Method for producing potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction

A technology of potassium hydroxide alkali method and potassium fulvic acid, which is applied in the field of papermaking, can solve the problems of non-specificity, ambiguity, and difficulty in specific implementation, and achieve the effects of less water, full water solubility, and reduced sewage treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

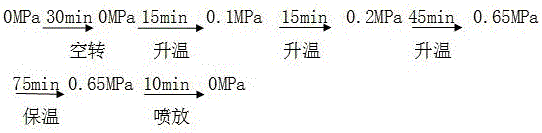

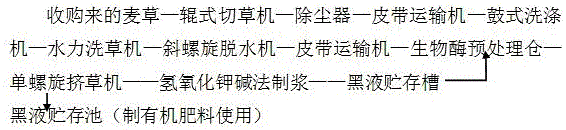

[0041] The specific embodiment of the technical scheme of the present invention is: biological enzyme pretreatment of wheat straw extraction black liquor, potassium hydroxide lye wheat straw pulping produces pretreatment black liquor and potassium fulvic acid organic fertilizer finished product production three parts:

[0042] 1. Extraction of Wheatgrass Black Liquor with Biological Enzyme Pretreatment

[0043] 1.1 Wet preparation:

[0044] Wheat straw purchased from farmers is used, transported to the grass cutter and cut into 15-30mm long pieces, after being dedusted by the claw dust collector, it is conveyed by a belt conveyor, washed by a water washing machine and a water power grass washing machine, and then dehydrated, and then sent to the next step. process.

[0045] 1.2 Extraction of wheatgrass black liquor by biological enzyme pretreatment:

[0046] The washed and dehydrated flakes prepared by the wet method are transported to the biological enzyme pretreatment bin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com