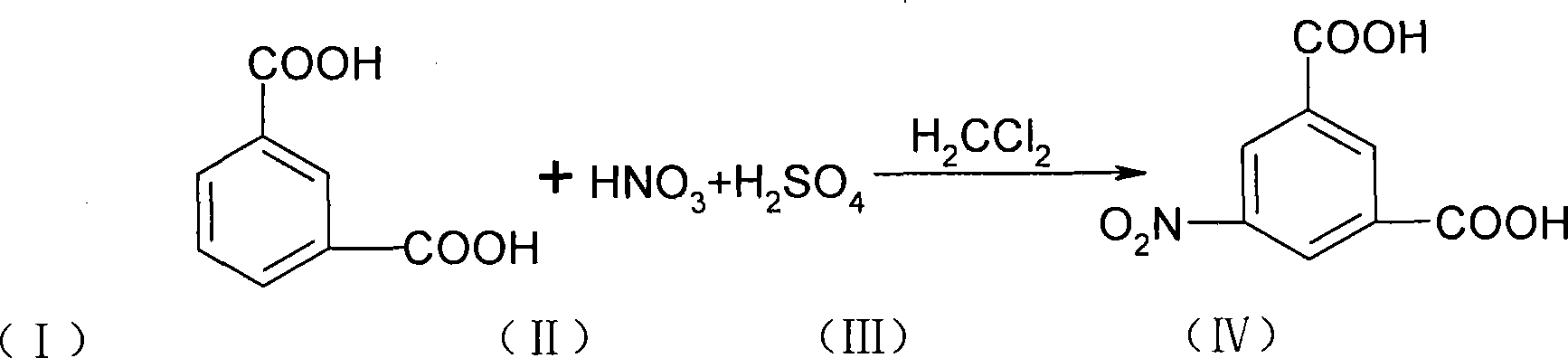

Method for producing 5-nitryl isophthalic acid

A technology of nitroisophthalic acid and nitro, which is applied in the field of preparation of 5-nitroisophthalic acid, can solve the problems of low yield, achieve the goal of increasing product yield, reducing pollution control costs, and reducing the generation of waste acid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) In a dry reaction flask, add 55 g of concentrated sulfuric acid and start stirring. Slowly add 23.9 g of fuming nitric acid dropwise under cooling in a water bath, controlling the temperature below 40°C. After the addition of nitric acid is completed, cool down to normal temperature to obtain mixed acid (II), which is ready for use.

[0014] (2) Add 30 g (0.18 mol) of isophthalic acid (I) into a dry and clean reactor, and then add 120 g of solvent (III), install a reflux condenser, start stirring, and heat to reflux.

[0015] (3) Under reflux, slowly add 78.9 g of mixed acid (II) dropwise, the rate of addition should not be too fast, and the addition is completed in about 2 hours.

[0016] (4) Continue the reflux reaction for 5h. After the reaction was completed, 90.8 g of the solvent (III) was distilled off.

[0017] (5) Add the nitro substance into 150ml of cold water (or ice water), cool to room temperature and filter, add 50ml of cold water to soak and filter...

Embodiment 2

[0019] (1) In a dry reaction flask, add 60 g of concentrated sulfuric acid and start stirring. Slowly add 25 g of fuming nitric acid dropwise under cooling in a water bath. Control the temperature below 40°C, finish adding nitric acid, and cool to room temperature to obtain mixed acid (II) for later use.

[0020] (2) Add 30 g (0.18 mol) of isophthalic acid (I) into a dry and clean reactor, and then add 120 g of solvent (III), install a reflux condenser, start stirring, and heat to reflux.

[0021] (3) Under the reflux state, slowly add 85g of mixed acid (II) dropwise, the dropping speed should not be too fast, and the addition is completed in about 2 hours.

[0022] (4) The reflux reaction was continued for 5 h, and after the reaction was completed, 91 g of the solvent (III) was distilled off.

[0023] (5) Add the nitro substance into 150ml of cold water (or ice water), cool to room temperature and filter, add 50ml of cold water to soak and filter, then rinse the filter cake...

Embodiment 3

[0025] (1) In the dry reaction flask, add 63.5 g of concentrated sulfuric acid and start stirring. Slowly add 25.4 g of fuming nitric acid dropwise under cooling in a water bath. Control the temperature below 40°C, finish adding nitric acid, and cool to normal temperature to obtain the mixed acid (II) for later use.

[0026] (2) Add 30 g (0.18 mol) of isophthalic acid (I) into a dry and clean reactor, and then add 120 g of solvent (III), install a reflux condenser, start stirring, and heat to reflux.

[0027] (3) Under the reflux state, slowly add 88.9g of mixed acid (II) dropwise, the dropping speed should not be too fast, and the addition is completed in about 2 hours.

[0028] (4) Continue the reflux reaction for 5h. After the reaction was completed, 91.2 g of the solvent (III) was distilled off.

[0029] (5) Add the nitro substance into 150ml of cold water (or ice water), cool to room temperature and filter, add 50ml of cold water to soak and filter, then rinse the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com