Flue gas desulfurization method

A technology for flue gas and coal-fired flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

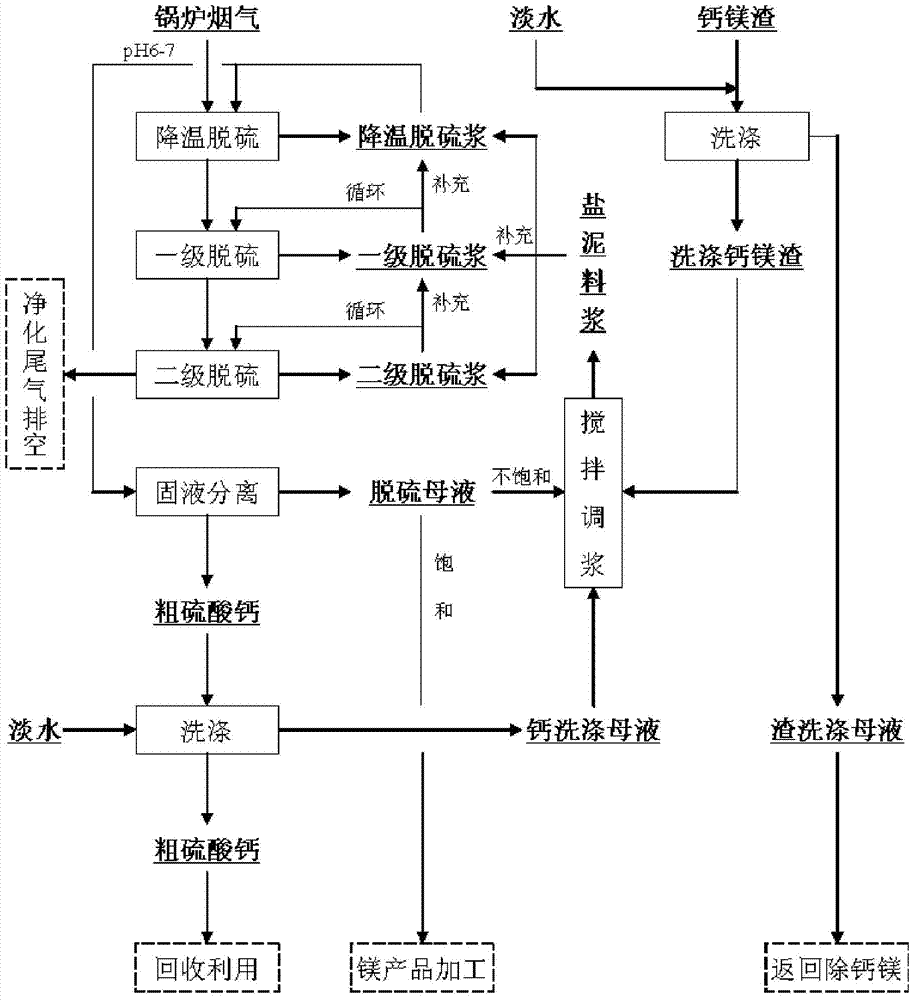

Image

Examples

Embodiment 1

[0039] The calcium-magnesium slag is washed with water, and the amount of water is 150% of the mass of the calcium-magnesium slag. The washed calcium-magnesium slag is mixed with water to prepare a salt mud slurry with a mass percentage of 10%.

[0040] The untreated boiler coal-fired flue gas is transported to the top of the cooling tower by an induced draft fan, and the top of the tower enters the cooling tower. The salt mud slurry is also pumped in from the top of the tower. After being atomized and dispersed, it is in parallel contact with the high-temperature coal-fired flue gas to absorb heat and reduce the temperature of the flue gas. It is a first-class flue gas at 75℃ The temperature-reducing desulfurization slurry is repeatedly used to cool the coal-fired flue gas until its PH value is 7, and the temperature-reducing desulfurization slurry is discharged, and the solid-liquid separation is carried out to obtain calcium sulfate and desulfurization mother liquor. The sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com