Patents

Literature

258results about How to "Adjust pH value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage purifier and sewage purification method

ActiveCN101928069AIncrease reproductive rateImprove purification effectSustainable biological treatmentBiological water/sewage treatmentPurification methodsMetal salts

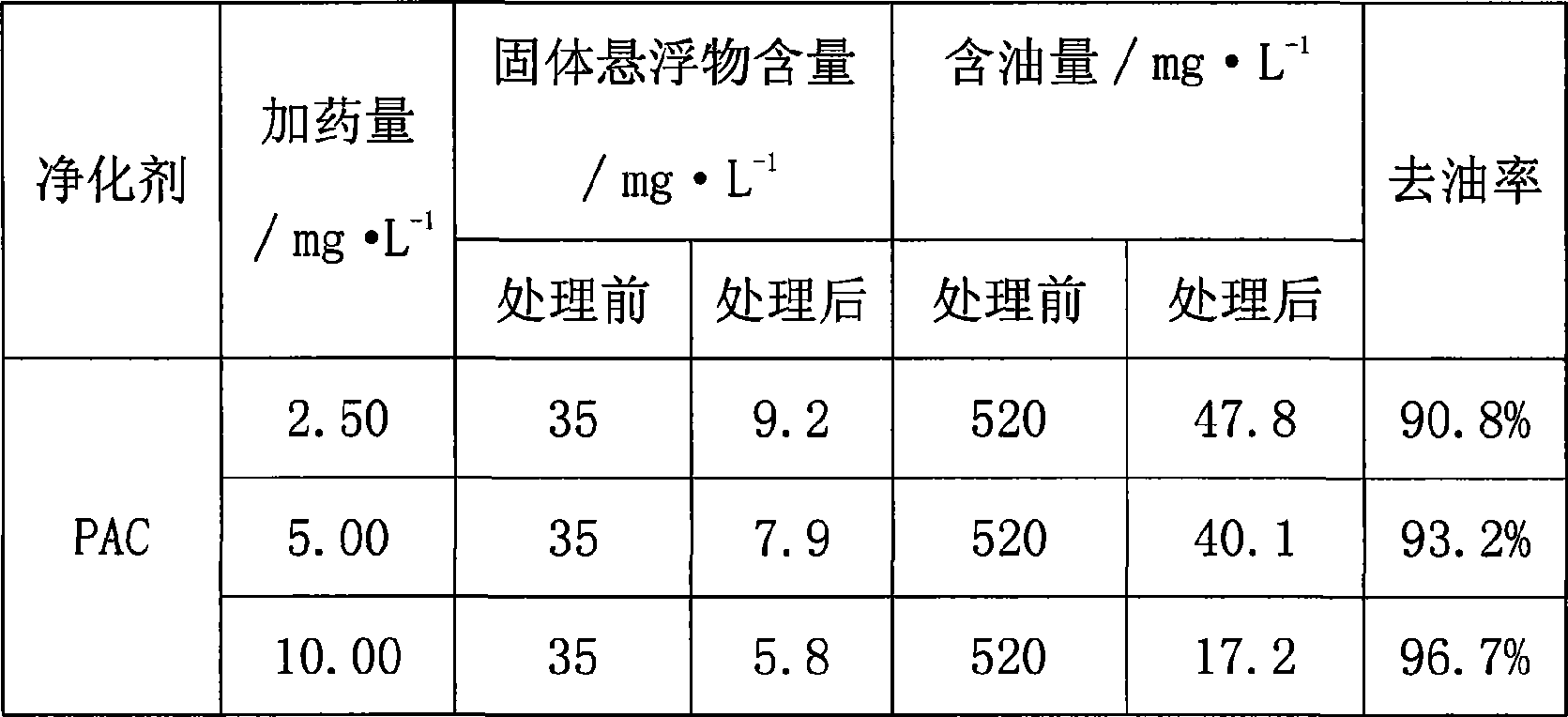

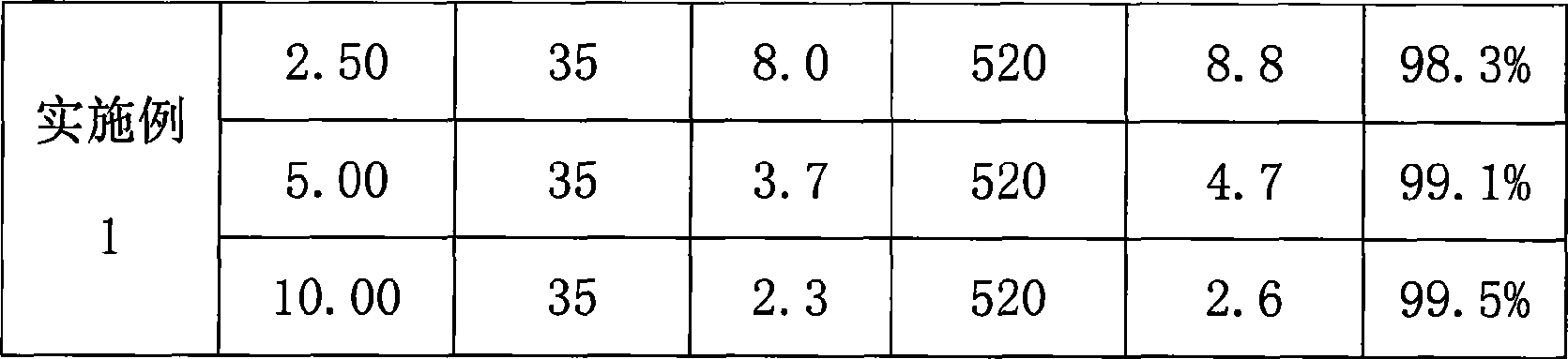

The invention discloses a sewage purifier, which comprises polyhydroxyalkanoate, diatomite, humic acid, a bioactivator, inorganic metal salt and other substances. The invention also discloses a sewage purification method by utilizing the sewage purifier. A completely biodegradable material polyhydroxyalkanoate is used as a sustained material of the bioactivator, and the completely biodegradable material is slowly degraded and releases the bioactivator so as to realize the long-term high-efficiency purification function of the bioactivator; and by combining the effects of aquatic plants, phosphorus, nitrogen, polycyclic aromatic hydrocarbon and heavy metals in the sewage are purified and treated, so the sewage purifier has better sewage treatment effect.

Owner:SHENZHEN ECOMANN BIOTECH

Saline-alkali land soil conditioner and preparation method thereof

ActiveCN102154013AReduce compactionImprove breathabilityOrganic fertilisersSoil conditioning compositionsAlkali soilFatty alcohol

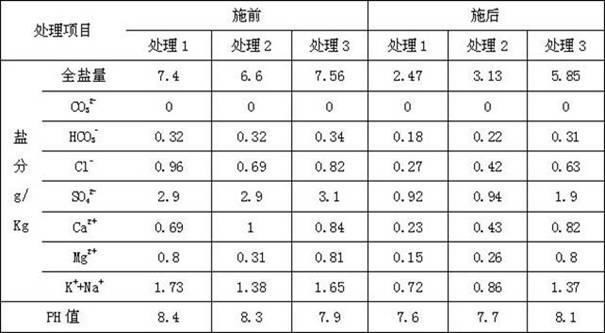

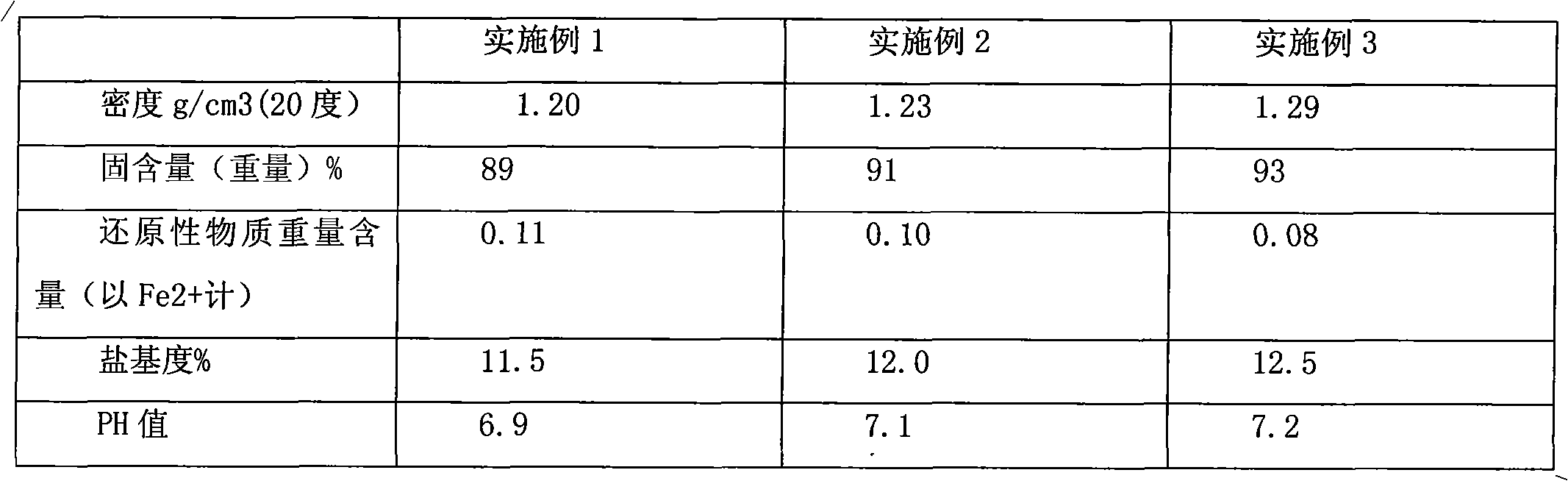

The invention discloses a saline-alkali land soil conditioner and a preparation method thereof. The saline-alkali land soil conditioner is prepared by adding water in citric acid, polymaleic acid-acrylic acid copolymer, sodium polycrylate and fatty alcohol-polyoxyethylene ether. The preparation method comprises the following steps: weighing raw materials in weight proportioning; adding partial water in a reaction kettle for heating to 50-60 DEG C; adding the fatty alcohol-polyoxyethylene ether, the polymaleic acid-acrylic acid copolymer, the sodium polycrylate and the citric acid in the reaction kettle in turn for fully dissolving; subsequently, adding rest water in the reaction kettle and cooling to 20 DEG C; and after sampling and qualified inspection, measuring and packaging to form a finished product. By using the conditioner, the physical and chemical properties of the saline-alkali soil are obviously improved, heavy metal ions are complexed, emulsification and oil removal are achieved, salinity infiltration is accelerated, alkaline of soil is neutralized, and the pH value is regulated; and the desalination amount of the conditioner can reach above 50%, and the conditioner has the advantages of short improvement period, durable management effect and universality, saves water, increases benefits, yield and income and is environment-friendly.

Owner:新疆昆仑雷士农业科技有限公司

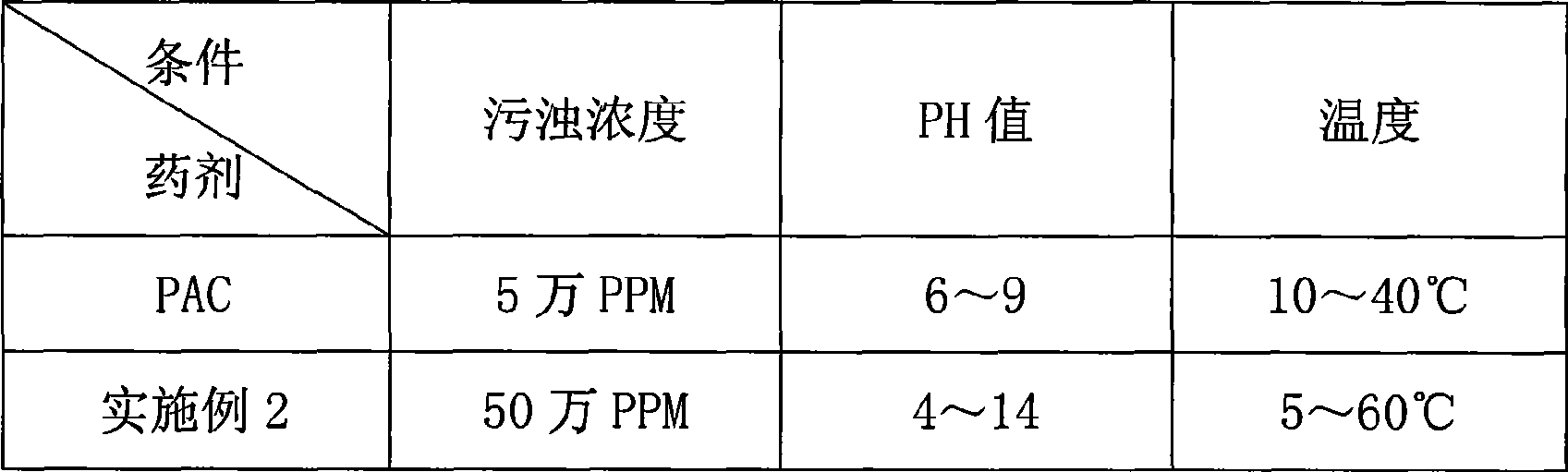

High-stability sewage treating agent and preparation method thereof

InactiveCN103787473AWork is easy to coordinateGood shape distributionWater/sewage treatment by flocculation/precipitationEnvironmental resistanceHazardous substance

The invention discloses a high-stability sewage treating agent and a preparation method thereof. The sewage treating agent comprises following materials by weight: 10-15 parts of citric acid, 50-70 parts of sodium carbonate, 10-15 parts of magnesium carbonate, 8-20 parts of ferric trichloride, 7-20 parts of calcium oxide and 10-15 parts of polyacrylamide. The preparation method includes uniformly mixing the materials in sequence and stirring. Compared with the prior art, the sewage treating agent and the preparation method has characteristics of multifunction, high efficiency, environment protection, high sewage treating speed, short treating time, capability of efficiently removing various pollutants and toxic materials with broad spectrum, high adaptability to high dirty concentration, wide pH value range and wide temperature change range of sewage, capability of effectively reducing odour of various types of sewage, high degree of alkalization, low corrosion, convenience for production, no pollution in production processes, simple product package, convenience for transportation, and low comprehensive cost.

Owner:徐忠

Fertilizer special for vegetables and preparation method thereof

InactiveCN106588501AHigh porosityImprove permeabilityExcrement fertilisersPotassium fertilisersEcological environmentSodium Bentonite

The invention discloses a fertilizer special for vegetables and a preparation method thereof. The fertilizer comprises the following raw materials in parts by weight: 60-80 parts of straws, 30-45 parts of animal wastes, 4-15 parts of powdered rock phosphate, 8-20 parts of potassium mineral powder, 1.5-3.5 parts of saccharides, 0.4-0.7 part of EM bacterium liquid, 5-9 parts of modified vermiculite power, 1-4 parts of bentonite, 1-4 parts of diatomite, 0.2-0.8 part of a plant growth regulator, 10-16 parts of traditional Chinese medicine dregs and 0.05-0.12 part of an enzymic preparation. According to the fertilizer special for vegetables and the preparation method thereof provided by the invention, the formula is reasonable, the occurrence rate of vegetable insect pests is reduced, and the stress resistance of the vegetables is improved. Meanwhile, the ecological environment of soil is improved, the soil fertility and sustainability are improved, the absorption of the vegetables on nutrients is comprehensive, the absorption efficiency is high, the quality of the vegetables is improved, and the yield of the vegetables is increased.

Owner:李梦

Natural plant enzyme preparation

InactiveCN102217745ANutritional balanceSimple production processFood preparationDietary fiberWater soluble

The invention discloses a natural plant enzyme preparation and relates to the field of biological medicines. The natural plant enzyme preparation is characterized by comprising the following components (by weight percent): 2%-15% of enzyme powder, 70%-90% of water-soluble dietary fiber and 0%-20% of fructooligosaccharides. The natural plant enzyme preparation has the characteristics of improving the abnormal conditions of red blood cells and activating the activity ability of white blood cells.

Owner:DALIAN QUANZHI BIOLOGICAL TECH

Water-soluble fertilizer containing chitin and humic acid and production method thereof

InactiveCN101638333AHigh activityImprove fertilizer efficiencyFertilizer mixturesDiseaseContinuous cropping

The invention discloses a water-soluble fertilizer containing chitin and humic acid and a production method thereof. The method is characterized by degrading chitin, a natural high polymer, and then mixing chitin with humic acid solution and nitrogen fertilizer to produce the water-soluble fertilizer containing chitin and humic acid. The produced water-soluble fertilizer contains 20-40g / l of chitin, 20-40g / l of nitrogen, 170-190g / l of humic acid and 1-5g / l of plant growth regulators. The method is simple, easy to operate and high in feasibility of implementation. The produced water-soluble fertilizer integrates the functions of nutrition supplement, bacteria immunity and virus immunity, improves soil conditions, prevents hardening, raises ground temperature, promotes prematurity, resists diseases and tolerates stress, resists continuous cropping and balances nutrition, and features stable status and lasting fertilizer efficiency.

Owner:山东润华联邦农业科技有限公司

Composite powdery calcium sulphate sewage treating agent and preparation method thereof

InactiveCN101456613AExcellent coagulation performanceBig alumWater/sewage treatment using germicide/oligodynamic-processTreatment using complexing/solubilising chemicalsChemistryBroad spectrum

The invention discloses a composite powered calcium sulfate sewage treatment agent and a method for preparing the same. The sewage treatment agent comprises the following materials in weight portion: 5 to 10 portions of tartaric acid, 3 to 5 portions of malic acid, 60 to 70 portions of calcium sulfate, 10 to 15 portions of magnesium carbonate, 10 to 20 positions of calcium carbonate, 10 to 20 portions of ferric chloride, 10 to 20 portions of calcium oxide and 2 to 3 portions of polyacrylamide. The method is to mix the materials. Compared with the prior art, the sewage treatment agent and the method have the advantages of multifunction, high efficiency, environment protection, quick sewage treatment speed, short treatment time, broad-spectrum and high-efficiency removal of various pollutants and harmful substances and strong adaptively to the sewage muddiness, wide pH value range and wide water temperature change of the sewage. The sewage treatment agent and the method have high alkalization degree, small corrosion, convenient production and no pollution in the production process, simple product package, convenient transportation and low composite cost.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Compound soil conditioner and preparation and use method

PendingCN108129239AStrong complexing abilityPromote plant growthExcrement fertilisersBioloigcal waste fertilisersAgricultureEdible mushroom

The invention discloses a compound soil conditioner and a preparation and use method. The compound soil conditioner comprises the following raw materials by mass percent: 40-60% of decomposed organicfertilizer, 10-20% of fulvic acid, 15-20% of edible mushroom dreg or biogas residue, and 15-20% of a compound microbial agent. The raw materials of the compound soil conditioner are rich, the formulais simple, the cost is low, the effect is good, and the compound soil conditioner is suitable for various types of soils and is convenient for large-area agricultural popularization and application. The compound soil conditioner effectively improves the soil and the soil fertility, the content of organic matters in the soil is increased, the microelement is better promoted to be absorbed by a plant root system, the adverse resistance of the plant is improved, the development of the plant root and the action of the beneficial bacteria are promoted, the ecological environment of the soil is improved, the use amount of a fertilizer is reduced, the utilization rate of the fertilizer is increased, and the quality of an agricultural product is improved.

Owner:营山县智达能源生态环保研究所

Formula fertilizer special for fruit tree and preparation method thereof

The invention discloses a formula fertilizer special for fruit trees. The formula fertilizer is prepared from the following raw materials in parts by weight: 34-38 parts of calcium superphosphate, 20-24 parts of urea, 20-23 parts of monoammonium phosphate, 16-19 parts of potassium chloride, 40-45 parts of wormcast, 10-12 parts of straw biologic carbon black, 10-12 parts of pyroligneous, 3-4 parts of ferrous sulfate, 2-3 parts of zinc sulfate, 3-4 parts of manganese sulfate, 3-4 parts of EM (Effective Microorganisms) bacterium, 4-6 parts of film agent and a proper amount of water. The fertilizer disclosed by the invention is rich in nutrition, the yield and the quality of crops can be remarkably improved, all nutrient elements required by crops in the growth process can be supplied, the ecological balance of soil organisms is improved, the fertilization effect is kept, the pH value of soil is adjusted, the moisture in the soil is kept, the breathability of the soil is improved, the soil is granulated, the temperature on the surface of the soil is improved, and underground plant diseases and insect pests can be prevented and treated.

Owner:DANGTU COUNTY KEHUI TRADING

Brown fermented milk base material, brown milk beverage and preparation method of brown fermented milk base material

The invention discloses a brown fermented milk base material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing raw materials to obtain a material liquid, wherein the material liquid comprises following components except for skimmed milk: 0.5-2g / L of low-poly xylose, 0.3-1g / L of sodium bicarbonate and 60-100g / L of fructose syrup; (2) sterilizing the material liquid at 115-123 DEG C for 300 seconds, performing Maillard reaction, cooling to 41-43 DEG C and pouring into a fermentation tank; (3) grafting a yogurt starter, wherein the yogurt starter includes 15-23g / T of Danisco 528, 11-13.7g / T of DSM1821 and 6-8mL / T of lactobacillus plantarum with the CGMCC No. 9405, and fermenting until the acidity is up to 70 degrees to obtain the brown fermented milk base material. A brown milk beverage prepared from the fermented milk base material has the comparable browning effect to similar products in the market and has better flavor, taste and nutrients compared with the similar products in the market; moreover, the production efficiency is greatly improved and the equipment utilization ratio is greatly increased.

Owner:河北新希望天香乳业有限公司

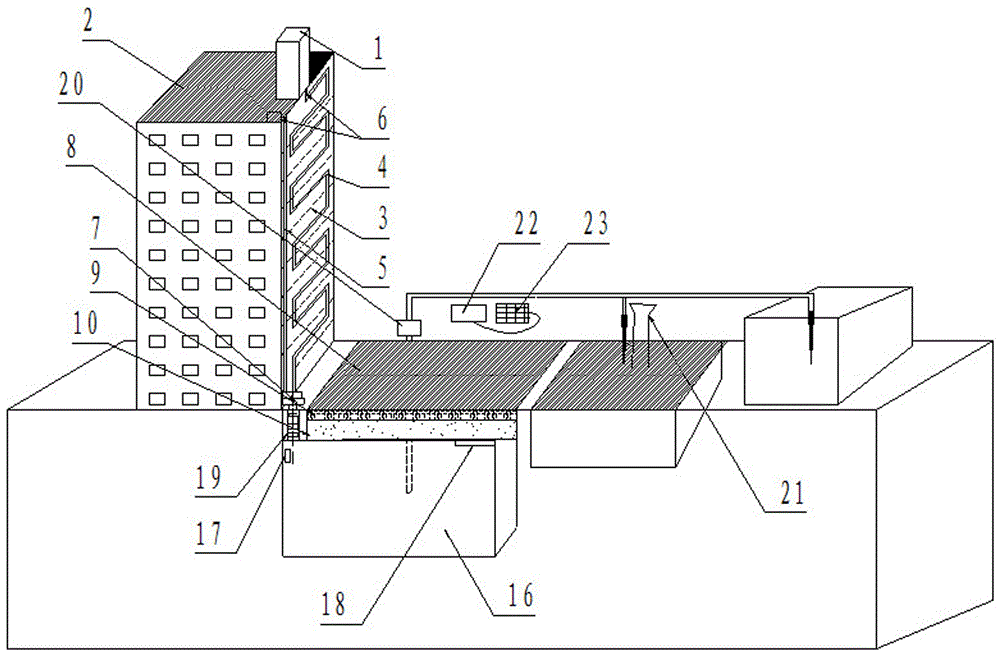

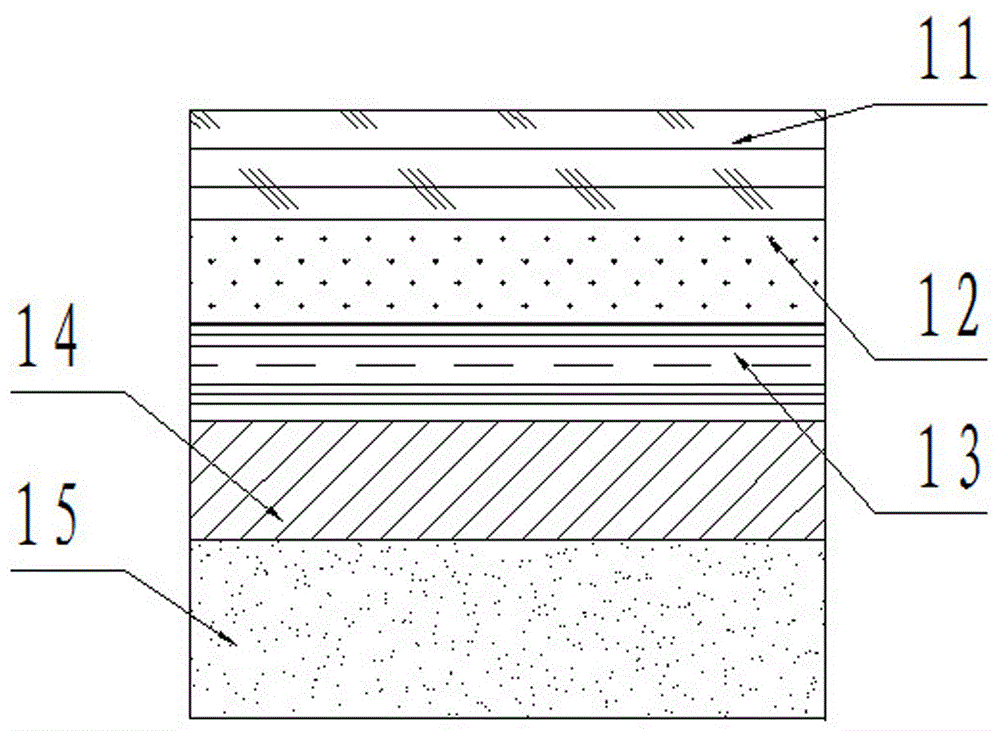

Intelligent rainwater purification landscape system

PendingCN106746205AExtension of timeDelay bufferTreatment involving filtrationEnergy based wastewater treatmentRainwater harvestingStormwater

The invention discloses an intelligent rainwater purification landscape system. The intelligent rainwater purification landscape system comprises a firefighting impounding reservoir, a roof plant greening layer, a wall vertical greening layer, an S-shaped rainwater pipeline, a rainwater falling pipe, a primary deposition oxidization pond, a rainwater storage unit, an intelligent rainwater control module, a solar cell panel and a landscape fountain oxygen aeration unit which are arranged on a roof. According to the technical scheme, rainwater is collected, filtered, stored, purified and used by utilizing different filtering layers, so that the collected and purified rainwater can be used for providing irrigation water for garden greening. The utilization rate of rainwater resources can be improved, the municipal water consumption problem can be relieved, and the rainwater resource waste and urban water logging problems can be solved while landscapes are formed.

Owner:ANQING NORMAL UNIV

Premixed fodder used specially for young milk-cow

InactiveCN1723792AImprove digestion and absorption rateImprove immune functionAnimal feeding stuffAccessory food factorsTrace elementRumen

Owner:陕西杨凌富仕特饲料股份有限公司

Preparation method of soil alkaline conditioner

InactiveCN101798513AAdjust pH valuePromotes the emergence of irrigationOrganic fertilisersSoil conditioning compositionsSalicylic acidSalinity

The invention provides a preparation method of a soil alkaline conditioner. The conditioner product is prepared from mixing different amounts of citric acid, lime, EDTA, fulvic acid, salicylic acid, tween, AESA and water step by step, stirring and synthesizing. By complexing salt ions and then eluviating to the deep layer of the soil, the conditioner has the advantage of fewer doses, but has multiple effects of improving the soil, promoting the eluviation of salt, improving the salinity tolerance of crops and the like.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Preparation method of composite adsorbing material of industrial wastewater heavy metal ions

InactiveCN105478086AImprove adsorption capacityAvoid releachingOther chemical processesHeterogenous catalyst chemical elementsWastewaterSlurry

The invention discloses a preparation method of a composite adsorbing material of industrial wastewater heavy metal ions. The composite adsorbing material comprises a carrier, functional components and catalytic components. The preparation method comprises the steps of mixing and ball-milling all components of the carrier into a corresponding grain size and mixing, mixing and preparing all components of the functional components into a solution, preparing all components in the catalytic components into suspension liquid, selecting all components in parts by weight, mixing, diluting and stirring to obtain slurry, drying and then crashing. The composite adsorbing material provided by the invention has the advantages that the adsorbing effect is good, the cost is low and the preparation is simple.

Owner:山东永辰环境科技有限公司

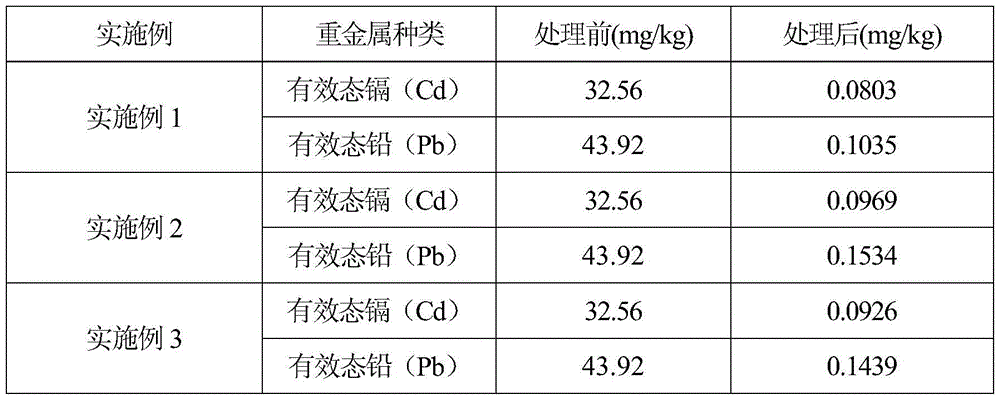

Cadmium-lead compound contaminated soil remediation agent and application thereof

InactiveCN105754612AEasy to prepareGood governanceContaminated soil reclamationOrganic fertilisersTreatment effectSoil remediation

The invention provides a cadmium-lead compound contaminated soil remediation agent, prepared from the following components by a weight ratio: 30-50% of biomass charcoal, 10-20% of polyepoxysuccinic acid, 10-20% of polyacrylamide, 10-20% of starch and 10-20% of sodium bentonite; the components give full play to the synergy, and effective state of cadmium and lead in soil are greatly reduced by carrying out chelation, precipitation, absorption, improvement, PH value adjustment and the like on the components; the prepared soil remediation agent has a good effect in remediation of the cadmium-lead compound contaminated soil; the remediation agent provided by the invention has the advantages of being simple and feasible in preparation method as well as good in treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

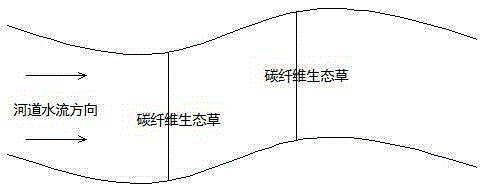

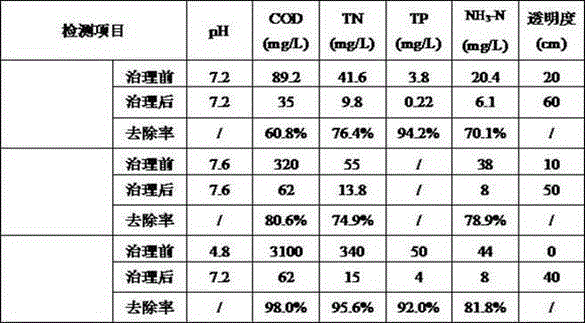

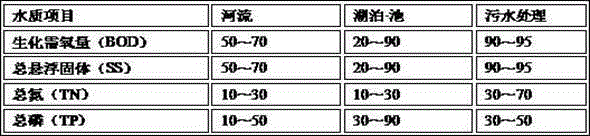

In-situ remediation method for water in black and odorous river

InactiveCN105399209AHigh temperature resistantFriction-resistantBiological water/sewage treatmentFiberCarbon fibers

An in-situ remediation method for water in a black and odorous river comprises steps as follows: (1), pollution indexes of the water in the river are detected; (2), the river is pre-treated, the water in the black and odorous river is oxygenized in a biological oxygen enrichment method, and the concentration of dissolved oxygen in a river aquatic system is kept between 2 mg / L and 8 mg / l; (3), carbon fiber ecological grass is laid in the black and odorous river in the downstream direction, one end of the carbon fiber ecological grass is fixed on an iron framework, the iron framework is fixed at the bottom of the river through a weight or an anchor, and the laying density of the carbon fiber ecological grass is 40 cm<2> / L after biofilm formation; (4), after primary biofilm formation of the carbon fiber ecological grass in 3-5 days, cultured indigenous microorganisms are sprayed to starting ends of different water area sections of the black and odorous river in a liquid water-surface spraying manner, the microorganism feeding area accounts for 41% of the water area, and the ratio of fed microorganisms to water amount in areas with different water quality is (2-5):104. The in-situ remediation method solves the increasingly serious blackening and odor problem of the river, and the water remediation method is low in development cost and operation expense and safe.

Owner:江苏青禾环境修复有限公司

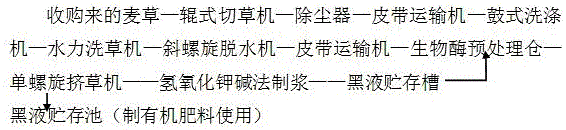

Nutrient solution for rejuvenating trees in gardens, and preparation method thereof

InactiveCN108929152AImprove natural insect and disease resistancePromote absorptionCalcareous fertilisersMagnesium fertilisersPhosphateMonopotassium phosphate

A nutrient solution for rejuvenating trees in gardens is a nutrient solution, containing macroelements, trace elements, organic substances, physiologically active substances and exogenous hormones required for the growth of plants, prepared from ammonium nitrate, potassium nitrate, urea, magnesium sulfate heptahydrate, potassium dihydrogen phosphate, calcium nitrate, calcium chloride dihydrate, sucrose, ferrous sulfate heptahydrate, disodium ethylenediaminetetraacetate, zinc sulfate, copper sulfate, manganese sulfate tetrahydrate, sodium chloride, boric acid, vitamin A, vitamin C, vitamin B1,vitamin B6, humic acid, naphthaleneacetic acid, indolebutyric acid, 6-benzyladenine and gibberellin. The nutrient solution for rejuvenating trees in gardens can improve the survival rate of transplanted trees and promote and accelerate the self-recovering ability of nursery plants in order to make the nursery plants reach an expected landscape effect. The nutrient solution has a good rejuvenatingeffect on famous and old trees planted for many years and having poor growth vigor, and can enhance the resistance, break the dormancy, promote the germination of new shoots and new sprouts and delayaging.

Owner:广州建筑园林股份有限公司

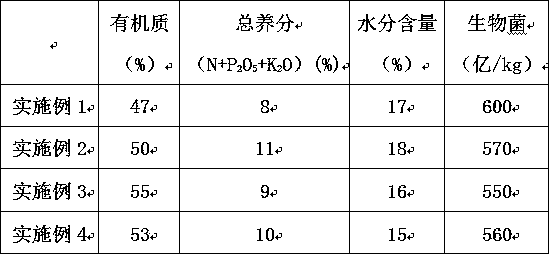

Method for preparing novel biological fertilizer from processing waste of feather

InactiveCN101289341AImprove soil structureImprove water retention capacityFertilizer mixturesNutrientChemistry

The invention discloses a method for preparing a feather-processing residue novel biological organic fertilizer and the steps include: (1) the feather-processing residue is taken as the main raw material, and beneficial organisms flora and water are added; (2) the mixed material is stirred and hermetically fermented; (3) quality is controlled; (4) deodorization is carried out; (5) drying is carried out; (6) the fertilizer is formed and packed The method is characterized in that in the hermetical circumstance, the feather dusts rich in solid proteins are fermented and decomposed in the artificially added beneficial organisms flora, and the fermentation process kills pernicious bacteria and ascarid eggs by utilizing the interaction among bacteria to prepare the novel biological organic fertilizer with a plurality of beneficial flora. The novel biological organic fertilizer thus prepared contains abundant organic matters, beneficial flora and secondary and micro-nutrients, and can, after being applied, effectively improve the structure of soils, enhance the fertilizer conserving capacity and the water retaining capacity of soils, facilitate the releasing of the indissoluble nutrients of soils, improve the feeder capability of soils, adjust (buffer) the PH value of soils and improve the adaptability of soils.

Owner:沈伟

Plant beverage and production method thereof

InactiveCN101396162AKeep the aromaAdjust pH valueFood preparationChemical compositionAdditive ingredient

The invention pertains to the field of beverage, and provides a plant beverage and a preparation method thereof. The beverage contains the following ingredients by weight percentages: 0.2-0.8 per mill of honeysuckle flower, 0.2-0.8 per mill of chrysanthemum, 0.2-0.8 per mill of mulberry leaf, 0.05-0.4 per mill of heartleaf houttuynia herb, 1-2.5 per mill of hawthorn fruit, and water and accessories. The plant raw materials of the plant beverage have the healthcare function of dispelling wind and heat from the body, and regulating pH value of human body; the plant beverage has a tender taste and good taste, and has no chemical composition that is harmful to the human body such as preservative, flavouring essence, pigment and the like; steam is used for distilling and extracting fragrance of the raw materials to ensure the active ingredients with the fragrance of the plant raw materials to be decomposed to small molecules, so the small molecules with the fragrance are not lost in filtration, thus ensuring the plant beverage to have the fragrance of the plant raw materials.

Owner:SHANTOU WANZHILIN HEALTH PRODS

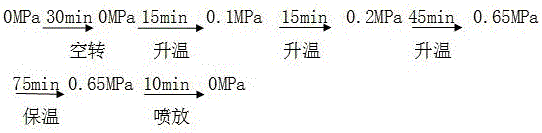

Method for producing potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction

InactiveCN106631564AImprove biological activityRetain inorganic nutrientsOrganic chemistryPulp by-products recoveryProduction lineMaterials preparation

The invention provides a method for producing a potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction, and belongs to the field of fertilizer production. The method comprises the three parts of pretreating wheat straw pretreatment black liquid by biological enzymes, extracting potassium hydroxide alkali process wheat straw boiling black liquid, and producing a finished product of the potassium fulvate organic fertilizer, wherein the process of pretreating wheat straw pretreatment black liquid by biological enzymes comprises the steps of wet process material preparation, wheat straw pretreatment by biological enzymes, and storage of black light containing rich potassium fulvic acid; the potassium hydroxide alkaline process wheat straw pulping extraction black liquid comprises extrusion of biological enzyme pretreatment wheat straws, mixing of wheat straws and potassium hydroxide medicine liquid in a pre-soaking machine, steaming ball steaming boiling spray discharging, and steamed and boiled black liquid collection and storage. The organic fertilizer production line comprises black liquid evaporation and concentration, guniting pelleting machine treatment, hot and cold sieving system treatment and organic fertilizer finished product packaging. The paper making black liquid is changed from waste into valuable materials; through biological enzyme pretreatment, the high-activity potassium fulvate organic fertilizer is produced.

Owner:宁夏同创秸科生物科技有限公司

Camellia soilless culture substrate and preparation method thereof

InactiveCN106748325APromote growthInhibition of reproductionBio-organic fraction processingExcrement fertilisersPeatChemistry

The invention discloses a camellia soilless culture substrate which is mainly prepared from the following raw materials of perlite, coco coir, peat, vermiculite, pine bark, biogas residue, bagasse powder, chicken manure and additive, wherein the additive is diluted pyroligneous. The camellia soilless culture substrate can provides microelements required in a camellia growth process, can keep fertilizer efficiency, has excellent breathability, has good water retention, is a particle material and not prone to hardening, effectively prevents microorganisms obstructing orchid growth from multiplying, has light character and is convenient to use; in addition, a PH value of the camellia soilless culture substrate is neutral and close to acidity, so that camellia growth is beneficiated; organic waste of the coco coir, the pine bark, the biogas residue, the bagasse powder, the chicken manure and the like is utilized as the main raw materials, so that environmental pollution is reduced, waste is turned into wealth, and a disadvantage is turned into an advantage; furthermore, a preparation method is simple and convenient to operate.

Owner:FLOWER RES INST GUANGXI ACADEMY OF AGRI SCI

High-efficiency environment-friendly nickel stripper and preparation method thereof

The invention discloses a high-efficiency environment-friendly nickel stripper and a preparation method thereof, which solve the problems of low stripping speed and high stripping temperature of a nickel layer and hostile operating environment. Based on 100 parts by weight, the high-efficiency environment-friendly nickel stripper comprises the following substances: 5.19 to 12.82 parts of ethanediamine, 5.19 to 12.82 parts of sodium metanitrobenzene sulfonate, 0.74 to 1.71 parts of citric acid, 1.48 to 2.56 parts of an organic amine additive and 70.09 to 87.40 parts of pure water. The invention also discloses the preparation method of the high-efficiency environment-friendly nickel stripper. According to the high-efficiency environment-friendly nickel stripper and the preparation method thereof, quick stripping of the nickel layer is promoted; in particular, after the organic amine additive is used, the stripping speed of the nickel layer is greatly increased, the stripping temperature is reduced, and a great deal of smoke generated during stripping is reduced.

Owner:英洛华科技股份有限公司

Fuel coal additive

The invention relates to a burning coal additive that belongs to coal fuel additive technology field. The main feature is that mixes the salt combustion adjuvant and calcium oxide absorbent as the ratio of 4-10%:96-90%. The invention uses the combustion supporting and catalysis of Na and Cl that could be decomposed from melt salt. The CO2 from burning calcium oxide could absorb the SO2 from burning coal and finally form CaCO3. Thus, the aim of benefit for the environment would be achieved. It also has notable economical benefit and social benefit.

Owner:陈列

A new type of quick-acting nutrient nitrogen fertilizer

The invention discloses a readily available nutritive nitrogenous fertilizer, and relates to the field of agricultural fertilizers. The novel readily available nutritive nitrogenous fertilizer is prepared by mixing 3 to 5 weight parts of ammonium chloride, 20 to 30 weight parts of urea, 1 to 2 weight parts of microelement, 4 to 6 weight parts of ammonium nitrate, 50 to 65 weight parts of ammonium sulfate, 5 to 7 weight parts of silicon-calcium-magnesium, and 0.01 to 0.03 weight part of plant growth regulator, and extruding and granulating. The novel readily available nutritive nitrogenous fertilizer has the characteristics of comprehensive nutrients, high utilization rate, good absorption, quick response, wide application range and the like, and can be widely used for quick-acting top application of various crops such as tobacco, vegetables, melons and fruits, flowers and trees and the like.

Owner:HUNAN ZHONGKE AGRI

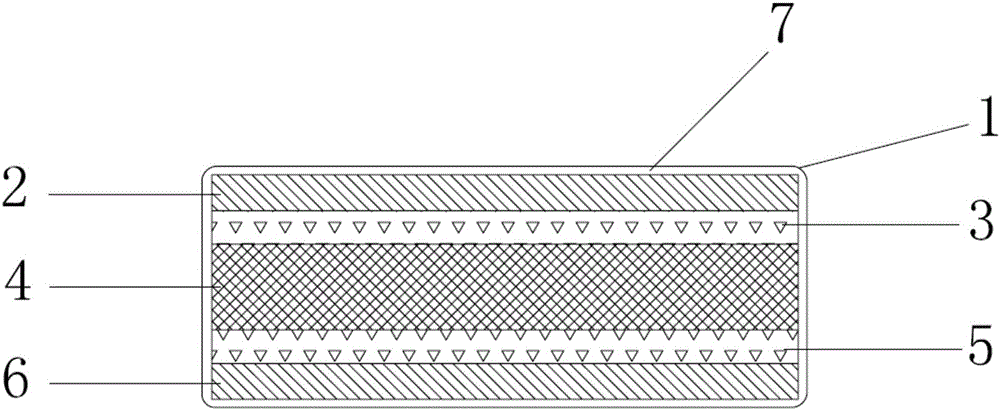

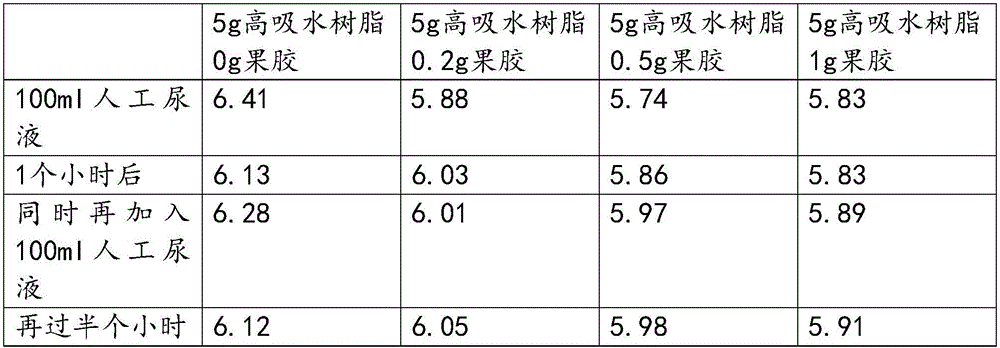

Water-absorbent layer core material of pectin highly water-absorbent resin paper diaper, manufacturing process of paper diaper and paper diaper

InactiveCN106618869AAdjust pH valueAbsorbent padsBaby linensSodium bicarbonatePulp and paper industry

The invention relates to the field of production of paper diapers, in particular to a water-absorbent layer core material of a pectin highly water-absorbent resin paper diaper, a manufacturing process of the paper diaper and the paper diaper. The water-absorbent layer core material of the pectin highly water-absorbent resin paper diaper consists of 100-200 parts of acrylic acid, 3-5 parts of chitosan, 2-3 parts of a triggering agent, 0.1-0.2 part of N,N-methylene bisacrylamide, 70-150 parts of KOH, 0.1-2 parts of sodium bicarbonate and 8-16 parts of pectin powder. The paper diaper provided by the invention, on the basis of using pectin, which can react with ammonium salt in urine, as a raw material of the paper diaper, can effectively regulate PH value of the paper diaper which absorbs the urine, so that rashes are prevented and skin, which gets into contact with the paper diaper, is kept in a comfortable environment.

Owner:阮镇锋

Method for planting Syzygium samarangense

InactiveCN106105986APrevent rotAchieve the function of drainage and water retentionCultivating equipmentsAreolaThinning

The invention relates to the technical field of plant plantation, and specifically relates to a method for planting Syzygium samarangense. The method comprises: (1) selecting land and preparing land; (2) planting; (3) performing field management: a, regulating in a production period, b, forcing flowers, c, blossom and fruit thinning, d, bagging; (4) harvesting fruits: when 70-90% of Syzygium samarangense areola is unfolded and variety inherent color appears, harvesting. The invention provides the method for planting Syzygium samarangense, and provides a technical scheme for Syzygium samarangense standardized planting, and meanwhile using production period regulation, the Syzygium samarangense come into the market staggering a selling season of July to August. The method improves quality of Syzygium samarangens, and improves economical benefits of Syzygium samarangens planting.

Owner:广西田阳共联农业综合开发有限公司

Special organic-inorganic compound fertilizer for apples

InactiveCN104355774APromote absorptionGrow fastAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseasePhosphate

The invention relates to a special organic-inorganic compound fertilizer for apples. The organic-inorganic compound fertilizer comprises the following raw materials in parts by weight: 180-220 parts of sugar residue, 20-50 parts of fulvic acid, 20-30 parts of an amino acid-trace element chelate, 20-30 parts of a binder, 180-220 parts of urea, 220-250 parts of monoammonium phosphate, 230-250 parts of potassium sulfate and 40-60 parts of ammonium sulfate; on the basis of the raw materials, 20-30 parts by weight of a nutritional regulator can be simultaneously added, the nutritional regulator comprises the following components in percentage by mass: 20-30% of chitosan oligosaccharide, 15-18% of ammonium molybdate, 20-35% of calcium propionate, 5-8% of ascorbic acid, 8-10% of amino acid and 18-25% of ZnCl2. The organic-inorganic compound fertilizer disclosed by the invention has the advantages that the soil is improved, the nutrient is evenly released, the diseases of apple trees are prevented, the resistance of plants is enhanced, the weight of single fruit is significantly increased, the color of the fruit is good, the yield is high and the like.

Owner:安徽沃福农业生物科技股份有限公司

Quick-acting nutrition nitrogenous fertilizer

The invention discloses quick-acting nutrition nitrogenous fertilizer, and relates to the filed of agricultural fertilizer. The quick-acting nutrition nitrogenous fertilizer is prepared by mixing and pelleting 60 to 85 weight parts of ammonium chloride, 2 to 5 weight parts of secondary microelements, 5 to 10 weight parts of urea, 5 to 20 weight parts of ammonium sulfate, 3 to 5 weight parts of silicon fertilizer and 0.02 to 0.04 weight part of plant growth regulator, has the characteristics of full nutrition, high utilization rate, good absorption, quick response and the like, and can be widely used as quick-acting additional fertilizer for planting crops such as paddy rice, vegetables, melons and fruits, flowers and trees and the like.

Owner:HUNAN ZHONGKE AGRI

Rose-water-containing astringent and preparation method thereof

InactiveCN102415974ASmooth skin effectRefreshing skinCosmetic preparationsToilet preparationsRose waterGlycerol

The invention discloses rose-water-containing astringent and a preparation method thereof. The rose water in the astringent is prepared by distilling roses and water, wherein the weight of water added into the roses is 8 to 10 times the weight of the roses, the distillation speed based on ratio of liquid distilled out per hour to total water weight is 10 to 20 percent, distillation is performed until the liquid distilled out finally is equal to the weight of the roses, and thus, the rose water is obtained. The astringent is added with natural glycerol, allantoin, complex amino acid and other natural components, so the whitening, moisturizing, skin softening, freckle-lightening effects of the astringent are much obvious. The astringent does not contain any materials that may cause allergy to skin, such as alcohol and preservative, retains the sweet, moist, fresh and elegant fragrance of natural roses and provides a new approach for developing and utilizing roses.

Owner:KUNMING UNIV OF SCI & TECH

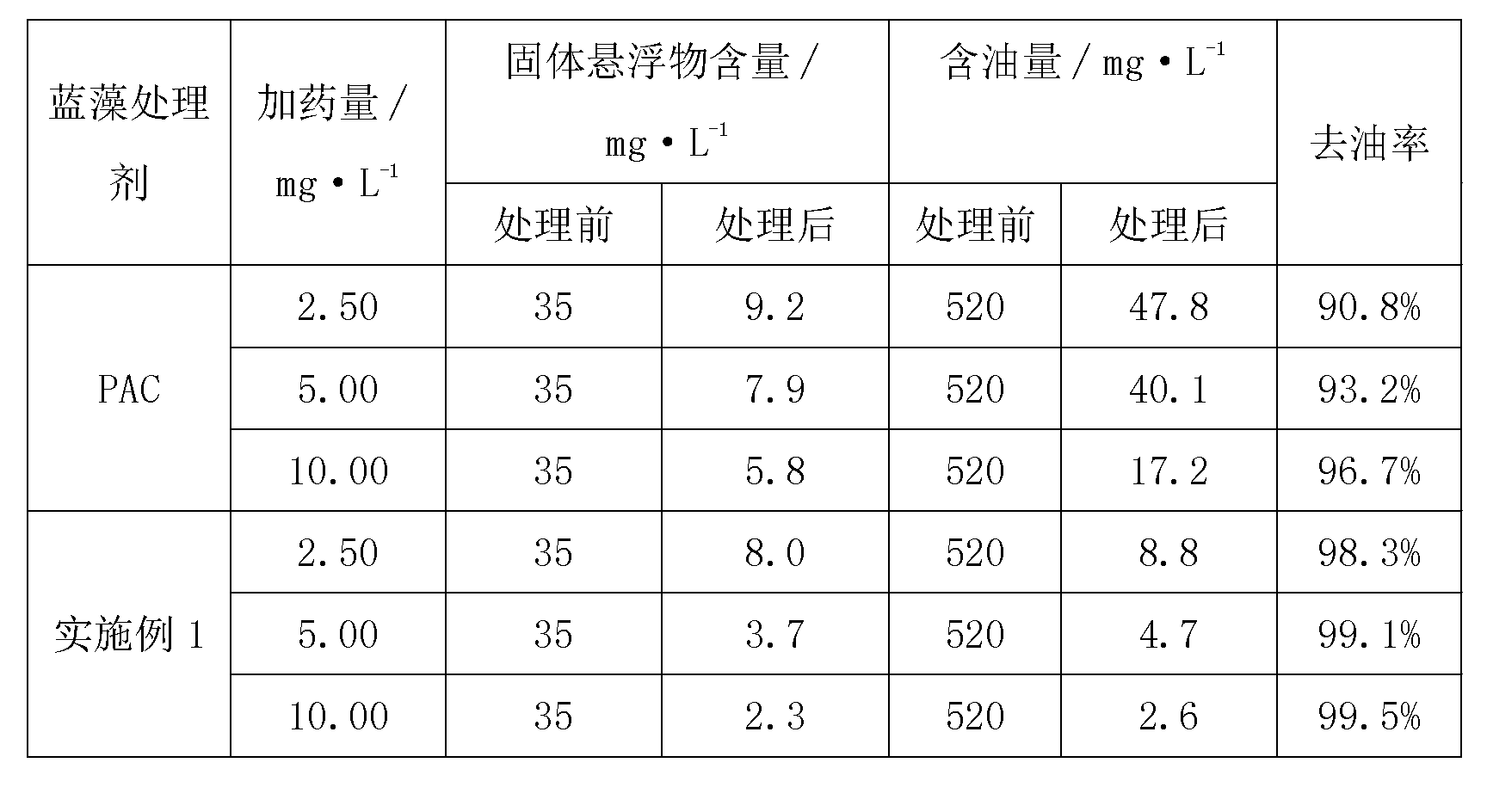

Composite powdery blue algae treatment agent and preparation method thereof

InactiveCN103172160AWork is easy to coordinateGood shape distributionWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationCarcinogenHazardous substance

The invention discloses a composite powdery blue algae treatment agent and a preparation method thereof. The composite powdery blue algae treatment agent is prepared from the following raw materials in parts by weight: 10-15 parts of dicalcium silicate, 15-40 parts of copper sulfate, 1-30 parts of potassium sulfate, 10-30 parts of aluminum potassium sulfate, 10-30 parts of calcium carbonate, 5-20 parts of malic acid, 10-25 parts of calcium oxide and 1-10 parts of polyacrylamide. The composite powdery blue algae treatment agent disclosed by the invention can remove heavy metal ions, radioactive substances, carcinogenic substances, blue algae, SS (suspended substances), COD (chemical oxygen demand), BOD (biochemical oxygen demand) and other pollutants and harmful substances, which are difficult to treat by using existing common blue algae sewage treatment agents, in a broad-spectrum and high-efficient manner, has a variety of significant effects of decolorization, deodorization, dehydration, deoiling, bacterial removal and the like, and has the advantages of small using quantity, high treatment speed, fast onset of action, low operation cost and very strong applicability to high dirt concentration of soil sewage, wide PH value range and wide sewage temperature changes.

Owner:章云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com