Method for measuring liquid level of tundish

A technology of liquid level measurement and tundish, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., and can solve problems such as tundish waste, negative impact on good billet rate, and potential safety hazards. To achieve the effect of reducing waste in the middle package, eliminating over-melting and measurement deviation problems, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

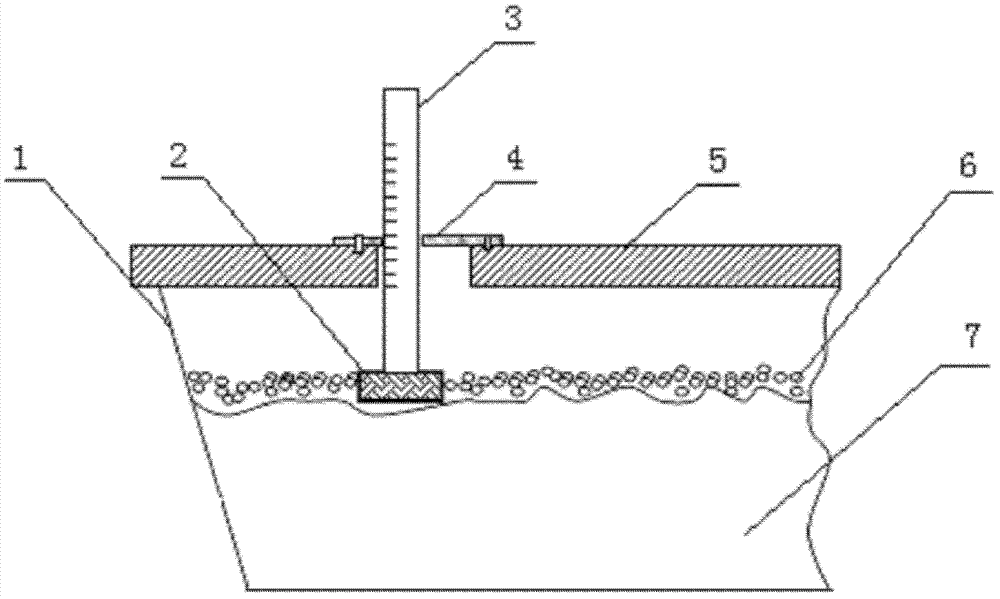

[0021] 1. Make ruler 3: Process one end of a ¢20×1.3mm steel pipe with external thread, and engrave the length mark in centimeters from the other end of the steel pipe. The length of the scale 3 and the length of the marked part shall be determined according to the specifications of the tundish 1 and the height of the molten steel level.

[0022] 2. Making buoy 2: Make a cuboid with a size of 100×80×50 mm from refractory materials, process a threaded ruler hole matching with the thread of the scale 3 at the center of the large surface of the cuboid, and coat the surface of the cuboid with zirconia. The physical and chemical indicators of the finished buoy 2 are: MgO86wt%; refractoriness 1680°C; bulk density 3.6g / cm 3 . To ensure that the buoy 2 is not melted, but also can always stay on the contact surface between the covering agent 6 and the molten steel 7.

[0023] 3. Make the positioning cover plate 4: Cut out a steel plate with a size of 200×150×20mm, process a ¢22mm po...

Embodiment 2

[0029] 1. Make ruler 3: Process one end of a ¢22×1.35mm steel pipe with external thread, and engrave the length mark in centimeters from the other end of the steel pipe.

[0030] 2. Making buoy 2: Make a cuboid with a size of 115×85×55mm from refractory materials, process a threaded ruler hole matching with the thread of the scale 3 at the center of the large surface of the cuboid, and coat the surface of the cuboid with zirconia. The physical and chemical indicators of the finished buoy 2 are: MgO89wt%; refractoriness 1700°C; bulk density 3.9g / cm 3 . To ensure that the buoy 2 is not melted, but also can always stay on the contact surface between the covering agent 6 and the molten steel 7.

[0031] 3. Make the positioning cover plate 4: Cut out a steel plate with a size of 210×160×22mm, process a ¢23mm positioning hole at the center of the steel plate, and process a bolt hole on both sides of the steel plate.

[0032] 4. Open a 130×105mm rectangular hole on the cover 5, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com