Tobacco remanufacturing process by spinning method

A tobacco and spinning technology, applied in the field of tobacco chemical industry, can solve the problems of difficulty in realizing small-scale production capacity expansion on demand, single product structure and shape, and uncertain taste, so as to eliminate industrial sewage and waste discharge and save The effect of pollution control cost and processing efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

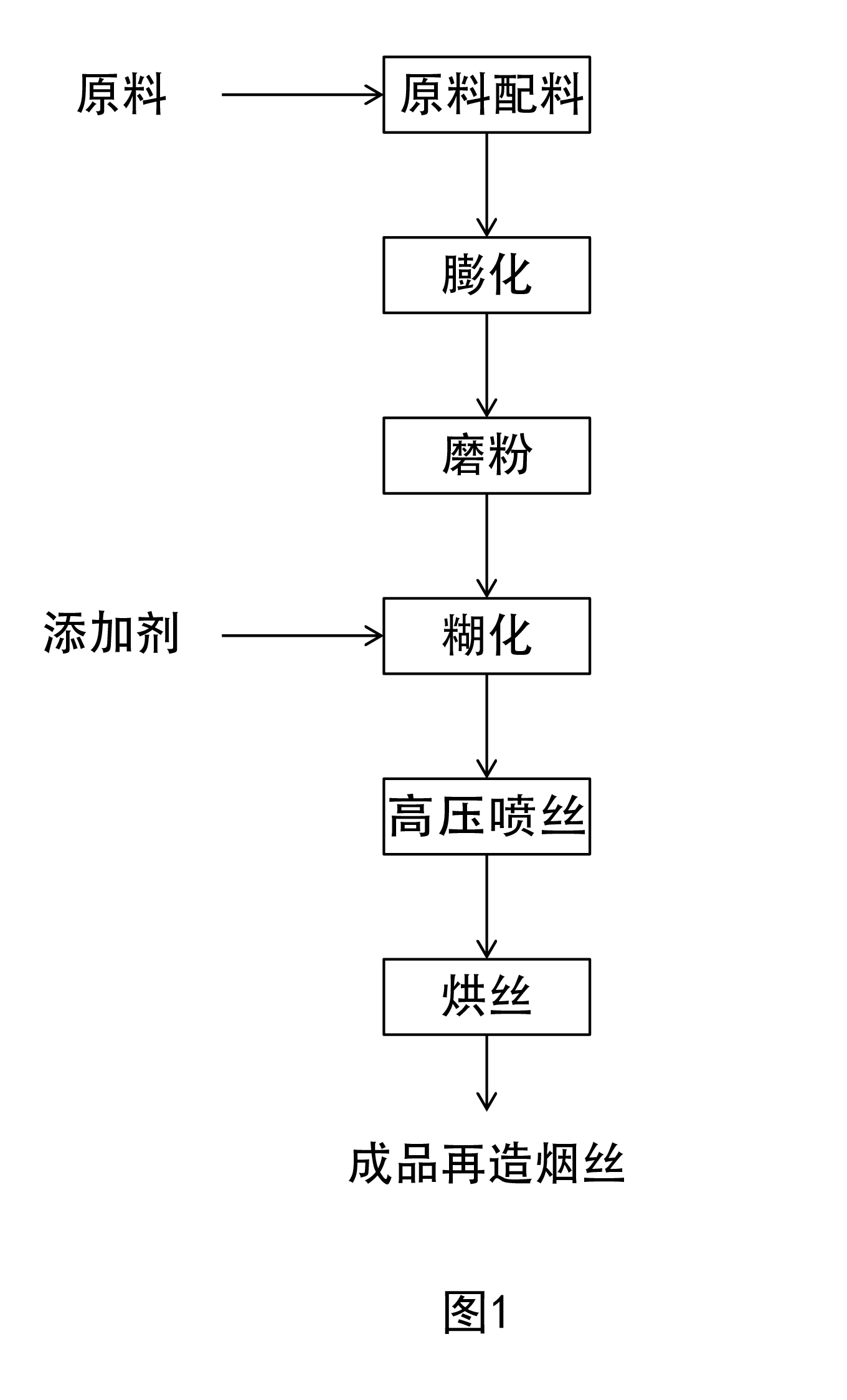

[0045] figure 1 , embodiment one process flow chart

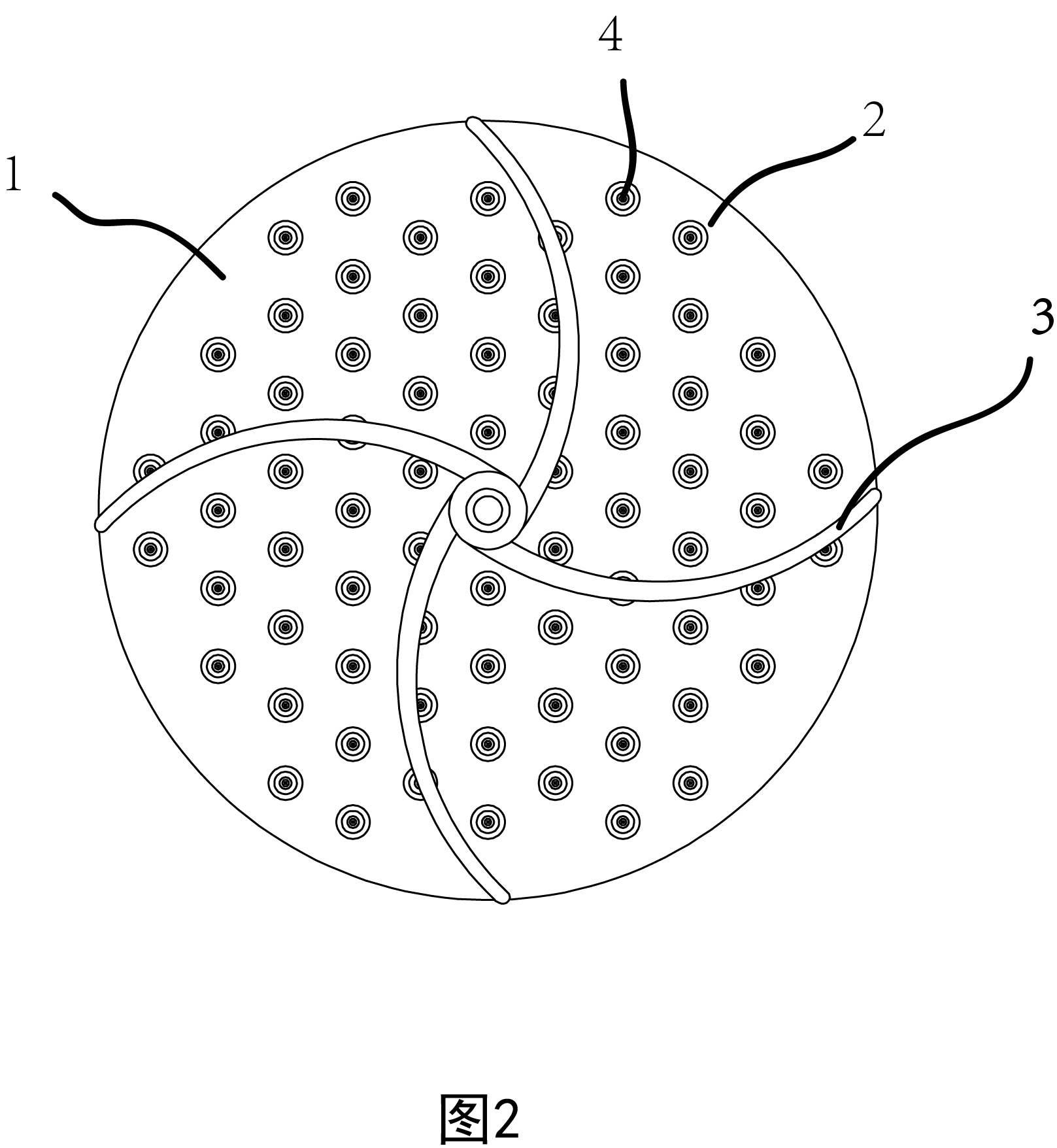

[0046] figure 2 , embodiment one Spinning orifice front view

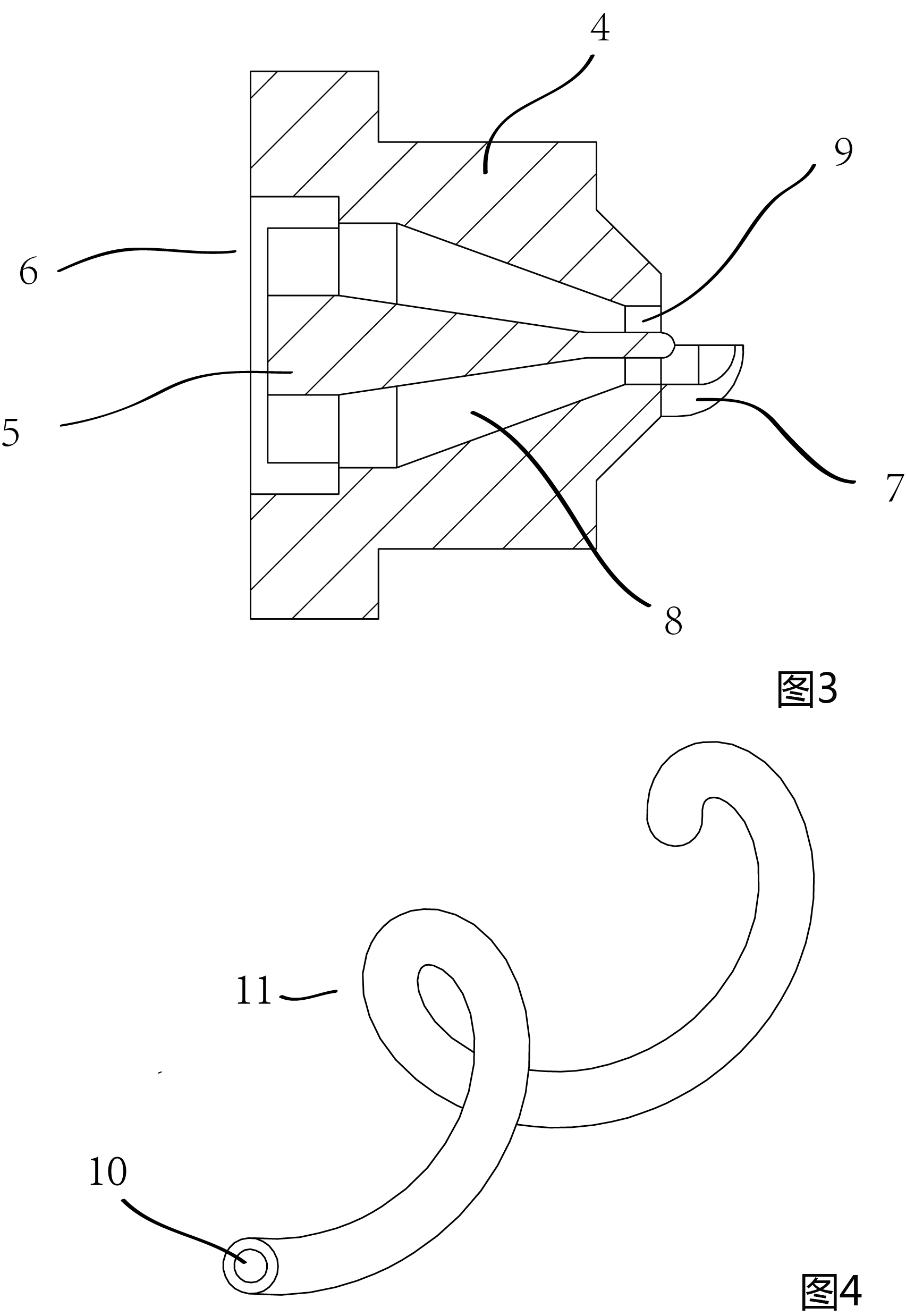

[0047] image 3 , embodiment one Spinning module sectional view

[0048] Figure 4 , Example 1 Schematic diagram of hollow spiral reconstituted tobacco

[0049] Figure 5 , embodiment two Spinning module front view

[0050] Figure 6 , embodiment two schematic diagram of flat reconstituted tobacco

[0051] Figure 7 , embodiment three Spinning module front view

[0052] Figure 8 , embodiment three schematic diagram of Y-shaped reconstituted tobacco

[0053] Figure 9 , embodiment four Spinning module front view

[0054] Figure 10 , Example 4 Schematic diagram of star-shaped hollow reconstituted tobacco

[0055] Embodiment one, combine figure 1 description, where

[0056] (1) Raw material batching process, store tobacco raw materials such as shredded tobacco chips, tobacco powder and tobacco stems, and tobacco powder recovered from production...

Embodiment 2

[0069] (1) Raw material batching process, the ingredients of the recipe in this example are 90% of flue-cured tobacco powder and shredded tobacco flakes, and 10% of tobacco stems.

[0070] (2) Puffing process, what this embodiment adopts is a large-flow dry-type screw overstock puffing machine, which adopts the same principle as the puffed food processing machine, puffed into a sheet-like tobacco fiber tissue puffed material, and the expansion volume ratio is 200% ± 50 , The outlet of the extruder is connected to a fluidized bed cooler, and the extruded material is cooled to 25°C±2, and the moisture content is reduced to 8%.

[0071] (3) Milling process. The cooled extruded material is pulverized using milling equipment. In this embodiment, a four-stage series dry mill is used, which are respectively connected in series with four-stage vibrating screens of 50 mesh and 300 mesh respectively. , 700 mesh and 900 mesh, puffed tobacco fine powder with particles less than or equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com