A device and method for measuring the normal emissivity of opaque solid materials based on solar simulator heating

A technology of normal emissivity and solar energy simulation, which is applied in the field of normal emissivity measurement devices and can solve problems such as poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

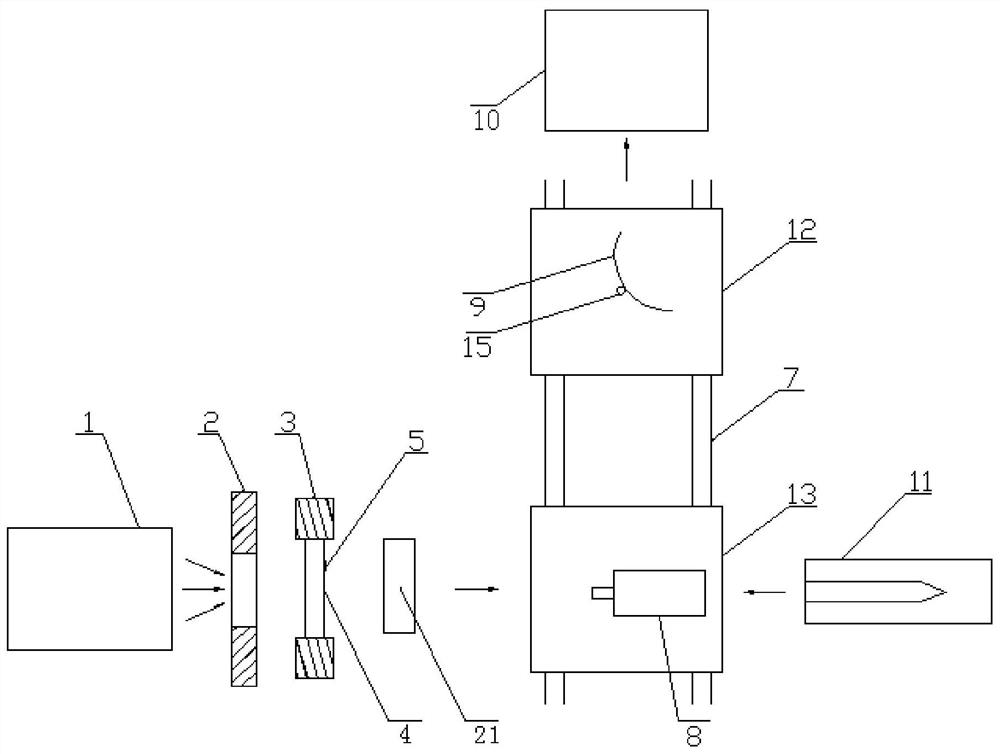

[0044] Specific implementation mode 1: This implementation mode is based on the normal emissivity measurement device of opaque solid material heated by a solar simulator

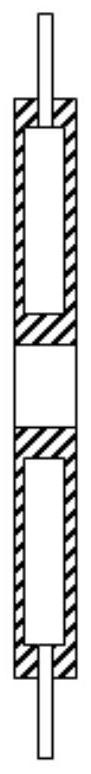

[0045] It consists of a solar simulator 1, a glass screen 2, a high-temperature sample holder 3, a thermocouple 5, a slide rail 7, an infrared thermal imager 8, a parabolic mirror 9, a Fourier infrared spectrometer 10, a blackbody furnace 11, a mirror base 12, The sample exit surface shielding device 21 and the thermal imager base 13 are composed;

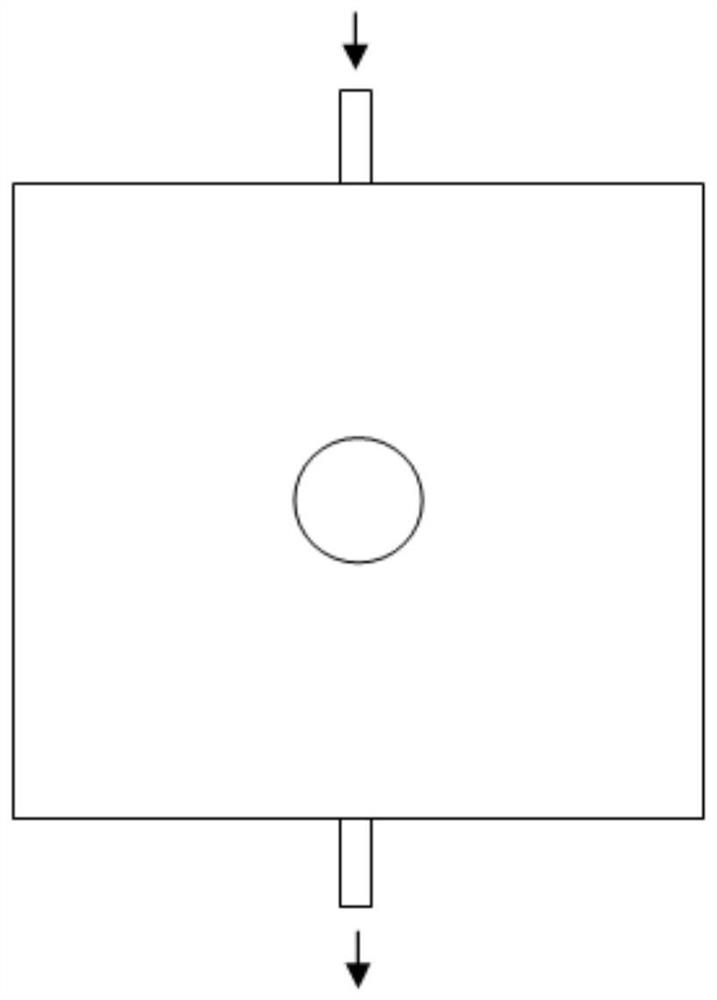

[0046] The sample exit surface blocking device 21 is composed of a front baffle 17, a rear baffle 16 and a double-track slideway 18; A cooling water inlet pipe and a cooling water outlet pipe communicating with the cavity are provided; the rear baffle 16 is plate-shaped, the middle part of the rear baffle 16 is a cavity, and the side of the rear baffle 16 is provided with a cooling water inlet communicating with the cavity. Water pipes and cooling water outlet p...

specific Embodiment approach 2

[0054] Embodiment 2: This embodiment differs from Embodiment 1 in that: the glass screen 2 is a plate-shaped hollow quartz glass, and the sides of the glass screen 2 are provided with cooling water inlet pipes and cooling water outlet pipes. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: a heat insulating material is provided between the annular inner surface of the high-temperature sample holder 3 and the sample. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com