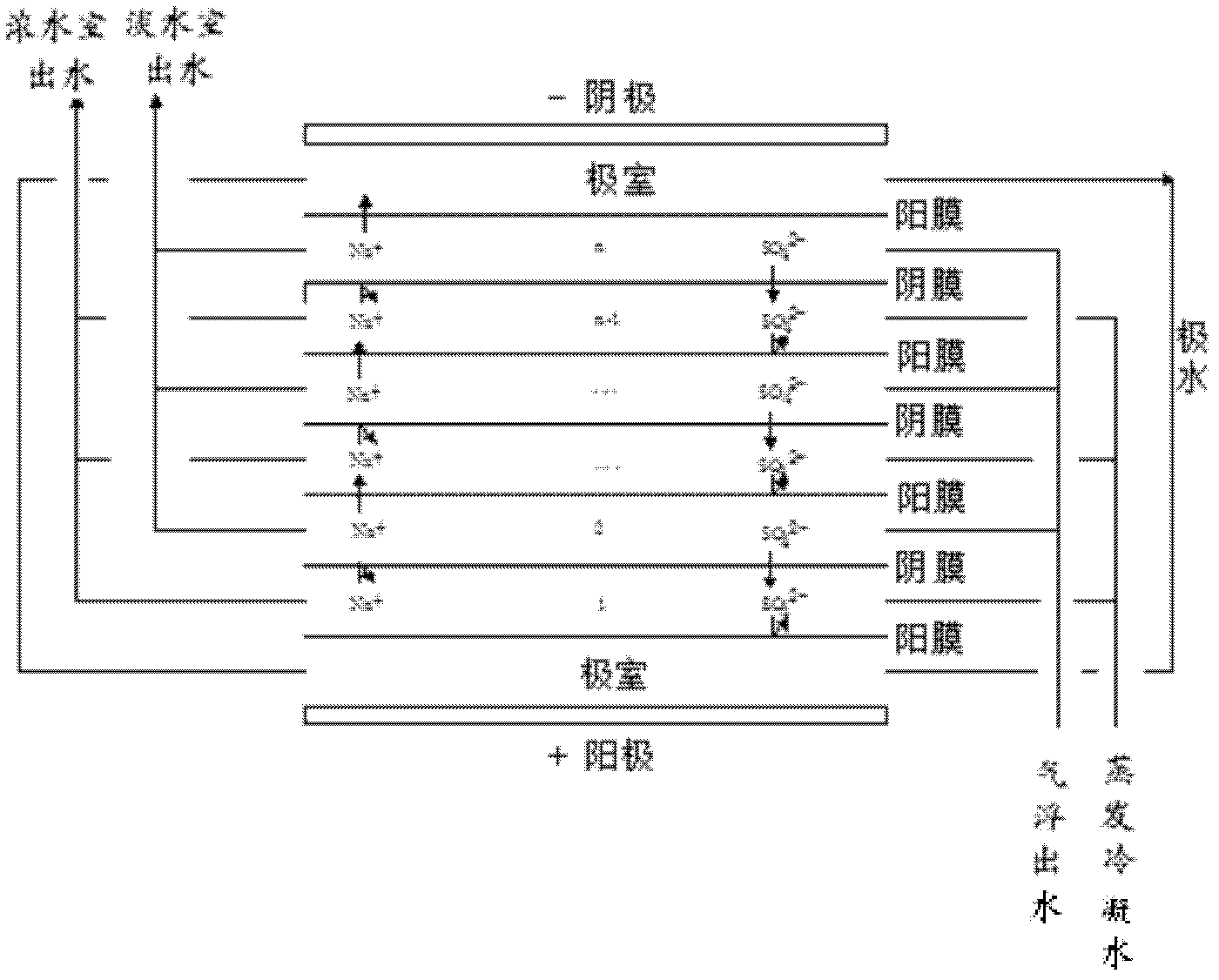

[0032] In this embodiment, the electrodialysis membrane used in the electrodialysis desalination device includes 50 anion exchange membranes and 50 cation exchange membranes, and the anion exchange membranes and the cation exchange membranes are arranged alternately;

[0033] The lignin wastewater after air flotation treatment is used as the fresh water phase of electrodialysi...

Embodiment 2

[0037] Step 1: Same as Step 1 of Example 1.

[0038] Step 2: Electrodialysis treatment

[0039]In this embodiment, the electrodialysis membrane used in the electrodialysis desalination device includes 50 anion exchange membranes and 50 cation exchange membranes, and the anion exchange membranes and the cation exchange membranes are arranged alternately;

[0040] The lignin wastewater after air flotation treatment is used as the fresh water phase of electrodialysis. In the initial stage of the lignin production wastewater treatment process of the present invention, clear water is used as the concentrated water phase of electrodialysis, and 0.5% sodium sulfate aqueous solution is used as the extreme water. Concentrated water pump, fresh water pump and pole water pump circulate in the electrodialyzer, the flow rate of the concentrated water phase is controlled at 1000L / h, the flow rate of the fresh water phase is controlled at 1450L / h, the pressure difference between the concentr...

Embodiment 3

[0044] Step 1: Same as embodiment 1 step 1.

[0045] Step 2: Electrodialysis treatment

[0046] In this embodiment, the electrodialysis membrane used in the electrodialysis desalination device includes 50 anion exchange membranes and 50 cation exchange membranes, and the anion exchange membranes and the cation exchange membranes are arranged alternately;

[0047] The lignin wastewater after air flotation treatment is used as the fresh water phase of electrodialysis. In the initial stage of the lignin production wastewater treatment process of the present invention, clear water is used as the concentrated water phase of electrodialysis, and 1.5% sodium sulfate aqueous solution is used as the extreme water. Concentrated water pump, fresh water pump and pole water pump circulate in the electrodialyzer, the flow rate of the concentrated water phase is controlled at 1000L / h, the flow rate of the fresh water phase is controlled at 900L / h, the pressure difference between the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com