High-stability sewage treating agent and preparation method thereof

A sewage treatment agent with high stability technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of insufficient polymerization degree, large dosage of chemicals, and reduced drug efficacy, etc., to achieve excellent coagulation performance, treatment The effect of short time and low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix 10 parts by weight of 100-mesh citric acid and 55 parts by weight of 100-mesh sodium carbonate for 40-60 minutes, then add 10 parts by weight of 100-mesh magnesium carbonate, stir and mix for 120-200 minutes, then add 8 parts by weight of 100-mesh sodium carbonate Ferric chloride, uniformly stirred and mixed for 30-60 minutes, then added 7 parts by weight of 100-mesh calcium oxide and uniformly stirred and mixed for 30-60 minutes, then added 10 parts by weight of 100-mesh polyacrylamide, stirred and mixed evenly for 30-60 minutes. .

Embodiment 2

[0025] Mix 10 parts by weight of 300-mesh citric acid and 50 parts by weight of 300-mesh sodium carbonate for 40-60 minutes, then add 10 parts by weight of 300-mesh magnesium carbonate, stir and mix for 120-200 minutes, and then add 8 parts by weight of 300-mesh sodium carbonate. Ferric chloride, uniformly stirred and mixed for 30-60 minutes, then added 7 parts by weight of 300-mesh calcium oxide and uniformly stirred and mixed for 30-60 minutes, then added 10 parts by weight of 300-mesh polyacrylamide, stirred and mixed evenly for 30-60 minutes, .

Embodiment 3

[0027] Mix 10 parts by weight of 500-mesh citric acid and 50 parts by weight of 500-mesh sodium carbonate for 40-60 minutes, then add 10 parts by weight of 500-mesh magnesium carbonate, stir and mix for 120-200 minutes, and then add 8 parts by weight of 500-mesh three Ferric chloride, uniformly stirred and mixed for 30-60 minutes, then added 7 parts by weight of 500-mesh calcium oxide and uniformly stirred and mixed for 30-60 minutes, then added 10 parts by weight of 500-mesh polyacrylamide, stirred and mixed evenly for 30-60 minutes. .

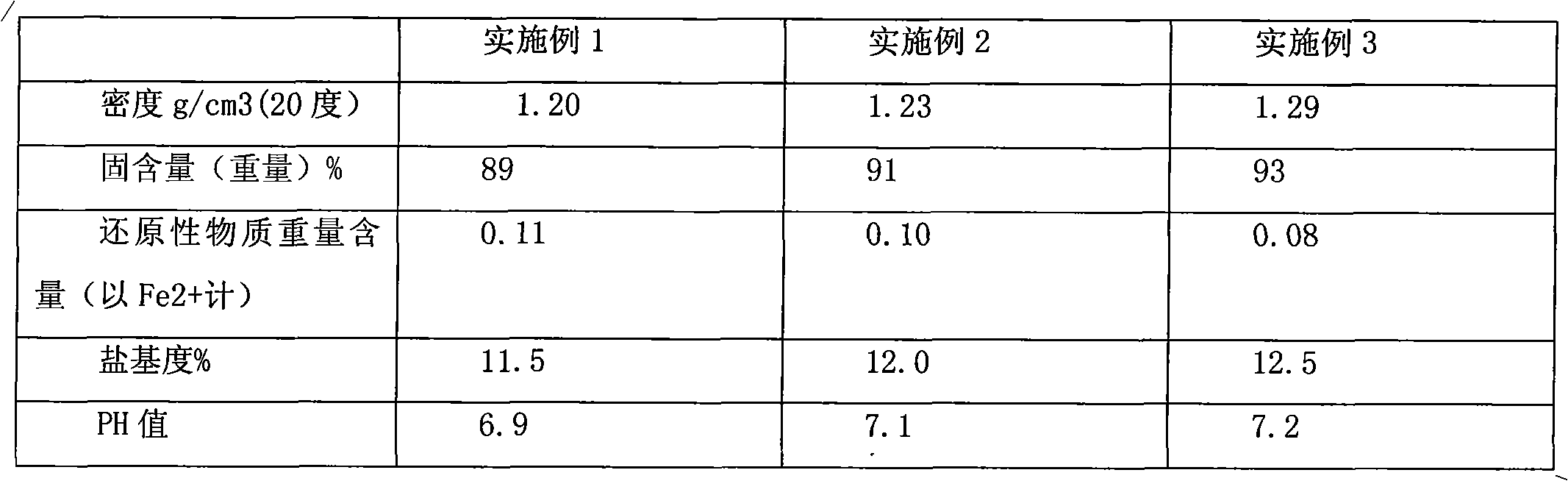

[0028] The technical index of embodiment 1-3 is as shown in table 1

[0029]

[0030] Table 1

[0031] In summary, the present invention has the advantages of multi-energy and high efficiency, green environmental protection, fast sewage treatment speed, short treatment time, broad-spectrum and high-efficiency removal of various pollution and harmful substances, high pollution concentration of sewage, and wide pH value range , Wide range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com