Patents

Literature

36 results about "Visual scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

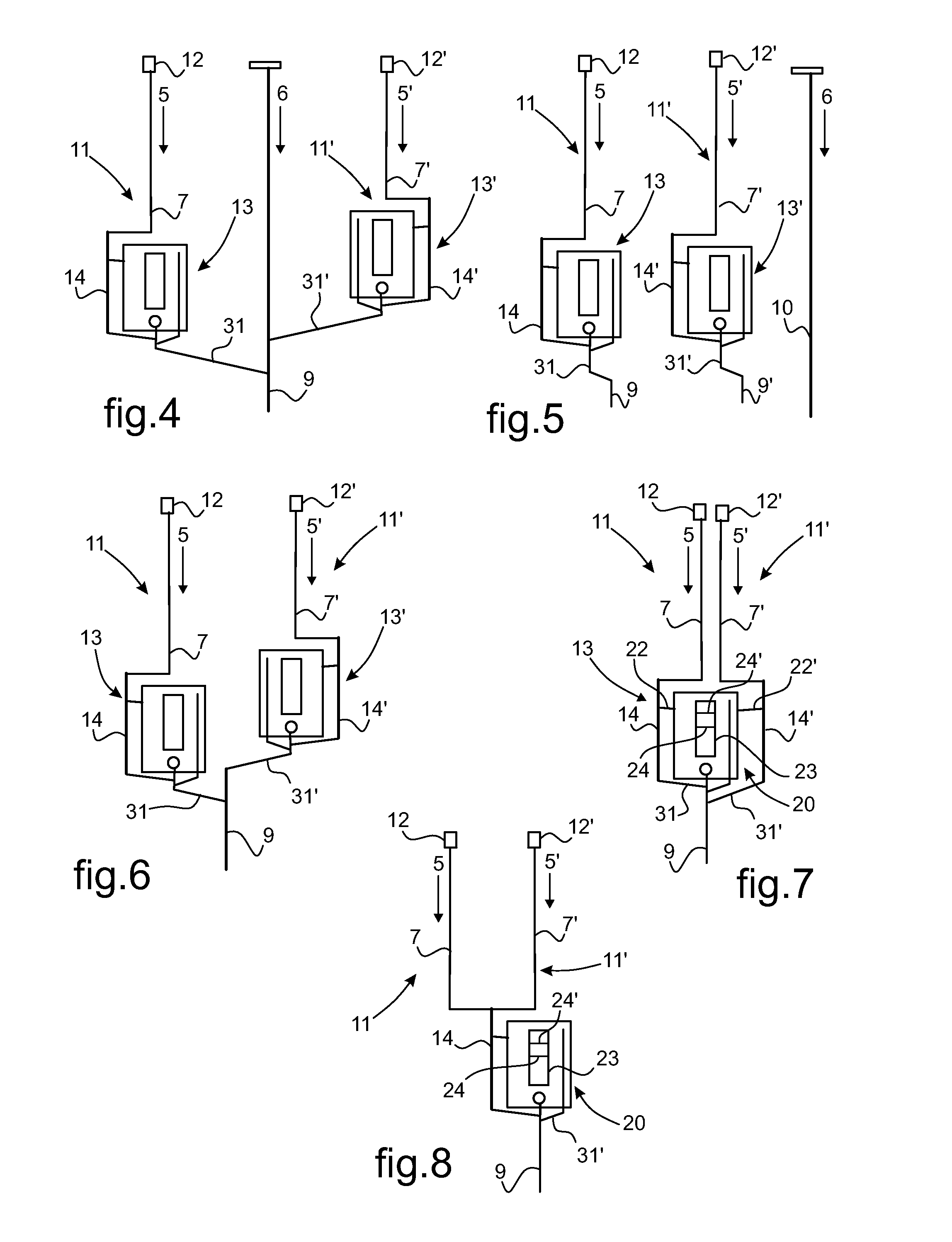

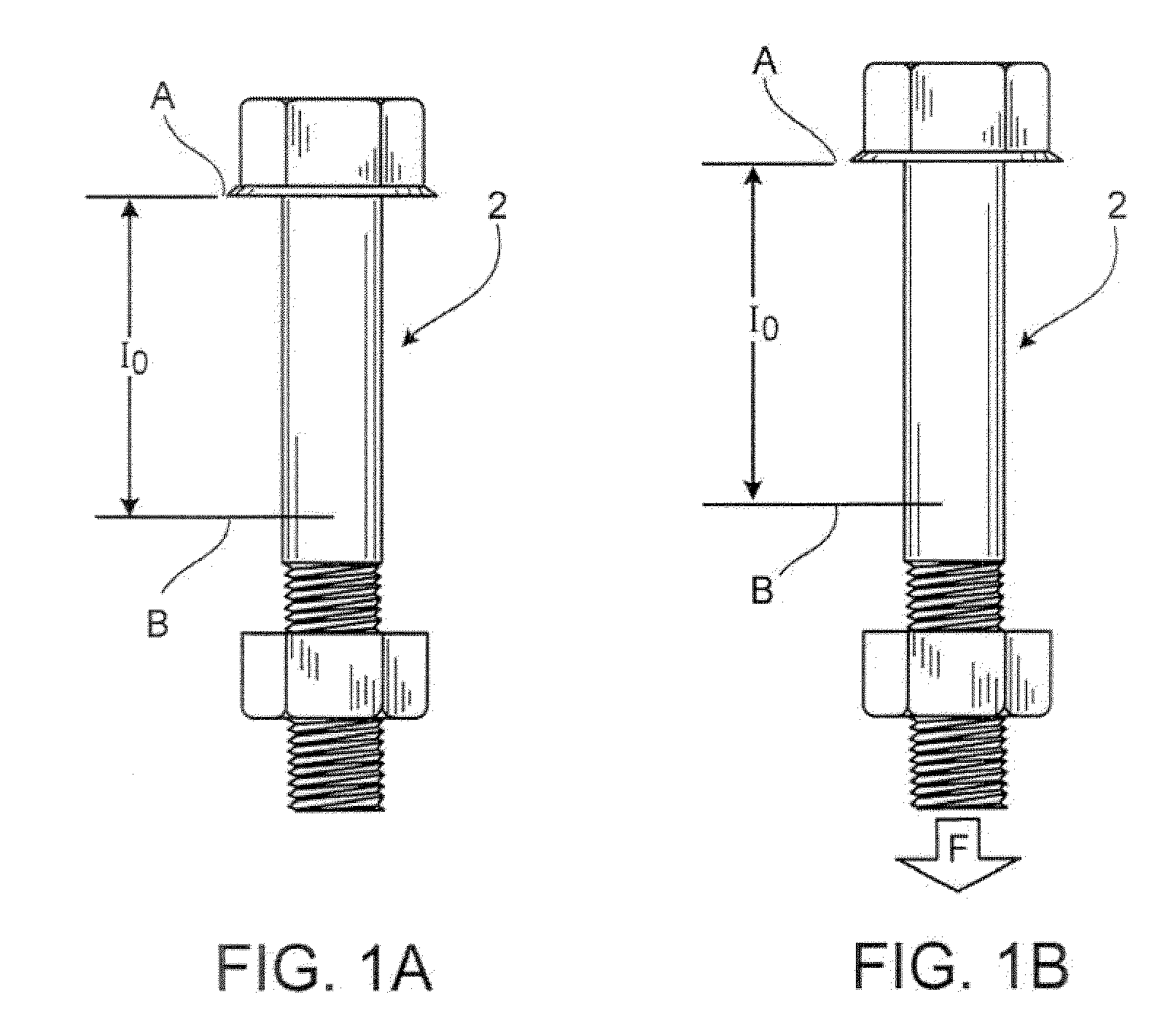

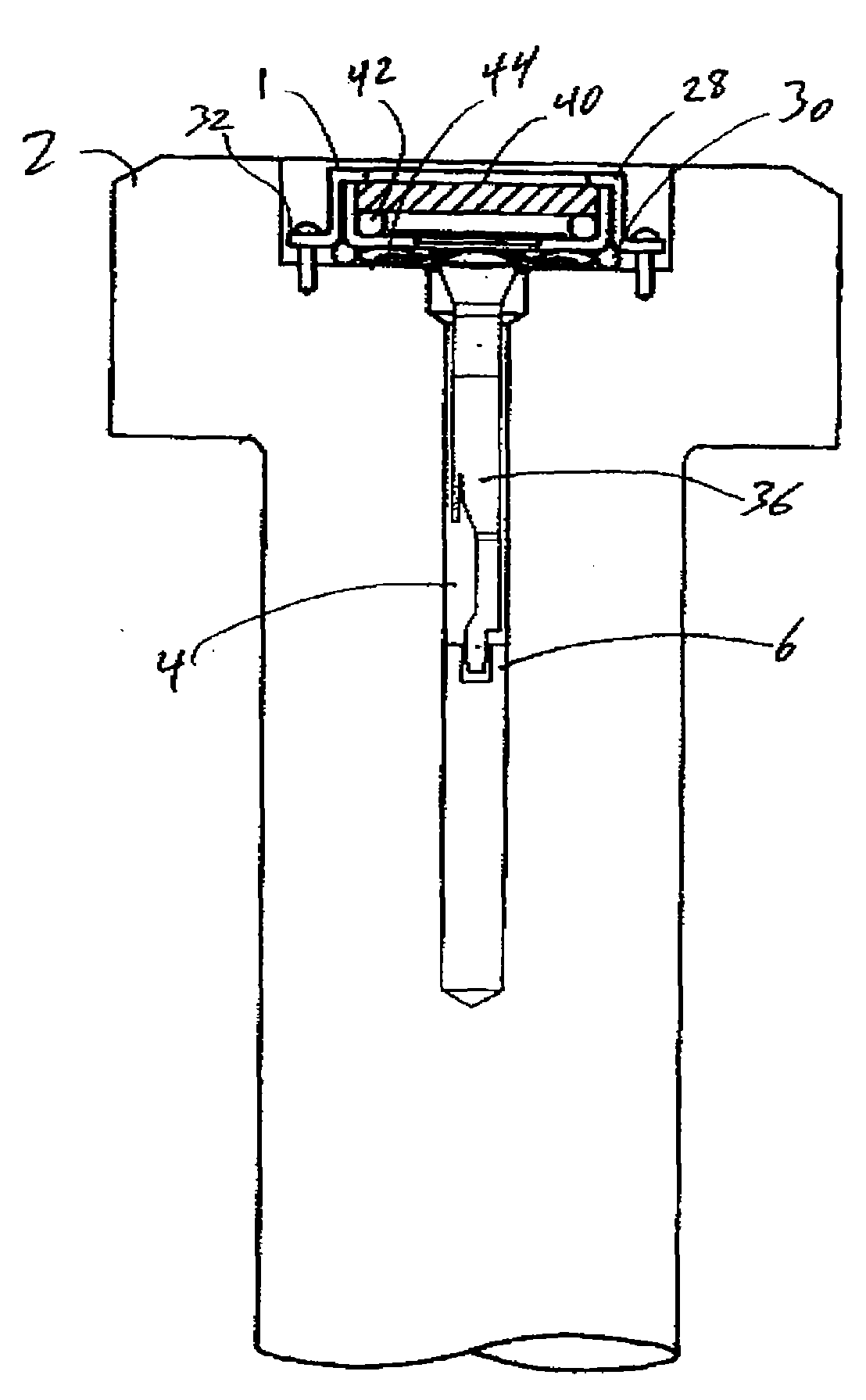

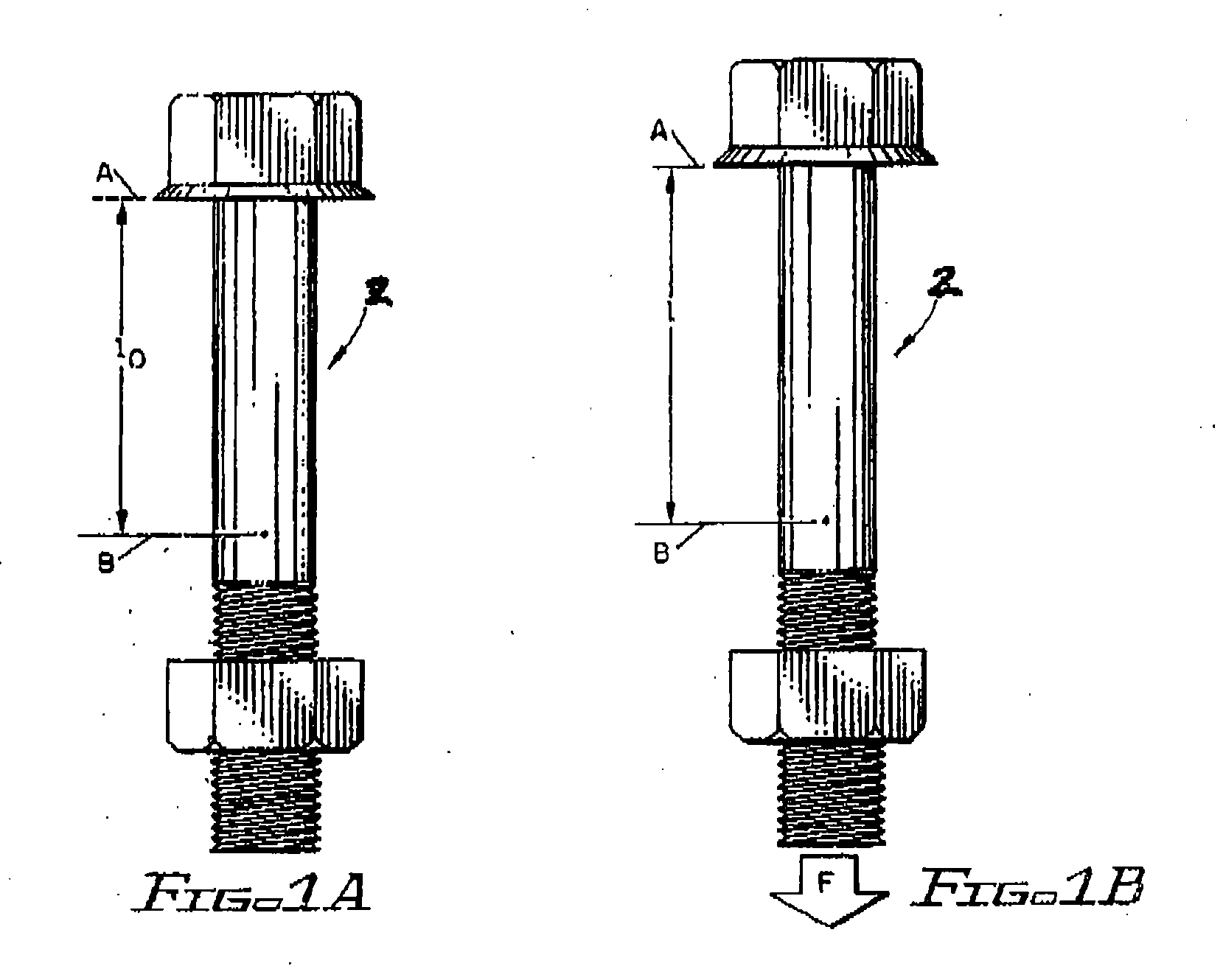

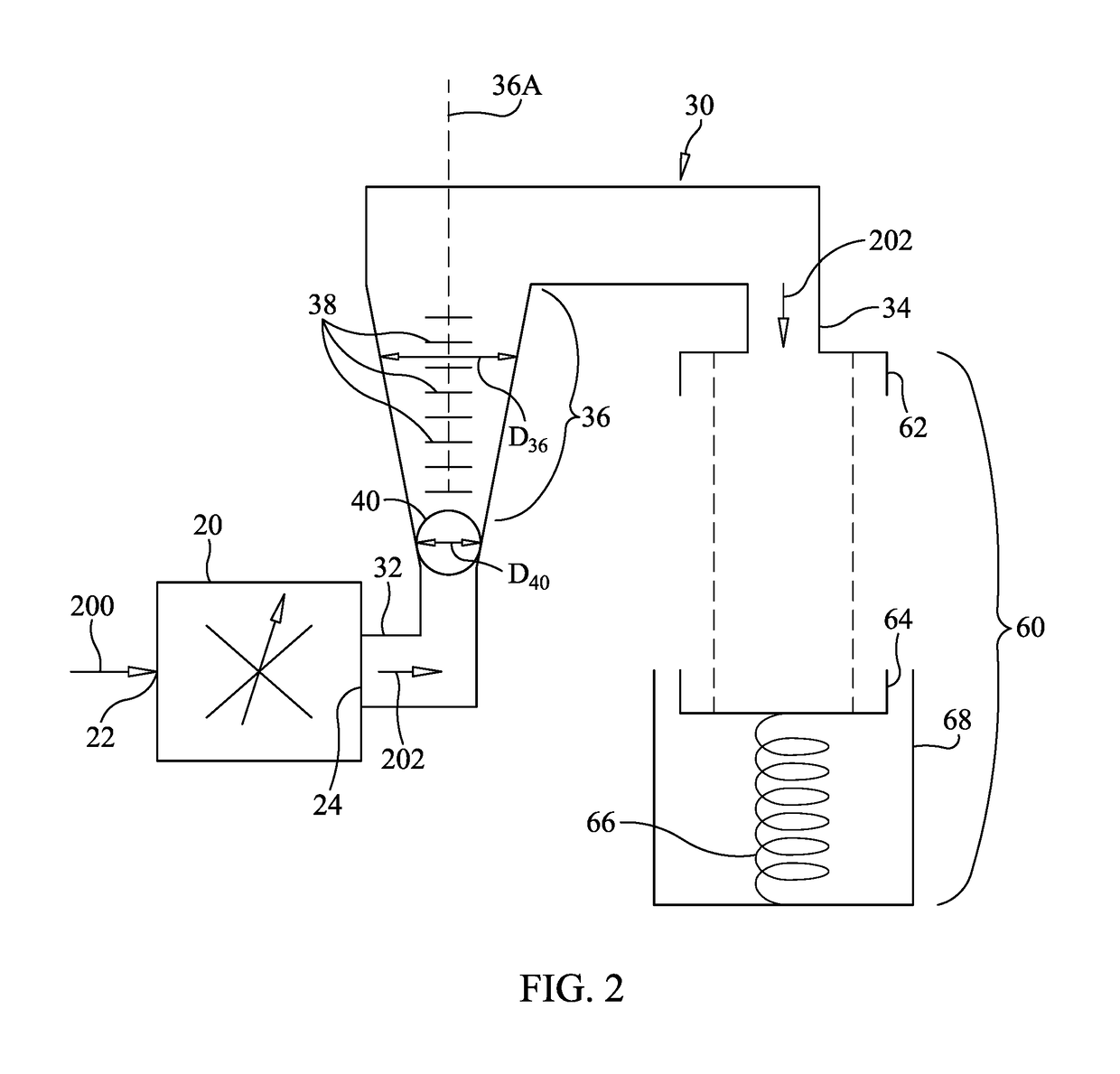

Indicating fastener loading

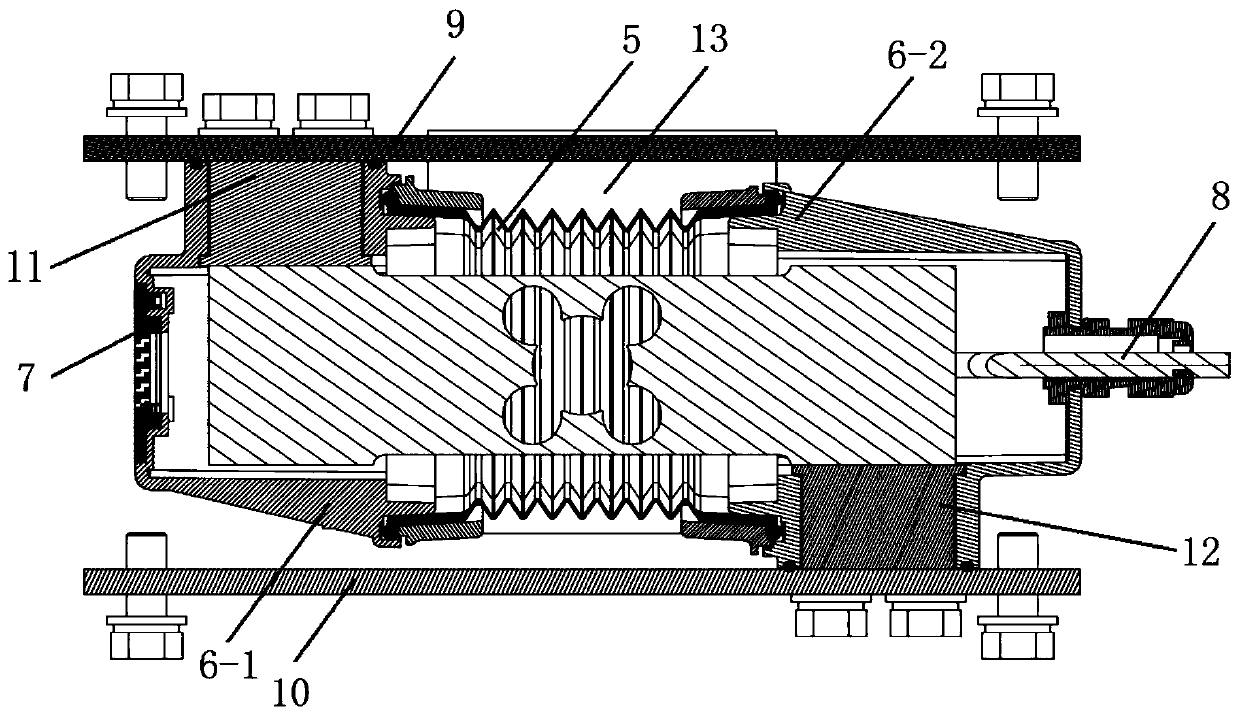

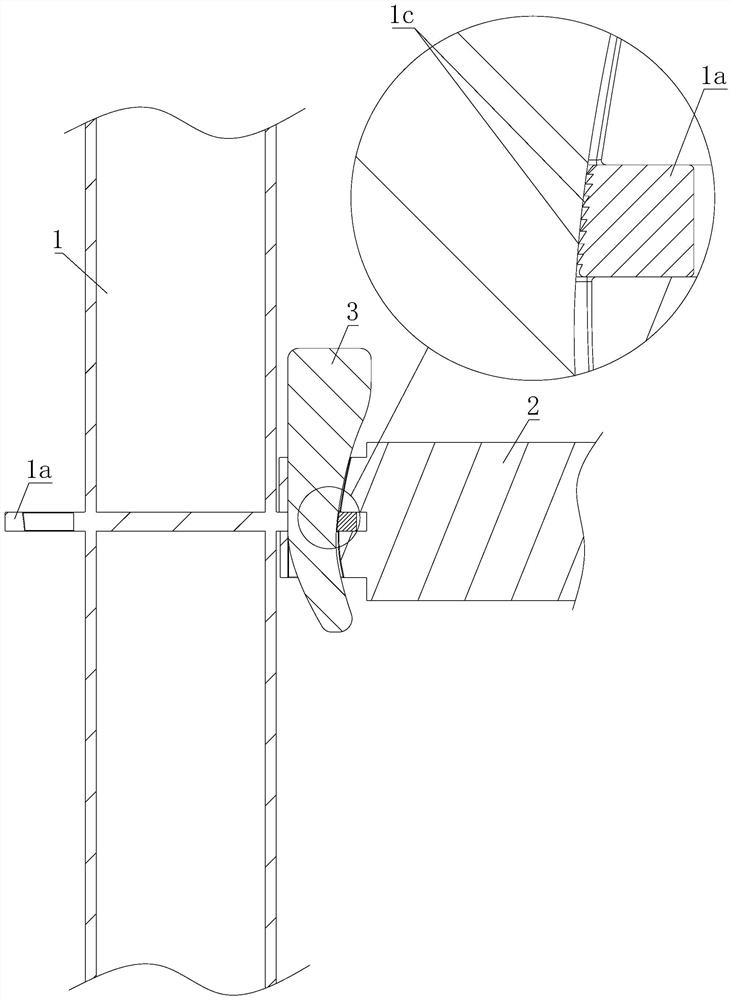

ActiveUS8024979B2Prevent intrusionReduced dimensionMeasurement of torque/twisting force while tighteningLoad modified fastenersDisplay deviceEngineering

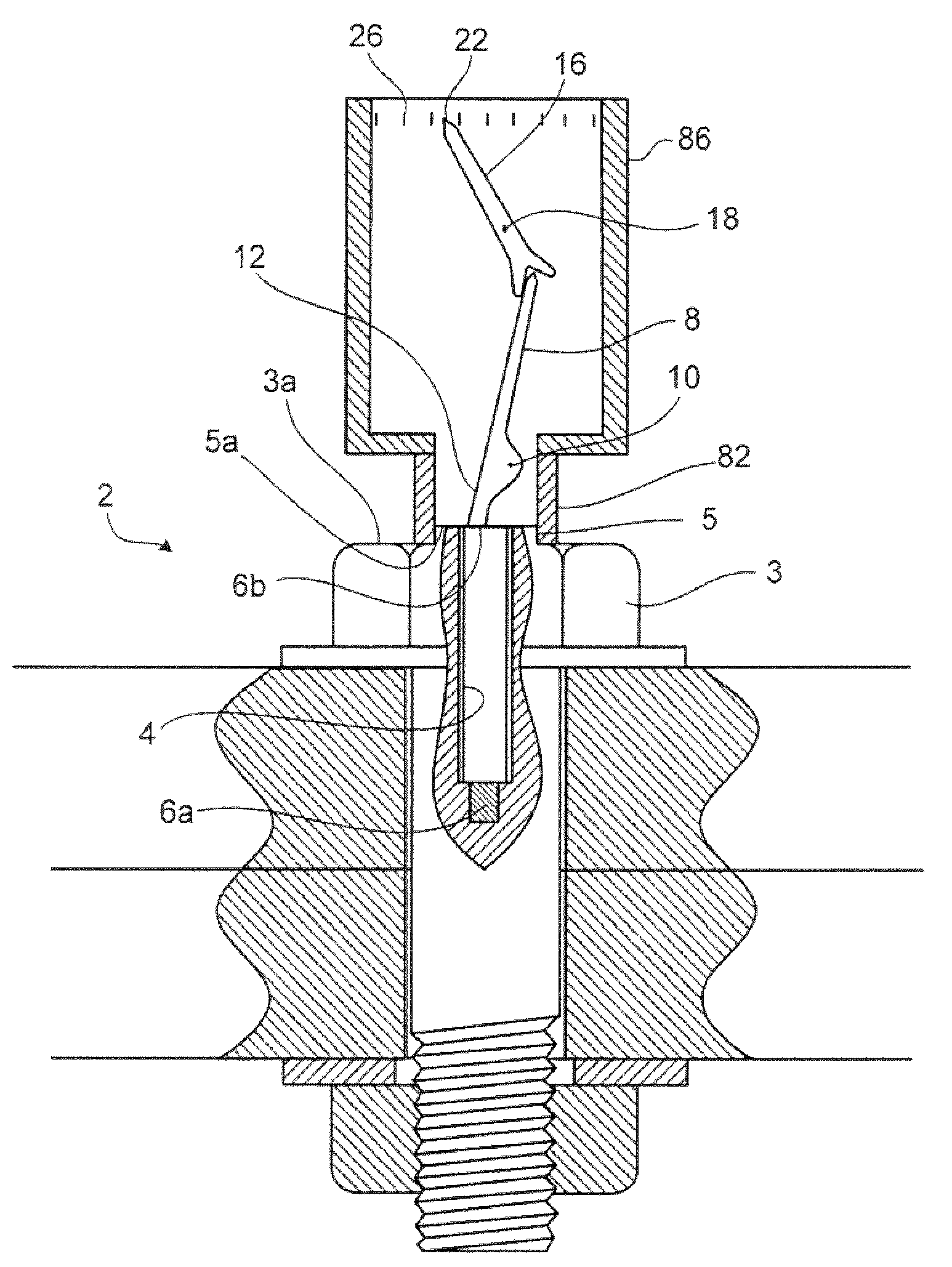

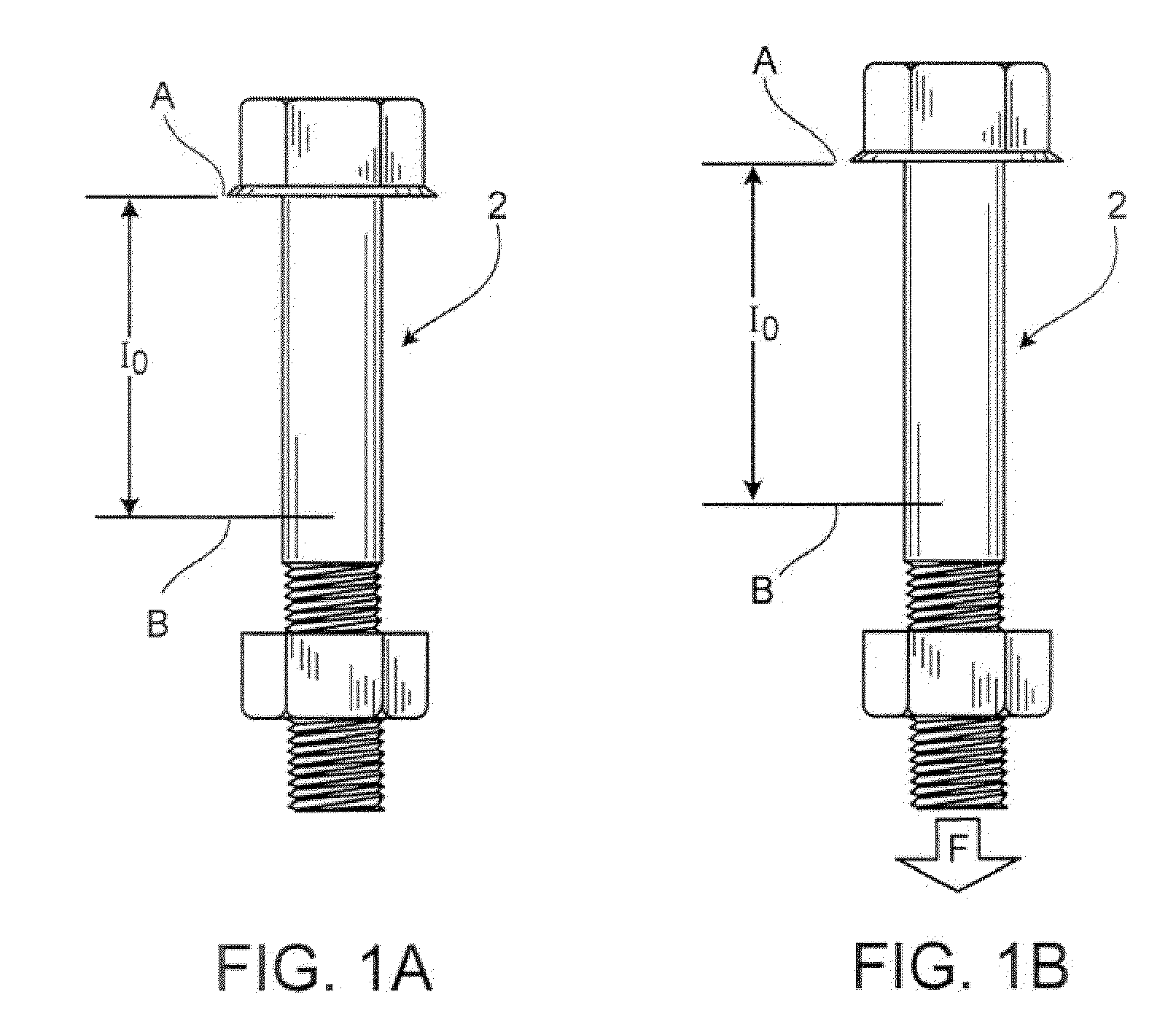

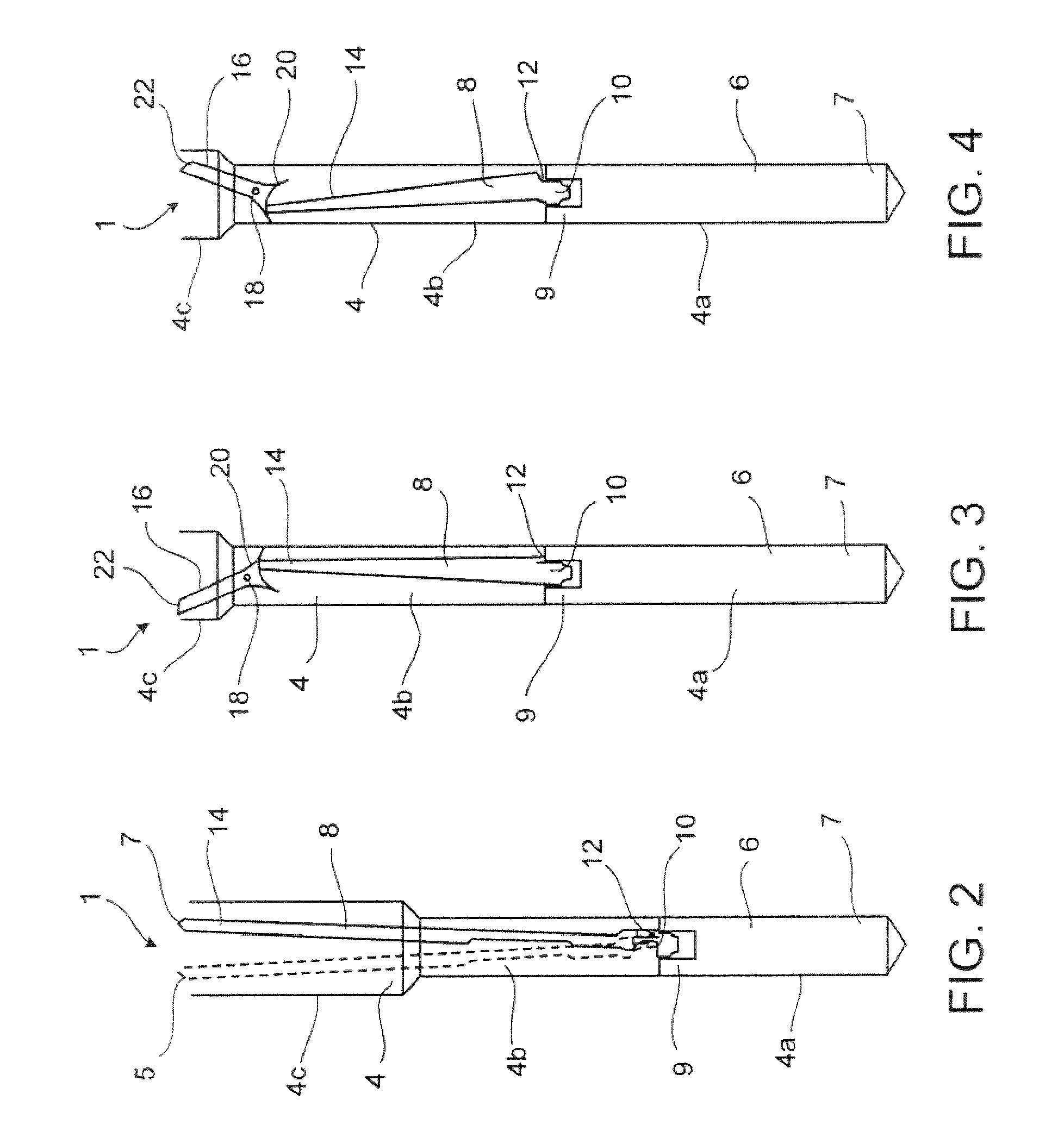

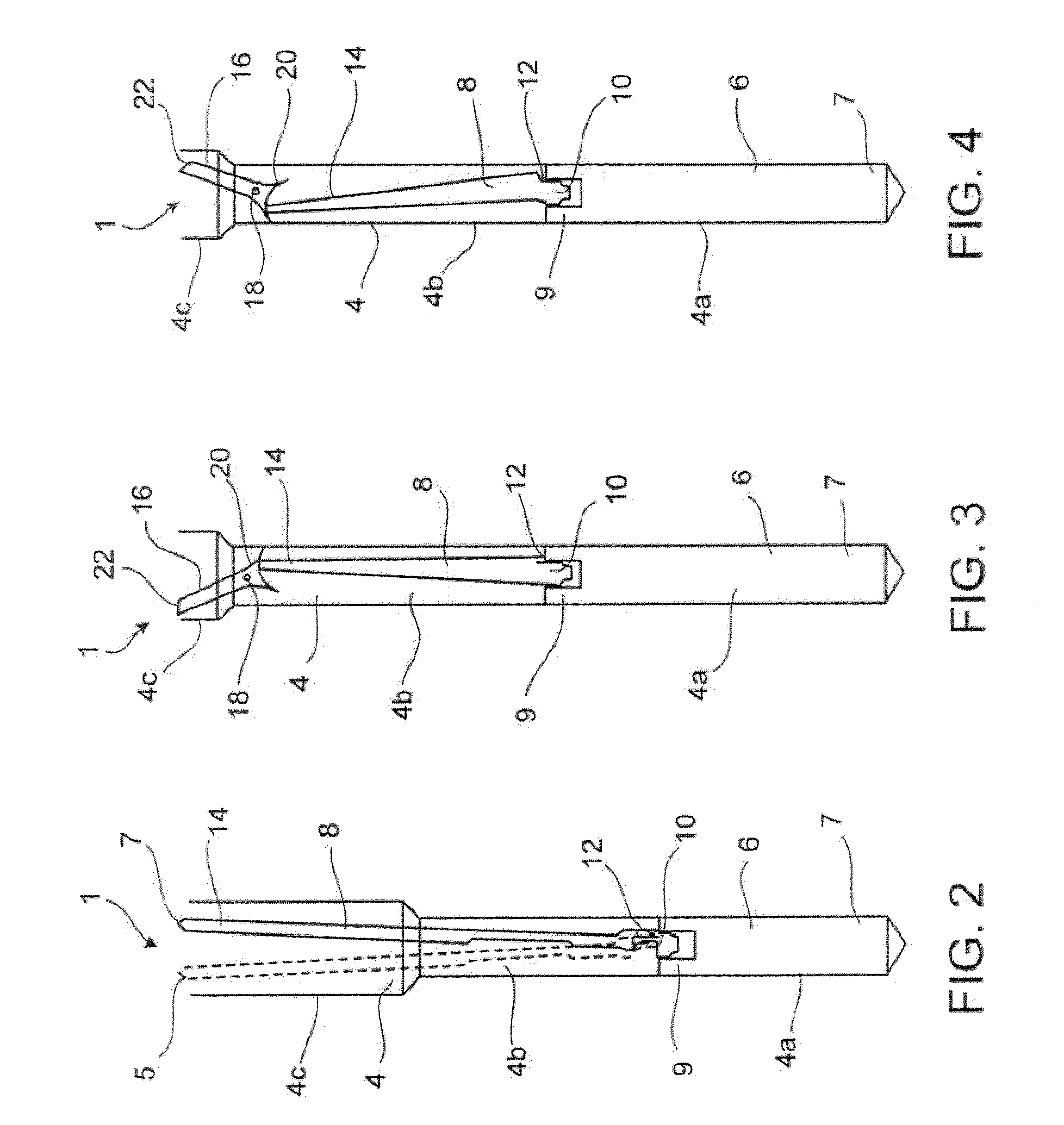

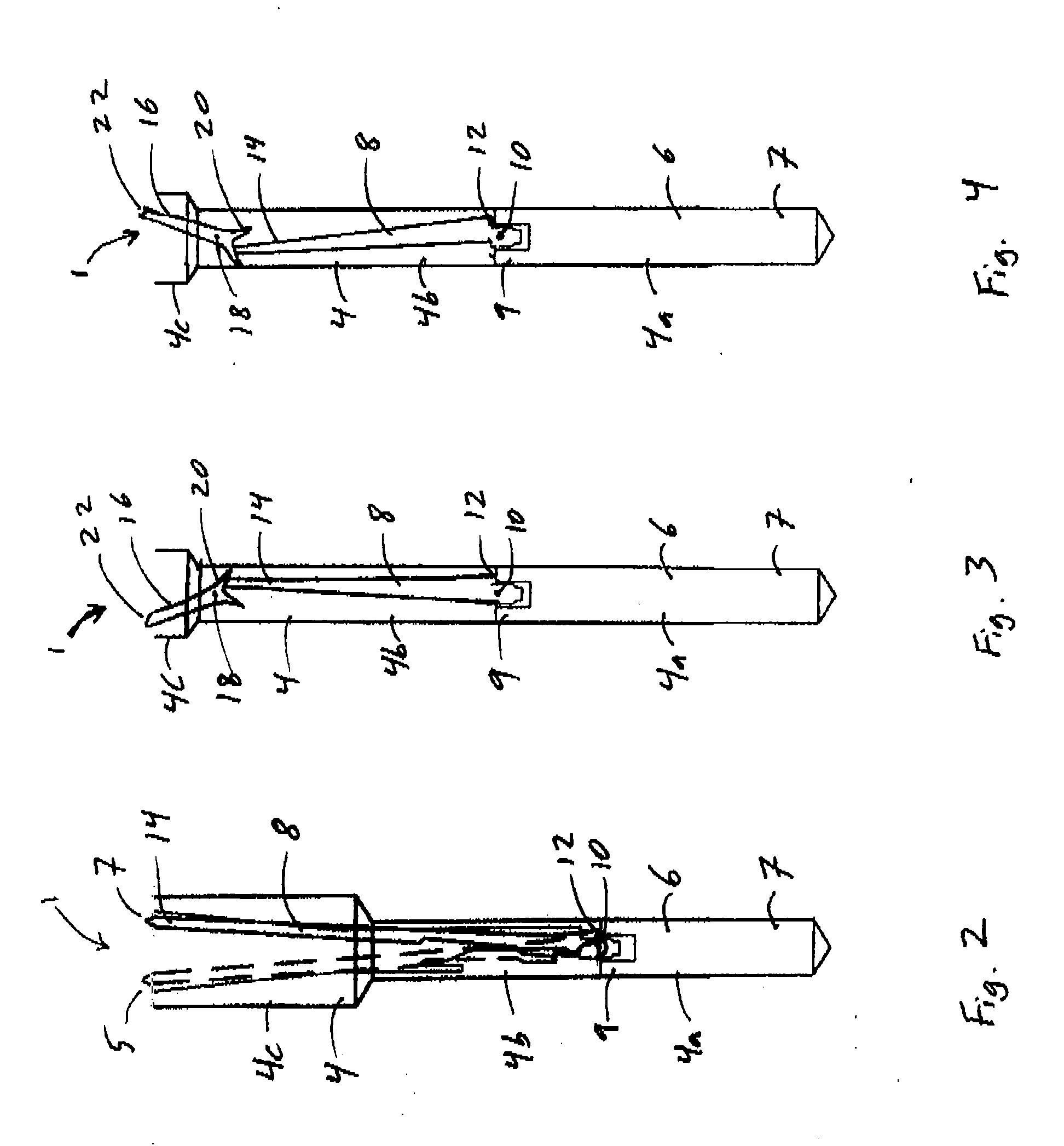

An amplified indication of the elongation of a fastener is provided for determining instantaneous loading conditions of a fastener. A load indicator is couplable to a fastener for instantaneous load measurement and includes a housing defining a fastener interface configured to removably couple the housing to a fastener. A moveable datum probe extends from the housing in contact with a datum rod anchored within an internal bore of the fastener. A first lever is pivotally mounted within the housing and is moveable in response to displacement of the datum probe. A load display indicates a degree of loading of a fastener as a function of displacement of the datum probe. A second lever can be used to further amplify the reading from the displacement of the datum probe. An inclined visual scale and a multi-faceted lens allows for viewing of loading values from multiple directions or angles.

Owner:VALLEY FORGE & BOLT MFG

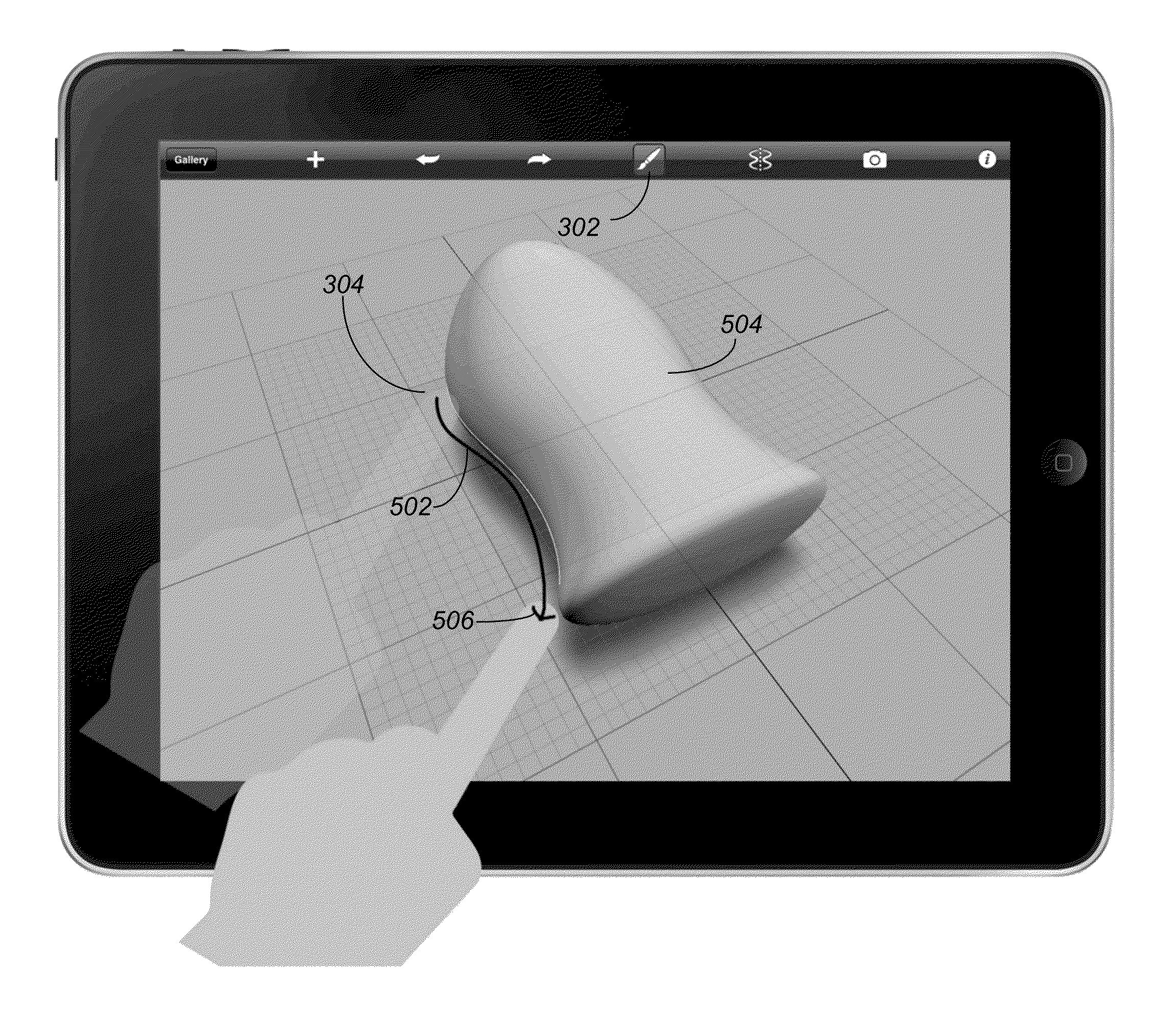

Gestures and tools for creating and editing solid models

ActiveUS20130181987A1Rapidly and dynamically createInput/output processes for data processing3D modellingApplication softwareVisual perception

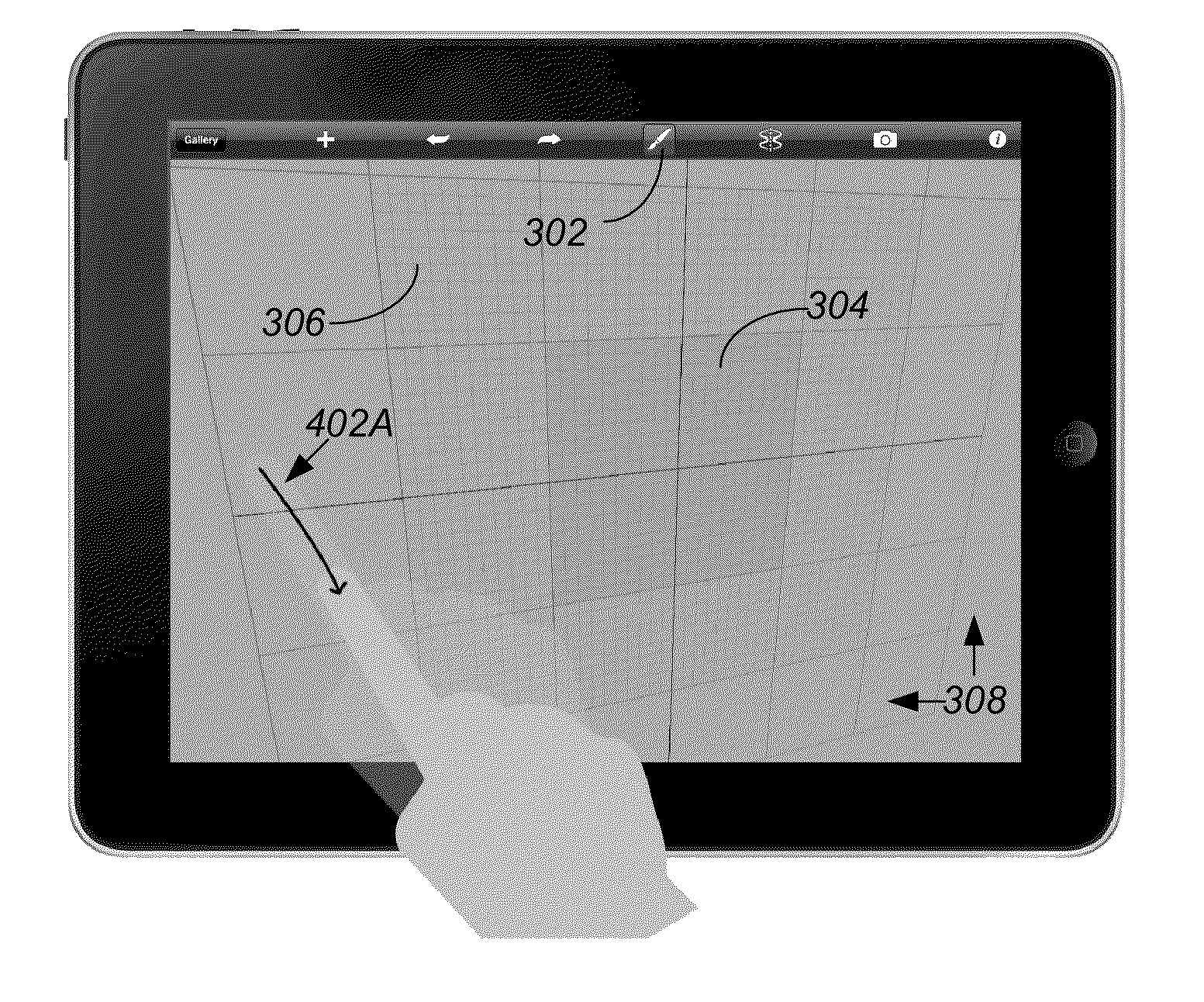

A modeling tool is activated in a 3D modeling application executing on a multi-touch device. A visual representation of a grid system tool is displayed in an active modeling plane and has three separate regions that determine the type of operation to be performed. An existing 3D form is displayed on the tool. A starting touch event of a gesture is received over the existing 3D form within one of the regions. As the gesture is received in the computer, the 3D form may be dynamically extended by adding 3D geometry to the 3D form (thereby adding faces to the 3D form). Alternatively, the 3D form may be scaled (i.e., if the starting touch event occurs over a visual scale grip. Alternatively, if the gesture consists of two taps, a bridge may be created joining the two tapped locations.

Owner:AUTODESK INC

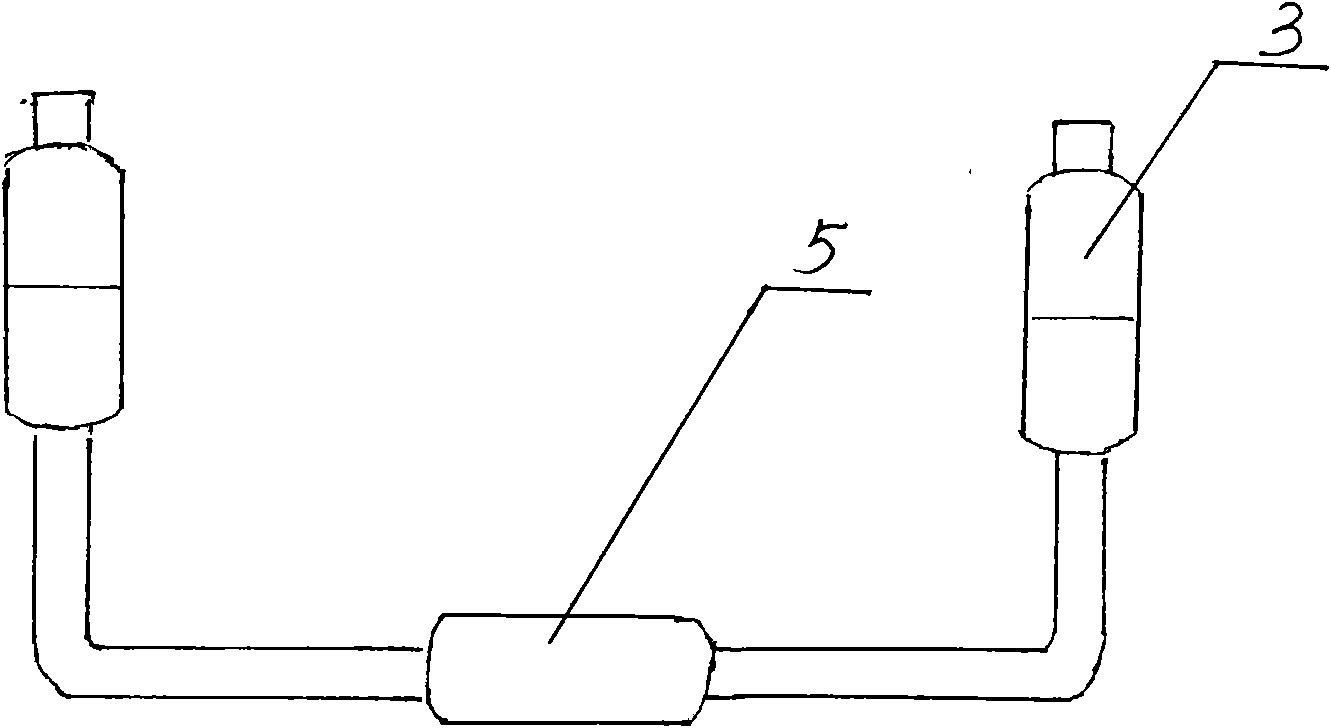

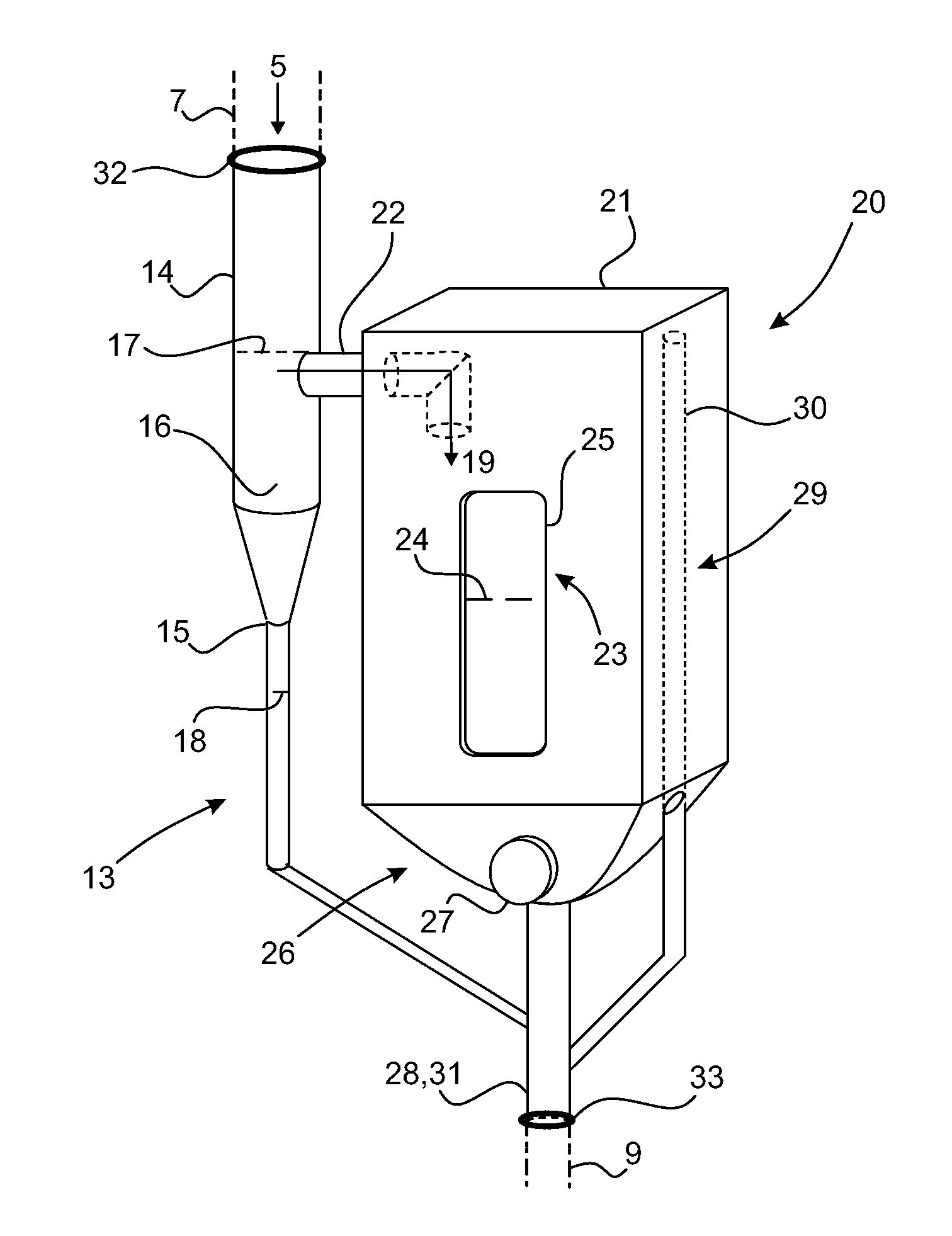

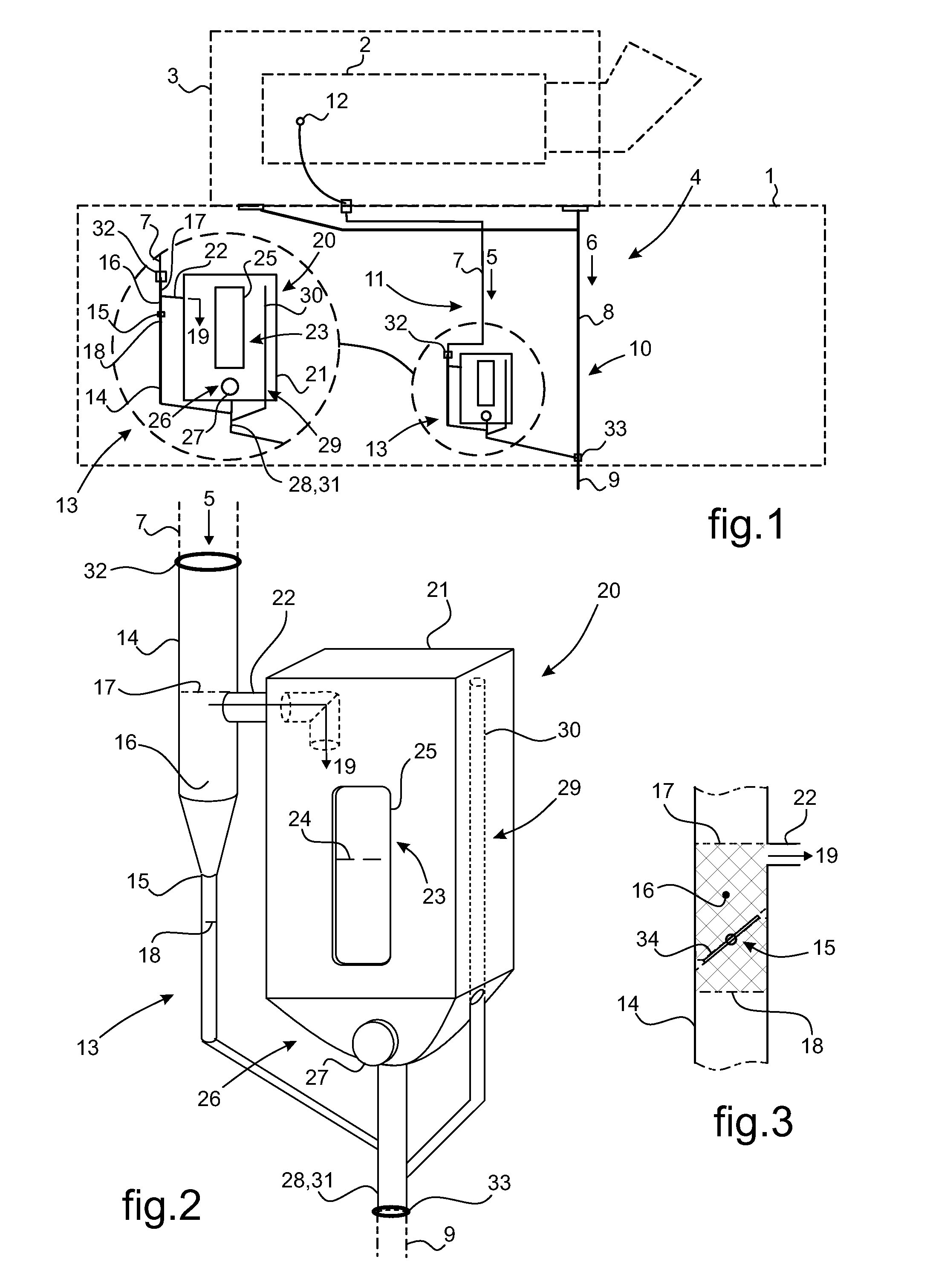

Drainage circuit for draining liquid coming from a power plant of a rotorcraft, the circuit incorporating an appliance for monitoring an excessive flow of the liquid

InactiveUS20130201023A1Easy to adaptEasy to installMeasurement of fluid loss/gain rateAlarmsPower stationEngineering

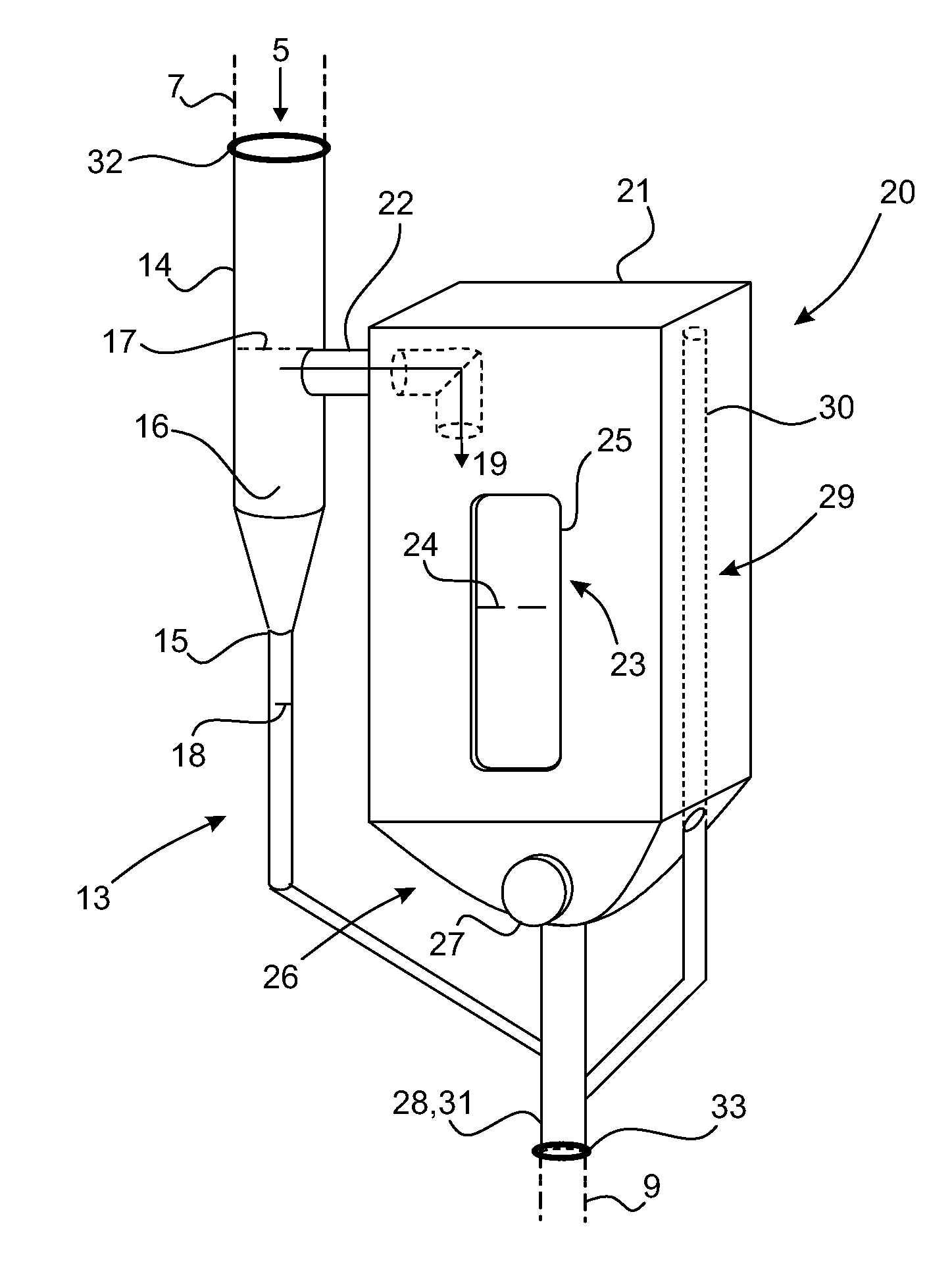

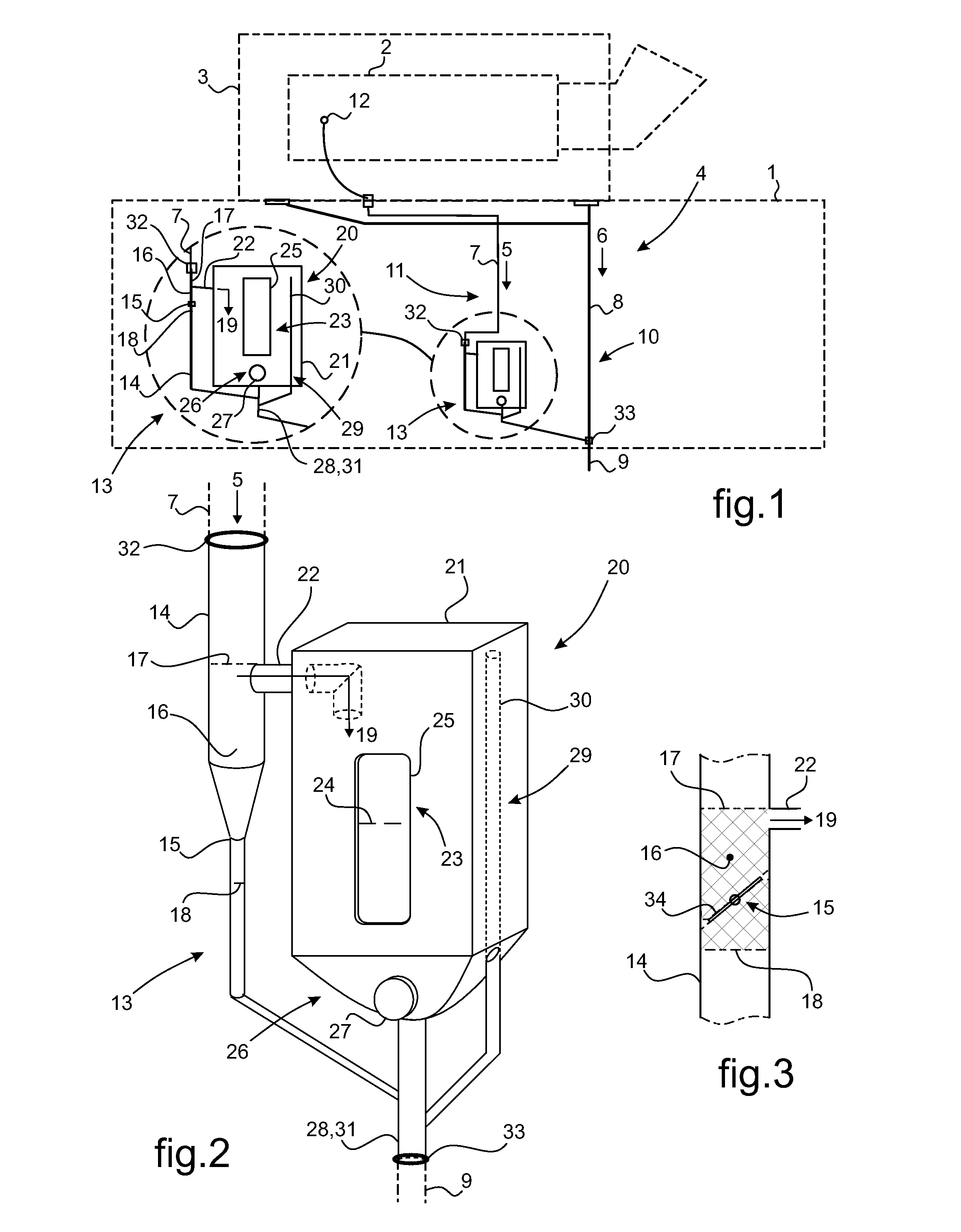

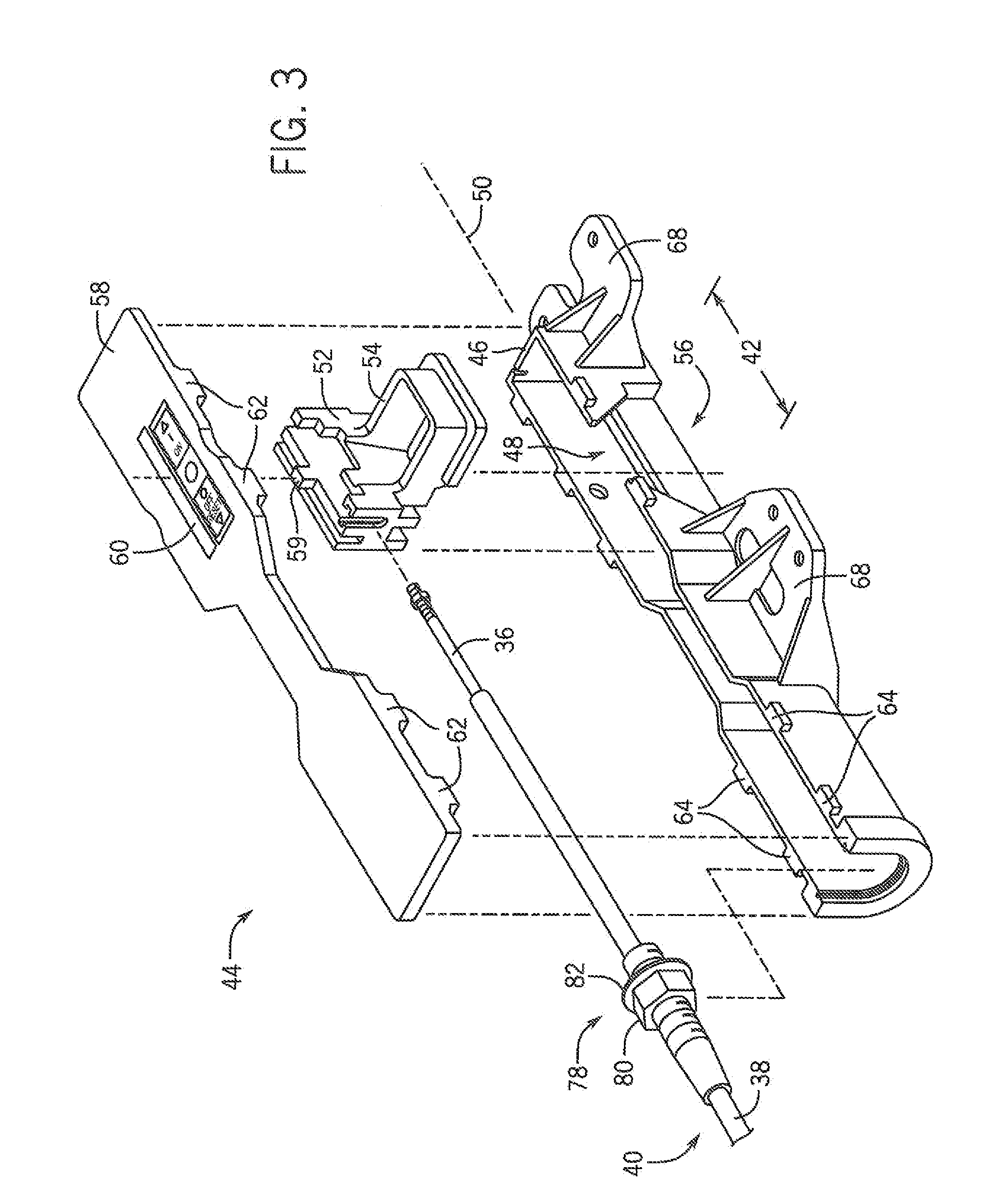

The invention relates to a drainage circuit (4) for a flow of a liquid (5), the circuit being fitted with a monitoring appliance (13) for monitoring an excess flow rate of the liquid (5). The monitoring appliance (13) comprises a monitoring duct (14) interposed between an upstream duct (7) for collecting the liquid (5) and a downstream duct (9) for discharging the liquid (5). The monitoring duct (14) has retaining means (15) for retaining part of the liquid (5) inside a chamber (16) arranged to receive a spillway (22) of the captured liquid (19) in a reserve (20) fitted with indicator means (23) with a visual scale for providing warning information relating to the quantity of liquid (24) contained in the reserve (20).

Owner:EUROCOPTER

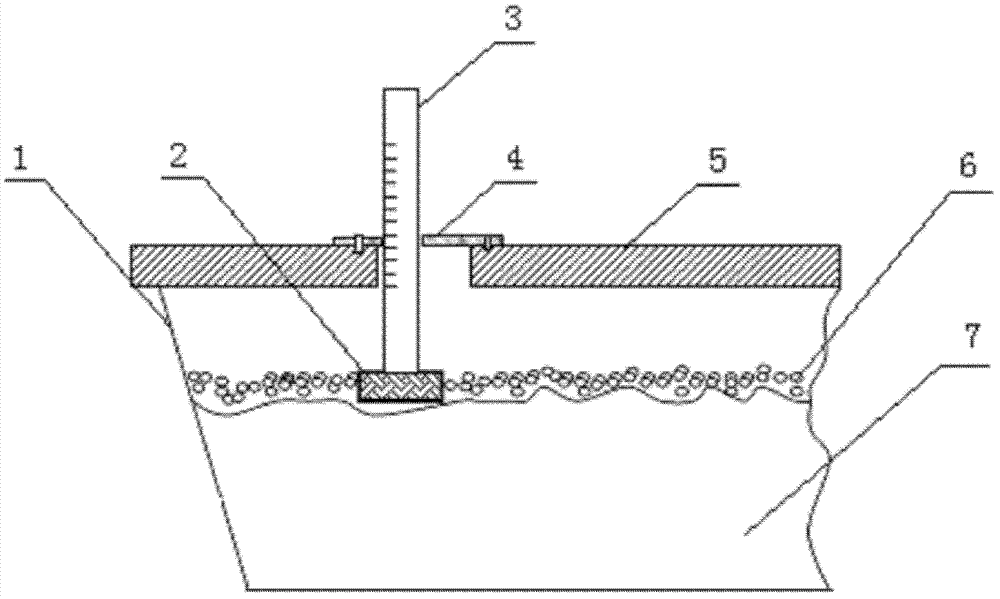

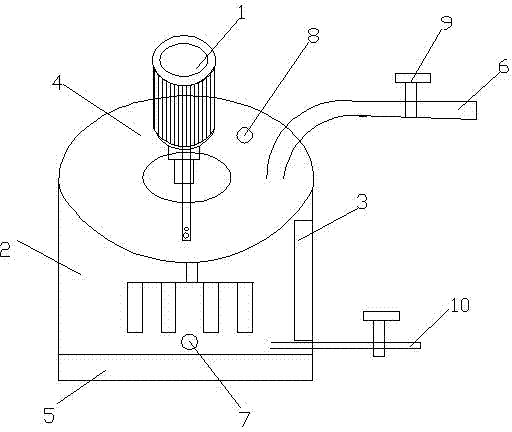

Method for measuring liquid level of tundish

InactiveCN102728802AEliminate overmeltEliminate measurement biasCasting parameters measurement/indication devicesRefractoryBuoy

The invention provides a method for measuring liquid level of tundish. The method comprises the following steps of: connecting the other end of a scale with a length marker to a refractory material buoy with the surface being plated with zirconium oxide; feeding a buoy and the scale into a contact surface between a covering agent and molten steel through a rectangular hole in a tundish cover; dropping a locating cover plate with a central locating hole and a bolt hole at a position covering the rectangular hole of the tundish cover and fixing by bolts; and reading the length displayed by the scale to obtain the depth of the molten steel. The method for measuring the liquid level of the tundish, disclosed by the invention, can not only effectively eliminate problems of super-melting and measurement deviation in an oxygen pipe using process and reduce tundish wastes, but also have fixed position of the buoy, exact measurement result and audio-visual scale display, and can exactly measure and feed back the liquid level of the tundish in real time so as to provide reliable evidence for pouring stoppage and deceleration, thus the loss in a pouring stoppage process is largely reduced, the yield of the molten steel is increased, and the personal safety of operators can be ensured at the same time.

Owner:ANGANG STEEL CO LTD

Indicating fastener loading

ActiveUS20090301383A1Reduced range of movementHigh sensitivityMeasurement of torque/twisting force while tighteningLoad modified fastenersDisplay deviceEngineering

An amplified indication of the elongation of a fastener is provided for determining instantaneous loading conditions of a fastener. A load indicator is couplable to a fastener for instantaneous load measurement and includes a housing defining a fastener interface configured to removably couple the housing to a fastener. A moveable datum probe extends from the housing in contact with a datum rod anchored within an internal bore of the fastener. A first lever is pivotally mounted within the housing and is moveable in response to displacement of the datum probe. A load display indicates a degree of loading of a fastener as a function of displacement of the datum probe. A second lever can be used to further amplify the reading from the displacement of the datum probe. An inclined visual scale and a multi-faceted lens allows for viewing of loading values from multiple directions or angles.

Owner:VALLEY FORGE & BOLT MFG

Flexible cable assembly for high-power switch gear

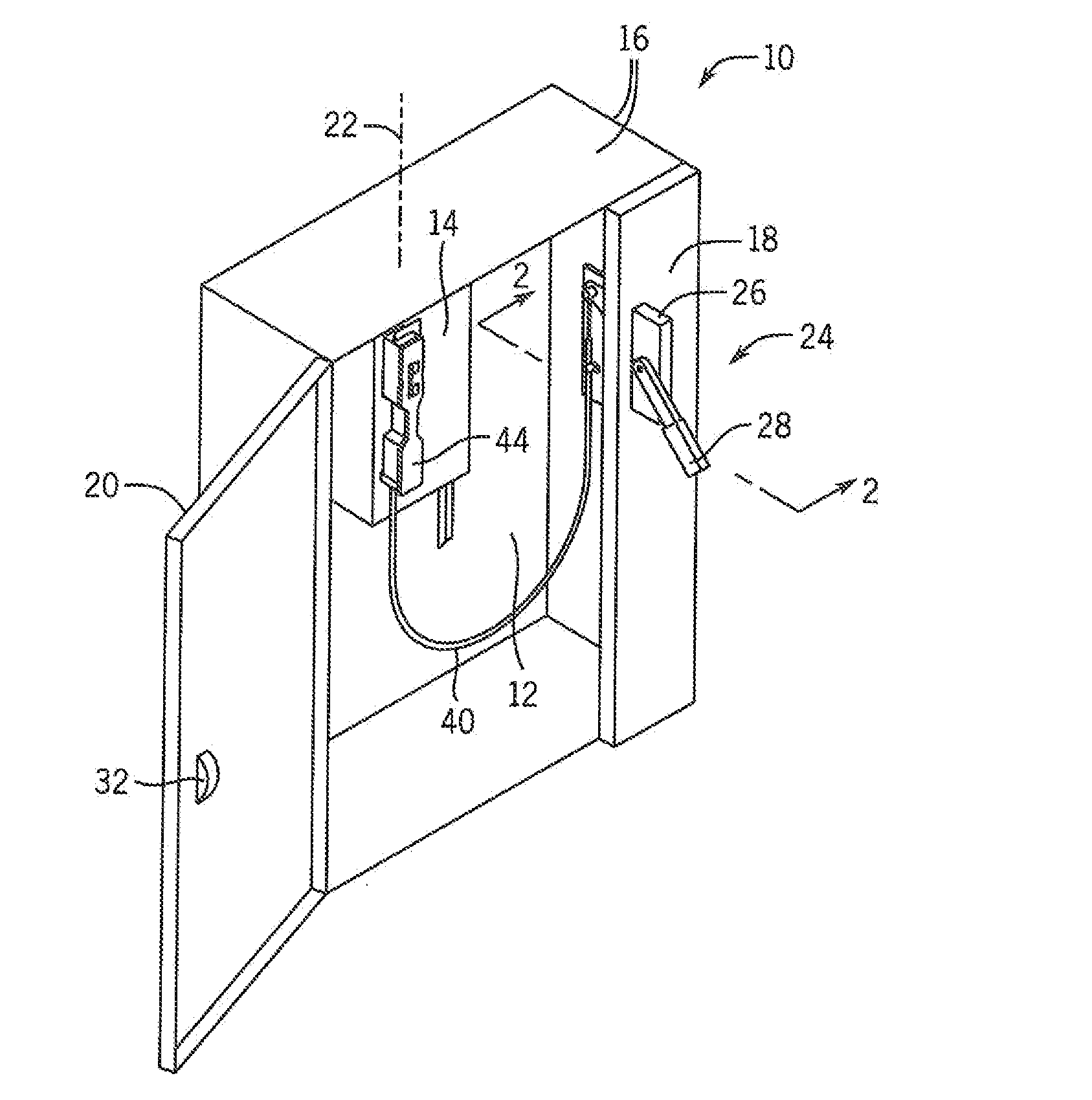

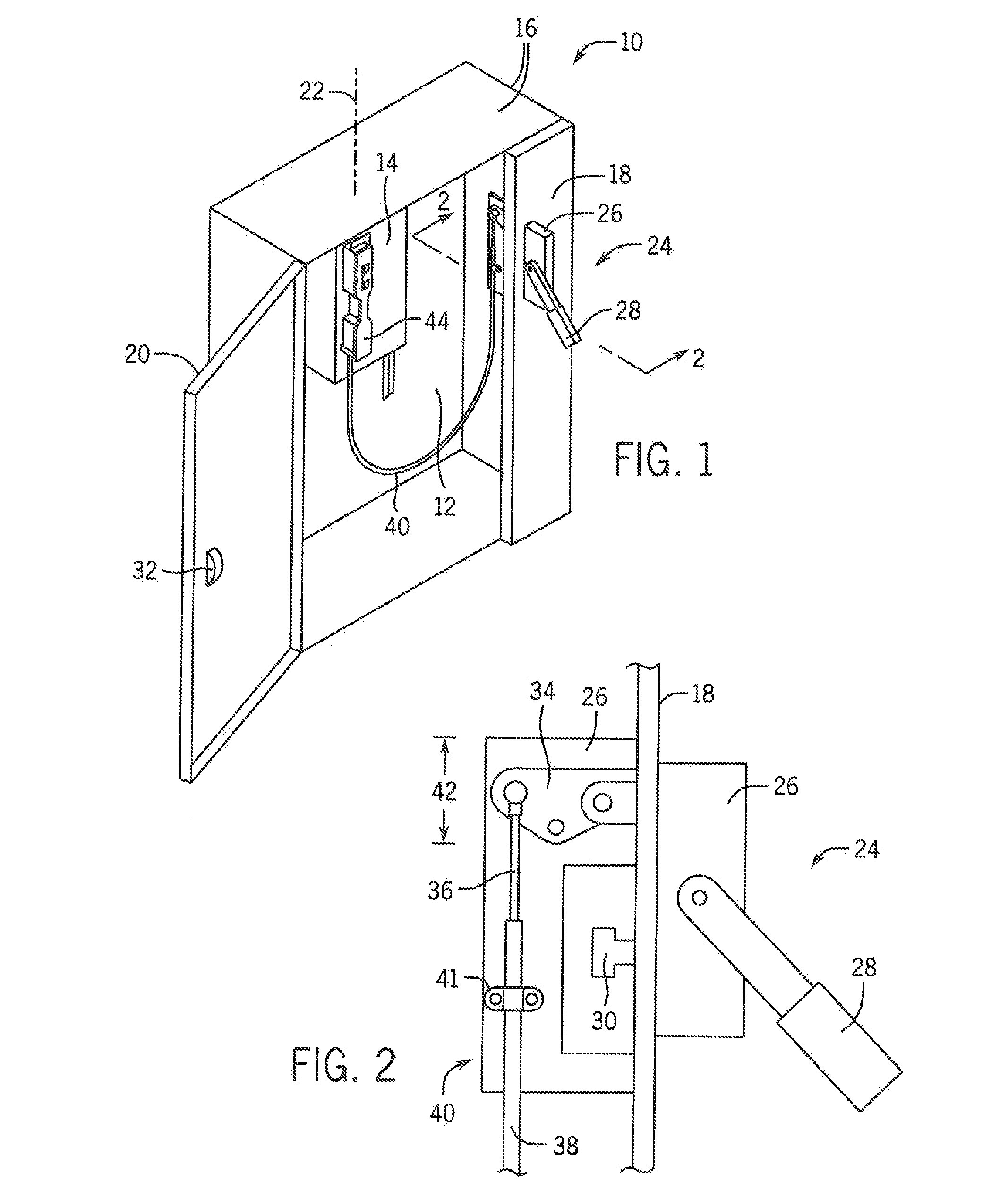

ActiveUS20150131208A1Accurate torqueEliminate needContact driving mechanismsContact operating partsElectronic switchActuator

A remote switching system for electronic switches in a cabinet provides an actuator assembly communicating through a flexible cable with a door handle. The actuator assembly on the electronic switch provides a rotatably captive threaded fastener holding the sheath of the flexible cable to the actuator assembly allow ring a simple single-point tuning of the actuator operation. This tuning may be facilitated by a visual scale showing relative positions between the actuator assembly and an internal slider communicating with the operator of the electronic switch.

Owner:ROCKWELL AUTOMATION TECH

Ball table with level adjustment device

The invention discloses a ball table with a level adjustment device, comprising a platform face and supporting legs, wherein the edge of the platform face is provided with at least two level display pipes, the outsides of the level display pipes are provided with visual scale plates, and the level display pipes are connected by a communication device. The height of liquid in the level display pipes is observed by the visual scale plates, the heights of the supporting legs are adjusted, and the faces of the ball table can be levelly adjusted by a plurality of points and a plurality of faces so as to enable the faces of the ball table to be on the same level plane.

Owner:刘敬芳

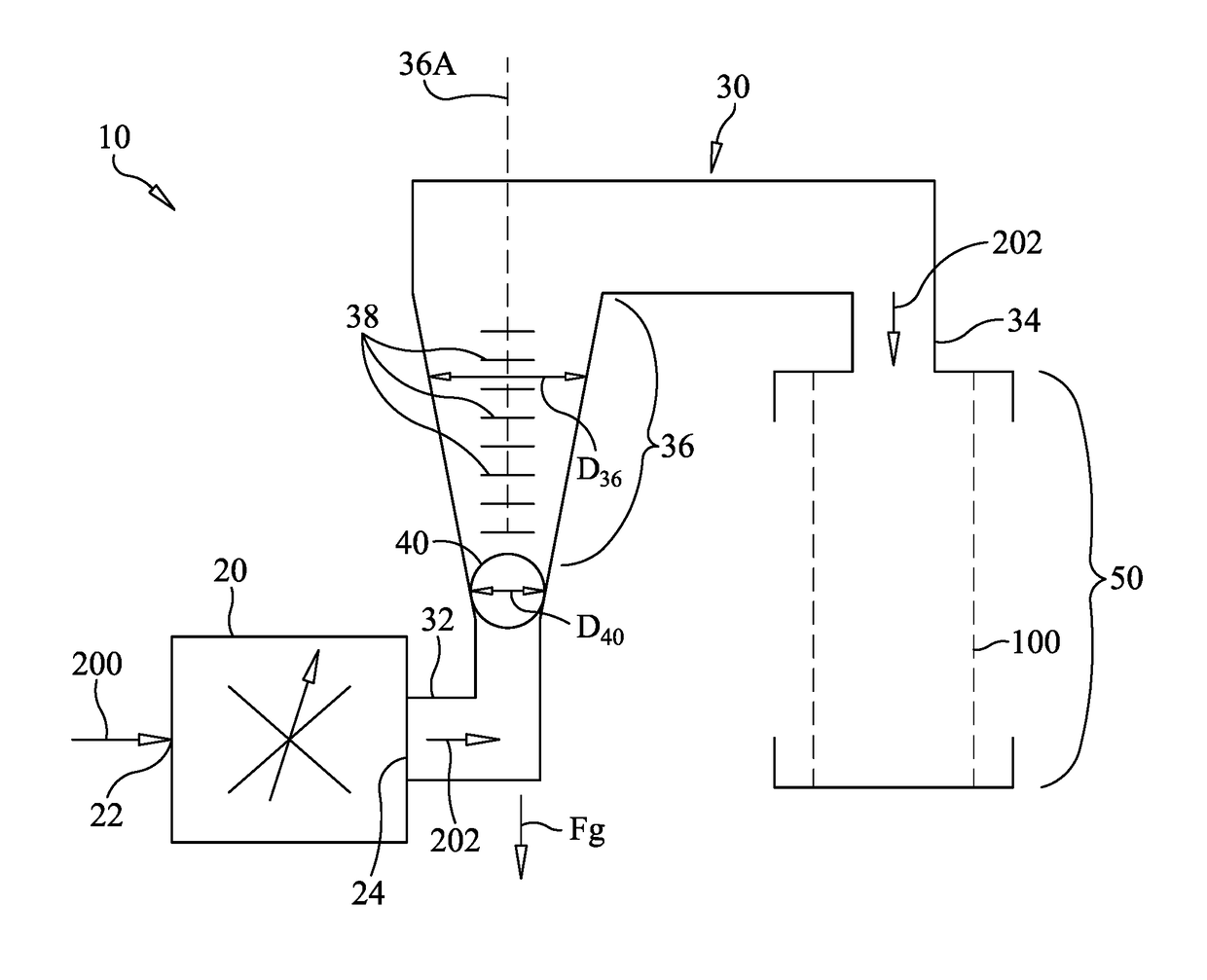

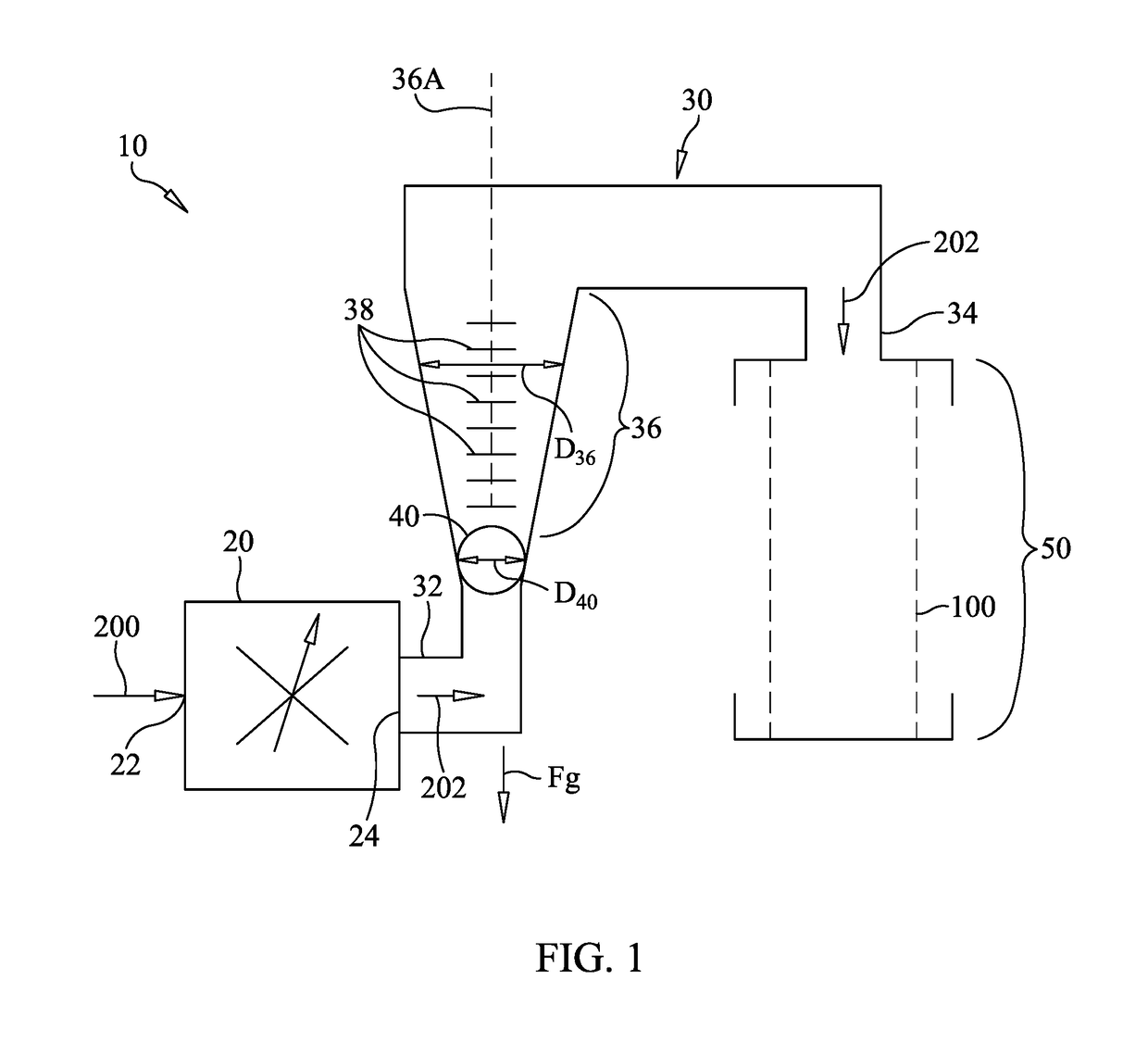

Method and apparatus for indicating a load

ActiveUS20080047353A1Degree of reductionReduced range of movementMeasurement of torque/twisting force while tighteningIndication apparatusVisual perceptionFastener

The present invention provides an innovative method and apparatus for determining continuous, visual clamp load status during tightening and throughout the life of a fastener. The present invention provides a pair of levers suitably configured and positioned within a fastener to provide an amplified indication of the deformation of the fastener as a load is applied to the fastener. In accordance with one aspect of the invention, a first lever is connected at an internal pivot point of a cartridge with the lower end of the first lever resting upon an abutment within the fastener, while the upper end displaces the lower end of a second lever such that movement of the upper end of the second lever is amplified with respect to movement of the lower end of the first lever. As the fastener is tightened, the fastener will elongate causing the abutment to move away from the lower end of the first lever. As the abutment moves, the first lever pivots or rotates causing the upper end or indicator of the second lever to move relative to a visual scale that is calibrated to indicate clamping force. The cartridge carrying the two levers is inserted into the fastener with the lower end of the first lever being displaced by the abutment a distance corresponding to a preselected elongation of the fastener, placing the indicator end of the second lever at the lower vales of the indicator scale. As the fastener is tightened, elongation of the fastener causes displacement of the abutment and a movement of the indicator up the indicator scale. If the fastener loses tension, the fastener will contract and the abutment will again displace the lower end of the first lever, rotating the indicator end of the second lever toward the lower values of the indicator scale. Assembly and calibration of the device requires the simple, inexpensive process of advancing the cartridge within a central bore in the fastener.

Owner:VALLEY FORGE & BOLT MFG +1

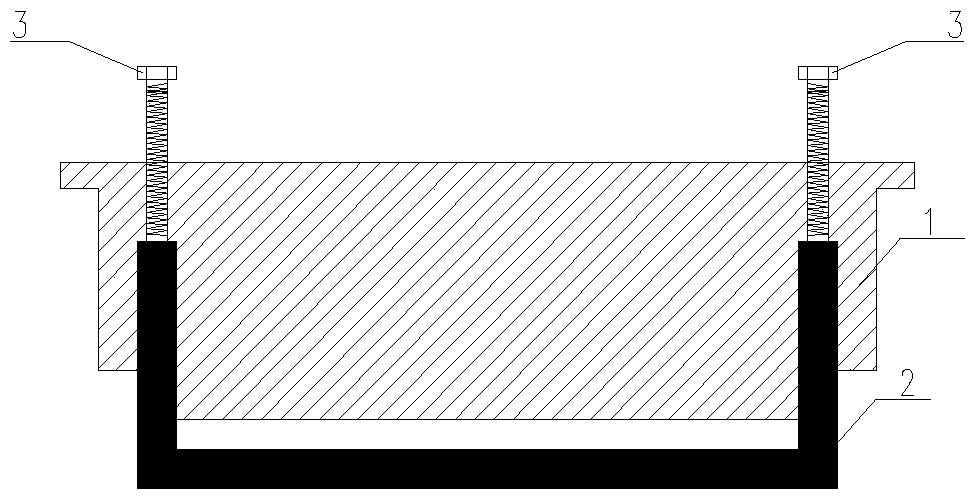

Method for manufacturing remolding soil test specimen

ActiveCN105571926ASmall quality errorEffective height controlPreparing sample for investigationHydraulic equipmentDensity difference

The invention provides a method for manufacturing a remolding soil test specimen in the technical field of geotechnical tests. A darby tray and a specimen making device are used. The darby tray is a rectangular tray, and an adjustable darby is attached to the upper part of the rectangular tray. The specimen making device consists of a concave press rod, a pad block and a transparent sleeve with scales. By using a one-step feeding mode, the characteristic of uniform loading of the existing servo hydraulic equipment in a laboratory is used; the problems of nonuniform and instable specimen making pressure, easy layering of the soil specimen and upper and lower density difference are solved; the visual scale characteristic of the specimen making device is used; the precise control on the test specimen volume is achieved; and further, the dry density is precisely controlled on the premise of precisely controlling the moisture content. The method is applicable to the preparation of cylindrical remolding soil test specimens, and has the characteristics that the system errors are small; the structure is simple; the laboratory equipment is integrally utilized; the multi-time repeated utilization can be realized, and the like.

Owner:ANHUI UNIV OF SCI & TECH

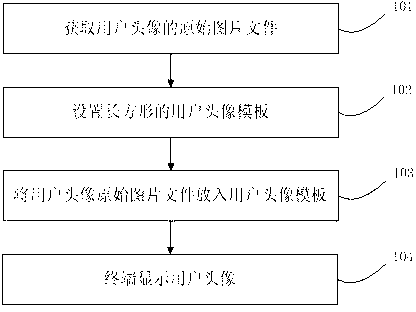

Method for displaying user head portrait

InactiveCN102880375AShow fullConform to visual proportionsInput/output processes for data processingThe InternetComputer terminal

The invention discloses a method for displaying a user head portrait. The method comprises the following steps: acquiring an initial image file of the user head portrait; setting a rectangular user head portrait template; putting the initial image file of the user head portrait into the user head portrait template; and displaying the user head portrait at the terminal. According to the technical scheme, the user head portrait on an internet social network platform is optimized, so that the user head portrait is fully displayed, the visual area is increased, and the optimal visual scale of human eyes is met.

Owner:DUOWAN ENTERTAINMENT INFORMATION TECH BEIJING

Beam enlarging lens

InactiveCN101435909AEasy to useEasy to operateUsing electrical meansMountingsDigital analog converterLiquid-crystal display

The invention relates to a beam expanding lens, which can ensure precision of regulating ratio and divergence and has convenient use. The beam expanding lens comprises a movable lens barrel and an adjusting ring, wherein a lens is fixed in the movable lens barrel. The beam expanding lens also comprises a displacement sensor, a digital-analog converter circuit, a nixietube or a liquid crystal display device which are connected in sequence, wherein the displacement sensor is connected with the movable lens barrel so as to induce information of a lens displacing along an optical axis of the lens; and the displacement sensor can be a variable resistor, a variable inductor, a photoelectric transducer or a magnetic Hall element. In the invention, position information of the lens is transferred to the digital-analog converter circuit by the displacement sensor, a corresponding position of the lens is displayed precisely by the nixietube or the liquid crystal screen, and visual scale is replaced by digital display technology, thereby operation simplification is realized, precision of the regulating ratio and the divergence is ensured. The beam expanding lens is applicable to both a fixed-power beam expanding lens and a variable power beam expanding lens.

Owner:王国力 +1

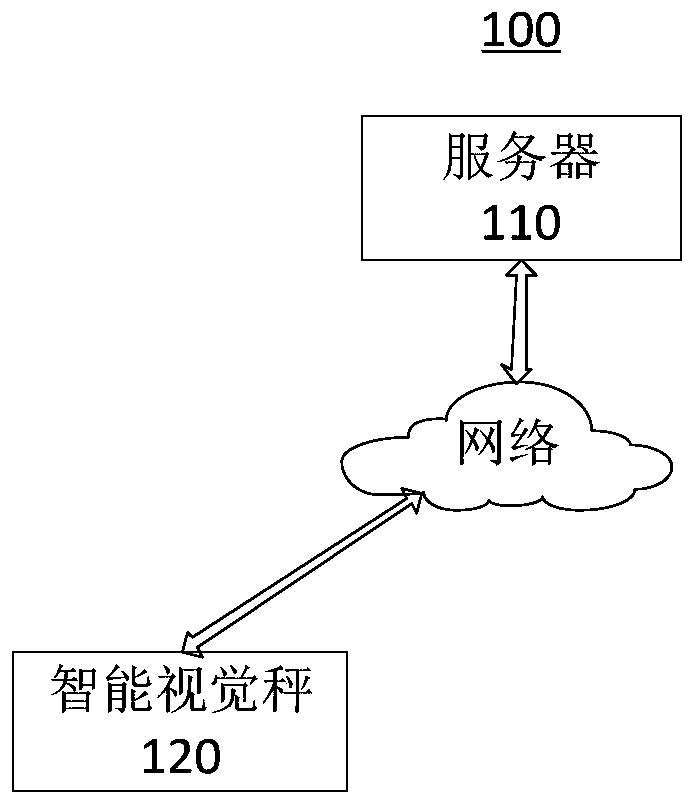

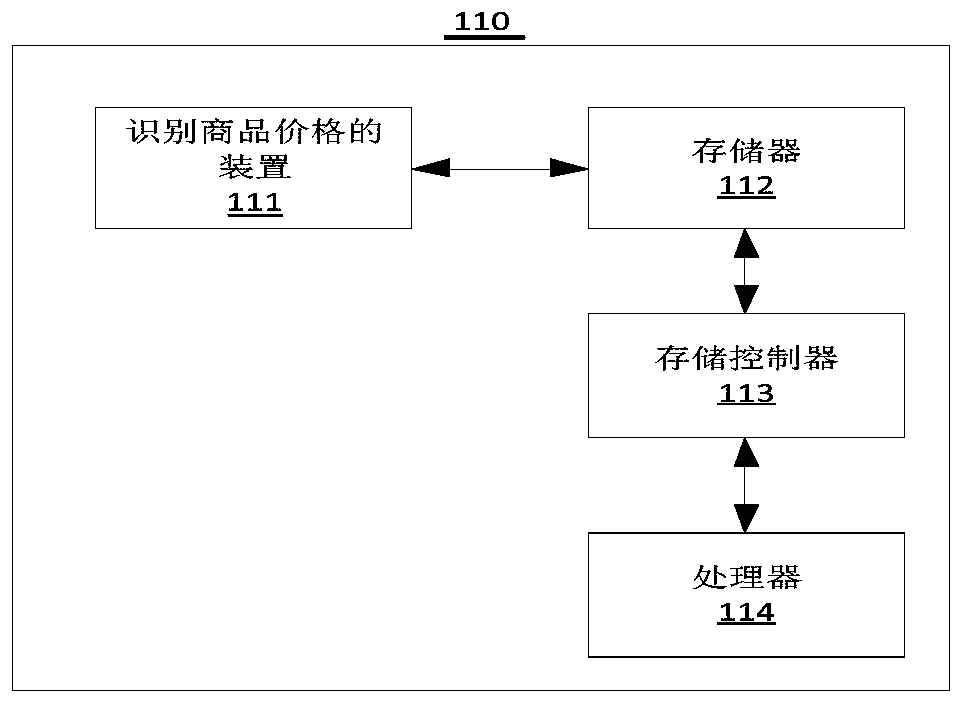

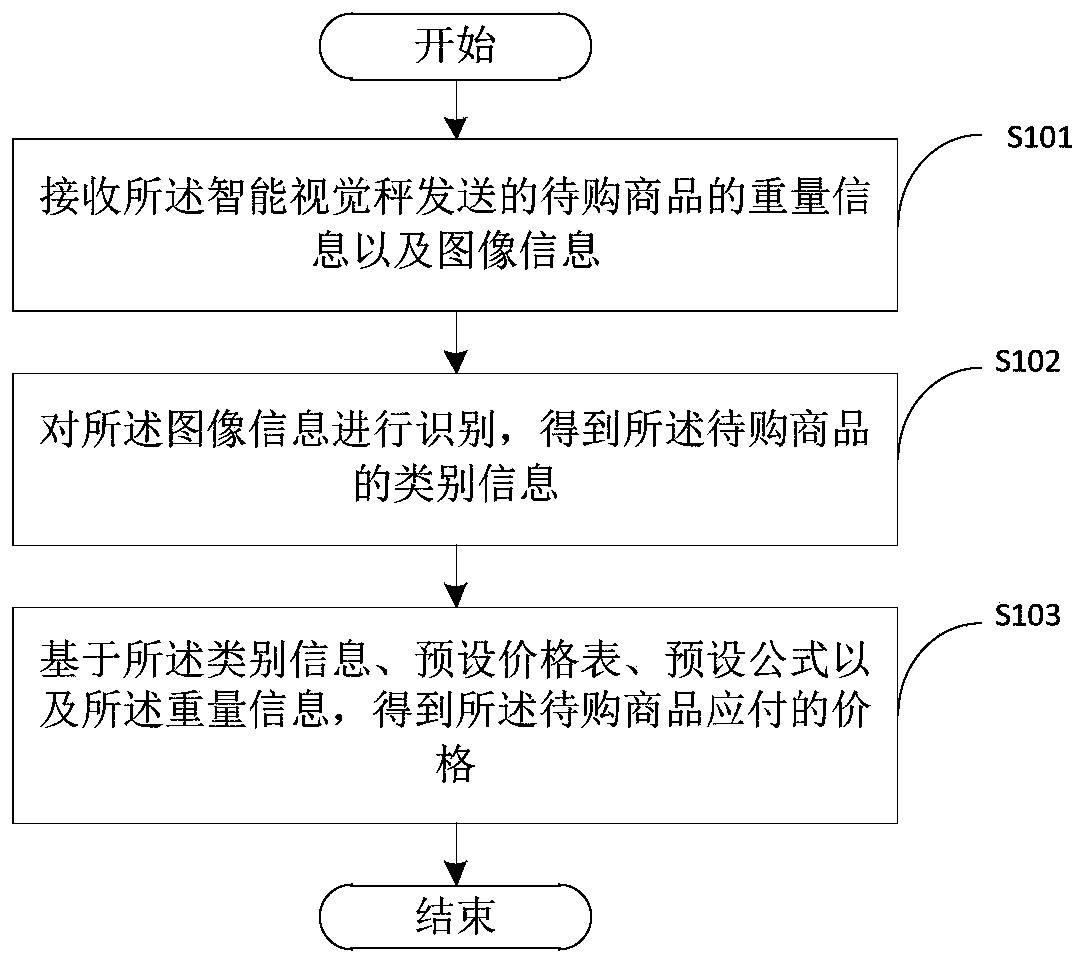

Commodity price identification method and device, unmanned transaction system and storage medium

InactiveCN110400135AReduce labor costsCharacter and pattern recognitionCash registersComputer scienceVisual perception

The invention relates to a commodity price identification method and device, an unmanned transaction system and a storage medium, and belongs to the technical field of weighing apparatuses. The commodity price identification method is applied to a server in an unmanned transaction system, and the unmanned transaction system further comprises an intelligent visual scale which performs data interaction with the server. The commodity price identification method comprises the following steps: receiving weight information and image information of a to-be-purchased commodity sent by the intelligentvisual scale; identifying the image information to obtain category information of the to-be-purchased commodity; and then obtaining the payable price of the to-be-purchased commodity based on the category information, the preset price list, the preset formula and the weight information, wherein the price required by the purchased commodity can be automatically identified without manual participation in the whole process, so that the labor cost is greatly reduced.

Owner:黑子信息科技(广东)有限公司

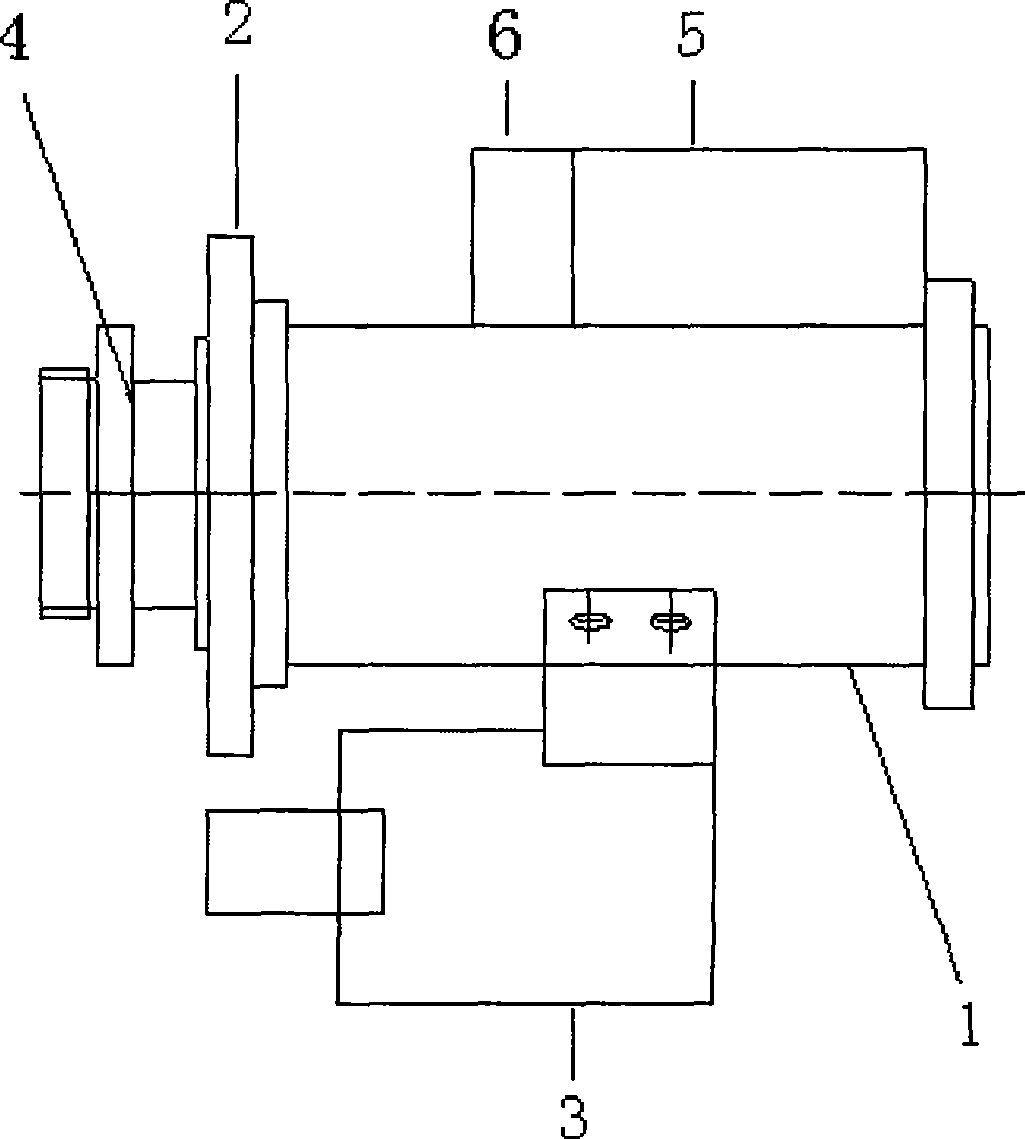

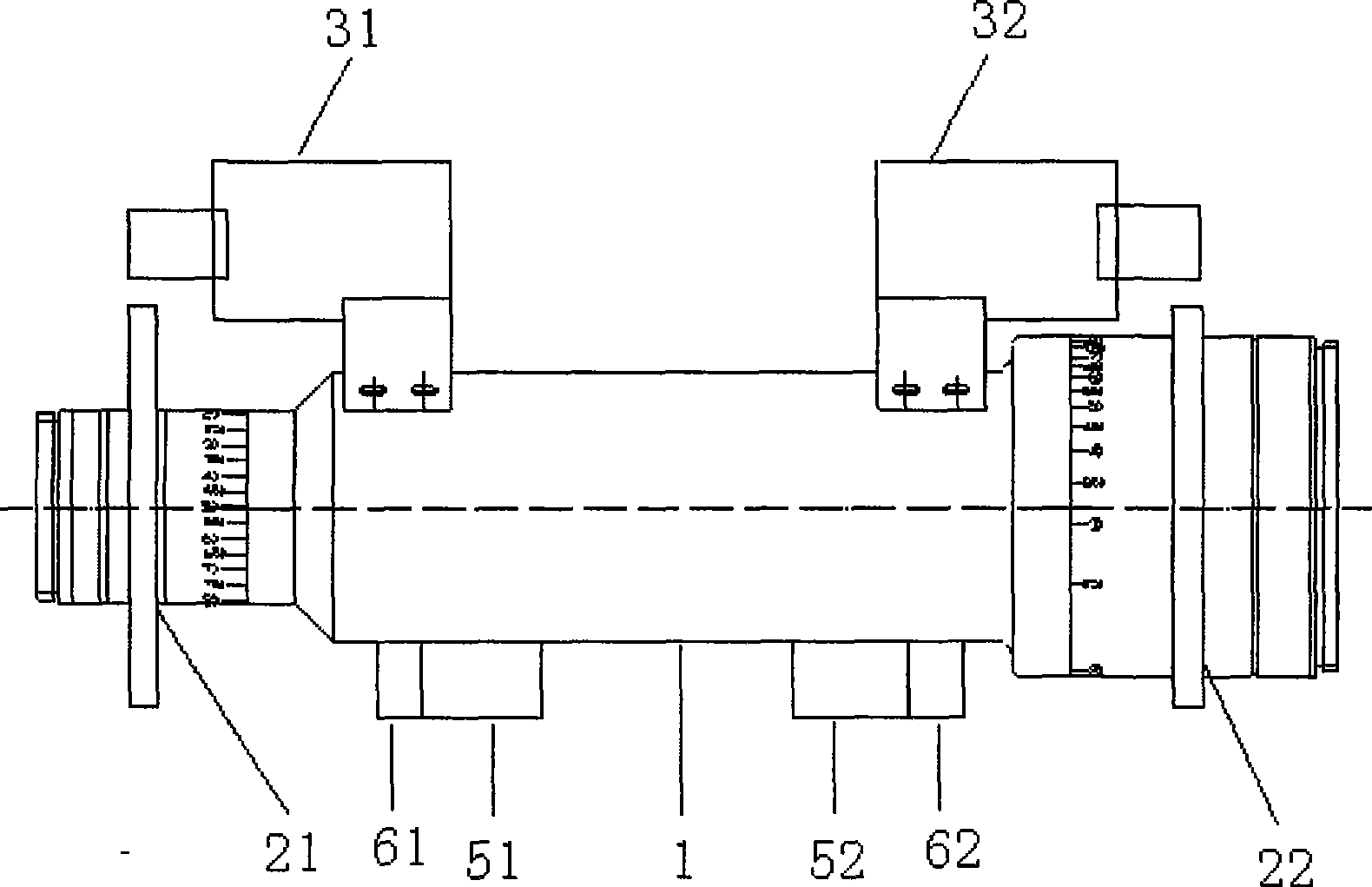

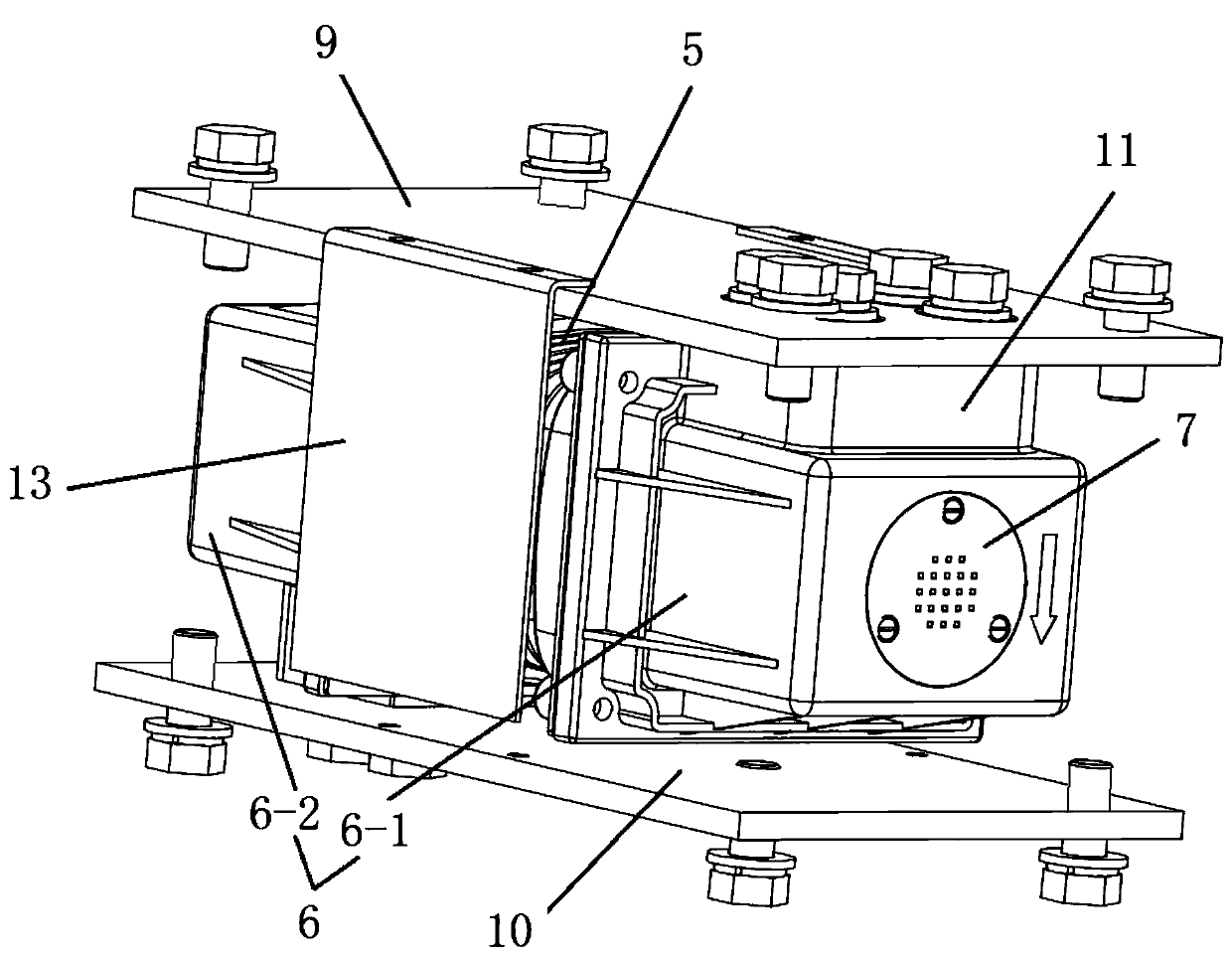

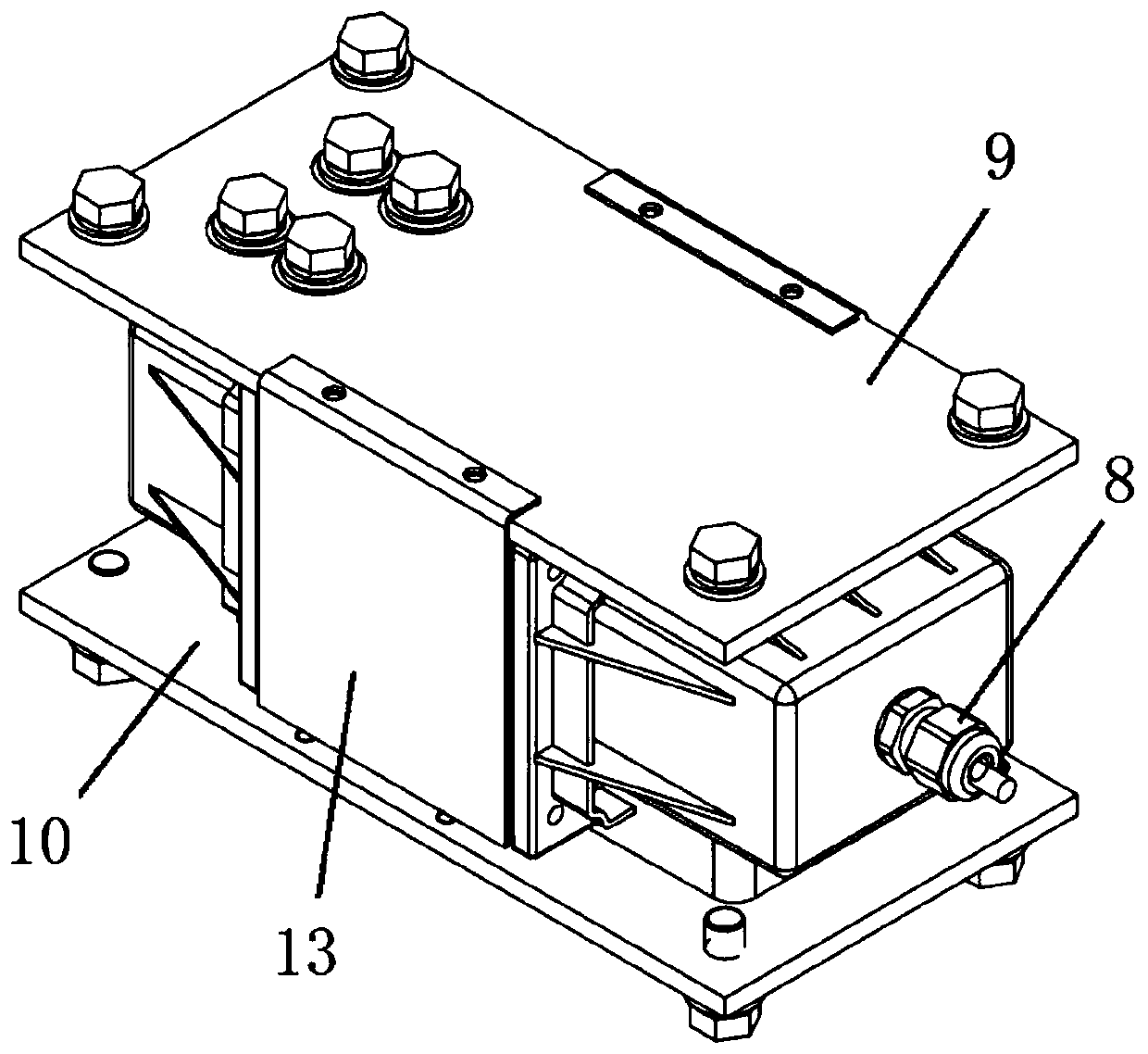

Waterproof and dampproof internet of things visual scale

PendingCN110332977AGuaranteed detection accuracyWaterproof, moisture-proof and breathableWeighing auxillary devicesSpecial purpose weighing apparatusComputer moduleLoad cell

The invention relates to a waterproof and dampproof internet of things visual scale. The waterproof and dampproof internet of things visual scale comprises an electronic scale base, a support rod andan electronic scale instrument, wherein the electronic scale base is provided with a sensor module group for weighing; the support rod is arranged on one side of the electronic scale base; the electronic scale instrument is connected with the top end of the support rod and is provided with a control circuit; the sensor module group is arranged below the electronic scale base and is electrically connected with the control circuit; a sensor module in the sensor module group is arranged in a waterproof and dampproof seal housing; the surface of the waterproof and dampproof seal housing is in sealing connection with a waterproof and dampproof ventilation assembly for adjusting the difference of the pressure inside and outside a cavity; a support plate is used for connecting a sensor and the waterproof and dampproof seal housing to form a weighing sensor module group. Both the sensor module group and the electronic scale instrument in the electronic scale adopt a full-seal design, have waterproof, dampproof and ventilation properties, and can ensure the detection precision of the sensor module; and the electronic scale improves multiple functional modules.

Owner:福州富日衡之宝电子有限公司

Gestures and tools for creating and editing solid models

ActiveUS8947429B2Rapidly and dynamically createDrawing from basic elementsInput/output processes for data processingVisual perception3d geometry

Owner:AUTODESK INC

Drainage circuit for draining liquid coming from a power plant of a rotorcraft, the circuit incorporating an appliance for monitoring an excessive flow of the liquid

InactiveUS8890698B2Easy to installDetection of fluid at leakage pointValve arrangementsEngineeringSpillway

The invention relates to a drainage circuit (4) for a flow of a liquid (5), the circuit being fitted with a monitoring appliance (13) for monitoring an excess flow rate of the liquid (5). The monitoring appliance (13) comprises a monitoring duct (14) interposed between an upstream duct (7) for collecting the liquid (5) and a downstream duct (9) for discharging the liquid (5). The monitoring duct (14) has retaining means (15) for retaining part of the liquid (5) inside a chamber (16) arranged to receive a spillway (22) of the captured liquid (19) in a reserve (20) fitted with indicator means (23) with a visual scale for providing warning information relating to the quantity of liquid (24) contained in the reserve (20).

Owner:EUROCOPTER

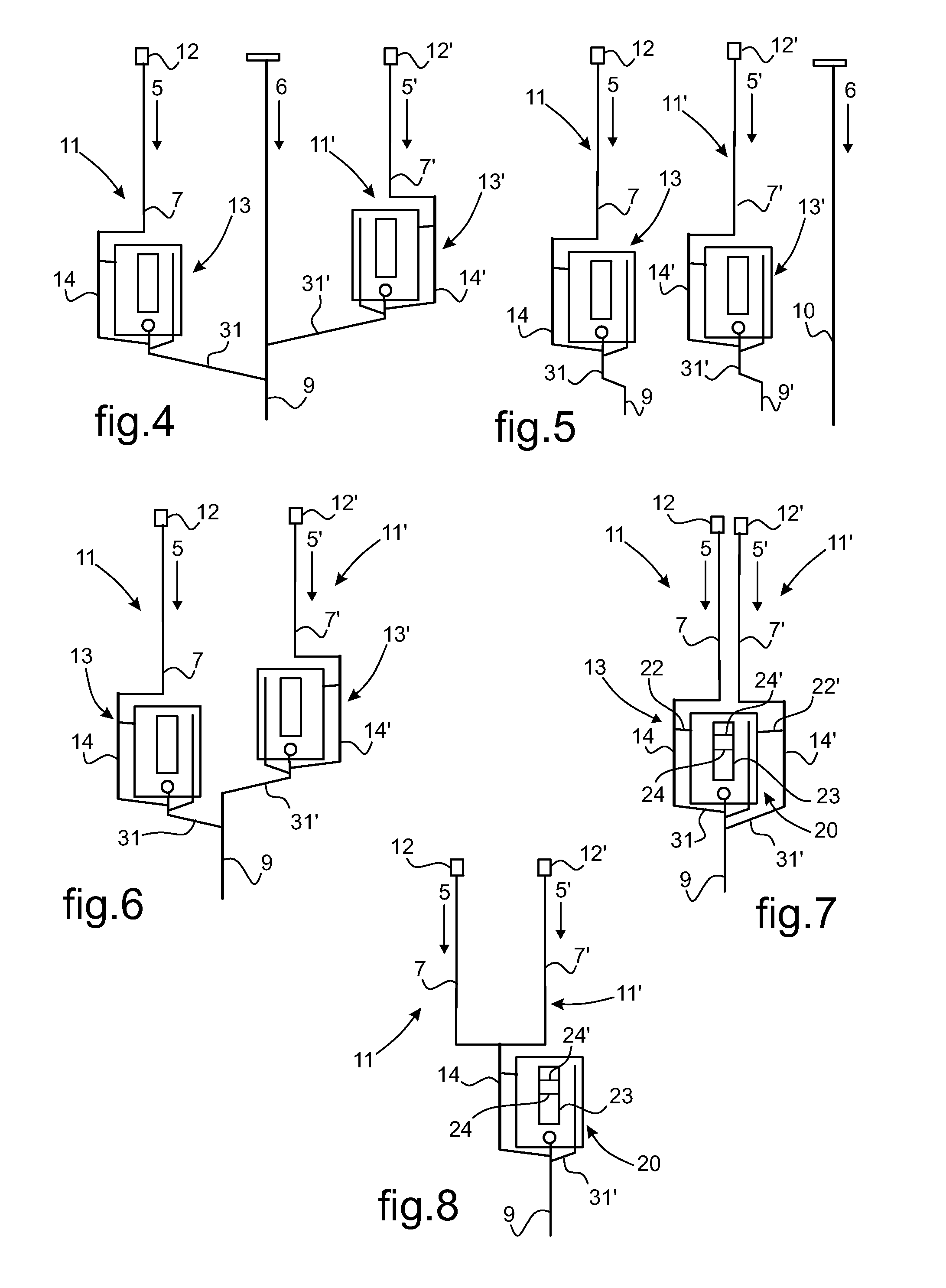

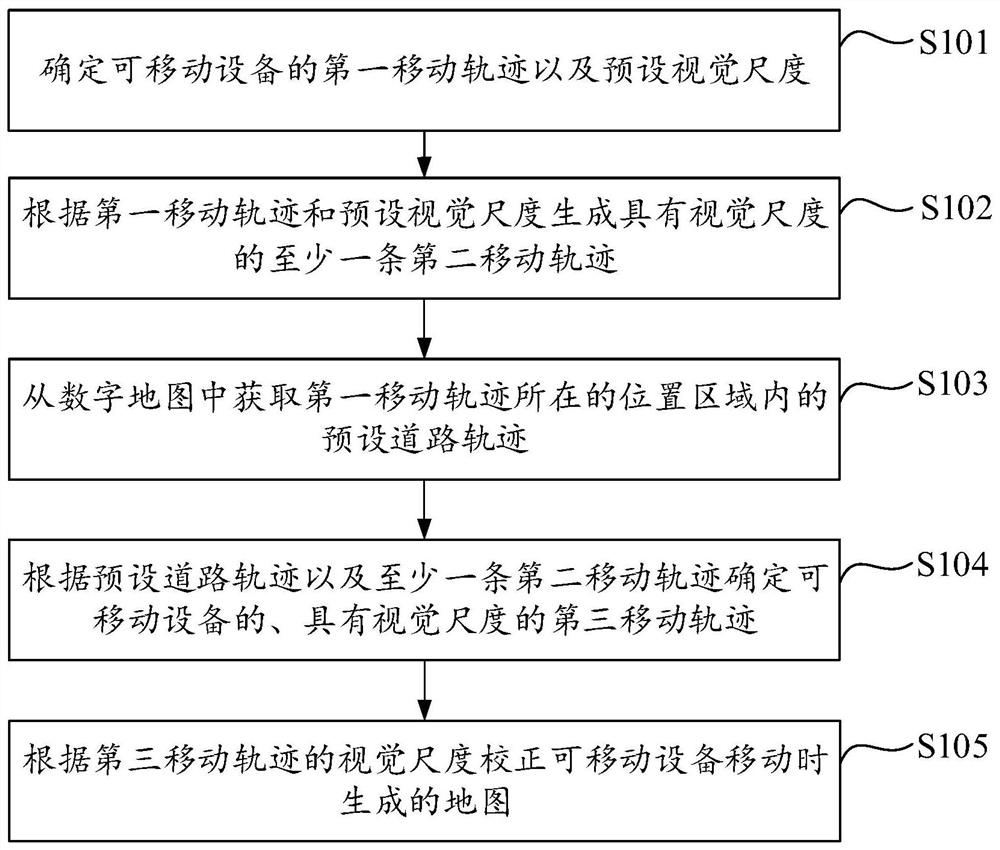

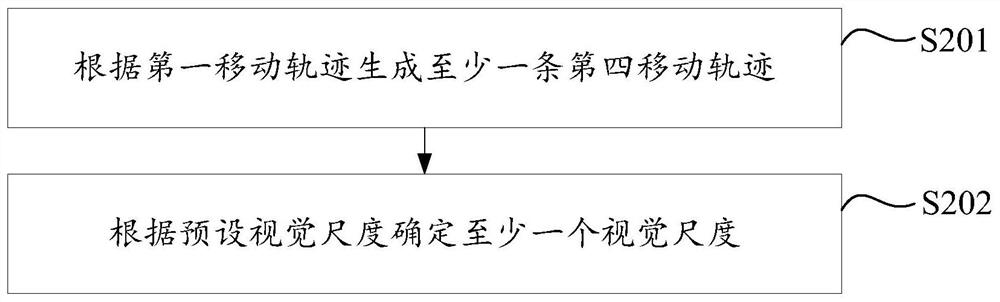

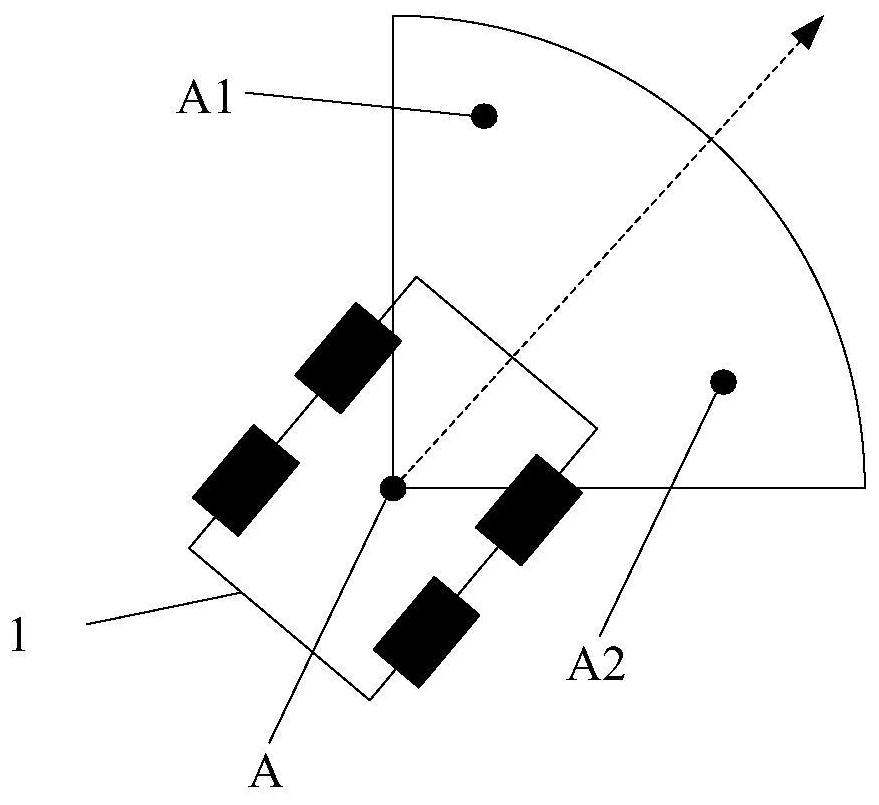

Map correction method and device and electronic device

The invention discloses a map correction method and device and an electronic device. The method comprises: determining a first moving track and a preset visual scale of the movable equipment, and generating at least one second moving track with the visual scale according to the first moving track and the preset visual scale; for example, determining at least one second moving track which is similar to the first moving track and has a visual scale around the first moving track, and then obtaining a preset road track in a position area where the first moving track is located; and according to the preset road track and the at least one second moving track, determining a third moving track with a visual scale of the movable equipment. The movable equipment often moves on the preset road track, in this way, the real moving track, namely the third moving track, of the movable equipment on the preset road track can be obtained, and then the map generated when the movable equipment moves is corrected according to the visual scale of the third moving track, so that the corrected map is objective and standard.

Owner:BEIJING HORIZON INFORMATION TECH CO LTD

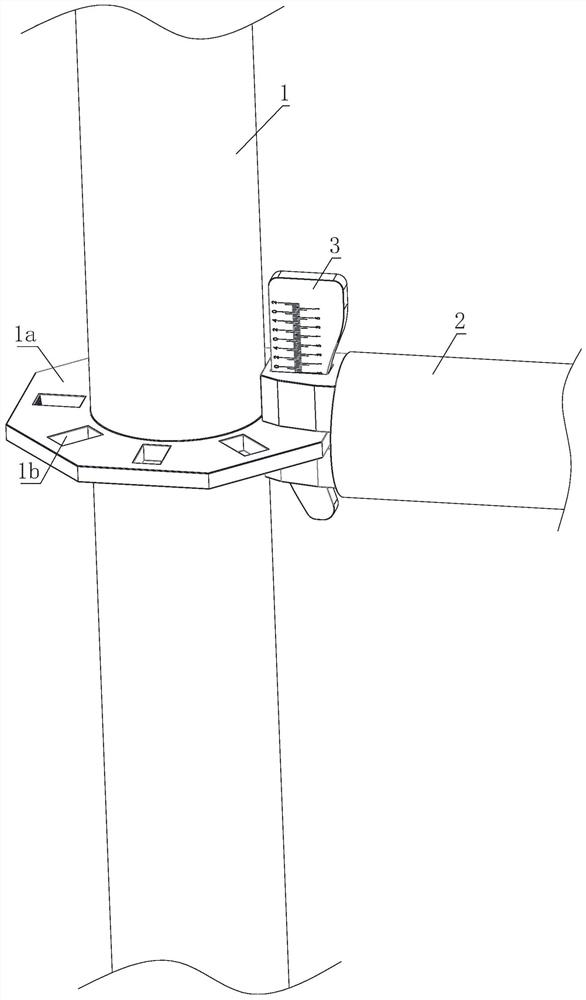

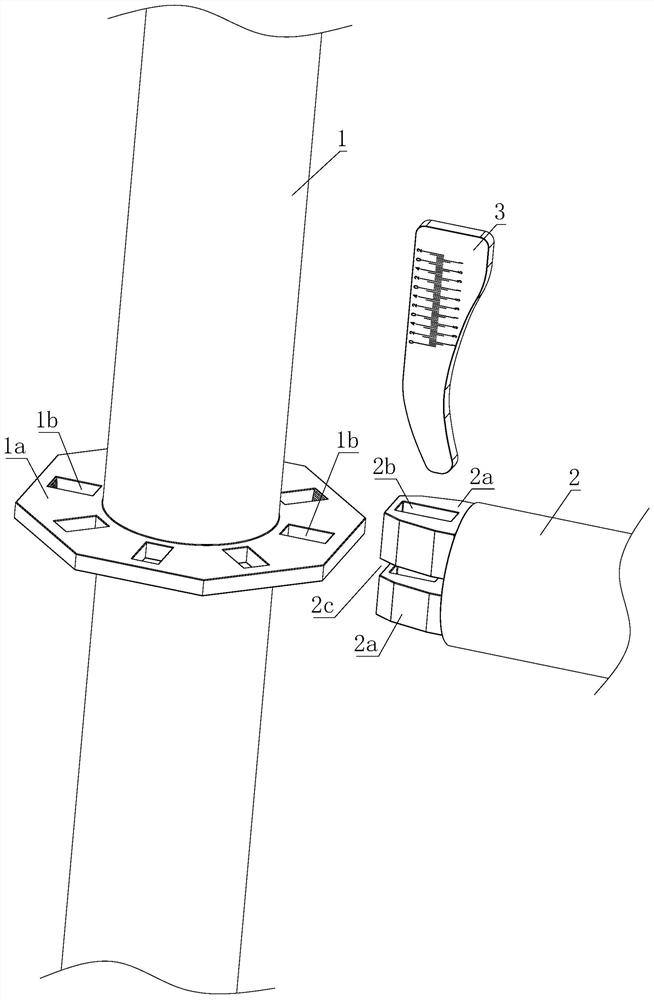

Disc buckle type scaffold connecting structure

PendingCN114856163AEasy to identifyImprove reliabilityScaffold connectionsClimate change adaptationCircular discEngineering

The invention discloses a disc buckle type scaffold connecting structure which comprises a vertical rod and a transverse rod, a disc is arranged on the vertical rod, connecting holes are distributed in the disc, the transverse rod is assembled on the connecting holes of the disc, a transverse rod casting head is arranged at the end of the transverse rod, and an assembling notch matched with the thickness of the disc is formed in the middle of the transverse rod casting head. A connecting hole is formed in the cross rod casting head, a locking channel coinciding with the connecting hole is formed in the cross rod casting head and penetrates through the height direction of the cross rod casting head, a wedge-shaped bolt is embedded in the locking channel, visual scales are arranged on the side wall of the wedge-shaped bolt, and the visual scales comprise a plurality of main scale lines distributed in an array mode in the height direction of the visual scales; the distance between any two adjacent main scale lines is 3 mm. The visual scale has the advantages that operators and managers can simply and efficiently recognize the sinkage of the plug pin by means of regular arrangement of the scale lines and end digital marking, the check threshold is lowered, the working efficiency is improved, the reliability of connection of the rod pieces of the disc buckle frame is improved, and the overall quality of the frame body is guaranteed.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

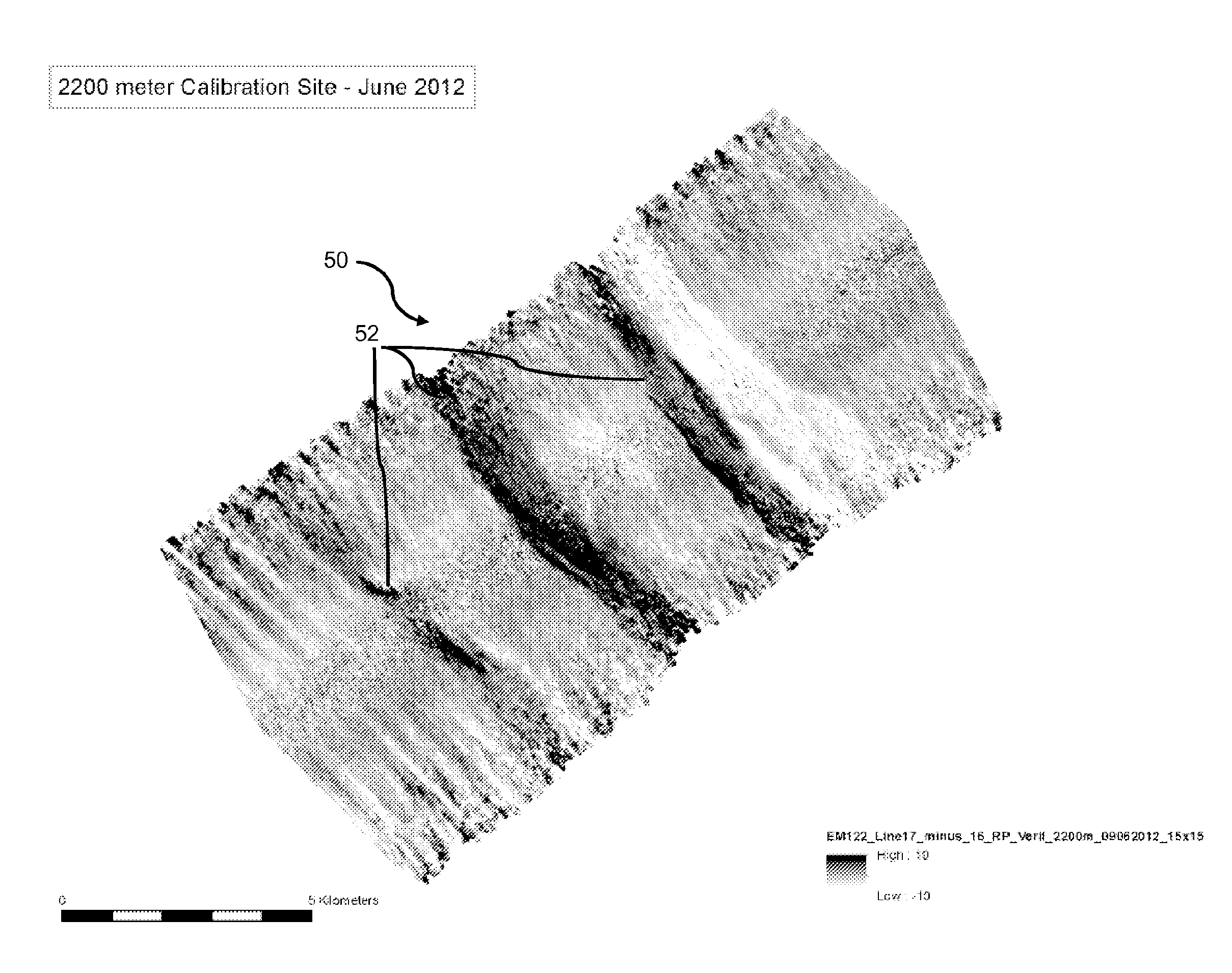

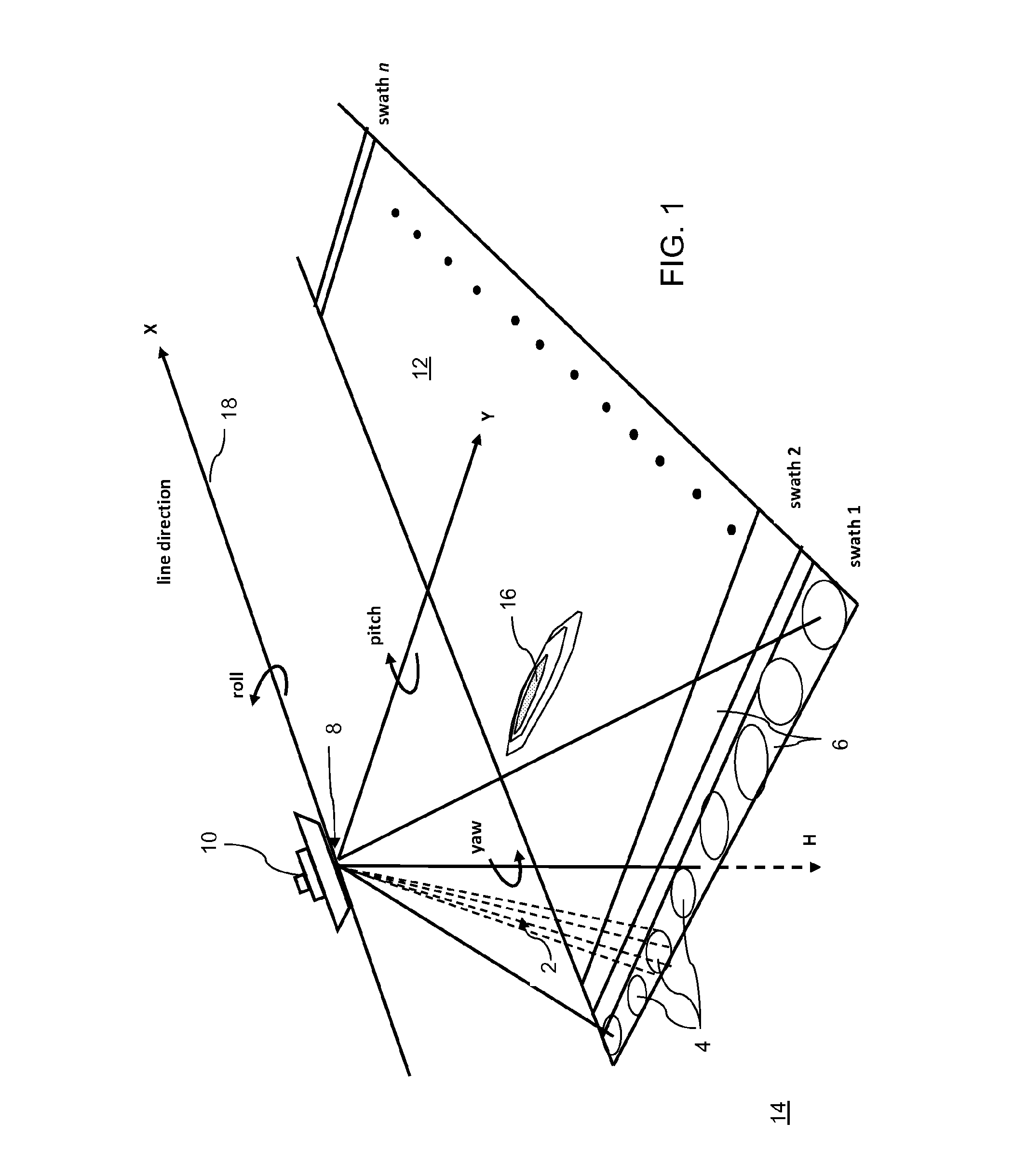

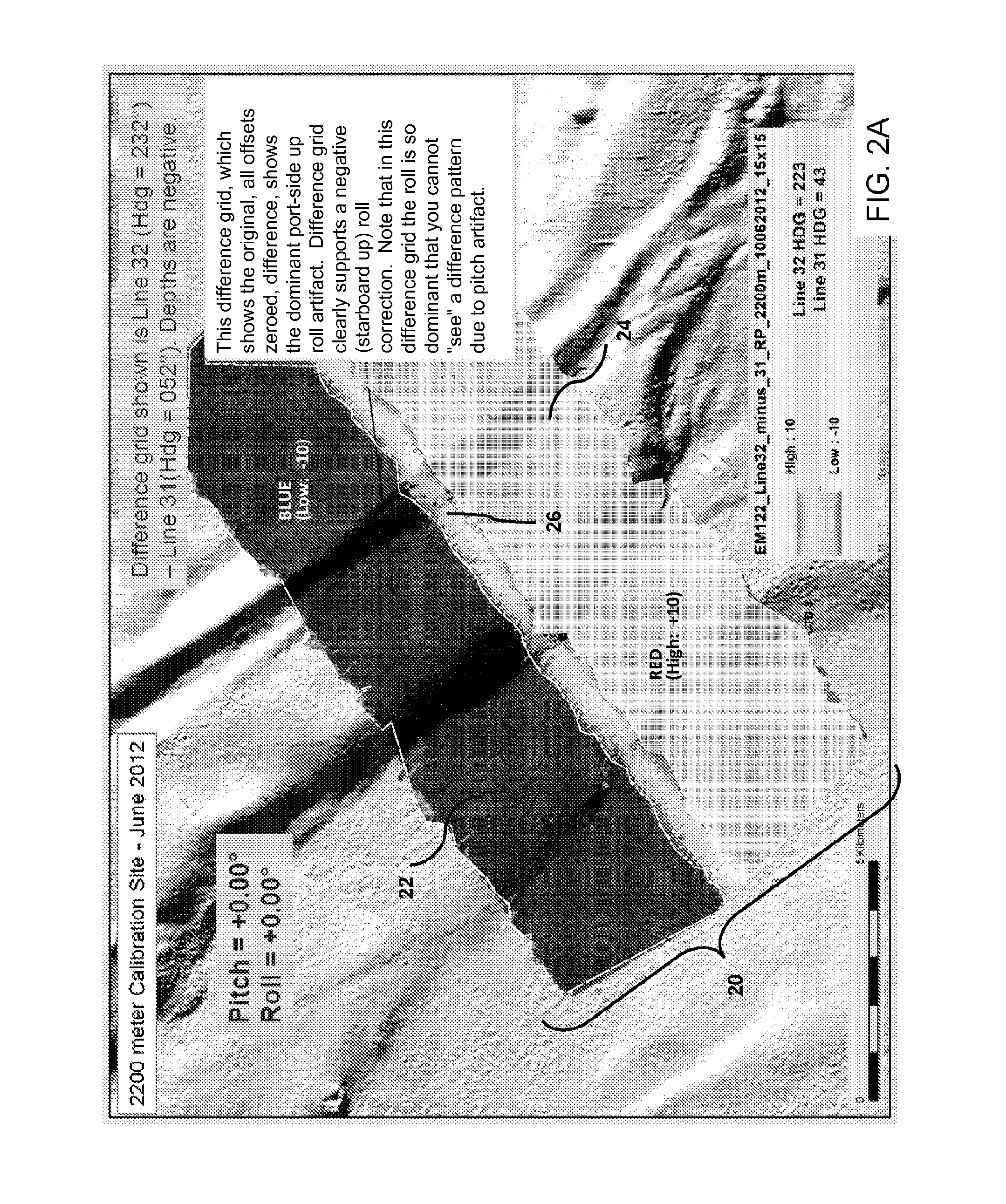

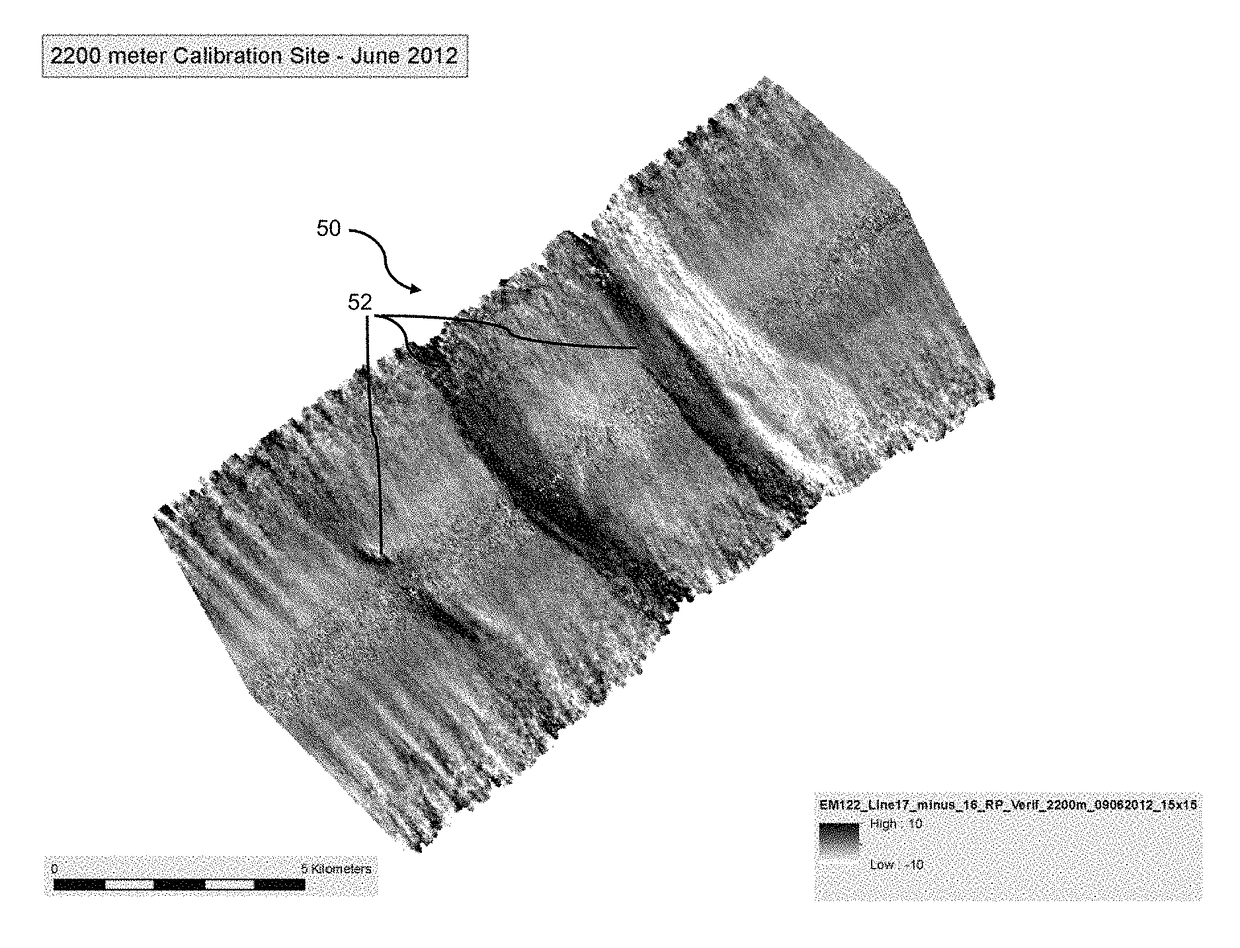

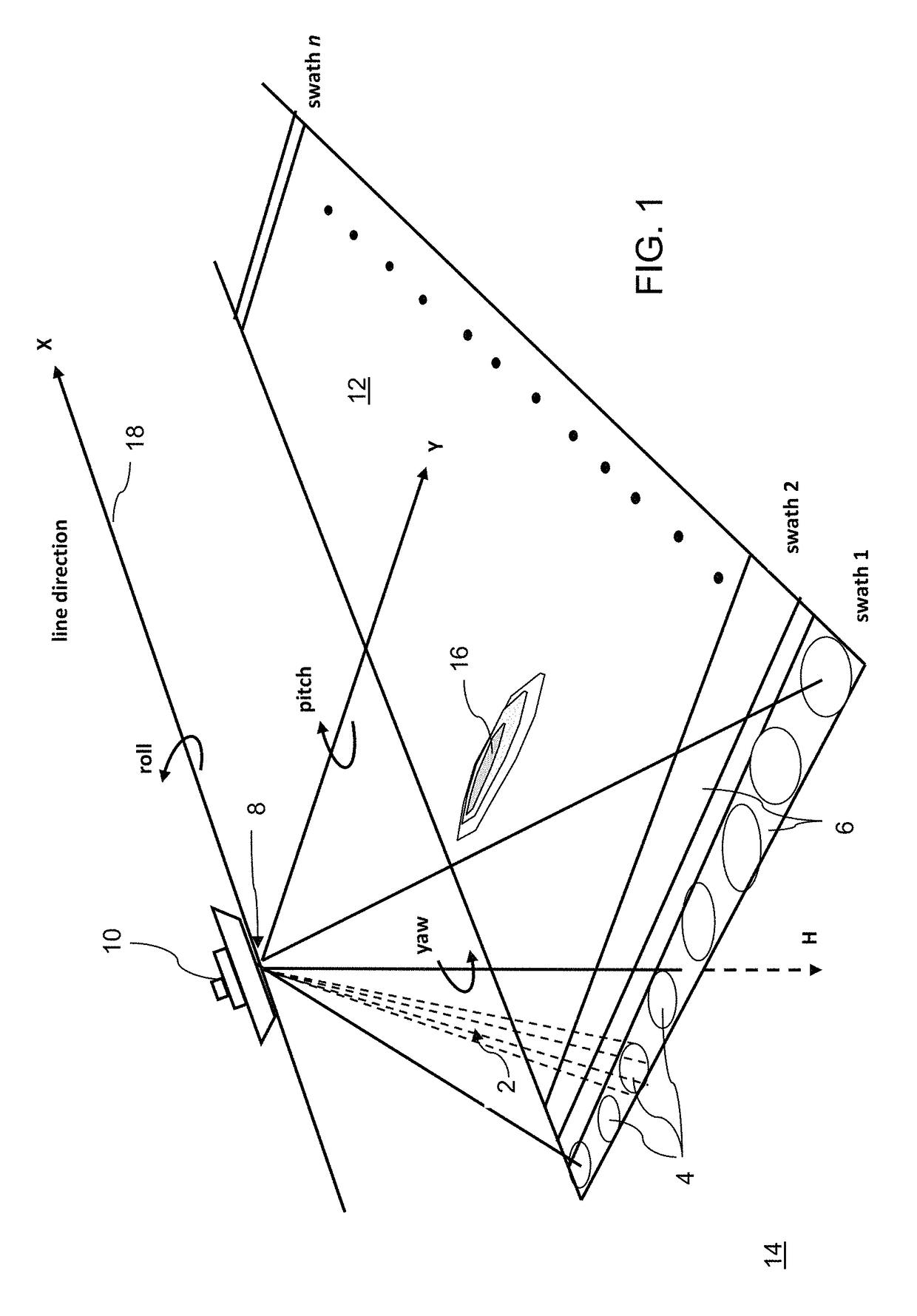

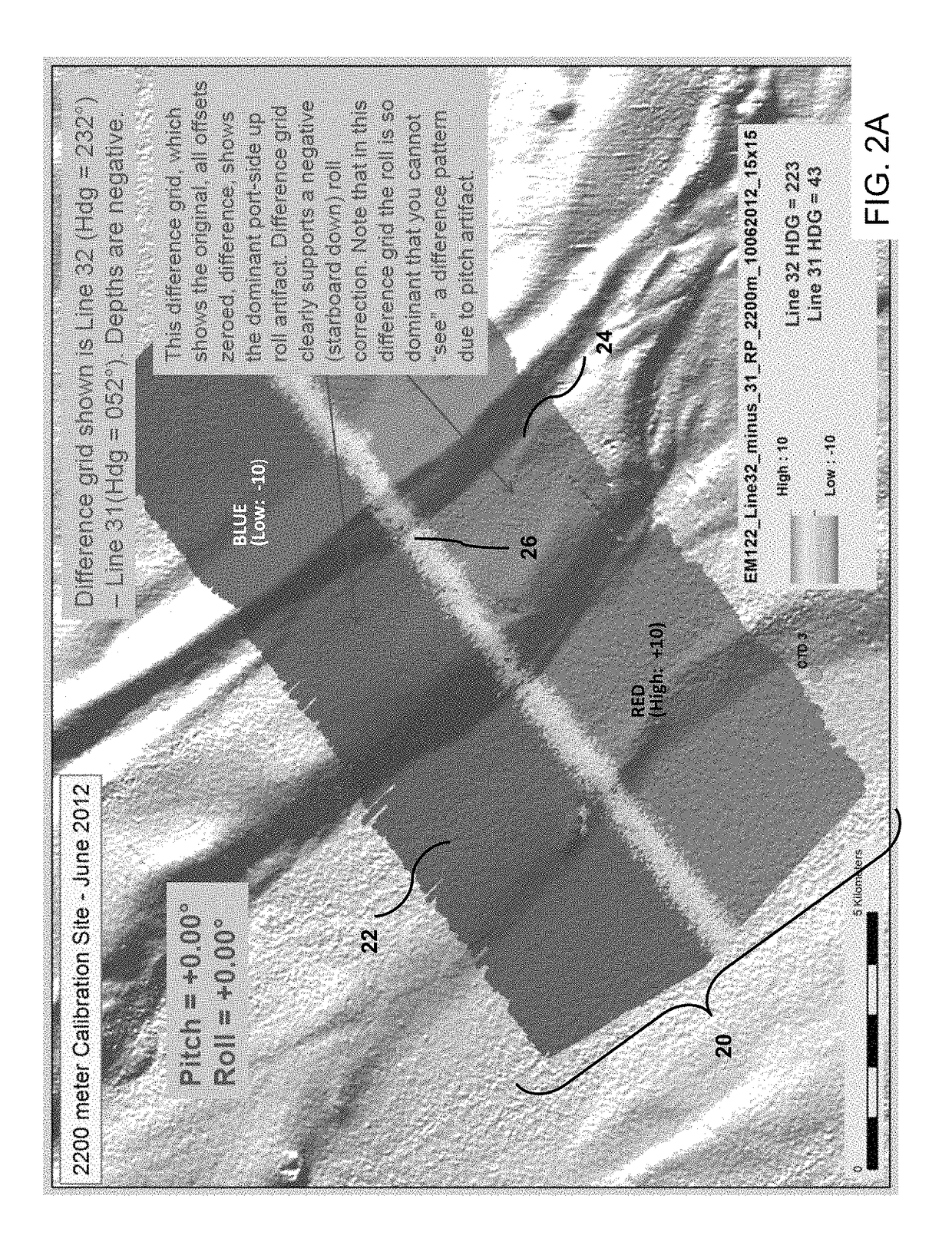

System and method for calibration of echo sounding systems and improved seafloor imaging using such systems

ActiveUS20160291140A1Improve distinguishabilityHigh densityAcoustic wave reradiationOcean bottomDisplay device

A system and method are provided for visualizing an offset in static parameters in an echo sounding system by generating a difference grid by subtracting a first survey line from a second survey line to determine difference values at each point in the grid; and displaying the difference grid on a display device, where the difference values are represented on a visual scale. The difference values may be used to calibrate the echo sounding system or check the quality of the calibration of an echo sounding system.

Owner:ORANGE DANIEL L

System and method for calibration of echo sounding systems and improved seafloor imaging using such systems

ActiveUS9772400B2High sensitivityAccurate CalibrationSeismology for water-covered areasAcoustic wave reradiationOcean bottomDisplay device

A system and method are provided for visualizing an offset in static parameters in an echo sounding system by generating a difference grid by subtracting a first survey line from a second survey line to determine difference values at each point in the grid; and displaying the difference grid on a display device, where the difference values are represented on a visual scale. The difference values may be used to calibrate the echo sounding system or check the quality of the calibration of an echo sounding system.

Owner:ORANGE DANIEL L

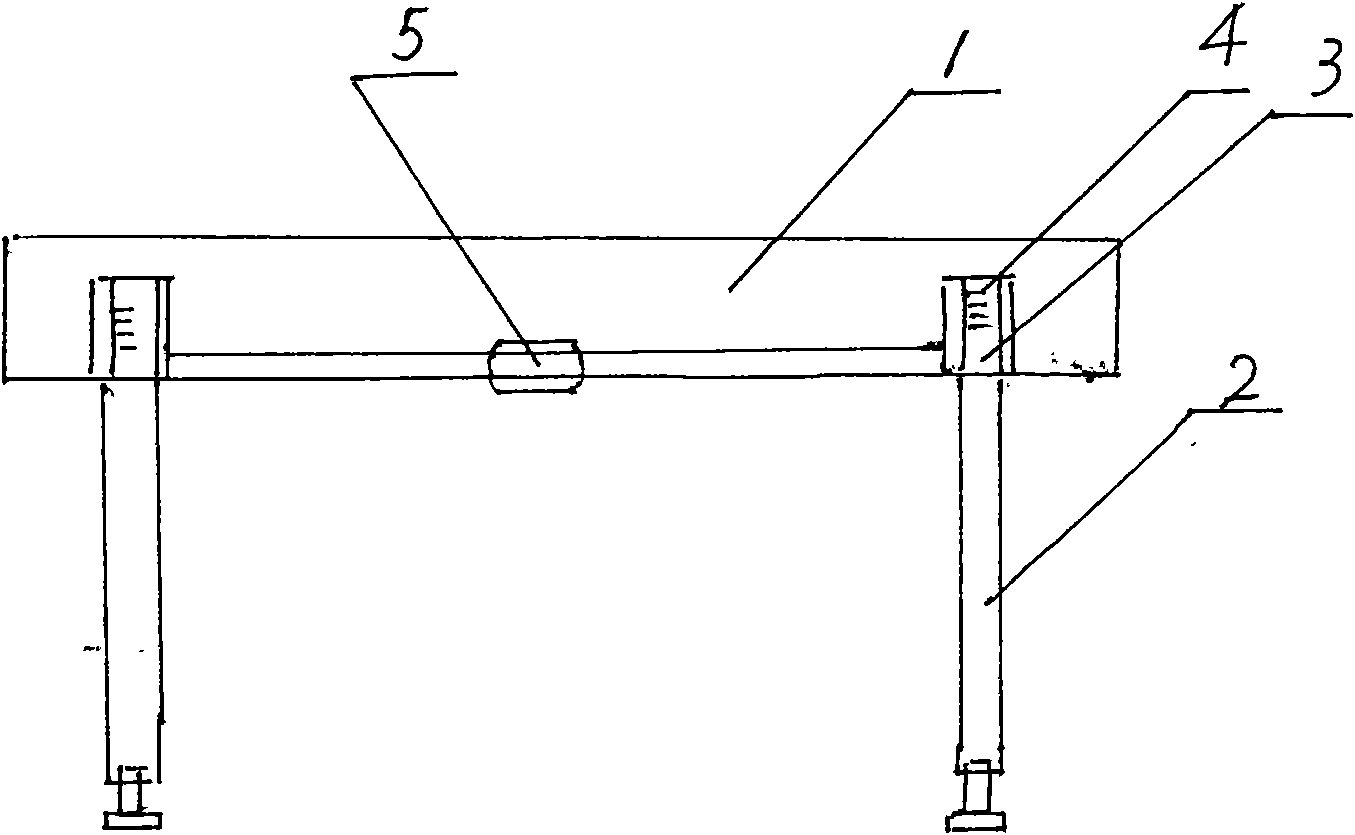

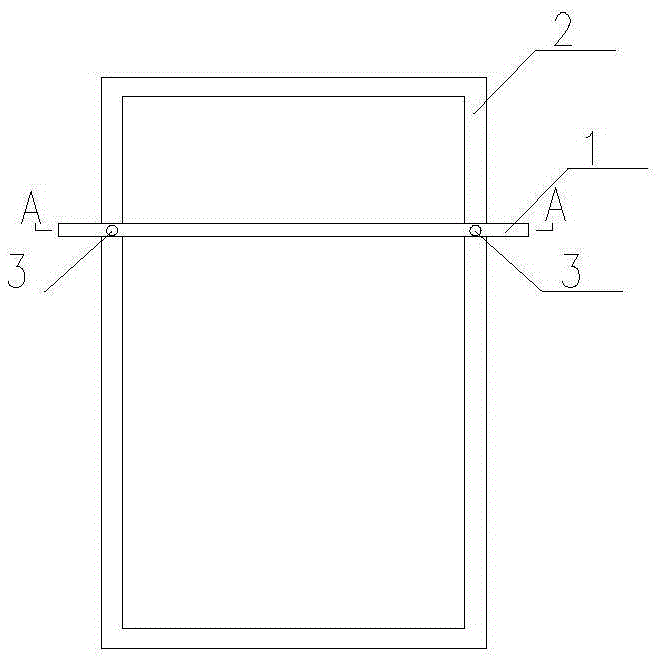

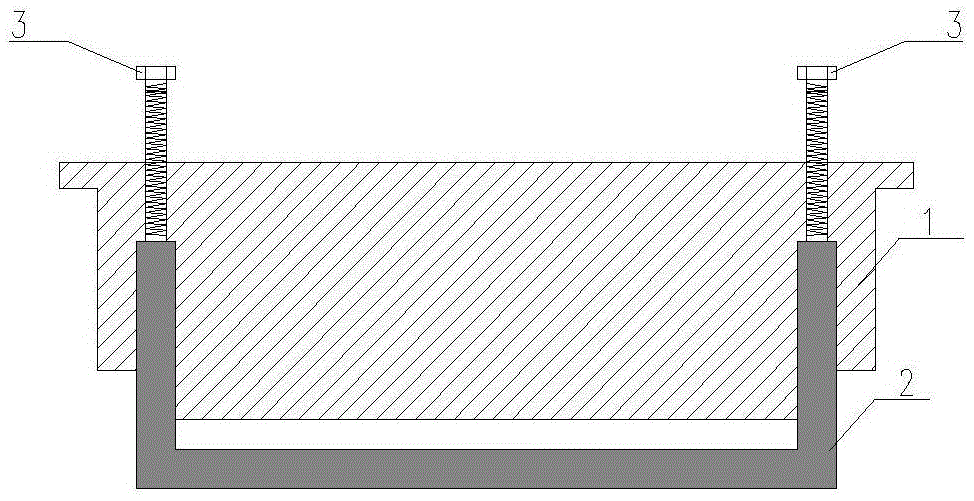

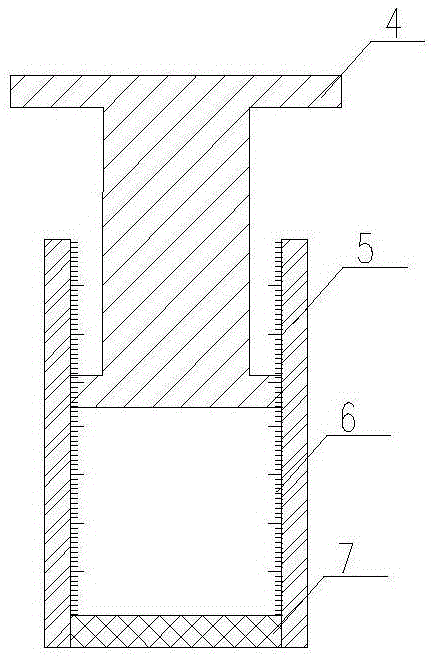

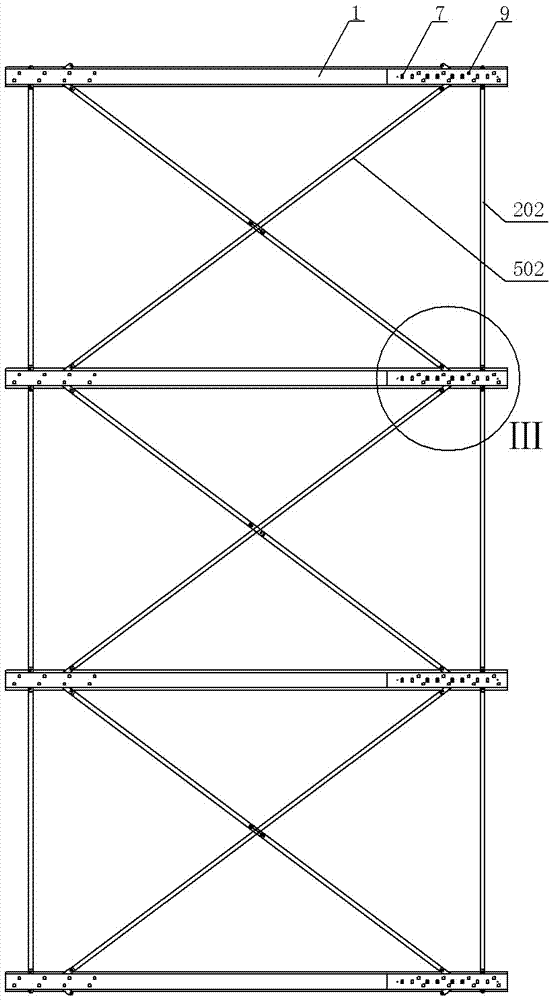

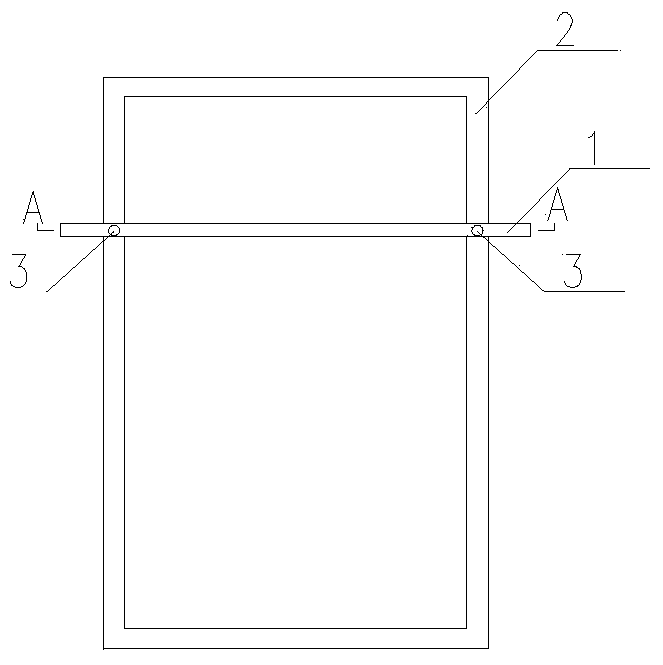

A steel structure modular prefabricated tooling

ActiveCN104929376BReduce construction measures and materialsLower construction auxiliary costsBuilding material handlingInsertion stentEngineering

The invention discloses a steel structure modularized prefabricated tooling, which comprises at least two sets of support systems arranged in parallel and at intervals and tie rods connecting two adjacent sets of support systems together, and each set of support systems respectively includes bottom plates arranged sequentially from bottom to top , Lower profile steel and upper profile steel, a horizontal adjustment mechanism is fixedly connected between the upper profile steel and the lower profile steel, the horizontal adjustment mechanism includes at least two hydraulic jacks, legs are provided between the lower profile steel and the bottom plate, the upper profile steel is box-shaped steel, and the upper profile steel The shaped steel includes a top panel, a bottom panel and two side panels arranged between the top panel and the bottom panel, and the two ends of the side panels are provided with scales. When in use, use the tie rods to connect the support systems together to form a rigid body. According to the data such as the center distance and specifications of the adjacent steel columns of the prefabricated steel structure module, adjust the level of the upper steel through the hydraulic jack in the horizontal adjustment mechanism. The prefabricated size of the steel structure module is visually displayed through the scale scale of the measuring mechanism.

Owner:SINOPEC NANJING ENG & CONSTR +1

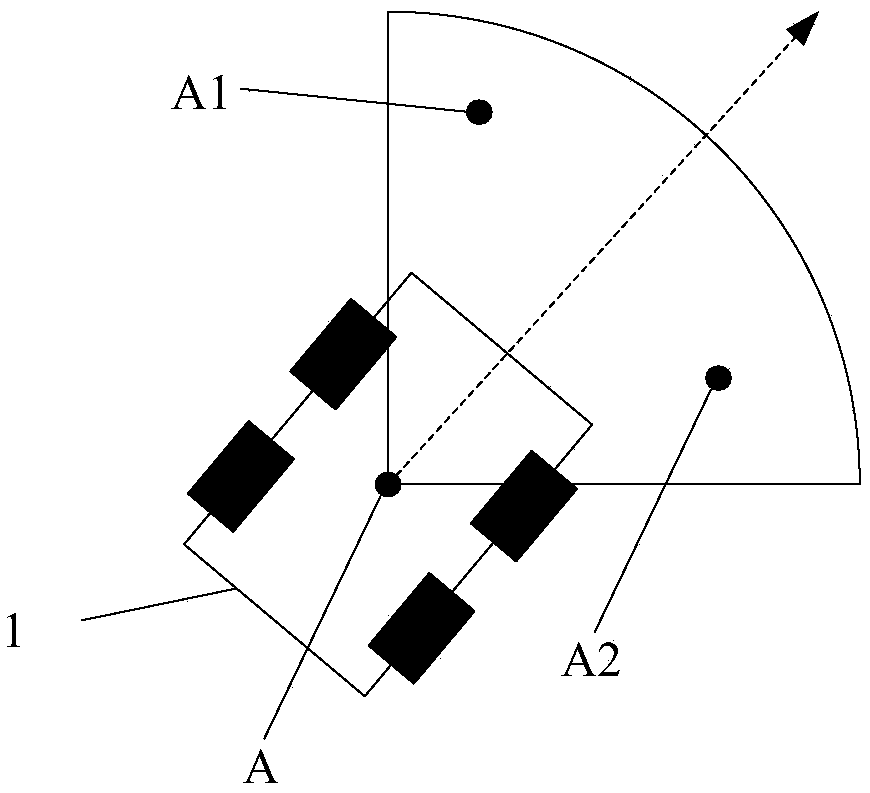

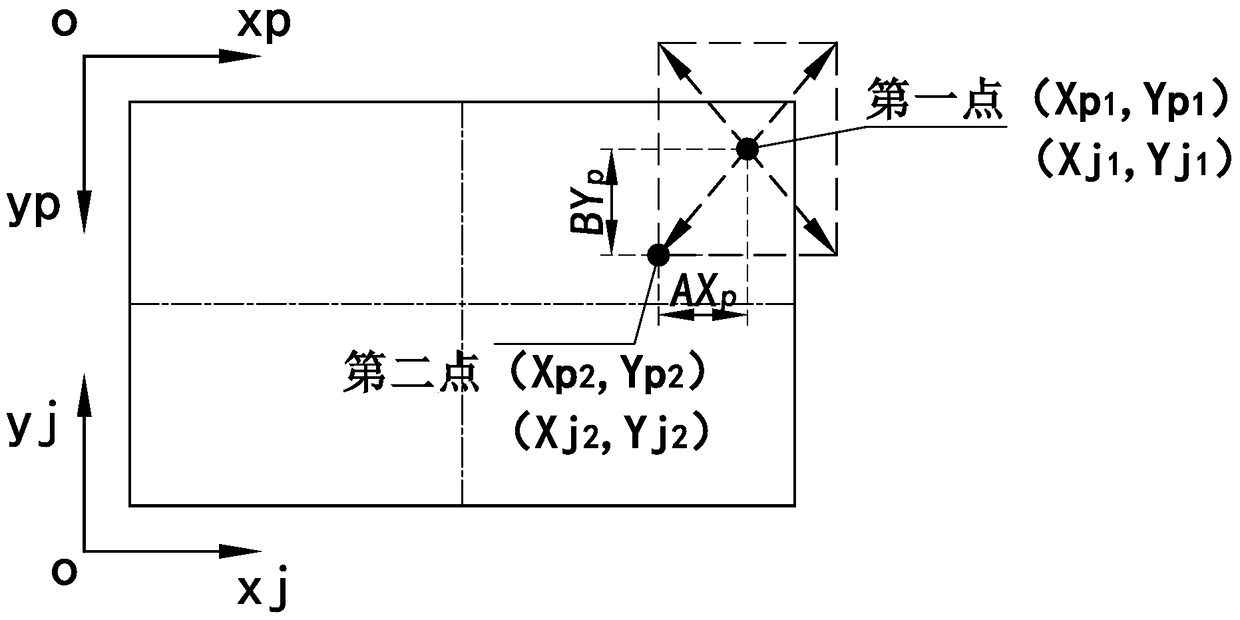

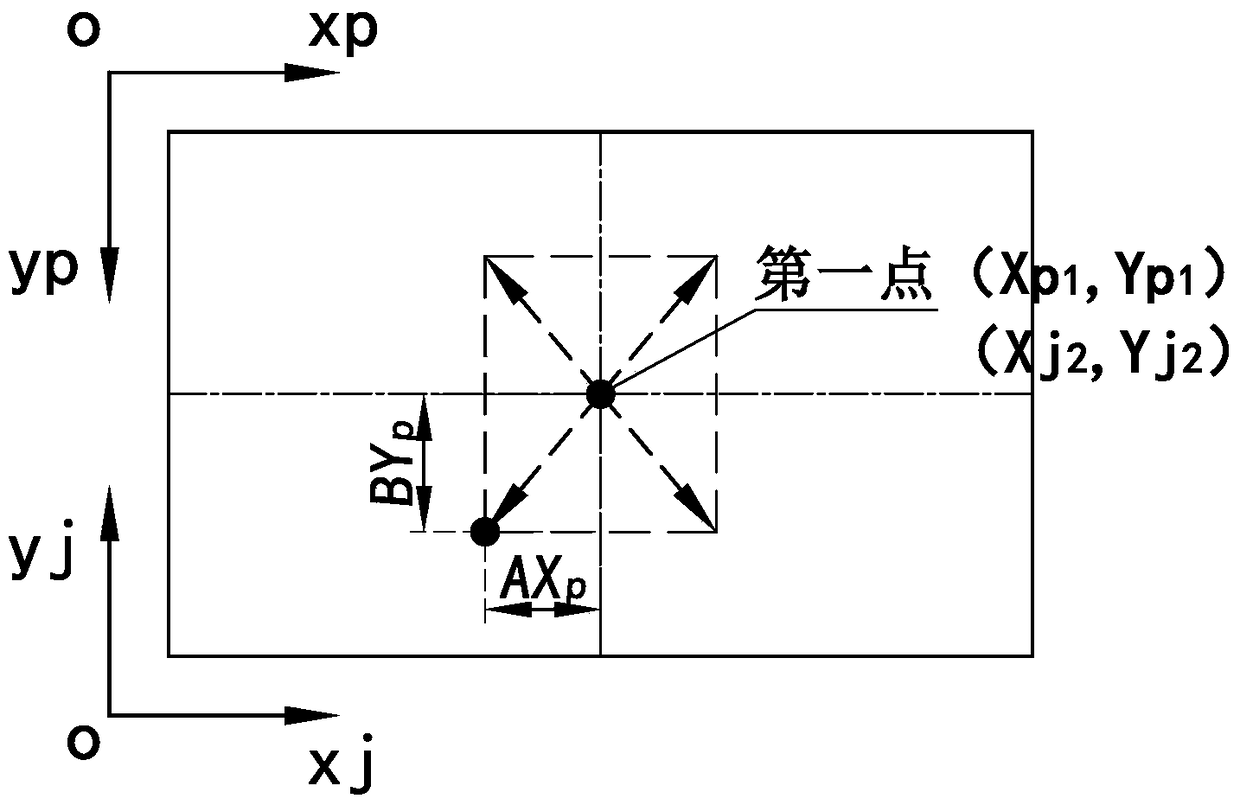

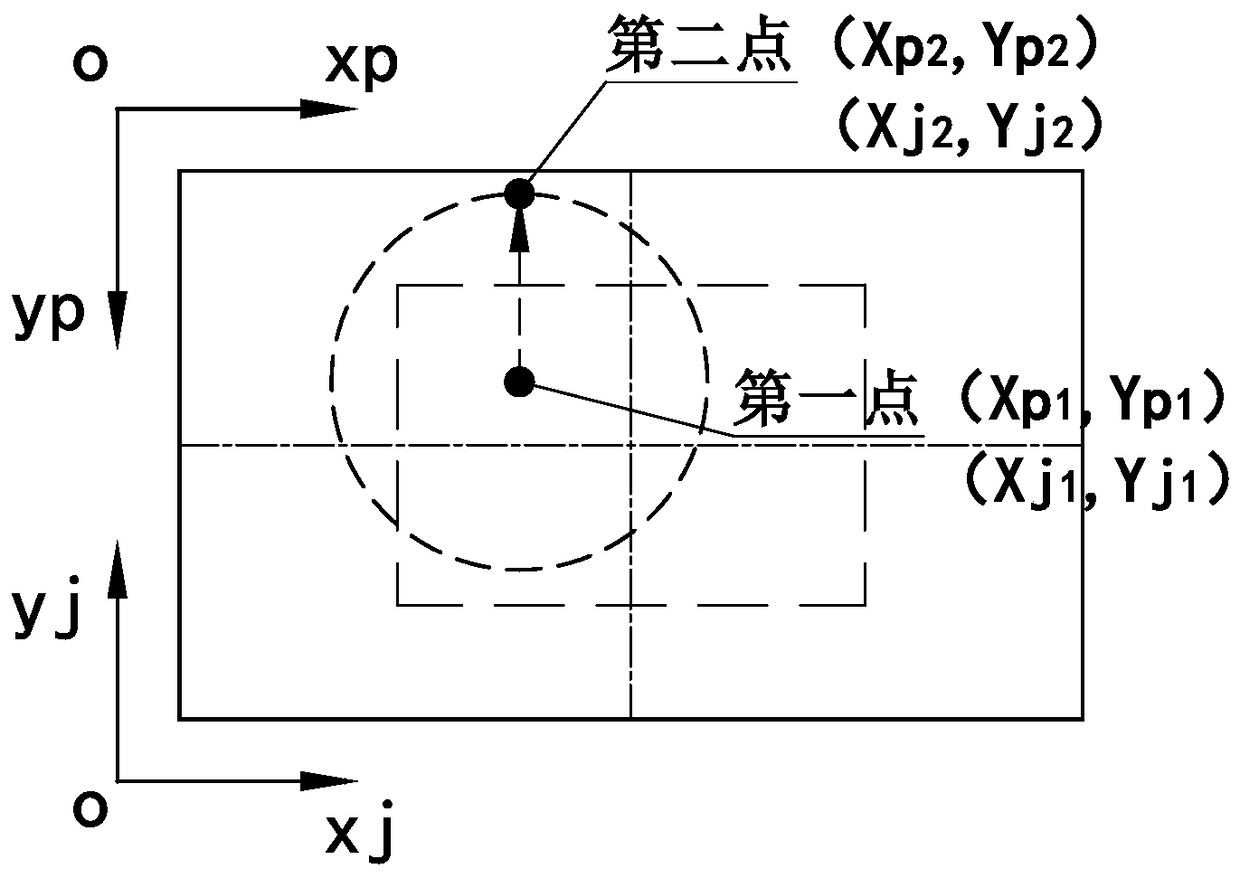

A method for obtaining visual scale coefficient based on machine vision

ActiveCN105627934BVisual scale factor is preciseImprove convenienceUsing optical meansFactor baseMachine vision

The invention discloses a vision proportionality coefficient obtaining method based on machine vision, and the method comprises the following steps: (a), building a machine coordinate system (xj, yj) and a pixel coordinate system (xp, yp) based on machine vision recognition according to the movement directions of x-axis and y-axis, wherein the machine coordinate system (xj, yj) and the pixel coordinate system (xp, yp) are mapped to each other; (b), providing a Mark point in a camera view field, obtaining the initial pixel coordinates (xp1, yp1) of the Mark point and the machine coordinates (xj1, yj1) at this moment; (c), moving the Mark point to a second point in the view field, obtaining the pixel coordinates (xp2, yp2) of the second point and the machine coordinates (xj2, yj2), calculating and obtaining the rough vision proportionality coefficients: X'vs=(xj2-xj1) / (xp2-xp1), Y'vs=(yj2-yj1) / (yp2-yp1); (d), enabling the Mark point to be moved to a third point (xp3, yp3) in the camera view field according to the rough vision proportionality coefficients, obtaining the machine coordinates (xj3, yj3) of the third point, enabling the Mark point to be moved to a fourth point (xp4, yp4) and a fifth point (xp5, yp5) in the camera view field, obtaining the machine coordinates (xj4, yj4) and machine coordinates (xj5, yj5) at this moment, and calculating and obtaining the vision proportionality coefficients: Xvs=(xj5-xj4) / (xp5-xp4), Yvs=(yj4-yj3) / (yp4-yp3).

Owner:NINGBO SUNNY OPOTECH CO LTD

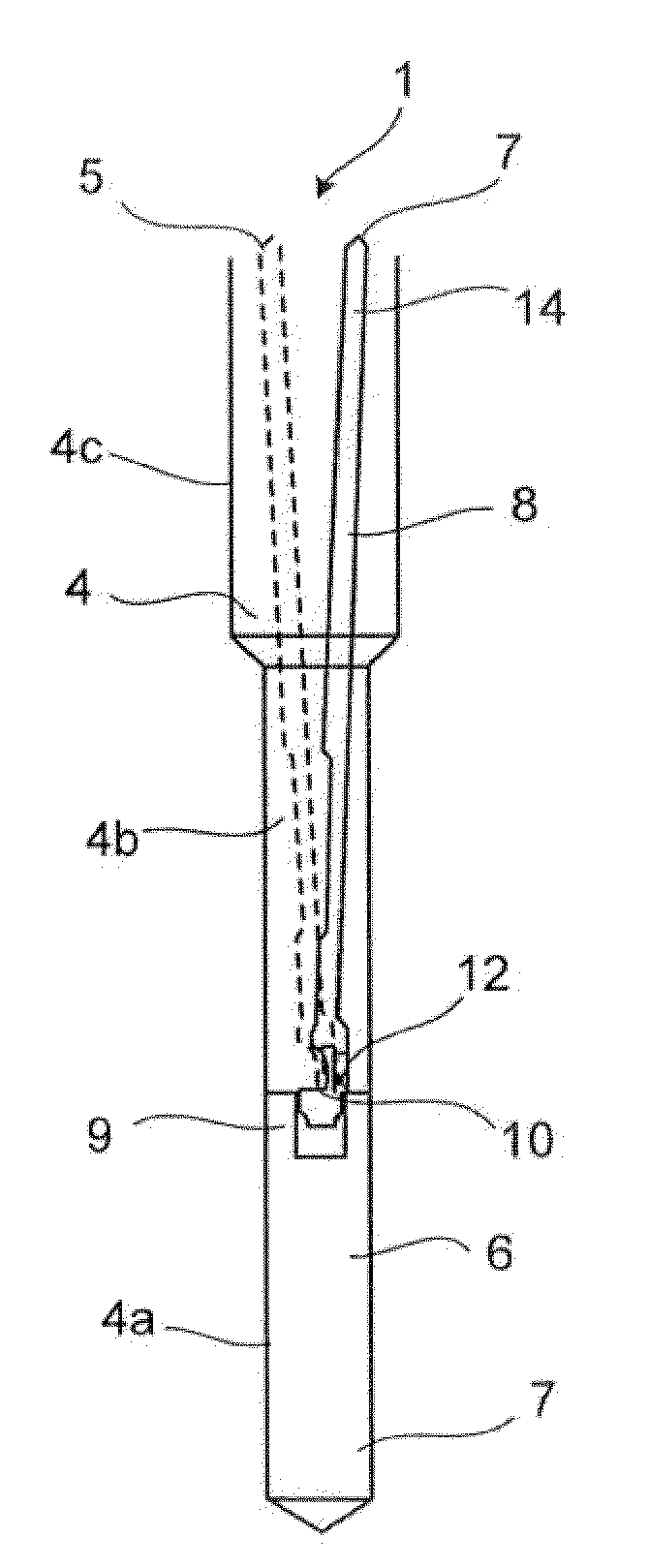

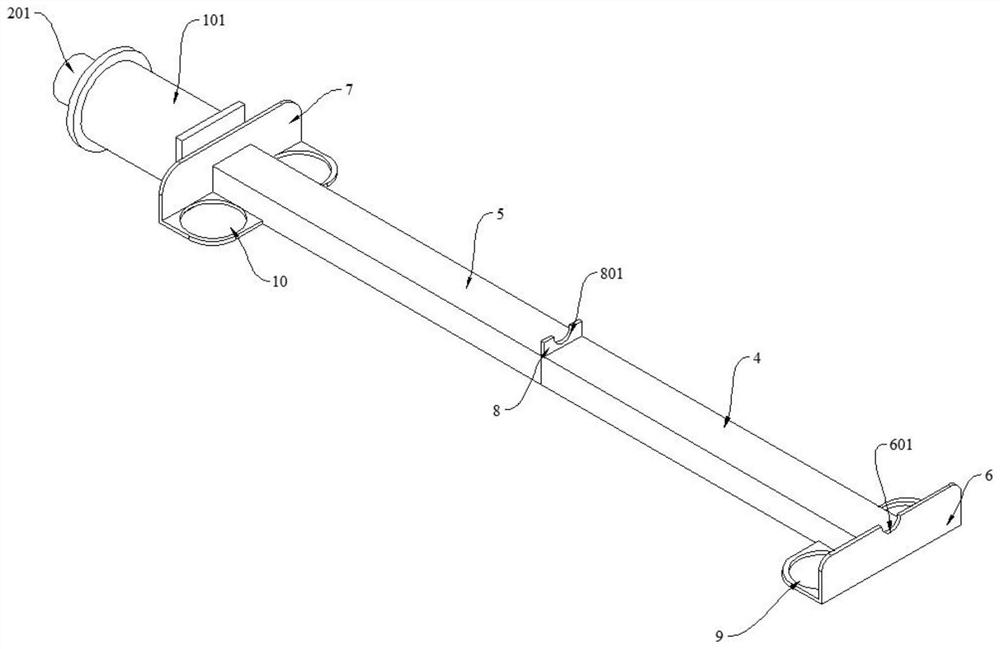

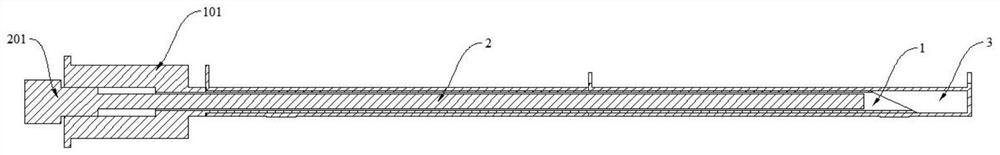

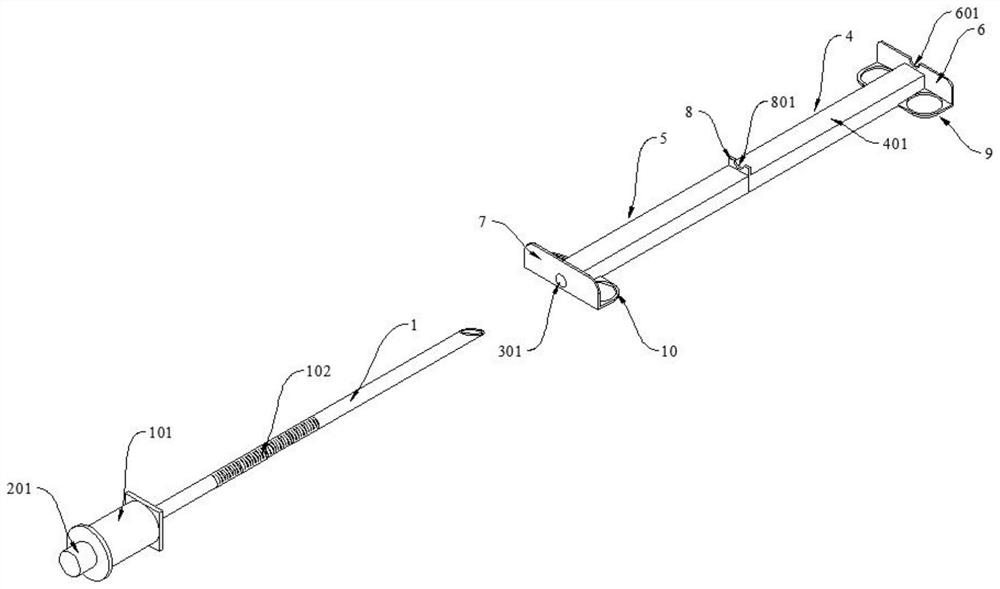

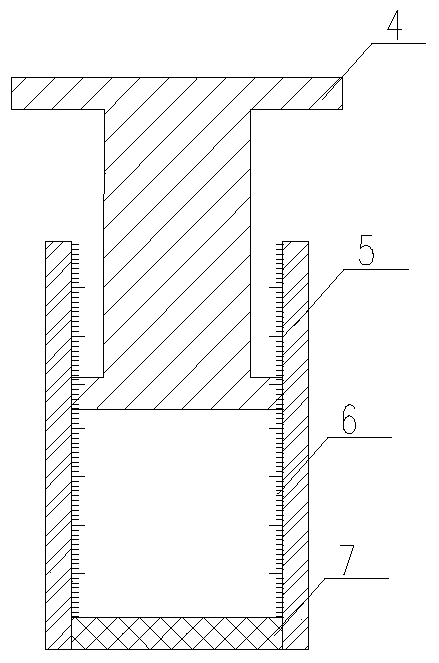

Visible scale puncture needle for pediatric anesthesia and use method

InactiveCN113598907APrecise identification of puncture depthAvoid blocking distractionsSurgical needlesVaccination/ovulation diagnosticsEngineeringApparatus instruments

The invention discloses a visual scale puncture needle for pediatric anesthesia and a use method, and relates to the technical field of medical instruments. The visual scale puncture needle comprises a needle head, a needle core and a needle head shield, wherein scales are arranged on the peripheral side surface of the needle head; the scales are positioned on the rear half section of the needle head and are gradually increased from the needle tip to the needle tail; needle head grooves for placing needle heads are formed in the needle head shield along the axial direction; the needle head shieldcomprises a first shield and a second shield, the rear end of the first shield is rotationally connected with the front end of the second shield, and an auxiliary positioning device is fixedly connected to one surface of the needle head shield. According to the invention, the scales are arranged on the peripheral side face of the needle head, and the scale lines are arranged on the rear half section of the needle head, so that shielding interference is avoided when the scales are read in the puncture process; the needle head shield can be folded to assist the needle head in puncturing, an auxiliary positioning device of the needle head is arranged on the needle head shield, and the auxiliary positioning device is used in cooperation with scales on the needle head, so that the purpose of accurately recognizing the puncturing depth is achieved.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

Map correction method, device and electronic equipment

Disclosed are a map correction method, device and electronic equipment. Determine a first movement track and a preset visual scale of the movable device, and generate at least one second movement track with a visual scale according to the first movement track and the preset visual scale. For example, at least one second movement trajectory with a visual scale similar to the first movement trajectory is determined around the first movement trajectory, and then a preset road trajectory within the location area where the first movement trajectory is located is acquired. A third movement trajectory with a visual scale of the movable device is determined according to the preset road trajectory and at least one second movement trajectory. Since the movable device often moves on the preset road trajectory, the real moving trajectory of the movable device on the preset road trajectory can be obtained, that is, the third moving trajectory, and then corrected according to the visual scale of the third moving trajectory The map generated when the mobile device moves, so that the corrected map can be objectively standardized.

Owner:BEIJING HORIZON INFORMATION TECH CO LTD

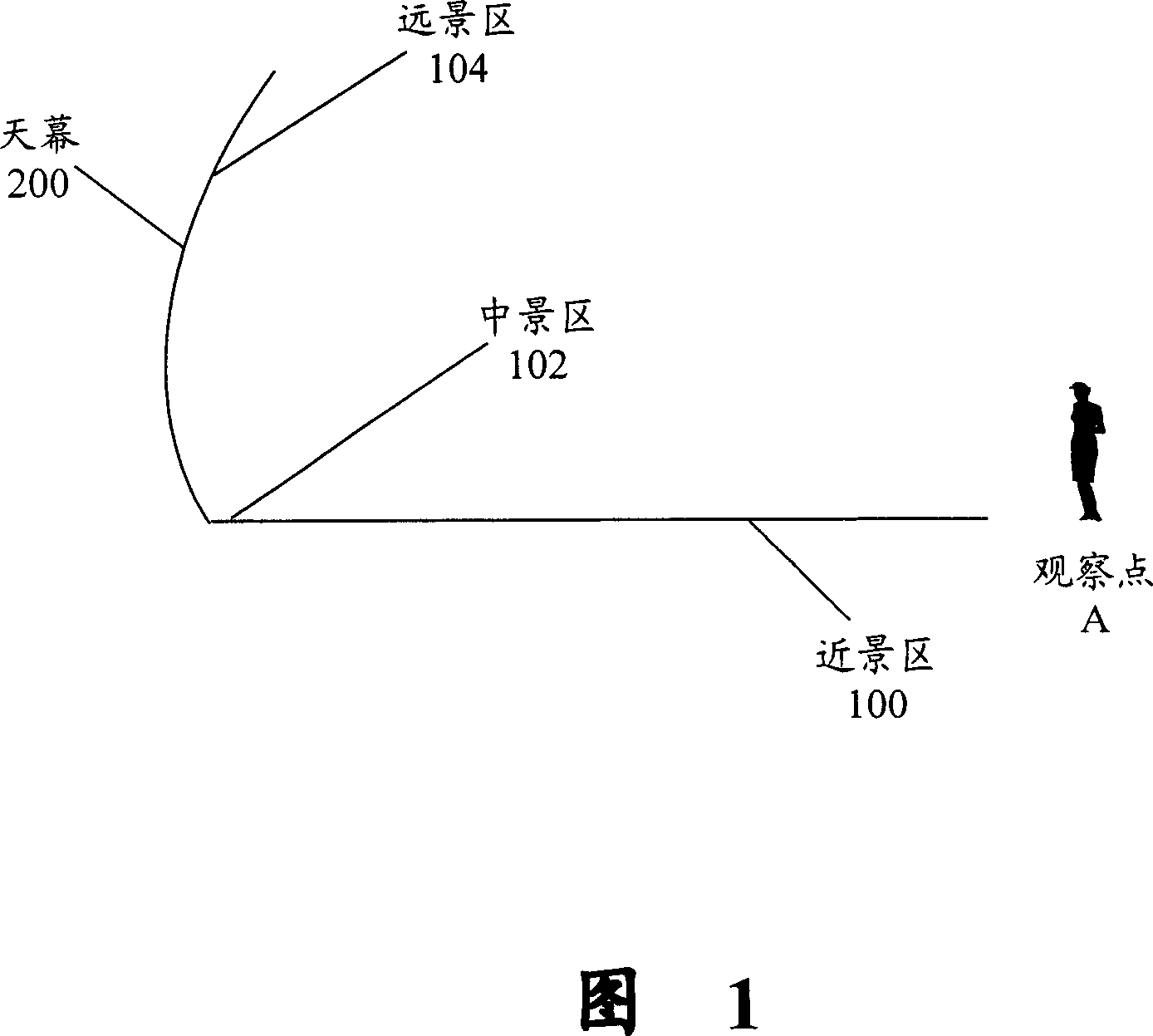

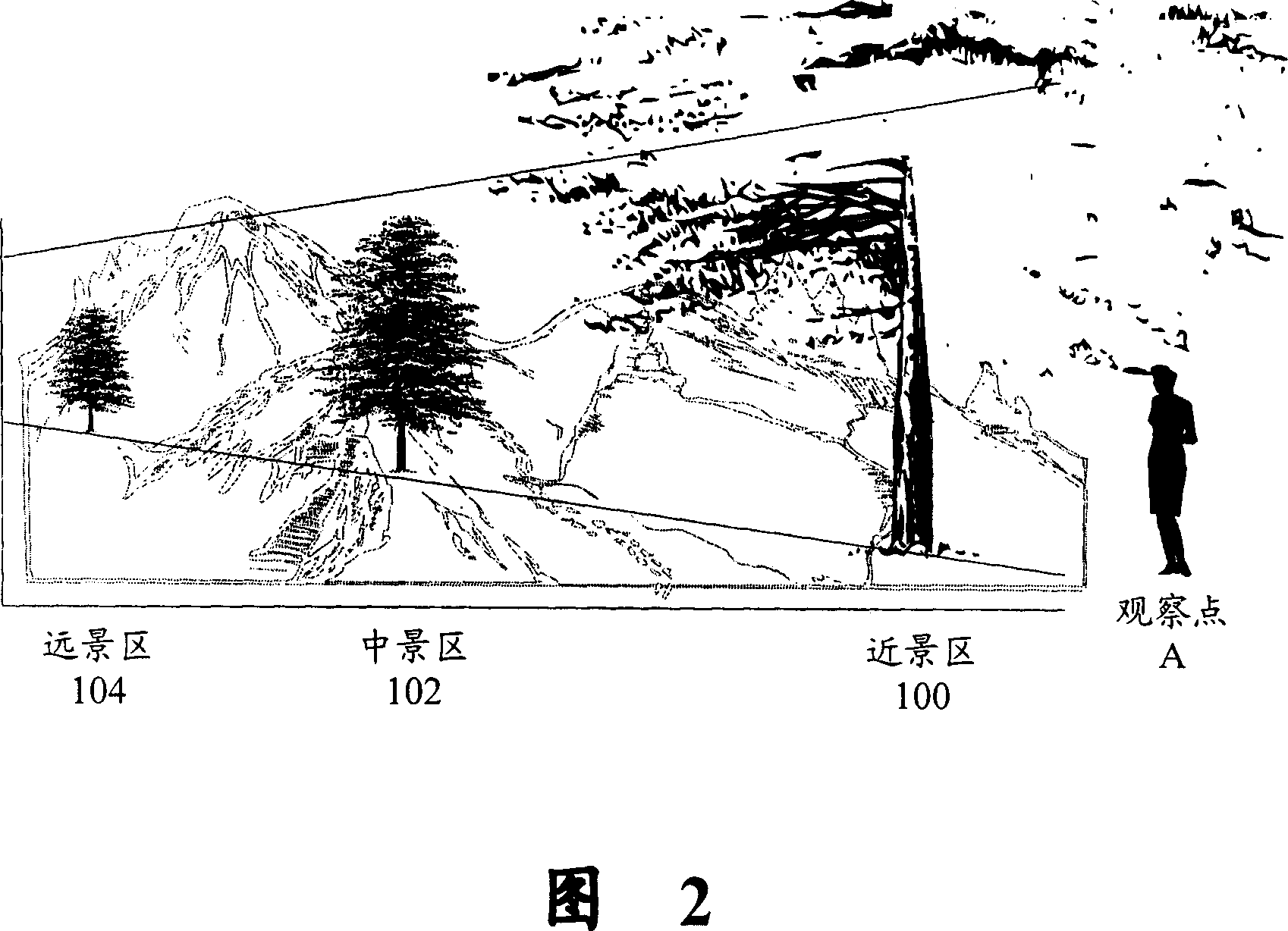

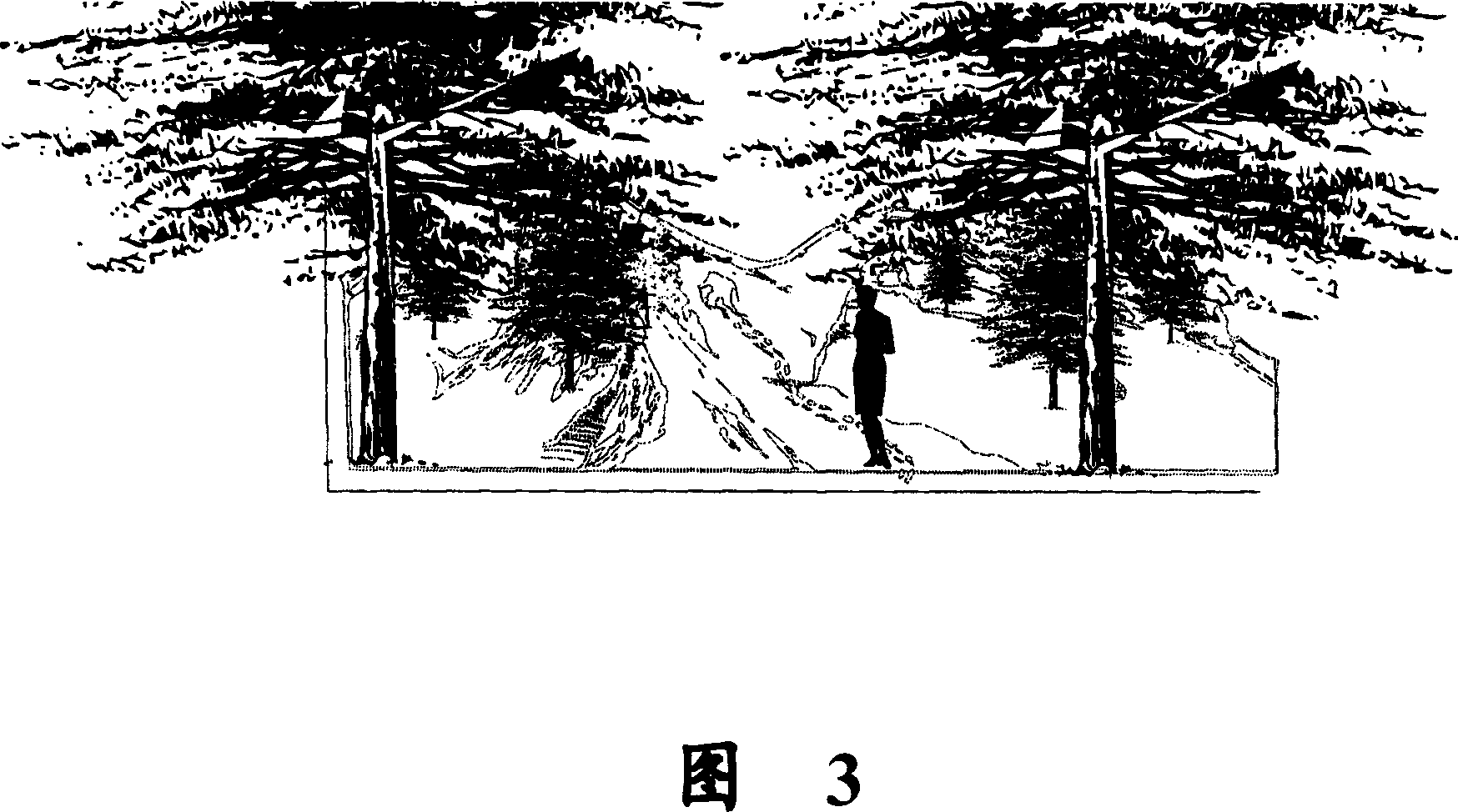

Method for raising artificial scene visual vivid effect

This invention discloses a kind of method to improve the raising vision vivid effect of man made circumstances, it divides the circumstances into close shot, medium shot and distant view, close shot keeps original size, medium shot and distant view shrink, the joint place of close shot and medium shot making use of landform to carry out the perspective line's covering and linking up. Using the technology scheme in the invention to make the circumstances prop of close shot , medium shot , distant view inventing adjust size according to vision proportion , in limited distance, reaches the effect of vision extension, reaching true effect in naked eye. In transition problem of medium shot and the distant view, circumstances prop keeps out the boundary between medium shot and distant view naturally, reaches true effect in man made environment.

Owner:SHANGHAI SCI & TECH MUSEUM

Gas detection flow rate controller

InactiveUS10077995B1Provide feedbackWithdrawing sample devicesVolume/mass flow by dynamic fluid flow effectCatheterGuide tube

A flow rate control apparatus includes an adjustable valve receiving a flow of a gas. A conduit has a first end coupled to the valve. The conduit includes a translucent or transparent portion thereof whose longitudinal axis is adapted to be aligned with a force of gravity with a visual scale being disposed on the translucent / transparent portion. The visual scale is indicative of gas flow rates moving through the conduit. A ball disposed in the translucent / transparent portion has an outer diameter that is less than an inner diameter of the translucent / transparent portion. A tube support, coupled to the second end of the conduit, is adapted to hold a gas detection tube wherein the gas flow flowing around the ball is introduced into the gas detection tube from the second end of the conduit.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

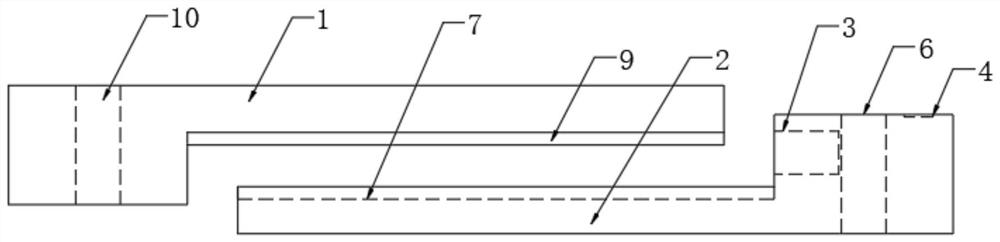

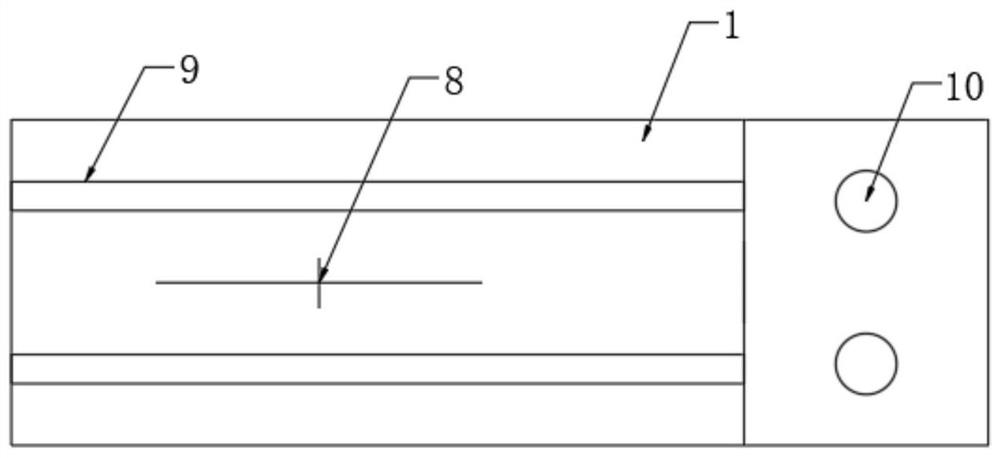

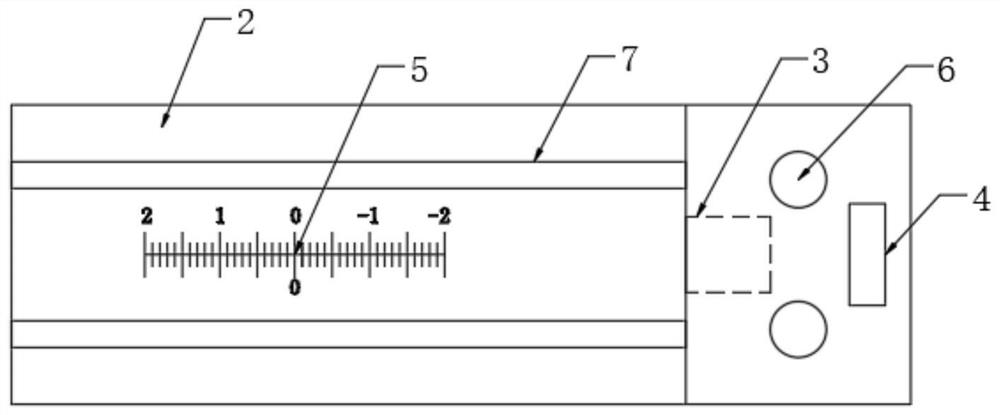

Building (structure) crack monitoring device and use method

PendingCN113686250AAvoid accidental errorSolve the problem of poor accuracy of manual measurementUsing optical meansMechanical measuring arrangementsArchitectural engineeringMechanical engineering

The invention discloses a building (structure) crack monitoring device and a use method, and belongs to the field of building construction. The building (structure) crack monitoring device comprises an upper cover plate and a lower base plate, the bottom side of the upper cover plate is slidably connected with the upper side of the lower base plate through a sliding assembly, and visual scale monitoring assemblies are arranged on the upper cover plate and the lower base plate; and a laser displacement sensor corresponding to the end part of the upper cover plate is arranged at one end of the upper side of the lower base plate. The upper cover plate and the lower base plate can be fixed to the two sides of a crack respectively, the upper cover plate and the lower base plate can be combined through the sliding assembly, the upper cover plate and the lower base plate relatively slide along with the increase of the crack to generate displacement, and the change scale of the crack can be directly read out through the visual scale monitoring assembly. The laser displacement sensor generates laser to the end of the upper cover plate and then emits the laser back so that the change of displacement is monitored in an electronic mode. Arrangement is convenient, reading is convenient, and monitoring is accurate.

Owner:SOUTHERN CONSTR CO LTD OF CHINA CONSTR EIGHTH ENG DIV

Novel dust-proof coating stirrer.

The invention discloses a novel dust-proof coating stirrer. The novel dust-proof coating stirrer comprises a motor, a barrel body, an upper cover, a lower cover, a filling pipe and an output pipe, wherein both the upper cover and the lower cover are connected with the barrel body through threads, the motor is arranged on the upper cover, the lower part of the motor is connected with a stirrer through a connecting rod, a visual scale bar is arranged on the outer wall of the barrel body, the filling pipe and a filling pipe connector are arranged on the upper cover, the output pipe is arranged at the lower part of the barrel body, valves are arranged on both the filling pipe and the output pipe, and an output pipe connector is arranged at the bottom of the barrel body. According to the technical scheme, various coatings and paints can be uniformly stirred through stirring the coatings with the motor, the mass is ensured, and external substances are prevented by a cover plate from falling in the coatings to affect coating quality; besides, the motor and the stirrer can be disassembled, the work is convenient to coordinate through arranging the filling pipe and the output pipe, and the use is flexible.

Owner:巫贤华

A method for making remolded soil samples

ActiveCN105571926BSmall quality errorEffective height controlPreparing sample for investigationHydraulic equipmentDensity difference

The invention provides a method for manufacturing a remolding soil test specimen in the technical field of geotechnical tests. A darby tray and a specimen making device are used. The darby tray is a rectangular tray, and an adjustable darby is attached to the upper part of the rectangular tray. The specimen making device consists of a concave press rod, a pad block and a transparent sleeve with scales. By using a one-step feeding mode, the characteristic of uniform loading of the existing servo hydraulic equipment in a laboratory is used; the problems of nonuniform and instable specimen making pressure, easy layering of the soil specimen and upper and lower density difference are solved; the visual scale characteristic of the specimen making device is used; the precise control on the test specimen volume is achieved; and further, the dry density is precisely controlled on the premise of precisely controlling the moisture content. The method is applicable to the preparation of cylindrical remolding soil test specimens, and has the characteristics that the system errors are small; the structure is simple; the laboratory equipment is integrally utilized; the multi-time repeated utilization can be realized, and the like.

Owner:ANHUI UNIV OF SCI & TECH

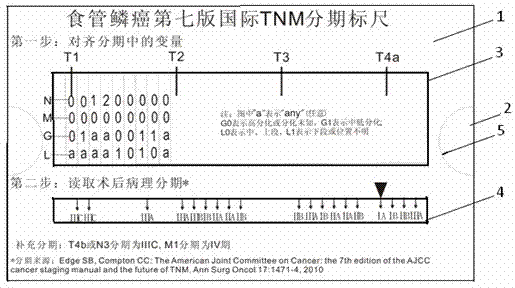

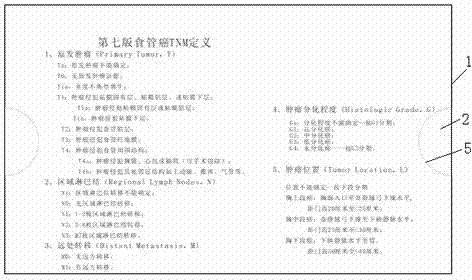

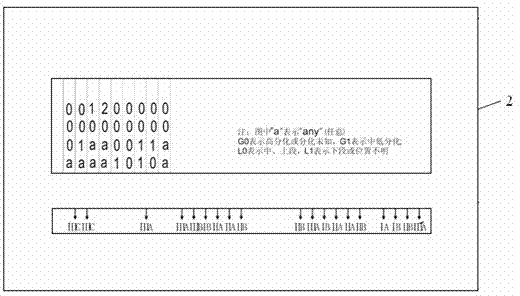

Drawing-type scale device for esophageal squamous carcinoma TNM staging

The invention provides a drawing-type scale device for esophageal squamous carcinoma TNM staging. The drawing-type scale device comprises a rectangular hollow sleeve with two ends open and a drawing plate marked with staging results. The drawing plate is inserted into the hollow sleeve and fits with the same in length. A first rectangular window and a second rectangular window are formed in the front of the hollow sleeve. A semicircular notch is formed in the middle of each open end of the hollow sleeve for the convenience of moving the drawing plate. The back and the front of the hollow sleeve are printed with related definitions of all staging variables. Due to displaying in a visual scale form, clinicians are helped to accurately and rapidly stage, and beneficially remember new staging regulations as soon as possible. For patients in later staging, early postoperative adjuvant treatment is suggested, and an optimal comprehensive treatment scheme is selected. Meanwhile, postoperative follow-up monitoring is enhanced to discover local and distant metastasis in time so as to prolong survival. Besides, convenience is brought to make better treatment schemes subsequently to form objective indicators in favor of effectively evaluating curative effect.

Owner:ZHEJIANG CANCER HOSPITAL

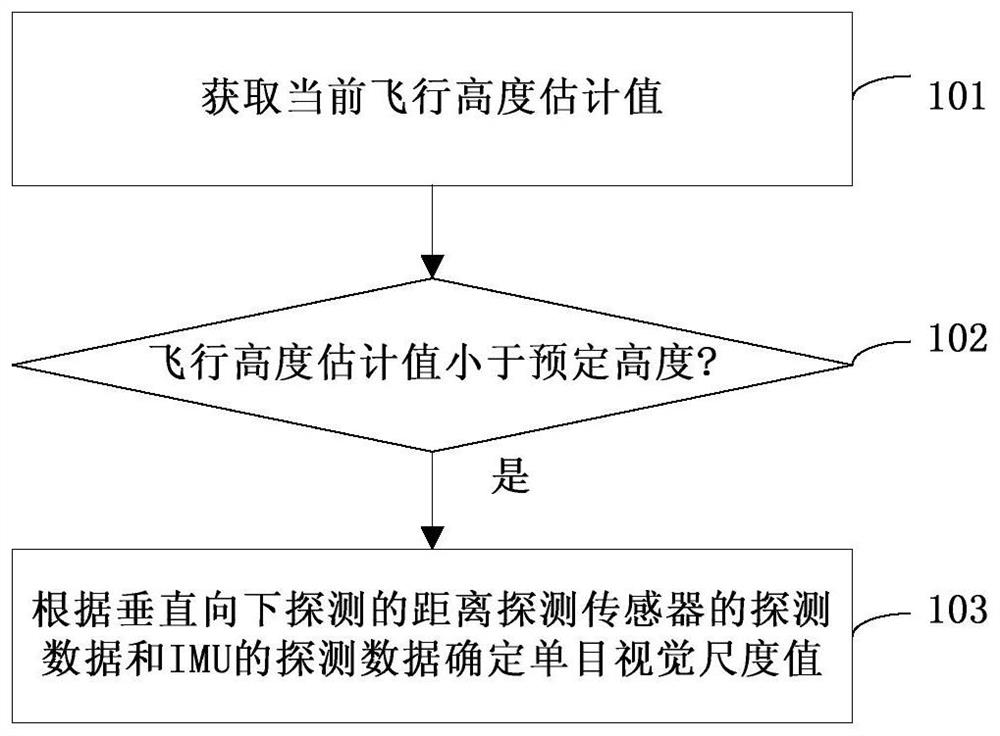

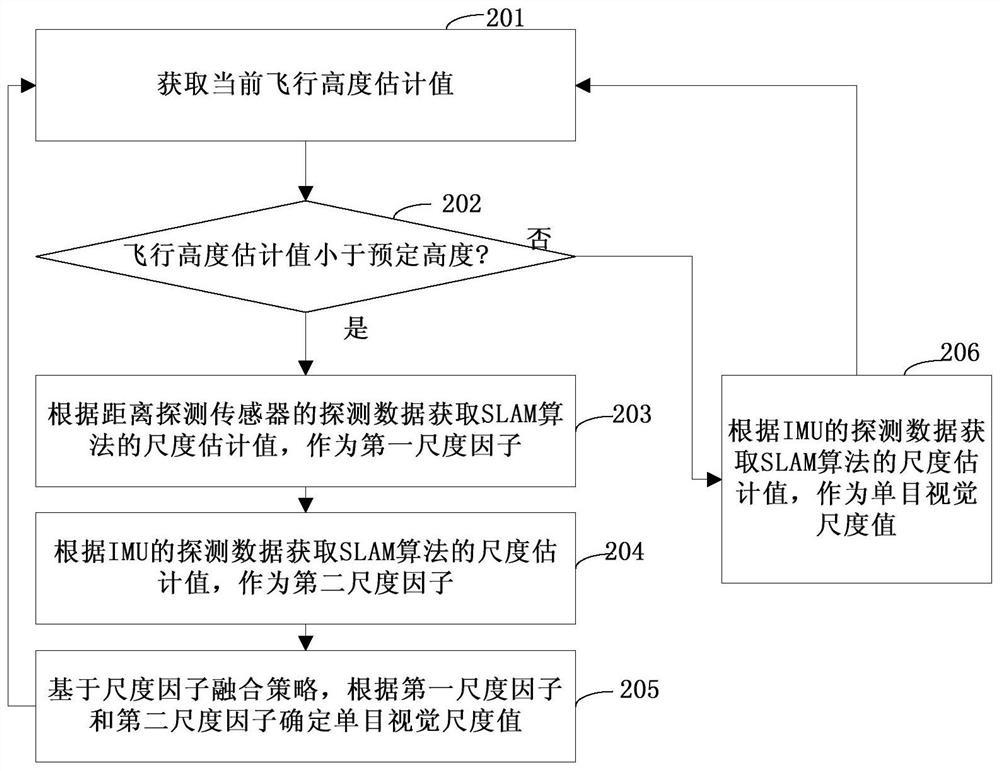

Aircraft monocular vision scale estimation method and device, aircraft navigation system and aircraft

ActiveCN110388917BImprove route reliabilityImprove accuracyNavigational calculation instrumentsNavigation by speed/acceleration measurementsScale estimationFlight height

The disclosure proposes a method and device for estimating a monocular visual scale of an aircraft, an aircraft navigation system and flight, and relates to the technical field of aircraft. The method for estimating the scale of the aircraft monocular vision of the present disclosure includes: obtaining the estimated value of the current flying height; when the estimated value of the flying height is less than the predetermined height, detecting the detection data of the sensor and the detection of the inertial measurement unit IMU according to the vertically downward detection distance The data determine the monocular vision scale value. Through this method, when the flying height of the aircraft is lower than the predetermined height, the distance detection sensor and the IMU can be used to obtain the monocular visual scale value. On the one hand, no manual participation is required, which improves the degree of automation. Combining the advantages of distance detection sensors and IMUs, it reduces the error caused by a single measurement method and improves the accuracy of scale estimation.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

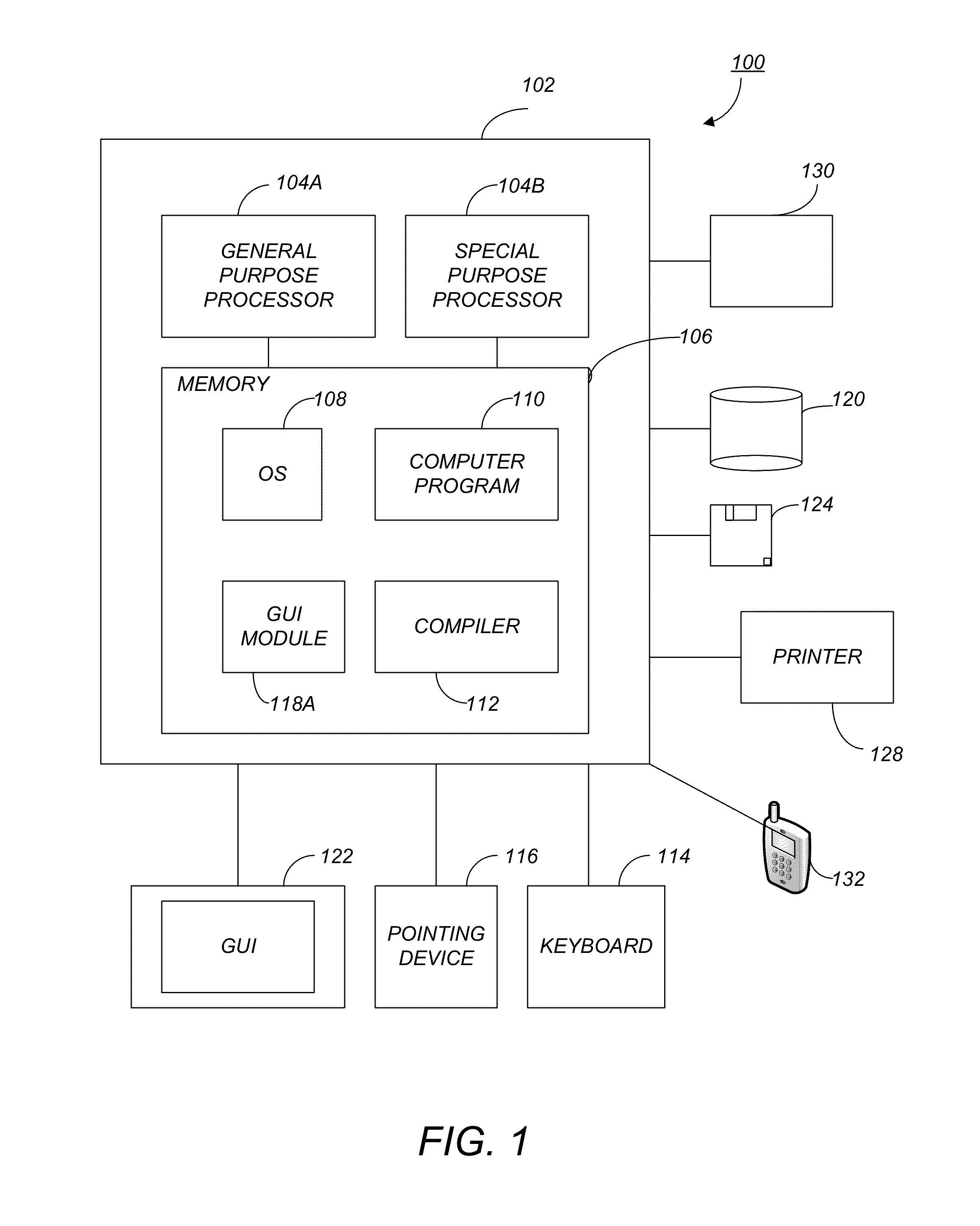

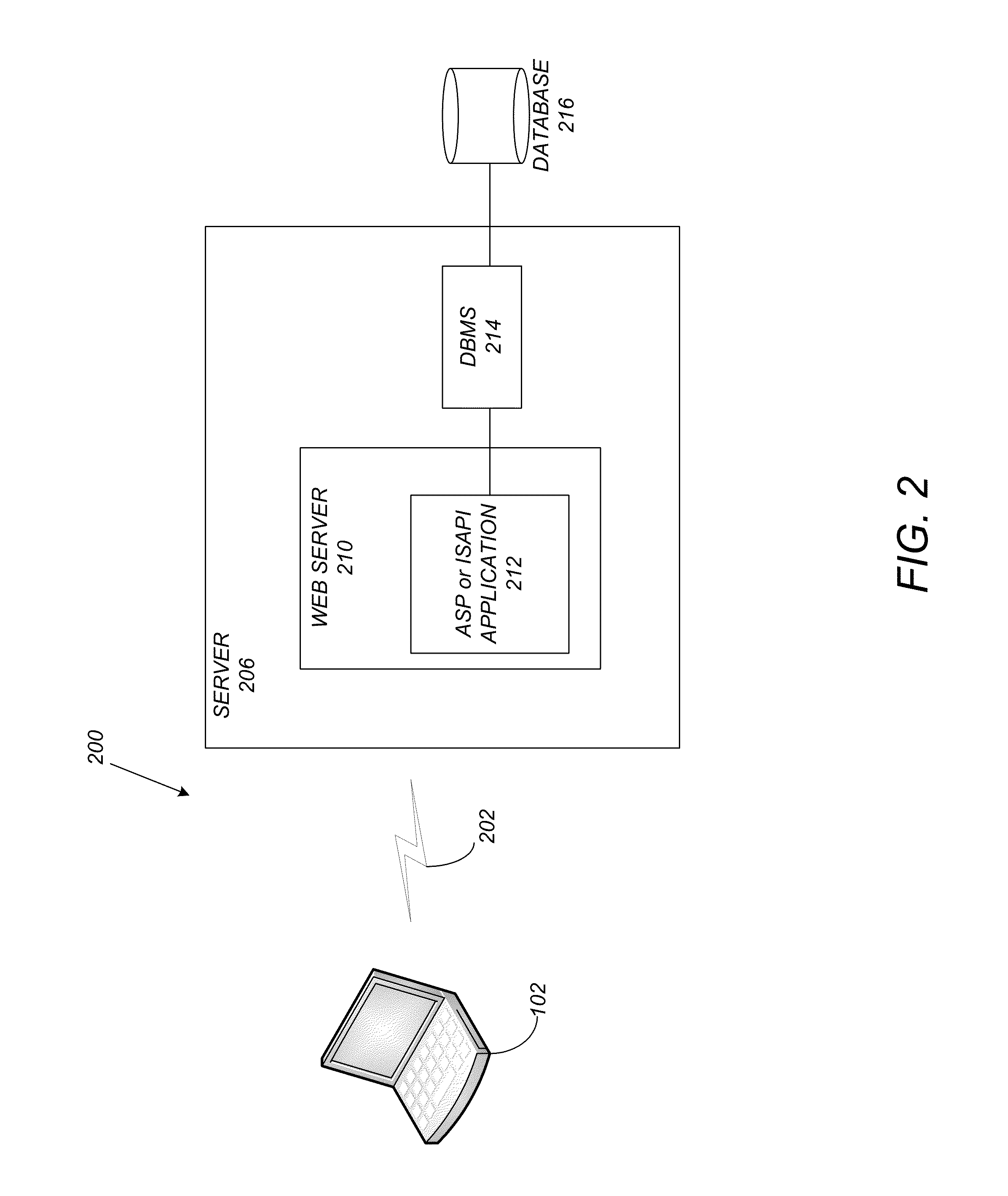

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com