Novel dust-proof coating stirrer.

A dust-proof coating and mixer technology, applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve problems such as inconvenient movement, affecting quality, and unbalanced stirring power, so as to achieve convenient coordination and use. Flexible, quality-assured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

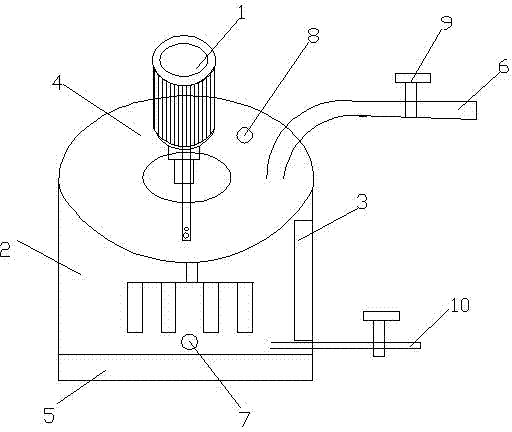

[0009] Such as figure 1 Shown, a kind of novel dust-proof paint mixer of the present invention comprises motor 1, barrel body 2, loam cake 4, lower lid 5, injection pipe 6 and output pipe 10, and described loam cake 4 and lower lid 5 all pass screw thread and The barrel body 2 is connected, the motor 1 is arranged on the upper cover 4, the lower part of the motor 1 is connected to the agitator through a connecting rod, the outer wall of the barrel body 2 is provided with a visible scale bar 3, and the upper cover 4 is provided with There is an injection pipe 6 and an injection pipe interface 8, an output pipe 10 is arranged below the barrel body 2, a valve 9 is arranged on the injection pipe 6 and the output pipe 10, and an output pipe interface 7 is arranged at the bottom of the barrel body 2 .

[0010] It should be noted that there are multiple injection pipe interfaces 8 and output pipe interfaces 7 .

[0011] It should be noted that both the motor 1 and the stirrer can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com